Page 1

Container

Refrigeration

Unit

Data Retrieval

for

Micro-Link and

Micro-Link 2/2i

DataCORDER

62--02575--07

Page 2

OPERATING INSTRUCTIONS

DATA RETRIEVAL

for

MICRO-LINK and MICRO-LINK 2/2i

DataCORDER

Carrier Refrigeration Operations, A member of the United Technologies Corporation family. Stock symbol UTX.

Carrier Transicold, Carrier Corporation, P .O. Box 4805, Syracuse, N.Y. 13221 U. S. A.

Carrier Corporation 2000 D Printed in U. S. A. 0700

Page 3

TABLE OF CONTENTS

PARAGRAPH NUMBER Page

DESCRIPTION 1-1...............................................................................

1.1 HARDWARE AND SOFTWARE 1-1..................................................

1.2 DataCORDER 1-1.................................................................

1.2.1 Micro-Link 2 Controller/DataCORDER 1-2..........................................

1.2.2 Micro-Link 2i Controller/DataCORDER 1-3.........................................

1.2.3 Micro-Link 1 Controller/DataCORDER 1-4..........................................

1.2.4 DataCORDER Capabilities (Micro-Link 2 and Micro-Link 2i only) 1-5....................

1.3 DataCORDER INTERFACE 1-6......................................................

1.3.1 Data Extraction 1-6.............................................................

1.3.2 Events 1-6....................................................................

1.4 USDA RECORDING 1-10............................................................

1.5 RELATIVE HUMIDITY 1-10.........................................................

SYSTEM SETUP 2-1..............................................................................

2.1 HARDWARE PLATFORMS SUPPORTED 2-1..........................................

2.2 INTERROGATION CABLES 2-1.....................................................

2.3 PRINTER SUPPORT 2-2............................................................

2.3.1 PERSONAL COMPUTER PRINTING CABLE CONNECTIONS 2-2.....................

NOTE

The format of Section Three follows the format of the Help File provided with the DataView program

DataView PROGRAM INSTRUCTIONS 3-1..........................................................

TOPIC 1 SYSTEM REQUIREMENTS 3-1........................................................

Desktop Computer 3-1...................................................................

HP Palmtop Computer 3-1................................................................

Pen--Based Computer 3-1.................................................................

Printers Supported 3-2...................................................................

TOPIC 2 DESKTOP QUICK START 3-2..........................................................

Installation From MS --DOS Prompt 3-2......................................................

Additional Steps For The HP Palmtop 3-3....................................................

Additional Steps F or The Pen--based Computer Without A Floppy Drive 3-3........................

Running The Program At The MS--DOS Prompt 3-4...........................................

Changing Program Behavior 3-4...........................................................

TOPIC 3 MENU BASICS 3-4....................................................................

TOPIC 4 RAW FILE CONVERSION 3-5..........................................................

TOPIC 5 MICRO-LINKS SELECTION SCREEN 3-6...............................................

TOPIC 6 MAIN MENU SCREEN 3-7.............................................................

TOPIC 7 INTERROGATION MENU 3-8..........................................................

TOPIC 8 DATAREADER 3-9....................................................................

TOPIC 9 SYSTEM TOOLS 3-10..................................................................

TOPIC 10 CONTROLLER UTILITIES 3-11.........................................................

View/Change Container ID 3-11.............................................................

Control Setpoint 3-12.....................................................................

Control Parameters 3-13...................................................................

Compressor Hour Meter 3-13...............................................................

Configuration 3-13.......................................................................

i

62--02575--07

Page 4

TABLE OF CONTENTS (Continued)

PARAGRAPH NUMBER Page

TOPIC 11 CONTROLLER CONFIGURATION 3-14.................................................

Fixed Configuration Variables 3-15..........................................................

Custom Controller Configuration 3-16........................................................

TOPIC 12 RECORDER UTILITIES 3-17...........................................................

Trip Functions 3-17.......................................................................

Configuration 3-18.......................................................................

Date And Time 3-19......................................................................

USDA Probe Calibration 3-19..............................................................

Update ISO Trip Header 3-20...............................................................

TOPIC 13 RECORDER CONFIGURATION 3-21....................................................

Standard Configuration 3-22................................................................

Generic Configuration 3-23................................................................

Recorder Sensors 3-24....................................................................

Controller Sensors 3-25...................................................................

TOPIC 14 PROBE CALIBRATION 3-26............................................................

TOPIC 15 CONTROLLER MONITOR 3-27.........................................................

TOPIC 16 PROGRAM SETUP 3-28................................................................

TOPIC 17 DIRECTORY SCREEN 3-29.............................................................

TOPIC 18 PRINTER SETUP 3-30..................................................................

TOPIC 19 VIEW DATA 3-31.......................................................................

TOPIC 20 SENSOR CONFIGURATION 3-32........................................................

TOPIC 21 TEXTUAL DATA 3-33..................................................................

Sensor Data 3-33.........................................................................

Event Data 3-34.........................................................................

Summary Data 3-34......................................................................

Raw Data 3-34..........................................................................

TOPIC 22 GR APHIC DATA 3-36...................................................................

TOPIC 23 PRINT DATA 3-37......................................................................

OPTIONAL HARDWARE 4-1......................................................................

4.1 DataReader 4-1....................................................................

4.2 OPERATOR INTERFACE 4-1.......................................................

4.3 MENU INTERFACE 4-2............................................................

4.3.1 Transfer Data 4-2...............................................................

4.3.2 File Utilities 4-2................................................................

4.3.3 DataSet Files 4-2...............................................................

4.3.4 Set Date/Time 4-3..............................................................

4.3.5 Power Off 4-3..................................................................

4.3.6 Micro-Link 1/2/2i 4-3...........................................................

62--02575--07

ii

Page 5

LIST OF ILLUSTRATIONS

FIGURE NUMBER Page

Figure 1-1. Micro-Link 2 Controller and DataCORDER 1-2.......................................

Figure 1-2. Micro-Link 2i Controller/DataCORDER 1-3..........................................

Figure 1-3. Micro-Link 1 Controller 1-4.......................................................

Figure 2-1. Communication Cable Connections 2-1..............................................

Figure 2-2. Parallel Printer Cable Connections 2-2...............................................

Figure 2-3. Serial Printer Cable Connections 2-2................................................

Figure 4-1. Hand Held DataReader 4-1........................................................

Figure 4-2. DataReader Menu 4-2............................................................

Figure 4-3. File Utilities 4-2................................................................

Figure 4-4. ML2 Menu 4-3.................................................................

Figure 4-5. Extract Data Menu 4-3...........................................................

Figure 4-6. Command Menu 4-4.............................................................

Figure 4-7. Configure Menu 4-5.............................................................

Figure 4-8. Display Menu 4-5...............................................................

LIST OF TABLES

TABLE NUMBER Page

Ta ble 1-1 DataView Software 1-1.............................................................

Table 1-2. Manual Cross Reference Chart 1-1....................................................

Table 1-3. Temperature Controller Events 1-6....................................................

Table 1-3. Temperature Controller Events -- Continued 1-7.........................................

Table 1-4 DataCORDER Events 1-7...........................................................

Table 1-4 DataCORDER Events -- Continued 1-8.................................................

Table 1-5 Controlled Atmosphere Events Recorded in the DataCORDER 1-8...........................

iii

62--02575--07

Page 6

SECTION 1

DESCRIPTION

1.1 HARDWARE AND SOFTWARE

This manual contains information on the Carrier Transicold DataView Program and its interface with the

DataCORDER. The DataView program is used to retrieve data stored in the DataCORDER.

Data retrieval can be accomplished with one of the following devices:

1. Stand-alone DOS based portable personal computer (PC) with appropriate cable and software

2. Carrier DataReader hand held interrogator (refer to Section 4)

The retrieved data can then be printed from a PC in short or long form reports. From the DataReader, it can be

transferred to a personal computer (PC) for l ong-term storage on a floppy or hard disk.

The DataView software for a portable computer is supplied on 3.5 inch floppy disks for DOS (refer to Table 1-1). This

software allows data extraction, screen view of the data, hard copy report generation, USDA cold treatment probe

calibration and file management.

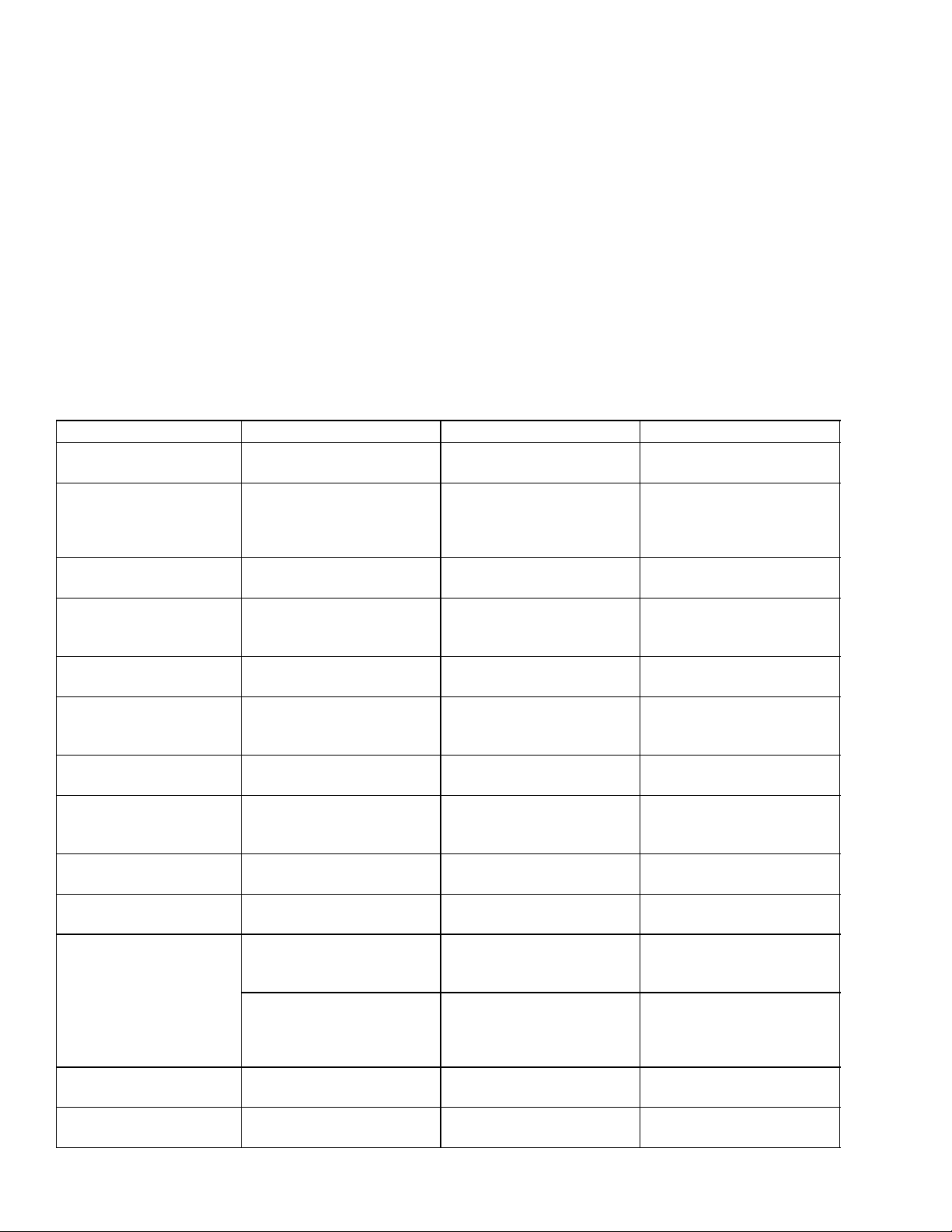

Table 1-1 DataView Software

PART NUMBER

DESCRIPTION APPLICATION

12-00413-05 3.5” DS/HD DataView Interrogator Software PC/DOS

12-00528-00 3.5”DS/HD DataView (Scroll) Interrogator Software PC/DOS

1.2 DataCORDER

The DataCORDER records and stores data. While this manual primarily addresses the interrogation of the

