Page 1

INSTALLATION, OPERATION & MAIN TE NANCE MANUAL (IOM)

MODEL 521

TOTAL TFE, GLOBE-PATTERN CON TROL VALVE

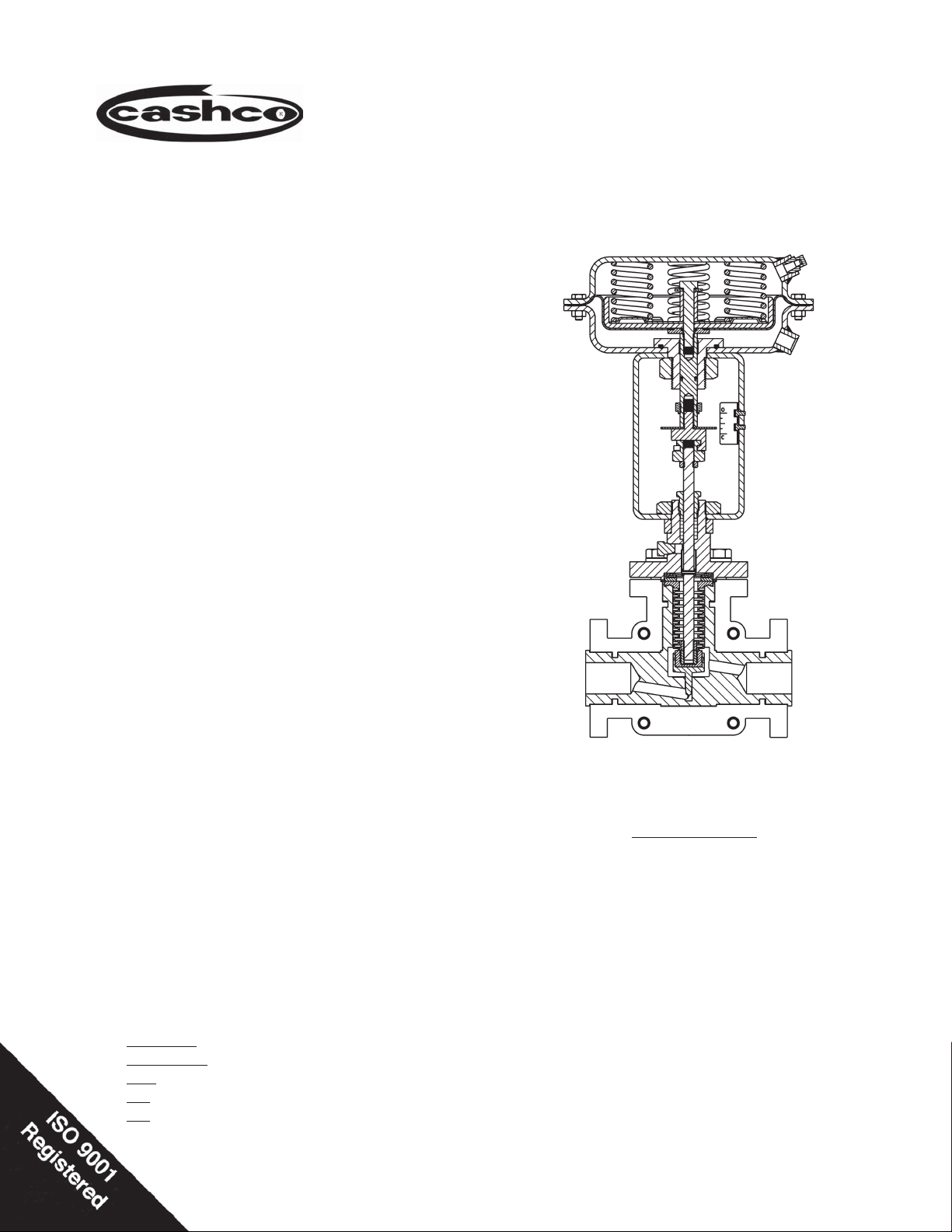

I. DESCRIPTION AND SCOPE

The Model 521 is a bellows sealed, globe-style control valve fabricated from a tee-block of isostatically

com pact ed virgin TFE. Sizes are 1/2", 1", 1-1/2" and

2". The split body jacket is CF8 (304 SST) material.

All wetted internal parts are of isostatically compacted

TFE material. The standard stem material is of 316

SST; two optional Hastelloy C-276 stem material

con struc tions are avail able.

End connections are available to mate with 150#,

300# or DIN PN16, 25 or 40 fl anges. Each fl ange

is drilled and tapped to receive stud bolting only.

IOM-521

12-13

BODY IOM

SECTION I

The valve is designed for chemical service with fl uids

that are normally corrosive to metallic materials.

For application pressure vs. temperature zone refer

to Model 521-TB, Graph No. 1 (pg. 3).

Actuators that may be mounted to a Model 521

body are Cashco Model C27 or Model C53, both

fi eld reversible.

II. REFERENCES

Refer to Technical Bulletin 521-TB for complete

tech ni cal specifi cations of a Model 521 coupled with

either Cashco Actuator C27 or C53.

www.cashco.com/techbulletins/521.pdf

Refer to following Installation, Operation & Main te nance Manuals (IOM’s) for either actuator and/or

devices that maybe mounted to a Model 521:

Actuators: www.cashco.com/IOM/C27-C53.pdf

Positioners:

P/P: www.cashco.com/techbulletins/9540l.pdf

I/P: www.cashco.com/techbulletins/srd991.pdf

I/P: www.cashco.com/iom/PS2iom.pdf

SECTION II

SST.......... Cast or Wrought Stainless Steel

HC ........... Wrought Hastelloy C-276

ATO-FC ... Air-to-Open, Fail Close

ATC-FO ... Air-to-Close, Fail Open

CCW ........ Counter Clockwise

CW ........... Clockwise

D or DIR ... Direct Acting

R or REV.. Reverse Acting

IAS ........... Instrument Air Supply

IOM .......... Installation, Operation and Maintenance

SIG .......... Output Signal from Instrument

LOAD ....... Positioner Output Air Pressure

V .............. Vent

Model 521

with ATO - FC Actuator

ABBREVIATIONS

Man u al

Page 2

SECTION III

III. INSTALLATION

A. Orientation

1. Recommended orientation when installed is

in a hor i zon tal pipeline with the stem vertical. Valves may be installed in a vertical or

hor i zon tal pipeline with the stem between

vertical and horizontal.

2. Outdoors, all installations may be oriented

at any angle from horizontal-to-vertical, as

per A.1. above.

3. Model 521 valves should not be installed

with the stem oriented below horizontal/

down wards.

4. In no case is additional weight to be applied

to the actuator assembly when installed in

an ori en ta tion other than vertical.

WARNING

The valve/actuator unit should not be used as a

“step” to sup port per son nel. Failure to comply

may cause leak age at the bonnet/body joint, al low ing pos si ble con tact with harm ful fl uids.

2. If pipe reducers are located before and/or

after the valve body, keep the reducers as

close as practical to the valve body; this is

especially important where the reducers are

more than one line size larger than the valve

body size, which is common in gaseous

ser vice.

3. Clean the piping of all foreign debris, including chips, weld scale, weld splatter,

oil, grease, sand or dirt prior to installing

the control valve; THIS IS AN ABSOLUTE

REQUIREMENT.

4. Field hydrostatic testing the completed

piping system, including the Model 521,

to 1-1/2 x CWP in di cat ed on Model 521

name plate is ac cept able. If hydro test pres sure ex ceeds the 1-1/2 x CWP limit, the 521

must be re moved for such testing. Before

pres sur iza tion, the valve plug should be

lifted from the seat if of re verse, ATO-FC

action.

5. Flow Direction: Install so the fl ow direc-

tion match es the arrow cast on the valve

body.

