Carrier SUPRA 850Mt, SUPRA 750Mt, SUPRA 950Mt Operation And Service Manual

Carrier TranCarrier Tran

sicold Division, Carrier Corporatiosicold Division, Carrier Corporatio

n, P.O. Box 4805, Syracuse, N.Y. 13221 n, P.O. Box 4805, Syracuse, N.Y. 13221

U. S. U. S.

A.A.

OPERATION ANDOPERATION AND

SERVICE MANUALSERVICE MANUAL

TRUCK REFRIGERATION UNITTRUCK REFRIGERATION UNIT

SUPRASUPRA

750Mt750Mt

©©

Carrier Refrigeration Operation 2004Carrier Refrigeration Operation 2004

DD

Printed in FrancPrinted in Franc

e 03-04 / 62-e 03-04 / 62-

-611XX--611XX-

-20-20

Carrier Transicold EurCarrier Transicold Eur

ope -ope -

- 10, Bd de l’O- 10, Bd de l’O

ise -ise -

- 95031 Cergy - 95031 Cergy

Pontoise Cédex Pontoise Cédex

--

- FRAN- FRAN

CECE

, 850Mt, 850Mt

, 950Mt, 950Mt

ii

62-62-

-611XX--611XX-

-20 -20

(03/04)(03/04)

TABLE OF CONTENTSTABLE OF CONTENTS

PagePage

Section 1Section 1

SSAAFFEETT

Y Y IINNSSTTRRUUCCTTIIOONNS S 11--11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2Section 2

DDEESSCCRRIIPPTTIIOON N

22--11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..1 1 IInnttrroodduuccttiioon n 22--11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..2 2 EEnnggiinne e DDaatta a 22--1111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..22..1 1 CCoooolliinn

g g cciirrccuuii

t t 22--1111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..3 3 CCoommpprreessssoor r RReeffeerreenncc

e e DDaatta a 22--1111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..4 4 RReeffrriiggeerraattiioo

n n SSyysstteem m DDaatta a 22--1111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..5 5 EElleeccttrriiccaal l DDaatta a 22--1122

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..6 6 TToorrqquue e VVaalluuees s 22--1133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..7 7 SSaaffeetty y DDeevviiccee

s s 22--1144

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..8 8 MMiiccrroopprroocceessssoor r CCoonnttrroolllleer r 22--1155

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..1 1 IInnttrroodduuccttiioon n 22--1155

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..2 2 KKeeyyppaad d 22--1166

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..3 3 SSwwiittcchhees s aann

d d ccoonnttrroolls s 22--1177

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..4 4 SSeettppooiinnt t 22--1177

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..5 5 DDiiggiittaa

l l DDiissppllaa

y y 22--1188

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..6 6 FFuunnccttiioonnaal l ppaarraammeetteerrs s 22--1188

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..7 7 UUnniit t DDaatta a 22--1199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..8 8 AAllaarr

m m DDiissppllaa

y y 22--2211

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..9 9 HHeeaatt//CCoooo

l l mmoodde e 22--2233

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..11

0 0 DDeeffrrooss

t t ccyyccll

e e 22--2233

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..11

1 1 CCoonnttiinnuuoouus s oor r SSttaarrtt//SSttoop p OOppeerraattiioo

n n 22--2244

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..11

2 2 OOppttiioonnaal l ccoonnttrroo

l l ppaannee

l l 22--2244

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..88..11

3 3 RReemmootte e MMoonniittoorriinng g

- - MMiiccrroolliinn

k k ((OOppttiioonnaall) ) 22--2266

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..9 9 RReeffrriiggeerraattiioo

n n ccoommppoonneenn

t t ooppeerraattiioo

n n 22--2266

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2.9.

1 1

ComCom

prepre

ssosso

r r

prepre

ssussu

re re

regreg

ulaula

ting ting

valval

ve ve

(CPR(CPR

) )

( (

see see

FigFig

ure ure

2-1 2-1

& &

FigFig

ure ure

2-2 2-2

) )

2-22-2

66

22..99..2 2 MMaaiin n HHeeaat t VVaallvv

e e MMHHVV1 1 ((NNOO) )

/ / MMHHVV2 2 ((NNCC) ) 22--2266

. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.92.9

.3 .3

HoHo

t Gat Ga

s Vs V

alal

veve

s Hs H

GV 1GV 1

, 2 , 2

& 3 & 3

(NC(NC

), L), L

iqiq

uiui

d Sd S

ucuc

tiotio

n Vn V

alal

veve

s Ls L

SV 1SV 1

, 2 , 2

& 3 & 3

(NC(NC

) )

2-2-

2727

22..99..4 4 AAccccuummuullaattoo

r r 22--2277

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2.9.

5 5

By-By-

-pass -pass

valval

ve ve

(NC) (NC)

(Sup(Sup

ra ra

850850

MtMt__oonnllyy) ) 22--2277

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..99..6 6 LLiiqquuiid d ssiigghhttggllaasss s 22--2277

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..99..7 7 FFiilltteer r ddrriiee

r r

( ( ssee

e e FFiigguurre e 22--

1 1

& & FFiigguurre e 22--

2 2

) ) 22--2288

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..99..8 8 SSeerrvviicc

e e vvaallvv

e e 22--2288

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..99..9 9 HHoo

t t ggaa

s s bbyyppaasss s uunnllooaaddeer r 22--2288

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..99..11

0 0 BBaatttteerr

y y cchhaarrggiinng g aalltteerrnnaattoor r 22--2299

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22..11

0 0 ggeenneerraattoo

r r ((SSiinnggll

e e pphhaass

e e aalltteerrnnaattoorr

) ) 22--3300

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

2.10.1 Use of diagnosis connection of control box (see Figure 2-16) 2-30

. . . . . . . . . . . . .

2.10.

2 Intervention on generato

r fo

r analysis 2-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1

1 Refrigeran

t Circui

t 2-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.

1 Coolin

g mode 2-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.

2 Heat an

d defros

t mode 2-33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

OPERATION

3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Pre-trip Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Starting an

d Stopping Instructions -- Engine driv

e 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Starting Instructions 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Starting and Stopping Instructions -- Standby motor drive 3-2. . . . . . . . . . . . . . . . . . . . .