Micro-Link 2 and the Micro-Link 2i DataCORDER (see Figure 1-1 and Figure 1-2), interrogation can also be done on

units with the Micro-Link 1 DataCORDER (see Figure 1-3). Additional information on the DataCORDER may be

found in the unit Operation and Service manuals. Please refer to the separately bound manuals listed in Table 1-2.

Table 1-2. Manual Cross Reference Chart

MANUAL NUMBER

UNIT MODEL NUMBERS COVERED TYPE OF MANUAL

T-259 69NT40-489 Operation and Service

T-267 69NT40-501 Operation and Service

T-268 69NT40-511-1 to 69NT40-511-199 & 69NT40-521 Operation and Service

T-285 69NT40-511-300 & UP Operation and Service

T-289 69NT40-489 with EverFresh Controlled Atmosphere Operation and Service

T-291

69NT40-489--100 and Up with EverFresh Controlled

Atmosphere

Operation and Service

T-292 69NT40-531 Operation and Service

T-294 69NT40-511-200 to 69NT40-511-299 Operation and Service

T-296 69NT40-511-310 Operation and Service

1-1 62-02575-07

Page 7

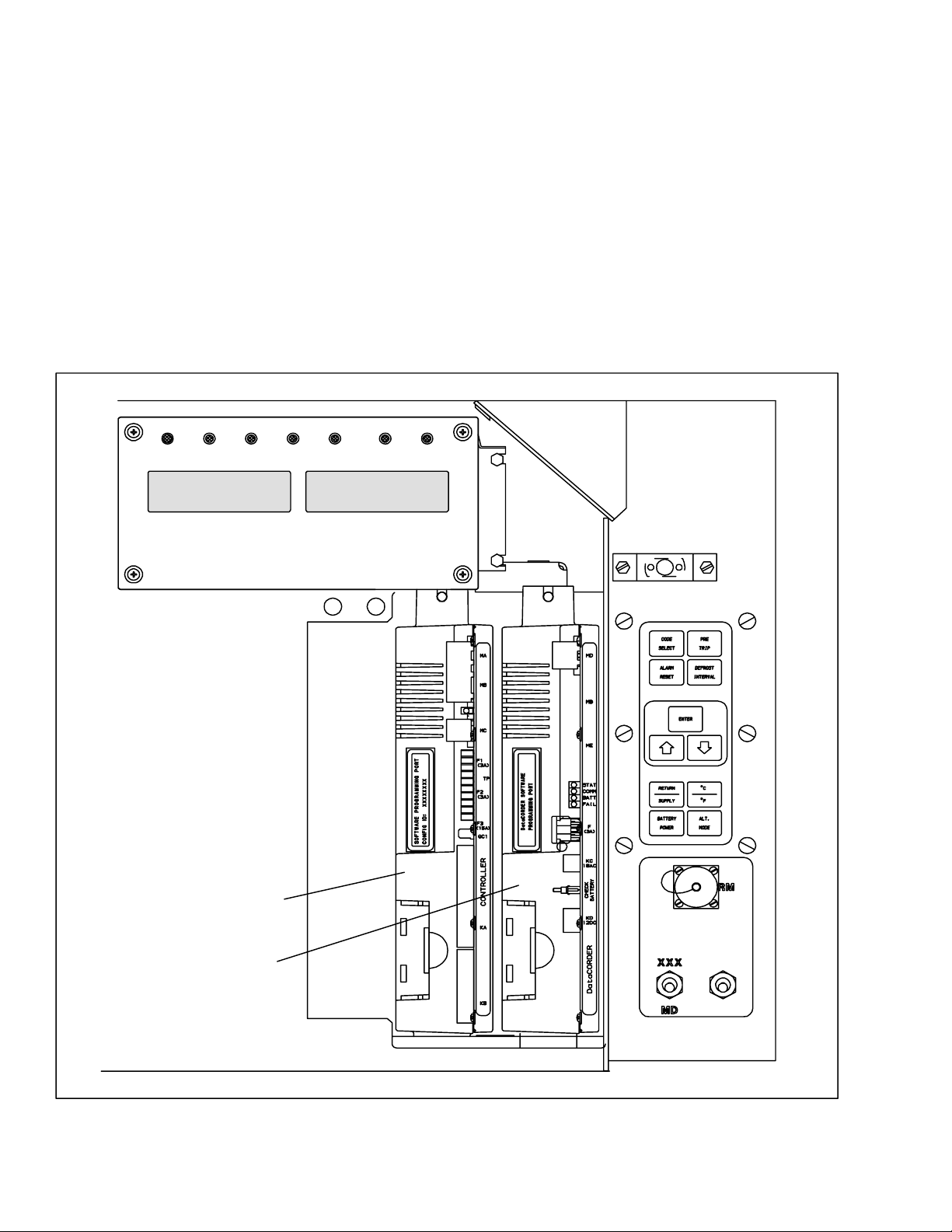

1.2.1 Micro-Link 2 Controller/DataCORDER

The Carrier Transicold Micro-Link 2 Controller (see Figure 1-1) is a custom-designed, microprocessor-based control

system which is fitted with a separate DataCORDER module. The DataCORDER consists of:

1. Microprocessor

2. Program memory

3. Data memory

4. Real time clock (RTC)

5. Six thermistor inputs (2 Air Temperature and 4 Cargo Temperature)

6. Two voltage inputs

7. Four status LED’s

8. Two communication ports (serial)

9. Power supply (optional battery pack)

CONTROLLER

DataCORDER

Figure 1-1. Micro-Link 2 Controller and DataCORDER

1-262-02575-07

Page 8

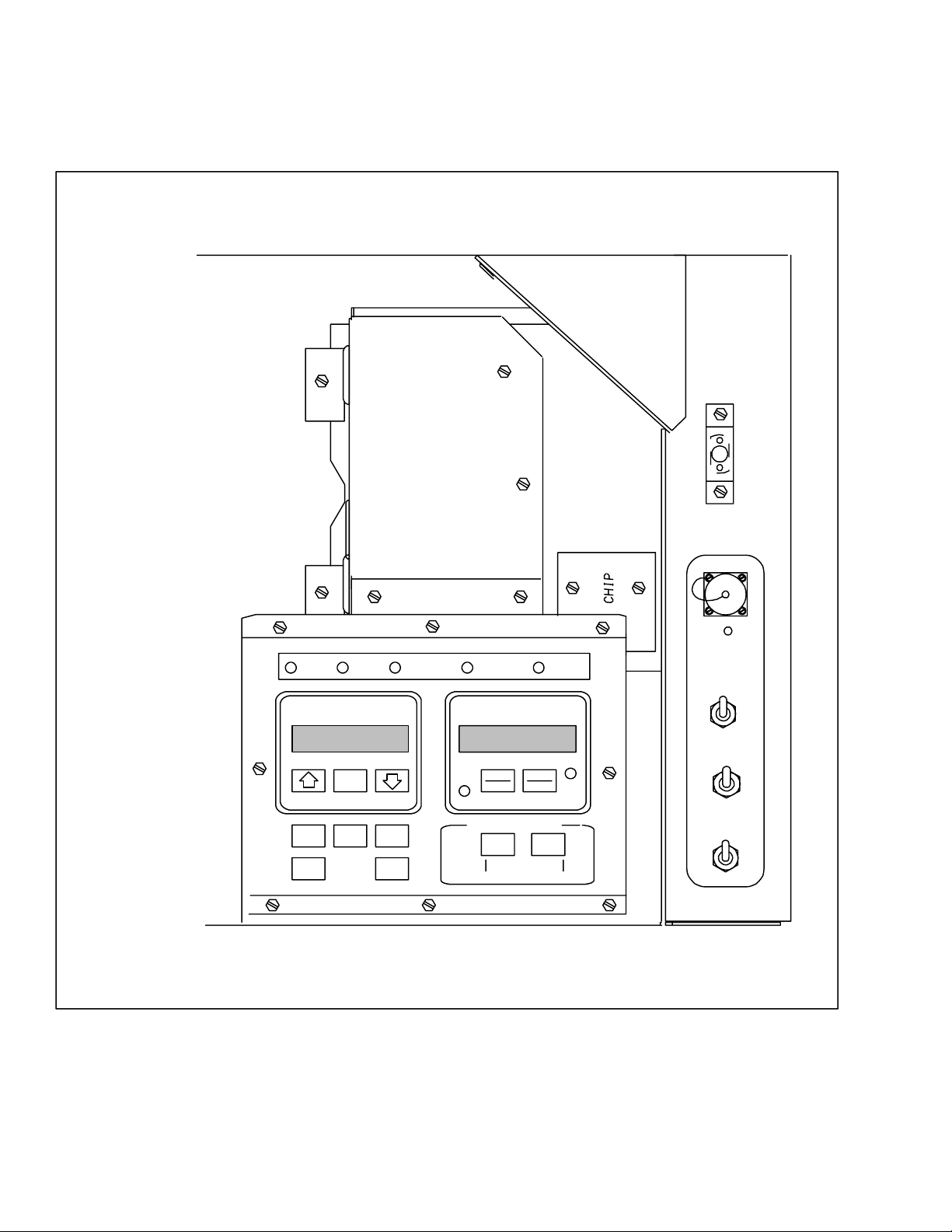

1.2.2 Micro-Link 2i Controller/DataCORDER

The Micro-Link 2i Controller is an integrated Controller and DataCORDER assembly, but is otherwise identical to

the Micro-Link 2 Controller. Scroll compressor units are also fitted with a controller Expansion Module located next

to the Controller/DataCORDER.

