Page 1

Carrier

installation instructloos^

Compressors and Condensing Units

Open, Water-Cooled

COMPRESSOR AND CONDENSING UNIT PHYSICAL DATA

*A!so used for low pressure oil line

connection.

¡This bank of cylinderson 5F30 only

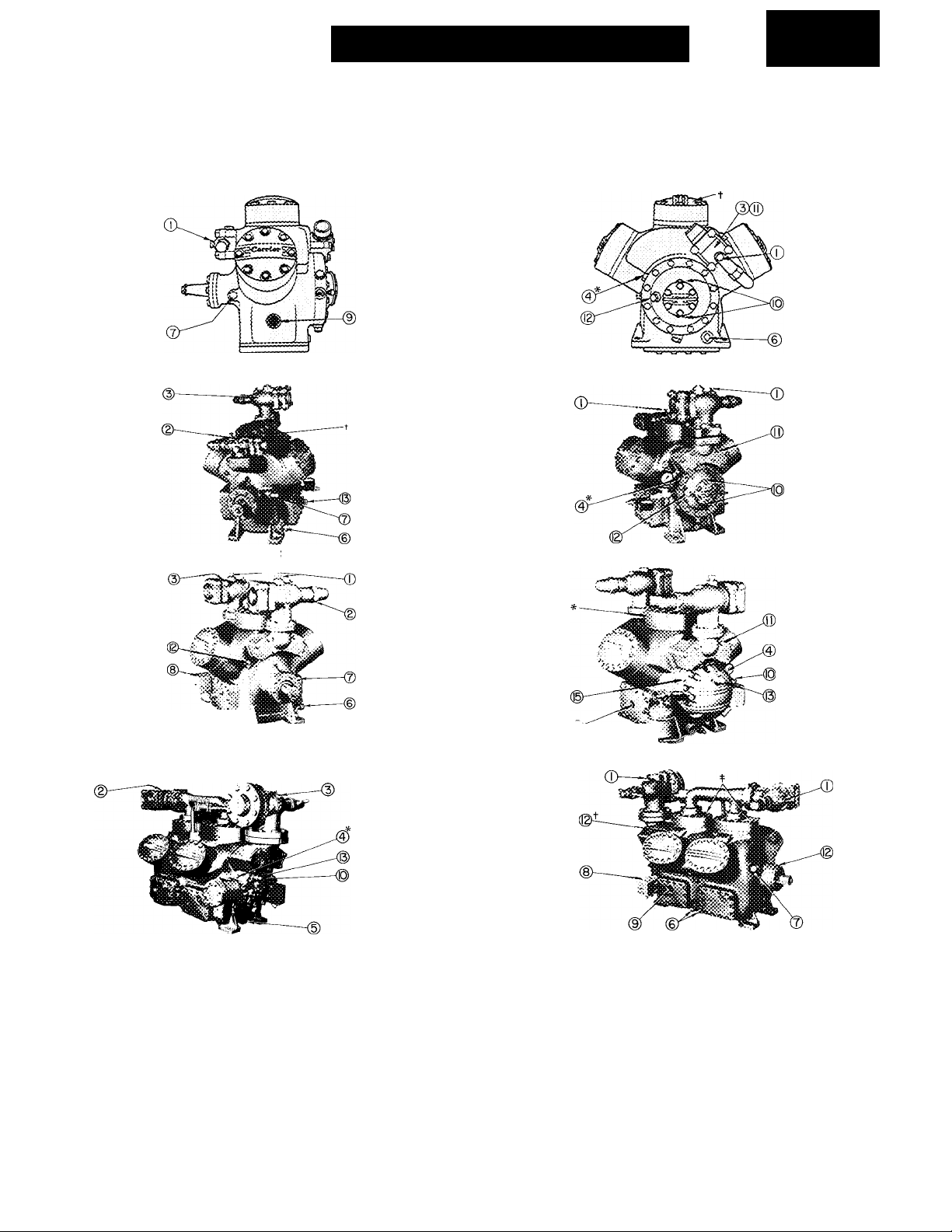

Fig. 1 - 5F20, 2-Cyl and 5F30, 3-Cyl Compressors

5F,H

*Also used for low pressure oil line

connection.

IThis bank of cyl inders on 5F60 only.

Fig. 2 - 5F40, 4-Cyl and 5F60, 6-Cyl Compressors

*This bank of cylinders on 5H60 and

66 only. @r

Fig. 3 - 5H40, 46, 4-Cyl and 5H60, 66, 6-Cyl Compressors

*Also used for lo^ pressure oil line

connection on 5Hl20 and 126.

["SHSO and 86 only.

IThese banks of cylinders on 5H120

and 126 only.

Fig. 4 - 5H80, 86, 8-Cyl and 5H120, 126, 12-Cyl Compressors

COMPRESSOR KEY

Gage connection 1/4-inch IPS.

(2) Discharge shut-off valve. (See Physical Data for size.)

Suet ion shut-off valve. (See Physical Data for size.)

Oil fi Iler plug

Crankcase drain (5/8-inch -18 plug on all 5F compressors,

shut-off valve on all 5H compressors)

Crankcase heater casing

© Oil pressure regulator

© Carrier Corporation 1968

Dual pressurestat.

