Page 1

58DX

HEATING A COOLING

Deluxe Downflow Condensing Furnaces

Installation, Start-Up and Service Instructions

For Sizes 040-100

NOTE: Read these instructions carefully and completely

before installing the furnace.

INTRODUCTION

Before installing the furnace, refer to “Procedure for Down

flow Condensing Furnaces” (packaged with the equipment)

for information concerning combustion, venting, piping, and

other standard installation practices. Further reference is

made to the current edition of the National Fuel Gas Code

NFPA 54-1988-1/ANSI Z223.1-1988.

>• Reference should eJso be made to the regulations of the

serving gas supplier and the local building, heating, plumb

ing, or other codes in effect in the area in which the installa

tion is made.

SAFETY CONSIDERATIONS

Installation emd servicing of heating equipment can be haz

ardous due to gas and electrical components. Only treiined

and qualified personnel should install, repair, or service

heating equipment.

Untrained personnel cem perform basic maintenance func

tions such as cleaning and replacing air filters. AU other

operations must be performed by trained service personnel.

When working on heating equipment, observe precautions

in the literature, tags, and labels attached to or shipped

with the unit and other safety precautions that may apply.

FoUow aU safety codes, including NFPA No. 54/ANSI

Z223.1-1988, National Fuel Gas Code, Wear safety glasses

and work gloves. Have fire extinguisher available during

startup and adjustment procedures and service call.

Recognize safety information. This is the safety-alert sym

bol A. When you see this symbol on the furnace and in

instructions or manuals, be alert to the potential for per

sonal injury.

Understand the signal word—DANGER, WARNING or

CAUTION. These words are used with the safety-alert sym

bol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING,

on the other hand could result in personal injury or death.

CAUTION is used to identify unsafe practices, which would

result in minor personal injury or product and property

damage.

Each Model 58DX is shipped from the factory completely

assembled with a multispeed direct-drive blower and wired

ready for an indoor heating installation. The furnace fea

tures a blower control center with easy-to-read, 24-volt ter

minal strip to ensure proper connections.

The output capacity and any representations of efficiency

for this furnace aie based on standard Department of

Energy test procedures.

The installed operation may vary, depending on installation,

weather, and other factors.

The design of the downflow gas-fired furnace is A.G.A. cer

tified for installation on noncombustible flooring. The fur

nace may be installed on combustible flooring when

installed with the accessory downflow subbase. This furnace

is designed for installation in alcoves, attics, basements,

closets, utility rooms, and manufactured housing (mobile

homes). This furnace line is not A.G.A. certified for installa

tion in a recreation vehicle or outdoors.

■ EFFICIENCY

■ RATING

I CERTIFIED

lama

Fig. 1 —Model 58DX

A WARNING

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poison

ing, explosion, fire, electrical shock, or other conditions

which may cause personeJ injury or property damage.

Consult a qualified installer, service agency, local gas

supplier or your Distributor or Branch for information

or assistance. The qualified installer or agency must use

only factory authorized kits or accessories when modi

fying this product. A failure to adhere to this warning

can cause electrical shock, fire, personal injury, or

death.

Series

A87414

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book] 1 I 4 PC 101 Catalog No. 535-887 Printed in U.S.A. Form 58DX-13Si Pg 1 6-89 Repiaces; 58DX-11Si

