Page 1

Standard Altitude Only 0–2000 ft

Installation Instructions

60,000–130,000 Btu/hr

Part Number: CPLPCONV006A00 2 to 5 Tons

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be hazardous due to system fuels. Only trained and qualified personnel

should install, service, or repair air conditioning equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils, or cleaning and replacing filters. All other

operations should be performed by trained service personnel.

When working onair conditioning equipment, observe precautions

in the literature, on tags, and on labels attached to the unit.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

Follow all safety codes. Wear safety glasses and work gloves.

Have a fire extinguisher available.

Before converting a unit to LP, remove the burner assembly

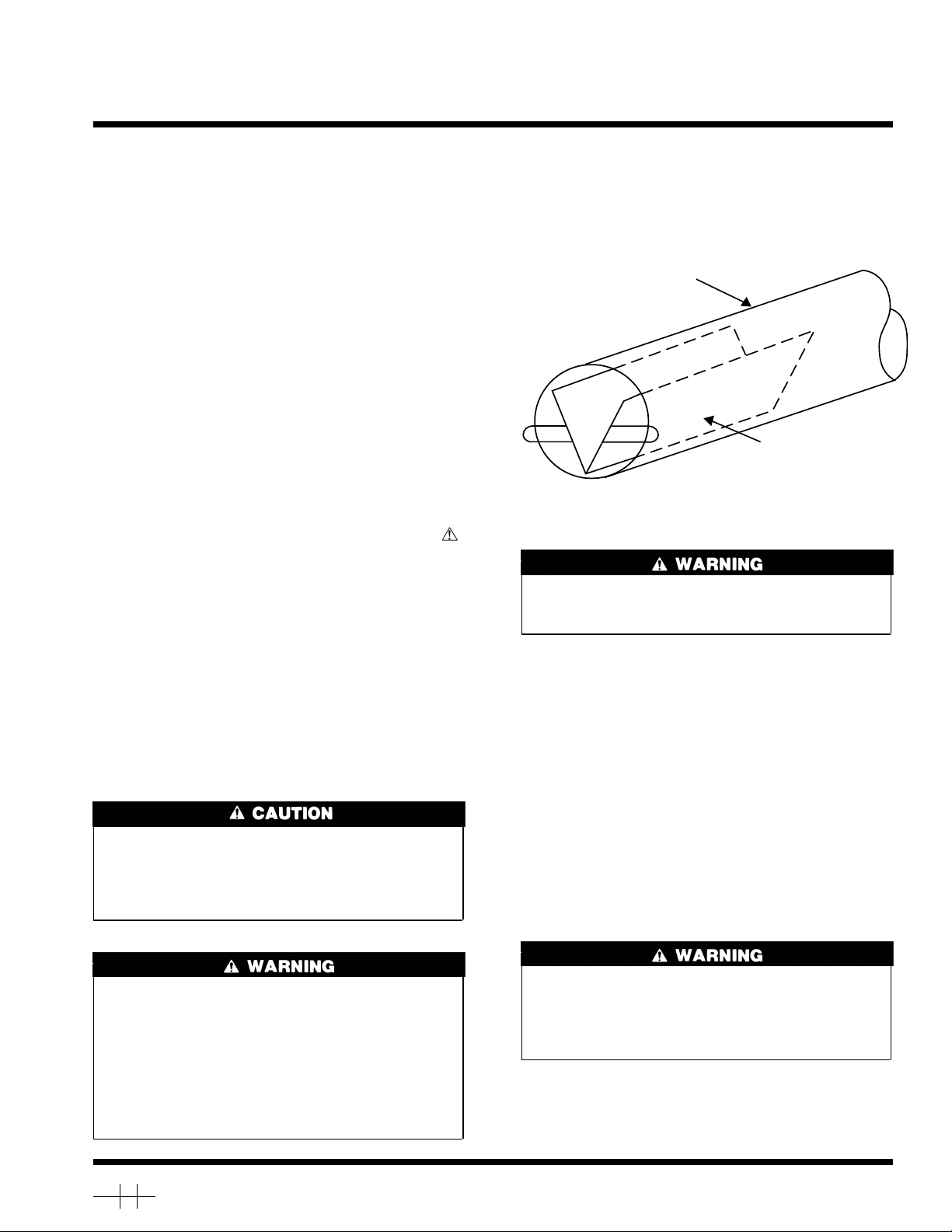

and inspect the heat exchanger tubes. If there are V-shaped

NOx baffles installed in the firing tubes (See Fig. 1). THEY

MUST BE REMOVED PRIOR TO CONVERTING

THIS UNIT TO LP. Discard the baffles after removal.

Small Packaged Products

Accessory LP Conversion Kit

Cancels: IIK 582A-18-6 IIK 582A-18-7

Firing Tube

NOx Baffle

→

.

This unit is designed to operate at 3.5 in. wg (±0.3 in. wg) of

manifold pressure with liquid propane (LP) gas. Exceeding

this pressure may result in explosion, injury or death.

→

These instructions cover the installation of a liquid propane

conversion kit on models 48GS, 582A, PY1P-B, 48GX, 583A,

PY2P-B, 48GP, and 583B that are equipped with a White Rodgers

combination automatic gas valve regulator.

This kit is applicable to units with heating inputs from 60,000 to

130,000 Btu/hrinstalled at standard altitudes from 0 ft to 2000 ft.

It cannot be used for high altitude installations or on units with

heating inputs of 40,000 Btu/hr. High altitude conversions

(2001–6000 ft) should use kit #CPLPCONV007A00. All conversions of 40,000 Btu/hr units should use Kit

#CPCLPCONV008A00 (applicable for any altitude from 0 ft to

6000 ft).

Fig. 1–Low NOx Baffle Location

INTRODUCTION

DESCRIPTION AND USAGE

INSTALLATION

1-01

C00151

This conversion kit is to be installed by qualified service

