Page 1

CRECOMZR076A00

CRECOMZR078A00

CRECOMZR080A00

Installation Instructions

Read these instructions completely before attempting to install the

Vertical EconoMi$er X Accessory.

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . .1

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

EconoMi$er X Sensor Usage . . . . . . . . . . . . . 2

ACCESSORIES LIST. . . . . . . . . . . . . . . . . . . . .2

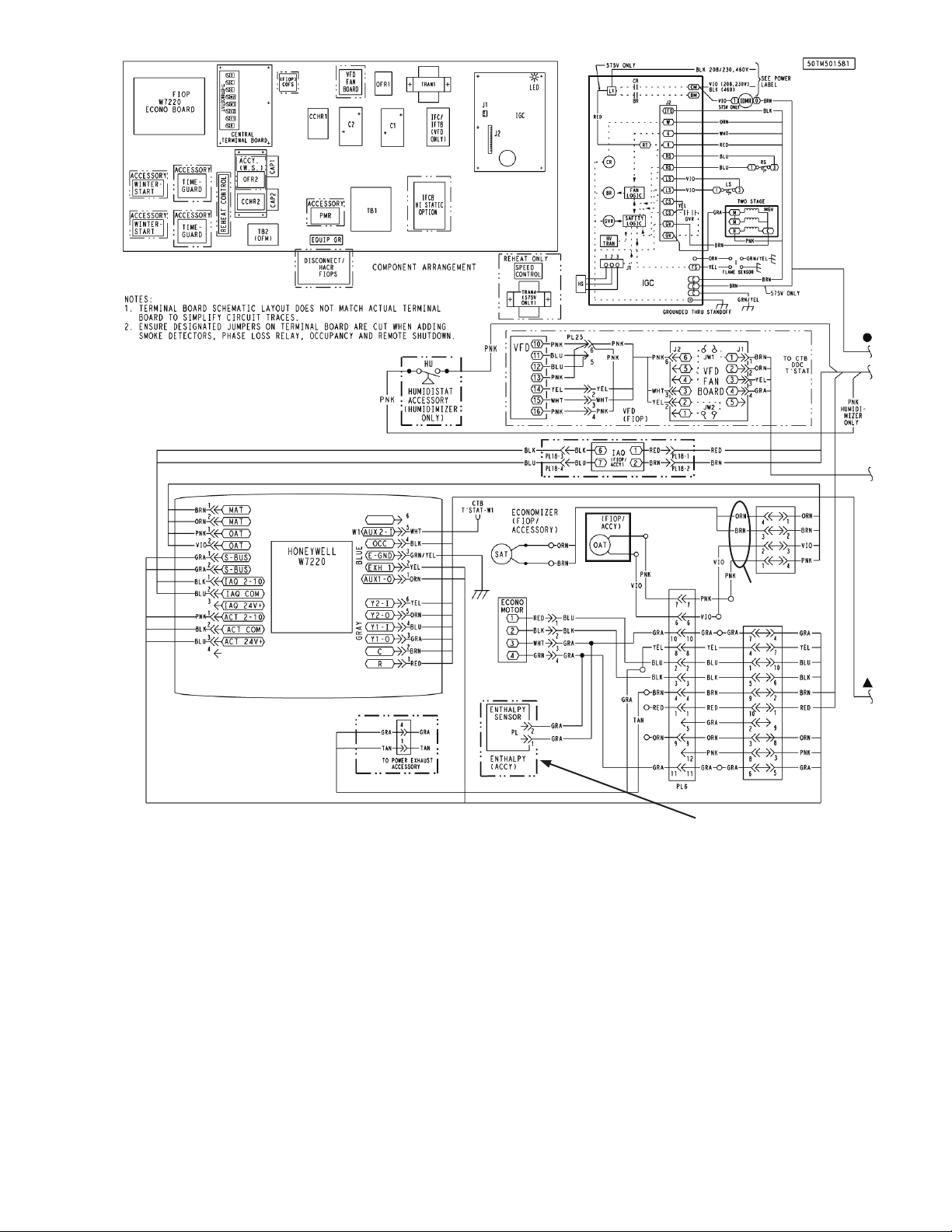

WIRING DIAGRAMS. . . . . . . . . . . . . . . . . . .5-7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .2-8

EconoMi$er X Standard Sensors . . . . . . . . . .8

EconoMi$er X Control Modes . . . . . . . . . .8-14

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . .16

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . .17

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or

use can cause explosion, re, electrical shock or other conditions which

may cause personal injury or property damage. Consult a qualied

installer, service agency, or your distributor or branch for information

or assistance. The qualied installer or agency must use factoryauthorized kits or accessories when modifying this product. Refer to

the individual instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloths for brazing operations and have a re extinguisher

available. Read these instructions thoroughly and follow all warnings

or cautions attached to the unit. Consult local building codes and

appropriate national electrical codes (in USE, ANSI/NFPA70,

National Electrical Code (NEC); in Canada, CSA C22.1) for special

requirements.

It is important to recognize safety information. This is the safety-alert

symbol . When you see this symbol on the unit and in instructions

or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and

NOTE. These words are used with the safety-alert symbol.

DANGER identies the most serious hazards which will result in

severe personal injury or death. WARNING signies hazards which

could result in personal injury or death. CAUTION is used to identify

unsafe practices, which may result in minor personal injury or product

and property damage.

NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or death. Before performing

service or maintenance operations on the unit, always turn off main power switch to

unit and install lock(s) and lockout tag(s). Unit may have more than one power switch.

Ensure electrical service to rooftop unit agrees with voltage an amperage listed on the

unit rating plate.

!

WARNING

!

Small Rooftop Products

Select 3 to 12 1/2 Tons

Vertical EconoMi$er X Accessory

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when handling parts and servicing

roof top units.

GENERAL

IMPORTANT: These economizers meet the economizer requirements

as laid out in California’s Title 24 mandatory section 120.2 (fault

detection and diagnostics).

The EconoMi$er X system utilizes the latest technology available

for integrating the use of free cooling with mechanical cooling for

packaged rooftop units. The solid-state control system optimizes energy

consumption, zone comfort, and equipment cycling by operating the

compressors when the outdoor-air temperature is too warm, integrating

the compressor with outdoor air when free cooling is available, and

locking out the compressor when outdoor-air temperature is too cold.

Demand control ventilation is supported.

This EconoMi$er X can be used with 1, 2, or 3 speed (48/50LC 07-12)

units.

The EconoMi$er X system utilizes gear-drive technology with a directmount spring return actuator that will close upon loss of power. The

EconoMi$er X system comes standard with an outdoor air temperature

sensor, mixed air temperature sensor. Outdoor enthalpy, indoor

enthalpy, indoor temperature, and CO2 sensors are available for eld

installation. See Table 3 for sensor usage.

Standard barometric relief dampers provide natural building

pressurization control. An optional power exhaust system is available

for applications requiring even greater exhaust capabilities. The power

exhaust set point is adjustable at the EconoMi$er X controller.

See Table 1 for package usage. See Table 2 for package contents. See

Table 3 for sensor usage.

Table 1 - Package Usage

UNIT SIZE PART NUMBER

Small Cabinet, Footprint size: 46 3/4” x 74 3/8” CRECOMZR076A00

Large Cabinet, Footprint size: 58 1/2” x 88 1/8” CRECOMZR078A00

Extra-Large Cabinet, Footprint size: 63 3/8” x 115 7/8” CRECOMZR080A00

Table 2 - Package Contents

PACKAGE NO. QTY CONTENTS

1

Hood Top and Sides

1

Hood Divider

1

Aluminum Filter

CRECOMZR076A00,

CRECOMZR078A00

CRECOMZR080A00

18

Screws

1

EconoMi$er X Assembly

1

HH79ZZ007 Mixed (supply)

Temperature Sensor

1

48TMHSRSE--A20 Harness

1

Hood Top and Sides

1

Hood Divider

1

Hood Filter Divider

2

Aluminum Filters

1

Hardware Bag

1

EconoMi$er X Assembly

1

HH79ZZ007 Mixed (supply)

Temperature Sensor

1

48TMHSRSE--A20 Harness

1

Page 2

Table 3 - EconoMi$er X Sensor Usage

ECONOMI$ER X WITH OUTDOOR AIR

APPLICATION

Outdoor Air

Dry Bulb

Mixed Air

Sensor

Single

Enthalpy

Differential

Enthalpy

CO2 for

DCV Control

Using a

Wall-Mounted

CO2 Sensor

CO2 for

DCV Control

Using a

Duct-Mounted

CO2 Sensor

†33ZCSENCO2 and CGCDXSEN004A00 are accessory CO2 sensors.

**33ZCASPCO2 and CGCDXASP00100 are accessory aspirator boxes required for ductmounted applications.

††CRCBDIOX005A00 is an accessory that contains both 33ZCSENCO2 and 33ZCASPCO2

accessories.