Tab I6al8a

Page 2

HOLE IN

FLOOR

3

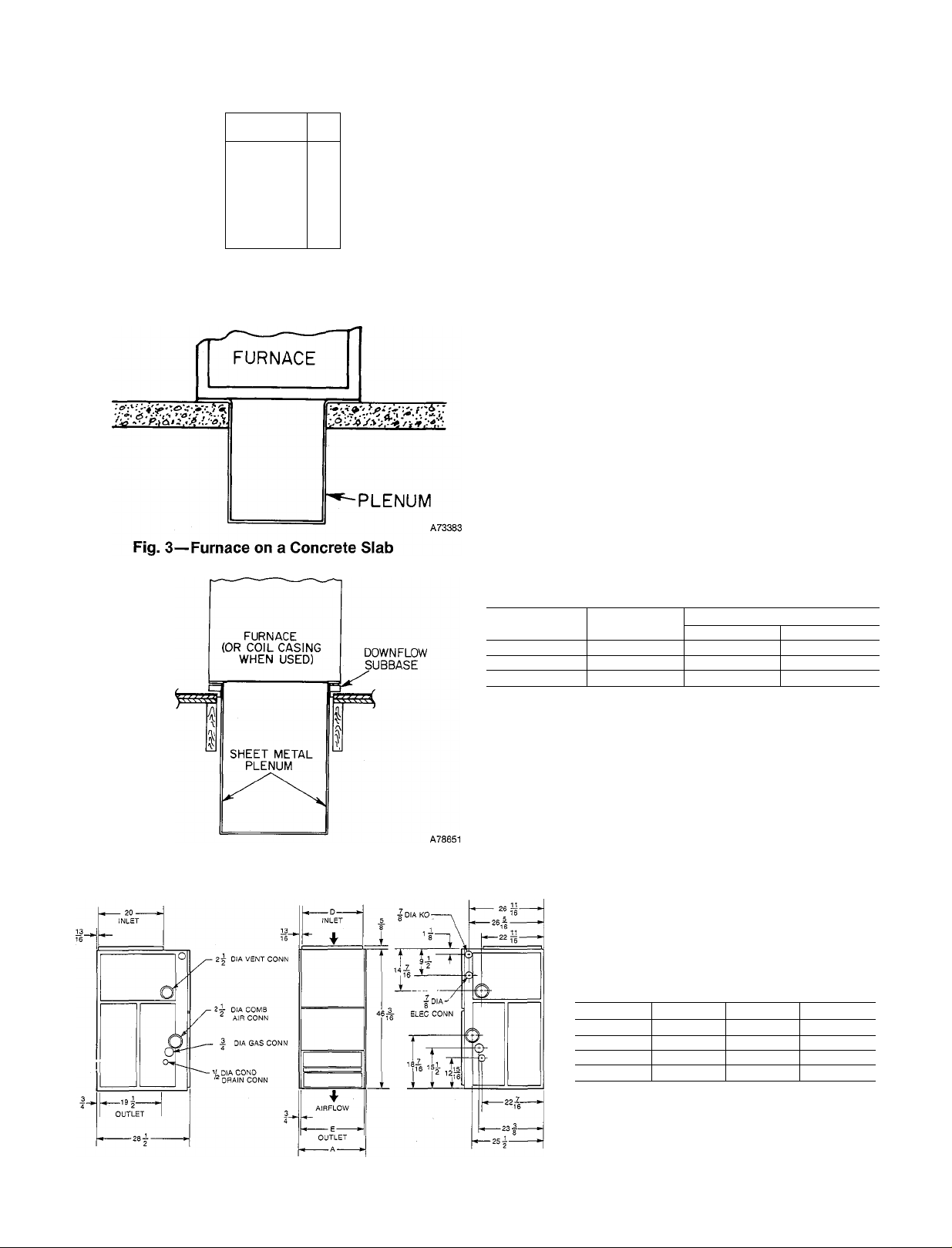

Fig. 2—Floor Opening for Concrete Slab

Insteillation requires the following;

*1. Inspection

*11. Furnace Location

*III. Gas Piping

*IV. Combustion-Air and Vent Piping

*V. Condensate Piping

VI. Supply-Air Plenum Installation

VII. Electrical

VIII. Sequence of Operation

IX. Fdter

*X. Startup and Adjustment

XI. Care and Maintenance

*For these sections (or installation steps), refer to the appro

priate sections of “Procedures for Downflow Condensing

Furnaces” booklet packaged with this unit.

For accessory instedlation details, refer to the applicable

installation hterature.

NOTE: Remove all shipping brackets and materials before

operating the furnace.

VI. SUPPLY-AIR PLENUM INSTALLATION

A. Installation on a concrete slab

1. See Fig. 5 for dimensions and location of supply-air

opening in furnace bottom.

2. Construct hole in floor per dimensions in Fig. 2 and

Table 1.

3. Place plenum and furnace as shown in Fig. 3.

Fig. 4—Furnace, Plenum, and

Base Installed on a Combustible Floor

Table 1—Opening Dimensions

Furnace A

Width

171/2

21

241/2

*These dimensions appiy when a Model 28RC or 28RD Evaporator Coil

casing is to be installed.

16 1/8

19 5/8 19 5/8

231/8

Furnace

19 5/8 19 7/16

19 5/8 19 7/16

B. Installation on a combustible floor

B

Furnace & Coil*

19 7/16

1. Read Installation Instructions packaged with down

flow subbase.

2. Cut and frame hole in floor per dimensions in Installa

tion Instructions packaged with downflow subbase. If

this requires cutting of a floor joint, tie ends of cut

joist into adjacent joists so that proper floor support

wUl be maintained.

