Page 1

SERVICE &

INSTALLATION

MANUAL

CARRIER COMMERCIAL REFRIGERATION, INC.

Frozen Food

& Ice Cream

Merchandisers

CMCT

2/03 51-1021-01

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

Page 2

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 8:00a.m. to 5:30 p.m., Eastern

Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

All data and information in this manual is subject to change without notice.

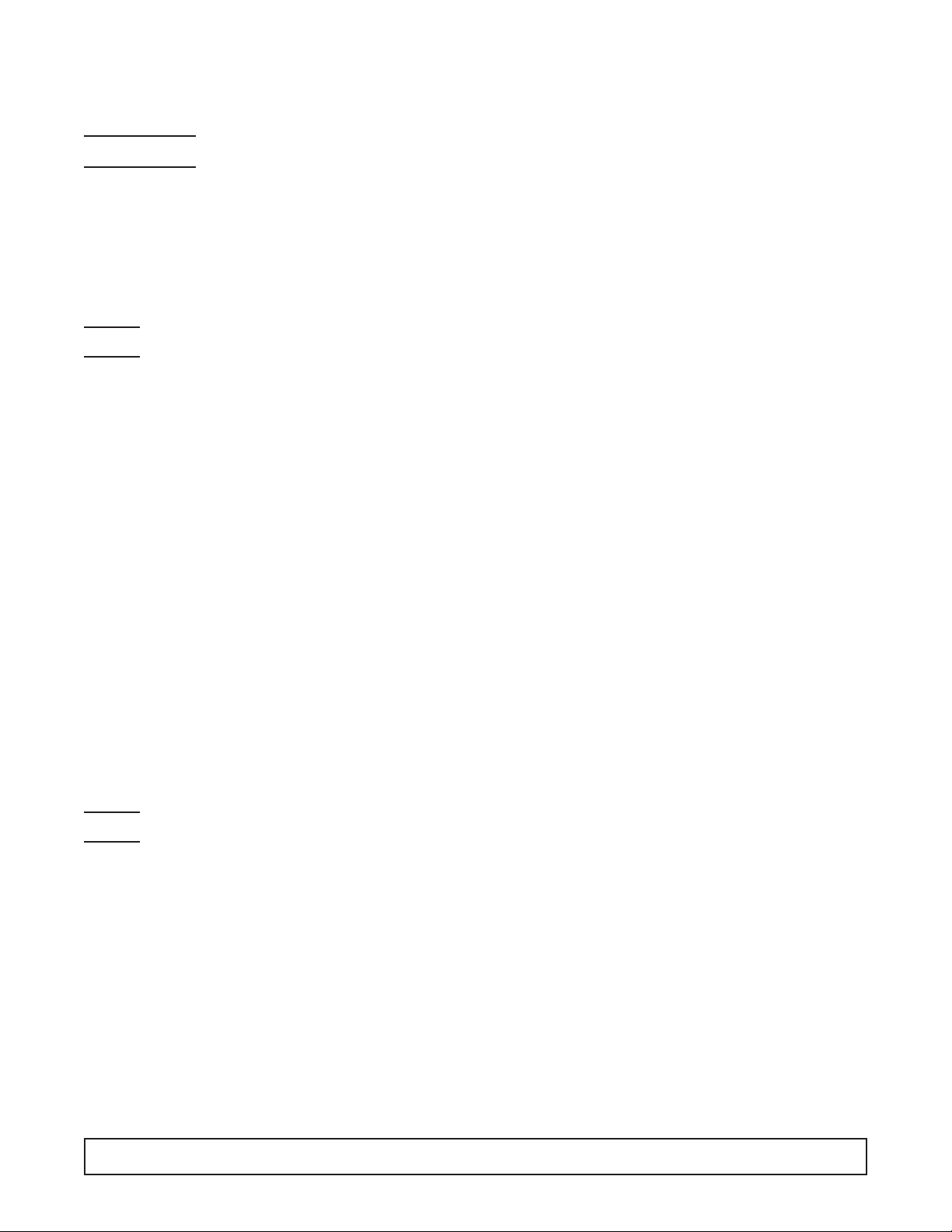

MODEL DESIGNATION INFORMATION

115V, 60HZ

PAR T # MODEL # DATA PLATE

52-2038-01 CMCT4-4 SL12/CMCT4

52-2038-03 CMCT6-4 SL20/CMCT6

52-2038-05 CMCT8-4 SL28/CMCT8

52-2038-06 CMCT10-4 SL36/CMCT10

EXPORT 220V, 50HZ

PAR T # MODEL # DATA PLATE

52-2040-01 ECMCT4-4 ECMCT4

52-2040-02 ECMCT6-4 ECMCT6

52-2040-04 ECMCT8-4 ECMCT8

Page 3

SECTION I

Introduction

Page 4

CMCT Merchandisers – Introduction

These cabinets are produced for the merchandising of frozen

food and ice cream markets. They range in size from 4' to 10'

in length. Operating ambients range from 70ºF. to 85ºF. with

cavity temperatures at load line between 0ºF. to -20ºF.

Except for routine cleaning, these cabinets will require little

maintenance. In the unusual event that repair should be

necessary, this manual presents information that is helpful in

maintaining, diagnosing, and repairing these cabinets.

INTRODUCTION 3

Page 5

TABLE OF CONTENTS

4TABLE OF CONTENTS

Due to the manufacturer’s policy of continuous quality improvement, specifications are subject to change without notice.

INTRODUCTION

Introduction .................................................................... 3

Table of Contents ............................................................ 4

Specifications & Illustrations............................................ 5

Handling & Installation .................................................... 6

Cleaning Instructions........................................................ 7

Cabinet Operation ............................................................ 7

Electrical Data .................................................................. 9

Refrigeration/Electrical Specs. (R404A)............................ 10

Refrigeration/Electrical Data Export Models...................... 11

Wiring Diagram CMCT Models 4, 6 & 8 .......................... 12

Wiring Diagram CMCT Models 10 .................................... 13

Wiring Diagram ECMCT Models 4, 6 & 8 (Export) .......... 14

Lamp Wiring Detail (Upper Raceway) .............................. 15

MAINTENANCE & REPAIR

Cabinet Temperature Control ............................................ 19

Electrical Box Layout ........................................................ 20

Defrost Timer Layout........................................................ 21

Cabinet Electrical Supply .................................................. 22

Condensing Unit Assembly .............................................. 23

Condensing Unit Layout.................................................... 24

Unit Compartment - Rear.................................................. 25

Evaporator Tubing Illustration .......................................... 26

New Lubricants ................................................................ 27

Back Pressure Valve ........................................................ 28

Light Channel Assembly .................................................. 29

Baffle Heater comp. ID & Removal .................................. 30

End Panel Breaker & Heater Removal .............................. 31

Refrig. Upper Section Comp. ID & Removal .................... 32

Upper Cross Section ........................................................ 33

Front Glass Heater Replacement ...................................... 34

Countertop........................................................................ 35

