Page 1

Gas-Fired Forced-Air Furnace

with Electronic Ignition

INSTALLATION

Before installing the furnace, refer to “Pro

cedures for Gas-Fired Furnaces” (packaged with the

equipment) for information concerning com

bustion, venting, piping, and other standard instal

lation practices. Further reference is made to the

current edition of the American National Standard

Z223.1 National Fuel Gas Code.

Each furnace is shipped from the factory com

pletely assembled with multispeed direct-drive

blower and wired ready for indoor heating installa

tion. All sizes feature a printed-circuit board control

center with easy-to-read low-voltage terminal strip

to ensure proper connections. The control center

also provides easy connections for line-voltage

air cleaners.

CAUTK)?i : Do not iosiaB famace in a corrosive

or contasninated atmospheres Miakesnre that ail

local ordinances for combnstion and oircalating

air supply axe observed.

Table 1 — Clearances (in inches)

SIZES

Sides

Single Wall Vent

Type B — Double Wall Vent

Back

Top of Plenum

Vent Connector

Single Wall

Type B — Double Wall

Front

____

______________

Combustion Air

Service

______

050 & 075

f

0

0

1

6

.

.......

“e

30

_____

100 thru 175

..

1

0

1

6

______

1 _

6

30

The design of the upflow gas-fired furnaces is

A.G.A. certified for installation on combustible

flooring in alcoves, basements, closets, or utility

rooms.

For accessory installation details, i.e., automatic

vent damper, humidifier, electronic air cleaner, etc.,

refer to applicable installation literature.

Electrical Connections

LINE VOLTAGE WIRING

IMPORTANT: Before proceeding with the elec

trical connections, make certain that voltage,

frequency, and phase correspond to that specified

on the unit rating plate. Also, check to be sure that

the service provided by the utility is sufficient to

handle the additional load imposed by this equip

ment. Refer to the unit rating plate for equipment

electrical requirements.

K0'S(4)

Installation comprises the following:

Inspection ....................................................................*

Location, Ventilation and Air

for Combustion........................................................*

Gas Piping....................................................................*

Venting

.........................................................................

Electrical ................................................................... 1

Filter

.............................................................................

Start-Up, Adjustment, and Safety Check

...............

Service....................................................................... 11

*To perform these installation steps, refer to the appropriate

sections of “Procedures for Gas-Fired Furnaces” booklet

packaged with this unit.

© Carrier Corporation 1978

*

7

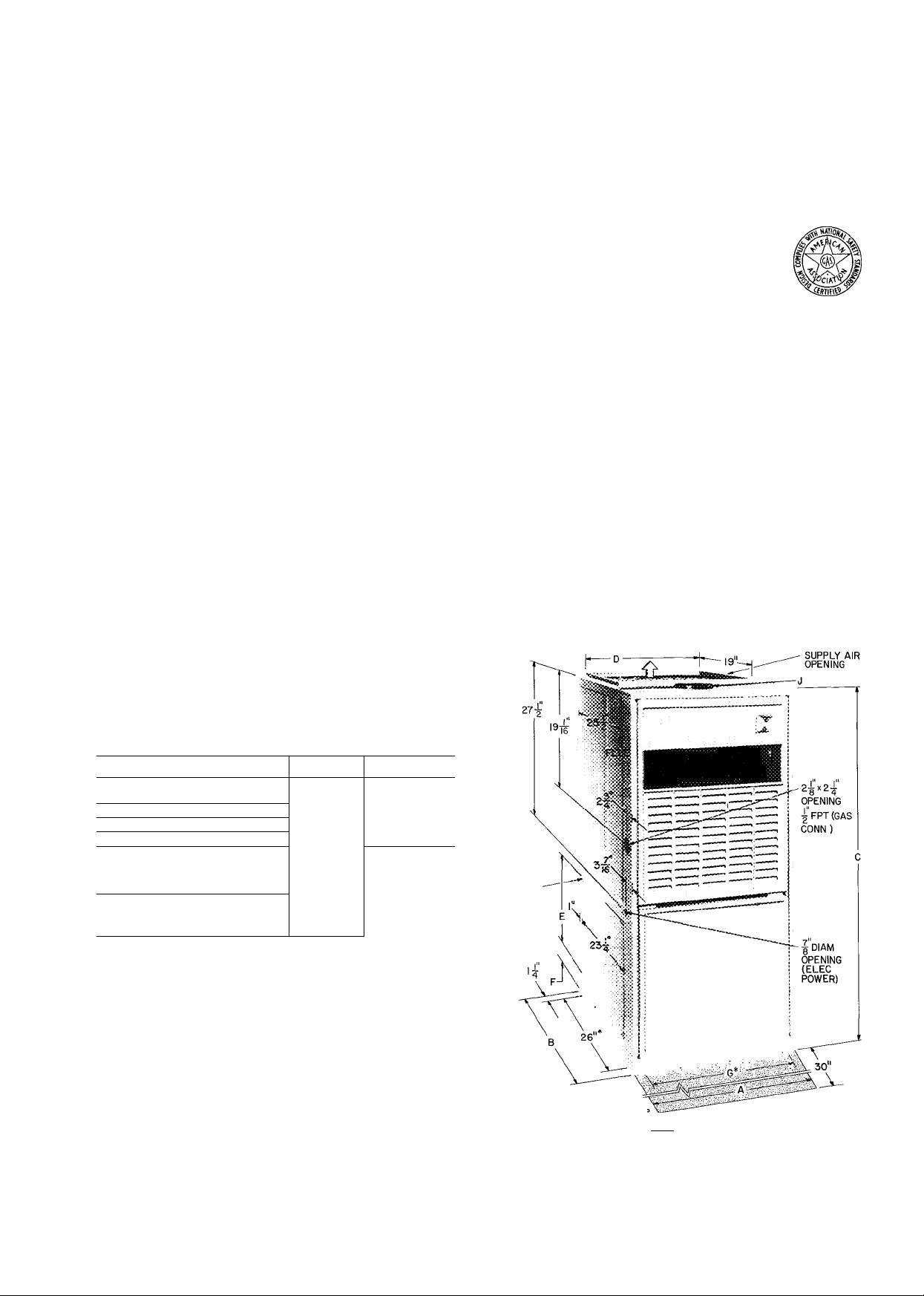

8

RETURN AIR OPENING

(SIDE) (FIELD CUT EITHER

SIDE) BEND FLANGES UP 90'

