Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL (IOM)

Model 5100 Pilot Operated

Pressure / Vacuum Relief Vent

I. DESCRIPTION AND SCOPE

IOM-5100

09-09

end-of-line

SECTION I

The maintenance of this Pilot Operated Vent Valve

(POVV) should only be done by quali ed valve

technicians. It is important that the technician be

familiar with the API and corporate standards,

corporate safety policies and the relief vent

manufacturer requirements. When repair services

are performed by an outside company, the company

needs to be a Cashco factory authorized repair

center which specializes in low pressure venting

devices.

II. VALVE DESIGN AND FUNCTION

The Model 5100 Pilot Operated Vents are used on

liquid storage tanks and other process vessels or

systems to prevent structural damage during the

process of lling or emptying of a tank or for changes

in atmospheric conditions. Excess pressure is

vented to atmosphere..

Storage tanks are pressurized when liquid is

pumped in, compressing the existing vapor or

when increasing temperature causes increased

evaporation or expansion of existing vapor.

Conversely, a vacuum may be created when uid

is pumped out or as atmospheric temperature

decreases. To prevent structural damage, vapor

must be allowed to escape or enter the tank at a

speci ed ow rate. The volume rate of venting is

dependent on the tank size, displacement rate and

the ash point of the uid. See API Standard 2000

for procedures to determine venting requirements.

For information on repair centers in your area, please

contact:

Valve Concepts, Inc.

%Cashco, Inc.

607 West 15

Ellsworth, KS 67439-0006

(785) 472-4461 (Phone)

(785) 472-3539 (Fax)

SECTION II

th

Street

Thus the vent valve is capable of operating at

pressures closer to the maximum allowable

working pressure of the tank. Operating at higher

pressures reduces evaporation and total venting

volume, thereby reducing product loss and the cost

of handling emissions.

Each application must be reviewed to ensure material compatibility with all metal and soft good

components with the service conditions. The pallet

assembly, wetted components and tubing are 316

SST. Diaphragm material is FKM, unless speci cied otherwise.

The pilot valve is factory set to comply with the

speci cations on the purchase order. The adjustable pressure range is a function of the installed

spring and will be stamped on the metal nameplate.

The set point pressure maybe changed within the

design parameters of the spring while installed on

line or in a maintenance shop. See Section IX

for setting and testing procedures.

A pilot operated relief vent has two principal

advantages over other relief vent designs:

1. Bubble tight shutoff up to 100% of set point.

2. Full open capacity for pressure relief is achieved

within 10% above set point.

This manual is intended to provide recommended

procedures and practices for installation, operation

and maintenance of the Model 5100 POVV. Although this manual cannot cover all possible contingencies, these guidelines will provide safe and

reliable pilot valve performance.

Page 2

III. SAFETY WARNINGS:

SECTION III

WARNING

Warning: Before beginning any relief vent inspection

or maintenance, carefully read and understand the

information in this manual. If there are any questions

concerning the information in this manual, please

contact the factory or an authorized repair center

before proceeding.

Tank or system protection is the primary function of

the Pilot Operated Vent Valve (POVV). It must be

selected to meet the total pressure ow requirements

within the maximum allowable working pressure

of the system on which it is installed. Consult API

Standard 2000 for tank protection sizing procedures.

Improperly speci ed relief vents may result in

structural damage to the tank or system, and can

cause severe personal injury or death.

In the event of a diaphragm failure, the Model 5100

will vent pressure to the atmosphere causing the

pressure relief valve to fail in the OPEN position.

The vent will now function like a weight loaded vent

under this condition with a lower set point. Consult

the factory for any questions related to this overpressure condition.

CAUTION

DO NOT attempt to change pressure set point beyond

the limit speci ed on the nameplate..

The 1/2” OD SST pilot valve sensing line must be

kept open and unobstructed to ensure that the pilot

“senses” the actual tank pressure. For applications

where tank vapors may condense or polymerize in

the sensing tubing or the pilot valve, a nitrogen purge

may be required to prevent internal obstruction of the

tube. Consult the factory for recommendations.

CAUTION

DO NOT attempt to remove the vent from the tank or

process vessel without rst bleeding all pressure from

the system. ALTERNATIVE MEANS OF PRESSURE

RELIEF MUST BE PROVIDED WHEN THE VENT IS OUT

OF SERVICE.

After isolating the relief vent, bleed all pressure

from both main and pilot valve before removing the

Model 5100 POVV.

NOTE: Both the pilot valve and main valve are

exposed to the process vapors. Observe all

plant procedures and Material Safety Data Sheet

recommendations before inspecting, adjusting or

servicing any components.

The vent on the spring bonnet of the pilot must

be clean and unobstructed for proper and safe

operation of the valve.

