Page 1

5F,H

HEATING A COOLING

Open-Drive Compressors

• Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS .................................. 1

INSTALLATION

Step 1 — Prepare for Installation

.......................................................

............................

I

• PREPARE EQUIPMENT ROOM

Step 2 — Receive Machine

.....................................

• BEFORE UNLOADING

• RIG UNIT CAREFULLY

Step 3 — Install Unit

..............................................

10

• TO MOUNT MOTOR ON BASE

• TO MOUNT CARRIER COMPRESSOR UNITS

AND CONDENSER PACKAGES

• TO MOUNT COMPRESSOR BASE ON

SUPPORT STANDS

Step 4 — Assemble Refrigerant Piping

and Components.................................................... 10

• COMPRESSOR DISCHARGE PIPING

• REFRIGERANT DRIER

• FELT FILTERS

Step 5 — Install Multiple Compressors

................

11

• EQUALIZING LINES

Step 6 — Make Electrical Connections

................

II

• GENERAL NOTES

• ATTACH POWER WIRES TO COMPRESSOR

MOTOR

• CHECK MOTOR ROTATION

• INSTALL CRANKCASE HEATER

Step 7 — Check Compressor/Motor

Alignment............................................................ 13

• BELT DRIVE

• DIRECT DRIVE

• HOT CHECK AND DOWELING

Step 8 — Assemble Water Piping

Step 9 — Prepare Lubrication System

........................

.................

13

13

• INSTALL OPTIONAL EQUIPMENT

• CHECK OIL LEVEL

PREPARE FOR INITIAL START-UP....................... 13

Evacuate, Dehydrate, and Leak Test

...................

13

Refrigerant Charging ............................................ 13

START-UP............................................................... 13

Preliminary Steps

..................................................

13

Start Compressor................................................... 14

Check Control Operation

.....................................

14

Check High-Pressure Switch................................ 14

Check Low-Pressure Switch

...............................

14

Adjust Capacity Control (if required)................... 14

SCHEDULED MAINTENANCE............................... 17

Check Lubrication System

...................................

17

Check Water-Cooled Heads.................................. 19

SERVICE INSTRUCTIONS

Service Notes

.........................................................

Lubrication System

Pressure-Relief Valves

Suction Strainer

.....................................................

Cylinder Head and Valve Assemblies

.....................................

...............................................

..........................................

..................

19

19

19

26

26

27

Cylinder and Unloader Sleeves............................ 27

Connecting Rods and Pistons

Capacity Control Operation

.............................

..................................

28

28

1

1

Capacity Control Inspection and Service

Crankshaft Inspection and Service

Pump-End Main Bearing

............................................

.........................

Center Main Bearing.................................................... 33

Seal-End Main Bearing

..............................................

Crankshaft Seal Inspection and

Replacement.............................................................. 34

TROUBLESHOOTING

.................................................

SAFETY CONSIDERATIONS

Installation, start-up and servicing of this equipment

can be hazardous due to system pressures, electrical

components and equipment location.

Only trained, qualified installation and service per

sonnel should install, start-up or service this equipment.

When working on this equipment, observe precautions

in the literature, tags, stickers and labels attached to the

equipment and any other safety precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky

equipment.

A WARNING

Before performing service or maintenance operations

on unit, shut off and tag main power supply to unit.

Electrical shock could cause personal injury.

INSTALLATION

Step 1 — Prepare for Installation

PREPARE EQUIPMENT ROOM — Locate compres

sor or condensing unit in a well-ventilated area. If natural

ventilation is inadequate, provide forced ventilation

through ductwork. Check applicable code requirements.

Provide freeze-up protection for water-cooled con

densers, water lines and accessories if freezing tempera

tures can occur during winter shutdown periods.

Provide sufficient clearance for removal of compressor

cylinder heads and valve plates. Allow space on the oil

pump end for crankshaft removal as follows:

5F20, 30, 40, and 60 compressors...............................20in.

5H40, 46, 60, and 66 compressors

5H80, 86, 120, and 126 compressors

Provide space equal to condenser length for tube

removal and cleaning.

Step 2 — Receive Machine (Fig. 1 through 8)

BEFORE UNLOADING — Check unit nameplates

against model and serial numbers recorded in job speci

fications. Check all items against shipping list, and

examine items carefully for any shipping damage. If

damage is found or any major component has torn loose

from its anchorage, have transportation inspectors

examine it before unloading. File claim immediately with

shipping company for any loss or damage.

..............................

..........................

(Continued on page 10.)

______

Page

31

32

33

34

37

20 in.

30 in.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

2a

PC 111

Catalog No 530-526

Printed inUS A Form5F,H-11SI

For replacement Items use Carrier Specllled Parts

Pg 1

2-86 Replaces: 5F,FI-9SI

Page 2

5F,H

HKATtNG A COOLING

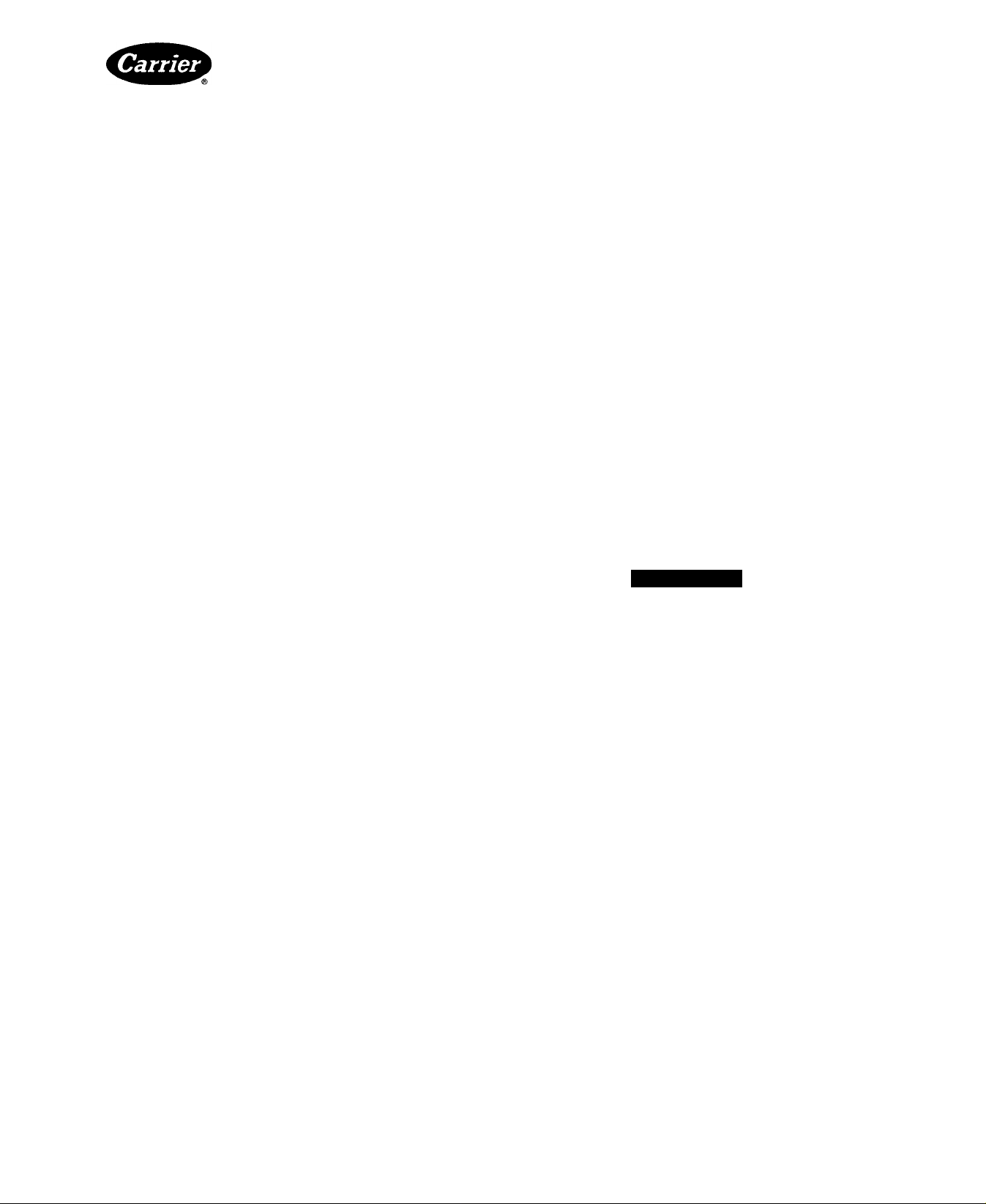

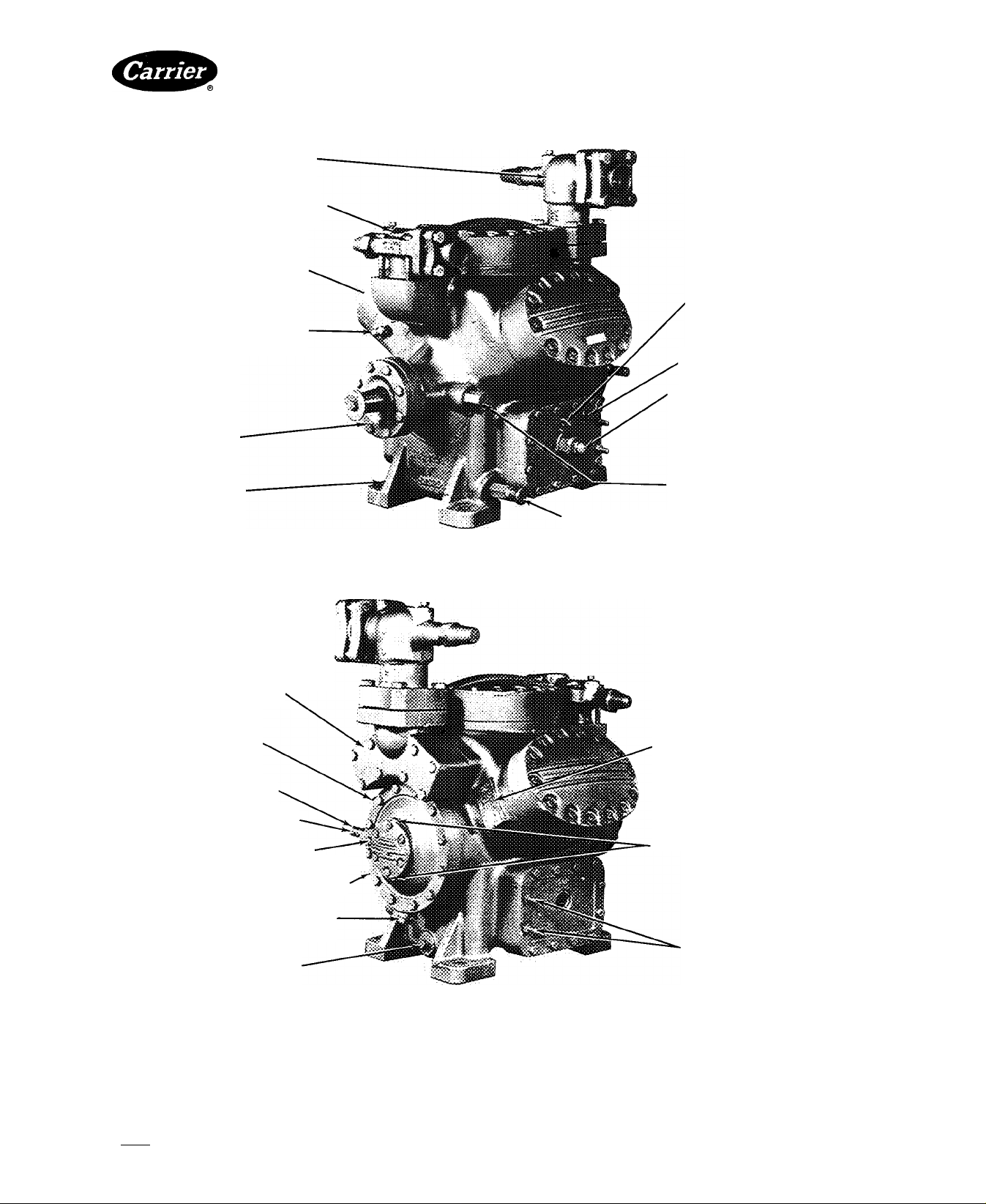

OIL FILLER PLUG

5/8"-18

OIL PRESSURE CONNECTION'

1/4" IPS

OIL DRAIN PLUG 5/8"-18

Open-Drive Compressors

SUCTION SHUTOFF VALVE

I- I /8" ODF

GAGE CONNECTION

1/4" IPS

OIL PUMP ROTATION

ARROWS

CRANKCASE HEATER CASING

(PIPE CAP 1/2" FPT)

PUMP INTAKE PLUG (MAGNETIC)

DISCHARGE SHUTOFF.

VALVE-7/8^ ODF

SUCTION AND DISCHARGE

MANIFOLD COVER-REMOVE

FOR ACCESS TO SUCTION

STRAINER

SEAL COVER

OIL PRESSURE REGULATOR

Fig. 1 — 5F20; 2-Cylinder Compressor

GAGE CONNECTION

1/4" IPS

OIL PRESSURE CONNECTION

5/8" - 18

OIL LEVEL SIGHT

GLASS

© Tab 2a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and wilhout incurring obligations.