*B0TT0M OPENING ISsjlj SERVICE CLEARANCE C> AIRFLOW

Certified dimension drawings available on request

Fig. 1 — Dimensions

Form 58GS-2SI

Page 2

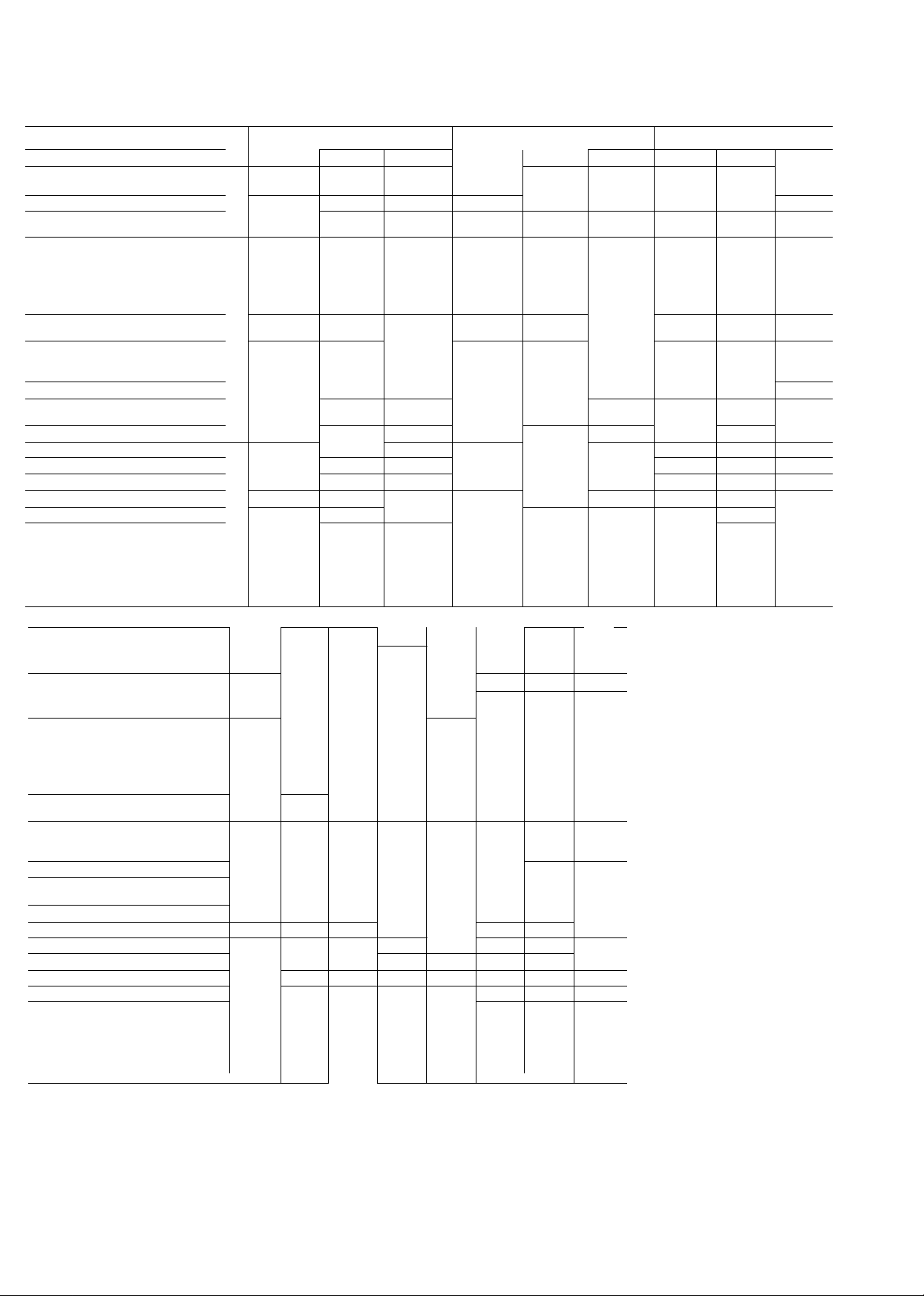

Table 2 — Dimensions апЭ Physical Data

MODEL NO 58GS

SERIES

DIMENSIONS* (in.)

Width

Depth

Height!

Casing Only

Air Openings

Supply

Side Return (E x 23-1 /4) E

From Opening to Floor F

Bottom Return

Flue (Equiv Round Pipe Dia.) J 4

A

В

c

D

G 11-11/16

FILTERt

Size X 27-3/4 (in.)

RATINGS** (Natural Gas)

Input (1000 Btuh)

Bonnet Cap (1000 Btuh)

Temp Rise!! (F)

Minimum Air for Heating

ESP (in. wg)

Cfm

Max Air Cfm (g) 0 5 in. wg ESP

DD Blower Wheel (nom. size — in.)

HP-Type

BURNERS(No)

APPROX SHIP WT(lb)

ELECTRICAL(S)

Unit Voltage (60-Hz)

Transformer (120-V/24-V)

A/C Blower Relay Rating

@ 120 V (amps)

Motor Full Load Amps

050

100

14-3/16 14-3/16

28-1/2 28-1/2

46-3/16

12-9/16

14-1/2

2-3/4

12-9/16 12-9/16

50

40

40-70 40-70

0 12

673 673

— 815

9x6 9x6

1/IOSh P 1/6Sh P

2

105 105

115 115

20 va

None 138

5

2P0

46-3/16

12-9/16

14-1/2

2-3/4

11-11/16

4

50

40

__

2 2

40 va

6

075

300

14-3/16

28-1/2 28-1/2

46-3/16 46-3/16

12-9/16

14-1/2

2-3/4 2-3/4 2-3/4 2-3/4 2-3/4 2-3/4 2-3/4

11-1 1/16

4

12-9/16 12-9/16 12-9/16

50 75

40 60

35-65 55-85

_

740 793

1170

10x6 9x6

1/3Sh.P 1/10Sh.P

105 122

115

40 va

138

99 5

100

14-3/16

12-9/16

14-1/2

11-11/16 11-1 1/16 11-11/16 15

4 4

0.12

—

3

115

20 va

None

200

14-3/16 14-3/16

28-1/2

46-3/16

12-9/16

14-1/2

75

60 60

55-85 45-75

793 925 925 987 1234

800

9x6 10x6

1/6Sh.P l/3Sh.P 1/6Sh.P

3

122

115 115 115 115 115

40 va 40 va

138

6 9 9 5 5

300

28-1/2 28-1/2 28-1/2 28-1/2

46-3/16

12-9/16 15-7/8 15-7/8 19-3/8

14-1/2 14-1/2

4 5 5 5

12-9/16 15-7/8

75

1150

3

125

138

100

17-1/2

46-3/16

100

80

65-95

0.15

9x7

4

160

20 va

None

100

200 300

17-1/2

46-3/16 46-3/16

14-1/2 14-1/2

15

15-7/8 19-3/8

100

80 80

60-90 45-75

1155 1610

10x7

1/3Sh.P 1/2PSC

4

160 175

40 va 40 va

13 8 13 8

9 9 8 5

21

18-1/2

100

10x8

4

MODEL NO. 58GS

SERIES

DIMENSIONS* (in.)

Width A 21

Depth B 28-1/2

Height!