3.4 Compartmen

t operatio

n 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Operatio

n with ca

b comman

d 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Operatio

n with auxiliar

y contro

l pane

l 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Contro

l Circui

t operatio

n 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Introduction 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Temperatur

e Contro

l Logi

c 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Sup

ra 950

Mt_specifi

c logi

c 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Sup

ra 850

Mt_specifi

c logi

c 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Rela

y operatio

n 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

SERVICE

4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Maintenanc

e schedule 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Descriptio

n of Servic

e Requirements 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Servicin

g engine relate

d components 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Coolin

g system 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Changing Lube Oi

l an

d Lube Oi

l filter

s 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Fuel filter an

d fuel circui

t 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Replacin

g solenoid

s (Figur

e 4-3) 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Engine ai

r cleane

r 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 Servicin

g fuel pump 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 Servicin

g Glow plug

s 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.8 Clutch contro

l 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.9 Servicin

g alternator 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Servicin

g an

d adjustin

g v-belt

s 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Belt tensio

n gaug

e 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Trapezoida

l V-belt 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Alternator V-belt 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Wate

r pump belt tensione

r 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Standby motor - Compress

or V-belt, Dies

el engi

ne - Compressor V-belt 4-9..

.

4.5 Pumping the unit down or removing the refrigerant charge 4-9. . . . . . . . . . . . . . . . . . . . .

4.6 Refrigeran

t leak checking 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

62-

-611XX-

-20

(03/04)

4.7 Evacuation an

d dehydratio

n 4-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 Genera

l 4-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 Preparatio

n 4-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.3 Procedur

e fo

r Evacuation an

d Dehydratin

g system 4-10

. . . . . . . . . . . . . . . . . . . . .

4.8 Charging th

e refrigeran

t system 4-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 Installing

a complete charge 4-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Checking th

e refrigeran

t charge 4-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Replacin

g th

e compressor 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

0 Checking 05

K

/ 05

G compressor oi

l leve

l 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Compre

ssor unlo

ader val

ve -

- For Supra 850Mt

_

& 950Mt

_

onl

y 4-13

. . . . . . . . . . . . . . . .

4.1

2 Checking an

d replacin

g filter-drier 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

3 Checking an

d replacin

g high pressure cutout switch 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.

1 Replacin

g high pressure switch 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.

2 Checking high pressure switch 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

4 Checking an

d replacin

g lo

w pressure cutout switch 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.

1 Replacin

g lo

w pressure switch 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.

2 Checking lo

w pressure switch 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

5 Replacin

g receiver sigh

t glas

s assembly 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

6 coil

s cleaning 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16.

1 Evaporator coil 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16.

2 Condense

r coil 4-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 Adjusting the compressor pressure regulating valve (CPR) 4-16. . . . . . . . . . . . . . . . . . . .

4.1

8 Thermostatic expansio

n valv

e 4-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

9 Microprocessor 4-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19.

1 Servic

e guidelines 4-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19.

2 Microprocessor configuratio

n 4-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19.

3 Controller sensor checkout 4-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19.

4 Suctio

n pressure transducer 4-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

TROUBLESHOOTING 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Diesel Engine 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Engine will no

t star

t 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Engine starts then stop

s 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Starte

r moto

r malfunctio

n 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Malfunctio

n in th

e engine starting circui

t 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Alternator (automotiv

e type

) 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Refrigeratio

n 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Unit will no

t cool 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 U

nit runs bu

t ha

s insufficient coolin

g 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Unit operates long or continuously in coolin

g 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Unit will no

t heat or ha

s insufficient heatin

g 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Defros

t cycl

e malfunctio

n 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

5.3.6 Abnormal pressure 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.7 Abnormal nois

e 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.8 Contro

l system malfunctio

n 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.9 No evaporator ai

r flow restricted ai

r flow 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1

0 Expansio

n valv

e malfunctio

n 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1

1 Ho

t ga

s valv

e malfunctio

n 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Standb

y moto

r malfunctio

n 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

EXTRACT FROM MATERIAL SAFETY DATA BULLETIN 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1

poe

oil

6-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 forane R404

a 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 7

ELECTRICA

L SCHEMATI

C WIRING DIAGRA

M 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

62-

-611XX-

-20

(03/04)

LIST OF FIGURES

Figure

2-1

Supra

750Mt

_

/ 850Mt

_

Model

s 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure

2-2

Supra

950Mt

_

Model

2-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

3 Evaporator MT

S mode

l 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

4 Evaporator MT

D mode

l 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

5 Electrical bo

x 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

6 Contro

l rela

y boar

d view 2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

7 Ca

b Comman

d 2-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

8 Auto Star

t Sequence 2-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-

9 Main Heat Valves -- NO an

d NC 2-26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-10 Ho

t ga

s

& Liquid Suctio

n Valves -- NC 2-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-11 Accumulato

r 2-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-12 By--pass valves -- NC 2-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-13 Compressor cylinder heat unloader Hot gas bypass 2-28. . . . . . . . . . . . . . . . . .

Figure 2-14 Compressor cylinder head loader Hot gas bypass 2-29. . . . . . . . . . . . . . . . . . .

Figur

e 2-15 50 Am

p Alternator an

d Regulato

r 2-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-16 Generato

r an

d connection in contro

l bo

x 2-30

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-17 Coolin

g Cycl

e 2-34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 2-18 Heat an

d Defros

t Cycl

e 2-35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figu

re

3-1 Temp

era

ture

Con

trol

ler

Oper

atin

g S

equ

enc

e (

Peri

sha

ble

Ran

ge) ........

Controller Set Point Above --12

_

C (+10

_

F

)

3-9

. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-2

Temperatur

e Con

troller Op

era

tin

g Seq

uence “Le

ad

” Eva

po

rat

or ........

.

(Perishable Range) Controller Set Point Above --12

_

C (+10

_

F

) 3-9. . . . . . . .

Figure 3

-3 Tempera

tur

e Controller

Ope

rating Sequence (

Frozen Range) ...........

Controller Set Point Below --12

_

C (+10

_

F

) 3-10

. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-4

Temperatur

e Con

troller Op

era

tin

g Seq

uence “Le

ad

” Eva

po

rat

or ........

.

(Frozen Range) Controller Set Point Below --12

_

C (+10

_

F

) 3-10

. . . . . . . . . . .

Figur

e 4-

1 Coolin

g circui

t 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

2 Fuel filter an

d fuel circui

t 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

3 Spee

d an

d ru

n contro

l solenoid

s 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

4 Electric fuel pump 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-5 Electronic Belt Tension meter (part no. 07-60098--00) 4-8. . . . . . . . . . . . . . . . .

