Carrier 58MVP100, 58MVP060 Installation Guide

58NVP

[HEATING & COOUNG

\isit_ v_wcarrier.corn

VariabMe-Capacity Condensing Gas Furnace

tnstammation, Start-Up, and Operating

For Sizes 040 120, Series t70

NOTE: Read the entire instruction

manual bei\_re starting the installation

A93040

4-VVay MuMtipoise Dkect-Vent

This symbol --> indicates a change since the last issue,

Index Page

DIMENSIONAL DRAWING ........................................................ 3

SAFETY CONSIDERATIONS ..................................................... 2

Clearances to Combustibles ...................................................... 4

<ODES AND STANDARDS ........................................................ 5

ELE< TROSTATIC DIS<HARGE (ESD) PRE(AUTIONS ........ 5

INTRODU< TION .......................................................................... 5

APPLICATIONS ............................................................................ 5

General ...................................................................................... 5

Upf]ow Applications ................................................................. 5

Downflow Applications ............................................................ 8

Horizontal Left (Supply-Air Discharge) Applications ............ 9

Horizontal Right (Supply-Air Discharge) Applications ........ 11

LO< ATION .................................................................................. 13

General .................................................................................... ]3

Low-Heat Only Installation .................................................... 14

Furnace Location Relative to ( ooling Equipment ................ 14

Hazardous Locations ............................................................... i4

INSTALLATION ......................................................................... 15

Leveling Legs (If Desired) ..................................................... 15

Installation In [pflow or Downflow Applications ................ 15

Installation In Horizontal Applications .................................. 15

Air Ducts ................................................................................. ] 5

General Requirements ....................................................... 15

Ductwork Acoustical Treatment ....................................... 17

Supply-Air Connections .................................................... 17

Return=Air < onnections ..................................................... 18

Filter Arrangement .................................................................. 18

Bottom Closure Panel ............................................................. i8

Gas Piping ............................................................................... l 8

Electrical ( onnections ............................................................ 20

] 15-v Wiring ...................................................................... 20

24-v Wiring ........................................................................ 21

Accessories ........................................................................ 22

Direct Venting ......................................................................... 22

Removal of Existing Furnaces fl'om

( ommon Vent Systems ......................... 22

Combustion-Air and Vent Piping .................... 24

Concentric Vent and Combustion-Air Temaination

Kit Installation ................................ 28

Multiventing and Vent Tem_inations ................. 3 l

Condensate Drain ................................. 34

As an ENERGY STAR're

Pmmer, Carrier CoLvora-

don has detem*ined that

this product meets the EN'-

FR(SY S fAR_ guidelines

fbr energy effldency

START-UP, ADJUSTMENTS AND SAFETY CHECK. _ 35

REGISTERED QUALITY SYSTEM

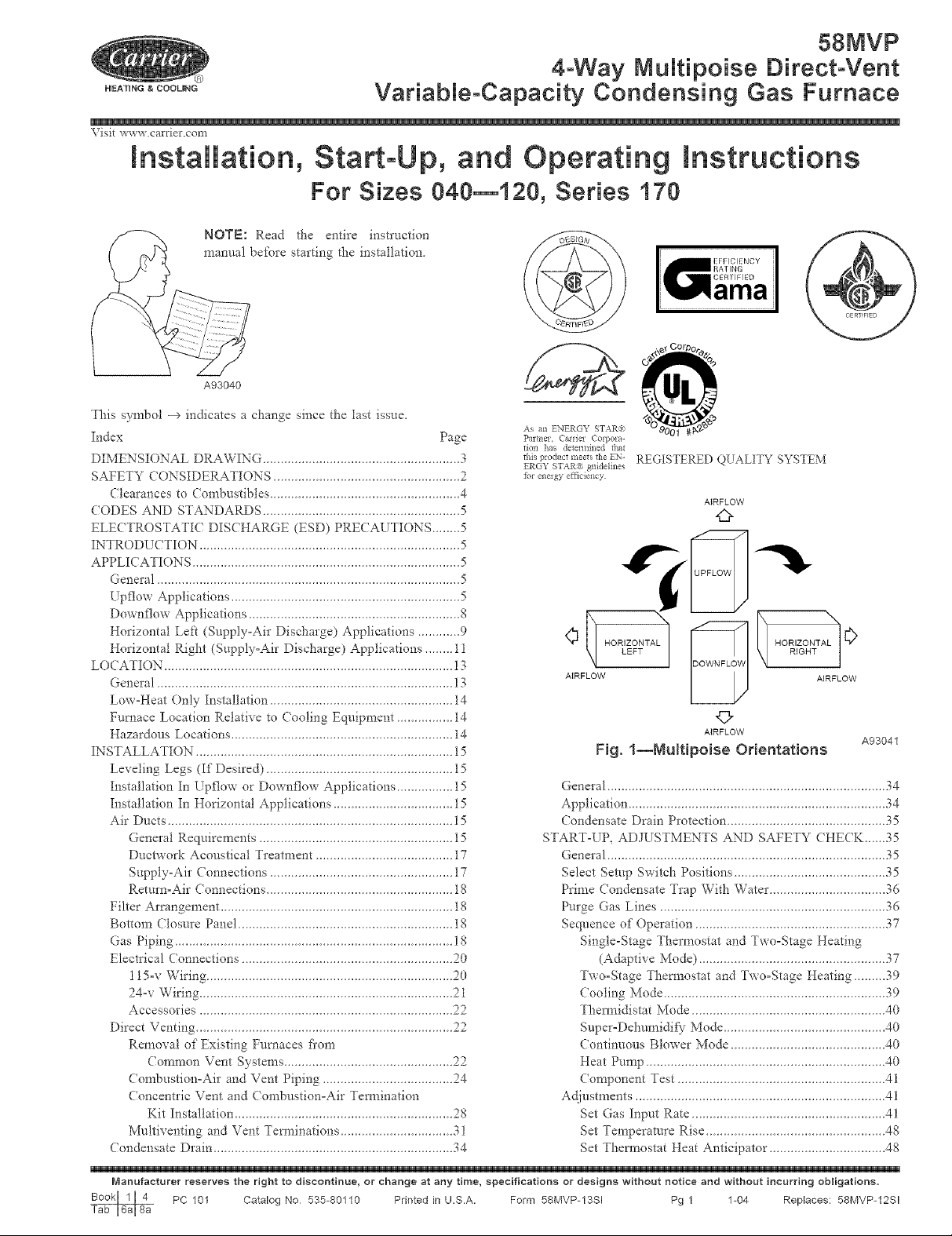

AIRFLOW

O

¢

HORIZONTAL HORIZONTAL

LEFT RIGHT

AIRFLOW AIRFLOW

©

AIRFLOW

Fig. 1--NuRipoise Orientations

General ............................................................................... 34

Application ........................................ 34

Condensate Drain Protection ...................... 35

General ......................................... 35

Select Setup Switch Positions ........................................... 35

Prime < ondensate Trap With Water ................................. 36

Purge Gas Lines ................................................................ 36

Sequence of Operation ...................................................... 37

Single-Stage Thermostat and Two-Stage Heating

(Adaptive Mode) .......................... 37

Two-Stage Them_ostat and Two-Stage Heating ...... 39

Cooling Mode .............................. 39

Them_idistat Mode .......................... 40

Supe*-Dehumidif) Mode ............................ 40

Continuous Blower Mode ...................... 40

Heat Pump ................................ 40

Component Test ............................ 41

Ac{iustments ................................... 4 l

Set Gas Input Rate .......................... 41

Set Temperam*e Rise .......................... 48

Set Them_ostat Heat Anticipator .................. 48

A93041

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 101 Catalog No 535-80110 Printed in U.S.A. Form 58MVP-13SI Pg 1 1-04 Replaces: 58MVP-12SI

(heck Safety Controls 49

Check Primary Limit Control 49

Check Pressure Switch ................................................. 49

(HE(KLIS7 ...................................................................... 49

SAFETY CONSIDERATtONS

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, unit leveling, and unit sizing. Improper

installation or misapplication of furnace can require excessive

servicing or cause premature component _hilure.

Improper installatiom adjustment, aheration, sela'ice, mainte-

nanc< or use can cause carbon monoxide poisoning, explo-

sion, tire, electrical shock, or other conditions which may

cause personal Jr!iraY or property damage. Consult a qualified

installer, sela-ice agency, local gas supplier, or your distribu-

tor or branch _br information or assistance. The qualified

installer or agency must use only _i_ctory-authorized and

listed kits or accessories when modit)'ing this product. Failure

to follow this warning could result in electrical shock, firQ

personal injury; or death.

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment°

Untrained personnel can perform basic maintenance fhnctions

such as cleaning and replacing air Jilters. All other operations nmst

be performed by trained service personnel. When working on

heating equipment, observe precautions in literature, on tags, and

on labels attached to or shipped with unit and other safety

precautions that may apply.

These instructions cover the minimum requirements and conform

to existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen-

tial construction practices. We require these instructions as a

minimum ibr a saf_ installation.

Wear safety" glasses and work gloves. Have a fire extinguisher

available during start-up and adjustment procedures and service

calls.

Recognize safety informatiom This is the safety=alert symbol _.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, CAU=

TION, and NOTE. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which will

result in severe personal injury or death. WARNING signifies

hazards which could resuh in personal Jr!jury or death. CAUTION

is used to identi_}' unsafe practices which would result in minor

personal injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

Sheet metal parts may have sharp edges or bun's. Use care and

wear appropriate protective clothing and gloves when hart=

dling parts. Failure to _bllow this caution could result in

personal injury.

propane gases (see t\trnace rating plate) and for installation in

alcoves, attics, basements, closets, utility rooms, crawlspaces, and

garages. The furnace is factory-shipped :_br use with natural gas A

C.S.A. (formerly AGA and CGA) listed gas conversion kit is

required to convert fhmace fbr use with propane gas

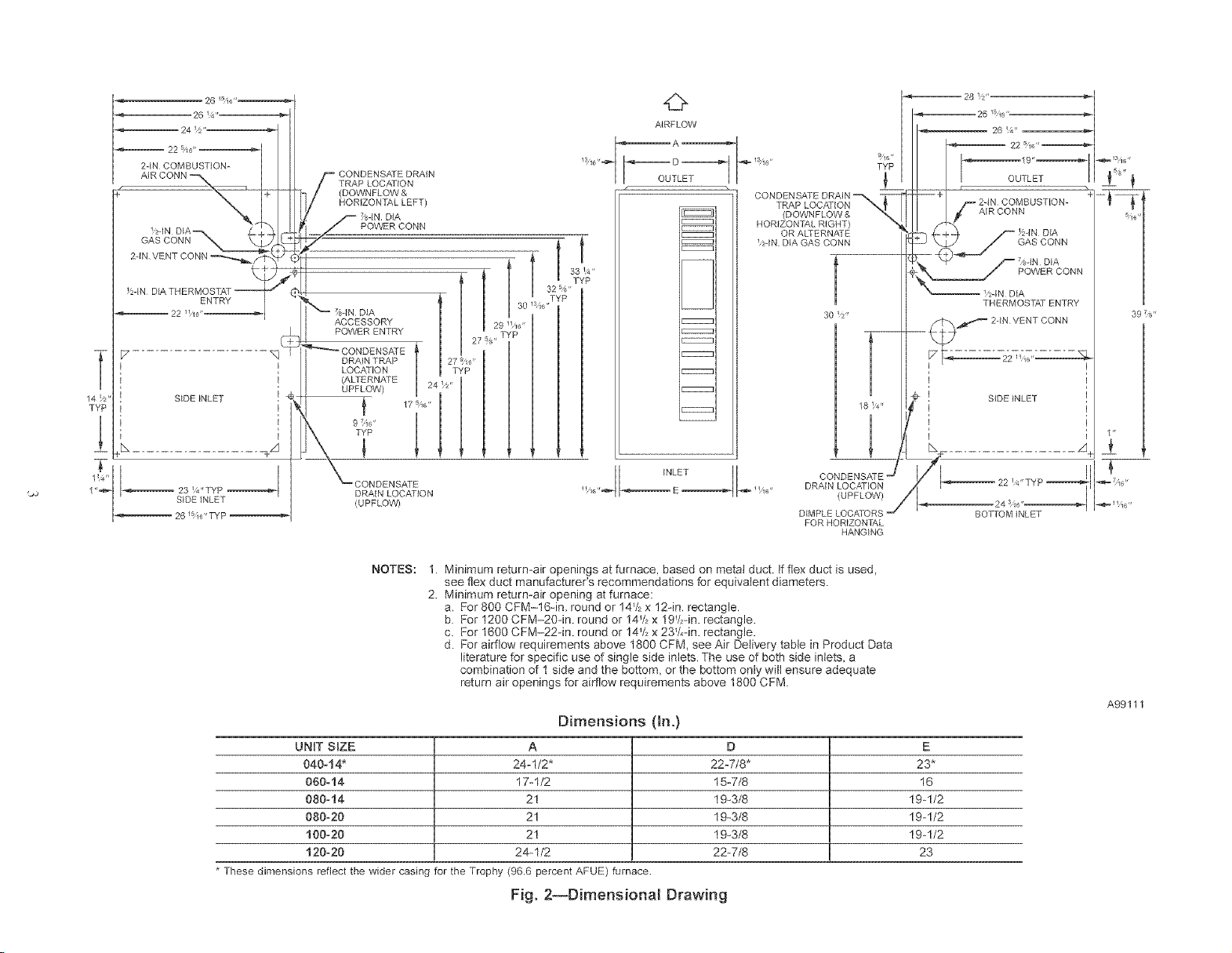

See Fig. 3 for required clearances to combustibles

Maintain a l-in clearance fi'om combustible materials to supply air

ductwork for a distance of 36 inches horizontally from the fl/rnace.

See NFPA 90B or local code ibr t:t_rther requirements.

