Page 1

48/50HJ004-024

*Where “XX” will be “04,” “16,” or “32.”

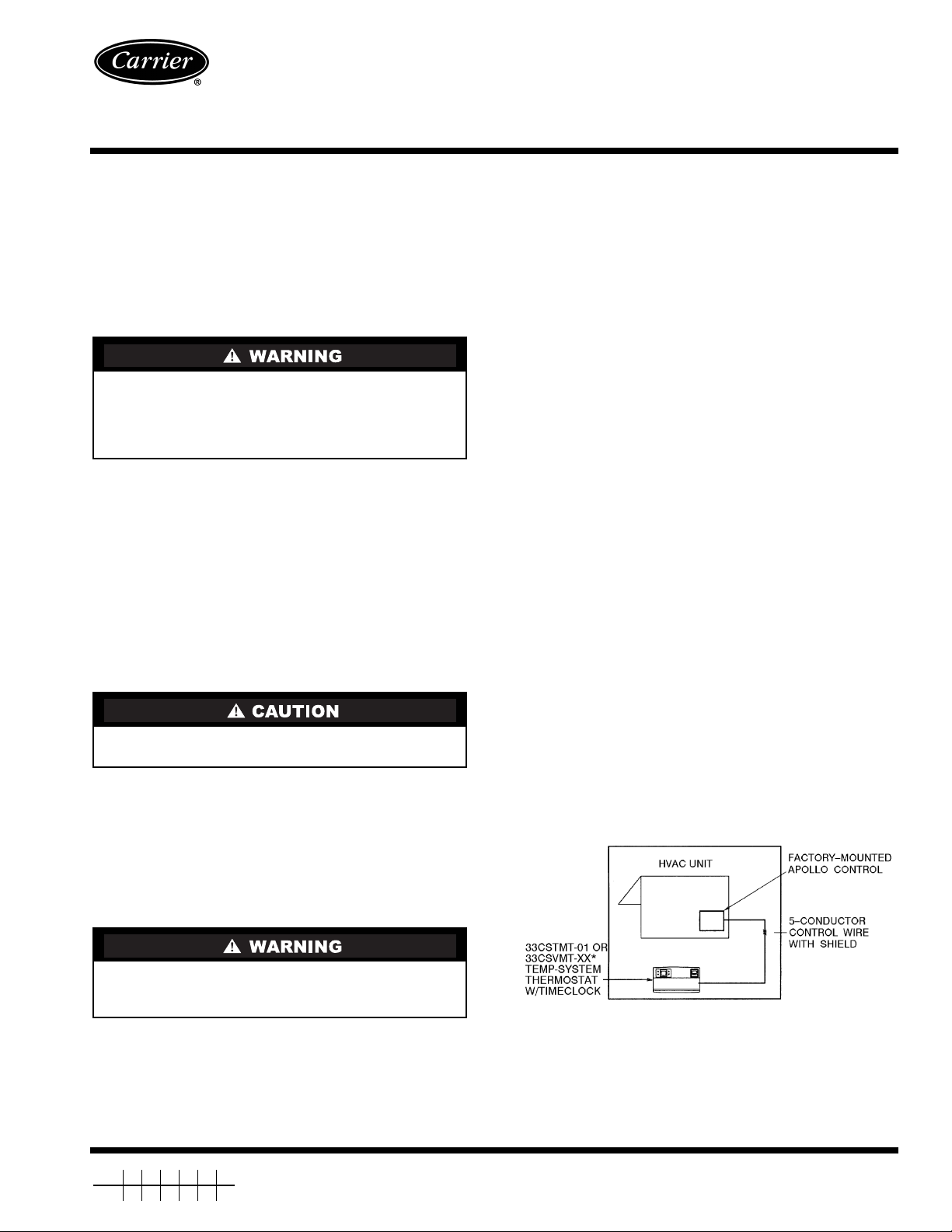

Fig. 1 — Carrier TEMP System Components

HVAC —

Heating, Ventilation, and Air Conditioning

50TFQ004-012, 48/50TF,TM004-014

50HJQ004-016, 48/50TJ,TM016-028

Apollo Control

Installation, Operation, and

Troubleshooting Instructions

SAFETY CONSIDERATIONS

Read these instructions entirely before modifying the base

rooftop unit.

