Page 1

Small Rooftop Products

Select 3 to 12 ½ Tons

(48/50LC 14 Not Included)

Horizontal EconoMi$er X Accessory

Installation Instructions

P/Ns CRECOMZR077A00, CRECOMZR079A00,CRECOMZR081A00

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ACCESSORIES LIST . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTRUCTIONS FOR 48/50LC

07-12 UNITS ONLY . . . . . . . . . . . . . . . . . . . . . . 11

Installing Optional HH57AC081 Single Outside Air

Enthalpy Sensor . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing Differential Return Air Sensor . . . . . . . 15

California’s Title 24 High Temperature Limit

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Demand Controlled Ventilation (DCV) . . . . . . . . . 15

Remote (Downstairs) Monitoring of Controller’s

Fault Detection and Diagnostics . . . . . . . . . . . 16

GENERAL JADE W7220 CONTROLLER AND

SENSOR INFORMATION . . . . . . . . . . . . . . . . . 17

W7220 Economizer . . . . . . . . . . . . . . . . . . . . . . . . 17

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using the Keypad with Menus . . . . . . . . . . . . . . . 17

Using the Keypad with Settings and Parameters 17

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programming the Jade W2770 Controller . . . . . . 17

• SETPOINTS

• SYSTEM SETUP

Checkout Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SETUP AND CONFIGURATION . . . . . . . . . . . . . . 23

W7220 Economizer Module Wiring . . . . . . . . . . . 23

Time-out and Screen Saver . . . . . . . . . . . . . . . . . 24

START-UP AND OPERATION . . . . . . . . . . . . . . . . 24

Cooling with EconoMi$er X . . . . . . . . . . . . . . . . . 24

Heating with EconoMi$er X . . . . . . . . . . . . . . . . . 24

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 25

Power Loss (Outage or Brownout) . . . . . . . . . . . 25

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• CLEARING ALARMS

SAFETY CONSIDERATIONS

Installation of this accessory can be hazardous due to system

pressures, electrical components and equipment, and equipment locations (such as a roof or elevated surface). Only

trained qualified installers and service technicians should install, start-up, and service this equipment.

When installing this accessory, observe precautions in the literature and on any labels attached to the equipment and all other safety precautions may apply.

• Follow all safety codes

• Wear safety glasses and work gloves

• Use care in handling and installing the accessory

It is important to recognize safety information. This is the safetyalert symbol . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

or death. Before performing service or maintenance operations on the unit, always turn off main power switch to unit

and install lock(s) and lockout tag(s). Unit may have more

than one power switch. Ensure electrical service to rooftop

unit agrees with voltage and amperage listed on the unit rating plate.

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing roof top units.

CAUTION

Failure to follow this caution may result in personal injury

and damage to the unit. Cover the duct opening as a precaution so objects cannot fall into the return duct opening. Be

sure to remove the cover when installation is complete.

GENERAL

IMPORTANT: These economizers meet all the economizer

requirements as laid out in California’s Title 24 mandatory

section 120.2 (fault detection and diagnostics).

Catalog No. 04-53480208-01 Printed in U.S.A. Form IIK-CRECOMZR77-03 Pg 1 11-18 Replaces: NEW

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Page 2

IMPORTANT: Read these instructions completely before attempting to install accessory economizer.

®

The EconoMi$er

X system utilizes the latest technology available for integrating the use of free cooling with mechanical cooling for packaged rooftop units. The code compliant Jade W7220

control system optimizes energy consumption, zone comfort,

and equipment cycling by operating the compressors when the

outdoor-air temperature is too warm, integrating the compressor

with outdoor air when free cooling is available, and locking out

the compressor when outdoor-air temperature is too cold. Demand controlled ventilation is supported.

This EconoMi$er X can be used with 1 or 2 speed indoor fan

motor units. (All other speed settings listed are for future use.)

The EconoMi$er X system utilizes gear-drive technology with a

direct-mount spring return actuator that will close upon loss of

power. The EconoMi$er X system comes standard with fault detection and diagnostics (FDD), an outdoor air temperature sensor, and mixed air temperature sensor (also called supply air

temperature sensor). Outdoor enthalpy, indoor (return) dry bulb

or enthalpy, and CO

sensors are available for field installation.

2

Standard integrated barometric relief dampers provide natural

building pressurization control. An optional power exhaust

system is available for applications requiring even greater exhaust capabilities. The power exhaust set point is adjustable at

the EconoMi$er X controller.

See Table 1-3 for package usage. See Table 4 for package contents. See Table 5 for sensor usage.

Table 1 — Carrier Package Usage

MODEL NUMBER

48/50FC 04-07

48/50GC 04-06

48/50HC, LC 04-06

48/50TC 04-07

50TCQ 04-07

50HCQ 04-06

50KCQ04-06

48/50KC 04-06

48/050HC 07-12

48/50LC 07

48/50TC 08-14

50TCQ 08-12

50HCQ 07-09

48/50HC 14

48/50LC 08-12

48/50TC 16

50TCQ 14

50HCQ 12

Small Cabinet

Large Cabinet

Extra Large Cabinet

ECONOMI$ER X

PART NUMBER

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

Table 2 — Bryant Package Usage

MODEL NUMBER

Small Cabinet

581K/551K 04-06

582K/559K 04-07

581J/551J 04-06

549J/547J/559J/582J 04-06

548J/580J/558J 04-07

Large Cabinet

581J/551J 07-12

580J/558J 08-14

548J 08-12

549J 07-09

Extra Large Cabinet

581J/551J 14

580J/558J 16

548J 14

549J 12

Table 3 — ICP Package Usage

MODEL NUMBER

Small Cabinet

RAV/RGV 036-072

RAW/RGW 036-060

RAH/RGH 036-060

RAS/RGS 036-072

RHS 036-072

RHX/RHH 036-060

RAX/RGX 036-060

Large Cabinet

RAH/RGH 072-120

RAS/RGS 090-150

RHH 072-102

RHS 090-120

Extra Large Cabinet

RAH/RGH 150

RAS/RGS 180

RHS 150

RHH 120

ECONOMI$ER X

PART NUMBER

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

ECONOMI$ER X

PART NUMBER

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

2

Page 3

Table 4 — Package Contents

PACKAGE NO. QTY CONTENTS

EconoMi$er Horizontal Damper

1

Assembly with Actuator and

HH79ZZ007 OA Sensor

Jade HW63AW002 (HW: W7220)

1

Controller with Attached Harness*

HH77ZZ007 Mixed Air Temp Sensor

1

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

*Shipped in hardware kit for field installation.

HW – Honeywell

(ring terminal)*

1 48TMHSRSE--A20 4-Wire Harness*

1 Hood Assembly

1 Aluminum Filter

1 Front Blank Off Panel

1 Filter Access Door

1 Hardware Bag*

EconoMi$er Horizontal Damper

1

Assembly with Actuator and

HH79ZZ007 OA Sensor

Jade HW63AW002 (HW: W7220)

1

Controller with Attached Harness*

HH77ZZ007 Mixed Air Temp Sensor

1

(ring terminal)*

1 48TMHSRSE--A20 4-Wire Harness*

1 Hood Assembly

1 Aluminum Filter

1 Front Blank Off Panel

1 Horizontal Blank Off Panel

1 Filter Access Door

1 Hardware Bag*

EconoMi$er Horizontal Damper

1

Assembly with Actuator and

HH79ZZ007 OA Sensor

Jade HW63AW002 (HW: W7220)

1

Controller with Attached Harness*

HH77ZZ007 Mixed Air Temp Sensor

1

(ring terminal)*

1 48TMHSRSE--A20 4-Wire Harness*

1 Hood Assembly

1 Aluminum Filter

1 Front Blank Off Panel

1 Horizontal Blank Off Panel

1 Filter Access Door

1 Hardware Bag*

Table 5 — EconoMi$er X Sensor Usage

APPLICATION

Outdoor Air

Dry Bulb

Mixed Air

Sensor

Single Enthalpy HH57AC081

Differential Dry

Bulb or Enthalpy

CO

for DCV

2

Control Using a

Wall-Mounted

CO

Sensor

2

for DCV

CO

2

Control Using a

Duct-Mounted

CO

Sensor

2

* Includes HH57AC081 sensor and wiring harness.

†Accessory CO2 sensors.

**Accessory aspirator boxes required for duct-mounted applications.

††CRCBDIOX005A00 is an accessory that contains both 33ZCSEN-

CO2 and 33ZCASPCO2 accessories.

ECONOMI$ER X WITH OUTDOOR AIR DRY

The HH79ZZ007 outdoor air dry bulb sensor is

factory installed on economizer.

HH79ZZ007 provided with economizer and field

installed in blower compartment.

CRDIFRASN01A00* (When available,

or MicroMetl 9901-2022-DIFF JC2)

33ZCSENCO2 or CGCDXSEN004A00

33ZCSENCO2 or

CGCDXSEN004A00†

33ZCSENCO2 or

CGCDXASP00100**

BULB SENSOR

ACCESSORIES REQUIRED

and

or CRCBDIOX005A00††

ACCESSORIES LIST

The EconoMi$er X has several field-installed accessories

available to optimize performance. Refer to Table 6 for authorized parts and power exhaust descriptions.