HH79ZZ007 is factory installed on economizer

HH79ZZ007 provided with economizer and eld installed

33ZCSENCO2 or

CGCDXSEN004A00†

33ZCASPCO2 or

CGCDXASP00100**

DRY BULB SENSOR

Accessories Required

in blower compartment

33ZCSENCO2

CGCDXSEN004A00

and

HH57AC081

HH57AC081

or

OR

CRCBDIOX005A00††

ACCESSORIES LIST

The EconoMi$er X has several eld-installed accessories available to

optimize performance. Refer to Table 4 for authorized parts and power

exhaust descriptions

Table 4 - EconoMi$er X Field-Installed

Accessories

DESCRIPTION PART NUMBER

Small Cabinet Power Exhaust 208-230 v 1 Ph CRPWREXH030A01

Small Cabinet Power Exhaust 460 v 3Ph CRPWREXH021A01

Large Cabinet Power Exhaust 208-230 v 1 Ph CRPWREXH022A01

Large Cabinet Power Exhaust 460 v 3 Ph CRPWREXH023A01

Extra Large Cabinet Power Exhaust 208-230 v 1 Ph CRPWREXH080A00

Extra Large Cabinet Power Exhaust 460 v 3 Ph CRPWREXH081A00

Outdoor Air Enthalpy Sensor HH57AC081

Indoor Air Enthalpy Sensor HH57AC081

Return Air CO2 Sensor (4 to 20 mA) CRCBDIOX005A00

CO2 Room Sensor (4 to 20 mA)

Aspirator Box for Duct Mount

CO2 Sensor (4 to 20 mA)

Space Temperature and CO2 Room Sensor

with Override (4 to 20 mA)

Space Temperature and CO2 Room Sensor

with Override and Set Point (4 to 20 mA)

33ZCSENCO2 or

CGCDXSEN004A00

33ZCASPCO2 or

CGCDXASP001A00

33ZCT55CO2

33ZCT56CO2

INSTALLATION

1. Turn off unit power supply(s) and install lockout tag.

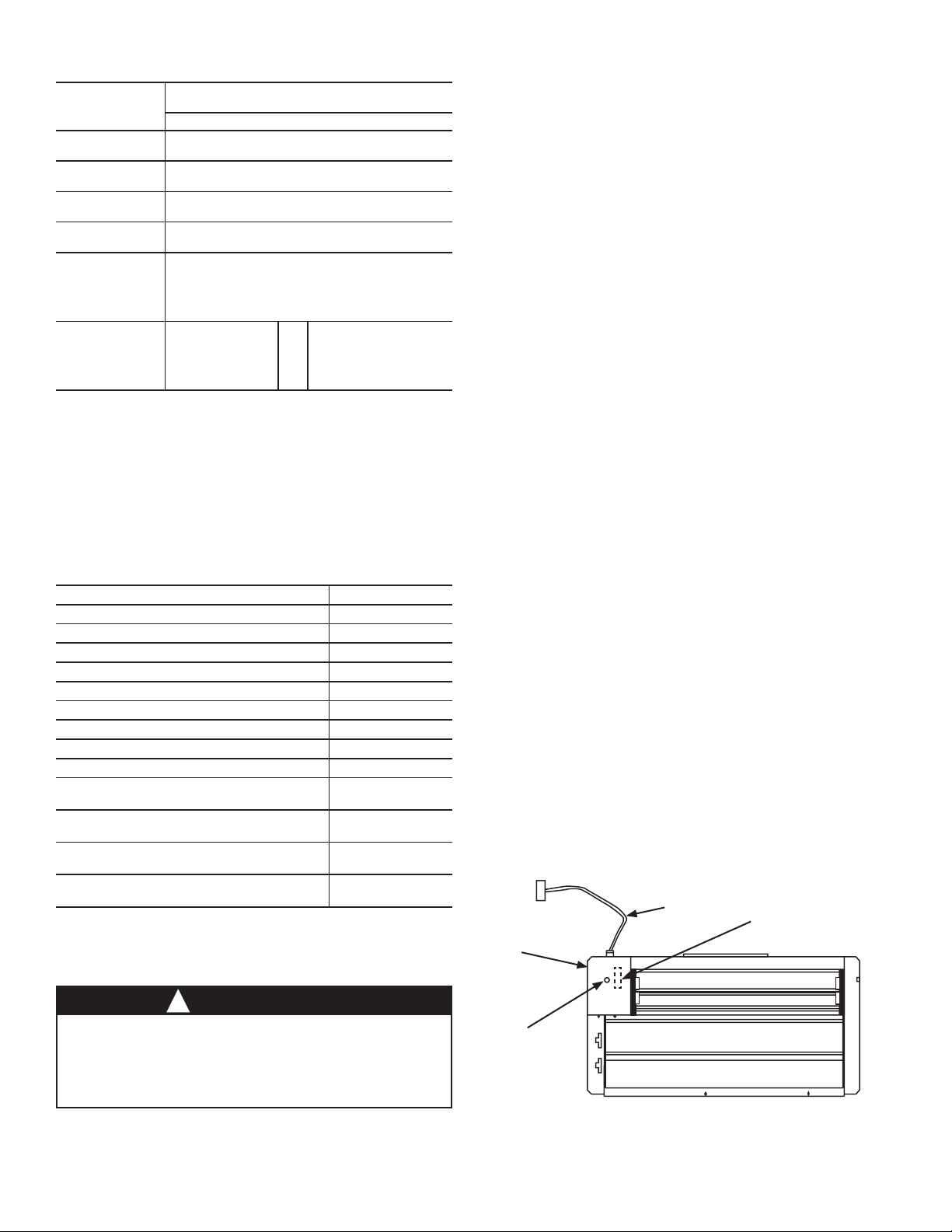

2. Remove the existing unit lter access panel. Raise the panel and

swing the bottom outward. The panel is now disengaged from the

track and can be removed. (See Fig. 2.)

3. Remove the indoor coil access panel and discard. (See Fig. 2.)

4. The EconoMi$er X hood components are shipped with the

EconoMi$er X. Remove hood from packaging. The hood top and

sides are shipped factory assembled.

NOTE: If the power exhaust accessory is to be installed on the unit,

the hood shipped with the EconoMi$er X will not be used and may be

discarded. Save the aluminum lter for use in the power exhaust hood

assembly.

5. Insert the hood divider between the hood sides. (See Fig. 3) Secure

hood divider with 2 screws (provided) on each hood side. Screws

should go through the hood sides into the divider. The hood divider

is also used as the bottom lter rack for the aluminum lter. On

hood for extra large cabinet install lter divider. (See Fig. 4A.)

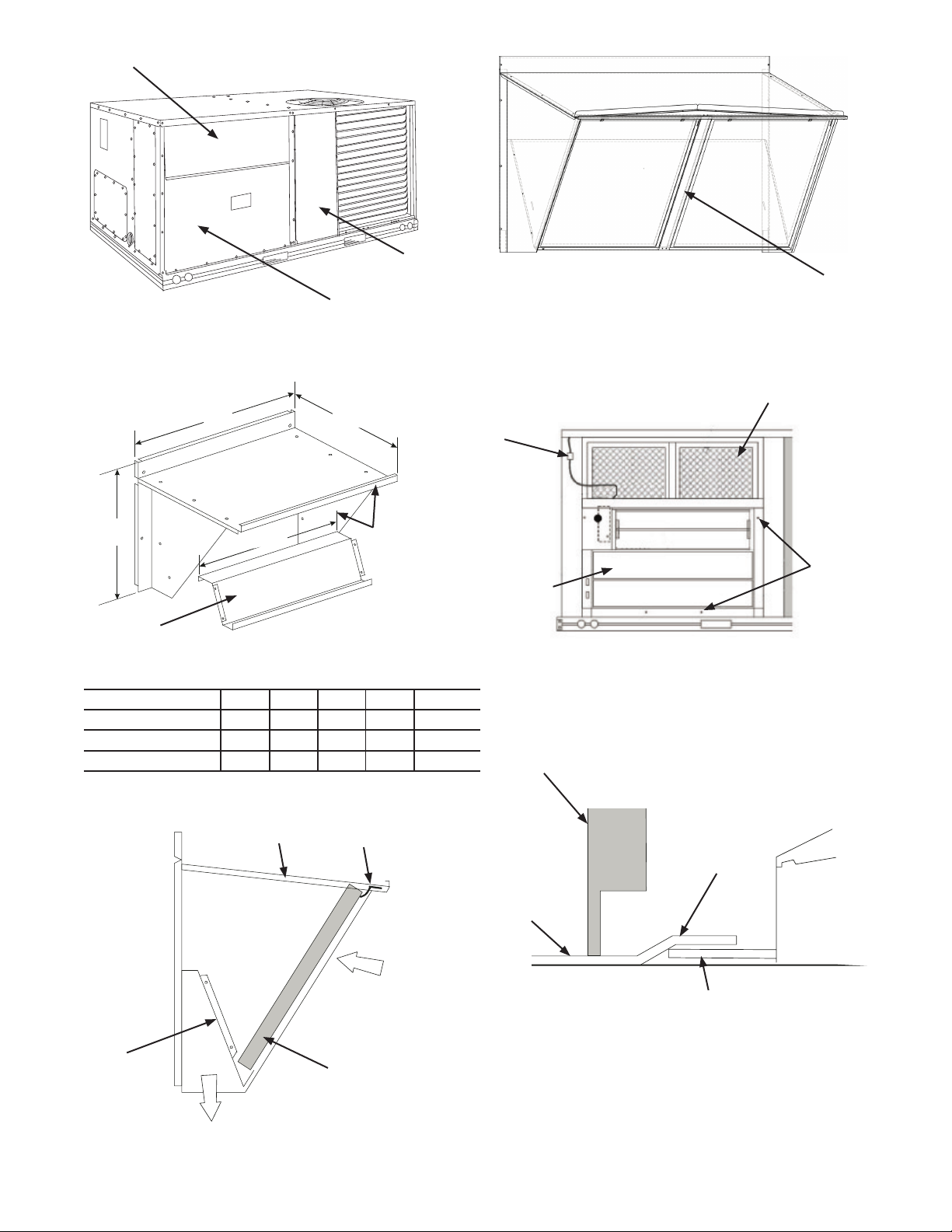

6. Set the EconoMi$er X upright. (See Fig. 5.)

7. Slide the EconoMi$er X assembly into the rooftop unit. (See

Fig. 5). On small and large cabinets be sure to engage the rear

EconoMi$er X ange under the tabs in the return-air opening of

the unit base. (See Fig. 6)

8. Secure the EconoMi$er X to unit along side and bottom anges

using the screws provided.