Before beginning any modification, make sure all power is

disconnected to the unit and locked out. Fai lure to disconnect power supply prior to servicing may result in serious

injury. All wiring must comply with applicable national

and local codes.

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of replacing filters. All other operations should be

performed by trained service personnel. When working on airconditioning equipment, observe precautions in the literature,

tags and labels attached to the unit, and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

When removing panels from the unit, be careful not to

damage the roof or other surfaces with the panels.

GENERAL

The Apollo control is a relay pack which is factory wired

and mounted in the Carrier rooftop unit. The Apollo control

allows the unit to be connected to a thermostat and a communication bus. The rooftop unit can then be used as part of a

system which is controlled by devices on the communication

bus. The thermostat and communication bus wiring must be

field installed.

The TEMP System thermostat maintains proper temperatures by controlling the amount of heated or cooled air supplied

to the area in which it is installed or the area it controls (if using

a remote room sensor).

Each thermostat is responsible for controlling the temperature conditions in its space. Each thermostat w ill maintain its

own independent occupied/unoccupied time schedule and heating (if applicable) and cooling set points. This allows the user

to program the TEMP S ystem thermost at so t hat it will mai ntain different temperature ranges at different times.

TEMP System Components —

System consists of one or more thermostats that communicate

by way of a communication bus. Each thermostat controls an

Apollo control which in turn controls the Carrier rooftop unit.

See Fig. 1.