Table 6 — EconoMi$er X Field-Installed Accessories

DESCRIPTION PART NUMBER

Small & Large Cabinet Power Exhaust

208/230-v 1 Ph

Small & Large Cabinet Power Exhaust

460-v 3 Ph

Extra Large Cabinet Power Exhaust

208/230-v 1 Ph

Extra Large Cabinet Power Exhaust

460-v 3 Ph

Enthalpy Sensor (OA) HH57AC081

Differential (Return) Sensor CRDIFRASN01A00*

CO

Sensor and Aspirator Box CRCBDIOX005A00

2

Return Air CO

Room Sensor (4 to 20 mA)

CO

2

Aspirator Box for Duct Mount

CO

Sensor (4 to 20 mA)

2

Hinged Filter Door Kit for Small Cabinet CRHNGPNL001A00

Hinged Filter Door Kit for Large Cabinet CRHNGPNL002A00

Hinged Filter Door Kit for Extra Large

Cabinet

*When available, or MicroMetl 9901-2022-DIFF JC2

Sensor (4 to 20 mA) CRCBDIOX002A00

2

CRPWREXH028A01

CRPWREXH029A01

CRPWREXH082A01

CRPWREXH083A01

33ZCSENCO2 or

CGCDXSEN004A00

33ZCASPCO2 or

CGCDXASP001A00

CRHNGPNL003A00

INSTALLATION

1. Turn off unit power supply(s) and install lockout tag.

2. Remove the existing unit filter access panel. Raise the

panel and swing the bottom outward. The panel is now

disengaged from the track and can be removed and discarded. See Fig. 2.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal inju-

ry and/or death.

Disconnect power supply and install lockout tag before at-

tempting to install accessory.

3. Remove the indoor coil access panel and discard. See

Fig. 2. Remove the horizontal cover panel (see Fig. 2).

Reinstall panel over return opening in bottom of unit.

4. The EconoMi$er X hood assembly is shipped assembled.

Aluminum filter must be installed on some models. See

Fig 3.

5. Set the EconoMi$er X assembly upright. See Fig. 4.

6. Insert the EconoMi$er X assembly into the rooftop unit,

positioning the EconoMi$er X to the far left side of the

opening. See Fig. 5.

3

Page 4

Damper

Compressor

Access Panel

Outdoor-Air Opening and

Indoor Coil Access Panel

Filter Access Panel

Horizontal

Cover Panel

B

A

HOOD

ALUMINUM

FILTER

FILTER

CLIP

CLEANABLE

ALUMINUM

FILTER

OUTSIDE AIR

RELIEF AIR

Wiring Harness PlugBarometric Relief

Outside Air

Temperature Sensor

Red Shipping Tape

Outside Air

Damper

Fig. 1 — EconoMi$er X Component Locations

Fig. 2 — Typical Outdoor Air Section Access Panel

Locations

Fig. 4 — EconoMi$er X Positioned for Installation in

Unit

Fig. 5 — Top View of EconoMi$er X Installation

ECONOMIZER P/N A B SHIP WT.

CRECOMZR077A00 25.1” 29.19” 95 lb

CRECOMZR079A00 25.1” 37.25” 150 lb

CRECOMZR081A00 24.81” 53.36” 245 lb

Fig. 3 — EconoMi$er X Hood Detail

4

Page 5

Fig. 6 — EconoMi$er X Installed in Unit

Barometric

Relief Dampers

Outside Air

Temperature

Sensor

HVAC

Filters

Outdoor

Air Damper

Mounting

Screws

ECONOMI$ER X

HOOD

ACCESS DOOR

TO FILTERS

SCREWS

ECONOMI$ER X

HOOD

HORIZONTAL

BLANK-OFF

FRONT BLANK-OFF PANEL

ECONOMI$ER X

HOOD

ACCESS DOOR

TO FILTERS

FRONT BLANK-OFF PANEL

FILTERS

ECONOMI$ER X

PLUG

ECONOMI$ER X

ACTUATOR

SCREW

WIRING

HARNESS

7. Slide the EconoMi$er X assembly all the way back into

the unit until it locks into the horizontal opening of the

HVAC (heating, ventilation and air conditioning) unit.

8. Secure the EconoMi$er X mounting flanges to the HVAC

unit with the screws provided. See Fig. 6.

9. Install a screw through the pre-punched hole in the

EconoMi$er X assembly into the flange on the horizontal

duct opening. See Fig. 5 and 10.

10. Remove the red tape securing the relief dampers for shipping purposes.

11. On some units, the EconoMi$er X assembly and hood does

not reach to the top of the unit. In this case a front blank-off

panel must be installed. Install provided front blank-off

panel above hood. Screw in place. (See Fig. 8 and 9.)

Fig. 8 — Horizontal Return Opening Blank-Off Panel

Fig. 9 — Front Blank-Off Panel Installation Panel

Fig. 7 — EconoMi$er X Hood Installation

Fig. 10 — Top View of EconoMi$er X Installed in Unit

NOTE: The front blank-off panel must be installed before the

hood because the top of the hood fits into a channel in the bottom

of the panel.

12. Install the EconoMi$er X hood over the EconoMi$er X.

Use screws provided. (See Fig. 7 and 9.) Insert screw

through right side flange of hood into EconoMi$er X

flange.

5

Page 6

13. On some units, the return damper does not reach to the top

0

500

1000

1500

2000

2500

0 0.05 0.1 0.15 0.2 0.25 0.3

Small Cabinet

Large a nd Extra

Large Cabinet

0

1000

2000

3000

4000

5000

6000

00.10.20.3 0.4

Small Cabinet

Large Cabinet

Extr a Large Cabinet

INDOOR FAN MOTOR

ACCESS PANEL

HEATING ACCESS

PANEL

THERMOSTAT

CONNECTION

ACCESS PANEL

CENTER POST

of the horizontal return opening in the unit. In this case, a

horizontal blank-off must be installed. Install the horizontal blank-off at the top of the horizontal return opening.

(See Fig. 8.) Screw in place through pre-punched holes.

14. Install access door next to hood. Screw bottom of door to

HVAC unit. (See Fig. 7 and 9.) For the economizer for the

extra large cabinet, install plastic inserts on right-hand vertical post and install long gasketed screws along the vertical edge. Use standard serrated screws along the bottom of

the panel for all units.

15. See economizer performance charts in Fig. 11 and 12. See

base unit installation manual to make adjustments to meet

building ventilation requirements.

ROOFTOP UNIT’S

12-PIN MALE PLUG

ECONOMI$ER X

12-PIN FEMALE PLUG

Fig. 13 — Connect EconoMi$er X Harness to Unit PL6

Economizer Harness

17. Remove and save the 12-pin jumper plug from the unit

economizer harness – located in the upper left corner of

RELIEF FLOW (CFM)

the unit. Insert the EconoMi$er X plug into the unit wiring

harness. See Fig. 13.

NOTE: The 12-pin jumper plug should be saved for future use, in

the event that the EconoMi$er X assembly is ever removed. The

RETURN DUCT STATIC PRESSURE (i n. wg)

jumper plug is not needed as long as the EconoMi$er X assembly

is installed.

Fig. 11 — Barometric Flow Capacity

18. Remove the indoor blower access panel and the panel(s)

covering the unit control box. See Fig. 14.

RETURN AIR F LOW (CFM)

RETURN DUCT STATIC PRESSURE DRO P (in. wg)

16. If the EconoMi$er X will be operating with an enthalpy

Fig. 12 — Return Air Pressure Drop

outside air sensor, remove the factory-installed

HH79ZZ007 dry bulb sensor from the front face of the

economizer (see Fig. 1), and install the accessory enthalpy

sensor HH57AC081 in the same location. Holes are prepunched. Connect the (2) wire gray harness with plug

from the EconoMi$er X to the enthalpy sensor. See wiring

diagram Fig. 25 and 30. Refer to the “Installing Optional

HH57AC081 Outside Air Enthalpy Sensor” section for

more details on enthalpy settings.

Fig. 14 — Typical Indoor Fan Motor Access Panel

Locations

19. In the hardware kit provided with the EconoMi$er X

assembly is the HH63AW002 Jade controller (Honeywell

W7220). The controller is attached to a mounting bracket

and the EconoMi$er X harness is attached to the controller. Mount the controller assembly on the left side of the

unit control box. Screw bracket to the control box through

pre-punched holes in control box. See Fig. 15.

6

Page 7

NOTE: Some control box configurations may differ.

CENTRAL

TE RM I NA L

BOARD

WHITE

WIRE

10-PIN

FEMALE

PLUG FROM

CONTROLLER

Fig. 15 — Mount Controller Assembly in Unit Control

Box

20. Unplug the 10-pin female ECON plug currently connected

to the Central Terminal Board (CTB). See Fig. 16.

Fig. 17 — Connect 10-pin Plugs Together

22. Connect the 10-pin female plug from the Jade controller

harness to ECON on the CTB. See Fig. 18 and 25.

Fig. 16 — Unplug ECON plug from Central

Terminal Board (CTB)

21. Connect the 10-pin female ECON plug removed from the

CTB to the 10-pin male plug from the Jade controller harness. See Fig. 17 and 25.

Fig. 18 — Connect 10-pin Jade Plug to Central

Terminal Board (CTB)

23. Connect the White wire from the Jade controller harness to

the W1 terminal on the CTB. See Fig. 18 and 25.

24. Connect the red and brown wires from the Jade controller

harness to the CTB. See Fig. 19 and 25. The red wire connects to “R” on the CTB, and the brown wire connects to

“C”.

7

Page 8

Fig. 19 — Connect Red and Brown Wires to Central

CENTRAL

TERMINAL

BOARD

Terminal Board (CTB)

25. Locate the green wire with yellow stripe from the Jade

controller harness and screw it to the control box (ground).

See Fig. 20.

4-PIN MALE PLUG

FROM CONTROLLER

48TMHSRSE--A20

HARNESS

Fig. 21 — Connect 48TMHSRSE--A20 Harness to

Harness from Controller

27. Route the 4-wire 48TMHSRSE--A20 harness through the

divider between the control box and the indoor blower section. See Fig. 22.

48TMHSRSE--A20

HARNESS

Fig. 20 — Connect Ground Wire From Controller

26. Locate the 48TMHSRSE--A20 harness (with 4-pin female

plug) provided in the hardware kit with the EconoMi$er X

assembly. Connect the 48TMHSRSE--A20 harness to the

4-wire harness with a male plug from the Jade controller

harness. See Fig. 21 and 25.

CONTROL

BOX

NOTE: Some control box configurations may differ.

