Page 1

58DRC

HEATING & COOLING

Counterflow Gas-Fired Furnaces

Installation, Start-Up and Service Instructions

for Sizes 045-095

NOTE. Energy Guide tag may be removed

from furnace when installation is complete.

INTRODUCTION

Before installing the furnace, refer to Procedures for

Gas-Fired Furnaces (packaged with the equipment) for

information concerning combustion, venting, piping,

and other standard installation practices. Further

reference is made to the current edition of the

National Fuel Gas Code, NFPA54-1984/ANSI Z223.1-

1984.

Each furnace is shipped from the factory completely

assembled with multispeed direct-drive blower and wired

ready for counterflow indoor heating installation only.

All sizes feature a printed-circuit board control center

with easy-to-read, low-voltage terminal strip to ensure

proper connections.

A CAUTION

Do not install furnace in a corrosive or contami

nated atmosphere. Make sure all combustion and

circulating air requirements listed in Procedures

for Gas-Fired Furnaces are adhered to, in addition

to all local codes and ordinances.

G

efficiency

RATING

CGRTIFIED

ama

A CAUTION

Do not block openings in front of furnace or on

furnace top along side vent pipe. These openings pro

vide air for combustion and ventilation. Never store

anything on or in contact with furnace, such as:

aerosol cans, rags, brooms and mops, cleaning tools

and aids, powders, bleaches, waxes, plastic items,

gasoline, kerosene, lighter fluids, cleaning fluids,

thinners, painting compounds or paper products.

The design of the counterflow gas-fired furnace is

A.G.A certified for installation on combustible flooring

(with optional floor base), in alcoves, basements, closets

or utility rooms. This furnace line is not A.G.A. certified

for installation in a mobile home, recreation vehicle, or

outdoors

Installation Procedures: Page

Inspection..........................................................................*

Location, Ventilation and Air

for Combustion................................................................*

Gas Piping.........................................................................*

Venting..............................................................................*

Supply-Air Plenum Installation.........................................1

Electrical Connections.......................................................3

Sequence of Operation.......................................................4

Filter Arrangement

Start-Up and Adjustment...................................................6

Care and Maintenance.......................................................6

*Refer to appropiiate sections in Pioceduies foi Gas-Fired Furnaces

packed with this furnace

For accessory installation details, refer to applicable

installation literature.

............................................................

5

Fig. 1 — Model 58DRC

Table 1 — Clearances (in.)

SIZE 58DRC

Single-Wall Vent 1

Type-BI Double-Wall Vent

Back

Top of Plenum 1

Single-Wall

.........

.. Type-B1 Double-Wall 1

„ Combustion Air

’ Service

ALL

1

0

6

6

30

NOTE. Some furnaces are shipped with paper across the

supply-air outlet. Remove the paper before installing

furnace.

INSTALLATION

Supply-Air Plenum Installation

INSTALLATION ON A CONCRETE SLAB

1 See Fig. 2 for dimensions and location of supply air

opening in furnace bottom

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookll 14 PC101 Catalog No 535-843 PrintedinUSA Form58DRC-1SI Pg 1 7-85 Replaces:New

Tab |6al8a

For replacement items use Carrier Specified Parts

Page 2

58DRC

HEATING & COOLING

Table 2 — Dimensions (in.)

SIZE

58DRC

045

065

080

095

A B

17'/2 15% 16 4

17'/2 15% 16

21

24'/2 22’%e 23 6

19% 19'/2

C

VENT

5

5

2. Construct hole in floor per dimensions in Fig. 3 and

Table 4.

3. Place plenum and furnace as shown in Fig. 4.

Counterflow Gas-Fired Furnaces

FURNACE

-fc-SHEET METAL

PLENUM

Fig. 4 — Furnace on a Concrete Slab

Table 4 — Floor Opening Dimensions (in.)

SIZE 58DRC

045, 065

080 19%

095 23'/i6

INSTALLATION ON A COMBUSTIBLE FLOOR

I. Read Installation Instructions packaged with com

bustible floor base. See Fig. 5.