personnel in accordance with these instructions and all codes

and requirements of the authority having jurisdiction, and in

Canada, in accordance with the requirements of the

CAN/CGA (Canadian Gas Association) B149.2 Installation

Code. Failure to follow these instructions could result in

serious injury, property damage or death. The qualified

agency performing this work assumes responsibility for this

conversion.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 1a 1a

PC 101 Catalog No. 534-80021 Printed in U.S.A. Form 48-15SI Pg 1 1-01 Replaces: 48-14SI

Before performing service or maintenance operations on unit,

turn off gas supply first, then the main power switch to unit.

Electrical shock could cause serious injury or death. TAG

DISCONNECT SWITCH WITH SUITABLE WARNING

LABEL.

→

1. Turn off gas supply first, then power to unit.

2. Remove the front access panel from unit.

3. Disconnect the gas pipe from the gas valve.

4. Disconnect orange sparker cable at the ignition control.

Page 2

5. Disconnect yellow flame sensor wire from the ignition control.

6. Remove the screw securing the brown wire from the burner

assembly and the green wire from the induced-draft motor at

the sheet metal partition. Save screw.

7. Disconnect the gray and brown wires from the gas valve, and

remove blue wires from the rollout switch.

→

LP Gas Orifice No. 41* 3

LP Gas Orifice No. 42* 3

LP Gas Orifice No. 46* 3

Conversion Label 1

Responsibility Label 1

* Refer to Table 2 to determine the correct orifice to use.

LP- Liquid Propane

→

8. Remove the screw attaching the gas manifold to the basepan,

Table 1–Kit Contents

ITEM QUANTITY

Warning Label 1

and slide out the entire burner rack assembly from unit. Save

screw.

→

9. Inspect the inlet of the heat exchanger tubes for presence of

V-shaped NOx baffles (see Fig. 1.) If baffles are present they

must be removed prior to converting unit for LP gas. Slide

the baffles out of the tubes (on some models a retaining clip

must be released). IMPORTANT: If it is expected that this

unit will be converted back to natural gas at a later time,

these baffles should be retained for reuse. Otherwise the

baffles may be discarded.