INDOOR

BLOWER

SECTION

Fig. 22 — Route 48TMHSRSE--A20 Harness to Indoor

Blower Section

28. Screw the HH79ZZ007 mixed air (MAT) sensor to the left

side edge of indoor blower through pre-punched hole, see

Fig. 23. Confirm that the screw does not interfere with

blower rotation. Connect the (2) spade terminals on the

HH79ZZ007 sensor to the orange and brown wires from

the 4-wire 48TMHSRSE--A20 harness. See Fig. 23

and 25.

8

Page 9

Connect (2)

green wires from

HH79ZZ007 sensor

to the brown and

orange wires from

the 48TMHSRSE--A20

HH79ZZ007

MAT sensor

(Ring

terminal)

PINK AND

VIOLET WIRES

FROM

48TMHSRSE--A20

HARNESS

INDOOR

BLOWER

Indoor blower

Fig. 23 — Mount and Connect Mixed Air Sensor

29. Connect the pink and violet wires from the 4-wire

48TMHSRSE--A20 harness to the pink and violet terminals in the wire bundle in the indoor blower section. See

Fig. 24 and 25.

Fig. 24 — Connect Pink and Violet Wires in Indoor

Blower Section

30. If using differential return sensor or DCV sensor, install it

now. See installation details later in the instructions and

the wiring diagram for further information.

9

Page 10

Plug

4-Pin Male

UNIT CONTROL BOX COMPARTMENT

Harness with

48TMHSRSE--A20

4-Pin Female Plug

MAT

ORG

1

4

ORG

BRN

2

BRN

Controller.

W7220 JADE

Unit Control Box

Field Mounted in

C

BRN

9

R

RED

10

OAT

OAT

MAT

VIO

PNK

Plug

10-Pin Male

334

1

2

S-BUS

ACT 24V

BLU

10

1

S-BUS

ACT COM

“R” ON CTB

BLK

GRA

GRA

RED

645913827

8

2

6

7

5

10

ACT 2-10

ORG

3

EXH1

AUX1 OUT

“C” ON CTB

YEL

BRN

4

9

E-GRD

IAQ 2-10

IAQ COM

BLK

BLU

GRN / YEL

CO2

(Optional)

from CTB

10-Pin Female

Plug Disconnected

AUX2 IN

WHT

Ground

“W1” on CTB

BLU

1

Y1 IN

Y1 OUT

GRA

2

Y2 OUT

ORG

3

OCC

Y2 IN

BLK

YEL

5

4

ECON on

10-Pin Female

Plug Connects to

6

Board

Central Terminal

7

8

Harness

50HE403859

GRN

Indoor Blower

Field Mount on

Mixed Air Sensor

HH79AH001

GRN

HONEYWELL C7250

Harness

Economizer

VIO

VIO

In Unit

6

PNK

PNK

7

BLU

2

12-Pin Female

Plug from Economizer

VIO

PNK

BLU

GRN

GRN

Sensor

Dry Bulb

Outside Air

ECONOMIZER RETURN CHAMBER INDOOR BLOWER SECTION

HH79AH001

1

HONEYWELL C7250

1

RED

1

BLK

BLK

2

BLK

2

PNK

RED

GRA

GRA

GRA

3

10

GRA

3

WHT

3

11

GRA

4

GRN

4

1

5

RED

Actuator

Economizer

YEL

BRN

ORG

Plug in Unit

12-Pin Male

8

9

4

12

ORG

GRA

GRA

PL6

Plug

S-Bus

S-Bus

123

OA

RA

DA

Temp & Humidity

HH57AC081

HH57AC081

BRN

Air Sensor

Enthalpy Outside

YEL

To Optional

Power Exhaust

1

Either the OAT or the Enthalpy

Sensor can be used but not both.

Remove OAT if Enthalpy’s used.

1

LEGEND

CTB: Central Terminal Board

Refer to Figure 31 for wiring optional

Refer to Figures 33 and 34 for Remote

2

MAT: Mixed Air Temperature Sensor

Differential Return Air Sensor kit.

Fault Detection and Diagnostic Monitoring.

3

OAT: Outside Air Temperature Sensor

Fig. 25 — Typical EconoMi$er X Wiring Diagram for 1 or 2 Speed Units

(Not for 48/50LC 07-12 Units)

10

Page 11

INSTRUCTIONS FOR 48/50LC

07-12 UNITS ONLY

IMPORTANT: This section is for economizer installation instructions on 48/50LC 07-12 units only.

1. Follow steps 1 through 19 in the Installation section.

2. The 48/50LC 07-12 units require different wiring than is

factory-attached to the W7220 Jade controller. Disconnect

the complete wiring harness factory-attached to the

W7220 Jade controller, as shown below in Fig. 26. This

harness can be discarded.

NOTE: The 4-wire 48TMHSRSE--A20 harness provided with the

economizer will also NOT be used on the 48/50LC 07-12 units,

see Fig. 27.

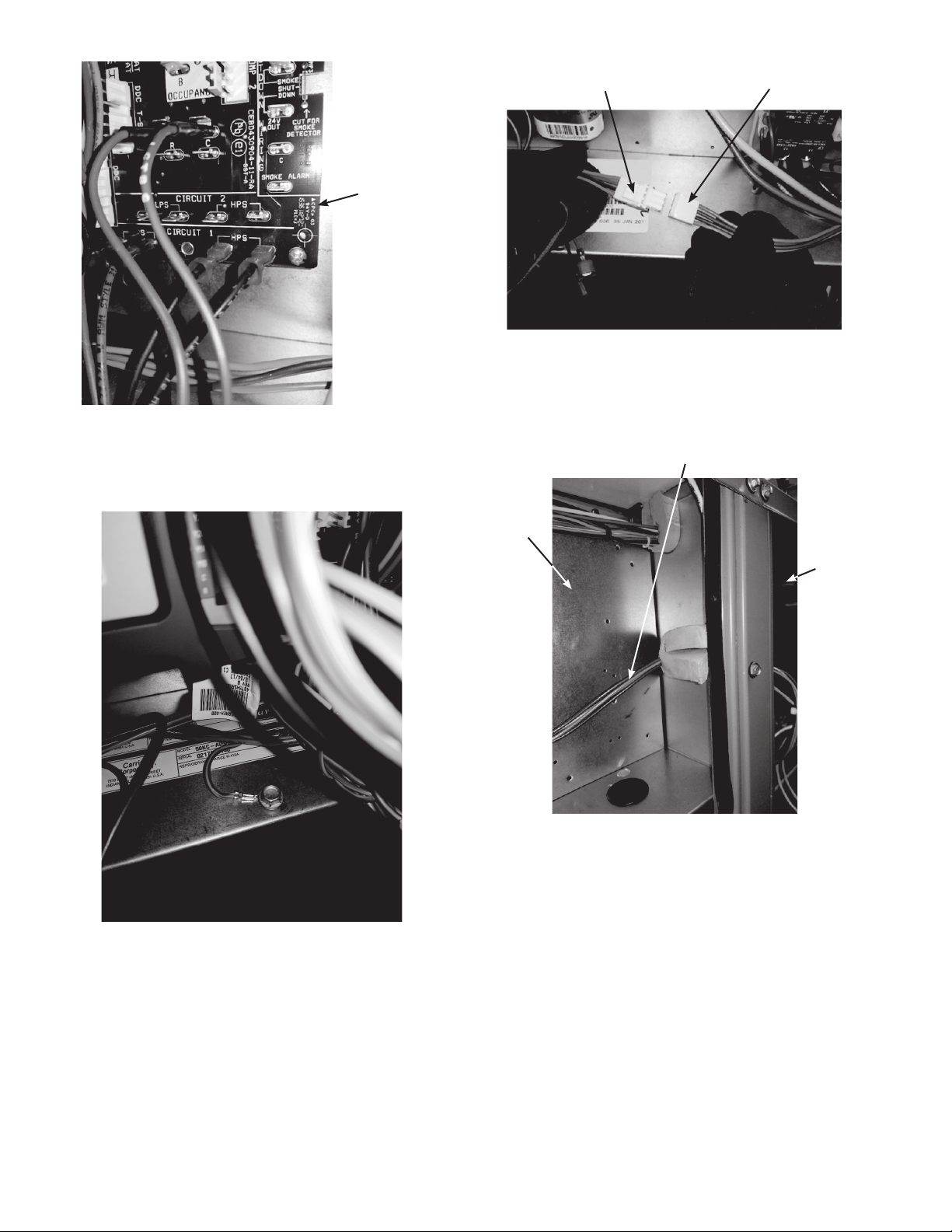

Fig. 26 — Remove Complete Harness Factory-

Attached to W7220 Controller

Fig. 27 — 48TMHSRSE--A20 Not

12 Units

3. The 48/50LC 07-12 units that do not have a factory-installed

economizer will have a new Jade W7220 controller wiring

harness shipped in the control box section of the HVAC unit.

This harness, Carrier part number 48LCHSRADH-A00, is

shown below in Fig. 28 and 30.

Used on 48/50LC 07-

Fig. 28 — 48LCHSRADH-A00 W7220 Controller Harness Shipped With 48/50LC 07-12 Units

11

Page 12

Fig. 29 — Photo of 48LCHSRADH-A00 W7220

Controller Harness Shipped With

48/50LC 07-12 Units

4. The connectors on the right side of Fig. 28 on the 48LCHSRADH-A00 harness attach to the Jade W7220 controller

installed in the unit control box. See Fig. 28 and 30.

48LCHSRADH-A00 harness connectors are labeled to easily identify the plug-in location on the controller.

5. Locate the Compressor Staging Control (CSC) board in

the HVAC unit. When a field-installed economizer is used,

the J5 jumper on the CSC must be removed. Remove the

J5 jumper. See Fig. 30.

6. The connectors on the left side of Fig. 28 on the 48LCHSRADH-A00 harness attach to the unit’s CSC board. Connect J3 and J5 plugs to the CSC board. See Fig. 30.