Book 12

PC111 Catalog No 530-526 PrintedinUSA Form 5F,H-11SI Pg2 588 2-86 Replaces: 5F,H-9SI

For replacement Items use Carrier Specified Parts

Page 3

5F,H

HEATING A COOLING

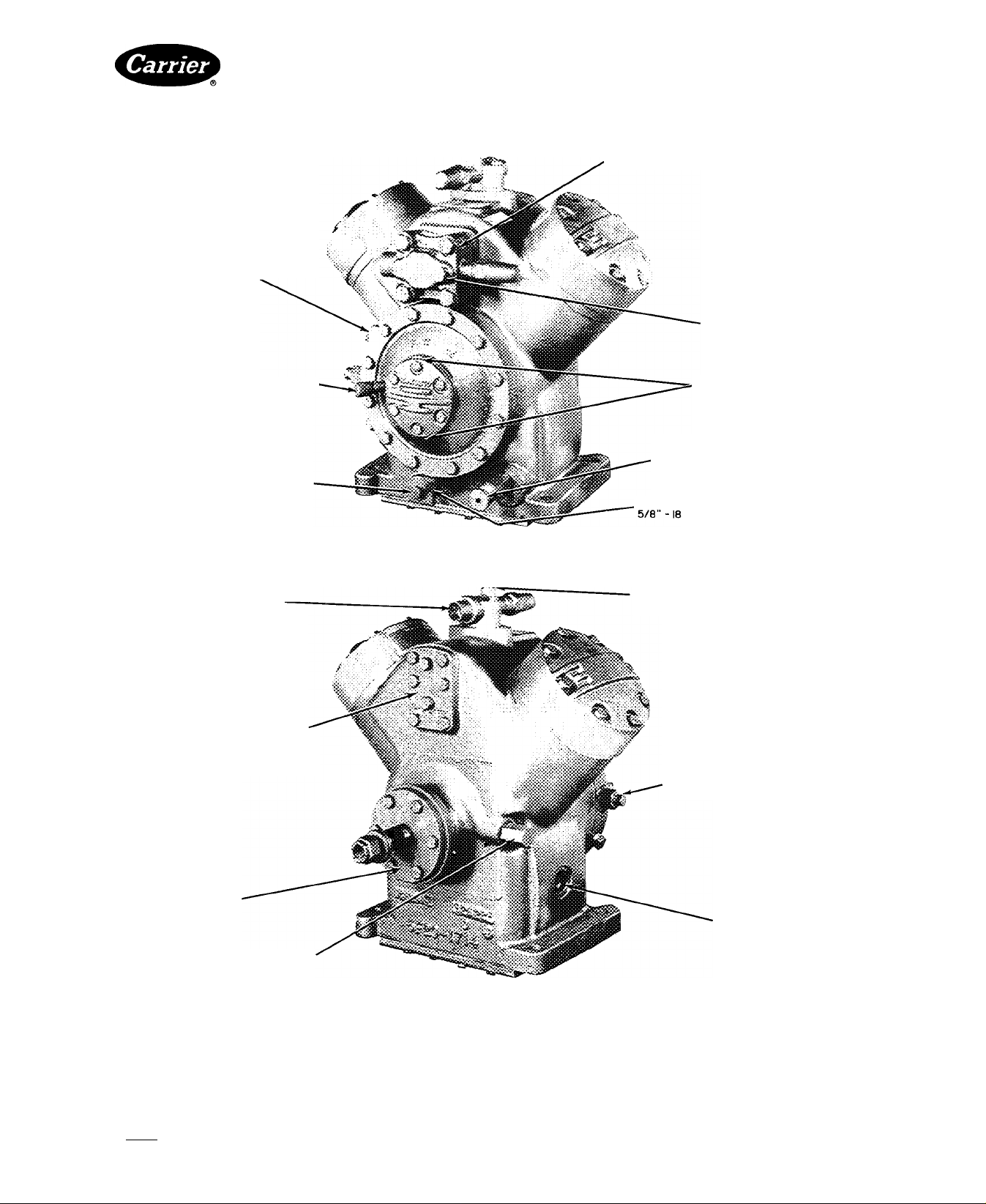

DISCHARGE SHUTOFF VALVE

1-3/8" ODF

GAGE CONNECTION

1/4"-IPS

SEAL COVER

Open-Drive Compressors

OIL PRESSURE

REGULATING VALVE

OIL LEVEL SIGHT

GLASS

OIL FILLER PLUG

5/8"-18

OIL PRESSURE CONNECTION

5/8"-18

OIL PRESSURE CONNECTION

1/4" IPS

OIL DRAIN PLUG (HIDDEN)

5/8"- 18

PUMP INTAKE PLUG (MAGNETIC)

5/8 '-18

Fig. 2 — 5F30; 3-Cylinder Compressor

SUCTION SHUTOFF VALVE

1-5/8" ODF (REMOVE FOR

ACCESS TO SUCTION STRAINER)

1/4" IPS GAGE CONNECTION

OIL PUMP ROTATION ARROWS

CRANKCASE HEATER

CASING (PIPE CAP 1/2" FPT)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book|2 PC 111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg3 2-86 Replaces: 5F,H-9SI

Tab 2a

For replacement Items use Carrier Specitled Parts.

Page 4

5F,H

HEATING A COOLING

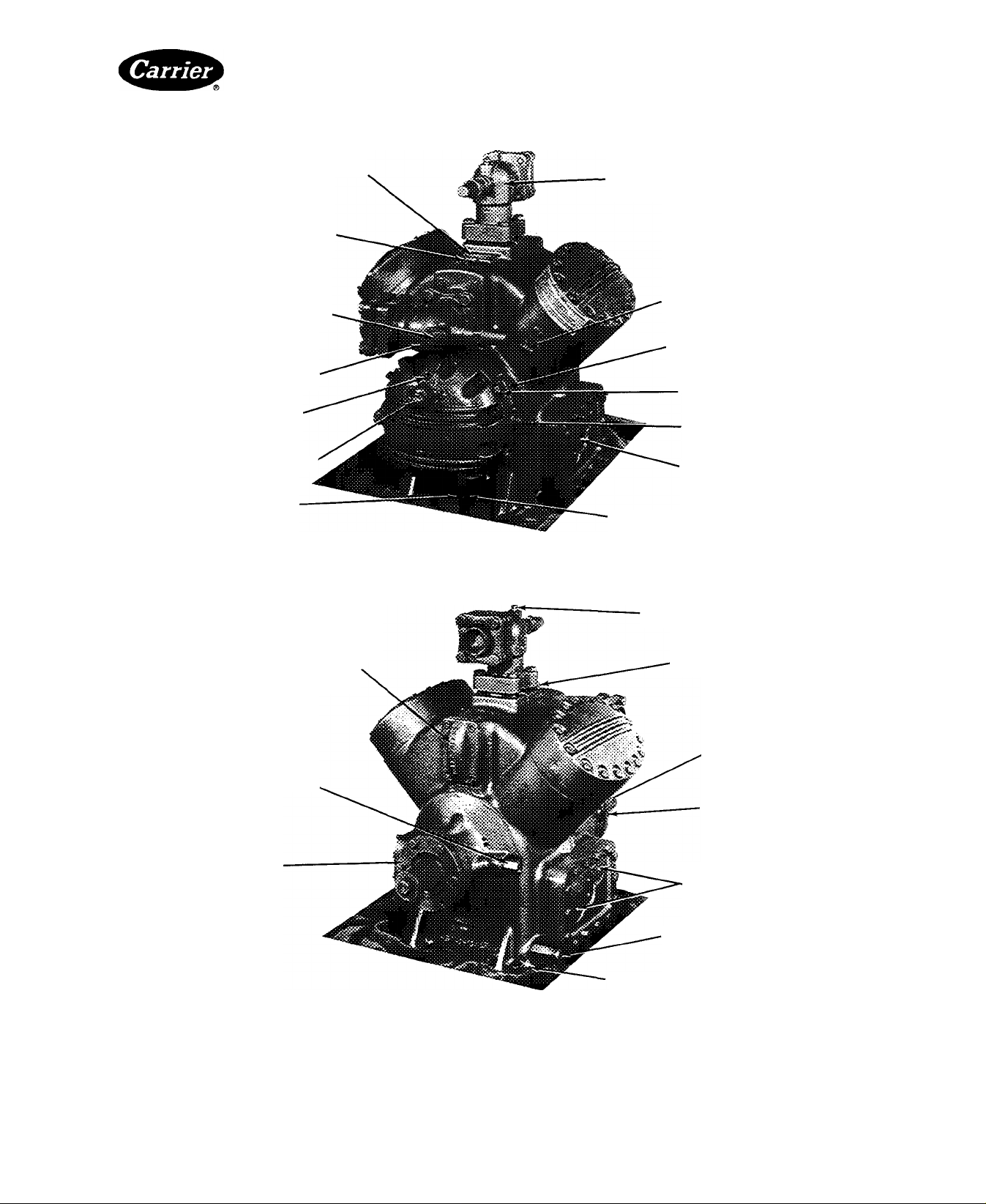

DISCHARGE SHUTOFF VALVE

1-3/8" ODF

HIGH-PRESSURE CONTROL

CONNECTION

1/4" IPS

SUCTION MANIFOLD COVER PLATE

(REMOVE FOR ACCESS TO SUCTION

STRAINER)

OIL PRESSURE REGULATOR

SEAL COVER

DOWEL HOLE

Open-Drive Compressors

1/4" IPS GAGE CONNECTION

1/4 IPS PNEUMATIC

CONTROL CONNECTION

OIL PUMP PRESSURE

3/8 IPS

OPENING TO CRANKCASE

CONTROL OIL PRESSURE

CAPACITY CONTROL VALVE

CRANKCASE HEATER CASING

(PIPE CAP 1/2" FPT)

SUCTION SHUTOFF VALVE

1-5/8" ODF

OIL FILLER PLUG

5/8"-18

OIL PRESSURE CONNECTION

1/4" IPS

DOWEL HOLE.

PUMP INTAKE PLUG (MAGNETIC)5/8"-l8

NAMEPLATE

Fig. 3 — 5F40; 4-Cylinder Compressor

1/4" IPS GAGE CONNECTION

OIL PUMP ROTATION ARROWS

OIL DRAIN PLUG 5/8 -18

LOW-PRESSURE CONTROL

CONNECTION TO DUAL

PRESSURESTAT 1/4" IPS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Bool<|2 PC 111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg4 2-86 Replaces: 5F,H-9SI

Tab 2a

For replacement items use Carrier Specified Parts.

Page 5

5F,H

HEATING A COOLING

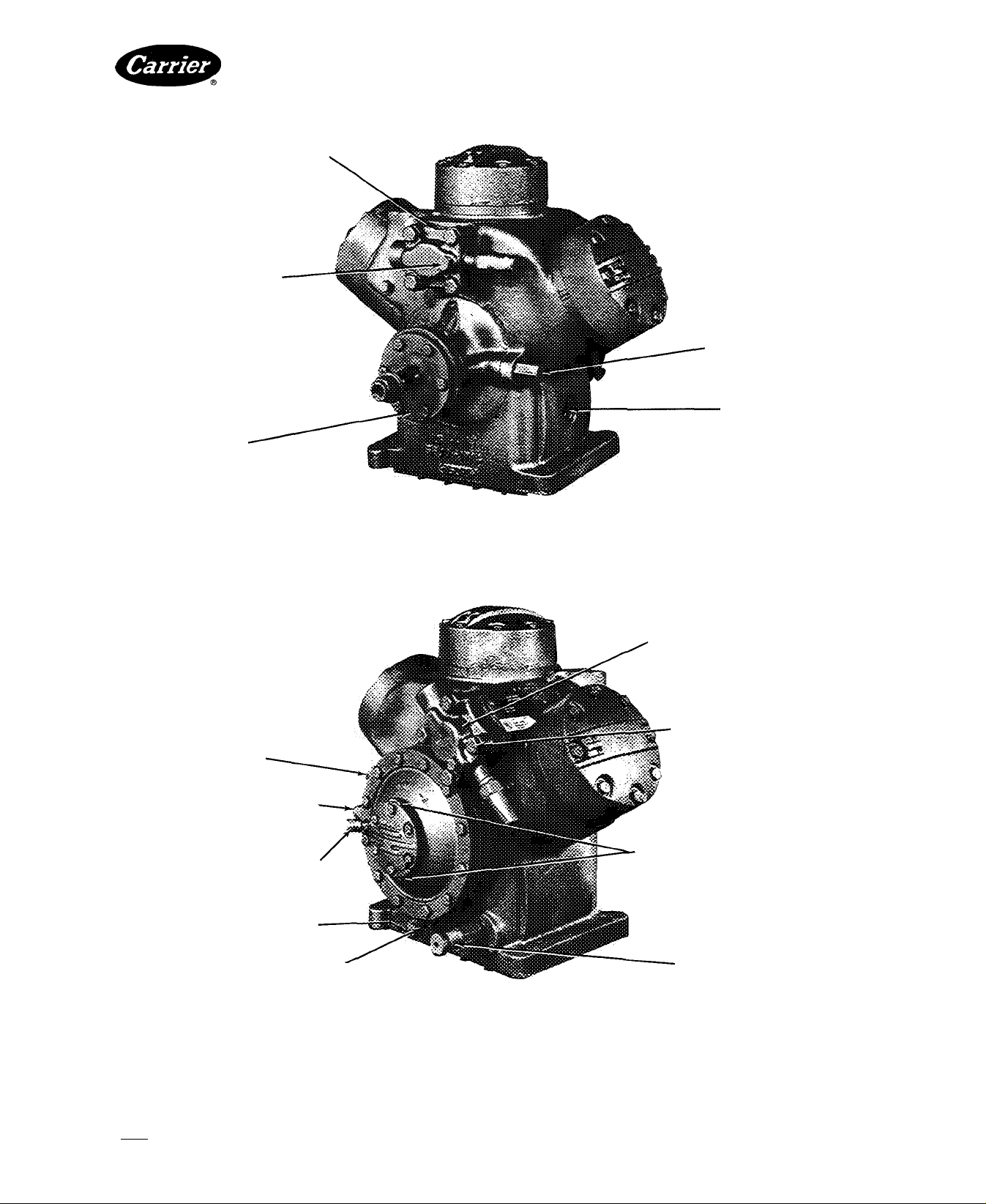

SUCTION SHUTOFF VALVE

2-1/8" ODF

DISCHARGE SHUTOFF VALVE

1-5/8" ODF

HIGH-PRESSURE CONTROL

CONNECTION (HIDDEN)

1/4" IPS

LOW-PRESSURE CONTROL

CONNECTION

1/4" IPS

SEAL COVER

DOWEL HOLE

Open-Drive Compressors

1/4" IPS PNEUMATIC

CONTROL CONNECTION

CONTROL OIL PRESSURE

CAPACITY CONTROL VALVE

OIL PRESSURE REGULATOR

CRANKCASE HEATER CASING{PIPE CAP 1/2" FPT)

I

SUCTION MANIFOLD

(REMOVE FOR ACCESS TO

SUCTION STRAINERS)

OIL FILLER PLUG

5/8"-l8

OIL PUMP PRESSURE

CONTROL OIL STRAINER

OIL PRESSURE CONNECTION

1/4" IPS

3/8" IPS (OPENING TO CRANKCASE)

PUMP INTAKE PLUG (MAGNETIC)

5/8"-18

OIL DRAIN PLUG 5/8"-18

Fig. 4 — 5F60; 6-Cylinder Compressor

NAMEPLATE

OIL PUMP ROTATION ARROWS

PRESSURE

CONTROL SWITCH STUDS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2 PC 111 Catalog No 530-526 Printed inUS A Form5F,H-11SI Pg5 2-86 Replaces: 5F,H-9SI

Tab |2a

For replacement items use Carrier Specified Parts.