These furnaces SHALL NOT be installed directly or* carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, factory accessow floor base MUST be

used when installed on combustible materials and wood flooring.

Special base is not required when this Nmace is installed on

manufacturer's (?oil Assembly Part No. CD5 or CK5, or when (Toil

Box Part No. KCAKC is used. These fl/rnaces are suitable for

.............. a structure built on site or a manufi_ctured building

completed at final site. The design of this Nmace line is NOT

C.S.A. (formerly AGA and CGA) design=certified for installation

in recreation vehicles or outdoors.

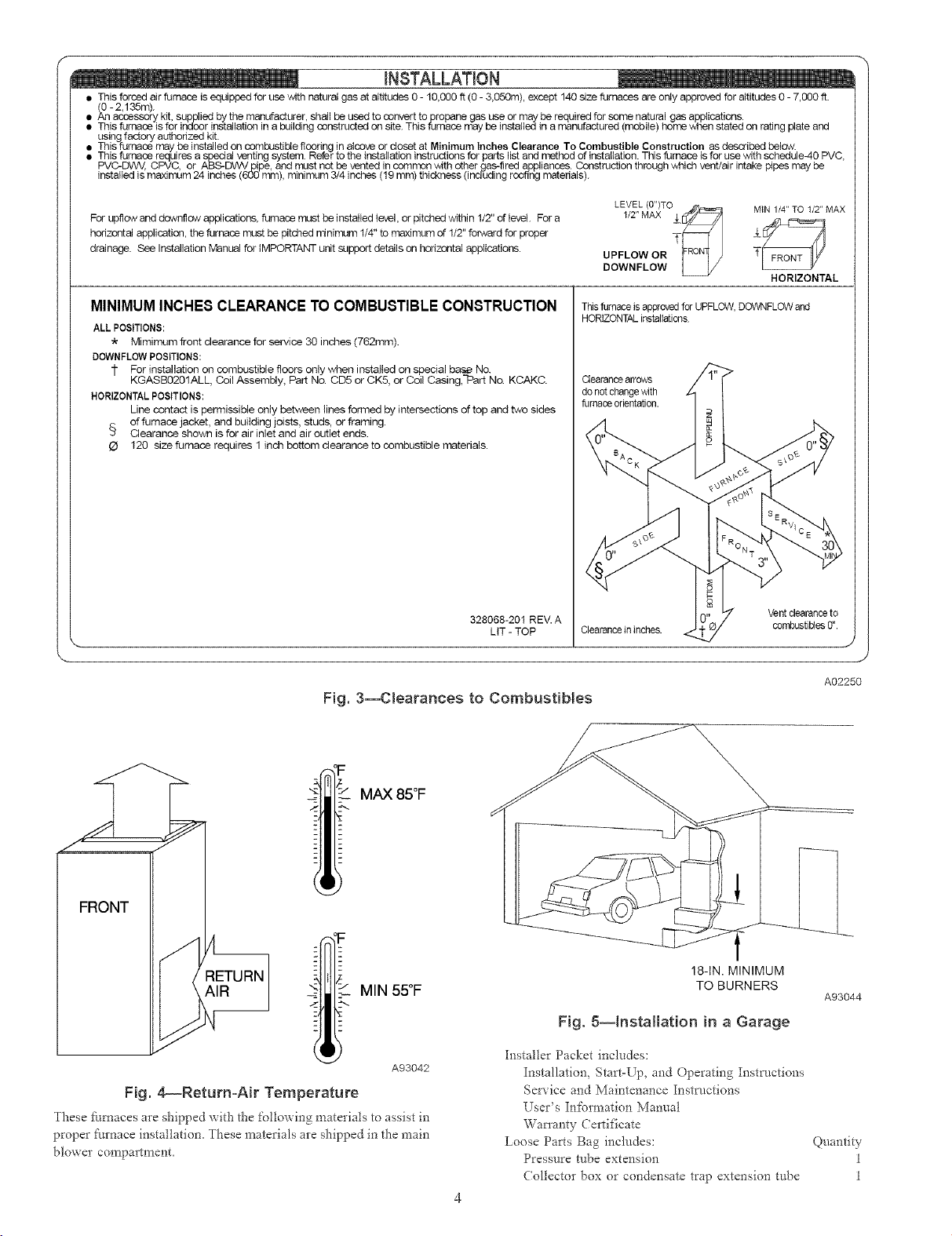

This t_umace is designed for continuous return-air minimum

temperature of 60 °F dh or intermittent operation down to 55°F db

such as when used with a night setback thermostat. Return-air

temperature must not exceed 85°F dh. Failure to lbllow these

return air limits may affect reliability of heat exchangers, motors

and controls. (See Fig. 4.)

These furnaces are shipped with the drain and pressure robes

connected for UPFLOW applications. Minor modifications are

required when used in DOW_NFLOW, HORIZONTAL RIGHT, or

HORIZONTAL LEFT (supply=air discharge direction) applica-

tions as shown in Fig. 1. See details in Applications section.

This furnace must be installed with a direct=vent (combustion air

and flue) system and a fi_ctory accessory temlination kit. In a

direct-vent system, all air for combustion is taken directly fiom the

outside atmosphere and all flue products are discharged to the

outside atmosphere. See fl/mace and factoo" accesso_' termination

kit instructions for proper installation.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections as specified in the GAS PIPING section

of these instructions.

Always install furnace to operate within the furnace's intended

temperature=rise range with a duct system which has an external

static pressure within the allowable range as specified in the SET

TEMPERATURE RISE section of these instructions.

When a furnace is installed so that the supply ducts car_- air

circulated by the fimaace to areas outside the space containing the

furnace, the remm air must also be handled by a duct(s) sealed to

the furnace casing and tem_inating outside the space containing the

ftmaace

A gas=fired furnace _br installation in a residential garage must be

installed as specified in the Hazardous Locations section and Fig.

5.

The furnace is not to be used for temporaw heating of buildings or

structures under construction unless the furnace installation and

operation complies with first CAUTION in the LOCATION

section of these instructions.

The 58MVP Muhipoise Condensing Gas=Fired Furnaces are

CSA, (formerly AGA and CGA) design-certified _br natural and

O

AIRFLOW

TYP

OUTLET

A m

, 1biN DiA GAS CONN

27

CONDENSATE DRAIN

TRAP LOCATION _

(DOWNFLOW &

HORIZONTAL RIGHT)

OR ALTERNATE

30 i_,,

7m-IN DIA

POWER CONN

I_z-IN DIA

THERMOSTAT ENTRY

)NN

1

18 _,_

i

I SiDE INLET

I

I

I

CONDENSATE

SiDE iNLET

DRAIN LOCATION

(UPFLO\A/}

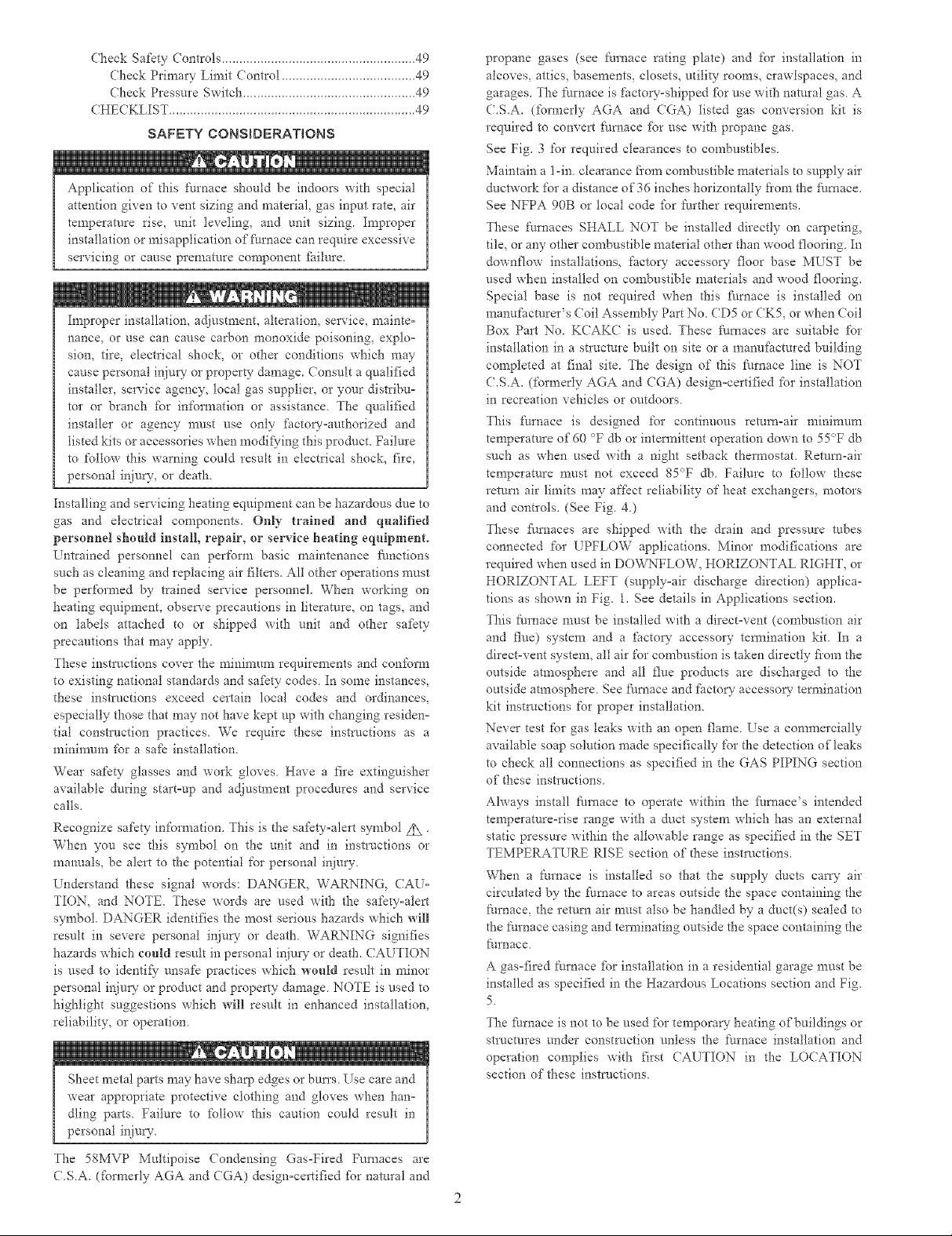

NOTES:

1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer's recommendations for equivalent diameters.

2. Minimum return-air opening at furnace:

a, For 800 CFM-16qn, round or 14V_x 12in, rectangle.

b. For 1200 CFM-20qn. round or 14V, x 19V2qn.rectangle.

c. For 1600 CFM-22-in. round or !4_/_x 23V,-in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data

literature for specific use of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only will ensure adequate

return air openings for airflow requirements above 1800 CFM.

UNIT SBZE A D E

040-14* 24-1/2" 22-7/8" 23*

060-14 17-1/2 15-7/8 16

080-14 21 19_3/8 19-1/2

080-20 21 19_3/8 19-1/2

100=20 21 19_3/8 19-1/2

120=20 24-1/2 22-7/8 23

* These dimensions reflect the wider casing for the Trophy (96,6 percent AFUE) furnace

Fig. 2--Dimensional Drawing

INLE_ DRA{N LOCATION

Dimensions (in.)

DIMPLE LOCATORS

FOR HORIZON 17_,L

HANGING

A99111

• This forced air furnace is equipped for use with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m), except 140size furnaces are only approved for altitudes 0 - 7,000 ft.

(C0- 2,135m).

• An accessory kit, supplied by the manufacturer, shall be used to convert topropane gas use or may be required for some natural gas applications.

• This furnace is for indoor installation in a building constructed on site. This furnace nay be installed in a manufactured (mobile) home wden stated on rating plate and

using factory authorized kit.

This furnace may de installed on combustible flooring in alcove or closet at Minimum Inches Clearance To Combustible Construction as described below.

This furnace requires a special venting system. Refer to the installation instructions for parts list and method of installation. This furnace is for use with schedule-40 PVC,

PVC-DWV, CPVC, or ABS-DWV pipe, and must not be vented in seron-on with other Igas-fired appliances. Construction through which vent/air intake pipes may be

installed is maximum 24 inches (600 ram), minimum 3/4 inches (19 mm) thickness (including roofing n',atedals).

For upflow and downflow applications, furnace must be installed level, or pitched within 1/2" of level. For a

horizontal application, the furnace must be pitched ninimum 1/4" to maximum of 1/2" fo_verd for proper

drainage. See Installation Manual for IMPORTANT unit support details on horizontal applications.

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSITIONS:

* Mimimum front clearance for service 30 inches (762mm).

DOWNFLOWPOSITIONS:

1" For installation on combustible floors only when installed on special bas,_ No.

KGASB0201ALL, Coil Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

HORIZONTALPOSITIONS:

Line contact is permissible only between lines fon-ned by intersections of top and two sides

of furnace jacket, and building joists, studs, or framing.

,_ Clearance shown is for air inlet and air outlet ends.

O 120 size furnace requires 1 inch bottom clearance to combustible materials.

328068-201 REV. A

LtT - TOP

Fig. 3--Clearances to CombustiNes

LEVEL (0")TO ,,#_1_,._=_

1/2"MAX __

UPFLOW OR r_-,i/J

DOWNFLOW L_..Y

Thisfurnace isapl_oved forUPFLOW,DOWNFLOWand

HORIZONTALinstallations

Clearancearrows

do not change,with

fumace orientation.