CONTROLLER/DataCORDER

EXPANSION MODULE

(Scroll Compressor Units Only)

Figure 1-2. Micro-Link 2i Controller/DataCORDER

1-3 62-02575-07

Page 9

1.2.3 Micro-Link 1 Controller/DataCORDER

The Carrier Transicold Micro-Link 1 Controller (see Figure 1-3) predates the Micro-Link 2 Controller. Micro-Link 1

units with the DataCORDER option are equipped with a DataCORDER that is an integral part of the Controller.

Interrogation of Micro-Link 1 and Micro-Link 2 Controllers will have some differences.

Figure 1-3. Micro-Link 1 Controller

1-462-02575-07

Page 10

1.2.4 DataCORDER Capabilities (Micro-Link 2 and Micro-Link 2i only)

The Carrier DataCORDER is a flexible recording device with the following capabilities:

a. Sensors

Up to six thermistor temperature probes can be connected directly to the DataCORDER.

These probes are referred to as:

1. Supply

2. Return

3. USDA 1

4. USDA 2

5. USDA 3

6. Auxiliary Cargo Probe

On separate DataCORDER modules (Micro-Link 2 only) there are also two 0-5vdc inputs available for future

expansion. In addition to these inputs, an additional eight sensors connected to the refrigeration or controlled

atmosphere controllers can be recorded.

1. This list of sensors includes:

2. Humidity Sensor

3. Controlled Atmosphere Gas Sensors

4. Temperature Controller Probes (including: supply, return, and defrost temperatures)

5. Controller Pressure Sensors

6. Current Sensors

7. Line Voltage Sensor

8. Frequency

NOTE

The supply and return sensors (SRS and RRS) used by the DataCORDER are not the same supply and return

sensors (STS and RTS) used by the Controller.

b. Log Interval

Micro-Link DataCORDER’s log data on 60 minute intervals from time of trip start. Micro-Link 2/2i DataCORDER

sensors can be recorded at intervalsof 15, 30, 60 (default), or 120 minutes. Data is logged on the exact interval, using a

precise real time clock (RTC). All clocks are set to Greenwich Mean Time at the factory and all recording i s done on

the exact interval (at 12:00 for example, rather than 12:03).

NOTE

Unless specified by your customer to set the DataCORDER clocks for another time zone, the clocks should

NOT be adjusted.

c. Sensor Recording Format

Sensors can be recorded in a wide variety of formats. A one byte temperature format can be used for compact data

storage. A two byte format can be used for high resolution over the entire temperature range.

1. One byte format (default): 0.25C(.45F) steps in chilled mode; 0.5C(.9F) steps in frozen mode

2. Two byte format: 0 .010C steps for entire range

d. Sampling Type

1. Averaged (default): shows average of data from every minute over the logging interval.

2. Snapshot: shows snapshot of data at the log interval.

3. USDA: shows snapshot of data at a 60 minute log interval.

1-5 62-02575-07

Page 11

1.3 DataCORDER INTERFACE

The DataCORDER is capable of performing the following functions initiated by the DataView Program

1.3.1 Data Extraction

a. Daily Header Data

Recorded days are presented in the following format:

1. Day 1 date (month, day, year), sensor data, events, ...

2. Day 2 date (month, day, year), sensor data, events, ...

b. Sensor Data

Sensor data will be read based on either standard or generic configuration. Pl ease refer to separately bound manuals

covering the Refrigeration Unit for further explanation of standard and generic configurations, see Table 1-2.

1.3.2 Events

Events will be transmitted to the DataCORDER as specified in Table 1-3, Table 1-4 and Table 1-5. The

DataCORDER compacts the events, disposing of repetitive events to save memory space. All events have a time and

date stamp.

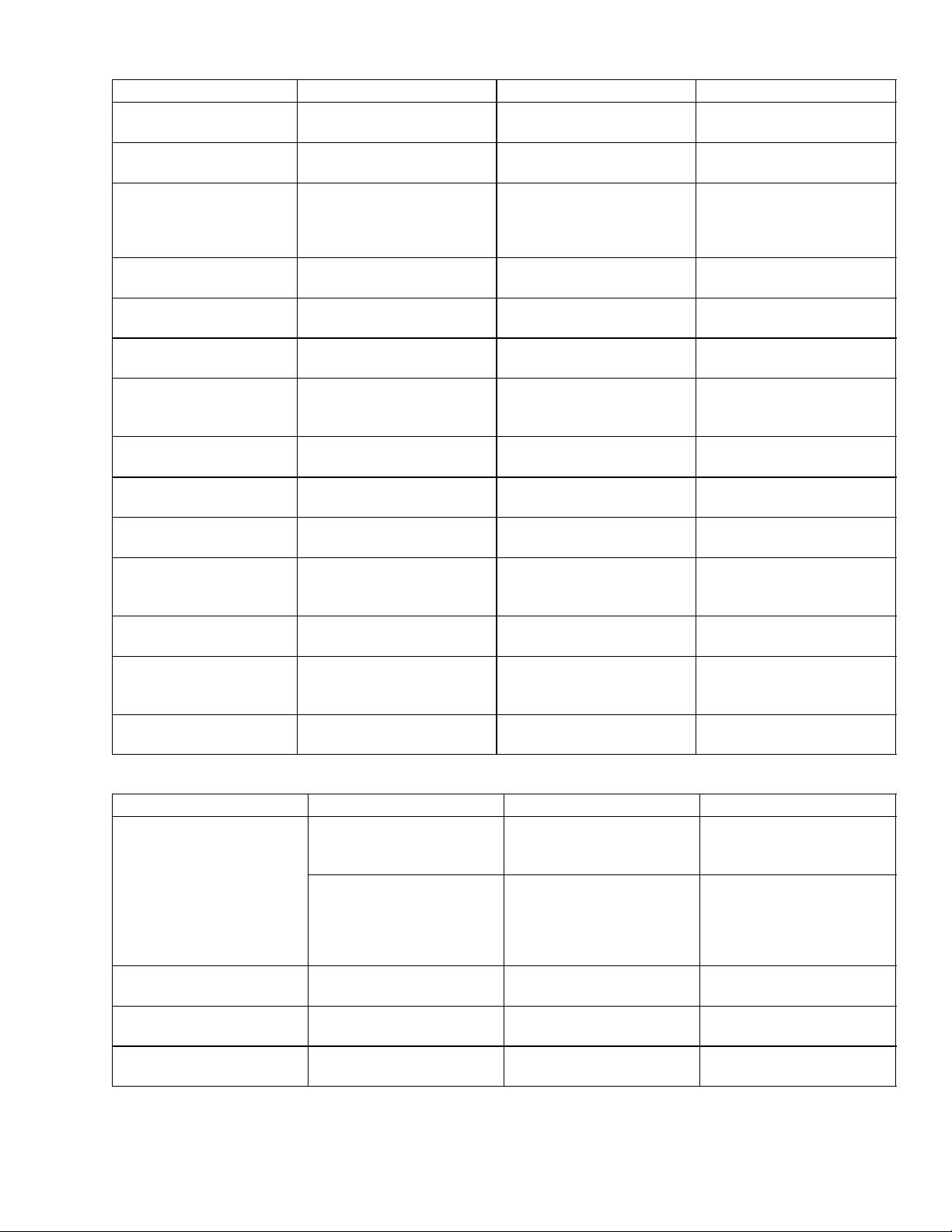

Table 1-3. Temperature Controller Events

Event

Set Point Change (SP)

Defrost Start (DS)

Defrost End (DE)

Pre-Trip Start (PS)

Pre-Trip End (PE)

Dehumidification Start

(DHS)

Dehumidification End

(DHE)

Humidification Start

(HS)

Humidification End

(HE)

Humidity Set Point

Change

ControllerAlarm

Activity (AL)

Controller S/W Upgrade

Container ID Change

When Event Occurs Data Stored Limits

Whenever the temperature

set point changes

Whenever a defrost cycle

is initiated and when the

system is in defrost mode

at midnight

Whenever a defrost cycle

is terminated

Whenever Pre-Trip starts

or is active at midnight

Whenever Pre-Trip completes.

Whenever dehumidification is initiated, or is active at midnight

Whenever dehumidification ends

Whenever humidification

is initiated, or is active at

midnight or “htESt” is run

Whenever humidification

ends

Whenever humidity set

point changes

Case 1: Whenever an

alarm changes state

New set point; method

used to change it

Source of initiation (keypad, communications, timer, or active from previous

day)

Source of termination

(normal, timer, or HTT)

Source of initiation (keypad, communications, or

active from previous day)

Pass/Fail data for each test

run since last power up

Set point, humidity reading type (active at midnight or normal)

Set point, humidity reading

Set point, humidity reading, method used to cause

it

Set point, humidity reading

New set point, method

used to change it

Case 1: Alarms active during this hour

Last 1 per hour, last 6 per

day.

First 1 per hour, first 10

per day.

Last 1 per hour, last 10 per

day

First 1 per hour, first 4 per

day.

Last 1 per hour, last 4 per

day.

First 1 per hour, first 10

per day.

Last 1 per hour, last 10 per

day

First 1 per hour, first 10

per day.

Last 1 per hour, last 10 per

day

N/A

Case 1: 1 per hour which

is a combination of all

alarm events in that hour

Case 2: At the end of any

hour where an alarm active

during that hour is inactive

Case 2: Currently active

alarms

Case 2: 1 per hour

at the end of the hour

Any change in the Con-

troller software revision.

Any time the container ID

is changed

New software version Last 1 per day.

New ID Last 1 per day

1-662-02575-07

Page 12

Event When Event Occurs Data Sent Limits

Trip Start (TS)

USDA Trip Comment

Pre-Trip Data

Economy Mode Start

(ECON_S)

Economy Mode End

(ECON_E)

ISO Trip Comment

Changed

Bulb Mode Start

(BULB_S)

Bulb Mode End

(BULB_E)

Controller Configuration

Change

Operating Mode Change

Power Management

Start

(Reciprocating Only)

Power Management End

(Reciprocating Only)

Airslide Position

Change

(Reciprocating Only)

Phase Switching

(Scroll Only)

Table 1-3. Temperature Controller Events -- Continued

Any time trip start is entered

When entered with

interrogation device

Any time a Pre-Trip test is

completed and Controller

is configured to send individual test data

Any time economy mode

is initiated

Any time economy mode

is terminated.