Table 2—Dimensions (In Inches)

Size A D E

040 171/2 15 7/8 16

060

080 21 19 3/8 191/2

100 24 1/2 22 7/8 23

171/2 15 7/8 . 16

WA

A87297

Fig. 5—Dimensional Drawing

2

Page 3

------------------

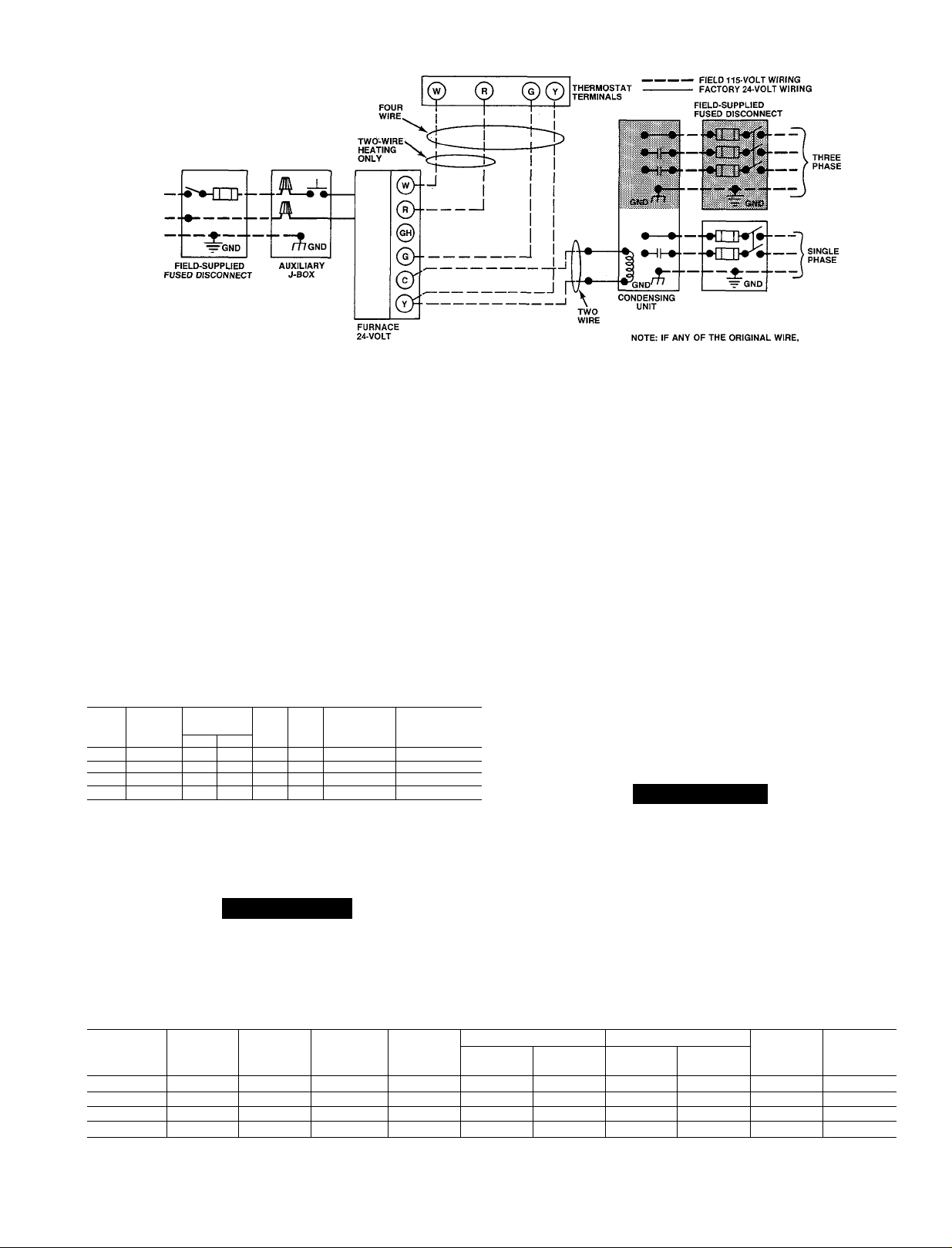

FIELD 24-VOLT WIRING

TERMINAL BLOCK

Fig. 6—Heating and Cooiing Application Wiring Diagram

3. Assemble and install downflow subbase per instruc

tions packaged with subbase.

4. When completed, downflow subbase, plenum, and fur

nace (or coil casing when used) should be installed as

shown in Fig. 4.

VII. ELECTRICAL CONNECTIONS

A. 115-Volt Wiring

iM PORT ANT: Before proceeding with the electrical connec

tions, make certain that voltage, frequency, and phase cor

respond to that specified on the unit rating plate and Table

3. Also, check to be sure that the service provided by the

utility is sufficient to handle the load imposed by this equip

ment. Refer to Table 3 for the equipment electrical

specifications.

Table 3—Electrical Data

Volts-

SIZE Hertz- Voltage Range

Phase Max* Min*

040 115—60—1 127 104

060

115—60—1

080 115—60—1 127 104

100 115—60—1 127 104

»Permissible limits of the voltage range at which the unit will operate sat

isfactorily.

fTime-delay fuse is recommended.

