Page 1

58DP,DR

HEATING« COOLING

Downflow Gas-Fired Natural-Draft Furnaces

58DP Series 150 and 160

58DR Series 130

Installation, Start-Up and Service Instructions

NOTE: Read the entire instructions before starting the

installation.

INTRODUCTION

Before installing the furnace, refer to “Procedures for

Natural-Draft Gas-Fired Furnaces” (packaged with the

equipment) for information concerning combustion, venting,

piping, and other standeird installation practices. Further

reference is made to the current edition of the National Fuel

Gas Code NFPA No. 54-1988/ANSI Z223.1-1988.

Reference should also be made to the regulations of the

serving gas supplier and the local building, heating, plumb

ing, or other codes in effect in the area in which the installa

tion is made.

SAFETY CONSIDERATIONS

Installation and servicing of heating equipment can be haz

ardous due to gas and electrical components. Only trained

and qualified personnel should install, repair, or service

heating equipment.

Untrained personnel can perform basic meuntenance func

tions such as cleaning and replacing air filters. AU other

operations must be performed by trained service personnel,

when working on heating equipment, observe precautions in

the literature, tags, and labels attached to or shipped with

the unit and other safety precautions that may apply.

Follow all safety codes, including NFPA No. 54/ANSI

Z223.1-1988, National Fuel Gas Code. Wear safety glasses

and work gloves. Have fire extinguisher available during

startup and adjustment procedures and service call.

Recomized safety information: This is the safety-alert sym

bol A. When you see this symbol on the furnace and in

instructions or manueils, be alert to the potential for per

sonal injury.

Understand the signal word—DANGER, WARNING, or

CAUTION. These words are used with the safety-alert sym

bol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

on the other hand could result in personal injury or death.

CAUTION is used to identify unsafe practices, which would

result in minor personal injury or product and property

damage.

Each furnace is shipped from the factory completely assem

bled with multispeed direct-drive blower and wired ready for

downflow indoor heating installation only. AU sizes feature

a printed-circuit board control center with easy-to-read, 24volt terminal strip to ensure proper connections.

Fig. 1—Model 58DP

Table 1—Clearances (In Inches)

(From Combustible Materials)

Sizes

Sides—Single-Wall Vent

Type-B Double-Wall Vent 0

Back 0 0

Top of Plenum 1

Vent Connector—Single-Wall 6 6

Type-B Double-Wall

Front—Combustion Air* 6 6

Service

*The 6-inch front clearance is needed for combustion-air entry and

drafthood relief.

»■NOTE: The furnaces covered by these instructions are

050 075 thru 150

1 1

1

1

1 1

30 30

design-certified for use with the vent damper specified on

the furnace rating plate. See instructions packaged with the

vent deunper for its installation.

A CAUTION

Application of this furnace should be indoors with spe

cial attention given to vent sizing and material, gas

input rate, air temperature rise, and unit sizing.

Improper installation or misapplication of the furnace

can require excessive servicing or cause premature com

ponent failure.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

'' I ^ PC 101 Catalog No. 565-873 Printed in U.S.A. Form 58DP,DR-4Si 5/89 Pg 1 Replaces: 58DP,DR-2SI