SECTION IV

IV. SHIPPING, INSPECTION AND

STORAGE:

The POVV vent is carefully packaged to prevent

damage or contamination during shipping. Inspect

the equipment when it is received and report any

damage to the carrier immediately. The POVV

should be stored in a clean environment with all

the protective ange covers in place to prevent

intrusion of foreign materials. If there are indications

of physical damage or internal contamination, the

valve may need to be disassembled, cleaned and

inspected prior to installation.

2

Lifting lugs may be provided on the main valve for

lifting and handling. To avoid damage to the lower

ange surface, rest the vent on a soft clean gasket

material until it is ready to be installed. DO NOT

store the POVV directly on the ground.

Make sure that any loading weights that might have

been shipped separately, to protect the vent during

shipping, are accounted for and stored with the vent.

These weights when required, will be installed during

installation,at installation.

IOM-5100

Page 3

V. INSTALLATION:

SECTION V

The Model 5100 POVV is a precision device that

must be handled carefully to ensure seat tightness.

WARNING

The vent must be installed in a vertical position. The

tank nozzle on which the vent is mounted should have

the same nominal diameter as the venting device. It

is recommended that the tank nozzle ange face be

within 1 degree of horizontal for best performance of

the venting device.

1. At installation, the POVV should be carefully

lifted into position using the lifting lugs on the

body. Use the case assembly (32,33) to help

align the body directly over the tank nozzle.

DO NOT use the pilot valve or pickup line to

pull the POVV into position.

2. Aluminum body vents should be mated to

at-faced 125# ASME anges. Mating anges

should be at within 0.020” and clean; free

of scratches, corrosion and tool marks. A full

faced gasket is recommended.

4. Center the gasket within the bolt circle of the

tank nozzle ange.

5. Lubricate all studs and nuts with an appropri ate thread lubricant. If stainless steel studs

and nuts are required, use an anti-seize lubri cant such as moly-disul de.

6. Remove ange protective covers and carefuly

set the POVV down on the gasket and face of

the nozzle ange.

WARNING

Minimum clearance between tank roof and vacuum

inlet port must be at least equal to the vents’ nominal ange bore. Tank nozzle bore must be greater

than or equal to vent inlet ange bore. Inlet piping

loads must be supported by appropriate structural

supports, NOT by the vent body.

7. Install lockwashers and nuts. Tighten nuts

to half the recommended torque value using

an alternating crossing pattern. See Table 2.

3. Install the ange gasket on the nozzel face.

Use either a full faced or ring gasket for

raised face anges. Ensure that the gasket

material is suitable for the service. See Table

1 for gasket dimensions.