6. Valves are not to be direct buried un der ground.

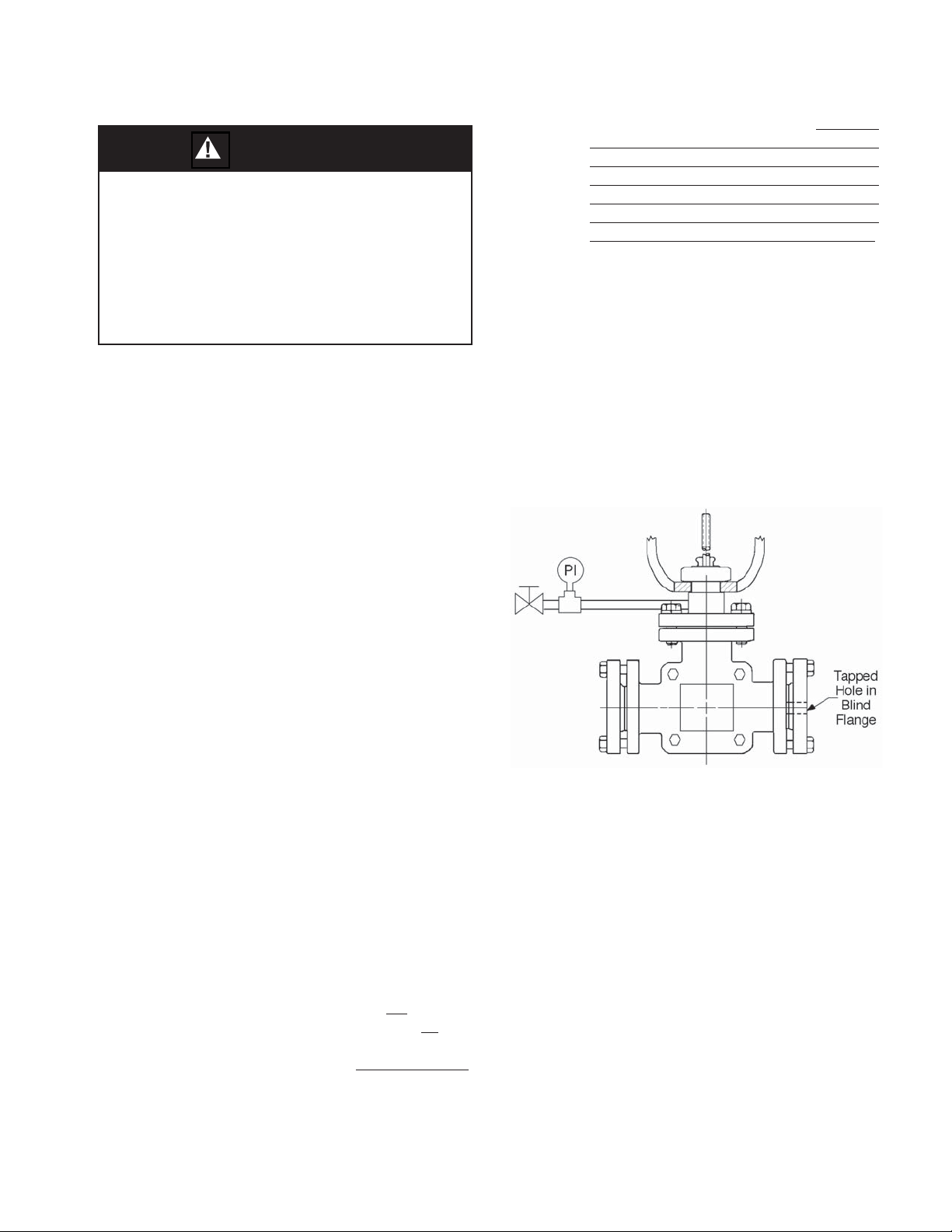

B. Piping System

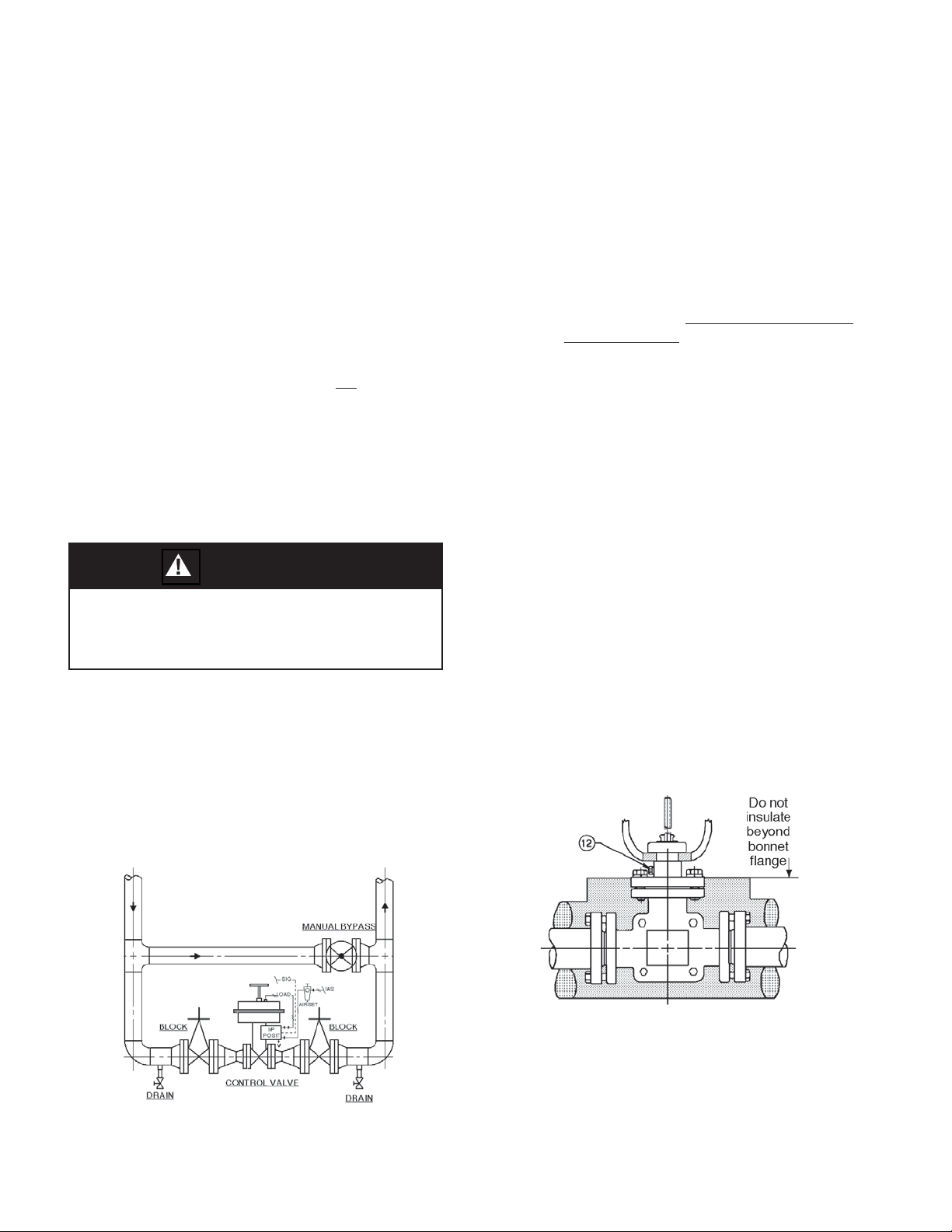

1. It is recommended that the control valve unit

be installed with a double-block and bypass

as indicated in Figure 1. This arrangement

is recommended especially where main te nance will be done on the valve body while

still installed in the pipeline.

Figure 1: Typical Control Valve Station

7. Insulation may be applied as indicated in

Fig ure 2. Drainage from the packing area

must be ensured when fully installed, sealed

and lagged for outdoors installation. Vented

pipe plug (12) should not be covered.

Figure 2: Body Insulation

8. Undue piping stress/strain or bending

torques may not be transmitted thru the

control valve body. One pipe (inlet or outlet)

should be anchored rigidly for piping that

is “hot” or “cold” with respect to ambient

IOM-5212

Page 3

tem per a ture; the re main ing pipe (inlet or

outlet) should be sup port ed and guided to

ensure uni di rec tion al ex pan sion/con trac tion. Properly align prior to installing valve

with required fl ange bolting.

9. The Model 521 is designed for a fl anged

con nec tion that is gasketless. The raised

face portion of end con nec tion fl ange serves

as the gasket.

