Page 1

HEATING & COOUNG

Gas-Fired Induced-Combustion Water Boilers

Installation, Start-Up, and Operating Instructions

Sizes 042—225, Series 101

NOTE: AFFIX THESE INSTRUCTIONS ADJACENT TO THE

BOILER.

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified person

nel should install, repair, or service heating equipment.

When working on heating equipment, observe precautions in the

literature, tags, and labels attached to or shipped with the unit and

other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code NFPA No. 54-

1988/ANSI Z223.1-1988. Wear safety glasses and work gloves.

Have fire extinguisher available during start-up and adjustment

procedures and service calls.

Recognize safety information. This is the safety-alert symbol ^ .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury,

Understand the signal word DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen

tial construction practices.

minimum for a safe installation.

Model 61SW is a low-pressure, sectional, cast-iron water boiler.

The design of model 61SW is certified by A.G.A. for use with

natural and propane gases (model 61SWC with natural gas and

61SWE with propane gas). It is tested for a maximum working

pressure of 50 psi on water in accordance with American Society

-of—Mechanical—Engineers-(A.S.M.E..)—Code_IM_Standards_for_

cast-iron boilers. It is to be installed indoors only. All boilers are

factory assembled.

“All installations are subjectTo Codes established by localTitiiities or

other authorities having jurisdiction. This jurisdiction normally

covers electrical wiring, gas piping, flue specification, and insula

tion of adjacent combustible material where required clearances

cannot be maintained. The installation must conform with the

National Fuel Gas Code, NFPA No. 54-1988/ANSI Z223.1-1988.

Where required by the authority having jurisdiction, the installa

tion must conform to the American Society of Mechanical Engi

neers’ Safety Code for Controls and Safety Devices for Automat

ically Fired Boilers, No. CSD-1.

We require these instructions as a

INTRODUCTION

61 sw

lama

Fig. 1—Model 61SW-075100

Consult the local building codes or ordinances that may apply.

INSTALLATION

£k CAUTION

Do not install the boiler in a corrosive or contaminated

"atmosphere. Make~sure~ all”combustion“and“circulating-air

requirements are adhered to, in addition to all local codes and

ordinances.

Do not use this boiler during construction when adhesives,

"sealersrand/or new carpets are being installed-If-lhe-boiler-is-

required during construction, use clean outside air for com

bustion and ventilation. Compounds of chlorine and fluorine

when burned with combustion àirïbim“aci3swKiclrwill cause

corrosion of the sections and metal vent systems. Some of

these compounds are found in paneling and dry wall adhe

sives, paints, thinners, masonry cleaning materials, and many

other solvents commonly used in the construction process.

Step 1—Location

1. The boiler must be installed on a level foundation. Metal

shims may be used to level if required. Locate the boiler near

a gas vent or a chimney.

A.S.M.E.

A85085

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4 PC 101

Tflh Iftalfta

Catalog No. 536-113 Printed in U.S.A.