Casing Only C

Air Openings

Supply D 19-3/8

Side Return (Ex 23-1/4) E 14-1/2

From Opening to Floor F 2-3/4

Bottom Return G 18-1/2 18-1/2 18-1/2

Flue (Equiv Round Pipe Dia ) J

100

46-3/16

5 5

200

21 21

28-1/2

46-3/16

19-3/8 19-3/8

14-1/2 14-1/2

2-3/4

FILTERt

Size X 27-3/4 (in.) 19-3/8

RATINGS** (Natural Gas)

Input (1000 Btuh) 125

Bonnet Cap (1000 Btuh)

Temp Riseft (F)

Minimum Air for Heating

ESP (in wg)

70-100

Cfm

Max Air Cf/n (g) 0.5 in wg ESP

DD Blower Wheel (nom size — in ) 9x8

HP-Type

1/5 Sh P

BURNERS(No)

APPROX SHIP WT(lb) 190

ELECTRICAL(S)

Unit Voltage (60-Hz) 115

Transformer (120-V/24-V) 20 va

A/C Blower Relay Rating

@ 120 V (amps)

Motor Full Load Amps

19-3/8

100

0 20

1089 1157

None

125 125 125

100 100

65-95

—

1230 1550

10x8 10x8

1/3Sh P 1/2 PSC

5

190

115

40 va 40 va 40 va

13 8 13 8

8

5

9 9 8 5

125

300

28-1/2

46-3/16

2-3/4

19-3/8

60-90

1234

190

115

400

24-1/2 24-1/2 24-1/2

28-1/2

46-3/16 46-3/16

22-7/8 22-7/8 22-7/8 22-7/8

14-1/2

2-3/4

5 5

— -

5 5 6 6

22

22-7/8

100

45-75

1543

2110

(2)10x6 10x10 10x10 (2)10x6 (2)10x6

1/2PSC 1/3Sh P 1/2 PSC 1/2 PSC

200

115

13 8 None 138

150

100 200

28-1/2 28-1/2

46-3/16

14-1/2 14-1/2

2-3/4 2-3/4

22 22 22 29

6 6 6 7

22-7/8 22-7/8

150 150 150

120 120 120 140

65-95 65-95 45-75 60-90

0 20

1388 1388 1851 1450

—

205

115 115

20 va 40 va

1600 2110 1980

220

9 5

300 300

24-1/2

28-1/2 28-1/2

46-3/16

14-1/2 14-1/2

2-1/16 2-1/16

22-7/8

— — —

230

115

40 va

13 8

9 5

-

175

31-1/2

46-3/16

29-7/8

29-7/8

1/2 PSC

6 7

40 va

13 8

85 85

175

250

115

ESP — External Static Pressure

DD — Direct Drive

PSC — Permanent Split Capacitor

Sh P — Shaded Pole

*See certified prints for complete

dimensional specifications

tSee Furnace-Coil-Plenum-Adapter

Combinations table in Product Data

Digest Refer to 28 Series literaturefor

plenum dimensions

iDuralast permanent cleanable filters

See manufacturer's recommenda

tions for cleaning

**Ratings shown are for elevations up to

2000 ft above sea level For elevations

above 2000 ft, deduct 4% of input ca

pacity for each 1000 ft above sea level

ttDo not exceed temperature rise speci

fied on furnace nameplate Air tem

perature rise may be calculated using

the following formula:

bonnet capacity

0 24 X specific wt of air x 60 xcfm

bonnet capacity

1 08 X cfm

NOTE: Refer to Application Data litera

ture for complete fan performance

curves

CAOTiON, Air <^.vwy iSOO

i>3ce be or e combioatKi» of

one side ano bottom^ of boisam

on^y for reiurti a>r.

Page 3

CAUTION: Use copper or copper-dad aluiainum conductors only. Use a separate branch

electrical circuit for this furnace. A disconnect

ing means must be located within sight of, and

readily accessible to, the furnace.

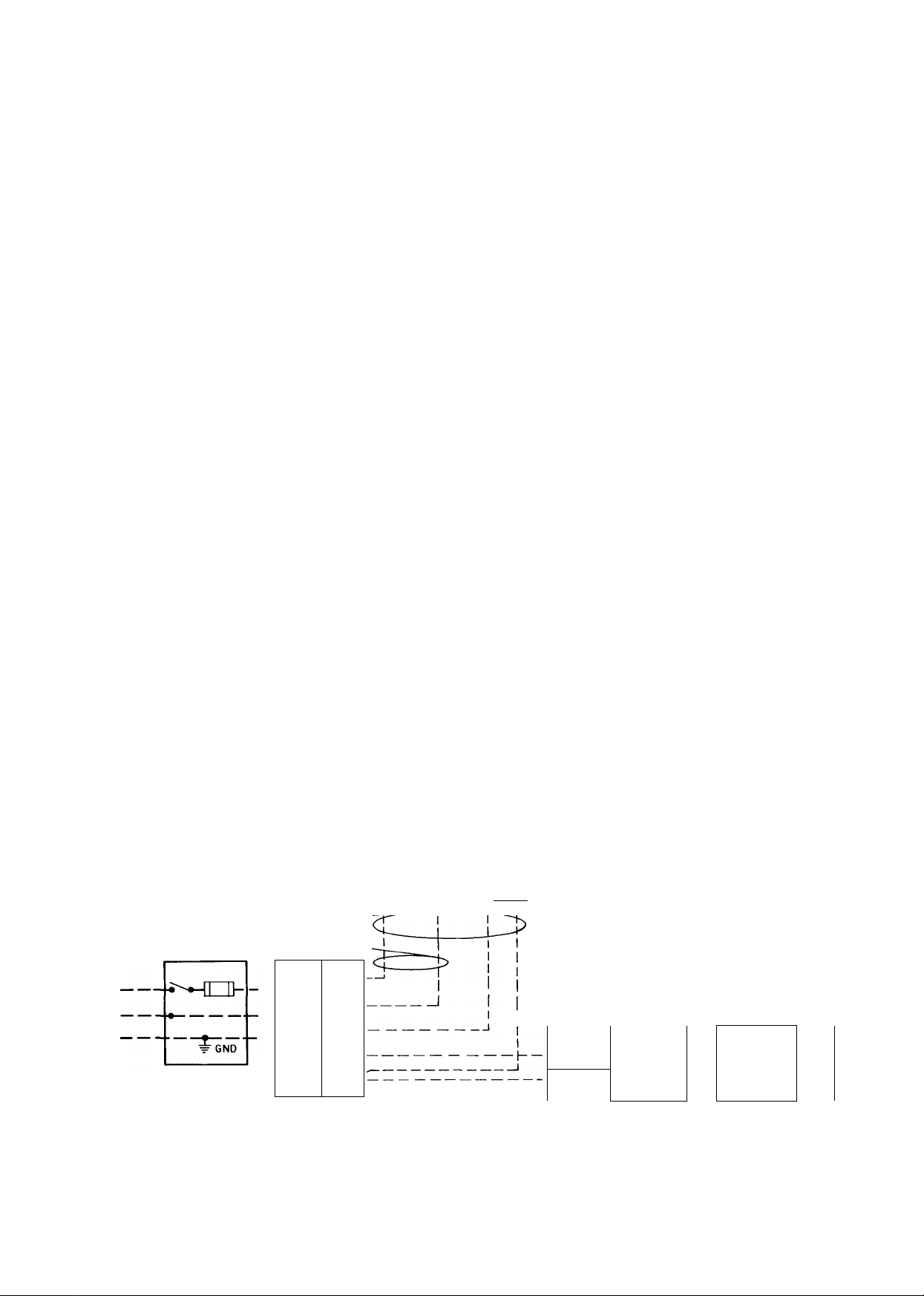

See Fig. 2 for wiring diagram showing the proper

field high- and low-voltage wiring. Make all elec

trical connections in accordance with the National

Electrical Code and any local codes or ordinances

that might apply.