^Length shown is as measured one way along wire path between unit

and service panel for maximum 2% voltage drop.

Operating

127 104

Max. Min.

Unit Wire Length HACR-Type

Amps Size Feett Ckt Bkr Amps

8.7 14 41 15

8.2 14 42 15

10.1 14 36 15

13.6 12 42 20

Max. Wire

Max. Fusef or

A CAUTION

Do not connect aluminum wire between the disconnect

switch and the furnace.

AS SUPPLIED, MUST BE REPLACED, USE

SAME TYPE OR EQUIVALENT WIRE.

A87502

See Fig. 6 for a wiring diagram showing the proper field

115- and 24-volt wiring. Be sure field wiring complies with

the National Electric Code and any local codes or ordnances

that may apply. Voltage to the furnace must be within the

limits shown in Table 3. Contact your local power company

for correction of improper voltage.

NOTE; Operation of unit on improper line voltage consti

tutes abuse and could affect unit reliability. Do not install

the furnace in a system where voltage may fluctuate above

or below permissible limits.

Use a separate fused branch electrical circuit containing the

properly sized time-delay fuse or HACR-type circuit breaker

for this furnace. See Table 3 for fuse and wire specifications.

A disconnecting means must be located within sight of, and

readily accessible to, the furnace. The blower door switch

may be acceptable in some areas as a disconnecting means.

Line voltage must enter the auxiliary J-box on the righthand side of the furnace.

A WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code. ANSI/

NFPA 70-1987, or local codes to minimize personal

injury if an electrical fault should occur. This may con

sist of electrical wire or conduit approved for electrical

ground when installed in accordance with existing elec

trical codes. Do not use gas piping as an electrical

ground. A failure to adhere to this warning can result in

an electrical shock, fire, or death.

Table 4—Ratings and Performance

Indoor

SIZE

040

060

080

100 110,000 101,000 100,000 40—70

*Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 feet, reduce ratings 4% for each 1000 ft above sea level.

tDetermined by U.S. Government tests.

»»Isolated combustion system; GAMA non-weatherized.

input

Btuh*

44,000

66,000 60,000

88,000 81,000 80,000 40—70

Capacity

Btuht

40,000 40,000 20—50 0.10 1335

ICS»*

Capacity

Btuht

60,000

Temperature

Rise

Range

40—70

Heating Cooling

Ext Static

Pressure

0.12 1275

0.15 1590

0.20 2000

Cfm

Ext Static

Pressure

0.5 1265 1/3 PSC

0.5 1170 1/3 PSC

0.5 1565 1/2 PSC

0.5 2035

Cfm

HP & Type

Motor

3/4 PSC 241

Approx

Shipping

Weight

179

187

202

Page 4

A CAUTION

If a manual disconnect switch is to be mounted on the

furnace, select a location where a drill or fastener will

not come in contact with electrical or gas components.

Check all electrical connections (both factory and field)

for tightness. This check should also be done after the

unit has reached operating temperatures.

If 115-volt wiring to the unit is encased in a nonmetallic

sheath, connect the incoming ground wire to the grounding

wire inside the furnace J-box. If properly grounded metallic

conduit is used, it will serve as the furnace ground.

B. 24-Volt Wiring

Make field 24-volt connections at the 24-volt terminal strip.

See Fig. 6.

NOTE: Use AWG No. 18 “color-coded” copper thermostat

wire for lengths up to 100 ft. For wire lengths over 100 ft,

use AWG No. 16 wire.

IMPORTANT: The thermostat heat anticipation must be

set to match the amp draw of the gas valve and other elec

trical components in the R-W circuit. The amp reading

should be taken after the blower has started. The room ther

mostat should be located where it will be in the natural cir

culation path of room air. Avoid locations where the ther

mostat would be;

1. Exposed to cold-air infiltration.

2. Exposed to drafts from windows, doors, or other open

ings leading to the outside.

3. Exposed to air currents from warm- or cold-air

registers.

4. Located behind doors, above or below shelves, mantels,

or any other location where the natural circulation of

air is cut off.

5. Exposed to heat from fireplaces, radios, televisions,

lamps, or the rays of the sun.

6. Located on a wall containing pipes or warm-air ducts,

or flue or vent pipes.

7. Located on a wall that is inadequately sealed from the

attic, crawlspace, or basement.

Any hole in the plaster or panel through which the wires

pass from the thermostat should be adequately sealed with

suitable material to prevent drafts from affecting the

thermostat.

