Page 1

HEATING & COOLING

Deluxe Gas-Fired Condensing Furnaces

Service and Maintenance instructions

For Sizes 040-100, Series 100

NOTE; Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified person

nel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by traiiied^ervice personnel. When working on

heating equipment, observe precautions in the literature, tags, and

labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes, including NFPA 54/ANSI Z223.1-1988,

National Fuel Gas Code. Wear safety glasses and work gloves.

Have a fire extinguisher available during start-up and adjustment

procedures and service calls.

Recognize safety information. This is the safety-alert symbol ^ .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal word—DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injurj> or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices, which would result in minor personal injury or

product and property damage.

58DXC, 58SXC

Fig. 1—Model 58SXC Upflow Furnace

A91098

A

WARNING

The ability to properly perform maintenance on this equip

ment requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any maintenance on this equipment other than those

procedures recommended in the User’s Manual. FAILURE

TO FOLLOW THIS WARNING COULD RESULT IN

POSSIBLE DAMAGE TO THIS EQUIPMENT, SERIOUS

PERSONAL INJURY, OR DEATH.

A WARNING

Never store anything on, near, or in contact with, the furnace,

such as;

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning com

pounds, plastic or plastic containers, gasoline, kerosene,

cigarette lighter fluid, dry cleaning fluids, or other volatile

fluids.

3. Paint thinners and other painting compounds, paper bags or

other paper products.

Failure to follow this warning can cause corrosion of the heat

exchanger, fire, personal injury, or death.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a

PC 101 Catalog No. 535-832

Printed in U.S.A,

Form 58D,S-8SM

Fig. 2—Model 58DXC Downflow Furnace

P0 1

7-92

A91103

Replaces: 58D,S-6SM

Page 2

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip

ment failure, it is essential that maintenance be performed annually

on this equipment. Consult your local dealer for maintenance and

the availability of a maintenance contract.

A WARNING

Turn OFF the gas and electrical supplies to the unit before

performing any maintenance or service. Follow the operating

instructions on the label attached to the furnace. Failure to

follow this warning could result in personal injury.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month as required.

2. Check blower motor and wheel for cleanliness and lubrication

each heating and cooling season. Clean and lubricate as

necessary. (See Step 2.)

3. Check electrical connections for tightness, and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage; clean as necessary.

5. Check for blockages of combustion-air and vent pipes.

A CAUTION

As with any mechanical equipment, personal injury could

result from sharp metal edges, etc. Be careful when removing

parts.

Step 1—Air Filter Cleaning and Replacement

The air filter anangement may vary depending on the application.

A CAUTION

Never operate unit without a filter or with filter access door

removed. Failure to follow this warning could result in a fire

or personal injury.