MIN 1/4" TO t/2" MAX

HORIZONTAL

J

A02250

MAX 85°F

MIN 55°F

A93042

Fig. 4_Return-Air Temperature

These timaaces are shipped with the following materials to assist in

proper furnace installation, These materials are shipped in the main

blower compa_lment,

18-IN. MINIMUM

TO BURNERS

Fig. 5--installation in a Garage

Installer Packet includes:

Installation, Start=Up, and Operating Insm/ctions

Service and Maintenance Instructions

User's Inforn_ation Manual

Wan'anty Certificate

Loose Parts Bag includes:

Pressure tube extension

Collector box or condensate trap extension tube

A93044

Quantity

1

1

Inducer housing drain robe 1

1/2°in CPVC street elbow 2

Drain tube coupling 1

Drain tube coupling grommet 1

Vent and combustion°air pipe support 2

Combustion-air pipe perforated disk assembly 1

Condensate trap hole Illler plug 3

Vent and combustion°air intake hole filler plug 2

For accessory installation details, refBr to applicable installation

literature

CODES AND STANDARDS

Follow all national and local codes and standards in addition {o

these instructions° The installation must comply with regulations

of the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and all authorities

having jurisdiction in Canada.

In the United States and Canada, follow all codes and standards for

the fbllowing:

Step l--Safety

* US: National Fuel Gas Code (NFGC) NFPA 54-2002/ANSI

Z223.1o2002 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI NFPA 90B

* CANADA: National Standard of Canada, Natural Gas and

Propane Installation Code (NSCNGPIC) CSA BI49.!-00

Step 2--General hstaHation

* US: NFGC and the NFPA 90B. For copies, contact the National

Fire Protection Association Inc., Battewmarch Park, Quincy,

MA 02269; or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W., Washington DC 20001

* CANADA: NSCNGPIC. For a copy, contact Standard Sales,

CSA International, 178 Rexdale Boulevard, Etobicoke (Tor-

onto), Ontario, M9W 1R3, Canada.

Step a--Combustion and Ventilation Air

* US: Section 8.3 of the NFGC, Air for (ombustion and

Ventilation

* CANADA: Part 7 of the NSCNGPIC, Venting Systems and Air

Supply fbr Appliances

Step 4--Duct Systems

* US and CANADA: Ab" (onditioning (ontractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning Con=

tractors National Association (SMACNA), or American Soci=

ety of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) 2001 Fundamentals Handbook Chapter 34.

Step 5--Acoustical Lining and Fibrous Glass Duct

* US and CANADA: current edition ofSMACNA, NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air Ducts

Step 6--Gas Piping and Gas Pipe Pressure Testing

* US: NFG(; chapters 5, 6, 7, and 12 and national plumbing

codes

* CANADA: NSCNGPIC Parts 3, 4, 5, A, B, E, G, and H

Step 7--Electrical Connections

* US: National Electrical Code (NEC) ANSIiNFPA 70°2002

* CANADA: Canadian Electrical Code CSA C2Z1

ELECTROSTATIC DBSCNARGE {ESD) PRECAUTIONS

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect tl_e l\lrnace electlonic control. Precautions will pre-

vent electrostatic discharges tiom personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electlostatic discharge

by putting the t:ornace, the control, and the person at the same

electrostatic potential

1. Disconnect all power to the furnace. Multiple disconnects may

be require& DO NOT TOUCH THE CONTROL OR ANY

WIRE CONNECTED TO THE CONTROL PRIOR TO DIS-

CHARGING YOUR BODY'S ELECTROSTATIC CHARGE

TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the fimaace

chassis which is close to the control. Tools held in a person's

hand during grounding will be satisfactorily discharged.

3. After touching the chassis, you may proceed to service ff*e

control or connecting wires as long as you do nothing that

recharges your body with static electricity (fbr example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded

objects, etc.).

4. If you touch ungrounded objects (recharge your bo@ with

static electricity), firmly touch fi/mace again befbre touching

control or wires.

5. Use this procedure for installed and uninstalled (ungrounded)

_/fnaces

6. Before removing a new contlol fiom its container, discharge

your bo@'s electrostatic charge to ground to protect the

control f?om damage. If d_e control is to be installed in a

fhmace, fbllow items 1 through 5 befbre bringing the control

or yourself into contact with the Nrnace. Put all used AND

new controls into containers before touching ungrounded

objects.

7. An ESD service kit (available from commercial sources) may

also be used to prevent ESD damage.

mNTRODUCTION

The model 58MVP 4-way multipoise, Gas-Fired, Categow IV,

direct=vent condensing fhmace is available in model sizes ranging

in input capacities of 40,000 to 120,000 Btuh,

APPLICATIONS

Step i--General

Some assembly and modifications are required %r l\zrnaces

installed in any of the 4 applications shown in Fig. 1. All drain and

pressure tubes are connected as shown in Fig 7 See appropriate

application instructions for these procedures.

NOTE: In Canada, installations shall be in accordance with

cmTent NSCNGPIC and/or local codes.

Step 2--Upflow Applications

An upflow ihmace application is where f_/rnace blower is located

below combustion and controls section of furnace, and conditioned

air is discharged upwards.

__D FURNACE

TRAP (INSIDE_ X[

OOR

/-- CONDENSATE

/ TRA uRNAOE7

J SIDV

/o

£_2% ......

_1 FURNACE

OOR

-- FURNACE

SIDE

FIELD--

DRAIN

CONN

TU% OOSO ETRAP

DRAIN TUBE LOCATION

UPFLOW APPLICATIONS

SIDE VIEW FRONT VIEW

DOWNFLOW AND ALTERNATE

EXTERNAL UPFLOW APPLICATIONS

s'-°7'-%:°:U7

(OPTIONAL) /

GUIDES

(WHEN USED)

FRONT VIEW SIDE VIEW

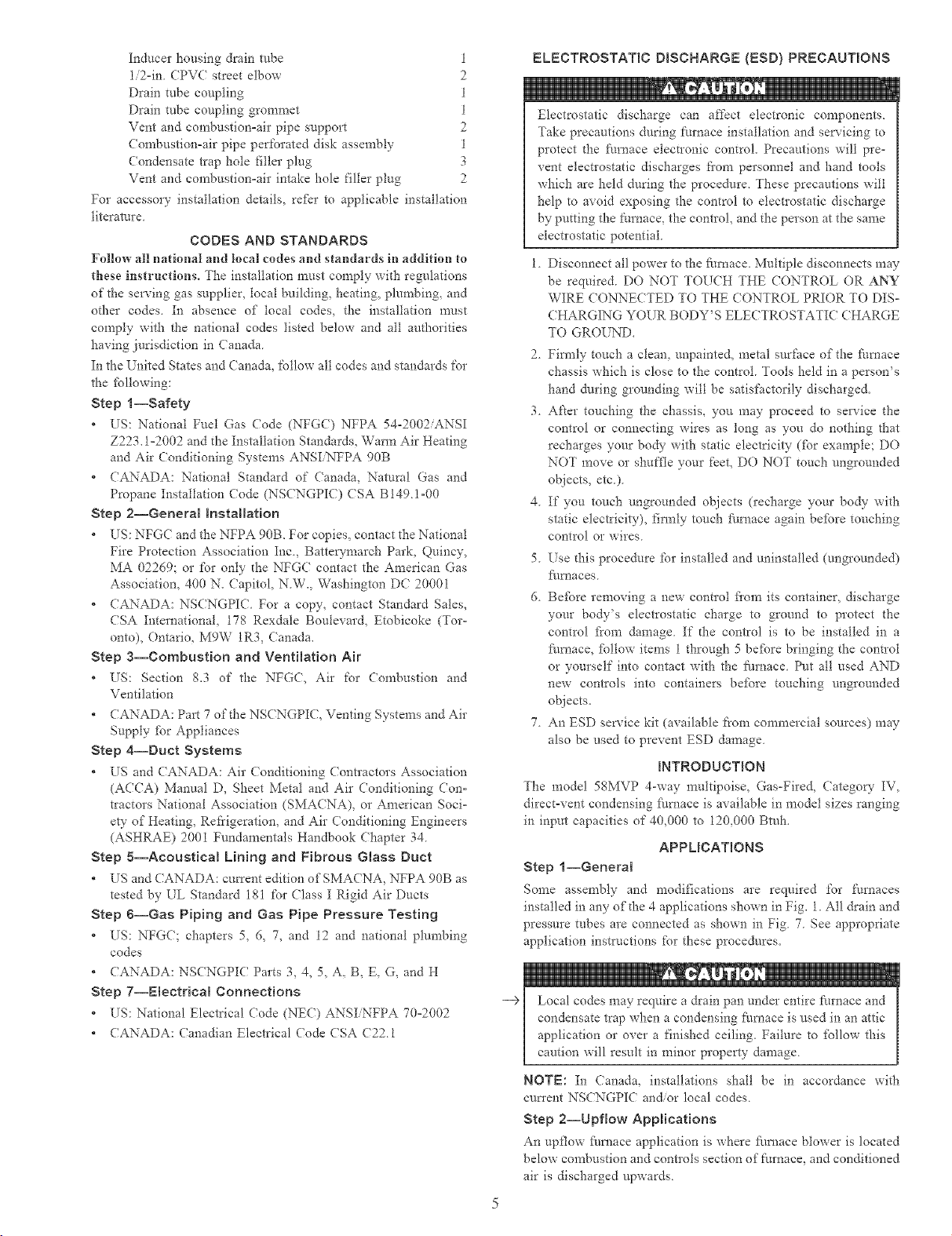

Fig. 6--Condensate Trap

71/8

l

FIELD --

DRAIN

CONN

END VIEW FRONT VIEW

COD

COLLECTOR BOX TO

TRAP RELIEF PORT

_OD

INDUCER HOUSING

DRAIN CONNECTION

'_OD

COLLECTOR BOX

DRAIN CONNECTION

SCREW HOLE FOR

UPFLOW OR DOWN-

FLOW APPLICATIONS

(OPTIONAL)

Y2-1N. PVC OR CPVC

¾

HORIZONTAL

APPLICATIONS

A93026

CONDENSATE TRAP LOCATION (FACTORY-SHIPPED

ORIENTATION)

The condensate trap is _lactory installed in the blower shelf and

_%cto*yconnected for UPFLOW applications A factow-supplied

tube is used to extend the condensate trap drain connection to the

desired furnace side for field drain attachment See Condensate

Trap Tubing (Factory=Shipped Orientation) section _br drain tube

extension details, (See Fig 6)

CONDENSATE TRAP TUBING (FA(TORY-SHIPPED

ORIENTATION)

NOTE: See Fig 7 or tube roudng label on main flul_ace door to

confirm tocation of these tubes

l. (ollector Box Drain, Inducer Housing Drain, Relief Pro1, and

Pressure Switch Tubes

These robes should be factory attached to condensate trap and

pressure switch tea@ for use in UPFLOW applications. These

robes can be identified by their connection location and also

by a color label on each robe. These robes are identified as

_bllows: collector box drain robe (blue label), inducer housing

&ain robe (violet label or molded), relief port tube (green

label), and pressure switch robe (pink label).

2. (ondensate Trap Drain Tube

The condensate trap drain connection must be extended for

field attachment by doing the ibllowing:

a Detemine location of field drain connection (See Fig. 2 or

7)

NOTE: If internal filter or side filter media cabinet is used, &ain

robe should be located to opposite side of casing fiom remm duct

attachment to assist in filter removal

b. Remove and discard casing drain hole plug button from

desired side.

c Install &ain robe coupling grommet (factow-supplied in

loose parts bag) in selected casing hole.

d. Slide &ain robe coupling (fi_ctory=supplied in loose parts

bag) through grommet so tong end of coupling _i_ces

blower.

e Cement 2 factory=supplied 1/2-in. street CPVC elbows to

rigid &ain tube connection on condensate trap (See Fig. 7)

These elbows must be cemented together and cemented to

condensate trap &ain connection.

NOTE: Failure to use CPVC elbows may allow &ain to kink,

preventing draining.

£ Connect larger diameter drain tube and clamp (factory-

supplied in loose parts bag) to condensate trap and clamp

securely,

COLLECTOR

DRAIN TUBE (BLUE

& WHITE STRIPED)

COLLECTOR

TUBE (PINK)

(MOLDED) DRAIN

TUBE (BEHIND

COLLECTOR BOX

DRAIN TUBE)

DRAIN TUBE (BLUE)

COLLECTOR BOX

TUBE (GREEN)

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (LEFT

DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

FACTORY-SUPPLIED

//2 -IN CPVC STREET

LEFT DRAIN OPTION

PLUG

CAP

FIELD-INSTALLED

ELBOWS (2) FOR

FIELD-INSTALLEE

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (RIGHT

DRAIN OPTION)

DRAIN TUBE (BLUE

& WHITE STRIPED)

COLLECTOR BOX

TUBE (PINK)

COLLECTOR BOX

TUBE (GREEN)

COLLECTOR BOX

DRAIN TUBE (GREEN)

TRAP

HOUSING

DRAIN TUBE

(VIOLET)

