Page 1

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS .............................. 1

INTRODUCTION ..................................................... I

DESCRIPTION AND USAGE .................................... 1

INSTALLATION ...........................................................5

COMMONLY ASKED QUESTIONS .........................7

MAINTENANCE OF CELLS ........................................8

TROUBLESHOOTING ........................................8

PARTS LIST ....................................................11

SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be hazardous due

to mechanical and electrical components. Only trained and

qualified personnel should install, repair, or service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning and replacing air filters. All other operations must be

performed by trained service personnel When working on this

equipment, observe precautions in the literature, on tags, and on

labels attached to or shipped with the unit and other safety

precautions that may apply Follow all safety codes. Installation

must be in compliance with local and national building codes

Wear safety glasses, prolecfive clothing, and work gloves. Have

fire extinguisher available Read these instructions thoroughly and

follow all wamlngs or cautions included in literature and attached

to the unit.

Recognize safety information. This is the safety-alert symbol Z_ ..

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury

Understand these sigmal words; DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identities the most serious hazards which will res_ait in

severe personal injuu¢ or death. WARNING signifies hazards

which could result in pemonal injury or death.. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

INTRODUCTION

These instructions cover the installation, operation and

maintenance of an EACB Electronic Air Cleaner

This electronic air cleaner is technically known as a two-stage

electrostatic precipitator. The air cleaner is designed to remove

airborne particulates, including dust, dirt, smoke, pollen, virus,

spores, bacteria and mold, from indoor air Air movement through

the unit is provided by the heating, air conditioning or ventilating

system blower As dirty air enters the air cleaner, the air passes

through a metal mesh prefilter The prefilter prevents lint, pet hair

and other large particulates from entering the air cleaner It is

important that these filters be in place to prevent excessive dirt

loading of the air cleaner collector cells These filters extend the

time between maintenance of the air cleaner collector cells_ This

allows the ionizing-collector cells to provide clean air for a longer

period between washings The prefiltered air then passes through a

two-stage Electronic Air Cleaner In the first stage, all airborne

particulate, even _bmic'ron size, are electronically charged

(,positive) as they pass through the ionizer The ionizer field is set

up by a corona discharge emanating from the fine, tightly strung

wires suspended between two adjacent flat plates In the second

stage, the charged particulate passes through an intense electrical

field established between alternately charged and grounded parallel

collector plates. Here, the positively charged particulate is attracted

to the negatively ground plates and removed from the air stream

DESCRIPTION AND USAGE

Unit Specifications

This air cleaner is easy to install, operate, and maintain See Fig. 1

for EACB assembly See Table I and Fig 2 for unit specifications.

pOWI_ FI_P_Y ASS_IBLY

P_R TFIAY

Fig. 1 - Unit Assembly

COVER _

CELL

Page 2

Table 1 - Unit Specifications

I

MODEL NO, EACBA_--O014 EACBA---0020 I EACBA---1614 EACBA---2020 EACBB---2020

AirflowSensor

Factory lnstaIled YES YES YES YES YES

Electrical Input 120v, 60Hz, 1 PH 120v, 60Hz, 1 PH 120v, 60Hz, 1 PH 120%60Hz, I PH 240v, 60Hz, 1 PH

Electrical Power Cord 6' / 1.8 p LHngth 6' l 1..8p LI-pgth 6' / t 8 p 14-1ngth 6' / t .8 p Li-pgth 6' t I 8 p 14_gth

Maximum Rated Airflow (2380 m3thr) (3400 m3[hr) (2282 m3Lhr) '2720-3400 m3Lhr) i (2720- 3400 m3Lhr)

Maximum Pressure Drop @ @ @ @ @

Cell t eight (2 per unit)

Unit t eight

Maximum Power Consumption

Electrical output

ApprovalsLCertJfications

Dimensions 20 x 7-1L4 x 25 20 x 7-1L4 x 21 - 1L4 21-_ 2I -31.8

Pressure drop at 2000 CFM Filler ef_c]ency ts ross than peak at this higher a_d]o_ Refer to the Efficiency and Pressure Drop Performance chad below for

differentapplications

1400 CFM 2000 CFM 1350 CFM 1600-2000 CFM* [ 1600-2000 CFM*

11 in. wg 14in. w.g 141n. wg .11-.22[n. wg. 11- 22in wg

1400 CFM 2000 CFM 1350 CFM !600-2000 CFM* 1600-2000 CFM*

10 lbs each 12 tbs each 7 Ibs each 9 lbs each 9 lbs each

(4 54 kg) (545 kg) (3 2 kg) (4.08 kg) (4 08 kg)

32 [bs 38 Ibs 29 tbs 30 Ibs 30 lbs

(14.8 kg) (164 kg) (13 2 kg) (13 6 kg) (136 kg)

40 t atts 48 t arts 40 t arts 40 t arts 40 t arts

2,5 mADC 3.2 rnADC 2.5 reADe 2.5 rnADC 2.5 rnADC

6200 kVDC 6200 kVDC 8200 kVDC 6200 kVDC 6200 kVDC

c UL us c UL us c UL us c UL us c UL us

24-1L2 x 7-1L4 x 25 24-112 x 7-1L4 x 24-112 x 7-1L4 x

100%

SD

80

L

70

60

5O

CFM

A

PRESSURE DROP

IN WD

The EACB basic components are:

Cabinet

Mounts to existing ductwork; houses the ionizing-collecting cells

and prefilters,

Ionizing-Collector Cells

Collect the dust, dirt, and other particulates in the air, They contain

the ionizing and collecting sections The cells must be installed

with ionizing wires on the air intake side_ A ,spring contact is

located on the top of each cell and must be in position to make

C 002

D

c ig. 2 = bfficiency and P_=sure a top Performance

Lo

o 224

007 011 0t5 --

006 -- 011 -- -- --

004 _ 0e7 -- -- e14

A EACB-2020

B EACB-1614

c EACB-OO14

D EACB-OO20

contact with the contact board assemblies on the bottom of the

power tray assembly

Prefilters

Trap large p;_licalates before it enters the ionizing-collector cells

Power Tray Assembly

Contains the indicating light, solid state power supply, contact

boards and electrical controls including ON/OFF switch, airflow

sensor and safety interlock switch_ A power cord at the rear of the

tray allows the unit to be connected to a standard 120-v or 240-v

outlet (see voltage of your EACB unit) A wiring compartment is

-- m

'D

A089t4

Page 3

providedattherearofthe tray allowing the option to permanently

wire the unit directly to a furnace control,

AirFlow Sensor (AFS)

This part controls the operation of the unit by sensing the

movement of air within the duct This helps to reduce power usage.

