Carrier FY4ANF042000, FY4ANF030000, FY4ANF024000, FY4ANF018000, FX4CNF060000 Installation Guide

...

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS ........................ 1

INTRODUCTION .................................. 1

HEATER PACKAGES .............................. 1

INSTALLATION ................................... 1

Step 1 - Check Equipment .......................... 1

Step 2 - Mount Unit ............................... 2

Step 3 - Air Ducts ................................ 4

Step 4 - Electrical Connections ...................... 4

Step 5 - Refrigerant Tubing Connection and Evacuation . .. 7

Step 6 - Refrigerant Flow-Control Device .............. 8

Step 7 - Condensate Drains ......................... 8

Step 8 - Accessories ............................... 9

Step 9 - Sequence of Operation ..................... 10

START-UP PROCEDURES ......................... 10

CARE AND MAINTENANCE ....................... 10

AIRFLOW PERFORMANCE TABLES ................ 11

PURON@ (R-410A) QUICK REFERENCE GUIDE ...... 12

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions

packaged with kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special

requirements.

Recognize safety information. This is the safety-alert symbol /b,.

When you see this symbol on the unit and in instruction manuals,

be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING. CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing unit, always turn off all power

to unit. There may be more than 1 disconnect switch. Turn

off accessory heater power, if applicable.

INTRODUCTION

Models FX4C and FY4A are designed for flexibility and can be

used for upflow, horizontal, or downflow (kit required) and

manufactured and mobile home applications. These units are

designed to meet the low air leak requirements currently in effect.

Because of this, the units need special attention in the condensate

pan and drain connection area and when brazing tubing. These

units are designed specifically for Puron c_)refrigerant and must be

used only with Puron (> refrigerant air conditioners and heat pumps

as shipped. These units are available for systems of 18,000 through

60,000 Btuh nominal cooling capacity. Factory-authorized.

field-installed electric heater packages are available in sizes 5

through 30kW. See Product Data literature for available accessory

kits.

HEATER PACKAGES

This unit may or may not be equipped with an electric heater

package. For units not equipped with factory-installed heat, a

factory-approved, field-installed, UL listed heater package is

available from your equipment supplier. See unit rating plate for a

list of factory-approved heaters. Heaters that are not factory

approved could cause damage which would not be covered under

the equipment warranty. If fan coil contains a factory-installed

heater package, minimum circuit ampacity (MCA) and maximum

fuse/breaker may be different than units with a same size

field-installed accessory heater. The differences is not an error and

is due to calculation difference per UL guidelines.

INSTALLATION

Step 1 -- Check Equipment

Unpack unit and move to final location. Remove carton taking care

not to damage unit. Inspect equipment for damage prior to

installation. File claim with shipping company if shipment is

damaged or incomplete.

Locate unit rating plate which contains proper installation

information. Check rating plate to be sure unit matches job

specifications.

Step 2 -- Mount Unit

Unit can stand or lie on floor, or hang from ceiling or wall. Allow

space for wiring, piping, and servicing unit.

IMPORTANT: When unit is installed over a finished ceiling

and/or living area, building codes may require a field-supplied

secondary condensate pan to be installed under the entire unit.

Some localities may allow as an alternative, the running of a

separate, secondary condensate line. Consult local codes for

additional restrictions or precautions.

