Casella CEL CEL-181 User Manual

Casella USA

17 Old Nashua Road #15

Amherst, NH 03031-2839

CEL-181

Personal Noise Dosimeter

Handbook

www.casellausa.com Page 1 of 14 tel: (800) 366-2966

info@casellausa.com

27 Jan 2006 fax: (603) 672-8053

Casella USA

17 Old Nashua Road #15

Amherst, NH 03031-2839

CONTENTS

Introduction 2

1 The Risk of Industrial Deafness 3

2 Technical Description 5

3 Operating the Instruments 6

3.1 Dosimeter Calibrator Type CEL-182 6

3.2 Noise Dose Meter CEL-180/181 6

3.2.1 Schedule of Parts 6

3.2.2 Controls and Indicators 7

3.2.3 Connection of the Batteries 8

3.2.4 Calibration Checks 8

4 Measurement Methods 9

5 Analysis of Results 11

6 Care and Maintenance Procedures 11

7 Manufacturer's Warranty and Service Arrangements 12

8 Specification 13

9 Calibration Certificate 14

10 Modifications and Post Production Developments 14

Introduction

These are personal integrating noise dose

meters that have been specifically developed for

the accurate and reliable assessment of the

degree of auditory hazard associated with any

given job function. The design concept allows

for a wide degree of flexibility in determining the

integration law and, hence, they can be preset

to conform to any of the damage risk criteria that

are currently in use. This is achieved by using a

wide range RMS detector followed by an

amplitude-weighting network and in both of

these circuits the main parameters may be

manufacturer preset. Particular attention has

been paid in the design to minimizing the

instrument's weight and physical dimensions in

order that it will be socially acceptable to the

subject and cause minimum interference with

the normal working routine. Special procedures

are employed to ensure the security of the

results, thereby preventing unauthorized access

to the accumulated data.

When worn by the subject the dose meter will

monitor the actual noise level to which he has

been exposed and calculate the percentage of

permitted exposure consumed in accordance

with the procedures laid down in the various

National Standards and Government control

orders that apply in each individual country.

When calibrated with a 5dB exchange rate (q =

5) the instruments comply to the OSHA

regulations published in the United States and

with q = 3 they comply with the International

Standard ISO R1999. Furthermore, the impulse

time constant may be, employed as required by

certain West German regulations. Each of these

calibration settings is clearly explained in this

manual and each instruments' calibration is

indicated by a letter code on the serial number

plate. An additional measurement range is

included in the CEL personal dose meter

enabling its range of applications to be extended

to cover measurements in both work areas

having lower noise levels and to undertake

certain environmental noise measurements.

Full details regarding the theory and practice of

industrial noise dose measurements are given in

the latter sections of this manual.

www.casellausa.com

info@casellausa.com

Page 2 of 14 tel: (800) 366-2966

27 Jan 2006 fax: (603) 672-8053

Casella USA

17 Old Nashua Road #15

Amherst, NH 03031-2839

1 The Risk of Industrial Deafness

It has been known for many years that people

employed in noisy occupations invariably

suffered from deafness. Only in recent years,

however, has the full extent of the hazard been

appreciated with the realization that the effects

of excessive noise exposure are non-reversible

but preventable.

The efficiency of the human ear, along with the

other body functions, naturally decreases with

advancing years. However, this effect known as

presbycusis would not, in general, leave an

individual with a 'social handicap' in later life. It

would not cause any problems with everyday

conversation or limit their ability to work or enjoy

a full social life. In addition to this natural

deterioration, however, will be added other

losses in hearing acuity resulting from disease,

accidents or excessive noise exposure, which

could well result in a total degree of deafness

that would present a considerable social

handicap quite early in life.

Within the ear is a very clever, yet delicate,

system that enables us to hear. A diaphragm

in these cases. The only 'cure' for industrial

deafness is, therefore, prevention-Hearing

Conservation.