Figur

e 4-

6 V-belt arrangemen

t 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

7 Dual Vacuum Pump Connection

s 4-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

8 Compressor

s 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-

9 Unloader solenoid valv

e 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-10 Typical setup for testing high pressure switch 4-15. . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-11 Compressor pressure regulating valv

e 4-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figur

e 4-12 Thermostatic expansio

n valv

e 4-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-13 Thermostatic expansion valve bulb and thermocouple 4-17

. . . . . . . . . . . . . . . .

Figu

re

7-1 -

-

Ele

ctri

cal

sch

ema

tic

dia

gram -- MICR

OPROC

ESSOR

CONT

ROLL

ER

7-2

.

vi

LIST OF TABLES

Table 2-

1 Condensers Mode

l Char

t 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

2 Evaporator

s Mode

l Char

t 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

3 Evaporator

s designatio

n 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

4 Safety Device

s 2-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

5 Function Parameters 2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

7 Unit Data Code

s 2-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-

8 Alar

m Displa

y 2-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-10 Batter

y Voltages 2-26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-11 Rela

y Operatio

n -- Microprocessor Controller 3-6. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-

1 Belt tensio

n 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-

2 Connection Poin

t Voltag

e 4-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-

3 Microprocessor Configuratio

n 4-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-4 Sensor Resistance (ATS, DTS, CDT, RAS, SAS & WTS) 4-20

. . . . . . . . . . . . . . . .

Table 4-

5 R-404A Temperature-Pressure char

t 4-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

62-611XX-

-

20

(03/04)

SECTION 1

SAFETY INSTRUCTIONS

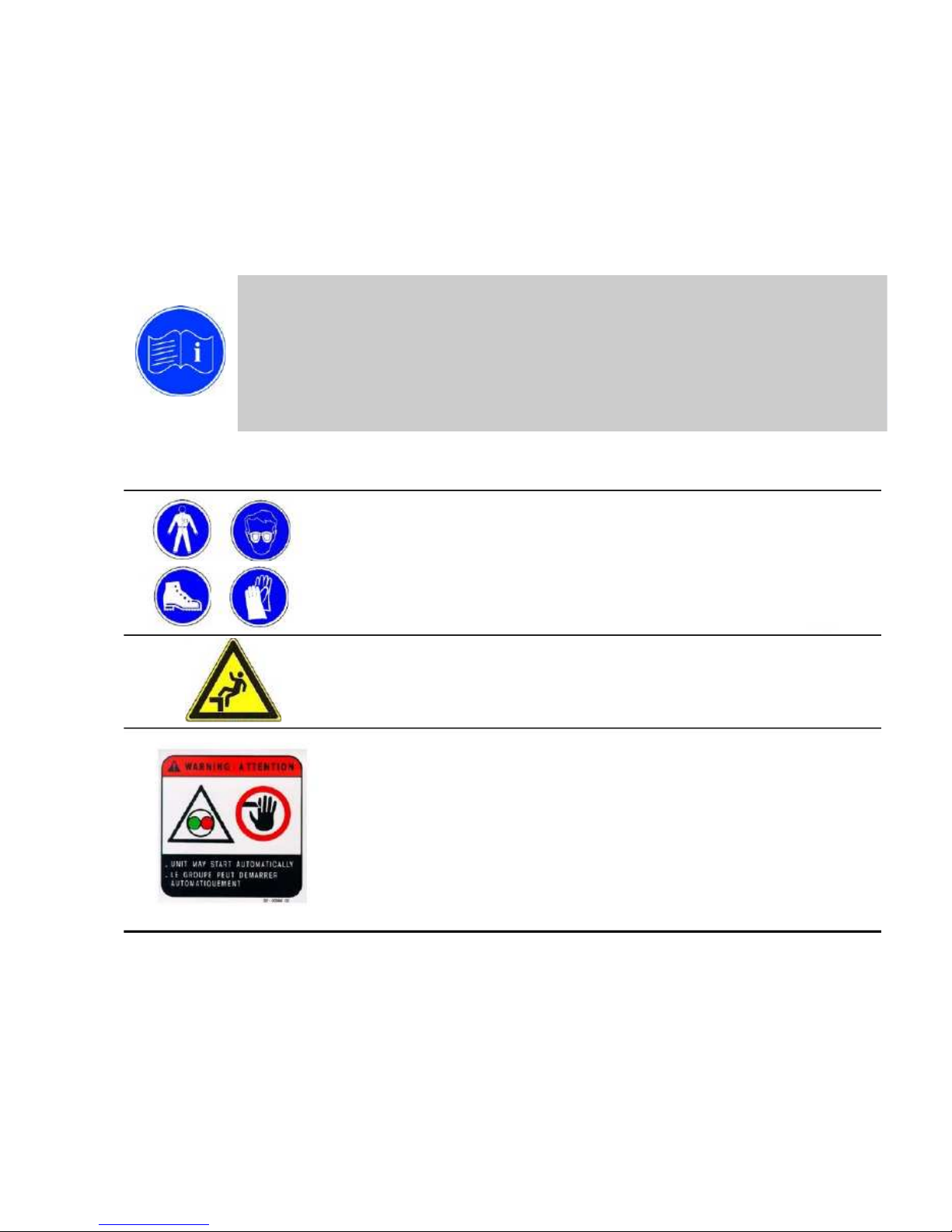

This manual contains safety and service instructions to follow in order to prevent any accident. Stickers have

been placed on the product for your

SAFETY

.

BEFOR

E

USIN

G

THIS

REFR

IGERA

NT

UNIT

,

read

care

fullyall

safetyinfo

rma

tion

exp

lai

ned

in this manual and indicated on the product. Be sure that everybody who will use this

refrigeration unit has been trained to use it in a safe way.

DURING THE USE OR MAINTENANCE OF THIS REFRIGERATION UNIT

, the

notes on safety are to be considered.

Personal Protective Equipment :

Always

use

adequ

ate

Person

al

Protectiv

e

Equipm

ent

before

doinganything

on

this

refrige

rant unit,

as explained in

this manual.

Working at height :

Take all necessary safety precautions when accessing this refrigeration unit : use

safe ladders, working

platform

s

with appropriate guards.

Automatic start :

This refrigeration unit is

equip

ped with

Auto-

-Start/Stop,

a valuable fuel

savin

g

fea

ture

. Whe

n

thisrefrige

rationunitis

set

for

Auto-

-start/

Stop

ope

rationit

may

star

t

at any time and without warning.

