Page 1

ComfortVu

TM

BACnet Thermostat Standard

Model TB-24-HM (24 Vac model)

Installation and Operation Guide

CARRIER CORPORATION ©2019

A member of the United Technologies Corporation family · Stock symbol UTX · Catalog No. 11-808-723-01 · 5/22/2019

Page 2

Table of Contents

Overview ………………………………………………………………………………………………………………………………..…. 4

Specifications ………………………………………………………………………………………………………………………..… 5-6

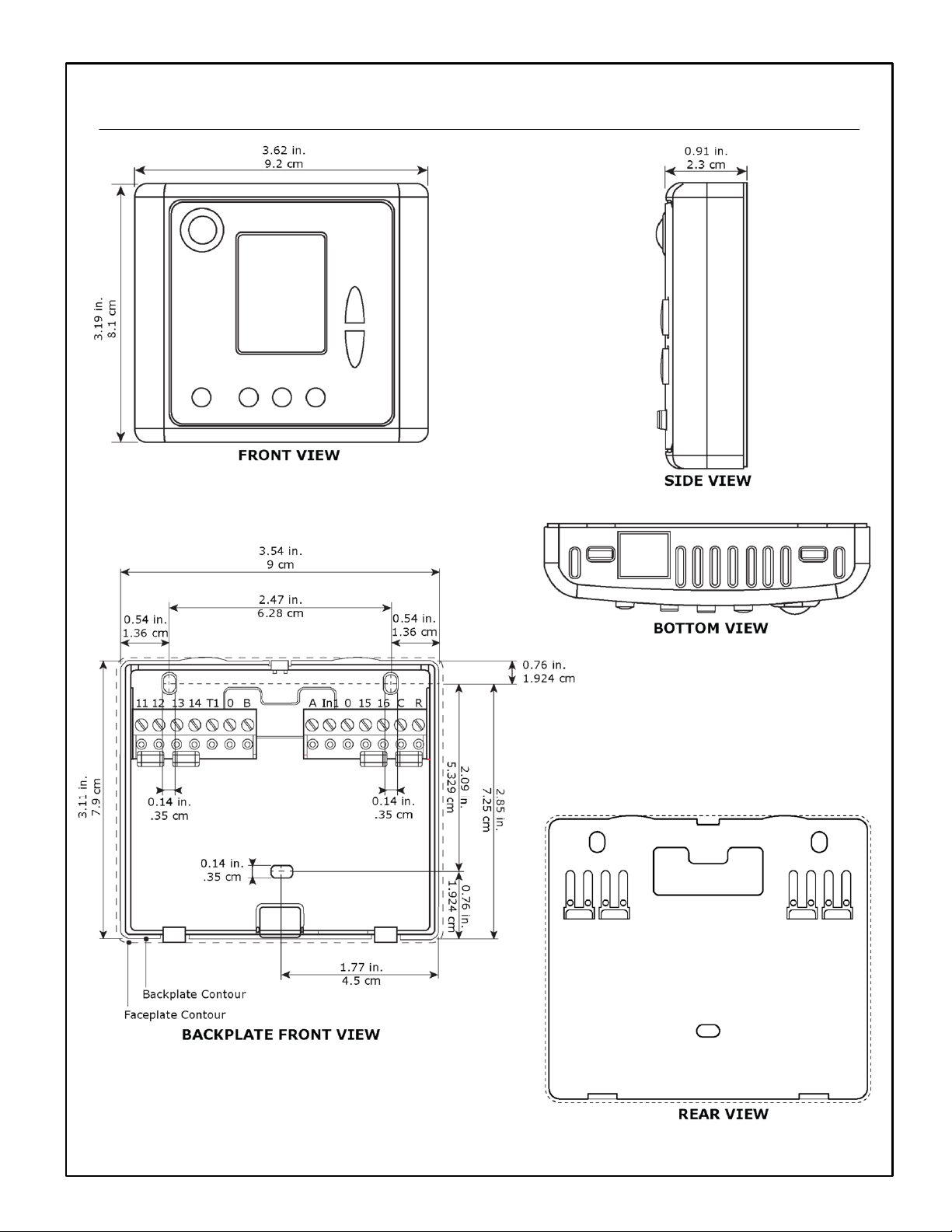

TB-24-HM Dimensions ……………………………………...………………….……………………………………………………..… 7

Operating instructions ……………………………………………………………………………………………………………..…… 8

Quick guide …………………………………………………………………………………………………………………..…….. 8

Turning the thermostat ON and OFF……………………………………………………………………………………....…….. 9

Selecting temperature scale………………………………………………………………………………………………..….…. 9

Adjusting the Setpoint temperature (for 1 setpoint and 2 setpoints configurations) ………………………………….……. 9

Selecting system mode…………………………………………………………………………………………………….…..… 10

Selecting Fan speeds (for 2 and 3 fan speeds configuration) ……………………………………………….……….…...… 10

Turning Auto fan ON or OFF (fan on demand) ………………………………………………………….….………….…...… 10

Locking the thermostat buttons ………………………………………………………………………………………….……… 10

Economy mode ………………………………………………………………………………………….…………….……...….. 11

Freeze Protection …………………………………………………………………………………………………….…...……... 11

Economizer ………………………………………………………………….……………………………………………………. 12

Weekly program ………………………………………………………………………………………….………………...……..… 13-17

MAC Address and BACnet Device Instance Number …………………………………………………………...….….……...… 18

Installation ………………………………………………………………………………………….………………………………....… 19

General ……………………………………………………………………………………...….…….….……………………..… 19

PIR detection area ……………………………………………………………………………………...….………..……...…… 19

Wiring terminals …………………………………………………………………………………….……………………....….… 20

DIP switch and jumper configurations………………………………………………...……………………....…….….……… 21

AC configurations ………………………………………………………………………………...……...….…….….…………. 22

FC configurations for 2-pipe systems …………………………………………………………………………………...……. 23

FC configurations for 4-pipe systems / Floor heating……………………………………………………...….…….….……. 24

Wiring and DIP switch configurations ………………………………………………………………………….………….. 25-39

Technician Settings ……………………………………………………………………………………...….……………...…….. 40-46

P01 – Offset for temperature readings calibration

P02 – Setpoint limit for cooling

P03 – Setpoint limit for heating

P04 – Lock the [Fan] button

P05 – Lock the [Mode] button

P06 – Lock the [On/Off] button

P07 – Lock the [+] and [-] buttons (Set buttons)

P08 – Functionality of T1 terminals

P09 – Functionality of IN1,0 terminals

P10 – Window contact (terminals IN1,0) polarity

P11 – Window contact delay time

P12 – Door switch (terminals T1,0) polarity

P13 – Door switch delay time

P14 – Enable/Disable Auto change over mode

P15 – Motion sensor logic (PIR)

P16 – Enable/Disable Motion sensor

P17 – PIR (Motion sensor) delay time

P18 – Door switch or key tag configuration

P19 – PIR (Motion sensor) polarity

P25 – Economy setpoint for cooling

P26 – Economy setpoint for heating

P27 – On-delay time on-delay between

heating stages

P28 – Off-delay time between heating stages

P29 – LCD Backlight ON or OFF

P30 – Beeper ON or OFF

P31 – Fan ON delay in cooling

P32 – Fan OFF delay in cooling

P33 – Fan ON delay in heating

P34 – Fan OFF delay in heating

P35 – Enable/Disable Freeze protection

P36 – Freeze protection cut-in setpoint

P37 – Freeze protection cut-out setpoint

P40 – View filter counter (hours) – Read only

P41 – Reset filter time

P42 – Adjust filter alarm delay counter (hours)

- 2 -

Page 3

Table of Contents

Technician Settings ……………………………………………………………………………………...….……………...…….… 47-62

P43 – Soft start in heat – cut-in temperature

P44 – Soft start in heat – cut-out temperature

P45 – Cool differential band

P46 – Cool differential band offset

P47 – Heat differential band

P48 – Heat differential band offset

P49 – Shift between Cool and Heat in Auto mode

P50 – Shift between Cooling stages

P51 – Shift between Heating stages

P52 – Cool valve proportional band

P53 – Cool proportional low limit

P54 – Cool proportional high limit

P55 – Heat valve proportional band

P56 – Heat proportional low limit

P57 – Heat proportional high limit

P60 – Proportional ON percent

P61 – Proportional OFF percent

P63 – Time on-delay between cooling stages

P64 – Time off-delay between cooling stages

P65 – Fan VFS proportional band in cooling

P66 – Fan VFS proportional band in heating

P67 – Fan VFS Low speed percent in cooling

P68 – Fan VFS Medium speed percent in cooling

P69 – Fan VFS High speed percent in cooling

P70 – Fan VFS Low speed percent in heating

P71 – Fan VFS Medium speed percent in heating

P72 – Fan VFS High speed percent in heating

P74 – VFS Medium speed differential

P75 – VFS High speed differential

P76 – Fan VFS Low limit in cooling

P77 – Fan VFS High limit in cooling

P78 – Fan VFS Low limit in heating

P79 – Fan VFS High limit in heating

P83 – View T2 temperature sensor readings

P84 – View T3 temperature sensor readings

P85 – De-ice in cool – cut-in temperature

P86 – De-ice in cool – cut-out temperature

P87 – De-ice in heat time

P88 – De-ice in heat break time

P89 – De-ice in heat – cut-in temperature

P90 – De-ice in heat – cut-out temperature

P91 – Compressor delay

P98 – Display setpoint only (hide room temperature)

P99 – One or Two setpoints

P101 – Screen dimming delay

P107 – Weekly program configuration

P108 – Weekly program - events per day

P109 – Weekly program event configuration

P111 – PIR Sensitivity

P114 – Cool PID Kp

P115 – Heat PID Kp

P116 – Cool PID Ki

P117 – Heat PID Ki

P118 – Cool PID Kd

P119 – Heat PID Kd

P122 – Cool Proportional output threshold in cooling

P123 – Heat Proportional output threshold in cooling

P160 – Minimum compressor ON time

P161 – Minimum compressor OFF time

P170 – Economizer low limit temperature

P187 – Display or hide humidity reading

P188 – Room temperature limit for disabling

dehumidification in unoccupied mode

P189 – Dehumidification cycle in unoccupied mode

P190 – Dehumidification break time in unocc. mode

P192 – Temperature setpoint for re-heat in

unoccupied mode

P193 – Display switching time (between temperature

and humidity)

P194 – Humidity differential band

P195 – Humidity sensor reading offset

P196 – Dead zone between humidification and

dehumidification

P197 – Humidity setpoint

P198 – Not in use

P200 – Restore defaults

Alarms and indications ………………………………………………………………………………………………………………… 63

Document revision history ……………………………………………………………………………………..……………..…….… 64

- 3 -

Page 4

Overview

The ComfortVu BACnet Thermostat Standard Model TB-24-HM can be used:

TM

As a stand-alone thermostat that can control equipment using built-in logic

As part of an MS/TP network of BACnet Thermostats that can be managed from a BMS front-end system

As part of a BACnet MS/TP network connected to an Carrier BACnet router in an i-Vu

provide trending and alarming of the BACnet Thermostat’s data.

