Page 1

2P

1

2

BLK

BLU

Transport Air Conditioning

Transport Air Conditioning

R

R

BRN

WHT

GRN/YEL

WHT

F

C

H

EVAP.

RED

WHT

YEL

2

1

C

RED

R

BLU

S

BLU

PTC

SERVICE MANUAL

for

Rooftop Air Conditioning Systems

T--298 Rev D

MODEL AirV

Page 2

SERVICE MANUAL

For

AirV

AIR CONDITIONING AND

HEATING EQUIPMENT

MODELS

68RV11302A

68RV14102A

68RV14103A

68RV14112A

68RV15102A

68RV15103A

Page 3

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautionsappearing elsewhere in

this manual. They are recommended precautions that must be understood and applied during operation and

maintenanceoftheequipmentcoveredherein.Thegeneralsafety notices arepresentedinthefollowingthree

sections labeled: First Aid, Operating Precautions and Maintenance Precautions. A listing of the specific

warnings and cautions appearing elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands clear of the evaporator blower and condenser fan.

No work should be performed on the unit until all circuit breakers and start--stop switches are turned off, and

power supply is disconnected.

Always work in pairs. Never work alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator blower & condenser fan. Do not remove the ceiling grill

assembly or the upper unit coverassembly beforeturningthe power off, and disconnecting the power supply.

Before disconnecting, discharge capacitors by shorting across the capacitors terminals. (See Paragraph

3.5.8)

When disassembling wiring, use numbered stickers to identify wire leads and terminals. This aids in quick,

accurate reassembly.

Besurepoweristurnedoffbeforeworkingonmotors,controllers, or electricalcontrolswitches.Taganycircuit

breakers and power supply to prevent accidental energizing of circuits.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires.

Problems with the system should be diagnosed and any necessary repairs must be performed by qualified

service personnel.

In case of electrical fire, open circuit switch and extinguish with CO

Usedrynitrogentopressurizethesystemforleakchecking. Be careful not to exceed150psigtestpressurein

the hermetic compressor.

Coil fins are sharp. Use care when removing the cover form the base pan to avoid personal injury.

Oil vapor in piping stubs can ignite from torch flame and cause serious injury. Exercise extreme care when

brazing, and keep brazing cloth and fire extinguisher handy for emergency use.

Disconnect power to the AirV unit before checking the capacitor.

(never use water).

2

Safety-- i

T-298

Page 4

SPECIFIC WARNING AND CAUTION STATEMENTS

The statements listed below are applicable to the refrigeration unit and appear elsewhere in this manual.

These recommended precautions must be understood and applied during operation and maintenance of the

equipment covered herein.

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Be sure to observe warnings listed in the safetysummary in the front of this manualbefore

performing maintenance on the AirV system

WARNING

Beforeworkingonthe unitbesuretofirstdisconnectall electricpowertotheunitto avoidthe

possibilityof electrical shock and personalinjury. Before disconnecting, discharge capaci-

tors by shorting across the capacitors terminals (Refer to paragraph 3.5.8)

WARNING

Shieldcoilswithcardboard to protecthandsagainstinjuryfromsharpmetaledgeswhen removing compressor and other components.

WARNING

Oil vapor in piping stubs can ignite from torch flame and cause serious injury. Exercise extreme care when brazing, and keep brazing cloth and fire extinguisher handy for emergency

use.

WARNING

Disconnect power to the AirV unit before checking the capacitor.

WARNING

Do not touch the metal of the screwdriver when discharging the capacitor.Y oucould receive

a shock.

WARNING

Before installing thermostat, turn off all power to unit. There may be more than one power

disconnect. Electrical shock can cause personal injury or death.

CAUTION

Do not use carbon tetrachloride, solvents, or waxes containing solvents to clean plastic sections.

T--298

Safety-- ii

Page 5

CAUTION

Coil fins are sharp. Use care when removing the cover form the base pan to avoid personal

injury.

CAUTION

ThechangefromFahrenheittoCelsiuswill bepermanent.Itcannotbechangedbackto Fahrenheit.

CAUTION

When re--assembling, ensure the battery springs are correctly placed in the battery spring

holders.

CAUTION

Improper wiring or installation may damage thermostat. Wiring must conform to local and

national electrical codes.

Safety--iii

T-298

Page 6

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

DESCRIPTION 1-1...............................................................................

1.1 INTRODUCTION 1-1.....................................................................

1.2 SERIAL NUMBER IDENTIFICATION 1-1....................................................

1.3 DESIGN CHANGE DESCRIPTIONS 1-1....................................................

1.4 AirV SYSTEM COMPONENT SPECIFICATIONS 1-9.........................................

1.4.1 Refrigerant Charge 1-9................................................................

1.4.2 Compressor - 115 Volts, 60 Cycles, 1 Phase 1-9..........................................

1.4.3 Compressor - 220 Volts, 50 Cycles, 1 Phase 1-9..........................................

1.4.4 Thermostat Range (All Free Blow Units) 1-9..............................................

1.5 START-UP 1-9...........................................................................

1.6 REFRIGERANT CYCLE-STANDARD SYSTEM 1-9...........................................

1.7 REFRIGERANT CYCLE - HEAT PUMP 1-10..................................................

1.7.1 Cooling 1-10..........................................................................

1.7.2 Heating 1-11..........................................................................

TROUBLESHOOTING 2-1.........................................................................

2.1 NO POWER TO UNIT 2-1.................................................................

2.2 DUCTED UNIT WILL NOT OPERATE 2-1...................................................

2.3 DUCTED UNIT WILL NOT COOL 2-1.......................................................

2.4 COMPRESSOR POWER SUPPLY OPEN 2-1...............................................

2.5 COMPRESSOR RUNS BUT CYCLES, FAN OPERATING ERRATICALLY 2-1....................

2.6 CYCLES ON COMPRESSOR OVERLOAD 2-2..............................................

2.7 INSUFFICIENT COOLING, COOLING AIR NOT ADEQUATE 2-2..............................

2.8 CONDENSER AIR NOT ADEQUATE 2-2....................................................

2.9 INSUFFICIENT COOLING 2-2.............................................................

2.10 COMPRESSOR FLOODING 2-2...........................................................

2.11 HEATERCYCLES ON LIMIT SWITCH (HEAT/ COOL VERSION ONLY) 2-2.....................

2.12 AIR SWEEP NOT WORKING (FREE BLOW VERSION ONLY) 2-2.............................

2.13 WATER LEAKAGE 2-2....................................................................

2.14 INADEQUATE HEAT (FREE-BLOW HEAT ONLY) 2-3........................................

2.15 INADEQUATE HEAT (HEAT-PUMP) 2-3....................................................

Clearing Diagnostic Alarms 2-3...................................................................

SERVICE AND MAINTENANCE 3-1................................................................

3.1 PREVENTATIVE MAINTENANCE 3-1......................................................

3.2 SERVICE - GENERAL 3-1................................................................

3.3 CEILING UNIT - FREE BLOW SYSTEMS 3-1...............................................

3.3.1 Filter Removal 3-1....................................................................

3.3.2 Ceiling Grill Removal 3-1..............................................................

3.3.3 Ceiling Panel Removal 3-2.............................................................

3.3.4 Master Control Switch 3-2.............................................................

3.3.5 Air Sweep Switch Removal 3-2.........................................................

3.3.6 Indoor Thermostat Removal 3-3........................................................

3.3.7 Air Sweep Removal

3.3.8 Heat Strip Assembly Removal 3-3......................................................

3-3...............................................................

i

T--298

Page 7

TABLE OF CONTENTS - Continued

3.4 CEILING UNIT - DUCTED SYSTEMS 3-4...................................................

3.4.1 Filter Removal 3-4....................................................................

3.4.2 Ceiling Grill Removal 3-4..............................................................

3.4.3 Control Box Assembly Removal 3-4.....................................................

3.4.4 Main PCB Board Removal 3-5..........................................................

3.4.5 PCB Display Removal 3-5.............................................................

3.4.6 Fuse Removal 3-5....................................................................

3.5 SERVICE - UPPER UNIT - STANDARD, HC & HP 3-5........................................

3.5.1 Exterior Cover Removal 3-5............................................................

3.5.2 Compressor Replacement 3-6..........................................................

3.5.3 Control Box Assembly Removal 3-6.....................................................

3.5.4 Upper Scroll Assembly Removal 3-7....................................................

3.5.5 Motor Assembly and Condenser Fan Removal 3-7........................................

3.5.6 Evaporator Blower Wheel Adjustment or Removal 3-8.....................................

3.5.7 Air Handling System Removal 3-8......................................................

3.5.8 Capacitor Troubleshooting 3-9..........................................................

3.5.9 Capacitor Testing and Replacement 3-9.................................................

3.5.10 Positive Temperature Coefficient Thermister (PTC) (Start Thermistor) Troubleshooting 3-9.....

3.5.11 Line Voltage - 10% 3-9................................................................

3.6 SERVICE - UPPER UNIT - LOW PROFILE 3-10..............................................

3.6.1 Exterior Cover Removal 3-10............................................................

3.6.2 Upper Scroll Assembly Removal 3-10....................................................

3.6.3 Condenser Fan Assembly Removal 3-11..................................................

3.6.4 Condenser Motor Removal 3-12.........................................................

3.6.5 Evaporator Motor/Blower Assembly Removal 3-12.........................................

3.6.6 Compressor Replacement 3-13..........................................................

3.6.7 Capacitor Removal 3-13................................................................

3.6.8 Remote Control (Fahrenheit to Celsius) 3-13..............................................

3.7 THERMOSTAT INSTALLATION AND STAR T-UP INSTRUCTIONS (WALL MOUNTED) 3-15........

3.7.1 Introduction 3-15......................................................................

3.7.2 Installation 3-15.......................................................................

3.7.3 Thermostat Location 3-15...............................................................

3.7.4 Install Thermostat - 12VDC 3-15.........................................................

3.8 LCD DISPLA Y 3-15.......................................................................

3.8.1 Cool Only Thermostat 3-15.............................................................

3.8.2 Heat/Cool Thermostat 3-15.............................................................

3.9 SET THERMOSTAT CONFIGURATION 3-15.................................................

3.9.1 Enter Configuration Mode 3-15..........................................................

3.10 CHECK THERMOSTAT OPERATION 3-16...................................................

3.10.1 Fan Operation (Cool Only) 3-16..........................................................

3.10.2 Fan Operation (Heat/Cool) 3-16.........................................................

3.10.3 Cooling Operation (Cool Only) 3-16......................................................

3.10.4 Cooling Operation (Heat/Cool) 3-16......................................................

3.10.5 Heating Operation (Heat/Cool) 3-16......................................................

T--298

ii

Page 8

TABLE OF CONTENTS - Continued

3.11 CHECK THERMOSTAT OPERATION 3-16...................................................

3.11.1 Temperature Display 3-16...............................................................

3.11.2 Timeguard Timer 3-17..................................................................

3.11.3 Cycle Timer 3-17......................................................................

3.11.4 Minimum On Timer 3-17................................................................

3.11.5 Error Messages 3-17...................................................................

WIRING SCHEMATICS 4-1........................................................................