9. Remove the tape securing the relief dampers in place.

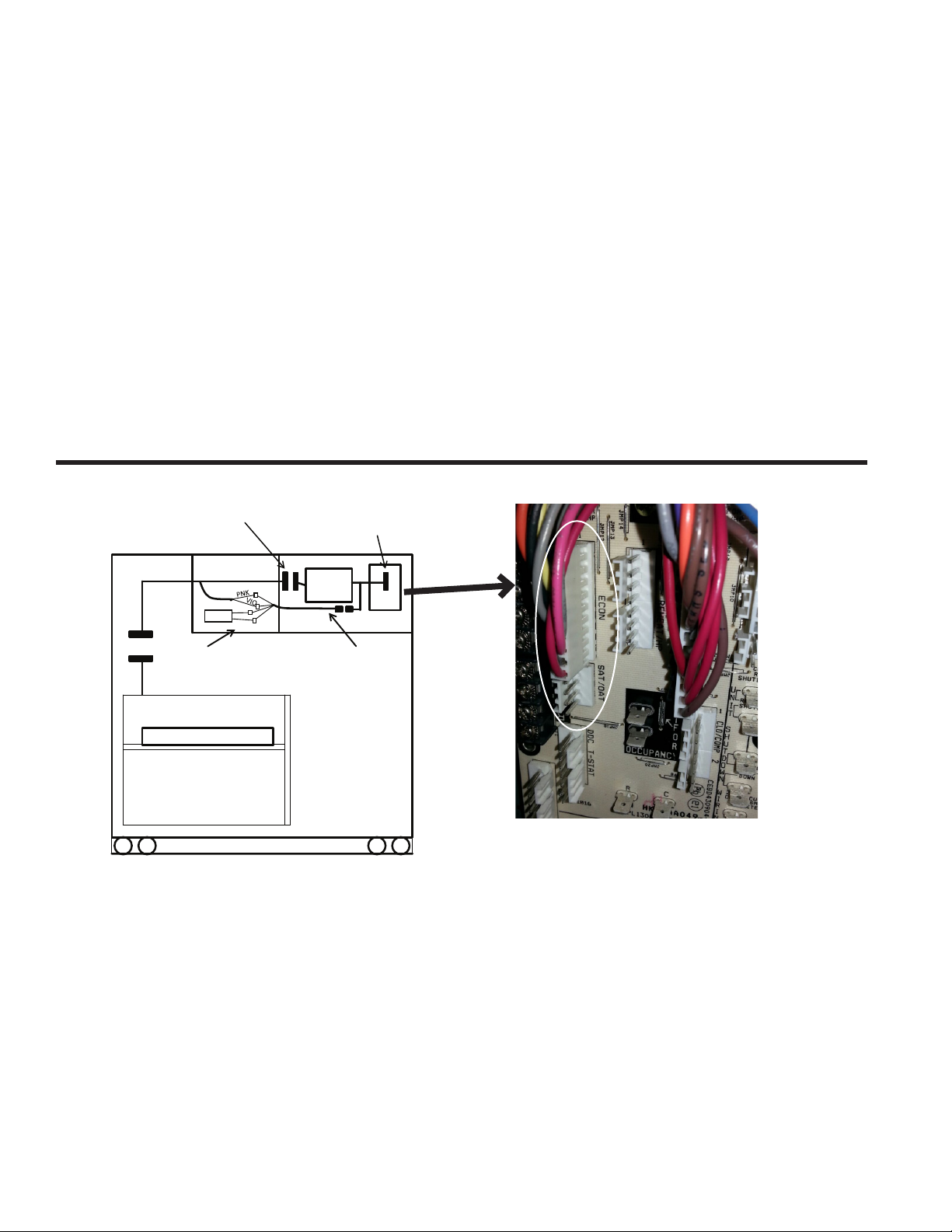

10. Remove and save the 12-pin jumper plug from the unit wiring

harness (located in the upper left corner of the unit). Insert the

EconoMi$er X plug into the unit wiring harness. Refer to Fig. 7

and 8 for wiring details.

NOTE: The 12-pin jumper plug should be saved for future use, in the

event that the EconoMi$er X is removed from the unit. The jumper plug

is not needed as long as the EconoMi$er X is installed.

11. If EconoMi$er X will be operating under enthalpy control, replace

the factory installed HH79ZZ007 outdoor dry bulb temperature

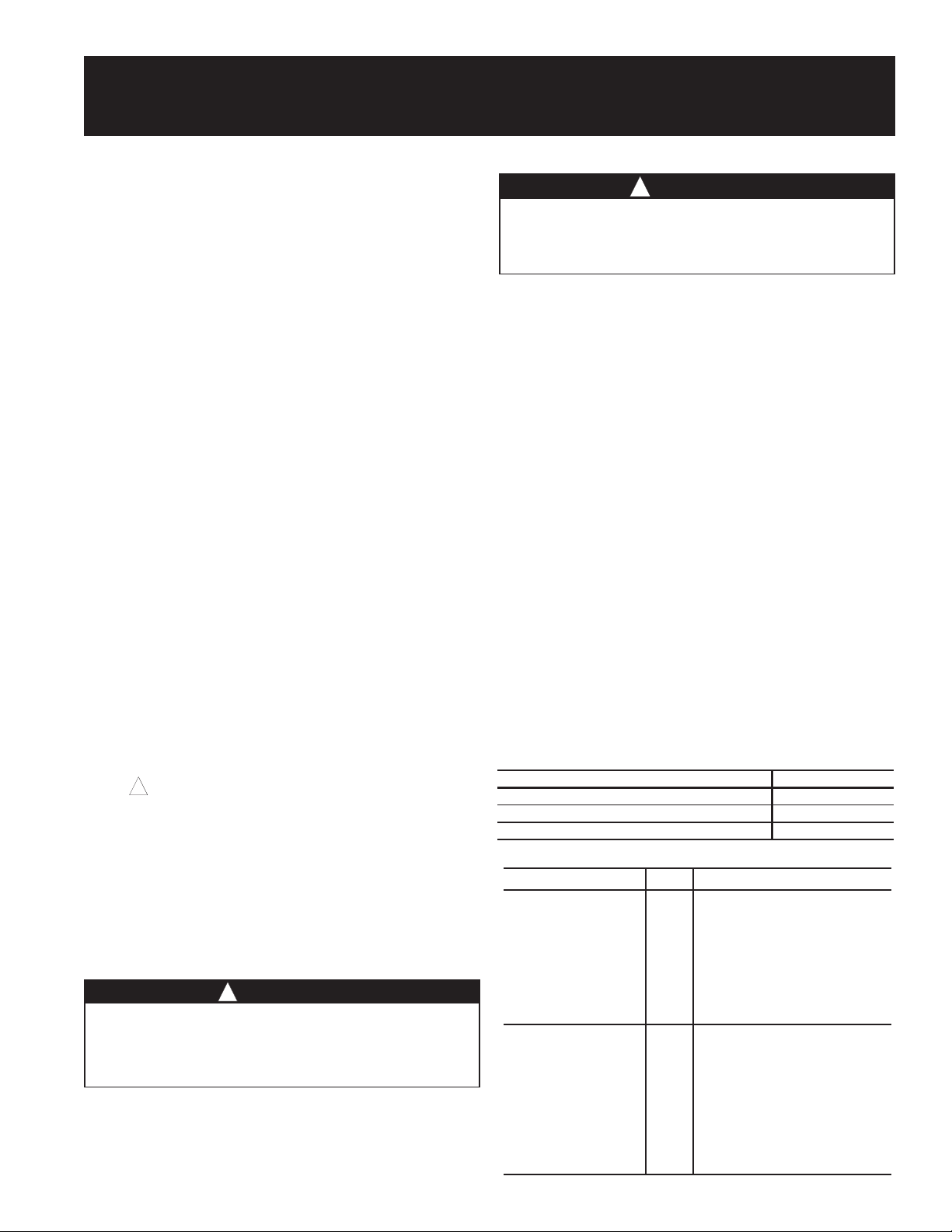

sensor with accessory enthalpy sensor HH57AC081. (See Fig. 1.)

12. Remove the indoor fan motor access panel. (See Fig. 9.)

13. The mixed (or supply) air temperature sensor looks like an eyelet

terminal with wires running to it. The sensor is located on the

“crimp end” and is sealed from moisture. Locate the sensor in

the economizer hardware bag. Mount the supply air temperature

sensor (provided) to the lower left section of the indoor fan blower

housing. (See Fig. 10.) Use the screw provided and use existing

hole. Locate the orange and brown wires in wire bundle in the

indoor fan section. Connect the orange and brown wires to the

corresponding connections on the supply air temperature sensor.