WARNING: The unit cabinet m.ust have an

uninterrupted or unbroken electrical ground to

minimize personal injury if an electrical fanlt

should occur. This may consist of electrical

wire or approved conduit when installed in

accordance with e.Kisting electrical codes.

exposed to cold air infiltration, drafts from win

dows, doors, or other openings leading to the out

side, or exposure to air currents from warm or cold

air registers; or to exposure where the natural circu

lation of the air is cut off — such as behind doors,

above or below mantels, shelves, etc.

The thermostat should not be exposed to heat

from nearby fireplaces, radios, televisions, lamps,

or rays from the sun. Nor should the thermostat be

mounted on a wall containing pipes or warm air

ducts, or a flue or vent that could affect its

operation and prevent it from properly controlling

the room temperature. Any hole in the plaster or

panel thru which the wires pass from the

thermostat should be adequately sealed with suit

able material to prevent drafts from affecting the

thermostat.

LOW-VOLTAGE WIRING — Make field lowvoltage connections at the low-voltage terminal

strip. See Fig. 2.

Set the thermostat heat anticipator at the

settings indicated below. If additional controls are

connected in the thermostat circuit, their amp draw

must be added to this setting. Failure to make the

setting will result in improper operation of the

thermostat.

58GS050 thru 150 sizes with

BDP 646AW gas valve.

Heat/Cool or Heat only models

................

0.55 amp

58GS175 size with Essex 242NS gas valve,

Heat/Cool models.......................................0.65 amp

With addition of automatic vent damper, antici

pator setting should be 0.12 amp.

The room thermostat should be located where it

will be in the natural circulating path of room air.