Cut and frame hole in floor per dimensions in Fig. 3

2.

and Table 4. If this requires cutting a floor joist, tie

ends of cut joist into adjacent joists so that proper floor

support is maintained.

Assemble and install combustible floor base per in

3.

structions packaged with base.

When completed, combustible floor base, plenum,

and furnace (or coil casing when used) should be

installed as shown in Fig. 6.

A

16%6

HOLE IN FLOOR

Fig. 3 — Floor Opening

Table 3 — Ratings and Performance*

SIZE

58DRC

045CB 60,000

065CB 80,000

080CB 100,000

095DB 120,000

PSC — Permanent Split Capacitor

‘Ratings are certified for altitudes to 2000 feet For elevation above 2000 ft, reduce ratings 4% for

each 1000 ft above sea level

tCFM at #3 speed tap

|CFM at #1 speed tap

“Preliminary data.

Bookll 14 PC 101 Catalog No 535-843 PrintedinUSA Form58DRC-1SI Pg2 7-85 Replaces: New

Tab I6al8a

INPUT

BTUH

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

HEATING

CAPACITY

(BTUH)**

45,000 30-60

65,000 30-60

80,000

95,000

TEMP

RISE

RANGE (F)

40-70

40-70

For replacement items use Carrier Specified Parts

HEATING!

Ext Static

Pressure

(in. wg)

12

12

15

20

CFM

1080 0 5 1206 'h

1240 0.5 1630

1165 0 5 1620

1830 0.5 2075

COOLING!

Ext Static

Pressure

(in. wg)

CFM

MOTOR HP

(PSC)

'/2 170

'/2 187

'/2 227

APPROX

SHIP. WT

(lb)