C. Blower Control Center

Each furnace features a blower control center. This device

will aid the installer and service technician when installing

or servicing the unit. A 24-volt terminal strip is marked for

easy connection of field wiring. See Fig. 7.

The blower control center features an adjustable blower-off

timing device. The “off” timing delay cem be varied over a

range of 80 to 240 seconds by turning the “off” timing

adjustment control in the direction indicated on the label

attached to the side of the control box. After a change in

adjustment, the time-delay circuit must be energized at

least 4 minutes to achieve the new “off” time delay setting.

The “off” timing adjustment is set at the factory for a delay

of approximately 240 seconds. See Fig. 7. The on-time delay

is not adjustable (60 seconds).

VIII. SEQUENCE OF OPERATION

Heating Cycle

The control circuit of the furnace shown in the schematic

wiring diagram. Fig. 8, results in the following sequence of

Km

Fig. 7—Blower Control Center

operation for the heating cycle:

When the blower door is in place, 115 VAC is supplied

through blower door interlock switch ILK. Trans

former TRAN is energized, supplying 24 VAC to heat

ing blower relay HFR, which opens normally-closed

blower relay contacts HFR in the low-speed circuit of

blower motor MTR.

The wall thermostat “calls for heat,” closing thé R and

2.

W circuit. This closed circuit supplies power to the 24VAC safety circuit containing automatic reset limit

switch LSI and manual reset auxüiary limit switch

LS2. Auxiliary limit switch LS2 will break electrical

circuit to gas valve if blower compartment or filters

overheat. The switch must be manually reset after

cause of overheat condition is corrected.

3. The inducer motor relay coU IDR is energized. Inducer

motor relay contacts in the 115-VAC circuit close,

starting inducer motor IDM. Simultaneously, another

set of contacts in inducer motor relay IDR close in the

24-VAC circuit, and lock in inducer motor relay coil

IDR. The coil is locked in until the R and W circuit or

safety circuit opens.

4. As inducer motor IDM comes up to speed, flow sensing

switch AFS actuates energizing the PILOT solenoid

coil of gas valve GV and the time-delay relay in spark

generator ICP through fusible link FL.

When the PILOT solenoid coil is energized, gas flows

5.

to the pilot. The internal pressure switch within gas

valve GV senses the pilot gas pressure and closes, com

pleting the HOLD circuit. The normally open timedelay relay within spark generator ICP closes after a

10-second purge delay, energizing spark generator. The

pilot gas is ignited by a spark produced by spark

generator.

After a short time delay, during which the pilot flame

6.

heats up flame sensing contacts PS, the normedly

closed contacts PS open. The PILOT solenoid coil

remains energized through the HOLD circuit. Spark

generator ICP shuts off when flame is sensed at the

spark electrode. The normally open flame-sensing con

tacts PS close 5 to 20 seconds later, energizing the

MGV solenoid coil of the GV. Six to 15 seconds later,

the MGV solenoid opens, allowing gas to flow to the

main burners where the gas is ignited by the pilot

flame.

7. Simultaneously, time-delay circuit AR in the blower

control center is energized. Approximately 50 seconds

A87298

I

Page 5

Page 6

after MGV solenoid coil is energized, heating relay coil

HFR is deenergized, closing the 115-VAC contacts of

heating relay HFR and steirting blower motor MTR on

heating speed. The H terminal is energized with 24

VAC when the blower motor is operating on heating

speed. Electronic air cleaner terminals (EAC) are ener

gized with 115 VAC when the blower is operating on

either heating or cooHng speed.

8. When the thermostat is satisfied, the R and W circuit

is broken, deenergizing gas valve GV, and the solidstate time-delay circuits for the inducer motor relay

IDR and blower motor relay HFR. The gas flow to the

pilot and main burners immediately stops. After

approximately 15 seconds, induced draft motor relay

IDR is deenergized and induced draft motor IDM

stops. Approximately 80 to 240 seconds (depending on

the blower off-time adjustment) after main burners are

extinguished, heating relay HFR is energized and

blower motor MTR stops.

NOTE: After a brief interruption of either the electric or

gas supply, the furnace will not resume operation until the

contacts of pilot-flame sensing switch PS move from the

normally open position to the normally closed position.

Cooling Cycle

1. The wall thermostat “calls for coohng.”

2. The R, G, and Y circuits are energized. Simultaneously,

the R and Y circuit starts the outdoor condensing unit,

and the R and G circuit energizes cooling relay coil

CFR. Normally open cooling contacts CFR close, ener

gizing the cooling speed of motor MTR and opening the

normally closed contacts of cooling relay CFR. The

EAC terminals are energized with 115 VAC when the

blower is operating on either heating or cooling speed.

