Page 1

Small Rooftop Units

Accessory Condensate Overflow Switch

Installation Instructions

Part No. CRCNDOVR003A00

3 to 15 Tons

50/60 Hz

SAFETY CONSIDERATIONS

Installation, start-up, and servicing of air-conditioning

equipment can be hazardous due to system pressures and electrical components, and equipment location (roofs, elevated

structures, etc.). Only trained and qualified service personnel

should install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance functions. All other operations should be performed by trained service

personnel. When working on air-conditioning equipment, observe precautions in the literature and on tags, stickers, and labels

attached to the unit, and other safety precautions that may apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Utilize Lockout/Tagout procedures.

• Use care in handling and installing this accessory.

Recognize safety information. This is the safety-alert symbol . When you see this symbol on the unit and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result

in severe personal injury or death. WARNING signifies a hazard which could result in personal injury or death. CAUTION

is used to identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced installation, reliability, or operation.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury and/or death.

Before beginning any modification, be certain that the

main-line electrical disconnect switch is in the OFF position. Close the main gas supply shutoff valve. Tag disconnect switch and gas valve with suitable warning labels.

INTRODUCTION

The condensate overflow switch accessory kit includes an

electronic controller and sensor for use in 3-15 ton light commercial rooftop units. The sensor can be used in downflow or

side discharge units. The control module is wired to turn off the

compressor(s) after 10 seconds of constant water contact if the

drain trap becomes plugged. It requires 5 minutes to reset after

the water has cleared. See Table 1 for control logic.

PRE-INSTALLATION

Remove accessory packaging and inspect shipment for

damage. See Table 2 for kit contents. File claim with shipping

company if accessory is damaged. Verify unit is level and adjust if necessary. See Table 3 for model usage.

With all Carrier direct digital controls (DDC) such as RTU

Open, PremierLink™, ComfortLink, and SystemVu™ controls, no alarms or alerts will be initiated based on this condensate overflow switch. In the event of a condensate overflow situation, compressors will shut down, any supply fans will continue operation, and no alarms will be communicated via the

unit controller to any connected networks.