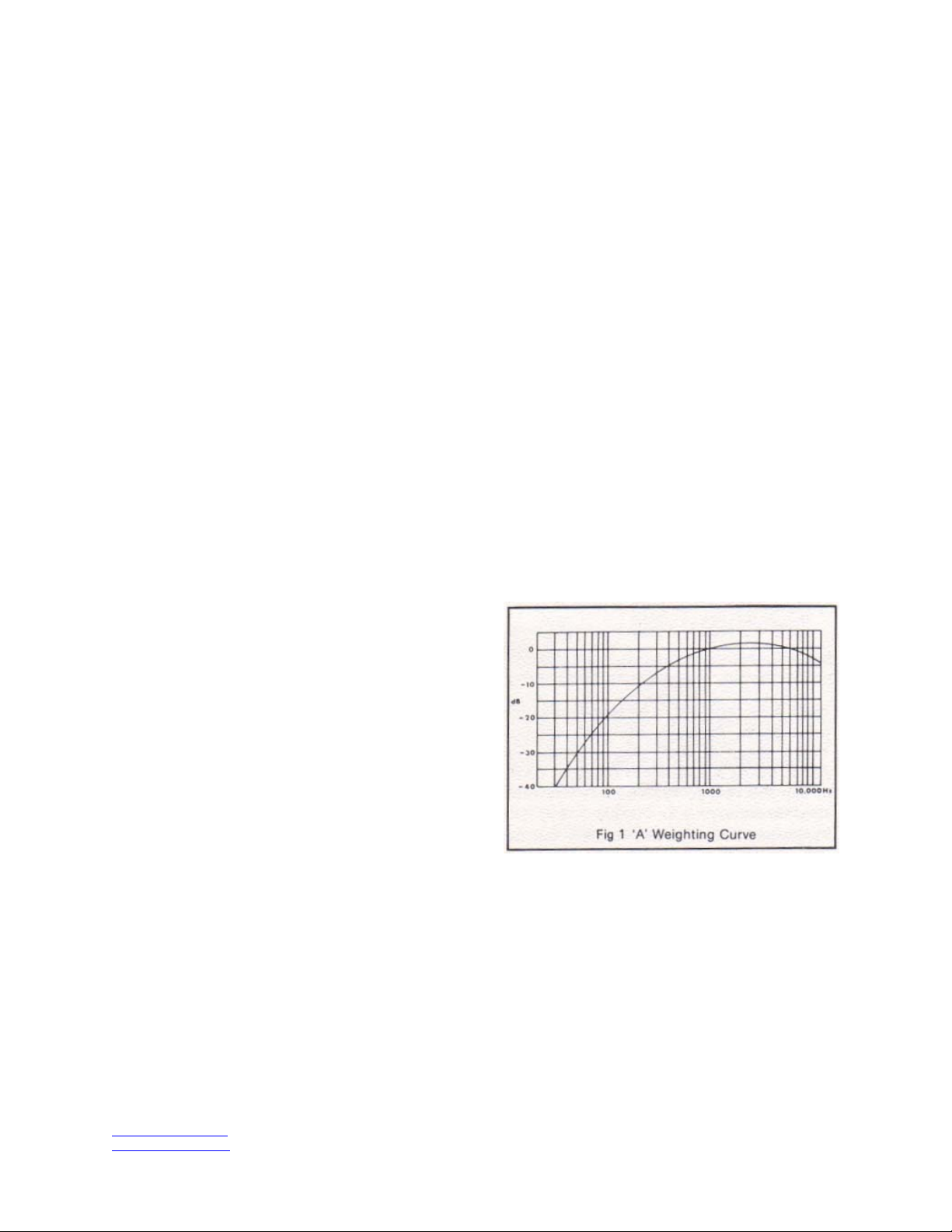

In order to fully understand the subject an

extensive research campaign was directed

towards establishing exactly how much noise

caused a given degree of deafness. Firstly, it

was established that certain frequencies were

more dangerous than others. To accommodate

this fact a special frequency filter has been

derived for use when the hazard potential of

sound is being assessed, The response of this

filter gives added weight to the more hazardous

frequencies in the range 1-5kHz and

proportionally derates those outside this band

according to a carefully defined formula. This 'A

weighted' response, as it is known is specified in

all the international and national standards

relating to the assessment of deafness risk that

are known to date. 'A weighting' is, therefore,

built into all CEL personal noise dose meters

and it is not necessary to make any further

separate measurements of frequency when

using these instruments to measure auditory

hazards.