(See Fig. 8.)

Wiring

Harness

Actuator

(Hidden)

HH57AC081

Enthalpy Accessory

Location (Field

Installed)

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury and/

or death.

Disconnect power supply and install lockout tag before attempting

to install accessory.

HH79ZZ007

Outside Air

Temperature

Sensor

Fig. 1 - EconoMi$er X Component Locations —

(Small Cabinet Economizer Shown)

2

Page 3

Filter Access Panel

Fig. 2 - Typical Outdoor-Air Section

Outdoor-Air Opening and

Indoor Coil Access Panel

Access Panel Locations

A

B

Compressor

Access Panel

Wiring

Harness

Hood Filter

Divider

Fig. 4A - Hood for Extra Large Cabinet

HVAC Unit Filters

C

Hood Divider

D

Hood Top and

Side Assembly

Fig. 3 - Hood Assembly

ECONOMIZER P/N A B C D SHIP WT.

CRECOMZR076A00 33.37” 17.43” 19.05” 29.5” 55 lb

CRECOMZR078A00 40.37” 22.28” 24.48” 36.27” 80lb

CRECOMZR080A00 52.92” 27.03” 33.41” 49.92” 98lb

NOTE: The CRECOMZR080A00 hood has 2 aluminum lters and a

hood lter divider that installs between the lters. (See Fig. 5A.)

Hood Top

Filter Clip

Outside Air

EconoMi$er X

Fig. 5 - EconoMi$er X Installed in HVAC Unit

Unit Filter

Rack

Unit Base

Insert

Screw in

EconoMi$er X

Flanges

(Small Cabinet Economizer Shown)

EconoMi$er X

Hold Down Tab

EconoMi$er X

Hood

Divider

EconoMi$er IV Rear Flange

Fig. 6 - Rear EconoMi$er X Flange Installation

(Small and Large Cabinet)

Cleanable

Aluminum Filter

Barometric

Airow

Fig. 4 - Filter Installation

3

Page 4

14. While everything is open install and wire any other accessories

Plug 10-pin plug from

and/or sensors as applicable and convenient, per their installation

instructions and/or the Conguration section of this instruction.

Some accessories require that unit ducting already be installed.

NOTE: If also installing a power exhaust accessory, skip step 16 and

follow the power exhaust instructions instead.

16. Install the EconoMi$er X hood over the EconoMi$er X. Use

screws provided.

17. The W7220 EconoMi$er X controller is shipped mounted to a

bracket. Install the controller / bracket in the top left corner of

the unit control box as shown in wiring diagram, Fig. 8. Screw in

place through pre-punched holes.

18. For 1 and 2 speed units connect the plugs coming from the

controller as shown in wiring diagram, Fig. 7 and 8A.

NOTE: Provided 48TMHSRSE--A20 harness will be connected as

shown below.

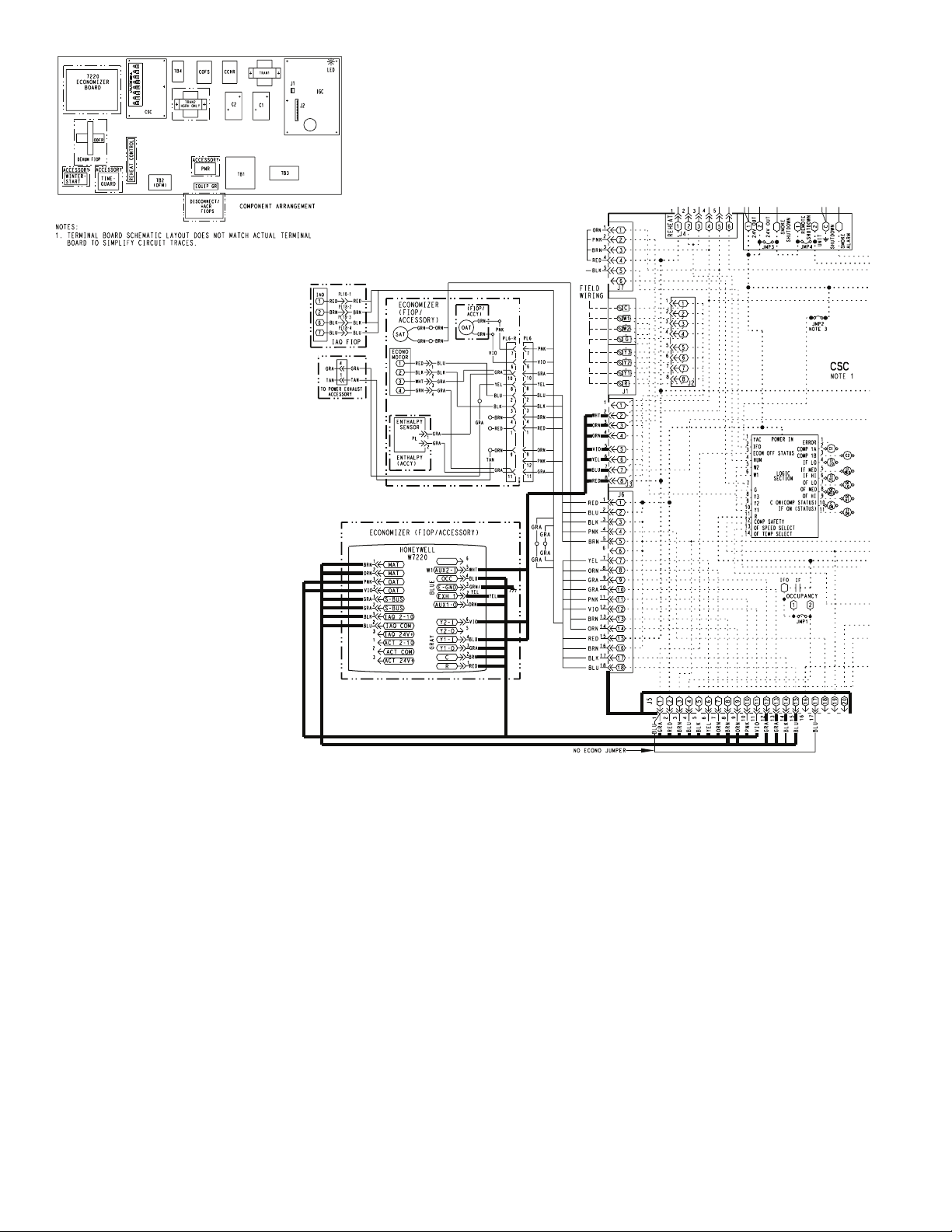

19. For 3 speed (48/50LC 07-12) units, the harness attached to the

W7220 econoMi$er X controller must be removed, and can be

discarded. Locate harness 48LCHSRADH--A00 shipped in

plastic bag in the control box of unit. Attach this harness to the

W7220 controller as shown in Fig 8B and 8C.

NOTE: Harness 48TMHSRSE--A20 provided with economizer is not

used with 3 speed (48/50LC 07-12) units.

20. Adjust controller settings (minimum position, outside air, etc.) per

instructions detailed later in this instruction.

21. Follow all local and other applicable codes.

Unplug the 10-pin plug from

PL6 from the Central Terminal

Board (in control box) and plug

into 10-pin plug from W7220

Indoor Blower

Section

SAT

PL6

Connect SAT sensor and Pink

and Violet wires from PL6 to

the 48TMHSRSE—A20

harness.

BRN

ORN

Control box

W7220 into ECONO

terminals on Central

Terminal Board

W7720

48TMHSRSE--A20

harness with 4- pin

plug

Central

Term Brd

See Picture

ECONO

Economizer X

Fig. 7 - Harness Detail

WIRING INSTRUCTIONS FOR 1 AND 2 SPEED UNITS:

A. Install W7220 (with harnesses attached) in unit control box. See

wiring diagram in instructions.

B. Unplug econo harness from PL6 with 10-pin plug shown above in

picture, from Central Terminal Board (CTB).

C. Attach 10-pin plug disconnected from (CTB) to 10- pin plug

harness from W7220 controller.

D. Connect other 10-pin plug from W7220 controller into ECONO

terminals on CTB. See picture above.

E. Connect 4-pin plug from the W7220 controller to the 4-pin

48TMHSRSE—A20 harness provided with economizer accessory.

F. Route 48TMHSRSE—A20 harness back to the indoor blower

section of the unit.

G. Mount Supply (or Mixed) Air Temperature sensor, and connect

Brown and Orange wires from harness to the SAT.

H. Connect Pink and Violet wires from 48TMHSRSE—A20 harness

to the Pink and Violet wires from PL6 economizer harness

4

Page 5

48TMHSRSE--A20

If using HH57AC081 outside air

enthalpy accessory, the OAT must be

removed and disconnected. Set sensor

dip-switches, see Table 11.

Fig. 8A - Typical EconoMi$er X Wiring Diagram For 1 and 2 Speed Units

(2 Speed Diagram Shown)

Harness

5

Page 6

Fig. 8B - Typical EconoMi$er X Wiring Diagram For 3 Speed Units (48/50LC 07-12)

(See 3 Speed Unit Instructions for Complete Diagram)

NOTES:

1. Wires shown in bold are part of 48LCHSRADH--A00 harness

which is provided with 48/50LC 07-12 3 speed units.

2. Harness 48TMHARSE--A20 which is provided with

economizer accessory is not used on 3 speed units.