Oil level sight glass

Oil pump rotation arrows

(iT) Suction valve, manifold or manifold cover. Remove for access

to suction strainer.

Oil pressure connection 1/4-Inch IPS (high pressure).

Capacity control adjustment.

@ Oil Filter

(l^y Oil pressure connection 1/4-inch IPS (low pressure).

5F,H-1SI

Page 2

C (in. OD) Disch

Table 2 - Compressor Connections

COMPRESSOR

CONN. Suet

20

1-1/8

7/8

5F

^30] 40

1-5/8 2-1/8

1-5/8

1-3/8

60

40,46'^

2-5/8

2-1/8

Table 3 - Min Rpm for Capacity Control

and Lubrication

60,66

3-1/8

2-5/8

5H

80,86 120,126

3-5/8 4-1/8

3-1/8 3-5/8

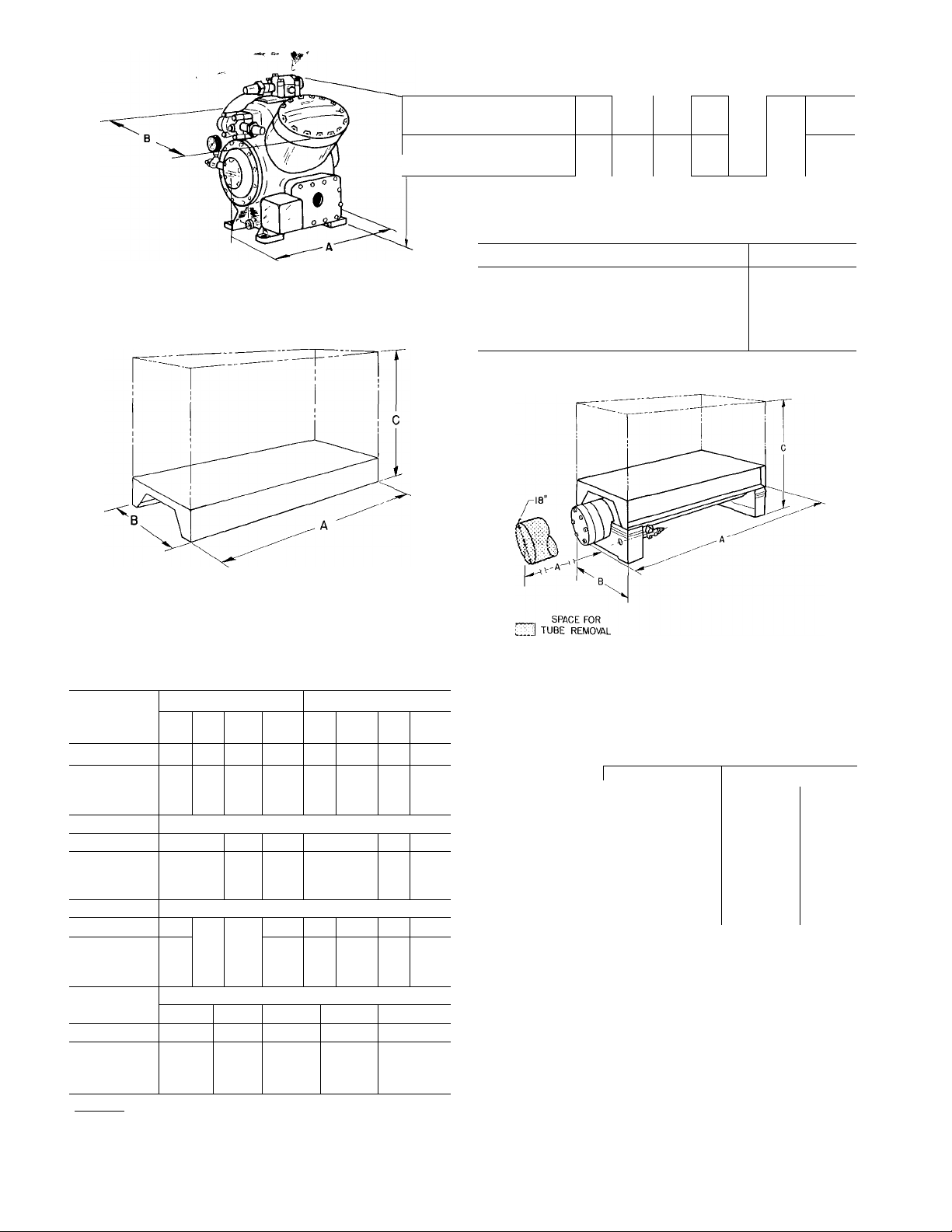

Fig. 5 - Bare Compressor

Fig. 6 - Belt Drive, Direct Drive and

Duplex Compressor Unit

Table 1 - Compressor Physical Data

BARE (Fig. 5)

5F 5H

COMPRESSOR

WT (lb) 175 215 355

DIM. ^

(ft-in ) “

WT (lb) 260 i 300- 515

DIM ^

(ft-in.) ^

c

WT (lb)

DIM p

(ft-in.) “

COMPRESSOR

WT (lb) 2210

DIM 3

(ft-in.)