The TB-24-HM thermostat has a white plastic enclosure with an LCD display and buttons for user control. It has on-board

temperature, humidity, and motion sensing, and its on-board inputs and outputs are used to control equipment and optional external

sensing devices. Inputs and outputs are configured using DIP switches and jumpers. The TB-24-HM thermostat requires 24 Vac

power.

See also:

ComfortVu

TM

BACnet Thermostat Points List and Technician Settings

®

system. The router’s control programs

- 4 -

Page 5

Specifications

Sensing Element: Range Accuracy

Temperature 41° F to 95° F (5° C to 35° C) ±1.0° F (0.5° C)

Humidity 10% to 90 % ±3.0% typical

Motion Sensing:

Sensor Type PIR, quad, omnidirectional

Distance 16.4 feet (5m)

Detection range (HxV) 90° x 30°

Movement speed 2.62 to 3.94 ft/s (0.8 to 1.2 m/s)

Detection object: 15.75 x 9.84 in. (400 x 250 mm)

Power 24 Vac, ±10%, 50-60Hz, 4VA

NOTE Devices connected to outputs, such as a fan, will increase VA requirements.

Communication BACnet MS/TP with baud rates up to 76.8 kbps, detected and set automatically by the

BACnet Thermostat. Max 127 devices.

Inputs T1, 0 – Normally open or normally closed dry contract, or

0-10 Vdc analog input, or

50 kOhm thermistor @ 25°C

A, B - Communication +/- (RS485)

IN1, 0 - Normally open or Normally closed dry contract, or

0-10 Vdc analog input, or

50 kOhm thermistor @ 25°C

C, R - Power: 24 Vac

Outputs 11, 12, 13 – Digital outputs, 3A max.

14 – Digital outputs 0.3A max

. 15 and 16 – Depends on application.

Digital output 0.3A max., or

Analog output 0-10 Vdc, 5 mA max., not isolated

Environmental Operating Range 50° to 122°F (10° to 50°C), 10 to 90% relative humidity, non-condensing

Mounting • If using an electrical box, mount the included wallplate to a standard 4" x 2" electrical

box using the two larger mounting screws, then mount the thermostat to

the wallplate using the three smaller mounting screws.

• If not using an electrical box, flush-mount thermostat to wall (no wallplate needed).

- 5 -

Page 6

Specifications (cont.)

Weight 4.8 oz (0.14 kg)

Compliance United States of America:

FCC CFR47, Chapter 1, Subchapter A, Part 15, Class B

Canada:

Industry Canada Compliant, ICES-003, Class B

Europe:

Mark, Low Voltage Directive: 2014/35/EU RoHS Compliant: 2011/65/EU

Australia and New Zealand:

C-Tick Mark, AS/NZS 61000-6-3

Title 24 compliant if connected to a BMS with custom programming for economizer fault

detection.

CA Prop 65 Warning: This product can expose you to chemicals including Styrene and 1,3

- Propane sultone, which are known to the State of California to cause cancer. For more

information, go to www.p65warnings.ca.gov.

- 6 -

Page 7

TB-24-HM Dimensions

- 7 -

Page 8

Operating instructions

Quick guide

Temperature/Humidity

indications:

Temperature scale

Ambient Humidity

Setpoint adjust.

Ambient/Setpoint indication

temperature

Ambient humidity indication

Thermostat On/Off indication

System MODE indication:

Fan only

Cooling

Heating

Auto mode

Clock / Weekdays

C/F

Prog

On/Off

Mode Fan

Fan speed indication:

Auto speed

High

Medium

Low

Fan on demand

Indications:

Alarm

Button locked

Program active

Program events indications:

Prog1234

Start

Stop

Clock

Event per day

Adjust start time

Adjust stop time

Adjust the clock

Setpoint adjustment

- Press to switch between

temperature scales (ºC/ºF)

- Press and hold to enter

weekly program settings

- Press and hold to enter

Technician Settings

(setpoint must be equal to

10ºC/50ºF)

- Press and hold to enter

MAC Address settings

(setpoint must be equal to

11ºC/52ºF)

- Press to select Fan speed:

Low/Medium/High/Auto

- Press and hold to activate

fan on demand

- Press to select System

Mode: Cool/Heat/Auto

- Press to turn unit On or Off

- 8 -

Page 9

Operating instructions (cont.)

Turning the thermostat ON and OFF

Press the [On/Off] button to turn the thermostat ON or OFF.

Selecting temperature scale

Press the [C/F] button to switch between temperature scales.

Adjusting the Setpoint temperature

In One setpoint configuration:

1. Press the [+] or [-] buttons once to view the setpoint temperature.

2. Press again to adjust the setpoint.

In Two setpoints configuration:

1. Press the [+] or [-] buttons once – “ ” and the setpoint temperature for cooling will

appear on display.

2. Use the [+] or [-] button to adjust the setpoint for cooling.

3. Press the [Mode] button or wait 3 seconds – “ ” and the setpoint temperature for heating

will appear on display.

4. Use the [+] or [-] button to adjust the setpoint for heating.

OFFON

Celsius Fahrenheit

Setpoint

Setpoint

For cooling

Setpoint

For heating

Notes:

The setpoint for cooling must be higher than the setpoint for heating.

For humidity setpoint, see Technician Setting P197.

- 9 -

Page 10

Operating instructions (cont.)

Selecting system mode

Press the [Mode] button to switch between system modes.

Notes:

During demand for cooling or heating, the active mode will flash.

In Auto mode, the active mode icon (Cool or Heat) will appear on display.

Auto mode is not available in 2-Pipe system configuration.

Selecting Fan speeds (for 2 and 3 fan speeds configuration)

Press the [Fan] button to switch between fan speeds.

Notes:

In Auto speed, the active fan speed icon will appear on display.

Medium speed available in 3 speeds configuration.

Cool Heat

Auto Fan only

Low Medium

Turning Auto fan ON or OFF (fan on demand)

In 1-speed configuration:

Press the [Fan] button to turn Auto fan ON or OFF.

In 2- and 3-speed configurations:

Press and hold the [Fan] button for 7 seconds to turn Auto fan ON or OFF.

When ON, the fan will run on demand for cooling or heating,

When OFF, the fan will run continuously.

Note: Auto fan cannot be selected in Fan only mode.

Locking the thermostat buttons

Press and hold both [-] and [Fan] buttons for 7 seconds to lock or unlock the thermostat buttons.

When locked, the lock icon will appear on display with any attempt to press the buttons.

Enable or disable the option to lock different buttons using Technician Settings P4-P7.

High Auto

Auto fan

Auto fan

OFF

indications

ON

Lock

- 10 -

Page 11

Operating instructions (cont.)

Economy mode

Activate Economy mode by triggering a window contact, door switch,

key-tag, remote economy switch, the built-in PIR sensor (passive

infrared sensor), or through communication – binary value

“UnoccupiedByNetwork”.

When Economy mode is active, the thermostat will use special

economy setpoints for cooling and heating set by technician.

See objects “EconomySetpointinHeat” and “EconomySetpointinCool”

in the Technician Settings section of this manual.

Freeze Protection

Economy by window contact

Economy by built-in PIR, by the

remote economy switch, or through

communication

Economy by door switch

Economy by Key-tag

The Freeze protection feature will not allow the room temperature to drop below

predefined cut-in temperature. Depending on which configuration the system is

operating under (W/WO Heat pump), this feature will force the system to operate

in heat mode and activate the fan.

This feature will take effect when the thermostat is either ON or OFF. When the

room temperature rises above the predefined cut-out temperature, the thermostat

will return to its previous state.

When freeze protection is activated, the display alternates between “AL” and

room temperature.

Temperature

Cut-out

Cut-in

Time

Normal work Freeze protection

- 11 -

Page 12

Operating instructions (cont.)

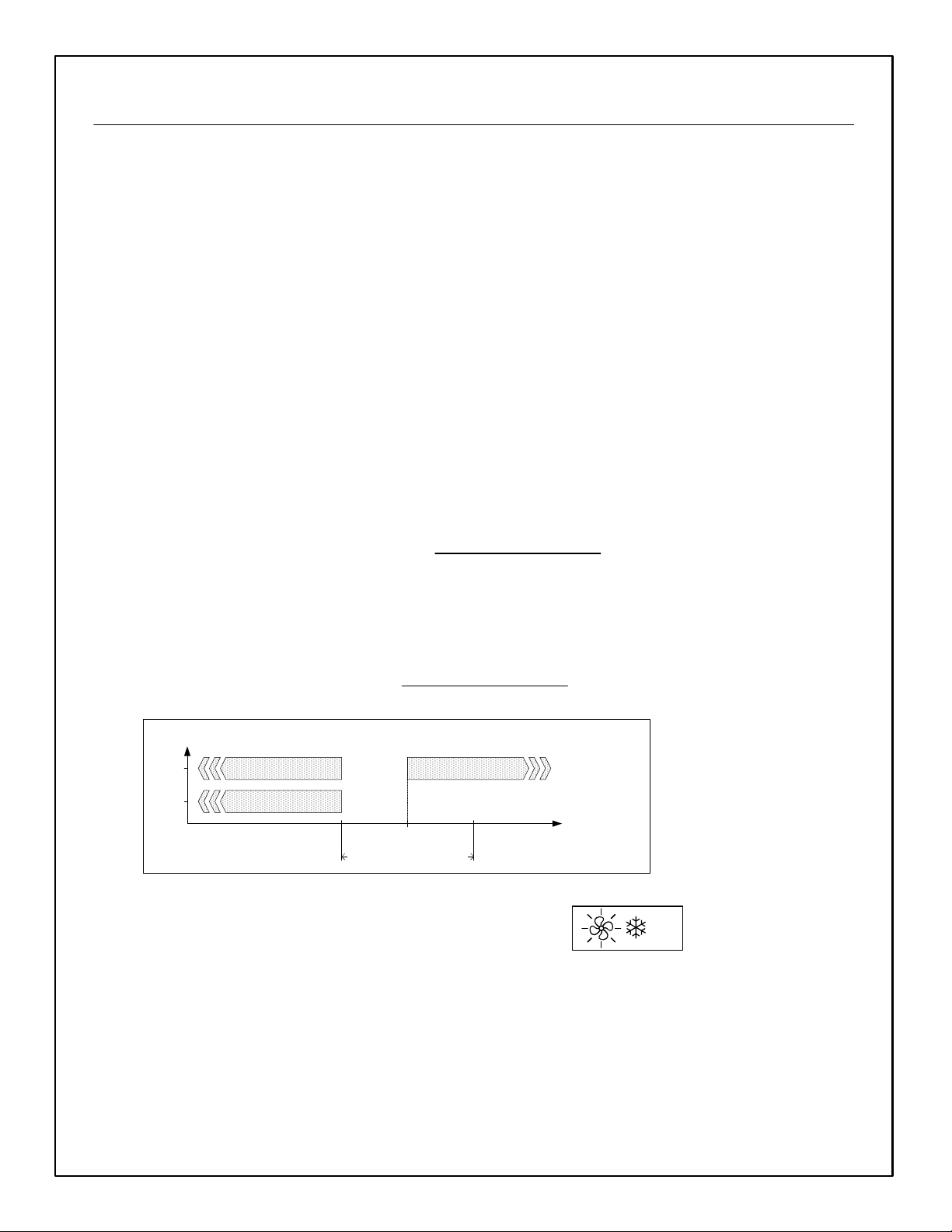

Economizer

Economizer is used to reduce the energy consumed by the cooling systems, by using low external air temperatures to assist in the

chilling process. When outdoor temperatures are lower relative to indoor (room) temperatures, the system utilizes the cool outdoor air

as a free cooling source.