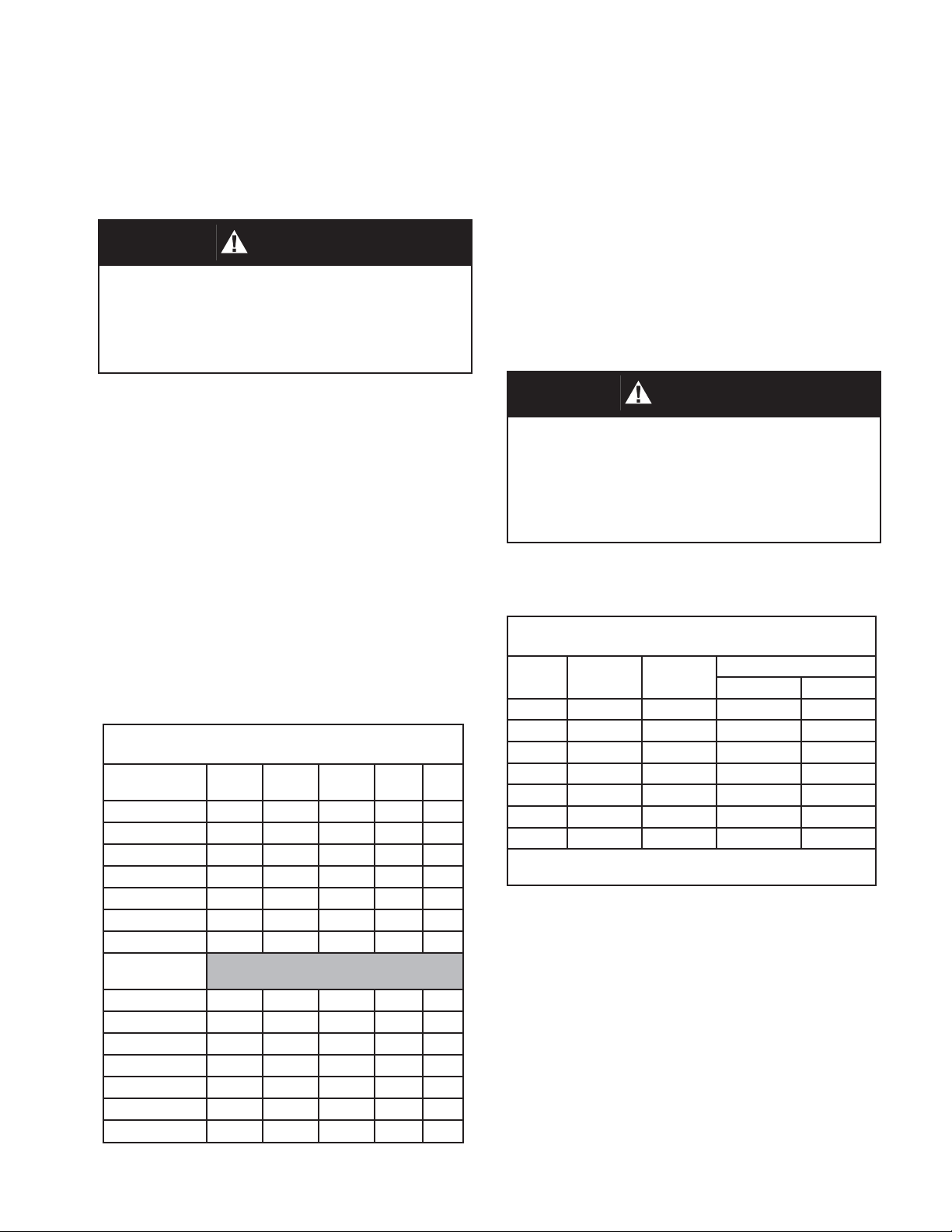

Table 1

Body Flange Gasket Dimensions

CS, SST

150# ASME RF

2’ 4.12 2.38 -- -- --

3” 5.38 3.50 -- -- --

4” 6.88 4.50 -- -- --

6” 8.75 6.62 -- -- --

8” 11.00 8.62 -- -- --

10” 13.38 10.80 -- -- --

12” 16.12 12.80 -- -- --

Alum w/ 125#

ASME FF

2” 6.00 2.00 4.75 .75 4

3” 7.50 3.00 6.00 .75 4

4” 9.00 4.00 7.50 .75 8

6” 11.00 6.00 9.50 .88 8

8” 13.50 8.00 11.75 .88 8

10” 16.00 10.0 14.25 1.00 12

12” 19.00 12.00 17.00 1.00 12

O.D. I.D. B.C. Hole Qty

Table 2

Recommended Minimum Torque Values *

Size

2” 4 5/8”-11 31 81

3” 4 5/8”-11 43 106

4” 8 5/8”-11 29 68

6” 8 3/4’10 51 101

8” 8 3/4”-10 78 142

10” 12 7/8”-9 75 138

12” 12 7/8”-9 93 179

* Torque vlaues are based on a gasket factor m = 3.5,

gasket factor y = 4000 psi, operating pressure = 30 psi

Qty

Holes

Bolt

(UNC)

Torque (lb-ft)

Raised Face Flat Face

8. Make sure that the gasket is compressed

evenly and the anges are not distorted.

NOTE: Misalignment of ange faces will cause

bending stresses at the ange and may damage

ange joint.

9. Finish tightening nuts to the point that no ad ditional rotation occurs.

10. If loading weights were shipped separate from

the vent, install weights on vacuum pressure

pallet. Ensure that all packing has been re

moved.

IOM-5100

3

Page 4

SECTION VI

VI. PILOT MAINTENANCE:

A. General:

1. Maintenance procedures herein after are

based upon removal of the pilot/vent valve

unit from the vessel/piping where installed.

2. Owner should refer to owner’s procedures for

re mov al, handling and cleaning of non re us able parts; i.e. gaskets, suitable solvents,

etc.

3. All indicated Item Numbers that are with

respect to the Pilot Assembly will be in

pa ren the sis and un der scored; i.e. (205). All

Item Numbers that are with respect to the

Vent Valve are not un der scored; i.e. (6).

B. Separation from Main Valve and Disassembly:

1. Disconnect sense tube (57) from ttings

(48) and (244). Remove the pilot valve assembly from the nipple (53) by rotating the

pilot body (201) CCW.

2. Secure body (201) in vise with ‘sensing”

port facing front. Disconnect tubing (243)

from connectors (232),(234).

3. Paint or embed a match mark between

upper case (202), spacer (245) and lower

case (203) along anged area. NOTE lo-

cation of 1/8” NPT tap from elbow (234) in

relation to body sensing port and straight

connector (232).

WARNING

SPRING UNDER COMPRESSION. Prior to re mov ing

ange bolts, relieve spring com pres sion by backing

out the adjusting screw. Failure to do so may result

in ying parts that could cause personal injury.

4. Rotate the closing cap (205) CCW for

removal. Loosen the adjusting screw nut

(214) two revolutions. Rotate Adjusting

screw (213) CCW and remove.

5. Remove diaphragm case nuts (209),

lockwashers (210), at washers (221) and

cap screws (220). Grasp spring bonnet

(204) and lift up until diaphragm case (202)

clears top of spring button (212).

6. Secure spring bonnet (204) in a vice with

the upper diaphragm case (202) orientated

upwards.