Whenever entered Data entered by user

NA NA

Up to 80 bytes of customer comment data

Last 1 per day

Pass/Fail for each sub-test,

and appropriate data points

Unlimited

for each test

NA NA

NA NA

Last 1 per hour, last 1 per

day

Evaporator fan speed,

Any time bulb mode starts

DTT opening temperature,

NA

dehumidification set point

Any time bulb mode ends NA NA

Whenever changed by user Configuration information

Whenever unit changes

mode

Whenever power management starts

Whenever power management ends

Whenever Makeup V ent

Slide Position is changed

Whenever Phase Sequence

is Checked

New operating mode

Power management mode

Method used to end power

management

Source of change command

Phase switched to correct/

incorrect

Last 1 per hour, last 1 per

day

Last 2 per hour, last 24 per

day

Last 4 per hour, last 24 per

day

Last 4 per hour, last 24 per

day

Last 1 per hour, last 6 per

day

Last 6 per hour, last 24 per

day

Event

DataCORDER Alarm Activity (DAL)

Battery Backup Start

(OFFWB)

Battery Backup End

(ONWB)

Power Loss (OFF)

Table 1-4 DataCORDER Events

When Event Occurs Data Stored Limits

Case 1: Whenever an

alarm changes state

Case 1: Alarms active

during this hour

Case 1: 1 per hour which

is a combination of all

events in that hour

Case 2: At the end of any

hour where an alarm active during that hour is inactive at the end of the

Case 2: Currently active

alarms

Case 2: 1 per hour

hour

Loss of main power with

battery pack present

Restoration of AC power

with battery pack present

Loss of AC power with no

battery pack present

NA NA

NA NA

NA NA

1-7 62-02575-07

Page 13

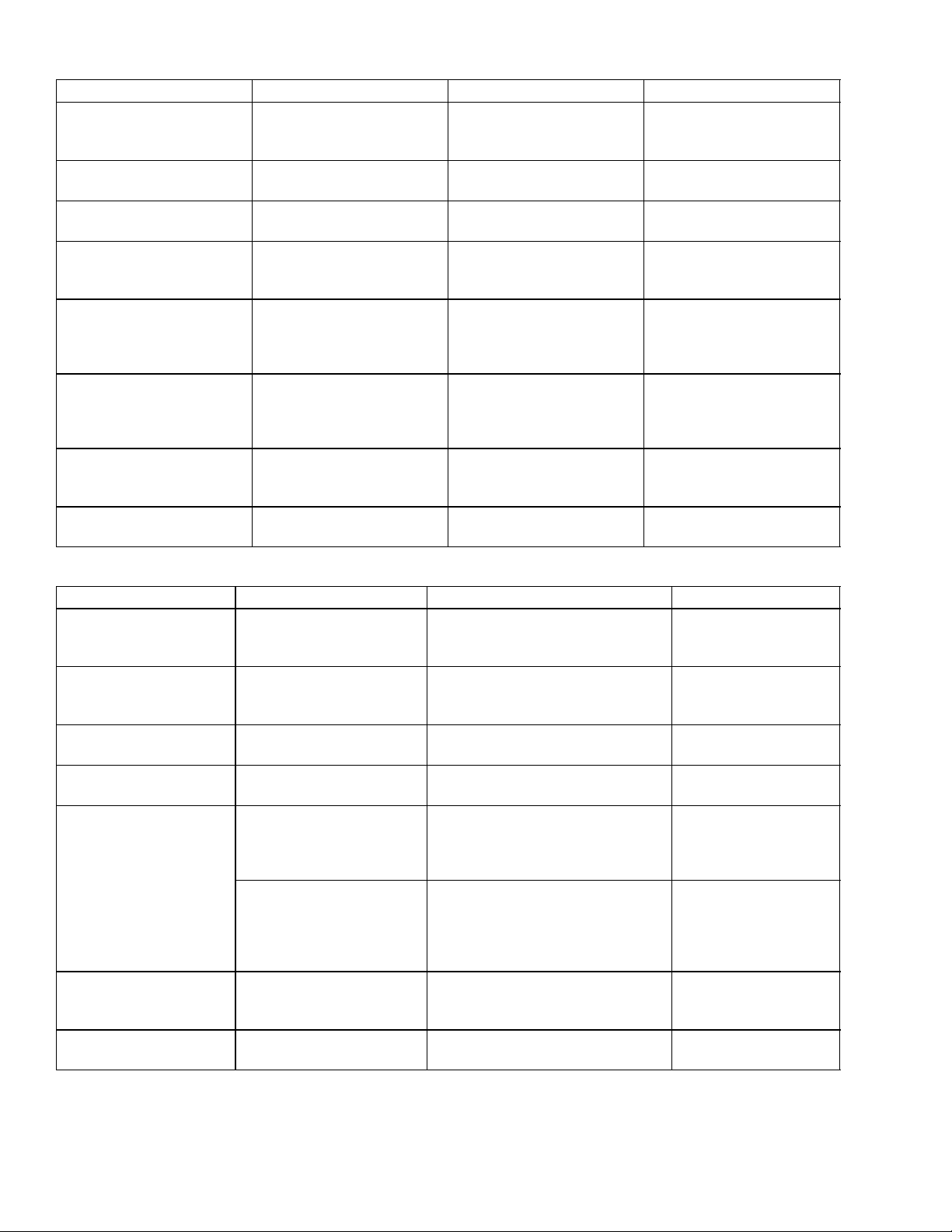

Event When Event Occurs Data Stored Limits

A

A

Power ON (ON)

Data Retrieval

Real Time Clock Change

RTC Battery Replaced

Controller Not

Responding (NWF)

Controller Responding

(NWR)

DataCORDER

Configuration Reset

Probe Calibration

Table 1-4 DataCORDER Events -- Continued

Restoration of AC power

with no battery pack pres-

NA NA

ent

Extraction of data from

the DataCORDER

User modifies the real

time clock (RTC)

NA NA

New Date and Time; Old

Date and Time

Real Time Clock (RTC)

battery internal to Data-

NA

CORDER is replaced

DataCORDER attempted

to communicate with

Controller, but received

NA NA

no response

DataCORDER was able to

establish communications

with Controller, after a

NA NA

failed attempt.

Whenever the Data-

CORDER detects an in-

NA

valid configuration

When Calibration offset

values are entered

NA

NA

Last 1 per hour, last 1 per

day

First 1 per hour, first 1 per

day

Last 6 per hour, last 24

per day

Table 1-5 Controlled Atmosphere (CA) Events Recorded in the DataCORDER

Event

CA Communications

Failure

CA Communications

Recovery

CA Set Point Change

(CA-SP)

CA Alarm Reset

C

larmActivity

(CA-AL)

CA Pre-Trip Start

(CA-PS)

CA Pre-Trip End

(CA-PE)

When Event Occurs Data Limits

When communication

with the CA controller is

lost

When communication

with the CA controller is

regained

Whenever the O2or CO

set point is changed

Whenever the CA alarm

list is reset

NA

NA

2

O2set point, CO2set point

First 1 per hour, first

24 per day

Last 1 per hour, first

24 per day

Last 1 per hour, last 6

per day

Last 2 per hour, last

10 per day

Case 1: 1 per hour

Case 1: Whenever an

alarm changes state

Case 1: Alarms active during this

hour

which is a combination of all events in

that hour

Case 2: At the end of any

hour where an alarm active during that hour is

Case 2: Currently active alarms Case 2: 1 per hour

inactive at the end of the

hour.

Whenever CA Pre-Trip is

initiated, or is active at

midnight

Whenever CA Pre-Trip is

completed

Source (keypad, communica-

tions, or active at midnight)

Test data for all CA Pre-Trip tests

run since the last power on.

First 1 per hour, first

4 per day

Last 1 per hour, first 4

per day

1-862-02575-07

Page 14

Table 1-5 Controlled Atmosphere (CA) Events Recorded in the DataCORDER -- Continued

Event When Event Occurs Data Limits

O2Air Calibration

O2Gas Calibration

CO2Zero Calibration

Lockout Start

Lockout End

CA Configuration

Change

CA Nitrogen Test

CA Service Activity

CA Software Upgrade

CA Controller Replaced

Door Lock (CA-DL)

Door Unlock (CA-UL)

Vent Mode Start

(CA-VS)

Vent Mode End

(CA-VE)

Whenever O2Air Calibration is completed

Whenever O2Gas Calibration is completed

Whenever CO2Zero Calibration is completed

Whenever the Temperature Controller initiates a

lockout of CA operation

Whenever the Temperature Controller enables

CA operation.

Any time the CA unit

configuration changes

Any time a nitrogen test

is completed

Any time ‘‘service the filter’’ hours or compressor

hours expires or is reset,

or the O

sensor’s life is

2

detected to be low, or the

sensor is detected re-

O

2

placed

Any time the CA soft-

ware revision changes

Any time the CA Con-

troller serial number

changes

Any time the CA door is

locked by the Controller

Any time the CA door is

unlocked by the Controller

Any time CA vent mode

is initiated

Any time CA vent mode

is terminated

New calibration value; Result

(pass, fail, or low) Source (keypad, communications, or timer)

New calibration value; Result

(pass or fail) Source (keypad,

communications, or timer)

New calibration value; Result

(pass or fail, no gas) Source (keypad, communications, or timer)

Type: normal, or active at midnight

Last 2 per hour, last

10 per day

Last 2 per hour, last

10 per day

Last 2 per hour, last

10 per day

First 1 per hour

NA Last 1 per hour.

Configuration variables

Last 2 per hour, last

10 per day

N2purity values for last low, medium, and high flow tests, and

flags to indicate whether low,

medium and high values are in

Last 2 per hour, last

10 per day

range

Filter hours expired; filter hours

reset; compressor hours expired;

compressor hours reset; O

sor life low; O2sensor expired;

2

sen-

First 1 per hour

filter, compressor, and total run

hours

New software version Last 1 per day

New serial number Last 1 per day

NA Last 1 per hour

NA Last 1 per hour

NA Last 1 per hour

NA Last 1 per hour

1-9 62-02575-07

Page 15

1.4 USDA RECORDING

A special type of recording is provided for USDA cold treatment purposes. Cold treatment recording requires that

three remote temperature probes are placed in the cargo at various locations. Provision is made to connect these probes

to the DataCORDER via receptacles located at the rear left-hand side of the unit. Four (five, on some units) receptacles

are provided. Four (three-pin) receptacles are for the probes and one (five pin) receptacle is provided for the

Interrogator. All receptacles are sized to accept a Deutsch HD16-5-16S size plug with a tricam coupling locking

device. The DataCORDER inputs are designed to accept a two wire thermistor probe.