Form 61S-2SI

pgi

10-92 Replaces: 61S-1SI

Page 2

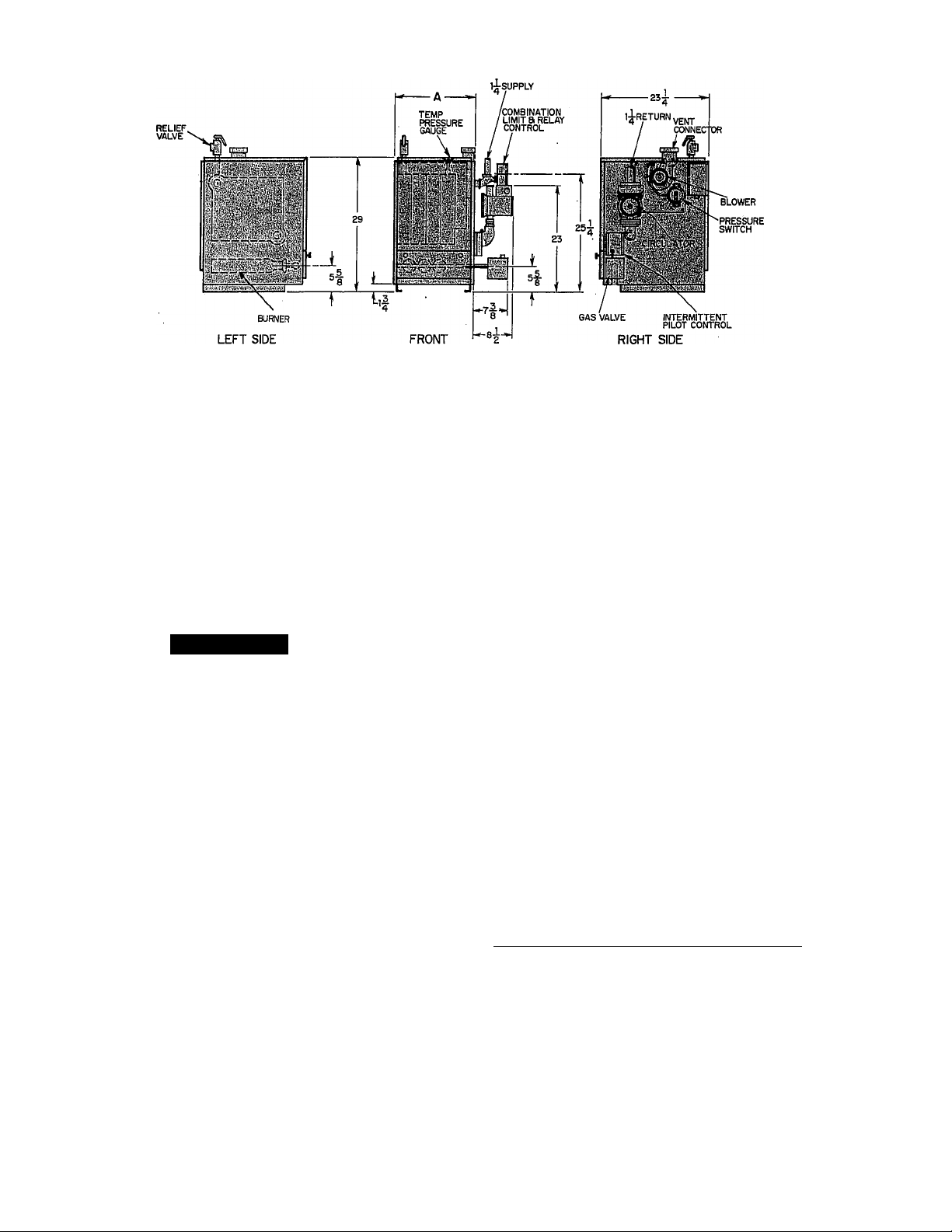

Fig. 2—Dimensional Drawing

A85084

2. Combustible floors-Do not install the boiler on carpeting.

When the boiler is installed on a combustible floor, you must

use a factory-supplied combustible floor installation kit con

taining a rectangular piece of insulation material. Position the

insulation on the combustible floor and place the boiler on top

of the insulation.

3. Alcove installation only — Maintain at least 6 in. from com

bustible material on the left-hand (LH) side, 6 in. from the

back and 6 in. from the top.

4. Leave enough room for service access on the right-hand (RH)

side and front. A minimum of 24 in. is required.

A WARNING

The boiler, when installed, must be electrically grounded in

accordance with the National Electrical Code, ANSI/NFPA

No. 70-1988.

Step 2—Air For Combustion and Ventilation

Table 2—Dimensions (In.)

MODEL

AND SIZE

61SW-042100

61SW-075100

61SW-112100

-etsw^rsoioo”

61SW-187100

61SW-225100

*With factory-supplied adaptor installed.

11

14-1/4.

17-1/2

■'20-3/4“

24

27-1/4

The relief-air supply must be in the same atmospheric pressure

zone as the combustion-air inlet supply to the boiler.

^^1 gas-fired equipment must'be'supplied^witlrthe airthat enters’

into the combustion process and is then vented to the outdoors.

Sufficient air must enter the boiler room to replace that air drawn

up the vent stack. Replacement air must be provided by means of

ducts from the outside to the boiler location or conditioned space.

Under all conditions, enough air must be provided to insure there

will not be a negative pressure condition within the boiler room or

space.

In the past, the infiltration of outside air assumed in heat loss

calculations (1 air change per hour) was assumed to be sufficient.

However, current construction methods using more insulation and

WA

VENT

CONNECTION

4*

4*

4*

■ 4*~

vapor barriers, tighter fitting and gasketed doors and windows or

weather-stripping, and mechanical exhaust fans now require the

positive introduction of outside air.

The requirements for combustion and ventilation air depend upon

whether the boiler is located in a confined or unconfined space.

An unconfined space is defined as a space whose volume is not

less than 50 cu ft per 1000 Btuh of the total gas input rating of all

appliances installed in that space.

Advise the owner of the necessity for keeping air passages to the

boiler area free of obstructions. This clearance is necessary so

combustion air can enter freely into the combustion chamber. It is

also necessary to provide adequate ventilating air.