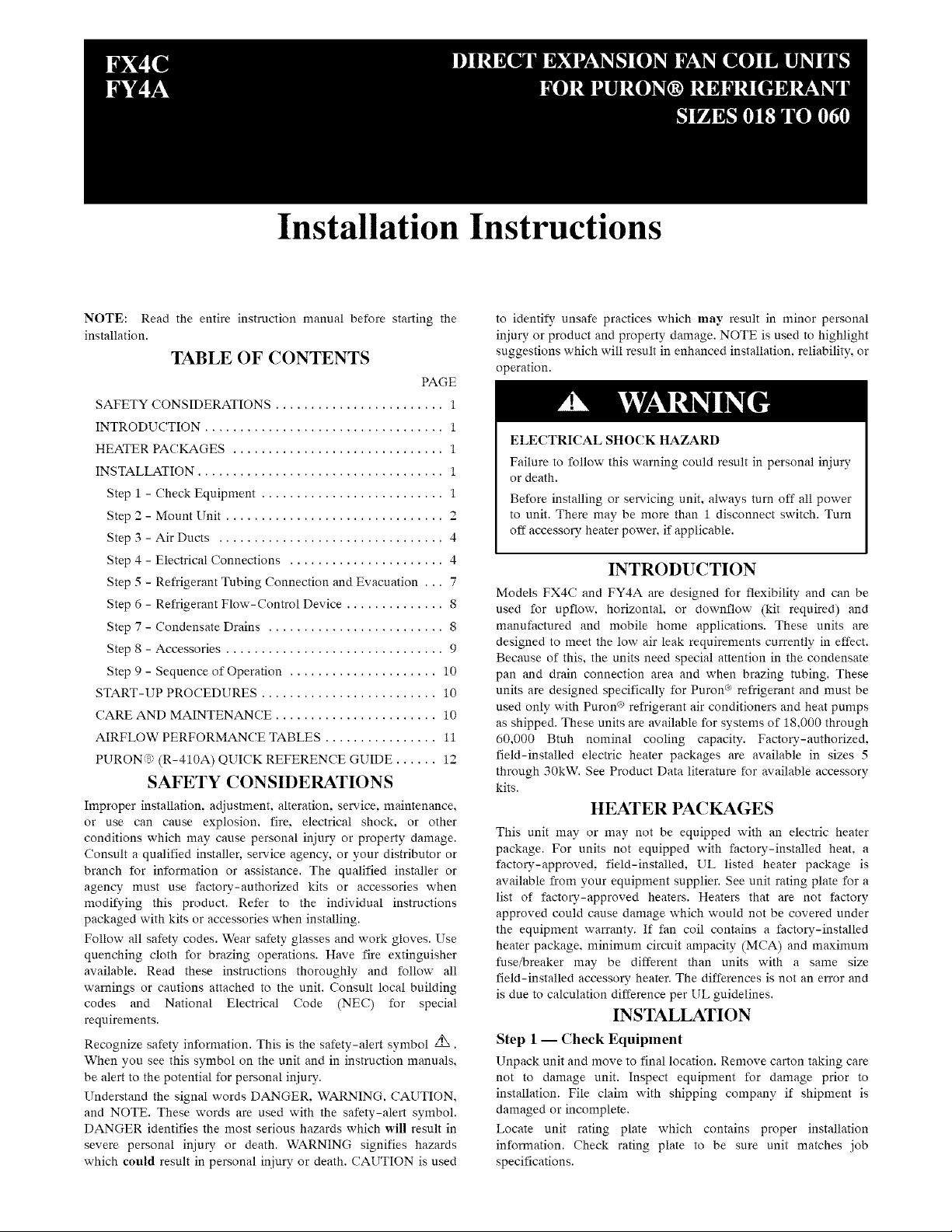

A. Upflow Installation

If return air is to be ducted through a floor, set unit on floor over

opening and use 1/8 to 1/4" (3 to 6 mm) thick fireproof resilient

gasket between duct, unit, and floor.

Side return is a field option on slope coil models. Cut opening per

dimensions. (See Fig. 1.) A field-supplied bottom closure is

required.

NOTE: Gasket kit number KFAHD0101SLP is also required for

all downflow applications to maintain low air leak/low sweat

performance.