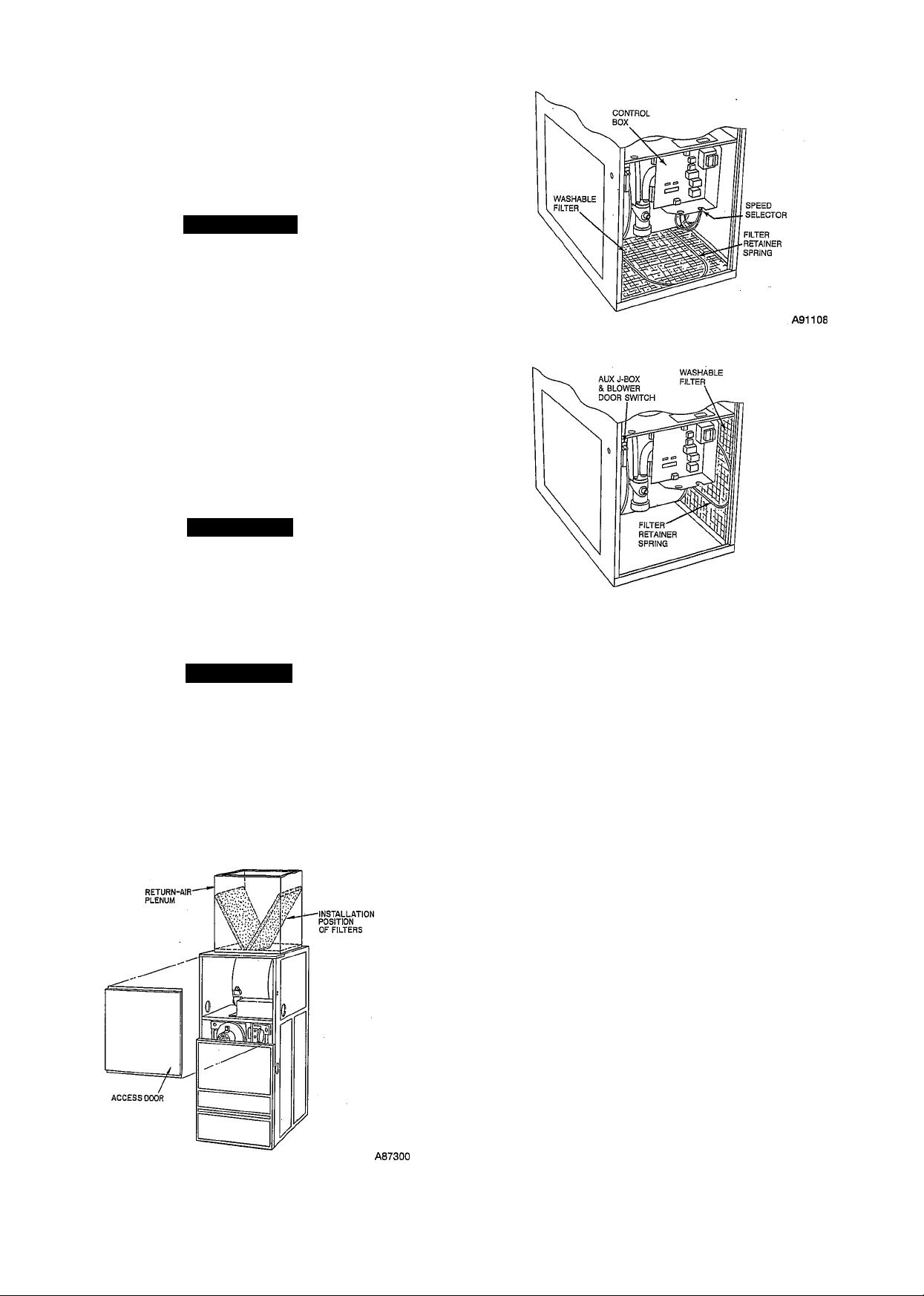

DOWNFLOW FURNACES ONLY - Each furnace accommo

dates 2 filters which are installed in the return-air duct. (See Fig.

3.) To clean or replace the filters, proceed as follows:

1. Turn OFF electrical supply to unit.

2. Remove blower access door.

Fig. 3—Position of Filters in Downflow Furnace

Fig. 4—Filter Installed for Bottom Inlet in Upflow

Furnace

A91109

Fig. 5—Filter Installed for Side Inlet in Upflow

Furnace

3. Reaching up behind top plate, tilt filters toward center-of

return-air plenum, remove filters, and replace or clean as

needed.

4. Furnaces are equipped with permanent, washable filters. Clean

these filters by spraying cold tap water through filter in

opposite direction of airflow.

5. Rinse filters and let dry. Oiling or coating of filters is not

recommended.

6. Reinstall filters with cross-mesh binding facing blower.

7. Replace access door.

8. Turn ON electrical supply to furnace.

UPFLOW FURNACES ONLY - To clean or . replace the air

filter, proceed as follows:

1. Turn OFF electrical supply to unit.

2. Remove access doors.

3. Release filter retainer spring from behind flange of furnace

casing. (See Fig. 4 and 5.)

4. Slide filter out.

5. Furnaces are equipped with permanent, washable filters. Clean

filter by spraying cold tap water through filter in opposite

direction of airflow.

6. Rinse filter and let dry. Oiling or coating of filter is not

recommended.

7. Place filter in furnace with cross-mesh binding either up or

facing blower.