EQUIPMENT LOCATED IN CONFINED SPACES

1. All Air From Inside Building

The confined space shall be provided with 2 permanent

openings communicating directly with an additional room(s)

of sufficient volume so that the combined volume of-all spaces

meets the criteria for an confined space. The total input of all

gas utilization equipment in the confined space shall be

considered in making this determination. Each opening shall

have a minimum free area of 1 square in. per 1000 Btuh of the

total input rating of all gas utilization equipment in the

confined space, but not less than 100 square in. One opening

shall be within 12 in. of the top and 1 within 12 in. of the

bottom of the enclosure. (See Fig. 3.)

—2wUl-Air-FTom-Outdoors

--------------------------^---------------------------

The confined space shall be provided with 2 permanent

openings, 1 within 12 in. of the top and 1 within 12 in. of the

bottom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl of

attic) that freely communicate with the outdoors.

a. When directly communicating with the outdoors, each

-^^opening^shall-have-a-minimumTreerareamf-l-square-in-per=

4000 Btuh of total input rating of all equipment in the

enclosure. (See Fig. 4.) Use F and G.

b. When communicating with the outdoors with vertical

ducts, each opening shall have a minimum free area of 1

square in. per 4000 Btuh of total input rating of all

equipment within the enclosure. (See Fig. 4.) Use D and E.

c. When communicating with the outdoors with vertical

ducts, each opening shall have a minimum free area of 1

square in. per 2000 Btuh of total input rating of all

equipment in the enclosure. (See Fig. 4.) Use A and B or A

and C.

Page 3

Table 1—Ratings and Capacities

MODEL

AND

SIZE

TYPE

Max Input Btuh

61SW-042100 Water 42,500 36,000

61SW-075100

Water

75,000 63,000

61SW-112100 Water 112,500

61SW-150100

Water

150,000 125,000

61SW-187100 ■ Water 187,500

61SW-225100 Water

‘The above gas inputs are certified for altitudes to 2000 ft.

are computed at 150 Btuh/sq ft.

The seiection factors providing for piping loss and starting

are based on an allowance of 1.15.

tin accordance with U.S. Government test procedures.

225,000 186,000

RATINGS*

For elevations above 2000 ft, reduce input 4 percent for each 1000 ft above sea level. Ratings in square ft

load are those recommended by the Institute of Boiler and Radiator Manufacturers. Net water boiler ratings

ill 12

I

___

= 1 SQ. INCH

•=• PER 1000

= BTUH

Heating Capacilyf

Btuh

94,000

155,000

12 MAX

i

RATINGS

Sq Ft

240

Btuh Sq Ft

31,000

420 55,000

620 82,000

827 109,000

1033 135,000

1240 162,000

Г'

12 MAX

1 so. INCH PER

2000 BTUH

NET

BOILER WATER APPROX

CAPACITY IN

GALLONS WEIGHT

207 1.75

367

547

727

3.00 263

4.25 320

5.50 369

900 6.75 426

TO VENTED

ATTIC

:i

1080

TO ROOF

¡1 so. INCH PER

4000BTUH

8.00 476

DUCTS

1 SO. INCH PER

SHIPPING

211

4000BTUH

VENT

TO ROOF

^=-1 SO. INCH

PER 1000

I^BTUH

____L____L____

L_.

12 MAX

A90060

Fig, 3—Air From Inside Building

d. When ducts are used, they shall be of the same cross-

-----------

“EQUIPMENT LOCATED IN ÜT^CONFÎNËD SPACÈS

seetional-area-as-the-free-area-of-the-openings-to-which-they“

connect. The minimum diniension of rectangular air ducts

shall not be less than 3 in.

An unconfined space is defined as a space whose volume is not

less than 50 cu ft per 1000 Btuh of the total gas input rating of all

appliances installed in that space. Rooms communicating directly

with the space in which the appliances are installed, through

openings not furnished with doors, are considered part of the

unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to

provide air for combustion, ventilation, and dilution of flue gases.

However, in buildings of tight construction (weather stripping,

heavily insulated, caulked, vapor barrier, etc.), additional air may

need to be provided using the methods described in section,

“Equipment Located in Confined Spaces.”

VENT

TO ROOF

DUCTS TO

OUTSIDE

1 SQ. INCH PER

2000 BTUH

.

12 MAX

_________

—;гт~7'

[.

12 MAX

L-

I so. INCH PER

4000BTÜH:—

TO VENTED

CRAWL .rn

RPACF DUCT TO

OUTSIDE

-------------------

Fig*-4—Air-From-Outdoor

LOUVERS, GRILLES, AND SCREENS

-In-calculating-the^ee-arear'Consideration“shall~be“given“tO“the“

blocking effect of louvers, grilles, or screens protecting openings.