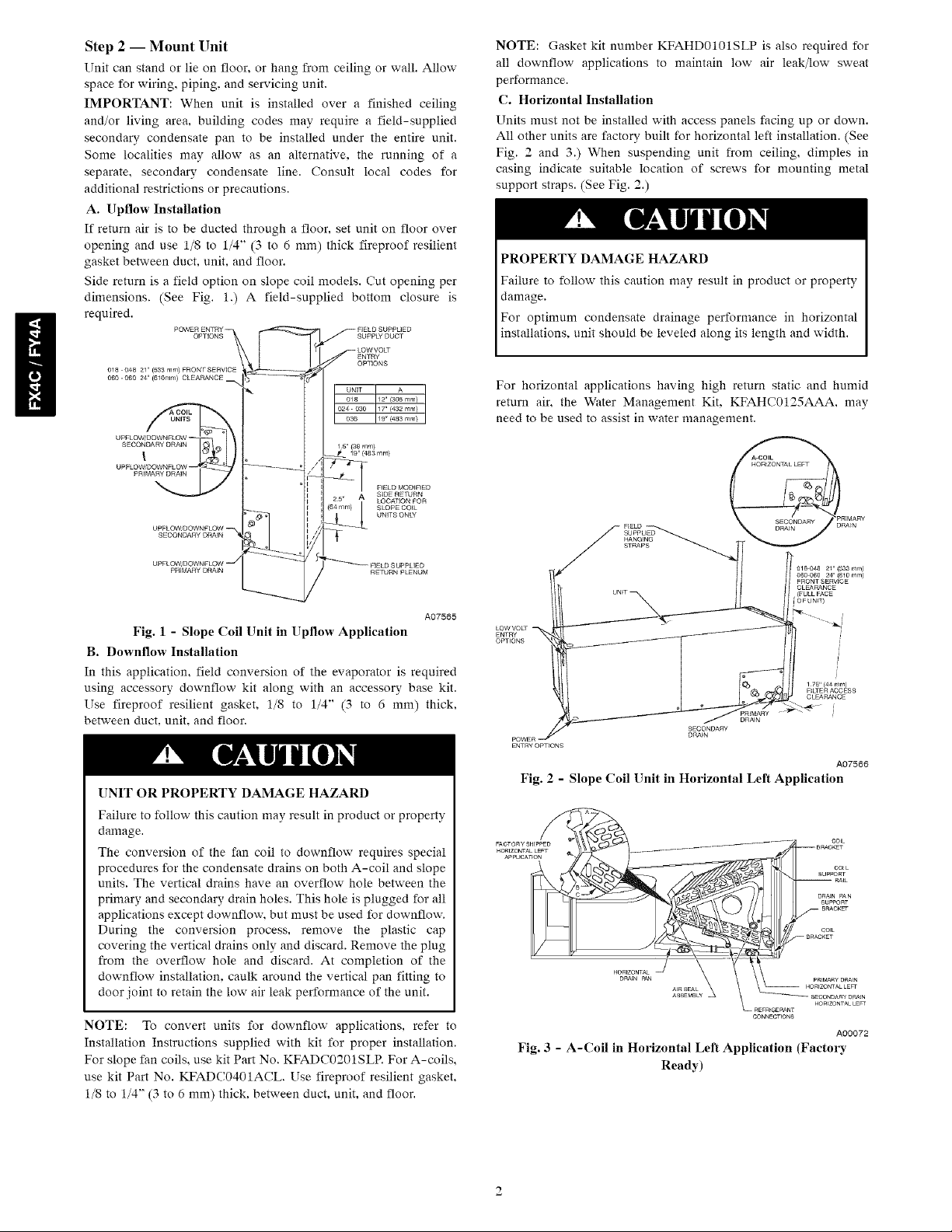

C. Horizontal Installation

Units must not be installed with access panels facing up or down.

All other units are factory built for horizontal left installation. (See

Fig. 2 and 3.) When suspending unit from ceiling, dimples in

casing indicate suitable location of screws for mounting metal

support straps. (See Fig. 2.)

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

For optimum condensate drainage performance in horizontal

installations, unit should be leveled along its length and width.

For horizontal applications having high return static and humid

return air, the Water Management Kit. KFAHC0125AAA. may

need to be used to assist in water management.

A07565

Fig. 1 - Slope Coil Unit in Upflew Application

B. Downflow Installation

In this application, field conversion of the evaporator is required

using accessory downflow kit along with an accessory base kit.

Use fireproof resilient gasket, 1/8 to 1/4" (3 to 6 mm) thick,

between duct, unit, and floor.