Page 6

5F,H

HEATINQ t COOLING

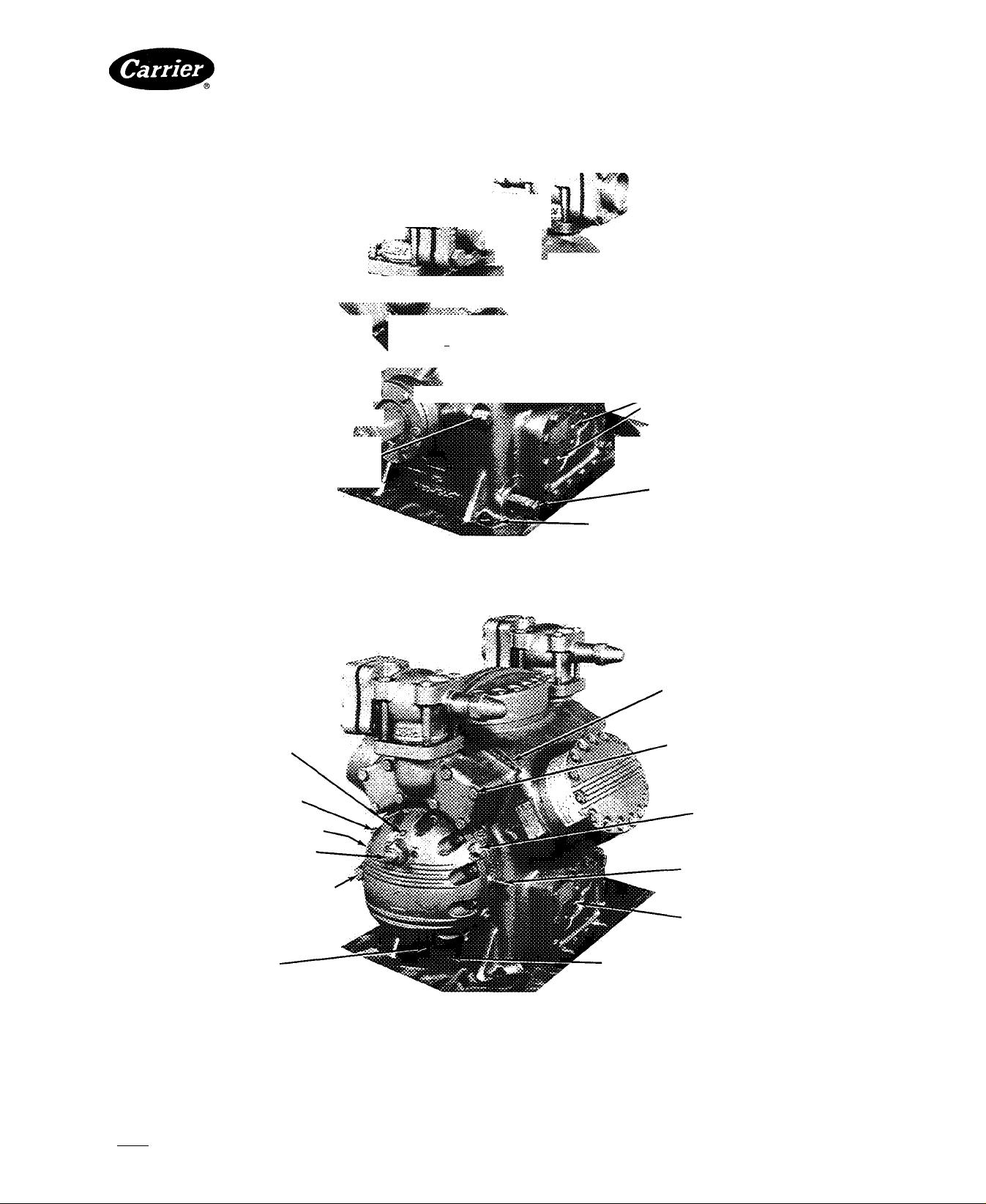

HIGH-PRESSURE CONNECTION

1/4" IPS

SUCTION GAGE CONNECTION

1/4" IPS

SUCTION SHUTOFF VALVE

2-5/8“ OOF

PNEUMATIC CONTROLCONNECTION

1/4" IPS

CAPACITY CONTROL VALVE'

DRAIN PLUG

NAMEPLATE

Open-Drive Compressors

DISCHARGE SHUTOFF VALVE

2-1/8" ODF

LOW PRESSURE CONNECTION

1/4" IPS

OIL PUMP ROTATION ARROW

OIL FILLER PLUG 5/8 -18

CONTROL OIL PRESSURE

OIL LEVEL SIGHT GLASS

CRANKCASE DRAIN

SUCTION DISCHARGE MANIFOLD COVER

(REMOVE FOR ACCESS TO SUCTION

STRAINER AND HIGH-PRESSURE

RELIEF VALVE)

OIL PRESSURE REGULATOR

SEAL COVER PLATE

Fig. 5 — 5H40, 46; 4-Cylinder Compressors

DISCHARGE GAGE CONNECTION

1/4" IPS

HIGH-PRESSURE CONTROL

CONNECTION 1/4" IPS

OPENING TO

CRANKCASE (HIDDEN)

1/4" IPS

OIL PUMP PRESSURE

PLUGGED OPENINGS

FOR INTERCONNECTION

(NOT STANDARD)

CRANKCASE HEATER CASING

(PIPE CAP 1/2" FPT)

DOWEL HOLE

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|2 PC 111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg6 2-86 Replaces: 5F,H-9SI

Tab |2a

For replacement Items use Carrier Specltled Parts

Page 7

5F,H

.......CO.... Open-Drive Compressors

i

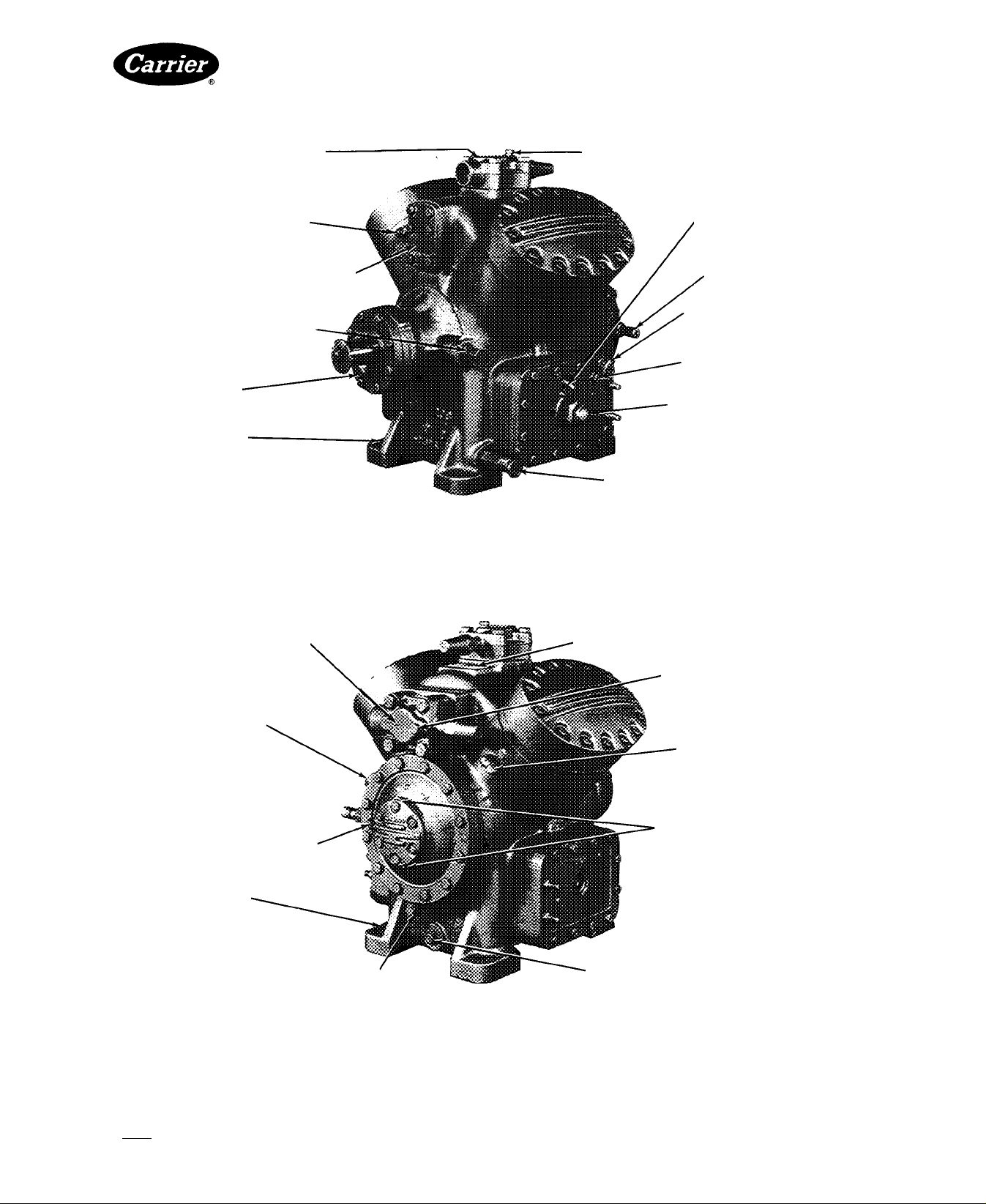

^ DISCHARGE SHUTOFF " I

'PS 3-1/8 OOF

i ^ . .

'.

......................

J W-

HIGH-PRESSURE CONTROL ’’'i ;

CONNECTION 1/4" IPS--------------------------------ig ?■

SEAL COVER PLATE—^ ■- sjfe-^ , (NOT STANDARD)

OIL PRESSURE REGULATORc^SmB .CRANKCASE HEATER

EilllllllllllllllKi^ № «>.

* C ■"

-DOWEL HOLE

PLUGGED OPENINGS

^ FOR INTERCONNECTION

CASING (PIPE CAP 1/2" FPT)

#

PNEUMATIC CONTROL

CONNECTION 1/4" IPS

OPENING TO CRANKCASE

1/4" IPS

OIL PUMP PRESSURE (HIDDEN)

CAPACITY CONTROL VALVE

CONTROL OIL STRAINER PLUG

5/8"-18

PUMP INTAKE PLUG

MAGNETIC 5/8"-18

Fig. 6 — 5H60. 66; 6-Cylinder Compressors

CRANKCASE DRAIN

ACCESS TO HIGHPRESSURE RELIEF VALVE

SUCTION MANIFOLD

(REMOVE FOR ACCESS

TO SUCTION STRAINER)

OIL FILLER PLUG

5/8"-18

CONTROL OIL PRESSURE

OIL LEVEL SIGHT GLASS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book I2 PC111 Catalog No 530-526 Printed in U.S A Form5F,H-11Si Pg7 588 2-86 Repiaces: 5F,H-9Si

Tab 2a

For replacement items use Carrier Specified Parts.

Page 8

5F,H

HEATING & COOLING

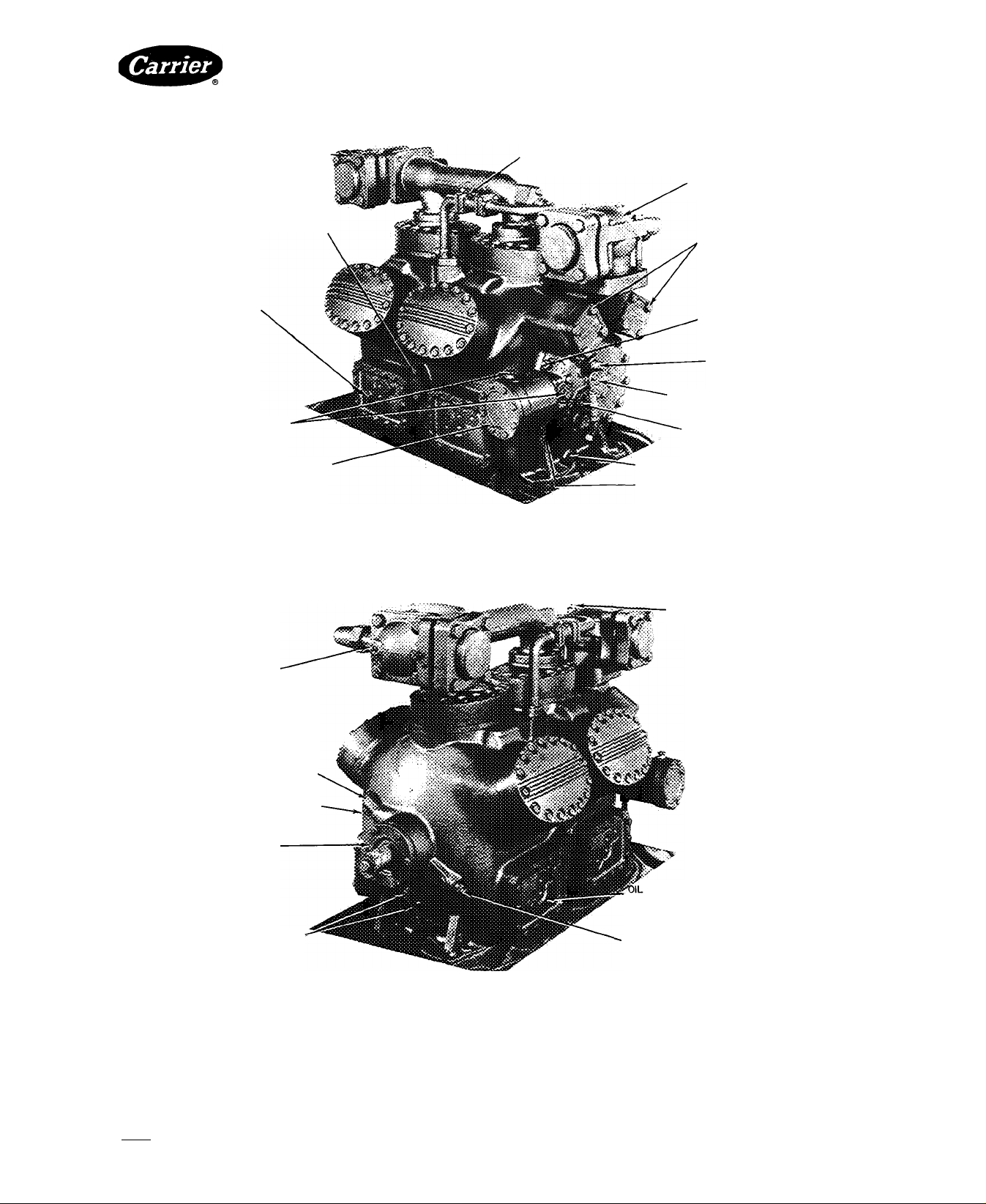

HIGH-PRESSURE RELIEF VALVE AND

MANIFOLD COVER PLATE

SEAL COVER PLATE

OIL PRESSURE REGULATOR

Open-Drive Compressors

NAMEPLATE

plugged openings

FOR interconnection

{NOT STANDARD)