157

Page 3

58DRC

HEATING & COOLING

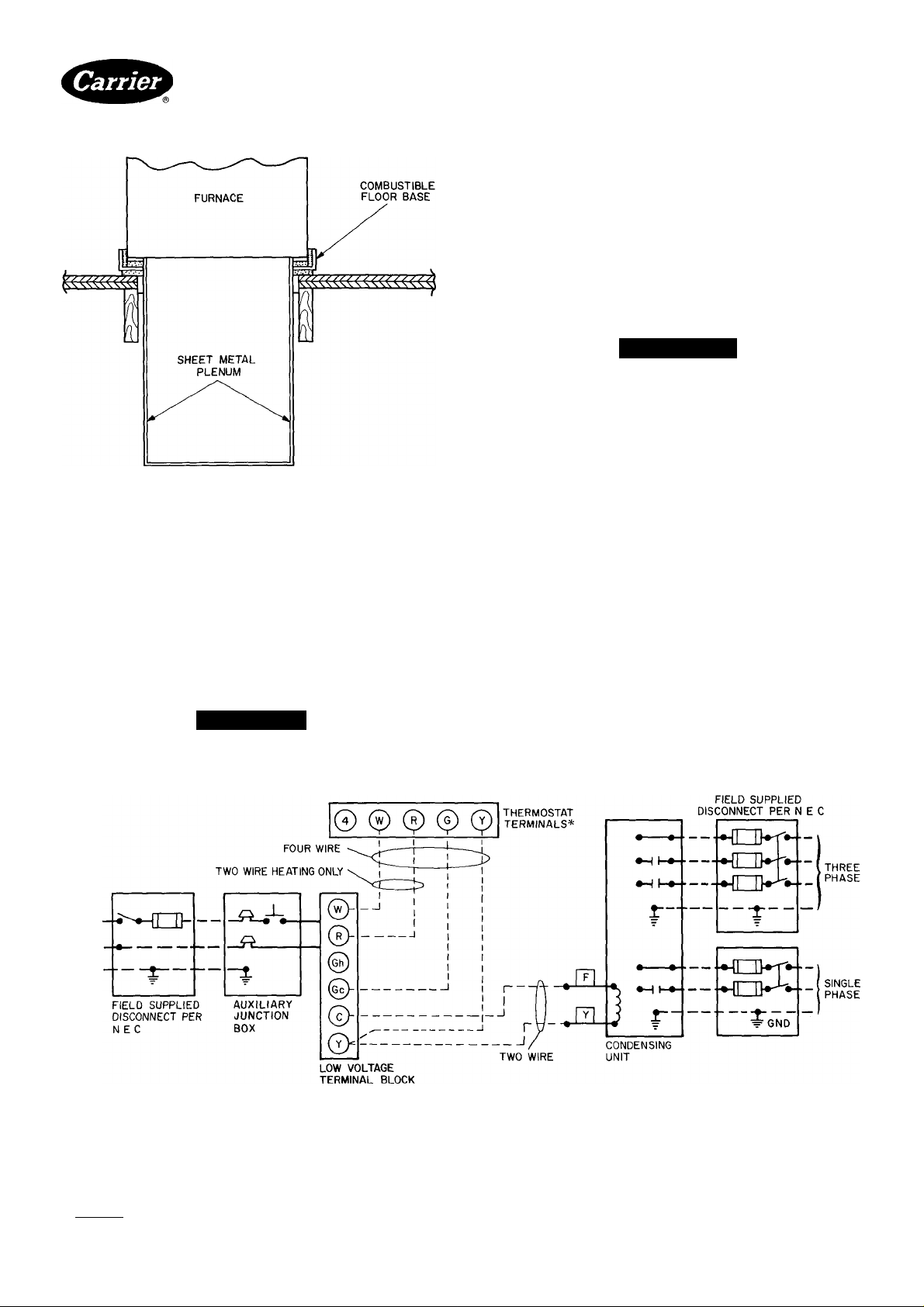

Fig. 6

Furnace, Plenum, and Base Installed

Counterflow Gas-Fired Furnaces

on a Combustible Floor

Electrical Connections

LINE-VOLTAGE WIRING

NOTE. For additional information, refer to Procedures

for Gas-Fired Furnaces (packaged with the equipment)

IMPORTANT: Before proceeding with the electrical

connections, make certain that voltage, frequency,

and phase correspond to that specified on the unit

rating plate. Also, be sure that the service provided

by the utility company is sufficient to handle the addi

tional load imposed by this equipment.

A CAUTION

Do not connect aluminum wire between disconnect

switch and furnace.

See Fig. 7 for wiring diagram showing the proper field

high- and low-voltage wiring Make all electrical connec

tions in accordance with the National Electrical Code

ANSI/ NFPA 70-1984 and any local codes or ordinances

that might apply.

Use a separate fused branch electrical circuit for this

furnace. A disconnecting means must be located within

sight from, and readily accessible from the furnace. In

some areas, the unit door switch may qualify as the dis

connecting means

A WARNING

The furnace must be electrically grounded in accord

ance with local codes, the National Electric Code,

ANSI/ NFPA 70-1984 Do not use gas piping as an

electrical ground.

If line voltage wiring to the unit is encased in a nonmetallic sheath, connect the incoming ground wire to the

grounding wire inside the furnace junction box. If

metallic conduit is used, it will serve as the ground.

LOW-VOLTAGE WIRING — Make field low-voltage

connections at the low-voltage terminal strip See

Fig 7.

NOTE: Use AWG no. 18 color-coded copper thermostat

wire for lengths up to 100 feet Above 100 ft, use AWG

no. 16 wire

IMPORTANT The thermostat heat anticipator

must be set to match the amp draw of the gas valve

and electrical components in the R-W circuit.

Accurate amp draw readings can be obtained at

thermostat subbase terminals R and W. Figure 8

illustrates an easy method for obtaining the actual

amp draw.

*Some thermostat subbases require a jumper wire between subbase terminals R and 4 for --------------------------------------------------

proper operation in heating and cooling applications that use a single transformer

NOTE If any of the original wire as supplied must be replaced, use same typeor equivalent wire

--------------------------------------------

-----------

-Field Low-Voltage Wiring

-

■ Field High-Voltage Wiring

Factory Low-Voltage Wiring

Fig. 7 — Heating and Cooling Application Wiring Diagram

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Bookj 1 |4 PC101 Catalog No 535-843 PrintedinUSA Foi m 58DRC-1SI Pg 3 7-85 Replaces New