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or property

damage.

The conversion of the fan coil to downflow requires special

procedures for the condensate drains on both A-coil and slope

units. The vertical drains have an overflow hole between the

primary and secondary drain holes. This hole is plugged for all

applications except downflow, but must be used for downflow.

During the conversion process, remove the plastic cap

covering the vertical drains only and discard. Remove the plug

from the overflow hole and discard. At completion of the

downflow installation, caulk around the vertical pan fitting to

door joint to retain the low air leak performance of the unit.

NOTE: To convert units for downflow applications, refer to

Installation Instructions supplied with kit for proper installation.

For slope fan coils, use kit Part No. KFADC0201SLP. For A-coils,

use kit Part No. KFADC0401ACL. Use fireproof resilient gasket.

1/8 to 1/4" (3 to 6 mm) thick, between duct, unit, and floor.

HANGING

STRAPS

ENTRY

OPTIONS

SECONDARY

DRA_N

DRA_N

Fig. 2 - Slope Coil Unit in Horizontal Left Application

CONNECTIONS

Fig. 3 - A-Coil in Horizontal Left Application (Factory

Ready)

018048 21" {833 ram)

060 060 24" (610 rnm)

FRONTSERVICE

CLEARANCE

{FULLFACE

[©FUNT

i

1 75" {44 ram)