How to Identify Which Air Cleamer Model You Own

The model number and serial number for your Electronic Air

Cleaner can be found on the data label located on the inside of the

access door

Facts You Should Know About Your New

Electronic Air Cleaner

Dus_g and "Whi_usW

Your new Electronic Air Cleaner will efficiently clean and filter

your household air. Unfortunately, it will not eliminate the need for

regular dusting of your furniture and belongings. Due to the design

of all duct-mounted air cleaners, they can only clean the air that

reaches tbe air cleaner.. Therefore, if the particulates are not being

carried to the air cleaner in the air _tream, the air cleaner cannot

remove them from your home Occasionally a "white dust" may be

noticed in bedrooms or newly furnished rooms. This is mainly

composed of lint which, because it is heavier than other

particulates, settles before it reaches your unit_ This "white dust" is

not mixed with airborne dirt particles, therefore, it is clean and has

no staining or soiling properties.. However, running the furnace

blower continuously, day and night, will help reduce this from

occurring.

Ozone

Under normal operating conditions all Electronic Air Cleaners

produce minute quantities of ozone as an incidental by-product._ In

fact, all electronic products, such as televisions, cordless phones

and refrigerators, produce some amount of ozone. The average

homeowner can detect the smell of ozone concentrations as low as

25 to 100 ppb (parts per billion) The design of this unit hag been

tested and ozone production is approximately half of the published

permias_le limits established by the Environmental Protection

Agency.. These limits recommend that the concentration of indoor

ozone not exceed 50 ppb.. Ozone is not harmful in these

concentrations. In fact, the ozone level in major cities can

sometimes reach as high as 100 ppb on a summer day. The

addition of optional charcoal after-filters can help reduce this

Normally, a new unit will produce more ozone than one that has

been in operation for several weeks.. This is due to sharp comers or

manufacturing burrs on the ionizing-conecting ceil(s) and is

normal. As the Electronic Air Cleaner arcs _md zaps, the voltage is

vaporizing these areas and tends to round them off This is part of

the breaking-in period of ownership and the issue is

self-correcting Also, high-altitude locations can be more

susceptible to noticing the presence of ozone. An

ionizing-collecting cell that has been damaged or bent (the

designed Macing between electrically charged and ground

components has been decreased) may also produce an abnormal

amount of ozone_

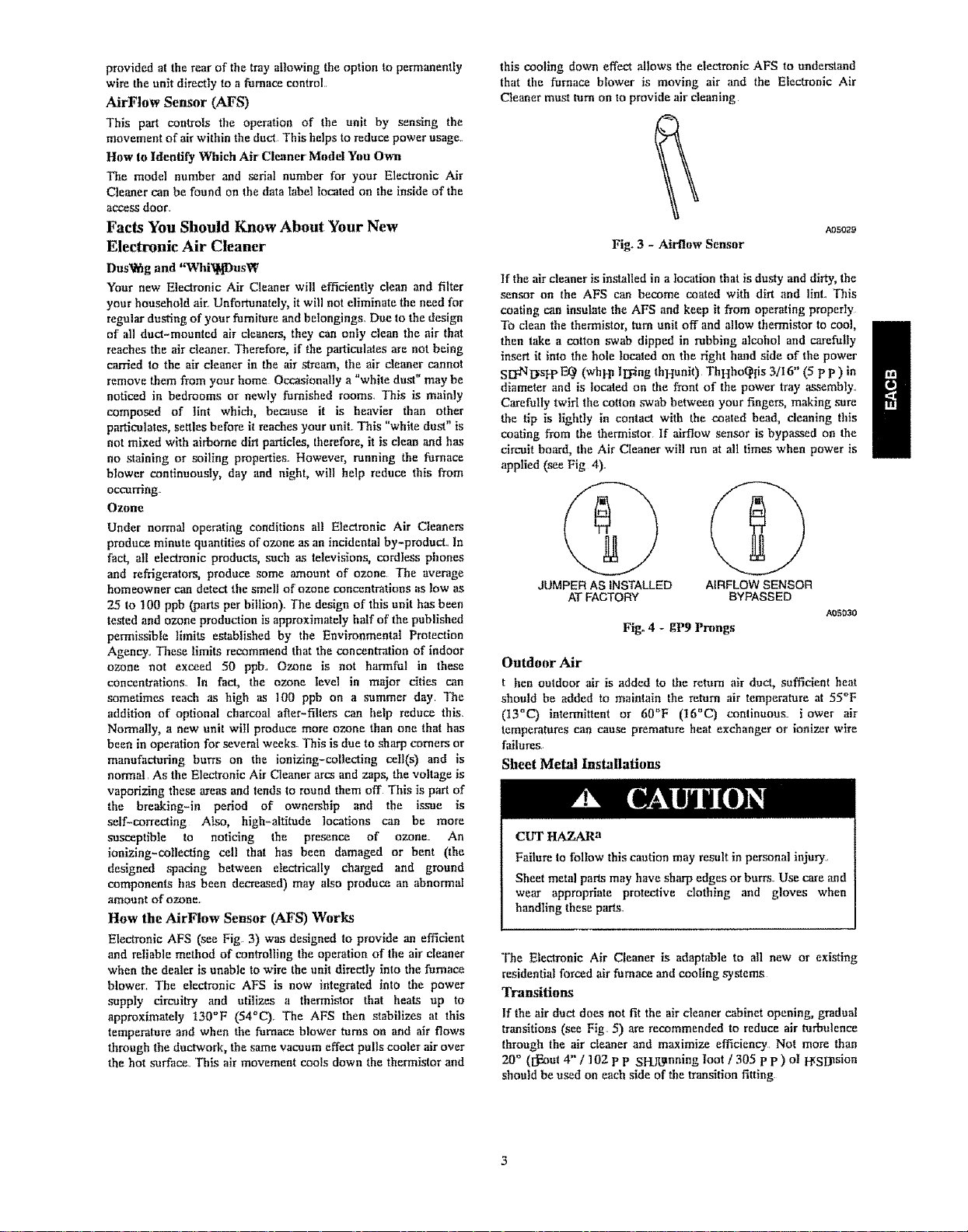

Hew the .'MrFlow Sensor (AFS) Works

Electronic AFS (see Fig 3) was designed to provide an efficient

and reliable method of controlling the operation of the air cleaner

when the dealer is unable to wire the unit directly into the furnace

blower. The electronic AFS is now integrated into the power

supply circuitry and utilizes a thermistor that heals up to

approximately 130°F (54_C). The AFS then stabilizes at this

temperature and when the furnace blower tams on and air flows

through the ductwork, the same vacuum effect pulls cooler air over

the hot surface. This air movement cools down the thermistor and

this cooling down effect allows the electronic AFS to understand

that the furnace blower is moving air and the Electronic Air

Cleaner must turn on to provide air cleaning

A05029

Fig. 3 - AJrflow Sensor

If the air cleaner is installed in a location that is dusty and dirty, the

sensor on the AFS can become coated with dirt and lint.. This

coating am insulate the AFS and keep it from operating properly

To clean the thermistor, tam unit off and allow thermistor to cool, 1

then take a cotton swab dipped in rubbing alcohol and carefully

insert it into the hole tocaled on the right hand side of the power

S[2dqt_sl-p E_ (whhn ll2_ing thHunit)ThHho_liS 3/I6" (5 p p ) in

diameter and is located on the front of the power tray assembly..