8. Replace access doors.

9. Turn ON electrical supply to furnace.

WA

Page 3

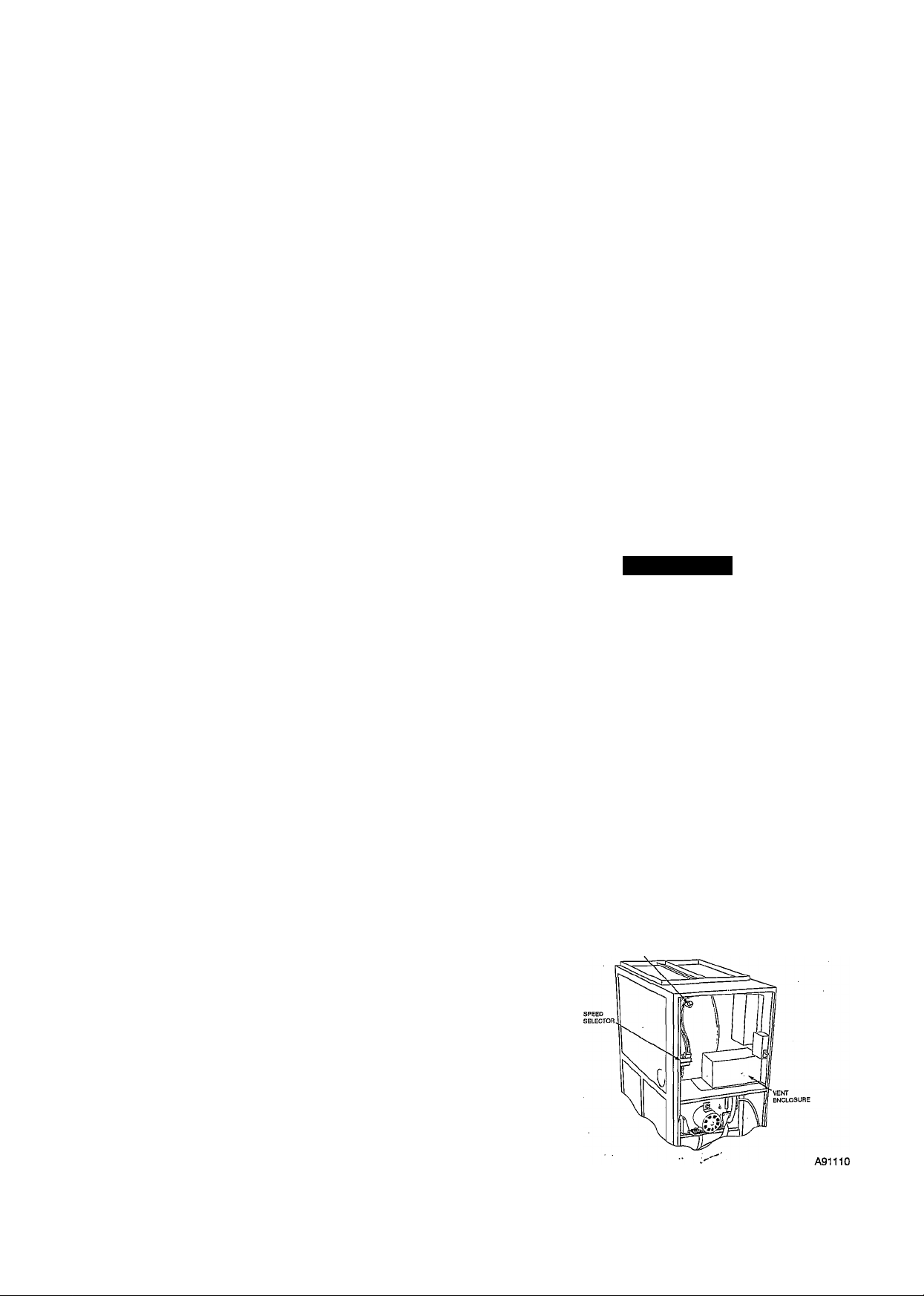

step 2—Blower Motor and Wheel Maintenance

For long life, economy, and high efficiency clean accumulated dirt

and grease from blower wheel and motor annually.

The following items should be performed by a qualified service

technician;

Some motors have prelubricated, sealed bearings and require no

lubrication. These motors can be identified by the absence of oil

ports on each end of the motor. For motors with oil ports, lubricate

as follows:

Lubricate motor every 5 years if motor is used for intermittent

operation (thermostat FAN switch in AUTO position), or every 2

years if motor is in continuous operation (thermostat FAN switch

in ON position).

Clean and lubricate' as follows:

1. Turn OFF electrical supply to unit.

2. Remove access doors.

3. Downflow furnace only — disconnect vent pipe, elbow, and

auxiliary limit switch. (See Fig. 6.)

a. Remove vent pipe enclosure from top side of blower shelf

and position to 1 side.

b. Loosen hose clamps on outlet elbow and remove elbow.

c. Loosen hose clamp on extension pipe outside of furnace

and remove pipe.

d. Disconnect wires from auxiliary limit on blower housing.

4. Note location of wires for reassembly, then remove electrical

leads from numbered side of blower speed selector. (See Fig.

4 and 6.)