6

Page 7

FIELD ATTACH TO W7220 CONTROLLER

CONNECT TO UNIT

(Provided with 3 Speed Units, Field Attached to W7220 Controller)

Fig. 8C - 48LCHSRADH--A00 Harness for 3 Speed Units (48/50LC 07-12)

BOARD

UNIT TERMINAL

CONNECT TO

TERMINAL BOARD

7

Page 8

Thermostat

Connection

Access Panel

Center Post

Heating Access

Panel

Indoor Fan Motor

Access Panel

Fig. 9 - Typical Indoor Fan Motor

Access Panel Locations

Mixed Air

Temperature

Sensor

Mounting

Location

Mixed Air

Temperature

Sensor

To Unit

Control Box

Fig. 10 - Mixed Air Sensor Placement

EconoMi$er X

The eld-installed accessory consist of the following:

• Low leak economizer assembly

• W7220 economizer controller

• HH79ZZ007 Mixed (supply) air temperature sensor

• HH79ZZ007 outside air temperature air sensor

• 48TMHSRSE--A20 harness (not used on 3 speed (48/50LC 07-

12) units.

W7220 Economizer

The economizer controller used on electro mechanical units is a

Honeywell W7220 which is to be located in the RTU base unit’s Control

Box. See the Installation Instruction for your base unit for the location

of the Control Box access panel.

The W7220 controller provide the following:

• 2-line LCD interface screen for setup, conguration and

troubleshooting.

• On-board fault detection and diagnostics

• Sensor failure loss of communications identication

• Automatic sensor detection

• Capabilities for use with multiple-speed indoor fan systems

User Interface

The user interface consists of a LCD display and a 4-button keypad on

the front of the economizer controller.

Fig. 11 - W7220 Controller

Using the Keypad with Menus

To use the keypad when working with menus:

• Press the ▲ (Up arrow) button to move to the previous menu.

• Press the ▼ (Down arrow) button to move to the next menu.

• Press the (Enter) button to display the rst item in the currently

displayed menu.

• Press the ↑ (Menu Up/Exit) button to exit a menu’s item and

return to the list of menus.

Using the Keypad with Settings and Parameters

To use the keypad when working with Setpoints, System and Advanced

Settings, Checkout tests and Alarms:

1. Navigate to the desire menu.

2. Press the (Enter) button to display the rst item in the currently

displayed menu.

3. Use the ▲ and ▼ buttons to scroll to the desired parameter.

4. Press the (Enter) button to display the value of the currently

displayed item.

5. Press the ▲ button to increase (change) the displayed parameter

value.

6. Press the ▼ button to decrease (change) the displayed parameter

value.

NOTE: When values are displayed, pressing and holding the

▲ or ▼ button causes the display to automatically increment.

7. Press the (Enter) button to accept the displayed value and store

it in nonvolatile RAM.

8. “CHANGE STORED” displays.

9. Press the (Enter) button to return to the current menu parameter.

10. Press the ↑ (Menu Up/Exit) button to return to the previous

menu.

Menu Structure

Table 5 illustrates the complete hierarchy of menus and parameters for

the EconoMi$er X system.

The Menus in display order are:

• STATUS

• SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

• CHECKOUT

• ALARMS

Keypad

The four navigation button (see Fig. 11) are used to scroll through the

menus and menu items, select menu items, and to change parameter and

conguration settings.

IMPORTANT NOTE: The default setting on the W7220 controller

is for a “Fan Type” with 2 speed, which is correct for 2 or 3 speed

units (48/50LC 07-12). If your unit is 1 (single) speed, the setting

under SYSTEM SETUP > FAN TYPE must be changed to 1 speed.

8

Page 9

IMPORTANT: Table 4 illustrates the complete hierarchy. Your menu parameters may be different depending on your conguration.

For example if you do not have a DCV (CO2) sensor, then none of the DCV parameters appear.

a

Notes

Menu Parameter

Parameter

Default

Value

Table 5 ─ Menu Structure

Parameter

Range and Increment

b

STATUS ECON AVAIL NO YES/NO YES = economizing available; the system can use

outside air for free cooling when required

ECONOMIZING NO YES/NO YES = outside air being used for 1st stage cooling

OCCUPIED NO YES/NO YES = OCC signal received from space thermostat

or unitary controller

YES = 24 Vac on terminal OCC.

NO = 0 Vac on terminal OCC.

HEAT PUMP n/a

c

COOL

HEAT

Displays COOL or HEAT when system is set to heat pump

(Non-conventional)

COOL Y1─IN OFF ON/OFF Y1─I signal from space thermostat or unitary controller for

cooling stage 1.

ON = 24 Vac on terminal Y1─I

OFF = 0 Vac on terminal Y1─I

COOL Y1─OUT OFF ON/OFF Cool stage 1 Relay Output to stage 1 mechanical cooling

(Y1─OUT terminal)

COOL Y2─IN OFF ON/OFF Y2─I signal from space thermostat our unitary controller for

second stage cooling.

ON = 24 Vac on terminal Y2─I

OFF = 0 Vac on terminal Y2─I

COOL Y2─OUT OFF ON/OFF Cool Stage 2 Relay Output to mechanical cooling

(Y2─OUT terminal)

MA TEMP _ _ . _oF 0 to 140oF Displays value of measured mixed air from MAT sensor.

Displays _ _ . _ oF if not connected, short or out-of-range.

DA TEMP _ _ . _oF 0 to 140oF Displays when Discharge Air sensor is connected and

displays measured discharge temperature.

Displays _ _ . _oF if sensor sends invalid value, if not connected, short or out-of-range.

OA TEMP _ _ . _oF -40 to 140oF Displays measured value of outdoor air temperature.

Displays _ _ . _oF if sensor sends invalid value, short or

out-of-range.

OA HUM _ _% 0 to 100% Displays measured value of outdoor humidity from OA

sensor.

Displays _ _% if not connected short, or out-of-range.

RA TEMP _ _ . _oF 0 to 140oF Displays measured value of return air temperature from

RAT sensor.

Displays _ _ . _oF if sensor sends invalid value, if not

connected, short or out-of-range

RA HUM _ _% 0 to 100% Displays measured value of return air humidity from RA

sensor.

Displays _ _% if sensor sends invalid value, if not connected, short or out-of-range

IN CO2 _ _ _ppm 0 to 2000 ppm Displays value of measured CO2 from CO2 sensor. Invalid if

not connected, short or out-of-range

DCV STATUS n/a ON/OFF Displays ON if above setpoint and OFF if below setpoint,

and ONLY if a CO2 sensor is connected.

DAMPER OUT 2.0V 2.0 to 10.0V Displays voltage output to the damper actuator.

EXH1 OUT OFF ON/OFF Output of EXH1 terminal:

ON = relay closed

OFF = relay open

EXH2 OUT OFF ON/OFF Output of AUX terminal; displays only if AUX = EXH2

ERV OFF ON/OFF Output of AUX terminal; displays only if AUX = ERV

MECH COOL ON 0 0,1, or 2 Displays stage of mechanical cooling that is active.

9

Page 10

Table 5 ─ Menu Structurea (cont)

Menu Parameter

Default

Value

SETPOINTS MAT SET 53oF 38 to 65oF;

LOW T LOCK 32oF -45 to 80oF;

DRYBLB SET 63oF 48 to 80oF;

ENTH CURVE ES3 ES1,ES2,ES3,ES4, or

DCV SET 1100ppm 500 to 2000ppm;

MIN POS 4.4 V 2 to 10 Vdc Displays ONLY if a CO2 sensor is NOT connected

Parameter

VENTMAX With 2-speed

4.4 V 2 to 10 Vdc

fan units VENTMAX

L (low speed fan) and

VENTMAX H (high speed

fan) settings are required

VENTMAX L 6 V

VENTMAX H 4.4 V

VENTMIN With 2-speed

2.8 V 2 to 10 Vdc

fan units VENTMIN L (low

speed fan) and VENTMIN

H (high speed fan) set

VENTMIN L 3.7 V

VENTMIN H 2.8 V

ERV OAT SP 32oF 0 to 50oF;

EXH1 SET With 2-speed

50% 0 to 100%;

fan units Exh1 L (low

speed fan) and Exh1 H

(high speed fan) settings

are required

Exh1 L 65%

Exh1 H 50%

EXH2 SET With 2-speed

75% 0 to 100%;

fan units Exh2 L (low

speed fan) and Exh2 H

(high speed fan) settings

are required

Exh2 L 80%

Exh2 H 75%

SYSTEM

INSTALL 01/01/10 Display order = MM/DD/YY

SETUP

UNITS DEG

o

F

EQUIPMENT CONV Conventional or HP CONV = conventional; HP O/B = Enable Heat Pump mode. Use AUX2 I

AUX2 I W SD/W or HP(O)/HP(B) In CONV mode: SD + Enables conguration of shutdown (default); W

FAN TYPE 2 speed 1 speed/2 speed

FAN CFM 5000cfm 100 to 15000 cfm;

AUX OUT NONE NONE

OCC INPUT INPUT or ALWAYS When using a setback thermostat with occupancy out (24 Vac), the 24

Parameter

Range and Increment

increment by 1

increment by 1

increment by 1

ES5

increment by 100

or

100 to 9990 cfm

increment by 10

or 100 to 9990 cfm

increment by 10

increment by 1

increment by 1

increment by 1

o

F or oC Sets economizer controller in degrees Fahrenheit or Celsius

increment by 100

ERV

EXH2

SYS

b

Notes

Setpoint determines where the economizer will modulate the OA

damper to maintain the mixed air temperature.