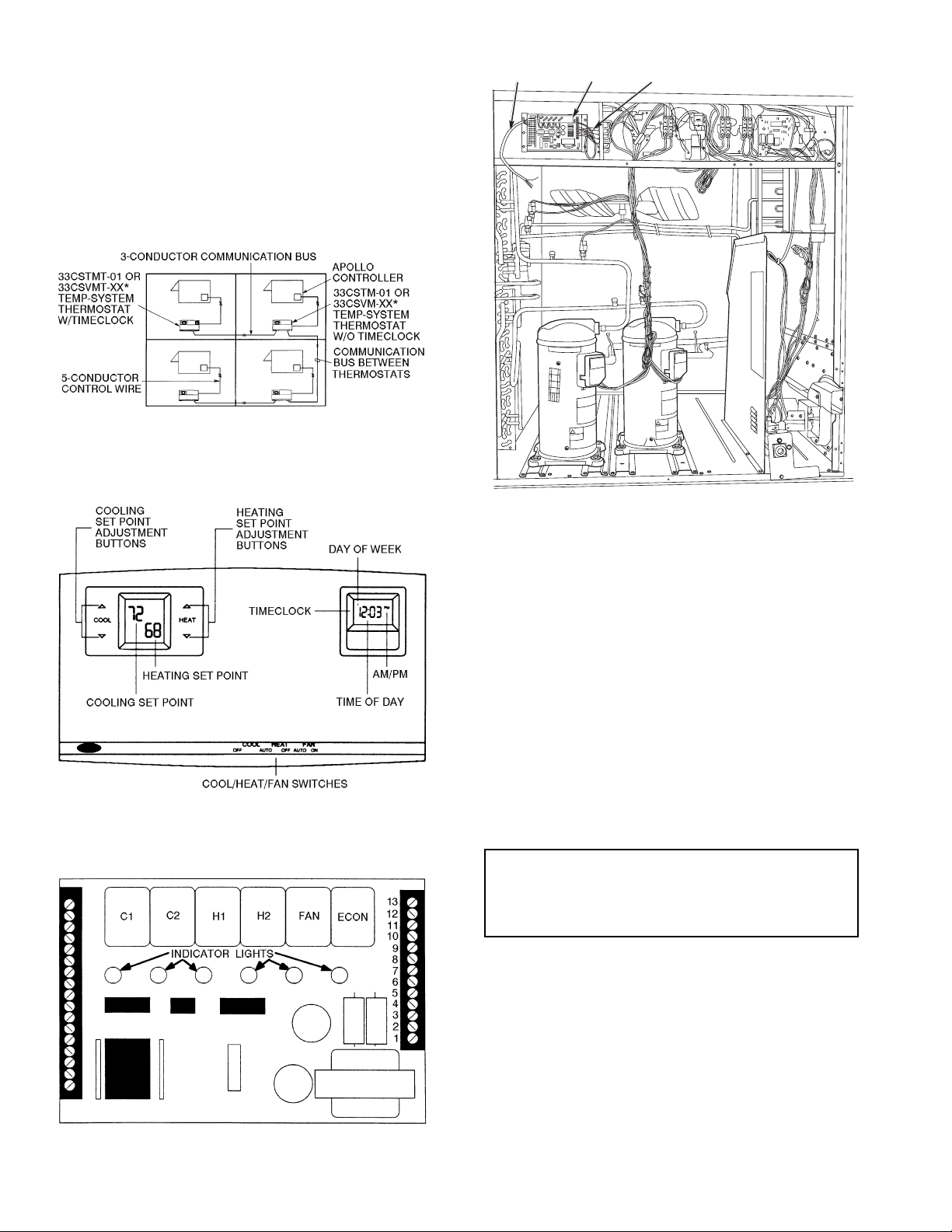

Each thermostat can be connected to others to provide communication between thermostats. Only one thermostat per system can have a timeclock that will broadcast time to the rest of

the system. Se e Fig . 2.

TEMP SYSTEM THERMOSTATS — The 33CSTMT-01,

or 33CSVMT-XX (with timeclock) and 33CSTM-01 or

33CSVM-XX (without timeclock) TEMP System thermostats

(see Fig. 3) have the following features:

• controls temperature to user- defin ed set points

• eliminates the need for external timeclocks, manual

override timer, night low limit thermostat, battery

backup, or unit time guard

• operates with 3 system switch es for supply-air fan and

the unit heating (if applicable) and cooling stages

NOTE: For 33CSVM(T)-XX thermostats, the “XX” will be

either “04,” “16,” or “32.”

The Carrier TEMP

Do not turn on unit power until Apollo control and thermostat have been installed. Unit is shipped with loose leads

which may cause electrical shock or death.

Carrier TEMP System —

usually consists of more than one thermostat and can be expanded to meet whatever number of single zone systems are

required.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 111444

Tab 1a1b5a5a6a6b

PC 111 Catalog No. 534-80082 Printed in U.S.A. Form 48/50H,T-15SI Pg 1 8-01 Replaces: 48/50H,T-2SI

The Carrier TEMP System

Page 2

APOL L O CO NT R OL — The Apollo control (see Fig. 4) has

Fig. 5 — Apollo Control Factory-Installed

In Typical Unit

the following features:

• serves as interface between thermostat, Carrier rooftop

unit, and any external field-supplied sensors

• powered by 24 vac/10 va; supplies thermostat with

10 vdc. This power is supplied by the Carrier rooftop

unit.

The Apollo control must be used in conjunction with a

Carrier 33CSTM(T)-01 or 33CSVM(T)-XX master thermostat. Figure 5 shows the Apollo control factory-installed in a

rooftop unit.

*Where “XX” will be “04,” “16,” or “32.”

Fig. 2 — TEMP System Communication

WIRING TO

THERMOSTAT

APOLLO

CONTROL

CONTROL

WIRING

Fig. 3 — TEMP System Thermostat

(With Timeclock Shown)

NOTE: The indicator lights verify each mode of operation.

Fig. 4 — Apollo Control

INSTALLATION

Wiring Requirements —

the TEMP Syst em a re:

THERMOSTAT TO THERMOSTAT COMMUNICATION

BUS — Use field-supplied, 18 gage, 3-conductor, shielded,

stranded wire, color coded (red, black, green), plenum rated (if

required by code). Be sure wire is long enough t o run from

thermostat to thermostat in daisy-chain configuration.