Carefully twirl the cotton swab between your fingers, making sore

the tip is lightly in contact with the coated bead, cleaning this

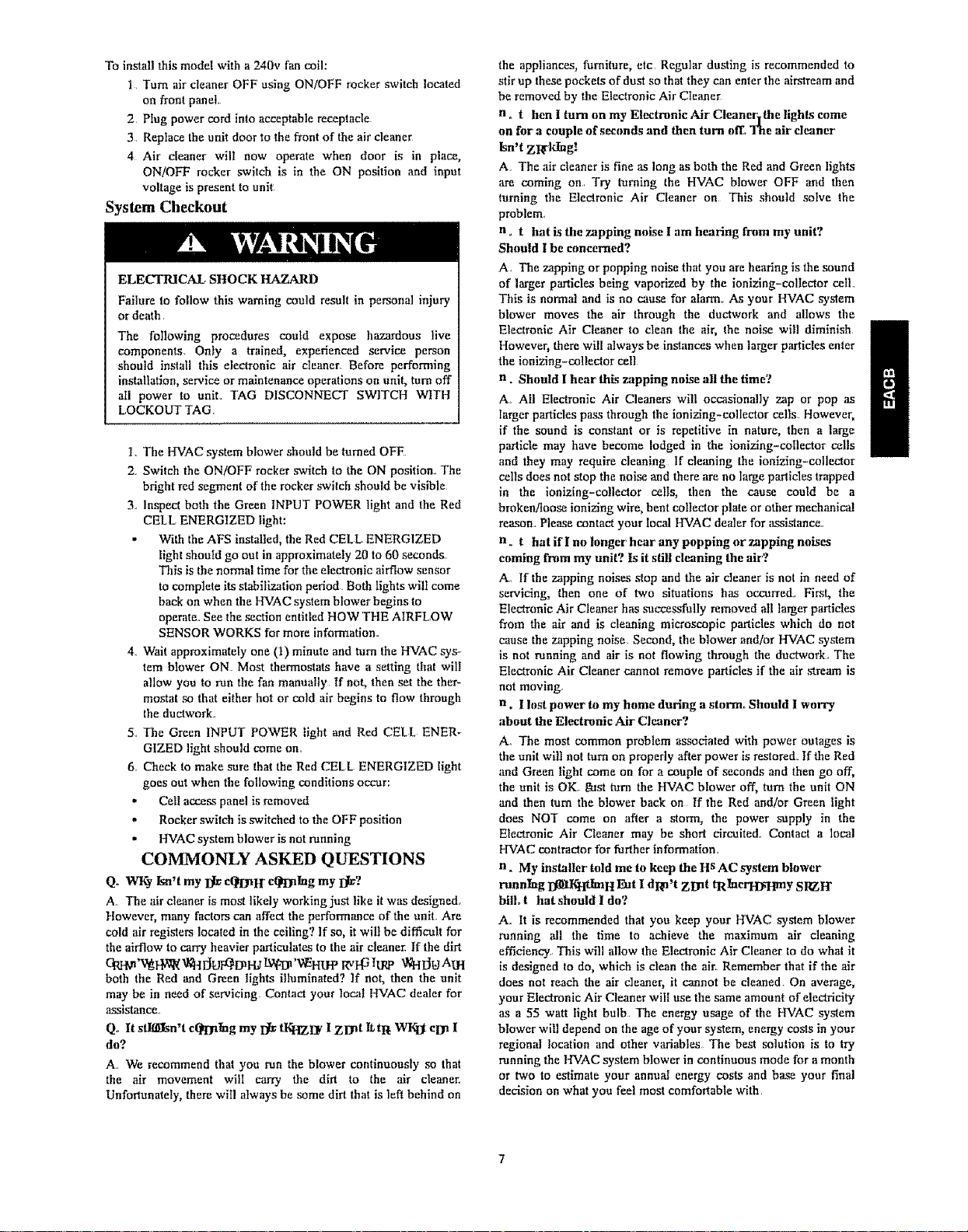

coating from the thermistor If airflow sensor is bypa_ed on the

circuit board, the Air Cleaner will run at all times when power is

applied (see Fig 4),

JUMPER AS INSTALLED

AT FACTORY

Fig. 4 - gP9 Prongs

AIRFLOW SENSOR

BYPASSED

AOSOaO

Outdoor Air

t hen outdoor air is added to the return air duct, sufficient heat

should be added to maintain the return air temperature at 55°F

(t3°C) intermittent or 60'_F (16"C) continuous lower air

temperatures can cause premature heat exchanger or ionizer wire

failures.

Sheet Metal Installations

CUT HAZARa

Failure to follow this caution may result in personal injury..

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing and gloves when

handling these pnrts.

The Electronic Air Cleaner is adaptable to all new or existing

residential forced air fumaca and cooling systums

qPransitions

If the air duct does not fit the air cleaner cabinet opening, gradual

transitions (see Fig. 5) are recommended to reduce air turbulence

through the air cleaner and maximize efficiency Not more than

20 ° ([_ut 4" / 102 p p SHJLanning loot / 305 p p ) o! FFSD_sion

should be used on each side of the transition fitting

/

Page 4

/

MAX 4"/102 mm DROP --

PER LINEAL 12"1305mm

AIR FLOW

2

AIR FLOW

CC3

"_"'_FURNACE

AIR

CLEANER

OPENING

ZZCZ

A_RCLEANER

TRANSITION SECTION

Fig. 5 - Transition to Unit

Turning Vanes

If the air cleaner is installed adjacent to a 90 ° duct elbow, add

turning vanes (see Fig. 6) inside the duct to improve air

distribution across the face of the air cleaner, Failure to follow this

recommendation can reduce the efficiency of the Electronic Air

Cleanet_

TURNIN G VANES

Fig, 6 - Turning Vanes

OPENING

FURNACE

A07sa?.