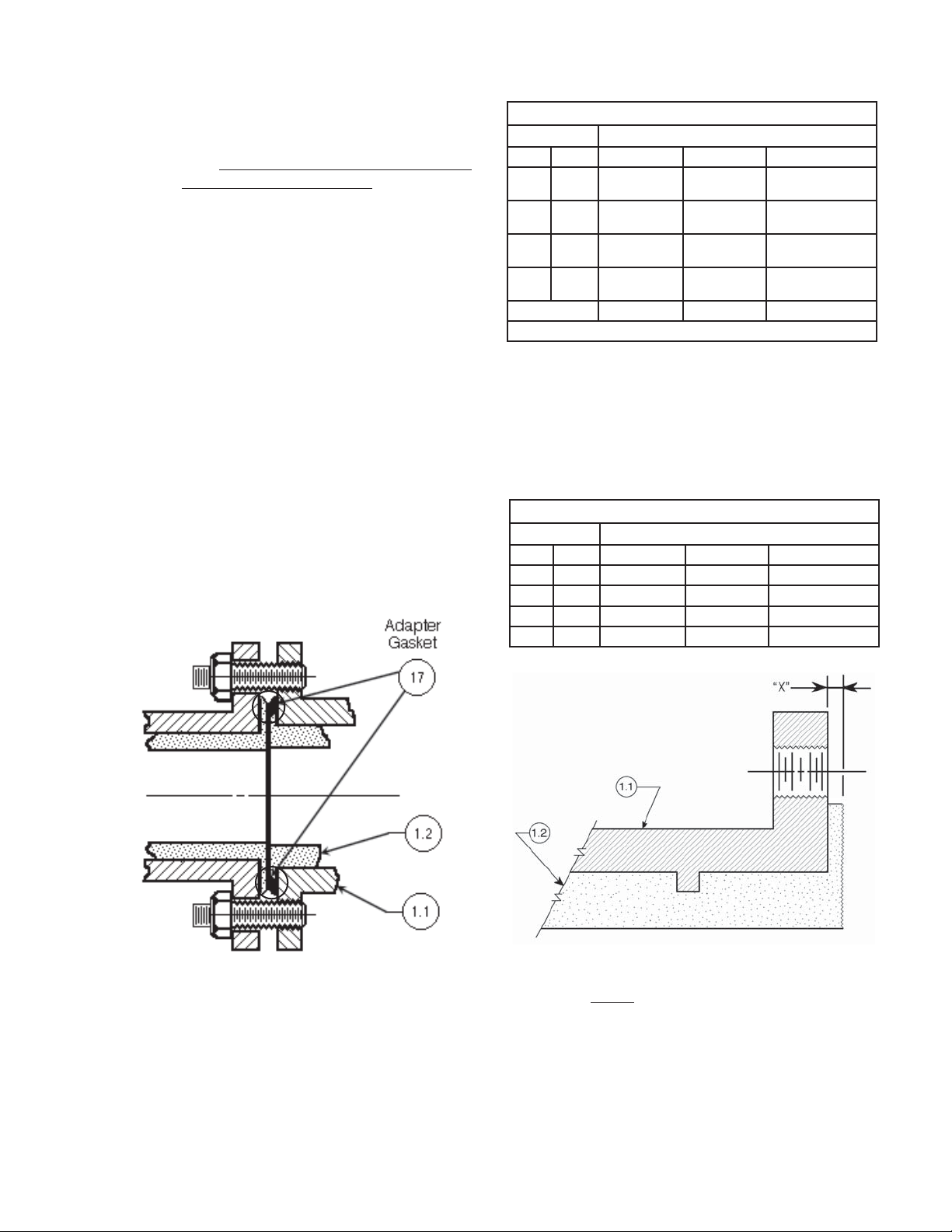

10. An ANSI/DIN adapter gasket (17) is supplied with all Model 521 valves provided

with DIN 16/25/40 end con nec tions. See

Figure 3. The purpose of this adapter gasket

(17) is to en sure prop er compression of the

body’s TFE core (1.2) when used with DIN

piping.

To assist during installation, place pipe

thread sealant on one side of adapter gasket

(17), and press the sealant covered side of

the adapter gasket over the exposed TFE

of the body core (1.2) end connection. The

sealant will hold the adapter gasket (17)

to its proper location prior to joining with a

piping fl ange.

TABLE 1

Body Size End Connection Flange Bolting

In. (DN) 150# 300# DIN 16/25/40

1/2" DN15

1" DN25

1-1/2" DN40

2" DN50

No. Bolt Holes 4 4 or 8 * 4

1/2" Ø - 1-3/4"

13 UNC-2B

1/2" Ø - 2"

13 UNC-2B

1/2" Ø - 2-1/2"

13 UNC-2B

5/8" Ø - 2-1/2"

11 UNC-2B

* 2" - 300 # requires 8 bolt holes; all others 4.

1/2" Ø - 1-3/4"

13 UNC-2B

5/8 Ø - 2"

11 UNC-2B

3/4" Ø - 2-3/4"

10 UNC-2B

5/8" Ø - 2-3/4"

11 UNC-2B

14 mm Ø - 45 mm

M12x1.75-6H

14 mm Ø - 52 mm

M12x1.75-6H

18 mm Ø - 70 mm

M16x2.0-6H

18 mm Ø - 70 mm

M16x2.0-6H

12. Tighten fl ange stud nuts uniformly in a cross-

ing pattern. Ensure fl ange facing align ment.

Do not use fl ange bolting to “pull” fl ang es

into alignment. Tighten fl ange bolting to

torque levels of Table 2 in increments of

1/2 rev o lu tion to ensure uniform loading of

valve’s raised facing.

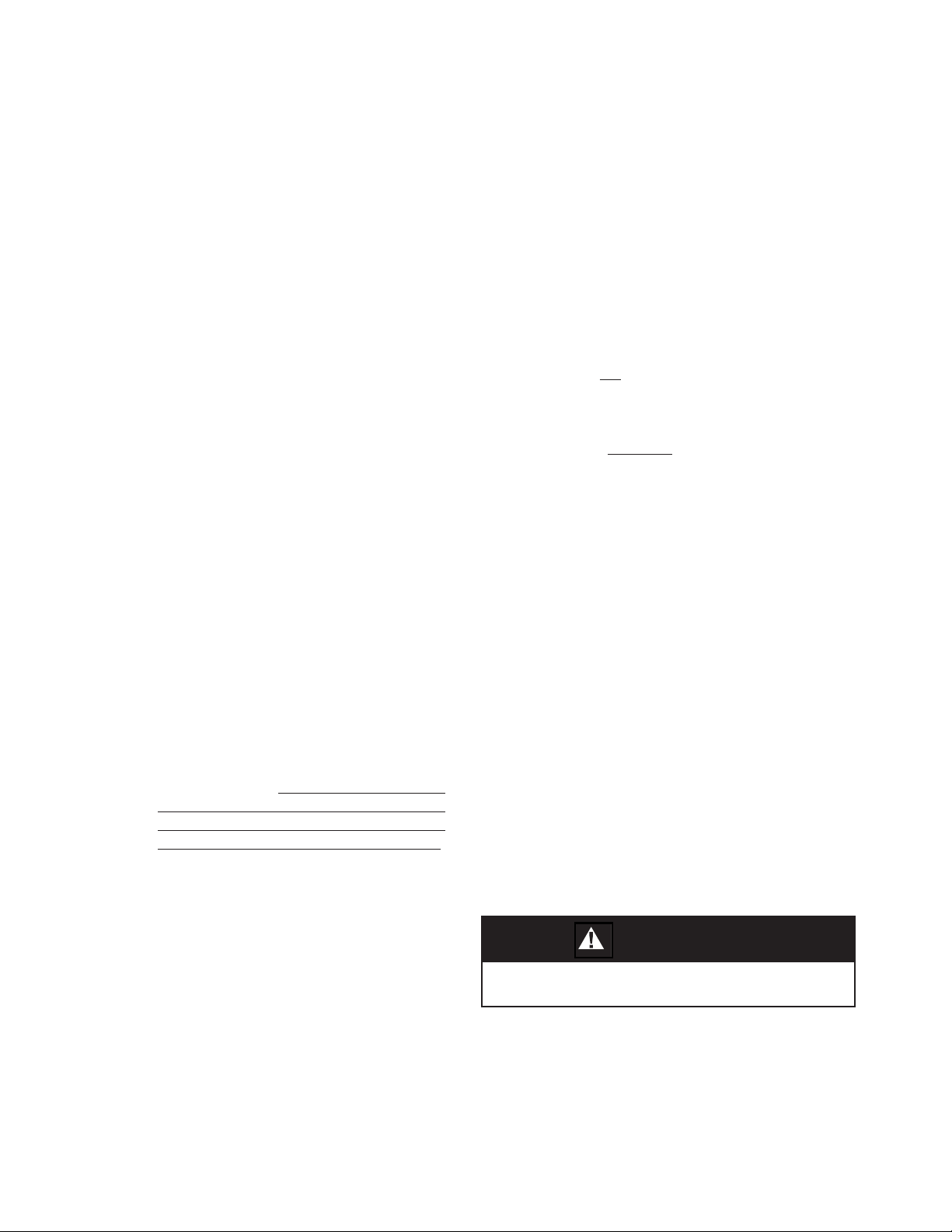

TABLE 2

Body Size End Connection Flange Bolting

In. (DN) ANSI-150 ANSI-300 DIN 16/25/40

1/2" DN15 10 - 12 ft-# 10 - 12 ft-# 15 - 18 N-m

1" DN25 10 - 12 ft-# 12 - 14 ft-# 21 - 25 N-m

1-1/2" DN40 10 - 12 ft-# 14 - 17 ft-# 18 - 22 N-m

2" DN50 35 - 40 ft-# 17 - 20 ft-# 50 - 60 N-m

Figure 3: ANSI/DIN Adapter Gasket

11. Flange bolting must be of the stud-type.

Each fl ange is drilled and tapped to accept

studs. The studs should be of a length to

penetrate the full depth of the bolt hole thru

the fl ange; DO NOT USE STUDS/BOLTS

OF TOO SHORT LENGTH. See Table 1

for stud size/thread/length requirements.

IOM-521

Figure 4: End Connection - Partial Section

NOTE: If the installed Model 521 has had

the fl ange bolting over-torqued, distortion

of TFE core (1.2) will occur. If dimension

“X” in Figure 4 is 0.040" (1 mm) or less, a

gasket is rec om mend ed upon reinstallation.

If dimension “X” is less than 0.020" (0.5 mm),

body re place ment is recommended.

3

Page 4

C. Auxiliary Detection:

1. When a fl uid is known to permeate TFE over

a fi nite time period and the fl uid is lethal or

is subject to stringent limits of fugitive emis sions, the vented pipe plug (12) should be

removed and one of, or a com bi na tion of, the

following methods should be considered to

monitor the integrity of the internal primary

stem (9) seal – the bellows sub-assembly

(8):

a. gas detector with alarm

b. pressure indicating gauge

c. pressure switch with alarm

d. inert gas, constant fl ow purge.