CRANKCASE HEATER CASINGS

(PIPE CAP 1/2" FPT)

SUCTION SHUTOFF VALVE

3-1/8“ ODF

SUCTION MANIFOLD COVER

(REMOVE FOR ACCESS TO

SUCTION STRAINER)

PNEUMATIC CONTROL

CONNECTION 1/4" IPS

OPENING TO CRANKCASE

1/4" IPS

CAPACITY CONTROL VALVE

ADJUSTING STEM

CONTROL OIL STRAINER

PLUG 5/8"-18

OIL FILLER PLUG

CRANKCASE DRAIN

Fig. 7 — 5H80, 86; 8-Cylinder Compressors

DISCHARGE SHUTOFF VALVE

3-1/8" ODF

GAGE CONNECTIONS

1/4" IPS

HIGH-PRESSURE CONTROL

CONNECTION 1/4" IPS

LOW-PRESSURE CONTROL

CONNECTION 1/4" IPS

CENTER MAIN BEARING

RETAINING SCREW ACCESS

OIL PUMP

ROTATION ARROW (TAG)

- CONTROL OIL PRESSURE

OIL LEVEL SIGHT GLASS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|2 PC 111 Catalog No 530-526 PrintedinUSA Form 5F,H-11SI Pg8 588 2-86 Replaces; 5F,H-9SI

Tab T2a

For replacement items use Carrier Specified Parts

Page 9

5F,H

HEATING A COOLING

DISCHARGE SERVICE-

i

VALVE 4-1/8" ODF

GAS EQUALIZER CONNECTION

OIL EQUALIZER

CONNECTION

OIL PUMP PRESSURE

(BEFORE OIL FILTER)

FULL FLOW HIGH-PRESSURE

OIL FILTER

Open-Drive Compressors

RELIEF VALVE DISCHARGE

PRESSURE

SUCTION SERVICE VALVE

4-1/8 "ODF

SUCTION MANIFOLD

COVER PLATE

(REMOVE FOR ACCESS

TO SUCTION

STRAINER)

OIL FILLER

PLUG (ALSO USED

FOR LOW-PRESSURE

OIL LINE CONNECTION)

CAPACITY CONTROL

VALVE

OIL PUMP ROTATION ARROW

ON OIL PUMP COVER

CONTROL aL PRESSURE

CONNECTION 1/4' FPT

CRANKCASE DRAIN PLUG

OIL PRESSURE GAGE SHUTOFF

VALVE (AFTER OIL FILTER)

DISCHARGE GAGE

CONNECTION 1/4" IPS

OIL PRESSURE REGULATOR

CENTER MAIN BEARING

RETAINING SCREW ACCESS

(HIDDEN)

SEAL COVER PLATE

SUCTION MANIFOLD OIL

PASSAGES

Fig. 8 — 5H120, 126; 12-Cylinder Compressors

SUCTION GAGE CONNECTION

1/4" IPS

LEVEL SIGHT GLASS

(ON OPPOSITE SIDE OF COMPRESSOR)

HIGH-PRESSURE OIL CONNECTION

1/4“ IPS

#

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book [2 PC 111 Catalog No 530-526 Printed inUS A Form5F,H-11SI Pg9 2-86 Replaces: 5F,H-9SI

Tab 12a For replacement items use Carrier Specified Parts.

Page 10

5F,H

HEATING A COOLING

RIG UNIT CAREFULLY — Check that rigging equip

ment can safely handle the approximate equipment

weights for compressors and condensing units.

Rig and move unit earefully to prevent damage to

mounting brackets, refrigerant piping or connections.

Step 3 — Install Unit

TO MOUNT MOTOR ON BASE -- The motor fasten

ing set supplied with all compressor units (except 5F20,

30, and all OEM models) includes motor blocks and

shims for motor alignment; cap screws, plate washers

and lock washers for fastening motor to base; taper dowel

pins for securing motor position after alignment; and

beveled washers for fastening the unit base to accessory

vibration isolators.

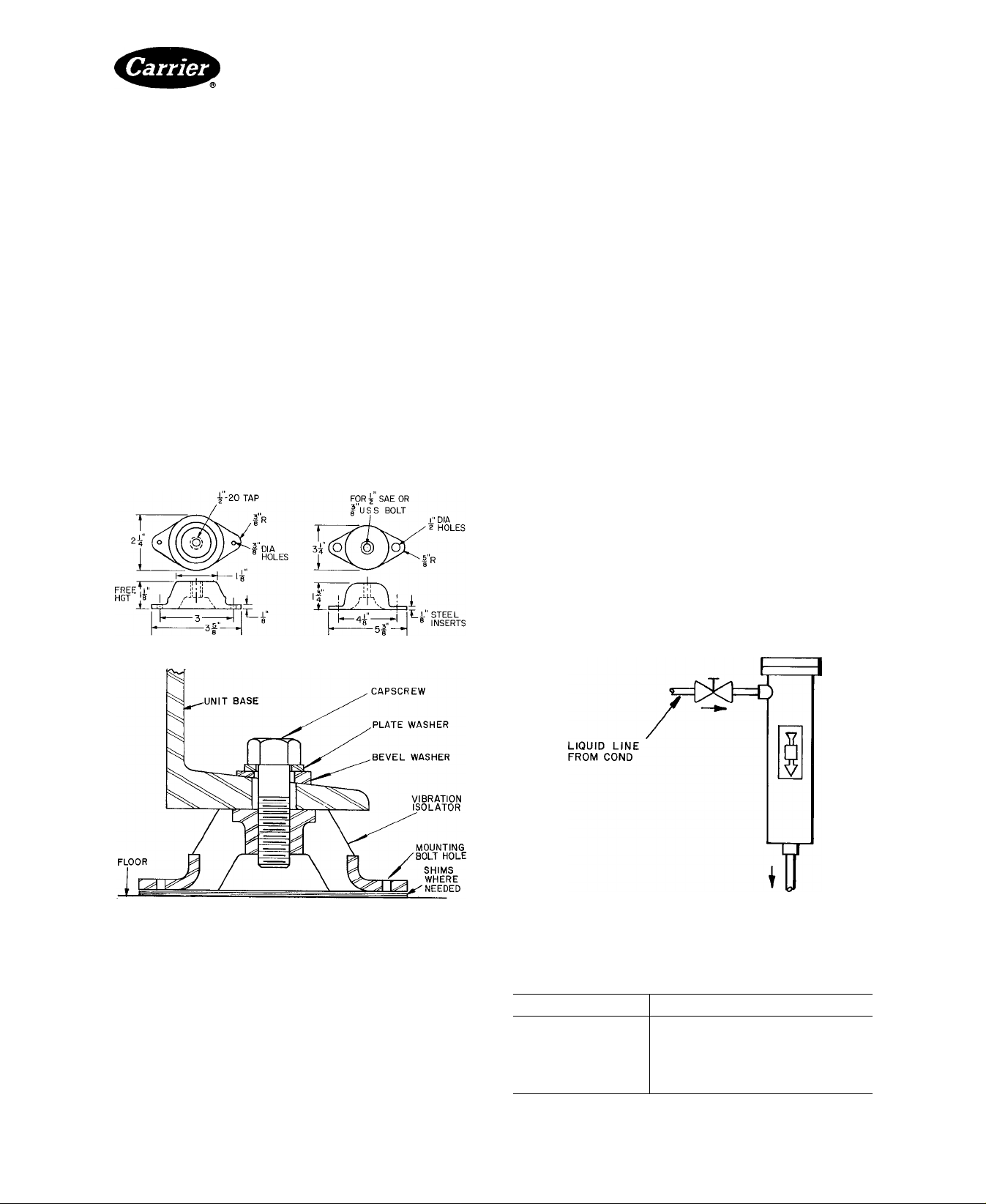

If vibration isolators are used, attach to base (Fig. 9)

To avoid damaging the isolators, lift unit from ends when

attaching isolators.

With compressor and motor positioned on the base,

check the height of the vibration isolators. Shim between

isolators and floor as required to level compressor base.

When level, secure vibration isolators to floor. Check that

beveled washer (Fig. 9) is in place.

Open-Drive Compressors

Remove soldered shipping cap from hot gas inlet. To

prevent solder from dripping into inlet pipe while un

soldering, rotate condenser until pipe is below horizontal

position. Return inlet to upright vertical position.

Tighten lower support straps enough to lift condenser

off stands. Place upper straps loosely in position with a

strip of protective material between condenser and strap

(5F20 and 5F30 units use lower strap only).

TO MOUNT COMPRESSOR BASE ON SUPPORT

STANDS — Place compressor base on support stands

with 2 extra strips of protective material between top of

condenser and base. Bolt base into position with cap

screws and lock washers provided.

Step 4 — Assemble Refrigerant Piping and Com

ponents — Refrigerant connection sizes are given in

Table 4.

COMPRESSOR DISCHARGE PIPING — Refer to

Condensing Unit Piping Installation Instructions for

information.

REFRIGERANT DRIER — A replaceable-core filter

drier is recommended for most systems, and is essential

on all low-temperature systems. Mount the field-supplied

filter drier in the liquid line. Include a shutoff valve to

permit isolation of drier for servicing (Fig. 10).

Install a moisture indicator on downstream side of

drier to indicate when drier cartridges need replacing.

FELT FILTERS — Install felt filter supplied with com

pressor in suction strainer (Fig. 1 through 5). Remove

filter after 50 hours of operation. If clean, discard it; if

dirty, clean with kerosene or neutral spirits and insert for

another 50 hours of operation.

filter was cleaned and reinstalled. Figure 10 and Table 1

give information on replacement filter packages.

Tag unit to show date that

Fig.

Fig. 9 — Typical Vibration Isolator Mounting

TO MOUNT CARRIER COMPRESSOR UNITS AND

CONDENSER PACKAGES — Bolt the compressor’s

lower support straps loosely to underside of each support

stand and place strips of protective material, such as

COMPRESSOR

Fabrica, on straps. Position condenser on stands with hot

gas inlet at top of condenser and liquid shutoff valve

connection facing compressor end of base. Check that

condenser overhangs support stands for same distance

on each end.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2 PC111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI PglO 2-86 Replaces: 5F,H-9SI

Tab 2a

For replacement Items use Carrier Specified Parts.

10 — Refrigerant Filter Drier and

Shutoff Valve Arrangement

Table 1 — Suction (Felt) Filter Packages

FILTER PACKAGE PART NO.

5F40

5F60

5H40,46

5H60,66

5H80,86

5H120,126

5F40-A352

5F60-A352

5H40-A382

5H60-A382

5H80-A382

5H120-A382

Page 11

5F,H

HEATING A COOLING

Step 5 — Install Multiple Compressors

EQUALIZING LINES — Compressors operating in

parallel require interconnecting lines for oil and gas

pressure equalization. Special handhole cover plates,

equipped with tapped holes for equalizing lines, are avail

able as options for sizes 5F40 and 5F60, as well as for

sizes 5H40, 46, 60, 66, 80, and 86 eompressors (Fig. 11).

An oil float system is an acceptable alternative to

equalizer lines.

5H120 and 126 Compressors include factory-supplied,

tapped cover plate. On these compressors, use only

lower connection for oil equalization (Fig. 11). Connect

gas equalizing line to flange connection shown. Mat

ing flange for 1-1/8 in. line is Carrier Part No.

DK24CA712 (Mueller Part No. A-5151); gasket Part No.

is DK29GA005 (Mueller Part No. A-5152).

GAS EQUALIZER

CONNECTION

i4"od flange

(5HI20-I26 ONLY!

Open-Drive Compressors

Step 6 — Make Electrical Connections

GENERAL NOTES

1. Factory wiring complies with National Electrical Code

(NEC). Any field modifications or additions must

comply with all applicable codes.

2. *For control circuit information, refer to Accessory

Control Panel Installation Instructions.

3. If control circuit power is supplied from a separate

source, rather than from a transformer, bring 115-v

power through a field-supplied, 15-amp disconnect,

in compliance with NEC Section 440-14 (disconnect

must be in sight from and readily accessible from

unit).

4. Open control-power disconnect only when servicing

unit. Crankcase heaters must remain energized

when unit is not operating.

5. *Factory wiring is for single pumpout control. Do not

use pumpout control on equipment used with DX

coolers. Wiring label shows field connections used

with DX cooler.

6. *Contactor C2 is used with 208-v motors, 25 through

60 hp, and 460-v motors, 50 through 150 hp.

7. *When field interlocks are used, remove jumpers

between terminals 3 and 4, and between terminals

7 and 8 on TB2.

♦Refers to compressor units and condensing units only.