IX. FILTER ARRANGEMENT

The two factory-suppHed filters are shipped in the blower

compartment. After the retum-air duct has been connected

to the furnace, install the filters (with cross-hatch binding

facing blower) in a V-formation inside the retum-edr plenum.

See Fig. 9.

A WARNING

Never operate the unit without a filter or with the filter

access door removed. A failure to adhere to this warn

ing can cause a fire, physical injury, or death.

A CAUTION

The unit must not be installed, operated, and then

turned off and left turned off, in an unoccupied struc

ture during cold weather when the temperature drops

to 32 °F and below. Freezing condensate left in the fur

nace will damage the equipment.

A. When winterizing the furnace, it is necessary to

proceed as foilows:

1. Mix a solution of equal amounts of ethylene glycol

(Prestone II antifreeze coolant or equivalent) and

water.

2. Turn off electrical supply to furnace.

3. Remove control emd blower access panels.

4. Disconnect drain tube from bottom of inducer outlet

elbow.

5. Insert funnel in drain tube and pour antifreeze/water

solution into furnace until it is visible at point where

condensate enters open drain.

6. Reconnect dredn tube to outlet elbow.

7. Replace control access panel.

B. Adjustment of Blower Speed

A CAUTION

Disconnect the electrical power before changing the

speed tap. A failure to adhere to this warning can cause

personal injury.

To change motor speed taps, remove the motor tap lead (See

Table 5.) and relocate it on the desired terminal on the plug-

Table 5—Speed Selector '

Speed Tap No.*

Common C

Hi 1

Med-Hi 2

Med-Low 3

Low 4

*White wire from control box to common; black wire from control box to

cooling speed selection; red wire from control box to heating speed

selection.

X. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Downflow Condensing Furnaces.”

NOTE: The furnace blower access panel must be in place to

complete the 115-volt circuit to the furnace.

A CAUTION

This furnace is equipped with a fusible link in the

burner enclosure. This link will melt if an over-heating

condition caused by an inadequate combustion-air sup

ply or improper venting practices develops. DO NOT

jumper this fuse. Correct the condition and replace the

fuse with an identical part.

The gas service pressure must not exceed 0.5 psig (14 in. wc)

for natural gas.

NOTE: The gas valve regulator has been nominally-set at

3.5 in. wc for natural gas. Refer to “Procedures for Down

flow Condensing Furnaces” for readjusting and checking

input.

Page 7

in terroinal block/speed selector located on the blower hous

ing. Check the temperature rise. It must be within the limits

specified on the unit rating plate.

C. Automatic Gas Control Valve

These units are equipped with an automatic gas control

valve. Check the proper operation of this valve by moving

the room thermostat pointer above and below the room tem

perature and observe that the main burners light when the

pointer is above and go off when the pointer is below the

room temperature setting.

XI. CARE AND MAINTENANCE

A CAUTION

Because of possible damage to the equipment or per

sonal injury, maintenance should be performed by qual

ified persons only.

A WARNING

Never store any flammables, chloride, or halogencontaining compounds near, or in contact with, the fur

nace. A failure to adhere to this warning can cause a

fire, personal injury, or death.

For continuing high performance, and to minimize equip

ment failure, it is essential that periodic maintenance be

performed on this equipment. Consult your local Dealer as

to the proper frequency of maintenance and the availability

of a maintenance contract.

A WARNING

The abihty to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools, and equipment. If you do not possess these, do

not attempt to perform any maintenance on this equip

ment other than those procedures recommended in the

Users Manual. A FAILURE TO ADHERE TO THIS

WARNING COULD RESULT IN SERIOUS PER

SONAL INJURY AND POSSIBLE DAMAGE TO

THIS EQUIPMENT.

A WARNING

Turn off gas and electrical supply to the unit before per

forming any maintenance or service on the unit. FoUow

the operating instructions attached to the furnace. A

failure to adhere to this warning can cause personal

injury.

The niinimum maintenance that should be performed on

this equipment is as follows;

1. Check and clean or replace air filter each month or as

required.

2. Check blower motor and wheel for cleanliness and lubri

cation each heating and cooling season. Clean and

lubricate as necessary. (See Section XI, B.)

3. Check electrical connections for tightness and controls

for proper operation each heating season. Service as

necessary.

4. Check for proper condensate drainage.

5. Check for blockages of combustion-air and vent pipes.

A WARNING

As with any mechanical equipment, personal injury can

result from sharp metal edges, etc.; therefore, be careful

when removing parts.

A. Air Filter

Remember to disconnect electrical power before removing

access panels. To clean or replace the air filter, proceed as

follows:

1. Remove blower access panel.

2. Reach up behind top plate, tilt filters toward center of

return-air plenum, remove filters. See Fig. 9.