©

O O

A94213

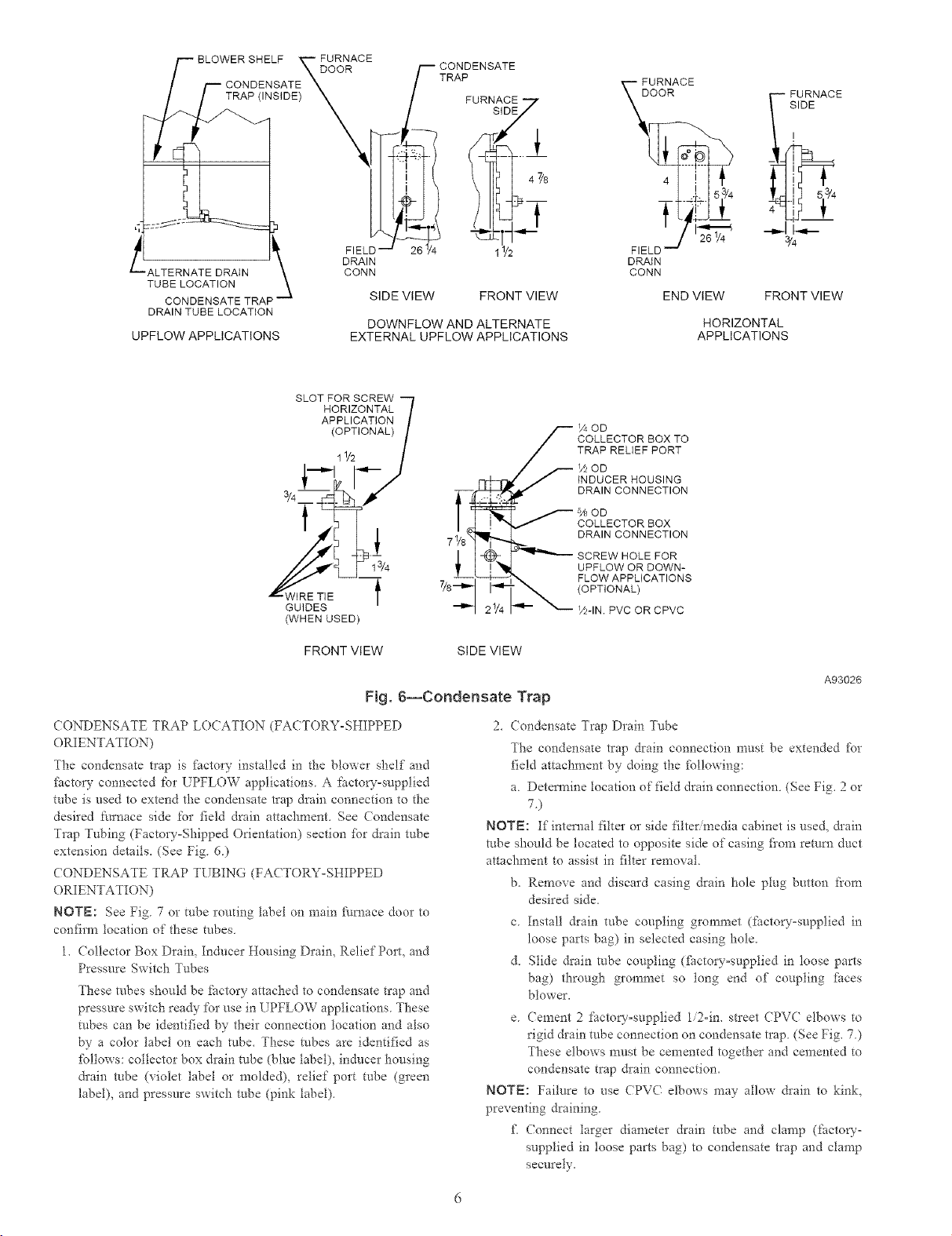

Fig. 7--Factory-SNpped Upflow Tube Configuration

(Shown With Blower Access Pane_ Removed}

g. Route tube to coupling and cut [o appropriate length

1",.Attach robe to coupling and clamp securely.

CONDENSATE TRAP LO(ATION (ALTERNATE UPFLOW

ORIENTATION)

An alteraate location _Pr the condensate tlap is the left=hand side

of casing. (See Fig 2 and 8)

NOTE: If the alternate lek=hand side of casing location is used,

the _i_ctory=cormected &ain and relief port robes must be discon=

nected and modified fo* attachment. See Condensate Trap Tubing

(Alternate Upflow Orientation) section for tubing attachment

To relocate condensate t_ap to the tef_-hand side, perfbm_ the

following:

1. Remove 3 tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs inward

and rotating t_ap.

3. Instal! casing hole filler cap ditctow-supplied in loose parts

bag) into blower shelf hole where trap was removed.

A94214

Fig. 8--ARernate Upflow Tube Configuration and

Trap Location

(using hole filler cap must be installed in blower shelf hole

when condensate trap is relocated. Failure to tbllow d_is

warning could result in electrical shock, fire, personal injury

or death.

4. Install condensate trap into left=hand side casing hole by

inserting tube connection stubs through casing hole and

rotating until tabs snap into locking position.

5. Fill unused condensate trap casing holes with plastic filler

caps (factory=supplied in loose parts bag).

CONDENSATE TRAP TUBING (ALTERNATE UPFLOW

ORIENTATION)

NOTE: See Fig. 8 or robe routing label on main Nrnace door to

confirm location of these robes.

1. Collector Box Drain Tube

Connect collector box &ain robe (blue label) to condensate

trap.

NOTE: On 17=1/2=in. wide fi/rnaces ONLY, cut robe between

con'ugated sections to prevent kinks.

2. Inducer Honsing Drain Tube

a. Remove and discard LOWER (molded) inducer housing

drain robe which was previously connected to condensate

trap

COLLECTOR BOX

DRAIN TUBE (BLUE)

PLUG

COLLECTOR BOX

TUBE (GREEN)

CA_

O O

TUBE (GREEN)

DRAIN TUBE (BLUE)

TUBE (PINK)

COLLECTOR

DRAIN TUBE (BLUE

& WHITE STRIPED)

EXTENSION TUBE

TRAP

©

INDUCER HOUSING

DRAIN TUBE(VIOLET) ._

A94215

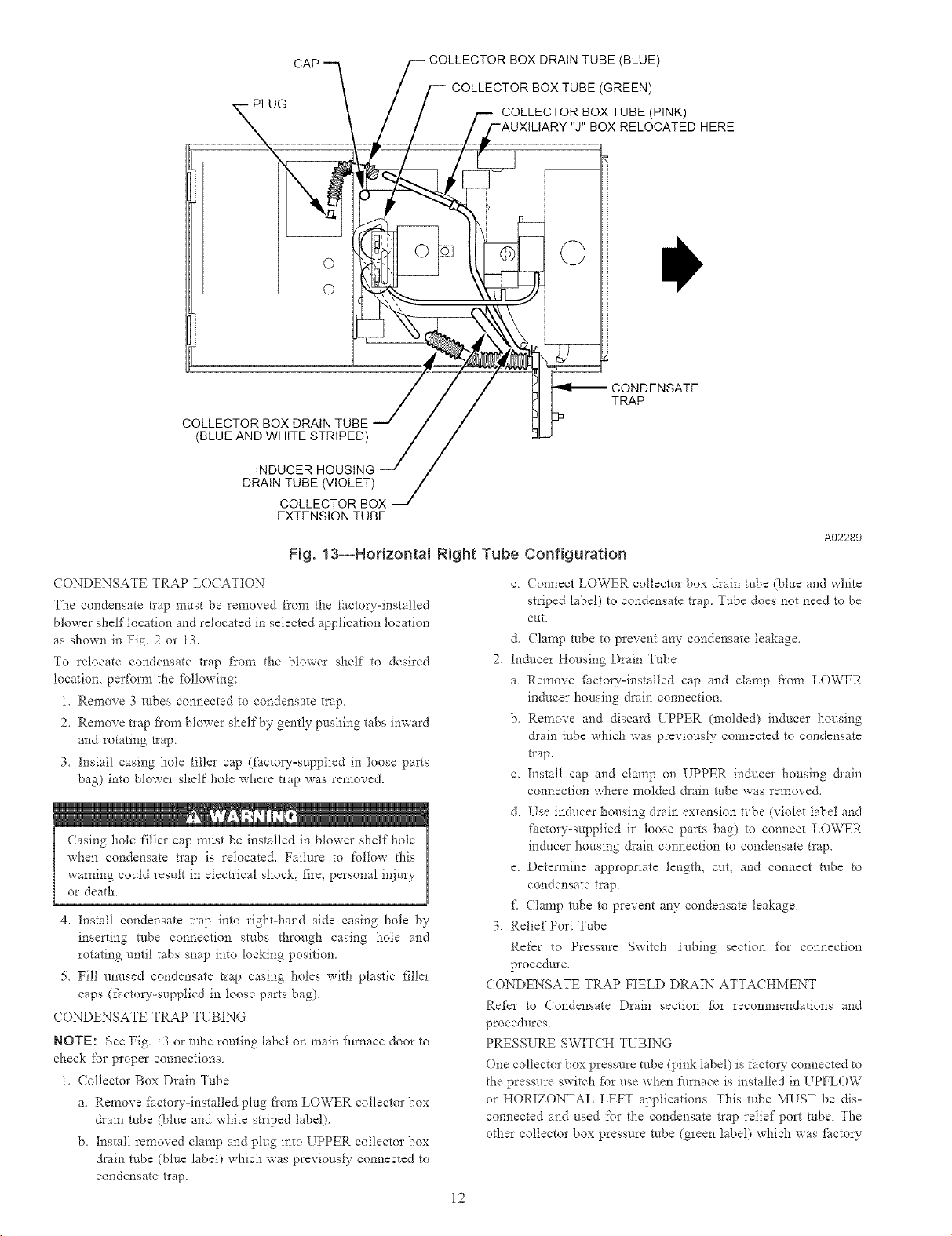

Fig. 9--Downflow Tube Configuration

(Left-Hand Trap Installation)

b. Use inducei housing &ain extension tube (violet label and

thctow-supplied in toose parts bag) to connect LOWER

inducer housing &ain connection to condensate trap.

c. Detem_ine appropriate tength, then cut and connect tube.

d. Ctamp robe to prevent any condensate leakage.

3. Relief Port Tube

a. (onnect relief port tube (green label) to condensate trap.

b. Extend this tube (if required) by splicing to small diameter

tube (fhctowosupplied in toose parts bag)

c. Detem_ine appropriate tength, then cut and connect tube.

(ONDENSATE TRAP FIELD DRAIN ATTACHMENT

Refkr to Condensate Drain section for recommendations and

procedures

PRESSURE SWITCH TUBING

The LOWER collector box pressure tube (pink 1abel) is factor

connected to the pressure switch and should not require any

modification.

NOTE: See Fig 7 or g or tube routing label on main [:umace door

to check fbr proper connections.

UPPER COLLECTOR BOX AND INDUCER HOUSING

(UNUSED) DRAIN CONNE(TIONS

Upper Collector Box Drain (7onnection

Attached to the UPPER collector box drain connection is a

fhctory=installed corn/gated, plugged robe (blue and white striped

label) This robe is plugged to prevent condensate leakage in this

application Ensure this robe is plugged

NOTE: See Fig. 7 or 8 or robe routing label on main furnace door

to check fbr proper connections.

TUBE (PINK)

COLLECTOR BOX

DRAIN TUBE (BLUE

& WHITE STRIPED)

COLLECTOR BOX

EXTENSION TUBE

DRAIN TUBE

(VIOLET)

CONDENSATE

TRAP

EXTENSION

DRAIN TUBE

'DRAIN TUBE

COUPLING

A94216

Fig. 10--Downflow Tube Configuration

(Right=Hand Trap Insta{lation)

Upper Inducer [Iousing Drain (onnection

Attached to the UPPER (unused) inducer housing &ain connection

is a cap and clamp. This cap is used to prevent condensate leakage

in this application. Ensure this connection is capped.

NOTE: See Fig. 7 or 8 or tube routing label on main fhrcmce door

to check fbr proper connections.

CONDENSATE TRAP FREEZE PROTECTION

Refer to Condensate Drain Protection section for recommenda-

tions and procedures.

Step 3--Downflow Applications

A downflow fm'nace application is where furnace blower is located

above combustion and controls section of furnace, and conditioned

air is discharged downwards.

CONDENSATE TRAP LOCATION

The condensate trap must be removed ti"om the fhctow-installed

blowe* shelf'location and relocated in selected application tocation

as shown in Fig. 2, 9, or 10

To relocate condensate trap fi'om the blower shelf to desired

location, per%tin the following:

1. Remove 3 tnbes connected to condensate t_ap.

2. Remove trap from blower shelf by gently pushing tabs inward

and rotating trap.

3. Remove casing hole filler cap flora casing hole (See Fig. 2

and 10.)

4. Install casing hole filler cap (fhctow-supplied in toose parts

bag) into blower shelf hole where trap was removed

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated. Failure to %llow this

warning could result in electrical shock, fire, personal injury

or death.