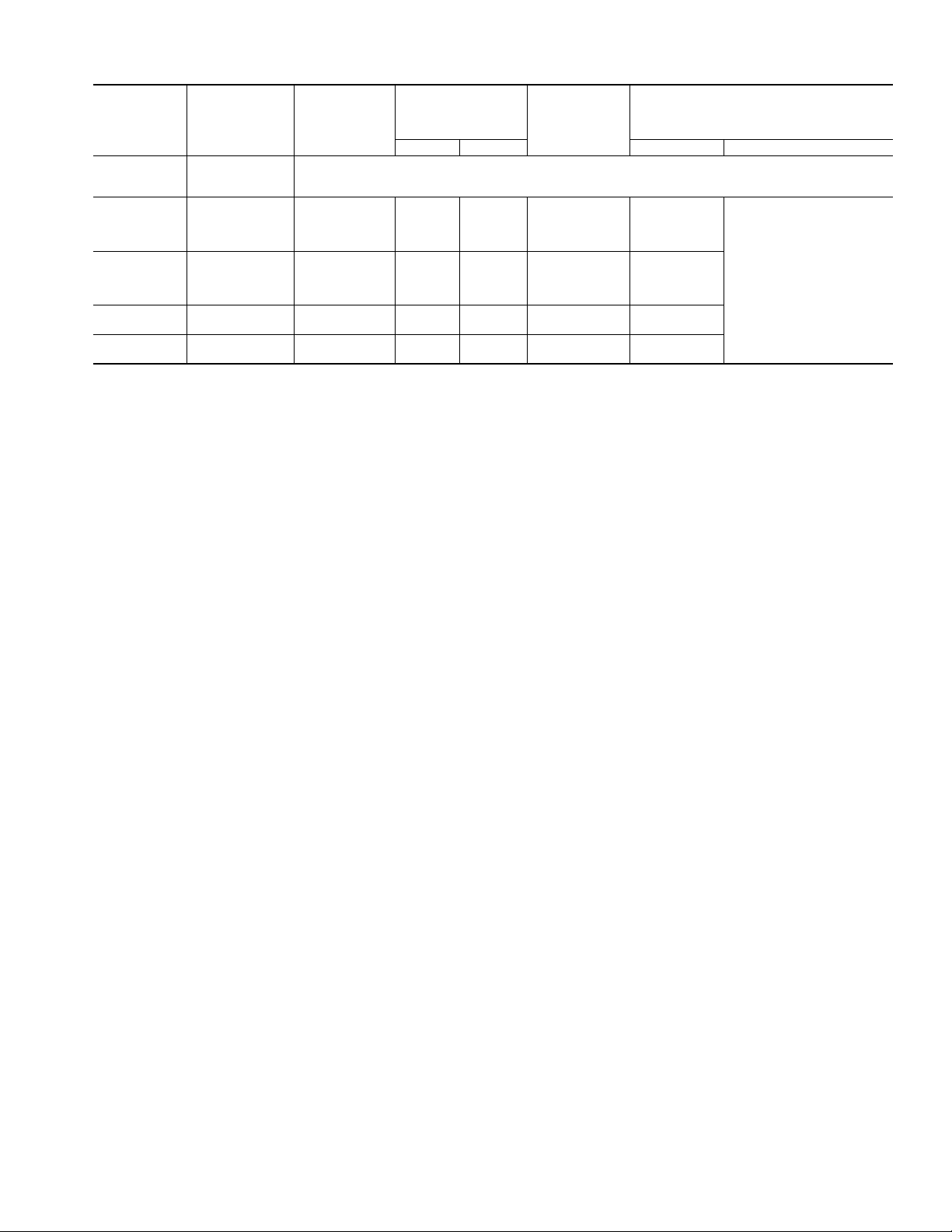

10. Using a 5/16 in. nut driver, remove the four screws securing

the manifold/gas valve assembly to the burner assembly. Save

these screws.