Page 4

58DRC

HEATING A COOUHG

Counterflow Gas-Fired Furnaces

Fig. 8 — Amp Draw Check with Ammeter

The room thermostat should be located where it will

be in the natural circulation path of room air. Avoid loca

tions where the thermostat would be exposed to cold-air

infiltration, drafts from windows, doors, or other open

ings leading to the outside, or exposure to air currents

from warm- or cold-air registers; or to exposure where

the natural circulation of the air iS- cut off — such as

behind doors, above or below mantels, shelves, etc

The thermostat should not be exposed to heat from

nearby fireplaces, radios, televisions, lamps, or rays from

the sun. Nor should the thermostat be mounted on a wall

containing pipes or warm-air ducts, or a flue or vent that

could affect its operation and prevent it from properly

controlling the room temperature. Any hole in the plaster

or panel through which the wires pass from the thermo

stat should be adequately sealed with suitable material to

prevent drafts from affecting the thermostat

Sequence of Operation

NOTE; The wiring diagram shown in Fig. 10 is for

heating/cooling units.

HEATING — Gas and electrical supplies must be turned

on at the furnace.

NOTE; When power is applied to heat relay coil 2 A in the

control circuit, the normally closed contacts in the blower

circuit will open.

BDP 646 Gas Valve (HD Models) — When the thermo

stat calls for heat, the control circuit is closed between

terminals R and W. Power from transformer 1A through

fusible link 11C and limit switches 7H1 / 7H2 energizes the

pilot valve portion of automatic gas valve 5F and pilot

igniter 6F. The pilot valve opens, permitting gas flow to

the pilot burner where it is ignited.

The pilot valve portion of automatic gas valve 5F is a

solenoid consisting of a PICK and a HOLD coil. Both

the PICK and the HOLD coils must be energized to open

the valve, but only the HOLD coil must be energized to

keep it open

PRlNTED-ClRCUlT CONTROL CENTER — Each

furnace features a printed-circuit control center. This will

aid the installer and service technician when installing and

servicing the unit. See Fig. 9. A low-voltage terminal

board is marked for easy connection of field wiring.

1A

4 è ^ Í

2A

2F

3D

4A

5F

6C1

6F

6H

Transformer 115/24

Relay-Heat (SPSTN C )

Relay-Cool (DPDT)

Blower Motor

Run Capacitor

Gas Valve (2-Circuit)

Printed-Circuit Board

Piiot Igniter

Safety Pilot (Flame

Sensing)

7H1 — Limit Switch (SPST-

7H2 — Auxiliary Limit Switch

9A

9G —

11C

N C )

(SPST-N C ) Manual

Reset

Summer/Winter

Switch (if equipped)

Blower Door Switch

(SPST-N O )

Fusible Link

Fig. 10 — Line-to-Line Wiring Diagram for

Fig. 9 — Printed-Circuit Control Center

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book|1 14 PC101 Catalog No 535-843 Printed in U S A Form 58DRC-1 SI Pg4 7-85 Replaces:New

ronlanorvionf Home iica Cna^iticw4 Dat-fc

Sizes 045-095 IID Natural Gas

Page 5

58DRC

HEATING & COOLING

Counterflow Gas-Fired Furnaces

When the pilot flame is established, pilot 6H switches

its contacts in approximately 40 to 60 seconds, ener

gizing the main valve portion of gas valve 5F and de

energizing pilot igniter 6F and the PICK coil portion of

the pilot solenoid in gas valve 5F.

The main valve portion of gas valve 5F is heat motor

operated; therefore, after approximately 10 seconds, this

portion of the valve opens, permitting gas flow to the

main burners where the gas is ignited by pilot 6H

BLOWER CIRCUIT — With power through the solidstate time-delay circuit on printed-circuit board 6C1 and

heat relay 2A, blower motor 3D is energized on heating

speed approximately 75 seconds after the pilot flame has

been proven

LIMIT CONTROL — If the furnace overheats for any

reason, limit control 7H1 switches, breaking the circuit

to automatic gas valve 5F The gas valve closes imme

diately, stopping gas flow to the main burners and the

pilot In addition, blower motor 3D continues to operate

because heat relay 2A is de-energized to cool down the

furnace.