The outdoor temperature (Teconomizer) triggering the activation of the economizer, can be measured by the temperature sensor

connected to T1,0 terminals (technician parameter P08="05") or by setting a temperature value manually through communication -

AV#129 "TEconomizerEffective".

When getting the temperature through communication, terminals T1,0 can be used for any other functionality like External sensor/Soft

start in heat sensor/Deicing in cool/Door switch/Key tag.

Whenever there is demand for cooling and the outdoor temperature conditions allow the operation of the economizer, it will operate

together with the regular cooling system and will not replace it.

Economizer will start when both of the following conditions are satisfied:

1.

Teconomizer temperature < Room temperature -

Room Temperature > Setpoint temperature

2.

Cool differential band

2

Economizer will stop when the following condition is satisfied:

Room Temperature < Setpoint temperature -

1.

Cool differential band

2

Economizer

ON

OFF

Teconomizer

Room Temp.

Room Temp.

Setpoint

Cool differential band

Indication for the Economizer operation:

When Economizer is active, the “Cool” symbol will appear (or flash when active)

on display and the “Fan” symbol will flash.

Temperature

Economizer

active

- 12 -

Page 13

Weekly program

General

Prior to programming, make sure that Technician Settings P107, P108, and P109 are configured correctly.

Program types

The thermostat can be configured to run four different types of weekly programs (set by Technician Setting P107):

7-day program with same settings for all days.

7- day program with different settings for each day of the week.

One schedule for the weekdays (Monday to Friday), one for Saturday, and another for Sunday.

One schedule for the weekdays (Monday to Friday) and another for Saturday and Sunday.

Daily events

Each daily program can use 2 or 4 schedule events per day (set by Technician Setting P108).

There are two options for settings the schedule events (set by Technician Setting P109):

“EU Type” - Start time and Stop time

“US Type” - Start time, setpoint temperatures, system mode, and fan speed

Enabling/Disabling/Overriding the program

Select “00” in Technician Setting P107 to disable programming capabilities.

The occupant can temporarily change the setpoint temperature to be different than the setpoint temperature specified by the program.

Changes will be effective until the next program event begins.

- 13 -

Page 14

Weekly program (cont.)

Programming procedure

The detailed programming procedure is described in the next sections. Make sure to follow the right

programming procedure, suitable for the program type and features selected by Technician

Settings.

Press the [C/F - Prog] button to enter and proceed through the steps of the real time clock and

programming procedure.

Use the [+] and [-] buttons to select or change value of a flashing icon.

We recommend that you select programming values prior to the actual programming.

Exit the programming procedure

At anytime during the programming procedure, press the [On/Off] button to exit and return to normal

display - any changed values will be saved.

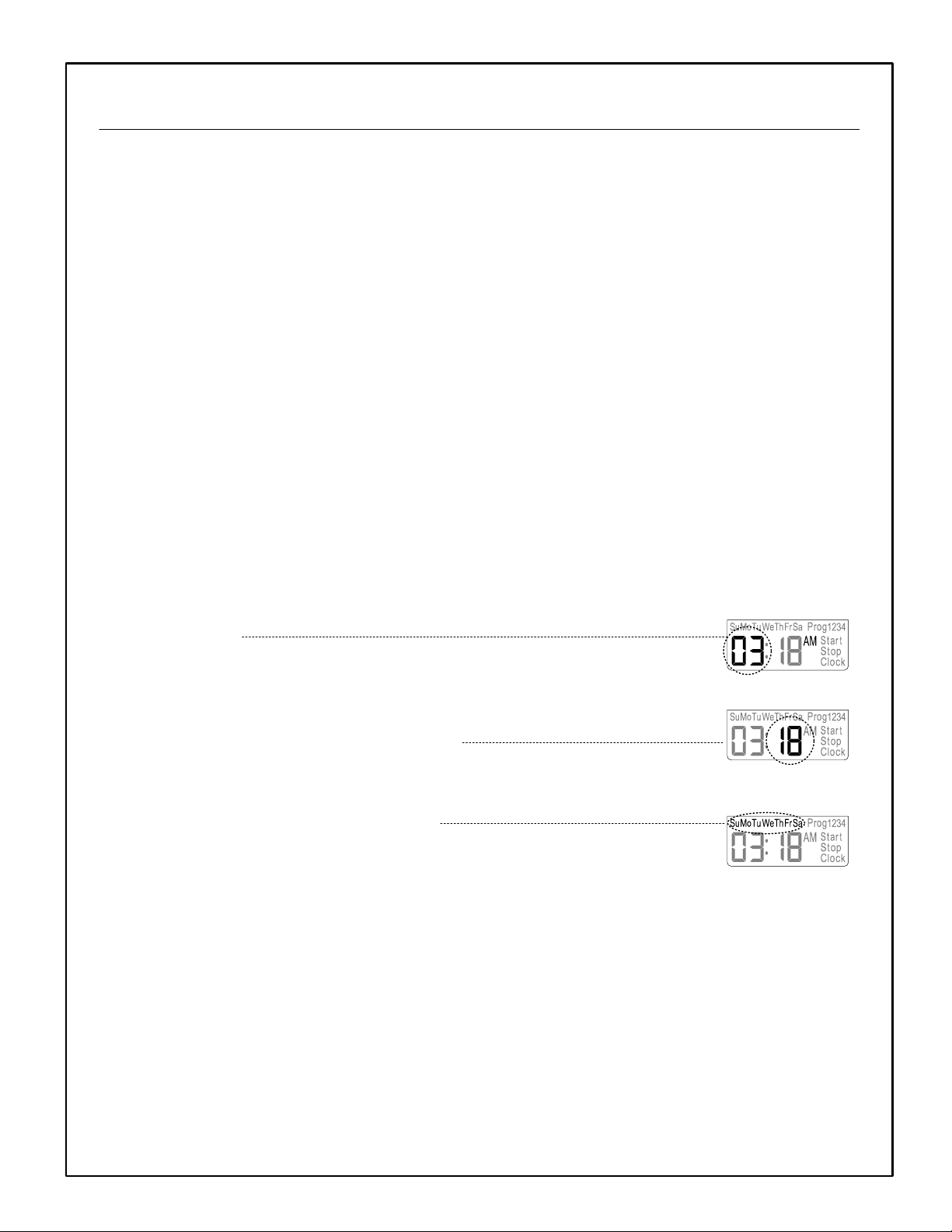

Adjusting the time and day of the week

The BACnet Thermostat will respond to a BACnet time sync, but you can manually set it using the

following instructions.

1. Press and hold the [C/F - Prog] button. The word “Clock” will appear on display, and

the HOURS will flash.

Hours

2. Use the [+] and [-] buttons to adjust the hours.

Minutes

3. Press the [C/F - Prog] button again. The MINUTES will flash.

4. Use the [+] and [-] buttons to adjust the hours.

Days

5. Press the [C/F - Prog] button again. The DAYS will flash.

6. Use the [+] and [-] buttons to select the day.

7. If Technician Setting P107 is not set to “00” (program is enabled), press the [C/F – Prog] button

to enter programming procedure. Make sure to follow the right programming procedure, suitable

for the program type and features selected by Technician Settings.

Section C – “EU Type”

Section D – “US Type”

Otherwise, press the [C/F - Prog] button to return to normal display.

- 14 -

Page 15

Weekly program (cont.)