5. Upflow furnaces only —remove drain trap and control box.

a. Remove control box from bottom side of blower shelf and

position to 1 side.

b. Using backup wrench, disconnect drain pipe at coupling in

blower compartment.

c. Loosen hose clamp and remove 7/8-in. diameter drain hose

from drain trap.

d. Loosen hose clamp and disconnect 5/8-in. diameter drain

hose at bottom of inducer housing located under blower

shelf.

e. Remove screw securing drain trap assembly.

6. Remove screws securing blower assembly to blower shelf and

slide blower assembly out of furnace.

7. Squeeze side tabs of blower speed selector and pull from

blower housing bracket.

8. Loosen screw in strap holding motor capacitor to blower

housing and slide capacitor from strap.

9. Mark blower wheel location on shaft before disassembly to

insure proper reassembly.

10. Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms, and blower housing so each

arm is positioned at the same hole location during reassembly. This

will insure that oilers point up.

11. Remove bolts holding motor mount to blower housing and

slide motor and mounts out of housing. Disconnect ground

wire attached to blower housing before removing motor.

12. Lubricate motor (when oil ports are provided).

a. Remove dust caps or plugs from oil ports located at each

end of motor. If motor does not have these caps or plugs,

bearings are sealed and need no further lubrication.

b. Use a good grade of SAE 20 nondetergent motor oil and

add 1 teaspoon (5 cc, 3/16 oz, or 16 to 25 drops) in each oil

port. The use of other types or grades of oil will damage the

motor. Excessive oiling can cause premature bearing fail

ures.

c. Allow time for total quantity of oil to be absorbed by each

bearing.

d. After oiling motor, wipe excess oil from motor housing.

e. Replace dust caps or plugs on oil ports.

13. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff plate location to

insure proper reassembly.

b. Remove screws securing cutoff plate and remove cutoff

plate from housing.

c. Remove blower wheel from housing.

14. Clean blower wheel and motor by using a vacuum with soft

brush attachment. Be careful not to disturb balance weights

(clips) on blower wheel vanes. Do not drop or bend wheel as

balance will be affected.

15. Reassemble blower by reversing items 13.a. through 13.c.

Ensure wheel is positioned for proper rotation.

16. Reassemble motor and blower by reversing items 6 through

11. If motor has ground wire, be sure it is reconnected.

A CAUTION

Ensure the motor is properly positioned in the blower

housing. The motor oil ports must be at a minimum of 30°

above the horizontal centerline of the motor after the blower

assembly has been reinstalled in the furnace.

17. Reinstall blower assembly in furnace.

18. Upflow furnace only—reinstall drain trap and control box.

a. Inspect drain trap and hoses to ensure they are not blocked

or restricted. Reinstall drain trap and hoses. Be sure to

tighten hose clamps.

b. Using backup wrench, attach drain pipe and tighten com

pression coupling.

c. Reinstall control box on bottom side of blower shelf. Be

sure edge connector is connected through top of blower

shelf.

19. Downflow furnace only — reconnect vent pipe, elbow, and

auxiliary limit switch.

a. Reinstall outlet elbow and extension pipe. Be sure connec

tions are tight and leak proof.

AUXILIARY

LIMIT

SWITCH

Fig. 6—Model 58DXC Downflow Furnace

Page 4

b. Reinstall vent pipe enclosure.

c. Reconnect red wires to auxiliary limit switch.

20. Connect electrical leads to blower speed selector. Note that

connections are polarized for correct assembly — do not force.

21. Turn ON electrical supply and check for proper rotation and

speed changes between heating and cooling; operate unit 5

minutes and carefully check for condensate leaks.

Step 3—Cleaning Heat Exchangers

The following items should be performed by a qualified service

technician:

If it becomes necessary to clean the heat exchanger because of

carbon deposits, soot, etc., proceed as follows:

NOTE: Deposits of soot and carbon indicate a problem exists that

needs to be corrected. Action must be taken to correct the problem.

1. Turn OFF gas and electrical supplies to furnace.

2. Remove control and blower access doors.

3. Loosen hose clamps on combustion-air pipe and move air pipe

aside.

4. Using backup wrench, disconnect gas supply at ground joint

union. Remove gas pipe from valve.

5. Disconnect hot surface ignitor and flame sensor leads at

3-circuit connector outside of burner enclosure.

6. Disconnect electrical wires from gas valve.

7. Disconnect pressure tubing from right side of burner enclosure

and outlet end of gas valve.