7. Use 5/32” allen wrench to remove cap

screws (237) and lock washers (239) to

separate the bonnet (204) from the upper

case (202). Replace bonnet gasket (222)

and reassemble item numbers (202, 204,

237 and 239). Remove bonnet from vice

and set assembly aside.

8. Lift range spring (215) and spring button

(212), up and set aside.

9. Grasp the at surfaces of wrench washers

(228) with a wrench and rotate piston stud

nut (235) CCW to remove nut, lock washer

(241), spring guide (211), washers (228).

10. Remove pressure ring (250), upper

pressure plate (246), upper diaphragm

(207) and spacer (245).

11. Remove upper diaphragm washer (219),

upper diaphragm gasket (226), and

diaphragm spacer (247).

For Intermediate & High Pressure Pilots Only:

Remove diaphragm case gasket (255)

and pressure ring (251).

12. Remove lower pressure plate (206), lower

diaphragm (207), lower diaphragm washer

(219) and lower diaphragm gasket (226).

13. Rotate 7/16” hex head cap screws (238)

CCW and remove lock washers (240).

Lift up on lower diaphragm case (203) to

remove. NOTE the alignment of the four

bolt holes and the sense hole in case (203)

with the holes in the body (201).

14. Grasp the cylinder (227) / piston (208)

assembly and lift upwards to extract this

assembly from the body (201). Remove

upper and lower body gaskets (225).

15. From top of assembly, press piston stud

(230) / piston (208) downward through

the center of the cylinder (227) to remove.

Apply Dow Corning 111 lubricant in o-ring

grooves and install new piston O-rings

(224).

4

IOM-5100

Page 5

16. From opposite end of assembly use 1/8”

allen wrench to remove retaining screw

(229) and piston cap (223). Remove and

replace with new seat O-ring (233).

17. Rotate blowndown needle jam nut

(236) CCW two rotations and remove

blowndown needle (217) from body (201).

Replace with new O-ring (218).

C. Re-assembly:

1. Install piston cap (223) and retaining

screw (229) into piston (208).

2. Lightly coat cylinder (227) bore with Dow

Corning Molykote 22 lubricant and insert

piston (208) through lower opening of the

cylinder (227) and press into place.

3. Position new body gasket (225) on top of

pilot body, align gasket holes and slide

piston (208) / cylinder (227) assembly

into the body (201). DO NOT COVER

SENSING HOLE.

4. Position another body gasket (225) on top

of cylinder ange. Align holes in the lower

diaphragm case (203) with the cylinder

and body. DO NOT COVER SENSING

HOLE. Use lock washers (240) and cap

screws (238) to secure lower diaphragm

case (203) tight to the body. (201).

5. Install new lower diaphragm gasket (226)

and one diaphragm washer (219) on

piston stud (230).

6. Place a new diaphragm (207) and the

lower pressure plate (206) on piston stud.

For Intermediate & High Pressure Pilots Only:

Install diaphragm case gasket (255) and

pressure ring (251).

7. Install diaphragm spacer (247), a new

upper diaphragm gasket (226) and

diaphragm washer (219) on psiton stud

(230).

8. Place the large spacer (245) above the

diaphragm and align match marks per

previous B 3.

9. Install another new diaphragm (207) on

piston stud (230) and align the bolt holes

with parts of previous Steps 6 and 7.

10. Stack the upper pressure plate (246), the

wrench washers (228), the spring guide

(211) and piston stud lock washer (242)

over the piston stud (230).

11. Install and tighten piston stud nut (235) to

secure all parts. (Check alignment of the

bolt holes around the circumference.)

12. Position the range spring (215) and spring

button (212) on the spring guide (211).

13. Place diaphragm pressure ring (250) on

top of diaphragm (207).

14. Lower the upper diaphragm case (202) /

spring bonnet (204) assembly over the

spring (215), allow to rest on the diaphragm

pressure ring (250). (Ensure alignment of

match marks per prervious B 3.)

15. Install diaphragm case screws (220), at

washers (221), lock washers (210) and

nuts (209) and tighten.

16 Apply a light coat of Bostik Never-Seez

to threads of blowndown needle (217).

Thread completely into body until the nut

(236) contacts the body (201) and then

back our two rotations. Rotate nut (236)

CW to secure nut tight.

17. Reinstall adjusting screw (213) and jam

nut (214) in spring bonnet (204).

18. Refer to Section IX for Calibration and

Testing

19. Install pilot body assembly on nipple (53)

tight with CW rotation. Ensure straight

connector (244) of the pilot valve assembly

is directly above sensing tube connector

(48) of the main valve assembly.

20. Reconnect tubing (243) to ttings (232),

(234) and tubing (57) to ttings (48),(244).

IOM-5100

5

Page 6

VII. VENT VALVE MAINTENANCE:

CAUTION

SECTION VII

Actuator Diaphragm Replacement:

a. Paint or embed a match mark between

upper case (33) and lower case (32) along

anged area.