SECTION IV

IV. STARTUP

A. General:

1. Ensure that the Model 521 unit has been

properly adjusted and calibrated, including

the po si tion er, if in stalled.

2. Recommend startup to be in “manual”

mode. This procedure assumes double

block (iso la tion) and bypass valves for the

“control valve station" per Figure 1.

3. Start with either of the two block valves

closed, with the other open. The bypass

valve should be closed. Pres sur ize system

if possible/prac ti cal.

4. Back out the airset’s adjusting screw until

loose.

5. Turn on air supply pressure.

6. Adjust the air supply airset (fi lter-regulator) to

the proper level as indicated in the technical

bulletin 521-TB. DO NOT STROKE THE

CON TROL VALVE WITH AN AIR SUPPLY

PRESSURE SET TING GREATER THAN

REC OM MEND ED MAX I MUM PRESSURE!

7. Place loop controller into “manual” mode.

Vary setting from minimum – mid-range—

maximum SIG out put. Ob serve response of

control valve unit to these changes of input

SIG. The valve should fully stroke at the

variation from minimum SIG to maximum

SIG; the mid-range SIG should have the

valve stem travel at/near 1/2 open.

8. Confi rm that action of controller and po si-

tion er – direct or reverse – are producing

the desired response in the control unit.

Confi rm that the control valve “fail” position

is as re quired.

9. Hereafter, the procedure assumes that

actual fl uid fl ow may be established. This

may not be practical/pos si ble in all cases;

if so, vary pro ce dure as required.

Always “heat” or “cool” down the system

pip ing SLOW LY by opening the control valve

station bypass valve in small increments.

10. With one of the control valve station block

valves still closed, and the loop controller

still in “man u al” mode, open bypass valve

and vary fl ow rate manually to observe the

re sponse of the controller and control valve

unit to geth er.

11. Attempt to develop manual control of the

loop by opening/closing the manual bypass

as required, or by manually controlling

main stream fl ow as required.

12. When the control valve is partially open,

crack open, slowly, the closed block valve

while si mul ta neous ly clos ing the bypass

valve; it may be necessary/desirable to vary

the man u al output SIG from the controller

si mul ta neous ly also. Continue this procedure until the by pass is closed and the block

valves are both fully open. The system is still

under “manual” mode control, but all fl ow is

passing thru the control valve.

CAUTION

DO NOT WALK AWAY AND LEAVE A MANUALLY

CONTROLLED CONTROL VALVE UNATTENDED!

13. Vary controller “manual” SIG output until

match ing the “automatic” SIG output, then

change the mode of the controller over to

“automatic”, and the loop will ex pe ri ence a

minimum of upset conditions, and will be in

automatic control.

IOM-5214

Page 5

SECTION V

V. MAINTENANCE

WARNING

Model 521 control valves fre quent ly are installed

in haz ard ous/le thal fl uid ser vic es. Be fore re mov al

from pipe line or any level of dis as sem bly, con sult

the Own er’s safety pro ce dures for proper fl ushing,

clean ing and han dling of a valve ex posed to po ten tial ly haz ard ous fl uids dur ing de-pres sur iza tion

and re mov al. Owner's safe ty procedures pre empt

any state ments or rec om men da tions con tained in

this IOM.

A. General:

1. Once fl uid pressure has been iso lat ed by

block valves, and piping fl ange bolting has

been only loos ened, care ful ly re move vented

pipe plug (12) from the bonnet (2), applying

the detection procedures of C. 1. above, as

a small quantity of fl uid may be “trapped” in

the void space of the bellows (8) interior due

to permeation. The plug (12) has a “groove”

notched in its threads to assure venting prior

to the threads fully disengaging. Once fully

vented and/or purged as required by safety

procedures, reinstall the plug (12) using a

fl uid compatible lubricant . DO NOT USE

THREAD SEAL ANT FOR VENT ED PIPE

PLUG (12) ON RE IN STAL LA TION.

6. The stem sub-assembly (9) is designed

for non-rotation when installed. DO NOT

AT TEMPT TO RO TATE WITH THE STEM

SUB-ASSEMBLY IN STALLED; FAILURE

TO HEED MAY CAUSE DAMAGE TO THE

STEM SUB-ASSEMBLY (9), THE BELLOWS SUB-AS SEM BLY (8), THE PLUG

(3) AND/OR THE BODY ASSEMBLY(1).

Exhibit special care when handling the stem

(9) sur face where it contacts the packing

(6).

B. Pressure Boundary Leakage Shop Test:

1. Secure the body assembly (BA) in a vise

with the valve stem (9) oriented vertically.

2. Remove vented pipe plug (12).

3. Install a pipe nipple, test pressure gauge and

isolation valve into the 1/8"-NPT (female)

open ing. (See Figure 5.)

2. Maintenance procedures hereinafter are

based upon removal of the valve/actuator

unit from the pipeline where installed.

3. Owner should refer to Owner’s procedures

for re mov al, handling and cleaning of nonreuseable parts and suitable sol vents, etc.

4. Valves supplied from the factory do not use

any sealing aids for the gasket such as oil,

sealant, or pipe dope in the wetted portions

of the valve body as sem bly. Sealing aids

should not be required and are not rec om mend ed.

5. All indicated Item Numbers that are with

re spect to actuator assembly (AA) will be in

pa ren the sis and un der scored; i.e. (20). All

Item Num bers that are with respect to the

body assembly (BA) are not underscored;

i.e. (32). Reference with respect to the

positioner is in double parentheses; i.e.

((AP)).

Figure 5: Pressure Boundry Testing Confi guration

4. Place a suitable adhesive tape (“duct tape”)

around the perimeter of the bonnet/body

fl ange. Place tape on the “joint lines” of the

shell halves (1.1) (see Figure 10). Place blind

fl ang es over the fl anged end connections

and bolt down; one of the blind fl anges must

have a hole thru the face; place tape over

the opening of the blind fl ange.

5. Using a source of acceptable fl uid such as

ni tro gen gas, pressurize the bellows “void

zone” to 30 psig (2.1 Barg). Tightly close off

the isolation valve of 3. above. Disconnect

the pressure source.

6. Poke small holes in the tape at the bonnet/

body fl ange and at the opening in the blind

fl ange.

IOM-521

5

Page 6

7. For units with Reverse Action (ATO-FC)

ac tu a tors pressurize to a level suffi cient to

initiate travel to approximately mid-stroke

to hold the plug (3) away from the body (1)

seat.

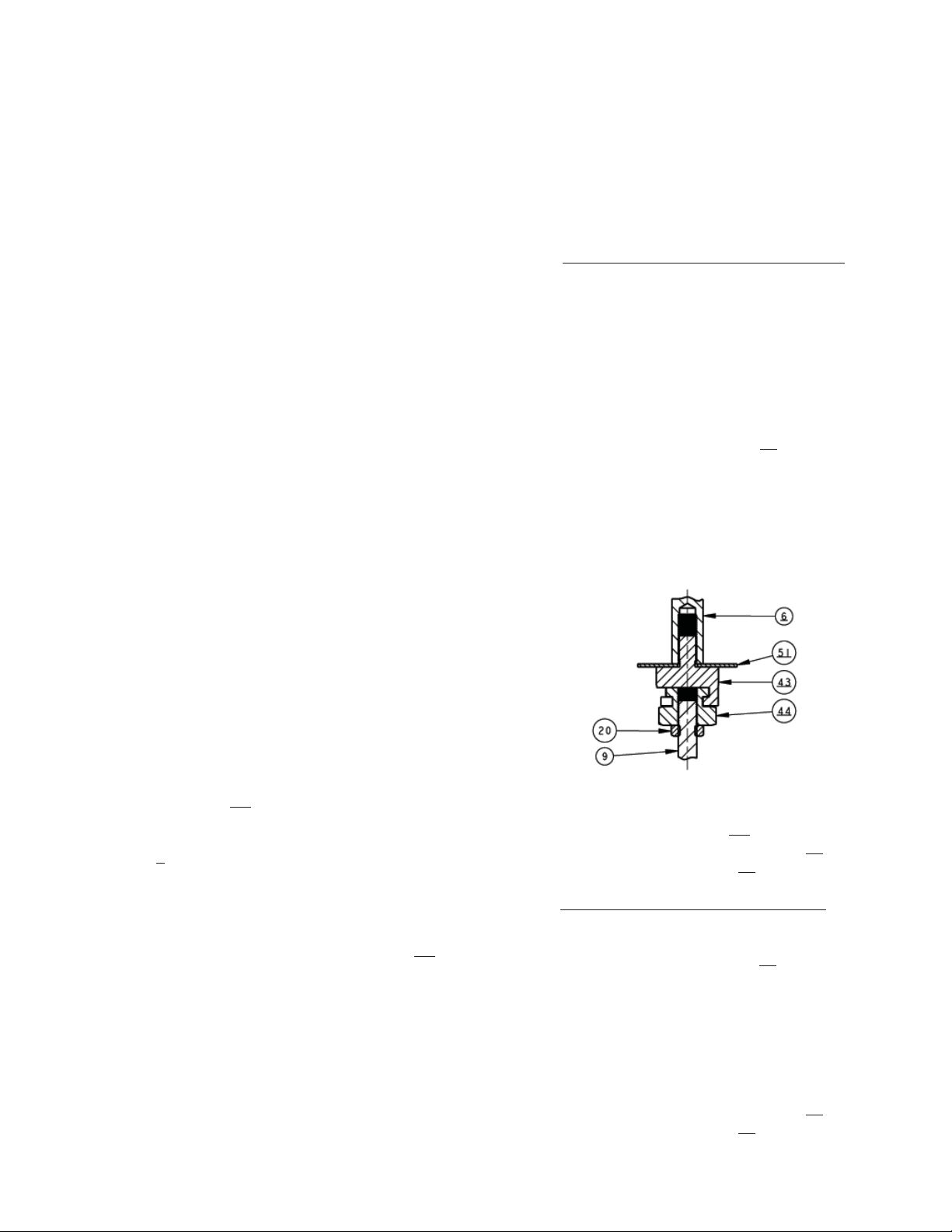

6. Loosen stem nut (20) by rotating nut CW

(viewed from above) to base of threads.