8. Remove burner enclosure front.

9. Remove diffuser from inside top of burner enclosure. Remove

screws that secure burner enclosure to cell panel. These

screws are located inside the burner enclosure.

10. Using care not to damage cell inlet panel gasket, remove gas

control assembly from furnace.

11. Remove vent pipe and drain.

a. Upflow furnace only:

(1.) Loosen hose clamps at vent pipe connection; discon

nect vent pipe and position to 1 side.

(2.) Loosen hose clamp and remove drain tube from

inducer outlet box.

b. Downflow furnace only:

(1.) Remove vent pipe enclosure.

(2.) Loosen hose clamps at vent pipe connection.

(3.) Loosen hose clamp and remove drain tube from

inducer outlet elbow.

12. Upflow furnace only —remove main control box.

a. Disconnect edge connector from main control box at

blower shelf.

b. Remove screws securing main control box to blower shelf

and position control box to 1 side.

13. Disconnect inducer motor connector from wiring harness.

Disconnect wires and pressure tube from pressure switch.

14. Loosen hose clamp and remove drain tube from inducer

housing.

15. Remove mounting screws securing inducer assembly to col

lector box and coupling box; remove inducer assembly.

16. Remove all old sealant from parts.

17. Remove coupling box(es).

a. Upflow furnace only:

(1.) Remove screws securing coupling box and remove

from furnace. Remove all old sealant from parts.

(2.) Remove choke plate (when used) from primary heat

exchanger outlet.

b. Downflow furnace only:

(1.) Remove screws securing intake (upper) coupling box

and remove from furnace. Remove all old sealant from

parts. ^

(2.) Remove screws securing primary (lower) coupling

box and remove box. Clean old sealant from parts.

18. Loosen hose clamp and remove 7/8-in. drain tube from trap.

19. Hold bucket under 7/8-in. drain tube.

20. Using garden hose, flush each cell of the condensing heat

exchanger with water. Use care not to spray water onto

interior surfaces of control compartment. Dry all surfaces. Be

careful not to remove sealant around cell openings in cell

panel.

21. Using field-provided small wire brush, steel spring cable,

reversible electric drill, and vacuum cleaner, clean primary

heat exchanger cells. Do not use wire brush or other sharp

object to clean condensing heat exchanger. Failure of the

condensing heat exchanger will occur—flush with water only.

a. Assemble wire brush and steel spring cable.

(1.) Use 4 ft of 1/4-in. diameter high-grade steel spring

cable (commonly known as drain cleaning or RotoRooter cable).

(2.) Use 1/4-in. diameter wire brush (commonly known as

25-caIiber rifle cleaning brush).

NOTE: The materials required in items (1.) and (2.) can be

purchased at local hardware stores.

(3.) Insert twisted wire end of brush into end of spring

cable, and crimp tight with crimping tool or strike with

ball-peen hammer. Tightness is very important.

(4.) Remove metal screw fitting from wire brush to allow

insertion into cable.

b. Clean each primary heat exchanger cell.

(1.) Attach variable-speed, reversible drill to end of spring

cable (end opposite brush).

(2.) Insert brush end of cable into upper opening of cell

and slowly rotate with drill. Do not force cable.

Gradually insert at least 3 ft of cable into 2 upper

passes of cell. (See Fig. 7.)

A884S9

Fig. 7—Cleaning Primary Heat Exchanger Cell

(3.) Work cable in and out of cell 3 or 4 times to obtain

sufficient cleaning. Do not pull cable with great force.

Reverse drill and gradually work cable out.

(4.) Insert brush end of cable in lower opening of cell, and

proceed to clean 2 lower passes of cell in same manner

as 2 upper passes.

Page 5

(5.) Repeat procedures (above) until each furnace cell has

been cleaned.

(6.) Using vacuum cleaner, remove residue from each cell.

' (7.) Using vacuum cleaner with soft brush attachment,

clean burner assembly.

Step 4—Reassemble Furnace (After Cleaning Heat Ex

changers)

1. Install choke plate (when used). Be sure choke plate bottom

conforms to top flange of condensing heat exchanger.

2. Reinstall coupling box(es);

a. Apply sealant releasing agent (Pam) to cell panel where

coupling box flange matches. (See Fig. 8.)

b. Apply a generous bead 3/16-in. dia) of G.E. RTV 122,162,

or Dow-Corning RTV 738 sealant (NO substitute is

permissible) to flange of coupling box. Your distributor

should have G.E. RTV 122, 162, or Dow-Corning RTV

738 sealants in stock.

c. Being careful not to smear sealant, position coupling box so

that slot in insulation is on left side and install coupling

box.