4.1 INTRODUCTION 4-1.....................................................................

LIST OF FIGURES

FIGURE NUMBER Page

Figure 1-1 Model/Serial Number Plate (Typical) 1-1...................................................

Figure 1-2 Roof Unit Component Identification 1-3....................................................

Figure 1-3 Ceiling Unit Component Identification (Free-Blow) 1-4.......................................

Figure 1-4 Component Identification - Low Profile - Upper Unit 1-5......................................

Figure 1-5 Component Listing-Ceiling Unit For Ducted Systems 1-6....................................

Figure 1-6 Ducted System Air Flow Arrangement 1-7.................................................

Figure 1-7 Serial Number Locations 1-8.............................................................

Figure 1-8 Refrigerant Flow Schematic (Standard System) 1-9.........................................

Figure 1-9 Refrigerant Flow Schematic - Heat Pump - (Cool Mode) 1-10.................................

Figure 1-10 Refrigerant Flow Schematic - Heat Pump - (Heat Mode) 1-11................................

Figure 3-1 Filter Removal - Free Blow 3-1...........................................................

Figure 3-2 Ceiling Grill - Free Blow 3-2..............................................................

Figure 3-3 Ceiling Panel Assembly 3-2..............................................................

Figure 3-4 Ceiling Panel With Heat Option 3-2.......................................................

Figure 3-5 Control Box Assembly - Free Blow 3-2....................................................

Figure 3-6 Indoor Thermostat 3-3..................................................................

Figure 3-7 Air sweep motor 3-3....................................................................

Figure 3-8 Heat Strip Assembly 3-3................................................................

Figure 3-9 Filter Removal - Ducted Unit 3-4.........................................................

Figure 3-10 Ceiling Grill - Ducted 3-4...............................................................

Figure 3-11 Control Box & PCB Cover 3-4...........................................................

Figure 3-12 Control Box Assembly - Ducted 3-5......................................................

Figure 3-13 Main/Display PCB’s 3-5................................................................

Figure 3-14 Cover Assembly - Standard 3-5.........................................................

Figure 3-15 Control Box 3-6.......................................................................

Figure 3-16 Control Box Removal 3-6...............................................................

Figure 3-17 Water Cover Removal 3-6..............................................................

Figure 3-18 Upper Scroll Assembly 3-7.............................................................

Figure 3-19 Motor Assembly 3-7...................................................................

Figure 3-20 Spring Clamp Removal 3-7.............................................................

Figure 3-21 Motor Clip Removal 3-7................................................................

Figure 3-22 Condenser Fan Removal 3-8...........................................................

Figure 3-23 Blower Wheel 3-8.....................................................................

Figure 3-24 Condenser With Motor Assembly & Compressor 3-8.......................................

Figure 3-25 Set-Up For Discharging a Capacitor 3-9..................................................

iii

T--298

Page 9

LIST OF FIGURES

Figure 3-26 Cover Assembly - Low Profile 3-10.......................................................

Figure 3-27 Upper Scroll Assembly Locking T abs (b.) & Screw Locations (c.) 3-10.........................

Figure 3-28 Upper Scroll Assembly Keeper T ab Release 3-10...........................................

Figure 3-29 Upper Scroll & Control Box Cover Removed 3-11...........................................

Figure 3-30 Condenser Fan Assembly & Retaining Ring 3-11...........................................

Figure 3-31 Condenser Fan Motor & Fan Assembly Stop 3-11..........................................

Figure 3-32 Condenser Fan Motor & Fan Assembly Tab 3-11...........................................

Figure 3-33 Condenser Motor Ground 3-12...........................................................

Figure 3-34 Evaporator Motor Locking Tabs 3-12......................................................

Figure 3-35 Evaporator Motor/Blower Assembly In Cradle 3-12.........................................

Figure 3-36 Evaporator Blower Wheel (Flush With End Of Motor Shaft) 3-13..............................

Figure 3-37 Control Box Assembly With Capacitor 3-13................................................

Figure 3-38 Remote Control Components 3-14........................................................

Figure 3-39 Remote Control PCB (FR9 Location) 3-14.................................................

Figure 3-40 Wall Thermostat Wiring Diagram - Cool Only Model 3-17....................................

Figure 3-41 Wall Thermostat Wiring Diagram - Heat/Cool Model 3-18....................................

Figure 4-1 Upper Unit Schematic - Standard & HC 4-1................................................

Figure 4-2 Upper Unit Schematic - Low Profile 4-1...................................................

Figure 4-3 Ceiling Unit Schematic - Cooling Only 4-2.................................................

Figure 4-4 Ceiling Unit Schematic - Heat/Cool 4-2....................................................

Figure 4-5 Ceiling Unit, Standard - Ducted 4-2.......................................................

Figure 4-6 Heat Pump - Upper Unit - Free Blow 4-3..................................................

Figure 4-7 Heat Pump - Ceiling Unit - Free Blow 4-3..................................................

Figure 4-8 Heat Pump - Upper Unit - Ducted 4-4.....................................................

Figure 4-9 Heat Pump - Ceiling Unit - Ducted 4-4....................................................

LIST OF TABLES

TABLE NUMBER Page

Table 1-1 Model Chart 1-2.........................................................................

Table 1-2 Additional Support Manuals 1-3............................................................

Table 2-1 System Self-diagnostics Function (Ducted Remote) 2-4.......................................

T--298

iv

Page 10

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains service instructions and electrical

data for the AirV, Carrier Transport Air Conditioning’s

Recreational Vehicle air conditioning unit.

The AirV units are two piece systems, consisting of the

UpperUnitandtheCeilingunit.TheUpperUnitcontains

the refrigeration system while the Ceiling Unit contains

thecontrols andvents. The Ceiling Units are availablein

a free--blow or ducted configuration.

The free--blow units (see Figure 1-2) deliver air to the

vehicle by means of front and rear end vents and one

downward vent (air shower). The vents may all be

opened or closed to direct air as desired. The front and

rear vents are fitted with motorized dampers that

oscillates to produce an “air--sweep” effect. These units

may be fitted with optional electric heat.

Theductedunits(seeFigure 1-5andFigure 1-6)deliver

air through ducting built in the vehicle ceiling. These

units are fitted with a 12 VDC microprocessor control

system, a display panel (PCB display) and a remote

controller. These units may be wired to provide

thermostatic control of the vehicle furnace.

Carrier’s AirV air conditioning models include cooling

only units, heating/cooling units, and heat pump units.

The cooling only units are available with free blow or

ducted air delivery. Cooling units with heat strips are

available for free blow only.

Operation of the AirV units is controlled automatically by

the temperature controller (thermostat), which

maintains the vehicle’s interior temperature at the

desired set point. Free Blow, cool--only units are

available with a wall mounted thermostat.

Table 1-1 lists model numbers and descriptions of the

AirV units, and Table 1-2 lists additional support

manuals that are available.

1.2 SERIAL NUMBER IDENTIFICATION

Separatepartnumbersandserialnumbersareprovided

for the upper and lower unit assemblies The numbers

may be found on a plate readable from inside the

vehicle, See Figure 1-7.

The first two numbers of the serial number, see

Figure 3-22, is theweektheunitwasmanufactured. For

example, 01 would designate the first week of the year

and 52 would designate the last week of the year.

The third and fourth numbers designate the year in

which the unit was manufactured. For example, 99

would represent the year 1999, 00 the year 2000, and

so on.

The letter Y and all the numbers after it designates the

unit serial number. Example: Y43210

Aserialnumber of 1303Y12345 designates that the unit

was manufactured the 13th week of 2003 and the serial

number is Y12345.

Carrier

Air Conditioning

C

Division ofCarrier Corporation

USE AMP20

TIME DELAY FUSE OR

CIRCUIT BREAKER

COMPRESSOR

FAN MOTOR

USE CEILING ASSY/ANY

DATEOFMfg

DESIGN PSIG HIGH 350 LO 150

R--22

MODEL No.

Part No.

VOLTS

CAPACITY

AMPS

SERIAL No.

68RV14102A

99--00468-- 01

115

ph

1

13,500

3,955

13.5

05/03

1303Y12345

oz

kg

RLA

FLA

99--00469-- 01

15.9

0.45

12.5

2.58

hz

V

60

Btu/h

W

A

Figure 1-1 Model/Serial Number Plate (Typical)

1.3 DESIGN CHANGE DESCRIPTIONS

The following list provides a description of changes in

design and serial number breaks for those changes.

1400Y A diode was added to the Ducted Ceiling

assembly control board to stop DC ripple from the

converters,

2900Y Cover screw coating was changed in order to

eliminate corrosion.

3400Y The plastic shroud was modified to improve

drainage.

5100Y A new compressor and capacitor is introduced,

improving stability and increasing capacity.

1201Y The temperature sensor was moved to the grill

to improve temperature sensing during furnace mode,

2501Y The dual air sweep was added.

4501Y A switch was added to skip compressor

malfunction test.

4601Y Change in material was made in order to

strengthen the fan propeller.

4901Y The mounting bolt lengths were increased 3/4

inch.

4901Y The polar whiteducted ceiling color was cut--in.

0703Y & 1903Y Newstyle PCB -- Cool Mode -- Control

& Power Assembly (Fans shut off in auto mode).

0803Y & 2603Y Newstyle PCB -- Heat Pump -- Control

& Power Assembly (Fans shut off in auto mode).

4204Y Minimumfurnacesetpoint loweredfrom 63°Fto

45°F.