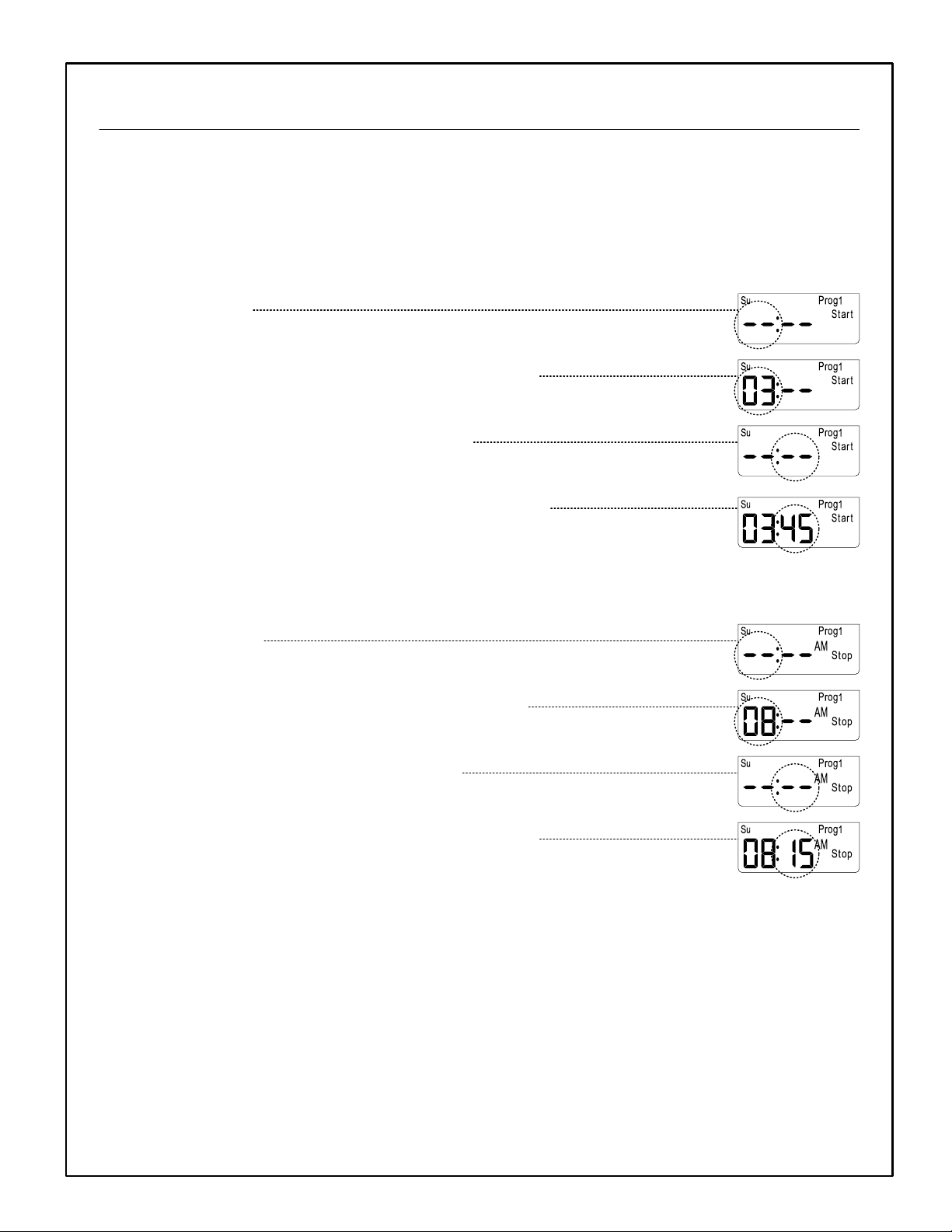

Adjusting “EU type” daily programs – Start time / Stop time

Start time

1. Press the [C/F – Prog] button. The programmed weekday(s), “Prog 1” indicating the

first program event of the day and the word “Start” will appear on display.

The HOURS will flash.

Note: If this is the first time a program is being set, the symbols “--“ will flash.

2. Use the [+] and [-] buttons to adjust the start time hours of the first event.

3. Press the [C/F – Prog] button again. The MINUTES will flash.

4. Use the [+] and [-] buttons to adjust the start time minutes of the first event.

Stop time

5. Press the [C/F – Prog] button again. T the word “Stop” will appear on display,

and the HOURS will flash.

6. Use the [+] and [-] buttons to adjust the stop time hours of the first event

7. Press the [C/F – Prog] button again. The MINUTES will flash

8. Use the [+] and [-] buttons to adjust the stop time minutes of the first event

Follow the steps above for the other schedule events of the same day

(Prog 2 for two events per day, or Prog 2, 3, and 4 for four events per day).

Follow the steps above for all the other days.

- 15 -

Page 16

Weekly program (cont.)

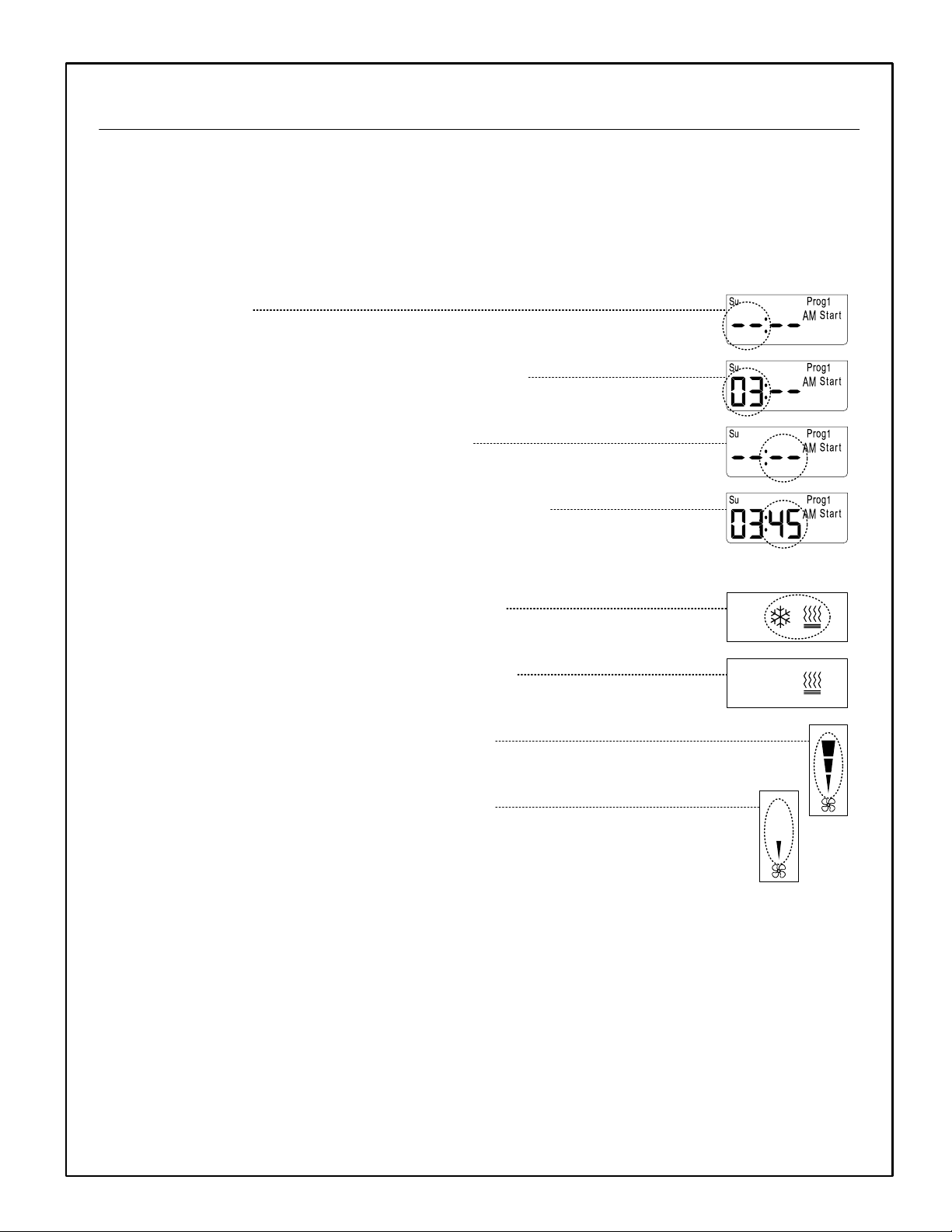

Adjusting “US type” daily programs – Start time / Stop time / Mode / Fan speed / Setpoints

Start time

1. Press the [C/F – Prog] button. The programmed weekday(s), “Prog 1” indicating the

first program event of the day and the word “Start” will appear on display.

The HOURS will flash.

Note: If this is the first time a program is being set, the symbols “--“ will flash.

2. Use the [+] and [-] buttons to adjust the start time hours of the first event.

3. Press the [C/F – Prog] button again. The MINUTES will flash.

4. Use the [+] and [-] buttons to adjust the start time minutes of the first event.

System mode

5. Press the [C/F – Prog] button again. The system MODES will flash.

6. Use the [+] and [-] buttons to select the system mode of the first event

7. Press the [C/F – Prog] button again. The FAN SPEEDS will flash.

8. Use the [+] and [-] buttons to select the fan speed of the first event.

Follow the steps above for setpoint temperatures.

Follow the steps above for the other schedule events of the same daily events

(Prog 2 for two events per day, or Prog 2, 3 and 4 for four events per day).

Follow the steps above for all daily periods.

- 16 -

Page 17

Weekly program (cont.)

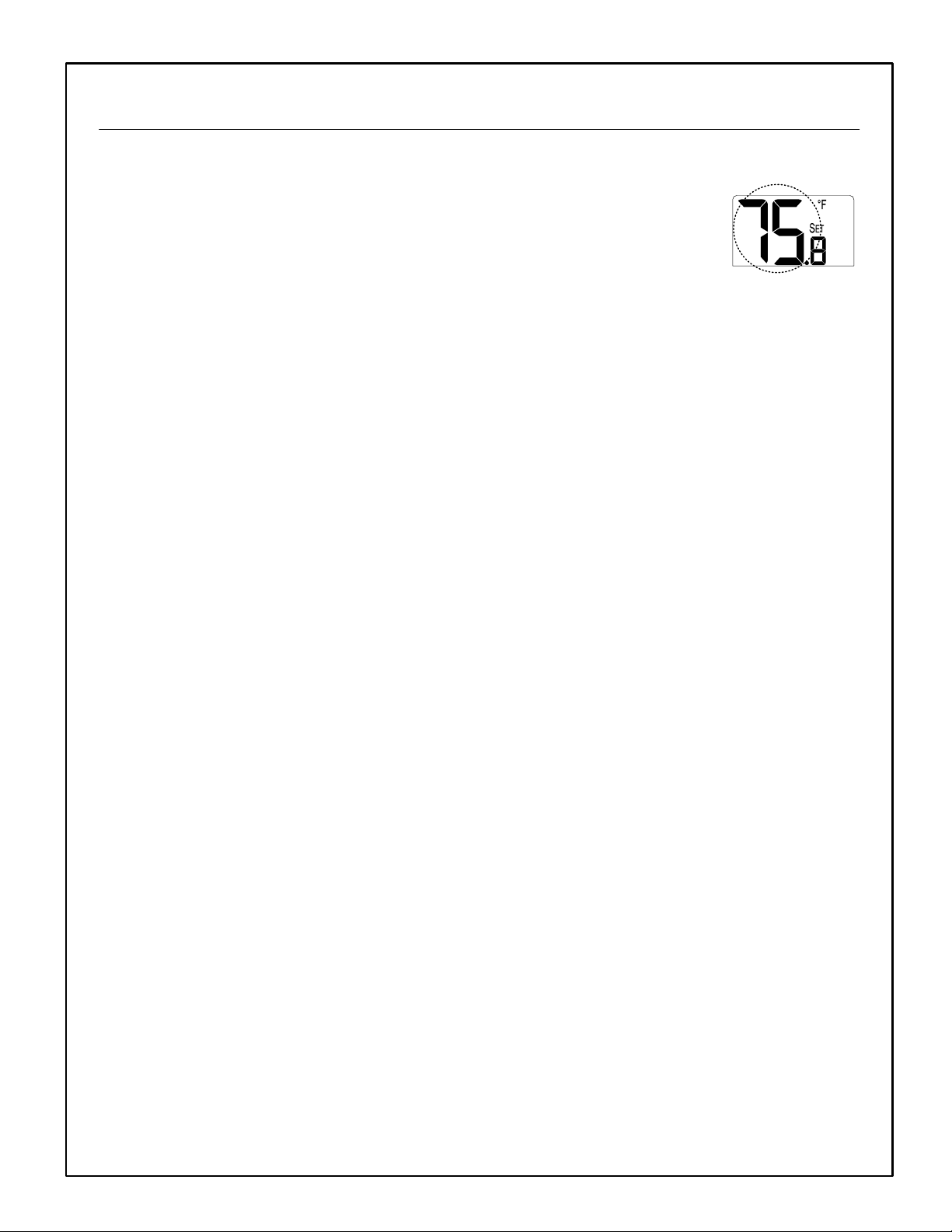

Setpoint

1. Press the [C/F – Prog] button again. The setpoint will flash.

Note: If the thermostat is configured to have two setpoints, first adjusts

the setpoint for cooling and then the setpoint for heating.

