Carrier BW9, DEHXX Owner's Manual

!

WARNING: FIRE OR EXPLOSION

HAZARD If the information in this manual is

not followed exactly, a fire or explosion could

result causing property damage, personal

injury or death.

— Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Model BW9

Gas-Fired

Direct Vent

Condensing

NOTE TO INSTALLER:

This manual must be left with the equipment user.

USER:

Please read all manuals and retain manuals for

future reference.

!

WARNING: CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in

personal injury or death. Carbon Monoxide is

invisible, odorless, and toxic! We recommend a

carbon monoxide alarm in your home, even if

you do not own a gas appliance. Locate the carbon monoxide alarm in the living area of your

home and away from gas appliances and doorways to attached garages. Follow the alarm

manufacturer’s instructions included with the

alarm.

Water Boiler

USER’S INFORMATION

MANUAL FOR THE

OPERATION AND

MAINTENANCE OF YOUR

NEW GAS-FIRED DIRECT

VENT CONDENSING BOILER

Do not use this furnace if any part has been under water. A flood-damaged furnace is extremely dangerous. Attempts to use the furnace can

result in fire or explosion. A qualified service

agency should be contacted to inspect the furnace and to replace all gas controls, control system parts, electrical parts that have been wet or

the furnace if deemed necessary.

Gas-Fired Direct Vent Condensing Water Boiler

Congratulations! Your new gas-fired indoor boiler is an excellent choice and sound investment in home heating comfort. Your modern boiler

represents the latest in engineering development and is the culmination of many years of experience from one of the most reputable manufacturers of residential hydronic heating systems.

Not only is your new boiler one of the most energy-efficient heating systems you can buy today, it is also one of the safest and most dependable.

With only minimal care, your new boiler will continue to deliver money-saving home comfort and enjoyment for many years to come. Spend

just a few minutes with this manual to learn the operation of your new boiler and the small amount of maintenance it takes to help keep it

operating at peak efficiency.