Manual reset auxiliary limit switch 7H2 is located on

the top right-hand corner of the furnace. In the event

of blower motor failure, this switch breaks the electrical

circuit to the gas valve, stopping gas flow to the main

burners The switch must be manually reset after the

blower motor has been replaced.

Fusible link IIC is provided in the transformer lA

secondary circuit as protection from overheating con

ditions in the vestibule area of the furnace. Should this

condition exist, the fuse opens and de-energizes gas valve

5F and heat relay 2 A, stopping the gas flow to the burners

and starting blower motor 3D

When the thermostat is satisfied, the circuit between

R and W is broken, de-energizing automatic gas valve

5F, pilot 6H, and the solid-state time-delay circuit on

printed-circuit board 6C1. The gas flow stops imme

diately to the pilot and main burners with the BDP646

gas valve. After approximately 105 seconds, heat relay 2A

is energized and blower motor 3D stops.

MODEL 58GS/SE VENT DAMPER (when used) —

With gas and electrical power supplied to the furnace, the

vent damper is in the closed position. On a call for heat

by the thermostat, the vent damper motor is energized

and the damper opens. When the damper reaches full

open position, the transformer energizes the gas valve.

When the thermostat is satisfied, it de-energizes the

gas valve and stops the gas flow. The vent damper motor

energizes and closes the damper. The damper remains

closed until the next thermostat cycle.

COOLING (cooling models only) — When the thermo

stat calls for cooling, power from transformer lA ener

gizes the condensing unit contactor, cooling relay coil 2F,

closing its contacts and energizing blower motor 3 D on its

cooling speed. It continues to operate until the thermostat

is satisfied.

When the thermostat is satisfied, the circuit to ter

minal Gc is broken, de-energizing cooling relay coil 2F

which, in turn, opens its contacts, stopping blower motor

3D.

Filter Arrangement — The 2 factory-supplied filters

are shipped in the blower compartment. After the returnair duct has been connected to the furnace, install the

filters in a V-formation inside the return-air plenum. See

Fig. 12.

A WARNING

Never operate unit without a filter or with filter

access door removed.

INSTALLATION

POSITION

OF FILTERS

Fig. 11 — Circuit for 58GS/SE Vent Damper

Manufacturer reserves the right to discontinue, or change at any time, specilications or designs without notice and without incurring obligations.

Book[1 [4 PC101 Catalog No 535-843 PrintedinUSA Form58DRC-1SI Pg5 7-85 Replaces: New

-----------------

iromc iiQA Carrier Soecifled Parts

Page 6

58DRC

HEATING A COOLING

Counterflow Gas-Fired Furnaces

START-UP AND ADJUSTMENT

In addition to the following information, refer to

Procedures for Gas-Fired Furnaces packaged with the

unit.

NOTE: There is a switch located in the blower compart

ment that breaks the electrical power supply when the

blower access door is removed. Be sure blower access

door is properly installed.

A CAUTION

This furnace is equipped with a fusible link in the

vestibule area that will melt if an overheating condi

tion caused by an inadequate combustion air supply

or improper venting practices develops. Do not

jumper this fuse. Correct the condition and replace

the fuse with an identical part.

The gas service pressure must not exceed 14 in. wg

(8.1 oz) for natural gas, or 11 in. wg (6.3 oz) for LP

(propane) gas.

NOTE; The gas valve regulator has been factory-set at

3 5 in. wg for natural gas and 10.5 in. wgfor LP (propane)

gas. Refer to Procedures for Gas-Fired Furnaces when

checking input.

Adjustment of Blower Speed

REGULATOR

ADJUSTMENT

, ~ . ^ PILOT

■ ADJUSTMENT

MANUAL

ON-OFF

DIAL

PILOT

TUBE

CONNECTION

Fig. 13 — Redundant Automatic Gas Control

Valve — BDP Model 646

NOTE: For ease of adjusting the pilot flame, disconnect

one power lead at main gas valve. For Model 646 gas

valve, disconnect terminal no. 1. This will prevent main

burner ignition and allow time to adjust the pilot. Re

connect the power lead after adjustment.