Tab I6al8a

Page 2

8 THERMOSTAT CONN

/

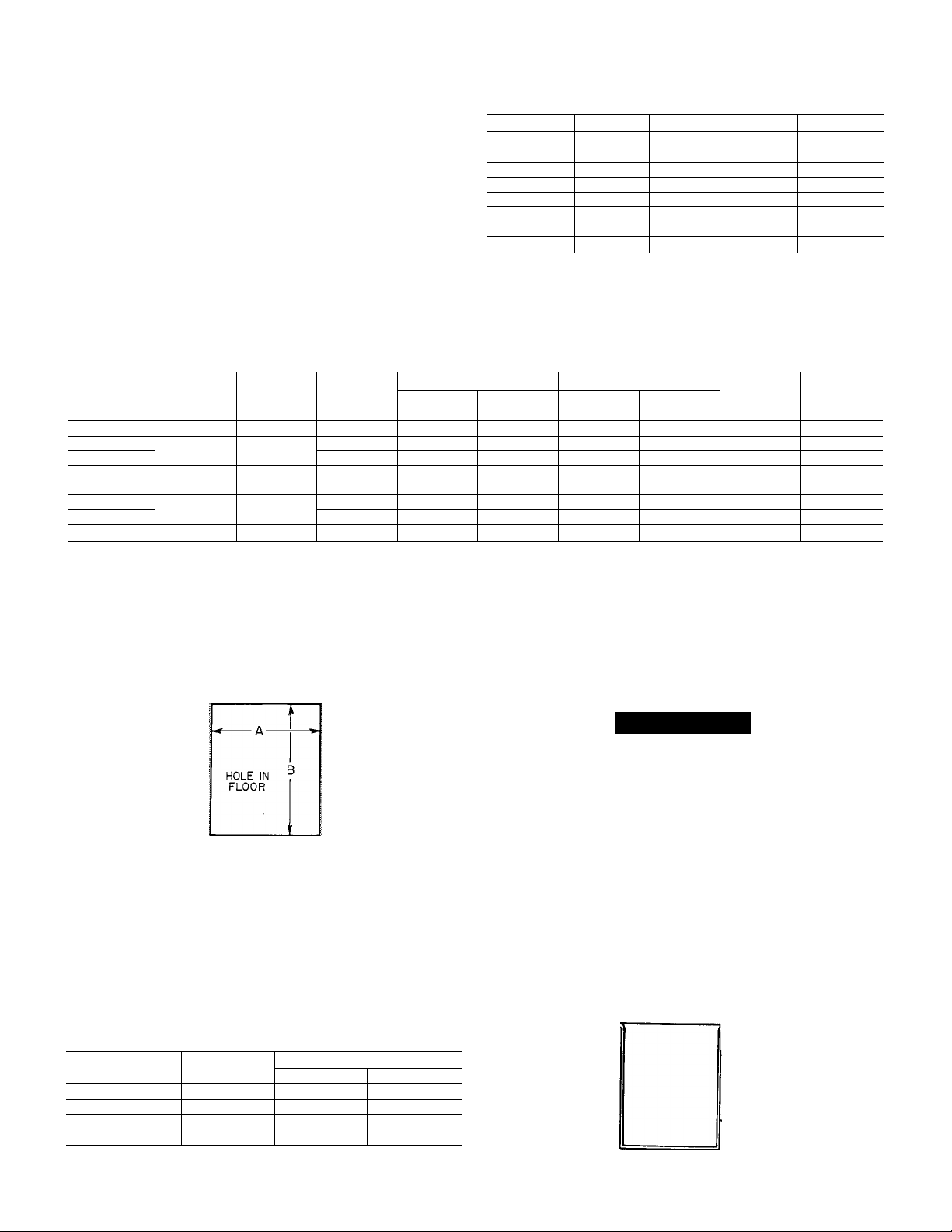

Table 2—Dimensions (In Inches)

A

14^6 12"/,e 12”/,6

17^2

M'k

M'b

17Ya

21 19%

2A'k

1

5. ^

r'

— -?>•

o:a

KNOCKOUT

AUX GAS

INLET

AIRFLOW

Size

050-BA

075-AA

075-BA

100-AA

100-BA

125-AA 21 19%

125-BA

150-BA

A78595

Fig. 2—Dimensional Drawing

Table 3—Ratings and Performance

Size

050-BA

075-AA

075-BA

100-AA

100-BA

125-AA

125-AA

150-BA

*The above gas input ratings are certified for eievations to 2000 ft. For elevations above 2000 ft, reduce input 4% for each 1000 ft above sea ievei.

tDetermined by U.S. Government tests.

tDeduct 1000 Btuh for Modei58DR. , ' ;

input

Btuh*

50,000 39,000t

75,000 58,000

100,000 78,000t

125,000 97,000t

150,000 116,000t

Capacity

Btuht*

Temp

Rise

Range

45—75 0.50

70—100 0.12

45—75 0.50

70—100 0.20

60—90 0.50

70—100 0.20

60—90 0.50

55—85 , 0.50

Ext Static

Pressure

Heating

CFM

600 0.5

630

895

850

960

1050

1195 0.5

1535

Ext Static

Pressure

0.5

0.5 1630 %-PSC

0.5 2075

Cooling

— —

— —

—

D E Vent

15^

15%

15%

15%

22%e

CFM

800 73-SP 129

1255 %-SP 157

—

1620 %-PSC 187

16

16

16 5

16 5

19Ya

19% 5

23 6

Motor

HP&

Type

%0-SP 148

Vs-SP 163

%-SP

Ya-PSC 227

Approx

Shipping

Weight

4

4

4

5

170

187

A73382

Fig. 3—Floor Opening for

Concrete Slab

Table 4—Opening Dimensions

Furnace Casing A B

Width Heat-Only Heat/Cool*

14%s

17%

21 19% 19%

24%

♦These dimensions appiy when a Model 28RC or RD Evaporator Coil cas

ing is to be installed.

13%

167,6

237,6

19=/s 197,6

19%

19%

. 197,6

197,6

197,6

This furnace is designed for a minimum continuous return

air temperature of 60 degrees F DB or an intermittent oper

ation down to 55 degrees F DB such as when used with a

thermostat night setback. Return air temperature must not

exceed a maximum of 85 degrees F DB.

A WARNING

Improper histaUation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poison

ing, explosion, fire, electrical shock, or other conditions

which may cause personal injury or property damage.

Consult a qualified installer, service agency, local gas

supplier or your Distributor or Branch for information

or assistance. The qualified installer or agency must use

only factory authorized and listed kits or accessories

when modifying this product. A failure to adhere to this

warning can cause electrical shock, fire, personal injury,

or death.