Avoid locations where the thermostat would be

FOUR WIRE-

NOTES FOR LABEL WIRING DIAGRAMS

1 Screw terminals for field wiring connections

1/4-in quick connect terminals

3 L" If J Heating fan relay contact is normally closed until

r " 115 vac is applied to furnace

4 To change motor speed, move black or red wire to desired speed

setting

5 If any of the original wire as supplied with the appliance must

be replaced, it must be replaced with AWM (105 C) wire or its

equivalent

6 Motor is thermally overload protected

7 Factory speed selection is tor average conditions See installa

tion instructions for optimum speed selection Motor may be 3

or 4 speed

8 Symbols are an electrical representation only

THERMOSTAT

©Cp

TERMINALS

TWO WIRE HEATING ONLY

JL

Jl ©-■

■=r

LOW-VOLTAGE

TERMINAL BLOCK

Field Low-Voltage Wiring

Field High-Voltage Wiring

Factory Low-Voltage Wiring

CONDENSING

I TWO WIRE

&

&-

NOTE: If any of the original wire as supplied, must be replaced,

use same type or equivalent wire

Fig. 2 — Heating and Cooljng Application Wiring Diagram

.q^JZL

-Ijj^

UNIT

— —

-CHMV

——

= GN0

—

SINGLE

PHASE

Page 4

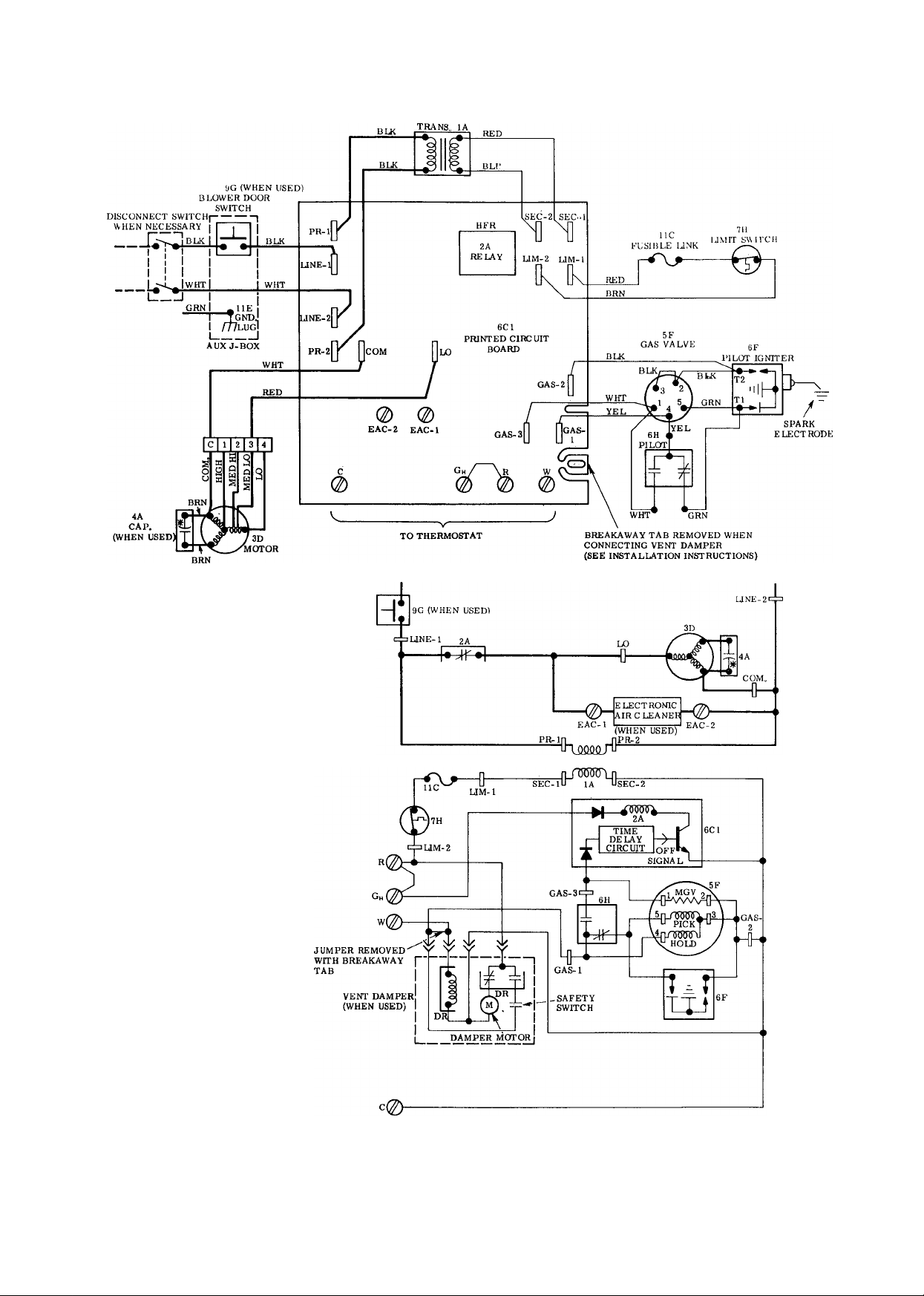

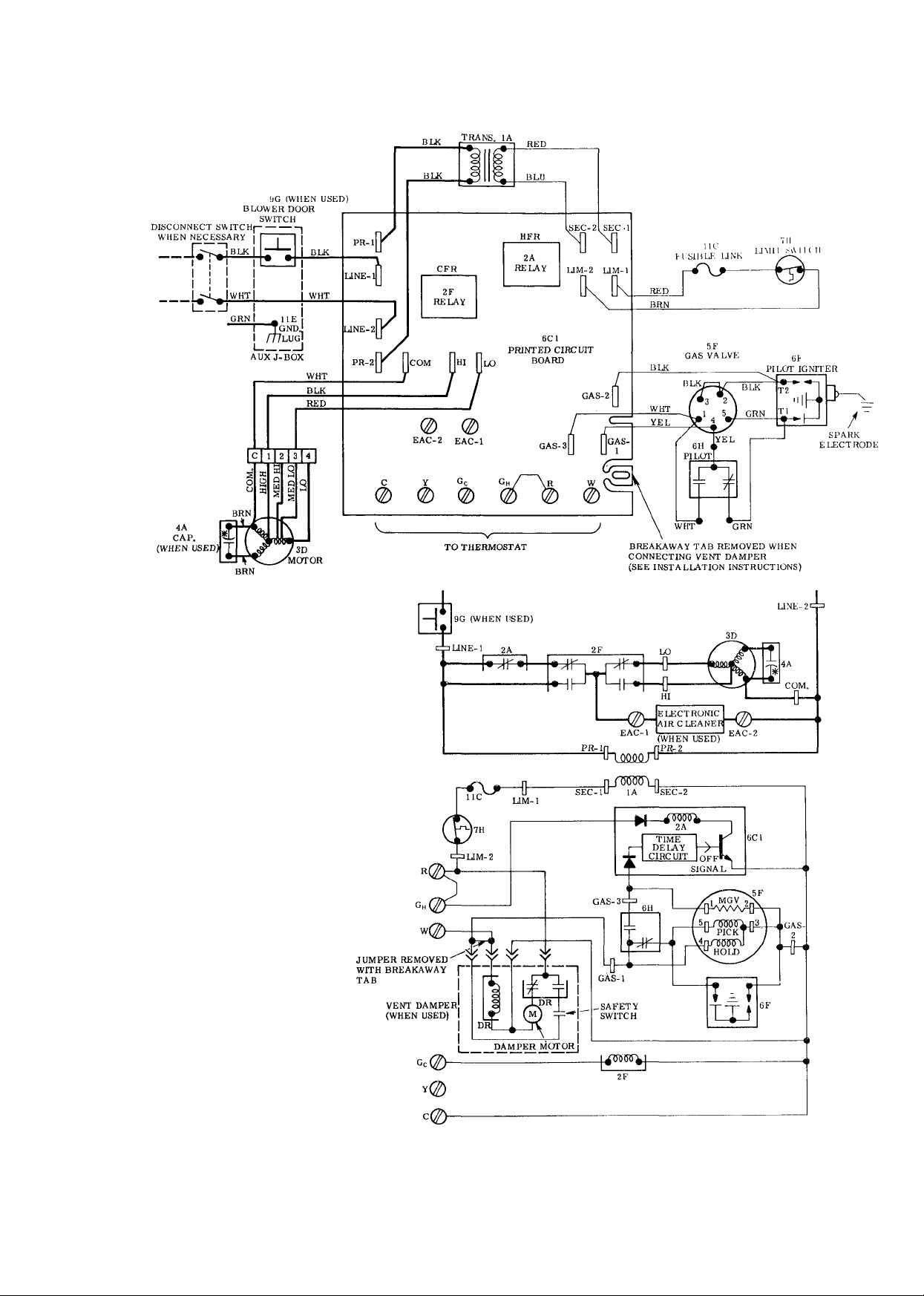

lA-TRANSFORMER 115/24

2 A-RE LAY-HEAT (SPST-NC)

3D-BLOWER MOTOR

4A-RUN CAPACITOR

5F-GAS VALVE

6C1-PRINT ED CIRCUIT BOARD

6F-PILOT IGNITER

6H-SAFETY PILOT (FLAME SENSING)

7H-UMIT SWITCH (SPST-NC)

9G-BLOWER DOOR SWITCH (SPST-N. O. )

IIC-FUSIBLE UNK

HE-GROUND LUG

•FACTORY HIGH-VOLTAGE WIRING

-FACTORY LOW-VOLTAGE WIRING

— — — —FIELD HIGH-VOLTAGE WIRING

Fig. 3 — Label Wiring Diagram; 58GS050-150 Sizes; Heating Only

Page 5

lA-TRANSFORMER lls/24

2A-RELAY - HEAT (SPSP-NC)

2F-RELAY - COOL(DPDT)

3D-BLOWER MOTOR

4A-RUN CAPACITOR

5F-GAS VALVE

6C1-PRINTED CIRCUIT BOARD

6F-PiLOT IGNITER

6H-SAFETY PILOT (FLAME SENSING)

7H-UMIT SWITCH (SPST-NC)

9G-BLOV.ER DOOR SWITCH (SPST-N. O. )

lie FUSIBLE UNK

Uh-GROUND LUG

—

-----------

FACTORY HIGH-VOLTAGE WIRING

--------FACTORY LOW-VOLTAGE WIRING

- — FIE LD HIGH- VOLTAGE WIRING

Fig. 4 — Label Wiring Diagram; 58GS050-150 Si2:es; Heat/Cool

5

Page 6

lA-TRANSFORMER 115/^4

2A-RELAY - HEAT (SPST-NC)

2F-RELAY - COOL. (DPDT)

3D-BLOWER MOTOR

4A-RUN CAPACITOR

5F-GAS valve (TWO CIRCUIT)

6C1-PRINTED CIRCUIT BOARD

6C2- PILOT IGNITER AND FLAME SENSING

7H-UMIT SWITCH (SPST-NC)

9G-BLOWER DOOR SWITCH (SPST-N. O )

nC-FUSIBLE UNK

llE-GROUND LUG

■ FACTORY HIGH-VOLTAGE WIRING

-FACTORY LOW-VOLTAGE WIRING

- — — —FIELD HIGH-VOLTAGE WIRING

Fig. 5 — Label Wiring Diagram; 58GS175 Size; Heat/Cool

Page 7

PRINTED-CIRCUIT CONTROL CENTER —

Each furnace features a printed-circuit control

center to aid the installer and serviceman when

installing and servicing the unit. See Fig. 6. A

low-voltage terminal board is marked for easy con

nection of field wiring and accessories.