7. Screw the green wire with yellow stripe in the 48LCHSRADH-A00 harness to the control box (ground). See

Fig. 20 and 30.

8. Mount the provided HH79ZZ007 mixed air temperature

(MAT) sensor to the indoor blower. Confirm that the

screws do not interfere with blower rotation (see Fig. 23).

Connect the (2) spade terminals on the HH79ZZ007 to

orange and brown wires in the indoor blower section wire

bundle.

9. If using a differential return sensor or DCV sensor, install

it now. See installation details later in this instructions and

the wiring diagram for further information.

12

Page 13

NOTE: Harness attached to the W7220 controller from the Carrier

factory is removed and not used with 48/50LC 07-12 units.

Fig. 30 — Typical EconoMi$er X Wiring Diagram For 48/50LC 07-12 Units

13

Page 14

Installing Optional HH57AC081 Single Outside

4/ (108)

2/ (70)

/ (21)

2/ (55)

Air Enthalpy Sensor

When using the HH57AC081 (Honeywell C7400S) enthalpy

sensor for outside air changeover (see Fig. 32), the existing

HH79ZZ007 dry bulb sensor must be removed. The enthalpy

sensor will be mounted in the same location as the dry bulb

sensor (see Fig. 1). When the enthalpy sensor’s OA temperature, enthalpy and dew point are below the respective set

points, the outside air can be used for free-cooling. When any

of these is above the set point, free-cooling will not be available. Figure 31 shows the enthalpy boundaries in the W7220

Jade controller. There are (5) enthalpy boundaries (set points

ES1 through ES5), which are defined by dry bulb temperature,

enthalpy, and dew point. ES3 is the default setting. Table 7

shows the High Limit Curves for each setting.

NOTE: To use the HH57AC081 sensor for outside air sensor, the

dipswitches on the sensor must be set to OFF-OFF-OFF. See

Tab le 8.

The (2) gray wires with a plug from the EconoMi$er X harness

in the return chamber plug directly into the HH57AC081 enthalpy sensor. See Fig. 25 and 30 for wiring.

Fig. 31 — Enthalpy Curve Boundaries

Table 7 — Single Enthalpy and Dual Enthalpy High Limit Curves

ENTHALPY

CURVE

ES1 80.0 60.0 28.0 80.0 36.8 66.3 80.1

ES2 75.0 57.0 26.0 75.0 39.6 63.3 80.0

ES3 70.0 54.0 24.0 70.0 42.3 59.7 81.4

ES4 65.0 51.0 22.0 65.0 44.8 55.7 84.2

ES5 60.0 48.0 20.0 60.0 46.9 51.3 88.5

HL 86.0 66.0 32.4 86.0 38.9 72.4 80.3

TEMP.

DRY BULB (°F)

TEMP.

DEW POINT (°F)

ENTHALPY

(BTU/LB/DA)

TEMP (°F) HUMIDITY %RH TEMP (°F) HUMIDITY %RH

POINT P1 POINT P2

Table 8 — HH57AC081 Sensor DIP Switch

USE

DA OFF ON OFF

RA ON OFF OFF

OA OFF OFF OFF

LEGEND

DA — Discharge Air or Supply Sensor

RA — Return Air

OA — Outside Air

DIP SWITCH POSITIONS FOR SWITCHES 1,2, & 3

123

Fig. 32 — HH57AC081 Sensor, Dimensions and DIP

Switch Location

14

Page 15

Installing Differential Return Air Sensor

12-PIN FEMALE

PLUG FROM ECONOMIZER

BLU

BLK

GRA GRA GRA

GRA GRA

GRA

GRA

PNK

VIO

6

7

2

3

10

11

5

1

12

9

4

8

RED

ORG

PL6

PLUG

12-PIN MALE

PLUG IN UNIT

BRN

YEL

*HH57AC081

DIFFERENTIAL RETURN

SENSOR. FIELD MOUNTED

IN RETURN DUCT

WIRING

HARNESS*

*PROVIDED IN

CRDIFRASN01A00 Kit

The CRDIFRASN01A00 differential return air sensor kit must

be field mounted in the system’s return duct work. The kit includes a wiring harness that connects the EconoMi$er X harness in the return chamber of the unit to the provided

HH57AC081 sensor. Wire per Fig. 33.

In addition to using the HH57AC081 (Honeywell C7400S) sensor (see Fig. 32) for a single enthalpy sensor, it can also be used

as a differential return enthalpy or dry bulb sensor. Figure 31

shows the dual enthalpy boundaries in the W7220 Jade controller. With dual enthalpy, the HIGH LIMIT boundary is ES1 when

there are no stages of mechanical cooling energized and HL

(high limit) when a compressor stage is energized. Table 7

shows the High Limit Curves for each setting.

NOTE: To use the HH57AC081 sensor for differential return air,

the dipswitches on the sensor must be set to ON-OFF-OFF. See

Table 8.

When using the CRDIFRASN01A00 differential return enthalpy or dry bulb temperature option, see Table 9 for California

Title 24 setting requirements by region.

Fig. 33 — Wiring Differential Return Air Sensor

California’s Title 24 High Temperature Limit Settings

California’s Title 24 code requires a high temperature limit setting for all dry bulb outside air economizer change over. The

temperatures vary by region within California. See Table 9 for

high limit settings.

Table 9 — California Title 24 Regional High Limit Dry

Bulb Temperature Settings

TABLE 140.4-B AIR ECONOMIZER HIGH LIMIT SHUT OFF

DEVICE TYPE*

Fixed Dry Bulb

Differential Dry Bulb

Fixed Enthalpy†

+ Fixed Dry Bulb

* Only the high limit control devices listed are allowed to be used and

at the set points listed. Others such as Dew Point, Fixed Enthalpy,

Electronic Enthalpy, and Differential Enthalpy Controls, may not be

used in any climate zone for compliance with Section 140.4(e)1

unless approval for use is provided by the Energy Commission

Executive Director.

† At altitudes substantially different than sea level, the Fixed

Enthalpy limit value shall be set to the enthalpy value at 75°F and

50% relative humidity. As an example, at approximately 6,000 foot

elevation, the fixed enthalpy limit is approximately 30.7 Btu/lb.

CONTROL REQUIREMENTS

REQUIRED HIGH LIMIT

CLIMATE

ZONES

1, 3, 5, 11-16 OAT exceeds 75°F

2, 4, 10 OAT exceeds 73°F

6, 8, 9 OAT exceeds 71°F

7 OAT exceeds 69°F

1, 3, 5, 11-16

2, 4, 10

6, 8, 9

7

OAT exceeds 28 Btu/lb of dry air

All

(ECONOMIZER

OFF WHEN):

DESCRIPTION

OAT exceeds

RA temperature

OAT exceeds return air

temperature minus 2°F

OAT exceeds return air

temperature minus 4°F

OAT exceeds return air

temperature minus 6°F

OAT exceeds 75°F

or

Demand Controlled Ventilation (DCV)

Refer to EconoMi$er X wiring diagram (Fig. 25 and 30) and

DCV instructions if demand controlled ventilation (CO

sor) is used. CO2 sensor will wire into the blue and black connections at the Jade controller as shown in Fig. 25, 30, and 34.

If a field-installed CO

sensor is connected to the

2

EconoMi$er X controller, a demand controlled ventilation

strategy will operate automatically. As the CO

level in the

2

space increases above the set point (on the EconoMi$er X controller), the minimum position of the dampers will be increased

proportionally, until the Maximum Ventilation setting is

reached. As the space CO

level decreases because of the in-

2

crease in fresh air, the outdoor damper will follow the higher

demand condition from the DCV mode or from the free cooling mode.

BLACK WIRE

IAQ 2-10 VDC

BLUE WIRE

IAQ COM

Fig. 34 — CO

Wiring Connections to Jade Controller

2

sen-

2

†

15

Page 16

Remote (Downstairs) Monitoring of Controller’s

CR

AUX2-1

OCC

E-GND

EXH1

AUX1-0

Y2-I

Y2-O

Y1-I

Y1-O

C

R

W7220 JADE

ECONOMIZER

U1

U1

R

Rc

C

A-L/A

FURNACE, AIR HANDLER,

OR RTU

TH8321R OR

TH8321WF

SUB-BASE

Fault Detection and Diagnostics

Many codes including IECC, Title 24, and ASHRAE 90.1 require that the economizer’s faults be accessible by operating or

service personal, or annunciated locally on zone thermostat. To

setup remote monitoring on the controller, under SYSTEM

SETUP, AUX1-OUT must be set to SYS.

The latest versions of Honeywell’s TH8321WF or TH8321R

thermostats are options for meeting this requirement. Figure 35

shows an example of the thermostat wiring to the Jade controller. Follow instructions provided with Honeywell thermostat.

Another option that is acceptable to some codes is an annunciator light visible by service personnel. See Fig. 36 for typical

wiring to the Jade controller. Refer to codes for proper labeling

of light.

W7220 Economizer Controller Module

Fig. 35 — Thermostat Wired for Remote FDD

MAT

MAT

OAT

OAT

IAQ (2-10V)

IAQ COM

IAQ 24V

ACT (2-10V)

ACT COM

ACT 24V

JADE Setting: Under the “System Setup” menu, set AUX1-OUT to

“SYS” which will close JADE relay on fault detection

AUC2-1

OCC

E-GND

EXH1

AUX1-0

Y21

Y2O

Y1I

Y1O

=CR

TO “AUX1-0” TERMINAL

TO “C” TERMINAL

Annunciator Light*

Examples of annunciator lights

would include these Grainger lights:

- Item #20C841

- Item #20C846

Fig. 36 — Annunciator Light Wired for Remote FDD

16

Page 17

GENERAL JADE W7220 CONTROLLER AND

SENSOR INFORMATION

W7220 Economizer

The economizer controller used on electromechanical units is a

Honeywell W7220, which is located in the RTU base unit’s

Control Box. See the base unit’s Installation Instructions for

the location of the Control Box access panel.