A label on the back panel of the unit shows which receptacle is used for each probe. The USDA #1, #2 and #3 probes

(and possibly the optional Cargo probe) are installed in these receptacles.

The DataCORDER records up to six probe temperatures(supply,return, USDA #1, #2, #3 and an optional cargo probe

#4), at the logging interval.

The standard DataCORDER reportdisplays the supply and return air temperatures. The cold treatment report displays

USDA #1, #2, #3 and return air temperatures. Cold treatment recording is backed up by a battery so recording can

continue if AC power is lost.

NOTE

There may be an additional (3-pin) receptacle for a cargo probe on some units. This should NOT be used for

USDA probes.

1.5 RELATIVE HUMIDITY

When the Relative Humidity Set Point mode is activated or de-activated (i.e., Controller function code Cd33 on

Micro-Link 2/2i), this status is stored in the DataCORDER memory and reported as an event.

1-1062-02575-07

Page 16

SECTION 2

SYSTEM SETUP

2.1 HARDWARE PLATFORMS SUPPORTED

The DataView S oftware will run on a variety of DOS based m achines. We recommend the use of a desktop or laptop

machine with at least 3MB free disk space and a VGA monitor for displaying graphics, for most printing and report

generation functions. Other, less capable computers may be used for the actual data extraction.

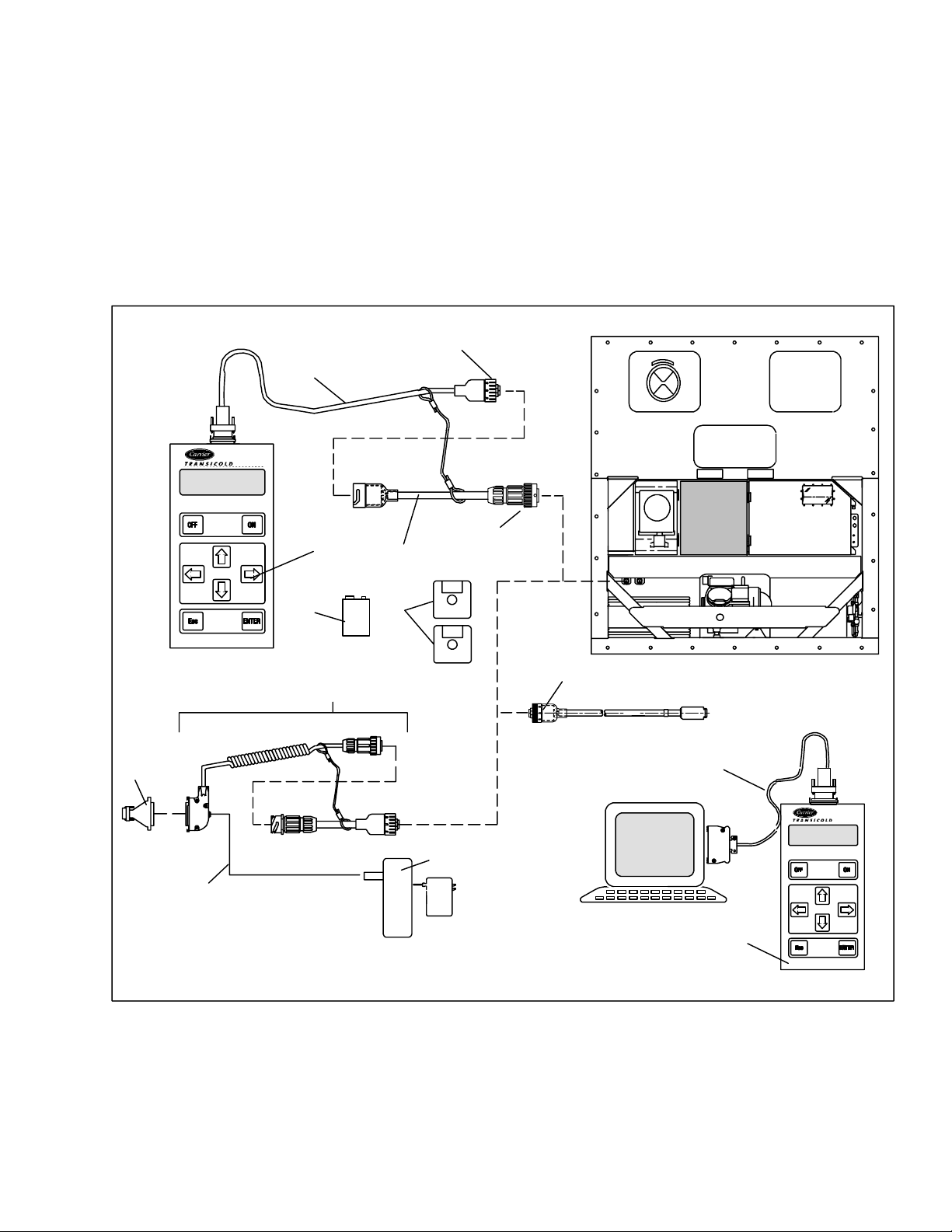

2.2 INTERROGATION CABLES

Cable requirements may differ between interrogation devices. For cable connections see Figure 2-1.

DEUTSCH PLUG

2

DataReader

10

1

5

9volt

9

3

6

VEAM PLUG

Micro-Link 2

DEUTSCH PLUG

H. P.

PALM TOP

4

7

DataReader

8

Computer Device

1

NOTE

DataReaderKit includes items 1 through 6, item 2 is not sold separately.

1. DataReader

2. Cable, Download

3. Cable, Adapter

4. Cable, Upload

5. Battery, Alkaline -- 9 Volt

Figure 2-1. Communication Cable Connections

6. Software, DataView (DOS)

7. Battery Pack with Charger

8. Cable, Battery

9. Cable Assembly

10. Adapter

2-1 62-02575-07

Page 17

2.3 PRINTER SUPPORT

Formatted reports can be generated on the following printers:

1. EPSON 85 dot matrix or compatible (most dot matrix printers will support this format)

2. HP LaserJet or equivalent (Many laser printers will support this format).

For printers that are not compatible with the above printers, select the FILE printer port option in printer setup. This

will send the report t o an ASCII print file.

2.3.1 PERSONAL COMPUTER PRINTING CABLE CONNECTIONS

After the DataCORDER has been interrogated, the data may be printed from a PC to a parallel or serial printer. Printer

cables will differ depending on the type of printer.

a. Parallel Printer

If you are connecting to a parallel printer, a standard Centronics type printer cable may be used (see Figure 2-2). The

printer cable connects to the printer port on a PC.

1

2

3

Figure 2-2. Parallel Printer Cable Connections

c. Serial Printer

1. Portable/Personal

Computer (Parallel Port)

2. Centronics Cable

3. Parallel Printer

If you are using a Serial Printer, a standard Null-modem type cable may be used (see Figure 2-3). Serial printers with

9-pin serial ports may require a standard 9-socket (female) to 25-pin (male) serial converter.

1

2

3

1. Portable/Personal

Computer (Serial Port)

2. Cable

(Standard Null--Modem type)

3. Parallel Printer

Figure 2-3. Serial Printer Cable Connections

2-262-02575-07

Page 18

SECTION 3

DATAVIEW PROGRAM INSTRUCTIONS

NOTE

The following is a copy of the software program at time of printing. If loading only one program

(12--00413 reciprocating unit interrogation or 12--00528 scroll unit interrogation program) the program disc instructions may be followed as written. If loading both programs on the same computer,

different resident directories must be created Where these differences exist, annotation has been added to the text provided herein.

Refer to the manual Table of Contents for a listing of the following Topics and the material provided

under the topic heading.

TOPIC 1 SYSTEM REQUIREMENTS

This section describes the PC and printer system requirements for the DOS DataView interrogator program.

Desktop Computer

1. MS--DOS compatible computer with an 80186 or higher microprocessor.

2. A hard--disk system (Or hard--disk emulation with electronic memory).

3. MS--DOS version 3.3 or higher.

4. A minimum of 640KB free System Memory (RAM).

5. A minimum of 3MB free hard--disk space.

6. One 3.5--inch disk drive. If the system has one diskette drive it will have a drive designator of A. If the system is

configured with two diskette drives the second drive will be designated as B.

7. One Serial Port not dedicated to a FAX--Modem.

8. One of the following ports available for a printing;

Serial port

Parallel port

Network Connection

9. Serial to serial, serial to parallel, or parallel to parallel printer cable.

HP Palmtop Computer

1. MS--DOS compatible computer with an 80186 or higher microprocessor.

2. MS--DOS version 3.3 or higher.

3. A minimum of 640KB free System Memory (RAM).

4. A minimum of 3MB ROM free space available.

5. One RS--232 serial port.

6. Connectivity Pack to transfer/receive files from a desktop computer to/from the HP Palmtop computer.

7. Serial to serial or serial to parallel printer cable.

Pen--Based Computer

1. MS--DOS compatible computer with an 80186 or higher microprocessor.

2. MS--DOS version 3.3 or higher.

3. A minimum of 640KB free System Memory (RAM).

4. A minimum of 3MB ROM free space available.

5. Optional 3.5 floppy disk drive.

6. One RS--232 serial port.

7. Optional parallel port.

8. Serial to serial, serial to parallel, or parallel to parallel printer cable.

3-1 62-02575-07

Page 19

Printers Supported

1. EPSON 85 dot matrix or compatible (most dot matrix printers support this format).

2. HP Laser Jet or equivalent (many laser printers support this format).

For printers that are not compatible with the above printers, select the FILE printer port option in printer setup. This

will send the report to an ASCII print file.

TOPIC 2 DESKTOP QUICK START

This section describes the installation procedure for the DOS DataView interrogator program.

Installation From MS--DOS Prompt

This installation procedure will copy the DataView Program to a hard --disk. Approx. 1.5MB of files will be copied.

NOTE

The data view package contains two diskettes. disc part number 12--00413--05 loads software for use with

reciprocating compressor units. Disc 12--00528--00 loads software for use with scroll compressor units. Both

software programs may be loaded on the same computer except differentresident directories must be created.

Each DOS DataView program comes on a single 3.5--inch diskette. To begin installation insert the diskette into drive

A:\ or drive B:\. Depending on the drive the diskette is loaded in, at the MS--DOS system prompt type A:\install or

B:\install and press the enter key. The installation program will take the user through the following steps:

a) The startup screen is displayed. Press enter to continue.

b) The product selection screen is displayed. Select which DOS DataView product to i nstall DataView onto: a PC,

Hewlett Packard (HP)Palmtop orpen based computer.Use the up/down arrow keys to highlight theproduct, andthe

space bar select the product, and press enter to continue.