2. Use the [+] and [-] buttons to select the system mode of the first event.

Follow the steps above for the other schedule events of the same day

(Prog 2 for two events per day, or Prog 2, 3 and 4 for four events per day).

Follow the steps above for all the other days.

- 17 -

Page 18

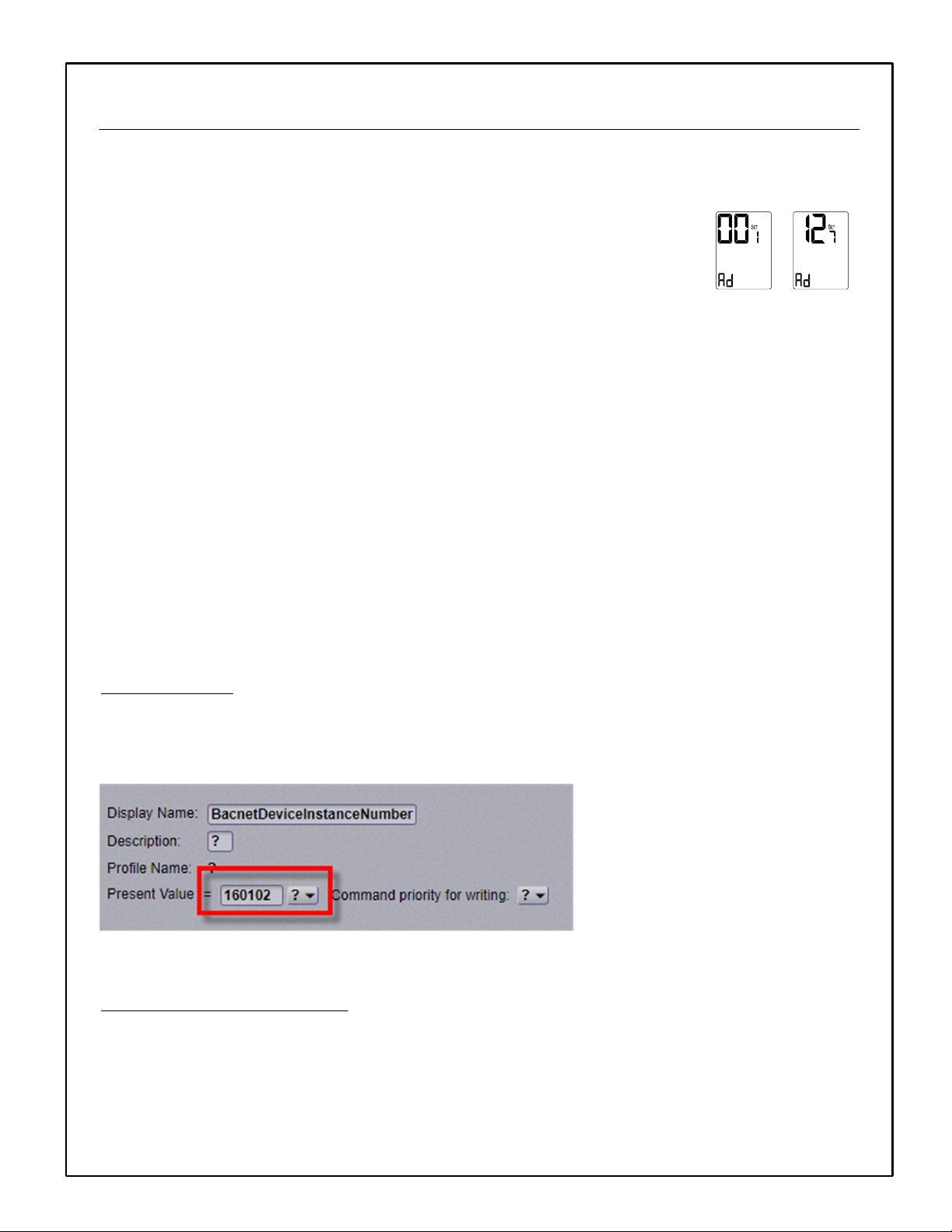

MAC Address and BACnet Device Instance Number

MAC Address

To set the communication MAC Address:

1. Adjust the setpoint temperature to 11ºC or 52ºF.

2. Press and hold the [C/F] button for 10 seconds to enter MAC Address configuration mode.

3. Use the [+] or [-] buttons to define the MAC Address (range 1...127).

4. When finished, press the [On/Off] button and readjust the setpoint.

5. Switch power supply off and on again for the MAC address changes to take effect.

Caution: Do not use the same MAC address for two devices on the same communication line!

MAC Address

1...127

BACnet Device Instance Number

By default, the BACnet Device Instance Number is generated automatically by the thermostat (Vendor ID + MAC address).

For example, Carrier’s vendor ID is 16, and if the MAC address is 075, the BACnet Device Instance Number is 16075.

Note: If you change the MAC address, you must cycle the thermostat’s power to reset the BACnet Device Instance Number.

You can override the automatically-generated BACnet Device Instance Number using the i-Vu application, an Analog Network

Output microblock in a control program, or some other BACnet utility. Write the new BACnet Device Instance Number to the

present_value property of Analog Value 42 (BACnetDeviceInstanceNumber).

Examples:

In the i-Vu application

1. Use the BACnet Discovery feature to discover the BACnet Thermostat and its BACnet objects.

2. In the navigation tree, select the Analog Value called BacnetDeviceInstanceNumber.

3. Change the Present Value field (shown below) to the desired BACnet Device Instance Number.

4. Click Accept.

In an Analog Network Output microblock

To change the BACnet Device Instance Number to 24113, the microblock’s address would be:

bacnet://16075/AV:42/present_value, or

bacnet://16075/BACnetDeviceInstanceNumber

- 18 -

Page 19

Installation

Mount the BACnet Thermostat on an interior wall in the room to be controlled approximately 1.5 meters (5 feet) from the floor. Locate it

where the occupant can easily read the LCD display and use the controls, and where the built-in PIR motion sensor can easily detect

any movement in the room (see PIR detection area below). If the built-in temperature sensor is being used to measure room

temperature, place the thermostat where the temperature is representative of the general room conditions. Avoid cold or warm air drafts,

radiant heat, and direct sunlight.

Installation procedure

Prerequisite: Disconnect power to the main board before installing the unit.

A. Separate the front panel from back panel by pressing the tab located in the top of the unit and pulling the back panel off of the two

bottom tabs.

B. Do one of the following:

• If using an electrical box, mount the included wallplate to a standard 4" x 2" electrical box using the two larger mounting screws,

then mount the thermostat to the wallplate using the three smaller mounting screws. Insert the screw cap into the wallplate’s

bottom screw hole.

• If not using an electrical box, flush-mount the thermostat to the wall (no wallplate needed).

C. Make electrical connections as shown in the picture below and the wiring diagram on page 20.

Set DIP switch positions as explained in this manual.

D. Reattach the cover by placing it on the back panel’s two bottom tabs and then pushing the cover until the top tab clicks into its slot

on the cover.

PIR detection area

Horizontal

(Top view)

90°

Vertical

(Side view)

20°

1.5m / 5ft

5m / 16ft

- 19 -

Page 20

Wiring terminals

For outputs 11-16, see Wiring

and DIP switch/jumper settings

(pages 25 through 39)

For T1,0 inputs:

Dry contact, 10 Vdc input, or 50 kOhm thermistor

See Technician Setting P8 (page 41).

MS/TP Communication (RS485):

BACnet

11 12 13 14 T1 0

B

(–)

Terminals

(+)

For IN1,0 inputs:

Dry contact, 10 Vdc input, or 50 kOhm thermistor

See Technician Setting P9 (page 42).

Power supply: 24 Vac

CAUTION Do not connect line

voltage to a thermostat that does

not show the following symbol:

A

0IN1 15 16 C * R *

- 20 -

Page 21

DIP switch and jumper configurations

SW4

JP2JP3

4321

87654321654321

SW3SW1

SW4.1 – Without valves control in FC config.

Enable = OFF (Open)

Disable = ON (Closed)

SW4.2 – Enable/Disable PIR detector

Enable = OFF (Open)

Disable = ON (Closed)

SW4.3 – Not used

Always OFF

SW4.4 - End of line resistor (120Ω)

OFF = Not end of line

ON = End of line

End of line

Communication line

End of line

SW1.1 through SW1.6, and SW3.1 through SW3.8

See Wiring and DIP switch/jumper settings (pages

25 through 39).

JP2, JP3 – Outputs 15,16 – Analog or Digital

JP2 – Output 16

Position 1- Analog output

Position 3- Digital output

JP2

3 1

3 1

JP3 – Output 15

Position 1- Analog output

Position 3- Digital output

JP3

- 21 -

Page 22

AC configurations

Find the configuration you want in the tables below, then find that configuration number (1 through 19) on the Wiring and DIP switch/

jumper settings pages starting on page 25.

AC Configurations without humidification/dehumidification

Outputs

Heat elements

Compressors

Heat pump

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

AC Configurations with humidification/dehumidification

Outputs

Heat elements

Configuration:

Configuration:

10

2 3 4 5 6 7

1

3

2

2 2 2 1

1

●●●

1 1

11 12 13

2 2 1 1

2 1

1 1 1

●

● ●

2 32 3 2 3

○○ ○

14 15

1 1

○ ○

8 9

2 1

2 2

●

1 1

○

○

16 17 18 19

2 1 1

Compressors

Heat pump

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

● Yes ○ Option

2 1 1 1

● ●

1 1 2 3

2 3

○

●

● ●

● ● ● ●

○

2 1

1

○

● ●

- 22 -

1 1 1 1

●

1

1 1 1 1

○

○ ○

● ● ● ●

● ● ● ●

●

● ●

Page 23

FC configurations for 2-pipe systems

Find the configuration you want in the tables below, then find that configuration number (20 through 30) on Wiring and DIP switch/

jumper settings pages starting on page 31.