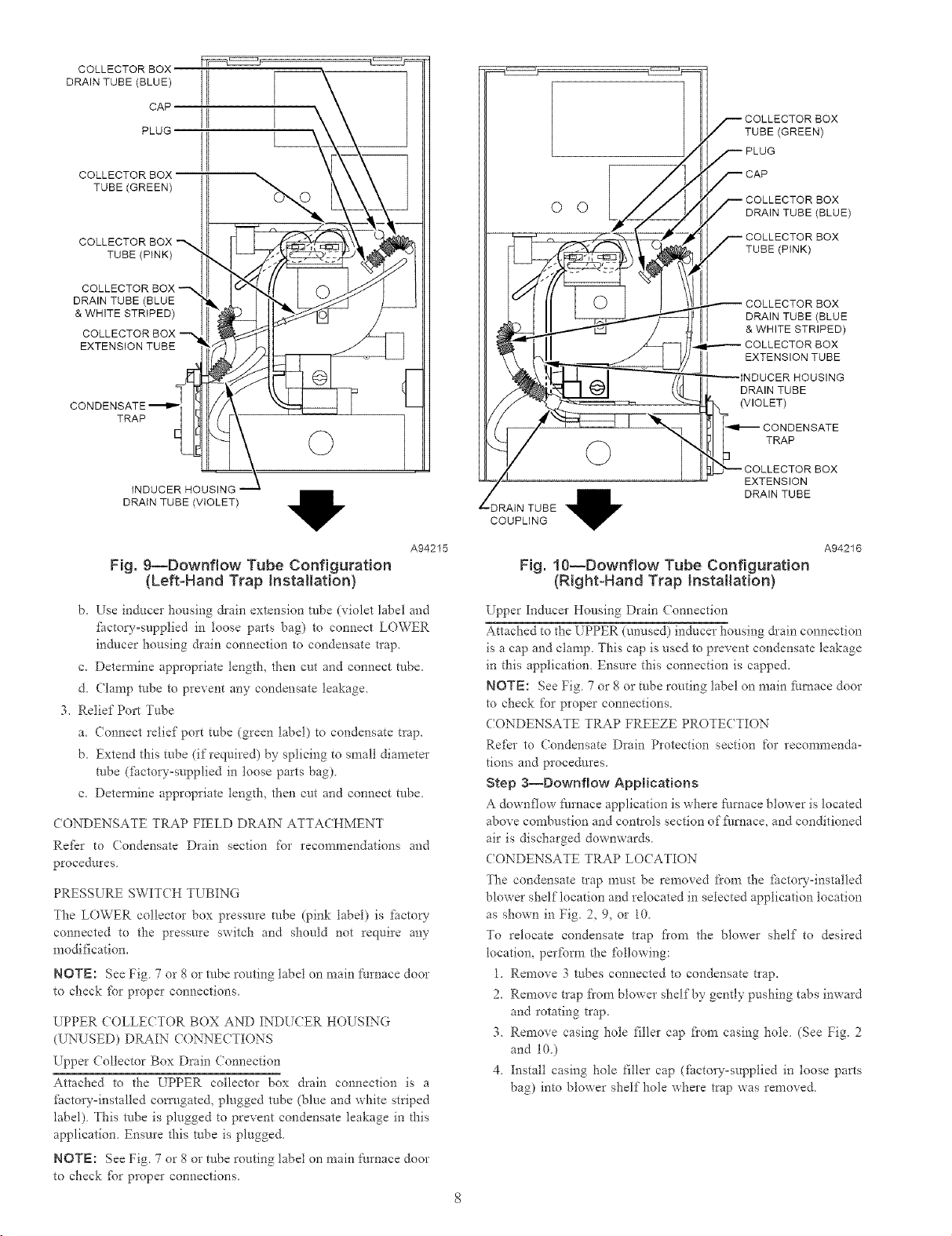

5. Install condensate trap into left-hand side casing hole by

inserting tube connection stubs through casing hole and

rotating until tabs snap into locking position,

6. Fill unused condensate trap casing holes with plastic filler

caps (flactory°supplied in toose parts bag)

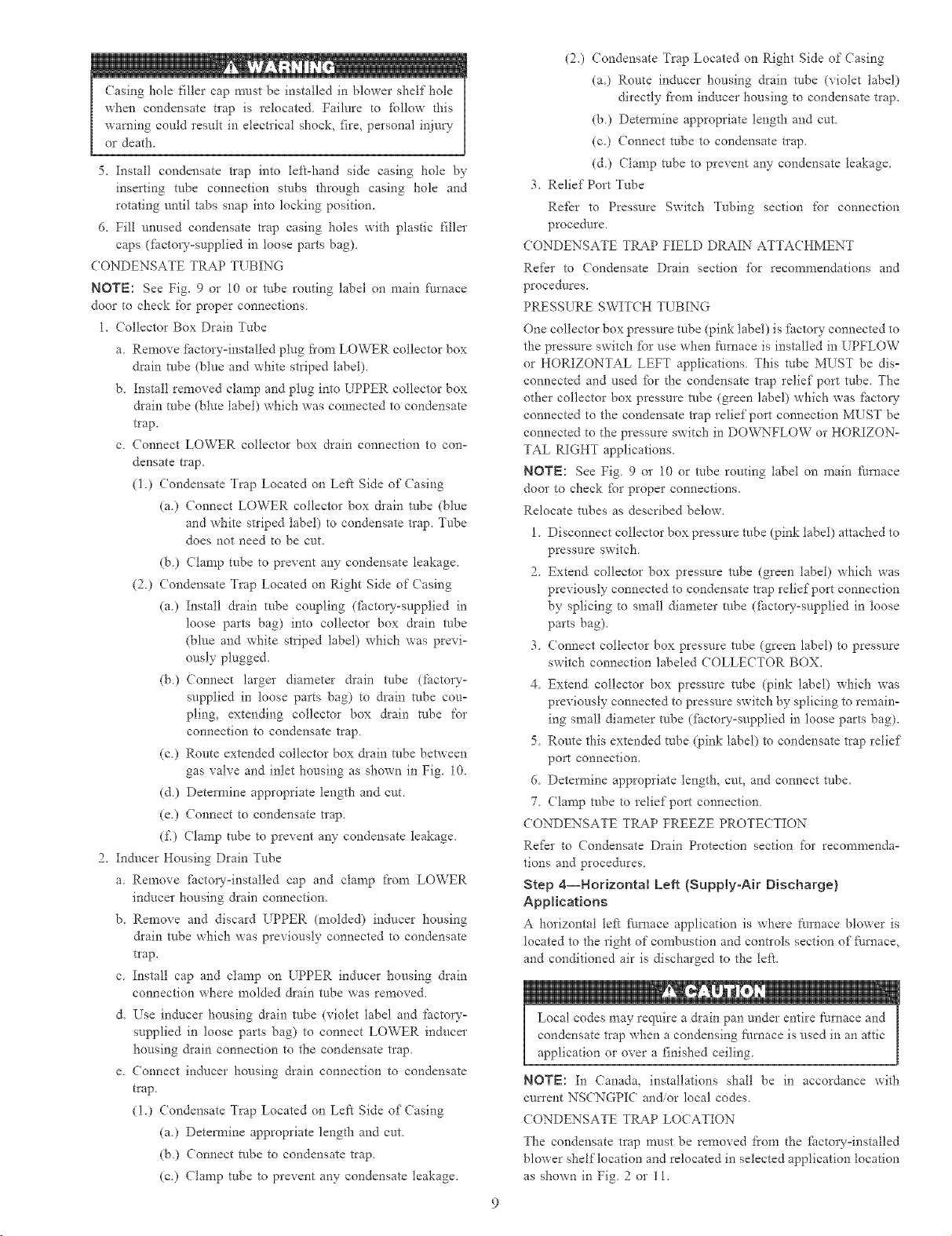

CONDENSATE TRAP TUBING

NOTE: See Fig. 9 or 10 or robe routing label on main fm'nace

door to check for proper connections

1. (ollector Box Drain Tube

a. Remove fi_ctory=installed plug flora LOWER collector box

drain robe (blue and white striped label).

b. Instal! removed clamp and plug into UPPER collector box

&ain tube Cblue label) which was connected to condensate

t_ap.

c. Connect LOWER collector box drain connection to con=

densate tlap.

(1.) Condensate Trap Located on Left Side of Casing

(aj Connect LOWER collector box &ain robe (blue

and white striped label) to condensate trap. Tube

does not need to be cut.

Cb.) Clamp tube to prevent any condensate leakage.

CZ) Condensate Trap Located on Right Side of (asing

Caj Install drain tube coupling (fhctow-supplied in

loose parts bag) into collector box drain robe

(blue and white striped label) which was previ=

ously plugged.

Cb.) Connect larger diameter &ain robe (g_ctory=

supplied in loose parts bag) to &ain tube cou=

piing, extending collector box drain robe for

connection to condensate trap

Cc) Route extended collector box &ain tube between

gas valve and inlet housing as shown in Fig. 10.

Cd) Dete*mine app*opriate length and cut

(e) Connect to condensate t*ap

(f.) Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

a. Remove titctoEv=installed cap and clamp from LOWER

inducer housing drain connection.

b. Remove and discard UPPER (molded) indocer housing

&ain robe which was previously connected to condensate

tlap.

c Install cap and clamp on UPPER inducm housing &ain

connection where molded &ain robe was removed.

d. Lse inducer housing &ain robe (violet 1abel and factory=

supplied in loose parts bag) to connect LOWER inducer

housing &ain connection to the condensate trap

e. (onnect inducer housing drain connection to condensate

trap.

Cij (ondensate Trap Located on Left Side of (asing

Ca.) Detem_ine appropriate lengd_ and cut.

(b.) Connect robe to condensate trap.

(c.) Clamp robe to prevent any condensate leakage.

(20 (ondensate Trap Located on Right Side of Casing

Ca.) Route inducer housing drain robe (violet label)

directly from inducer housing to condensate trap.

Cb) Determine appropriate length and cut

(c.) (onnect robe to condensate trap.

C&) Clamp robe to prevent any condensate leakage.

3. Relief Port Tube

Re_kr to Pressure Switch Tubing section ibr connection

procedure.

CONDENSATE TRAP FIELD DRAIN ATTACHMENT

Re_kr to Condensate Drain section %r recommendations and

procedures.

PRESSURE SWITCH TUBING

One collector box pressure tube (pink label) is factory connected to

the pressure switch %r use when furnace is installed in UPFLOW

or HORIZONTAL LEFT applications. This robe MUST be dis-

connected and used ibr the condensate trap relief port robe. The

other collector box pressure robe (green label) which was ifctory

connected to the condensate trap relief port connection MUST be

connected to the pressure switch in DOVv_FLOW or HORIZON-

TAL RIGHT applications.

NOTE: See Fig. 9 or 10 or robe routing label on main furnace

door to check %r proper connections.

Relocate tubes as described below.

1. Disconnect collector box pressure robe (pink label) attached to

pressure switch.

2. Extend collector box pressure robe Cgreen label) which was

previously connected to condensate trap relief port connection

by splicing to small diameter robe Cflactou-supptied in loose

parts bag).

3. (onnect collector box pressure robe (green label) to pressure

switch connection labeled COLLECTOR BOX.

4. Extend collector box pressure tube (pink label) which was

previously connected to pressure switch by splicing to remain-

ing small diameter tube Cfactow-supplied in loose parts bag).

5 Route this extended tube {pink label) to condensate trap relief

port connection.

6. Determine appropriate length, cut, and connect robe.

7. (lamp robe to relief port connection.

CONDENSATE TRAP FREEZE PROTECTION

Refer to (ondensate Drain Protection section for recommenda-

tions and procedures.

Step 4--Horizontal Left (Supply°Air Discharge)

Applications

A horizontal te_ _hmace application is where furnace blower is

located to the right of combustion and controls section of _hrnace,

and conditioned air is discharged to the left.

Local codes may require a drain pan under entire furnace and

condensate trap when a condensing thmace is used in an attic

application or over a finished ceiling.

NOTE: In Canada, installations shall be in accordance with

cmTent NSCNGPI( and/or local codes

CONDENSATE TRAP LO(ATION

The condensate trap must be removed from the fi_ctory=installed

blower shelf location and relocated in selected application location

as shown in Fig 2 or 11.

PLUG --

AUXILIARY "J" BOX --_ \ ] f-- COLLECTOR BOX

TRAP X\\ XX \ TUBE(GREEN)

RELOCATE TUBE BETWEEN BLOWER SHELF AND INDUCER HOUSING FOR

\ \ ] / DRAIN TUBE

_/ / / (BLUE AND WHITE STRIPED)

t Ii_ \ \ \ \\ ""--INDUCER HOUSING

COLLECTOR BOX _ & _ \\ DRAIN TUBE (VIOLET)

EXTENSION TUBE X X X _COLLECTOR BOX

060, AND 080 HEATING INPUT FURNACES

V CAP

.... C_(D_-_L_E.C_T.O_R_ N \ DRAIN TUBE (BLUE)

BOX EXTENSION N \

DRAIN TUBE X X

DRAIN TUBE COUPLING _

COLLECTOR BOX TUBE (PINK)

Fig. 11--Horizontal Left Tube Configuration

x

A02288

To relocate condensate trap from the blower shelf to desired

location, perform the tbllowing:

1 Remove 3 robes connected to condensate trap

2 Remove trap fiom blower shelf by gently pushing tabs inward

and rotating trap

3 Remove casing hole filler cap fiom casing hole (See Fig 2 or

11.)

4. Install casing hole filler cap (facto_ supplied in loose parts

bag) into blower shelf hole where trap was removed

Casing hole filler cap must be installed in blower shelf hole

when condensate tIap is relocate& Failure to follow this

warning could result in electrical shock, fire, personal injury

or death

5. Install condensate trap into tell hand side casing hole by

inserfing robe connection stubs through casing hole and

rotating until tabs snap into locking position

6 Fill unused condensate trap casing holes with plastic filler

caps (ihctoryosupptied in loose parts bag)