; 1 Compressor units (except 5H80) with slightly different

dimensions and horsepower requirements are available to accom

modate oversize condensers and motors See certified prints for

dimensions.

*Belt drive units not available for 5H46,66,86 and 126 sizes

A

30 40 60

20

1-6

1-3V,

1-6%

1-6%

3-2 !3-3

1- 9%: 1-9%

2- 5 (2-4%

-

-

40/60

8-7%

2-8%

3-4%

1- 9%

1- 7

1-8%

1- 8%

1-6

3- 9%

2- 2%

2- 1%

m

3-11%

1- 9%

2- 1%

60/80 80/80

2713 3225

9-2%

2-8%

3-6%

BELT DRIVE* * (Fig 6)

DIRECT DRIVE (Fig 6)

5H DUPLEX (Fig. 6)

40,

60,

46

66

400

610 795 1115 1580

2- 7%

2-6%

1-11%

1- 9

2-0%

2- 0%

600

3- 9%

2- 2%

2- 6%

565 880 1065 Î7ÎÛ

4- 0%

1- 9%

2- 6%

10-10%

2- 8%

3- 6%

2- 3%

2-5

2- 5%

915 1 Î095

4-8%| 4- 9%

2-8%| 2-10

3-l%j3- 2%

4-9%

4-10%

2- 3%

2-0%

3-1%

3- 3%

80/120 120/120

3840 4305

11-5%

2-8%

3-9%

80,86120,

126

3-11

3-7%

2-0%

2- 3%

2-10%

2-8

1650 2215

5-6%

5- 7%

3-9%

3-11%

3- 4%

3-6%

2210

6-4

6- 7'.,

2- 7%

2- 7%

3- 7%

3- 9%

11-10%

2- 8%

3- 9%

COMPRESSOR

5F20

5F30

5F40; 5H40,46; 5H40/60

5F60; 5H60,66,120,126; 5H120/120

5H80,86; 5H60/80,80/80,80/120

EITHER END

RPM

600

700

800

900

1100

Fig. 7- Direct Drive, Belt Drive Condensing Unit

(Table 5)

Table 4 - Condenser Water Connections

(in. FPT)

CONDENSER

5F20

5F30

5F40,60

09RH027

09RH043,054,070

09RH084,097

09RH127

*Two connections required.

tMPT

UPS

MAX PASSES MIN PASSES

In and Out

1/2

3/4

1-1/4 1-1/4 1-1/2

2 2 2-1/2

2 2

2-1/21 2-1/21

3t

In*

1/2

3/4

31

Out

11

11

3

41

51

INSPECT SITE

Provide Clearance for removing cylinder heads

and valve plates. Allow space on pump end for

crankshaft removal. Space for 5F20,30,40,60,

5H40,46,60 and 66 is 20 inches; for 5H80,86,120

and 126, 30 inches.

Space at end of condenser must be equal to

length of condenser to facilitate tube removal

and cleaning.

L

Page 3

Table 5 - Condensing Unit Physical Data (Fig. 7)

DRIVE

COMPR

COND

WT (lb)

DIM.

(ft-in.)

DRIVE

COMPR

COND

WT (lb)

DIM

(ft-in.)

DRIVE

COMPR

COND

WT (lb)

DIM.

(ft-m.)

DRIVE

COMPR

COND

WT (lb)

DIM.

(ft-in.)

20

385

A

3- 2V,

B

C

054

2390

A 7-lTA

2-lOV,

B

C

4- 0%

60

1060

A

6- 2

B 1- 9%

C 3- 2V,

; 054

2930

A

B

C

5F20

30 20 30

425 430

3-4%

1-

9%

2- 5

3-2%

5F30

40*

460 830

3- 4%

5- 3

1--9% 2- 3 2- 3

2

-4%

2- 9%

5H60 5H80

054T (070 043

2710 2845 2990 3050 3385 3690 3589 3664 3955 3240

2650

7-11%

3-

8%

4-

3%

5F60

027 027 043

1605 1890 1890 2025

1385

6- 7% 7-11%

5H40

054

043

6-5 6-5 6-7% 6- 7%

2-0% 2-2 2- 2

3-9%

3-4%

3-11% 3-11% 4- 0%

5H80 5H86

; 070

7-11%

2-

6%

084 097

2990 3315

8-3%

4-

-5%

3620

10- 3% 7-11%

2

-9% 2- 6%

070

2990 3315 3620 4230

4- 5%

BELT

30 40

790 960

4-3% 5-3

2-10%

5F40

60 40

1050

6- 2 5- 3

1070

5F60

60 60 027

1230

6-2~' 6-2

2-

3%

3-

1%

BELT

070

084 097

8-3%

10- 3%

054

070 ; 084

7-11%

3-9%

4-5% 4-

DIRECT

5H46 5H60

054

070 043

2095 2025 2190

7-

11%

6- 7% 7-11%

2- 4%

064 '