CARE AND MAINTENANCE

A WARNING

Disconnect the electrical power before changing the

speed tap.

To change motor speed taps, remove the motor tap

lead (see Table 5) and relocate it on the desired terminal

on the plug-in terminal block/speed selector located on

the blower.

A CAUTION

When adjusting the blower speed, make certain that

the temperature rise across the heat exchanger does

not exceed that specified on the rating plate.

Table 5 — Speed Selector

SPEED COLOR TAP NO.

Common

Hi

Med-Hi

Med-Low

Low Red 4

White

Black

Yellow

Blue

Automatic Gas Control Valve — These units are

equipped with an automatic gas control valve. See

Fig. 13. If not already checked when lighting the main

burner, check the proper operation of this valve by

moving the room thermostat pointer above and below

room temperature and observing that the main burners

light on call for heat and go off when the pointer is moved

below room temperature setting.

C

1

2

3

A CAUTION

Because of possible damage to the equipment or per

sonal injury, maintenance should be performed by

qualified service agency.

A WARNING

Never store anything on, or in contact with, the

furnace, such as

1 Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds, plastic or plastic containers, gas

oline, kerosene, cigarette lighter fluid, dry clean

ing fluids, or other volatile fluids.

3, Paint thinners and other painting compounds,

paper bags or other paper products

For continuing high performance, and to minimize

possible equipment failure, it is essential that periodic

maintenance be performed on this equipment. Consult

your local dealer as to the proper frequency of mainte

nance and the availability of a maintenance contract

The ability to properly perform maintenance on this

equipment requires certain mechanical skills and tools.

If you do not possess these, contact your dealer for

maintenance.

A WARNING

Turn off gas and electrical supplies to unit before

performing any maintenance or service on unit.

Follow relighting instructions on plate attached to

furnace

/■

i

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Bookll [4 PC101 Catalog No 535-843 Printed in U S A Form58DRC-1SI Pg6 7-85 ReplacesiNew

Tab l6al8a

For replacement items use Carrier .Specified Parts

Page 7

58DRC

HEATINC A COOLING

Counterflow Gas-Fired Furnaces

The minimum maintenance that should be performed

on this equipment is as follows.

1. Check and clean or replace air filter each month or as

required.

2. Check blower motor and wheel for cleanliness and

lubrication each heating and cooling season. Clean

and lubricate as necessary.

3. Check electrical connections for tightness and controls

for proper operation each heating season. Service as

necessary.

A WARNING

As with any mechanical equipment, personal injury

can result from sharp metal edges, etc.; therefore,

be careful when removing parts.

Air Filter — Each furnace accommodates 2 filters

which are installed above the furnace in the return-air

plenum. See Fig. 12.

To clean or replace the filters, proceed as follows;

1 Disconnect electrical power before removing access

panel.

2. Remove upper access panel.

3. Reach up behind top plate, tilt filters toward center of

return-air plenum, remove filters, and replace or clean

as needed.

4 Some furnaces are equipped with reusable, washable

filters.

a. Clean with tap water.

b. Rinse and let dry. No oiling or coating of filters is

required.

c. Reinstall filters with cross-hatch binding facing

blower.

Blower Motor and Wheel (Fig. 14) — Clean and

lubricate as follows;

1. Remove upper access panel.

2. Loosen screw in vent pipe enclosure front and remove

vent enclosure front by sliding forward (toward front

of unit).

3. Disconnect vent pipe at first joint above unit and

swing vent pipe assembly to the side, supported by

suitable means (block of wood, etc.).

4. Slide vent pipe upward through the rectangular open

ing in top plate and remove vent pipe from furnace

5. Remove 4 screws in vent pipe enclosure back and

remove enclosure back by tilting top toward blower,

and sliding bottom toward front of furnace.

6. Disconnect electrical leads from right side of Molex

speed selector. Note location of wires for reassembly.

7. Remove screws holding blower assembly against

blower deck and slide blower assembly out of furnace.

8. Squeeze side tabs of Molex speed selector and pull

it from blower housing.