002038

Select Location for Air Cleaner

Remember to select a location that is readity access_le for periodic

inspection and cleaning of this air cleaner, Allow a minimum of

24" (610 ram) FtearanFe in IrRnt and 12" (305 ram) !_earanFe

above the air cleaner for component removal and service space

Planning the Installation

Application

Air cleaners are used in Iorced air heating cooling and ventilating

systems The air cleaner should be installed in the system so that all

the system air is circulated through the air cleaner The air cleaner

will only remove the airborne contaminants delivered to it,

Maximum performance is obtained when the system blower is set

for continuous operation

Installation Requirements

The best location for the air cleaner is in the return air duct next to

the blower compartment, In this location, the blower molor and

cooling coils will be kept clean.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this caution may result in reduced airflow

and potential operating problems

a o not install the air cleaner in the diseharge air duct

Before instaning the air cleaner, consider the application and type

of e VAC sy_em present, See Fig, 7 for the most common types, If

a transition between the ductwork and air cleaner is required, refer

to section entitled Transitions and Fig 5,, The unit must be readily

access_le for periodic inspection and cleaning of the prefilters and

electronic cells to maintain maximum efficiency and trouble-free

operation,

Air Conditioning

The air cleaner should be installed upstream of the cooling coil

This will keep the coil clean and reduce air conditioning coil

maintenance Improved cooling efficiency is the result and directly

affects energy costs A clean coil will reduce utility costs.

Humidifiers

An evaporative humidifier can be mounted upstream of the air

ctcanem, It is best to install an atomizing humidifier downstream of

the air cleaner because hard water salt deposiL_ and water droplets

may damage the air cleaner

UP_iL.OW F'_RN,K_

UPFLOW FURNACE UPFLOW FU_HAC_

_R FLGW

DO_FT_

/L98179

Fig. 7 - Typical Installations

4

Page 5

If an atomizing humidifier must be mounted upstream of this air

cleaner:

I Mount it as lar upmream as poss_le (recommended 6'/2m

minimum)

2 Install a standard di.cposable furnace filter between the

humidifier and the air cleaner to trap water droplets and

hard water salts

3 Clean the air cleaner more frequently to prevent a hard

water salt buildup

Direction of Airflow Through the Air Cleaner

This air cleaner is set up for left to right airflow when you are

facing the access door Cor right to left airflow, follow these

directions:

l, Oemove the prefilter(s) and cells from the cabinet., A plastic

positioning spacer is located inside the bottom of the

cabinet This spacer (see Cig 8) is secured to the cabinet

using a #6-32 round head rrhillips drive thread cutting

screw to assure installation of tile cells in the proper position

with respect to airflow.

20emove the screw and reposltion the spacer in the alternate

hole at the bottom of the cabinet

AOS2_S

Fig. 8 - Plastic Positioning Spacer

3. O eplace the screw to insure the plastic spacer is not

aceidentaIly knocked out of place during normal

maintenance It must be in.ailed in the hole provided

closest to the air leaving side of the cabinet. Peal the unused

hole with duct tape

4, Oemove the cell handle and reatlach to the opposite end of

the cell. Turn cells around, replace in cabinet and replace

prefiltars on the air entering side. The directional arrows on

the cel! end plates must point in the direction of airflow

INSTALLATION

This blectronic Air Cleaner _an be installed in any position, except

with the access door facing down Cig 7 shows examples of proper

air cieaner mounting with a variety of furnace installations

ELECTRICAL SHOCK HAZARD

eailure to follow this warning could result in personal injury

or death

The following procedures could expose hazardous live

components I nly a trained, experienced service person

should install this electronic air cleaner Before performing

installation, service or maintenance operations on uniL tam off

all power to unit TAd a IPCI NNbCr Pt 1TC e t IT e

il CKt rTTAd

ELECTRICAL SHOCK HAZARD

Cailure to follow this warning could r_'ult in personal injury

or death.,

The power mapply should be removed before installation To

remove the power supply, remove the two (2) screws in the top

front of the cabinet Oemember to keep this hardware for

reinstallation of the power supply when the air cleaner

installation is _mplete.

Prior to installing this product:

] Ocad rules and instructions carefully for safe operation

Cailure to follow them could damage the product or cause a

hazardous condition.

2 Check the ratings given on the product to make sure it is

suitable for your application.,

3 Pelect a location for the air cleaner,

40emove the old furnace filter and discard

5 The air cleaner cannot remove existing dirt from the blower

and ducts Clean the area thoroughly before you begin

60emove unit access panel, and slide the prefilters and

ionizing-collecting cells out of the cabinet, trlace them

safely aside for later use.

NOTE: The following is a typical installation of the air cleaner on

a upflow furnace, You may have to alter the installation to fit your

particular application,

Installation of the EAC

ELECTRICAL SHOCK HAZARD

Cailureto follow this warning could result in personal injury

ordeath,

The following procedures could expose hazardous live

components, t nIy a trained, experienced service person

should install this electronic air cleaner Before performing

installation, service or maintenance operations on unit, turn off

all power to unit TAd a tPCI NNbCT pt ITC e t ITe

il CKI rTTAd.

1. iocate the cabinet in the cold air return duct so that all of

the return air flows through the unit. If the furnace and air

cleaner openings are different, use a transition

2, Mounting holes are provided for ductwork attachment, The

,140" Koles (see) ig. 9) are sized lot #8 skeet metal screws,

Page 6

or1/8"rivets.Ifthe adjoining ductwork is flanged, install

the screws so that the screw heads are inside the cabinet

This will prevent damage to the prefiIters and optional

charcoal after-filler during removal and installation after

cleaning.

MOUNTtNG HOLES

AO7883

Fig. 9 - Mounting Hole Location

3. Alter tile unit has been secured I seat seams air tight with foil

tape or caulking

4. a etermlne direction of airflow and make any changes

necessary.

5, f_nstall prefilters and ionizer-collector ceils.

6. OeinstaIl power tray assembly into the cabinet

7., Oeinstat! unit access panet

ELECTRICAL INSTALLATION

Wiring Procedure

This air cleaner is powered by plugging the power cord into an

acceptable receptacle (see c [g, 1O)

W BL I g_[_tY_41_ff_S't-tf_t

3 5_ V,_ 5_Tran_e_

--- @

AO7Bt4

Fig., 10 - Typical Wiring Diagram

1.. Turn air cleaner I ec using I k ,q ec rocker switch located

on front panel.