12

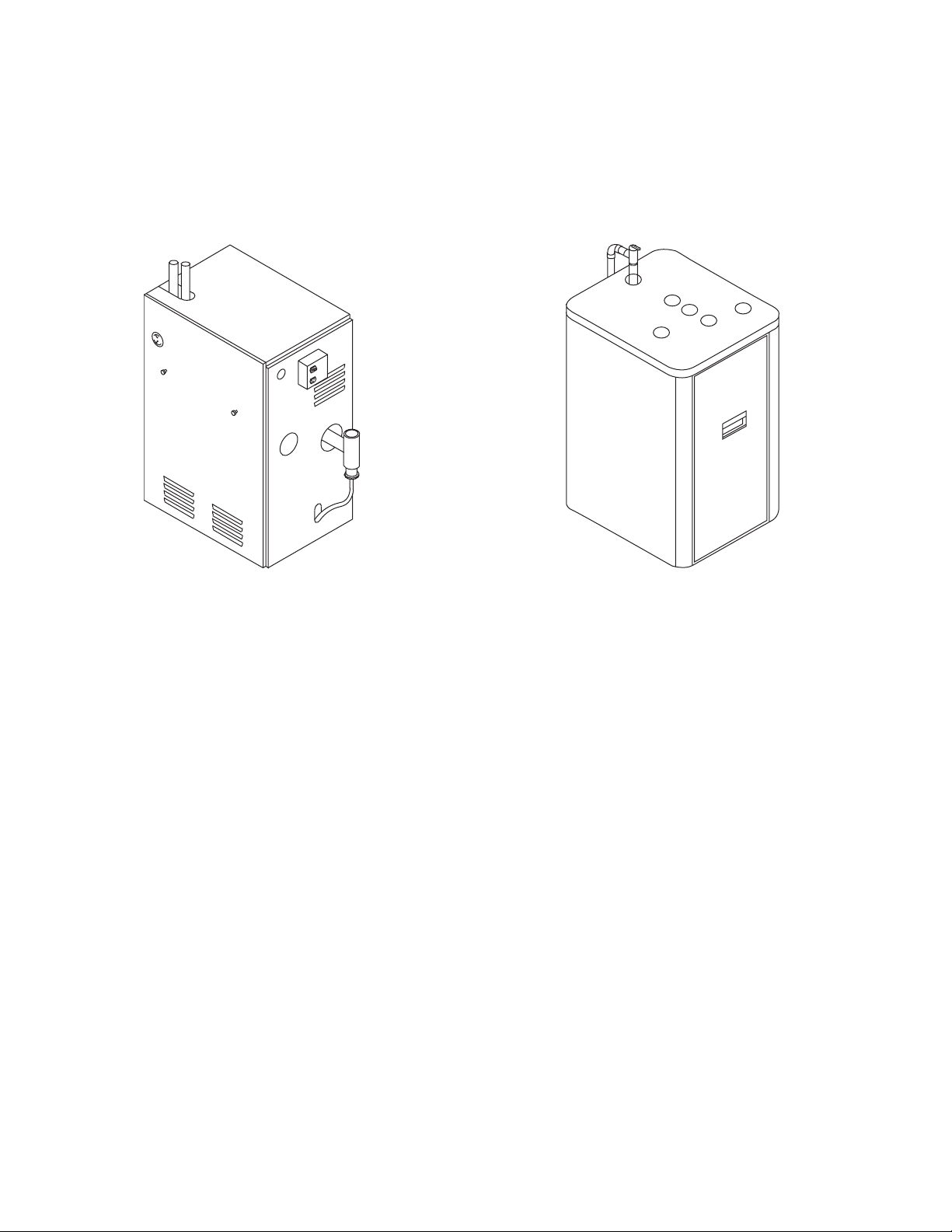

Model BW9-50 Through 100 Model BW9-125 Through 200

Gas-Fired Direct Vent Gas-Fired Direct Vent

Condensing Water Boiler Condensing Water Boiler

BOILER IDENTIFICATION

For your convenience, record the product and serial numbers of your new boiler on the form below. Should you ever require service, you will

have ready access to the information needed by the service representative.

Product No. ___________________________________________________________________________________________

Serial No.______________________________________________________________________________________________

Date Installed __________________________________________________________________________________________

Dealer Name __________________________________________________________________________________________

Address_______________________________________________________________________________________________

City___________________________________________________________________________________________________

State_______________________________________________________________ Zip________________________________

Telephone _____________________________________________________________________________________________

—2—

Typical boiler and piping arrangements are shown in Fig. 3 through 6. Since there are many variations in boiler piping systems,

your system may not look the same as shown. Your dealer is your best resource to explain your particular boiler piping arrangement.