7. Loosen packing (6) by turning packing gland

nut (5) CCW 2-3 revolutions.

8. Apply leak detection fl uid to all the potential

leak paths:

a. Packing gland nut (5). (Tighten as nec es-

sary.)

b. Body (1)-to-bonnet (2) fl ange tape hole.

c. Body (1) and bonnet (2) bolting (13, 14,

1.3, 1.4, 1.5).

d. End connection blind fl ange tape hole.

e. Test pressure piping con nec tions.

9. If leakage occurs at:

a. a. above, there is a packing (6) or a pack-

ing (6) /stem sub-assembly (9) failure.

b. b. above, there is a bonnet gasket (11)

failure.

c. c. above, there is a bonnet gasket (11),

or TFE core (1.2) failure.

d. d. above, there is a bellows sub-as sem bly

(8) failure.

10. Following this test procedure may help

to solve main te nance problems when

combined with visual ex am i na tion of disassembled body assembly (BA).

8. Rotate yoke nut (15) CCW to fully loosen

nut.

9A. For ATO-FC Reverse Action Actuators:

a. Connect a temporary air source

to the actuator and pressurize the

actuator to upper limit of the bench

range specifi ed on the valve name

plate. (Pressure will lift the plug head

(3) away from the body's (1) integral

seat until the plug (3) is 100% open.)

b. Place a wrench on the hex surface of

the swivel lower knuckle (44) and rotate

knuckle CCW (viewed from above ac tu a tor) until lower knuckle dis-engages from

stem (9). Keep track of the number of

full rev o lu tions to dis-engage and record

here. _______________

c. Maintain lift support from above the

C. Separation of Body/Actuator:

1. Reference the Actuator IOM-C27-C53 for

item number call outs and drawings for

actuator.

2. Secure the body in a vise with the actuator

assembly (AA) oriented vertically. Place

matchmarks between the body (1) bon net

fl ange, the bonnet (2) fl ange, and the yoke

(3) to assist in fi nal ori en ta tion when the

body is dis as sem bled and/or the ac tu a tor

removed. If actuator has handwheel - see

Actuator IOM for removal instructions.

3. Secure and rig the actuator assembly (AA)

for a ver ti cal lift using an overhead hoist.

Remove slack from rigging.

4. This procedure assumes that the body as sem bly (BA) has been fully assembled thru

the bonnet (2), including the packing gland

nut (5) and packing (6).

5. Remove vented pipe plug (12) from body.

Figure 6: Swivel-Type Connector

actuator assembly (AA). Dis-engage

(slide) the swivel lower knuckle (44) out

of the upper knuckle (43) slot.

9B. For ATC-FO Direct Action Actuators:

a. Place a wrench on the hex surface of

the swivel lower knuckle (44) and rotate

knuckle CCW (viewed from above ac tu a tor) until lower knuckle dis-engages from

stem (9). Keep track of the number of

full rev o lu tions to dis-engage and record

here. ________________

b. Maintain lift support from above the

actuator assembly (AA). Dis-engage

(slide) the swivel lower knuckle (44) out

of the upper knuckle (43) slot.

IOM-5216

Page 7

10. Raise the actuator assembly (AA) over stem

(9). Release any ac tu a tor air pressure. Lay

actuator assemby aside on work surface.

D. Body Disassembly:

1. Access to body assembly (BA) internals

may be accomplished with the actuator assembly (AA) intact with the bonnet (2) (i.e.

locknut (15) is still fully tight ened), or with

the body assembly (BA) separated as per

above para graph V.C. Steps 1-10.

2. Maintenance procedures hereinafter are

based upon the actuator assembly (AA) fully

in ter con nect ed with the valve stem assembly

(9) during disassembly.

3. Secure the body in a vise with the actuator

assembly (AA) oriented vertically upwards.

Place matchmarks between the body (1)

bon net fl ange and the bonnet (2) fl ange to

assist in fi nal ori en ta tion when the body is

dis as sem bled and/or the ac tu a tor removed.

The valve body (1) is ma chined after the shell

halves (1.1) have been bolted (1.3, 1.4, 1.5)

around the TFE core (1.2). Dis as sem bly of

the body sub-assembly (1) will cre ate align ment problems during reassembly. The

TFE core (1.2) is not replaceable, except

as a body sub-as sem bly (1).

10. Make a visual inspection of the trim portions

still in ter con nect ed to the actuator assembly

(AA) for ob vi ous problems.

11. Hand-grasp the bellows sub-assembly

(8) and rotate CCW (viewed from plug (3)

end) to removal. Do not use any wrench,

vise, etc., for grasping the bellows subassembly (8)! The bellows (8) should only

be hand-tight.

12. Loosen packing gland nut (5) 2-3 revolutions out of the bonnet (2) by rotating CCW

(viewed from stem (9) end).

13. Loosen jam nut (20) 1-2 revolutions.

4. Secure and rig the actuator assembly (AA)

for a ver ti cal lift using an overhead hoist.

Remove slack from rigging.

5. Loosen all bon net cap screws (14) ap prox i mate ly 1/4" (6 mm) by rotating CCW (viewed

from above).

6. Raise actuator assembly (AA) with overhead

hoist approximately 1/8" (3 mm).

7. Continue to loosen and remove bonnet cap

screws (14 and lockwashers (13).

8. Using overhead hoist, lift the actuator as sem bly (AA) with the interconnected valve stem

sub-as sem bly (9), bellows sub-assembly

(8), bonnet (2), bonnet spacer (19), locknut

(15), packing gland nut (5), packing rings

(6), Belleville spring washers (7), bonnet

gas ket (11), plug (3) and plug retainer (4).

Lay this as sem bly down on a horizontal work

surface carefully, so as to not damage the

valve’s internals.

9. Make a visual inspection of the body subassembly (1) exterior, which includes two

shell halves (1.1), TFE core (1.2), and four

body cap screws (1.3) with body nuts (1.4)

and lock wash ers (1.5).

NOTE:

OF THE BODY SUB-ASSEMBLY (1)!

DO NOT DISASSEMBLE THE PARTS

14. Grasp the valve’s stem sub-assembly (9)

in the lower area (normally surrounded by

the bellows (8.1)) using soft jawed pliers

to pre vent marring stem surface. Place

a wrench on the hex surface of the swivel

lower knuckle (44) and rotate knuckle CW

(viewed from plug (3) end) until lower knuckle

dis-engages from stem (9). Keep track of

the number of full rev o lu tions to dis-engage

and record here. _______________

15. Retract the stem sub-assembly (9) down wards thru the bonnet (2) until stopped by

locknut (20). Rotate lock nut (20), CCW until

it is removed.

16. Fully withdraw stem sub-assembly (9).

17. Visually inspect parts for wear, general

cor ro sion, localized corrosion, dirty service

fl uid, uneven alignment, seat leakage wire

draw ing, excess plug-to-seat loading, fl ange

fac ings, looseness of plug-to-bellows con nec tion, primary seal at TFE Core (1.2)

-to-bel lows (8.1) joint, secondary seat at

bonnet gasket (11) (See Figure 9), blisters

on TFE sur fac es, etc.

18. Attempt to determine the reason for a failure.

Evaluate if process conditions need cor rec tion, if alternate materials are required for

the stem sub-assembly (9), or if effects of

IOM-521

7

Page 8

pos si ble permeation need considerations

similar to those outlined in Section III.C.1.

E. Plug, Bellows, or Both Replacement:

1. Disassemble the body assembly (BA) per

V.D.1.-11. previous.

2. Hand-grasp the bellows sub-assembly (8)

and hand-rotate the plug head (3) until the

plug retainer strip (4) ends come into view

thru the slot located on the side of the plug

head (3).

3. Using a pointed end pick tool, get under one

end of the plug retainer strip (4) and extract

thru the plug’s (3) slot. Manually rotate the

plug head (3) end to allow more of the plug

retainer strip (4) to be extracted. When able

to grasp with needle nose pliers, lightly pull

the plug retainer strip (4) and rotate the plug

head (3) as necessary until the strip (4) is

fully re moved.