CONDENSATE TRAP TUBING

NOTE: See Fig 11 or robe routing label on main ihrnace door to

check for proper connections

1 Collector Box Drain Tube

a. Install &ain tube coupling (fhctovosupplied in loose parts

bag) into collector box drain tube (blue label) which was

previously connected to condensate trap

b (onnect large diameter drain tube and clamp (factory

supplied in loose parts bag) to drain robe coupling, extend

ing collector box &ain robe

c Route extended tube (blue label) to condensate nap and cut

to appropriate lengfl_

d (lamp robe to prevent any condensate leakage

2 Inducer Housing Drain Tube

a Remove and discard LOWER (molded) inducer housing

drain robe which was previously connected to condensate

trap

N

b Use inducer housing &ain extension tube (violet label and

ihctoryosupplied in loose parts bag) to connect LOWER

inducer housing &ain connection to condensate trap

c Determine appropriate length, cut, and connect tube

d (lamp robe to prevent any condensate leakage

3 Relief Port Tube

a Extend collector box robe (green label) which was previ

ously connected to condensate trap by splicing to small

diameter robe (fhctoryosupplied in loose parts bag)

b Route extended collector box pressure robe to relief port

connection on condensate trap

c Determine appropriate length, cut, and connect robe

& Clamp robe to prevent any condensate leakage

CONDENSATE TRAP FIELD DRAIN ATTACHMENT

Ref?r to (ondensate Drain section fbr recommendations and

procedures

10

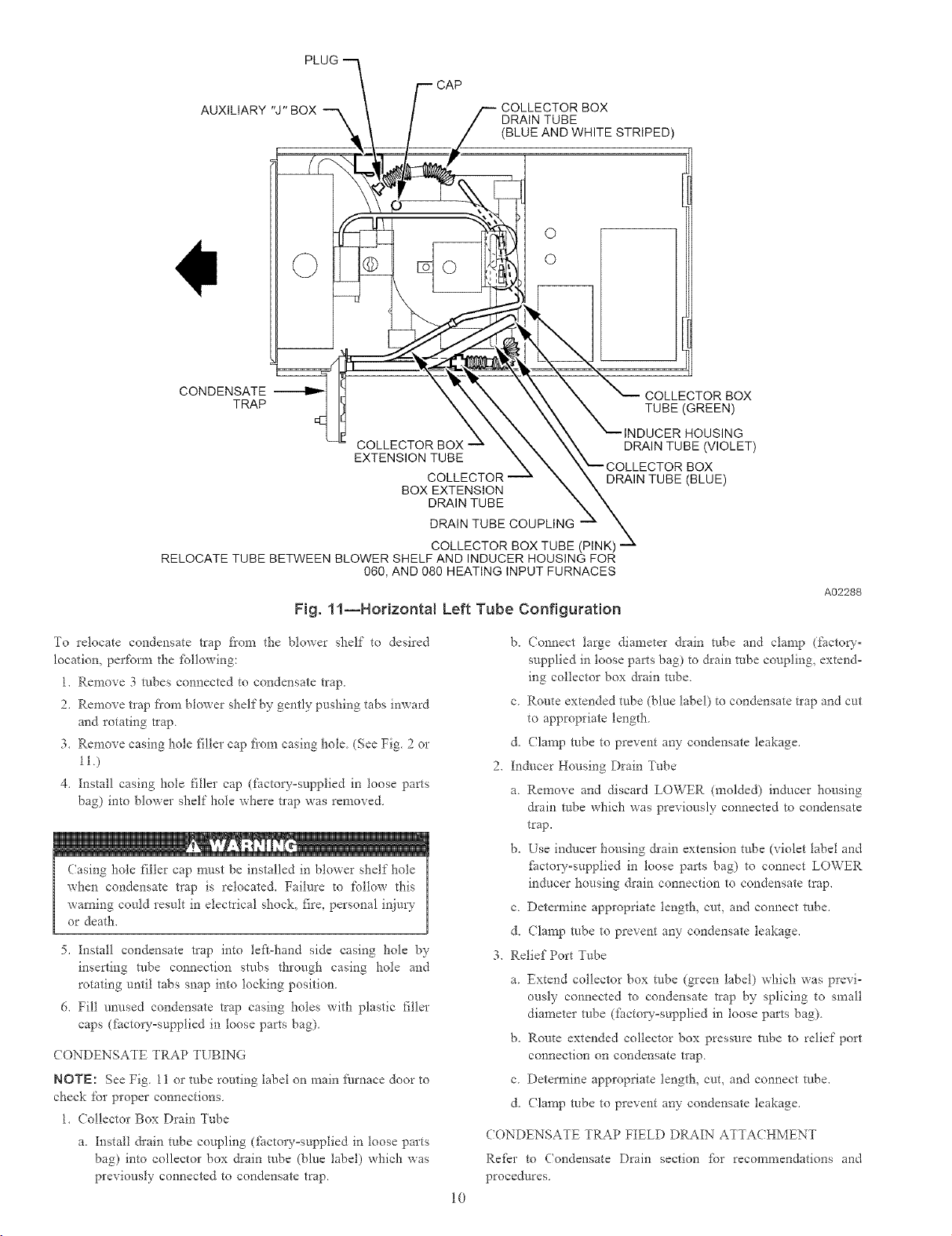

INTAKE

A 12-1N MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

SHORT (5 TO 8 FT) VENT SYSTEMS

TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE

SHUTOFF

GAS VALVE

SEDIMENT

TRAP

CONDENSATE

TRAP

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

Fig. 12--Attic Location and Working Platform

PRESSL RE SWIT(H TL BING

The LOWER collector box pressure tube (pink label) is factor

connected to the High Pressure Switch fbr use when _hrnace is

installed in UPFLOW applications. This robe MUST be discon-

nected, extende& rerouted, and then reconnected to the pressure

switch in HORIZONTAL LEFT applications _br 050 and 080

heating input ihrnaces.

NOTE: See Fig. 11 or tube routing label on main Nrnace door to

check for proper connections.

Modif}" robe as described below.

1. Disconnect collector box pressure tube (pink label) attached to

High Pressure Switch.

2. Use smaller diameter tube (factory-supplied in loose parts

bag) to extend robe disconnected in item 1

3. Route extended robe:

a. Behind inducer housing.

b. Between blower shelf and inducer housing.

4. Detem_ine appropriate length, cut, and reconnect tribe to High

Pressure Switch connection labeled COLLE(TOR BOX.

ACCESS OPENING

FOR TRAP

DRAIN

A93031

NOTE: (ombustion=air and vent pipes are restricted to a mira-

mum length of 5 ft. (See Table 7.)

NOTE: A 12-in. minimum offset pipe section is recommended

with short (5 to 8 ft) vent systems. This recommendation is to

reduce excessive condensate droplets flora exiting the vent pipe.

(See Fig. 12 or 35.)

Step 5--Horizontal Right (SupplyoAir Discharge)

Applications

A horizontal right furnace application is where t:urnace blowei is

located to d_e left of combustion and conhols section of _i/rnace,

and conditioned air is discharged to the right.

CONDENSATE TRAP FREEZE PROTECTION

Re_kr to Condensate Drain Protection section %r recommenda-

tions and procedures,

CONSTRUCT A WORKING PLATFORM

(onstruct working platfbm_ where all required [k_rnace clearances

are met. (See Fig 3 and 12)

NOTE: In (anada, installations shall be in accordance with

cun'ent NSCNGPIC Installation Codes and/or local codes

NOTE: The auxiliaLy junction box (J-box) MUST be relocated to

opposite side of furnace casing. (See Fig. 13.) See Electrical

Connection section for J-box relocation.

11

CAP

O

O

COLLECTOR BOX DRAIN TUBE

(BLUE AND WHITE STRIPED)

DRAIN TUBE (VIOLET)

COLLECTOR BOX

EXTENSION TUBE

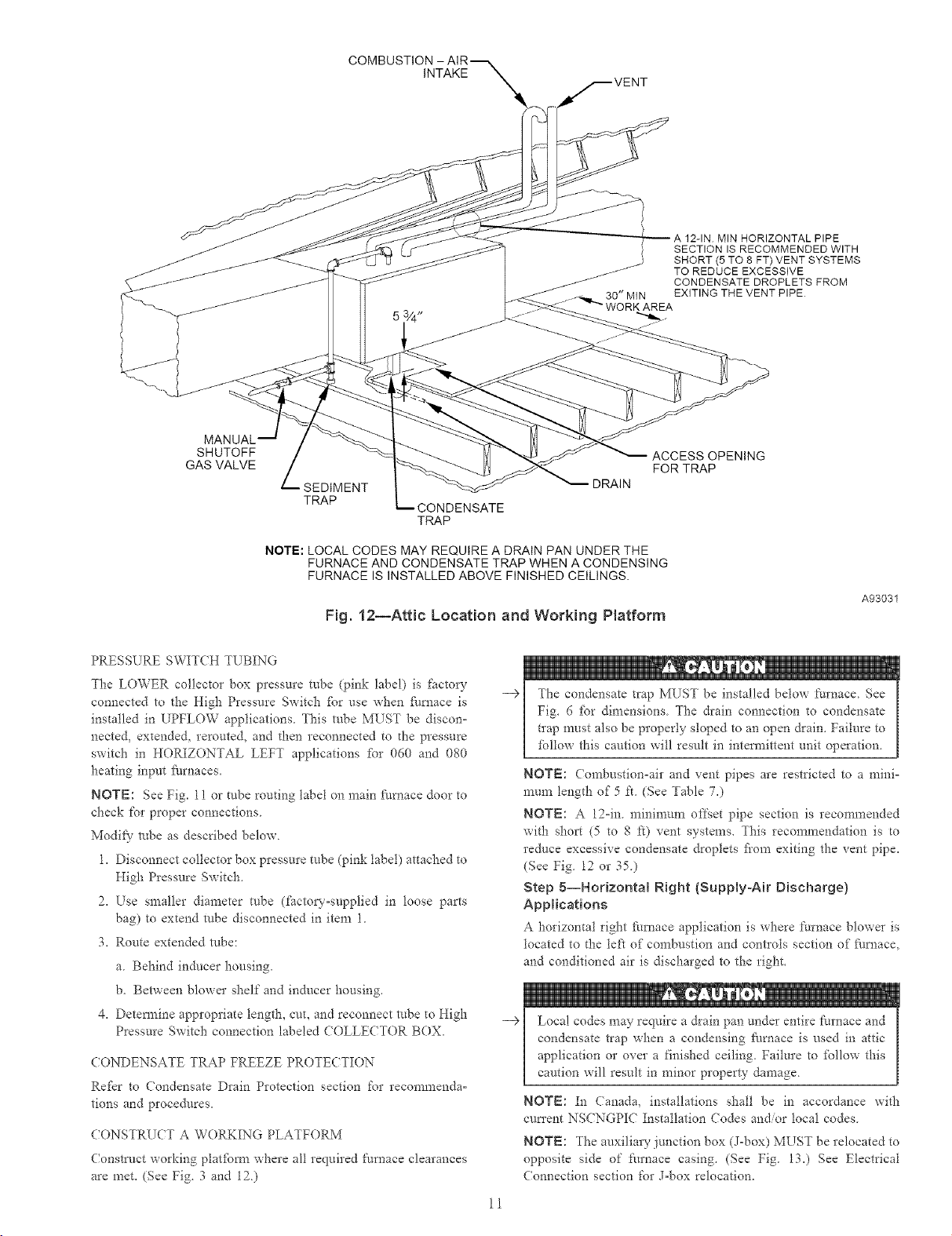

Fig. 13--Horizontal Right Tube Configuration

CONDENSATE TRAP LOCATION

The condensate tlap n-rest be removed from the factow-installed

blower shelf location and relocated in selected application location

as shown in Fig. 2 or 13.

To relocate condensate trap from the blower shelf to desired

location, perfom_ the [bllowing:

1. Remove 3 robes connected to condensate trap.

2. Remove trap fiorn blower shelf by gently pushing tabs inward

and rotating trap.

3. Install casing hole filler cap (factory-supplied in loose parts

bag) into blower shelf hole where trap was removed.

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated. Failure to follow this

warning could result in electrical shock, fire, personal injury

or death.

4. Install condensate trap into rightohand side casing hole by

inserting robe connection stubs through casing hole and

rotating until tabs snap into locking position

5. Fill unused condensate trap casing holes with plastic filler

caps (fi_ctoryosupplied in loose parts bag)

(ONDENSATE TRAP TUBING

NOTE: See Fig. 13 or robe routing label on main fhrnace door to

check for proper connections.

1. (ollector Box Drain Tube

a. Remove fi_ctoryoinstalled plug fiom LOWER collector box

&ain robe (blue and white striped label).

b. Install removed clamp and plug into UPPER collector box

&ain robe (blue label) which was previously connected to

condensate trap.

BOX DRAIN TUBE (BLUE)

COLLECTOR BOX TUBE (GREEN)

-- COLLECTOR BOX TUBE (PINK)

BOX RELOCATED HERE

CONDENSATE

TRAP

A02289

c (onnect LOWER collector box drain robe (blue and white

striped label) to condensate trap Tube does not need to be

cut.

d. Clamp robe to prevent any condensate leakage.

2. Inducer Housing Drain Tube

a. Remove fhctoryoinstalled cap and clamp from LOWER

inducer housing drain connection.

b. Remove and discard UPPER (molded) inducer housing

&ain robe which was previously connected to condensate

tlap.

c. Install cap and clamp on UPPER inducer housing &ain

connection where molded &ain robe was removed.

d. Use inducer housing &ain extension robe (violet label and

factoryosupplied in loose parts bag) to connect LOWER

inducer housing &ain connection to condensate trap.

e. Detem_ine appropriate length, cuk and connect robe to

condensate trap.

f\ (lamp robe to prevent any condensate leakage.

3. Relief Port Tube

Refer to Pressure Switch Tubing section for connection

procedure.

CONDENSATE TRAP FIELD DRAIN ATTACHMENT

Refkr to Condensate Drain section for recommendations and

procedures.

PRESSURE SWITCH TUBING

One collector box pressure tube (pink label) is J:ilctory connected to

the pressure switch fbr use when ft_rnace is installed in UPFLOW

or HORIZONTAL LEFT applications. This tube MUST be dis-

connected and used for the condensate trap relief port robe. The

other collector box pressure robe (green label) which was fhcto_

12

connected to the condensate trap relief port connection MUST be

connected to the pressure switch in DOWNFLOW or HORIZON°

TAL RIGHT applications,

ROTE: See Fig. 13 or tube routing 1abel on main fhmace door to

check for proper connections

Relocate tubes as described below,

1, Disconnect collector box pressu*e tube (pink 1abet) attached to

pressure switch.

2. Extend collector box pressure robe (green label) which was

previously connected to condensate trap relief port connection

by splicing to small diameter robe (factow-supplied in loose

parts bag).

3. (onnect collector box pressure tube (green label) to pressure

switch connection labeled COLLE(TOR BOX.

4. Use remaining small diameter tube (factory-supplied in loose

parts bag) to extend collector box pressure robe (pink label)

which was previously connected to pressure switch.

5. Route this extended robe (pink label) to condensate trap relief

port connection.

6. Detem_ine appropriate length, cut, and connect robe.

7. Clamp robe to relief port connection.

CONDENSATE TRAP FREEZE PROTECTION

Re*kr to Condensate Drain Protection section for recommenda=

tions and procedores.

CONSTRUCT A WORKING PLATFORM

Construct working platfbrm where all required [:urnace clearances

are met, (See Fig. 3 and 12.)