BW9 050, 075, 100

Typical Single Zone Piping

SERVICE

VALVE

CIRCULATOR

CAN VENT

SHUT OFF VALVE

PURGE VALVE

SERVICE

VALVE

EXPANSION TANK

3

SUPPLY TO

SYSTEM

GATE VALVE

FEED

WATER

REDUCED PRESSURE

BACKFLOW PREVENTER

PRESSURE

REDUCING VALVE

RETURN FROM

SYSTEM

4

BW9 125, 150, 175, 200

Typical Single Zone Piping

ZONE SERVICE

VALVE

SUPPLY TO

ZONES

FEED

WATER

RETURN FROM

ZONES

ZONE SERVICE

VALVE

GATE VALVE

REDUCED PRESSURE

BACKFLOW PREVENTER

EXPANSION TANK

SHUT OFF VALVE

PURGE VALVE

PRESSURE

REDUCING VALVE

CAN VENT

ZONE VALVE

CIRCULATOR

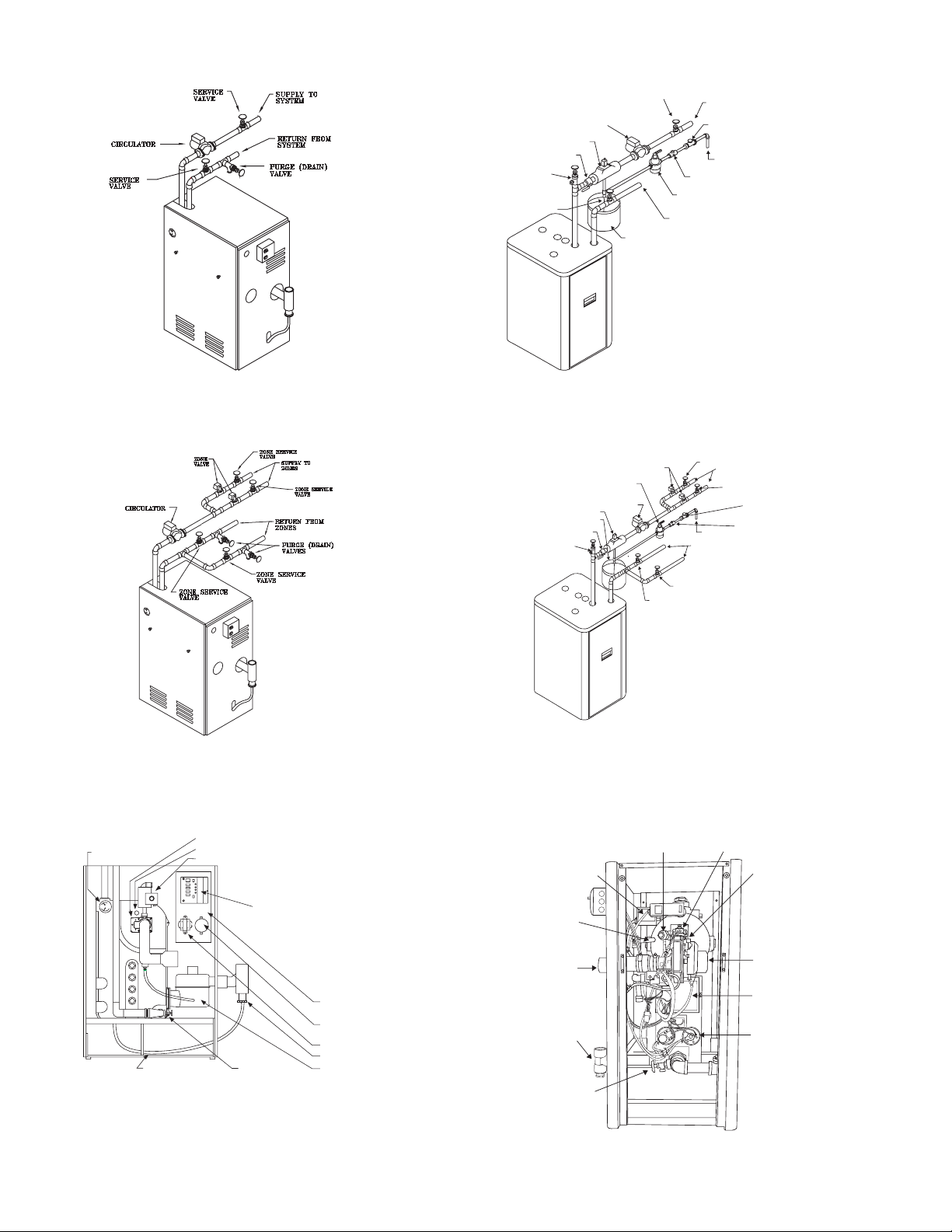

BW9 050, 075, 100

Typical Multi-Zone Piping

PRE-MIX BURNER

TEMPERATURE/

PRESSURE GAUGE

CONDENSATE TUBE

SIGHT GLASS

GAS VALVE

INTEGRATED

BOILER CONTROL

WITH DIAGNOSTICS

BOILER DRAIN

5

CONTROL PANEL

AIR PRESSURE SWITCH

TRANSFORMER

EXHAUST TEE WITH DRAIN

FLUE EXHAUSTER

Typical Multi-Zone Piping

LOW WATER CUT-OFF

MANUAL GAS

SHUT-OFF

COMBUSTION

AIR INTAKE

EXHAUST TEE

WITH DRAIN

BOILER DRAIN

ZONE SERVICE

VALVE

ZONE SERVICE

VALVE

BW9 125, 150, 175, 200

SIGHT GLASS HOT SURFACE

IGNITOR

PRE-MIX

BURNER

COMBUSTION

AIR BLOWER

INTEGRATED BOILER

CONTROL WITH

DIAGNOSTICS

PRESSURE

SWITCHES

6

BW9 050, 075, 100

Component Location

7

8

BW9 125, 150, 175, 200

Component Location

—3—

Loading...

Loading...