THERMOSTAT TO APOLLO CONTROL — Use fieldsupplied, 18 gage, 5-conductor, shielded, stranded wire,

color-coded (red, white, blue, yellow , gr een), plenum rated (if

required by code). Be sure wire is long enough to run from

thermostat to the Apollo control. The Apollo control is easily

accessible in the Carrier rooftop unit. It is found in the unit

control box.

IMPORTANT: Do not run the thermostat communication

bus and the control wire in the same conduit for more than

5 ft. Never run wires near any c able carrying AC voltage.

For further wiring information, consult your local Carrier

distributor.

Factory-supplied power required by each Apollo control is

24 vac/10 va. T ypical wiring is 18-gage thermostat wire. Power

to the Apollo control may be wired to the Carrier rooftop unit

transformer if transformer is of sufficient va capacity. Otherwise, a dedicated transformer has been factory provi ded. The

maximum load of a relay contact is 24 vac, 1 amp. A short in

the field wiring or Carrier rooftop unit will cause non-warranty

damage to the relay board. Test wiring before attaching to

Apollo control.

Call your local Carrier representative for more information

about wiring the Apollo control as needed.

2

The wiring requirements for

Page 3

Thermostat Installation —

stallation by determining where the thermostat will be located.

In most cases, this will be pre-determined by the building

plans.

Locate the thermostat on an interior wall, about 5 ft from the

ground. The thermostat should be located away from direct

sunlight, drafts, or interior heat sources which may influence

temperature readings.

The thermostat may also be m ounted in a re mote location

with the use of an optional remote room sensor. Refer to the

specific thermostat information for more details on thermostat

installatio n.

Begin the thermostat in-

Wiring Connections

Electric shock can cause injury or death. Ensure power to

the rooftop unit has been disconnected, before wiring.

WIRE APOLLO CONTROL TO THERMOSTAT — Wire

each thermostat to its respective Apollo control as shown in

Fig. 6. Make wiring connections at the wiring connector board

of the thermostat.

WIRE THERMOSTAT TO COMMUNICATION BUS —

The thermostat is connected to the communication bus through

the thermostat wiring connection block. Connect the black, red,

and green wires from the communication bus to the thermostat

wiring connection block. See Fig. 6. To connect other devices

to the communication bus, refer to the application manual for

that device.

Provide Power To Apollo Control —

ing has been completed, provide power to the Apollo control.

Once power has been provided, the Apollo control will power

the thermostat. The heating (if applicable) and/ or cooling set

points will appear on the thermostat display screen. The thermostat is now ready to be programmed. If the display is blank

or blinking, recheck the wiring connections between the thermostat and Apollo control.

After the wir-

OPERATION

There are 3 system switches which are used to control operation at the thermostat: Heat, Cool, and Fan. The Heat and

Cool switches can be set to either AUTO. or OFF position. The

Fan switch can be set to either AUTO or ON position. When

the fan is running, the F AN indicator will be shown on the thermostat display screen. When Cooling mode is energized, the

COOL indicator will be shown on the thermostat display

screen. When Heating mode is energized, the H EAT indicator

will be shown on the thermostat display screen. When the

second stage of heating or cooling is energized, a decimal point

is displayed between the heating and cooling set points.

AUTO. Fan Mode —

system energizes heating or cooling. The only exception is

when the thermostat controls a gas heating rooftop unit. In this

application, the thermostat will allow the rooftop unit to control

the fan during Heating mode, and the fan will run in Cooling

mode.

ON Fan Mode —

ing the occupied mode. In unoccupied mode, t he fan wil l only

operate when a system mode is energized.

AUTO. Heating Mode —

AUTO. position, the Apollo control will energize heating when

the heating demand is 1.5° F or greater. The second stage of

heating will energize when the demand becomes 2.0° F or

greater.

OFF Heating Mode —

OFF position, the Apollo control will not allow the rooftop unit

to energize heating.

AUTO. Cooling Mode —

to AUTO. position, the Apollo control will energize cooling

when the cooling demand is 1.5° F or greater. The second stage

of cooling will energize when the demand becomes 2.0° F or

greater.