1-1

T--298

Page 11

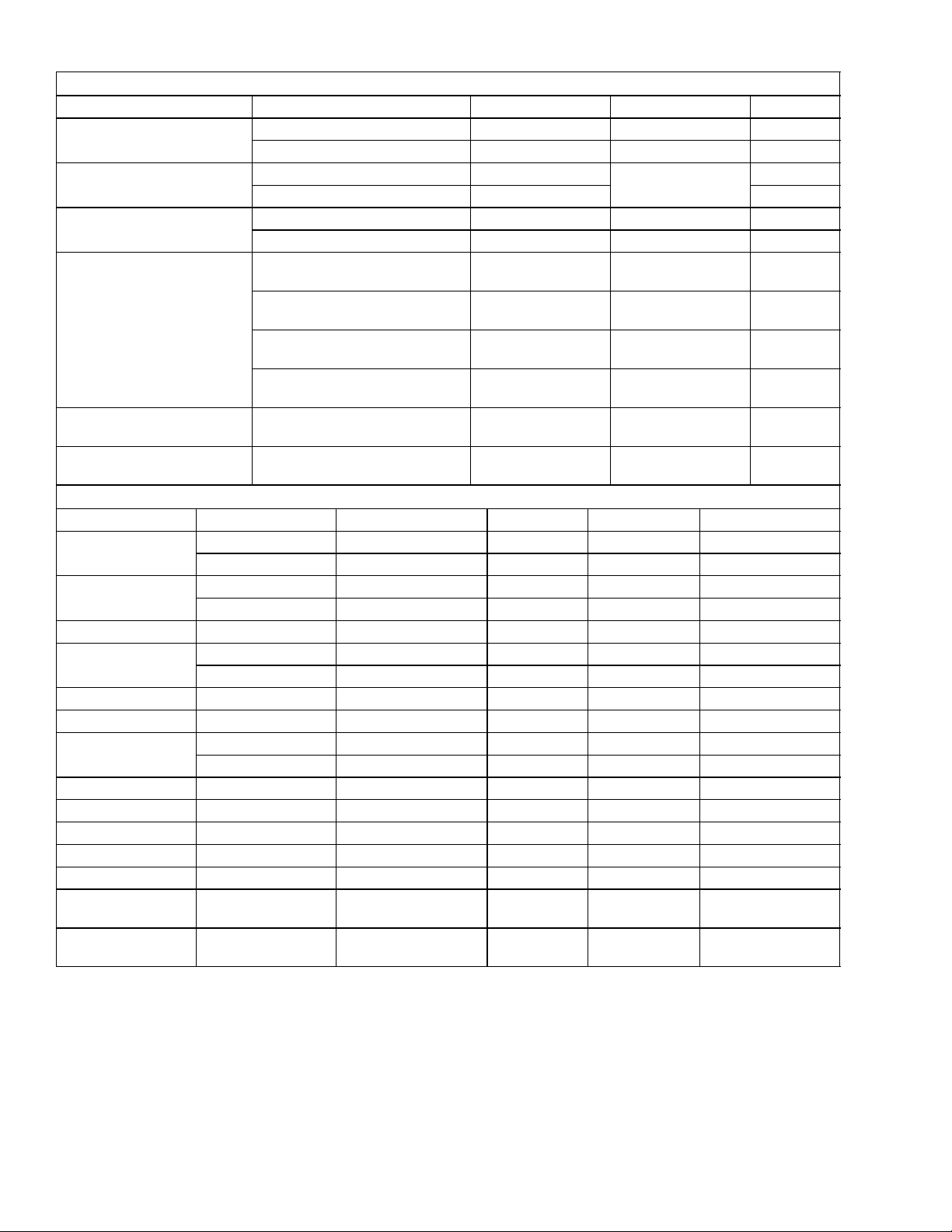

Table 1-1. Model Chart

115VStandardSyste

m

220VStandardSyste

m

5.3Cool

y

HighCapacit

y

R

V

A

A

R

V

B

A

R

V

A

A

R

V

C

A

UPPER UNIT (ROOF)

Model Number Part Number Voltage Amps Color

115VStandard System

68RV14102A

220VStandard System

68RV11302A

HighCapacit

68RV15102A

Heat Pump

Systems

68RV14112A

LOW PROFILE

68RV15103A

LOW PROFILE

68RV14103A

(Free Blow -- High Capacity)

99--00468--00 1 15/1/60 12.8 White

99--00468--01 1 15/1/60 12.8 Ivory

99--00468--02 220/1/50

99--00468--03 220/1/50

5.3 Cool

6.7 Heat

99--00468--08 1 15/1/60 14.5 White

99--00468--09 1 15/1/60 14.5 Ivory

99--00468--04

(Free Blow)

99--00468--05

(Free Blow)

99--00468--06

(Ducted)

99--00468--07

(Ducted)

99--00468--10

99--00468--12

(Free Blow -- Standard)

1 15/1/60

1 15/1/60

1 15/1/60

1 15/1/60

1 15/1/60

1 15/1/60

12.7 Cool

10.9 Heat

12.7 Cool

10.9 Heat

12.7 Cool

10.9 Heat

12.7 Cool

10.9 Heat

15.1 Cool

13.8 Heat

15.0 Cool

13.7 Heat

White

Ivory

White

Ivory

White

Ivory

White

White

CEILING UNIT

Model Number Part Number Voltage Color Options Interface

68

68

0010

0010

99--00469--00 1 15/1/60 White Cool Only Free Blow

99--00469--01 1 15/1/60 Ivory Cool Only Free Blow

99--00469--02 1 15/1/60 White Heat/Cool Free Blow

99--00469--03 1 15/1/60 Ivory Heat/Cool Free Blow

68RV0010KA 99--00469--06 1 15/1/60 (12VDC) White Cool Only Ducted

68

0030

99--00469--04 220/1/50 White Cool Only Free Blow

99--00469--05 220/1/50 Ivory Cool Only Free Blow

68RV0030BA 99--00469--08 220/1/50 White Heat/Cool Free Blow

68RV0030KA 99--00469--10 220/1/50 White Cool Only Ducted

68

0012

99--00469--11 115/1/60 White Heat Pump Free Blow

99--00469--12 1 15/1/60 Ivory Heat Pump Free Blow

68RV0011LA 99--00469--13 1 15/1/60 (12VDC) White Heat Pump Ducted

68RV0010AB 99--00469--23 1 15/1/60 White Cool Only Free Blow

68RV0010AB 99--00469--24 1 15/1/60 Ivory Cool Only Free Blow

68RV0010BB 99--00469--25 1 15/1/60 White Heat/Cool Free Blow

68RV0010BB 99--00469--26 1 15/1/60 Ivory Heat/Cool Free Blow

68RV0040MA 99--00469--22 115/1/60 White Cool Only

68RV0010DB 99--00469--29 115/1/60 White Cool Only

Ducted

Wall Thermostat

Free Blow

Wall Thermostat

T--298

1-2

Page 12

Table 1-2 Additional Support Manuals

MANUAL--FORM NO.

71LC6A54310 AirV 115 Volts--Free Blow (Cool Only) Owner’s Guide

71LH6A54070 AirV 115 Volts--Free Blow (Heat--Cool) Owner’s Guide

71LD6A54070 AirV 115 Volts--Ducted (Cool Only) Owner’s Guide

71LH6A54070 AirV 220 Volts--Free Blow (Heat--Cool) Owner’s Guide

71RQ6A5401A AirV 115 Volts--Free Blow (Heat Pump) Owner’s Guide

71DQ6A5401A AirV 115 Volts--Ducted (Heat Pump) Owner’s Guide

71DW6A54070 AirV 115 Volts--Ducted Wired Thermostat Owner’s Guide

71LC6A54310 AirV 115 Volts--Free Blow (Cool Only) Owner’s Guide

71LH6A54070 AirV 115 Volts--Free Blow (Heat--Cool) Owner’s Guide

71RW6A54310 AirV 115 Volts--Free Blow Wired Thermostat Owner’s Guide

T--298PL AirV Service Parts ALL

62--50455--00 Basic refrigeration Service Training ALL

EQUIPMENT COVERED TYPE OF MANUAL (For) PART NO.