OIL EQUALIZER

connection

l" IPS

GAS EQUALIZE

connection

Fig. 11 — Special Handhole Cover and

Equalizer Connections (Typical)

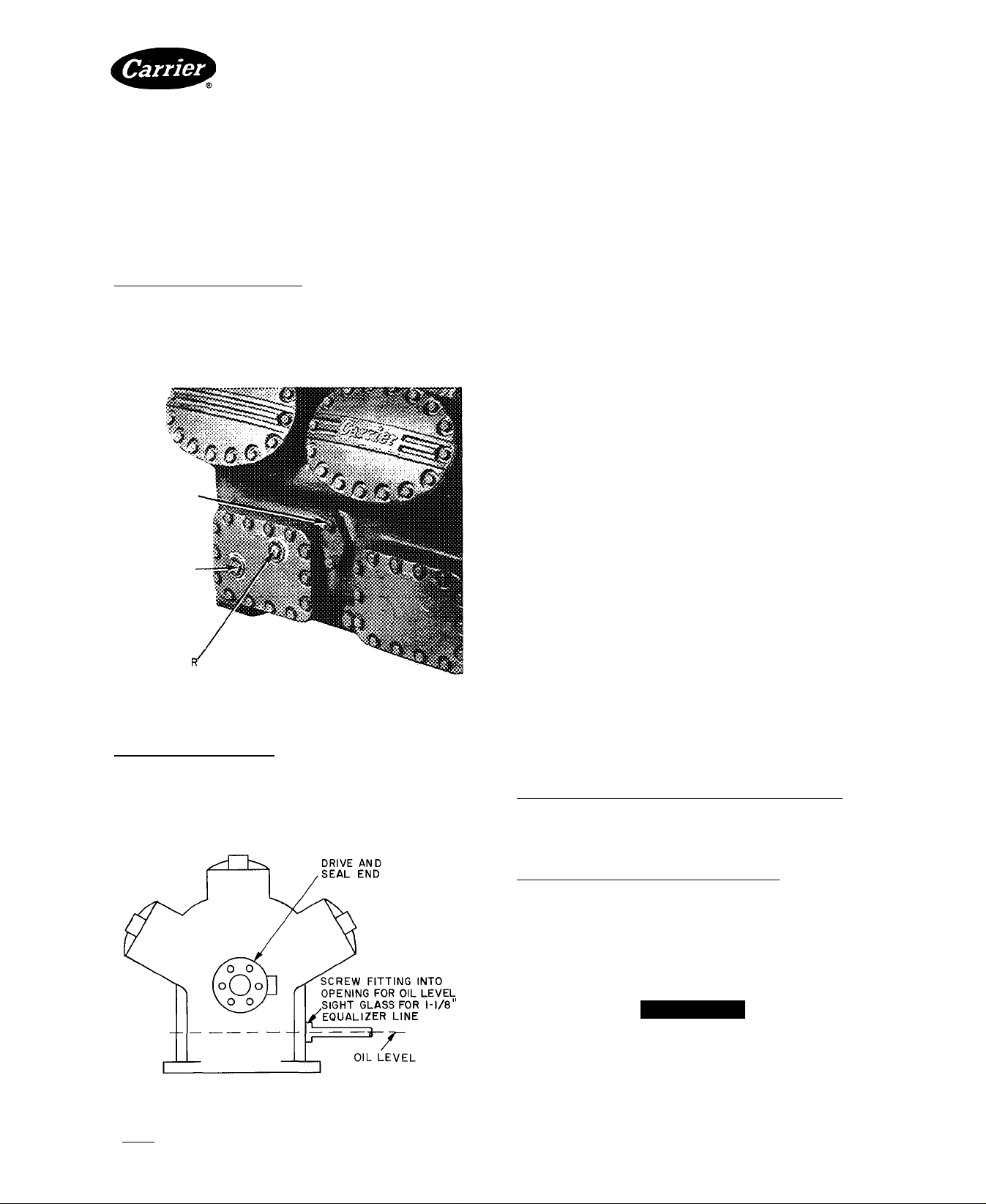

5F20 and 30 Compressors have no special tapped cover

plate. Use opening for oil sight glass to attach the I -1 / 8 in.

line for gas and oil equalization (Fig. 12). Accessory

Package No. 06DA900072 provides two I/8-in. line

adapters to thread into the sight glass opening. If addi

tional equalization is desired, run a 3/8-in. line to the oilfilter plug connection (Fig. I and 2).

ATTACH POWER WIRES TO COMPRESSOR

MOTOR — Attach power wires in accordance with

motor manufacturer’s instructions and in compliance

with NEC and applicable local codes.

CHECK MOTOR ROTATION — Before connecting

motor to compressor, check direction of motor rotation.

Rotation must be in same direction as that indicated by

arrow on compressor pump cover (or on plate attached

near pump-end bearing housing). If direction is not the

same, reverse motor rotation by reversing any 2 power

leads to motor.

If rotation of oil pump is reversed, reverse direction of

pump rotation arrow as well. At that time make the

following adjustments:

All 5F Compressors and 5H120and 126 Compressors —

Remove 6 cap screws from oil pump cover (Fig. 1-4, 8).

Do not damage gasket. Rotate cover 180 degrees and

replace. Arrow at top of oil cover will indicate new direc

tion of rotation.

5F40, 46, 60. 66. 80 and 86 Compressors — Drain oil

below level of pump-end dome cover (Fig. 5-7). Remove

pump-end cover to expose oil pump cover in center of

main bearing housing. Rotate oil pump cover 180 degrees

and replace it. Replace pump-end cover and reverse

external arrow to match new direction of rotation. Proper

direction can later be checked without removing pumpend cover.

#

A CAUTION

If the special gasket between oil pump cover and

oil pump is damaged, replace with correct gasket

only. Check oil pressure immediately after starting

Fig. 12 — Equalizer Connections (5F20 and 5F30)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

BookI 2 PC 111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pgll 2-86 Replaces: 5F.H-9SI

For replacement items use Carrier Specitled PartsTab 2a

compressor.

Page 12

5F,H

HEATING A COOLING

INSTALL CRANKCASE HEATER — Wire heater to

relay or set of normally closed auxiliary contacts on

compressor starter to de-energize it when compressor

is operating.

Remove rubber plug from crankcase heater casing

(Fig. 1-8), and insert heater element entirely into casing.

Element should fit snugly, not loosely. Wire to comply

with applicable electrical codes.

When crankcase heater is installed, system can be

operated on single pumpout cycle, unless used with a DX

cooler.

Table 2 lists crankcase heater packages. Table 3 shows

corresponding relays. Use of 2 heaters on a 5H80 or

5H120 compressor requires only one relay.

Control circuit voltage determines relay coil voltage.

This voltage must be specified when ordering relays.

See Accessory Compressor Crankcase Heater Instal

lation Instructions for additional information.

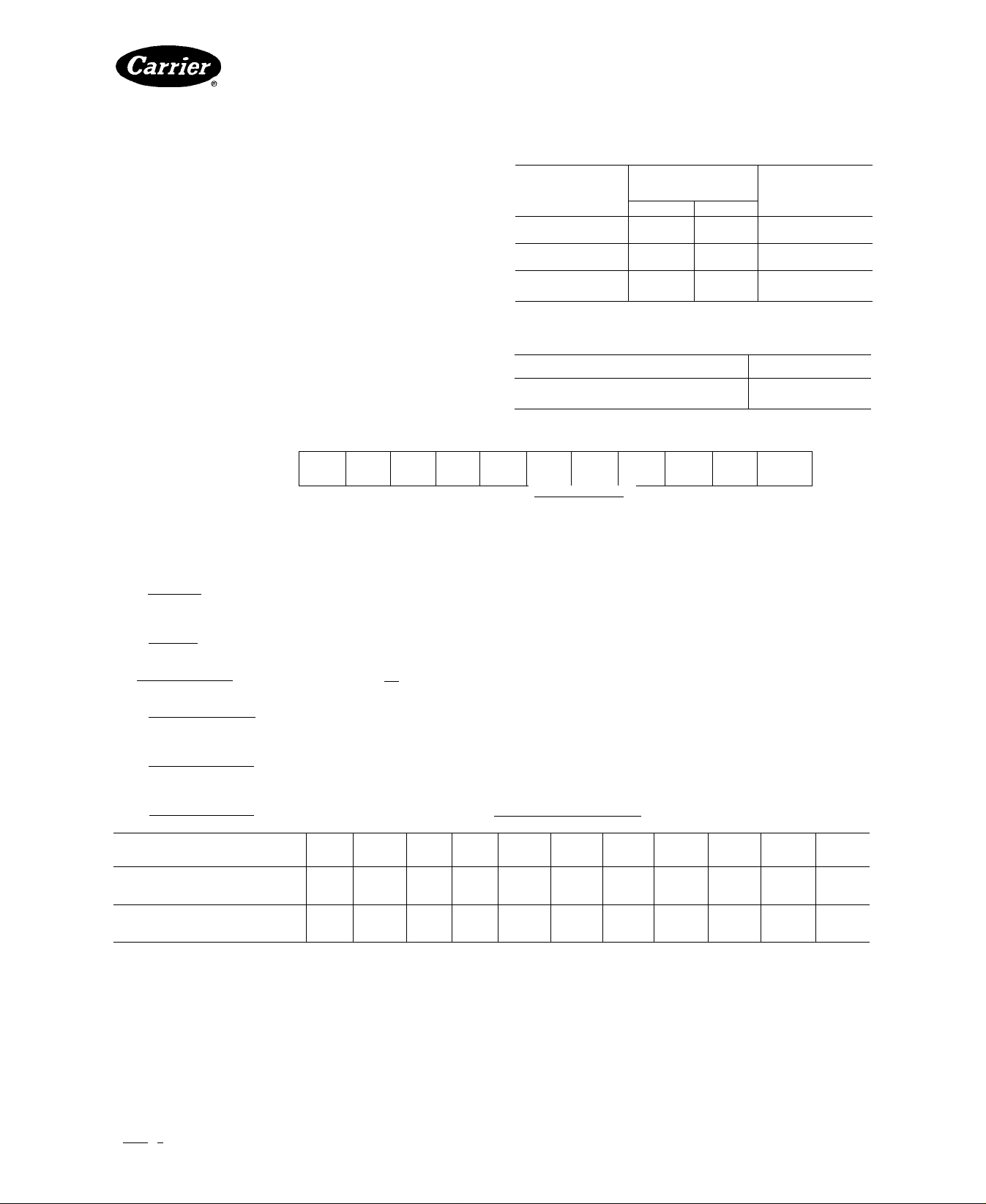

Table 4 — Physical Data

COMPRESSOR UNIT AND

CONDENSING UNIT

REFRIGERANT

COMPRESSOR DATA

Maximum Rpm

Minimum Rpm

Minimum Rpm Capacity

Control

Number of Cylinders

Bore (in.)

Stroke (In.)

Compressor Connections

(in. O.D.)

Suction

Discharge

Oil Charge* (pt) (See Notes)

Normal Oil Pressure*

Oil Flow Rate (gpm)

Oil Safety Switch

Cut-in (psig) (See Notes

Cutout (psig) 3 and 4)

High-Pressure Switchf

Cutout Range

Differential (psi)

Factory Setting (psig)

Low-Pressure Switchf

Cutout Range

Differential (psi)

Factory Setting (psig)

Low Side Maximum Pressure

CONDENSER DATA

Maximum Refrigerant Storage

Capacity** (lb)

Minimum Refrigerant Operating

Charge (ib)

Maximum Operating Pressure

Refrigerant Side

Water Side

__________

___________

R-12

R-22

R-502

R-12

R-22

R-502

5F20 5F30

600

2

2'/2

2

VA

Ve

5F40 5F60 5H40 5H46 5H60 5H66 5H80 5H86 5H120

700 800

3

2'/2

2

IVs

1%

4

2'/2

2

V/e

1%

55 12 13 18 18 21 21 41

1 5_____________I_____________________

5F20f 5F30f 5F40

40 4 50 7 79.4

37 2

38.2

1 8 27

1.9 2.9

20

46.4 72 8

47.9 75.0

30 140

127 14.5 33.0

13.1 15.0 34.4 38.2

150 psig

900 800 800 900 900 1100

6

2'/2

2

2Ve

VA

Open-Drive Compressors

Table 2 — 5F,H Compressor Crankcase

COMPRESSOR

5F20,30,40,60

5H40,46,60,66

5H80,86,120,126

Table 3 — Crankcase Heater Relay (60 Hz)

CONTROL CIRCUIT VOLTAGE

208/230

R-12, R-22, R-502

400 (required for proper lubrication)

4

3Va

2%

2%

2'A

45-55 psig above suction pressure —

150-395 (adjustable) nominal

Cutout, 300 ± 15, Cut-in, 210 ± 10

20 in Hg vac to 60 psig (adjustable)

Cutout, 50 ± 4; Cut-in, 120 ± 6

5F60

09RH-

89 6 154 212

82 0 139 193

84.6 145 199

027

160 37.0 41 0 51 0

1750

4

3’/4

3%

2%

2'A

6

3%

2%

3'A

3'A

3_0

15 - 19.5

11 - 15

60-150 (adjustable)

60-90 (adjustable)

245 psig

09RH-

043

37 0 46.0 46 0 71

09RH-

054

263

239

248 223 265 337

47.3 47.3 73 94

385 psig

Heater Package

ELECTRICAL

CHARACTERISTICS

Volts Watts

115

230

115

230

115

230

115

6

3'/4

3y,6

3'A

3'A

___________

8

3'/4

2%

3'A

3'A

09RH-

070

238 282 358 475

216

51 0 78

250 psig

PACKAGE NO.

100

100

200

200

200

200

-5-F-20—381

-5-F-20—391

-5-H-40—381

-5-H-40—391

-5-J-40—281

-5-J-40—291

PART NO.