OFF Cooling Mode —

OFF position, the Apollo control will not allow the rooftop unit

to energize cooling.

Temperature Trend Staging —

ture Trend Staging option has been configured at the thermostat, the thermostat tracks the tempera tures at regular interva ls

in each cooling or heating mode. As long as the space temperature is improving, the Apollo control will not allow the second

stage to be energized. If the space temperature stays the s ame

or the demand becomes greater, the second stage will energize.

Heating Lockout —

ture set point has been configured, and the heating lockout option has been configured to ON, the Apollo control will not allow heating to energize when the outdoor-air temperature rises

above the heating lockout set point.

Cooling Lockout —

ture set point has been configured, and the cooling lockout option has been configured to ON, the Apollo control will not allow cooling to energize when the outdoor-air temperature

drops below the cooling lockout set point.

Time-Delay Relay —

control utilize a 5-minute time delay between the different

modes of operation for the rooftop unit. When a mode of operation is deenergized, another mode cannot begin for 5 minutes.

The fan will energize any time the

The fan will operate continuously dur-

When the Heat switch is set to

When the Heat switch is set to

When the Cool switch is set

When the Cool switch is set to

When the Tempera-

When the heating lockout tempera-

When the cooling lockout tempera-

The thermostat and the Apollo

3

Page 4

NOTE: Refer to Product Support Bulletin No. 93-005 for shielded wire applications when wiring the thermostat to the Apollo control and for all communication

bus wiring connections or contact your local representative.

Fig. 6 — Thermostat and Apollo Control Wiring

4

Page 5

TROUBLESHOOTING

See Fig. 7-10 for Apollo factory, control, and system wiring.

Blank Display or Blinking Display at the

Thermostat

1. Check to ensure there is at least 20.5 vac across the 2 terminals labelled 24 vac. If there is n ot at least 2 0.5 vac, check

the unit transformer which is powering the Apollo control.

2. If an ac voltage between 20 .5 and 30 v ac is read, chec k for

10 vdc between the terminals labelled WHT and RED. If

there is 0 vdc between the terminals, replace the Apollo

control. If a value between 1 an d 10 vdc is read, check the

wiring between the thermostat and the Apo llo contr ol.

3. If the thermostat display is blinking on and off, this is an

indication that there is a communication problem between the thermostat and the Apollo control. The thermostat and the Apollo control communicate on the blue and

yellow wires. If either one is shorted, open, or crossed, it

will cause the thermostat display to blink.

To check the wiring between the thermostat and the Apollo

control:

1. Remove the thermostat and connector board.

2. Wire the connector board to the Apollo control with a

short piece of field-supplied 5-conductor cable.

3. Plug the thermostat into the connector board.

a. If thermostat powers up, there is a wiring problem.

Find the open or shorted wire, or replace the wiring

between the thermostat and the Apollo control.

b. If the thermostat does not power up, try another

thermostat. If the new thermostat powers up,

replace the off thermostat. If the new thermostat

will not power up, replace the Apollo control.

The Control Will Not Energize Heating

1. The thermostat is not displaying the heat indicator:

a. Check the heating lockout temperature set point

and options to make sure the outdoor -air temperature is locking out Heating mode.

b. Ensure that a sensor in the system is not reading

above the heating high limit temperature. If a supply air sensor or a direct expansion (DX) coil sensor is not connected to the Apollo control, turn off

the High and Low Limits option at the thermostat.

c. Check the Heat switch and make sure it is in the

AUTO. position.

2. The thermostat is displaying the heat indicator.

a. Check to see if the H1 LED (light-emitting diode)

is lit on the Apollo control. If it is not, replace the

Apollo control. If the H1 LED is lit on the Apollo

control, check the voltage across the H1 relay contact. If it reads 24 vac, replace the Apollo control.

If it reads 0 to 2 vac, check the H1 contactor and

the unit transformer.