99--00469--00

99--00469--01

99--00469--02

99--00469--03

99--00469--06

99--00469--08

99--00469--09

99--00469--11

99--00469--12

99--00469--13

99--00469--22

99--00469--23

99--00469--24

99--00469--25

99--00469--26

99--00469--29

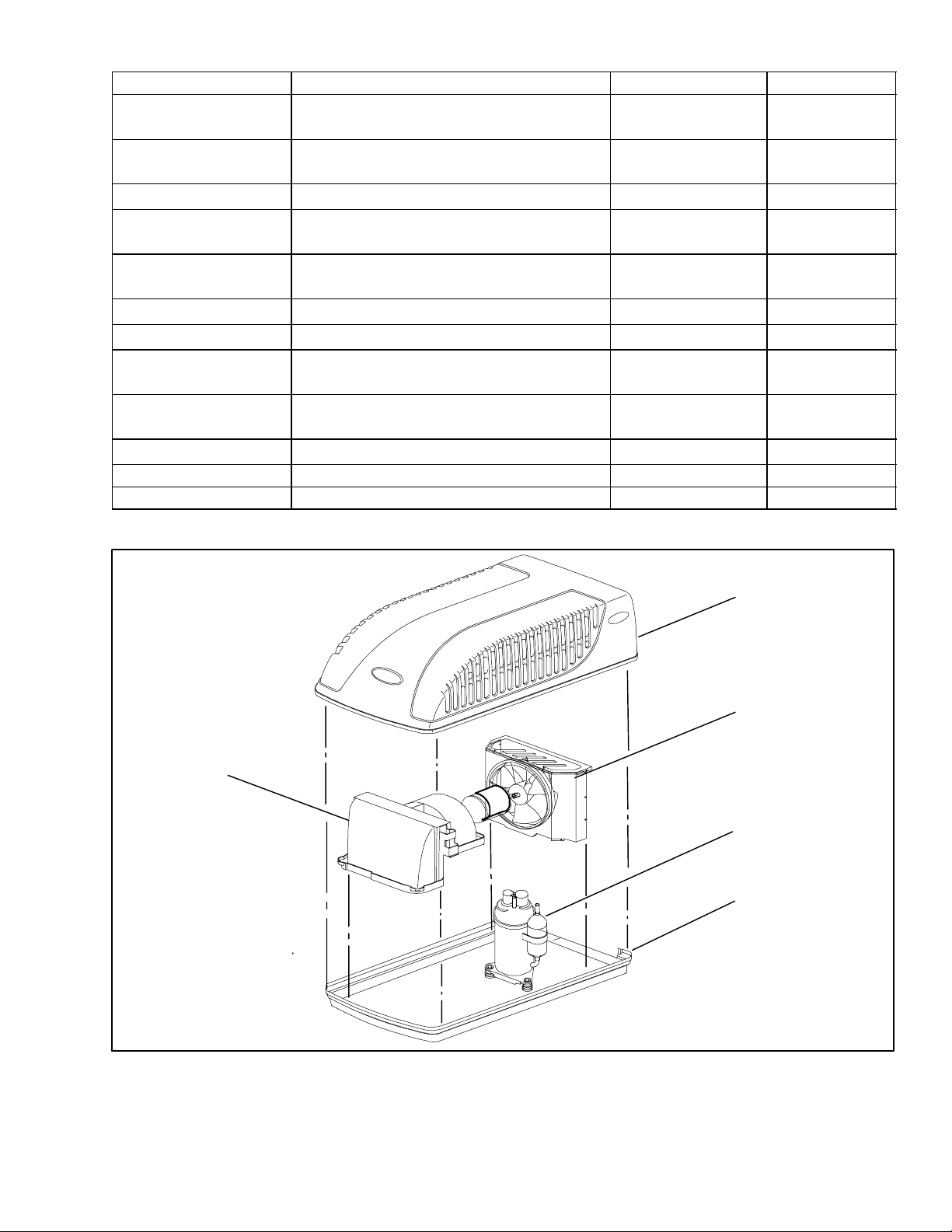

1

2

3

4

5

1. Cover

2. Condenser

3. Evaporator

4. Compressor

5. Base Pan

Figure 1-2 Roof Unit Component Identification

1-3

T--298

Page 13

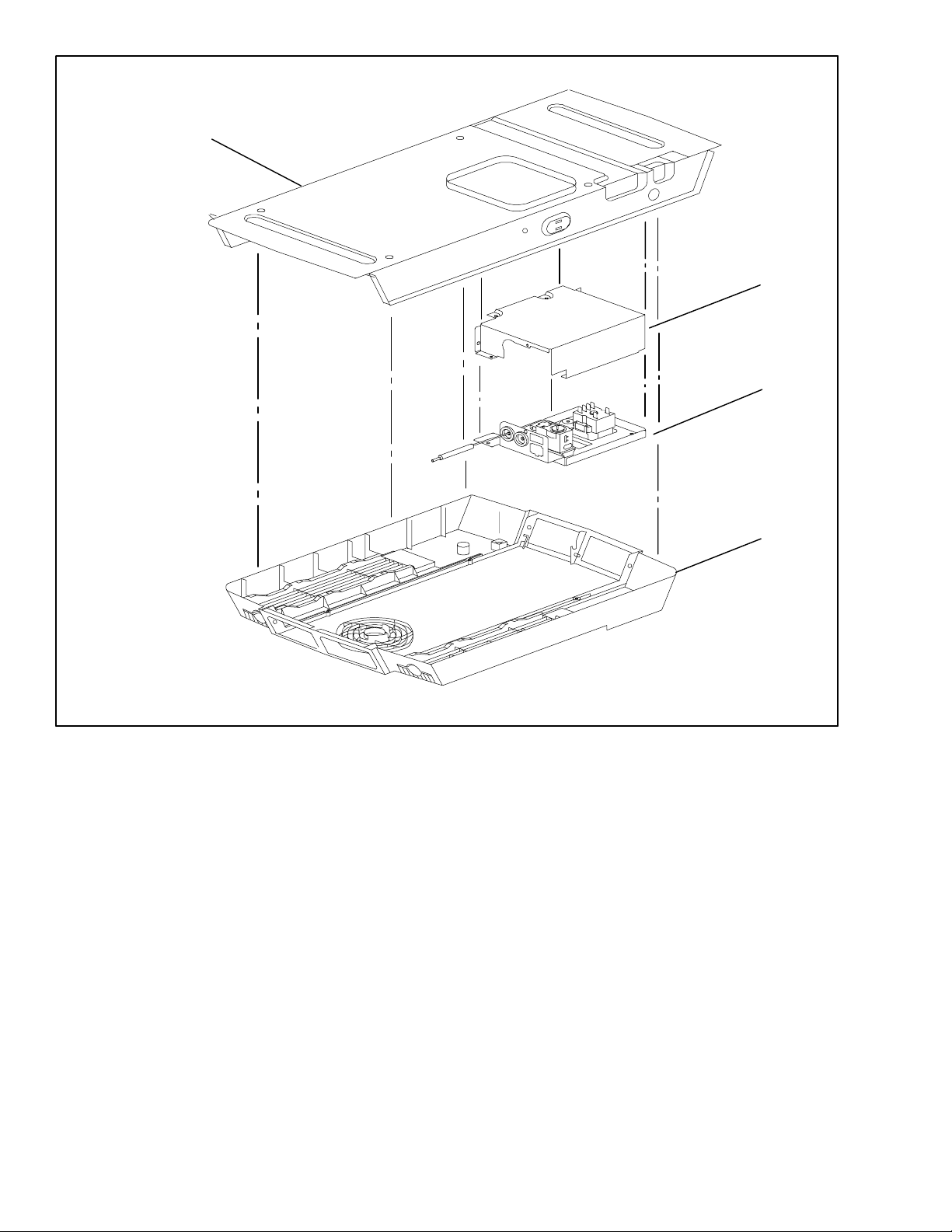

1

2

3

4

1. Ceiling Panel Assembly

2. Control Box Cover

Figure 1-3 Ceiling Unit Component Identification (Free--Blow)

T--298

3. Control Assembly

4. Ceiling Grill Assembly

1-4

Page 14

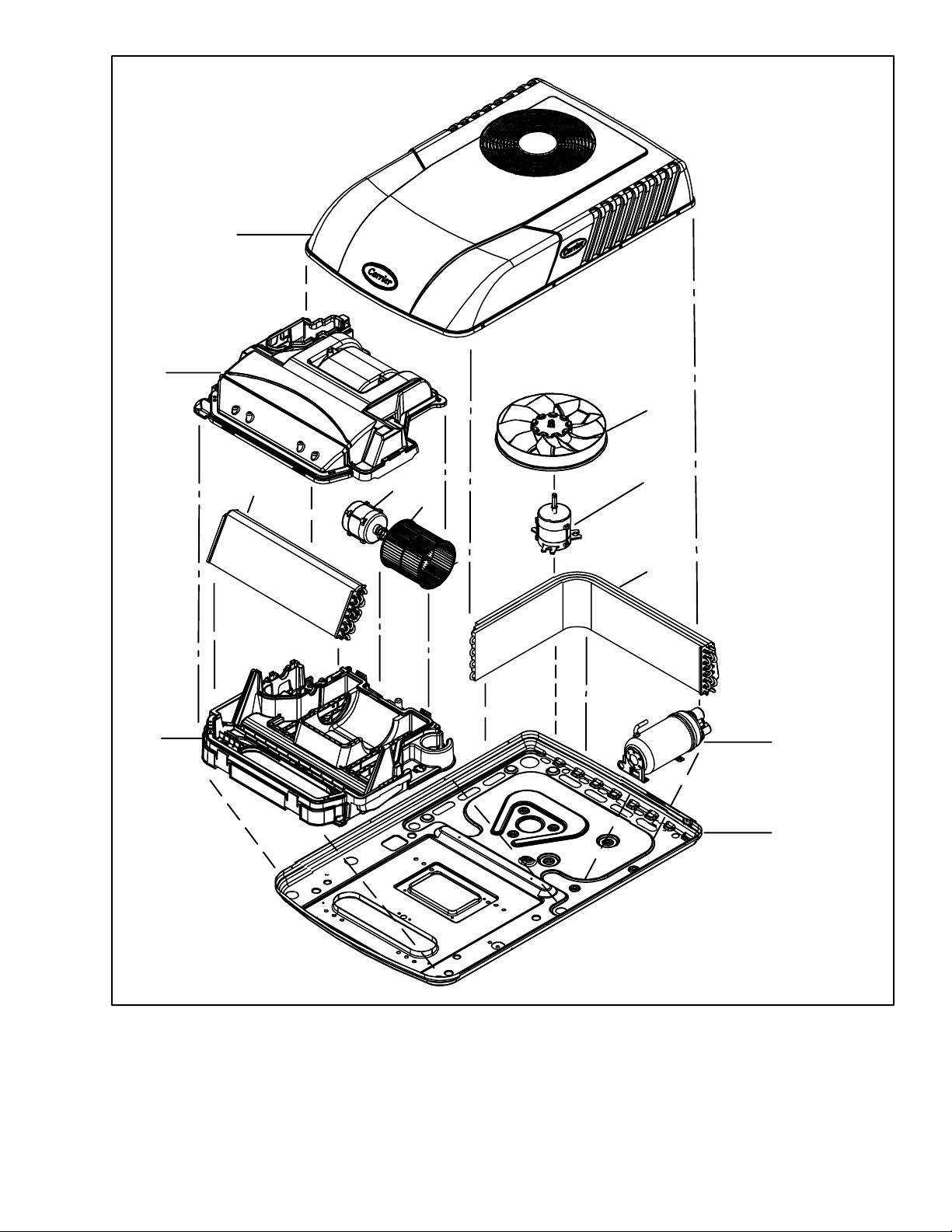

1

2

3

9

8

5

6

4

7

10

11

1. Cover Assembly

2. Scroll Assembly -- Upper

3. Condenser Fan

4. Condenser Motor

5. Evaporator Motor

6. Evaporator Blower Wheel

Figure 1-4 Component Identification -- Low Profile -- Upper Unit

7. Condenser Coil

8. Scroll Assembly -- Lower

9. Evaporator Coil

10. Compressor

1 1. Base Pan Assembly

See Figure 1-3 for Ceiling Package (Free--Blow)

1-5

T--298

Page 15

1

2

3

12

11

10

4

5

6

7

9

8

1. Telescoping Divider (3 different sizes available)

2. Divider Assembly

3. Frame Panel, Insulation Assembly

4. Control Box Assembly

5. Control Box Cover

6. Suction Packing Assembly

Figure 1-5 Component Listing--Ceiling Unit For Ducted Systems

T--298

7. Remote Control Assembly

8. Remote Control Bracket Assembly

9. Filter Assemblies (2)

10. PCB Cover

1 1. PCB Main Assembly

12. PCB Display

1-6

Page 16

1

4

5

SCHEMATIC VIEW

1

2

3

5

1

SUPPLY AIR

4

INSTALLED VIEW

1. Vehicle Duct System (Connection)

2. Telescoping Divider (3 different sizes available)

3. Return Air Suction Area

Figure 1-6 Ducted System Air Flow Arrangement

SUPPLY AIR

2

3

RETURN AIR

4. Control Box Assembly

5. Supply Air Discharge Area

1-7

T--298

Page 17

Serial number

of Upper Unit

Serial Number

of Ceiling Unit

Free Blow Type

Upper Unit

Ceiling Unit

(Cover Removed)

Bottom of

Upper Unit

Serial Number of

Ceiling Unit

(Side of Control Box)