070

2740

2-

4%

4-

0%

DIRECT

084 097

127

070

: 084

3570 3870 4130 4740

8-3%

4-3%

10-3%

2-

7%

4-6% 4-10%

8- 4%

2-10%

7-11% 8-3% 10-3%

2- 5%

4- 8%

5H40

1500 1715

6- 5 6- 7% 6- 5

2-8%

3-8% 3- 9% 3-11%

5H120

097

8-3%

3-

11%

10- 3% 5- 3 6- 2

8%

084

2800

054

2190 2740 2800 3105

8-3% 72-7%

4-3%

24-

5H120

097

127 097 127 -

8- 4%

2-

7%

4-

8%

2-10% 2- 7%

5- 0%

5H60

043

027 ; 043

1955 1925 2165

2-10%

3-10% 4-0%

DIRECT

5F40

40 60

880

970

1-

9%

2-10%

5H66

070 ; 084

11%

8- 3%

4%

0%

4- 3%

5H126

4130 4740

10- 3% 8- 4%

2-10%

4- 8%

5- 0%

2-

6-7%

-

-

-

-

-

097

10-3%

7%

4-4%

-

-

-

-

-

I ) 5F Condenser No.

*Special order only.

tFor 60- and 75-hp motors.

COMPR

COND

CONN.

Suction

Liquid

COMPR

COND

CONN.

Suction

Liquid

COMPR

COND

CONN.

Suction

Liquid

• 07öT c8<ä i 097 : 070 i 084 i 097 i 127 • 054 T 070 ; 084 i 097 j 127 : 097 1 127

J 5F Condenser No.

*For 60- and 75-hp motors.

09RH Condenser No.

Table 6 - Condensing Unit Refrigerant Connections (in. OD)

5F20 5F30

20 1 30 20

1.30 1

40 30 1 40 1 60 40 1 60 i 027 • 60 !

1% 1% 1%

% % 1 %

5H46

043 i 054 ! 070

1 5H60

1 027 1 043 054 i; 054* 1

2% 3% 3%

1% 1 1% 1% 1 1%

5H80

5H86 1 5H120

3% 3%

1% 2% 1% 2% 1% 1 2%

09RH Condenser No.

5F40 5F60 5H40

% i % 1 1% % 1 1% 1 1% 1% 1 1%

070

084 ^ 054 i :070v 084 i

1 2%

2%

4%

1 5H66

1%

1_ 2%

027 1 043

2%

m : 043

1 5H126

_

-

-

1 5H80

054

3%

1% 1%

-

4%

2Vs

Page 4

Machine Room Temperature and Ventilation -

Locate compressor or condensing unit in well

ventilated space. Check code requirements. Pro

vide forced ventilation thru ductwork when natural

ventilation is inadequate.

Protect water-cooled condensers, water lines,

and accessories from freezing during winter

shutdown periods.

PREPARE FOUNDATION

Fasten compressor to: (a) steel base and vibra

tion isolators on floor; (b) steel base and condenser

support stand or (c) concrete base.

Floor Foundations - Locate compressors over

joists or beams wherever possible.

Weak floors in old buildings must be reinforced

with steel beams or timbers to support the heavy

compressors or condensing units. Use care in

placing supports to avoid transmitting objection

able vibrations to other areas.