3. Clean filter with cold tap water. Spray in direction op

posite to airflow.

4. Rinse and let dry. DO NOT oil or coat filter.

5. Place dry filter in furnace with cross-hatch binding fac

ing blower.

B. Blower Motor and Wheel

For long Ufe, economy, and high efficiency; clean accumu

lated dirt emd grease from blower wheel and motor amnually.

The following steps should be performed by a qualified

serviceperson, or agency.

> Some motors have prelubricated sealed bearings and require

no lubrication. These motors can be identified by the

absence of oil ports on each end of the motor. For those

motors with oil ports lubricate as follows:

Lubricate motor every 5 years if motor is used on intermit

tent operation (thermostat FAN switch in AUTO position),

or every 2 years if motor is in continuous operation (thermo

stat FAN switch in ON position).

Remember to disconnect electrical supply before removing

access panels.

Clean and lubricate as follows:

1. Remove access panels.

2. Remove vent pipe enclosure from top side of blower

shelf and position out of way.

3. Note location of wires for reassembly, then remove

electrical leads from numbered side of blower speed

selector. See Table 5.

4. Loosen hose clamps on outlet elbow and remove elbow.

5. Loosen hose clamp on extension pipe outside of furnace

and remove pipe.

6. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace.

7. Squeeze side tabs of blower speed selector and puU

from blower housing bracket.

8. Loosen screw in strap holding motor capacitor to

blower housing and shde capacitor from strap.

9. Mark blower wheel location on shaft to insure proper

reassembly.

10. Loosen setscrew holding blower wheel on motor shaft.

11. Remove bolts holding motor mount to blower housing

and slide motor and mount out of housing. Disconnect

ground wire attached to blower housing before remov

ing motor.

►12. Lubricate motor (when oilers are provided).

a. Remove dust caps or plugs from oil ports located at

each end of motor. If motor does not have these

caps or plugs, bearings are sealed emd need no fur

ther lubrication.

b. Use a good grade of SAE 20 nondetergent motor oil

Page 8

and add one teaspoon (5 cc, 3/16 oz, or 16 to 25

drops) in each oil port. The use of other types or

grades of oil will damage the motor. Excessive oil

ing can cause premature bearing failures.

c. Allow time for total quantity of oil to be absorbed

by each bearing.

d. After oiling motor, wipe excess oil from motor

housing.

e. Replace dust caps or plugs on oil ports.

13. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff plate loca

tion to insure proper reassembly.

b. Remove screws securing cutoff plate and remove

cutoff plate from housing.

c. Remove blower wheel from housing.

14. Clean blower wheel and motor by using a vacuum with

soft brush attachment. Be careful not to disturb bal

ance weights (clips) on blower wheel vanes. Do not drop

or bend wheel because balance wül be affected.

15. Reassemble blower by reversing steps 13a through c.

Be sure wheel is positioned for proper rotation.

16. Reassemble motor and blower by reversing steps 7

through 11. If motor has ground wire, be sure it is

reconnected. Be sure motor oiling plugs are pointed up

when motor is installed, and wheel is centered in blower

housing. Spin blower wheel to check clearance.

17. Reinstall blower assembly in furnace.

18. Reinstall outlet elbow and extension pipe. Be sure con

nections are tight and leak proof.

19. ReinsteJl vent pipe enclosure.

20. Connect electrical leads to blower speed selector. Note

that coimections are polarized for correct assembly—

DO NOT force.

21. Turn on electrical power and check for proper rotation

and speed changes between heating and cooling; oper

ate unit 5 minutes and carefully check for condensate

leaks.

C. Cleaning Heat Exchangers

If it becomes necessary to clean the heat exchangers, pro

ceed as follows:

1. Turn off gas and electrical supphes to furnace.

2. Remove control and blower access panels.

3. Loosen hose clamps on combustion-air pipe and move

air pipe aside.

4. Using backup wrench, disconnect gas supply at ground

joint union. Remove gas pipe from valve.

5. Disconnect pilot leads at 3-circuit connector outside of

burner enclosure.

6. Disconnect high-voltage lead at spark generator.

7. Disconnect electriced wires from gas valve.

8. Disconnect pressure tubing from right-hemd side of

burner enclosure and outlet end of gas VEilve.

9. Remove burner enclosure front.

10. Remove diffuser from inside top of burner enclosure.

Remove screws that secure burner enclosure to cell

panel. These screws are located inside the burner

enclosure.

11. Using care not to damage cell inlet panel gasket, re

move gas control assembly from furnace.

12. Remove vent pipe enclosure.

13. Loosen hose clamps at vent pipe connection.

14. Loosen hose clamp and remove dredn tube from inducer

outlet elbow.