Ceiling Assembly Frame

Ducted Type

T--298

Serial Number

of Upper Unit

Figure 1-7 Serial Number Locations

1-8

Bottom View After Installation

(With Grille Removed)

Page 18

1.4 AirV SYSTEM COMPONENT SPECIFICATIONS

1.4.1 Refrigerant Charge

Standard -- High Capacity -- Heat Pump

R--22 -- 15.9 Ounces

Low Profile (All)

R--22 -- 16.9 Ounces

1.4.2 Compressor -- 115 Volts, 60 Cycles, 1 Phase

a. Locked Rotor Amps -- Standard -- High

Capacity -- Heat Pump

64.5 AMPS6

b. Locked Rotor Amps -- Low Profile

High Capacity

59.0 AMPS

c. Fully Loaded Amps -- Standard

Cooling -- Approximate 12.8 AMPS

Heating -- N/A

d.Fully Loaded Amps -- High Capacity

Cooling -- Approx. 14.5 AMPS

Heating -- Approx. 11 AMPS

e. Fully Loaded Amps -- Low Profile

Cooling -- Approx. 14.1 AMPS

Heating -- Approx. 13.8 AMPS

f. Fully Loaded Amps -- Heat Pump

Cooling -- Approx. 12.8 AMPS

Heating -- Approx. 11 AMPS

1.4.3 Compressor -- 220 Volts, 50 Cycles, 1 Phase

a. Locked Rotor Amps

23.6 AMPS

1.4.4 Thermostat Range (All Free Blow Units)

61° F(16° C) to 89° F(32° C)

1.5 ST ART--UP

Refer to operating instructions in Owners Guide (see

Table 1-2) packaged with the vehicle system.

DISCHARGE

LIQUID

SUCTION

COMPRESSOR

Figure 1-8 Refrigerant Flow Schematic (Standard System)

1.6 REFRIGERANT CYCLE--STANDARD SYSTEM

The cooling cycle is energized when the thermostat,

located on the ceiling unit, calls for cooling. The main

components of the system are the compressor,

air-cooled condenser coil, strainer, capillary tube,

evaporator coil and accumulator.

The compressor raises the pressure and the

temperature of the refrigerant and forces it through the

discharge line into the condenser coil. (See Figure 1-8.)

The condenser fan circulates surrounding air (which is

at a temperature lower than the refrigerant) over the

outside of the coil tubes. Heat transfer is established

from the refrigerant (inside the tubes) to the air (flowing

over the tubes). The tubes have fins designed to

improve the transfer of heat from the refrigerant gas to

the air. This removal of heat causes the refrigerant to

liquefy, thus liquid refrigerant leaves the coil and flows

through a strainer to the capillary tube. The strainer

removes any impurities within the refrigerant system.

The capillary tube meters the flow of liquid refrigerant to

the evaporator coil. As the refrigerant flows through the

capillary tube, there is a reduction in pressure and

temperature.

CAPILLARY

TUBE

EVAPORATOR

ACCUMULATOR

CONDENSER

STRAINER

Theevaporator blower (fan)pullsvehicleairthroughthe

filters, which remove particulate matter, and then pass

the cleaned air through the evaporator coil.

The low pressure, low temperature liquid that flows into

the evaporator coil tubes is colder than the air that is

circulated over the tubes. Heat transfer is established

from the vehicle air (flowing over the tubes) to the

refrigerant (flowing inside the tubes). The evaporator

coil tubes have aluminum fins to increase heat transfer

from the air to the refrigerant; therefore the cooler air is

circulated to the interior of the vehicle.

The transfer of heat from the air to the low temperature

liquid refrigerant in the indoor coil causes the liquid to

vaporize. This low temperature, low pressure vapor

passes into the accumulator. The accumulator is

designed with the inlet tube delivering refrigerant to the

bottom of the tank and the outlet tube taking refrigerant

form the top of the tank. This arrangement ensures that

only vapor refrigerant is returned to the compressor,

where the cycle repeats.

When ventilation only is selected, the indoor fan

functions to circulate air throughout the vehicle. The

refrigerant cycle will remain off.

1-9

T--298

Page 19

1.7 REFRIGERANT CYCLE -- HEAT PUMP

DISCHARGE

LIQUID

SUCTION

ACCUMULATOR

COMPRESSOR

Figure 1-9 Refrigerant Flow Schematic -- Heat Pump -- (Cool Mode)

1.7.1 Cooling

The cooling cycle is energized when the thermostat,

located in the ceiling unit, calls for cooling The system

controls are positioned for “normal”refrigerant flow,with

the compressor discharge delivered to the outdoor coil

and liquid delivered to the indoor coil. (See Figure 1-9.)

The main components of the system are the

compressor, reversing valve, air-cooled outdoor coil,

strainer,capillary tube, indoor coil, and theaccumulator.

The compressor raises the pressure and the

temperature of the refrigerant and forces it through the

discharge line and reversing valve into the outdoor coil.

The outdoor fan circulates surrounding air (which is at a

temperature lower than the refrigerant)over the outside

of the coil tubes. Heat transfer is established from the

refrigerant (inside the tubes) to the outdoor air (flowing

over the tubes). The tubes have fins designed to

improve the transfer of heat from the refrigerant gas to

the air; this removal of heat causes the refrigerant to

liquefy, thus liquid refrigerant leaves the coil and flows

through the strainer to the capillary tube. The strainer

removes any impurities within the refrigerant system.

The capillary tube meters the flow of liquid refrigerant to

the indoor coil. As the refrigerant flows through the

CAPILLARY

INDOOR COIL

REVERSING VALVE

OUTDOOR COIL

TUBE

STRAINER

capillary tube, there is a reduction in pressure and

temperature.

The indoor blower (fan) pulls inside air through the

filters, which remove particulate matter, and then pass

the cleaned air through the indoor coil.

The low pressure, low temperature liquid that flows into

the indoor coil tubes is colder than the air that is

circulated over the tubes. Heat transfer is established

from the indoor air (flowing over the tubes) to the

refrigerant (flowing inside the tubes). The indoor coil

tubes have aluminum fins toincrease heat transfer from

the air to the refrigerant; therefore the cooler air is

circulated to the interior of the vehicle.

The transfer of heat from the air to the low temperature

liquid refrigerant in the indoor coil causes the liquid to

vaporize. This low temperature, low pressure vapor

passes into the accumulator. The accumulator is

designed with the inlet tube delivering refrigerant to the

bottom of the tank and the outlet tube taking refrigerant

form the top of the tank. This arrangement ensures that

only vapor refrigerant is returned to the compressor,

where the cycle repeats.

When ventilation only is selected, the indoor fan

functions to circulate air throughout the vehicle. The

refrigerant cycle will remain off.

T--298

1-10

Page 20

DISCHARGE

LIQUID

SUCTION

CAPILLARY

INDOOR COIL

REVERSING VALVE

ACCUMULATOR

COMPRESSOR

OUTDOOR COIL

TUBE

Figure 1-10 Refrigerant Flow Schematic -- Heat Pump -- (Heat Mode)

STRAINER

1.7.2 Heating

The heating cycle is energized when the thermostat,

located in the ceiling unit, calls for heat The system

controls are positioned for “reverse” refrigerant flow,

with the compressor discharge delivered to the indoor

coil and liquid delivered to the outdoor coil. (See

Figure 1-10.)

The main components of the system are the

compressor, reversing valve, indoor coil, capillary tube,

strainer, air-cooled outdoor coil, and the accumulator.

The compressor raises the pressure and the

temperature of the refrigerant and forces it through the

discharge line and reversing valve into the indoor coil.

The indoor blower (fan) pulls inside air through the

filters, which remove particulate matter, and then pass

the cleaned air through the indoor coil.

Thevehicle air (which is at a temperature lower than the

refrigerant) passes over the outside of the coil tubes.

Heat transfer is established from the refrigerant (inside

thetubes) to thevehicleair(flowingoverthetubes).The

tubes have fins designed to improve the transfer of heat

from the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid refrigerant

leaves the coil and flows through the strainer to the

outdoor coil. The strainer removes any impurities within

the refrigerant system.

The capillary tube meters the flow of liquid refrigerant to

the outdoor coil. As the refrigerant flows through the

capillary tube, there is a reduction in pressure and

temperature.

The low pressure, low temperature liquid that flows into

the outdoor coil tubes is colder than the outdoor air that

is circulated over thetubes. Heat transfer isestablished

from the outdoor air (flowing over the tubes) to the

refrigerant (flowing inside the tubes). The outdoor coil

tubes have aluminum fins toincrease heat transfer from

the air to the refrigerant.

The transfer of heat from the air to the low temperature

liquid refrigerant in the outdoor coil causes the liquid to

vaporize. This low temperature, low pressure vapor

passes into the accumulator. The accumulator is

designed with the inlet tube delivering refrigerant to the

bottom of the tank and the outlet tube taking refrigerant

form the top of the tank. This arrangement ensures that

only vapor refrigerant is returned to the compressor,

where the cycle repeats.

When ventilation only is selected, the indoor fan

functions to circulate air throughout the vehicle. The

refrigerant cycle will remain off.

1-11

T--298

Page 21

SECTION 2

TROUBLESHOOTING

For ducted units, the green operation indicator LED (SeeFigure 3-9) will flash if there is a problem.

Refer to Table 2--1 for diagnostic information.

SYMPTOM AND PROBABLE CAUSE

2.1 NO POWER TO UNIT

1. Master switch off

2. Open circuit breaker

3. Defective wiring

4. Loose electrical connections

5. Faulty switches, thermostat, or fan

6. 12 VDC not connected (Ducted System)

7. 12 VDC in--line fuse open (Ducted)

2.2 DUCTED UNIT WILL NOT OPERATE

1. Display not illuminated

2. Display illuminated

2.3 DUCTED UNIT WILL NOT COOL

1. Green LED light flashes 5 times

2. Unit cools for a few moments then stops cooling

2.4 COMPRESSOR POWER SUPPLY OPEN

1. Loose leads at compressor terminals

2. Defective motor overload switch

3. Defective capacitor

4. Open compressor windings

5. Seized compressor

6. Capacitor incorrectly wired

2.5 COMPRESSOR RUNS BUT CYCLES, FAN OPERATING ERRATICALLY

1. Loose lead at fan motor

2. Defective or burned out motor

3. Outdoor air restricted or recirculating

4. Overcharge or noncondensables in system

5. Restricted discharge line

6. Defective motor overload switch

1. Reset master switch

2. Reset circuit breaker

3. Replace wiring

4. Tighten connections

5. Replace defective components

6. Connect to 12 VDC power source

7. Replace fuse

1. Check 12 Volt DC in--line fuse

2. Check 1 15 Volt AC Connections

1. Check 1 15 volt AC power source

Momentarily disconnect 12 VDC power source

Disable compressor malfunction test switch.