FURNACE

■PLENUM

A73383

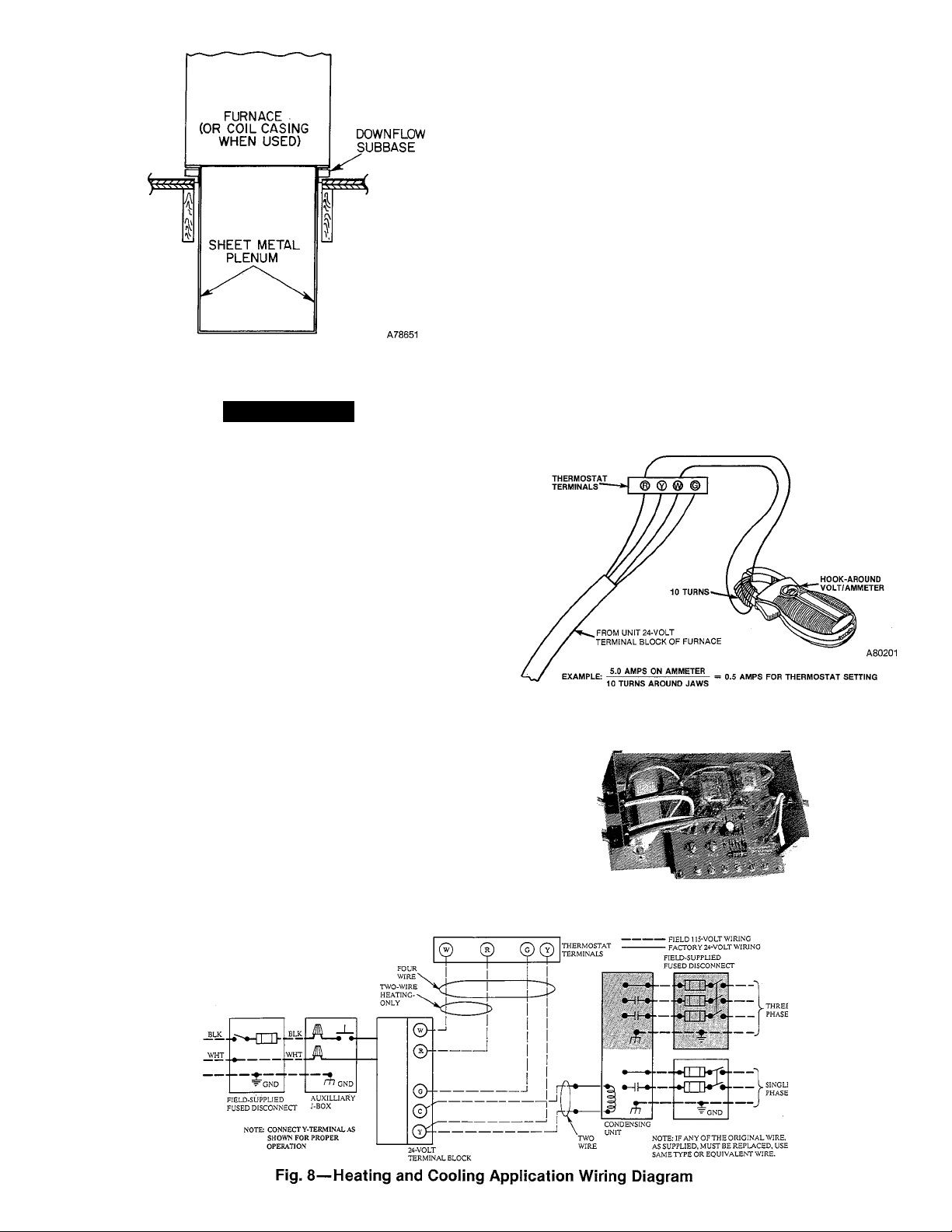

Fig. 4—Furnace on a Concrete Siab

WA

Page 3

Fig. 5—Furnace, Plenum, and

Base Installed on a Combustible Floor

A CAUTION

Do not insteill furnace in a damp, corrosive, or contami

nated atmosphere. Make sure all combustion and circu

lating air requirements listed in “Procedures for

Natured-Draft Gas-Fired Furnaces” are adhered to, in

addition to all local codes and ordinances.

Do not use this furnace during construction when adhe

sives, sealers and/or new carpets are being installed. If

the furnace is required during construction, use clean

outside air for combustion and ventilation. Compounds

of chlorine and fluorine when burned with combustion

air form acids which wiU cause corrosion of the heat

exchangers and metal vent system. Some of these com

pounds are paneling and dry wall adhesives, paints,

thinners, masonry cleaning materials, and many other

solvents commonly used in the construction process.

*IV. Venting

V. Supply-Air Plenum Installation

VI. Electrical

VII. Sequence of Operation

VIII. Füter

IX. Startup and Adjustment

X. Care and Maintenance

*To perform these sections (or installation steps), refer to

the appropriate sections of “Procedures for Natural-Draft

Gas-Fired Furnaces” booklet packaged with this unit.

For accessory installation details, refer to the applicable

installation hterature. Terminals EAC-1 and EAC-2 in the

control box are for direct connection of an electronic air

cleaner.

V. SUPPLY-AIR PLENUM INSTALLATION

A. Installation on a concrete slab

1. See Fig. 2 for dimensions and location of supply-air

opening in furnace bottom.

2. Construct hole in floor per dimensions in Fig. 3 and

Table 4.

3. Place plenum and furnace as shown in Fig. 4.

The design of the downflow gas-fired furnace is A.G.A. cer

tified for installation on noncombustible flooring. The fur

nace may be installed on combustible flooring when

installed with the accessory downflow subbase. This furnace

is for installation in alcoves, basements, closets, or utility

rooms. This furnace fine is not A.G.A. design certified for

installation in a mobile home, recreation vehicle, or

outdoors.

Installation comprises the following:

*1. Inspection

*11. Location, Ventilation, and Air for Combustion

*III. Gas Piping

Fig. 6—Amp Draw Check With Ammeter

A79077

Fig. 7—PrInted-CIrcult Control Center

- FIELD24-VOLTWIRlNC

Page 4

FUSED DISCONNECT

SW ITCH (WHEN REQ'D)

CAP

(WHEN USED)

ILK SWITCH

TRAN

BREAKAWAY TAB REMOVED WHEN CONNECTING VENT DAMPER (SEE INSTALLATION INSTRUCT IONS)-

NOTES:

m DOWNFLOW FURNACES ONLY

I.

I

----

rz—I HEATING FAN RELAY CONTACT IS

•-rkF* NORMALLY CLOSED UNTIL 115V AC IS

HFR APPLIED TO FURNACE.