APPLY RELEASE AGENT TO AREA

INDICATED BY SHADING

A86100

Fig. 9—Backside of Inducer Assembly Housing

COUPLING BOX

(INSIDE VIEW)

A87318

Fig. 8—Inside View of Coupling Box

NOTE: Downflow furnace only—position primary (lower) cou

pling box so that tallest end is on right side.

3. Reinstall inducer assembly.

a. Upflow furnace only —Be sure small round gasket(s) is in

place between blower shelf and inducer housing.

b. Apply sealant releasing agent (Pam) to collector box. (See

Fig. 9.)

c. Apply 1/8-in. diameter bead of G.E. RTV 122, 162, or

Dow-Corning RTV 738 sealant to back of inducer housing.

Apply sealant around inlet air opening. (The sealant should

be about 1/4 in. from the edge of the inlet air opening.)

d. Install inducer assembly on collector box and support

bracket to coupling box.

e. Connect inducer motor plug-in connector to wiring har-

ness.Reconnect wires to pressure switch using furnace

wiring diagram. (See Fig. 17.)

f. Reconnect pressure tubes to pressure switch. (See Fig. 13 or

14.)

4. Connect small drain tube from top of trap to fitting on bottom

of inducer housing. (See Fig. 13 or 14.)

BURNER FUME

5. Connect 7/8-in. drain tube to trap and collector box, and

tighten hose clamps. (See Fig. 13 or 14.)

6. Reinstall vent pipe and drain tube.

a. Upflow furnace only:

(1.) Reconnect vent pipe. Be sure clamps are tight.

(2.) Connect drain tube from collector box to inducer

outlet box.

b. Downflow furnace only:

(1.) Reconnect vent pipe. Be sure clamps are tight..

(2.) Reinstall vent pipe enclosure.

(3.) Connect drain tube from collector box to inducer

outlet elbow.

7. Upflow furnace only—reinstall main control box.

a. Reinstall main control box on blower shelf.

Page 6

13/32"-

'Vaa"

\X

1b

B

IF

il—fl

/

' IGNITOR

ASSEMBLY

K

/

Ig IGNITOR

(g BURNER

\

IGNITOR

ASSEMBLY

Fig. 12—Position of Ignitor to Burner

^8 OD

PRESSURE

TUBING

HEAT EXCHANGER

DIFFERENTIAL

PRESSURE

SWITCH

% OD

PRESSURE

TUBING

VZ OD

DRAIN

TUBING

(TUBE PASSES

THROUGH

BLOWER SHELF)

■DRAIN

TRAP

A91113

Fig, 13—Upflow Furnace Pressure and Drain Tub

ing Diagram

b. Reconnect edge connector at main control box on blower

shelf.

8. Check condition of gasket on cell inlet panel of burner

enclosure. Replace gasket if necessary. (See Fig. 10.)

9. Install gas control assembly in furnace.

10. Install diffuser and burner enclosure front.

11. Reconnect hot surface ignitor and flame sensor leads at

3-circuit connector. .

12. Refer to furnace wiring diagram and connect wires to gas

valve. (See Fig. 17.)

13. Reconnect pressure tubes to gas valve and burner enclosure.

Be sure tubes are not kinked.

14. Using backup wrench, install gas pipe in gas valve.

A91064

HEAT EXCHANGER

DIFFERENTIAL

FRESSURE

SWITCH

A91112

Fig. 14—Downflow Furnace Pressure and Drain

Tubing Diagram

15. Reconnect gas pipe at ground joint union.

16. Reconnect combustion-air pipe. Tighten hose clamps.

17. Replace blower door only.

18. Turn ON gas and electrical supplies.

19. Check furnace operation through 2 complete operating cycles.

Look through sight-glass in burner enclosure to check burners.

Burner flames should be clear blue, almost transparent. (See

Fig. 11.)

A WARNING

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

20. Check for gas leaks.

21. After condensate starts to drain, check for condensate leaks.

22. Replace control door.

Step 5—Clean Condensate Drainage System

1. Disconnect 5/8-in. drain tube from bottom of inducer housing.

(See Fig. 13 or 14.)

2. Disconnect 7/8-in. drain tube from collector box. (See Fig. 13

or 14.)

3. Disconnect condensate drain line from drain trap at compres

sion fitting.