NOTE

If loading scroll software on the same computer as reciprocating software the destination directory must be

changed. Suggested change is C:\SCROLLDV. If the destination directory is not changed, installation of new

reciprocating software will overwrite the scroll software.

c) The destination directory selection screen is displayed. Enter t he directory the DataView program will reside in and

press enter. The default directory is “C:\DATAVIEW.” If this directory does not exist on the PC, the installation

program will automatically create the directory.

d) To preserve the previous sensor configuration file, sensors.cnf, the file is copied to sensors.sav.

e) To preserve the previous program configuration file, ml2.cnf, the file is copied to ml2.sav.

f) The custom.cnf, *.DCX, and *.PRN files will not be delete and will remain in the directory.

g) The previous version of the DataView program will be deleted prior to installing the new program.

h) All of the files are downloaded to the directory defined in step c. As the files are downloaded to the computer, a

progress bar is displayed to indicate the amount of files successfully downloaded. The following files will reside in

the directory defined in step c.

DATAVIEW.EXE

Main Program

RPTVIEW.EXE Report Generator Program

PRNTFILE.EXE Print Report Program

COREMON.EXE Micro-Link 2/2i Monitor Program

CTD2.EXE Micro-Link 1 Program

SELFILE.EXE

DataReader Program -- not included with the HP Palmtop or

Pen--Based computer.

HELP.DAT Help data file

CONTHELP.DAT Controller Monitor Help data file

CGA.BGI Graphics driver

EGAVGA.BGI Graphics driver

ML2.CNF Program configuration file

MODELS2.CNF Model controller configuration file

SENSORS.CNF Sensor configuration f ile

3-262-02575-07

Page 20

i) Creates the sub directory C:\“directory”\DATA, where “directory” is the directory defined in step c. This is the

working directory where the DCX files are stored.

j) Creates the sub directory C:\“directory”\PRN_FLS, where “directory” is the directory defined in step c. This is the

print file directory where the ASCII Text print f iles are stored.

k) The user shall be notified when the installation is complete via the Installation Completion Screen and given direc-

tions on how to proceed.

l) To restore the previous customized version of the sensor configuration file, execute the following commands at the

MS--DOS prompt:

1. “del sensors.cnf” -- deletes the new sensors.cnf file

2. “ren sensors.sav sensors.cnf” -- restores the old sensors.cnf file

m) To restore the previous customized version of t he program configuration file, execute the following commands at

the MS--DOS prompt:

1. “del ml2.cnf” -- deletes the new ml2.cnf file

2. “ren ml2.sav ml2.cnf” -- restores the old ml2.cnf file

Additional Steps For The HP Palmtop

This section describes the steps required to transfer the DataView program from a PC to an HP Palmtop.

a) Prior to transferring the DataView program the user will create the following directories on the HP Palmtop:

Reciprocating Software Scroll Software

1. A:\DATAVIEW 1. A:\SCROLLDV

2. A:\DATAVIEW\DATA 2. A:\SCROLLDV\DATA

3. A:\DATAVIEW\PRN_FLS 3. A:\SCROLLDV\PRN_FLS

b) If a previous version of the DataView program exist on the HP Palmtop, delete all the files in A:\DATAVIEW direc-

tory, “DEL A:\DATAVIEW\*.*.” or “DEL A:\SCROLLDV\*.*.”

c) The HP Palmtop is supplied with the “HP Connectivity Pack Program.” Prior to transferring the files the user will

ensure this program resides on the HP Palmtop and the PC.

d) Using the cables provided with the HP Palmtop, connect the HP Palmtop to the PC.

e) Start the HP Connectivity Software Program on the HP Palmtop and the PC.

f) Copy all the program files located on the PC in the C:\”directory” where ”directory” is the directory defined in the

installation instructions step c, to the A:\DATAVIEW or A:\SCROLLDV directory on the HP Palmtop.

Additional Steps For The Pen--based Computer Without A Floppy Drive

This section describes the steps required to transfer the DataView program from the PC to a Pen--Based computer.

a) Using a serial cable the user shall connect the Pen--Based computer to the PC.

b) The user shall start the Windows Terminal program on the Pen--Based computer and the PC.

c) The user shall copy the installation files located on the PC’s hard drive (i.e., C:\) or the floppy drive (i.e., A:\ or B:\).

The installation files are copied into a temporary directory on the Pen--Based computer (i.e., C:\Temp).

d) After the installation files are copied to the Pen--Based computer, type C:\Temp\Install to start the installation pro-

gram.

e) Follow the steps defined above to install the program onto the Pen--Based computer.

f) To run the program the CONFIG.SYS file needs to be modified. These changes are required to increase the amount

of system memory used by the DataView program. If these changes are not made, the DataView program will run

out of memory. An out of memory message is displayed, to indicate t he problem. For example; when the user is

viewing a file, only a portion of the file will be processed and displayed. The user is notified of the date range that

was processed and can be viewed. The user can continue and view t he data or cancel the operation.

3-3 62-02575-07

Page 21

To modify the CONFIG.SYS file, the following entries must be in the CONFIG.SYS file to execute the DataView

program:

i. DEVICE = \DOS\HIMEM.SYS

ii. DEVICE = \DOS\EMM386.EXE X=C800--CFFF I=DOOO--DFFF V

iii. DEVICE = \DOS\POWER.EXE

iv. DEVICE = \DOS\INTERLINK.EXE

v . DOS = HIGH, UMB

vi. FILES = 40

vii. BUFFERS = 30

The other entries should have “REM” entered before each entry. This will retain the information in the file, but the

entry will not be executed. For example; the entry, “DEVICE = \PCM\DPMS.EXE” should be changed to “REM

DEVICE = \PCM\DPMS.EXE.”

Running The Program At The MS--DOS Prompt

This section describes the procedure for executing the program from the MS--DOS prompt.

1. Reboot the computer into the MS-DOS mode. DO NOT start windows, this will reduce the amount of memory

available for the Data View program.

2. Change directory to the DataView directory by typing: CD \DATAVIEW <ENTER> or CD \SCROLLDV

<ENTER>

3. At the MS--DOS prompt type: DATAVIEW <ENTER> to run the program.

Changing Program Behavior

This section describes the two methods to change the behavior of the DataView program.

1) Start the DataView program and go to the Program Setup screen. From this screen the user can set up the program

to run on their computer.

2) Toadd control parameters to the DataViewmain program, start at the MS--DOSprompt and type “directory --“parameter” <ENTER> where “directory” is the resident directory (DATAVIEW,SCROLLDV or other directory designation), then space dash and “parameter” is the parameter you want to change.

The following are valid parameters:

1. To set the temperature units to Celsius, type: “DIRECTORY” --TC <ENTER>.

2. To set the temperature units to Fahrenheit, type: “DIRECTORY” --TF <ENTER>.

3. To convert the RAW files to DCX files, type: “DIRECTORY” --CONVERT <ENTER>.

4. To run on monochrome monitors (i.e., HP Palmtop), type: “DIRECTORY” --P <ENTER>.

5. To run on color monitors, type: “DIRECTORY” --D <ENTER>.

6. To set the communications port (i.e., port where the Carrier module is connected), type: “DIRECTORY” --COM1

<ENTER> or “DIRECTORY” --COM2 <ENTER>

The above options can be combined. For instance, type: DATAVIEW --TF --D <ENTER> would set the reciprocating

software program to run with Fahrenheit temperature units and a color monitor.

TOPIC 3 MENU BASICS

This section describes how to use the DOS DataView interrogator menu system.

Nearly the entire DataView Program can be run with these keystrokes:

1. RIGHT and LEFT Arrow keys move through the boxes on the screen.

2. UP and DOWN Arrow keys move vertically within a menu box.

3. ENTER selects an option.

4. ESC cancels the current screen and moves back to the previous screen.

5. H displays the help screen.

6. ALT--X exits the program and returns to the DOS prompt.

7. F9 attempts to reconnect the DataView program to the DataCORDER.

Throughout the program the user will be able to use the alphanumeric keys to select a feature without using the arrow

keys. Upon pressing an alphanumeric key the selected feature is executed. In addition the user will be able to use the

mouse to select a feature. Upon single clicking the left mouse button, the feature the pointer is on is executed.

3-462-02575-07

Page 22

Throughout the program two major types of menus are used:

1. Check boxes allow the selection of all menu items that apply and look like t his:

[] Graph

[X] Tabular Data

[ ] Raw Events

2. Radio buttons allow the selection of only one item and look like this:

(*) Metric Units

( ) Standard Units

To select or deselect an item in either of these two menu’s, use the UP and DOWN arrow keys to highlight the selection

and press <ENTER> to select.

TOPIC 4 RAW FILE CONVERSION

The raw file conversion feature, C:\DATAVIEW\DATAVIEW --CONVERT, converts a RAWformatted file to a DCX

formatted file. A DCX formatted file can be viewed and/or printed using the DataView program. The Raw File

Conversion process is the same process used when the DataView program interrogates a data recorder and produces a

DCX formatted file.

The Raw File Conversion screen will be displayed when the DataView program is started with the convert argument.

The following is a summary of the options available to the user:

<D> Directories -- Provides the user with the ability to change the current and working directories. The following

describes the directories;

1. <C> Current -- The current directory is the location of the RAW files. The RAW files will have the file extension,

“.RAW”, but it is not required. This feature allows the user to view and/or change the current directory.

2. <W> Working -- The working directory is the location where the DCX files will be stored. These files contain the

interrogated recorder data. This feature allows the user to view and/or change the working directory.

<F> Files -- Allows the user to list the files within the selected directory (i.e., current or working). The file menu box

allows the user to scan through the files available by pressing the up arrow, down arrow,page up, and page down keys.

If no files are found, the “NO FILES FOUND” message is displayed.

3-5 62-02575-07

Page 23

<G> Go -- Allows the user t o start the RAW to DCX file conversion. The following steps are processed:

1. The Raw File Conversion screen is cleared.

2. The File Processing popup is displayed.

3. Each file in the current directory is checked to verify if it is a RAW formatted file. If not, it skips this file and checks

the next file.

4. Each RAW formatted file found within the current directory is convertedto the DCX formatand stored in the working directory with the same filename and the new file extension, “.DCX.”

If a problem occurs while converting the RAW file to a DCX formatted file, a message box is displayed with the failed

file and describing the problem. The program will end and return to the MS--DOS prompt.

TOPIC 5 MICRO-LINKS SELECTION SCREEN

This section describes the features available on the Micro-Links selection screen.

The Micro -Links selection screen will be displayed when the DataView program is started without being connected to

the Recorder. The user is allowed to select which program to run: the Micro-Link 1 or Micro-Link 2/2i. The following

screen is displayed when the program starts up.