TO CHANGE MOTOR SPEED, MOVE RED WIRE TO

2.

DESIRED SPEED SETTING.

IF ANY OF ORIGINAL WIRE AS SUPPLIED WITH

3.

THE APPLIANCE MUST BE REPLACED, IT MUST

BE REPLACED WITH AWM C105°C) WIRE OR ITS

EQUIVALENT.

MOTOR IS THERMALLY OVERLOAD PROTECTED.

4.

FACTORY SPEED SELECTION IS FOR AVERAGE

5.

CONDITIONS, SEE INSTALLATION INSTRUCTIONS

FOR OPTIMUM SPEED SELECTION. MOTOR MAY

BE 3 OR 4 SPEED.

SYMBOLS ARE ELECT. REPRESENTATION ONLY.

6.

FACTORY CONNECTED WHEN ACCESSORY NOT USED.

7.

LEGEND

ALS

CAP

CFR

FL

FU2

GV

HFR

ILK

LOD

LS

MTR

PCB

PI

SP

TRAN

VSS5

/fy

AUXILIARY LIMIT SWITCH, MANUAL-RESET

C5PST-NC)

RUN CAPACITOR

COOLING FAN RELAY CDPDT

FUSIBLE LINK

FIELD FUSE

GAS VALVE

HEATING FAN RELAY CSPST-NC)

SWITCH, BLOW. DOOR INTERLOCK CSPST-NO)

LOCKOUt TIMER DEVICE CSPST-NO)

LIMIT SWITCH, AUTO.-RESET CSPST-NC)

MOTOR, BLOWER

PRINTED CIRCUIT BOARD

PILOT IGNITER

SAFETY PILOT (FLAME SENSING)

TRANSFORMER

VENT SAFETY SHUTOFF SWITCH, MANUAL-

RESET CSPST-NC)

FIELD SPLICE

PLUG RECEPTACLE

JUNCTION

UNMARKED TERMINAL

O

TERMINAL PCB FACTORY CONN.

FACTORY WIRING. C120V AC)

FACTORY WIRING CLOW VOLTAGE)

FIELD WIRING C120V AC)

FIELD WIRING C24V AC)

CONDUCTOR ON PRINTED CIRCUIT BOARD

SCREW TERMINAL FOR FIELD WIRING

0

FIELD GROUND

EQUIP. GROUND

TO THERMOSTAT

314296-401 REV. A

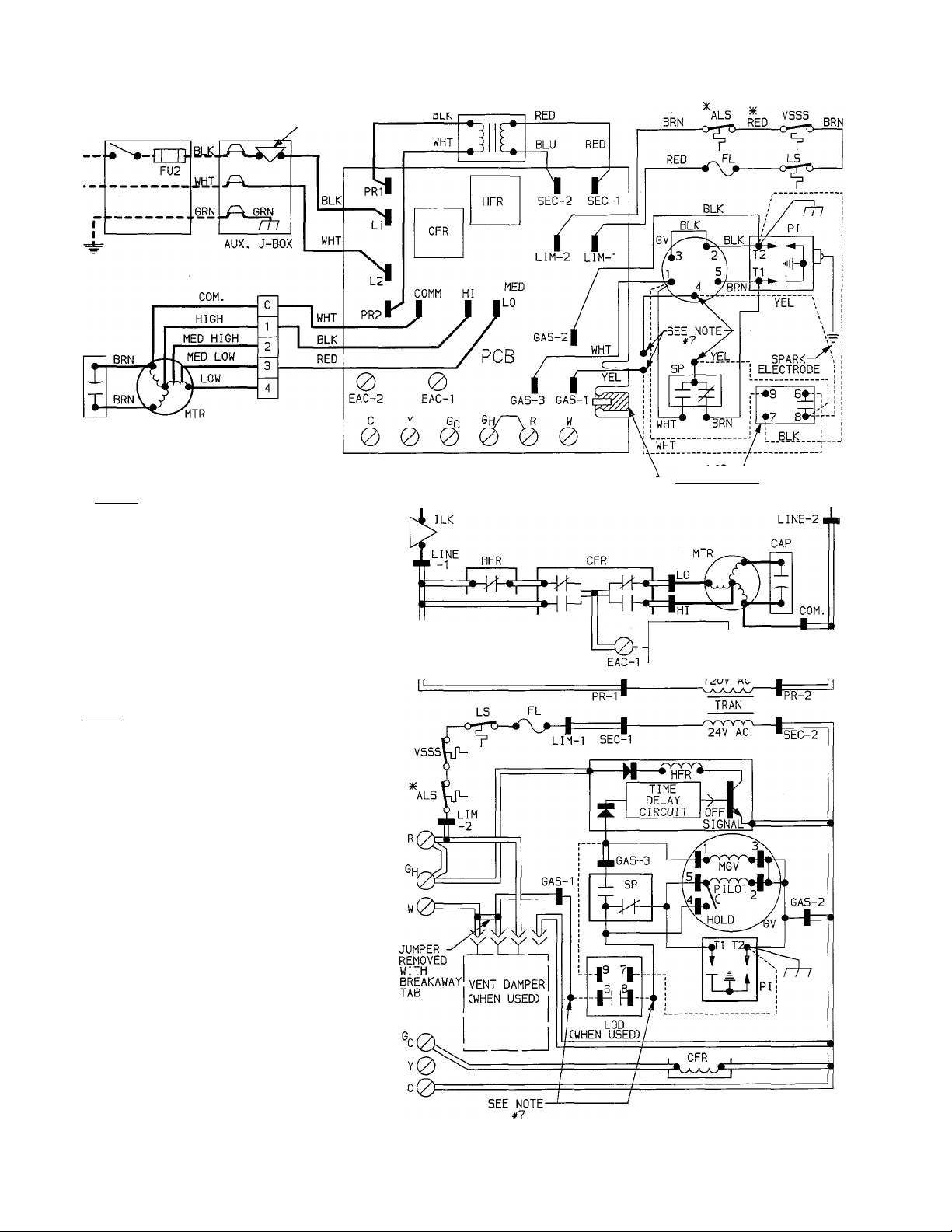

Fig. 9—Wiring Diagram (IID Pilot)