11. Remove the natural gas orifices from the manifold using a

9/16 in. wrench and install the correct LP gas orifices in the

manifold (See Table 2 to select correct orifice size based on

input. See Fig. 2 for orifice installation).

12. Replace the manifold/gas valve assembly into the burner

assembly using the four screws saved from Step 10.

13. Reconnect the blue wires to the rollout switch and reinstall

rollout switch.

14. Reconnect the gray wire removed in Step 7 to terminal 1 (M1)

of the gas valve. Reconnect the brown wire to terminal 2 (C2)

on the main gas valve.

15. Reconnect orange sparker cable and the yellow flame sensor

wires at the ignition control.

16. Slide burner rack assembly into basepan. Align burner rack

with screws on sheet metal partition and slide assembly back

tight to the partition. Replace the screw attaching the burner

rack to the basepan, removed in Step 8.

17. Reconnect the brown wire from the burner assembly and the

green wire from the induced-draft motor to the sheet metal

partition.

18. Remove the 1/8” pipe plug on the gas manifold and connect a

pressure manometer.

19. Reconnect electrical power and gas supply to the unit.

20. Fire unit and verify proper ignition. Verify that the pressure

manometer reads 3.5–in. ± 0.3–in. wc. If the pressure is

outside this range, adjust the gas valve settingby removing the

slotted brass fitting and turning the nylon adjustment screw.

Replace brass fitting.

21. Turn off unit, remove pressure manometer and replace the

1/8–in. pipe fitting on the gas manifold.

22. Attach warning label (P/N 48GS500615) to visible side of gas

valve.

23. Attach conversion label (P/N 48GS500614) above unit rating

plate on exterior of unit.

24. Attach completed conversion responsibility label (see Fig. 3,

P/N 48SS500283) inside service access panel.

25. IMPORTANT: Restart unit and leak check all gas connections including the main service connection, gas valve, gas

spuds, and manifold pipe plug.