Evaporator Coil Removal .................................................. 36

Troubleshooting Guide...................................................... 38

PAR TS LISTS

CMCT Cabinet Exterior Parts ID ...................................... 40

Parts List CMCT-4, 6, 8 & 10............................................ 41

Parts List EMCT-4, 6 & 8.................................................. 42

Page 6

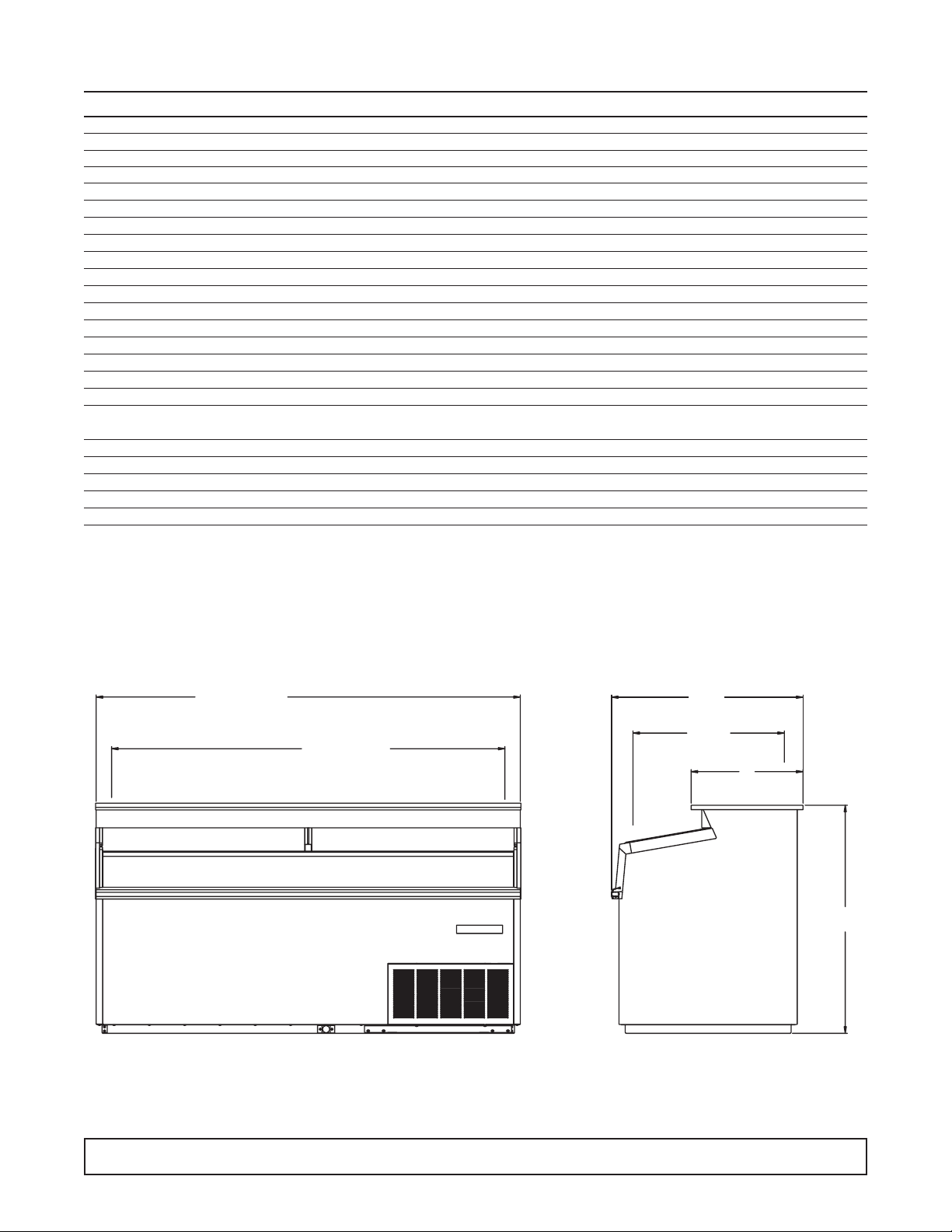

Specifications - Specifications Subject to Change without Notice.

CMCT-4 CMCT-6 CMCT-8 CMCT-10

Temperature Range 0° to -20°F 0° to -20°F 0° to -20°F 0° to -20°F

Insulation 21⁄2" Urethane Foam in Place 21⁄2" Urethane Foam in Place 21⁄2" Urethane Foam in Place 21⁄2" Urethane Foam in Place

Number of Lids 2234

Lid Construction 3/16" Glass Radiant Heated 3/16" Glass Radiant Heated 3/16" Glass Radiant Heated 3/16" Glass Radiant Heated

Capacity 11 cu. ft. 19 cu. ft. 27 cu. ft. 35 cu. ft.

Capacity (1/2 gallons) 120 225 322 435

Novelty Baskets Load Level 10 14 20 26

Capacity Novelty Baskets Total 16 24 36 48

Shipping Weight (Approx.) 486 lbs. 624 lbs. 780 lbs. 874 lbs.

Compressor Size 1/2 HP 1/2 HP 3/4 HP 1 HP

Condenser Type Bare Tube Forced Air Bare Tube Forced Air Bare Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Gravity Coil & Cold Wall Fin & Tube Gravity Coil & Cold Wall Fin & Tube Gravity Coil & Cold Wall Fin & Tube Gravity Coil & Cold Wall

Refrigerant Type R404A R-404A R-404A R-404A

Refrigerant Control Capillary Capillary Capillary Capillary

Defrost System Electric Electric Electric Electric

Rated Amps 8.0 8.0 12 4.8 (11V0/6.7 (230V)

Electrical Specs. (V/Hz/Ph) 115/60/1 115/60/1 115/60/1 115 & 230/60/1

Power Cord 15 Amp Cord 15 Amp Cord 15 Amp Cord Conduit Connected / Max. Fuse

with 5-15P NEMA Plug with 5-15P NEMA Plug with 5-15P NEMA Plug Size 15A Min. Circuit Ampacity 15A

NSF-7 (Ice Cream Storage) Yes Yes Yes Yes

UL & CUL Listed Yes Yes Yes Yes

Interior Finish White Baked Enamel White Baked Enamel White Baked Enamel White Baked Enamel

Exterior Finish White Baked Enamel White Baked Enamel White Baked Enamel White Baked Enamel

Lighted Sign Standard Standard Standard Standard

INTRODUCTION 5

481/16 (CMCT4)

721/16 (CMCT6)

961/16 (CMCT8)

1201/16 (CMCT10)

3/4 (CMCT4)

42

663/4 (CMCT6)

783/4 (CMCT8)

114 3/4 (CMCT10)

INSIDE

32

9/16

253/4

INSIDE

19

38

3/4

Page 7

FREIGHT DAMAGES AND SHORTAGES

The cabinet was inspected and

packaged at the factory, and should

arrive in excellent condition.The transportation company

or other parties involved in the shipment are responsible

for loss and/or damage. Always make an inspection

before and after uncrating. Inspect the crated unit(s)

before locating (preferably at the point of unloading by

the transportation company).

INSPECTING FOR DAMAGES

Always use care when removing shipping

tape, blocks, pads, hardware or other material

until you are satisfied that the unit is completely operational.

Check the cartons or containers. If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected:

1. Have the driver note the nature and extent of the

damage on the freight bill.

2. Notify the transpor tation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the transpor ta-

tion company.

FILING A CLAIM

File a claim for loss at once with the transportation

company for:

A. A cash adjustment; B. Repairs; or C. Replacement

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

The refrigeration system of the cabinet is

designed to operate with the cabinet located

on a level surface. Do not tilt the cabinet more than

10° to any side. If the cabinet must be tilted on an

angle for handling or moving purposes, allow it to sit in

an upright position 30 minutes prior to starting.

CHOOSING A LOCATION

This model cabinet should be situated to allow proper air

circulation. Cabinets require a 2" minimum clearance

behind for proper air circulation.

The cabinet must be installed on a sturdy, solid, level

floor.

The cabinet must be located so it can be plugged or

wired into a properly grounded three-prong electrical

outlet of 115/220 volt, 60 hz.The electrical outlet should

not be controlled by a wall switch which might be turned

off accidentally.

UNCRATING THE CABINET

The cabinet should be moved as close as possible to

the operating location before removing crate base. Be

sure to follow the steps in the “INSPECTING FOR

DAMAGES” instructions.

INSTALLING THE CABINET

After removing the skid from the cabinet, slide cabinet

into location.Level cabinet to insure proper draining of

the defrost water.

To meet NSF requirements, these cabinets must be

sealed to the floor with an NSF or FDA approved

sealant.

Remove the front grill from cabinet. Remove front hold

down bolts and pull unit out of cabinet. Remove shipping band from compressor.Be sure that the compressor “floats” freely on the compressor springs. Check

refrigeration lines to see that they are “free” and no

damage was done in shipping.Check fan blade for free

operation.

Check voltage and amp draw on the serial plate to

determine proper fuse and line size.Voltage should be

checked at the compressor terminals as the compressor is starting, to determine if there is excessive “voltage drop.” This voltage drop should not exceed 10% of

the rated compressor voltage. If the voltage reads 115

or 230 with no load and it drops below 103 or 208 when

the compressor tries to start, it is an indication that the

supply wiring is too small in size or too long in length.

It is recommended that a separate circuit be run for each

cabinet to prevent the possibility of another appliance

blowing a fuse causing subsequent loss of product.

SECTION I – HANDLING & INSTALLATION

6 INTRODUCTION

NOTE:

IMPORTANT:

NOTE:

Page 8

CLEANING INSTRUCTIONS

CLEANING THE CABINET EXTERIOR

Wipe the exterior occasionally with a cloth dampened in

mild detergent water; rinse, and wipe dry with a soft,

dry cloth. Do not use abrasive or caustic cleaners or

scouring pads.

CLEANING THE CONDENSER

Periodic cleaning of the condenser can be easily

accomplished by brushing the coils with a soft brush

and/or using a vacuum cleaner with a brush attachment.

Be sure that dirt, dust, and a collection of other debris

do not build up to a point that air circulation through the

condenser is restricted.

CLEANING THE STORAGE COMPARTMENT

1. Remove product and store it in another suitable cab-

inet, if possible. Be sure to prevent spoilage of the

product which may occur if it is left at room temperature.

2. Turn OFF the thermostat and unplug the cabinet.

3. Defrost completely prior to cleaning.

4. Wash the entire interior storage area with warm

water and baking soda solution — about a tablespoon of baking soda per quart of water.Rinse thoroughly with clean water and wipe dry.

5. A drain hose is provided. Connections are made to

fit a standard garden hose for ease of draining water

from inside of the tank area.

IMPORTANT:

Do not use any objects or cleaners which may leave

residues, odors, or particles. Avoid the use of strong

chemicals or abrasive cleaners which may damage the

interior surfaces and contaminate product within the

storage area.

6. Be sure to correctly plug in to cabinet, set the tem-

perature control, and allow time for cooling of the

storage area before storing product.