--€

The condensate trap MUST be installed below fimaace See

Fig. 6 _br dimensions. The drain connection to condensate

trap must also be properly sloped to an open &ain Failure to

follow this caution will result in intermittent unit operation.

ROTE: Combustion-air and vent pipes are restricted to a mira°

mum length of 5 ft. (See Table 7.)

ROTE: A 12-in. n_ininlum offset pipe section is recommended

with short (5 to 8 ft) vent systems. This recommendation is to

reduce excessive condensate &oplets fi'om exiting the vent pipe.

(See Fig. 12 or 35.)

LOCATION

Step l--General

This _hmace must

* be installed so the electrical components are protected from

water.

* not be installed directly on any combustible material other than

wood flooring (refer to SAFETY CONSIDERATIONS).

* be located so combustion-air and vent pipe maximum lengths

are not exceeded. Re_kr m Table 7.

* be located where available electric power and gas supplies meet

specifications on the furnace rating plate.

* be attached to an air distribution system and be located as close

to the center of the distribution system as possible. Re_r to Air

Ducts section.

* be provided with ample space for servicing and cleaning.

Always comply with minimum fire protection clearances

shown on the Nrnace clearance-to-combustibles label. (See

Fig. 3.)

This Nmace may be located in a confined space without special

provisions for dilution or ventilation air.

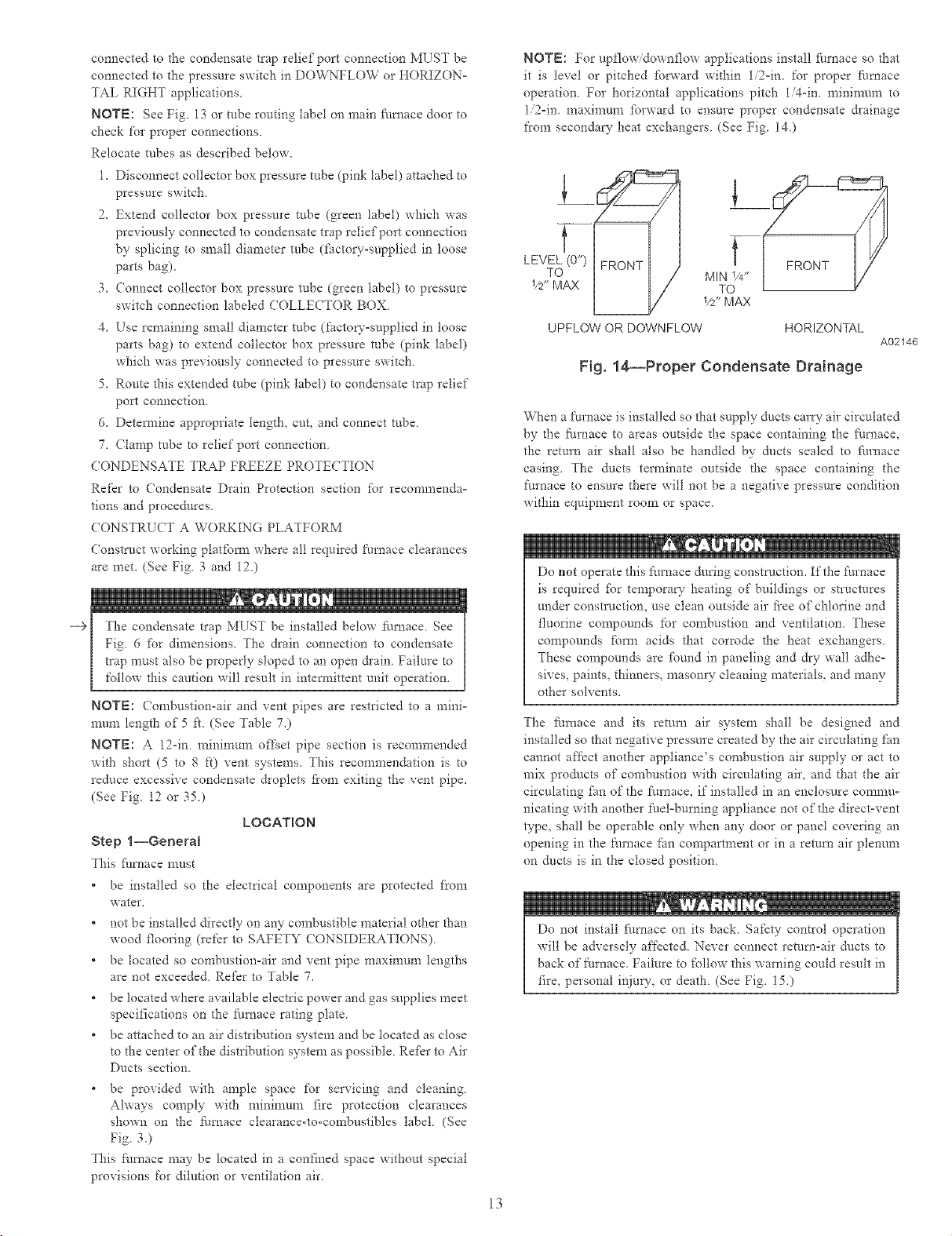

NOTE: For upflowidownflow applications install fi_.rnace so that

it is level or pitched fbrward within 1/2=in. for proper fitmace

operation. For horizontal applications pitch 1/4-in. minimum to

1/2=in maximum forward to ensure proper condensate &ainage

from secondaw heat exchangers (See Fig. 14)

LEVEL (0")

TOL_ MIN 1/4"

1/2" MAX TO

UPFLOW OR DOWNFLOW HORIZONTAL

_/2"MAX

Fig. 14--Proper Condensate Drainage

When a t\N'nace is installed so that supply ducts car W air circulated

by d_e furnace to areas outside the space containing the flu_ace.

the return air shall also be handled by ducts sealed to filrnace

casing. The ducts terminate outside the space containing the

furnace to ensure there will not be a negative pressure condition

within equipment room or space.

Do not operate this fitrnace during construction. If the furnace

is required _br temporary heating of buildings or structures

under constrllction, use clean outside air fl'ee of chlorine and

fluorine compounds for combustion and ventilation. These

compounds fbma acids that corrode tiae heat exchangers

These compounds are tbund in paneling and dw- wai! adiae=

sires, paints, thinners, masom'y cleaning materials, and many

other solvents.

The furnace and its return air system shall be designed and

installed so that negative pressure created by the air circulating fan

cannot affect another appliance's combustion air supply or act to

mix prodtlcts of combustion with circulating air, and that the air

circulating _hn of the furnace, if installed in an enclosure comnm-

nicating with another fuel-burning appliance not of the direct-vent

type, shall be operable only when any door or panel covering an

opening in the 5m_ace fan compartment or in a return air plenum

on ducts is in the closed position.

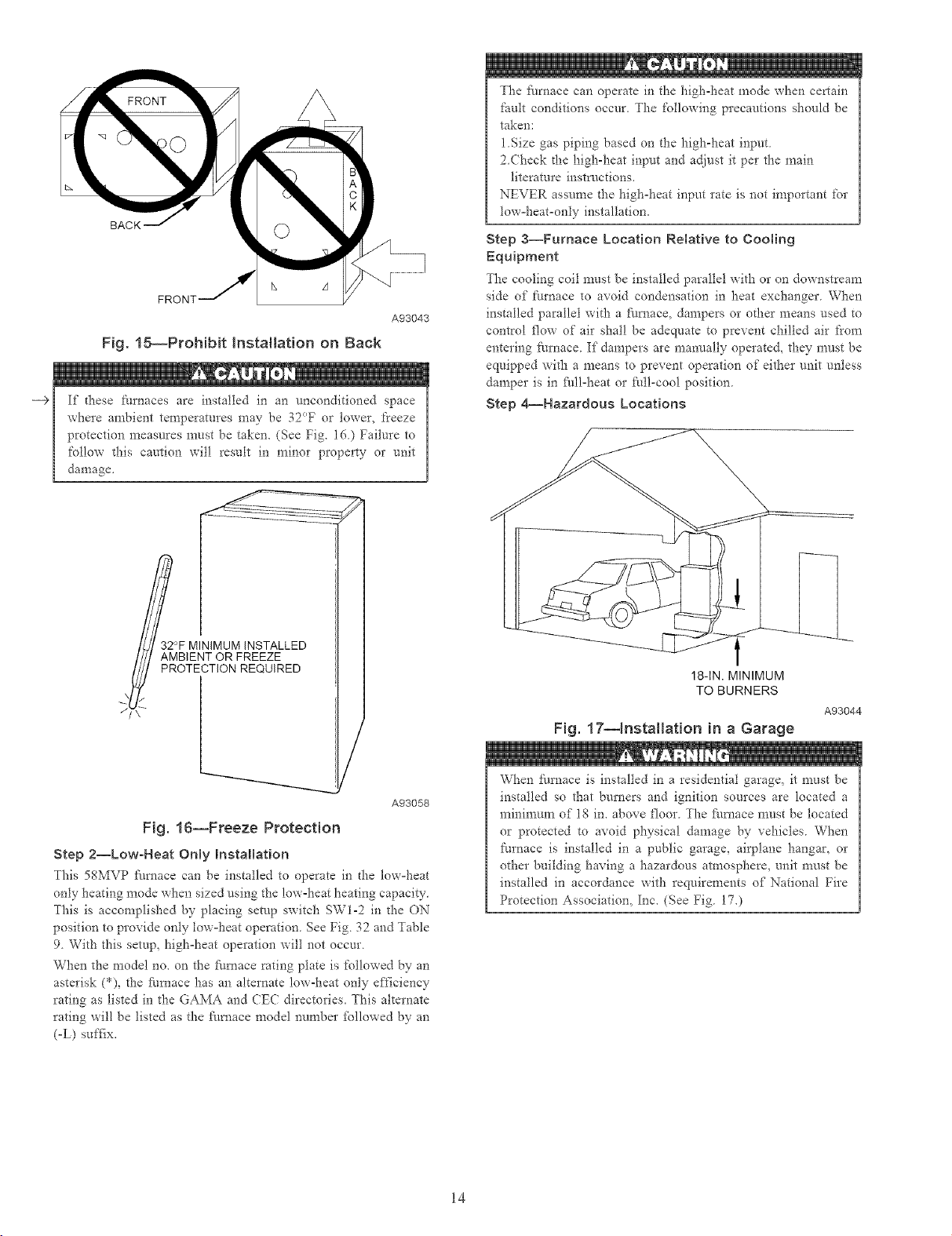

Do not install fllrnace on its back. Safety control operation

will be adversely affected. Never connect return-air ducts to

back of furnace. Failure to _bllow this warning could result in

fire, personal injury, or death (See Fig. 15.)

13

A02146

BACK

Fig. 15--Prohibit Installation on Back

,_ , t 1

--€

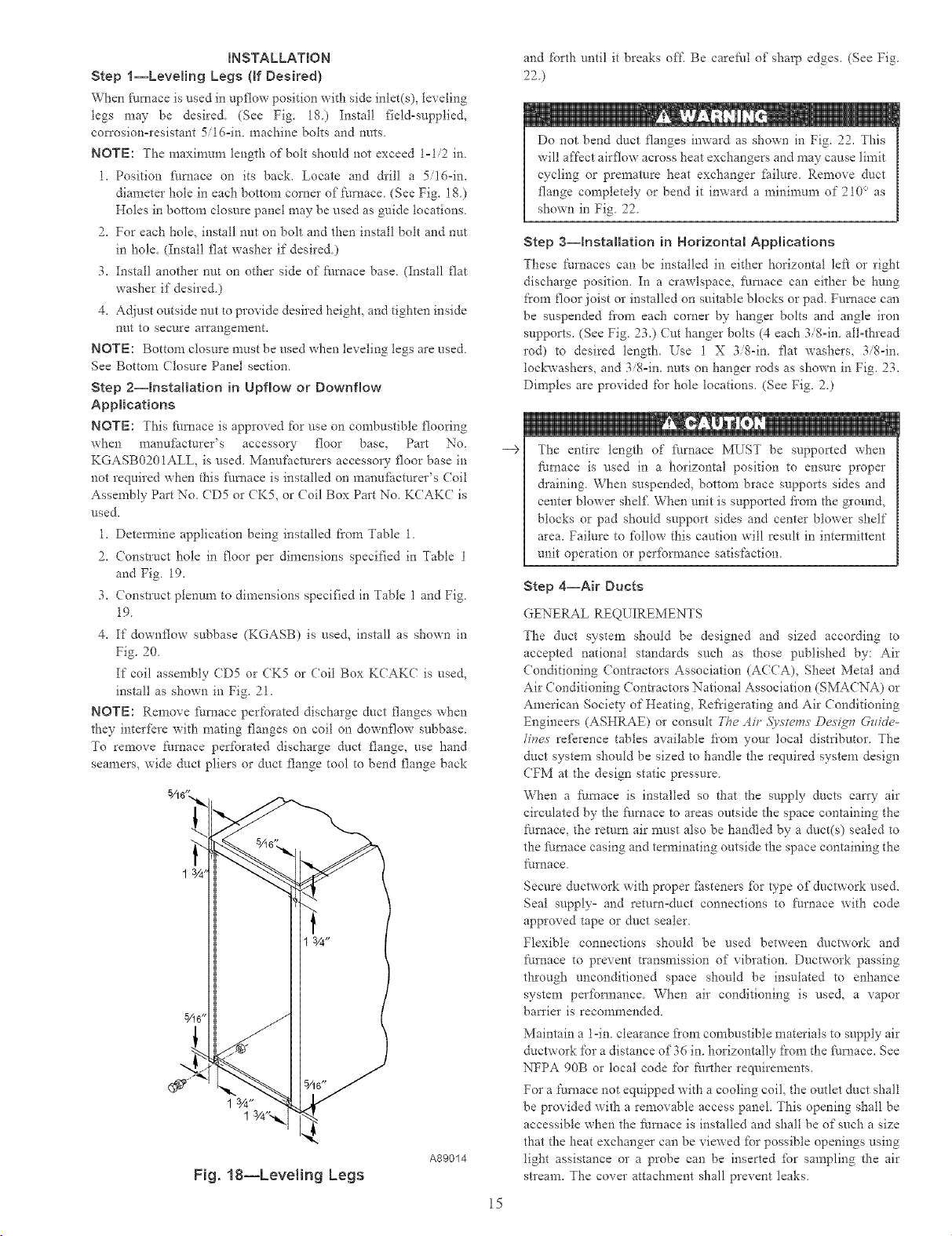

If d-*ese furnaces are installed in an unconditioned space

where ambient temperatures may be 32°F or lower, t'reeze

protection measures must be taken. (See Fig. 16) Failure to

follow d_is caution will result in minor property or unit

damage.