CONTROL BOX

w c ^

^ ^ ^

Fig. 6 — Printed Circuit Control Center

Filter

CAUTION: Air deHvety above cfm re

quires that both sides of faraace be used.,

or a combination of one side and bottom,

or bottom only.

FILTER ARRANGEMENT — The filter is factory

installed in the bottom of the furnace. This is for

bottom inlet application. See Fig. 7.

NOTE: Remove and discard bottom closure panel

when bottom inlet is used.

For side inlet application, see Fig. 1 for the

opening size. Remove the filter from the bottom of

furnace and relocate at the side by performing the

following steps:

1. Remove screws from filter retainer clips at both

sides of furnaee.

2. Remove retainer spring and position both clips at

inlet side of furnace.

3. Remove filter from bottom and position on inlet

side of furnace.

4. Place retainer spring over filter, making certain

to position front of retainer spring behind flange

of the casing side.

5. Install the retainer spring in the holes provided —

one in the bracket at bottom rear and the other

in the hole in blower deck. See Fig. 8.

Fig. 7 — Filter Installed for Bottom Inlet

Fig. 8 — Filter Installed for Side Inlet

Page 8

BOTTOM CLOSURE PANEL — When the side

inlet is used, the bottom opening must be properly

sealed by installing a bottom closure panel shipped

under the filter in each furnace. To install the

bottom closure panel, perform the following steps:

After filter has been installed for side return, re

1.

move bottom closure panel from furnace.

With furnace either tilted or raised, install panel

in opening on bottom of furnace, making certain

that locating tabs rest securely against sides

of cabinet. See Fig. 9.

WARNING: Never operate unit without a iiiter

or with filler acce.ss door removed-

START-UP. ADJUSTMENT AND

SAFETY CHECK

Sequence of Operation

HEATING — Sizes 050 thru 150 (BDP 646AW gas

valve)

TIME (sec)* ACTION

Thermostat calls for heat. The control circuit be

0

tween R and W is closed: power from transformer

simultaneously opens solenoid of pilot gas valve

(inside main gas valve) and energizes spark

igniter

PiTot^as ignites

TTlof coritacTslnbffnaTly closed) open.'Spark

igniter ceases to spark

35

“”45'’

11b

20

75

‘Times are approximate: variance ±20%

Pilot contacts (normally open) close, energizing

heat motor in main gas valve and solid-state

timing circuit in printed circuit control centejr^

Heat motor opens main gas valve; main Burners

ignite from pilot flame

SoHd^itife tirning'cnxuiUswitches iti contacts

and blower motor starts

Thermostat is satisfied. Circuit between R and W

is broken; automatic gas valve is de-energized,

closing solenoid valve Solid-state timing circuit

is de-energized

T^in gas "valvelmd pilot valve close, extinguishing

flame

Piiot safety contacts open.

PIloTcontacts cioseTready for new cycle Solid-

state timing circuit switches its contacts, stopping

blower motor

______

eorroM

aosu!^ PANEL

Fig. 9 — Installing Bottom Closure Panel

LOCATING TASS

HEATING — Size 175 (Essex 242 gas valve)

TIME (sec)*

0

75

75

‘Times are approximate, variance ±20%

Thermostat calls for heat, power from transformer

simultaneously opens solenoid of pilot gas valve

(inside main gas valve) and energizes spark

igniter Solid-state timing circuit is energized

Pilot gas ignites

Once pilot flame is proven electrically, igniter

ceases to spark, main gas valve opens and mam

burners ignite from pilot flame

Solid-state timing circuit switches its confacfs

and blower motor starts

Thermostat is satisfied Pilot and main gas valves

are de-energized Solid-state timing circuit is

de-energized _ _

Pilot and main burners are extingmsh^_

1

Solid-state timing circuit switches its contacts,

stopping blower motor

ACTION

____________

LIMIT SWITCH — If the furnace overheats for

any reason, the limit switch will open, breaking the

circuit to automatic gas valve, so the gas valve

closes immediately. Without low-voltage current

applied to heat relay, its normally closed contacts

energize blower motor.

Page 9

#

m

OVERHEAT FUSE LINK — The furnace is

equipped with a fusible element to protect against

overtemperature conditions in the vestibule that can

result from inadequate combustion air supply.

WARNÌNG: 0o rtot bjpass tììc fusible element

ob&îÏÊCtéd betwëèù tbe ÌKmti;|ÌIIÌ

lì ii;i©pe}3Sÿi)Sîaife^:

4ÏÎÉ:

m

the combiìi!tìou: air soppìy:..

etemeut vwth au idejRîicaîpari;

HYïOLFm.

REGULATOR

ADJUSTMENT

Fig. 10 - BDP 646AW Gas Valve

PILOT ADJUSTING SCREW CAP

MANUAL SHUTOFF VALVE

AND PILOT COCK

LOW VOLTAGE

CONNECTIONS

REGULATOR ADJUSTING

COVER (ADJUST "Hi"

SIDE SCREW)

PILOT GAS LINE

CONNECTION

MAIN GAS CONNECTION

PRESSURE TAP

Fig. 11 — Essex 242 Gas Valve

PILOT

ADJUSTMENT

PILOT

TUBE

CONNECTION

COOLING — When the thermostat calls for cool

ing, power from the transformer energizes the

blower relay coil, closing its normally open contacts,

and energizing the blower motor on its cooling

speed. It continues to operate until the thermostat

is satisfied.

When the thermostat is satisfied, the circuit to

terminal (G) is broken, de-energizing the blower

relay coil which, in turn, opens its contacts, stopping

the blower motor.

AUTOMATIC GAS CONTROL VALVE The

automatic gas valve controls the flow of gas to both

pilot and main burners. All models have the manual

valve built into the automatic valve body. The

manual valve has only 2 positions: OFF and ON. It

does not have an intermediate position for pilot gas

flow only.

To shut off the gas manually, turn knob from ON

to OFF position. When in OFF position, the main

burners and the pilot flame are extinguished.

Starting Procedure — Check to be sure that all

connections have been properly made, then pro

ceed as follows:

Use the procedure outlined on the Lighting In

struction Plate attached to the furnace. See Se

quence of Operation and perform the following

additional steps:

1. If supply line was not purged before connecting

furnace, it will be full of air. It is recommended

that pilot supply line be disconnected at pilot

shutoff valve or main gas valve, and supply line

be allowed to purge until odor of gas is detected.