F_LTE R ACCESS

CLEARANCE

A07566

cot L

SUPPORT

RAtL

DRAENPAN

SUPPORT

A00072

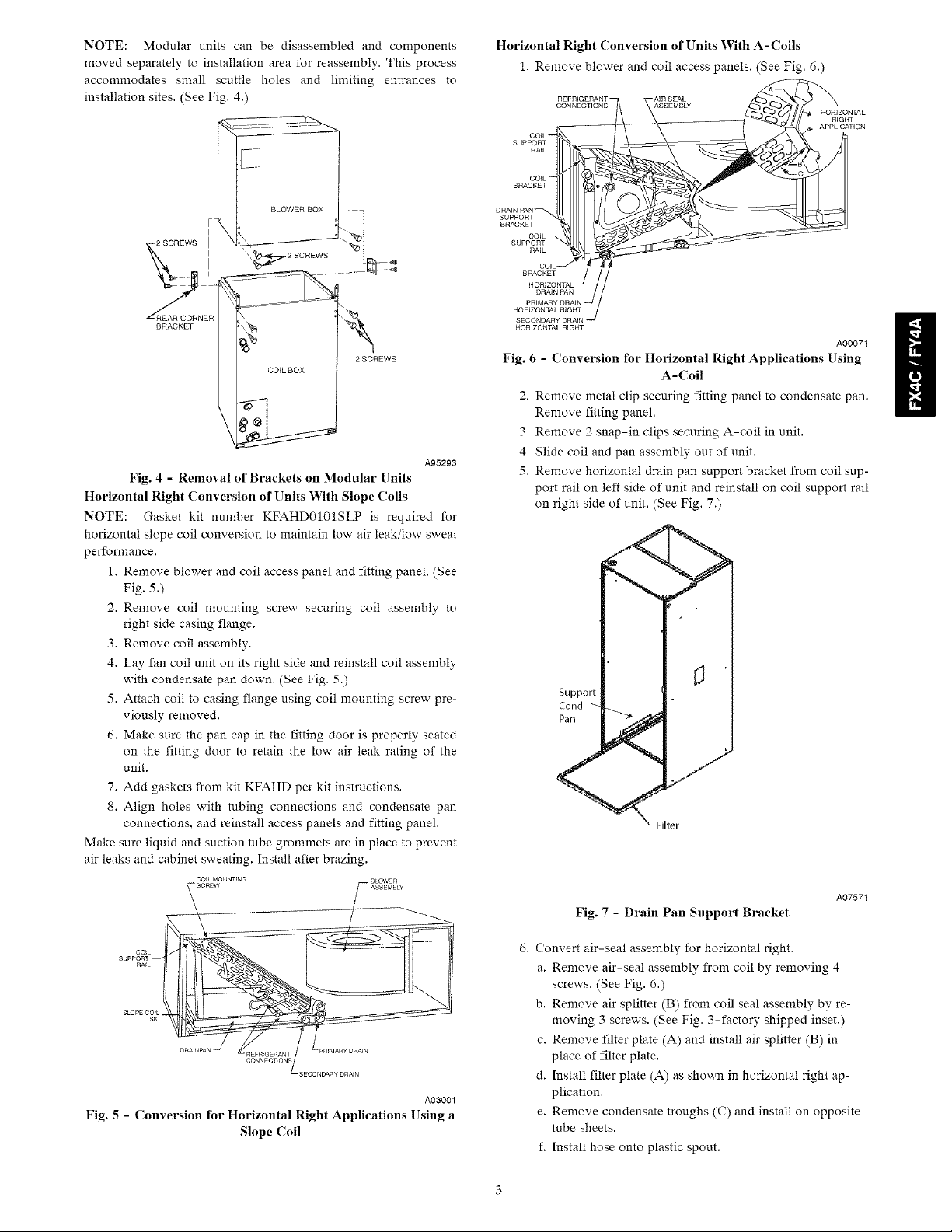

NOTE:Modularunitscanbedisassembledandcomponents

movedseparatelytoinstallationareaforreassembly.Thisprocess

accommodatessmallscuttleholesandlimitingentrancesto

installationsites.(SeeFig.4.)

BRACKET _ _

COIL BOX

Fig. 4 - Removal of Brackets on Modular Units

Horizontal Right Conversion of Units With Slope ('oils

NOTE: Gasket kit number KFAHD0101SLP is required for

horizontal slope coil conversion to maintain low air leak/low sweat

performance.

1. Remove blower and coil access panel and fitting panel. (See

Fig. 5.)

2. Remove coil mounting screw securing coil assembly to

right side casing flange.

3. Remove coil assembly.

4. Lay fan coil unit on its right side and reinstall coil assembly

with condensate pan down. (See Fig. 5.)

5. Attach coil to casing flange using coil mounting screw pre-

viously removed.

6. Make sure the pan cap in the fitting door is properly seated

on the fitting door to retain the low air leak rating of the

unit.

7. Add gaskets from kit KFAHD per kit instructions.

8. Align holes with tubing connections and condensate pan

connections, and reinstall access panels and fitting panel.

Make sure liquid and suction tube grommets are in place to prevent

air leaks and cabinet sweating. Install after brazing.

2 SCREWS

A95293

Horizontal Right Conversion of Units With A-Coils

1. Remove blower and coil access panels. (See Fig. 6.)

CONNECTIONS

SUPPORT

SUPPORT

SUPPORT

HORIZONTAL RIGHT

HORIZONTAL RIGHT

-AIR SEAL

APPLICATION

Fig. 6 - Conversion for Horizontal Right Applications Using

A-Coil

2. Remove metal clip securing fitting panel to condensate pan.

Remove fitting panel.

3. Remove 2 snap-in clips securing A-coil in unit.

4. Slide coil and pan assembly out of unit.

5. Remove horizontal drain pan support bracket from coil sup-

port rail on left side of unit and reinstall on coil support rail

on right side of unit. (See Fig. 7.)

i7 F[

A00071

A03001

Fig. 5 - Conversion for Horizontal Right Applications Using a

Slope Coil

A07571

Fig. 7 - Drain Pan Support Bracket

6. Convert air-seal assembly for horizontal right.

a. Remove air-seal assembly from coil by removing 4

screws. (See Fig. 6.)

b. Remove air splitter (B) from coil seal assembly by re-

moving 3 screws. (See Fig. 3-factory shipped inset.)

c. Remove filter plate (A) and install air splitter (B) in

place of filter plate.

d. Install filter plate (A) as shown in horizontal right ap-

plication.

e. Remove condensate troughs (C) and install on opposite

tube sheets.

f. Install hose onto plastic spout.