Check AMP draw.

Check ∆ T

2. Remove grill, verify evaporator coil probe is

inserted into coil.

Check AMP draw.

Check ∆ T

Replace unit

1. Tighten leads

2. Replace switch

3. Replace capacitor -- Refer to Paragraph 3.5.8

4. Replace compressor

5. Replace compressor

6. Verify capacitor wiring (Refer to wiring diagram)

1. Tighten lead.

2. Replace motor.

3. Check for dirty condenser coil, proper clearance

around unit, remove any obstructions.

4. Check AMP draw

5. Check for obstruction in line.

Check ∆ T.

Replace unit.

6. Replace switch.

PROBABLE REMEDY

2-1

T--298

Page 22

SYSTEM AND PROBABLE CAUSE

PROBABLE REMEDY

2.6 CYCLES ON COMPRESSOR OVERLOAD

1. Defective run capacitor

2. Defective compressor bearings or valves

3. Greatly restricted evaporator air, iced evaporator

1. Replace capacitor -- Refer to Paragraph 3.5.8

2. Replace unit.

3. Defrost evaporator coil.

coil.

4. Low refrigerant charge

5. Evaporator capillary restricted

6. Liquid line restricted

7. Compressor hot

4. Replace unit.

5. Replace unit.

6. Replace unit.

7. Verify refrigerant charge.

Check AMP draw.

Check ∆ T.

8. Weak or inconsistent line power

8. Check line voltage at time of compressor start--up.

2.7 INSUFFICIENT COOLING, COOLING AIR NOT ADEQUATE

1. Dirty evaporator coil

2. Iced evaporator coil, slightly low refrigerant charge

3. Improper fan operation

4. Defective fan motor

5. Return air filter is dirty

1. Clean as required.

2. Defrost or Recharge.

3. Verify fan rotation (Refer to wiring diagram)

4. Replace fan motor.

5. Remove and clean filters (Refer to paragraphs 3.3.1

& 3.4.1)

2.8 CONDENSER AIR NOT ADEQUATE

1. Outside Air Restricted

2. Dirty coil

3. Defective fan motor

1. Check for obstruction at coil. Remedy as required.

2. Clean coil.

3. Replace fan motor.

2.9 INSUFFICIENT COOLING

1. Unit undersized

2. Capillary restricted

1. Re--evaluate unit for proper capacity.

2. Check AMP draw.

Check ∆ T.

Replace unit.

2.10 COMPRESSOR FLOODING

1. Unit overcharged

1. Check AMP draw.

Check ∆ T.

Replace unit.

2. Low evaporator airflow

3. Defective electrical connections

2. Clean filter and/or evaporator coil.

3. Check connections per wiring diagram and tighten

any loose connections.

2.11 HEATER CYCLES ON LIMIT SWITCH (HEAT/ COOL VERSION ONLY)

1. Dirty filter

2. Blocked evaporator air inlet (indoor)

3. Low airflow due to fan motor speed

1. Clean or replace filter.

2. Remove blockage.

3. Check fan motor. Repair or replace as necessary.

2.12 AIR SWEEP NOT WORKING (FREE BLOW VERSION ONLY)

1. Ceiling grill not properly aligned

2. Linkage in upper control box stuck

3. Air sweep motor failure

1. Align ceiling grill.

2. Align and lubricate linkage.

3. Replace motor.

2.13 WATER LEAKAGE

1. Water dripping from ceiling unit. 1. Verify vehicle is level

Tighten unit mounting bolts evenly or replace unit

gasket.

T--298

2-2

Page 23

SYSTEM AND PROBABLE CAUSE

2.14 INADEQUATE HEAT (FREE--BLOW HEAT ONLY)

1. No heat from heat strip. 1. Verify AMP draw . ( 13.8 AMP)

Verify resistance through heating element. (9 OHM)

Check bi--metal switch. If open, replace switch.

2.15 INADEQUATE HEAT (HEAT--PUMP)

NOTE: Allow unit to operate 15 minutes after switch-

ing from cooling mode.

1. Reversing valve not operating

2. Outdoor coil icing.

1. Check for 115 volts at reversing valve coil

Check for reversing valve restriction

Verify compressor operation

2. Check outdoor coil sensor

PROBABLE REMEDY

Clearing Diagnostic Alarms

When a repair has been accomplished due to a corresponding alarm, the alarm must be cleared. This is done by

disconnecting the 12 VDC power to the ducted ceiling assembly for one or two seconds. Once the 12 VDC power is

reconnected, the alarm should have been cleared.

2-3

T--298

Page 24

Table 2--1 System Self--diagnostics Function (Ducted Remote)

Flashes

2

Error Codes

(Priority)

1 ROOM AIR THERM-

Error Contents

(Malfunction)

ISTOR FAILURE

3 2 INDOOR COIL

THERMISTOR FAIL-

URE

4 3 OUTDOOR COIL

THERMISTOR

FAILURE

5 4 COMPRESSOR

DRIVE

MALFUNCTION

Display Pattern Allowed Modes

FAN Mode

FAN Mode

3sec

.

0.5 sec (3

Times)

0.5 sec.

(Twice)

3sec

.

FURNACE Mode

3sec

.

0.5 sec. (4

Times)

3sec.

FAN Mode

FURNACE Mode

3sec.

0.5 sec. (5

Times)

3sec

.

FAN Mode

FURNACE Mode

6 5 REVERSING VALVE

DRIVE MAL--

FUNCTION

1

6 DISCHARGE AIR

THERMISTOR FAIL-

URE

Continuous 7 THERMISTOR

WIRING WRONG

(only in cooling

test mode)

3sec

.

3sec

.

3sec

.

0.5 sec.

(6Times)

0.5 sec.

(Once)

3sec.3sec

.

0.5 sec. (Continuous)

3sec

.

3sec

.

FAN Mode

FURNACE Mode

FAN Mode

FURNACE Mode

FAN Mode

NOTE:

If more than two errors occur, the highest ranked code is displayed. If the highest ranked error is cleared, the

next highest ranked error code is displayed.

T--298

2-4

Page 25

SECTION 3

SERVICE AND MAINTENANCE

3.1 PREVENTA TIVE MAINTENANCE

Cleaning--Clean evaporator coil and condenser coil.

Hold flashlight behind coil to see if all spaces are clear.

Dust accumulation obstructs or reduces airflow and

results in loss of cooling capacity. Both coils may be

vacuumed when dry. Coils may also be brushed with a

stiff brush and then blown out with compressed air.

Thoroughly clean base pan, motors, fan wheels, and

other components.

Clean cover and ceiling grill. Mild detergents reduce

electrostatic charges on plastic sections of the grill and

are good cleaners.

WARNING

Before working on the unit be sure to first

disconnect all electric power to the unit to

avoidthepossibilityofelectricalshockand

personal injury. Before disconnecting, dis-

charge capacitors by shorting across the

capacitors terminals (Refer to paragraph

3.5.8)

WARNING

CAUTION

Do not use carbon tetrachloride, solvents,

or waxes containing solvents to clean plastic sections.

Painting--Paint any parts that show evidence of rust

with a good rust--prevention paint.

Wiring-- Check all wiring for deterioration and all

electrical contacts for tightness or corrosion.

Mounting--Make sure unit is secure on roof according

to installation instructions provided in Owner’s Guide.

Checkfanstoinsurethatthey arecorrectly positionedin

the center of the orifice, and tight on the shaft.

Leaks--Check any connections that show evidence of

oil or leaks. When unit is properly installed (refer to

Owner’sGuide) check gaskets for possible air leakage.

Controls--Check unit to ensure all controls are

functioning correctly and unit operation is normal.

Vibrations can cause unwanted noise.

NOTE

Check to ensure that piping is not vibrating

against side of the unit.

Shield coils with cardboard to protect

hands against injury from sharp metal

edges when removing compressor and other components.

3.3 CEILING UNIT -- FREE BLOW SYSTEMS

3.3.1 Filter Removal

The filters (Figure 3-1) are located in the ceiling grill. To

remove the filters, do the following:

a. Grasp the edge of the filter at recess in the end of the

ceiling grill.

b. Pull filter completely out of the filter slot.

c. Vacuum filter or wash filter in luke--warm water.

Shake off excess water and dry thoroughly.

d. Replace filter by sliding the filter into the filter slot in

the ceiling grill until the filter frame is flush with the in-

terior grill.

Filters

NOTE

For proper cleaning and flushing, use a UL

approved refrigerant recovery/recycling

system.

NOTE

Refrigerant removal must always include

recovering the refrigerant, not allowing it to

escape to the atmosphere.

3.2 SERVICE -- GENERAL

General Notes—These Service Instructions are

provided to assist the trained and qualified Carrier

service technician in repairing or replacing components

of the AirV units.

Figure 3-1 Filter Removal -- Free Blow

3.3.2 Ceiling Grill Removal

To remove the ceiling grill (Figure 3-2) do the following:

a. Before working on unit place the master switch in the

OFF position and disconnect all electrical power.

b. Remove 4 screws located on the ceiling grill, making

sure to support the weight of the grill.

c. Lower the ceiling grill from the ceiling panel.

3-1

T--298

Page 26

d. To replace the grill, place the grill up against the ceil-

ingpanelandalignthescrew holes in thegrill with the

ceiling panel.

e. Replace 4 screws.

Mounting

Screws

Figure 3-2 Ceiling Grill -- Free Blow

3.3.3 Ceiling Panel Removal

To remove the ceiling panel (Figure 3-3) do the

following:

a. Remove the ceiling grill. (Refer to paragraph 3.3.2.)

b. Remove 5 screws securing the duct plate to the ceil-

ing panel.

Heat Strip

Connection

Heater Assembly

Option

Figure 3-4 Ceiling Panel With Heat Option

3.3.4 Master Control Switch

To remove the master control switch, do the following:

a. Remove ceiling grill. (Refer to paragraph 3.3.2.)

b. Remove 5 screws that secure the control assembly

(Item 2, Figure 1-3) to the control box cover.

c. Remove the master control switch knob by grabbing

the outside edge of the knob and pulling it off of the

switch stem.

d. Remove 2 screws securing the master control switch

to the control assembly.

e. Carefully disconnect wires from the master control

switch. Label wires to aid in reassembly.

f. Reverse above procedure for reassembly.

c. Remove 4 mounting bolts making sure to support the

weight of the ceiling panel.

d. Disconnect the unit harnesses and main power wires

from the ceiling panel.

e. Lower the ceiling panel from the air conditioning unit.

f. Reverse above procedure for reassembly.