The Control Will Not Energize Second Stage

Heating

1. The thermostat is not displaying the second stage indicator. A decimal point on the thermostat display screen is the

indication that the thermostat is asking for second st age.

a. Check to see if the space demand is equal to or

greater than 2° F. The control must see a 2° F

demand before it will call for second stage.

b. Check the Temperature Trend Staging option. If

this option is configured to “on” and space conditions are improving, the control will not energize

the second stage.

2. The thermostat is displaying the decimal point.

a. Check to see if the H2 LED is lit on the Apollo

control. If it is not lit, replace the Apollo control.

b. The LED is lit, but second stage is not energized.

Check the voltage across the H2 relay contact. If it

reads 24 vac, replace the relay board. If it reads 0 to

2 vac, check the H2 contactor and the unit transformer.

The Control Will Not Energize Cooling

1. The thermostat is not displaying the cool indicator.

a. Check the cooling lockout temperature set point

and options to make sure the outdoor-air temperature is not locking out Cooling mode.

b. Ensure that a sensor in the system is not reading

below the cooling low limit temperature. If a supply air sensor or a direct expansion (DX) coil sensor is not connected to the relay pack, turn off High

and Low Limits at the thermostat.

c. Check the Cool switch and make sure it is in the

AUTO. position.

2. The thermostat is displaying the cool indicator.

a. Check to see if the C1 LED is lit on th e Apollo con -

trol. If it is not, replace the Apollo control. If the C1

LED is lit on the Apollo control, check the voltage

across the C1 relay contact. If it reads 24 vac, replace

the Apollo control. If it reads 0 to 2 vac, check the C1

contactor and the unit transformer.

The Control Will Not Energize Second Stage

Cooling

1. The thermostat is not displaying the second stage indicator. A decimal point on the thermostat display screen is the

indication that the thermostat is as king for s econd stage.

a. Check to see if the space demand is equal to or

greater than 2° F. The control must see a 2° F

demand before it will call for second stage.

b. Check the Temperature Trend Staging option. If

this option is configured to “on” and space conditions are improving, the control will not energize

the second stage.

2. The thermostat is displaying the decimal point.

a. Check to see if the C2 LED is lit on the Apollo

control. If it is not lit, replace the Apollo control.

b. The LED is lit, but second stage is not energized.

Check the voltage across the C2 relay contact. If it

reads 24 vac, replace the relay board. If it reads 0

to 2 vac, check the C2 contactor and the unit

transformer.

The Control Will Not Energize The Fan

1. The fan indicator is not lit on the thermostat.

a. The Fan switch is in the AUTO. position and the

control is not in a mode (HEAT or COOL

position).

b. The fan switch is in the ON position but the ther-

mostat is in setback and has no mode.

c. The thermostat has just received power or has just

reset and is going through its initialization process.

2. The fan indicator is lit on the thermostat.

a. Check the fan LED on the Apollo control. If it is

not lit, replace the Apollo control.

b. If the fan LED is lit, check the voltage across the

fan relay contact. If it reads 24-vac, replace the

relay board. If it reads 0 to 2 vac, check the fan

contactor and the unit transformer.

5

Page 6

LEGEND

COM —

ECONO —

NC —

Communication

Economizer

Normally Closed

Fig. 7 — Factory-Supplied Wiring to Rooftop Unit and Apollo Control

*Filter status switch and humidity sensor cannot function

simultaneously. Only one sensor can be wired.

LEGEND

C—

CHAS —

COM —

DX —

ECON —

GND —

HT —

Contactor

Ground

Common

Direct Expansion

Economizer

Ground

Heat

IAQ —

NC —

NO —

OAT —

SAT —

Indoor Air Quality

Normally Closed

Normally Open

Outdoor-Air Thermostat

Saturated-Air Temperature

Factory Wiring

Field Wiring

Fig. 8 — Apollo Control Wiring Schematic — 48/50HJ, 3 to 20 Ton Units;

48/50TF,TM, 3 to 12-1/2 Ton Units; 48/50TJ,TM, 15 to 25 Ton Units; 50HJQ/TFQ, 3 to 10 Ton Units

6

Page 7

*Filter status switch and humidity sensor cannot function

simultaneously. Only one sensor can be wired.