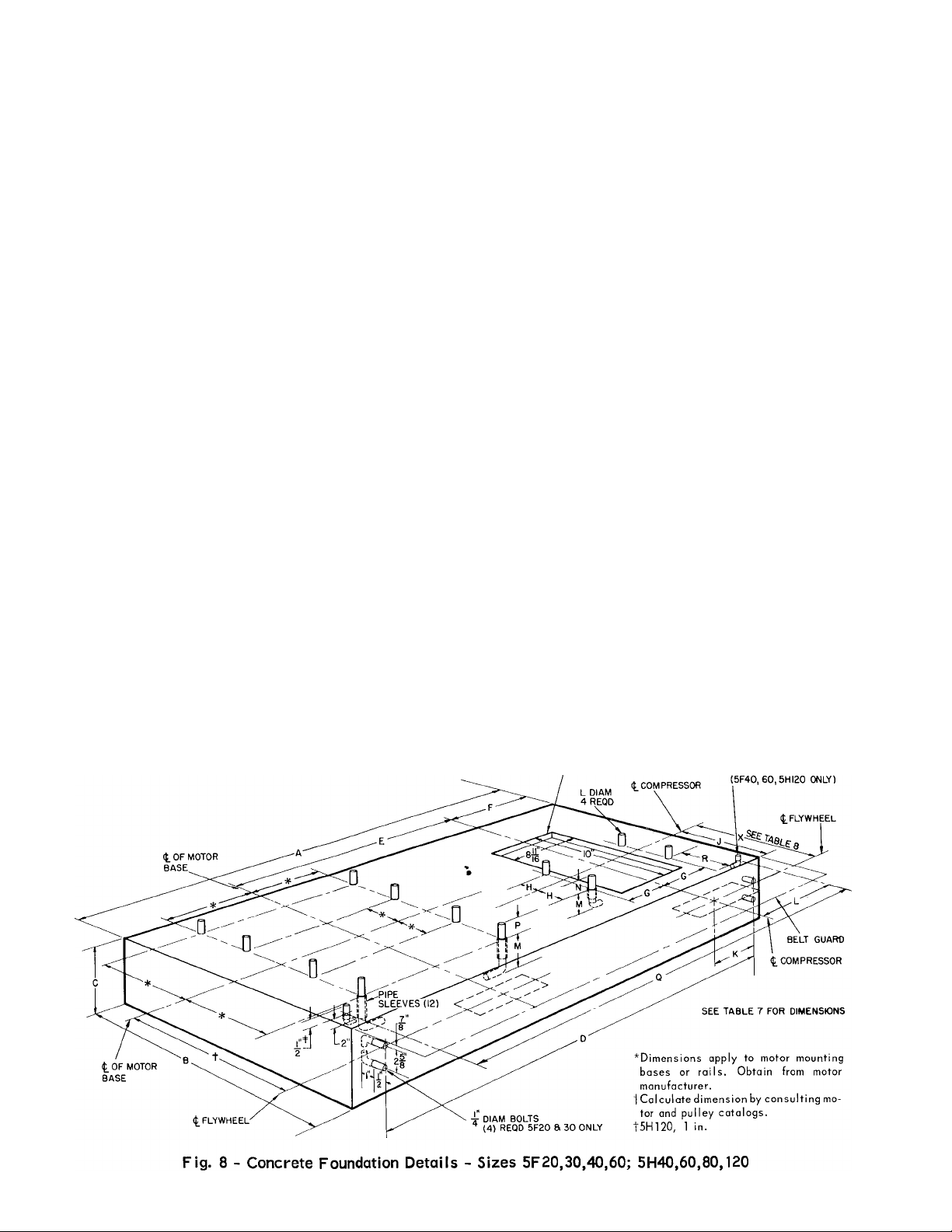

Concrete Foundations one to two times the weight

of the machinery they support will absorb vibra

tion. See Fig. 8 and Tables 7 and 8 for recom

mended dimensions. Let foundation set sufficiently

before compressor is installed (approximately 3

days). Allow for 3/8 inch to 1/2 inch grout after

compressor is installed.

Heavy aggregate concrete weighs about 150

pounds per cubic foot.

INSPECT UNIT

Inspect shipment for damage or loss. File

claim immediately with shipping company for any

loss or damage.

Move and rig unit carefully to prevent damage

to gages, mounting brackets, refrigerant piping

and connections.

COMPRESSOR INSTALLATION

Compressor on Steel Base and Vibration Isolators

on Floor — Install vibration isolators on one end of

unit at a time. See Fig. 9 for typical vibration

isolator mounting.

Motor fastening set supplied with all com

pressors (except 5F20,30) includes several beveled

washers. Washers are installed under heads of

capscrews used to fasten unit base to vibration

isolators or floor.

Position compressor and motor on frame and

check height of vibration isolators. Shim between

vibration isolators and floor to level compressor

base Secure vibration isolators to floor. If beveled

washer (Fig. 9) is omitted, end of capscrew may

strike the floor and cause vibration isolator to

rupture when it is secured to floor.

Condenser and Stand Assembly - Place cast iron

condenser stands in their correct location. Make

distance ”C" (Fig. 10) between tapped holes on

top of stand equal to holes in lower flange of com

pressor unit base. See Table 9 for dimensions.

Shipping caps are soldered to the 5F20,30,40

and 60 condensers at the factory. To remove caps

turn condensers upside down. This prevents solder

from falling into condensers.

Bolt lower support strap loosely to lower side

of each condenser stand.

Place condenser on stands with front water

head at compressor end of base. Position con-

L

569

DEPRESSION FOR COMPRESSOR

BOTTOM PLATE 5F30 ONLY

CORNER BOLTS (2)

Page 5

Table 7 - Concrete Base Dimensions (Fig. 8)

DIMEN

20 1 30 40

(in )

A 36

В

C

7 1 9

D 33-1/8

cr

t

F 8

G

H

20.2*

19.31

2-7/8 6

J 5-l/32|6-15/16

к 9-9/16

L 1/2

м

N 1-1/2

P

Q

R

*1450 rpm.

1 1750 rpm.

5F

60

40 60

48

19 26 28 30

10

45 - -

25.5*

26.6t

5

6-23/32

9-1/2 10-1/2 11-1/2 12

7-1/8 -

3 4

_

-

2

1-3/4

45

...2

53 57

13

30.7

32.21

10

5-1/2

7-3/4

1-3/4

2-1/4

-

- -

*

8-1/2

14

5/

-

80

60

40

15

38.2*

36.71

14-1/2

5-1/2

14-1/2

16-1/2

2-1/2 [

2-1/2

6

120

71

37

16

66

18-1/2

12

66

1-3 M

Table 8 - Distance Between Compressor and

Flywheel Centerlines (Fig. 8)

COMPR

SIZE

5F20

5F30

5F40

5F60

5H40

5H60

5H80

5H120

MOTOR

HP

5,7-1/2,10 1750 & 1450 (2)

5

7-1/2

7-1/2

10,15

7-1/2,10,15,20 1750 & 1450

10,15,20

10,15,20,25 1750 & 1450

20,25,30,40,50

30,40,50 1450

30

30

40,50 1750 & 1450 (5)

60,75

40,50 1750

40,50 1450

60 1750 & 1450 (6)

75 1750 (6)

60,75

100 1750

60

60

75,100 1750 & 1450

COMPRESSOR

RPM

1450

1750

1450

1750 & 1450

1750 & 1450

1750 & 1450

1750 & 1450

1450

1750

1450

1750

1450

BELTS

(No.) Size

(2)

(3)

(3)

(3)

(4)

(3)

(5)

(3)

(5)

(5)

(5)

(6)

(9)

(9)

(9)

(9)

(9)

D1MEN X

(in.)