2. Plug power cord into acceptable receptacle

3. o eplace the unit door to the front of the air cleaner

4. Air cleaner will now operate when door is in place I

I k/l cc rocker switch is in the I k position and inpuf

voltage is present to unit

Furnace Application

Acs will turn unit on when airflow is sensed. Air cleaner should

only operate when blower motor is running. The unit will also

operate normally if the air cleaner is hard wired directly to the

furnace control board To bypass the airflow sensor install the

jumper on the _9 prongs as shown in Cig 4 k ow theI air cleaner

will mn at all times when power is applied

UNIT DAMAGE HAZARD

Cailureto follow this caution may re_tt in damage to this

unit.

This unit cannot be powered directly from blower motor

leads Back Ej e (electromagnetic field) voltages can exceed

190 volts for 120v motors or possibly double with 240v fan

coil motors

ELECTRICAL SHOCK HAZARD

Cailure to follow this warning could result in personal injury

or death_

The following procedures could expose hazardous live

components, l nly a trained experienced service person

• . . L *

should install thls electrome air cleaner Before performing

installation service or maintenance operations on unit turn off

all power Its unit TAd a fSCl k kECT St fTC e! t iT e

i 1 Chl r TTAd..

The Electronic Air Cleaner is designed to take advantage of the

AcS (AirClow Sensor) into&water into the power supply. This

airflow sensor will sense the air movement within the duct and turn

the Electronic Air Cleaner on ,and off accordingly.

Fan Coil Application of 2020 Model (240v)

I ne j ode! 2020 is a 240v power supply model designed tu match

your fan coil Acs will turn unit on when airflow is sensed, Air

cleaner should only operate when blower motor is running,.

UNIT DAMAGE HAZARD

Caihre to follow this caution may result in damage to this

unit

This unit cannot be powered directly from blower meier

leads, Back Ej c (electromagnetic field) voltages can exceed

190 volts for 120v motors or poss_ty double with 240v fan

coil motors,

Page 7

To install this mode[ with a 240v tim cot!:

1 Turn air cleaner OFF using ON/OFF rocker switch ]o_ted

on front panel.

2 Plug power cord into acceptable receptacle

3 Replace the unit door to the front of the air cleaner

4 Air cleaner will now operate when door is in place,

ON/OFF rocker switch is in the ON position and input

voltage is present to unit

System Checkout

ELECTRICAL. SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

The following procedures could expose hazardous live

components Only a trained, experienced service person

should install this electronic air cleaner. Before performing

installatlon, service or maintenance operations on unit, turn off

all power to unit. TAG DISCONNECT SWITCH WITH

LOCKOUT TAG.

l. "lqre HVAC system blower should be turned OFF

2. Switch the ON/OFF rocker switch to the ON position. The

bright red segment of the rocker ,.switch should be visible

3. Inspect both the Green INPUT POWER light and the Red

CELL ENERGIZED light:

• With the AFS installed, the Red CELL ENERGIZED

light should go out in approximately 20 to 60 seconds.

This is the normal time for the electronic airflow sensor

to complete its stabilization period Both lights will come

back on when the HVAC system blower begins to

operate.. See the section entitled HOW THE AIRFLOW

SENSOR WORKS for more information.

4. Wait approximately one (I) minute and turn the HVAC sys-

tem blower ON Most thermostats have a setting that wilt

allow you to run the fan manually If not, then set the ther-

mostat so that either hot or cold air begins to flow through

the ductworko

5. The Green INPUT POWER light and Red CELL ENER-

GIZED light should come on.

6 Check to make sure that the Red CELL ENERGIZED light

goes out when the following conditions occur:

" Cell access panel is removed

- Rocker switdl is switched to the OF F position

,' HVAC system blower is not running

COMMONLY ASKED QUESTIONS

Qo WKy Isn't my Bl_ cqtDaH` cQEnlag my Blv?

A. The air cleaner is most likely working just like it was designed.

However, many factors can affect the performance of the unit_ Are

cold alr registers located in the ceiling? If so, it will be difficult for

the airflow to carry heavier particulates to the air cleaner If the dirt

chrw'v_r/,_'_lorqtoaru_:t_'_rarp _tt_ _OoAm

both the Red and Green lights illuminated? If not, then the unit

may be in need of servicing. Contact your local HVAC dealer for

asslstance_

Qo It s_n't eqtDalng my I_ tKHZI_ I zUnt It,tit WIrq3teEn I

do?

A. We recommend that you run the blower continuously so that

the air movement will carry the dirt to the air cle,'mer.

Unfortunately, there will _flways be some dirt that is left behind on

the appliances, furniture, etc Regular dusting is recommended to

stir up these pockets of dust so that they can enter the alrstrcam and

be removed by the Electronic Air Cleaner

n ,, t hen I turn on my Eh:ctronic Air Cleanerlthe lights come

on for a couple of seconds and then turn off., The air cleaner

Isn't zRrklng!

A The air cleaner is fine as long as both the Red and Green lights

are coming on. Try turning the HVAC blower OFF and then

turning the Electronic Air Cleaner on This should solve the

problem.

n t hat is rite zapping noise I am hearing from my unit?

Should I be concerned?

A. The zapping or popping noise that you are hearing is the sound

of larger particles being vaporized by the ionizing-collector cell.

This is normal and is no cause for alarm.. As your HVAC system

blower moves the air through the dnctwork and allows the

Electronic Air Cleaner to clean the air, the noise will diminish

However, there will always be instancea when larger particles enter

the ionizing-collector cell

n Should I hear thL_ zapping noise all the time?

A._ All Electronic Air Cleaners will occasionally zap or pop as

larger particles pass through the ionizing-collector cells. However,

if the sound is constant or is repetitive in nature, then a large

particle may have become lodged in the ionizing-collector cells

and they may require cleaning If cleaning the ionizing-collector

cells does not stop the noise and there are no large particles trapped

in the ionizing-collector cells, then the cause could be a

bruken!toose ionizing wire, bent collector plate or other mechanica!

reason. Please contact your local HVAC dealer for a._sistance..

n o t hat if I no longer' hear any popping or zapping noises

coming from my unit? Is it still denning the air"?

A. If the zapping noises stop and the air cleaner is not in need of

servicing, then one of two situations has occurred.. Flint, the

Electronic Air Cleaner has successfully removed all larger particles

from the air and is cleaning microscopic particles which do not

cause the zapping noise Second, the blower and/or HVAC system

is not running and air is not flowing through the ductwork. The

Electronic Air Cleaner cannot remove particles if the air stream is

not moving.

n. I lost power to my home during a storm,, Should I worry

about the Electronic Air Cleaner'?