The W7220 controller provides the following:

• 2-line LCD interface screen for setup, configuration, and

troubleshooting.

• On-board fault detection and diagnostics

• Sensor failure loss of communications identification

• Automatic sensor detection

• Capabilities for use with multiple-speed indoor fan systems

User Interface

The user interface consists of a LCD display and a 4-button keypad on the front of the economizer controller.

Keypad

The four navigation buttons (see Fig. 37) are used to scroll

through the menus and menu items, to select menu items, and

to change parameter and configuration settings.

6. Press the ▼ button to decrease the displayed parameter

value.

NOTE: When values are displayed, pressing and holding the ▲or

▼ button causes the display to automatically increment.

7. Press the (Enter) button to accept the displayed value

and store it in nonvolatile RAM.

8. The message “CHANGE STORED” displays.

9. Press the (Enter) button to return to the current menu

parameter.

10. Press the (Menu Up/Exit) button to return to the previous menu.

Menu Structure

Table 11 illustrates the complete hierarchy of menus and parameters for the EconoMi$er X system.

The Menus in display order are:

•STATUS

•SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

• CHECKOUT

•ALARMS

IMPORTANT: The default setting on the W7220 controller

is for a “Fan Type” with 2 speed, which is correct for 2 or 3

speed units (48/50LC 07-12). For a 1 (single) speed unit, the

setting under SYSTEM SETUP > FAN TYPE must be

changed to 1 speed.

Fig. 37 — W7220 Controller

Using the Keypad with Menus

To use the keypad when working with menus:

•Press the ▲ (Up arrow) button to move to the previous

menu.

•Press the ▼ (Down arrow) button to move to the next

menu.

• Press the (Enter) button to display the first item in the

currently displayed menu.

• Press the (Menu Up/Exit) button to exit a menu’s item

and return to the list of menus.

Using the Keypad with Settings and Parameters

To use the keypad when working with set points, system and

advanced settings, checkout tests, and alarms:

1. Navigate to the desired menu.

2. Press the (Enter) button to display the first item in the

currently displayed menu.

3. Use the ▲ and ▼ buttons to scroll to the desired parameter.

4. Press the (Enter) button to display the value of the

currently displayed item.

5. Press the ▲ button to increase the displayed parameter

value.

IMPORTANT: Table 11 illustrates the complete hierarchy.

Menu parameters may be different depending on configuration. For example, none of the DCV parameters appear for a

system that does not have a DCV (CO

) sensor.

2

Programming the Jade W2770 Controller

The next several pages detail the different status displays, set

points, setup, and alarms available on the controller. The list

below and Table 10 summarize the inputs required for a standard application with a single outside air sensor.

NOTE: Instead of setting the SETPOINTS, you can use the defaults already set in the Jade controller – see default settings below. See Table 10 for summarized standard settings or, for more

detail, see Table 11 – Menu Structure.

SETPOINTS

• MAT SET: this sets the mixed air temperature (MAT) setting. The controller has a default of 53°F, but the range is

anywhere from 38°F to 70°F.

• LOW T LOCK: This setting locks out the compressor (or

mechanical cooling) at a given temperature. The default is

32°F, but the controller’s range is from –45°F to 80°F.

• DRYBULB SET: if you have an economizer with a dry

bulb outside air sensor, you will see and set the DRYBULB SET. The default setting is 63°F but the controller’s

range is 48°F to 80°F.

• ENTH CURVE: if you have a single enthalpy outside air

sensor instead of a dry bulb, you will see and set the ENTH

CURVE setting. There are 5 setting options: ES1 thru ES5.

Check Table 7 for the limits for each of these settings. ES3

is the default setting.

• MIN POS: The minimum position allows for ventilation

even when not in the free-cooling mode. If you have a single speed unit there will be only one minimum position

17

Page 18

setting. The default is 4.4 volts, but the range is 2 to

10 vdc.

• MIN POS H and MIN POS L: If your unit is 2 speed, there

will be 2 minimum position settings that show up on the

menu. The first is MIN POS H (for high speed), which has

a default of 4.4-v. The second is MIN POS L (for low

speed), which has a default of 6.0-v. Note that MIN POS H

and MIN POS L are only displayed if under SYSTEM

SETUP, AUX2 IN is set to “W1”, and FAN TYPE is set to

2 speed.

Table 10 — Standard Jade W7220 Controller Configuration

SYSTEM SETUP

• INSTALL: Allows you to set the current date. Use the keypad buttons to scroll to the correct date.

• EQUIPMENT: Always set to CONV even if the unit is a

heat pump.

• AUX2 IN: Always set to W.

• FAN TYPE: Set for either single speed or 2 speed. The default setting is 2 speed.

• AUX OUT: If remote Fault Detection and Diagnostic

(FDD) monitoring is required, select SYS.

• OCC: occupancy, always set to INPUT

CONTROLLER

MENU ITEM

MAT SET 53°F 38°F to 70°F 53°F 38°F to 70°F

LOW T LOCK 32°F –45°F to 80°F 32°F –45°F to 80°F

DRYBLB SET 63°F 48°F to 80°F 63°F 48°F to 80°F Only displayed if using single DB OA sensor

ENTH CURVE ES3 ES1 to ES5 ES3 ES1 to ES5 Only displayed if using a single enthalpy OA sensor

MIN POS 4.4 vdc 2 to 10 vdc n/a n/a Only displayed if set up for single speed unit

SET POINTS

MIN POS H n/a n/a 4.4 vdc 2 to 10 vdc Only displayed if set up for 2 speed unit

MIN POS L n/a n/a 6.0 vdc 2 to 10 vdc Only displayed if set up for 2 speed unit

INSTALL 1/1/2010 Current date 1/1/2010 Current date

EQUIPMENT CONV CONV CONV CONV Always set to CONV, even on HP units

AUX2 IN W W W W Always set to W

FAN TYPE 2 speed 1 speed 2 speed 2 speed See Note 3

AUX1 OUT NONE SYS NONE SYS Set to SYS for remote FDD monitoring

OCC INPUT INPUT INPUT INPUT Always set to INPUT

SYSTEM SETUP

n/a — Not applicable

NOTES:

1. For 2 speed unit, under SYSTEM SETUP: EQUIPMENT= CONV,

AUX2 I = W, and FAN TYPE = 2 SPEED

2. More sophisticated controller setups, including for DCV or power

exhaust, are available by referring to Table 11 options

3. Fan speed options are:

1) 1 Speed

2) 2 Speed

3) 2 Speed: 1 Heat, 1 Cool.

4) 3 Speed: 1 Heat, 2 Cool.

4. Do not use 3 speed setting for LC units.

FOR SINGLE SPEED UNIT FOR 2 SPEED UNIT

Default Set to: Default Set To:

NOTE

18

Page 19

Table 11 — Menu Structure

1

MENU PARAMETER

ECON AVAIL NO YES/NO

ECONOMIZING NO YES/NO

OCCUPIED NO YES/NO

HEAT PUMP n/a

COOL Y1-IN OFF ON/OFF

COOL Y1-OUT OFF ON/OFF

COOL Y2-IN OFF ON/OFF

COOL Y2-OUT OFF ON/OFF

MA TEMP _ _ . _°F (or °C)

DA TEMP _ _ . _°F (or °C)

STATUS

OA TEMP _ _ . _°F (or °C)

OA HUM _ _% 0 to 100%

RA TEMP _ _ . _°F (or °C)

RA HUM _ _% 0 to 100%

IN CO2 _ _ _ppm 0 to 2000 ppm

DCV STATUS n/a ON/OFF

DAMPER OUT 2.0V 2.0 to 10.0-v

ACT POS _ _% 0 to 100%

ACT COUNT n/a 1 to 65535

ACTUATOR n/a

EXH1 OUT OFF ON/OFF

EXH2 OUT OFF ON/OFF

PARAMETER

DEFAULT

VALUE

PARAMETER

RANGE AND

INCREMENT

COOL

HEAT

0°F to 140°F

(–18°C to 60 °C)

0°F to 140°F

(–18°C to 60 °C)

–40°F to 140°F

(–40°C to 60°C)

0°F to 140°F

(–18°C to 60°C)

OK/Alarm

(on Alarm menu)

2

ECONOMIZING AVAILABLE

YES = economizing available; the system can use outside air for free cooling

NOTES

when required

ECONOMIZING ACTIVE

YES = Outside air being used for 1st stage cooling

NO = Economizing not active

OCCUPIED

YES = OCC signal received from space thermostat or unitary controller

YES = 24 vac on terminal OCC.

NO = 0 vac on terminal OCC.

HEAT PUMP MODE

(Not available on 2-speed configuration)

FIRST STAGE COOLING DEMAND (Y1-IN)

Y1-I signal from space thermostat or unitary controller for cooling stage 1.

ON = 24 vac on terminal Y1-I

OFF = 0 vac on terminal Y1-I

FIRST STAGE COOLING RELAY OUTPUT

ON = 24 vac on terminal Y1-O; Stage 1 mechanical cooling called on

OFF = 0 vac on terminal Y1-O; no mechanical cooling

SECOND STAGE COOLING DEMAND (Y2-IN)

Y2-I signal from space thermostat our unitary controller for second stage

cooling.

ON = 24 vac on terminal Y2-I

OFF = 0 vac on terminal Y2-I

SECOND STAGE COOLING RELAY OUTPUT

ON = 24 vac on terminal Y2-O; stage 2 mechanical cooling called on

OFF = 0 vac on terminal Y2-O; no stage 2 mechanical cooling

MIXED AIR TEMPERATURE, Cooling Mode

Displays value of measured mixed air from MAT sensor. Displays _ _ . _ if

not connected, short or out-of-range.

DISCHARGE AIR TEMPERATURE, after Heating section

(Accessory sensor required)

Displays when Discharge Air sensor is connected and displays measured

discharge temperature. Displays _ _ . _ if sensor sends invalid value, if not

connected, short or out-of-range.