Never purge gas lines into combustion chamber.

Immediately upon detection of gas odor, re

connect pilot supply tube. Allow 5 minutes to

elapse before lighting furnace.

2. Pilot flame should be soft blue in color.

For natural gas controls, flame should be of

sufficient length to provide good impingement

on element of pilot. Flame should extend upward

between carryover ports of 2 adjacent burners.

3. Pilot adjusting screw is located on main gas

valve, or pilot shutoff valve.

a. Remove capscrew; turn pilot gas full on and

adjust adjusting screw until desired appear

ance is obtained.

b. Replace capscrew.

Gas Input — Determine the gas input as follows:

1. Natural Gas

a. Turn off all other gas appliances and pilots.

b. Measure time (in seconds) for gas meter test

dial to complete one revolution.

c. Divide 3600 by time noted and multiply result

by number of cu ft per revolution of test dial

(read off meter test dial).

________3600________ ^

seconds per revolution

cu ft per _ cu ft

revolution per hr

Page 10

d. Multiply cu ft per hour times heating value of

gas (Btu/cu ft). Obtain heating value of gas

from local utility.

X heat value of gas

= gas input, Btuh

Example:

Time for one revolution of 2 eu ft dial = 72

seconds.

Heat value of gas = 1070 Btu/cu ft

3600

X 2 = 100 cu ft/hr

72

100 X 1070 = 107,000 Btuh

e. To adjust input rate, remove cap that con

ceals regulator adjustment. Turn adjusting

screw counterclockwise (out) to decrease

input. When adjusting, DO NOT change

manifold pressure more than 0.3 in. wg. Any

major adjustment should be made by chang

ing orifices.

2. High Altitude

Ratings are approved for altitudes to 2000 ft

for all gases. Ratings for altitudes over 2000 ft

are 4% less for each 1000 ft above sea level.

3. Adjust air temperature rise by adjusting blower

speed. Increase blower speed to reduce tempera

ture rise. Decrease blower speed to increase

temperature rise.

Adjustment of Blower Speed

WARN!N<?: Disconnect ekctrical power before changing speed, tap.

To change motor speed, remove the electric lead

from left side of Molex speed selector (see Fig. 7)

and relocate it on the desired terminal on the plug-in

terminal block/ speed selector located on the blower.

The white lead remains in the “C” (common) ter

minal at all times. The black lead (on heat/cool

models) is used to select the proper speed for

cooling mode and the red lead is used to select the

speed for heating mode.

CAOTTON: "Whien adjasisn^ ihe blower speed,

make cefiain that the temperature rise across

the heat exchanger does not exceed that speci

fied on the rating plate.

Table 3 — Speed Selector

Adjust Main Burner Flame — The main burner

flame should be clear blue, almost transparent, with

a well-defined inner cone. If there is too much pri

mary air, the flame will be well defined, but with a

tendency to float or lift off the burner ports.

1. Allow unit to operate 5 minutes.

2. When burners are equipped with primary air

adjustment, adjust each burner by closing air ad

justment device until slight yellow tip appears on

flame; then open, just enough to clear yellow

from flame.

Temperature Rise — Determine the air tem

perature rise as follows:

1. Place duct thermometers in return and supply

ducts as near furnace as possible. Be sure

thermometers do not “see” heat element so that

radiant heat will not affeet thermometer read

ings. This is particularly important with straightrun ducts.

2. When thermometers stabilize, subtract return air

temperature from supply air temperature to

determine air temperature rise.

SPEED

Common C

Hi

Med-Hi

Med-Lo 3

Lo 4

TAP NO

......................1......................

2

.......................

NOTE: Series 100 (heating only) and 150-200 have

3-speed motor.

Limit Control Safety Check — This control

shuts off the gas and energizes the blower

motor if the furnaee becomes overheated.

The recommended method of checking the

limit control is to gradually block off the return

air after the furnace has been operating for a

period of at least 5 minutes. As soon as the

limit has proven safe, the return air opening

should be unblocked to permit normal air circu

lation. By using this method to check the limit

control, it can be established that the limit is

functioning properly and will “fail-safe” if there

is a motor failure.

10

Page 11

SERVICE

CAUTION: Tixe abüîty to properly perform

maintenance on this equipment requires certain

mechanical skills and tools. If yott are at all

uncertain, contact your Carrier deaier lor

qualified maintenance and .service..

proper procedure for checking and cleaning the

filter.

Blower Motor and Wheel — For long life,

economy, and high efficiency, clean accumulated

dirt and grease from blower wheel and motor

annually.

Regular maintenance, exercised with care, results

in more efficient operating life of your furnace.

Periodic filter changes, along with inspection

and cleaning of the heat exchanger, inspection

and lubrication of blower motor and wheel, and

checking for tight electrical connections and proper

operation of controls each season, help insure

reliable service.

WARNîNC: Tura oft ali gas and electrical

power to furnace before performing my main

tenance or service on unit. Failure to take this

precaution may result in personal injury' dtte to

electrical shock or uncontrolled gas leakage.

Air Filter

SAFETY INSTRUCTIONS; in order to

acquaint the user of the furnace with proper

procedure for checking and cleaning the filter,

the installer should instruct the user to perform

the steps described below.

Remember to disconnect electrical power before

removing access panels. To clean or replace air

filter, proceed as follows;

1. Remove blower access door.

2. Release filter retainer spring from behind flange

of furnace casing.

3. Slide filter out.

4. Clean filter with tap water.

5. Rinse and let dry. No oiling or coating of filter

is required.

6. Place filter in furnace with cross-sectional

binding up or facing blower.

CAUTION: As with any mechanical equipment,

personal injury can result from sharp metal

edges, etc.; therefore, be careful when removing

parts.

Lubricate motor every 5 years if motor is used on

intermittent operation (thermostat FAN switch in

AUTO, position), or every 2 years if motor is in con

tinuous operation (thermostat FAN switch in ON

position).

Remember to disconnect electrical supply before

removing access panels.

Clean and lubricate as follows:

1. Remove access panels.

2. Remove electrical leads from left side of Molex

speed selector. See Fig. 7. Note location of

wires for reassembly.

3. Remove screws holding blower assembly

against blower deck and slide blower assembly

out of furnace.

4. Squeeze side tabs of Molex speed selector and

pull it from blower housing.

5. Loosen a screw in strap holding motor capacitor

to blower housing and slide capacitor from

under strap.

6. Mark blower wheel, motor, and motor

support in relation to blower housing before dis

assembly, to insure proper reassembly.

7. Loosen setscrew holding blower wheel onto

motor shaft.

NOTE: Eurnaces with dual blowers, remove right

blower and wheel first as shown in Fig. 12.

CAUTION: Personal injury or property

damage may result if furnace is operated with

the blower cotnpartmeni door removed. A lack

of adequate combustion air may cause the main

burner flame to be drawn out of the furnace

unless blower compartment door is secured.