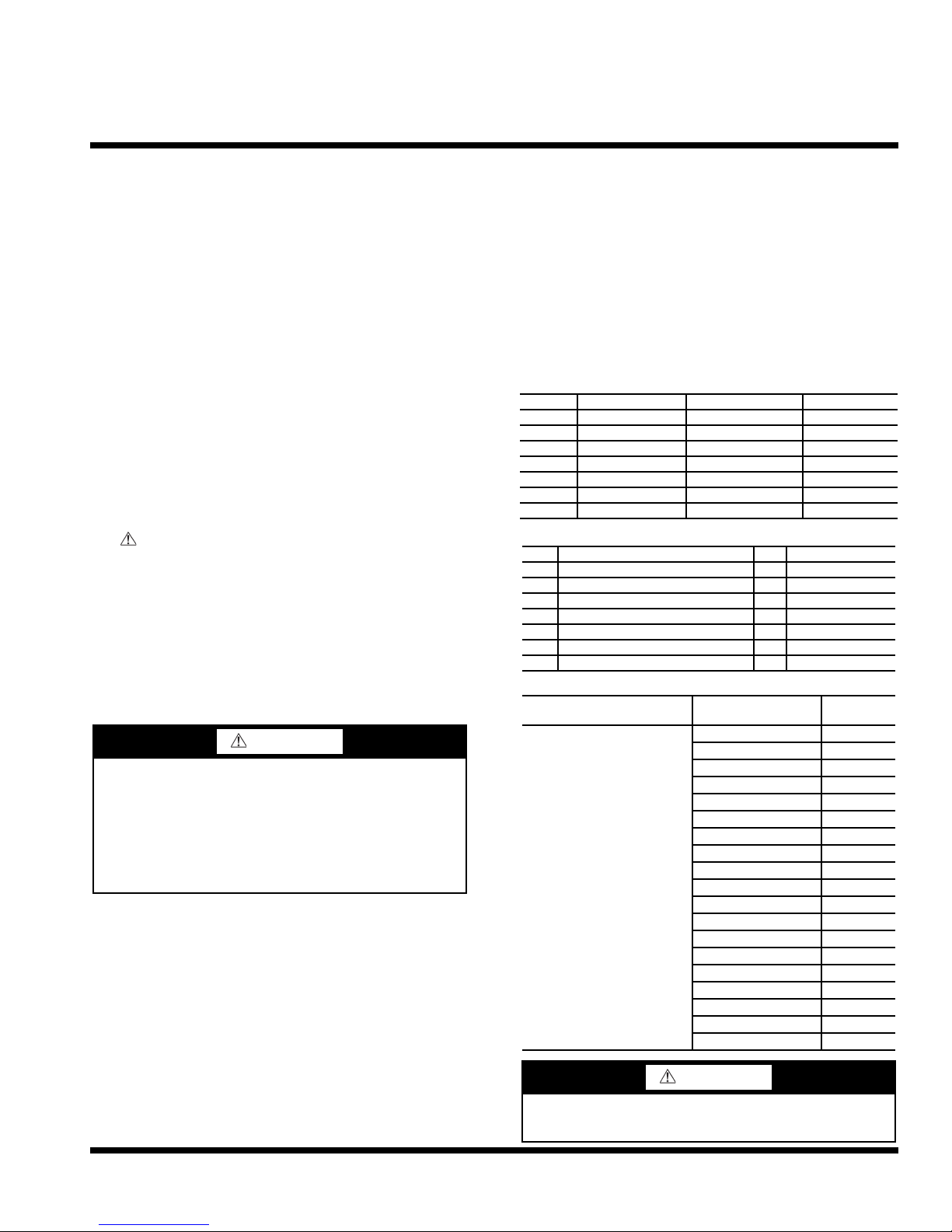

Table 1 — Control Logic

POWER SENSOR RELAYS LIGHT

OFF DRY OPEN OFF

OFF WET OPEN OFF

ON DRY CLOSED OFF

ON WET OPEN ON

ON DRY TO WET OPEN AT 10 SEC. ON AT 10 SEC.

ON WET TO DRY CLOSED AT 5 MIN. OFF AT 5 MIN.

ON DISCONNECTED OPEN BLINKS

Table 2 — Accessory Kit Contents

ITEM DESCRIPTION QTY PART NUMBER

1 INSTRUCTIONS 1 IIK-CRCNDOVR-01

2 CONTROLLER, CONDENSATE 1 HL39ZZ008

3 SCREWS, #6 x 3/8" 2 AC41AB080

4 SENSOR, 90" CONDENSATE 1 HL39ZZ009

5 BRACKET 1 48TM503400

6 SCREWS, BRACKET, #10 x 5/8" 2 AL48AM217

7 TIES, WIRE 10 Field Supplied

Table 3 — Model Usage

ACCESSORY PART

NUMBER USAGE

CRCNDOVR003A00

MODEL SIZE

48/50HC 04-14

48/50KC 04-06

48/50TC 04-16

48/50LC 04-12

50HCQ 04-12

50KCQ 04-06

50TCQ 04-14

580J/558J 04-16

581J/551J 04-14

582J/559J 04-06

547J 04-06

548J 04-14

549J 04-12

RGH/RAH 036-150

RGS/RAS 036-180

RGX/RAX 036-060

RHH 036-120

RHS 036-150

RHX 036-060

WARNING

To avoid the possibility of electrical shock, open all disconnects before installing or servicing this accessory.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. IIK-CRCNDOVR-01 Printed in U.S.A. Form IIK-CRCNDOVR-01 Pg 1 8-16 Replaces: New