Be

forese

rvicing

ref

rig

era

tionun

it,makesure

themainpowersw

itchisontheOFF

position. Ensure the unit will not restart.

Lock--out / Tag--out can be performed by disconnecting and enclosing:

-- The negative battery cable in diesel mode;

-- The electrical plug in electrical mode.

1-2

Belts and fans :

This refrigeration unit is equipped with Auto--start/stop, it may start at any time

and without warning.

When the unit is running beware of belts and fans that are moving.

Before servicing refrigeration unit, make sure the main power switch is on the

OFF position. Ensure the unit will not restart. Lock--out / Tag--out can be

performed as described above.

When there is protective structure (fan grid or guard for example) make sure

they are in place. Never removed them when the refrigeration unit is running.

Always keep your hands, body

parts, clothes, hairs and

tools far

from moving

parts.

Electricity :

When this refrigeration unit is running in electrical operation, some devices are

powere

d

up especiall

y

in the

electri

cal control box.

Before servicing refrigeration unit, make sure the main power switch is on the

OFF position. Ensure this refrigeration unit is disconnected from the local

electrical network.Lock--out / Tag--out can be performed as described above.

Before working in the electrical control box, it is required to control the lack of

tension.

WHEN IT IS NECESSARY TO WORK IN THE ELECTRICAL CONTROL BOX

UNDER TENSION, PEOPLE MUST BE QUALIFIED FOR WORKS UNDER

LOW OR HIGH VOLTAGE.

Always use adequate tools and Personal Protective Equipme

nt when

workin

g

on electrical devices : safety gloves and safety glasses.

Engine coolant :

This refrigeration unit is equipped with a pressurised cooling system. Under

normal operating conditions, the coolant in the engine and radiator is under high

pressure and very hot.

Coolant is very slippery. It can be harmful in case of ingestion.

Never remove the cap from a hot radiator when this refrigeration unit is running

or immediately after.

If the cap must be removed, wait at least 10 minutes and then do so very slowly

in order to release the pressure without spray.

In case of leakage, immediatly clean the floor to prevent slipping.

Avoid contac

t

with the

skin and eyes.

Always use Personal Protective

Equipment when handling engine coolant : safety clothes, safety gloves and

safety glasses.

Refrigerant :

The refrigerant contained in this refrigeration unit can cause frosbite, severe

burns or blindness in case of projection and direct contact with the skin or eyes.

In contact with flame or heat refrigerant generate toxic gas.

Refrigerant handling must be done by qualified people.

Keep any flame, any lighted object or any source of sparks away from the refri-

gerant unit.

Always use Personal Protective Equipm

ent when handling refrigeran

t : safety

clothes

,

safety glov

es and safety gl

asses.

1-3

62-611XX-

-

20

(03/04)

Burning with hot and cold :

When this refrigeration unit is running or even after, different components can

be very cold or hot (exhaust pipe, tubes, coils, receiver, accumulator or engine

for example)

Beware when operating closed from cold or hot components.

Always use adequate safety gloves when doing any

mainte

nance on this

refrigeration unit.

Cutti

ngs

:

Beware when handling or operating closed from parts that could be sharp (coils,

evaporators, clamps for example).

Always

use

adequ

ate

safety

glove

s

when

doing

any

mainte

nance

on

this

refrigeration unit.

Battery :

This refr

ige

rati

on

unit may

be

equ

ipp

ed

with a

lead--acid

type

batt

ery. Whe

n

charging the battery normally vents small amounts of flammable and explosive

hydrogen gas.

Projections of acids on the skin or eyes can cause severe burns.

Keep any flame, any lighted object or any source of sparks away from the battery

elements.

Always use Personal Protective Equipm

ent when handlin

g and charging battery:

safety clothes, safety gloves and safety glasses.

Environment :

Think about protection of environment during all the life of this refrigeration unit.

Topre

ventenv

iron

men

tal

dam

agesNEV

ER

rel

easerefr

ige

rantinthe

atmo

sph

ere

,

NE

VER

thr

ow coolant, oil, batte

ry and chemicals in the natur

e.

It must

be

recuperate and recycle according to current regulations.

When disposing this refrigerant unit do it in an environmentally sound way and in

accordance with current regulations.

CAUTION

Under no circumstances should anyone attempt to repair the Logic or Display Boards. Should a problem

develop with these component, contact your nearest Carrier Transicold dealer for replacement.

Under no circumstances should a technician electrically probe the processor at any point, other than the

conne

ctor

termina

ls

where the

harnes

s

attaches

.

Microp

rocess

or

compo

nents operate

at

differe

nt

voltage

level

s and

at extremely low current levels. Improper use of

voltmete

rs, jumper wires, continuity testers, etc.

could permanently damage the processor.

Mostele

ctro

nic

com

pon

entsare

sus

cep

tibleto

dam

age

cau

sedbyele

ctri

cal

staticdis

cha

rge

(ESD

).Incert

ain

cases

,

the human body can have enough static electricity to

cause resulta

nt damage to

the componen

ts by

touch. This is especially true of the integrated circuits found on the truck/trailer microprocessor.

2-1

SECTION 2

DESCRIPTION

2.1 INTRODUCTIO

N

WARNING

Beware

of

una

nno

unc

ed starting

of

engine or standby motor caused by the

unit thermostat or

the start/st

op

cycle

.

Per

sona

l

Pro

tec

tiveEqui

pme

nt:bef

ore

doing anything

on this product,

as

exp

lain

ed

in

this

man

ual.

Alw

ays

use

saf

ety

pre

cau

tions bef

ore

doing

any

maintenance on the unit

safet

y glasse

s

, gloves

,

safety shoes , safety clothe

s

a.

Sys

tem

This

man

ual

con

tai

ns

Ope

rati

ng

Data

,

Ele

ctri

cal

Data and Service Instructions for the refrigeration units

listed in Table 2-1. Also Table 2-1 charts some signifi-

cant differences between these models.

The

Supra

Multi-T

emp,

multipl

e

compa

rtment

refrig-

era

tion syste

ms offer

the versa

tili

ty

of

two

or three

compa

rtment

tempera

ture con

trol in

truck.

The Mu

lti-

Temp allows the shipper to ship frozen and perishable

com

mod

itiesin

the

sameloadundersep

araterefr

ige

ra-

tion control.

b.

Truc

k condens

ing units

The Supra 750Mt

_

, 850Mt

_

and 950Mt

_

mod

els

are

one piece condensing units designed for truck applica-

tionsava

ila

ble

for

R404arefr

ige

rant.They

are

equ

ipp

ed

with an

electric standby motor

.