A. The most common problem associated with power outages is

the unit will not turn on properly after power is restored. If the Red

and Green light come on for a couple of seconds and then go off,

the unit is OK gust turn the HVAC blower off, turn the unit ON

and then turn the blower back on If the Red and/or Green light

does NOT come on after a storm, the power supply in the

Electronic Air Cleaner may be short circuited. Contact a local

HVAC contractor for further information_

n. My installer told me to keep the H s AC system blower

running _KHtlmH l_t I dRn't Z13at tRlncrHyHmy SIGH"

bill, t hatshould I do?

A.. It is recommended that you keep your HVAC sy_em blower

running all the time to achieve the maximum air cleaning

efficiency. This will allow the Electronic Air Cleaner to do what it

is designed to do, which is clean the air. Remember that if the air

does not reach the air cleaner, it cannot be cleaned On average,

your Electronic Air Cleaner will use the same amount of electricity

as a 55 watt light bulb. The energy usage of the HVAC system

blower will depend on the age of your system, energy costs in your

regional location and other variables The best solution is to try

running the HVAC system blower in continuous mode for a month

or two to estimate your annual energy costs and base your final

decision on what you fee! most comfortable with.

Page 8

Remove

Soak

Rinse

Fig_ 11 - "l_pieal Call and Prefiller Cleaning

Drip Dry

Replace

CO203S

I

MAINTENANCE OF CELLS

Washing Ceils and Prefilters

Regular washing is necessary to ensure proper performance (see

Fig 11). A thorough washing once every two months wilt be

adequate for most installations More frequent washing (once a

month) may be nece_ary on some installations (new homes for

example) where there is new carpeting, plaster dust, or excessive

cigarette smoke

To remove cells and prefilter

1. Push air cleaner switch to the OFF position Wait 15

seconds. Open door access panel.

2. Carefully remove cells and prefilter(s) and set aside in a safe

place,

3 Do not drop the ionizing-collector cell This could cause

damage to the cell plates or ionizing wires and cause

excessive arcing and noise,

To wash cells and prefilter(s)

To wash cells and prefilter(s) We suggest that you follow the

instructions below to properly and thoroughly clean your collector

cells

i Place enough hot water in a utility tub to cover the first ceil.

Dissolve 2 to 4 oz of granulated automatic dishwasher

detergent (not laundry detergent) in the water.

2 Allow the cell to soak for 30 minutes Agitate it up and

down in the solution until it appears clean and remove

3 Repeat with second cell.

4 Agitate the prefitters up and down in the solution until they

appear clean.

5 With a hose, rinse the cells and prefilters The hose should

be heCI I'_RU\M0 " (254 pp) fzRp _ FetiDp(_ El_d IJAiD

slight angle for better cleaning results Be careful not to

spray the ionizing wires directly with the hose The water

pressure can cause the wire to snap and break, The ceil

frame should be thoroughly rinsed along the edges to

dislodge any trapped lint or dirt. Carefully wipe a damp

cloth or .sandpaper (not emery cloth) along the ionizing

wires,,

6 Ptand cells and prefilters up to drain. [_t dry two hours

You may experience a slight discoloration of the aluminum

collector cells after washing This is a normal chemical

reaction and will not harm your unit or affect its

performance.

To replace cells in air cleaner

I. Replace prefilter and cells in cabinet.. Cheek that arrow on

cells poinLs in same direction as air flows through the duct

(ff you have to force it past the positioning screw on

bottom, it is probably in the wrong position).

2.. Replace access door (engage tabs on lower edge of door

into slots in cabinet) Carefully close door_

3. Turn air cleaner switch to ON

TROUBLESHOOTING

ELECTR1 CAL SHOCK HAZARD

Failure to follow this warning could result in persona[ injury

or death.

The following procedures could expose hazardous live

components Only a trained, experienced service person

should install this electronic air cleaner When the circuit has

been de-energized, always discharge any residual current in

the secondary with an insulated handle screwdriver Always

ground power supply and ionlzing-coltecting cell when bench

testing. Before performing installation, service or maintenance

operations on unit, turn off all power to unit TAd

DfPCONNbCT PWfl'C e WITe LOCh O r T TAd.

Recommended Service Tools

1.. 6FrewdrLy_r, 8" FRP P Rn wLW IasuO.j_iJ hDldO (,p(?t_x_)

2. Pcrewdrivers Phillips #1 and #2 with plastic insulated

handles

3, Needle nose pliers

4 Multimeter

5. e igh voltage probe

Indication of Electrical Trouble

The air cleaner is equipped with a Red CbLL bNbRd fWbD light

for indicating proper unit operation. When the unit is in normal

operation (with the e s AC system fan running, access door in place

and rocker switch in the ON position) and the Red CbLL

bNbRdfWbD light is not lit, the problem is a shorled secondary.

Although failure of the indicating light itself should not be

overlooked, this condition is unusua| and rather remote.

Primary Circuit with Blower Operating

ff there is supply line voltage at the connections and no input

voltage to the power supply, the outage can be located by checking

operation of the safety switch and the interconnecting wiring with a

multimeter Refer to Circuit Diagram, to check operation of the

switches. Following these steps to test for proper operation of the

circuit board and power supply assembly:

1 bnsure that the circuit breaker controlling the furnace

blower is in the ON position and the main fuse is not open.

2 The power supply board has a built-in internal fuse to

protect the 24 s transformer ft can be checked visually by

inspecting the fuse ff the fine wire inside the fuse is broken,

this indicates a problem in the 24s circuit of the power

supply board.. Do NOT replace this fuse The entire power

supply board must be replaced The purpose of the fuse is

not to protect the power supply board, but to function as a

troubleshooting feature of the product and to protect the

transformer from damage

Page 9

3. If the fuse is NOT blown, check the ON/OFF _vitches and

safety interlock witch for proper engagement and

operation This can be completed using a volt ohm

millimeter on a scale that will measure ohms as low as 1 0

If you are using the recommended meter previously

mentioned in this manual, set the meter to read 200 ohm

and proceed with Steps 4 through 6

4 Remove the fuse Connect one lead to the test pin located

direclly beside the wire that connects the ON/OFF switch to

the power supply board Connect the other lead to the fuse

connection closest to the front panel,

5 Turn the ON/OFF switch to the ON position and depress

the safety interlock switch The meter should have the

capability of reading levels as low as I 0 ohm

6 If there is no reading on the meter, begin the process of

elimination by disconnecting the wire from the test point

and connecting it to the terminal with the blue wire located

on the safety interlock .switch. Depress the safety interlock

switch lfthe reading on the meter is greater than ] 0 ohm,

the safety interlock switch is defective and must be replaced.