Screens used must not be smaller than 1/4-in. mesh. If the free area

through a design of louver or grille is knotvn, it should be used in

calculating the size opening required to provide that free area

specified. If the design and free area is not known, it may be

assumed that wood louvers will have a 20- to 25-percent free area

and metal louvers and grilles will have a 60- to 75- percent free

area. Louvers and grilles that provide combustion and dilution air

must be constructed so they cannot be closed.

Step 3—Water Line Connection

For water-type boilers with the circulator pump mounted on the

RH side, the water outlet (supply to system) must be on the RH

liso. INCH PER

) 2000 BTUH

------------------

A90059

Page 4

Table 3—Fresh Air Duct Capacities for Tightly

Sealed Houses*

FRESH AIR

DUCT SIZE

(IN.)

3 X 12

8x8

8 X 12

8-1/2 X 16

‘Based on opening mesh soreen, or metal louvers.

1/4-MESH

SCREEN

(BTUH)

144,000

256,000

384,000

512,000 128,000

WOOD

LOUVERS

(BTUH)

36,000

64,000

96,000

FRESH

METAL

LOUVERS

(BTUH)

108,000

192,000

288,000

384,000

^AIR

DUCT

FRESH AIR DUCT

FOR TIGHTLY

SEALED HOUSE

Fig. 5—Fresh Air Duct for Tightly Sealed Buildings

side. (See Fig. 6.) Any other piping method will short-circuit water

flow through the boiler and insufficient heat will result from the

premature limit control cutout. When a boiler is installed on an

oversized piping system (a typical example is replacement of a

gravity boiler with a forced circulation boiler) and piping or

radiation are not changed, an adjustable flow control valve or

square head cock must be added to reduce the water flow through

the boiler. This allows proper water temperature (160° F mini

mum) to be obtained which eliminates continuous condensate on

the sections. If more than 1 return is used, use a flow control valve

or square head cock in each return. (See Fig. 6.)

RETURN

BOILER

A90065

SUPPLY

exposed to refrigerated air circulation, the boiler piping system

must be equipped with flow control valves or other automatic

means to prevent gravity circulation of the boiler water during the

cooling cycle.

A84191

Fig. 7—Piping With Refrigeration System

Step 5—Gas Piping

The gas supply line should be a separate line directly from the

meter to the boiler, if possible. Refer to Table 4 for the recom

mended gas pipe sizing. Do not use cast-iron or galvanized pipe.

For additional information, refer to “National Fuel Gas Code”

NFPA No. 54-1988/ANSI Z223.1-1988.

Table 4-Gas Pipe/Tubing Capacity

NATURAL GAS

Iron Pipe—Btuh Input

(Ft)*

20

40

60

1/2 in.

92,000 190,000

63,000

50,000

3/4 in.

130,000 245,000

105,000 195,000

PROPANE GAS

Length

(Ft)*

20

40 . 90,000

60 72,000

‘The length of pipe or tubing should be measured from the gas meter or

propane second stage regulator.

Copper Tubing—OD

5/8 in.

3/4 in.

131,000 216,000 189,000

145,000

121,000

1 in. 1-1/4 in.

350,000

625,000

445,000

365,000

Iron Pipe

-1/2 in. 3/4 in.

393,000

129,000

103,000

267,000

217,000

FLOW CONTROL VALVE

SQUARE HEAD COCK

OR

A84190

Fig. 6—System Water Line Connection

Step 4—Boiler With Refrigeration System

When a water boiler is used in connection with a chilled-water

system, it must be installed so that the chilled medium is piped in

parallel with the heating boiler with appropriate valves to prevent

the chilled medium from entering the heating boiler. An example

of such piping is shown in Fig. 7. When the boiler is connected to

heating coils located in air handling units where they may be

"liTOidTow spbfriiTlohgTTihTbf piperld's'best to'^slope all pipeTiyA--

in. every 15 ft to prevent traps. All horizontal runs should slope

away from the meter to risers. Risers should be used to connect to

the boiler and to the meter.

Joint compounds (pipe dope) should be applied sparingly and only

to the male threads of the joints. Consult your local supplier for the

-type-of-compound-to.-berusedzThisTpipe-dQp.ermusl-be-resistant-tothe action of propane gas.

Install a sediment trap in the riser leading to the boiler. This

sediment trap will serve as a trap for dirt or condensate. This

sediment trap can be installed by connecting a tee to the riser

leading to the boiler, so that the straight-through section of the tee

is vertical. Then, connect a capped nipple into the lower end of the

tee. The capped nipple should extend below the level of the gas

controls. (See Fig. 8.)

When a gum filter is required by local codes, install it in

accordance with their requirements.