4. Remove two 1/4-in. screws securing strap on drain trap to:

a. blower housing (upflow furnaces only).

b. bracket from cell panel (downflow furnaces only).

5. Remove drain trap/hose assembly from furnace and flush with

water until clean.

6. Flush external condensate drain line with water until clean.

7. Reassemble condensate drainage system by reversing items 1.

through 5.

Step 6—Hot Surface Ignitor

When removing the burner assembly, use care to avoid breaking

the hot surface ignitor. See Fig. 12 for the conect ignitor

Page 7

__________

FIELD 24-VOLT WIRING

— —FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-, 208/230-, 460-VOLT WIRING

(w>-

e>-

(¡>-

115-VOLT

SINGLE

PHASE

—^-»-rrn-

-JL—

■=*GND

115-VOLT

FIELD-SUPPLIED

FUSED DISCONNECT

----

1^0

AUXILIAHY

J-BOX

o^-

-VOLT

Fig. 15—Heating and Cooiing Appiication Wiring Diagram

location. When reinstalling ignitor, use care to insure all wiring is

away from the burners and is not touching the bottom of the sheet

metal enclosure.

Step 7—Electrical Controls and Wiring

NOTE; There may be more than 1 electrical supply to the unit.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig, 15 for field wiring information

and to Fig. 17 for unit wiring information. If the polarity is not

correct, the microprocessor control will shut off the gas flow

shortly after completion of the ignition trial period. The control

system also requires an earth ground for proper operation of the

niicroprocessor.

The 24-v circuit contains an automotive-type, 3-amp fuse (FUl)

located on the main control board. (See Fig. 16.) Any direct shorts

during installation, service or maintenance may cause this fuse to

"blow." If fuse replacement is required, use only a fuse of identical

size.

With power disconnected to the unit, check all electrical connec

tions for tightness. Tighten all screws on electrical connections. If

any smokey or burned connections are found, disassemble the

connection, clean all parts, strip wire, and reassemble properly and

securely.

Reconnect electrical power to the unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation; if there are any discrepancies in

the operating cycle, contact your dealer and request service.

NOTES:

1. CONNECT Y-TERMINAL AS SHOWN FOR PROPER COOLING OPERATION.

2. IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED, MUST BE REPLACED,

USE SAME TYPE OR EQUIVALENT WIRE.

3. PROPER POLARITY MUST BE MAINTAINED FOR 115-VOLT WIRING.

Step 8—Winterizing

A CAUTION

The unit must not be installed, operated, and then turned off

and left off in an unoccupied structure during cold weather

when the temperature drops to 32° F and below. Freezing

condensate left in the furnace will damage the equipment.

If the furnace will be off for an extended period of time in a

structure where the temperature will drop to 32° F or below,

winterize as follows;

1. Mix a solution of equal amounts of ethylene glycol (Prestone

II antifreeze/coolant or equivalent) and water.

2. Turn OFF electrical supply to furnace.

3. Remove control access door.

4. Disconnect drain tube from bottom of inducer outlet box/el-

bow.

5. Insert funnel in drain tube and pour antifreeze/water solution

into furnace until it is visible at point where condensate enters

open drain.

6. Reconnect drain tube to outlet box/elbow.

7. Replace control access door.

ELECTRONIC

AIR CLEANER

TERMINALS

A87502

Page 8

TO 115VAC FIELD DISCONNECTIONS

HUM-1 (TPl)

0=

BLWR

HSIR

I NOTE #5

j EQUIPMENT GROUND

SCHEMATIC DIAGRAM

(NATURAL GAS S PROPANE)

GVR

RED

YEL

Otpb

OtP7

W Y R C G

0 0 0 0 0

0_R

LEGEND

ALS

AUXILIARY LIMIT SWITCH, OVERTEMP.-

BLWR

BLOWER MOTOR RELAY, SPST-(N.O.)

BLWM

BLOWER MOTOR

CAP

CAPACITOR

CPU

MICROPROCESSOR AND CIRCUITRY

EAC-1

ELECTRONIC AIR CLEANER CONNECTION (115 VAC 1 AMP MAX.)

EAC-2

ELECTRONIC AIR CLEANER CONNECTION (COMMON)

FR5

FLAME ROLLOUT SWITCH

FSE .

FLAME SENSING ELECTRODE

FUl

FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FACTORY INSTALLED

FU2

FUSE, FIELD INSTALLED

GV

GAS VALVE-REDUNDANT OPERATORS

6VR

MAIN GAS VALVE RELAY, DPST-(N.O.)