FC Configurations for 2-Pipe systems without humidification/dehumidification

Outputs

Cl/Ht valve / Cl/Ht valve PID

Heat element (2nd stage)

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

FC Configurations for 2-Pipe systems with humidification/dehumidification

Outputs

Cool/Heat valve

1

21 22 23

20Configuration:

PID PID

● ●

●

● ●

2 3

2 3

1

○

○

○

○

25 26 27

24Configuration:

● ●

●

●●

○○

28 29 30

● ●

Cool/Heat valve PID

Heat element (2nd stage)

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

● Yes ○ Option

● ●

● ● ●

2 3

1

1

○

○

2 3

○

○

●

○ ○

● ●

● ● ● ●

●

●

●●

2 3

1

1

○

○

●

3

3

2

2

1

○

○

○

○

●

+

● ●●

- 23 -

Page 24

FC configurations for 4-pipe systems / Floor heating

Find the configuration you want in the tables below, then find that configuration number (31 through 47) on the Wiring and DIP

switch/jumper settings pages starting on page 34.

FC Configurations for 4-Pipe systems without humidification/dehumidification

Outputs

Cool valve / Cool valve PID

Heat valve / Heat valve PID

Heat element (2nd stage)

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

Floor heating

FC Configurations for 4-Pipe systems with humidification/dehumidification

Outputs

1

32 33 34

31Configuration:

● ●

PID PID

● ●

2 3

2 3

1

1

○

○

○

○

● ●

41

40Configuration:

● ●● ●

2 3

2 3

1

○

○

○

○

42 43 44

35 36 37 38

● ●

●

PID PID

● ●

●

● ● ●

2 3

1

○

○

45 46 47

○ ○○

39

PID PID

PID

●

2 3

1

○

○

Cool valve / Cool valve PID

Heat valve / Heat valve PID

Heat element (2nd stage)

Fan VFS

Fan speeds

Economizer

Humidifier

Dehumidifier

Reheat (Dehumidify)

Floor heating

● Yes ○ Option

●

●

● ●

2 3

1

○

○

1

PID

●

2 3

○

●●

○

●

● ●

2 3

1

○

○

PID

1

2 3

○

●

PID

2 3

1

1

○

○

○

PID

● ●

2 3

○

PID

1

○

● ●

2 3

1

○

○

2 3

○

○

● ●●

● ●●

- 24 -

Page 25

Wiring and DIP switch/jumper configurations – AC systems

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 1:

HC32

1 Speed fan

Heat element 3

(3rd stage heat)

Heat element 2

(2nd stage heat)

Fan (1 speed)

Compressor 2

Compressor 1

Heat element 1

(1st stage heat)

654321

1

JP2

JP3

3 1

3

Config. 2:

HP42

1 Speed fan

Heat element 2

(4th stage heat)

Heat element 1

(3rd stage heat)

Fan (1 speed)

Compressor 2

(3) (3) (3) (3)

(2)

87654321

Compressor 1

Heat pump

654321

JP2

JP3

3 1

3 1

(2) (2) (2)

87654321

Config. 3:

HP22

2/3 Speeds fan

Fan high

Fan medium

(or Economizer )

(5) (5)

Fan low

Compressor 2

Compressor 1

Heat pump

654321

JP2

JP3

3 1

3 1

2/3 Speeds fan

Fan medium

(or Economizer )

Heat element

Compressor

87654321

JP2

Config. 4:

HP21

Fan high

Fan low

Heat pump

654321

3 1

3 1

JP3

(2)

87654321

(1)

SW3.1, SW3.2 – Fan speeds: 2 speeds (Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds (Low, Med., and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 25 -

Page 26

Wiring and DIP switch/jumper configurations – AC

systems

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 5:

HC21

2/3 Speeds fan

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element 2

(2nd stage heat)

Compressor

(3) (3) (3)

Heat element 1

(1st stage heat)

654321

1

JP2

JP3

3 1

3

Economizer

(option – SW1.6 ON)

Compressor

(2)

87654321

JP2

Config. 6:

HP11

Fan VFS

X

X

Heat pump

Fan VFS

3 1

3 1

Config. 7:

HC11

Fan VFS

X

(5)

Economizer

(option – SW1.6 ON)

X

(2) (2)

Heat element

Compressor

Fan VFS

87654321

654321

JP3

JP2

3 1

3 1

(5)

87654321

654321

JP3

(1)

SW3.1, SW3.2 – Fan speeds: 2 speeds (Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds (Low, Med., and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 26 -

Page 27

Wiring and DIP switch/jumper configurations – AC

systems

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 8:

HC22

1 Speed fan,

Economizer

Heat element 2

(2nd stage heat)

Economizer

(option – SW1.6 ON)

(5)

Fan (1 speed)

Compressor 2

Compressor 1

Heat element 1

st

(1

stage heat)

(3) (3)

654321

1

JP2

JP3

3

3 1

1 Speed fan,

Economizer

Heat element

(3rd stage heat)

Economizer

(option – SW1.6 ON)

Fan (1 speed)

Compressor 2

Compressor 1

(2)

Heat pump

87654321

JP2

Config. 9:

HP32

3 1

3 1

(5)

(2)

87654321

654321

JP3

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Terminal not in use

See drawing on page 21 for DIP switch and jumper locations.

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 27 -

Page 28

Wiring and DIP switch/jumper configurations – AC systems

w/wo Humidifier for humidification, with Reheat for dehumidification

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 10:

HC22

1 Speed fan,

Humidifier,

Reheat for

Dehumidification

Heat element 2

(2nd stage heat)

Heat element 1

(1st stage heat)

Fan (1 speed)

Compressor 2

Compressor 1

Humidifier

654321

1

JP2

JP3

3 1

3

Config. 11:

HP31

1 Speed fan,

Humidifier,

Reheat for

Dehumidification

Heat element 2

(3rd stage heat)

(2) (2)

Heat element 1

(2nd stage heat)

Fan (1 speed)

Heat pump

(3) (3) (3) (3)

Compressor

(2)

Humidifier

87654321

JP2

3 1

87654321

654321

JP3

3 1

Config. 12:

HC11

2/3 Speeds fan,

Humidifier,

Reheat for

Dehumidification

Fan high

Fan medium

(or Economizer )

(5) (5)

Fan low

Heat element

Compressor

Humidifier

654321

JP2

JP3

3 1

3 1

2/3 Speeds fan,

Dehumidification

(or Economizer )

(2)

87654321

Heat element

(2nd stage heat)

Config. 13:

HP21

Reheat for

Fan high

Fan medium

Fan low

Compressor

Heat pump

654321

654321

JP2

JP3

3 1

3 1

(2)

(2)

87654321

87654321

(1)

SW3.1, SW3.2 – Fan speeds: 2 speeds (Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds (Low, Med., and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Humidifier: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 28 -

Page 29

Wiring and DIP switch/jumper configurations – AC systems

with Humidifier for humidification

Config. 15:

Outputs

11

12

Config. 14:

HC12

1 Speed fan,

Humidifier

Heat element

Economizer

(option – SW1.6 ON)

(2)

(5) (5)

HP21

1 Speed fan,

Humidifier,

Reheat for

Dehumidification

Heat element

(2nd stage heat)

Economizer

(option – SW1.6 ON)

(2)

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

Fan (1 speed)

Compressor 2

Compressor 1

Humidifier

654321

1

JP2

JP3

3 1

3

Fan (1 speed)

Heat pump

(3) (3)

Compressor

(2)

Humidifier

87654321

654321

JP2

JP3

3 1

3 1

87654321

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Terminal not in use

See drawing on page 21 for DIP switch and jumper locations.

Humidifier: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 29 -

Page 30

Wiring and DIP switch/jumper configurations – AC systems

with Humidifier for dehumidifier

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 16:

HC21

1 Speed fan,

Humidifier,

Dehumidifier

Heat element 2

(2nd stage heat)

Heat element 1

(1st stage heat)

Fan (1 speed)

Compressor

Humidifier

Dehumidifier

654321

1

JP2

JP3

3 1

3

Config. 17:

HC11

1 Speed fan,

Humidifier,

Dehumidifier

Heat element

(2)

Economizer

(option – SW1.6 ON)

(2) (2) (2)

(5)

Fan (1 speed)

(3) (3) (3) (3)

Compressor

Humidifier

(4) (4) (4)

87654321

Dehumidifier

654321

JP2

JP3

3 1

3 1

87654321

Config. 18:

HP11

1 Speed fan,

Humidifier,

Dehumidifier

Heat pump

Economizer

(option – SW1.6 ON)

(5)

Fan (1 speed)

Compressor

Humidifier

Dehumidifier

654321

JP2

JP3

3 1

3 1

Config. 19:

HP21

1 Speed fan,

Humidifier,

Dehumidifier

Heat pump

Heat element

(2nd stage heat)

Fan (1 speed)

Compressor

Humidifier

Dehumidifier

87654321

654321

654321

JP2

JP3

3 1

3 1

87654321

87654321

(2)

SW3.4 – HP (Heat pump): ON = Heat pump active in cool, OFF = Heat pump active in heat

HC (not heat pump): ON = Electrical heater, OFF = Oil/Gas heater (no fan)

(3)

SW3.5 – Compressor delay: ON = Disable, OFF = Enable

(4)

SW1.3 – Dehumidification: ON = Use dehumidifier, OFF = Use reheat for dehumidification

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Terminal not in use

See drawing on page 21 for DIP switch and jumper locations.