4. Slide plug head (3) off the stub-end of the

bellows sub-assembly (8).

5. Discard the plug head (3), if worn. Always

discard the plug retainer strip (4); only use

a new plug retainer strip (4) at reassembly.

6. Do not attempt to fi eld remove embedded

nut (8.2) from inside the bellows (8.1); these

parts are only available as a sub-assembly

(8). If embedded nut (8.2) is badly corroded,

re place the entire bellows sub-as sem bly (8)

and give strong consideration to alternate

ma te ri als for stem sub-assembly (9) and

bellows nut (8.2). If em bed ded nut (8.2)

is “loose”, consider po ten tial causes and

re place bellows sub-as sem bly (8).

F. Packing Ring Replacement:

1. Disassemble the body assembly (BA) per

V.C. previous, including separation of body

as sem bly (BA) from actuator assembly (AA).

2. Loosen packing gland nut (5) until fully disengaged from bonnet (2) by rotating CCW

(viewed from stem (9) end). Remove packing rings (6) from packing box (re cess) in

bon net (2).

3. Examine wall surface inside the bonnet (2)

for any sign of cor ro sion.

4. Hone the bonnet’s (2) packing box to a #16

RMS fi nish. Burnish the stem sub-assembly

(9) to a #4 RMS fi nish in the packing (6)

contact area.

G. Reassembly of Body Assembly:

1. Place body assembly (BA) (1) in a vise with

the bonnet (2) end directed upwards.

2. Join the stem sub-assembly (9) to the bellows sub-assembly (8) (with new plug head

(3) already installed) by ro tat ing the stem's

(9) lower end into em bed ded nut (8.2) CW

(viewed from bellows (8.1) open end). Rotate the stem sub-assembly (9) as far as

possible while hand-grasping the bellows

(8.1) DO NOT USE A WRENCH IN THIS

OP ER A TION. A light coat of Fluorolube

(™ of Occidental Chem i cal Co.) lubricant

may be applied to the en gaged (threaded)

end of the stem sub-assembly (9) if fl uid

com pat i ble.

3. Place spacer washer (10) over the threaded

upper end of stem sub-assembly (9).

7. If bellows sub-assembly (8) is to be reused,

thor ough ly clean the valleys of the bellows

(8.1) con vo lu tions (inside and outside) for

the smallest of debris. Clean the grooves

of the bellows (8.1) and the plug head (3)

where the plug retainer strip (4) locates.

8. Place the plug head (3) over the bellows

sub-as sem bly (8) end. Insert a new TFE

plug re tain er strip (4) into the slot/groove.

Rotate the plug head (3) as necessary while

feeding the strip (4) until the strip (4) is fully

located into the groove. (No cutting of the

strip (4) should be required.)

4. Referring to Figure 7 for proper orientation

and quantity of Belleville spring washers (7),

place the spring washers (7) over the upper

end of stem sub-assembly (9).

5. Position a new bonnet gasket (11) into recess

of body sub-assembly (1).

6. Observe the underneath side of bonnet (2)

where square recess is located. Position

com bined bellows sub-assembly (8) and

stem sub-assembly (9) so that the antiro ta tion "stop" (square part of stem)is aligned

to slip into the bonnet’s (2) square recess.

IOM-5218

Page 9

1/2" (DN 15) & 1-1/2" (DN 40) Body Sizes

1" (DN 25) Body Size

and align ment of parts (10) (8) (11) (7),

re move temporary spacer while continuing downward force on the stem (9) while

si mul ta neous ly holding the bonnet (2) from

drop ping down wards.

13. Lower bonnet (2) carefully downwards into

the recess of the body sub-assembly (1)

while con tin u al ly applying downward force

on the stem (9).

14. At this point, downward force on stem (9)

may be exchanged for down ward force on

the bon net (2). Hand-tighten all bonnet cap

screws (14); relax down ward force on bonnet

once cap screws have taken up all slack.

15. Using a torque wrench, tight en bonnet cap

screws (14) in alternating cross-pat tern in

1/4 rev o lu tion in cre ments to 40 ft-# (55 N-M).

CAUTION

2" (DN 50) Body Size

Figure 7: Belleville Spring Washer Orientation

7. Center the loose parts (10) (7) surrounding

the stem (9) as close as possible.

8. Position the bonnet (2) over the exposed

upper stem sub-assembly (9), ensuring

that the anti-rotation "stop" (square or fl at

surface of the stem) is properly en gaged

into the bonnet (2) square recess.

9. Place a temporary spacer device (screw driv er blade, nuts, plain washers, etc.)

equallyspaced on the body (1) fl ange to hold

the bonnet (2) up, as bonnet is lowered into

the body, maximizing the gap between the

bonnet fl ang es (1) (2).

10. Place anti-seize thread lubricant on bonnet

cap screws (14). Engage all bonnet cap

screws (14) with lockwashers (13) ap prox i mate ly 1-1/2 revolutions.

11. Visually observing the gap between the

bon net (2) lower fl ange surface and the

body sub-assembly (1) bon net fl ange, ap-

ply downward force tend ing to seat the plug

end (3). This will pull the bellows (8.1) into

proper position for the primary bon net seal.

12. When visually satisfi ed of concentricity

Improper bonnet bolting torques may lead to

premature failure of the primary and secondary

bonnet seals.

16. Engage threaded, vented pipe plug (12) into

the 1/8" NPT tap on the bon net (2) if it was

removed. If a lubricating oil is compatible with

the fl uid, a light coat ing will aid in pre vent ing

galling of the plug (12). En sure that the tip

of the notch on the threads is in the bonnet

(2) at least 1-1⁄2 revolutions. Do not overtighten to min i mize chanc es of galling.

Do not use thread sealing com pound that

might “fi ll in” the notch and negate the pur-

pose of the notch.

17. The packing ring set (6) de sign is identical

for all unit body sizes. It consists of seven

V-rings (6.1) and one each male (6.2) and

female (6.3) adapter. (See Figure 8.)

The

purpose of the packing rings (6) is to minimize moisture ingress, and to serve as a

sec ond ary stem seal in the event of bellows

sub-as sem bly (8) failure.

Carefully install rings (6) as indicated in

Fig ure 8, one at a time, using a hollow tool

to press the rings (6) to their fi nal position.

Take care in slipping the rings (6) over the

threaded end of the stem (9) so as to not

mar the ring’s (6) internal surfaces. Do not

reverse ori en ta tion for vacuum service. Do

not “split” rings (6) for ease in replacement.

Do not reuse re moved packing rings (6).

IOM-521

9

Page 10

Figure 8: Packing Ring Set

18. Place anti-seize thread lubricant on threads

of packing gland nut (5). Place gland nut

(5) over the stem (9) end and engage with

the bonnet (2) by rotating CW (viewed from

ex posed stem (9) end); continue fi nger-

tight en ing to the point of resistance. Wrench

tighten gland nut (5) 1/8 revolution past the

manual tightening re sis tance point.

19. Place bonnet spacer (19) down over

threaded portion of the bonnet (2).

4. This procedure assumes that bonnet (2) has

been bolted to the body sub-assembly (1).

5. Engage stem jam nut (20) to body as sem bly’s stem (9) by rotating CW (viewed from

valve stem (9) end). Rotate jam nut (20) all

the way to root of the stem (9) threads.

6. Lower actuator assembly (AA) until the

open ing of the actuator yoke (1) is at the

level of jam nut (20).

7. Place yoke nut (15) over valve stem (9) and

lower the nut to rest upon the yoke (3).

8. Push valve stem (9) downward towards

seat ing po si tion. NOTE: The valve bellows

(8) may give “spring action” to keep the plug

(3) par tial ly away from the seat.

9. For Direct Action ATO-FC Only: Connect

a temporary air supply hose that has an

adjustable airset with gauge connected at

the lower actuator inlet. Pressurize actuator

to a suffi cient level to the upper pressure

level of the bench setting; i.e. for 5–15 psig

(.34–1.03 Barg) range, set pres sure at 15

psig (1.03 Barg).

20. Valve body assembly (BA) is completed, and

may be pressure tested up to 275 psig x 1.5

= 413 psig (19.0 Barg x 1.5 = 28.5 Barg) at

ambient tem per a ture. Before pressurizing

for hydro, ensure that plug (3) is away from

body (1) seat. NOTE: Use soft gas kets on

body as sem bly (BA) end fl anges to prevent

dis tor tion of TFE fl ange fac ings.

H. Mounting Actuator Assembly to Body

Assembly:

1. Reference Actuator IOM-C27-C53 for item

number call outs and drawings for actuator.

This procedure assumes that accessory

plate ((AP)) or indicating washer (51) was

not removed or has been secured to the

actuator stem(6) by the swivel upper knuckle

(43) - tighten with 20-30 ft.lbs. (27-40 N M).

DO NOT allow actuator stem (6) to rotate.

Secure fl ats on bottom of stem (6) when

rotating knuckle (43).

2. Secure the body as sem bly (BA) in a vise

with the valve stem (9) oriented vertically.