HN61AJ-101

HN61AJ-108

1100 900 900

8

3'/4

3V,6

3'A

3'A

41

12

3'/4

2%

4'/e

4'A

61 61

4.5

09RH-

257

084

09RH-

097

327 432

100 126

91 114

12

3'/4

3V,6

4'A

4'A

09RH-

127

447

118

‘Nominal oil pressures shown in Physical Data table are above suction

pressure, i e , pressure differential between suction pressure and dis

charge pressure of oil pump

tSee Table 5 for typical pressure switch settings

fShell-and-coil condensers All other 5F,H condensers are shell-and-

tube

‘‘Condenser storage capacity 80% filled with liquid refrigerant at 90 F

NOTES:

1 Oil flow rate is the nominal oil pump capacity

2 The following oil (or equivalents) are specified for use in 5F,H

compressors

5F20 and 30: Witco Chemical Co — Suniso 4GS

5F40-5H126: Witco Chemical Co. — Suniso 3GS

3 Differential switch (oil safety switch) has time delay of 30 to 60 seconds

4 Oil safety switch has manual reset

Texaco, Inc — WF32

Shrieve Chemical Co — Zerol 150 (synthetic)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 12 PC 111 Catalog No 530-526 Printed inUS A Form5F,H-11SI Pg12 2-86 Replaces: 5F,H-9SI

Tab 12a

For replacement items use Carrier Specified Parts.

Page 13

5F,H

HEATING A COOLING

Step 7 — Check Compressor/Motor Alignment

BELT DRIVE — See Accessory Belt Drive Package

manual for installation and alignment instructions.

DIRECT DRIVE — Install and align compressor,

coupling and motor as described in manual for Flexible

Couplings for Direct-Drive Units.

HOT CHECK AND DOWELING — To help maintain

alignment, and to ensure exact repositioning of the

motor after servicing, the motor and eompressor must

be doweled to tbe base. Install doweling only after

motor!eompressor alignment has been hot checked

(checked after the compressor has warmed up to oper

ating temperature after initial alignment).

After hot check and while components are still at

Open-Drive Compressors

PREPARE FOR INITIAL START-UP

Evacuate, Dehydrate and Leak Test the entire

refrigerant system as described in Carrier Standard

Service Techniques Manual, Chapter 1, Sections 1-6

and 1-7.

LEAK TESTING

Preferred Method — Charge the system to 10 psig with

refrigerant. Add dry nitrogen or dry air (DO NOT USE

OXYGEN) until system pressure is 150 psig. Check for

leaks with a halide or electronic leak detector.

Alternate Method — Charge the system with dry

nitrogen or dry air (DO NOT USE OXYGEN) to 40 psig

and use soap-bubble test to find large leaks.

operating temperature, drill and ream 2 holes through

diagonally-opposite motor and compressor feet and the

base. Use a 9/32-in. drill and a no. 6 taper reamer. Secure

the motor and compressor to the base with the no. 6 x

2-1/2 in. taper dowel pins provided in the motor fasten

Do not use compressor to build up pressure. Do not

overcharge the system.

A CAUTION

ing set.

Coat the dowels with white lead or other lubricant to

prevent rusting, and tap the dowel lightly into position

so that 1/16 of taper is left above the motor foot.

Check that all dowels are tight and that they do not

bottom.

Step 8 — Assemble Water Piping — See WaterCooled Condensers Installation Instructions and WaterCooled Heads Installation Instructions for information.

Step 9 — Prepare Lubrication System

m

INSTALL OPTIONAL EQUIPMENT — Consult local

Carrier representative for information on these

accessories.

Refrigerant Charging — Use the sight glass method

to charge the system. See Section 1-8 of Carrier Standard

Service Techniques Manual, Chapter 1, for details.

Charge the system to a clear sight glass while holding

saturated condensing pressure constant at 125 F for air

cooled systems or 105 F for water-cooled systems. Add

additional refrigerant to fill condenser subcooler

coils, if required.

5F,H CONDENSING UNITS ^ After a clear sight glass

is obtained, add charge until liquid refrigerant reaches

the condenser liquid level test cock.

5F,H COMPRESSOR UNITS — See condenser data for

additional charge requirements.

Oil Filter — Oil filter for 5H40 through 5H86 com

pressors is available as separate accessory package. Refer

to Accessory Oil Filter Package Installation Instructions

for installation procedures.

If an accessory oil cooler is also installed (see below),

pipe oil filter into system as shown on diagrams in Acces

sory Oil Cooler Installation Instructions.

Oil Cooler — Refer to Accessory Oil Cooler Installation

Instructions included with this accessory package.

Readjust oil-cooler water flow so that it maintains

specified oil temperature when compressor has reached

operating temperature.

Oil Separator — If oil separator is used in system piping,

pipe oil return line to compressor suction line. To mini

mize possibility of flooding compressor with oil, oil

return line diameter should not exceed 1/4 inch. In addi

tion, line should have manual shutoff valve to throttle

oil flow as required and to isolate separator for service.

CHECK OIL LEVEL — Check that oil level is visible

at center of compressor sight glass. Compressors that use

optional equipment such as filter, cooler, and oil

separator described above will require a greater oil

charge than listed in Table 4. Recheck oil level after

operating compressor. If unit needs additional oil, use

only dehydrated, wax-free, refrigeration-grade oil of

suitable viseosity. Table 4 lists oil suitable for use in

m

reciprocating compressors.

Preliminary Steps

1. Energize crankcase heater for at least 24 hours before

starting unit.

2. If control transformer is not used, operate electrical

control circuit with main power switch OFF to ensure

that field connections have been properly made.

3. Install felt sock filter for the first 50 hours of com

pressor operation. Remove and inspect the filter,

clean it if required and replace it for another 50 hours.

Remove sock when system is clean. (Not applicable for

5F20 and 5F30 units.)

4. Cheek that motor rotates in direction that the arrow

on the eompressor oil pump cover indicates. Refer to

Installation, Step 5, under Check Motor Rotation.

5. Check that oil fills 1/3 to 1/2 of the compressor

sight glass.

6. Open water supply valve to condenser. Open pressure

line valve of water-regulating valve (if used). If

eompressor unit is equipped with air-cooled con

denser, turn on condenser fan.

7. Backseat (open) compressor suction and discharge

service valves. Open liquid line valve at receiver.

8. Start evaporator fan or chilled water pump.

START-UP

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab

2a

PC111

Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pgi3

For replacement Items use Carrier Specified Parts

2-86

Replaces: 5F,Fi-9SI

Page 14

5F,H

HEATING A COOLING

Start Compressor — Close main power switch

supplying current to the compressor motor.

Immediately recheck oil level and check oil pressure.

Pressure should exceed suction pressure by 45-55 psi.

If correct pressure is not reached in 10-12 seconds, stop

compressor immediately and check oil pump.

A CAUTION

If any safety device shuts down the compressor, do

not reset the control more than once before deter

mining cause of shutdown.

Check Control Operation — Refer to Carrier

Standard Service Techniques Manual, Chapter 2, for

complete instructions on checking electrical components.

HIGH- AND LOW-PRESSURE SWITCHES — A115F

and 5H units except 5F20 and 30 have factory-installed,

automatic reset, high- and low-pressure switches. (These

switches are available as accessories for 5F20 and 30

units.) Figure 13 illustrates adjustment procedures for

both switches.

Check High-Pressure Switch — Throttle the con

denser water on water-cooled unit or block the airflow

on air-cooled unit, allowing head pressure to rise grad

ually. Compressor should shut off within 15 psi of cutout

value listed in Table 4. Now reverse procedure; com

pressor should start within 10 psi of cut-in value given.

Check Low-Pressure Switch — Slowly close the

suction service valve; suction pressure will decrease.

Compressor should shut off within 4 psi of cutout value

listed in Table 5. Reverse procedure; compressor should

start within 6 psi of cut-in value given.

Open-Drive Compressors

ROBERTSHAW

A-RANGE ADJUSTMENT SCREW

TOP

B-DIFFERENTIAL ADJ SCREW

RANCO

A-RANGE ADJUSTMENT SCREW

TOP

0'^B-

DIFFERENTIAL ADJ SCREW

Table 5 — Typical Pressure Switch Settings

PRESSURESTAT

REFRIG

ERANT

CONDENSER

Water-Cooled 175 95 16 76

Air-Cooled

Water-Cooled

Air-Cooled 325

Water-Cooled 280 200 45

Air-Cooled 325

Hi!

(ps

Cutout Cut-in Cutout Cut-in

g)

225 145 16 76

280 200 36

245 36

245 45

Low

(psig)

96

96

105

105

OIL PRESSURE SAFETY SWITCH — To check, move

contact arm at left side of switch forward (Fig. 14).

Compressor should stop in approximately 45 seconds.

If compressor continues to run, check the wiring to

safety switch. If wiring is correct, switch is faulty and

should be replaced.

After completing test, wait 3 minutes; then press

restart button on front of safety switch and restart

compressor.

Check oil level in compressor sight glass after 15-20

minutes of operation. If the oil level is low, add oil by the

methods described in Carrier Standard Service Tech

niques Manual, Chapter 1, Section 1-11.

If an accessory oil cooler is provided, adjust the

water flow as required to maintain a lOOF to 120F

crankcase return oil temperature.

Screw A raises or lowers both cutout and cut-in points by a like

amount.

Range and Differential scales are on the front of the switch.

High Pressure Set cutout point first, with screw A; then set

Low Pressure: Set cut-in point first, with screw A, then set

cut-in point with screw B

cutout point with screw B

LOCATION AND ADJUSTMENTS

Fig. 13 — High- and Low-Pressure Switches

For additional information, see Oil Safety Switeh

Accessory Package Installation Instructions.

Adjust Capacity Control (if required) — See

Fig. 17 for unloading sequence.

5F20 AND 5F30 COMPRESSORS ^ Referto Capacity

Control Valve Installation Instructions for additional

information.

5F40 THROUGH 5H126 COMPRESSORS — Deter

mine the refrigerant usage:

If the system is to use R-I2, replace the 11-lb range

adjustment spring (Fig. 15) with the 7-lb spring .supplied

with compressor. A change in 1982 reversed which range

adjusting spring a customer received. The R-22/R-502

spring is now standard with the compressor. See instruc

tion tag for spring replacement procedure.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book! 2 PC111 Catalog No 530-526 PrIntedInUSA Form5F,H-11SI Pg14 2-86 Replaces: 5F,H-9SI

Tab 2a

For replacement items use Carrier Specified Parts.

Page 15

5F,H

HEATING A COOLING

CONTACT ARM

HIGH-PRESSURE

CONNECTION TO

OIL PUMP

DISCHARGE

Fig. 14 — Oil Pressure Safety Switch

RESISTANCE

CONNECT IN

SERIES WITH

CONTROL CIRCUIT

REFER TO UNIT LABEL

WIRING DIAGRAM)

LOW-PRESSURE

CONNECTION

TO CRANKCASE

T

240

VAC

±

VAC

Open-Drive Compressors

An external adjusting stem (Fig. 15) sets the control

point (suction pressure at which first step of cylinder

unloading occurs). The control point is adjustable

as follows:

R-22 and R-502 .............................................. 0 to 85psig

R-12................................................................. 0to50psig

One full clockwise turn of adjusting stem will raise the

control point approximately 6psig with R-12, or lOpsig

with R-22 and R-502.

Control oil pressure is an indication of cylinder loading

condition (Table 6). Refer to Fig. 3-8 for location of

control oil-pressure gage connection. See Accessory

Unloader Paekage Installation Instructions for addi

tional information.

Table 6 — Control Oil Pressures for

Cylinder Loading and Unloading

APPROXIMATE

COMPRESSOR STEP*

5F20 1 19 8

5F30

5F40,60; 1 30.0

5H40,46, 2

60,66,80, 3

86,120,126

1

2

4 20 0

CONTROL OIL PRESS. (psIg)

Loading Unloading

13.0

30 0

198

26.0 160

23 0

20 2

130

19.0

120

9.0

SPRING DETAILS

7-LB SPRING

R-12 USAGE

11-LB SPRING

R-22, R-502

USAGE

‘Capacity control reduction steps

To Adjust Control Point

1. Impose an artificial load on the compressor until

suction pressure exceeds control point.

2. Slowly close suction valve to lower compressor

suction pressure to eontrol point pressure.

3. When at control point pressure, turn external

adjusting stem clockwise until first step of unloading

takes place, as indicated by ehanges in control

oil pressure, current draw and sound of compressor.

Control point is now set. Reopen suction service valve.

Compressor will be fully loaded when suction pressure is

3psig (4psig with R-22 and R-502) above control point,

and will be fully unloaded when suction pressure is 4psig

(7 psig with R-22 and R-502) below control point.

5F20 AND 5F30 COMPRESSORS — Two capacity

control packages are available as accessories. One is

suitable for R-12 applications; the other for R-22 and

R-502 applications.

The adjusting stem (Fig. 15) is shipped in a backseated

(fully eounterclockwise) position. Compressor will be

fully loaded under all conditions. Adjust the capacity

control set point by the same 3-step procedure described

above for 5F40 through 5H126 compressors.

*When compressor Is received, the capacity control adjusting

stem will be backseated. (Compressor will be fully loaded under

all conditions )

m

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Bookl 2 PC111 Catalog No 530-526 PrintedinUSA Form 5F,H-11SI Pg15 2-86 Replaces: 5F.H-9SI

Tab I 2a For replacement items use Carrier Specified Parts

Fig. 15 — Capacity Control Valve

Page 16

5F,H

HEATING A COOLING

Open-Drive Compressors

CONTROL OIL

PRESSURE

CRANKCASE

PRESSURE

5F20

Fig. 16 — 5F,H Capacity Control System (Except 5H120)

d

5F30

5H60.66

OIL PUMP

PRESSURE

B

Fig. 17 — Cylinder Unloading Sequence

Manufacturer reserves the right to discontinue, or change at any lime, specifications or designs without notice and without incurring obiigatlons.

BookI 2 PC111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg16 2-86 Replaces; 5F,H-9SI

Tab 2a

For replacement Items use Carrier Specified Parts.