DESCRIPTION OF REFRIGERATION

SYSTEM: CONDENSING UNIT

All CMCT cabinets are equipped with Copelametic

compressors utilizing 404A refrigerant:

1/2 HP on the CMCT-4 and CMCT-6

3/4 HP on the CMCT-8

1 HP on the CMCT-10

A back pressure valve is used to protect the compres-

sor against excessive pressures during initial cabinet

start-up and upon termination of the defrost cycle. This

valve is factory pre-set to limit the crankcase pressure

to 10# and should not be changed.

CABINET OPERATION

REFRIGERATION CYCLE:

Refrigeration is accomplished by both a “wrap-around”

tank coil and fin coil. This tank coil consists of several

passes of copper tubing wrapped completely around the

tank or product compartment.The fin coil located behind

the light fixture serves two purposes — it creates a blanket of cold air over the product and collects moisture in

the form of frost from the warm air entering the cabinet,

thus reducing frost collection on the tank coil.The refrigerant enters the top of the tank coil first and progresses

downward to the bottom of the tank;from there it enters

the top of the fin coil and again downward. By circuiting

the refrigeration in this manner, it assures the fin coil of

being the coldest part of the system.

DEFROST CYCLE:

Because of the large size and fin arrangement, the

CMCT fin coils have the ability to collect a large amount

of frost before becoming bloc ked.These f eatures permit

the CMCT cabinets to operate on one defrost cycle per

24 hours, thus reducing product shock to the ice cream.

The fin coil and drain pan are defrosted with one 4-

pass heater located on the underside of the evaporator

assembly. The back pass of the heater lays in the drain

trough which slopes from left to right along the back

edge of the drain pan.

WARNING:

To avoid the possibility of an electrical shock, turn OFF

thermostat and unplug the electrical cord of the cabinet

before cleaning or touching electrical connections or parts.

INTRODUCTION 7

Page 9

Defrosting is initiated by the time clock and terminated

by a temperature thermostat set to close at 76°F. When

this thermostat closes, it energizes a solenoid in the

time clock which in turn trips the clock mechanism off

defrost. Should this ther mostat fail to close, the defrost

cycle will be terminated by the failsafe pin on the time

clock (set at 40 minutes).

As an additional safety feature , the temper ature limiting

thermostat is wired in series with the defrost heater.

This thermostat will also open the heater circuit when

the top coil reaches 76°F. should any malfunction of the

defrost thermostat occur.

Any time the system has been opened and

exposed to the atmosphere, a new drier

should be installed, system completely evacuated, and

recharged to the specified refrigerant and amount listed on the serial plate located inside the unit compartment on the left wall.

DO NOT ATTEMPT CHARGING BY

PRESSURES ALONE!! Charge is

very critical! Charging should be accomplished by

means of weighing, or the use of a charging cylinder.

NOTE:

IMPORTANT:

8 INTRODUCTION

Page 10

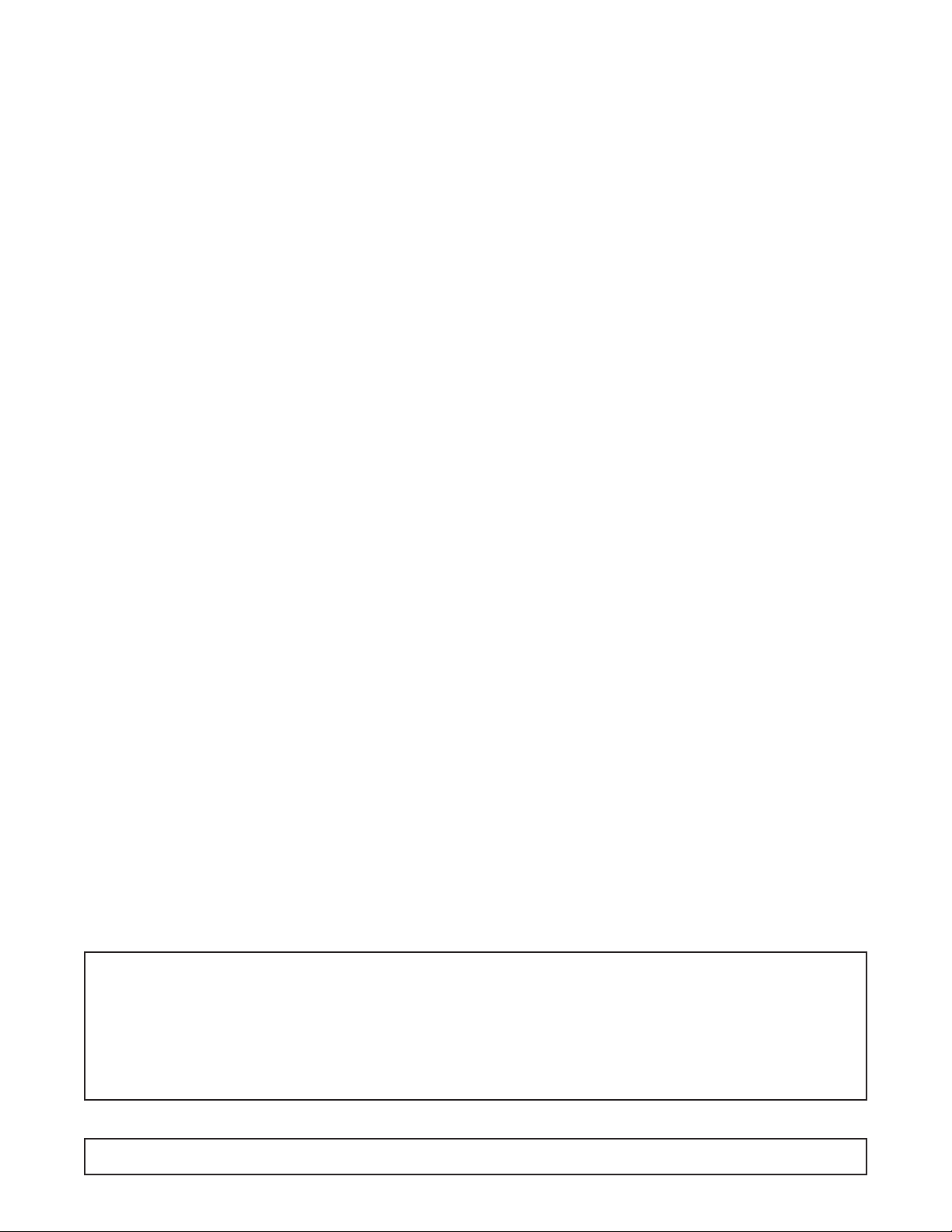

CMCT ELECTRICAL DATA

CMCT-4 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

24.7 582 4.8 120

of Top Coil

Control Bellows Heater below

1600 9 .075 120

Def. Controls

End Breaker Heater behind

960 15 .12 120

each End Breaker

Glass Heater around

262 56 .46 120

Front Glass

CMCT-8 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

11.8 1200 10 120

of Top Coil

Control Bellows Heater below

1600 9 .075 120

Def. Controls

End Breaker Heater behind

960 15 .12 120

each End Breaker

Glass Heater around

134 107 .89 120

Front Glass

CMCT-6 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

15.9 904 7.5 120

of Top Coil

Control Bellows Heater below

1600 9 .075 120

Def. Controls

End Breaker Heater behind

960 15 .12 120

each End Breaker

Glass Heater around

175 82 .68 120

Front Glass

CMCT-10 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

3.38 1561 6.7 230

of Top Coil

Control Bellows Heater below

1600 9 .075 120

Def. Controls

End Breaker Heater behind

960 15 .12 120

each End Breaker

Glass Heater around

190 132 1.1 120

Front Glass

INTRODUCTION 9

Page 11

10 INTRODUCTION

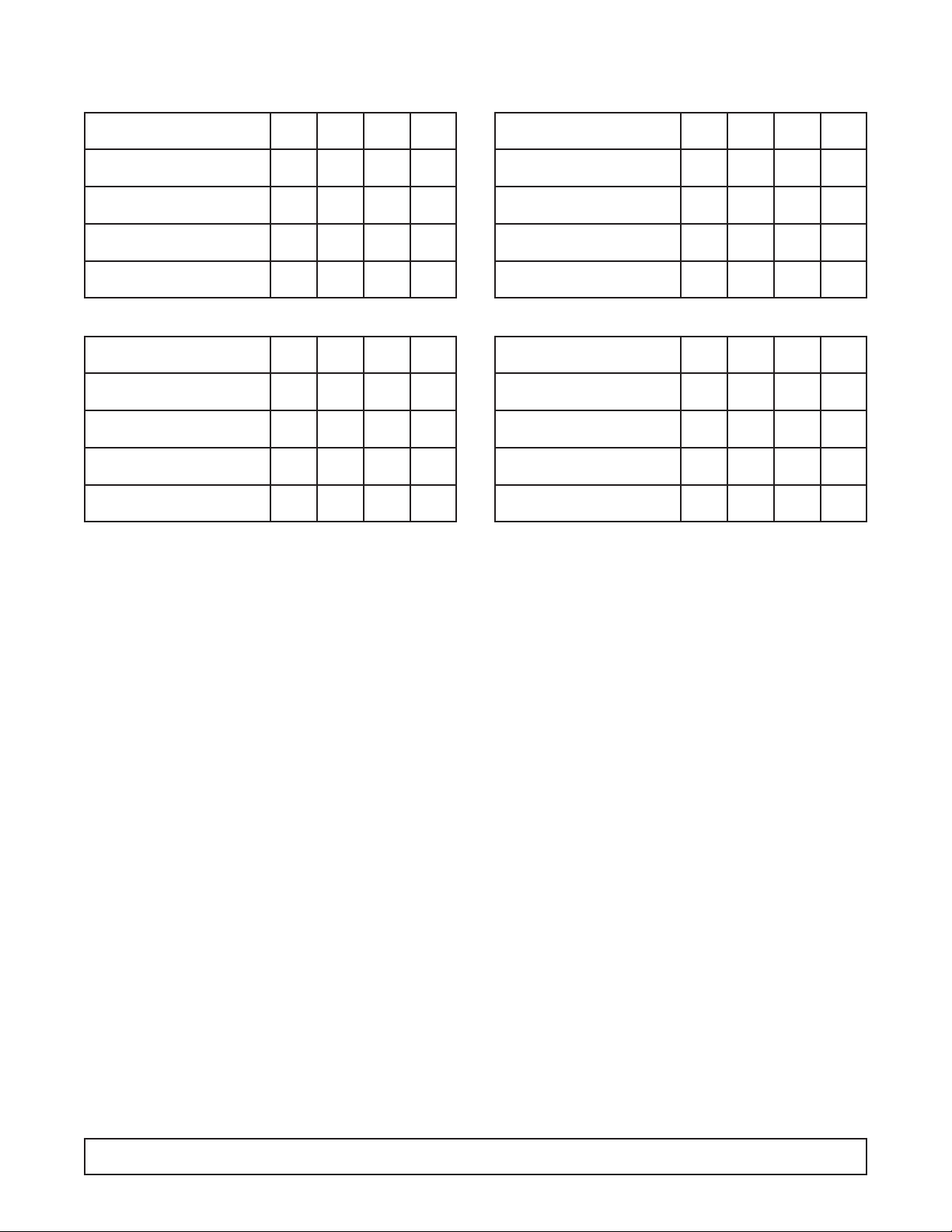

REFRIGERATION/ELECTRICAL SPECIFICATIONS

CMCT (404A)

CABINET START RUN

MODEL MFG. MODEL HP VOLTS AMPS AMPS

CMCT-4 Copeland KAGB-005E-IAA-222 1/2 115 45 8.0

CMCT-6 Copeland KAGB-005E-IAA-222 1/2 115 45 8.0

CMCT-8 Copeland KAJB-007E-IAA-222 3/4 115 59 12.0

CMCT-10 Copeland KALB-010E-CAV-221 1 230/208 33.5 8.1

REFRIGERATION CYCLE (80° Ambient)

CABINET REFRIG. DEFROST CAP. CONTROL CAVITY

MODEL CYCLE CYCLE REFRIG. OZ. TUBE SUCT. DISCH. SETTING TEMP.

CMCT-4 8.0 - 115V 6.8 - 115V 404A 22 8' x .042 ID 2# 225# No. 7 -22°F

CMCT-6 8.0 - 115V 8.4 - 115V 404A 23 8' x .042 ID 5# 223# No. 7 -19°F

CMCT-8 12.0 - 115V 12.0 - 115V 404A 27 7' x .049 ID 2# 228# No.7 -22°F

8.1 - 230V 6.7 - 230V

CMCT-10 404A 29 7' x .054 ID 2# 223# No. 7 -27°F

4.8 - 115V 4.8 - 115V

NOTE: Refer to Data plate for refrigerant type and charge.

Condenser Fan ............G.E. 5KSM51GG37845 or Temperature Control ........RANCO A10-4491-00

5KPM51BL-40466 (Reversible Motor)

230 - V.E.M.S. ESP-L35-EM2 Back Pressure Valve ............Sporlan 10# setting

CRO-4-0-20

Time Clock..............115 Paragon 145-00B (24 Hr.) CRO-6-0-60 (CMCT-10)

230V Paragon 145-20B (24 Hr.)

Page 12

INTRODUCTION 11

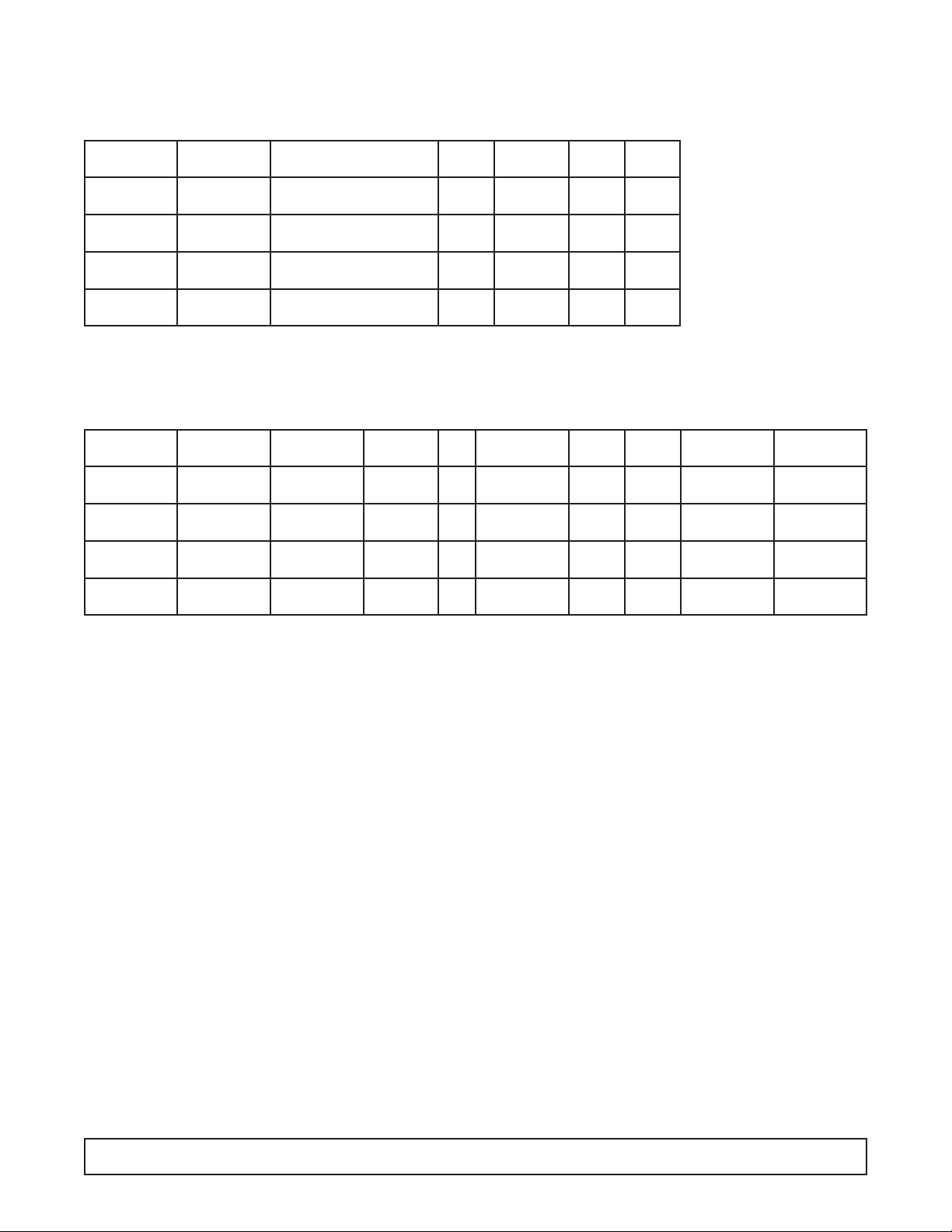

ECMCT REFRIGERATION/ELECTRICAL DATA

Export Models (R-404A)

ECMCT-4 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

72.4 582 2.7 215

of Top Coil

Control Bellows Heater below

5375 9 .04 215

Def. Controls

End Breaker Heater behind

3071.4 15 .07 215

each End Breaker

Glass Heater around

826.9 56 .26 215

Front Glass

Heated Glass Lid

41.3 14 .58 24

(each)

ECMCT-6 OHMS WATTS AMPS VOLTS

Def. Heater on Bottom side

51 904 4.2 215

of Top Coil

Control Bellows Heater below

5375 9 .04 215

Def. Controls

End Breaker Heater behind

3071.4 15 .07 215

each End Breaker

Glass Heater around

565.8 82 .38 215

Front Glass

Heated Glass Lid

26.1 22 .92 24

(each)

COMPRESSOR AMPERAGE

CABINET RUN CAP.