26. After all leaks are eliminated, replace service panel.

2

Page 3

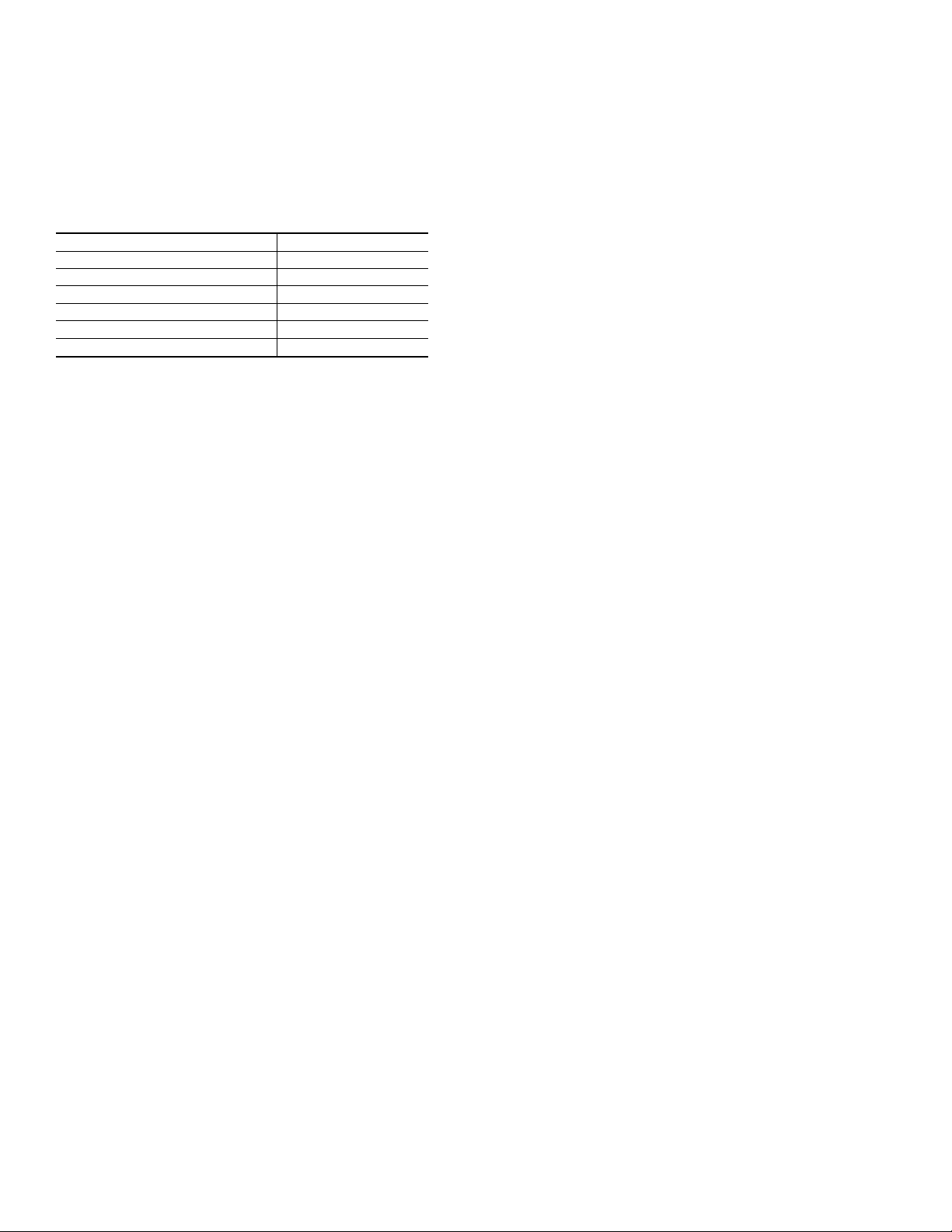

→

UNIT SIZES

018040

024040

030040

024060

030060

036060

042060

036090

042090

048090

060090

048115

060115

048130

060130

Table 2–LP Gas Orifice Sizes

LP NOMINAL

HEATING

INPUT (BTUH)

40,000

57,000 2 4.0 13.0 3.5

85,500 3 4.0 13.0 3.5

115,000 3 4.0 13.0 3.5

127,000 3 4.0 13.0 3.5

NUMBER OF

ORIFICES

57,000 BTUH AND HIGHER. FOR 40,000 BTUH MODELS USE KIT # CPLPCONV008A00

GAS SUPPLY

PRESSURE

(IN W/C) (LP)

MIN MAX 0–2000 2001–6000

THIS KIT APPLIES TO MODELS WITH HEATING INPUT OF

MANIFOLD

PRESSURE

(IN W/G) (LP)

LH32RF080

No. 46

LH32RF080

No. 46

LH32RF094

No. 42

LH32RF096

No. 41

LP GAS ORIFICE

PART NO.

AND SIZE

ALTITUDE (FT)

THIS KIT APPLIES

TO STANDARD ALTITUDE

INSTALLATIONS ONLY.

ABOVE 2000 FT

USE HIGH ALTITUDE

LP CONVERSION KIT

#CPLPCONV007A00

3

Page 4

MANIFOLD

FLAME

SENSOR

CLOSED END

BURNER (3)

CLOSED END

BURNER RACK

PIPE PLUG

PIPE PLUG

ORIFICE (3)

FLAME SENSOR

MANIFOLD

SPARKER

GAS VALVE

85,500 BTUH TO 127,000 BTUH UNITS

CLOSED END

BURNER (2)

CLOSED END

BURNER RACK

SPARKER

→

GAS VALVE

ORIFICE (2)