Page 5

An accessible manual shutoff valve shall be installed upstream of

the gas controls and within 5 ft of the gas boiler.

Place a ground joint union between the gas control manifold and

the manual gas shutoff valve, or use an approved flexible or

semi-rigid conductor.

Support all piping with the appropriate straps, hangers, etc. (1

hanger every 10 ft minimum).

Piping should be pressure tested before any appliance or shutoff

valve has been attached, in accordance with the requirements of

the local plumbing or gas code.

if the pressure exceeds 0.5 psig (14-in. wc), the gas supply pipe

must be disconnected from the furnace before the pressure test. If

the test pressure is equal to or less than 0.5 psig (14-in. wc), close

the manual shutoff valve located on the gas valve before the test.

If is recommended that the ground joint union be loosened before

pressure testing.

3. If venting into a masonry chimney without a liner, line

chimney from top to bottom with either:

a. listed Type-Bl vent pipe

b. listed flexible vent liner

c. poured ceramic liner

4. Outside chimneys should not be used unless they are either:

a. enclosed in a chase

b. lined with Type-Bl vent pipe

5. The vent connector from the boiler to the chimney should run

as directly as possible with as few elbows as possible.

6. The vent connector from the boiler to the chimney must be

4-in. pipe. The boiler’s induced-draft blower has a 3-in. outlet.

A 3- X 4-in. adaptor fitting is included in the parts bag. Locate

the adaptor fitting on the outlet of the induced-draft blower,

and ensure it is gastight with a bead of the furnished silicone

‘ sealant.

The boiler installation for chimney venting is not complete

unless the 3- x 4-in. adaptor fitting is located and secured.

7. Where possible, it is recommended to common vent the water

heater and boiler. Each appliance must have its own vent

connector. The 2 vent connectors at the chimney must be kept

at least 6 in. apart. (See Fig.'9.)

A WARNING

-Never-puige-aJine_intQ_a combustion chamber. Never use

matches, candlesrflameror-other-sources-of-ignition-forahepurpose of checking leakage. Use a soap-and-water solution

to check for leakage. After all connections have been made,

purge the lines and check for leakage.

Step 6—Venting

-This-is a-very-important-par.t-of_your heating system. It must be

clean, the right size, properly constructed and in GOOD CONDI

TION.

1. Use local codes for installation or National Fuel Gas Code,

NFPA No. 54-1988/ANSI Z223.1-1988. It is very important to

properly size the venting system for induced-draft appliances.

Consult the New Vent Sizing Tables, available from A.G.A. or

Venting Tables Category I Central Furnaces, available from

Gas Appliance Manufacturers Association (GAMA) for cor

rect sizing information.

2. These are high-efficiency boilers with a low stack or exhaust

temperature.

Fig. 9—Type»B1 Venting Through the Roof

—8.-Tf-the-hoiler is the only appliance connected to thejyejihj^ype^

B1 vent pipe is recommended for the vent connector.

9. Slope pipe up from boiler to chimney 1/4 iii. per ft.

10. End of vent pipe must be flush with the inside face of the

chimney flue. Use a sealed-in thimble for the chimney

connection.

11. 'The sections ofVenf’p^ipfrsIiouId'be'fastened'with-sheet-raetalscrews to make the piping rigid. Use stovepipe wires to

support the pipe from above.

12. Do not connect to fireplace flue.

13. Do not install a damper on this boiler.

MINIMUM VENT PIPE CLEARANCE

If the vent pipe must go through a crawl space, Type-Bl vent pipe

should be used. Where vent pipe passes through a combustible

wall or partition, use a ventilated metal thimble. The thimble

should be 4 in. larger in diameter than the vent pipe.

Page 6

If boiler is installed with single wall vent, it must have a 6-in.

clearance between its surface and any combustible material. A new

Type-Bl vent pipe or flexible liner must be installed in accordance

with the instructions furnished with the vent.

Check the vent pipe to see if it is firestopped where it goes through

the floor or ceiling. It should have an approved vent cap with

clearances from the roof as shown in Fig. 9. If clearances are less

than shown in Fig. 9, have the vent checked by local authorities.

- LINER

- CHIMNEY

A92406

Fig. 10—Venting Boiler Into Masonry Chimney

For boilers connected to gas vents or chimneys, vent installations

shall be in accordance with Part 7, Venting of Equipment, of the

National Fuel Gas Code, ANSI Z223.1-latest issue and applicable

provisions of the local building codes.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

The induced-combustion boiler can be common vented with a

water heater. (See Fig. 11.)

REMOVAL OF EXISTING BOILER FROM COMMON VENT

SYSTEM

1. In replacement installations where an existing vent system

may be used, inspect the vent system for condition, size, type

of material, and height to meet the appliance application

requirements. If it is oversized, condensation could corrode

the venting system. Installation of a new venting system may

be required.