Setpoint determines outdoor temperature when the mechanical cooling

cannot be turned on. Commonly referred to as the Compressor lockout.

Setpoint determines where the economizer will assume outdoor air

temperature is good for free cooling; e.g.; at 63oF unit will economize at

62oF and below and not economize at 64oF and above. There is a 2oF

deadband.

Enthalpy boundary “curves” for economizing using single enthalpy

Displays only if CO2 sensor is connected. Setpoint for Demand Control

Ventilation of space. Above the setpoint, the OA dampers will modulate

open to bring in additional OA to maintain a space ppm level below the

setpoint.

Displays only if a CO2 sensor is connected. Used for Vbz (ventilation

max cfm) setpoint. Displays 2 to 10 V if <3 sensors (RA,OA, and MA).

In AUTO mode dampers controlled by CFM

Displays only if a CO2 sensor is connected. Used for Ba (ventilation min

cfm) setpoint. Displays 2 to 10 V if <3 sensors (RA, OA, and MA). Va

is only set if DCV is used. This is the ventilation for less than maximum

occupancy of the space. In AUTO mode dampers controlled by CFM.

Only when AUX1 O = ERV

Setpoint for OA damper position when exhaust fan 1 is powered by the

economizer.

Setpoint for OA damper position when exhaust fan 2 is powered by the

economizer. Only used when AUX is set to EHX2.

Setting order = DD, MM, then YY.

for Heat Pump input from thermostat or controller.

= Informs controller that system is in heating mode. In HP O/B mode:

HP(O) = energize heat pump on Cool (default); HP(B) = energize heat

pump on heat.

Sets the economizer controller for operation of 1 speed or 2 speed

supply fan. (Note: for 3 speed units (48/50LC 07-12), setpoint is a 2

speed.)

This is the capacity of the RTU. The value is found in the Project

Submittal documents for the specic RTU.

• NONE = not congured (output is not used)

• ERV = Energy Recovery Ventilatio

n

• EXH2 = second damper position relay closure for second exhaust fan

• SYS = use output as an alarm signal

Vac is input “INPUT” to the OCC terminal. If no occupancy output from

the thermostat then change program to “ALWAYS” OR add a jumper

from terminal R to OCC terminal

10

Page 11

Table 5 ─ Menu Structurea (cont)

Menu Parameter

Default

Value

Parameter

SYSTEM

FACTORY DEFAULT NO NO or YES Resets all set points to factory defaults when set to YES. LCD will

SETUP

ADVANCED

MA LO SET 45oF 35 to 55oF;

SETUP

FREEZE POS CLO CLO or MIN Damper position when freeze protection is active (closed or MIN POS).

CO2 ZERO 0ppm 0 to 500 ppm;

CO2 SPAN 2000ppm 1000 to 3000 ppm;

STG3 DLY 2.0h 0 min, 5 min, 15 min,

SD DMPR POS CLO CLO or OPN Indicates shutdown signal from space thermostat or unitary controller.

DCVCAL ENA MAN MAN (manual)

MAT T CAL 0.0oF +/-2.5oF Allows for the operator to adjust for an out of calibration temperature

OA T CAL 0.0oF +/-2.5oF Allows for the operator to adjust for an out of calibration temperature

OA H CAL 0% RH +/-10% RH Allows for operator to adjust for an out of calibration humidity sensor.

RA T CAL 0.0oF +/-2.5oF Allows for the operator to adjust for an out of calibration temperature

RA H CAL 0% RH +/-10% RH Allows for operator to adjust for an out of calibration humidity sensor.

DA T CA; 0.0oF +/-2.5oF Allows for the operator to adjust for an out of calibration temperature

CHECKOUT DAMPER VMIN─HS n/a n/a Positions damper to VMIN position

DAMPER VMAX─HS n/a n/a Positions damper to VMAX position

DAMPER OPEN n/a n/a Position damper to the full open position.

DAMPER CLOSE n/a n/a Positions damper to the fully closed position

CONNECT Y1─O n/a n/a Closes the Y1─O relay (Y1─O)

CONNECT Y2─O n/a n/a Closes the Y2─O relay (Y2─O)

CONNECT AUX n/a n/a Energizes the AUX output. If Aux setting is:

ALARMS(#) Alarms display only when they are active. The menu title

MA T SENS ERR n/a n/a Mixed air sensor has failed or become disconnected - check wiring then

CO2 SENS ERR n/a n/a CO2 sensor has failed, gone out of range or become disconnected -

OA SYLK T ERR n/a n/a Outdoor air enthalpy sensor has failed or become disconnected - check

OA SYLK H ERR n/a n/a

RA SYLK T ERR n/a n/a Return air enthalpy sensor has failed or become disconnected - check

RA SYLK H ERR n/a n/a

DA SYLK T ERR n/a n/a Discharge air sensor has failed or become disconnected - check wiring

OA SENS T ERR Outdoor air temperature sensor has failed or become disconnected -

Parameter

Range and Increment

Incremented by 1

o

Increment by 10

Increment by 10

then 15 min intervals.

Up to 4 h or OFF

AUTO

b

Notes

briey ash YES and change to NO but all parameters will change to

the factory default values.

Temperature to achieve Freeze Protection (close damper and alarm if

temperature falls below setup value).

CO2 ppm level to match CO2 sensor start level.

CO2 ppm span to match CO2 sensor.

Delay after stage 2 cool has been active. Turns on 2nd stage of cooling

when economizer is 1st stage and mechanical cooling is 2nd stage.

Allows three stages of cooling, 1 economizer and 2 mechanical.

OFF = no Stage 3 cooling

When controller receives 24 Vac input on the SD terminal in conventional mode, the OA damper will open if programmed for OPN and OA

damper will close if programmed for CLO. All other controls, e.g., fans,

etc. will shut off.

Turns on the DCV automatic control of the dampers. Resets ventilation

based on the RA, OA, and MA sensor conditions. Requires all 3 RA,

OA, and MA sensors.

sensor.

sensor.

sensor.

sensor.

Exhaust fan contacts enable during the DAMPER OPEN test. Make

sure you pause in the mode to allow exhaust contacts to energize due

to the delay in the system.

• NONE ─ not action taken

• ERV ─ 24 Vac out. Turns on or signals an ERV that the conditions

are not good for economizing but are for ERV operation.

d

• SYS ─ 24 Vac out. Issues a system alarm

“ALARMS(#)” includes the number of active alarms in parenthesis ( ). When using SYLK bus sensors, “SYLK” will appear on the

screen, and when using 20k OA temperature sensors, “SENS T”

will appear on the screen

replace sensor if the alarm continues.

check wiring then replace sensor if the alarm continues.

wiring then replace sensor if the alarm continues.

wiring then replace sensor if the alarm continues.

then replace sensor if the alarm continues

check wiring then replace if the alarm continues.

11

Page 12

Table 5 ─ Menu Structurea (cont)

Menu Parameter

Default

Value

Parameter

ALARMS(#)

ACT ERROR n/a n/a Actuator has failed or become disconnected - check for stall, over

CONTINUED

FREEZE ALARM n/a n/a Check if outsoor temperature is below the LOW Temp Lockout on

SHUTDOWN ACTIVE n/a n/a AUX2 IN is programmed for SHUTDOWN and 24 V has been applied

DMP CAL RUNNING n/a n/a If DCV Auto enalbe has been programmed, when the Jade is

DA SENS ALM n/a n/a Discharge air temperature is out of the range set in the ADVANCED

SYS ALARM n/a n/a When AUX1-0 is set to SYS and there is any alarm (e.g., failed

ACT UNDER V n/a n/a Voltage received by Actuator is above expected range.

ACT OVER V n/a n/a Voltage recieved by Actuator is below expected range.

ACT STALLED n/a n/a Actuator stopped before achieving commanded position.

a

Table 5 illustrates the complete hierarchy. Your menu parameters may be different depending on your conguration.

For example if you do not have a DCV (CO2) sensor, then none of the DCV parameters appear

b

When values are displayed, pressing and holding the ▲ or ▼ button causes the display to automatically increment.

c

n/a = not applicable

d

ERV Operation: When in Cooling mode AND the conditions are NOT OK for economizing - the ERV terminal will be energized.

In the Heating mode the ERV terminal will be energized when the OA is below the ERV OAT setpoint in the setpoint menu.

Parameter

Range and Increment

b

Notes

voltage, undervoltage and actuator count. Replace actuator if damper

is moveable and supply voltage is between 21.6 V and 26.4 V. Check

actuato count on STATUS menu

setpoint menu. Check if Mixed air temperature on STATUS menu is

below the Lo Setpoint on Advanced menu. When conditions are back in

normal range then the alarm will go away.

to AUX 2IN terminal.

completing a calibration on the dampers, this alarm will display. Wait

until the calibration is completed and the alarm will go away. Must have

OA, MA and RA sensors for DCV calibration; set up in the Advanced

setup menu.

SETUP Menu. Check the termperature of the discharge air.

sensors, etc.), the AUX1-0 terminal has 24 Vac out.

12

Page 13

Checkout Tests

Use the Checkout menu (see Table 5) to test the damper operation and

any congured outputs. Only items that are congured are shown in

the Checkout menu.

NOTE: See User Interface on page 3 for information about menu navigation and use of the keypad.