A93043

The fi_rnace can operate in the high-heat mode when certain

fault conditions occur. The following precautions should be

taken:

1Size gas piping based or* the high-heat input

2 (hock dte high-heat input and adjust it per the main

literature instrnctions.

NEVER assume the high°heat input rate is not important for

tow°heat=only installation.

Step 3--Furnace Location Relative to Cooting

Equipment

The cooling coil must be installed parallel with or on downstream

side of furnace to avoid condensation in heat exchanger When

installed parallel with a filmace, dampers or other means used to

control flow of air shal! be adequate to prevent chilled air from

entering furnace If dampers are manually operated, they must be

equipped with a means to prevent operation of either unit unless

damper is in fidl=iaeat or full-cool position

Step 4--Hazardous Locations

°F MINIMUM INSTALLED

I//I AMBIENT OR FREEZE II

_/ PROTECTION REQUIRED II

A93058

Fig. 16--Freeze Protection

Step 2--Low-Heat Only mnstallation

7his 58MVP furnace can be installed to operate in [he low°heat

only heating mode when sized using the low°heat heating capacity.

This is accomplished by placing setup switch SW1-2 in the ON

position to provide only tow-heat operation. See Fig. 32 and Table

9. With this setup_ high=heat operation will not occur.

When the model no. or* the ft/mace rating plate is followed by an

asterisk (*), the fitmace has an alternate low-heat only efficiency

rating as listed in the GAMA and CEC directories. This alternate

rating will be listed as the fi/mace model number _bllowed by an

(-L) suffix.

18-1N. MINIMUM

TO BURNERS

A93044

Fig. 17--Installation in a Garage

When furnace is installed in a residential garage, it must be

installed so that burners and ignition sources are located a

mininmm of 18 in. above floor. The fi/mace must be located

or protected to avoid physical damage by vehicles. Wiaen

furnace is installed in a public garage, airplane hangar, or

other building having a hazardous atmosphere, unit must be

installed in accordance with requirements of National Fire

Protection Association, Inc. (See Fig. 170

14

mNSTALLATION

Step l--Leveling Legs (If Desired)

When f_lmace is need in upgow position with side inlet(s), leveling

togs may be desire& (See Fig. 18) Install field=supplied,

cmTosion=resistant 5716-in machine bolts arid nuts.

NOTE: The maximum length of bolt should not exceed 1=1/2 in.

1. Position ihmace on its back. Locate and dril! a 5/16=in.

diameter hole in each bottom corner of furnace. (See Fig. 1K)

Holes in bottom closure panel may be used as guide locations.

2. For each hole, install nut on bolt and then install bolt and nut

in hole. (Install flat washer if desired.)

3. Install another nut on other side of _i/rnace base. (Install flat

washer if desired.)

4. A({iust outside nut to provide desired height, and tighten inside

nut to secure arrangement.

NOTE: Bottom closure must be used when leveling legs are used.

See Bottom Closure Panel section.

Step 2--hstaHation in Upf!ow or Downflow

Applications

NOTE: This furnace is approved for use on combustible flooring

when manuf_cturer's accesso W floor base, Part No

KGASB0201ALL, is used. Manufacturers accessory floor base in

not required when this filmace is installed on manufhcmrer's (Toil

Assembly Part No. CD5 or CK5, or Coil Box Part No. KCAKC is

used.

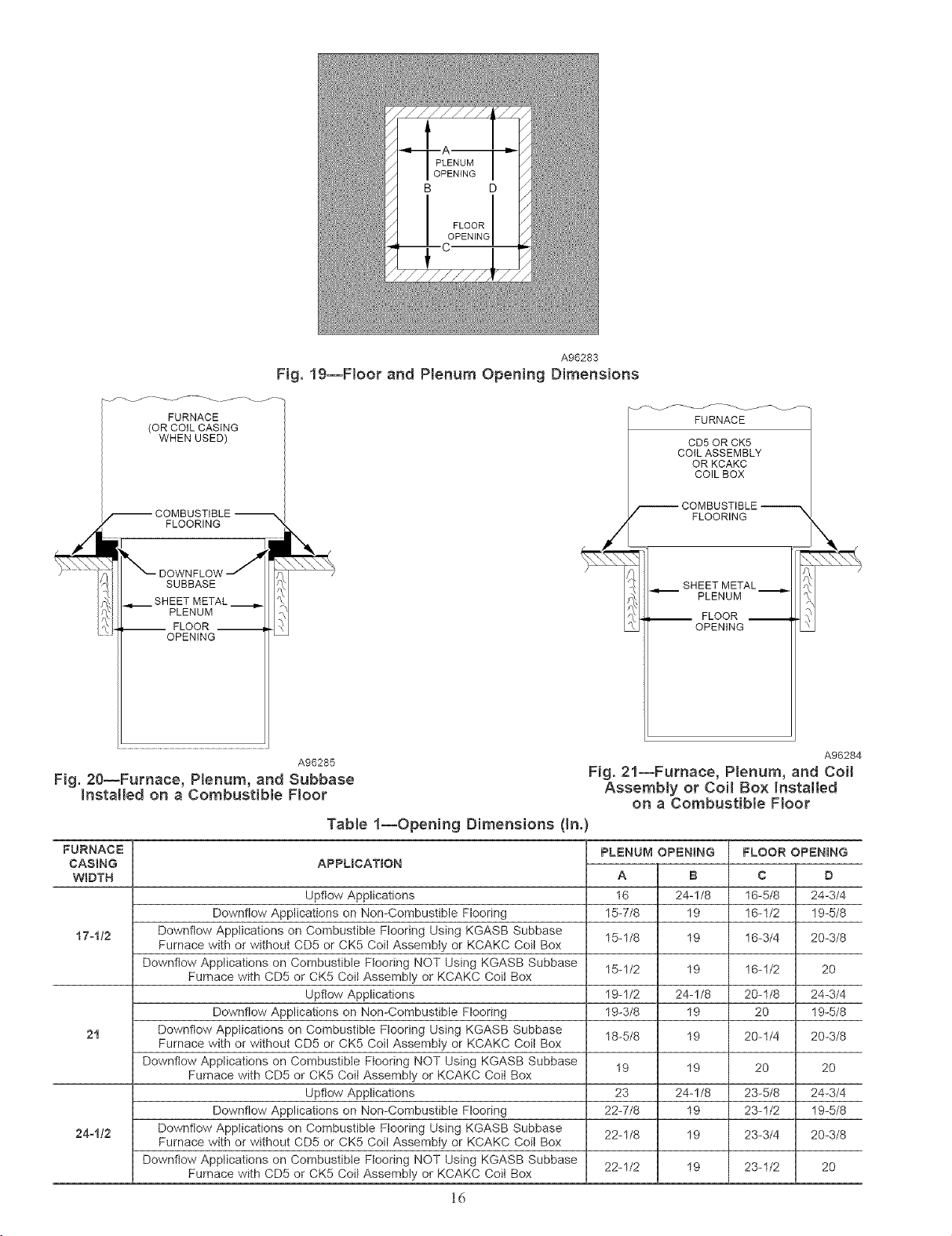

1. Detem_ine application being installed t'rom Table 1.

2. (onstruct hole in floor per dimensions specified in Table 1

and Fig. 19.

3. (onstruct plenum to dimensions specified in Table 1 and Fig.

19.

4. If downflow subbase (KGASB) is used, install as shown in

Fig. 20.

If coil assembly (D5 or CK5 or (Toil Box KCAKC is used,

install as shown in Fig. 21.

NOTE: Remove furnace perforated discharge duct ganges when

they interfere with mating flanges on coil on downflow subbase.

To remove Nrnace peribrated discharge duct flange, use hand

seamers, wide duct pliers or duct flange tool to bend flange back

A89014

Fig. 18--Leveling Legs

and %rth until it breaks off, Be careful of sharp edges, (See Fig.

22 )

Do not bend duct flanges inward as shown in Fig. 22, This

will affect airflow across heat exchangers and may cause limit

cycling or premature heat exchanger ihilnre, Remove duct

flange completely or bend it inward a mininmna of 210° as

shown in Fig. 22

Step 3--installation in Horizontal Applications

These thrnaces can be installed in either horizontal left or right

discharge position. In a crawlspace. :[hmace can either be hung

from floor joist or installed on suitable blocks or pad. Furnace can

be suspended fiom each comer by hanger bolts and angle iron

supports. (See Fig. 23.) Cut hanger bolts (4 each 3/8=in. all-thread

rod) to desired length. Use 1 X 3/8-in. flat washers, 3/8=in.

tockwashers, and 3/8=in. nuts on hanger rods as shown in Fig. 23.

Dimples are provided for hole locations. (See Fig. 2.)

--€

The entire length of ihrnace MUST be supported when

furnace is used in a horizontal position to ensure proper

&aining. When suspended, bottom brace supports sides and

center blower shelf When unit is supported fi'om the ground,

blocks or pad should support sides and center blower shelf

area. Failure to follow this caution will result in intermittent

unit operation or perfbnnance satisfaction.

Step 4--Ak Duets

GENERAL REQUIREMENTS

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

(onditioning (ontractors Association (A((A), Sheet Metal arid

Air Conditioning ( ontractors National Association (SMA(NA) or

American Society of Heating, Refrigerating and Air (onditioning

Engineers (ASHRAE) or consuh The Ah +<_)'st_'ms Desigs_ Gzlide-

line,s re_krence tables available fiom your local distributor. The

duct system should be sized to handle the required system design

CFM at the design static pressure.

When a furnace is installed so that the supply ducts can'y air

circulated by the _ilrnace to areas outside the space containing the

furnace, the remm air must also be handled by a duct(s) sealed to

the fimaace casing and terminating outside the space containing the

furnace.

Secure ductwork with proper ihsteners for type of ductwork used.

Seal supply° and return=duct connections to furnace with code

approved tape or duct sealer.

Flexible connections should be used between ductwork and

furnace to prevent transmission of vibration. Ductwork passing

through unconditioned space should be insulated to enhance

system peribnnance. When air conditioning is used, a vapor

ban'ier is recommended.

Maintain a 1=in. clearance fiom combustible materials to supply air

ductwork for a distance of 36 in. horizontally t'rom the ihmace. See

NFPA 90B or local code for Nrther requirements.

For a thmace not equipped with a cooling coil, the outlet duct shall

be provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size

that the heat exchanger can be viewed _br possible openings using

light assistance or a probe can be inserted ibr sampling the air

stIeam. The cover attachment shall prevent leaks.

15

A96283

Fig. 19--Floor and Plenum Opening Dimensions

FURNACE

(OR COiL CASING

WHEN USED)

FLOORING

SUBBASE

SHEET METAL

PLENUM

-- FLOOR --

OPENING

A96285 A96284

FURNACE

CD5OR CK5

COILASSEMBLY

OR KCAKC

COILBOX

FLOORING

SHEET METAL._

PLENUM

__ FLOOR __

OPENING

Fig. 20--Furnace, Plenum, and Subbase Fig. 21--Furnace, Plenum, and Coil

Installed on a Combustib{e Floor Assembly or Coi! Box Installed

on a Combustible Floor

Tab{e 1--Opening Dimensions (In.)

FURNACE

CASING

APPUCATION

WIDTH

Upftow Applications 16-5/8

Downflow Applications on Non-Combustible Flooring 16-1/2

17olt2 Downflow Applications on Combustible Flooring Using KGASB Subbase 16-3/4

Furnace with or without CD5 or CK5 Coil Assembly or KCAKC Coil Box

Downflow Applications on Combustible Ftooring NOT Using KGASB Subbase

Furnace with CD5 or CK5 Coil Assembly or KCAKC Coil Box

Upflow Applications 20-1/8

Downflow Applications on Non-Combustible Flooring 20

21 Downflow Applications on Combustible Flooring Using KGASB Subbase 20-1/4

Furnace with or without CD5 or CK5 Coil Assembiy or KCAKC Coil Box

Downflow Applications on Combustible Flooring NOT Using KGASB Subbase

Furnace with CD5 or CK5 Coit Assembly or KCAKC Coil Box

Upftow Applications 23-5/8

Downflow Applications on Non-Combustible Flooring 23-1/2

24o112 Downflow Applications on Combustible Flooring Using KGASB Subbase 23-3/4

Furnace with or without CD5 or CK5 Coil Assembly or KCAKC Coil Box

Downflow Applications on Combustible Ftooring NOT Using KGASB Subbase

Furnace with CD5 or CK5 Coil Assembly or KCAKC Coil Box

PLENUM OP_=N_NG

A B

16 24-1/8

15-7/8 19

15-1/8 19

15-1/2 19

19-1/2 24-1/8

19-3/8 19

18-5/8 19

19 19

23 24-1/8

22-7/8 19

22-1/8 19

22-1/2 19

FLOOR OPENING

C

D

24-3/4

19-5/8

20-3/8

16-1/2

20

24-3/4

19-5/8

20-3/8

20

20

24-3/4

19-5/8

20-3/8

23-1/2

20

16

Loading...

Loading...