YEL

LOD-

CWHEN USED)

ELECTRONIC

AIR CLEANER

(WHEN USED)

EAC-2

A89168

Page 5

FUSED DISCONNECT

-■D3-

FU2

D)

BLK

WHT

ILK SWITC^l^

BLK

)JHT

BLK

TRAN

RED

CWHEN USED)

GRN

CAP

CWHEN USED)

NOTES:

DOWNFLOW FURNACES ONLY

HEATING FAN RELAY CONTACT IS

NORMALLY CLOSED UNTIL IlSV AC IS

HFR ■ APPLIED TO FURNACE.

2. TO CHANGE MOTOR SPEED, MOVE BLK OR RED

WIRE TO DESIRED SPEED SETTING.

3. IF ANY OF ORIGINAL WIRE AS SUPPLIED WITH

THE APPLIANCE MUST BE REPLACED, IT MUST

BE REPLACED WITH AWM C10S°C) WIRE OR ITS

EQUIVALENT.

4. MOTOR IS THERMALLY OVERLOAD PROTECTED.

5. FACTORY SPEED SELECTION IS FOR AVERAGE

CONDITIONS, SEE INSTALLATION INSTRUCTIONS

FOR OPTIMUM SPEED SELECTION. MOTOR MAY

BE 3 OR 4 SPEED.

6. SYMBOLS ARE AN ELECTRICAL REPRESENTATION ONLY.

LEGEND

ALS AUXILIARY LIMIT SWITCH, MANUAL-RESET

CAP RUN CAPACITOR

CFR COOLING FAN RELAY CDPDT)

FL FUSIBLE LINK

FUl FUSE IN LINE 2 AMP

FU2 FIELD FUSE

GV GAS VALVE

HFR HEATING FAN RELAY CSPST-NC)

ILK SWITCH, BLOWER DOOR INTERLOCK (SPST-NO)

LS LIMIT SWITCH, AUTOMATIC-RESET CSPST-NC)

MTR MOTOR, BLOWER

PCB PRINTED CIRCUIT BOARD

TRAN TRANSFORMER

VSSS VENT SAFETY SHUTOFF SWITCH, MANUAL-RESET

-•

--------

Q MARKED TERMINAL

O UNMARKED TERMINAL

--------

---------- FACTORY WIRING CLOW VOLTAGE)

---------

— CONDUCTOR ON PRINTED CIRCUIT BOARD

CSPST-NC)

CSPST-NC)

FIELD SPLICE

PLUG RECEPTACLE

JUNCTION

TERMINAL PCB FACTORY CONN.

FACTORY WIRING Cl20V AC)

FIELD WIRING C120V AC)

GRN^

AUX. J-BOX

0 SCREW TERMINAL FOR FIELD WIRING

^ FIELD GROUND

fj-/ EQUIP. GROUND

TO THERMOSTAT

BREAKAWAY TAB

REMOVED WHEN

CONNECTING VENT

DAMPER CSEE

INSTALLATION

INSTRUCTIONS)

310471-402 REV. B

BRN

-> Fig. 10—Wiring Diagram (Match-iit Pilot)

A89167

Page 6

B. Installation on a combustible floor

1. Read Installation Instructions packaged with acces

sory combustible floor base.

2. Cut eind frame hole in floor per dimensions listed in

Installation Instructions packaged with combustible

floor base. If this requires cutting of a floor joist, tie

ends of cut joist into adjacent joists so that proper

floor support will be maintained.

3. Assemble and install downflow subbase per instruc

tions packaged with subbase.

4. When completed, subbase, plenum, and furnace (or coil

casing when used) should be installed as shown in

Fig. 5.

VI. ELECTRICAL CONNECTIONS

A. 115-Volt Wiring

NOTE: Refer to “Procedures for Natural-Draft Gas Fur

naces” (packaged with the equipment) for additional

information.

A CAUTION

Do not connect aluminum wire between disconnect

switch emd furnace. Use only copper conductors.

See Fig. 8 for wiring diagram showing the proper field 115and 24-volt wiring.

Use a separate fused branch electrical circuit containing a

properly sized fuse or HACR-type circuit breaker for this

furnace. A disconnecting means must be located within

sight from, and readily accessible to, the furnace. In some

areas, the unit door switch may qualify as the disconnecting

A WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/

NFPA 70-1987, or local codes to minimize personal

injury if an electrical fault should occur. This may con

sist of electrical wire or conduit approved for electrical

ground when installed in accordance with existing elec

trical codes. Do not use gas piping as an electrical

ground. A failure to adhere to this warning can result in

an electrical shock, fire, or death.

If 115-volt wiring to the unit is encased in a nonmetaUic

sheath, connect the incoming ground wire to the grounding

wire inside the furnace J-box. If metallic conduit is used, it

win serve as the ground.

B. 24-Volt Wiring

Make field 24-volt connections at the 24-volt terminal strip.