The model/serial number plate is located inside of

the uni

t

on

the fram

e

as shown in Figu

re

2-1 and

Figure 2-2.

fixed on

the frame

fixed on

the micro

The control system is a microprocessor controller

(Re

fertose

ction2.8).Oncethecontroller(

rem

oteCab

Command within the cab of the truck ) is set at the de-

sired temperature, the unit will operate automatically to

maintain the desired temperature within very close lim-

its. The control system automatically selects high and

lowspeedcoolingorhighandlowspeedheatingasnec-

essary to

mainta

in the

desire

d t

emper

ature.

The

mic

rop

roce

ssorcon

trol

ler

hasanautostart/st

op

feature. The auto start/stop operation provides auto-

ma

tic

cyclingofthedie

selengine,which

inturn

of

fersan

energy efficient alternative to continuous operation of

the

eng

ine

with

con

troloftemp

era

turebyalte

rnatecoo

l-

ing and heating of the supply air (evaporator outlet air).

A

remote

standb

y

recepta

cle

is

standa

rd

with

all

units.

c.

Multite

mpera

ture evapora

tors

The compartments of the Multi-Temp system are

equip

ped with

separa

te evapora

tors.

For Multi-Temp applications, single discharge and

double discharge evapora

tors are availabl

e.

The

eva

por

atorsare

dif

ferentin

size,cap

acityand

num

berof

fans(seeTab

le 2-2),butallworkonthe

sa

mepri

nciple

and use the sa

me single-phase 50Hz/60Hz fa

n

assembly. The electrical heaters vary according to the

type of condensing unit used and number o

f

compa

rtments. ( see Figure 2-

3 and

Figure 2-4 )

The evaporator is constructed with plastic profiles

design

ed

to meet

the spec

ific requiremen

ts

of

the

tran

sportind

ustry.

The

air

out

let

pro

filesare

des

ignedto

adjust to allow different airspeeds and velocity.

Inside the evaporator housing are one or more of

the following :

240 Volt Single phase backward curved impeller

which supplies high air volumes at low noise levels;

expansion valve; check valve; 12V hot gas solenoid;

12V liquid line solenoid

;12V wa

ter

dra

in heate

r;

electrical heater element; sensor ( defrost termination

sensor ); safety heating thermostat.

2-2 62--611XX--2

0 (03/04

)

Table 2-1 Condensers Model Chart

R-404A

Model

L

B KG

Engin

e Compressor Standb

y Moto

r

SUPRA 750Mt

_

05K 2 Cylinders

SUPRA 850Mt

_

13.

6 6

.

2 C

T3-44TV

05K 4 Cylinders

refer

to

section

2.5

c.

SUPRA 950Mt

_

17.

2 7.

8 CT3-69TV 05

G

6 Cylinder

s

.

.

Table 2-2 Evaporators Model Chart

Model Discha

r

e Le

n th PowerWatts Number of fa

ns

MTS 70

0 H0

6 Single 70

0 mm 60

0

1

MTS 70

0 H1

2 Single 70

0 mm 1200

1

MTS 70

0 H2

4 Single 70

0 mm 2400

1

MTS 1100 H1

2 Single 1100 mm 1200

2

MTS 1100 H2

4 Single 1100 mm 2400

2

MTS 1450 H1

2 Single 1450 mm 1200

2

MTS 2200 H2

4 Single 2200 mm 2400

3

MTD 70

0 H2

4 Double 70

0 mm 2400

1

MTD 1100 H2

4 Double 1100 mm 2400

2

MTD 1450 H2

4 Double 1450 mm 2400

2

MTD 2200 H2

4 Double 2200 mm 2400

3

Table 2-3 Evaporators designation

M

T

S

0

7

H

2

4

3

A

3

b

b

b

POWER:

HEAT /

b

b

b

b

06: 600W

b

:

A: Electrical

b

ENTILA-

NOMINAL

SIZE:

12:

1200W

-

460V 3Ph

FAN

MOTORS

UNIT:

TION :

07: 700mm

AIR FLOW:

H: Hi h ai

r

15: 1500W

-

RANT:

B:

Electrical

230V 1Ph

TENSION:

MULTI

M: Maxima

T: Truck

D: Dual

Discharge

09:

900mm

flow

20: 2000W

24: 2400W

3: R404A

C: Hot gas

1:

12

VDC

V: Vector

S:

Single

11:

1100mm

L:

Low

air

flow

30:

3000W

4: R22

D: Hot gas /

2:

24

VDC

3: 220 VAC

Discharge

:

mm

22: 2200mm

38:

3800W

:

ec rca

3Ph

4: 400 VAC

40: 4000W

E:

Hot

gas

/

Electrical 230V

45: 4500W

1Ph

2-3

1. Muffler

2.

Engin

e (refe

r to T

able

2-1)

3.

Compre

ssor (

refer to

T

able

2-1)

4.

Alte

rna

tor

(12

V)

5.

Ele

ctri

c Sta

ndb

y Mo

tor

6.

Fit

tin

gs

for

Mt_evaporators

7.

Compre

ssor p

ressure

regula

ting va

lve (CP

R)

8.

Fil

ter drie

r

9.

Con

den

ser

10.

Coo

lant bott

le

Figure 2-

1

Supra

750Mt

/

850Mt

Models

TOP VIEW

1.

2.

3.

4.

7.6.5.

8.

9.

10.

2-4 62--611XX--2

0 (03/04

)

1. --

Batte

ry

2. + Micro

3.

Fuel lines

4. + Batter

y

5.

Seri

al/M

ode

l p

lat

e

6.

Fuel fil

ter

7.

Spe

ed &

Run

sol

eno

id

8.

Oil

fil

ter

9.

Oil gaug

e

10.

Air cl

ean

er (d

ry ai

r type

)

1

1.

Recei

ver

sight

glass

12.

Moistu

re

indic

ation

sight

glass

13.

Rec

eiv

er

14.

Ele

ctri

cal

box

CURBSIDE VIEW

ROADSIDE VIEW

1.

2.

3.

4.

5.

6.

7.

8.

10.

1

1.

13.

14.

9.

12.

2-5

Figure 2-

2

Supra

950Mt

Model

TOP VIEW

1.2.3.4.5.

1. Muffler

2.

Engine

(refer to

T

able

2-1)

3.

Compre

ssor (r

efer to

T

able

2-1)

4.