57,000 BTUH UNITS

C00149

Fig. 2–Orifice Installation

4

Page 5

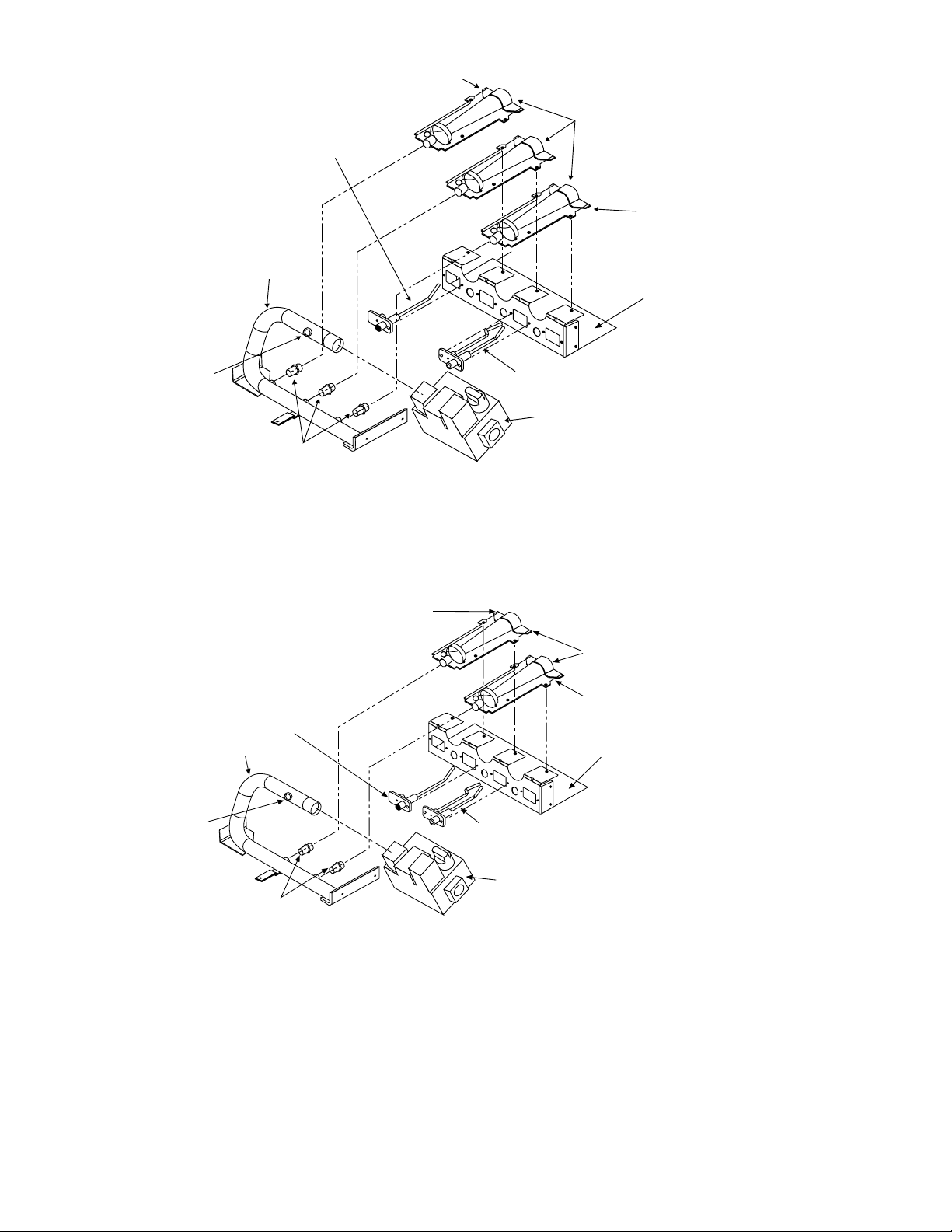

→

THIS APPLIANCE HAS BEEN CONVERTED

TO LP. GAS. KIT NO. _______________________

BY _______________________ DATE: ________

WHO ACCEPTS THE RESPONSIBILITY FOR

THE CORRECTNESS OF THIS CONVERSION.