Page 2

INSTALLATION

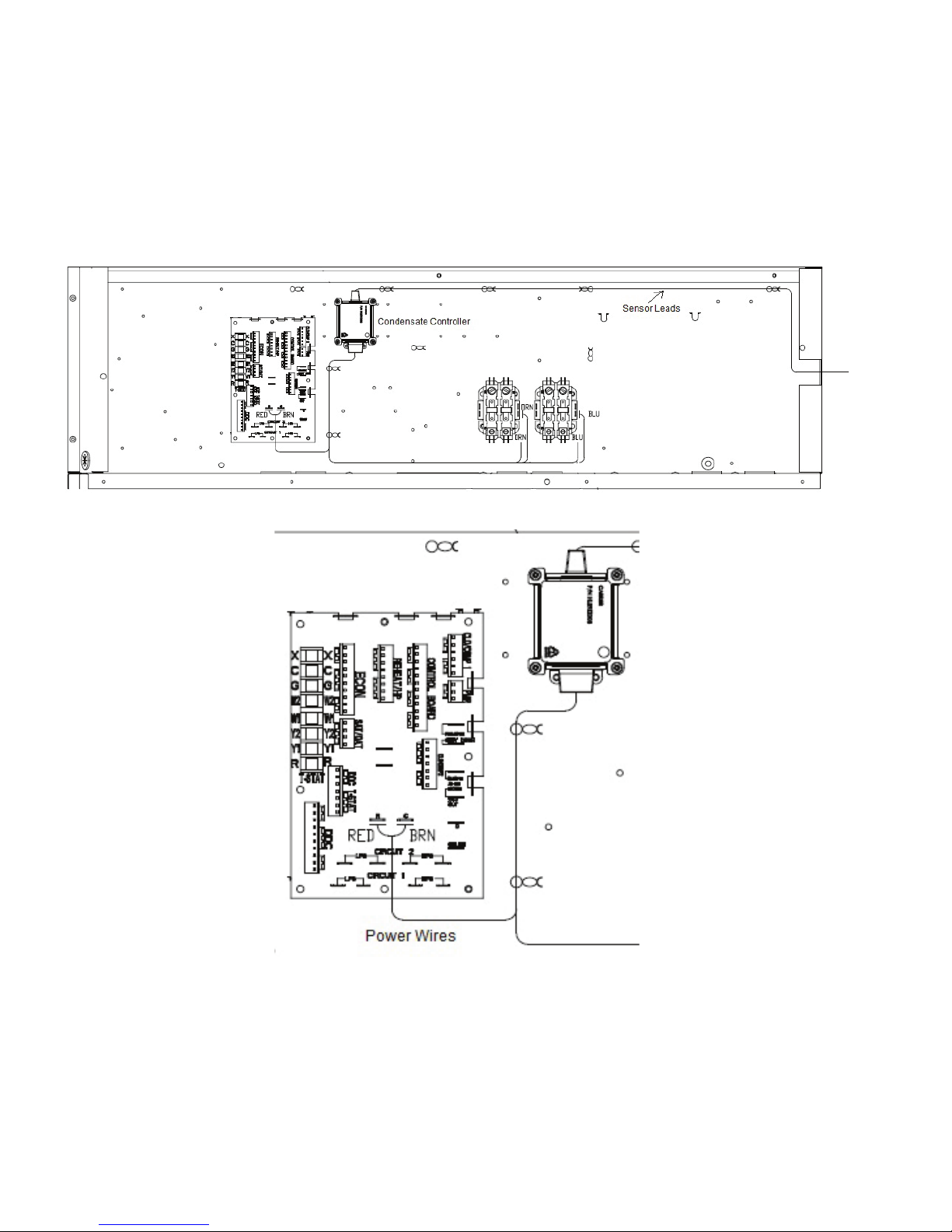

Fig. 1 — Control Box

Fig. 2 — Main Circuit Board

Step 1 — Install Condensate Overflow Switch

1. Remove panel that covers the control box.

2. Use 2 Item 3 supplied screws to fasten condensate controller to box as shown in Fig. 1.

3. Connect RED and BRN power wires from controller to

circuit board terminals as shown in Fig. 2.

Step 2 — For SINGLE Compressor Units

1. Remove wire from C1 coil and connect to BLU “Cond

1 In” wire from controller. Connect BLU “Cond 1

Out” wire from controller to open terminal on C1 coil.

See Fig. 3.

2. The (2) extra ORN wires should be tied back.

Step 3 — For DUAL Compressor Units

1. Remove wire from C1 coil and connect to BLU “Cond 1

In” wire from controller. Connect BLU “Cond 1 Out” wire

from controller to open terminal on C1 coil. See Fig. 4.

2. Remove wire from C2 coil and connect to ORN “Cond

2 In” wire from controller. Connect ORN “Cond 2

Out” wire from controller to open terminal on C2 coil.

See Fig. 4.

2

Page 3

Step 4 — Run Sensor Lead

Fig. 3 — Single Compressor

Fig. 4 — Dual Compressor

1. Remove blower compartment panel and run sensor lead

across top of box and pass through grommet on right side

for connection to sensor. See Fig. 1 and Fig. 5.

Step 5 — Install Sensor

1. If an economizer is installed on unit it must be removed

to access filter rack and condensate pan.

2. Remove air filters and filter rack. See Fig. 6.

3. Remove indoor coil bracket on left side. See Fig. 7.

4. Install sensor (Item 4) on bracket (Item 5) and tighten

thumb screw into hole in bracket. Fasten to indoor coil

bracket using (2) Item 6 screws. See Fig. 8 and 9.

5. Remove wire ties holding economizer wire harness. Place

indoor coil bracket back into slot in condensate pan as

shown in Fig. 9 and pass sensor wire into blower compartment. Leave excess wire in blower compartment for

later connection.

6. Run wire harness through U-slot while placing indoor

coil bracket back into position. See Fig. 10. Refasten with

previously removed screws and replace wire ties.

7. Reinstall filter rack and filters. See Fig. 6.

Step 6 — Connect Wire

1. Connect wire lead from controller to sensor lead and wire

tie excess wire to wire harness. See Fig. 5.

2. Reassemble unit.

3

Page 4

Fig. 5 — Sensor Wire Connection

4

Page 5

Fig. 6 — Filters and Filter Rack

Fig. 7 — Indoor Coil Bracket

INDOOR COIL BRACKET

5

Page 6

Fig. 8 — Sensor and Bracket

CORRECT INSTALLATION CORRECT INSTALLATION INCORRECT INSTALLATION

Fig. 9 — Bracket Installation

6

Page 7

REFERENCE VIEWS

Fig. 10 — Wire Harness

7

Page 8

© Carrier Corporation 2016

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. IIK-CRCNDOVR-01 Printed in U.S.A. Form IIK-CRCNDOVR-01 Pg 8 8-16A 8-16 Replaces: New

Loading...

Loading...