Page 17

5F,H

HEATING «COOLING

SUCTION SHUTOFF VALVE

3-1/8“ ODF

SUCTION MANIFOLD COVER

(REMOVE FOR ACCESS TO

SUCTION STRAINER)

PNEUMATIC CONTROL

CONNECTION 1/4“ IPS

OPENING TO CRANKCASE

1/4" IPS

CAPACITY CONTROL VALVE

ADJUSTING STEM

CONTROL OIL STRAINER

PLUG 5/8“-18

OIL FILLER PLUG

CRANKCASE DRAIN

Open-Drive Compressors

DISCHARGE SHUTOFF VALVE

3-1/8“ ODF

GAGE CONNECTIONS

1/4“ IPS

HIGH-PRESSURE CONTROL

CONNECTION 1/4" IPS

LOW-PRESSURE CONTROL

CONNECTION 1/4“ IPS

CENTER MAIN BEARING

RETAINING SCREW ACCESS

OIL PUMP

ROTATION ARROW (TAG)

CONTROL OIL PRESSURE

OIL LEVEL SIGHT GLASS

Fig. 18 — 5H80, 86 8- Cylinder Compressor

m

SCHEDULED MAINTENANCE

for 5H40 through 5H86 eompressors (Fig. 19). Replace

oil filter after the first 50 hours of operation, or whenever

5F,H compressor and condensing units provide long

life and dependable service when properly operated and

regularly maintained. Establish a maintenance schedule

based on factors such as operating hours, load eonditions

and water quality. Maintenance schedules listed in this

section are offered as guides. Modify them as needed to

satisfy individual machine requirements.

Check Lubrication System — Always check com

pressor oil level before starting unit. If oil is required,

record date and amount added. Refer to Fig. 1-8 for loca

tion of oil filter plug. Table 4 shows specified types and

quantities of oil.

Use of accessory oil separator requires additional oil.

Oil level and separator float valve movement during

initial compressor operation should agree with instruc

tions furnished with the oil separator.

the oil is changed or becomes dirty.

Check yearly for clogged filter, indicated by a greater

than normal difference between oil pressure ahead of

fdter and after filter. When this difference exceeds 5 psig,

change filter as follows;

1. Close oil-line shutoff valves on each side of filter

(Fig. 19).

2. Disconnect oil lines at filter connections.

3. Loosen filter bracket; remove and replace filter body.

Refer to Accessory Oil Filter Instructions for

additional information.

The full-flow oil filter on 5H120 and 5H126 com

pressors contains a replaceable cartridge. Replaee the

filter cartridge after the first 100 hours of compressor

operation. After the initial filter change, check yearly for

filter clogging. If the pressure difference across the filter

exceeds 5 psig, pump down the compressor and then

OIL FILTER MAINTENANCE — A bleed-type, highpressure, disposable filter is available as an accessory

remove the cartridge. Figure 20 illustrates complete

filter assembly.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2 PC111 Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg17 588 2-86 Replaces: 5F.H-9SI

Tab 2a

For replacement items use Carrier Specified Parts

Page 18

5F,H

HEATING A COOLING

SHUTOFF VALVES

PLAIN ELBOW (PART

NO DDI0CA052)

OIL FILTER'

HOUSING

-ORIFICE ELBOW (PART NO

DD40CA05I)

Fig. 19 — Oil Filter Accessory Package

(5H40 through 5H86)

CHECK OIL AND SHAFT SEAL TEMPERATURE

— The normal operating temperature of the oil in the

crankcase ranges from 100 F to 135 F when fully loaded.

Do not permit maximum oil temperature to exceed 150 F.

Conditions under which such excessive temperatures

could occur include situations where the compressor

Open-Drive Compressors

operates in a fully unloaded condition for an extended

period, because the compressor would not be able to

remove all of the heat generated by compression and

friction. In such situations, use an oil cooler to maintain

safe operating temperatures. Refer to 5F,H Application

Data for more information.

When crankcase oil temperature falls within the 120

to 135 F range, the shaft seal housing temperature should

be approximately 140 to 150 F. Shaft seal housing tem

peratures above 170 F may cause shaft seal to age rapidly,

and harden and crack. Therefore:

If shaft seal housing temperature exceeds 170 F,

STOP THE COMPRESSOR. DO NOT restart until

the cause of overheating has been identified, and

the condition corrected.

OIL COOLER USAGE — The accessory oil cooler

maintains safe operating oil temperatures when:

1. The suction gas becomes highly superheated (Table 7).

2. a. The compression ratio exceeds 5:1 on R-22

systems,

b. Application data indicates the need for an oil cooler

for R-12 and R-502 systems. This is especially

likely in increased displacement compressors such

as the 5H46, 66, 86 and 126. The compression ratio

can be determined from the following formula:

Compression _ Absolute Discharge Pressure

Ratio Absolute Suction Pressure

t

OIL PRESS 6AGE CONN

(BEFORE FILTER )

OIL FILTER HOUSING

OIL FILTER

COVER

PUMP END BEARING HEAD

OIL FILL PLUG

CAPACITY CONTROL VALVE ADJUSTING STEM

BUSHING LOC

CONTROL OIL PRESS. GAGE CONN

DRIVE DISC

OUTER GEAR

INNER GEAR

SPRING

OIL PRESS. GAGE CONN (AFTER FILTER)

OIL FILTER

SPRING RETAINER

OIL FILTER SPRING

Fig. 20 — Oil Pump and Filter Assembly (5H120, 126)

COVER GASKET

OIL PUMP COVER

m'

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book[2 PC111 Catalog No 530-526 PrIntedInUSA Form5F,H-11SI Pg 18 2-86 Replaces: 5F,H-9SI

Tab 2a

For replacement items use Carrier Specified Parts

Page 19

5F,H

#

HEATING A COOLING

Table 7 — Actual Suction Gas

Temperature Limits (F), R-12, R-22, R-502

SAT. SUCT

TEMP (F)

ACTUAL

SUCTION

GAS

TEMP(F)

NOTES:

1 For continuous operation with R-22

2 Do not operate unloaders at saturated suction temperatures

at or below 0°F without prior approval from Carrier/Carlyle

Engineering

R-12

R-502 25

R-22

SAT. SUCT TEMP (F)

-60 -50

— —

-40 to 40

40 to 50

-40

-30 -20 -10

35 45 55 65

35 45 55 65 75

See Note 1

MAX. SUPERHEAT (F)

25

15

Oto 50

65

75

3. The compressor operates fully unloaded for prolonged

periods. Under these conditions, suction gas levels

may not suffice to remove the heat of compression

and friction. This condition can occur in any applica

tion, but is most likely in low-temperature systems or

variable-volume applications that use hot-gas bypass

to maintain specified conditions under low evaporator

load. Refer to 5F,H Application Data for additional

information.

Adjust water flow through oil cooler to maintain

crankcase return oil temperature at 100 to 120 F. Crank

case temperature must remain below 140 F; shaft seal

temperature at the seal housing should not exceed 170 F.

Tables 8 and 9 list maximum working pressures for

oil and water and estimated water flow rates for various

oil cooler/compressor combinations. For additional

information, see Accessory Oil Cooler Installation

Instructions.

Table 8 — Oil Cooler Maximum Working Pressure

OIL

WATER 150 psig

150 psig

Table 9 — Oil Cooler Estimated Water Flow Rates

COMPRESSOR

5F ’/4-1

5H40-66

5H80,86

5H120.126

*Flow rate based on 80 F entering water.

GPM*

1-2

1 '/2 - 3

2-4

Check Water-Cooled Heads — To prevent oil

breakdown and sludge formation, the discharge gas

temperature must remain below 275 F. Water-cooled

cylinder heads are available as an accessory for this

purpose. See Accessory Water-Cooled Head Package

Installation Instructions for additional information.

Open-Drive Compressors

SERVICE INSTRUCTIONS

Service and repair of Carrier reciprocating com

pressors and other refrigeration components should be

performed only by fully trained and qualified personnel.

Service Notes

1. Compressor components are shown in normal order

of removal from compressor (Fig. 21 and 22).

2. For replacement items, use Carrier specified parts.

See Carrier 5F,H Specified Parts list for compressor

part interchangeability.

3. Before servicing compressor, pump down the refrig

erant as follows:

a. Start compressor, close suction service valve,

and reduce crankcase pressure to 2 psig. (Bypass

low pressurestat with jumper.)

b. Stop compressor; close discharge service valve to

isolate it from system.

c. Bleed any residual refrigerant. Drain oil if

neeessary.

4. After disassembly, clean all parts with solvent. Use

mineral spirits, white gasoline or naphtha.

5. Before assembly, coat all parts with compressor oil

and clean and inspect all gasket surfaces. Replace all

gaskets with new, factory-made gaskets, and lightly

coat with oil. See Table 10 for torque values.

6. After reassembly, evacuate compressor and open

suction and discharge valves. Restart compressor

and adjust refrigerant charge.

Lubrication System

OIL PUMP (For 5H120 and 126 compressors, manu

factured in 1969 or later, refer to Gear Rotor Type

Oil Pump.)

Drain oil below level of pump-end bearing head.

Remove bearing head. Complete end bell assembly must

be removed on 5H40, 46, 60, 66, 80 and 86 models. Check

oil-pump rotor for end play. Maximum allowable move

ment of rotor is 0.0025 in. (Table 11). If there is excessive

end play, reposition oil-pump bushing in bearing head as

described below.

Turn rotor; if there is more than a slight drag, remove

pump cover and disassemble oil pump. Check all parts

(Fig. 20, 23 and 24) for wear and damage. Inspect oilpump bushing for scoring. Replace hushing if scored. If

bearing head is scored, replace complete bearing head and

oil-pump assembly.

Oil-Pump Bushing Installation — Position bushing oil

groove at top when the bearing head is installed.

Machined cireumferential lines mark the lead, or

entering, end of the bushing. Press new bushing into the

pump-end bearing head from the inner side of the head

(Fig. 25 and 26).

Oil Pump Bushing Positioning (Fig. 25 and 26)

1. Place 0.001-in. cireular, field-fabricated shim against

bushing and install pump. (Shim between bushing and

oil pump rotor.)

(Continued on page 25.)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

2a

PC 111

Catalog No 530-526

PrintedinUSA Form5F,H-11SI Pg 19

For replacement items use Carrier Specified Parts

2-86 Replaces: 5F,H-9SI

Page 20

5F,H

HEATING A COOLING

DISCHARGE VALVE

INNER SEAT

HANDHOLE COVER

ASSEMBLY

HANDHOLE COVER

GASKET

SHAFT SEAL BELLOWS

COVER PLATE ASSEMBLY

SEAL

CYLINDER HEAD

CYLINDER HEAD GASKET

VALVE PLATE

VALVE PLATE GASKET

Open-Drive Compressors

PUMP END COVER

PUMP END

BEARING HEAD

ASSEMBLY

PUMP END BEARING WASHER

AND CONTROL

VALVE ASSEMBLY

i

OIL FILTER SCREEN

PUMP END BEARING

HEAD GASKET

HANDHOLE

COVER GASKET

HANDHOLE COVER'

Fig. 21 — 5H Compressor External Components

OIL FILTER

(ACCESSORY)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 12 PC111 Catalog No 530-526 PrintedInUSA Form5F,H-11SI Pg 20 2-86 Replaces: 5F.H-9SI

Tab |2a

For replacement Items use Carrier Specified Parts.

Page 21

5F,H

KEATING A COOLING

CYLINDER SLEEVE

CYLINDER SLEEVE

SNAP RING

UNLOADER SPRINGS-»^ %

UNLOADER PINS

UNLOADER FORK

o>

cf

% \

V ^

Open-Drive Compressors

PISTON RINGS { COMPRESSION - TAPERED )

igll.. Ill

PISTON RING (OIL)

PISTON PIN

PISTON

PISTON RING (OIL)

CONNECTING ROD

----

PISTON PIN LOCK RING

CONNECTING ROD BOLTS

ELASTIC LOCK NUT

UNLOADER

POWER ELEMENT

UNLOADER BRACKET

GASKET

SEAL END

BEARING WASHER

(BRONZE)

---------------

ASSEMBLED

PISTON AND

CONNECTING ROD

CRANKSHAFT

SEAL END

THRUST WASHER (STEEL)

Fig. 22 — 5H Compressor Internal Components

CONNECTING

ROD BEARING

INSERTS

CONNECTING

ROD CAP

#

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without ii^curring obligations.

Book 2

Tab 2a

PC 111

Catalog No 530-526 PrintedinUSA Form5F,H-11SI

For replacement Items use C arr ier Specltied Parts.

Pg 21

2-86

Replaces: 5F,H-9SI

Page 22

5F,H

HEATING A COOLING

SIZE

THREADS

DIAU

(in.)

'U

V.

%

%

%

%

'h

V.

Vs

Vs

1V2

18 NEF

No. 6

'U

Vb

'/4

'/4 28 NF

TORQUE

PER IN.

Pipe

28 NF

24 NF

Pipe

16 NC

24 NF 45-50

20 NF

13 NC

11 NC

18 NC

10 NC

Pipe

Pipe 15-20

Pipe

RANGE

(Ib-ll)

20-25

20-25

20-25

10-15

10-15

12-15

12-15

12-15

10-12

22-25

15-20

30-35

25-29

25-29

25-29

25-29

25-29

25-29

25-29

25-30

80-85

80-85

120-130

60-75

60-75

60-75

60-75

60-75

18-22

50-60

70-80

34-45

32

8-10

10-15

20-25

20-25

20-25

12-16

8-12

8-12

Table 10 — Torque Values

USAGE

Pipe Plug — Pump End Bearing Head

Pipe Plug — Crankshaft

Pipe Plug — Suction and Discharge

Manifold Cover

Unloader Power Element Assembly —

Crankcase

Unloader Cylinder Cover Plate —

Unloader Cylinder Bracket

Discharge Valve Cap Screw —

Inner Seat

Discharge Valve Guide Assembly —

Valve Plate

Oil Pump Cover — Pump End

Bearing Head

Auxiliary Control Valve Cover —

Valve Body

Connecting Rod Bolt — Locknut

Capacity Control Valve —

Hand Hole Cover

Pipe Plug — Pump End Bearing Head

Cylinder Head — Crankcase

Shaft Seal Cover Plate — Crankcase

Bottom Plate — Crankcase

Suction and Discharge Manifold

Cover — Crankcase

Pump End Bearing Head Assembly —

Crankcase

Hand Hole Cover — Crankcase

Suction Manifold — Crankcase

Flywheel Screw — Crankshaft

Oil Return Check Valve Assembly —

Crankcase

Suction Service Valve — Crankcase

Discharge Service Valve — Crankcase

Suction Service Valve —

Suction Manifold

Magnetic Plug — Crankcase

Magnetic Plug — Pump End

Bearing Head

Oil Bypass Plug — Pump End

Bearing Head

Modulating Valve Adapter —

Pump End Bearing Head

Lock Screw — Pump End Bearing Head

Oil Relief Valve Assembly — Crankcase

Cap-Oil Relief Valve Assembly

Flywheel Locknut — Crankshaft

Sight Glass Clamping Gland —

Hand Hole Cover

Auxiliary Control Valve Cover —

Valve Body

5H UNITS

Pipe Plug — Auxiliary Control

Valve Body

Pipe Plug — Pump End Bearing Head

Pipe Plug — Crankcase

Pipe Plug — Pump End Cover

Pipe Plug — Crankshaft

Oil Pump Cover — Pump End

Bearing Head

Auxiliary Control Valve Cover —

Valve Body

Special Cap Screw — Auxiliary

Control Valve Body

Open-Drive Compressors

5H UNITS (cont)

SIZE

THREADS

DIAM

'-ÍB

(In.)