7.Installhorizontalpanonrightsideofcoilassembly.

8.Slidecoilassemblyintocasing.Besurecoilbracketoneach

cornerofverticalpanengagescoilsupportrails.

9.Reinstall2 snap-inclipstocorrectlypositionandsecure

coilassemblyinunit.Besureclipwithlargeoffsetsisused

onrightsideofunittosecurehorizontalpan.

10.Removetwoovalfittingcapsfromtheleftsideofthecoil

doorandfittingpanel.

11.Removeinsulationknockoutsonrightsideofcoilaccess

panel.

12.Remove2 ovalcoilaccesspanelplugsandreinstallinto

holesonleftsideofcoilaccesspanelandfittingpanel.

13.Installcondensatepanfittingcaps(fromitem10)inthe

rightsideofthecoildoormakingsurethatthecapsnaps

andseatscleanlyonthebacksideofthecoildoor.Make

surenoinsulationinterfereswithseatingofthecap.

14.Reinstallaccessfittingpanels,aligningholeswithtubing

connectionsandcondensatepanconnections.Besuretore-

installmetalclipbetweenfittingpanelandverticalconden-

satepan.

Makesureliquidandsuctiontubegrommetsareinplacetoprevent

airleaksandcabinetsweating.

D. Manufactured and Mobile Home Housing Applications

1. Fan coil unit must be secured to the structure using field-

supplied hardware.

2. Allow a minimum of 24" (610 mm) clearance from access

panels.

3. Recommended method of securing for typical applications:

a. If fan coil is away from wall. attach pipe strap to top of

fan coil using no. 10 self-tapping screws. Angle strap

down and away from back of fan coil. remove all slack,

and fasten to wall stud of structure using 5/16-in. lag

screws. Typical both sides of fan coil.

4" (102mm) MAX

SECURE FAN COILTO STRUCTURE

UNIT AWAY FROM WALL

PIPE STRAP

(TYPICAL BOTH SIDES)

,%,. oR

_NST W,_

125" (3mm)

MOUNTING BRACKET

(TYPICAL BOTH SIDES)

brackets to fan coil using no. 10 self-tapping screws

and to wall stud using 5/16-in. lag screws. (See Fig. 8.)

Step 3 -- Air Ducts

Connect supply-air duct over the outside of 3/4" (19 mm) flanges

provided on supply-air opening. Secure duct to flange, using

proper fasteners for type of duct used, and seal duct-to-unit joint.

If return-air flanges are required, install factory-authorized

accessory kit.

Use flexible connectors between ductwork and unit to prevent

transmission of vibration. When electric heater is installed, use

heat-resistant material for flexible connector between ductwork

and unit at discharge connection. Ductwork passing through

unconditioned space must be insulated and covered with vapor

barrier.

Units equipped with 20-30kW electric heaters require a 1" (25

mm) clearance to combustible materials for the first 36" (914 mm)

of supply duct.

Ductwork Acoustical Treatment

Metal duct systems that do not have a 90 ° elbow and 10' (3m) of

main duct to first branch takeoff may require internal acoustical

insulation lining. As an alternative, fibrous ductwork may be used

if constructed and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts. Both

acoustical lining and fibrous ductwork shall comply with National

Fire Protection Association as tested by UL Standard 181 for Class

1 air ducts.