If the vent valve must be removed from the tank for

any reason, make sure that all pressure has been released before the ange fasteners are loosened. Refer

to your company procedures before venting the tank

pressure and when handling toxic or otherwise hazardous materials. Observe all standard safety precautions as speci ed on Material Safety Data Sheets for

the product(s) in the system while removing the valve

and during the repair.

A. General:

1. The Model 5100 POVV does not require

routine lubrication or adjustments. It

should be checked periodically, at least

twice a year, to con rm that the vent is

functioning properly and that the set point

is correct.

2. The pilot valve is designed to function in a

failsafe manner. The failure of a seal or a

diaphragm will cause pressure to be vented to the atmosphere; the resulting loss in

pressure will cause the main valve to open

under rising pressure.

b. Loosen and remove nuts (35), lock

washer (37), at washer (36) and cap screw

(34).

c. Lift up and remove the upper case (33)

assemby and set aside.

d. Remove diaphragm (41) and replace

with new diaphragm. Position and align bolt

holes in the circumference of the diaphragm

with the holes in the lower case (32).

e. Reposition upper case assy (33) on dia-

phragm (41). Align marks of a. above.

f. Install cap screws (34), at washer (36),

lock washer (37) and nuts (35) and tighten.

g. Install pilot body assembly on nipple (53)

tight with CW rotation. Ensure straight connector (244) of the pilot valve assembly is

directly above sensing tube connector (48)

of the main valve assembly.

3. Periodic inspection for seat tightness

should be done to ensure compliance with

local air pollution control requirements. If

the vent relieves to the atmosphere, this

maybe accomplished with a gas detector

calibrated for the principle product in the

system.

4. The vent valve will need to be removed

from the tank for inspection of diaphragms,

gaskets and seals. When this is done, the

vent must be handled carefully using the

lifting lugs and the body.

5. The main and pilot valve housings, bodies,

pallet assemblies and other components

are exposed to the process vapor.

B. Disassembly:

1. Disconnect the tubing connections (pilot to

main Valve) (48, 57 and 244) and remove

the pilot by rotating the pilot body (201) assembly CCW from nipple (53).

h. Reconnect tubing (57) to ttings

(48),(244). Refer to Section IX for Calibration and Testing.

Pressure Pallet Diaphragm Replacement:

a. Paint or embed a match mark between

weatherhood (17) and body (1) along anged

area.

b. Rotate jam nuts (55) CCW coming to

rest against top of jack screw (7). Rotate

jack nuts (54) CCW coming to rest against

nuts (55).

c. Rotate jack screw (7) CCW and remove

from threaded end of pallet guides (16).

d. Grasp the case assy (AA) (32/33) and lift

straight up to remove (AA) and weatherhood

assy (17) from pallet guides (16).

CAUTION

Do not grasp weatherhood around the bottom edge,

it maybe sharp.

6

IOM-5100

Page 7

NOTE: Support plate (40) and pressure pal-

let stem(10) assembly will also lift out of

the body (1). (continue with step i. unless

changing gasket (49)).

p. Push cotter pin (61) into hole in stem

(10) and secure. Remove pallet (4) assembly from vise.(continue with step t. unless

changing gasket (13)).

To Remove Adapter Gasket: steps (e - h).

e. Lay the (AA) and weatherhood assy on

at surface.

f. Paint or embed a match mark between

weatherhood (17) and lower case adapter

assy (32).

g. Loosen and remove adapter bolts (38)

and washers (39). Set weatherhood (17)

to the side and remove pressure plate (29).

Remove and replace adapter gasket (49).

h. Align bolt holes in pressure plate (29)

and weatherhood (17) with lower case

adapter assy (32) and install lock washers

(39) and adapter bolts (38). Tighten securely.

i. Remove cylinder of wire screen (27) .

Inspect seating surface of seat ring (3).

j. Straighten the bent ends of cotter pin

(62) and remove pin from support plate

(40). Slide pallet(4) assembly out of tube

end.

k. Carefully secure stem (10) in a vise,

oriented such that the pallet (4) assembly

is directed upwards.

l. Remove cotter pin (61), nut (23), lock

washer (19), washer (24), diaphragm retainer plate (6), diaphragm (5) and pallet

(4) from stem (10).

m. Re-install pallet (4) on stem (10).

NOTE: Apply small amount of TFE paste

around the center opening (top surface) of

the pallet (4).

To Remove Seat Ring/Gasket: steps (q - s).

q. Place a wrench on the milled ats of

the pallet guides (16), rotate CCW to remove the guides (16) and stud spacers

(69). Mark the location of guides on the

seat ring (3) for reference at re-assembly.

r. Remove four socket head cap screrws

(11) and lift out the seat ring (3). Remove

seat gasket (13) and clean sealing surface.

s. Apply TFE paste to both sides of new

gasket and install in body(1). Position

seat ring (3) on gasket (13) and install cap

screws (11), guides (16) and stud spacers

(69). Tighten cap screws (11) and supports (16) to 15 ft. lbs.

t. Reposition cylinder of wire screen (27)

around top surface of seat ring (3).

u. Install stem (10)/pallet (4) assembly in

the tube end of support plate (40). Align

the drilled holes and insert cotter pin (62).