MODEL MFG. MODEL HP VOLTS LRA AMPS OZ. TUBE

ECMCT-4 Copeland KAJB-010E-CAV 1 200 40 8.0 20 8' x .042

ECMCT-6 Copeland KAJB-010E-CAV 1 200 40 8.0 25 8' x .042

Page 13

12 INTRODUCTION

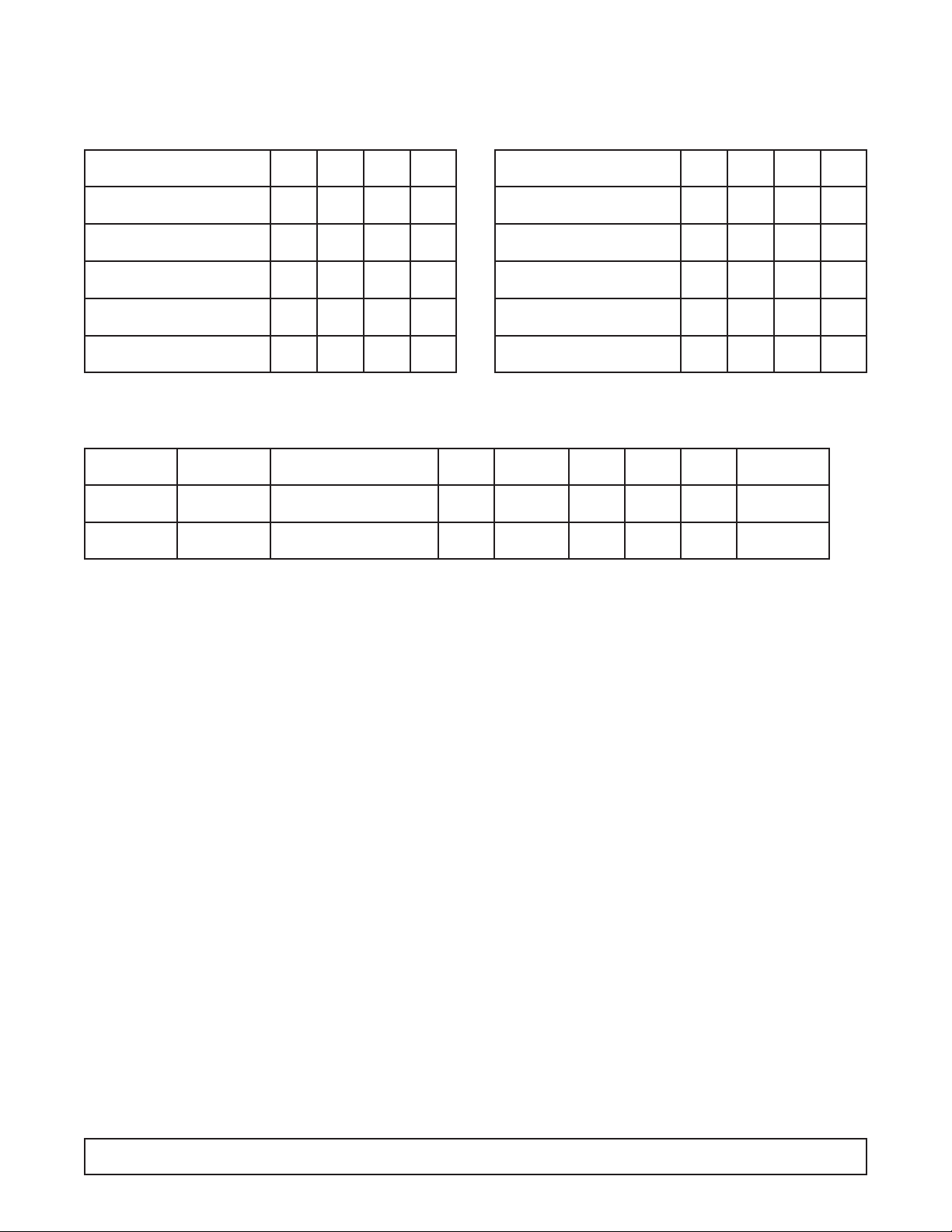

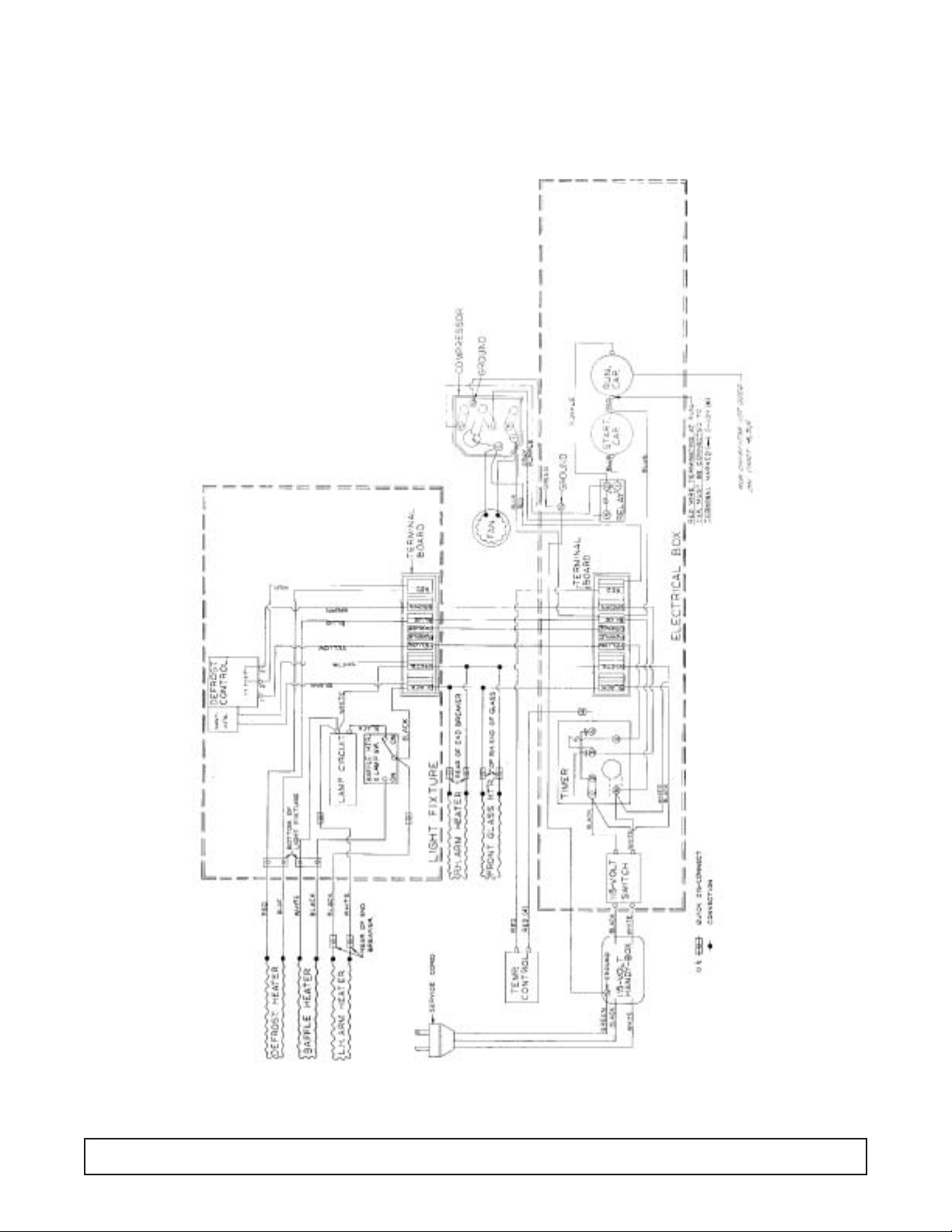

WIRING DIAGRAM – 00-1667-00

CMCT-4, 6, & 8

Page 14

INTRODUCTION 13

WIRING DIAGRAM – 00-1670-00

CMCT-10

Page 15

14 INTRODUCTION

WIRING DIAGRAM – 00-1934-00

ECMCT-4, 6, & 8 (Export Models)

Page 16

INTRODUCTION 15

LAMP WIRING DETAIL –

Upper Raceway (Typical)

Page 17

SECTION II

Maintenance & Repair

Page 18

MAINTENANCE & REPAIR 19

CABINET TEMPERATURE CONTROL

Disconnect the power supply before

servicing the cabinet.

Remove the front grill.

The control is located in the machine compartment in

the upper righthand corner, just above the electrical

box. Control settings are numbered from #1 (warmest)

to #7 (coldest) positions.

The control capillary is inser ted in a copper bulb well

just to the right of the control. The well is approximately 20" long and is secured to the cold wall evaporator.

The control reacts to the evaporator temperature which

is approximately -40°F in order to maintain a cavity

temperature of -20°F.

CAUTION:

COLD OUT NORMAL OUT NORMAL IN WARM IN

-30°F -23°F -15°F -2°F

TERMINALS: .25 QUICK CONNECT TAB

CAP TUBE LENGTH: 24"

1. Temperature Control

2. 115V Cabinet Power Switch (115V models)

3. 230V Cabinet Power Switch (230V models)

11

11

22

22

33

33

Page 19

ELECTRICAL BOX LAYOUT

Disconnect the power supply before

servicing the cabinet.