Alte

rna

tor

(12

V)

5.

Ele

ctri

c sta

ndb

y mo

tor

6. Fitti

ng

for

Mt_evaporators

7.

Compre

ssor pre

ssure re

gulati

ng val

ve (CPR

)

8.

Fil

ter

drie

r

9.

Con

den

ser

10.

Coo

lant bot

tle

7.

8.

9.

10.

6.

2-6 62--611XX--2

0 (03/04

)

CURBSIDE VIEW

ROADSIDE VIEW

1. --

Batt

ery

2. + Micro

3.

Fuel lines

4. + Ba

tte

ry

5.

Seri

al/M

ode

l p

late

6.

Fuel fil

ter

7.

Sol

eno

id

8.

Oil

fil

ter

9.

Oil gaug

e

10.

Air c

lea

ner (

dry a

ir typ

e)

1

1.

Receiv

er

sight

glasse

s

12.

Moisture

indica

tion

sight

glass

13.

Rec

eiv

er

14.

Ele

ctri

cal

box

15.

Air

clean

er -

-

Silent version

16.

Muffle

r --

Silent version

15.

16.

1.

2.

3.4.5.

6.

7.

8.9.10.

1

1.

12.

13.

14.

Silent version

Standard version

2-7

1.

Eva

por

ator

Coi

l

2. Turbi

ne f

an (

1, 2

or 3

accord

ing to

the model)

3. RAS Sens

or

4. Coi

l

5. Heat

ers

6.

Exp

ans

ion

val

ve

7.

Pressure

tap

Figure 2-3

Evapor

ator MTS m

odel

1.

2.

3

. 4.

5.

6.

7.

2-8 62--611XX--2

0 (03/04

)

1.

Evap

ora

tor

Coi

l

2. Turbin

e fa

n (1

, 2 o

r 3

accord

ing to

the model)

3.

RAS

Sensor

4. Coil

5. Heate

rs

6.

Expa

nsi

on

val

ve

7.

Pressure

tap

Figure 2-4

Evapor

ator MTD m

odel

1.

2.

3.

4.

5.

6.7.7.

2-9

Figure 2-

5

Elect

rical

box

1.

Cap

aci

tors

2.

Stan

dby m

otor c

ont

acto

r (MC)

3.

Moto

r Over

loa

d rel

ay (M

OL)

4.

Man

ual

run

/stop

swi

tch

5.

EHR

con

tact

ors

6.

Mai

n fu

se (

80

amp

s )

7. Buzz

er

8.

Cap

aci

tors

9.

Rel

ay a

nd

Fuse

boa

rd

10.

Regul

ation

Bypass

RBPR

relay

( Supra 850 Mt

_

only )

1.

7.

8.

8.

9.

10.

2.

3.

4.

6.

5.

2-1

0 62--611XX--2

0 (03/04

)

This control

relay board

allows a better

maintenance using pin

connections (

TP01 to TP

17 ).

With a multimet

er

, an

output

voltag

e can be

measur

ed,

pin by pin, to check

relay

s power

supply.

Figure 2-6

Control r

elay boar

d view

FUSE IDENTIFICATION

Rep

. Item Amps

F

1 Main fuse 60

A

F

2 RC

R fuse

5

A

F

3 Ru

n Rela

y fuse 15

A

F

4 Heater rela

y fuse 10

A

F

5 Spee

d rela

y fuse

5

A

F

6 Unloader fuse

3

A

F7 Defrost damp

er relay fu

se 7.5

A

F8 Electric fan motor fuse 7.5

A

F9 Electric fan motor fuse 7.5

A

F10 Electric fan motor fuse 5 A

F11 F

uel pump fuse

3

A

RELAY IDENTIFICATION

Rep

. Item

SSR Starter soleno

id rela

y

CAR Ca

pacitor alternat

or rela

y

CR1

,2,3 Cool

rel

ay (

1st

, 2n

d ,

3rd

comp

art

men

t)

EHR

1,2

,3

Ele

ctr

ical heat rel

ay

(1st , 2nd , 3rd compartment)

FLR Flashi

ng rel

ay

UFR Unload

er front relay

FHR

Fuel heater relay (optio

n)

S

R Spee

d rela

y

HGR

1,2

,3

Hot

gas

rel

ay

(1st , 2nd , 3rd compartment)

DER Diesel electric rela

y

RR1

,2,3 Run

rel

ay

(1s

t ,

2nd

, 3

rd

comp

art

men

t)

GPR Gl

ow plug rel

ay

R

CR Run control rel

ay

MHR Main heat rel

ay

RBPR Regu

lat

ion

by-

-pass

rel

ay

2-11

2.2 EN

GINE DATA

Engine Model

CT3-44T

V (D722) CT3-69TV (D1105

)

Used on

SUPRA

750Mt

/

850Mt

SUPRA 950Mt

Displacemen

t 71

9 cc (43.

9 in3) 1105 cc (67.

5 in3)

No. Cylinder

s

3

3

Horsepowe

r 9.

3 kw (12.

5 hp

) @2400rpm 14.9 kw (2

0 hp

) @2400rpm

Weigh

t 63 kg (139 lbs) 89 kg (214 lbs)

Coolant Capacity 3,7 liters (3.9 U.S. quarts) 4,7 liters (5.5 U.S. quarts)

Oil

Capac

ity

withou

t

oil bypass kit

8,1 liters (8.5 U.S. quarts) 9,4 liters (11 U.S. quarts)

Oil Capacity with oil

bypass kit

*

8,9 liters (9.4 U.S. quarts

) no

t availabl

e

Operating

High

SUPRA

750Mt

_

: 2200 rpm

SUPR

A

850

Mt_: 2400 rpm

2250

rpm

pee s

Low 1800 rp

m 1800 rp

m

Injection Settin

g 14

0 to 15

0 kg/c

m2(1991 to 2133 psi)

*

Quantity includes oil bypass filter volume

2.2.1 Cooling circuit

Water temperature sensor (WTS)

This a

thermisto

r type

senso

r

locate

d on

the engine

cylinder head which measures the temperature of the

coolant.

Unit shuts down :

Ambien

t < 50_C (120

_

F)

if temperature exceeds 110

_

C (230

_

F)

Ambien

t > 50_C (120

_

F)

if temperature exceeds 116

_

C (240

_

F) or

if temperature stays between 110

_

C (240

_

F) and

1

16_C (230

_

F) for 5 min.