Bend prongs of pin around the stem to secure it in place.

v. Grasp the case assembly (AA) (32/33)

and install on pallet guides (16). Ensure

alignment of weatherhood (17) and body

(1) per step a. above.

w. Install jack screw (7) on threaded end

of pallet guides and tighten securely. Rotate jack nut (54) CW in equal increments

until they rest tight against lower case (32)

x. Rotate jam nut (55) CW to secure tight

to jack nut (54).

n. Place a new diaphragm (5) on the pal-

o. Install the diaphragm retainer plate (6),

IOM-5100

let (4). NOTE: Apply small amount of TFE

paste around the center opening (top surface) of the diaphragm (5).

washer (24), lock washer (19) and nut (23).

Secure nut tight to lock washer (19).

y. Install pilot body assembly on nipple

(53) tight with CW rotation. Ensure straight

connector (244) of the pilot valve assembly

is directly above sensing tube connector

(48) of the main valve assembly.

z. Reconnect tubing (243) to ttings

(232), (234) and tubing (57) to ttings

(48),(244).

7

Page 8

Vacuum Pallet Diaphragm Replacement:

a. Remove cover bolts (22), cover as-

sembly (2) and cover gasket (12). Inspect

cover for corrosion, damage or product

build up. Clean with a suitable solvent.

NOTE: During re-assembly, install new

cover gasket (12) (5/32-inch dia. Gortex

rope joint sealant).

b. Lift upwards to remove vacuum pal-

let (9) assembly, including any loading

weights (18) that may be resting on the

CAUTION

DO NOT change pressure ratings by removing or adding additional weights to the pallet assembly without

consulting the factory or your VCI representative.

pallet(4).

c. Place stem (9) in a vise with the

threaded end up. Remove cotter pin (61),

nut (23), lock-washer (19) and washer

(24). Lift up to remove diaphragm plate

(6) and diaphragm (5) NOTE: Apply TFE

paste to threads of the stem and around

the hole on the pallet (4).

c. Apply TFE paste to both sides of new

gaskets and install in body (1).

d. Re-assemble vacuum vent side

in reverse order, making sure that the

vacuum pallet and loading weights are in

their proper location. Tighten bolts (11),

guides (8) and spacers (69) to 15 ft. lbs.

e. Install cover gasket (12). When

installing the cover (2) ensure the vacuum

stem (9) is inserted in the stem guide in the

cover (2).

To Remove Inlet Screen:

a. Rotate bolts (15) CCW and remove.

Inspect and clean screen (14) and reinstall

to body (1).

d. Install new diaphragm (5). Re-install

washer (24), lock-washer (19) and tighten

nut (23) on stem. Insert cotter pin (61)

through hole in stem and secure.

e. Inspect and clean seat ring (3). Check

seat surface for any nicks, corrosion, pitting or product build-up. Seat surface must

be clean and smooth for vent to preform

properly.

To Remove Seat Ring/Gasket:

a. Rotate bolts (11) CCW and remove.

Remove guides (8) and spacers (69) (Use the slot on top of guides and rotate

CCW.) Mark the location of these items

on the seat ring (3) for reference at reassembly.

b. Lift up to remove seat ring (3) and

gasket (13). Inspect guides (8) and inside

of the body cavity (1) for any corrosion or

product build up. Clean as necessary.

8

IOM-5100

Page 9

SECTION VIII

VIII. ORDERING INFORMATION:

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was

stamped on the metal name plate and attached to the unit. This information can also be found on the Bill of

Material (parts list) that was provided when unit was originally shipped.) (Serial Number typically 6 digits).

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code. With

this information they can provide a quotation for a

new unit including a complete description, price

and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory.

All purposed changes will require a new name plate with

appropriate ratings and new product code to accomodate the recommended part(s) changes.

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product

code. Identify the parts and the quantity

required to repair the unit from the Bill of Materials sheet that was provided when unit was

originally shipped.

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for

part identi cation and selection.

Local Sales Representative will provide quotation for appropriate Kit Number, Price and

Availability.

IOM-5100

9

Page 10

SECTION IX

IX. PRESSURE CALIBRATION AND

TESTING PROCEDURE FOR PILOT:

1. To determine set pressure, slowly increase

the pilot inlet pressure. Simulated actuator

pressure will rise with inlet. As set pressure

is approached, the actuator pressure will begin to decrease. Continue to increase the

inlet pressure slowly until the actuator pressure is 90% (+/- 10%) of the inlet pressure.

This is the set pressure.

2. Rotate the set pressure adjusting screw

(213) CW to increase set pressure or CCW

to decrease set pressure. Continue to rotate

the adjusting screw and repeat the test per

Step 1 previous until the speci ed set pressure is achieved.