(the tympanic membrane) converts the air

pressure fluctuations that constitute sound into a

mechanical motion. This motion is then

transmitted through the middle ear, with some

mechanical advantage by a system of small

bones (the ossicles), to the inner ear, Here, the

mechanical movement is converted into nerve

impulses by the cochlea which are then

transmitted to the brain, for interpretation, by the

eighth nerve. Sudden very high intensity sounds,

such as those associated with explosions, can

cause a rupture of the tympanic membrane and,

in severe cases, a disruption of the auditory

ossicles. Such dramatic effects are not,

however, as serious as would first appear. Many

eardrums wiII, in fact, heal themselves and,

thanks to modern medical and surgical methods,

many types of malfunction of the outer and

middle ear can be rectified. Far more serious

damage will result from prolonged exposure to

much lower levels. Continued exposure to even

only moderately intense sounds will result in a

permanent reduction in the ability of the cochlea

to produce nerve impulses for transmission to

the brain and, because of its nature and

location, treatment for a noise-damaged cochlea

is just not possible. As nerve signals to the brain

are not being generated, amplification of the

sounds by a hearing aid would be of little benefit

www.casellausa.com Page 3 of 14 tel: (800) 366-2966

info@casellausa.com

27 Jan 2006 fax: (603) 672-8053

The other parameter of risk was established as

the total noise immission which is proportional to

the measured noise level in dB (A) and the

duration of exposure, Results of large scale

investigation of noise exposed workers that

compared their total noise immission with the

degree of deafness acquired has shown that if

noise immission is contained to around 90dB(A)

for an eight hour working day they should not

acquire a degree of deafness that would

constitute a social handicap after a working

lifetime. As the noise level is increased so the

Figure 1

Casella USA

17 Old Nashua Road #15

Amherst, NH 03031-2839

exposure duration must be reduced in order to

contain the total noise immission or ‘noise dose'.

One of the main variables found between

different noise control regulations is the

relationship between noise level and exposure

time. The International Standards Organization

followed by most European countries favor an

'equal energy' concept where the exposure

duration is halved for each 3dB increment in

noise level (q = 3) whilst in North America the

'exchange rate' calls for a halving of exposure

for each 5dB increment in noise level (q = 5). At

other times regulations calling for q = 4 and q =

6 have been noted.

The problem that arises in actual industrial

situations is that the noise level is never a

constant level to compare against the criteria but

it is continually changing as machines come on

and off load, pressures are vented and

processes move through various phases. It is

necessary, therefore, to continually monitor the

noise climate and process the results such that

the total noise is accumulated in the correct

manner in order to provide a noise dose figure

for comparison against the damage risk criteria.

Therefore, noise dose is proportional to the time

integral of the instantaneous level that is

amplitude weighted and referred to a criterion

level. A constant factor is added to scale the

results in terms of exposure and to provide an

answer of 100 for one daily dose enabling

results to be expressed as a percentage of

permitted exposure.