3. Rig actuator assembly (AA) to be supported

from above.

10. Apply Loctite Nickel Anti-Seize to grove and

top surface of swivel lower knuckle. Engage

(slide) the lower knuckle (44) into the upper

knuckle (43) saddle.

11. Continue lowering the actuator assembly

(AA) until the swivel lower knuckle (44)

connector and the valve's stem (9) just

touch. NOTE: For ATO-FC may need to

slowly reduce air pressure in the actuator

to connect the stem and knucle.

12. Thread yoke nut (15) onto bonnet (2) threads

by hand as far as possible to help stabilize

topworks. Wrench-tight en one-half (1/2)

extra revolution.

13. Engage valve stem (9) threads to swiv el

lower knuckle (44). Rotate swivel knuckle

(44) CW (viewed from actuator end) to

engage with valve stem (9), refer to V.C.

Steps 9A or 9B for the number of rev o lutions

recorded to dis-engage the lower knuckle.

14. Remove overhead rigging to allow ac tu a tor

assembly (AA) to fully rest on the bonnet (2).

Refer back to V.C. Step 2 for alignment of

match marks. Hand-tighten yoke nut (15).

IOM-52110

Page 11

15. For Direct Action ATC-FO Only: Release

all air pressure from actuator assembly (AA),

see step 9 previous and remove temporary

air supply.

16. Re-tighten packing gland nut (5).

VI. CALIBRATION

17. Tighten yoke nut (15) to 85 ft--# (115 N-M)

18. Calibrate actuator to valve per Section VI.

SECTION VI

A. General:

1. This section only covers calibration of this

control valve with Actuator Models C27-C53.

2. Positioner, if installed, requires reference to

the spe cifi c positioner model IOM for proper

cal i bra tion pro ce dure.

3. All indicated Item Num bers that are with

re spect to IOM-C27-C53 will be in pa ren the sis and un der scored; i.e. (20). All Item

Num bers that are with respect to this IOM521 are not un der scored; i.e. (32).

B. Procedure – Reverse Ac tion, ATO-FC:

1. Reference the name plate (40) at tached to

the actuator yoke (3). De ter mine the bench

set ting of the installed range springs (10)

from the name plate (40).

2. Connect a temporary air supply with an inline ad just able airset reg u la tor and gauge

to the lower actuator con nec tion. DO NOT

LOAD with any air pressure at this point.

3. To determine when stem/plug (9) begins to

lift out of the seat, touch the stem below the

jam nut with one fi nger. (Stem will begin to

move when actuator pressure exceeds the

spring load.)

4. Slowly pressurize the ac tu a tor to a pres sure

equal to the lower pres sure level of the bench

setting; i.e. for 5-15 psig (.34–1.03 Barg)

range, set pressure at 5 psig (.34 Barg).

Take note of pressure reading when the

stem fi rst begins to move.

5. If the loading pressure for the start of stem

movement is below the lower end of the

desired bench setting, then the com bined

stem (9, 6) length is too short.

a. Rotate jam nut (20) down to base of

threads on stem (9).

b. Increase pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate lower knuckle (44) CCW to in-

crease the combined stem length. DO

NOT allow actuator stem (6) to rotate

in the actuator.

d. Release all pressure from the actuator

and repeat Step 4 previous.

6. If the loading pressure for the start of stem

movement is above the lower end of the

desired bench setting, then the com bined

stem (9, 6) length is too long.

a. Rotate jam nut (20) down to base of

threads on stem (9).

b. Increase pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate lower knuckle (44) CW to shorten

the combined stem length. DO NOT

allow actuator stem (6) to rotate in the

actuator.

d. Release all pressure from the actuator

and repeat Step 4 previous.

7. Observe the location of the in di ca ting washer

(51) to the "C" mark on the in di ca tor plate

(23), mak ing sure to use the “top edge” of

the in di ca ting washer (51) as the ref er ence

point. Adjust indicator plate as needed.

8. Remove vented pipe plug (12) from the neck

of the bonnet (2).

9. Slowly increase the pressure in the actuator

until the indicating washer (51) is in alignment with the "O" mark on the indicator plate.

As pressure increases, thru the hole where

the vent ed pipe plug (12) was re moved,

watch for the anti-ro ta tion al "stop" (square

or fl at surface of the stem) to appear.

IOM-521

11

Page 12

NOTE: This "stop" should not function as

an up travel stop and push up against the

bonnet (2) (metal to metal). A gap of approximately 1/16" (1-1/2 mm) should exist

between these two surfaces.

NOTE: The purpose of a correct calibration

of the stem stroke is to cause the up travel

to be limited by the actuator travel stop nut.

10. To limit the up travel, rotate the travel stop

nut (52) CW and secure to bottom of attachment hub (4).

NOTE: Secure the actuator stem (6) by the

fl ats when rotating the travel stop nut.

NOTE: "Stroke" length is indicated on the

nameplate (40), and is the distance between

the "C" and "O" marks of the indicator plate

(23).

NOTE: The proper calibration of the actua-

tor / valve unit will occur when at the lower

pressure level of bench setting the valve

plug (3) will just begin to travel from the "C"

position. At the upper level of the bench

setting, the actuator pressure should be

within ±8% of the upper bench range for

the desired stroke length.

11. Engage threaded, vented pipe plug (12)

into the 1/8" NPT tap on the bon net (2). If

a lubricating oil is compatible with the fl uid,

a light coat ing will aid in pre vent ing galling

of the plug (12). En sure that the tip of the

notch on the threads is in the bonnet (2) at

least 1-1⁄2 revolutions.

Do not over-tighten to min i mize chanc es of

galling.

Do not use thread sealing com pound that

might “fi ll in” the notch and negate the pur-

pose of the notch.

12. Release all pressure from actuator.

(Stem movement will stop when the plug

engages the seat.)

4. Slowly pressurize the ac tu a tor to a pres sure

equal to the upper pres sure lev el of the

bench setting; i.e. for a 5-15 psig (.34 -1.0

Barg) range, set pressure at 15 psig (1.0

Barg). Take note of the pressure reading

when stem travel actually stops.

5. If the loading pressure, when stem movement stops, is below the upper end of the

desired bench setting, then the com bined

stem (9, 6) length is too long.

a. Rotate jam nut (20) down to base of

threads on stem (9).

b. Decrease pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate lower knuckle (44) CCW to

shorten the combined stem length. DO

NOT allow actuator stem (6) to rotate

in the actuator.

d. Release all pressure from the actuator

and repeat Step 4 previous.

6. If the loading pressure, when stem movement stops, is above the upper end of the

desired bench setting, then the com bined

stem (9, 6) length is too short.

a. Rotate jam nut (20) down to base of

threads on stem (9).

b. Decrease pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate lower knuckle (44) CW to in-

crease the combined stem length. DO

NOT allow actuator stem (6) to rotate

in the actuator.

d. Release all pressure from the actuator

and repeat Step 4 previous.

C. Procedure – Direct Action, ATC-FO:

1. Reference the nameplate (40) attached to

the actuator yoke (3). Determine the bench

set ting of the installed range springs (10)

from the nameplate (40).

2. Connect a temporary air supply with an inline ad just able airset regulator and gauge

to the upper actuator con nec tion. DO NOT

LOAD with any air pressure at this point.

3. To determine when stem/plug (3) makes

contact with the seat and travel stops, touch

the stem below the jam nut with one fi nger.

7. Increase pressure in the actuator to the upper pressure level of the bench setting.

8. Observe the location of the in di ca ting washer

(51) to the "C" mark on the in di ca tor plate

(23), mak ing sure to use the “top edge” of

the in di ca ting washer (51) as the ref er ence

point. Adjust indicator plate as needed.

8. Remove vented pipe plug (12) from the neck

of the bonnet (2).

9. Slowly release air pressure in actuator until

indicating washer (51) is in alignment with

the “O” mark on the indicator plate (23).

IOM-52112

Page 13

As pressure decreases, thru the hole in

the bonnet where the vented plug (12) was

removed, watch for the anti-rotational "stop"

(square or fl at surface of the stem) to appear.

NOTE: This "stop" should not function as

an up travel stop and push up against the

bonnet (2) (metal to metal). A gap of approximately 1/16" (1-1/2 mm) should exist

between these two surfaces.

NOTE: The purpose of a correct calibration

of the stem stroke is to cause the up travel

to be limited by the actuator travel stop nut.

10. To limit the up travel, rotate the travel stop

nut (52) CW and secure to bottom of attachment hub (4).

NOTE: Secure the actuator stem (6) by the

fl ats when rotating the travel stop nut.

NOTE: "Stroke" length is indicated on the

nameplate (40), and is the distance between

the "C" and "O" marks of the indicator plate

(23).

NOTE: The proper calibration of the actua-

tor / valve unit will occur when at the upper

pressure level of bench setting, the valve

plug (3) will be in the "C" position. At the

lower level of the bench setting, the actuator pressure should be within ±8% of the

lower bench range for the designed stroke

length.