3. To determine reseat pressure, slowly decrease the inlet pressure and the actuator

pressure will begin to increase. Reseat occurs when the actuator pressure equal the

inlet pressure.

4. The difference between set and reseat

pressure,”blowdown”, can be adjusted with

the blowdown needle (217). Maximum

clockwise rotation provides rapid relief valve

opening, “snap action”’ and maximum blowdown. Standard blowdown, unless otherwise speci ed is 7 - 10% below set pressure.

7. A small interaction occurs between set

pressure and blowdown adjustments. Readjustment of both may be required until

the speci ed set pressure and blowdown

are achieved. After completion, lock both

screws and locknuts and replace closing cap

(205) on adjusting screw (213).

8. Hold the valve at the set pressure while

preforming a soap bubble test of all bolted,

anged and threaded connections.

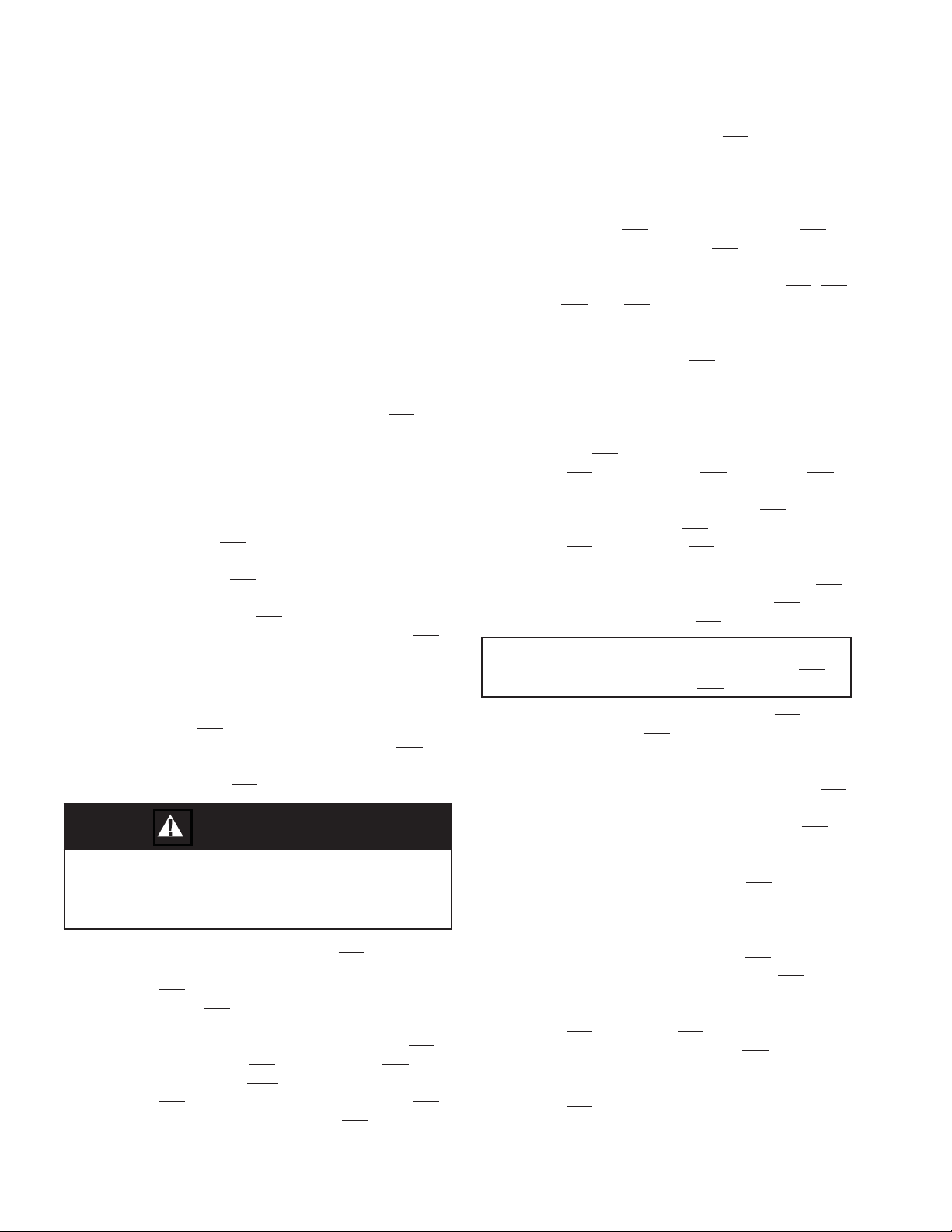

9. Refer to Table 3 for standard setting Speci cations.

SETTING SPECIFICATIONS - PILOT VALVE

Pilot Action

Snap 2” - 8” WC +/- 0.2”WC 75 90 +/- 3

Snap

Snap

Modulating 2” - 8” WC +/- 0.2” WC 75 100

Modulating

Modulating

Set

Pressure

8.1” WC -

1.0 psig

1.1 - 15.0

psig

8.1” - 1.0

psig

1.1 - 15.0

psig

TABLE 3

Set

Pressure

Limits

+/- 3% 90 90 +/- 3

+/- 3% 95 93 +/- 3

+/- 3% 90 100

+/- 3% 95 100

Maximum

Cracking

Pressure %

of Set

Reseat

Pressure

% of Set

5. Increased counter clockwise rotation of

blowdown screw provides “modulating” action and minimum (zero) blowdown. Reseat

pressure is the same as set pressure.