2. When removing an existing boiler from a venting system

serving other appliances, the vent system is likely to be too~

large to vent the remaining attached appliances properly.

The following steps shall be followed with each appliance

remaining, connected to the common venting system placed in

“operation7while-the"otherappliances-remaining-connected-to-

the common venting system are not in operation:

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, conosion and other deficiencies which

could cause an unsafe condition.

c. Insofar as is practical, close all building doors and windows

and all doors between spaces in which appliances remain

ing connected to the common venting are located and other

spaces of the building. Turn on clothes dryers and any

appliance not connected to the common venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum speed.

Do not operate a summer exhaust fan. Close fireplace

dampers.

d. Follow the lighting/operating instructions. Place the appli

ance being inspected in operation. Adjust thermostat so

appliance will operate continuously.

e. Test for spillage at the drafthood relief opening after 5

minutes of main burner operation using the flame of a

match or candle.

f. Mter it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning

appliance to their previous conditions of use.

g. If improper venting is observed during any of the above

tests, the common venting system must be corrected. The

vent system or vent connectors may need to be resized

-----

according-to-these-instruetions-to-approaeh-the-minimum—

sizénñsiñgfKeTppWpfiáté^GAMA'Vehting Tables7Paft 7 bf~

the National Fuel Gas Code NFPA 54-1988/ANSI Z223.1-

1988.

-ELECTRICAL-

IMPORTANT: Before proceeding with the electrical connections,

make certain the volts, hertz, and phase correspond to that

specified on the boiler rating plate. -

The specific unit Installation Instructions contain wiring diagrams

which show the proper field high- and low-voltage wiring. Make

all connections in accordance with the National Electrical Code

and any loeal codes or ordinances that might apply.

The boiler, when installed, must be electrically grounded in

accordance with the National Electrical Code, ANSI/NFPA No.

70-1990.

A permanent, separately fused electrical power supply, complete

with manual disconnect switch, must be provided for this unit.

Page 7

If a manual disconnect switch is to be mounted on the appliance,

select a location where a drill or fastener will not contact electrical

or gas components.

NOTE: Use only copper wire between the disconnect switch and

the unit.

Check all electrical connections (both factory and field) for

tightness. Recheck tightness of electrical connections after the unit

has reached operating temperatures.

Step 1—Filling The Boiler

Check to be sure that all connections have been made. Before

atternpting any operations, fill the system with water.

A CAUTION

I Never light a burner under an empty boiler.

1. Close air vents on all radiation units,

2. Open water supply valve on each radiation unit.

3. Close drain cock and air bleed screw on boiler expansion tank.

4. Open valve in line from boiler to expansion tank.

5. Open water inlet valve to boiler and leave open.

6. Starting with lowest radiation unit, open air vent.

7. Working from the lowest to the highest radiation unit, repeat

item 6 until you have vented every radiation unit in the

system.

NOTE: Systems with an automatic vent on each radiation unit

will not require manual venting.

8. Check temperature/pressure gage. It should read between 10

and 15 psig.

9. Check system piping connections for leaks.

START-UP AND ADJUSTMENTS

NOTE: Safe lighting and other performance criteria were met

with the gas manifold and control assembly provided with the

boiler when it underwent testing as specified in ANSI Z21.13b-

1991.

Check to be sure that all connections have been made. Before

attempting any operation, fill thé system with water. For steam

boilers, fill to the water line. Never light a burner under an empty

boiler.

CHECK PILOT TO BE SURE THAT ALL CONNECTIONS

HAVE BEEN PROPERLY MADE.

Light the pilot, using the procedure outlined on the lighting

instruction plate attached to the boiler.

___________________

A CAUTION

The boiler is equipped with an intermittent-type ignition

device that functions during each thermostat on cycle. DO

NOT USE MATCH OR OTHER OPEN FLAME TO LIGHT

-pilot:

flame should not touch the boiler section. If the pilot flame

does not have the appearance as described, it can be adjusted.

a. The gas valve is equipped with an adjustable screw.

Remove capscrew to expose adjustable screw. Turn screw

until flame has desired appearance.

b. Replace capscrew.

A WARNING

The boiler is equipped with an intermittent ignition device

(IID). Check the safety pilot operation as follows; Attach a

low-voltage test light to the electrical leads of the gas valve at

terminals marked 1 (or TH) and 2 (or TR). With the

thermostat set above room temperature (pilot and main

|

burners operating), turn OFF the gas supply to burners and

pilot with main shutoff valve. If the test light goes out within

45 sec, the safety pilot is functioning properly. If the light

, does not go out within 60 sec, replace the safety pilot. Place

the boiler in normal operation by following the lighting

instructions on the boiler.