To perform a Checkout test:

1. Scroll to the desired test in the Checkout menu using the ▲ and

▼ buttons.

2. Press the button to select the item.

3. RUN? appears.

4. Press the button to start the test.

5. The unit pauses and then displays IN PROGRESS.

6. When the test is complete, DONE appears.

7. When all desired parameters have been tested, press the ↑ (Menu

up) button to end the test.

Checkout test can be performed at any time during the operation of the

system as a test that the system is operable.

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to equipment

Be sure to allow enough time for compressor startup and shutdown

between checkout tests so that you do not short-cycle the compressors.

Table 6 - Economizer Module -

Left Hand Terminal Blocks

Label Type Description

Top Left Terminal Block

MAT

MAT

OAT

OAT

S─BUS

S─BUS

20k NTC

and COM

20k NTC

and COM

S─BUS

(Sylk Bus)

Mixed Air Temperature Sensor

(Polarity insensitive connections)

Outdoor Air Temperature Sensor

(Polarity insensitive connection)

Enthalpy Control Sensor

(Polarity insensitive connection)

Bottom Left Terminal Block

IAQ 2─10 2─10 Vdc Air Quality Sensor Input

(e.g. CO2 sensor)

IAQ COM COM Air Quality Sensor Common

IAQ 24V 24 Vac Air Quality Sensor 24 Vac Source

ACT 2─10 2─10 Vdc Damper Actuator Output (2─10 Vdc)

ACT COM COM Damper Actuator Output Common

ACT 24V 24 Vac Damper Actuator 24 Vac Source

Table 7 - Economizer Module -

Right Hand Terminal Blocks

SETUP AND CONFIGURATION

W7220 Economizer Module Wiring

Use Fig. 12 and Tables 6 and 7 to locate the wiring terminals for the

economizer module.

NOTE: The four terminal blocks are removable. You can slide out

each terminal block, wire it, and then slide it back into place.

HJW10

50048848-002

NA

AUX2-

OCC

E-GND

EXH1

AUX1-O

Y2-

Y2-O

Y1-

Y1-O

C

R

Rev. A

MAT

MAT

OAT

OAT

S-BUS

S-BUS

IAQ 2-10

IAQ COM

IAQ 24V

ACT 2-10

ACT COM

ACT 24V

50040839-001

Rev. G

MA

MA

OA

OA

SB

SB

SB

SB

SB

SB

V

C

R

V

C

R

NA

NA

A2

OCC

EX

A1

Certied FDD Product

California Title 24, Part 6

www.energy.ca.gov

Y2I

Y2O

Y1I

Y1O

C

R

Fig. 12 - W7220 Economizer Module Terminal

Connection Labels

Label Type Description

Top Right Terminal Block

n/a The rst terminal is not used

AUX2 I 24 Vac IN Shut Down (SD) or Heat (W)

Conventional only

and

Heat Pump Changeover (O?B) in

Heat Pump mode.

OCC 24 Vac IN Occupied / Unoccupied Input

E - GND E─GND Earth Ground - System Required

EXH1 24 Vac OUT Exhaust Fan 1 Output

AUX1 O 24 Vac OUT Programmable:

Exhaust fan 2 output

or

ERV

or

System alarm output

Bottom Right Terminal Block

Y2─1 24 Vac IN Y2 in - Cooling Stage 2 Input from

space thermostat

Y2─O 24 Vac OUT Y2 out - Cooling Stage 2 Output to

stage 2 mechanical cooling

Y1─I 24 Vac IN Y1 in - Cooling Stage 2 Input from

space thermostat

Y1─O 24 Vac OUT Y1 out - Cooling Stage 2 Output to

stage 2 mechanical cooling

C COM 24 Vac Common

R 24 Vac 24 Vac Power (Hot)

Time-out and Screen Saver

When no buttons have been pressed for 10 minutes, the LCD displays a

screen saver, which cycles through the Status items. Each Status item

displays in turn and cycles to the next item after 5 seconds.

13

Page 14

HH79ZZ007 Dry Bulb Sensor

Economizers are shipped standard with an HH79ZZ007 outside air dry

bulb sensor, which looks like an eyelet terminal with 2 green wires.

This sensor is factory installed on the front of the economizer in the out-

20k Sensor

GREEN

1/4 Terminal (2)

side air stream. System default setting (high temp limit) is 63 degrees F,

and has a range of 48 to 80 degrees F. Note: a 2nd HH79ZZ007 sensor

is provided for mixed (supply) air temperature.

NOTE: California high temperature setting requirements by region are

shown below.

Device Type

a

Climate Zones

Fig. 12A - HH79ZZ007 Sensor

Required High Limit (Economizer Off When):

Description

GREEN

1, 3, 5, 11-16 Outdoor air temperature exceeds 75°F

Fixed Dry Bulb

2, 4, 10 Outside air temperature exceeds 73°F

6, 8, 9 Outdoor air temperature exceeds 71°F

7 Outdoor air temperature exceeds 69°F

1, 3, 5, 11-16 Outdoor air temperature exceeds return air temperature

Differential Dry Bulb

2, 4, 10 Outdoor air temperature exceeds return air temperature minus 2°F

6, 8, 9 Outdoor air temperature exceeds return air temperature minus 4°F

7 Outdoor air temperature exceeds return air temperature minus 6°F

Fixed Enthalpyb + Fixed

Dry Bulb

a

Only the high limit control devices listed are allowed to be used and at the setpoints listed. Others such as Dew Point, Fixed

All

Outdoor air enthalpy exceeds 28 Btu/lb of dry airb or

Outdoor air temperature exceeds 75°F

Enthalpy, Electronic Enthalpy, and Differential Enthalpy Controls, may not be used in any climate zone for compliance with Section 140.4(e)1 unless approval for use is provided by the Energy Commission Executive Director.

b

At altitudes substantially different than sea level, the Fixed Enthalpy limit value shall be set to the enthalpy value at 75°F and

50% relative humidity. As an example, at approximately 6,000 foot elevation, the xed enthalpy limit is approximately 30.7 Btu/lb.

Table 8 - California Title 24 Regional High Limit Dry Bulb Temperature Settings

TABLE 140.4-B AIR ECONOMIZER HIGH LIMIT SHUT OFF CONTROL REQUIREMENTS

Fig. 13 - Single Enthalpy Curve boundaries

14

Page 15

Table 9 - Single Enthalpy and Dual Enthalpy High Limit Curves

Enthalpy

Curve

ES1 80.0 60.0 28.0 80.0 36.8 66.3 80.1

ES2 75.0 57.0 26.0 75.0 39.6 63.3 80.0

ES3 70.0 54.0 24.0 70.0 42.3 59.7 81.4

ES4 65.0 51.0 22.0 65.0 44.8 55.7 84.2

ES5 60.0 48.0 20.0 60.0 46.9 51.3 88.5

HL 86.0 66.0 32.4 86.0 38.9 72.4 80.3

Temp.

Dry Bulb (oF)

Temp.

Dewpoint (oF)

Enthalpy

(btu/lb/da)

Temp (oF) Humidity %RH Temp (oF)

Point P1 Point P2

Enthalpy Settings (Optional Accessory)

If installing the optional HH57AC081 enthalpy sensor. The

HH79AH001 dry bulb outside air sensor must rst be removed. Wire

enthalpy to S-BUS connections on W7220 controller thru (2) gray

wires.

When the OA temperature, enthalpy and dew point are below the

respective setpoints, the Outdoor Air can be used for economizing. Fig.

13 shows the new single enthalpy boundaries in the W7220. There are

5 boundaries (setpoints ES1 thru ES5), which are dened by dry bulb

temperature, enthalpy and dew point.

Refer to Table 9 for ENTH CURVE setpoint values.

To use enthalpy the W7220 must have a HH57AC081 enthalpy control

sensor for OA. The W7220 calculates the enthalpy and dewpoint using

the OA temperature and humidity input from the OA sensor. When the

OA temperature, OA humidity and OA dew point are all below the

selected boundary, the economizer sets the economizing mode to YES,

economizing is available.

When all of the OA conditions are above the selected boundary, the

conditions are not good to economize and the mode is set to NO.

Fig. 13 shows the 5 current boundaries. There is also a high limit

boundary for differential enthalpy. The high limit boundary is ES1

when there are no stages of mechanical cooling energized and HL (high

limit) when a compressor stage is energized.

Table 8 provided the values for each boundary limit.

If using OA enthalpy sensor HH57AC081 accessory, remove and

discard the dry bulb sensor shipped with the economizer. System

enthalpy default is ES3 curve.

See Table 8 for California Title 24 high limit settings.

Enthalpy control Sensor Conguration

The optional Enthalpy Control sensor (Part Number: HH57AC081)

communicates with the W7220 Economizer controller on the two-wire

communications bus and can either be wired using a two pin header or

using a side connector. This sensor can be used for outdoor enthalpy,

or indoor dry bulb or enthalpy depending on the dip-swtich setting.

System enthalpy default is ES3 curve. See Table 8 for California Title

24 high limit settings.

Use Fig. 14 and Table 10 to locate the wiring terminals for each

Enthalpy Control sensor.

Use Fig. 14 and Table 11 to set the DIP switches for the desired use of

the sensor.

If using differential (return) enthalpy or temperature, see Table 8 for

California Title 24 setting requirements by region.