See Fig. 8.

NOTE: Use AWG No. 18 “color-coded” copper thermostat

wire for lengths up to 100 ft. Above 100 ft, use AWG No. 16

wire.

IMPORTANT: The thermostat heat anticipation must be set

to match the amp draw of the gas valve and electrical com

ponents in the R-W circmt. Accurate amp draw readings

can be obtained at thermostat subbase terminals R & W.

Fig. 6 illustrates an easy method for obtaining the actual

amp draw.

The room thermostat should be located where it will be m

the natural circulation path of room air. Avoid locations

where the thermostat would be exposed to cold-air infiltra

tion, drafts from windows, doors, or other openings leading

to the outside, or exposure to air currents from warm- or

cold-air registers; or to exposure where the natural circula

tion of the eiir is cut off—such as behind doors, above or

below mantels, shelves, etc.

The thermostat should not be exposed to heat from nearby

fireplaces, radios, televisions, lamps, or rays from the sun.

Nor should the thermostat be mounted on a wall containing

pipes or warm-edr ducts, or a flue or vent that could affect

its operation and prevent it from properly controlling the

room temperature. Any hole in the plaster or panel through

which the wires pass from the thermostat should be ade

quately sealed with suitable material to prevent drafts from

affecting the thermostat.

C. Blower Control Center

Each furnace features a printed-circuit control center. This

will aid the installer and serviceman when installing and

servicing the unit. See Fig. 7. A 24-volt terminal board is

marked for easy connection of field wiring.

VII. SEQUENCE OF OPERATION

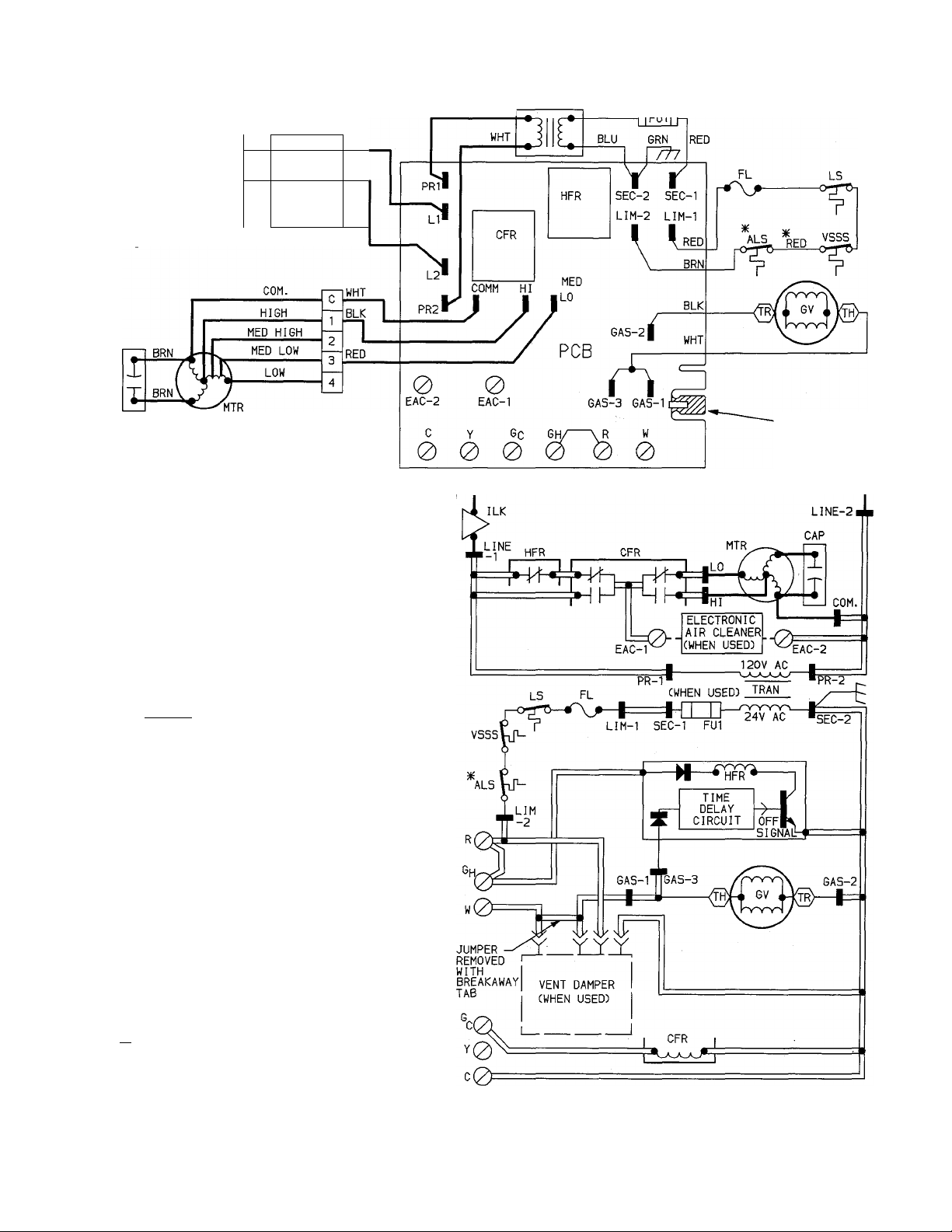

NOTE: The wiring diagrams shown in Figs. 9 and 10 cover

heating/coofing units.

A. Heating

Gas and electrical supplies must be turned on at the

furnace.