11. Reinstall vented pipe plug (12) using “Fluorolube” grease on threads.

12. Release all pressure from actuator.

NOTES

IOM-521

13

Page 14

SECTION VII

VII. TROUBLE-SHOOTING GUIDE:

1. Valve is "jumpy" in stroking.

Possible Causes Remedies

A. Excess packing friction. A1. Re-align body--stem--actuator.

B. Installed backwards. B. Install per fl ow arrow. Direction is only FTO.

2. Valve/actuator makes "screeching" noise.

Possible Causes Remedies

A. Excess pressure drop. A. Bring pressure drop within design limits.

3. Valve exhibits "excess" vibration.

Possible Causes Remedies

A. Excess pressure drop. A. Bring pressure drop within design limits.

B. Excessive cavitation in liquid service. B. Change operation parameters to relieve causes of cavitation.

C. High outlet velocity. C1. Reduce fl ow rate and/or pressure drop.

A2. Packing follower too tight; back packing gland nut out.

A3. Install positioner.

A4. Increase bench set by changing to stiffer actuator range spring. May require

positioner if not installed. May require different airset.

C2. Use multiple valves in series or parallel.

C3. Increase outlet pipe size.

C4. Use larger valve body with reduced trim.

4. Valve exhibits "excess" seat leakage.

Possible Causes Remedies

A. Excess pressure drop. A1. Reduce pressure drop conditions.

B. Excess body and/or plug wear. B1. Oversized valve operating too close to seat; go to reduced trim.

5. Bonnet gasket leakage.

Possible Causes Remedies

A. Improper bonnet bolting drawdown. A1. Remove bonnet taking necessary safety precautions. Inspect bellows to

B. Cantilevered actuator. B1. Do not allow use of the actuator as a "step" upon which personnel may climb.

6. Body fl ange leakage.

Possible Causes Remedies

A. Over-tightening fl ange bolting. A. Loosen bolting, replace/install new gasket, retighten fl ange bolting in s

B. Improper pipe supports and anchors. B. Provide piping anchors and guides at control valve station.

C. Corroded fl ange bolting. C. Replace with corrosion resistant fl ange bolting.

D. Used outside pressure/temperature limits. D. Bring process variables within range of application; see Graph 1 in 521-TB.

A2. Convert to reduced trim.

A3. Increase actuator thrust by changing actuator range spring.

B2. Remove abrasive particulate.

B3. Possible excess cavitation in liquid service. Change operation parameters.

B4. Replace body assembly if seat is badly worn. Replace plug if badly worn.

determine if primary seal at body/bellows is damaged. If bellows is damaged,

replace bellows.

A2. Inspect secondary seal bonnet gasket for uneven thickness.

Replace bonnet gasket.

A3. Draw down bonnet bolting evenly and in a cross pattern; use bonnet bolting

torque levels indicated herein.

B2. Do not "set" any added weight on the actuator.

B3. Install vertically.

cross-pattern evenly.

Restrain bending movements.

IOM-52114

Page 15

7. Bellows failure.

Possible Causes Remedies

A. Overstroke of actuator. A. Recalibrate valve/actuator unit.

B. Abrasive particulate in fl uid. B. Remove all fl uid particulate.

C. Pressure, temperature, or pressure drop

outside limits.

D. Fluid absorption. D1. Reduce pressure/temperature if possible.

E. Frequent stroking causing fatigue failure of

TFE material.

F. Corrosion of embedded nut. F1. Consult factory.

8. Corrosion of stem sub-assembly at packing area.

Possible Causes Remedies

A. Loose packing. A. Disassemble valve and replace stem. Reassemble and tighten packing.

B. Fluid permeation of bellows.

C. Bellows failure. C. See No. 7 of this section.

C. Bring process variables within range of application; see Graph 1 in 521-TB..

D2. Reduce number of startups/shutdowns, or rapid depressurizations.

E1. Stabilize input SIG.

E2. Stabilize positioner output LOAD.

E3. Stabilize process variations to steady state, steady fl ow.

E4. Excess "play" in actuator swivel adapter; replace adapter.

E5. Cycle life reached; replace bellows.

F2. Use alternate stem material.

B1. Bring process variables within range of application; see Graph 1 in 521-TB.

B2. Use alternate stem materials construction.

B3. Locate, or position valve to be out of ambient moisture.

B4. Modify insulation if "trapping" moisture around packing gland nut.

B5. Purge "void zone".

9. Corrosion of silver soldered joint in sub-assembly (1-1/2" or 2" sizes only).

Possible Causes Remedies

A. Fluid permeation with chemical attack of

silver solder.

10. Corrosion surrounding vented pipe plug on bonnet.

Possible Causes Remedies

A. Fluid permeation and loose vented pipe plug. A1. Tighten plug.

B. Bellows Failure. B. Replace bellows.

11. External corrosion of jacket halves, bonnet, and body and bonnet bolting.

Possible Causes Remedies

A. Corrosive ambient environment. A1. Determine location of corrosive fl uid and maintain cause of leakage.

12. Blisters on TFE internals.

Possible Causes Remedies

A. Effects of absorption. A1. Reduce pressure/temperature levels.

A1. Use alternate stem materials construction.

A2. Purge "void zone".

A2. Replace corroded plug.

A3. Purge "void zone".

A2. Coat exposed portions with suitable corrosive resistant epoxy to degree able,

A2. Reduce startups/shutdowns and rapid depressurizations.

A3. Replace body assembly.

13. General corrosion of internals in "void zone", including Belleville washers ,embedded nut, bonnet, anti-rotation stop, and stem.

Possible Causes Remedies

A. Permeation together with ingress of

moisture in "void zone".

A1. Remove moisture source to greatest degree possible.

A2. Purge "void zone".

IOM-521

15

Page 16

Figure 9: Primary & Secondary Body/Bonnet

IOM-52116

Page 17

NOTE: No. varies

by body size

Figure 10: Control Valve Internals

ITEM NO. DESCRIPTION

1 Body Sub-Assembly

1.1 * Half Shell

1.2 * TFE Core

1.3 * Cap Screw

1.4 * Nut

1.5 * Lockwasher

2 Bonnet

3 Plug Head

4 Plug Retainer Strip

5 Packing Gland Nut

6 Packing Set

* Sub-level parts that make up the body sub-assembly; NOTE: DO NOT DISASSEMBLE THE PARTS OF THE

BODY SUB-ASSEMBLY (1)! The valve body (1) is ma chined after the shell halves (1.1) have been bolted (1.3,

1.4, 1.5) around the TFE core (1.2). Dis as sem bly of the body sub-assembly (1) will cre ate align ment problems

upon com plet ed reassembly. The TFE core (1.2) is not replaceable, except as a body sub-as sem bly (1).

IOM-521

ITEM NO. DESCRIPTION

7 Belleville Spring Washer

8 Bellows Sub-Assembly

9 Stem Sub-Assembly

10 Spacer

11 Bonnet Gasket

12 Vented Pipe Plug

13 Lockwasher

14 Bonnet Cap Screw

15 Yoke nut

Not Shown

18 Rating Tag

19 Bonnet Spacer

20 Jam Nut

17

Page 18

SECTION VIII

VIII. ORDERING INFORMATION:

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped

on the metal name plate and attached to the unit. This information can also be found on the Bill of Material

("BOM"), a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits).

Product Code typical format as follows: (last digit is alpha character that refl ects revision level for the product).

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the "BOM" sheet that was provided

when unit was originally shipped.

–

7

TO RETURN A VALVE FOR REPAIR: (RGA)

Before returning this Model - Contact Cashco Inc.

for permission to return the unit (as a whole or any

part of) and to obtain an "RGA" identifi cation num-

ber. This number must be marked clearly on the

outside of the returned container. In addition, affi x

to the outside of the container a signed statement

attesting to the fact that the valve and/or parts has

been fl ushed out for a specifi c period of time using

an "OSHA"acceptable neutralizing agent. The name

of the agent, the manufacturer's company name

and the total concentration level must be included

for both the valve service medium, as well as the

neutralizing agent.

NO returns wil be accepted at Cashco Inc. without

an M.S.D.S. (Material Safety Data Sheet) affi xed to

the outside of the returned container.

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to

modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

IOM-52118

Page 19

Figure 11: Body Assembly (BA)

Note: End fl ange

tapped bolt holes

straddle horizontal and

vertical centerlines.

ITEM NO. DESCRIPTION

1 Body Sub-Assembly

2 Bonnet

3 Plug Head

4 Plug Retainer Strip

5 Packing Gland Nut

6 Packing

7 Belleville Spring Washer

8 Bellows Sub-Assembly

IOM-521

ITEM NO. DESCRIPTION

9 Stem Sub-Assembly

10 Spacer

11 Bonnet Gasket

12 Vented Pipe Plug

13 Lockwasher

14 Bonnet Cap Screw

15 Yoke nut

18 Rating Tag

19 Bonnet Spacer

20 Jam Nut

Not Shown

17 ANSI/DIN Adapter Gasket

43 Upper knuckle See Fig. 6

44 Lower knuckle See Fig. 6

51 Indicating Washer See Fig. 6

19

Page 20

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. 521-IOM

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

Loading...

Loading...