GAS INPUT-DETERMINE THE GAS INPUT

1. Natural gas

a. Turn off all other gas appliances and pilots.

b. Measure time (in sec) for gas meter test dial to complete 1

revolution.

c. Refer to Table 5 for cu ft of gas per hr.

d. Multiply cu ft/hr X heating valve' of gas. Obtain heating

valve of gas from local gas utility.

EXAMPLE: .

Btu heating input = Btu/cu ft x cu ft/hr

Heating value of gas = 1070 Btu/cu ft

Time for 1 revolution of 2-cu ft dial = 72 sec

Gas rate = 100 x 1070 = 107,000 Btuh

e. The measured gas input should not exceed the gas input

shown on the unit rating plate.

f. Observe manifold pressure. It should be adjusted to read

3.5- ±0.3-in. wc. Adjust pressure by using an adjusting

screw in the gas pressure regulator stem. (This screw is

concealed under the regulator sealing cap.) Turn screw

clockwise to increase pressure and counterclockwise to

decrease pressure.

-Small-changes~ihHnput-can-be-made--by-changing-the-manifold“

pressure as previously described. However, the manifold pressure

should not vary more than 0.3-in. wc from the rated pressure.

A further change in gas rate can be accomplished, if necessary due

to high altitude, by changing the fixed orifice at the burners.

___________________________

1. If the gas supply line was not purged before connecting the

^^=^boilerrit‘will“be~full'of'aii77'is'it"would'talce^long time to vent

this air through the small pilot port, it is recommended that

pilot supply line be disconnected and be allowed to purge until

the odor of gas is detected. Never purge gas lines into the

combustion chamber. Iinmediately upon detection of gas

odor, reconnect pilot supply tube. Allow 5 minutes to elapse,

then light pilot using the procedure outlined on the lighting

instruction plate attached to the boiler.

2. The pilot flame should be soft blue in color and should be

checked periodically. The flame lies under the carryover ports

■ of burners and merges with the carryover flames. The pilot

A CAUTION

I Do not under any circumstances redrill orifices.

2. Propane gas models

a. These units are equipped with pressure regulators. The

burner orifices are sized to give rated input at a manifold

pressure of 10-in. wc. Check manifold pressure and, if

necessary, adjust pressure.

3. High altitude ratings are approved for altitudes to 2000 cu ft

for all gases. Ratings for altitudes over 2000 ft are 4 percent

less for each 1000 ft above sea level.

________________

Page 8

Table 5—Gas Rate Cu Ft/Hr

SECONDS

FOR 1

REVOLUTION

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42<

43

44

45

46

47

48

49

SIZE OF TEST DIAL

2

1

cu.ft

cu ft

360 720 1800

327 655 1636 51

300 600

277 555

514

257

240 480

450

225

424

212

200 400 100

189

180 360 900

171

164

157 .

150 300 750

144 288

138

133

129 257

124 248

120 240 600

116 232

113 225

109 218 545 86

106 212 529

103

100 200

97 195

95

92 185

90

88

86

84

82 164

80

78

76

75

73

1059

379 947

343 857

327 818 64

313 783 66

277.

267

, 643 76

621 78

581 82 44

563

206

514 90

500 92

466 94

189 474

462 98 37

180

450 100 36

176 439 102 35 71 .

172 429 104

167 419 106 34

409 108

160 400 110

157- 391 112 32

153 383 116 31

150 375 120 30

147 367

SECONDS

FOR 1

5

REVOLUTION

cu ft

50

1500 52 69

1385 53

1286

1200 55

1125 56

720 70 51

692

667

54

57

58 62 124

59

60

62 58

68 53

72 50

74 48 97

80 45

84

88 41

96 ■ 38

MAIN BURNER FLAME — The main burner flame should be

clear blue, almost transparent, with a well-defined inner cone. If

there is too much primary air, the flame will be well defined, but

with a tendency to float or lift off the burner ports. (See Fig, 12.)

OUTER MANTLE

OUTER CONE

INNER CONE

SIZE OF TEST DIAL

1

2 5

cu ft

cu ft

144

72

71

141 355

136 346

68 136

67

133 333

65 131 327

64 129

63 126 316

61 122

60 120 300

116 290

56

112 281

54

109 273

106 265

103 257

100 250

47

95

46 92

90 225

88 220

43

86

42

84 209

62 205

40

80 200

39 78 196

38 76 192 ■

75 188

74 184

72 180

35 69’ 173

33 67 167

33 65

.178 ■

68 170

64 161

62 155

60 150

A86002

Fig. 12—Proper Flame Appearance

____

IHERM.QS.TAT-HEAT=ANTIGIPATQR-GHEGK--------------------------^------The thermostat heat anticipation must be set to match the amp

draw of the gas valve and electrical components in the R-W circuit.

cu ft

360

340

321

310

305

243

237

231

214.