The electrical box can be accessed by removing the

front grill.

The electrical box can be pulled out for component

troubleshooting.

The following components are located within the box.

CAUTION:

1. Defrost Timer - 1/24 Hours 5. Main Terminal Board

2. Run Capacitor 6. 115V Power Supply Switch (115V models)

3. Start Capacitor 7. 230V Power Supply Switch (230V models)

4. Potential Relay

11

11

22

22

33

33

44

44

55

55

66

66

77

77

20 MAINTENANCE & REPAIR

Page 20

DEFROST TIMER LAYOUT

After the cabinet is connected to proper voltage supply,

the time clock should be set to the correct time of day

by turning the inner knob counterclockwise until the

correct time is opposite the time indicator on the clock.

The time clock is set to go into defrost once every

24 hours. This defrost occurs at midnight. Under

extreme humidity conditions it might be necessary to

add a second defrost.

MAINTENANCE & REPAIR 21

Page 21

CABINET ELECTRICAL SUPPLY

The connection points can be accessed by removing

the rear grill. Models CMCT-4 up through CMCT-8 have

115V service cords. CMCT-10 is 230V, hard wire connected.

These cabinets must be on a dedicated circuit unto themselves. Failure to do so could

result in loss of product.

Wiring and connections in power

supply system must meet all applicable (local and national) electrical codes. Consult these

codes for wire lengths and sizes prior to cabinet installation.

The wiring diagram should be consulted before

attempting any electrical service.

NOTE:

IMPORTANT:

24 MAINTENANCE & REPAIR

Page 22

This product utilizes the pull out feature on its low temperature applications.This is to aid service personnel in

the event service is needed.

Disconnect the power supply before

servicing the cabinet.

1. Remove front grill.

2. Remove two (2) hold down bolts that are located in

the front base rail. Pull unit out for service.

CONDENSING UNIT ASSEMBLY

CAUTION:

MAINTENANCE & REPAIR 23

Page 23

CONDENSING UNIT LAYOUT

24 MAINTENANCE & REPAIR

Page 24

UNIT COMPARTMENT – REAR

CMCT-10 models still use fin and tube

condensers.

NOTE:

11

11

22

22

33

33

44

44

1. Accordian Coil

2. Process Tube Evaporator

3. Suction Line

4. Cap Tube Inlet

MAINTENANCE & REPAIR 25

Page 25

EVAPORATOR TUBING ILLUSTRATION

EVAPORATOR TANK WRAP –

RH SIDE VIEW:

Evaporator inlet tube

on top row.

1. Tank Wrap Inlet

2. #2 Pass

3. #3 Pass

4. Thermostat Bulb Well

5. Condensate Drain

NOTE:

TANK WRAP – FRONT SIDE

6. #1 Pass

7. #2 Pass

8. #3 Pass

9. #4 Pass

10. #5 Pass

Upper evaporator coil

connections are on the

top, left back wall.

NOTE:

EVAPORATOR TANK WRAP –

RIGHTHAND REAR OF CABINET:

Capillary tube and heat exchange are

foamed in place. Three lines exit the

cabinet shell:

11.

1

⁄4" Process Line

12. Capillary T ube

13. Suction Line

If the capillary tube should ever become

restricted, the 1⁄4" process tube can be

substituted as an evaporator inlet.

26 MAINTENANCE & REPAIR

11

11

22

22

33

33

44

44

55

55

66

66

77

77

88

88

99

99

111100

00

111111

11

111122

22

111133

33

Page 26

NEW LUBRICANTS

In switching from refrigerant 502 to refrigerant 404A,

the compressor lubricants had to be changed. Oils

used in the compressors in the past were mineral

based. The new oils used are polyol esters. Special

consideration must be made when handling these oils.

Processing procedures must be more rigorous to avoid

absorbing moisture. Also, P.O.E.’s are better solvents

which means they will dislodge and carry debris

through a system to a far greater extent than do mineral oils. The oil used in Copeland compressor is Mobil

Artic EAL-22-CC.

MAINTENANCE & REPAIR 27

Page 27

BACK PRESSURE VALVE – #1

These models are equipped with a back pressure

valve. The purpose of this valve is to limit the suction

pressure at the compressor during initial cabinet start

up and start up after a defrost cycle.This valve is set at

10 PSIG and should not be changed.To check this

setting it is necessary that the pressure on the inlet side

or evaporator side of the valve be above 10 PSIG. Put

cabinet into defrost cycle to obtain high-low side pressure. With gauge installed on suction service valve,

check valve setting after cabinet comes off the defrost

cycle.Allow the compressor to run a few minutes before

determining correct setting. (CRO6 shown)

11

11

28 MAINTENANCE & REPAIR

Page 28

LIGHT CHANNEL ASSEMBLY – Component Identification

Disconnect the power supply before

servicing the cabinet.

Wiring from the pull out electrical box is connected via

a wiring harness to the upper lighting channel which

houses the following components:

CAUTION:

1. Product Reflector 4. Light Ballast

2. Defrost Termination Control 5. Lamp Receptable & Starter

3. Upper Terminal Board 6. Ambient T emper ature Compensator

11

11

22

22

33

33

44

44

55

55

66

66

MAINTENANCE & REPAIR 29

Page 29

BAFFLE HEATER COMPONENT IDENTIFICATION

& REMOVAL INSTRUCTIONS

1. Baffle Heater

2. Light Switch

3. Light Receptacle – Lefthand side

When light switch is ON, baffle heater

is de-energized.

NOTE:

Disconnect the power supply before

servicing the cabinet.

The baffle heater is located just behind the light fixture

at the warm air intake to coil.

The baffle can be accessed by removing screws located

at the bottom edge of V baffle.The heater is attached at

the back side of the V baffle with self-adhesive tape.

The heater resistance can be checked by unplugging

the heater at the plug-in connector on the lefthand end

of the light channel.The heater is only energized when

the light is turned OFF.

CAUTION:

11

11

11

11

22

22

33

33

30 MAINTENANCE & REPAIR

Page 30

END PANEL BREAKER & HEATER REMOVAL

Disconnect the power supply before

servicing the cabinet.

1. Remove eight (8) screws in the end panel breaker

(A) and pull breaker down and out.

2. Disconnect heater leads from end panel breaker

heater (A) and pull end panel breaker out.

3. To remove end panel breaker heater, remove tape.

CAUTION:

The heater is taped to the back side of the side arm breaker.

NOTE:

AA

AA

BB

BB

MAINTENANCE & REPAIR 31

Page 31

REFRIGERATED UPPER SECTION COMPONENT

IDENTIFICATION & REMOVAL INSTRUCTIONS

1. Defrost Heater Lead Connection 4. Defrost Heater

2. Air Baffle 5. Defrost Heater Retainer Bracket

3. Upper Fin Coil 6. Fro n t Co il Housing Cover Bracket

REMOVAL INSTRUCTIONS:

Disconnect the power

supply before servic-

ing the cabinet.

1. Disconnect the defrost heater

leads located on the lower righthand side of the lamp channel –

Figure #1.

2. Remove the air diverter shown as

Figure #2. This will expose the

defrost heater rack which is mounted to the evaporator fin coil.Heater

and rack assembly can now be

removed.

3. Reattach new heater to rack.

NOTE: Last pass of the defrost

heater must lay down in the drain

trough.

4. Reassemble in reverse order.

CAUTION:

11

11

22

22

33

33

44

44

55

55

66

66

32 MAINTENANCE & REPAIR

Page 32

UPPER CROSS SECTION – CMCT Models

Page 33

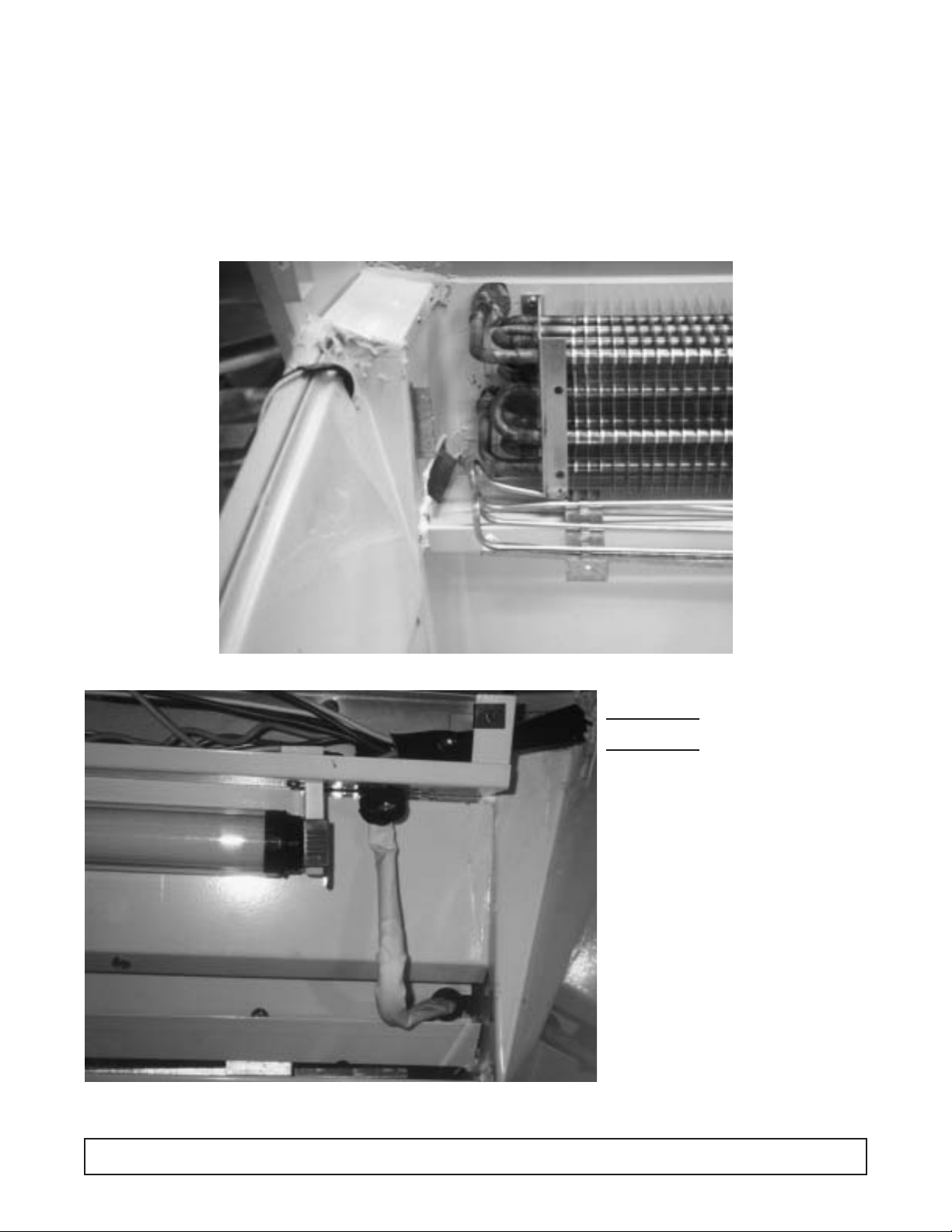

FRONT GLASS HEATER REPLACEMENT

Disconnect the power supply before

servicing the cabinet.

Photograph shows the electrical connection between

the cabinet and the front glass heater.

CAUTION:

REMOVAL OF FRONT GLASS HEATER

AND/OR END TRACK:

1. Remove glass lids.

2. Remove side arm trim (A) at both sides per detail

‘A’.

3. Remove three (3) screws in vertical trim post (F)

and pull vertical trim post forward.Typical at both

ends.

4. Remove three (3) screws in end track (B). Pull

track forward and lift up.Typical both ends. (Not

necessary for glass removal.)

5. Remove two (2) screws in the front of center

track (G) and swing center track from dotted line

position to solid line position.

6. Remove two (2) screws (one each end) on glass

rail (C) and lift glass rail straight up.

7. Pull top of front glass (D) forward and lift glass

and heater (E) up.

8. To remove end track only, execute the first four

steps.To remove front glass heater, execute the

first seven steps, omitting step number 4.

NOTE: Pay close attention to the way the heater

wire is arranged on the front glass when replacing.

34 MAINTENANCE & REPAIR

Page 34

CMCT Models

The countertop can be raised in order to service various

interior components, as shown below.

1. Product Reflector 4. Upper Electrical Component Housing

2. Defrost Heater Plug 5. Righthand Ar m Heater Leads

3. Lamp

MAINTENANCE & REPAIR 35

11

11

22

22

33

33

44

44

55

55

Page 35

EVAPORATOR COIL REMOVAL

Disconnect the power

supply before servicing

the cabinet.

A. Raise up the counter top.

B. Remove screws along the back wall

of the sub top.

C. Remove the high air intake baffle

located on the righthand side of the

sub top.

D. Remove the cabinet lids and lid rails.

E. Remove the screws that hold the

light channel to the sub top.

F. Pull the defrost ter mination bulb out

of the evaporator coil bulb well. Lift

the sub top up and out of the cabinet.

CAUTION:

1. Defrost Termination & High Limit Control 3. Defrost Heater Receptacle

2. Defrost Termination Bulb Well 4. Sub Top

G. Lift the insulation up and out of the cabinet.Do not

break.This will expose the coil housing cover.This

cover is attached by three screws, one on each

end and one at the rear on the top.

5. Upper Coil Insulation

6. V Baffle Insulation

7. V Baffle Front

36 MAINTENANCE & REPAIR

Reseal bulb well and coil cover with permagum

as shown.

8. Coil Cover

9. V Baffle Heater

NOTE:

11

11

22

22

33

33

44

44

55

55

66

66

77

77

88

88

99

99

Page 36

EVAPORATOR COIL REMOVAL – continued

10. Sub Top

11. Air Diverter

12. Defrost Termination Bulb Well

The view below illustrates the evaporator coil and

tube connections on the lefthand end of the cabinet. Take care when reinstalling the coil housing

cover. Reseal areas where moisture could migrate

down into the coil area. This coil area runs at a

temperature of -40°F.

13. Upper Coil Inlet 14. Upper Coil Outlet

MAINTENANCE & REPAIR 37

111100

00

111111

11

111122

22

111133

33

111144

44

Page 37

CMCT TROUBLESHOOTING GUIDE

The following is a guide to aid in the proper diagnosing

of service problems.

High Head Pressure & High Back Pressure

1. Air in system.

2. Defective fan motor or fan blade dragging on con-

denser shroud.

3. Defrost heater on during refrigeration cycle due to

heater going to ground or defective time clock.

4. Refrigerant over charge.

5. Blocked condenser (dirty)

Low Back Pressure & Low Head Pressure

1. Defective back pressure valve—check for proper

setting as described under “Back Pressure Valve.”

2. Shortage of refrigerant—place a temperature indicat-

ing device on outlet of top coil (lower lefthand side of

coil).Temperature should read within 3 to 4 degrees of

low side pressure taken at the compressor suction

service valve. Add gas slowly until these conditions

are obtained or remove charge with certified recovery

equipment, and recharge with correct charge.

3. Cap tube plugged due to moisture or dirt.

Pressures Normal – Cabinet Warm

1. Top coil blocked with frost—see corrective mea-

sures under “Coil Block With Frost.”

2. Refrigerant under charge. Due to the fact that it

takes a considerable amount of under charge bef ore

it has any great effect on pressures and inaccuracy

of gauges it is possible to have normal pressures

and yet have an under charge of refrigerant. This

under charge will “starve” the top coil and seriously

affect cabinet temperature. To determine correct

charge see #2 under “Low Back Pressure … .”

Coil Blocked With Frost

1. Bad timer or timer motor.

2. Bad drafts in store caused by heating or air condi-

tioning fans; cabinet located too close to door.

3. Defective defrost heater.

4. Defective defrost terminating thermostat, safety

thermostat or defective solenoid in time clock.

4. Either of these (#4) can keep the cabinet from going

through a defrost cycle.The defrost ther mostat (see

wiring diagram) should be in open position between

terminals 1 & 2 when the cabinet goes into defrost.

4. After the coil reaches 76°F, it closes, energizing a

solenoid in the time clock which in turn trips the time

clock mechanism off defrost.Should this thermostat

be in the closed position when the clock trips into

the defrost cycle, it will immediately trip it off again.

(NOTE: Switch between terminals 1 & 2 will not

open until thermostat drops below 59°F).

4. If the solenoid in the clock is stuck closed (plunger

up), it will have the same effect.To deter mine which

is at fault, remove the wire from X on the clock and

turn clock dial into defrost cycle; if cabinet goes into

defrost, it is the defrost thermostat that is bad. If it

still does not go into defrost, remove clock and

inspect the plunger of the solenoid coil.

5. Defective safety thermostat.

5. This thermostat has a SPDT switch with one side

wired in series with the defrost heater. Contacts

between terminals 2 & 3 should be in the closed

position during the refrigeration cycle. Its only purpose is, in case of failure of the defrost timer during

the defrost cycle, it will open the heater circuit when

the coil reaches 76°F, preventing any ov er heating of

the defrost heater.

5. If this thermostat is in the open position when the

cabinet goes into the defrost cycle, the heater will

remain off. For access to thermostat connections to

check continuity, refer to wiring diagram. Disconnect

this thermostat and check with ohmmeter.

5. If for any reason the temperature termination feature

is inoperative, the fail safe settings on the timer

should be set for 30 minutes defrost time.

Defrost Cycle Too Long – Terminating On

Fail Safe (Heater On)

1. Bad solenoid in time clock (opening winding).

1. If there is an open circuit in the coil of this solenoid,

it will not trip the time clock off defrost when the thermostat closes. The cabinet will stay on defrost for

the length of time the fail-safe le v er on the time cloc k

is set. (Factory set at 40 minutes.)

2. Defrost terminating thermostat not closing when coil

reaches 76°F.