NOTE: The blowdown needle is located

in a pressure containing chamber, and is

retained by the blowdown o-ring (218) and

blowdown locknut (236). DO NOT remove

the blowdown needle while under pressure.

6. Remove body vent and install a exible tube

in this port. Immerse this pilot discharge

bubble tube in water approximately 1/4” below surface to detect cracking and reseat

pressure.

10

Pilot Valve Test Stand

IOM-5100

Page 11

MODEL 5000 PILOT VALVE

ITEM NO. DESCRIPTION Repair Part ITEM NO. DESCRIPTION Repair Part

201 Body 229 Retaining Screw

202 Upper Diaphragm Case 230 Piston Stud

203 Lower Diaphragm Case 231 Tee

204 Spring Bonnet 232 1/8”NPT x 1/4 Tube Connector

205 Closing Cap 233 Seat O-ring *

206 Lower Pressure Plate 234 1/8”NPT x 1/4 Tube Connector

207 Diaphragm * 235 Piston Stud Nut

208 Piston 236 Blowdown Needle Jam Nut

209 Diaphragm Case Nut 237 Button Head Cap Screw

210 Diaphragm Case Lock Washer 238 Hex Head Cap Screw

211 Spring Guide 239 Lock Washer

212 Spring Button 240 Lock Washer

213 Adjusting Screw 241 Piston Stud Lock Washer

214 Adjusting Screw Jam Nut 242 Exhaust Vent (Elbow)

215 Range Spring 243 Tubing

216 Bug Screen Vent 244 3/8”NPT x 1/2 Tube Connector

217 Blowdown Needle 245 Actuator Spacer

218 Blowdown Needle O-ring * 246 Upper Pressure Plate

219 Diaphragm Washer (TFE) * 247 Diaphragm Spacer

220 Diaphragm Case Cap Screw 248 Check Valve

221 Diaphragm Case Flat Washer 249 Sense Nipple

222 Spring Bonnet Gasket * 250 Sense Diaph. Pressure Ring

223 Piston Cap 251 Boost Diaphragm Pressure Ring #

224 Piston O-ring * 252 Street 3/8” NPT Pipe Plug

225 Body Gasket * 253 Exhaust Coupling

226 Diaphragm Gasket * 254 Exhaust Nipple

227 Cylinder 255 Diaphragm Case Gasket # *

228 Wrench Washer 256 3/8 FNPT Elbow

# Intermediate & High Pressure Pilots ONLY

IOM-5100

11

Page 12

MODEL 5100 RELIEF VENT

Valve Concepts, Inc./ Cashco, Inc.

607 W. 15th Street

Ellsworth, KS 67439

PH (785) 472-4461

FAX (785) 472-3539

www.cashco.com

email: vcisales@cashco.com

Printed in U.S.A. Model 5100

ITEM NO. DESCRIPTION Repair Part ITEM NO. DESCRIPTION Repair Part

1 Body 34 Case Bolts

2 Cover Assembly 35 Case Nuts

3 Seat Ring Pallet 36 Flat Washer

4 Pallet 37 Lock Washer

5 Diaphragm * 38 Adapter Bolt

6 Diaphragm Retainer Plate 39 Adapter Lock Washer

7 Jack Screw 40 Support Plate (Weldment)

8 Vacuum Pallet Guide 41 Actuator Diaphragm *

9 Vacuum Stem 42 Stiffener Plate

10 Pressure Pallet Stem 43 Strainer

11 Seat Ring Bolts 46 Pipe Plug (Sense)

12 Cover Gasket * 47 Tee

13 Seat Ring Gasket * 48 Sense Tube Connector

14 Inlet Screen Assembly 49 Adapter Gasket *

15 Bolts 50 Name Plate

16 Pressure Pallet Guide 51 Drive Screw

17 Weather Hood 52 Caution Decal

18 Pallet Weight 53 Pilot Mounting Nipple

19 Lock Washer 54 Jack Nut

22 Cover Bolts 55 Jam Nut

23 Pallet Nut 57 Sense Tubing

24 Plain Washer 61 Cotter Pin

26 Diaphragm Retainer 62 Cotter Pin

27 Outlet Screen 69 Stud Spacer

29 Pressure Plate 72 Flat Washer

32 Lower Case Assembly 73 Washer

33 Upper Case Assembly 74 Nut

75 Stud

Loading...

Loading...