%

PER IN.

18 NC

24 NF

%

Vb 16 NC

14 NC

%

20 NF 40-45 Connecting Rod Bolt — Locknut*

%

'/2 Pipe

V2

13 NC

Vb 11 NC 140-150

Va 18 NF

V» 14 NF

V4

1

1V2 18 NEF 35-45

No. 6 32 8-10

NC — National Coarse

NEF — National Extra Fine

NF — National Fine

•Steel Rod

TORQUE

RANGE

(Ib-fl)

Oil Pump Cover — Pump End

16-20

16-20

16-20

16-20

18-22

18-22

18-22

18-22

18-22

Pipe

Pipe 45-50 Pipe Plug — Crankcase

Pipe 50-55 Pipe Plug — Crankcase

30-35

30-35

25-29

28

35-60

55-60

55-60

55-60

53-60

55-60

55-60

35-40

35-40

30-35

30-35

80-90

80-90

60-75

60-75

60-75

60-75

60-75

80-90

45-55

80-90

60-75

55-65

Bearing Head

Capacity Control Valve — Pump

End Bearing Head

Auxiliary Control Valve — Pump

End Bearing Head

Manifold Cover Plate — Crankcase

Unloader Power Element — Crankcase

Capacity Control Valve —

Pump End Cover

Discharge Valve Guide Assembly —

Valve Plate

Discharge Valve Guide — Inner Seat

Cylinder Bracket

Pipe Plug — Pump End Bearing Head

Pipe Plug — Crankshaft

Capillary Tube Assembly — Pump

End Bearing Head

Connecting Rod Bolt (Aluminum Rod)

Suction and Discharge Manifold Cover

— Crankcase

Discharge Manifold — Cylinder Heads

Valve Plate — Crankcase

Cylinder Head — Crankcase

Hand Hole Cover — Crankcase

Shaft Seal Cover

Pump End Cover and Pump End

Bearing Head — Crankcase

Pipe Plug — Crankcase

Pipe Plug — Pump End Bearing Head

Pressure Relief Valve — Suction and

Discharge Manifold Cover

Pressure Relief Valve — Crankcase

Suction and Discharge Manifold —

Crankcase

Suction Manifold Cover — Crankcase

Suction Manifold Cover and Suction

Manifold — Crankcase

Magnetic Plug — Pump End

Bearing Head

Modulating Valve Adapter — Crankcase

Oil Bypass Plug — Crankcase

Oil Bypass Plug — Pump End

Bearing Head

Oil Bypass Plug — Pump End Cover

Hoi low Lock Screw — Pump End Cover

and Center Main Bearing Housing

Oil Pressure Relief Valve — Orankcase

Cap-Oil Pressure Relief Valve Assembly

Seal Plug — Pump End Bearing Head

Oil Pressure Relief Valve — Orankcase

Sight Glass Clamping Gland —

Hand Hole Cover

Auxiliary Control Valve Cover —

Valve Body

USAGE

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book [2 PC111 Catalog No 530-526 PrintedinUSA Form 5F,FI-11 SI Pg22 489 2-86 Replaces: 5F,Fi-9SI

Tab 12a For replacement items use Carrier Specified Parts.

Page 23

5F,H

#

HEATING A COOLING

COMPRESSOR PART

SEAL END

Main Bearing Diameter — 5F20, 30

Journai Diameter — 5F20, 30

PUMP END

Main Bearing Diameter — 5F20, 30

(Assembieid) — 5F40, 60

Journal Diameter

CENTER (5H80,86,120,126)

Main Bearing Diameter

Main Bearing Thickness

Journal Diameter

CONNECTING ROD

Bearing Diameter

Bearing Thickness

Crankpin Diameter

Seal End Bearing Washer Thickness

Seal End Thrust Washer Thickness

Pump End Bearing Washer Thickness

CYLINDERS

Bore

Piston Diameter —Steel, Standard Stroke

Piston Pin Diameter

Piston Pin Bushing

Piston Ring End Gap (compression and oil)

Piston Ring Side Clearance

Compression Side

Oil Side

OIL PUMPt

Axial Clearance

Drive Shaft Diameter

Drive Shaft Bushing Diameter (10)

Drive Shaft Diameter (5H120 & 126)

Drive Shaft Bushing Diameter

(ID — 5H120 & 126)

SUCTION VALVE

Suction Valve Disc

(depth of wear below face)

Suction Valve Seat

DISCHARGE VALVE

Discharge Valve Disc

(depth of wear below face)

Discharge Valve Seat

— Aluminum, Long Stroke

— 5F40, 60

— 5F40, 60

Body

Ring Groove (OD)

Open-Drive Compressors

Table 11 — Wear Limits; 5F,H Compressors

COMPRESSOR

5F20,30,40,60

Factory

Tolerances (in.)

Max

1 6264

2 0636

1 6240 1 6233

2 061 2 060

1 6264

1 6264 1.6250 001 —

1 6240

—

— — — —

_

1 6255

—

1 6240 1 6233

131 .129

157 155

131 129

2 501 2.500

—

— — —

—

7500

009

0015 0005

0012 0002

0015

4361 4356

4375

— — — 6250

Min

1 6250

2.0618

1.6250

1 6233

—

—

1 6245

06225

2.4980

_

7498

—

004 .030

.0005

— —

— 012

—

012 .002

Maximum

Allowable

Wear (in.)

002

.001

.003

.002

002 2 2530

.002

— 2 6264

—

002 2.2505

001

003

*

*

*

003 3 2515

003

—

001

001

003 0015

0025 0015

—

002

005

5H40,46,60,66,80,86,120,126

Factory

Tolerances (in.)

Max

2 6278

— —

2 6235

—

Min

2 6250

2 6225

—

2 2502

—

2 249

2 6235

— 06225

— 2 248

188

188

188

3 2485

3 241

3 235

— .9998

1.000

.017

0012

4361

.4375

6270

—

—

2 248

2 6250

.0942

2 6225

2.2495

186

186

186

3 2505

3 2480

3 240

3 232

—

007 030

0005

0002

0005

4356

4370

.6240 —

6260

012

012

Maximum

Allowable

Wear (in.)

001

—

002

—

001

—

002

001

001

002

002

.001

002

*

003

003

003

003

001

001

003

0025

—

—

_

005

002

005

002

#

•Replace thrust and bearing washers when end clearance

exceeds maximum listed

CRANKSHAFT END CLEARANCE (In.)

5F20-5F60

5H40,46

5H60,66

5H 80,86

5H120,126

011 to 035

010 to 036

011 to 037

014 to 042

014 to 044

tReturn assemblies for factory exchange

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book 2 PC 111

Tab 2a

Catalog No 530-526 PrintedinUSA Form5F,H-11SI Pg 23

For replacement items use Carrier Specified Parts.

2-86

Replaces: 5F,H-9SI

Page 24

5F,H

HEATING A COOLING

OIL FILL

CONNECTION

Open-Drive Compressors

BRONZE BEARING WASHER

PUMP END BEARING HEAD

OIL PUMP ROTOR

OIL PUMP IDLER

OIL PUMP COVER GASKET

ROTATION ARROW

OIL PUMP COVER

PUMP INTAKE PLUG

( MAGNETIC)

OIL PRESSURE CONNECTION

CRANKCASE PRESSURE CONNECTION

OIL PRESSURE CONNECTION

(REMOVE FOR ACCESS TO CONTROL OIL STRAINER)

Fig. 23 — 5F Oil Pump Assembly

PORT FOR INSERTING BEARING HEAD

SLEEVE WHEN USING OIL COOLER

ACCESSORY. (SEE ACCESSORY OIL

COOLER INSTALLATION INSTRUCTIONS)

OIL PUMP

ROTOR

(Hii

ACCESSORY OIL FILTER

CONNECTION

Fig. 24 — 5H40-5H86 Oil Pump Assembly

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 12 PC 111 Catalog No 530-526 PrIntedinUSA Form5F,H-11SI Pg 24 2-86 Replaces: 5F.H-9SI

Tab 2a

For replacement Items use Carrier Specified Parts

Page 25

5F,H

HKATING ft COOLING

Fig. 25 — Setting Oil Pump Bushing

(Typical 5F20 through 5H86 —

5H40 Bearing Head Shown)

Open-Drive Compressors

6. Install bearing head on compressor. Line up tang on

oil-pump rotor shaft with slot in end of crankshaft.

Check oil pump for proper direction of rotation.

1. Refill compressor oil to proper level.

Observe oil pressure when starting compressor. If

correct pressure (Table 4) is not reached in 8 to 12

seconds, stop compressor and recheck oil pump.

GEAR ROTOR TYPE OIL PUMP (Models 5H120 and

126 manufactured from 1969 on) — Remove bearing

head and oil-pump cover (Fig. 20). Disassemble oil pump.

Check all parts for wear and damage. Inspect bushing for

scoring. Replace hushing if scored. If bearing head is

scored, replace complete bearing head and oil-pump

assembly.

Install New Oil-Pump Bushing — Reinstall oil pump into

bearing head with 1 / 64-in. shim between port insert and

oil-pump cover. Install oil-pump cover without gasket for

this operation. Press new bushing into bearing head from

inner side so that the bushing oil groove is at the top

when the bearing head is installed (similar to Fig. 26).

Machined circumferential lines mark the lead, or enter

ing, end of the bushing. Press on bushing until port insert

bottoms against the 1/64-in. shim. Remove pump cover

and shim. Reinstall pump cover with gasket and install

assembled bearing head on compressor. Check oil pump

for proper direction of rotation.

Fig. 26 — Setting Oil Pump Bushing

(Typical 5H120, 126)

2. Complete assembly of oil pump.

A WARNING

Oil pump assembly must be flush with coverplate

surface, but must not protrude beyond bearing

head surface.

3. Tap bushing with a cylindrical positioning tool to

seat it against shim (Fig. 25 and 26).

4. Disassemble oil pump and remove shim.

5. Reassemble oil pump; check for binding.

OIL PRESSURE REGULATING VALVE (nonadjust-

able, Fig. 27) is located on the side of compressor adjacent

to seal housing. Regulator maintains correct oil pressure

(Table 6) and ensures satisfactory unloader operation.

A.

OIL REGULATING

VALVE BODY

GASKET

OIL REGULATING

VALVE CAP

Fig. 27 — Oil Pressure Regulating Valve

(Nonadjustable)

Unscrew regulator from crankcase; use 5/ 16-in. Allen

wrench on all compressors except 5H120, which requires

1/2-in. Allen wrench. Regulator must not be clogged and

plunger must not be stuck. Check drillings to regulator

for fouling.

The nonadjustable oil pressure regulator is inter

changeable on all current 5F,H compressors except

5 H120 and 5 H126 models. 5 H120 and 5 H126 units have

larger, nonadjustable regulators. Early 5F,H com

pressors were equipped with an adjustable-type oilpressure regulator. When an adjustable-type regulating

valve needs replacing, use a

nonadjustable regulator.

OIL RETURN CHECK VALVE (5F20 through 5H86)

allows oil to return from suction manifold to crankcase.

This normally open valve closes when crankcase pressure

becomes higher than suction pressure (Fig. 28).

Two disc-type check valves on 5F20 and 5F30 com

pressors are located beneath partition between suction

manifold and crankcase, one on each side of compressor.

Remove check valves through bottom cover or pump

end of eompressor.

Manufacturer reserves the right to discontinue, or change at any lime, specifications or designs without notice and without incurring obligations.

Book|2 PC 111 Catalog No 530-526 PrIntedInUSA Form5F,H-11SI Pg 25 2-86 Replaces: 5F.H-9SI

Tab 2a

For replacement items use Carrier Specified Parts.

Page 26

5F,H

HEATING A COOLING

Leaf-type check valve on 5F40 and 60 and 5H40, 46,

60, 66, 80, and 86 compressors is accessible through, and

located at top center of, handhole cover opening.

Remove check valves and check to see that flutter

valve or leaf does not stick, and that it seats tightly.

CHECK VALVE

LEAF TYPE

Fig. 28 — Oil Return Check Valves

Open-Drive Compressors

¡^‘'^PRESSURE RELIEF VALVE

(SEE NOTE)

NOTE: The pressure-relief valve is not part of the valve plate

assembly The valve mounts in the crankcase in the left side

cylinder deck (looking at pump end). The valve plate opening

outlined, slips over the pressure-relief valve when assembled

Fig. 30 — Pressure Relief Valve (5F60)

DISCHARGE MANIFOLD

PRESSURE RELIEF VALVE

OIL SEPARATOR

IMPELLER

\

Centrifugal Oil Separator Impeller

CENTRIFUGAL OIL SEPARATOR on 5HI20 and

126, mounted on crankshaft (Fig. 29), returns oil to

compressor crankcase. To remove or replace oil

separator, see Crankshaft Inspection and Service.

OIL FILTER SCREEN (Fig. 21) in compressor crank

case is accessible through handhole cover or bottom

plate. Remove and inspect it for holes, then clean it with

solvent and replace.

Pressure-Relief Valves — When pressure differ

ential between high- and low-pressure sides exceeds 350

± 35 psi (5F60: 400 ± 40 psi), pressure-relief valve bleeds

refrigerant from high to low side.

Check relief valves for evidence of leaking. Change if

defective or if valve has ever opened due to excessive

pressure.

5F60 COMPRESSORS — Internal relief valve screws

into crankcase and projects up through left cylinderbank valve plate (Fig. 30). Use a standard socket-type

screwdriver to remove and replace valve.

IP*

SUCTION AND DISCHARGE