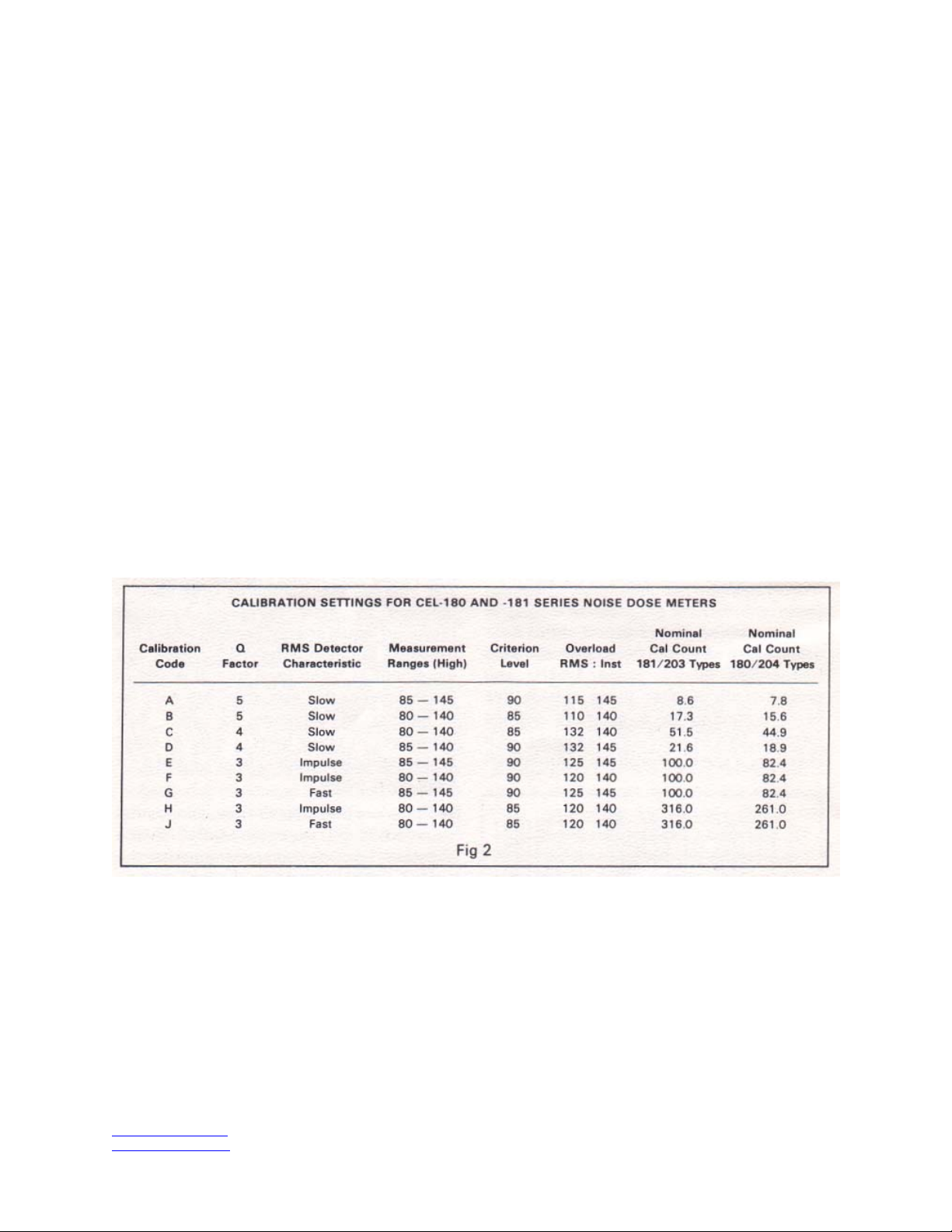

The basic criteria discussed above are accepted

in most countries of the world; however, as an

added complication some have advanced

further than others with their noise control

programmes and have been able to reduce the

criterion in order to give a better safety margin in

respect of the more noise susceptible subjects.

In order to accommodate these requirements all

CEL personal noise dose meters are available

having their criterion levels set accordingly;

these calibration settings are also manufacturer

preset. The various settings are indicated by a

letter code on the serial number plate and a

complete schedule is set out below:

Figure 2

www.casellausa.com Page 4 of 14 tel: (800) 366-2966

info@casellausa.com

27 Jan 2006 fax: (603) 672-8053

Casella USA

17 Old Nashua Road #15

Amherst, NH 03031-2839

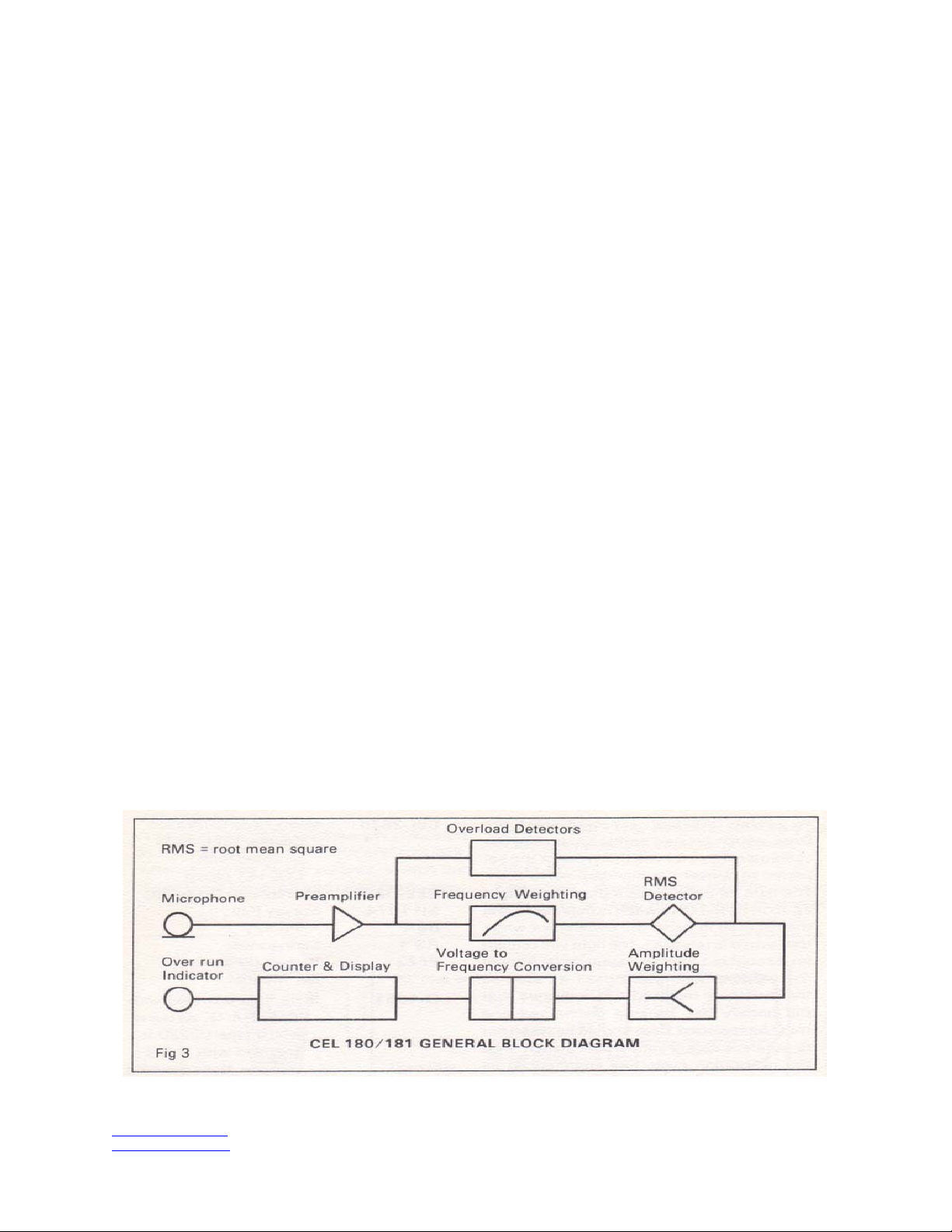

2 Technical Description

The CEL-180 meets all the essential requirements for Precision Sound Level Meters. These

are defined in the International Standard IEC

651 type 1 (IEC 179) and the British Standard

BS 4197. As this instrument conforms to the

highest standard of accuracy it is no longer

necessary to make any special provision for

possible instrumentation errors when applying it

to industrial situations. The CEL-181 meets the

lower accuracy requirements outlined in the

relevant sections of IEC 651 type 2, BS 3489

and ANSI S1.4

The microphones employed in the CEL-180

Noise Dose Meters are half-inch (12.7mm)

Precision Measurement Microphones type

CEL-186. These microphones have extremely

uniform frequency response and very high

calibration stability. The signal from the

microphone is passed to the main unit over

approximately 0.5m of cable where they are

amplified and applied to an 'A' frequency

network. The CEL-181 types have similar

configuration but employ a 12mm piezo-electric

type of microphone.

A wide dynamic range RMS detector is used in

the device and this feeds a separate amplitude

weighting circuit. The device has, therefore, a

very wide degree of flexibility in its specification

allowing the dynamic range; count rate, q factor

and RMS time constant to be specified within

wide limits. Basically, the RMS detector has a

range of 40dB plus a 23dB crest factor giving a

total input range of 63dB, whist the voltage to

frequency converter can handle a ratio of

10,000:1 (213). The converter can, therefore,

handle the full 40dB RMS level in the q3 mode

as this signal will obviously double in

significance 13 times (40/3). In the q4, q5 or q6

modes the significance of the signal becomes

much less severe with increasing amplitude;

when q = 6, for example, we only have 6.6

doublings so it is only in the q3 case that we

have to consider the voltage to frequency

converter as a possible limitation. The RMS

detector will, however, control all modes of the

instrument and, as mentioned before, this will

handle levels over the range of 40dB with an

additional 23 dB for impulses. To protect against

incorrect answers being given, the instruments

employ a dual overload indication system. The

overload indicator will be set by either an

instantaneous level 63dB up on the threshold or

by an RMS level that is 40dB up. These

overload indication levels can be reduced to

lower levels if required, e.g. to conform to the

USA OSHA regulation the RMS overload level

should be set at 115dB(A) slow.

The active circuit elements are mounted on

glass fiber double-sided printed circuit panels

and extensive use is made of integrated circuits.

The assembly is contained within a high impact

ABS case that has neoprene surface treatment.

A general block diagram of the instrument is

shown in Fig 3. The various versions have

similar layout of the main circuit elements and

differ only in detail. This diagram is provided for

general information only - for full technical and

servicing information reference should be made

to the service manual.

Figure 3

www.casellausa.com Page 5 of 14 tel: (800) 366-2966

info@casellausa.com

27 Jan 2006 fax: (603) 672-8053

Loading...

Loading...