В

7-15/16

В 9-21/32

В 10-31/32

В 10-3/4

В

11-7/16

В

11-13/16

С 13-3/8

13-3/4

С

С 14-1/8

14-1/2

С

14-1/2

С

14-1/2

С

20-1/2

С

18-5/8

С

С 18-5/8

18-5/8

С

С 21-3/8

с 21-3/8

20-5/8

с

21-1/2

с

21-1/2

с

Fig. 9 - Typicai Vibration Isolator Mounting

UPPER STRAP

FABRICA STRIP

' IPS VENT PLUG

WATER CONN. INLETS FOR 4-PASS

(5F40,60); 3-PASS ON 09RH

BOTTOM FOR INLET, TOP FOR

OUTLET FOR 8-PASS (5F40,60l;

6-PASS ON 09RH

WATER CONN

OUTLET

FOR 4-PASS

(5F40,60) 3-PASS

09RH. PLUG FOR

6-PASS AND 8-PASS

NAMEPLATE

denser so hot gas inlet is on top and ends over

hang stands same distance on each end.

condenser.

Compressor on Steel Base and Support Stand -

Place compressor unit on top of condenser stands

and bolt into place with capscrews and lock

washers provided.

HOT GAS INLET

Assemble upper straps loosely around the

' TAPPED MOUNTING

■.y,. HOLE

RELIEF VALVE 385 PSIG ON

5F40.60 AND ALL 09RH *

WATER PRESSURE REGULATOR CONN

LIQUID SHUT-OFF VALVE

TAPPED MOUNTING HOLE

CONDENSER STAND

LOWER STRAP (MOUNTED TO UNDER

SIDE OF CONDENSER STAND)

*5F20 AND 30 HAVE FRANGIBLE DISC

Fig. 10 - Typical Assembled Condenser Package

5

Page 6

Table 9 - Dimension "C" (ft-in.) (Fig. 10)

COMPR

20

30

5F

40

60

60*

40

46

60

66

60*

5H

66*

80

86

120

126

*Overs bas

J

Belt

2-8-3/8

2- 8-3/8

3- 7-7/8

3- 7-7/8

4- 2-3/4

4-2-3/4

4-7-3/4

4-7-3/4

Loosely connect compressor discharge line

and adjust condenser position so discharge line

is in line with condenser inlet. Assemble discharge

lines for 5H Series compressors as shown on

special diagram sheet included in 5H condenser

piping packages. Before making joints, try coup

ling or belt guard to ensure piping clearance.

Place strips of Fabrica provided between lower

support straps and condenser. See Fig. 10.

Tighten lower strap enough to lift condenser

off stands.

Sweat discharge line to condenser. Adjust con

denser position as required to prevent distortion

of discharge line. Instructions are included in the

piping assembly package.

DRIVE

Direct

3-7-7/8

3- 7-7/8

4- 2-3/4

4-2-3/4

4-2-3/4

4-2-3/4

4-2-3/4

4-5-1/2

4- 5-1/2

5- 9-3/4

5-9-3/4

5-9-3/4

5-9-3/4

CRANKCASE HEATER

Energizing crankcase heater helps prevent oil

and refrigerant from mixing and accumulating in

crankcase when compressor is off.

Wire heater to relay or set of normally closed

contacts in compressor starter so it will be de

energized when compressor is operating.

Installation of Heaters- Remove rubber plug from

crankcase heater casing (see Fig, 1 thru 4).

Insert heater element entirely into casing.

Element should fit snugly, not loosely.

Wire in accordance with local codes and dia

gram (Fig. 11).

Relay Coil voltage is determined by control cir

cuit voltage which must be specified when ordering

relays.

Mount relays vertically.

When crankcase heater is installed, system can

operate on a single pumpout cycle as shown in

schematic. Fig. 11.

Crankcase heater packages are given in Table

10 and corresponding relay is in Table 11. When

two heaters are usedona 5H80or 120 compressor

only one relay is required.

Place Fabrica strips (see Fig. 10), between

condenser and upper straps. Tighten strap bolts

to secure condenser to stand. NOTE; Use lower

straps only for 5F20 and 30 units. Place the two

extra strips of Fabrica between top of condenser

and base. Assemble discharge line as described

above.

Compressor Bolted to Concrete Base - See Fig. 8.

Set compressor level on foundation bolts. (Level

in two directions.) Removal of discharge shut-off

valve exposes face of mounting flange on com

pressor which can be used as a leveling pad. Lo

cate and level motor slide rails. Provide for 3/8

inch to 1/2 inch grout. Tighten foundation bolts

handtight. Do not use wrench.

Wet top of concrete, pour grout and tamp to

fill all spaces between machinery and concrete.