OUTSIDE AIR TEMPERATURE

Displays measured value of outdoor-air temperature. Displays _ _ . _ if

sensor sends invalid value, short or out-of-range.

OUTSIDE AIR RELATIVE HUMIDITY

Displays measured value of outdoor humidity from OA sensor. Displays __%

if not connected, short, or out-of-range.

RETURN AIR TEMPERATURE

Displays measured value of return air temperature from RAT sensor.

Displays _ _ . _ if sensor sends invalid value, if not connected, short or outof-range

RETURN AIR RELATIVE HUMIDITY

Displays measured value of return air humidity from RA sensor. Displays

__% if sensor sends invalid value, if not connected, short or out-of-range

SPACE/RETURN AIR CO

(CO2 sensor required, accessory or factory option)

Displays value of measured CO

short or out-of-range

DEMAND CONTROLLED VENTILATION STATUS

(CO

sensor required, accessory or factory option)

2

Displays ON if above set point and OFF if below set point, and ONLY if a

CO

sensor is connected.

2

Displays voltage output to the damper actuator.

0% = OA Damper fully closed

2

from CO2 sensor. Invalid if not connected,

2

100%= OA Damper full open

Displays actual position of outdoor air damper actuator

2.0-v = OA Damper fully-closed

10.0-v = OA Damper full open

Displays number of times actuator has cycled.

1 cycle equals accrued 180° of actuator movement in any direction

Displays Error if voltage or torque is below actuator range

EXHAUST STAGE 1 RELAY OUTPUT

Output of EXH1 terminal:

ON = relay closed

OFF = relay open

EXHAUST STAGE 2 RELAY OUTPUT

Output of AUX terminal; displays only if AUX = EXH2

ON = relay closed

OFF = relay open

19

Page 20

Table 11 — Menu Structure1 (cont)

MENU PARAMETER

3

ERV

STATUS

(cont)

MECH COOL ON 0 0,1, or 2 Displays stage of mechanical cooling that is active.

FAN SPEED n/a LOW or HIGH

W (HEAT ON) n/a ON/OFF

MAT SET 53°F (12°C)

LOW T LOCK 32°F (0°C)

DRYBLB SET 63°F (17°C)

DRYBLB DIFF 0°F

ENTH CURVE ES3

DCV SET 1100ppm

MIN POS 4.4 V 2 to 10 vdc

MIN POS L 6.0V 2 to 10 vdc

SETPOINTS

MIN POS M 5.4V 2 to 10 vdc

MIN POS M 4.4V 2 to 10 vdc

VENTMAX L 6.0 V 2 to 10 vdc

VENTMAX M 5.4 V 2 to 10 vdc

VENTMAX H 4.4 V 2 to 10 vdc

VENTMIN L 3.7 V 2 to 10 vdc

VENTMIN M 3.4 V 2 to 10 vdc

VENTMIN H 2.8 V 2 to 10 vdc

PARAMETER

DEFAULT

VALUE

PARAMETER

RANGE AND

INCREMENT

OFF ON/OFF

38°F to 65°F

(3°C to 18°C);

increment by 1°

–45°F to 80°F

(–43°C to 27°C);

increment by 1°

48°F to 80°F

(9°C to 27°C);

increment by 1°

0°F to 6°F;

increment by 2°F

ES1,ES2,ES3,ES

4, or ES5

500 to 2000ppm;

increment by 100

2

ENERGY RECOVERY UNIT RELAY OUTPUT

Output of AUX terminal; displays only if AUX = ERV

ON = relay closed

NOTES

OFF = relay open

SUPPLY FAN SPEED

Displays speed setting of fan on a 2‒speed fan unit.

HEAT DEMAND STATUS

Displays status of heat demand on a 2‒speed fan unit.

MIXED AIR SET POINT

Set point determines where the economizer will modulate the OA damper to

maintain the mixed air temperature.

COMPRESSOR LOW TEMPERATURE LOCKOUT

Set point determines outdoor temperature when the mechanical cooling

cannot be turned on. Commonly referred to as the compressor lockout.

OA DRY BULB TEMPERATURE CHANGEOVER SETPOINT

Setpoint determines where the economizer will assume outdoor air

temperature is good for free cooling; e.g.: at 63°F (17°C), unit will economize

at 62°F (16.7°C) and below and not economize at 64°F (17.8°C) and above.

There is a 2°F (1.1°C) deadband.

DRYBULB SET is only displayed if the economizer has a single dry bulb

sensor

Dry bulb Differential will only show if using dual dry bulb - i.e. when an

outdoor air temperature sensor C7250 is attached to OAT terminals and

C7400S sensor is wired to S-Bus and configured for RAT (return air).

Free cooling will be assumed whenever OA temp is at or below RAT minus

this dry bulb setting.

ENTHALPY CHANGEOVER CURVE

(Requires enthalpy sensor option)

Enthalpy boundary “curves” for economizing using single enthalpy

DEMAND CONTROLLED VENTILATION SET POINT

Displays only if CO

Ventilation of space. Above the set point, the OA dampers will modulate

open to bring in additional OA to maintain a space ppm level below the set

point.

VENTILATION MINIMUM POSITION.

Only displayed if controller is set for single speed unit under FAN TYPE, and

if DCV is NOT used.

VENTILATION MINIMUM POSITION AT LOW SPEED.

Only displays if unit is set for 2 or 3 speed and CO

speed with 1 heat and 1 cool then set for HEATING ventilation. If using 3

speed with 1 heat and 2 cool then set for LOW SPEED COOLING

ventilation.

sensor is connected. Set point for Demand Control

2

is not used. IF using 2

2

VENTILATION MINIMUM POSITION AT MEDIUM SPEED.

Only displays if unit is set for 3 speed with 1 heat and 2 cool, and CO

used. Set for HEATING ventilation.

VENTILATION MINIMUM POSITION AT HIGH SPEED.

Only displays if unit is set for 2 or 3 speed and CO

speed with 1 heat and 1 cool then set for COOLING ventilation. If using 3

speed with 1 heat and 2 cool then set for HIGH SPEED COOLING ventilation

DCV MAXIMUM DAMPER POSITION AT LOW SPEED

Displays only if a CO

cfm) set point. Displays 2 to 10 V if <3 sensors (RA,OA, and MA). In AUTO

sensor is connected. Used for Vbz (ventilation max

2

is not used. IF using 2

2

mode dampers controlled by CFM

DCV MAXIMUM DAMPER POSITION AT MEDIUM SPEED.

Only displays if unit is set for 3 speed with 1 heat and 2 cool. Set for

HEATING ventilation.

DCV MAXIMUM DAMPER POSITION AT HIGH SPEED.

Only displays if unit is set for 2 speed or 3 speed with 1 heat and 2 cool. IF

using 2 speed with 1 heat and 1 cool then set for COOLING ventilation. If

using 3 speed with 1 heat and 2 cool then set for HIGH SPEED COOLING

ventilation

DCV MINIMUM DAMPER POSITION AT LOW SPEED.

Only displays if unit is set for 2 speed or 3 speed with 1 heat and 2 cool. IF

using 2 speed with 1 heat and 1 cool then set for HEATING ventilation. If

using 3 speed with 1 heat and 2 cool then set for LOW SPEED COOLING

DCV MINIMUM DAMPER POSITION AT MEDIUM SPEED.

Only displays if unit is set for 3 speed with 1 heat and 2 cool. Set for

HEATING ventilation.

DCV MINIMUM DAMPER POSITION AT HIGH SPEED.

Only displays if unit is set for 2 speed or 3 speed with 1 heat and 2 cool. IF

using 2 speed with 1 heat and 1 cool then set for COOLING ventilation. If

using 3 speed with 1 heat and 2 cool then set for HIGH SPEED COOLING

ventilation

is not

2

20

Page 21

Table 11 — Menu Structure1 (cont)

MENU PARAMETER

ERV OAT SP 32°F (0°C)

EXH1 SET 50% 0 to 100%

EXH1 L SET 65% 0 to 100%

EXH1 M SET 60% 0 to 100%

SETPOINTS

(cont)

EXH2 H SET 50% 0 to 100%

EXH2 L SET 80% 0 to 100%

EXH2 M SET 77% 0 to 100%

EXH2 H SET 75% 0 to 100%

INSTALL 01/01/10

UNITS DEG °F °F or °C Sets economizer controller in degrees Fahrenheit or Celsius

EQUIPMENT CONV

AUX2 I W

SYSTEM

SETUP

FAN TYPE 2 speed 1 speed/2 speed

* These Fan Type (speed) settings are for future use only. Do not use for 3 speed LC units.

FAN CFM 5000cfm

AUX OUT NONE

OCC INPUT

MA LO SET 45°F (7°C)

FREEZE POS CLO CLO or MIN

CO2 ZERO 0ppm

CO2 SPAN 2000ppm

ADVANCED

SETUP

STG3 DLY 2.0h

SD DMPR POS CLO CLO or OPN

DCVCAL ENA MAN

PARAMETER

DEFAULT

VALUE

PARAMETER

RANGE AND

INCREMENT

0°F to 50°F

(–18°C to 10°C);

increment by 1°

2

Conventional or

HP

W required for

2-speed mode

100 to 15000 cfm;

increment by 100

NONE

ERV

EXH2

SYS

INPUT or

ALWAYS

35°F to 55°F

(2°C to 12°C);

incremented by 1°

0 to 500 ppm;

Increment by 10

1000 to 3000 ppm;

Increment by 10

0 min, 5 min, 15

min, then 15 min

intervals. Up to 4 h

or OFF

MAN (manual)

AUTO

NOTES

ENERGY RECOVERY VENTILATION UNIT OUTDOOR AIR

TEMPERATURE SETPOINT

Only displayed when AUX1 O = ERV

Exhaust fan set point for single speed units. Based on OA Damper position

to activate power exhaust.