After inspecting or replacing the filter, be

sure that blower compartment door is securelyfastened in place.

NOTE: If external filter rack is used in place of

internal filter mounting, inform the user of the

Fig. 12 — Dual Blower with Right-Hand

Housing and Wheel Removed

Page 12

8. Remove bolts holding motor mount to blower

housing and slide motor and mount out of

housing. Some motors have a ground wire

attached to blower housing: disconnect it also.

9. Lubricate motor.

a. Remove dust caps or plugs from oil ports

located at each end of motor.

b. Use a good grade of SAE 20 nondetergent

motor oil and put 16 to 25 drops in each oil

port.

c. Allow time for total quantity of oil to be

absorbed by each bearing.

d. After oiling motor, be sure to wipe excess

oil from motor housing.

e. Replace dust caps or plugs on oil ports.

10. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff

location to insure proper reassembly.

b. Remove screws holding cutoff plate and

remove cutoff plate from housing.

c. Lift blower wheel from housing thru

opening.

11. Clean blower wheel and motor by using vacuum

with soft brush attachment. Care must be exer

cised not to disturb balance weights (clips) on

blower wheel vanes. Also, do not drop or bend

wheel, as balance will be affected.

12. Reassemble blower by reversing procedures 10a

thru c. Be sure wheel is positioned for proper

rotation.

13. Reassemble motor and blower by reversing

procedures 4 thru 8. If motor has ground wire,

be sure it is connected as before.

14. Reinstall blower assembly in furnace.

15. Connect electrical leads to Molex speed

selector. Please note that connections are

polarized for assembly — do not force.

16. Turn on electrical power and check for proper

rotation and speed changes between heating

and cooling.

FLUE baffles

Fig. 13 — Removing Baffles

8. Replace flue baffles and chokes. Be sure all

screws are in place and tight.

9. Replace draft diverter and vent connector. Be

sure screws are replaced and tight.

10. Replace secondary air baffle and burners.

11. Turn on gas and electricity. Check for gas leaks.

WARNING: Never use a match or other open

flame to check for gas leaks. Use a soap-andwater solution.

Pilot — Pilot should be checked and cleaned if

necessary at the beginning of each heating season.

Pilot flame should be high enough for proper

impingement of the flame sensing probe. Remove

accumulation of soot, dirt, and carbon from probe

and electrode if necessary.

Cleaning Heat Exchanger — If it becomes neces

sary to clean the heat exchanger because of carbon

deposits, soot, etc., proceed as follows:

1. Turn off gas and electrical supply.

2. Remove access panels.

3. Remove vent connector and draft diverter.

Screws are located inside draft diverter opening.

Remove chokes.

4.

Remove flue baffles from flue outlets of heat

5.

exchanger. See Fig. 13.

Remove secondary air baffle and burners. To

6.

remove pilot burner, disconnect pilot supply

tube at gas valve.

Clean flue ways with brush and/or vacuum.

7.

Check heat exchanger for leaks and cracks.

Replace if necessary.

Electrical Controls and Wiring

NOTE: There may be more than one electrical

supply to unit.

With power disconnected to unit, check all

electrical connections for tightness. Tighten all

screws on electrical connections. If any smoky or

burned connections are noticed, disassemble the

connection, clean all parts and stripped wire, and

reassemble properly and securely. Electrical con

trols are difficult to check without proper instru

mentation. Therefore, reconnect electrical power to

unit and observe unit thru one complete operating

cycle. If there are any discrepancies in the operating

cycle, contact your Dealer and request service.

12

Page 13

^ OF PILOT

«.OFPJLOr

(ESSEX 242 GAS VALVE)

Fig. 14 — Position of Electrode to Pilot Shield

Fig. 15 — Proper Location of Carry-Over in

Relation to Top of Burner

13

Page 14

Table 4 — Trouble Analysis Chart

WARNING: Turn off gas and power supply to ur»it before servicing.

(Unless specific test requires gas and electrical supplies.}

Blower operates continuously

Inadequate heating

Aldehyde odors, (CO),

sooting flame — floating flame

CAUSE

No spark at electrode

Spark shorting out to main burner

No gas at pilot burner

Noll 5-volt power to furnace

No 24-volt power to control circuit

Miswired or loose connections

No gas at main burners

Flame probe or connecting lead is

shorted or open

Dirty pilot — yellow flame

Thermostat fan switch in ON position

Fusible link blown

Dirty filter causing limit operation

Defective heat relay

Furnace undersized for application

Gas input to furnace too low

Limit switch cycles main burners

Incomplete combustion — poor

flame characteristics

REMEDY

Check air gap between electrode tip and pilot burner It should

be 1/8 +1/16 on BDP gas valve; 3/32 +0 025 onEssexgas

-0 -0.005

valve Readjust if necessary

Check moisture or dirt accumulation on electrode ceramic —

clean ceramic with cloth

Cracked ceramic — replace pilot electrode assembly

Check for loose or broken wiring at and between electronic con

trol box and electrode Replace wire as necessary

Check fuse or circuit breaker for 11 5-volt supply to furnace.

Check 24-volt input to electronic control box If you read 24 volts

and above steps have been completed, replace electronic

control box assembly

Realign electrode tip away from main burner but maintain

spark gap to pilot burner as jtote^above ___

Check to see if pilot valve is opening Look for loose or broken

wiring connections If no deficiency is found, replace valve

assembly

Connect to power supply Check fuse, wiring, or circuit breal^r

Check transformer — replace

Check_all wiring and wirenut connections.

Check to see if main valve is opening Look for loose or broken

wiring connections If no deficiency is found, replace valve

assembly _

Correct electrical shorting or open circuit

Clean pilot orifice

Move thermostat fan switch to AUTO position

Correct combustion air and venting practice — replace fuse

link with identical part

Clean dirty air filter — reinstall

Replace printed circuit board

Replace with proper size furnace _

Check gas pressure at manifold Clock gas meter for input If

too low, increase manifold pressure, or replace with correct

orifices

pFF setting of fan control set too high — reset. ____ _

Dirty air filters — clean and reinstall.

____

_ _

_____________________

_______________________

_

___ ______

slower speed too low — use faster speed tap

Registers closed, restricted ductwork — open or remove

restriction

Check heat anticipator setting on thermostat — readjust

Air shutter on burners — closed — adjust to soft blue flajjip^

Check all screws around flue outlets and burner compartment

— tighten

LACK OF COMBUSTION AIR — see instructions.

Cracked heat exchanger — replace.

Overfired furnace — reduce input, or change orifices

Check vent for restriction — clean as required

__

14

Page 15

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without noticeand without incurring obligations.

Book 1

Tab

4

6a

8a

Form 58GS-2SI Supersedes 58GS-1 SI Printed in U S.A 8-78

PC 101

Catalog No 535-880

Loading...

Loading...