HI/LO

BLOWER MOTOR SPEED CHANGE RELAY, DPST-(N.O.)

H5!

HOT SURFACE IGNITOR (115 VAC)

HSIR

HOT SURFACE IGNITOR RELAY, DPST-(N.O.)

HUM-1

24VAC HUMIDIFIER CONNECTION (.5 AMP. MAX.)

HUMR

HUMIDIFIER RELAY, DPST-(N.O.) -

!DM ■

INDUCED DRAFT MOTOR

I DR

INDUCED DRAFT RELAY, DPST-(N.O.)

ILK

BLOWER DOOR INTERLOCK SWITCH, 5PST-(N.O.)

JB

JUNCTION BOX

JH9

INDUCER OFF DELAY JUMPERi CUT-15 SEC DELAY, UNCUT -5 SEC DELAY

LGPS

LOW GAS PRESSURE SWITCH, SPST-(N.O.)

LS

LIMIT SWITCH, OVERTEHPERATUR^-AUTO RESET, 5PST-(N.C.)

PCB

PRINTED CIRCUIT BOARD

PLl

11-CIRCUIT EDGE CONNECTOR (PCB)

24V AC

COMMON

nCX

MANUAL RESET, SP5T-CN.C.)

HUM-1 (TP

.5 AMP. MAX.

DELAY

HUMR

0

JW9 NOTE /8

SELF

CPU

BLOWER OFF

^ ^ ^ ^

90 135 180 225 I® ^

NOTE #7 STl ST2

>—I

GROUND SCREW REQUIRED

NOTE #1

PC8

PL2 2-ClRCUIT HSI CONNECTOR

PL3 2-CIRCUlT I DM CONNECTOR

PL4 1-CIRCUIT FSE CONNECTOR

PL5 5-CIRCUIT BLWM CONNECTOR

PL6 3-CIRCUIT FSE/HSI CONNECTOR

PRS PRESSURE SWITCH, 5PST-(N.O.)

ST1-ST2 SELF TEST PINS

TP1-TP7 TEST POINT (1) THRU (7)

TRAN TRAN5F0RMER-115VAC/24VAC

JUNCTION

UNMARKED TERMINAL

o

PCB TERMINAL

MARKED TERMINAL

5

FACTORY WIRING (11SVAC)

FACTORY WIRING (24VAC)

FIELD WIRING CllSVAC)

FIELD WIRING (24VAC)

CONDUCTOR ON PCB

FIELD WIRING SCREW TERMINAL

FIELD GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG RECEPTACLE

Fig. 17—^Wiring Diagram

NOTES:

1. COMMON SIDE (5EC-2 AND C) OF 24VAC TRANSFORMER CONNECTED TO

GROUND THROUGH THIS REQUIRED MOUNTING SCREW.

2. IF ANY OF THE ORIGINAL EQUIPMENT WIRE IS REPLACED USE WIRE

RATED FOR lOS-C.

3. INDUCER (lOM) AND BLOWER CBLWM) MOTORS CONTAIN INTERNAL

AUTO-RESET THERMAL OVERLOAD SWITCHES.

4. BLOWER MOTOR SPEED SELECTIONS (PL5) ARE FOR AVERAGE CONDITIONS

SEE INSTALLATION INSTRUCTIONS FOR DETAILS ON OPTIMUM SPEED

SELECTION.

5. USE ONLY COPPER WIRE BETWEEN THE DISCONNECT SWITCH-AND THE

FURNACE JUNCTION BOX CJB).

6. AUXILIARY LIMIT SWITCH CALS) USED ON DOWNFLOW MODELS ONLY

7. BLOWER MOTOR (BLWM) ADJUSTABLE OFF-DELAY.

8. JW9 TO BE CUT FOR IS-SEC. INDUCER POST-PURGE FOR CONDENSING

FURNACES.

9. FACTORY CONNECTED WHEN LGPS NOT USED.

10. REPLACE ONLY WITH A 3 AMP FUSE. 317275-401 REV. B

A91063

Page 9

START

TROUBLESHOOTING GUIDE

HSI CONDENSING FURNACES

Page 10

Copyright 1992 CARRIER Corp. • 7310 W. Morris St. ■ Indianapolis, IN 46231

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a

PC 101

Catalog No. 535-832

Printed in U.S.A. Form 58D,S-8SM Pg 10

7-92 Replaces: 58D,S-6SM

15063

Loading...

Loading...