EXHAUST FAN 1 SETPOINT AT LOW SPEED

On 2 speed or 3 speed with 1 heat and 2 cool. Based on economizer OA

damper position to activate power exhaust.

EXHAUST POINT 1 SETPOINT AT MEDIUM SPEED

Only displays if unit is set for 3 speed with 1 heat and 2 cool. Based on

economizer OA damper position to activate power exhaust.

EXHAUST FAN 1 SETPOINT AT HIGH SPEED

On 2 speed or 3 speed with 1 heat and 2 cool. Based on economizer OA

damper position to activate power exhaust.

EXHAUST FAN 2 SETPOINT AT LOW SPEED

On 2 speed or 3 speed with 1 heat and 2 cool. Based on economizer OA

damper position to activate power exhaust.

EXHAUST FAN 2 SETPOINT AT MEDIUM SPEED

Only displays if unit is set for 3 speed with 1 heat and 2 cool. Based on

economizer OA damper position to activate power exhaust.

EXHAUST FAN 2 SETPOINT AT HIGH SPEED

On 2 speed or 3 speed with 1 heat and 2 cool. Based on economizer OA

damper position to activate power exhaust.

Display order = MM/DD/YY

Setting order = DD, MM, then YY.

Always set to CONV even for heat pump

Always set to W

Sets the economizer controller to the number of unit fan speeds.

Fan Type options:

1 Speed units

2 speed units

*2 speed units: 1 for heat and 1 for cool

*3 speed units: 1 for heat and 2 for cool

UNIT DESIGN AIRFLOW (CFM)

Enter ONLY if using DCVCAL ENA = AUTO

• NONE = not configured (output is not used)

• ERV = Energy Recovery Ventilation

• EXH2 = second damper position relay closure for second exhaust fan

• SYS = use output as an alarm signal

Always set to INPUT

MIXED AIR TEMPERATURE LOW LIMIT

Temperature to achieve Freeze Protection (close damper and alarm if

temperature falls below setup value).

FREEZE PROTECTION DAMPER POSITION

Damper position when freeze protection is active

CLO = closed

MIN = MIN POS or VENTMIN

CO

ppm level to match CO2 sensor start level.

2

ppm span to match CO2 sensor.

CO

2

COOLING STAGE 3 DELAY

Delay after stage 2 for cool has been active. Turns on 2nd stage of cooling

when economizer is 1st stage and mechanical cooling is 2nd. Allows three

stages of cooling, 1 economizer and 2 mechanical.

OFF = no Stage 3 cooling

Function NOT AVAILABLE with 2-speed mode

Indicates shutdown signal from space thermostat or unitary controller. When

controller receives 24 vac input on the SD terminal in conventional mode, the

OA damper will open if programmed for OPN and OA damper will close if

programmed for CLO. All other controls, e.g., fans, etc. will shut off.

Turns on the DCV automatic control of the dampers. Resets ventilation

based on the RA, OA, and MA sensor conditions. Requires all 3 RA, OA, and

MA sensors.

For single speed units only.

21

Page 22

Table 11 — Menu Structure1 (cont)

MENU PARAMETER

PARAMETER

DEFAULT

VALUE

MAT T CAL 0.0°F (or °C) ±2.5°F (±1.4°C)

OA T CAL 0.0°F (or °C) ±2.5°F (±1.4°C)

OA H CAL 0% RH ±10% RH

ADVANCED

SETUP (cont)

RA T CAL 2.0°F (or °C) ±2.5°F (±1.4°C)

RA H CAL 0% RH ±10% RH

DA T CAL 0.0°F (or °C) ±2.5°F (±1.4°C)

2SP FAN DELAY 5 minutes

DAMPER VMINHS

DAMPER VMAXHS

n/a n/a Positions OA damper to VMIN High Speed position

n/a n/a Positions OA damper to VMAX High Speed position

DAMPER OPEN n/a n/a

CHECKOUT

DAMPER CLOSE n/a n/a Positions damper to the fully closed position

CONNECT

Y1-O

CONNECT

Y2-O

CONNECT

AUX1O

n/a n/a Closes the Y1-O relay (Y1-O)

n/a n/a Closes the Y2-O relay (Y2-O)

n/a n/a

Alarms display only when they are active. The menu title “ALARMS(_)” includes the number of active alarms in parenthesis

( ). When using SYLK bus sensors, “SYLK” will appear on the screen, and when using 20k OA temperature sensors, “SENS

T” will appear on the screen

MA T SENS ERR n/a n/a

CO2 SENS ERR n/a n/a

OA SENS T ERR n/a n/a

ALARMS(_)

OA SYLK SENS

ERR

n/a n/a

DA T SENS ERR n/a n/a DISCHARGE AIR TEMPERATURE SENSOR ERROR

SYS ALARM n/a n/a

ACT UNDER V n/a n/a

ACT OVER V n/a n/a

ACT STALLED n/a n/a

See Legend and Notes for Table 11 on page 23.

PARAMETER

RANGE AND

INCREMENT

2

0 to 20 minutes in

1 minute

increments

NOTES

MIXED AIR TEMPERATURE CALIBRATION

Allows for the operator to adjust for an out of calibration mixed air

temperature (MAT) sensor

OUTSIDE AIR TEMPERATURE CALIBRATION

Allows for the operator to adjust for an out of calibration outside air

temperature (OAT) sensor

OUTSIDE AIR HUMIDITY CALIBRATION

Allows for the operator to adjust for an out of calibration outside air enthalpy

sensor

RETURN AIR TEMPERATURE CALIBRATION

Allows for the operator to adjust for an out of calibration return air

temperature (RA) sensor

RETURN AIR HUMIDITY CALIBRATION

Allows for the operator to adjust for an out of calibration return air enthalpy

sensor

DISCHARGE AIR TEMPERATURE CALIBRATION

Allows for the operator to adjust for an out of calibration discharge air

temperature (DAT) sensor

TIME DELAY ON SECOND STAGE ECONOMIZING

While in the Economizing mode, this is the delay between thermostat Y2

call and Y1-O output to mechanical cooling stage, to allow high speed fan

operation to attempt to cool space first.

Position OA damper to the full open position.

Exhaust fan contacts enable during the DAMPER OPEN test. Make sure to

pause in the mode to allow exhaust contacts to energize due to the delay in

the system.

Energizes the AUX1O output. If Aux setting is:

• NONE—no action taken

• ERV—24 vac out. Turns on or signals an ERV that the conditions

are not good for economizing but are for ERV operation.

• SYS—24 vac out. Issues a system alarm

d

MIXED AIR TEMPERATURE SENSOR ERROR

Mixed air sensor has failed or become disconnected - check wiring then

replace sensor if the alarm continues.

SENSOR ERROR

CO

2

CO

sensor has failed, gone out of range or become disconnected - check

2

wiring, then replace sensor if the alarm continues.

OUTSIDE AIR TEMPERATURE SENSOR ERROR

Outdoor-air temperature sensor has failed or become disconnected - check

wiring (OAT sensor connected at input terminals OAT), then replace if the

alarm continues.

OUTSIDE AIR ENTHALPY SENSOR ERROR

OAT sensor connected on S-bus.

When AUX1-0 is set to SYS and there is any alarm (e.g., failed sensors,

etc.), the AUX1-0 terminal has 24 vac out.

ACTUATOR VOLTAGE LOW

Voltage received by Actuator is below expected range.

ACTUATOR VOLTAGE HIGH

Voltage received by Actuator is over expected range.

ACTUATOR STALLED

Actuator stopped before achieving commanded position.

22

Page 23

Legend and Notes for Table 11.

NA

AUX2-

OCC

E-GND

EXH1

AUX1- O

Y2-

Y1-

Y2-O

Y1-O

C

R

50048848-002

Rev. A

NA

A2

OCC

EX

A1

Y2I

Y2O

Y1I

Y1O

C

R

Cert Product

California Title 24, Part 6

HJW10

www.energy.ca.gov

MAT

MAT

OAT

OAT

S-BUS

S-BUS

IAQ 2-10

IAQ COM

IAQ 24V

ACT 2-10

ACT COM

ACT 24V

MA

MA

OA

OA

SB

SB

SB

SB

SB

SB

V

C

R

V

C

R

NA

50040839-001

Rev. G

LEGEND

n/a — Not applicable

LCD — Liquid Crystal Display

MAT — Mixed Air Temperature

OAT — Outdoor Air Temperature

OCC — Occupied

RAT — Return Air Temperature

RTU — Rooftop Unit

NOTES:

1. Table 11 illustrates the complete hierarchy. Menu parameters may

be different depending on configuration. For example, none of the

DCV parameters appear for a system that does not have a DCV

) sensor.

(CO

2

2. When values are displayed, pressing and holding the

ton causes the display to automatically increment.

3. ERV Operation: When in Cooling mode AND the conditions are

NOT OK for economizing - the ERV terminal will be energized. In

the Heating mode the ERV terminal will be energized when the OA

is below the ERV OAT set point in the set point menu.

▲ or ▼ but-

Checkout Tests

Use the Checkout menu (see Table 11) to test the damper operation and any configured outputs. Only items that are configured are shown in the Checkout menu.

NOTE: See User Interface for information about menu navigation

and use of the keypad.

To perform a Checkout test:

1. Scroll to the desired test in the Checkout menu using the

▲ and ▼ buttons.

2. Press the button to select the item.

3. RUN? appears.

4. Press the button to start the test.

5. The unit pauses and then displays IN PROGRESS.

6. When the test is complete, DONE appears.

7. When all desired parameters have been tested, press the

(Menu up) button to end the test.

Checkout test can be performed at any time during the operation of the system as a test that the system is operable.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to

equipment.

Be sure to allow enough time for compressor startup and

shutdown between checkout tests. Do not short-cycle the

compressors.

SETUP AND CONFIGURATION

W7220 Economizer Module Wiring

Use Fig. 38 and Tables 12 and 13 to locate the wiring terminals

for the economizer module.