The following is a summary of the options available to the user:

<M> Micro-Links -- Allows the user to select which program to execute;

1. Micro-Link 1 -- CTD2.exe Interrogation program for the Micro-Link 1 units.

2. Micro-Link 2/2i. -- DataView Interrogation program for the Micro-Link 2/2i units.

<G> Go -- Starts the selected program.

3-662-02575-07

Page 24

TOPIC 6 MAIN MENU SCREEN

This section describes the features available from the main menu. The following screen will be displayed when the

program starts up.

The following is a summary of the options available to the user:

<I> Interrogate -- This will allow the user to extract the data from the Recorder. The available interrogation m ethods

are: By Trip, By Date, Last 30 Days, and All Data.

<D> DataReader -- This will allow the user to transfer copied data from the DataReader to the computer, erase files

from the DataReader, or upload Data Set files to the DataReader.

<T> System Tools -- This will allow the user to change the operation of the Controller or Recorder. Users can change:

the Controller set point; user selectable functions such as defrost interval; view the compressor hour meter; configure

the controller for a specific temperature unit; change recorder Time and Date, recording Configuration, and Probe

Calibration; enter Trip Starts and Comments. Users can also monitor the operation of t he controller input/output

functions, enter the I SO Trip Header.

<S> Program Setup -- This will allow the user to setup a Printer, a Communication port, and a Working Directory. In

program setup the user can also change the Screen Display, Temperature Units, and enable the Function Keys.

<V> View Data -- This will allow the user to view the data i n a numerical format or to filter the data and display it in a

graphical and tabular form. Users can also select and edit new sensor configurations, name the new sensor

configuration, and save each configuration in a file.

<P> Print Data -- This will allow the user to print reports of numerical and formatted data with or without graphics, to a

printer or t o a file. Users can also select and edit new sensor configurations, name the new sensor configuration, and

save each configuration in a file.

<H> Help -- Displays to the help screen.

<X> Exit -- Exits the program and returns the user to the DOS prompt.

3-7 62-02575-07

Page 25

TOPIC 7 INTERROGATION MENU

This section describes how to retrieve data from the recorder. The following screen is displayed when this option is

selected.

The following is a summary of the options available in Interrogation.

<T> By Trip -- All data logged from the TripStart selected until the next Trip Start (or the last date in the recorder) will

be downloaded.

<B> By Date -- All data logged between two user specified dates will be downloaded.

<L> Last 30 Days -- All data logged in the last 30 calendar days will be downloaded.

<A> All Data -- All data logged in the recorder will be downloaded.

<W> Working Directory -- Allows the user to view and/or change the working directory where the interrogated files

will be stored.

<H> Help -- Displays the help screen.

<ESC> Close -- Closes the window and returns the user t o the Main Menu Screen.

As the data is being downloaded to the file in the working directory, a progress window is displayed to indicate how

much data has been copied and how much remains. Upon completion of copying the file the user is asked to enter a

comment about the interrogation file. This i s optional. If the user does not wish to enter the comment, press <ESC> to

skip.Toenterthe comment,the followingfields are available to enter information: Billing of Lading#, Point of Origin,

Origin Date, Point of Destination, Destination Date, and Comment.

For an ML2i product, the following comment fields initialized by reading the ISO Trip Header from the data recorder.

The point of origin, origin date, point of destination, and comment fields. The bill of lading and destination date are

initialized to blank fields.

The final step convert the raw file to a DCX format file. This format is used to view and print the file.

3-862-02575-07

Page 26

TOPIC 8 DATAREADER

The DataReader Interfaceprogram communicateswith the DataReader. It provides the user with the ability toview the

files on the DataReader, read the files from the DataReader and store the data into the DCX file format on the users

computer.The program also allows the user to erase all the files on the DataReader. The following screen is displayed

when this option is chosen.

The following is a summary of the options available in DataReader Interface Utility.

<W> Working Directory -- Allows the user to view and/or change the working directory where the interrogated data

files will be stored.

<F> Files -- Provides the user with a list of the files located in the DataReader. The user will be allowed to select one of

the DataReader files.

<U> Upload -- Allows the user to read the files from the DataReader, converts the files to DCX file format, and store

them into the working directory on the computer. The DataReader files must be selected before up loading files to the

computer.

<E> Erase -- Allows the user to delete all the files on the DataReader.

3-9 62-02575-07

Page 27

TOPIC 9 SYSTEM TOOLS

The system tools screen provides the user with the ability to view and/or modify the recorder and controller data

values. The following screen is displayed when this option is chosen.

The following is a summary of the options available in System Tools.

<C> Controller Utilities -- This will allow the user to set the controller configuration, enter a new container ID, change

how the controller operates via the selectable parameters, change the set point and view the compressor hour meter.

For further information refer to the following sections: TOPIC 10 -- Controller Utilities and TOPIC 11 -- Controller

Configuration.

<R> Recorder Utilities (DataCORDER) -- This will allow the user to change the recorder configuration, reset the

recorder time and date, enter a trip start and comment, calibrate USDA probes, and ISO trip header. For further

information refer to the following sections: TOPIC 12 -- Recorder Utilities, TOPIC 13 -- Recorder Configuration, and

TOPIC 14 -- Probe Calibration.

<N> Controller Monitor -- This feature displays the values of the controller data in real time to enable an overview of

the controller operation when trouble shooting. The user has the ability to log the controller data values into a

spreadsheet formatted file. This file is compatible with most spreadsheet programs (i.e., MS--Excel and Lotus). For

further information refer to TOPIC 15.

<H> Help -- Displays the help screen.

<ESC> Close -- Closes the window and returns the user t o the Main Menu Screen.

3-1062-02575-07

Page 28

TOPIC 10 CONTROLLER UTILITIES

This section describes the features available on the controller utilities.

View/Change Container ID

This will allow the user to view and modify the current container I D read from the controller. Upon changing the

container ID, the new ID is sent to the controller, the DataView program informs the user that the container ID was

successfully sent, and returns the user to the System Tools Screen. The following screen is displayed when t his option

is chosen.

Upon pressing <ESC> to Cancel, the container ID is canceled and the user is returned to the System Tools Screen.

3-11 62-02575-07

Page 29

Control Setpoint

This will allow the user to view and modify the current control setpoint being read from the controller. Upon changing

the setpoint, the new setpoint value is sent to the controller, the DataView program informs the user that the setpoint

was successfully sent, and returns the user to the System Tools Screen. The following screen is displayed when this

option is chosen.

Upon pressing <ESC> to Cancel, t he setpoint is canceled and the user is returned to the System Tools Screen.

3-1262-02575-07

Page 30

Control Parameters

The following screen is displayed for the user to view and modify the current settings of the controller user selectable

parameters.

The following is a summary of the options available in Controller Parameters.

<D> Defrost Interval -- Allows the user to view and modify the automatic defrost interval.

<U> Units -- Allows the user to view and modify the temperature units which are used when displaying controller

temperature sensors.

<M> Shutdown Mode -- Allows the user to view and modify how the refrigeration unit will shutdown.

<R> In-Range Band -- Allows the user to view and modify the in-range band width of the control temperature sensor.

<C> Current Limit -- Allows the user to view and modify the refrigeration unit’s current limit setting.

<T> Stagger Start -- Allows the user t o view and modify the stagger start time of the refrigeration unit.

<S> Send -- Allows the user to send the parameter changes to the controller.Upon completion the DataView program

informs the user that the parameters have been successfully sent.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels all settings and returns the user to the System Tools Screen.

Compressor Hour Meter

This feature allows the user to view the compressor run time.

Configuration

This will allow the user to select the controller configuration required by a particular model or to customize a models

configuration. For further information, refer to TOPIC 11.

3-13 62-02575-07

Page 31

TOPIC 11 CONTROLLER CONFIGURATION

The Controller Configuration allows the user to view and modify the current controller configuration. The current

model configuration, the selectable configuration variables, and the fixed configuration variables are listed. The user

can select another m odel configuration and modify the selectable configuration variables. The following screen is

displayed when this option is chosen.

The following is a summary of the options available in Controller Configuration.

<G> Configuration Available -- This lists the models available for the controller.

Selectable Configuration Variables -- This will list the selectable configuration variables for the currently selected

configuration model.

<F> Fixed Configuration Variables -- This will display a screen with the fixed configuration variables.

<C> Custom -- This will allow the user to change the selectable configuration variables.

<S> Send -- Sends the new controller configuration to the controller.Upon completion the DataView programinforms

the user that the configuration was successfully sent to the recorder.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the new controller configuration and returns the user to the System Tools Screen.

3-1462-02575-07

Page 32

Fixed Configuration Variables

Allows the user to view the fixed configuration variables for the selected configuration model. These variables

describe the refrigeration unit and cannot be modified by the user. The following screen is displayed when this option

is chosen.

The following is a summary of the options available in Fixed Configuration Variables.

<G> Configuration Available -- This lists the models available for the controller.

<F> Fixed Configuration Variables -- This lists the fixed configuration variables for the currently selected

configuration model.

<H> Help -- Displays the help screen.

<ESC> Close -- Closes the window and returns the user to the Controller Configuration Screen.

3-15 62-02575-07

Page 33

Custom Controller Configuration

Allows the user to change the selectable configurationvariables andsave those values into a new configurationmodel.

The following screen is displayed when this option is chosen.

The following is a summary of the options available in Custom Controller Configuration.

<D> Dehumidification -- Allows the user to configure or not configure the controller with a dehumidification device.

<I> Defrost Interval Save -- Allows the user to save or not save the defrost interval.

<V> Advance Pre--trip -- Allows the user to set the advanced pre--trip test to AUTO 1 (i.e., NO) or AUTO2 (i.e., YES).

<T> Suction Temperature Sensor -- Allows the user to configure or not configure the controller with a suction

temperature sensor.

<M> Economy Mode -- Allows the user to set the custom economy mode.

<A> Arctic Mode -- Allows the user to enable/disable the arctic mode.

<B> Bulb Mode -- Allows the user to enable/disable the bulb mode.

<C> Discharge Pressure Sensor -- Allows the user to configure or not configure the controller with adischarge pressure

sensor. This is an Micro-Link 2i Controller variable only.

<P> Probe Check Logic -- Allows the user to set the probe check logic to standard or special. This is an Micro-Link 2i

Controller variable only.

<F> Snap Freeze -- Allows theuser to enable/disable the snap freeze. This is an Micro-Link 2i Controller variable only.

<U> Suction Pressure Sensor -- Allows the user t o configure or not configure the controller with a suction pressure

sensor. This is an Micro-Link 2i Controller variable only.

<G> Degree C Lockup -- Allows the user to configure or not configure the controller with degree C lockout. This is an

Micro-Link 2i Controller variable only.