9. For units with motor capacitor, loosen screw in strap

holding capacitor to blower housing and slide capac

itor from under strap.

Fig, 14 — Dual Blower with Left-Hand Housing

and Wheel Removed

Mark blower wheel, motor, and motor support in

10.

relation to blower housing before disassembly, to

ensure proper reassembly.

Loosen setscrew holding blower wheel onto motor

II.

shaft.

Remove bolts holding motor mount to blower

12

housing and slide motor and mount out of housing.

Some motors have a ground wire attached to blower

housing; disconnect it also.

13. Lubricate motor.

a. Remove dust caps or plugs from oil ports located

at each end of motor

b. Use good grade of SAE 20 nondetergent motor oil

and put 16 to 25 drops in each oil port

c. Allow time for total quantity of oil to be absorbed

by each bearing.

d. After oiling motor, be sure to wipe excess oil from

motor housing.

e. Replace dust caps or plugs on oil ports.

14 Remove blower wheel from housing

a. Mark blower wheel orientation and cutoff loca

tion to ensure proper reassembly.

b. Remove screws holding cutoff plate and remove

cutoff plate from housing.

c. Lift blower wheel from housing through opening.

15. Clean blower wheel and motor by using vacuum with

soft brush attachment. Care must be exercised not

to disturb balance weights (clips) on blower wheel

vanes. Also do not drop or bend wheel, as balance

will be affected.

16. Reassemble blower by reversing procedures 14a-14c.

Be sure wheel is positioned for proper rotation.

17 Reassemble motor and blower by reversing pro

cedures 8-12. If motor has ground wire, be sure it is

connected as before.

18. Reinstall blower assembly in furnace.

19. Reinstall vent enclosure back.

20. Reinstall vent pipe through opening in top plate,

secure to draft hood and connect remainder of vent

pipe assembly.

21 Reinstall vent enclosure front, and secure with screw.

22. Reinstall access panel

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Bookll ¡4 PC 101 CatalogNo 535-843 PrintedinUSA Form58DRC-1SI Pg7 7-85 Replaces;New

Tah I6al8a

For replacement items use Carrier Specified Parts

Page 8

58DRC

HEATING A COOLING

Counterflow Gas-Fired Furnaces

Cleaning Heat Exchanger — If it becomes neces

sary to clean the heat exchanger because of carbon

deposits, soot, etc., proceed as follows’

1. Turn off gas and electrical supply to furnace.

2. Remove front access doors

3. Remove vent pipe enclosure front and flue pipe.

4. Remove draft diverter. Screws are located inside

draft diverter opening.

5. Remove flue baffles from flue outlets of heat

exchanger.

6. Remove secondary air shield and burners. To remove

pilot burner, disconnect pilot supply tube at gas

valve.

7. Clean flue ways with brush and/or vacuum. Check

heat exchanger for leaks and cracks. Replace if

necessary.

8. Replace flue baffles. Be sure all screws are in place

and tight.

9 Replace draft diverter and vent connector. Be sure

screws are replaced and tight.

10. Using vacuum with soft brush attachment, clean

burners, then replace burners and secondary air

shield.

11. Turn on electricity first, then turn on gas. Check for

gas leaks.

A WARNING

Never use a match or other open flame to check for

gas leaks. Use a soap-and-water solution.

Pilot — See Fig. 15 Check the pilot and clean if neces

sary at the beginning of each heating season. The pilot

flame should be high enough to light the burners. Remove

the accumulation of soot and carbon from the sensing

probe.

I ■*'32

16

Fig. 15 — Position of Electrode to Pilot (in.)

Electrical Controls and Wiring

NOTE: There may be more than one electrical

supply to unit

With power disconnected to unit, check all electrical

connections for tightness. Tighten all screws on electrical

connections If any smoky or burned connections are

noticed, disassemble the connection, clean all parts and

stripped wire, and reassemble properly and securely.

Electrical controls are difficult to check without proper

instrumentation; therefore, reconnect electrical power

to unit and observe unit through one complete operating

cycle. If there are any discrepancies in the operating cycle,

contact your dealer and request service.