Humidifier, Dehumidifier: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Heat pump, Compressors, Economizer: 24 Vac, 0.5A max

- 30 -

Page 31

Wiring and DIP switch/jumper configurations – FC systems – 2-pipe

Config. 20:

2-Pipe,

1/2/3 Speeds

Outputs

11

12

(or Economizer )

13

14

15

Heat element

(2nd stage heat)

Cool/Heat valve

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

(1)

fan

Fan high

Fan medium

Fan low

X

654321

1

JP2

JP3

3 1

3

(5)

(2)

(3)

87654321

Config. 21:

2-Pipe, 1/2/3

Speeds fan

(1)

Cool/Heat PID

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cooll/Heat

valve PID

(3)

X

654321

JP2

JP3

3 1

3 1

(option – SW1.6 ON)

(2)

(2nd stage heat)

Cool/Heat valve

87654321

Config. 22:

2-Pipe,

Fan VFS

X

Economizer

X

Heat element

Fan VFS

654321

JP2

JP3

3 1

3 1

Config. 23:

2-Pipe,

Fan VFS,

Cool/Heat PID

X

(5)

Economizer

(option – SW1.6 ON)

X

(2) (2)

(3)

Heat element

(2nd stage heat)

Cooll/Heat

valve PID

(3)

Fan VFS

87654321

654321

JP2

JP3

3 1

3 1

(5)

87654321

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds/VFS)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS, PID valves: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 31 -

Page 32

Wiring and DIP switch/jumper configurations – FC systems – 2-pipe

with Humidifier for humidification and Reheat for dehumidification

Outputs

11

12

13

14

15

16

SW3

Config. 24:

2-Pipe,

1/2/3 Speeds fan ,

(1)

Humidifier,

Reheat for

Dehumidification

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

(2)

Cool/Heat valve

Humidifier

87654321

Config. 25:

2-Pipe,

1/2/3 Speeds fan ,

Cool/Heat PID,

Humidifier,

Reheat for

Dehumidification

Fan high

Fan medium

(or Economizer )

Fan low

Heat element

(2nd stage heat)

(3)

Cooll/Heat

valve PID

Humidifier

(1)

Config. 26:

2-Pipe,

Fan VFS,

Reheat for

Dehumidification

X

(5)

Economizer

(option – SW1.6 ON)

(5) (5)

X

(2) (2) (2)

(3) (3)

Heat element

(2nd stage heat)

Cool/Heat valve

(3)

Fan VFS

87654321

87654321

Config. 27:

2-Pipe,

Fan VFS,

Cool/Heat PID,

Reheat for

Dehumidification

X

Economizer

(option – SW1.6 ON)

X

Heat element

(2nd stage heat)

Cooll/Heat

valve PID

Fan VFS

87654321

SW1

654321

JP2

1

JP3

3 1

3

JP2

Jumpers

JP2, JP3

for analog

outputs

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

654321

JP3

3 1

3 1

JP2

654321

JP3

3 1

3 1

JP2

654321

JP3

3 1

3 1

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds/VFS)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS, PID valves, Hum., Dehum.: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off. Heat elements, Cool/Heat valves, Humidifier, Economizer: 24 Vac, 0.5A max

- 32 -

Page 33

Wiring and DIP switch/jumper configurations – FC systems – 2-pipe

with Dehumidifier, w/wo Humidifier

Outputs

11

12

13

14

15

16

SW3

Config. 28:

2-Pipe,

1/2/3 Speeds fan ,

(1)

Humidifier,

Dehumidifier

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Cool/Heat valve

(3) (3)

Humidifier

Dehumidifier Dehumidifier

87654321

Config. 29:

2-Pipe,

1/2/3 Speeds fan ,

(1)

Cool/Heat PID,

Dehumidifier

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cooll/Heat

valve PID

Dehumidifier

(option – See SW1.3)

(2)

(3)

(4)

87654321

Config. 30:

Fan VFS,

Dehumidifier

Economizer

(option – SW1.6 ON)

Cool/Heat valve

Fan VFS

2-Pipe,

X

(5)

Fan low

87654321

SW1

654321

JP2

1

JP3

3 1

3

JP2

Jumpers

JP2, JP3

for analog

outputs

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

654321

JP3

3 1

3 1

JP2

654321

JP3

3 1

3 1

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(4)

SW1.3 – Dehumidification: ON = Use dehumidifier, OFF = Use reheat for dehumidification

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds/VFS)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS, PID valves, Hum., Dehum.: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 33 -

Page 34

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

w/wo Floor heating

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 31:

4-Pipe,

1/2/3 Speeds

(1)

fan

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cool valve

(3)

Heat valve

(1st stage heat)

654321

1

JP2

JP3

3 1

3

Speeds fan ,

Floor heating

(or Economizer )

Floor heating (1

stage heat – no fan)

(2nd stage heat)

87654321

Config. 32:

4-Pipe, 1/2/3

(1)

Fan high

Fan medium

Fan low

Cool valve

Heat valve

654321

JP2

JP3

3 1

3 1

Config. 33:

4-Pipe, 1/2/3

Speeds fan ,

Cool valve PID

Fan high

(5) (5) (5)

Fan medium

(or Economizer )

Fan low

st

(3) (3) (3)

Heat element

(2nd stage heat)

Cool valve PID

(2)

Heat valve

(1st stage heat)

87654321

JP2

3 1

87654321

654321

JP3

3 1

Config. 34:

4-Pipe,1/2/3

Speeds fan ,

(1)

Cool valve PID,

Floor heating

Fan high

Fan medium

(or Economizer )

Fan low

Floor heating (1

stage heat – no fan)

Cool valve PID

Heat valve

(2nd stage heat)

654321

JP2

JP3

3 1

3 1

st

87654321

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS, PID valves: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 34 -

Page 35

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 35:

4-Pipe,

Fan VFS

X

Economizer

(option – SW1.6 ON)

(5) (5) (5)

X

Heat valve

Cool valve

Fan VFS

654321

1

JP2

JP3

3

3 1

Config. 36:

4-Pipe,

1/2/3 Speeds fan ,

Heat valve PID

Fan high

Fan medium

(or Economizer )

Fan low

Heat element

(2nd stage heat)

Cool valve

Heat valve PID

(1st stage heat)

87654321

JP2

3 1

Config. 37:

(1)

4-Pipe,

Fan VFS,

Heat valve PID

X

(5)

Economizer

(option – SW1.6 ON)

X

(2)

Cool valve Heat valve

(3)(3)

Heat valve PID

(3)

Fan VFS

87654321

654321

JP3

3 1

JP2

3 1

87654321

JP3

3 1

Config. 38:

4-Pipe,

Fan VFS,

Cool valve PID

X

Economizer

(option – SW1.6 ON)

X

Cool valve PID

Fan VFS

654321654321

JP2

JP3

3 1

3 1

(3)

87654321

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds/VFS)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

Fan VFS, PID valves: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 35 -

Page 36

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

Config. 39:

Outputs

4-Pipe,

1/2/3 Speeds fan ,

Heat valve PID,

Cool valve PID

(1)

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cool valve PID

Heat valve PID

654321

1

JP2

JP3

3

3 1

(2)

(3)

87654321

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

PID valves: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 36 -

Page 37

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

with Reheat for dehumidification, without Humidifier

Outputs

11

12

13

14

15

16

SW3

Config. 40:

4-Pipe,

1/2/3 Speeds fan ,

(1)

Reheat for

Dehumidification

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cool valve

(3)

Heat valve

87654321

Config. 41:

4-Pipe,

1/2/3 Speeds fan ,

(1)

Cool valve PID,

Reheat for

Dehumidification

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat element

(2nd stage heat)

Cool valve PID

(2)

(3)

Heat valve

87654321

SW1

654321

JP2

1

JP3

3

3 1

JP2

Jumpers

JP2, JP3

for analog

outputs

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

654321

JP3

3 1

3 1

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(2)

SW3.4 – 2nd heating stage: ON = Enable, OFF = Disable

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

PID valves: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 37 -

Page 38

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

with Humidifier, without Reheat for dehumidification

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 42:

4-Pipe,

1/2/3 Speeds fan ,

(1)

Humidifier

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat valve

Cool valve

(3) (3)

Humidifier

87654321

654321

1

JP2

JP3

3 1

3

Config. 43:

4-Pipe,

1/2/3 Speeds fan ,

(1) (1)

Cool valve PID,

Humidifier

Fan high

Fan medium

(or Economizer )

(5) (5)

Fan low

Heat valve

Cool valve PID

Humidifier

87654321

654321

JP2

JP3

3 1

3 1

Config. 44:

4-Pipe,

1/2/3 Speeds fan ,

Heat valve PID,

Humidifier

Fan high

Fan medium

(or Economizer )

Fan low

Cool valve

(3)

Heat valve PID

Humidifier

87654321

654321

JP2

JP3

3 1

3 1

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

PID valves, Humidifier: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 38 -

Page 39

Wiring and DIP switch/jumper configurations – FC systems – 4-pipe

with Dehumidifier

Outputs

11

12

13

14

15

16

SW3

SW1

Jumpers

JP2, JP3

for analog

outputs

Config. 45:

4-Pipe,

1/2/3 Speeds fan ,

(1)

Dehumidifier

Fan high

Fan medium

(or Economizer )

(5)

Fan low

Heat valve

Cool valve

Dehumidifier

87654321

654321

1

JP2

JP3

3 1

3

Config. 46:

4-Pipe,

1/2/3 Speeds fan ,

(1) (1)

Cool valve PID,

Dehumidifier

Fan high

Fan medium

(or Economizer )

(5) (5)

Fan low

Heat valve

Cool valve PID

(3)(3)

Dehumidifier

87654321

654321

JP2

JP3

3 1

3 1

Config. 47:

4-Pipe,

1/2/3 Speeds fan ,

Heat valve PID,

Dehumidifier

Fan high

Fan medium

(or Economizer )

Fan low

Cool valve

(3)

Heat valve PID

Dehumidifier

87654321

654321

JP2

JP3

3 1

3 1

(1)

SW3.1, SW3.2 – Fan speeds: 1 speed (Low): SW3.1 = ON, SW3.2 = OFF

2 speeds(Low and High): SW3.1 = OFF, SW3.2 = ON

3 speeds(Low, Medium, and High): SW3.1 = OFF, SW3.2 = OFF

(3)

SW3.5 – Chilled beam option: ON = Enable chilled beam (fan will not run with cooling)

(5)

SW1.6 – Terminal 12 operation: ON = Economizer

OFF = Fan Medium (3 speeds) / Terminal not in use (1/2 speeds)

Important: Economizer will not work in 3 fan speeds configuration.

See drawing on page 21 for DIP switch and jumper locations.

PID valves, Dehumidifier: 0-10 Vdc, 0.5 mA Not isolated

Control – Fan on/off, Heat elements, Cool/Heat valves, Economizer: 24 Vac, 0.5A max

- 39 -

Page 40

Technician Settings

Enter Technician Settings mode:

1. Adjust the setpoint temperature to 10ºC or 50ºF.

2. Press and hold the [C/F] button for 10 seconds to enter Technician Settings mode. “P01” will appear on display.

View objects and make adjustments:

Use the [Mode] button to step forward between different settings.

Use the [Fan] button to step backward between different settings.

Press the [On/Off] button to exit Technician Settings and return to normal display.

If no button is pressed for 60 seconds, the thermostat will automatically exit Technician Settings and return to normal display.

Use the [+] and [-] buttons to make adjustments when required.

P01 – Offset for temperature readings calibration

Range: -6…+6°C / -9…+9°F.

Default: 0°C / 0°F.

Note: The offset will influence both internal

or external sensors.

P02 – Setpoint limit for cooling

Range: 5…35°C / 41…95°F.

Default: 10°C / 50°F.

Note: The thermostat will stop cooling regardless of

the user’s setpoint

P03 – Setpoint limit for heating

Range: 5…35°C / 41…95°F.

Default: 30°C / 86°F.