NOTE: When power is apphed to heat relay coU HFR in the

control circuit, the normally-closed contacts in the blower

circuit wUl open.

1. White Rodgers 36E Gas Valve (IID Models). See Fig. 9.

When the thermostat “calls for heat,” the control circuit is

closed between terminals R and W. Power from transformer

TRAN through fusible link FL, hmit switches LS & ALS

and vent safety shut-off switch VSSS, energizes the pilot

valve part of automatic gas valve GV and pilot igniter PI.

The pilot valve opens, permitting gas flow to the pilot

burner where it is ignited.

The pilot valve portion of automatic gas valve GV has a

“pick” solenoid coil and latching “hold” device. The “pick”

coU must be energized to open the pilot valve, but only the

“hold” device must be energized to keep it open.

The “hold” device varies with the gas valve design used on

the furnace. It could be an internal pressure switch in series

with the “pick” solenoid coil, an internal electrical resistor

in series with the solenoid “pick” coU, or a separate electri

cal solenoid coil.

When the pilot flame is estabhshed, safety pilot SP switches

its contacts in approximately 40 to 60 seconds, energizing

the main valve portion of gas valve GV and deenergizing

safety pilot igniter SP and the “pick” coil of the pilot sole

noid portion in gas valve GV. The pilot valve is held open by

the “hold” device within gas valve GV.

The main valve portion of gas valve GV has a delayed open

ing operator that opens within 6 to 15 seconds after it is

energized, permitting gas flow to the main burners where

the gas is ignited by pilot SP.

2. Honeywell VR800A and VR8200H Gas Valves (MatchLit Models). See Fig. 10

The furnace pilot must be ht to energize the thermal magnet

circuit of gas valve GV, thus permitting gas flow to the

remedning portion of the valve.

When the thermostat “calls for heat,” the control circuit is

closed between terminals R and W. Power from transformer

TRAN through fusible linkn FL, hmit switch LS & ALS and

vent safety shutoff switch VSSS energizes gas valve GV,

causing the valve to open and permitting gas flow to the

main burners, where it is ignited by the phot.

Page 7

3. Blower Circuit

With power through the solid-state time-delay circuit on

printed-circuit board PCB and heat relay HFR, blower

motor MTR is energized on heating speed approximately 75

seconds after gas valve GV has been energized (or the pilot

flame has been proven in the case of IID systems).

4. Limit Control

If the furnace overheats for any reason, limit control LS

switches, breaking the circuit to automatic gas valve GV.

The gas valve closes immediately, stopping gas flow to the

main burners and the pilot. In addition, blower motor MTR

continues to operate because heat relay HFR is deenergized

to cool down the furnace.

Manual reset auxiliary limit switch ALS is located on the

top right-hand comer of the furnace. In the event of blower

motor failure, this switch breeiks the electrical circuit to the

gas valve, stopping gas flow to the main burners. The

switch must be manually reset after the blower motor has

been replace.

Fusible link FL is provided in the transformer TRAN sec

ondary circuit as protection from overheating conditions in

the vestibule area of the furnace. Should this condition

exist, the fuse opens and deenergizes gas valve GV and heat

relay HFR, stopping the gas flow to the burners and start

ing blower motor MTR.

When the thermostat is satisfied, the circuit between R and

W is broken, deenergizing automatic gas valve GV, pilot SP

(when used), and the solid-state time-delay circuit on

printed-circuit board. The gas flow stops immediately to the

pilot Emd main burners with the IID controls, and to the

main burners only with standing pilot controls. After

approximately 105 seconds, heat relay HFR is energized

and blower motor MTR stops.

5. Vent Safety Shut-off System Switch

The purpose of this control is to safely shutdown the fur

nace if a completely blocked vent condition occurs.

During a blocked vent condition, temperature in the

drafthood relief opening wfll rise causing vent safety shut

off switch to open, breaking the circuit to gas valye GV. The

gas valve closes immediately, stopping gas flow to the main

burners and pilot, and the blower wfll run continuously.

The furnace wiU remain in this mode until the vent safety

shut-off system switch is manually reset.

B. Vent Damper (When Used)

With gas and electrical power supplied to the furnace, the

vent damper motor is deenergized, and the vent damper is

closed until the thermostat “calls for heat.”

On a “call for heat” by the thermostat, the vent damper

motor is energized and the deunper opens. When the vent

damper reaches the full-open position, the damper motor is

deenergized and a circuit is completed to the main gas valve

via the pilot. At this time, the main gas valve is energized

and the main burners are ignited; the vent damper will

remain open until the thermostat is satisfied.

When the thermostat is satisfied, it wfll deenergize the main

gas valve and stop the gas flow. The vent damper motor wfll

energize and close the damper. When the vent damper

reaches the full-closed position, the damper motor is

deenergized and will remain so until the next “call for heat”

by the thermostat.

C. Cooling (Cooling Models Only)

When the thermostat “calls for cooling,” power from trans

former TRAN energizes the condensing unit contactor, cool

ing relay coil CFR, closing its contacts and energizing

blower motor MTR on its cooling speed. It continues to

operate until the thermostat is satisfied.

When the thermostat is satisfied, the circuit to terminal Gc

is broken, deenergizing cooling relay coil CFR which, in

turn, opens its contacts, stopping blower motor MTR.

VIII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return-air duct has been connected

to the furnace, install the filters hi a V-formation inside the

return-air plenum. See Fig. 11.

A WARNING

Never operate the unit without a filter or with the filter

access door removed. A failure to adhere to this warn

ing can cause a fire, physical injury, or death.