If the reading on the meter is less than t 0 ohm, the

ON/OFF switch is defective and must be replaced.

Ionizing-Collecting Cell

Secondary Circuit

The cell is electrically energized through a contact terminal located

at the top center of the cell. The ionizing wires and alternating

collector plates are electrically charged while the interleaving plates

are grounded If the space between the charged and grounded

plates is bridged with conductive or semi-conductive materiaI, a

short circuit develops The bridging or short may be caused by

damaged plates, or foreign material lodged between/on the

components.

Since the cell should be periodically removed from the unit to

wash away collected dirt, it is s'uscept_le to physical damage. The

cell also contains the ionizing wires which, due to their function,

have been designed with minimal structural support and are

suscept_le to breakage. However, trouble related to a shorted

collector cell is readily shown by the Red CELL ENERGIZED

light and can be quickly isolated by a simple procedure.

To determine if a short exists in one or both of the collector cells,

tam the Electronic Air Cleaner OFF and remove both electronic

cells from the cabinet. Shut the door and repower the unit. If the

Red CELL ENERGIZED light comes on, an electrical short exists

in one or both of the electronic cells. Replace the cells in the unit,

one at a time, to determine which ceil is shorted Most troubles in

the colt can be visually detected and corrected.

NOTE: The ionizer collector cells ,are not designed for field repair.

Ionizing wires ,and insulators can be field replaced It is not

recommended that you attempt to replace other cell components

(i e Collector plates, end plates, ionizer supports)

Replacing the Ionizing Wires

Ionizing wire breakage is minimal because of the constant tension

design and fixed location of the ionizing wire supports. When an

ionizing wire breaks, the efficiency of the Electronic Air Cleaner

will decrease slightly. However, the unit will continue to operate

with broken ionizing wires as long as the broken wires have not

caused a short circuit of the unit Remove all loose and broken

wires as soon as they are identified. Although the replacement of

the ionizing wires can be attempted by a homeowner, it is

recommend that you should contact a qualified HVAC contractor

for replacement parts and/or servicing.

Wires are supplied in a coiled spring configuration, with a clinch

nut on each end of the wire Replacement requires a pair of needle

nose pliers Exercise caution in removing any broken wires in the

collector cell.. This will prevent accidental shorting of the cell and

reduce the need for further maintenance U_ the following

procedure when replacing an ionizing wire

I. Ensure that alt power to the Electronic Air Cleaner is OFF,

remove the access door and remove the ionizing-collector

cells from the uniL

2 Carefully remove a!l remains of the broken wire

3 Grip the neW wire at each end of the wire with your thumb

and index finger While stretching the wire to approximately

6" (152 ram) _ RnH_GRI kh_Hzl_lq'_l_ UnFRIDEH_FFP

your thumb and index finger.

4 n'laca one end of the wire in the slot of the stainless steel

.support on the collector cell fi'om the front of the cell This

_pport is partially covered by the cell brace in front of the

support

5.. Grip the other end of the ionizing wire with needle nose

pliers and insert the terminated end of the wire into the slot

on the support bar of the opposite end of the collector cell

6. The wire should be tight enough to be self supporting and

remain suspended between the two support slots in the

_pport bar.

ELEfYI"RICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death

]'he following procedures could expose hazardous five

components. Only a trained, experienced service person

should install this electronic air cleaner Before performing

installation, service or maintenance operations on unit, turn off

all power to unit TAG DISCONNECT SWITCH WITH

LOCh OUT TAG.

AFS Troubleshooting

1. Make sure the furnace blower is not operting, the rocker

_,viteh is OFF, and the circuit breaker is turned OFF or the

cord is disconnected

2.. Remove the access door

3. Remover power tray assembly

4.. Locate the AFS It is the circuit board with a small gray disc

connected to the circuit board by two (2) silver wires.

Carfutly bend the thermistor so that it is located in the center

RI WHt_t_Iag _G i$S1Rxlml:_-_) I/8" (3 ram) tlRm WH

inside edge of the power pack assembly

5.. Reinstall the power tray assembly and access door

High Altitude Operation

Because the air is Iess dense at higher altitudes, there is a poss_ility

of nuisance arcing The homeowner can quickly and easily correct

this condition..

]. Turn the unit OFF Turn off circuit breaker or disconnect the

power cord

2_ Remove the two screws that secure the cover to the power

tray and remove it from the unit (The entire power supply

tray may be removed from the cabinet by removing two

screws from inside cabinet.) Do not lose these ,screws

I

Page 10

3,, k_cate the jumper terminal (see 12)_ wire support bar with end of the high voltage probe, The

meter reading should be 62 kVDC - 2 kVDC

ELECTRICAL SHOCK HAZARD

Cailure to follow this warning could result in personal injury

or death

The following procedures could expose hazardous live

components Only a trained, experienced service person

should install this electronic air cleaner. Before performing

O0203g

Fig. 12 - Jumper Terminal Adjuslment

installation, service or maintenance operations on unit, turn off

all power to unit TAG DISCONNECT SWITCH WITH

LOCh O r T TAG

4, With a pair of needle nose pliers, carfia!ly adjust the jumper

settings from HIGH to MED Ensure that the jumper is

firmly seated in the terminal.

5 Replace the power tray cover and secure it with the two

SCrews

6.. Replace the access door and turn the unit ON.

This procedure will slightly reduce the output voltage, minimize

aming, and reduce ozone production.. If the condition does not

improve, repeat the above procedure and move the jumper setting

from MED to L.OW If this does not correct the situation, contact

your local HVAC dealer All Electronic Air Cleanem are produced

at the factory with the jumpers set in the HIGH position However,

the output voltage may be lowered in any situation where the unit

is arcing excessively or there is excessive ozone production..

Checking the Power Supply

If the output light remains out with the collector cells removed

from the cabinet, the power supply is defective. Specific problems

on the power tray assembly can be isolated by using a multimeter

and high voltage probe to check the output voltages. To check the

secondary circuit, a high voltage meter is required.. See the section

entitled Recommended Service Tools To check for proper

operation, it is imperative that the procedure be followed as

outlined below:

L Make sure the furnace blower is operating, the control

switch is on, and input voltage is correct..

2. Remove front door assembly panel

3.. Remove power pack access cover

4.. Check tile high voltage contact board assembly(s) for

damage or carbon tracking.

NOTE: The cell contacts should be visually checked for

corrosion, excessive dirt build up, and electrical are tracking

(carbon path from stainless steel spring to grounded metal) Clean

or replace as required.