Lubrification System

Oil pressure switch (OP)

Closes a

bove

1.05 bars (1

5 psi)

¦

0.2 (3 psi)

LubeOilViscosity:(APIclassi

fic

ationCDminimum)

Outdoor Temperatur

e SA

E

Centigrad

e Fahrenheit SA

E

0_C Belo

w 32_ 0W30

0_to 25

_

C

32_to 77

_

F

10W30

or

15W40

Over +25

_

C Over 77_F

10W30

or

15W40

2.3

COMPR

ESSOR

REFER

ENCE

DA

TA

Model

05G 05K2 05K4

Displacement

600 cc /

664 cc

(36.6 /

40.5 in

3

)

400 cc

24.4 in

3

)

200 cc

(12.2 in

3

)

No. Cylinder

s

6

4

2

No. Unloader

s

1

1

0

Weight

75

kg

(165 lbs)

49 kg

(108 lbs)

38 kg

(84 lbs)

Oil Charge

3.8

L

(6.90 pts)

2.6 L

(4.75 pts)

1.9 L

(3.45 pts)

APPROVED COMPRESSOR OIL

Refrigerant 05

G 05

K

-40

4

o rctc 68

2.4

REFRI

GERA

TION

SYSTE

M DATA

a.

Defr

ost T

imer

1h30, 3h, 6h, or 12 hours

b.

Defr

ost Therm

ostat

Ope

ns

at:

10

_

¦

3_C (50

_

F¦5_F)

Clo

ses

at:

7

_

¦

3_C (45

_

F¦5_F)

2-1

2 62--611XX--2

0 (03/04

)

c.

High Pres

sure Cutout S

witch (HP

1)

Cu

tout at: 32.7¦0.7 bars (469

¦

10 psig)

Cut-in at: 24.6¦0.7 bars (350

¦

10 psig)

d.

High Press

ure Cutout Swit

ch (HP2)

Cu

tout at: 27.5¦0.7 bars (393

¦

10 psig)

Cut-in at:

23¦0.7 bars (330

¦

10 psig)

e.

Refr

igerant

charge

Refer to Table 2-1.

f.

Com

pre

ssorPr

ess

ureRegula

tingValve(CPR)in

heat mode

CPR Setting

MODEL

bar

s psig

SUPRA 750Mt

_

1

.

7 24,5¦1

SUPRA 850Mt

_

1.8 26¦1

SUPRA 950Mt

_

1

.

9 27,5¦1

g.

Thermos

tatic Expans

ion Valve superhea

t

Setting at ---20

_

C (0_F) box temperature:

MODEL SETTIN

G

All

Units

8

to

10_F (4 to 6

_

C)

h. Com

pre

ssor

Dis

cha

rge Temp

era

ture Sen

sor

(CDT)

Unit shuts down at :

154_C (310

_

F) for 3 minutes or 177

_

C (350

_

F)

i.

Bypas

s pre

ssure

switch

(if us

ed)

Open

s at :

1.4 b

ar (2

0 ps

ig)

Clo

ses

at:

1.9

bar

(20

psi

g)

2.5

ELE

CTR

ICAL DATA

a.

Evapor

ator Fa

n Motors

Die

sel

high

spee

d

Die

sel

low

spee

d

Voltage 23

0

V 23

0

V

Frequency 60 HZ 50 HZ

Speed 2738 rp

m 2541 rp

m

Power 27

2

W 19

5

W

Current 1.19

A 0.86

A

No maintenanc

e:

Lubric

ated for

life.

b.

Genera

tor (Single phase alter

nator)

Power

SUPRA

750Mt

_

/850Mt

_

: 1.5

kW

SUPRA 950Mt

_

: 2 k

W

Volts 24

0 va

c

Speed 3000

/ 3600 rp

m

Cosϕ1

GENERATOR RESISTANCE VALUES (see section 2.10)

Units

Voltage

and

frequency

Stator

Auxili

ary

coil

Stud 5 & 2

Stator

Main coil

Stud 6 & 1

Stud 3 & 4

Rotor

Auxili

ary

coil

Rotor

Main coil

Capacitors

450V

Diodes

( Qty:2 )

Supra 750Mt

_

/850Mt

_

110/220V

-- 50/60Hz

12.2

Ω

1.7Ω1.1Ω5.6Ω12µF

6A

Supra 950Mt

_

1

10/

20V

-- 50/60Hz

6.15

Ω

0.87

Ω

1.42

Ω

6.97

Ω16µ

F

1000V

2-13

c.

Standby

motors

Rotation speed : 1760 rpm @ 60 hz / 1500 rpm @

50hz

750 Mt

850 Mt

950 Mt

d.

Alte

rnator

:

50 amps

e.

Standby

Motor Ov

erload

The function of the motor overload is to protect the

standby motor against high amperage draw. The over-

load provides an adjustable knob to set the maximum

amperage draw.

Themo

torover

loadisalsoequippedwitharesetbu

t-

ton. This button has three positions : automatic reset,

manual and test. In the application the button should

remain in the automatic reset position.

STANDBY MOTOR OVERLOAD

SETTING

MODEL

400

V 230V

SUPRA 750Mt

_

1

1

A 19.2

A

SUPRA 850Mt

_

1

1

A 20.5

A

SUPRA 950Mt

_

2

0

A 34.6

A

2.6 TORQUE VALUES

Assembl

y kg-m ft-l

b

Power Tray to Fram

e 5.

5 40

Standby Moto

r to Powe

r Tray 5.

5 40

Engin

e to Powe

r Tray 7.

0 50

Compresso

r to Powe

r Tray 5.

5 40

Standby Moto

r Pulley 4.

5 32

Engin

e Pulley 3.

0 22

Compresso

r Pulley 3.

0 22

Evaporato

r Fa

n Moto

r 1.

8 13

Evaporato

r Fa

n Grille 1.

0

7

Condenser Coil to Chassi

s 1.

0

7

Tensioner to Powe

r Tray 3.

0 22

Engin

e Suppor

t 5.

5 40

Run

& Spee

d Solenoid

s 1.

0

7

Condenser Fa

n Blad

e 2.

5 18

Engin

e Clutch 5.

5 40

2-1

4 62--611XX--2

0 (03/04

)

2.7 SA

FETY DEVICE

S

System components are protected from damage caused by unsafe operating conditions by automatically shutting

down the unit when such conditions occur. This is accomplished by the safety devices listed in Table 2-4.