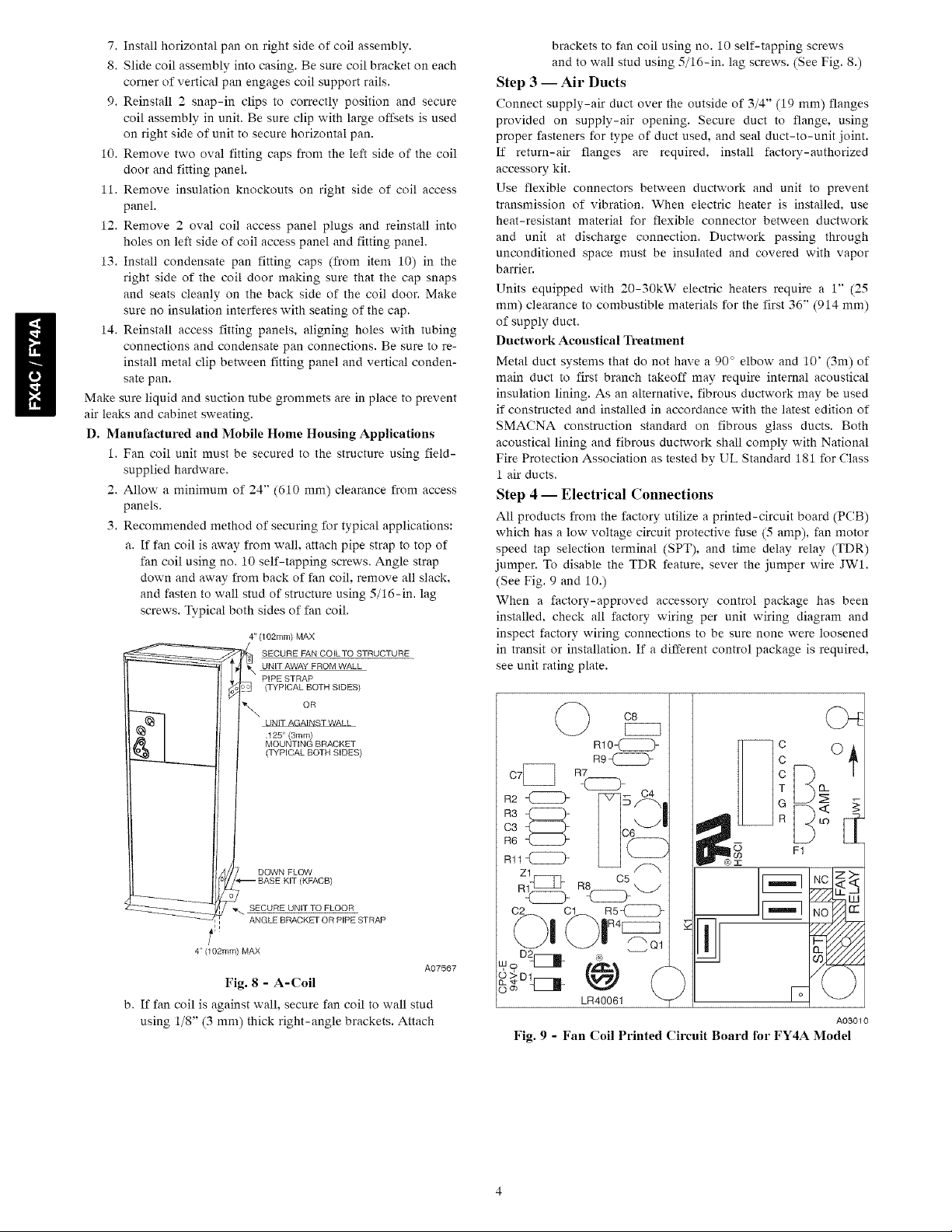

Step 4 -- Electrical Connections

All products from the factory utilize a printed-circuit board (PCB)

which has a low voltage circuit protective fuse (5 amp), fan motor

speed tap selection terminal (SPT), and time delay relay (TDR)

jumper. To disable the TDR feature, sever the jumper wire JW1.

(See Fig. 9 and 10.)

When a factory-approved accessory control package has been

installed, check all factory wiring per unit wiring diagram and

inspect factory wiring connections to be sure none were loosened

in transit or installation. If a different control package is required.

see unit rating plate.

DOWN FLOW

(KFACB)

_._ SECURE UNtTTO FLOOR

ANGLE BRACKET OR PIPE STRAP

_=

4" (102ram) MAX

Fig. 8 - A-Coil

b. If fan coil is against wall, secure fan coil to wall stud

using 1/8" (3 mm) thick right-angle brackets. Attach

A07567

R2

R3

03

[16

[111

Fig. 9 - Fan Coil Printed Circuit Board for FY4A Model

Loading...

Loading...