5.. Make connections from the high voltage probe to the

mu(tM_14lq" In IyocRrGD_cHwl3/€ WH RS_'VmDml;9 ThH

meter should be set for reading DC voltage on the 20 volt

full scale

6.. Attach the high voltage probe ground lead to the cabinet.

While depressing the safety switch lever, touch the ionizer

Z tf no voltage is measured, remove the first cell ,'rod check

the second cell The meter should read 6.2 kVDC - .2

kVDC

8. If proper voltage is measured, the first cell is shorted

9. If no voltage is present, remove the second cell Ins-tall cell

number one and me,_sure voltage as described above. If

voltage is present, the second cell, which is now out of the

cabinet, is shorted

I0. If no voltage is present, remove both cells and measure the

power supply output. Wlaile drpressing the safety switch,

touch the end of the high voltage probe (see Cig 13) to

either the front or rear contact board assembly The meter

should read 62 kVDC or higher

11 If no voltage is present, check the power supply.. Set the

multimeter for reading AC voltage at 200 volt full scale and

attach meter test leads

12 While depressing the safety lever, touch the two transformer

output lead junctions to the power supply board with the

meter leads and read the meter.

13 If there is no oputput voltage from 24 volt transformer,

replace the 24 volt tranformer and power apply board

J

A_717_

Fig_ 13 - High Voltage Operation Check

(Ionizer Wire Support Bar)

10

Page 11

\

PARTS LIST

-CELL

CONTACT

J

Reference Number

1

2

3

4

5

6

7

8

9

10

tl

12 (120v model)

12 (240v model)

13

14

15

CO4D05

PARTS LIST

Description

Power Tray Assembly

High Frequency Power Supply

ON/OFF Switch

interlock Switch

Cabinet Assembly

Prefilter (2 required)

Celt, Ionizing - Collecting

Ionizing Wire Assembly

Front Penet Assembly

Contact Board Assembly (2 required)

Charcoal Filter (optional, not shown)

Stepdown Transformer t20v to 24v

Stepdown Transformer 240v to 24v

Insulator

Cell Key (not shown)

Power Tray Cover

Fig. 14 - Unit Parts l)c,scripfien

Page 12

"t:, = _

°° i

%

_NN

_ m

z

m

)

o

b.

]2

m

Page 13

CAC / BDP

FOR SERVICE OR REPAIR, FOLLOW THESE STEPS IN ORDER:

FIRST: Contact the Installer You may find their name on the product or in your Homeowner's Packet ifthe installer's name is not known cell your

builder or home reta';_erif yours isa new residence

SECOND: Contact the nearest dist_butor (See telephone yellow pages )

THIRD: Contact:

CAC 1BDP

Consumer Relations

P O Box 4808

Syracuse, New Ye_'k 13221

Phone: 1-800-227_7437

Mode No Unit Sedal No

Date ofInstallation Installed by

Name of Owner Address of _nstallation

EAC- Limited Warranty

FIVE-YEAR LIMITED WARRANTY-- CAC t BOP (hereinafter also interred to as "COMPANY') warrants this cabinet/product to be free from defects in

matada] and workmanship If a defect is found v_thin five years from date of original installation of product (whether or not actua! use begins on that

date) Company will provide a new or remanufa_ured part. at Company's sole oplJon_ to replace any defec_Jve part, without charge for the pad ilseft

THIS WARRANTY DOES NOT INCLUDE LABOR OR OTHER COSTS incurred for diagnosing, repairing, remo,c;ng, installing, shipping, servlcing_ or

handling of either defective parts or mpIacement pads

WARRANTY CONDITIONS:

1_ Warranties apply only te profilers in their original testel]etion location,

2., Instagetion, use, care, and maintenance must be norto!! and in accordance with instructions coet,_ined in the Owner's Manual

and Company's service Infonoatian..

3., D_f_ctivepartemust_erotumedt_thedist_butorthr_ugharog_steredserv_ctegdea_rf_rcrsdiL

4., All work shall be performed during normal working hours,

LIMITATIONS OF WARRANTIES - ALL IMPLIED WARRANTIES {INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE) ARE HEREBY UMITED IN DURATION TO THE PERIOD FOR WHICH THE LIMITED WARRANTY tS GIVEN AND

_PL!ES_,,SOME,STATES, DO,NO T ALLOW,LIM!TATIONS,ON HOW LONG,AN,IMPLIED WARRANTY LASTSt SO THE ABOVE MAY NOT APPLY

TO YOU. THE EXPRESSED WARRANTIES MADE IN THIS WARRANTY ARE EXCLUSIVE AND MAY NOT BE ALTERED 1ENLARGED OR

CHANGED BY ANY D_STRIBUTOR, DEALER, OR OTHER PERSON WHATSOI::_VER,

COMPANY WILL NOT BE RESPONSIBLE FOR:

't., Normal maintenance as outlined in the installation and servicing instructions or owner's manual, including filter cleaning andlor

replacement and lubricatlon_

2 Damage_rro_a_rsroquirodasac_nsequ_nce_ffau_tyi_stat_otion`misappIicati_n_b_mpr_p_rservicing_una_th_dzed

alteration or improper oporstton_

3 Failure to start due to voltage conditions, blown fuses, open circuit breakers, or damages due to the inadequacy or Interruption

of electrical service,,

4. Damage as a result of floods, winds, fires, lightning, accidente, corrosive envtronmenLs or other conditions beyond the control

of Company.,

5_ Pad_ not supplied or designated by Company, or damages resulting from their uso_

6_ Company products installed outside the continental U S,A_, Aiaska, Hawaii, and Canada,,

7_ E_ectri_ityorthe_c_sts_ori_crs_se_ineIectricity_rfue_c_tafr_manyreas_nwh_tsoever_nc_udingadd_at_r_nusua_s_

of supplemental electric heal

8., ANY SPECIAL INDIRECT OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGE OF ANY NATURE WHATSOEVER.

Some states do not allow the exclusion of incidental or consequential damages, so the above limitation may not appfy to you,

Catalog 63EA-CA0

05-03

This warranty gives you specific legal rights, and you may also have other fights which vary from state to state

39004DP290

t3

Page 14

Copyright 2007 CAC / BDP • 73_0 W, Morris SL • Indianapolis= IN 4_31 prir_ in Cl-_rt_ EdiUon D_t0:09/07

i i

Matt_lac_ur_' rm_erves tho right 1och_ng_ at _ny Ume_ Bp{tclflc=tlon_; at_dd _sEgn= wit hour noUco and wit haut ob[ig=Uo_=,

Catalog No: IM-EACB-03

Replaces:tM-EACB-02

Loading...

Loading...