Allow grout to dry slightly then trowel smooth.

Suggested mixture for grout is one part Port

land cement to two or three parts of sharp sand.

Tighten foundation bolts moderately tight when

grout has hardened for 24 to 36 hours. Overtight

ening bolts may cause compressor misalignment.

NOTE; Auto-suction stop valve (flooded systems only)

— Compressor

c

CH — Crankcase Heater

HPS — High Pressure Switch

— Liquid Line Solenoid

LLS

EPS — Low Pressure Switch

- Overload

OL

PS — Pressure Switch

- Relay

R

T — Thermostat

Terminal Connections,

□

Marked

Component Connection,

o

Unmarked

Component Connection,

0

Marked

—

dd W

iring

Fig. 11 - Wiring Schematic Single Pumpout Cycle

Page 7

Table 10 - 5F,H Compressor Crankcase

Heater Package

ELECTRICAL

COMPRESSOR

5F20,30,40,60

5H40,46,60,66

5H80,86,120,126

CHARACTERISTICS

Volts Watts

115

230

115

230

115

230

100

100

200

200

200

200

PACKAGE NUMBERS

-5-F—20---------381

-5-F—20---------391

-5-H—40

--------

-5-H—40

--------

-5-J__40-------291

-5-J—40

-------

Table 11 - Crankcase Heater Relay (60-Cycle)

381

391

291

CONTROL CIRCUIT VOLTAGE

115

208/230

PART NUMBER

HN61AJ-101

HN61AJ-108

COMPRESSOR OPERATION

Motor Rotation - Start motor before connecting to

compressor. Rotation direction must be same as

arrow cast on pump cover or plate attached near

pump end bearing housing. To rotate compressor

in opposite direction the manually reversible oil

pump must be reversed as follows:

5H120 AND 126; ALL 5F COMPRESSORS - Remove

6 capscrews from oil pump cover. Do not damage

gasket. Rotate cover 180° and replace. Arrow will

now be on top and show new direction of rotation,

5H40,46,60,66,80 AND 86 COMPRESSORS - Drain

oil below level of end bell cover. Remove end bell

assembly and pump end cover. Rotate cover 180°

and replace. Reverse direction of external arrow

(shows compressor rotation without removing end

bell). Arrow on pump end cover must match arrow

on main bearing housing. Replace end bell and

refill with specified oil.

CAifTJON* it b&twsen oli putnp

cowr stsi oil ï«tnî*> IS- àaîîaagôd, relace xt'with

correct gasket onJy. Check oïî ^CÊinp rotor esá

■ cîearaixce í Checktcéí ■ ísresstfre

íttiíítedxaTeíy aíter ¿starting: cort^eascr.

Oil Safety Switch installation instructions are in

cluded in Oil Safety Switch Packages.

Motor Fastening Set supplied with all compressor

units (except 5F20,30) includes motor blocks and

shims for motor alignment; capscrews, plate

washers and lock washers for fastening motor to

base; taper dowel pins for securing motor position

on base (after alignment); beveled washers for

fastening unit base to vibration isolators or floor.

Install and Align Belt Drive — Clean motor and

compressor shafts, flywheel and motor pulley

bores with fine emery cloth.

Install motor pulley, flywheel and keys tightly

on shafts.

Slide motor forward on rails to install belt. Line

up flywheel and motor pulley with a straight edge

Fig, 12 - Correct Belt Alignment

or string (Fig. 12) or by placing a round rod in belt

grooves. Slide motor pulley on shaft to correct any

parallel misalignment. Loosen motor hold-down

bolts and turn motor frame to correct any angular

misalignment.

Move motor backward with adjusting bolts to

tighten belts. Tighten belts just enough to prevent

slippage.

Determine belt tension by (a) loosening belts

until they slip when motor starts (belt squeals),

then tighten enough to eliminate slippage, (b)

amount belt is depressed at center of span (heavier

belts deflect approximately 1 inch for a 24-inch

span; lighter belts or longer span deflect propor

tionately more)

Install Direct Drive — Instructions for installation

are in the coupling package

Securing Motor to Base — Align motor and

compressor. Drill and ream two holes thru motor

feet and base. Secure motor to base with two

#6 X 2-1/2 taper dowel pins provided in motor

fastening set. Locate holes diagonally opposite

motor feet. Use 9/32-inch diameter drill and #6

taper reamer.

REFRIGERANT PIPING

Refer to Carrier System Design Manual, Part

3 for proper piping techniques.

Venting - Replace vent plugs (front and rear heads)

and drain plug (front head) with nipples and valves

if frequent draining of condenser (water side) is

desired.

Refrigerant Drier - See System Design Manual,

Part 3, Page No. 3-75.

Felt Filter - Install felt filter (supplied with com

pressor) in suction line screen. Remove after 50

hours of compressor operation. If dirty, clean with

kerosene or neutral spirits and replace for another

50 hours operation. If filter is clean, leave it out.

Indicate on tag that filter has been cleaned and

reinstalled.

569

Page 8

Oil Filter should be replaced after 50 hours opera

tion and whenever oil is changed or becomes dirty.

Oil Separator (Optional) - Install separator so its

weight is carried by supports or hangers and not

piping.