48SS500283

A99309

Fig. 3–Conversion Responsibility Label

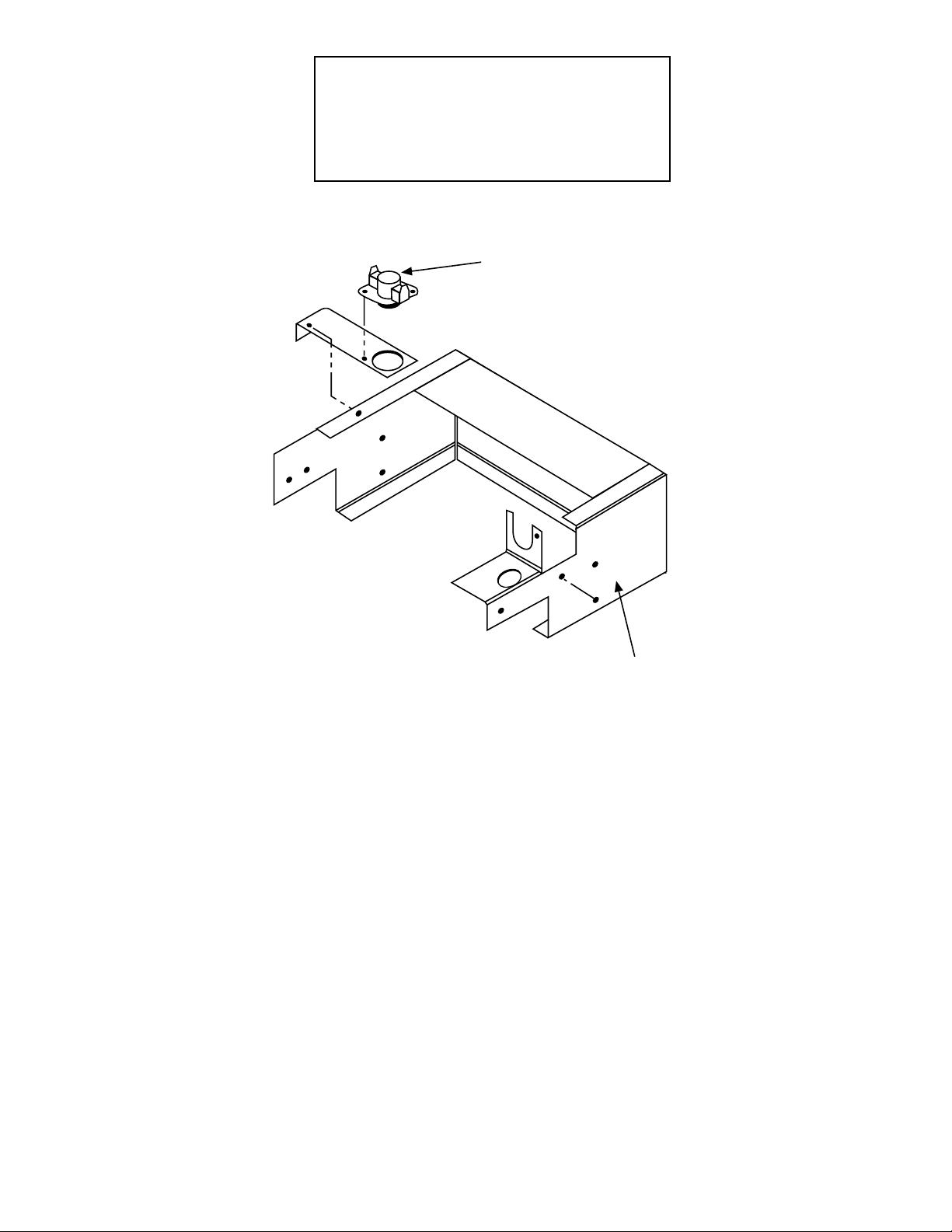

ROLLOUT SWITCH

→

BURNER

BRACKET

C00150

Fig. 4—Burner Bracket

5

Page 6

6

Page 7

7

Page 8

Copyright 2001 Carrier Corporation iik582a187

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 1a 1a

PC 101 Catalog No. 534-80021 Printed in U.S.A. Form 48-15SI Pg 8 1-01 Replaces: 48-14SI

Loading...

Loading...