Table 2-4 Safety Devices

Unsaf

e Conditions Safety Device

1. Low engi

ne lubricating oil pressu

re

Oil pressure safety sw

itch OP automatic rese

t

2.

High eng

ine

coo

ling wate

r

temp

erat

ure Water

temp

era

ture

sen

sor

WTS

3.

Excess

ive curre

nt draw by

glow p

lug cir

-

cuit , control circuit or starter solenoid (SS)

Fuse (F1)

4. Excessive current dr

aw

by controll

er Fuse (F2)

5. Excessive cu

rre

nt

draw by contr

ol circu

it

Fuse (F3

)

6.

Excess

ive curre

nt draw b

y speed

control

solenoid

Fuse (F4)

7.

Excess

ive

compre

ssor

discha

rge p

ressure

High

pressu

re cu

tout s

witch

HP

automa

tic re

set

8.

Excess

ive com

presso

r discha

rge temp

era-

ture

Compressor discharge temperature sensor CDT

9.

Excess

ive cu

rrent dra

w by e

vapor

ator fan

motors

Fuses (F21, F22, F23)

10. Heater over temperature High temperature klixon

1

1. Excessive current dr

aw

by heaters Fuses (F

14

to F19, F30

to F32)

2-15

2.8

MIC

ROP

ROC

ESS

OR

CON

TRO

LLER

1. Display

2. Up and down arrow keys

3. Function change key

4. Run/Stop switch

5. Road key

6. Comp. 1 ON/OFF switch

7. City speed key

8. Comp. 2 ON/OFF switch

9. Manual defrost key

10. Comp. 3 ON/OFF switch

11. Buzzer off key

12. Standby key

13. Pretrip key ( not used )

14. Auto-start/Stop key

15. Unit data key

16. Fault alarm led

17. Enter key

1.

3.

2.

17.

4.

5.

7.

9.

1

1.

12.

13.

14.

15.

16.

6.

8.

10.

Figure 2-

7

Cab C

ommand

2.8.1 Introduction

The microprocessor controller is housed in the con-

trolbox.Thisco

ntrollerconsistsof 2co

ntr

ol boardsan

d

a relay module :

1.

The Processor Board includ

es the

microp

rocess

or,

program memory, and necessary input/output cir-

cuitry to interface with the unit.

2.

The

Rel

ay

Mod

ule

con

tains repl

ace

able rel

ays

,

diodes and fuses along with the wiring harness.

The Cab Command is remote mounted in the

truck.

The Cab Command includes the LCD display, keypad

and keypad interface (see Figure 2-7).

CAUTION

Unde

rnocir

cum

sta

ncesshoul

d

anyo

ne

attempt to repair the Logic or Display

Boards!

Shoul

d a prob

lem devel

op

with the

se

components, contact yo

ur nearest

Carrier Transicold dealer fo

r

replacement.

2-1

6 62--611XX--2

0 (03/04

)

The Carrier Transicold microprocessor controller in-

corpora

tes

the following features :

a. Controlssupplyor

returnair

temperat

ureto

tightli

m-

itsbypro

vid

ing

refr

ige

rationcon

trol,heatanddefrost

to ensure conditioned air delivery to the load.

b. Dualindependentreadoutsofsetpointandsupplyor

return air

tempera

tures.

c.

Dig

ital readout and abili

ty

to sele

ct data. Refer to

Table 2-5 for Function Codes and Table 2-7 for Unit

Data.

d.

For alarm digital display iden

tificati

on Refer

to

Table 2-8.

e. A se

lf-test check on prog

ram memo

ry and data

mem

ory.The

sel

f-testis

exe

cutedeachtime

the

sys-

tem is switched from “Stop” to

“Start.” Errors, if

any

,

shall be indicated on the display as a ERR.X, where

X is a number corresponding to the number of the

test. The unit shall display this error for 5 seconds

and then reset the micro.

ERROR

CAUSE

ERR.1

ERR.2

ERR.3

Processor failure

Check chip installation or replace

microprocessor

ERR.4 Display board to logic board

communication failure.

This can be caused by a defec-

tive ribbon cable or ribbon cable

not plugged in properly.

2.8.2 Keypad

Thekeyp

adhas12keyswhichwillallowtheope

rat

or

to initiate various functions, display operating data and

change operating parameters.

1.

Display window : shows set--point, box temperature,

operating mode, alarm displays, as well as data on the

unit itself (battery voltage, water temperature etc.).

Function Change key

The

func

tion

cha

nge

key

is used to

displ

ay

the operating parameters. Each

time this key is pressed the display will

adv

anceto

the

nextpara

mete

r.

Thiskey

,

in conjunction with the

up/down arrow

and

ente

r

key

s

, will allow the user to

change the parameters.

Arrows key

The UP ARROW and DOWN ARROW

keys are

used to

alter the set-

-poin

t.

Presstheup

ordownarrowkeys

un

tilthe

desired se

tpoint

is displayed on

the

left-

-hand

side of

the

dis

play win

dow

.

When

the

correct

set-

-point i

s

displ

ayed,

pre

ss the

ENT

ER key

to confi

rm

the

setting.

The UP ARROW and DOWN ARROW

keys are also used to change the unit

functions and scroll through th

e

FUNCTION and

UNIT

DA

TA screens.

Enter key

The ENTER key confirms changesmade

to unit operatio

n.

It must

be

pre

ssed to

cha

nge the

setp

oint afte

r

using the arrow keys to adjust it. If the

ENTER key is not pressed, the setpoint

wi

ll

revert

to

the previous

ly enter

ed

setting.

The ENTER key must also be pressed

whene

ver a

FUNCTION setting is being

altered. If this key is not pressed, the

func

tion

willrevertto

its

pre

vioussett

ing

.

RUN/STOP switch

The ma

in unit RUN/STOP swit

ch

contro

ls the unit operatio

n. When

switched to the Run (I) position, the unit

wi

ll

sta

rt

in

the opera

ting mo

de last

entered (Road or Standby). The

set-

-poin

t

will be

at

the

last set-

-poin

t

entered on the keypad.

Road key

The ROAD key puts the unit into Road

(or engine) operation when the unit has

beenpre

vio

uslyope

ratedin

the

Stan

dby

mode.

City Speed key

The CITY SPEED key toggles the unit

be

twe

en high speed and low speed

(diesel mode). When City Speed issele

cte

d,

the unit

wi

ll run only

in low

speedexc

ept

dur

ing

defr

ost

cyc

les.This

feature is useful in areas where noise is

restricted.

Loading...

Loading...