Note: The thermostat will stop heating regardless of

the user’s setpoint

P04 – Enable/Disable the option to lock the [Fan] button

“LF” + “ ” [Fan] button can be locked

“LF” only [Fan] button cannot be locked

Note: When enabled, press and hold both [-] and [Fan] buttons

for 7 seconds to actually lock the buttons.

Offset for temperature calibration

(°F)(°C)

Setpoint limit for cooling

(°F)(°C)

Setpoint limit for heating

(°F)(°C)

[Fan]

Can

be locked

[Fan]

Cannot

be locked

- 40 -

Page 41

Technician Settings (cont.)

P05 – Enable/Disable the option to lock the [Mode] button

“L1” + “ ” [Mode] button can be locked

“L1” only [Mode] button cannot be locked

Note: When enabled, press and hold both [-] and [Fan] buttons

for 7 seconds to actually lock the buttons.

P06 – Enable/Disable the option to lock the [On/Off] button

“L0” + “ ” [On/Off] button can be locked

“L0” only [On/Off] button cannot be locked

Note: When enabled, press and hold both [-] and [Fan] buttons

for 7 seconds to actually lock the buttons.

P07 – Enable/Disable the option to lock the [+] and [-] buttons (SET)

“LS” + “ ” [+] and [-] buttons can be locked

“LS” only [+] and [-] buttons cannot be locked

Note: When enabled, press and hold both [-] and [Fan] buttons

for 7 seconds to actually lock the buttons.

P08 – Functionality of T1 terminals

“00” - T1 terminals are not in use

“01” - External sensor

“02” - T3 Soft start in heat sensor (FC) *

or De-icing in cool (AC )**

“03” - Door switch

“04” - Key tag

“05” - T Economizer

(DIP switch SW1.6 must be ON)

T1 terminals

Not in use

[Mode]

Can

be locked

[On/Off]

Can

be locked

[+] and [-]

Can

be locked

T1 sensor

(External

sensor)

[Mode]

Cannot

be locked

[On/Off]

Cannot

be locked

[+] and [-]

Cannot

be locked

T3 Soft start in

heat sensor (FC)

or De-icing in

cool sensor (AC)

* In heating mode, the fan will not start before there

is hot water in the coil.

Note: To view T3 on the BACnet Thermostat,

see Technician Settings P84.

** Allow de-icing operation of indoor coil in cooling.

Door switch Key tag T Economizer

- 41 -

Page 42

Technician Settings (cont.)

P09 – Functionality of IN1,0 terminals

“00” - IN1,0 terminals are not in use

“01” - T2 (Change over sensor) *

“02” - T3 (Soft start in heat sensor) **

“03” - Remote On/Off switch

“04” - Remote Economy switch

“05” - External Passive Infrared detector ***

* In 2-Pipe system, T2 will sense the water temperature

in the pipe in order to select/allow effective system

mode. Note: To view T2 on the BACnet Thermostat,

see Technician Settings P83.

** Where T1 terminals are used for external sensor, the

IN1,0 terminals can be used for T3 sensor.

Note: To view T3 on the BACnet Thermostat, see

Technician Settings P84.

*** External PIR – only if internal PIR is disabled (DIP

Switch SW4.2 ON).

“IN1,0”

terminals

Not in use

Window contact

Remote

On/Off

*T2 change over

sensor (FC) /

De-icing in cool

(AC)

Window contact

Remote

Economy

**T3 Soft start in

heat sensor (FC)

or De-icing in

cool sensor (AC)

***External

PIR sensor

P10 – Window contact (terminals IN1,0) polarity

“01” - Normally open

“00” - Normally close

P11 – Window contact delay time

Range: 0…999 seconds.

Default: 60 seconds.

P12 – Door switch (terminals T1,0) polarity

“01” - Normally open

“00” - Normally closed

P13 – Door switch delay time

Range: 0…999 seconds.

Default: 180 seconds.

Win. contact

Normally close

Door switch

Normally closed

Win. contact

Normally open

Window contact

delay time (sec.)

Door switch

Normally open

- 42 -

Door switch

delay time (sec.)

Page 43

Technician Settings (cont.)

P14 – Enable/Disable Auto change over mode

“00” - Disable Auto change over mode

“01” - Enable Auto change over mode

P15 – Motion sensor logic (PIR)

“00” - Thermostat turns off when unoccupied

and back on when re-occupied.

“01” - Thermostat turns off when unoccupied

and remains off when re-occupied.

“02” - Thermostat uses economy setpoints.

“03” - Unoccupancy – Dehumidification logic.

(only available with dehumidification configuration

– see DIP switch settings)

P16 – Enable/Disable Motion sensor

“00” - Disable

“01” - Enable

Disable

Auto mode

Unocc. – Off

Re-occ. - On

Economy

setpoints

Disable

occ. sensor

Enable

Auto mode

Unocc. – Off

Re-occ. - Off

Dehumidification

logic

Enable

occ. sensor

P17 – PIR (Motion sensor) delay time

before switching to unoccupied mode (ON delay)

Range: 0…250 minutes.

Default: 20 minutes.

P18 – Door switch or key tag configuration

“00” - Switch On or Off by door switch or key tag

“01” - Changing the setpoint temperature

“02” - Switching fan speed to Low

- 43 -

Switch

On or Off

Change

setpoints

PIR ON delay

(sec.)

Switch to

fan low

Page 44

Technician Settings (cont.)

P19 – PIR (Motion sensor) polarity

“00” - Normally open

“01” - Normally closed

P25 – Economy setpoint for cooling

Range: 5…35°C / 41…95°F.

Default: 30°C / 86°F.

P26 – Economy setpoint for heating

Range: 5…35°C / 41…95°F.

Default: 10°C / 50°F.

P27 – On-delay time between heating stages

Range: 0….600 seconds

Default: 5 seconds

PIR

Normally open

EC setpoint in cooling

EC setpoint in heating

PIR

Normally closed

(°F)(°C)

(°F)(°C)

On delay

heating stages

P28 – Off-delay time between heating stages

Range: 0….600 seconds

Default: 1 second

P29 – LCD Backlight ON or OFF

“00” - LCD Backlight ON

“01” - LCD Backlight OFF

- 44 -

Backlight

ON

Off delay

heating stages

Backlight

OFF

Page 45

Technician Settings (cont.)

P30 – Beeper ON or OFF

“01” - Beeper ON

“00” - Beeper OFF

P31 – P34

Fan on/off delay

with fan on demand

(auto fan) active.

Valve

Fan

P31 – Fan ON delay in cooling (FC Only!)

Range: 0…120 seconds

Default: 0 seconds (no delay)

P32 – Fan OFF delay in cooling

Range: 0…120 seconds

Default: 0 seconds (no delay)

ON

OFF

Fan ON

delay

Beeper

ON

Fan OFF

delay

Beeper

OFF

Time

(sec.)

Fan ON delay

in cooling

(seconds)

P33 – Fan ON delay in heating (FC Only!)

Range: 0…120 seconds

Default: 0 seconds (no delay)

P34 – Fan OFF delay in heating

Range: 0…120 seconds

Default: 30 seconds

Fan OFF delay

in cooling

(seconds)

Fan ON delay

in heating

(seconds)

Fan OFF delay

in heating

(seconds)

- 45 -

Page 46

Technician Settings (cont.)

P35 – Enable/Disable Freeze protection

“00” - Disable Freeze protection

“01” - Enable Freeze protection

Note: If enabled, freeze protection will start when the thermostat

is either ON or OFF and regardless of the current system

mode.

P36 – Freeze protection cut-in setpoint

Range: 8...15°C / 46…59°F

Default: 8°C / 46°F

The room ambient temperature which will trigger Heating ON.

P37 – Freeze protection cut-out setpoint

Range: 10...17°C / 50…63°F

Default: 10°C / 50°F

The room ambient temperature which will switch the Heating back OFF.

P40 – View filter counter (hours) – Read only

Range: 0…999 hours

Disable freeze

protection

Freeze protection cut-in setpoint

Freeze protection cut-out setpoint

Enable freeze

protection

(°F)(°C)

(°F)(°C)

The filter counter is related to Fan running time.

P41 – Reset filter time

Press the [+] button to reset the filter counter.

The display will change from “00” to “01” and back to “00”.

P42 – Adjust filter alarm delay time counter (hours)

Range: 0…999 hours

Default: 0 hours (0 = Disable)

View filter

Counter (hours)

Reset filter

counter

Adjust filter alarm

delay time (hours)

- 46 -

Page 47

Technician Settings (cont.)

P43 – P44

Soft start in heat

with fan on demand

(auto fan) active.

Heat valve

Fan

P43 – Soft start in heat – cut-in temperature (FC Only!)

The fan will not start before the temperature

on T3 sensor reaches the cut-in temperature.

See Technician Settings P08/P09.

Range: 14...37°C / 57…99°F

Default: 36°C / 97°F

P44 – Soft start in heat – cut-out temperature (FC Only!)

The fan will stop if the temperature on T3 sensor

drops below the cut-out temperature.

See Technician Settings P08/P09.

Range: 12...35°C / 54…95°F

Default: 32°C / 90°F

ON

OFF

Fan cut-out

temperature

T3

Fan cut-in

temperature

Soft start heat cut-in temperature

Soft start heat cut-out temperature

Temp.

(°F)(°C)

(°F)(°C)

- 47 -

Page 48

Technician Settings (cont.)

P45 – P46

Cool differential band / offset

(with cool differential band offset = 0)

Compressor / Valve

P45 – P46

Cool differential band / offset

(with cool differential band offset ≠ 0)

Compressor / Valve

P45 – Cool differential band

Range: 0.5...5°C / 1…10°F

Default: 1°C / 2°F

P46 – Cool differential band offset

Range: -5…+5°C / -9…+9°F

Default: 0°C / 0°F

ON

OFF

ON

OFF

Setpoint

Cool differential band

Setpoint

Cool differential band

Offset

Room

Temp.

Room

Temp.

Cool differential band

(°F)(°C)

Cool differential band offset

(°F)(°C)

- 48 -

Page 49

Technician Settings (cont.)

P47-48

Heat differential band / offset

(with heat differential band offset = 0)

Compressor / Valve

P47-48

Heat differential band / offset

(with heat differential band offset ≠ 0)

Compressor / Valve

P47 – Heat differential band

Range: 0.5...5°C / 1…10°F

Default: 1°C / 2°F

P48 – Heat differential band offset

Range: -5…+5°C / -9…+9°F

Default: 0°C / 0°F

Room

Temp.

Room

Temp.

ON

OFF

Setpoint

Heat differential band

ON

OFF

Setpoint

Heat differential band

Offset

Heat differential band

(°F)(°C)

Heat differential band offset

(°F)(°C)

- 49 -

Page 50

Technician Settings (cont.)

P49

Shift between Cool and Heat

ON

OFF

in Auto change over mode

(from cooling to heating)