To determine which is at fault, turn clock into defrost,

place jumper across X and N on clock. If solenoid is

good, this will trip the clock off defrost indicating that it

is the defrost thermostat that is at fault.

Be certain that the defrost thermostat has

reached 76°F before determining that either

the solenoid coil or the thermostat is defective.

NOTE:

38 MAINTENANCE & REPAIR

Page 38

SECTION III

Parts List

Page 39

CABINET EXTERIOR PARTS IDENTIFICATION

CMCT Models

1. Vertical Trim Post (RH) 6. Center Track 11. Nameplate

2. End Track (LH) 7. Glass Lid 12. Front Bumper

3. Countertop 8. Glass Rail 13. Bumper Trim

4. End Trim 9. Front Glass 14. Front Tr im Panel – Upper

5. Lighted Sign 10. Front Tr im Panel – Lower 15. Front Grill

PAR TS LIST 41

Page 40

DOMESTIC CMCT PARTS LIST – R-404

42 PARTS LIST

Parts List - CMCT's

Description CMCT-4 CMCT-6 CMCT-8 CMCT-10

Compressor 16-0322-00 16-0322-00 16-0323-00 16-0324-00

Start Relay 17-0163-00 17-0163-00 17-0163-00 17-0167-00

Start Capacitor 17-0164-00 17-0164-00 17-0165-00 17-0168-00

Run Capacitor 17-0166-00 19-2678-00

Condenser Coil 51-0709-02 51-0709-02 51-0709-03 18-0533-00

Fan Motor 19-0933-00 19-0933-00 19-0933-00 19-0304-00

Fan Blade 19-0101-00 19-0101-00 19-0101-00 19-0706-00

Drier/ Filter 18-1109-00 18-1109-00 18-1109-00 18-1109-00

Heat Exchanger 50-1106-01 50-1106-01 50-1106-03 50-1109-00

CRO Valve 18-0365-00 18-0365-00 18-0365-00 18-0315-00

Capillary Tube 14-2402-00 14-2402-00 14-2405-00 14-2403-00

Evaporator Coil 18-0079-06 18-0079-08 18-0079-10 18-0009-07

Heater, Defrost 19-1243-01 19-1243-03 19-1243-05 19-1243-06

Thermostat, Defrost Term 19-0833-00 19-0833-00 19-0833-00 19-0833-00

Heater, Front Glass 19-0231-01 19-0231-03 19-0231-05 19-0231-06

Heater, Baffle 19-0235-07 19-0235-09 19-0235-11 19-0235-12

Heater, End Breaker 19-0853-00 19-0853-00 19-0853-00 19-0853-00

Thermostat, control 19-0190-00 19-0190-00 19-0190-00 19-0190-00

Switch, Power 19-0103-00 19-0103-00 19-0103-00 19-0103-00

Time Clock 24-0513 24-0513 24-0513 19-0624-00

Service Cord 19-0620-00 19-0620-00 19-0620-00

Switch, Light 19-0133-00 19-0133-00 19-0133-00 19-0133-00

Ballast, Lamp 30 Watt 19-0458-00 19-0458-00 19-0458-00 19-0458-00

Ballast, Lamp 20 Watt 19-0146-00

Lamp, Fluorescent 30 Watt 19-0150-00 19-0150-00 19-0150-00 19-0150-00

Lamp, Fluorescent 20 Watt 19-0149-00

Lamp, Fluorescent 34 Watt 19-0151-00

Lampholder 19-0142-00 19-0142-00 19-0142-00 19-0142-00

Lampholer w/Starter Socket 19-0143-00 19-0143-00 19-0143-00 19-0143-00

Lamp Starter, 30-40 watt 19-0145-00 19-0145-00 19-0145-00 19-0145-00

Lamp Starter, 20 watt 19-0144-00

Track, LH End 08-0161-01 08-0161-01 08-0161-01 08-0161-01

Track, RH End 08-0161-02 08-0161-02 08-0161-02 08-0161-02

Track, Center 08-0190-00 08-0190-00 08-0190-00 08-0190-00

Track, Lid Slide 10-0200-00 10-0200-01 10-0200-02 10-0200-03

Bumper, Front 08-0165-01 08-0165-03 08-0165-05 08-0165-06

Trim, Front Bumper 10-0936-01 10-0936-03 10-0936-05 10-0936-06

Rail, glass 08-0168-01 08-0168-03 08-0168-05 08-0168-06

Post, Vertical Trim LH 08-0518-01 08-0518-01 08-0518-01 08-0518-01

Post, Vertical Trim RH 08-0518-02 08-0518-02 08-0518-02 08-0518-02

Trim, side Arm 10-0935-00 10-0935-00 10-0935-00 10-0935-00

Breaker, End Panel LH 10-0094-01 10-0094-01 10-0094-01 10-0094-01

Breaker, End Panel RH 10-0094-02 10-0094-02 10-0094-02 10-0094-02

Handle, Lid 10-0218-01 10-0218-03 10-0218-05 10-0218-06

Front Grill 50-4192-04 50-4192-04 50-4192-04 50-4192-04

Glass, Front 20-0008-01 20-0008-03 20-0008-05 20-0010-00

Lid Assy, Glass 50-1756-07 50-1756-09 50-1756-11 50-1756-12

Glass, Lid 20-0047-01 20-0047-03 20-0047-05 20-0047-06

Counter Top 12-0522-01 12-0522-03 12-0522-05 12-0522-06

Page 41

EXPORT CMCT PARTS LIST – R-404

PAR TS LIST 19

Export Parts List - CMCT's

Description ECMCT-4 E CMCT-6 ECMCT-8

Compressor 16-0298-00 16-0298-00 16-0290-00

Start Relay 17-0167-00 17-0167-00 17-0167-00

Start Capacitor

Run Capacitor 19-2678-00 19-2678-00 19-2678-00

Condenser Coil 51-0709-03 51-0709-03 51-0709-03

Fan Motor 19-0501-00 19-0501-00 19-0501-00

Fan Blade 19-0101-00 19-0101-00 19-0101-00

Drier/ Filter 18-1109-00 18-1109-00 18-1109-00

Heat Exchanger 50-1106-02 50-1106-02 50-1106-03

CRO Valve 18-0365-00

Capillary Tube 14-2402-00 14-2402-00 14-2405-00

Evaporator Coil 18-0079-06 18-0079-08 18-0079-10

Heater, Defrost 19-0891-01 19-0891-03 19-0891-05

Thermostat, Defrost Term 19-0833-00 19-0833-00 19-0833-00

Heater, Front Glass 19-0890-01 19-0890-03 19-0890-05

Heater, Baffle 19-0907-01 19-0907-03 19-0907-05

Heater, End Breaker 19-0893-00 19-0893-00 19-0893-00

Thermostat, control 19-0190-00 19-0190-00 19-0190-00

Switch, Power 19-0103-00 19-0103-00 19-0103-00

Time Clock 19-0864-00 19-0864-00 19-0864-00

Service Cord 19-0620-00 19-0620-00 19-0620-00

Switch, Light 19-0133-00 19-0133-00 19-0133-00

Ballast, Lamp 30 Watt 19-0911-00 19-0911-00 19-0911-00

Ballast, Lamp 20 Watt 19-0912-00 22-0200

Lamp, Fluorescent 30 Watt 19-0150-00 19-0150-00 19-0150-00

Lamp, Fluorescent 20 Watt 19-0149-00

Lamp, Fluorescent 34 Watt 19-0151-00

Lampholder 19-0142-00 19-0142-00 19-0142-00

Lampholer w/Starter Socket 19-0143-00 19-0143-00 19-0143-00

Lamp Starter, 30-40 watt 19-0145-00 19-0145-00 19-0145-00

Lamp Starter, 20 watt 19-0144-00

Track, LH End 08-0161-01 08-0161-01 08-0161-01

Track, RH End 08-0161-02 08-0161-02 08-0161-02

Track, Center 08-0190-00 08-0190-00 08-0190-00

Track, Lid Slide 10-0200-04 10-0200-05 10-0200-06

Bumper, Front 08-0165-01 08-0165-03 08-0165-05

Trim, Front Bumper 10-0936-01 10-0936-03 10-0936-05

Rail, glass 08-0168-01 08-0168-03 08-0168-05

Post, Vertical Trim LH 08-0518-01 08-0518-01 08-0518-01

Post, Vertical Trim RH 08-0518-02 08-0518-02 08-0518-02

Trim, side Arm 10-0935-00 10-0935-00 10-0935-00

Breaker, End Panel LH 10-0094-01 10-0094-01 10-0094-01

Breaker, End Panel RH 10-0094-02 10-0094-02 10-0094-02

Handle, Lid 10-0218-01 10-0218-03 10-0218-05

Front Grill 50-4192-04 50-4192-04 50-4192-04

Glass, Front 20-0008-01 20-0008-03 20-0008-05

Lid Assy, Glass 50-1756-07 50-1756-09 50-1756-11

Glass, Lid 20-0047-01 20-0047-03 20-0047-05

Counter Top 12-0522-01 12-0522-03 12-0522-05

Loading...

Loading...