15. Disconnect edge connector from inducer control box.

16. Loosen hose clamp and remove drain tube from inducer

housing.

17. Remove mounting screws securing inducer assembly to

collector box; remove inducer assembly with outlet

elbow.

18. Remove all old sealant from parts.

19. Remove screws securing intake (upper) couphng box

and remove from furnace. Remove all old sealant from

parts.

20. Remove screws securing primary (lower) coupling box

and remove box. Clean old sealant from parts.

21. Loosen hose clamp and remove 7/8-in. drain tube from

trap.

22. Hold bucket under 7/8-in. drain tube.

23. Using garden hose, ffush each cell of the condensing

heat exchemger with water. Use care not to spray water

on to interior surfaces of control compartment. Dry

aU surfaces. When drying, be careful not to remove

sealant on face of cell panel around individual cell

opemngs.

24. Using ffeld-provided small wire brush, steel “snake”

cable, reversible electric drill, and vacuum cleaner;

clean primary heat exchanger cells. NOTE: DO NOT

use a brush (or other sharp object) to clean the condens

ing heat exchanger. Damage to the heat exchemger

coating may result. Flush with water and a mild deter

gent only.

D. Reassemble Furnace

1. Apply sealant releasing agent (Pam) to flange of intake

couphng box.

2. Apply a generous bead (3/16-in. dia) of G.E. RTV 122,

162, or Dow-Corning RTV 738 sealant (NO substitute

is permissible) to flange of couphng box over releasing

agent. Your Distributor should have G.E. RTV 122,

162, or Dow-Corning RTV 738 sealants in stock.

3. Being careful not to smear sealant, position intake cou

phng box so that slot is on left-hand side and instah

couphng box.

4. Repeat steps 1 thru 3 to instah primary couphng box.

Position box so tahest end is toward right-hand side of

casing.

5. Apply sealant releasing agent (Pam) to cohector box.

6. Apply 1/8-in. diameter bead of G.E. RTV 122, 162, or

Dow-Coming RTV 738 sealant to back of inducer hous

ing. Apply sealant euround inlet air opening. (The seal

ant should be about 1/4 in. from the edge of the inlet air

opening.)

7. Using stainless steel screws, instah inducer assembly

on coUector box and support bracket to couphng box.

8. Connect drain tube from collector box to inducer outlet

elbow.

9. Connect smah drain tube from top of trap to fitting on

bottom of inducer housing.

10. Connect 7/8-in. drain tube to trap and coUector box,

and tighten hose clamps.

11. Reconnect vent pipe. Be sure clamps are tight.

12. Reinstah vent pipe enclosure.

13. Check condition of gasket on ceU inlet panel of burner

enclosure. Replace gasket if necessary. See Fig. 10.

14. Instah gas control assembly in furnace,

15. Instah diffuser and burner enclosure front.

16. Reconnect phot leads at 3-circuit connector.

17. Reconnect high-voltage lead to spark generator.

Page 9

18. Refer to furnace wiring diagram and connect wires to

gas valve.

19. Reconnect pressure tubes to gas valve and burner en

closure. Be sure tubes are not kinked.

20. Using backup wrench, install gas pipe in gas valve.

21. Reconnect gas pipe at ground joint union.

22. Reconnect combustion-air pipe. Tighten hose clamps.

23. Turn on gas and electrical supplies.

A

WARNING

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. A failure to adhere to this warning can cause a

fire, personal injury, or death.

24. Check for gas leaks.

25. Check furnace operation through two complete operat

ing cycles.

Check pilot tube and gas valve manifold connection for

26.

gas leaks while furnace is in operation.

27. After condensate starts to drain, check for condensate

leaks.

28. Replace control and blower access panels.

E. Pilot

Check the pilot and clean if necessary at the beginning of

each heating season. The pilot flame should be high enough

for proper impingement of the safety element and to light

the burners. Remove any accumulation of soot and carbon

from the safety element. Check spark electrode gap. See

Fig. 11 for proper spark gap.

F. Electrical Controls and Wiring

NOTE: There may be more than one electrical supply to

unit.

With power disconnected to unit, check all electrical con

nections for tightness. Tighten all screws on electrical con

nections. If any smoky or burned connections are noticed,

disassemble the connection, deem all parts, strip wire, and

reassemble properly and securely. Electrical controls are dif

ficult to check without proper instrumentation; therefore,

reconnect electrical power to unit and observe unit through

two complete operating cycles.

Fig. 10—Burner Enclosure

A79080

Page 10

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookl 1 I 4 PC 101 Catalog No. 535-887 Printed in U.S.A. Form 58DX-13SI Pg 10 6-89 Replaces: 58DX-11SI

Tab 16a 18a

Loading...

Loading...