Air Sweep Cam

Serial/Model

Number Tag

Duct Plate &

Mounting Holes

Mounting Bolts

Junction Box

Figure 3-3 Ceiling Panel Assembly

Junction Box

Air Sweep Switch

With Cover

Thermostat

Master Control

Switch

Figure 3-5 Control Box Assembly -- Free Blow

3.3.5 Air Sweep Switch Removal

To remove the air sweep switch, do the following:

a. Remove ceiling grill. (Refer to paragraph 3.3.2.)

b. Remove 5 screws securing the control assembly

(Item 2, Figure 1-3) to the control box cover.

c. Disconnect wires from the air sweep switch.

d. Pinch tabs on either end of the switch and slide out of

lower control box cover.

e. Reverse above procedure for reassembly.

T--298

3-2

Page 27

3.3.6 Indoor Thermostat Removal

To remove the indoor thermostat (Figure 3-6) do the

following:

a. Remove ceiling grille. (Refer to paragraph 3.3.2.)

b. Remove 5 screws securing the control assembly

(item 3, Figure 1-3) to the control box cover.

c. Remove the indoor thermostat knob by grabbing the

outside edge of the knob and pulling it off of the thermostat stem.

d.Remove2screwsthatsecuretheindoorthermostatto

the lower control box cover.

e. Carefully disconnect the 2 wires from the indoorther-

mostat.

f. Remove the sensing bulb from the plastic clip.

g. Carefully slide the sensing bulb through the rubber

grommet.

h. Remove the thermostat from the control assembly.

i. Reverse above procedure for reassembly.

Thermostat

Air Sweep Motor

Figure 3-7 Air sweep motor

3.3.8 Heat Strip Assembly Removal

To remove the heat strip assembly (Figure 3-8) do the

following:

a. Remove ceiling grille. (Refer to paragraph 3.3.2.)

b. Unplug electrical connection at air sweep motor as-

sembly.

c. Remove two screws securing heat strip assembly to

the ceiling panel assembly.

d. Slide heat strip assembly away from air sweep motor

assembly and pull down, easing the the electrical

connection through the access hole.

e. Reverse the procedures for reassembly.

Sensing Bulb

Figure 3-6 Indoor Thermostat

3.3.7 Air Sweep Removal

To remove the air sweep, do the following:

a. Remove ceiling grille. (Refer to paragraph 3.3.2.)

b. Remove cam (See Figure 3-3) from air sweep motor

shaft.

c. Remove 4 screws securing air sweep motor bracket

to the ceiling panel assembly.

d. Carefully disconnect air sweep motor wire termina-

tions.

e. Remove 2 screws securing air sweep motor

(Figure 3-7) to control box and remove motor.

f. Reverse above procedure for reassembly.

Heat Strip

Figure 3-8 Heat Strip Assembly

3-3

T--298

Page 28

3.4 CEILING UNIT -- DUCTED SYSTEMS

3.4.1 Filter Removal

The filters (Figure 3-9) are located in the ceiling grill. To

remove the filters, do the following:

a. Grasp the edge of the filter at recess in the end of the

ceiling grill.

b. Pull filter completely out of the filter slot.

c. Vacuum filter or wash filter in luke--warm water.

Shake off excess water and dry thoroughly.

d. Replace filter by sliding the filter into the filter slot in

the ceiling grill until the filter frame is flush with the in-

terior grill.

c. Remove two screws securing control box cover to

control box assembly. See Figure 3-11.

d. Remove control box assembly cover.

Mounting Screws

Filters

Operation Indicators

Figure 3-9 Filter Removal -- Ducted Unit

3.4.2 Ceiling Grill Removal

Toremovetheceilinggrill(Figure3--10)dothefollowing:

a. Before working on unit place the master switch in the

OFF position and disconnect all electrical power.

b. Remove filters (Refer to paragraph 3.4.1).

c. Remove 4 screws located on the ceilinggrill, (two are

underthefilters) making sure to support the weightof

the grill.

d. Lower the ceiling grill from the ceiling panel.

e. To replace the grill, place the grill up against the ceil-

ingpanelandalignthescrew holes in thegrill with the

ceiling panel.

f. Replace 4 screws and 2 filters.

3.4.3 Control Box Assembly Removal

To remove the control box assembly (Figure 3-11 &

Figure 3-12) do the following:

a. Remove ceiling grill. Refer to paragraph 3.4.2.

b. Disconnect 115 volt (AC) and 12 volt (DC) power

wires.

Figure 3-10 Ceiling Grill -- Ducted

e. Disconnect blue furnace wires.

f. Unplug two connectors from upper unit.

g. Unplug DC power plug #1 (red/yellow/black wires)

SeeFigure3-12

h. Unplug relay signal plug #2 (brown/red/orange/

yellow wires). See Figure 3-12

i. While supporting control box assembly remove two

screws securing control box assembly to ducted ceil-

ing unit.

j. Pull controlboxassemblyfromtheductedceilingunit.

k. Reverse above procedure to reassemble.

Control Box

Control Box

Cover Screws

Fuse

PCB Cover

PCB Cover

Screws

Figure 3-11 Control Box & PCB Cover

T--298

3-4

Page 29

1 15V AC

3.4.5 PCB Display Removal

To remove the PCB display assembly (Figure 3-13) do

the following.

12V DC

a. Remove ceiling grill. Refer to paragraph 3.4.2.

b. Push large clip away from PCB display assembly.

Fuse

Upper Unit

Connectors

Figure 3-12 Control Box Assembly -- Ducted

3.4.4 Main PCB Board Removal

To remove the Main PCB board (Figure 3-13) do the

following:

a. Remove ceiling grill. Refer to paragraph 3.4.2.

b. Remove three screws securing the PCB cover to the

ducted ceiling unit.

c. Carefully turn over the PCB cover exposing the PCB

main and the PCB display assemblies.

d. Gentlypushholdingclipaway from PCB mainassem-

bly.

e. Lift PCB main assembly from PCB cover assembly.

f. Unplug display wiring plug #4. Figure 3-13

#2

#1

Furnace

Wires (blue)

c. Push center clip towards large clip.

d. Pull PCB display assembly from PCB cover.

e. Unplug display wiring from PCB main assembly.

f. Reverse above procedures of reassembly.

3.4.6 Fuse Removal

To remove the fuse (Figure 3-11) do the following:

a. Remove ceiling grill. Refer to paragraph 3.4.2.

b. Turnfuseholderindirectionofarrow(counter--clock--

wise).

c. Pull fuse from fuse holder.

d. Test and/or replace.

e. Reverse above procedures for reassembly.

3.5 SERVICE -- UPPER UNIT -- STANDARD,

HC&HP

3.5.1 Exterior Cover Removal

CAUTION

g. Unplug thermistor/thermostat wiring plug #3.

Figure 3-13

h. Unplug power wiring plug #1. Figure 3-12

i. Unplug signal wiring plug #2. Figure 3-12

j. Reverse above procedures for reassembly.

Holding Clips

PCB Display

PCB Main

#4

Coil fins are sharp. Usecarewhenremoving

the cover form the base pan to avoid personal injury.

To remove the exterior cover, do the following:

a. Before working on unit place the master switch in the

OFF position and disconnect all electrical power.

b. Remove 15 screws securing the unit cover to the

base pan assembly. See Figure 3-14.

c. Carefully lift the exterior cover off of theunit base pan

assembly.

d. Reverse above procedure for reassembly.

#3

Figure 3-13 Main/Display PCB’s

3-5

Cover Screws

Figure 3-14 Cover Assembly -- Standard

T--298

Page 30

3.5.2 Compressor Replacement

Observe the same procedures for rotary compressors

as for reciprocating compressors.

a. Follow all safety codes. Reminder: use protective

goggles, work gloves, and water soaked quenching

cloth.

b. Remove exterior cover.refer toparagraph 3.5.1.Dis-

connect all wiring from the compressor.

c. Apply field--supplied, line--tap--valves to the suction

and discharge lines as close to the compressor as

possible.

d. Recover therefrigerant charge from the unit. Afterre-

covering,cut the discharge and suction line process

tubes below the tube crimps. If you choose a good

tubing location for cutting the refrigeration lines initially, the location is easily accessible when making

the final joints.

WARNING

Oil vapor in piping stubs can ignite from

torch flame and cause serious injury. Exercise extreme care when brazing, and keep

brazing cloth and fire extinguisher handy

for emergency use.

Control Box

Screws

Figure 3-15 Control Box

Water

Cover

e. Connectanitrogen supply to theunitatoneoftheline

--tap--valve connectors (5--psig maximum flow), leaving the other connector open to the atmosphere.

Braze angle valves with stubs to each process tube.

f. Remove compressor from unit (3 bolts).

g. Remove line--tap--valves from suction and discharge

lines.Carefullybrazetheholesclosedfromwherethe

line--tap--valves were removed.

h. Cleansystem:addorreplaceliquidlinefilter drier.For

proper cleaning and flushing use a UL approved re-

frigerant recycling system.

i. Install new compressor and braze into place with

field--supplied copper slip couplings.

j.Connect wiring: replace wire terminals if necessary.

k. Proceed with evacuation and charging (15.9 OZ. --

.45 KG R22). Pinch off lines where angle valves were

added. Cut off angle valves above pinch--off , and

braze tubes.

l. Start up unit.

3.5.3 Control Box Assembly Removal

To remove the control box assembly, do the following:

a. Removeexterior cover assembly.Refertoparagraph

3.5.1.

b. Remove 2 screws securing control box assembly to

the lower scroll assembly. (SeeFigure 3-15.)

Figure 3-16 Control Box Removal

c. Slide control box out of the lower scroll assembly.

(See Figure 3-16.)

d. To open control box remove 2 screws securing the

water cover to the control box cover.

e. Gently lift the water cover off of the control box. (See

Figure 3-17.)

f. Reverse above procedure for reassembly.

Control Box

Cover

Figure 3-17 Water Cover Removal

T--298

3-6

Page 31

3.5.4 Upper Scroll Assembly Removal

a. Removeexterior cover assembly.Refertoparagraph

3.5.1.

b. Remove 4 screws securing upper scroll assembly to

the lower scroll assembly. (See Figure 3-18)

c. Gently pry 4 snap clips open and lift the upper scroll

assembly off of the lower scroll assembly.

d. Reverse above procedure for reassembly.