NOTE: The four terminal blocks are removable. Slide out each

terminal block, wire it, and then slide it back into place.

Fig. 38 — W7220 Economizer Module Terminal

Table 12 — Economizer Module — Left Hand

LABEL TYPE DESCRIPTION

MAT

MAT

OAT

OAT

S-BUS

S-BUS

IAQ 2-10 2-10 vdc

IAQ COM COM Air Quality Sensor Common

IAQ 24V 24 vac Air Quality Sensor 24 vac Source

ACT 2-10 2-10 vdc Damper Actuator Output (2-10 vdc)

ACT COM COM Damper Actuator Output Common

ACT 24V 24 vac Damper Actuator 24 vac Source

Connection Labels

Terminal Blocks

Top Left Terminal Block

20k NTC

and COM

20k NTC

and COM

S-BUS

(Sylk Bus)

Bottom Left Terminal Block

Mixed Air Temperature Sensor

(Polarity insensitive connections)

Outdoor Air Temperature Sensor

(Polarity insensitive connection)

Enthalpy Control Sensor

(Polarity insensitive connection)

Air Quality Sensor Input

(e.g. CO

sensor)

2

23

Page 24

Table 13 — Economizer Module — Right Hand

Terminal Blocks

LABEL TYPE DESCRIPTION

Top Right Terminal Block

n/a The first terminal is not used

Shut Down (SD) or Heat (W)

AUX2 I 24 vac IN

OCC 24 vac IN Occupied / Unoccupied Input

E - GND E-GND Earth Ground - System Required

EXH1 24 vac OUT Exhaust Fan 1 Output

AUX1 O 24 vac OUT

Y2-1 24 vac IN

Y2-O 24 vac OUT

Y1-I 24 vac IN

Y1-O 24 vac OUT

C COM 24 vac Common

R 24 vac 24 vac Power (Hot)

Conventional only

and

Heat Pump Changeover (O?B) in Heat

Pump mode.

Programmable:

Exhaust fan 2 output

or

ERV

or

System alarm output

Bottom Right Terminal Block

Y2 in - Cooling Stage 2 Input from space

thermostat

Y2 out - Cooling Stage 2 Output to stage 2

mechanical cooling

Y1 in - Cooling Stage 2 Input from space

thermostat

Y1 out - Cooling Stage 2 Output to stage 2

mechanical cooling

Time-out and Screen Saver

When no buttons have been pressed for 10 minutes, the LCD

displays a screen saver, which cycles through the Status items.

Each Status item displays in turn and cycles to the next item after 5 seconds.

START-UP AND OPERATION

Cooling with EconoMi$er X

For Occupied mode operation of EconoMi$er X, there must be

a 24-v signal at terminals R and OCC (provided through PL6-3

from the unit’s IFC coil). Removing the signal at OCC places

the EconoMi$er X control in Unoccupied mode. See Table 14

for Damper Position Control.

Table 14 — Damper Position Control, 2-Speed Fan Motor, Economizer Cooling Not Available

During Occupied mode operation, indoor fan operation will be

accompanied by economizer dampers moving to Minimum Position set point for ventilation. If indoor fan is off, dampers will

close. During Unoccupied mode operation, dampers will remain closed unless a Cooling (by free cooling) or DCV demand is received.

When free cooling using outside air is not available, the unit

cooling sequence will be controlled directly by the space thermostat. Outside air damper position will be closed or Minimum

Position as determined by Occupancy mode and fan signal.

When free cooling is available as determined by the appropriate changeover command (dry bulb, outdoor enthalpy, differential dry bulb, or differential enthalpy), a call for cooling (Y1

closes at the thermostat) will cause the economizer control to

modulate the dampers open and closed to maintain the unit

supply air temperature. Default supply air temperature is 53°F,

with a range of 38°F to 70°F. Compressor will not run.

Should 100% outside air not be capable of satisfying the space

temperature, space temperature will rise until Y2 is closed. The

economizer control will call for compressor operation. Dampers will modulate to maintain SAT set point concurrent with

Compressor 1 operation. The “Low T Lock” setting (default

32°F) will lock out compressor operation when outside air temperature is below set point.

When space temperature demand is satisfied (thermostat Y1

opens), the dampers will return to Minimum Damper position

if indoor fan is running or fully closed if fan is off.

If accessory power exhaust is installed, the power exhaust fan

motors will be energized by the economizer control as the

dampers open above the EXH1 SET set point and will be energized as the dampers close below the EXH1 SET set point.

Damper movement from full closed to full open (or vice versa)

will take between 1

1

/2 and 21/2 minutes.

Heating with EconoMi$er X

During Occupied mode operation, indoor fan operation will be

accompanied by economizer dampers moving to Minimum Position set point for ventilation. If indoor fan is off, dampers will

close. During Unoccupied mode operation, dampers will remain

closed unless a DCV demand is received.

When the room temperature calls for heat (W1 closes), the

heating controls are energized.

INPUT VOLTAGE

OCC 0 - V 24 - V 24 - V 24 - V 24 - V

Y1 0 - V 0 - V 24 - V 24 - V 0 - V

Y2 0 - V 0 - V 0 - V 24 - V 0 - V

W1 0 - V 0 - V 0 - V 0 - V 24 - V

SUPPLY FAN

MOTOR SPEED

DAMPER POSITION

NO CO

SENSOR CLOSED MIN POS-L MIN POS-L MIN POS-H MIN POS-H

2

SENSOR CLOSED

W/ CO

2

OFF LOW LOW HIGH HIGH

FROM

VENTMIN L

TO

VENTMAX L

FROM

VENTMIN L

TO

VENTMAX L

FROM

VENTMIN H

TO

VENTMAX H

24

FROM

VENTMIN H

TO

VENTMAX H

Page 25

TROUBLESHOOTING

For a list of common operating issues and concerns, see

Table 15.

Power Loss (Outage or Brownout)

All set points and advanced settings are restored after any power loss or interruption, as all settings are stored in the Economizer controller’s non-volatile flash memory.

NOTE: If the power goes below 18 vac, the W7220 controller

module assumes a power loss and the 5 minute power up delay

will become functional when power returns above 18 vac.

Alarms

The economizer module provides alarm messages that display

on the 2-line LCD.

NOTE: Upon power up, the module waits several seconds before

checking for alarms. This allows time for all the configured devices (e.g., sensors, actuator) to become operational.

If one or more alarms are present and there has been no keypad

activity for at least 5 minutes, the Alarms menu displays and

cycles through the active alarms.

The Alarms menus can be navigated at any time. See Table 11

for the Alarms menu.

CLEARING ALARMS

Once the alarm has been identified and the cause has been re-

moved (e.g., replaced faulty sensor), the alarm can be cleared

from the display.

To clear an alarm, perform the following:

1. Navigate to the desired alarm.

2. Press the button.

3. ERASE? displays.

4. Press the button.

5. ALARM ERASED displays.

6. Press the (Menu up/Exit) button to complete the

action and return to the previous menu.

NOTE: If an alarm still exists after it has been cleared, it will redisplay within 5 seconds.

Table 15 — Operating Issues and Concerns

ISSUE OR CONCERN POSSIBLE CAUSE AND REMEDY

My outdoor temperature reading on the STATUS menu is

not accurate

If my enthalpy sensor drifts in accuracy over time, can I

recalibrate it?

Can I go back to factory defaults and start over?

Will I be able to see the LCD screen when it is in the unit? The LCD screen has a backlight that is always illuminated.

What is a good set point for the Mixed Air Temperature

(MAT)?

I am using enthalpy sensors. Why did the control ask me to

input a dry bulb changeover temperature?

In checkout, the outdoor damper closes when I command it

to open.

How do I set my minimum position when using a CO

sensor?

What if my damper does not go completely closed in the

checkout operation?

How do I set the OCC?

Does the economizer save my program values if the unit

loses power?

If the unit is left in checkout, how long will the unit stay in

checkout mode without input?

2

Check the sensor wiring:

• Enthalpy sensors are to be wired to the S-Bus terminals.

• Temperature sensors are to be wired to the OAT and MAT terminals.

The sensor is not able to be re-calibrated in the field. However, there is a menu item

under the ADVANCED menu to input a limited offset in temperature and humidity for

each sensor that is connected to the economizer.

Under the SYSTEM SETUP menu, you can change the set points to the factory

defaults.

The Mixed Air Temperature is the temperature of air to supply to the space. In a

commercial building, this is between 50°F and 55°F (10°C and 13°C). Mixed air is the

combination of return air and outdoor air.

If the humidity sensor in the enthalpy sensors fails, the backup algorithm in the control is

to default to the temperature sensor in the enthalpy sensor.

Check the actuator linkage or rotation. In the CHECKOUT mode, the outdoor damper

should drive open or closed with the return air damper having the opposite effect.

The minimum position is set using the VENTMIN and VENTMAX setup in the

SETPOINTS menu. VENTMIN is the minimum ventilation required when using an

occupancy sensor and VENTMAX is the minimum ventilation when not using an

occupancy sensor for Demand Control Ventilation. The VENTMAX position is set the

same as with the potentiometer on the analog economizers and is the output voltage to

the damper actuator. The range is 2 vdc closed OA damper and 10 vdc open OA

damper.

Check the damper linkage or hub to make sure the damper is able to close completely.

There are two settings for the OCC setting: INPUT and ALWAYS. INPUT is from the

space thermostat, if it has an occupancy output. ALWAYS is the unit in the occupied

mode, if the economizer is powered (fan on).

Yes, once the changes are stored in the controller they will be stored until they are

changed by the operator.

The unit will remain in checkout for 10 minutes, then return to normal operation.

25

Page 26

Page 27

Page 28

© Carrier Corporation 2018

Catalog No. 04-53480208-01 Printed in U.S.A. Form IIK-CRECOMZR77-03 Pg 28 11-18A 11-18 Replaces: NEW