(Used for Outdoor Enthalpy, or Indoor Return

Nbr Label

1 S─BUS S─BUS

2 S─BUS S─BUS

a DA = Discharge Air or Supply Sensor

b RA = Return Air

c OA = Outside Air

Fig. 14 - HH57AC081 Accessory

Temperature or Enthalpy)

Table 10 - HH57AC081 Sensor

Wiring Terminations

Terminal

Type Description

S─Bus Communications

(Enthalpy Control Sensor Bus)

S─Bus Communications

(Enthalpy Control Sensor Bus)

Table 11 - HH57AC081 Sensor DIP Switch

Use

DA

RA

OA

DIP Switch Positions for Switches 1,2, & 3

1 2 3

a

b

c

OFF ON OFF

ON OFF OFF

OFF OFF OFF

Humidity

%RH

a

15

Page 16

OPERATION

Cooling, Unit with EconoMi$er X

For Occupied mode operation of EconoMi$er X, here must be a 24-v

signal at terminals R and OCC (provided through PL6-3 from the unit’s

IFC coil). Removing the signal at OCC places the EconoMi$er X

control in Unoccupied mode.

During Occupied mode operation, indoor fan operation will be

accompanied by economizer dampers moving to Minimum Position

setpoint for ventilation. If indoor fan is off, dampers will close. During

Unoccupied mode operation, dampers will remain closed unless a

Cooling (by free cooling) or DCV demand is received.

When free cooling using outside air is not available, the unit cooling

sequence will be controlled directly by the space thermostat. Outside

air damper position will be closed or Minimum Position as determined

by Occupancy mode and fan signal.

When free cooling is available as determined by the appropriate

changeover command (dry bulb, outdoor enthalpy, differential dry bulb

or differential enthalpy), a call for cooling (Y1 closes at the thermostat)

will cause the economizer control to modulate the dampers open and

closed to maintain the unit supply air temperature. Default supply air

temperature is 53°F, with a range of 38° to 70°F. Compressor will not

run.

Should 100% outside air not be capable of satisfying the space

temperature, space temperature will rise until Y2 is closed. The

economizer control will call for compressor operation. Dampers will

modulate to maintain SAT at setpoint concurrent with Compressor 1

operation. The “Low T Temp” setting (default 32°F) will lock out

compressor operation.

When space temperature demand is satised (thermostat Y1 opens),

the dampers will return to Minimum Damper position if indoor fan is

running or fully closed if fan is off.

If accessory power exhaust is installed, the power exhaust fan motors

will be energized by the economizer control as the dampers open above

the EXH1 SET setpoint and will be-energized as the dampers close

below the EXH1 SET setpoint.

Damper movement from full closed to full open (or vice versa) will

take between 1-1/2 and 2-1/2 minutes.

Heating with EconoMi$er X

During Occupied mode operation, indoor fan operation will be

accompanied by economizer dampers moving to Minimum Position

setpoint for ventilation. If indoor fan is off, dampers will close. During

Unoccupied mode operation, dampers will remain closed unless a DCV

demand is received.

When the room temperature calls for heat (W1 closes), the heating

controls are energized.

Demand Controlled Ventilation

If a eld-installed CO2 sensor is connected to the EconoMi$er X control,

a Demand controlled Ventilation strategy will operate automatically.

As the CO2 level in the space increases above the setpoint (on the

EconoMi$er X controller), the minimum position of the dampers will

be increased proportionally, until the Maximum Ventilation setting is

reached. As the space CO2 level decreases because of the increase in

fresh air, the outdoor damper will follow the higher demand condition

from the DCV mode or from the free cooling mode.

DCV operation is available in Occupied and Unoccupied periods with

EconoMi$er X. However, a control modication will be required on

the units to implement the Unoccupied period function.

Table 12 - Damper Position Control, 2-Speed Fan Motor, Economizer Cooling Not Available

INPUT

OCC 0 - V 24 - V 24 - V 24 - V 24 - V

Y1 0 - V 0 - V 24 - V 24 - V 0 - V

Y2 0 - V 0 - V 0 - V 24 - V 0 - V

W1 0 - V 0 - V 0 - V 0 - V 24 - V

SUPPLY FAN

MOTOR SPEED

DAMPER POSITION

NO CI2 SENSOR CLOSED MIN POS MIN POS MIN POS MIN POS

W/ CO2 SENSOR CLOSED

OFF LOW LOW HIGH HIGH

FROM

VENTMIN L

TO

VENTMAX L

FROM

VENTMIN L

TO

VENTMAX L

FROM

VENTMIN H

TO

VENTMAX H

FROM

VENTMIN H

TO

VENTMAX H

16

Page 17

TROUBLESHOOTING

Power Loss (Outage or Brownout)

All setpoints and advanced settings are restored after any power loss

or interruption, as all settings are stored in the Economizer controller’s

non-volatile ash memory.

NOTE If the power goes below 18 Vac, the W7220 controller module

assumes a power loss and the 5 minute power up delay will become

functional when power returns above 18 Vac.

Clearing Alarms

Once the alarm has been identied and the cause has been removed

(e.g. replaced faulty sensor). The can be cleared from the display.

To clear an alarm, perform the following:

1. Navigate to the desired alarm.

2. Press the button.

3. ERASE? displays.

4. Press the button.

5. ALARM ERASED displays.

Alarms

The Economizer module provides alarm messages that display on the

2-line LCD

NOTE: Upon power up, the module waits several seconds before

6. Press the ↑ (Menu up/Exit) button to complete the action and

return to the previous menu.

NOTE: If the alarm still exists after you clear it, it is redisplayed

within 5 seconds.

checking for alarms. This allows time for all the congured devices

(e.g. sensors, actuator) to become operational.

If one or more alarms are present and there has been no keypad activity

for at least 5 minutes, the Alarms menu displays and cycles through the

active alarms.

You can also navigate to the Alarms menus at any time.

See Table 5 for the Alarms menu.

Table 13 - Operating Issues and Concerns

Issue or Concern Possible Cause and Remedy

My outdoor temperature reading on the

STATUS menu is not accurate

If my enthalpy sensor drifts in accuracy

over time, can I re-calibrate it?

Can I go back to factory defaults and start

over?

Will I be able to see the LCD screen when it

is in the unit?

What is a good setpoint for the Mixed Air

Temperature (MAT)?

I am using enthalpy sensors. Why did

the control ask me to input a dry bulb

changeover temperature?

In checkout, the outdoor damper closes when

I command it to open.

How do I set my minimum position? The minimum position is set using the VENTMIN and VENTMAX setup in the

What if my damper does not go completely

closed in the checkout operation?

How do I set the OCC? There are two setting for the OCC setting, INPUT and ALWAYS, INPUT is from the

Does the economizer save my program values if the unit loses power?

If the unit is left in checkout, how long will the

unit stay in checkout mode without input?

Check the sensor wiring:

• Enthalpy sensors are to be wired to the S-Bus terminals.

• Temperature sensors are to be wired to the OAT and MAT terminals.

The sensor is not able to be re-calibrated in the eld. However there is a menu

item under the ADVANCED menu where you are able to input a limited off set in

temperature and humidity for each sensor you have connected to the economizer.

Under the SYSTEM SETUP menu you can change the setpoints to the factory

defaults.

The LCD screen has a backlight that is always illuminated.

The mixed are temperature is the temperature of air that you want to supply to the

space. In a commercial building, this is between 50 to 55oF (10 to 13oC). The mixed

are is the mixing of the return air and the outdoor air.

In the even the humidity sensor in the enthalpy sensors fails, the backup algorithm in

the control is to default to the temperature sensor in the enthalpy sensor.

Check the actuator linkage or rotation. In the CHECKOUT mode, the outdoor damper

should drive open or closed with the return air damper having the opposite effect.

SETPOINTS menu. VENTMIN is the minimum ventilation required when using an

occupancy sensor and VENTMAX is the minimum ventilation when not using an

occupancy sensor for Demand Control Ventilation. The VENTMAX position is set the

dame as with the potentiometer on the analog economizers and is the output voltage

to the damper actuator. The range is 2 Vdc closed OA damper and 10 Vdc open OA

damper.

Check the damper linkage or hub to make sure the damper is able to close

completely.

space thermostat, if it has an occupancy output. ALWAYS is the unit in the occupied

mode, if the economizer is powered (fan on).

Yes, once the changes are stored in the controller they will be stored until they are

changed by the operator.

The unit will remain in checkout for 10 minutes, then return to normal operation.

17

Page 18

Fig. 15 - Barometric Relief Flow Capacity

0

500

1000

1500

2000

2500

0 0.05 0.1 0.15 0.2 0.25 0.3

RELIEF FLOW (CFM)

RETURN DUCT STATIC PRESSURE (in. wg)

Small

Cabinet

Large and

Extra

Large

Cabinet

0

1000

2000

3000

4000

5000

6000

0 0.1 0.2 0.3 0.4

RETURN AIR FL OW (CFM)

RETURN DUCT STATIC PRESSURE DROP (i n. wg)

Small Cabinet

Large Cabinet

Extra Large C abinet

Fig. 16 - Return Air Pressure Drop

Copyright 2014 Carrier Corporation ● 7310 W. Morris St. ● Indianapolis, IN

Manufacturer reserves the right to discontinue, or change at any time, specication or designs without notice and without incurring obligations

Catalog No. IIK-CRECOMZR76-02Edition Date: 04/14

Replaces: IIK-CRECOMZR076-01

18

Loading...

Loading...