<S> Save -- Allows the user to save the configuration variable values. Upon pressing the “S” key,the user is allowed to

enter up to 14 characters for the custom configuration name. Upon accepting the new name, the configuration is saved

in the custom.cnf file. The new name will be displayed in the available configurations on the controller configuration

screen.

3-1662-02575-07

Page 34

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the changes to the custom controller configuration and returns t he user to the Controller

Configuration Screen.

TOPIC 12 RECORDER UTILITIES

This section describes the features available on the recorder utilities menu.

Trip Functions

This feature will allow the user to initiate a Trip Start and enter specific Trip comments. The following screen is

displayed when this option is chosen.

The following is a summary of the options available in Trip Functions

<T> Trip start -- This feature will allow the user to initiate a Trip Start. The trip start request is sent to the Recorder.

Upon completion the DataViewprogram informsthe user that the trip start was successfully sent and updates the “Last

Trip Start” with the current date and time. Trip starts are used when extracting data from the recorder “By Trip.”

<C> TripComment -- This feature will allow the user to enter a trip comment. Comments are limited to 50 characters.

The screen displayed when this option is chosen is shown on the following page.

The user enters the comment, the comment is sent to the recorder and the DataView program informs the user that the

comment was successfully sent.

Upon pressing <ESC> to Cancel, t he comment is canceled and the user is returned to the Trip Functions Screen.

<H> Help -- Displays the help screen.

<ESC> Close -- Closes the window and returns the user t o the System Tools Screen.

3-17 62-02575-07

Page 35

Configuration

This allows the user to modify the recorder configuration. For a full description of the configuration selections and

illustrations of the applicable screens, refer to TOPIC 13.

3-1862-02575-07

Page 36

Date And Time

This allows the user to view and/or modify the recorder date and time. The computer time and date are displayed as an

aid to the user. The following screen is displayed when this option is chosen. The recorder date is displayed in

Greenwich Mean Time (GMT).

The user enters the date and time, the date and time is sent to the recorder, the DataViewprogram informs the user that

the date and time was successfully sent, and returns the user to the System Tools Screen.

Upon pressing <ESC> t o Cancel, the date and time are canceled and the user is returned to the System Tools Screen.

USDA Probe Calibration

This allows the user to calibrate the USDA and Cargo sensor probes on the data recorder. For a full description of the

USDA Probe Calibration selections and illustrations of the applicable screens, refer to TOPIC 14.

3-19 62-02575-07

Page 37

Update ISO Trip Header

This allows the user to view and/or modify the data recorder ISO trip header. Each field has a maximum size of 13

characters. A maximum of 128 total characters are allowed. The date and time are initialized from the current date and

time on the data recorder. The following screen is displayed when this option is chosen.

The user enters the trip header fields, one at a time. Upon pressing <Enter> the current field is accepted and the cursor

is moved t o the next field. Upon pressing <Alt--S> to Send, the trip header is sent to the recorder and the DataView

program informs the user that the trip header was successfully sent.

Upon pressing <ESC> to Cancel, the trip header is canceled and the user is returned to the System Tools Screen.

3-2062-02575-07

Page 38

TOPIC 13 RECORDER CONFIGURATION

The Recorder Configuration allows the user to view and modify the current recorder configuration. The Recorder

Configuration screen shows all of the sensors installed to a unit and whether they are configured to be recorded. It also

shows the recording interval. The following screen is displayed when this option is chosen.

The following is a summary of the options available in Recorder Configuration.

<I> Recording Interval -- Allows the user to change the recording interval time 15 / 30 / 60 / 120 minutes.

<T> Standard Configuration -- Allows the user to select a standard recorder configuration.

<G> Generic Configuration -- Allows the user to select a generic recorder configuration.

Recorder Sensors -- Displays the configured recorder sensors.

Controller Sensors -- Displays the configured controller sensors.

<S> Send -- Sends the new recorder configuration to the recorder.Upon completion the DataViewprogram informs the

user that the configuration was successfully sent to the recorder.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the recorder configuration and returns the user to the System Tools Screen.

3-21 62-02575-07

Page 39

Standard Configuration

This feature will allow the user to select a standard recorder configuration, set the alarms, set the sample t ype for the

recorder sensors, set t he sample size for the recorder sensors, and set the sample type for the controller sensors. The

following screen is displayed when this option is chosen.

The following is a summary of the options available in Standard Configuration.

<S> Standard Configuration -- Allows the user to select the configuration. When a configuration is selected with a

USDA and/or Cargo probe sensors, the Recorder Sensor Alarm Configuration Screen is displayed.

<T> Sample Type -- Allows the user to select the sample type for the recorder sensors. The ”2--Averaged, 3--USDA”

sets the Supply Air and Return Air to an averaged value. And the USDA 1, USDA 2, and USDA 3 to a snapshot value.

<Z> Sample Size -- Allows the user to select the sample size for the recorder sensors.

<Y> Sample Type -- Allows the user to select the sample type for the controller sensors.

<A> Accept -- Allowsthe userto accept the changes made. These values willbe stored in temporary memory until they

are sent to the recorder from the Recorder Configuration screen.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the standard configuration and returns the user to the Recorder Configuration Screen.

3-2262-02575-07

Page 40

Generic Configuration

The Recorder Generic Configuration allows the user to view and modify the current recorder configuration. The

Recorder Generic Configuration screen shows all of the sensors installed to a unit and whether they are configured to

be recorded. It allows the user to modify the recording interval, recorder sensors, and controller sensors. Thefollowing

screen is displayed when this option is chosen.

The following is a summary of the options available in Recorder Generic Configuration.

<I> Recording Interval -- Allows the user to change the recording interval time 15 / 30 / 60 / 120 minutes.

<T> Standard Configuration -- Allows the user to select a standard recorder configuration.

<R> Recorder Sensors -- Allows the user to directly activate the recording of a sensor directly connected to the

Recorder. For further information, refer to the Recorder Sensors description below.

<C> Controller Sensors -- Allows the user to directly activate the recording of a sensor connected to the Controller.For

further information, refer to the Controller Sensors description below.

Recorder Sensors -- Displays the configured recorder sensors.

Controller Sensors -- Displays the configured controller sensors.

<S> Send -- Sends the new recorder configuration to the recorder.Upon completion the DataViewprogram informs the

user that the configuration was successfully sent to the recorder.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the generic configuration and returns the user to the Recorder Configuration Screen.

3-23 62-02575-07

Page 41

Recorder Sensors

This displays the active sensors connected to the recorder. It also displays t he sample type and sample size

configuration for each sensor. The following screen is displayed when this option is chosen.

The following is a summary of the options available in Recorder Sensors Configuration.

<R> Recorder Sensors -- Allows the user to select one or all of the sensors for the recorder configuration.

<T> Sample Type -- Allows the user to select how the sensor data will be logged; averaged or snapshot. The average

accumulates the sensor values received once per minute over the recorder interval period and logs the average value at

that interval. The snapshot takes the sensor value received at the recorder interval and logs the value at that interval.

<Z> Sample Size -- Allows the user t o select how the sensor data will be logged; low or normal resolution. The low

resolution allows the user to select a 1 byte thermistor sensor value. Low resolution utilizes less memory than normal

resolution, however temperature values will be less accurate. The normal r esolution allows the user to select a 2 byte

thermistor sensor value. Normal resolution is the recommended sample size for all temperature sensors.

<L> Alarm -- Allows the user to select how the alarm will be handled for a sensor. This feature is only available for

USDA and Cargo probe sensors.

<A> Accept -- Allowsthe userto accept the changes made. These values willbe stored in temporary memory until they

are sent to the recorder from the Recorder Configuration screen.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the recorder sensors change and returns the user t o the Recorder Generic Configuration

Screen.

3-2462-02575-07

Page 42

Controller Sensors

This displays the active sensors connected to the controller. It also displays the sample type and sample size

configuration for each sensor. The following screen is displayed when this option is chosen.

The following is a summary of the options available in Controller Sensors Configuration.

<S> Available Sensors -- Allows the user to select a total of eight controller sensors for t he recorder configuration.

<C> Controller Sensors -- Displays the controller sensors selected.

<T> Sample Type -- Allows the user to select how the sensor data will be logged; averaged or snapshot. The average

accumulates the sensor values received once per minute over the recorder interval period and logs the average value at

that interval. The snapshot takes the sensor value received at the recorder interval and logs the value at that interval.

<A> Accept -- Allowsthe userto accept the changes made. These values willbe stored in temporary memory until they

are sent to the recorder from the Recorder Configuration screen.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the controller sensors change and returns the user to the Recorder Generic Configuration

Screen.

3-25 62-02575-07

Page 43

TOPIC 14 PROBE CALIBRATION

Describes how to calibratethe probe sensors. Probe calibration allows the user to calibrate the probesensors using two

different methods; external and internal. The following screen is displayed when this option is chosen.

The following is a summary of the options available in Probe Calibration.

<P> Select Probes -- Allows the user to select which probes to calibrate. Only used for external and internal probe

calibration.

<C> Calibration Types -- Allows the user to select the calibration method. Only one probe calibration m ethod can be

chosen.

1. External -- Upon selecting this option the External Probe Calibration popup is displayed. In this calibration mode,

the user simply enters a new calibration offset value for each probe selected. It is completely the user’s responsibility to enter the offset values correctly. A valid offset value is within the temperature range of -- 2.00_C to 2.00_C.

2. Internal -- Uponselecting this option the Internal Probe Calibration popup is displayed. In this calibrationmode, the

user must place the probes to be calibratedinto anice bath.The user then enters the bath temperature to calibrate the

probes. A valid bath temperature value is within the range of --1.00_C t o 1.00_C.

3. Automatic -- This is a special case of the Internal calibration in which the probe offsets will be calculated using a

non--changeable water bath temperature of 0.0_C.

<S> Send -- Sends the probe calibration to the recorder.Upon completion t he DataView program informs the user that

the probe calibration was successfully sent to the r ecorder.

<H> Help -- Displays the help screen.

<ESC> Cancel -- Cancels the probe calibration and returns the user to the System Tools Screen.

3-2662-02575-07

Page 44

TOPIC 15 CONTROLLER MONITOR

The controller monitor program displays the activity of the controller data. This program allows the user to view the

controller data in real time to enable an overview of the container unit operation to be obtained when trouble shooting.

The following screen is displayed when this option is chosen.

The following is a summary of the options available in Controller Monitor program.

<S> Sensors -- Displays the current value of the controller sensors.

<P> Switches/Protectors -- Displays the current value of the container unit internal protectors and switches.

<O> Outputs -- Displays the current value of the controller outputs.

<M> Misc. -- Displays the current setpoint and SMV values.