Screws

4 Places

i. Remove condenser fan from motor shaft and lift fan

out through the top of the condenser orifice. (See

Figure 3-22)

j. Remove motor assembly.

k.Reverse above procedure for reassembly.

Ground screw

Motor Ground

Lead

Figure 3-19 Motor Assembly

Snap Clip

4 Places

Figure 3-18 Upper Scroll Assembly

3.5.5 Motor Assembly and Condenser Fan

Removal

a. Removeexterior cover assembly.Refertoparagraph

3.5.1.

b. Remove control box assembly. Refer to paragraph

3.5.3.

c. Remove upper scroll assembly. Refer to paragraph

3.5.4.

d. Remove 4 screws securing the condenser cover to

the condenser orifice. (See Figure 3-24.)

e. Carefully disconnect motor wire terminations from

within the control box.

f. Remove 1 screw securing the motor ground lead to

the motor bracket assembly. (See Figure 3-19)

g. Using flat--nosed pliers, depress the motor spring

clamp and slide it off of the condenser fan (See

Figure 3-20).

h. Liftandslidemotortowardsevaporatorcoiltoremove

condenser fan from the motor shaft.

Spring Clamp

Figure 3-20 Spring Clamp Removal

Motor Clip

Figure 3-21 Motor Clip Removal

3-7

T--298

Page 32

Condenser Fan

3.5.7 Air Handling System Removal

a. Removeexterior cover assembly.Refertoparagraph

3.5.1.

b. Remove control box assembly. Refer to paragraph

3.5.3.

c. Remove upper scroll assembly. Refer to paragraph

3.5.4.

d. Remove motor assembly. Refer to paragraph 3.5.5.

e. Remove 8 screws securing lower scroll assembly to

the base pan assembly.

f. Remove 1 screw from clamp securing suction tubeto

the base pan assembly.

g. Remove 3 nuts securing the compressor to the base

pan assembly.

h. Remove 2 screws securing the condenser orifice to

the base pan assembly.

Figure 3-22 Condenser Fan Removal

3.5.6 Evaporator Blower Wheel Adjustment or

Removal

a. Remove exterior cover assembly. Refer to Exterior

Cover Assembly Removal instructions 3.5.1

b. Remove control box assembly. Refer to Control Box

Assembly Removal instructions 3.5.3

c. Remove upper scrollassembly.Refer to Upper Scroll

Assembly Removal instructions 3.5.4

d. Loosen motor assembly. Refer to Motor Assembly

Removal instructions 3.5.5.

e. Mark shaft at a point where wheel hub and motor

shaft meet to aid in reassembly.(See Figure 3-23.)

f. Remove 1 set screw holding the blower wheel to the

motor shaft. (See Figure 3-23)

g. Slide off blower wheel from motor shaft

h. Reverse above procedure for reassembly.

Set Screw

i. Remove 2 screws securing the condenser coil as-

sembly to the base pan assembly.

j. Carefully lift the entire assembly off of the base pan

assembly.

k. Reverse the above procedure for reassembly,ensur-

ing that the air handling system is positioned correctly. Tighten all screws.

Compressor

Condenser Cover

Condenser

Cover Screws

Motor Assembly

T--298

Figure 3-23 Blower Wheel

Base Pan

Base Pan

Figure 3-24 Condenser With Motor Assembly &

Compressor

3-8

Page 33

3.5.8 Capacitor Troubleshooting

WARNING

WARNING

Disconnect power to the AirV unit before

checking the capacitor.

To test capacitor to determine if good, open or shorted,

an ohm meter can be used. Todetermine a capacitor’s

capacitance, a capacitor meter is required.

Capacitors showing signs of leaks or bulging should be

replaced immediately.

3.5.9 Capacitor Testing and Replacement

Capacitors must be discharged properly before testing.

a. Place a 20,000 ohm, 2 watt resistor across the termi-

nals of the capacitor for approximately 30 seconds

(See Figure 3-25 for a suggested tool).

INSULATED SCREWDRIVER

Do not touch the metal of the screwdriver

when discharging the capacitor. You could

receive a shock.

b. After the capacitor has been dischargedand all wires

removed from the capacitor terminals, use an ohm-meter to test its resistance.

c. Set the scale to R x 1K or 10K ohm and place the

ohmmeter leads across the capacitor terminals.

d. Iftheohmmeterfirst reads 0, then rises towardinfinity

or some higher resistance, the capacitor is good.

e. If the ohmmeter goes to 0 or a low resistance and

stays there, the capacitor is shorted and needs to be

replaced.

f. If the ohmmeter reads infinity (OL) the capacitor is

open and needs to be replaced.

20,000 -- OHM

2 -- WATTRESISTOR

CLIP TO

SCREWDRIVER

Figure 3-25 Set--Up For Discharging a Capacitor

3.5.10 Positive Temperature Coefficient Thermister

(PTC) (Start Thermistor) Troubleshooting

a. Disconnect power from the AirV unit.

b. Disconnect the wires to the PTC.

c. Using an ohm meter, check for continuity across the

PTC.

If the PTC does not havecontinuity, it must bereplaced.

If continuity exists, reconnect the wires to the PTC.

d. Reconnect power to the AirV unit.

e. Turn on the AirV unit to start.

f. Use a clamp--on amp probe to monitor the amp draw

of the compressor during its start--up.

ATTACH TO CLEAN UNPAINTED

METAL PART OF UNIT FRAME

TOUCH TO CAPACITOR TERMINALS

TO DISCHARGE CAPACITOR

When the compressor starts, an amp draw will be

indicated for almost a second.

If no amp draw is indicated or if the amp draw occurs for

much longer than a second, the PTC is defective and

must be replaced.

3.5.11 Line Voltage -- 10%

Line voltage should be checked during peak electrical

load periods.

With the AirV unit onandthecompressoroperating,use

a voltmeter to check the voltage being supplied to the

AirV unit. The voltage must be within 10% of the units

required voltage. A voltage drop greater than 10% will

cause a premature compressor failure and needs to be

corrected immediately.

3-9

T--298

Page 34

3.6 SERVICE -- UPPER UNIT -- LOW PROFILE

3.6.1 Exterior Cover Removal

CAUTION

b. b.

Coil fins are sharp. Usecarewhenremoving

the cover form the base pan to avoid personal injury.

To remove the exterior cover, do the following:

a. Before working on unit place the master switch in the

OFF position and disconnect all electrical power.

b. Remove (8) screws securing the unit cover to the

base pan assembly. See Figure 3-26.

c. Carefully lift the exterior cover off of theunit base pan

assembly.

d. Reverse above procedure for reassembly.

Screws

Screws

b.

b.

c.

b.

Figure 3-27 Upper Scroll Assembly

Locking Tabs (b.) & Screw Locations (c.)

b.

Figure 3-26 Cover Assembly -- Low Profile

3.6.2 Upper Scroll Assembly Removal

To remove the upper scroll assembly, do the following:

a. Removeexterior cover assembly.Refertoparagraph

3.6.1.

b. Releasethe(2)front,(2)rear,(1) left sideand(1)right

sidelockingtabs(SeeFigure 3-27) bypullingbackon

the tabs (See Figure 3-28).

c. Remove the screw (1) from the control box cover

(See Figure 3-27).

d. With all (6) locking tabs released and control box

screw removed, lift the upper scroll assembly off of

the lower scroll assembly.

e. Reverse above procedure for reassembly.Ensure all

(6) locking tabs snap shut & lock.

Figure 3-28 Upper Scroll Assembly

Keeper Tab Release

T--298

3-10

Page 35

Evaporator Coil

Condenser Coil

Retaining

Ring

Figure 3-30 Condenser Fan Assembly

& Retaining Ring

Fan Stop

Figure 3-29 Upper Scroll & Control Box

Cover Removed

3.6.3 Condenser Fan Assembly Removal

To remove condenser fan assembly, do the following:

a. Perform steps outlined in Section 3.6.2.

b. Depress and remove Retaining Ring (See

Figure 3-30).

c. Using both hands, carefully pull up on fan assembly

until it is free of the motor shaft.

d. When replacing the fan assembly make sure the fan

assembly is against the stop on the shaft (See

Figure 3-31)

13MM

Bolt

Condenser Motor

Grommet

Figure 3-31 Condenser Fan Motor

& Fan Assembly Stop

Tab

13MM

Bolt

e. Push back on tab to allow fan assembly to rest

against stop (See Figure 3-32). Fan assembly will

now be flush with the end of the motor shaft.

f. Reverse above procedure for reassembly.

3-11

Figure 3-32 Condenser Fan Motor

& Fan Assembly Tab

T--298

Page 36

3.6.4 Condenser Motor Removal

To remove condenser fan motor, do the following:

a. Perform steps outlined in Section 3.6.2.

b. Remove (3) 13MM bolts (See Figure 3-31).

c. Remove (3) Grommets. Inspect, replace or reuse.

d. Cut Tie--Wraps & discard (2 locations). When re-

assembling, tie--wrap at same 2 locations.

e. Remove ground wire from compressor bracket (See

Figure 3-33).

f. Un--plug (yellow/brown/white) from control box as-

sembly.

g. Reverse above procedure for reassembly.

Cond. Motor

Ground Screw

Blower Side Locking T abs

Outside Locking T abs

Comp. Mounting Bolt

Figure 3-33 Condenser Motor Ground

3.6.5 Evaporator Motor/Blower Assembly

Removal

To remove the evaporator motor, do the following:

a. Perform steps outlined in Section 3.6.2.

b. Pull back on and release the (4) locking tabs. There

are 2 on each side of the control box assembly. (See

Figure 3-34).

c. Lift control box assembly from lower scroll assembly,

exposing evaporator motor.

d. Un--plug (black/blue/white/brown) evaporator motor

from control box assembly.

e. Remove ground wire (green/yellow) from motor

housing.

f. Lift motor/blower assembly from lower scroll assem-

bly cradle.

g. Carefully remove the blower wheelfrom theevapora-

tor motor shaft by pushing out from the motor side.

Figure 3-34 Evaporator Motor Locking Tabs

Lower Scroll

Assembly

Capacitor

Cradle

Figure 3-35 Evaporator Motor/Blower Assembly

In Cradle

T--298

3-12

Page 37

NOTE

When reassembling the blower wheel on to

the motor shaft ensure that the blower

wheel is flush with the end of the motor

shaft (SeeFigure 3-36).

h. Reverse above procedure for reassembly.

NOTE

When placing the evaporator motor/blower

assembly back into the lower scroll assembly cradle, make sure that the assembly is

seated securely in the cradle.

(See Figure 3-35).

3.6.6 Compressor Replacement