164

THEHHOSTAT y I

TERMINALS

---------

H ® ® ® © I

HOOK-AROUND

VOLT/AMMETER

10 TURNS AROUND JAWS

= 0.5 AMPS FOR THERMOSTAT SETTINO

A80201

Fig. 13—Amp Draw Check With Ammeter

CARE AND MAINTENANCE

A CAUTION

Because of possible damage to the equipment or personal

injury, maintenance should be performed by qualified persons

' only.

A WARNING

Never store anything on, or in contact with, the boiler, such

as;

Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners, or other cleaning tools.

Soap powders, bleaches, waxes, or other cleaning com

pounds, plastic or plastic containers, gasoline, kerosene,

cigarette lighter fluid, dry cleaning fluids, or other volatile

fluids.

Paint thinners and other painting compounds, paper bags, or

other paper products.

For continuing high performance, and to minimize possible

equipment failure, it is essential that periodic maintenance be

performed on this equipment. Consult your local dealer as to the

proper frequency of maintenance and the availability of a mainte

nance contract.

The ability to properly perform maintenance on this equipment

-requires-eertain-mechanical-skills-and'toolsrlfyoTTdoTiot possess'

"these skiliraiidlodls, contact'your dealer for maintenance.

A WARNING

Turn OFF gas and electrical supplies to the unit before

performing-any maintenance or service. Follow the relighting

instructions ou-the-plate-attached-to-the-boileri

--------------------

—

terminals R and W. Fig. 13 illustrates an easy method of obtaining

the actual amp draw. The amp reading should be taken after the

pump motor has started.

FLUE PASSAGES — Flue passages between the sections should

be examined yearly and cleaned as required.

BOILER CONTROLS — Check all boiler controls for proper

operation at the start of each heating season. If the boiler is

operated year-round, check the controls at least every 6 months.

DRAINING BOILER — Do not drain the boiler between heating

seasons. In fact, the boiler should never be drained, flushed, or

boiled out unless it is absolutely necessary.

LEAKAGE — Make certain that there is no leakage in the system

at any time.

Page 9

FLUE — Inspect the flue connection and chimney annually to

make sure they are in good condition and have not become

obstructed.

CIRCULATOR SYSTEM LUBRICATION ' - The circulator is a

water self-lubricating type and does not require any further

lubrication.

Step 1—Cleaning The Boiler

1. Remove burner access door.

2. Remove burners and pilot.

3. Remove vent pipe.

4. Remove top panel and swing aside.

5. Remove flue collector.

6. Use flexible handle wire brush to clean passageways. (See Fig

14.)

7. Using vacuum cleaner with soft brush attachment, clean

burners. After cleaning, reinstall burners and pilot.

8. Reassemble boiler.

A66289

Fig. 14—Cleaning Boiler Passageways

Page 10

LINE-TO-LINE WIRING DIAGRAM

If any of the original wire as supplied with the boiler must be replaced, it must be replaced with the same type wire or its equivalent.

o

TJ

>

o

3]

m

3J

o

TJ

=. (O

3. a

œ A«

5‘

C •

Ò) d:

> i

3 ?

w

IÒ

CO

<5 â

-

X (O

fi> íL

o —

o (Q

2

4^

HOT

PRESSURI

SWITCH

INTERMITTENT

PILOT CONTROL

NEUTRAL

TO GAS VALVE

NEUTRAL

HOT _

FUSED

DISCONNECT

120/60/1

POWER SUPPLY

PRESSURE

swrrcH

24-V THERMOSTAT

L8148A AQUASTAT

DRAFT INDUCER

] AT 140C TRANSFORMER

S’ ^

Û > -5,

iiaOw S

B

^ of

ROLLOUT

SWITCH

VR8204A/VR8304M

GAS VALVE

5i 6

G

--------

UNE-VOLTAGE WIRING

--------

LOW-VOLTAGE WIRING

--------

LOW-VOLTAGE FIELD WIRING

B - BLACK

BT - BLACK WITH TRACER

W-WHITE

G - GREEN

R - RED

O- ORANGE

INTERMITTENT PILOT

bC

oc

CONTROL

á

S8600F - NATURAL GAS

to

S8600M - NATURAL OR

TO PILOT

pv

MV;PV

MV

PROPANE GAS

Fig. 15—Boiler Wiring Diagram

A92408

Loading...

Loading...