Connect separator inlet to compressor dis

charge and separator outlet to condenser. Con

nect oil return line (1/4-inch or 3/8-inch copper

tubing) between separator and compressor crank

case. Make line long enough to be flexible and free

from strain. Connect oil return line to upper oil

and gas equalizer line connection (if available) on

compressor. When two compressors are installed

in parallel, connect oil return line to oil equalizer

line between the two compressors. Install shut

off valve in oil return line to facilitate service and

minimize refrigerant loss.

An additional oil charge is required when an

oil separator is used. Watch oil level and check

separator float valve operation during initial

compressor operation. Follow instructions fur

nished with oil separator.

Compressor Muffler (Optional) - Mufflers are in

cluded in condenser piping packages for all 5H

condensing units. They are recommended for all

remote installations. Install mufflers either hori

zontally or vertically (refrigerant flow downward).

Arrow on muffler indicates flow direction. Place

outlet at bottom in horizontal installations to pre

vent trapping oil. Locate muffler as close as pos

sible to compressor.

Special Handhole Cover Plates (Optional) have

tapped holes for connecting equalizer lines. When

operating compressors in parallel, replace stan

dard covers with special covers. See Fig. 13.

5H120 AND 126 - Tapped cover plate is standard

on 5H120 and 126 compressors. Use only lower

connection for oil equalization. Connect gas equal-

GAS EQUALIZER ■

CpiMNECTION - j . .

|| OD FLANGE --CC

Ì

OIL EQUALIZER

CONNECTION

I" IPS .-.1 i

Fig. 14- Equalizer Connections

(5H120 and 126)

ization line at flange connection. See Fig. 14.

Mating flange for 1-1/8 inch OD is Mueler part

no. A-515; gasket no. A-5152.

5F20 AND 30 compressors have no special tapped

cover plate. Use opening for oil sight glass with

1-1/8-inch line for gas and oil equalization. For

additional equalization, run a 3/8-inch line to oil

fill plug. See Fig. 15.

Fig. 13 - Special Handhole Cover

with Equalizer Connections

GAS

EQUALIZER

CONNECTION

OIL

EQUALIZER

CONNECTION

Cooled Heads - When used, install water-cooled

heads and piping as shown in Fig. 16.

5F20,30,40,60; 5H40,46,60,66,80 AND 86 com

pressors have one water circuit piped to flow in

either direction. See Fig. 16.

5H120 AND 126 compressors have two parallel

circuits with two 1/2-inch IPS water inlet con

nections and one 1/2-inch IPS water outlet con

nection. See Fig. 16.

Install manually operated valve in each water

circuit, adjusted for 100 F maximum leaving water

temperature.

Page 9

Table 12 - Compressor Oil Charge

COMPRESSOR

OIL CHG (pt) 5

f '

itec.

Sr2e>aci

QiiilSA—y^ “~0

/ N

5F20 5F30

5-1/2 12 13

5F40

5F60

erri mres

8UiS-^0

5H40,

5H46

18

5H60,

5H66

21 41

5H80,

5H86

O'

5H120,

5H126

81

Fig. 16 - Schematic Piping for

Water-Cooled Heads

CONDENSER WATER PIPING

Piping - Use piping for maximum pass operation,

Fig. 17, when ample water pressure is available.

Use minimum pass operation. Fig. 18, for low

water pressure or when cooling tower is used.

Water Regulating Valve Adjustment - Set shut-off

point at least 10 F below condensing temperature

to be maintained at maximum load, but not above

90 F. Select shut-off point high enough to close

valve when unit is not operating.

LUBRICATION

Compressors are charged with oil at the fac

tory. Oil quantities are given in Table 12.

Maintain oil level at center of sight glass.

When adding oil, use only a dehydrated, wax-

free refrigeration grade oil of suitable viscosity.

Compressors are charged with refrigeration

grade oil (Carrier No. PP36) for evaporator tem

peratures above -45 F. When evaporator tempera

ture is -40 or below, replace oil with Carrier

No. PP33.

111

cîîifî>'0a>ii>e3?>Kï7

Fig. 17 - Condenser Maximum Pass Connections

WfiMAt. ON COOLiMG TOWSfi;

oas«os4.^as7, iz?

Fig. 18 - Condenser Minimum Pass Connections

1072

Page 10

REFRIGERANT CHARGING

Refer to 5F,H Start-Up and Service Instructions and Carrier

Standard Service Techniques Manual, Chapter 1, for complete

charging information.

Pneumatic Control may be connected to capacity control valve

on all 5F,H compressors except 5F20 and 5F30. A 1/4-inch IPS

connection is located above the capacity control valve on each

compressor.

The capacity control valve is set as described in the Start-Up

and Service book.

The pneumatic control, in effect, resets the control point

upward by the amount of air pressure applied. Do not apply

more than 25 psig. For example, if system suction pressure is 40

psig and the control point setting is 35 psig, an applied air

pressure of 5 psig causes first cylinder to unload.

969

10

Page 11

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 3 5F,H1SI Supersedes 5H 40-1035 Printed in USA 1072 2-68 Codes C and MB Catalog No. 530-516

Loading...

Loading...