Table 6 — Trouble Analysis Chart

A WARNING

Turn off gas and power supply to unit before servicing

(unless specific test requires gas and electric supplies)

SYMPTOM

Pilot will not light

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookM |4 PC101 Catalog No 535-843 Printed in U S A Form 58DRC-1 SI Pg8 7-85 Replaces:New

Tab I6al8a

CAUSE

No spark at electrode

For replacement items use Carrier Specified Parts

REMEDY

Readjust, if necessary, so that gap between electrode tip and pilot burner is as shown in Fig. 15.

Clean dirt or moisture accumulation from electrode

ceramic with cloth

Cracked ceramic

assembly

Check for loose or broken wiring at and between

spark generator and electrode Replace wire or

tighten connection as necessary______________________

Check fuse or circuit breaker for 115-volt supply to

furnace.

Check blower access panel for proper installation.

Check 24-volt input to spark generator. If reading is

24 volts, and above steps have been completed,

replace spark generator assembly

replace pilot electrode

Page 9

58DRC

HEATtNG & COOLING

SYMPTOM CAUSE

Pilot will not light

(cont)

Burners will not ignite

Blower operates

continuously

Inadequate heating

Aldehyde odors, (CO),

sooting flame — floating

flame

Spark shorting out to main burner

No gas at pilot burner Clean pilot orifice

No 115-volt power to furnace

No 24-volt power to control circuit Replace transformer

Miswired or loose connections

No gas at main burners Check voltage to terminals 1 and 2 of gas valve

Dirty pilot — yellow flame

Thermostat fan switch in ON

position

Fusible link blown Correct combustion air and venting practice —

Dirty filter causing limit operation Clean dirty air filter — reinstall.

Defective heat relay Replace printed-circuit board.

Furnace undersized for application Replace with proper size furnace.

Gas input to furnace too low Check gas pressure at manifold Clock gas meter for

Limit switch cycles main burners Clean dirty air filter — reinstall.

Manual reset limit switch contacts

open

Thermostat anticipator set too low Check thermostat circuit amps and set anticipator

Incomplete combustion — poor

flame characteristics

Counterflow Gas-Fired Furnaces

Table 6 — Trouble Analysis Chart (cont)

REMEDY

Readjust electrode as specified

Check voltage to terminals 3 and 5 of gas valve

Check for proper opening of pilot valve, broken

wires, or loose connections If no deficiency is

found, replace valve assembly

Connect to power supply Check fuse, wiring, or

circuit breaker

Check all wiring and all wire nut connections.

Check for proper opening of main gas valve, broken

wires, or loose connections If no deficiency is

found, replace gas valve assembly

Clean pilot orifice

Move thermostat fan switch to AUTO, position.

repiace fuse link with identical part

input If too low, increase manifold pressure or

install correct orifices

Increase blower speed

Open registers — ductwork restricted.

Blower motor failure — replace motor.

accordingly. See Fig 8

Adjust air shutter on burners to provide soft, blue

flame Check all screws around flue outlets and

burner compartment Tighten

See “Location & Air for Combustion & Ventilation”

(Procedures for Gas-Fired Furnaces)

Replace cracked heat exchanger

Reduce input and check orifices — furnace

overfired

Check vent for restriction.

0

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations

Book|1 |4 PC 101 Catalog No 535-843 Printed in U S A Form58DRC-1SI Pg9 7-85 Replaces: New

Tab )6a|8a

For repiacemenf items use Carrier Specified Parts

Page 10

58DRC

HEATING A COOLING

Counterflow Gas-Fired Furnaces

TO OBTAIN INFORMATION ON PARTS: Consult your Installing dealer or classified section of your local telephone directory under the

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book| 1 |4 PC101 Catalog No 535-843 PrintedinUSA Form58DRC-1SI PglO 7-85 Replaces:New

Tab I6al8a

''Heating-Equipment” or "Air Conditioning Contractors & Systems” headings for dealer listing by brand name.

Have available the Model No., Series Letter, and Serial No. of your equipment to insure correct replacement part.

For replacement items use Carrier Specified Parts.

Loading...

Loading...