LEGEND

C—

CHAS —

COM —

DX —

ECON —

GND —

HT —

Contactor

Ground

Common

Direct Expansion

Economizer

Ground

Heat

IAQ —

NC —

NO —

OAT —

SAT —

Indoor Air Quality

Normally Closed

Normally Open

Outdoor-Air Thermostat

Saturated-Air Temperature

Factory Wiring

Field Wiring

Fig. 9 — Apollo Control Wiring Schematic — 50HJQ, 121/2 and 15 Ton Units

7

Page 8

DAT

VIO

WHT

RED

EC

ONLY

ACCESSORY

VIO

PNK

OAT

TAN

LEGEND

OAH

COM

24 COM

GND

BRN

GRN

+15V

CLG1

BLU

RAT

CLG2

PNK

RAH

COM

CONTROLLER

OAT

24 VAC

RED

ECONOMI$ER OPTION/ACCESSORY

+15V

CO2+

DM

DAT

COM

COM

REM POT

CO2 COM

B1Y1Y2GCOM

YEL

WHT

BLK

AO

LED

COM

Carbon Dioxide

—

2

CO

Common

COM —

Discharge Air Thermistor

Damper Motor

Direct Expansion Coil Sensor

Enthalpy Control

Heating, Ventilation, and Air Conditioning

Indoor-Air Quality

Normally Closed

Outdoor-Air Thermostat

Reversing Valve

Supply-Air Temperature Sensor

Temperature

Transformer (Field Supplied)

Carrier TEMP System

Variable Volume/Variable Temperature

Field-Supplied Wiring

DAT —

DM —

DX —

EC —

HVAC —

IAQ —

NC —

OAT —

RV —

SAT —

TEMP —

TRAN —

VTS —

VVT® —

TO CARRIER

HVAC UNIT

FIELD SUPPLIED

WIRING

24 VAC/10 VA

FAN

HEAT 2

HEAT 1 NC

HEAT 1

HEAT/FAN COM

COOL 2

COOL 1

COOL COM

R

C

RV

FAN

4

3

JUMPERS

GROUND

SINGLE ZONE

RELAY PACK

WITH AUXILARY

RELAY

AUXILIARY

RELAY**

987654321

13

12

11

10

2

COOL HEAT

1

1234567891011121314151617

YEL

BLU

GRN

RED

WHT

FAN STATUS

IAQ STATUS†

BLK

TSP01

TERMINAL

NUMBER

REMOTE ROOM

TEMP. SENSOR

ADDITIONAL SENSORS*

#1

WHT

#2

RED

HUMIDITY

DX

SAT

OAT

#10

GRN

SENSOR

#11

BLK

FILTER

2-10VDC

SIG COM (J5-3)

4-20mA (J5-2)

-

+

+

20 VA

TRAN

(FIELD

24 VAC

ALARM

RELAY

CONTACTS

NC

COM

NO

24 V

SUPPLIED)

OR

H G 24 VAC

+ - 24 VDC

GROUND

8 7 6 5 4 3 2 1

2 1

2

INDOOR AIR QUALITY (CO ) SENSOR

(33ZCSENCO2) TYPICAL WIRING DIAGRAM

BLK

RED

GRN

NETWORK

RED

Copyright 2001 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book111444

PC 111 Catalog No. 534-80082 Printed in U.S.A. Form 48/50H,T-15SI Pg 8 8-01 Replaces: 48/50H,T-2SI

Tab 1a1b5a5a6a6b

SINGLE ZONE RELAY PACK CIRCUIT BOARD

#10

GRN

STATUS

#11

BLK

sensor.

2

*Filter status switch and humidity sensor cannot function simultaneously. Only one sensor can be wired.

†Such as a CO

**Set auxiliary option to “2” — IAQ Control per VTS or VVT Installation Instructions.

Fig. 10 — Apollo Wiring as Part of an Indoor-Air Quality System

NOTE: Sensors are field-supplied and wired.

Loading...

Loading...