,-INSTALLATION

POSITION

OF FILTERS

A78654

Fig. 11—Position of Fiiters

IX. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Natural-Draft Gas-Fired Furnaces” packaged with

the unit.

NOTE: There is a switch located in the blower compartment

that breaks the electrical power supply when the blower

access door is removed. Be sure the blower access door is

properly installed.

A CAUTION

This furnace is equipped with a fusible link in the vesti

bule area that wfll melt if an overheating condition

caused by an inadequate combustion-Eur supply or

improper venting practices develops. Do not jumper

this fuse. Correct the condition and replace the fuse

with an identical part.

The gas service pressure must not exceed 0.5 psig (14

in. wc).

NOTE: The gas valve regulator has been nominally-set at

3.5 in. wc for natural gas. Refer to “Procedures for NaturalDraft Gas Furnace Installation” for readjusting when

checking input.

A. Adjustment of Blower Speed

A WARNING

Disconnect the electrical power before changing the

speed tap. A failure to adhere to this warning can cause

personal injury.

Page 8

To change motor speed taps, remove the motor tap lead (See

Table 5.) and relocate it on the desired terminal on the plug

in terminal block/speed selector located on the blower.

A CAUTION

When adjusting the blower speed, make certain that

the temperature rise across the heat exchanger does not

exceed that specified on the rating plate.

Table 5—Speed Selector

Speed

Common C

Hi

Med-Hi

Med-Low 3

Low

*Furnaces without a cooling fan relay are equipped with a 3-speed motor.

fWhite wire from control box to common; black wire from control box to

cooling speed selection (when used); red wire from control box to heat

ing speed selection.

B. Automatic Gas Control Valve

Tap No.*t

1

2

4

These units are equipped with an automatic gas control

valve. If not already checked when lighting the msdn

burner, check the proper operation of this valve by moving

the room thermostat pointer above and below room temper

ature and observing that the main burners Hght on “caU for

heat” and go off when the pointer is moved below room tem

perature setting.

NOTE: For ease of adjusting the IID pilot flame, disconnect

one power lead at main gas valve. For Model 36E Gas

Valve, discoimect terhnnal No. 1; and for Model VR800A or

VR8200H Gas Valve, turn manual valve knob to PILOT.

This wiU prevent main burner ignition and allow time to

adjust the pilot. Reconnect the power lead or turn manual

valve knob to ON after adjustment.

A CAUTION

Be sure to foUow startup and pilot safety check proce

dures as outlined in “Procedures for Natural-Draft

Gas-Fired Furnaces” instructions packaged with the

equipment.

X. CARE AND MAINTENANCE

A CAUTION

Because of possible deunage to the equipment or per

sonal injury, maintenance should be performed by qual

ified persons only.

A WARNING

Never store anything on, or in contact with, the fur

nace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds, plastic or plastic containers, gasoline,

kerosene, cigEirette lighter fluid, dry deeming fluids,

or other volatile fluids.

3. Paint thinners and other painting compounds,

paper bags or other paper products.

A failure to adhere to this warning can cause corrosion

of the heat exchanger and vent system, fire, personal

injury, or death.

^ Fig. 13—Honeywell Model VR8200H

For continuing high performance, and to niininiize possible

equipment failure, it is essential that periodic maintenance

be performed on this equipment. Consult your local Dealer

as to the proper frequency of maintenance and the availabil

ity of a maintenance contract.

The ability to properly perform maintenance on this equip

ment requires certain mechanical skills and tools. If you do

not possess these, contact your Dealer for maintenance.

A WARNING

Turn off the gas and electrical supplies to the unit

before performing any mEiintenance or service. Follow

the relighting instructions on the label attached to the

furnace. A failure to adhere to this warning can cause

persond injury.

The minimum maintenance that should be performed on the

equipment is as follows:

1. Check and clean or replace air filter each month or as

required.

-> 2. Check blower motor and wheel for cleemliness and lubri

cation (when oilers are provided) each heating and cool

ing season. Clean and lubricate as necessary.

3. Check electrical connections for tightness and controls

for proper operation each heating season. Service as

necessary.

A WARNING

As with any mechanical equipment, personal injury can

result from sharp metal edges, etc.; therefore, be careful

when removing parts.

Page 9

PILOT

ADJUSTMENT-

IN LE'

PRES

TAP

Fig. 14—White Rodgers Model 36E

A. Air Filter

OUTLET

PRESSURE TAP

A87230

Each furnace accommodates two filters which can be

installed above the furnace in the return-air plenum. See

Fig. 11.

To clean or replace the filters, proceed as follows:

1. Disconnect electrical power before removing access

panel.

2. Remove upper access door.

3. Reach up behind top plate, tilt filters toward center of

return-8ur plenum, remove filters, and replace or clean

as needed.

4. Some furnaces are equipped with permanent, washable

filters. Clean those filters as follows:

a. Clean with tap water.

b. Rinse and let dry. No oihng or coating of filters is

required.

c. Reinstall filters with cross-hatch binding facing

blower.

B. Blower Motor Wheel

For long life, economy, and high efficiency; clean accumu

lated dirt and grease from blower wheel and motor annually.

Lubricate motor every 5 years if motor is used on intermit

tent operation (thermostat FAN switch in AUTO position),

or every 2 years if motor is in continuous operation (thermo

stat FAN switch m ON position).

Clean and lubricate as follows:

1. Remove upper access door.

2. Loosen screw in vent pipe enclosure front and remove

vent enclosure front by sliding forward (toward front of

unit).

3. Disconnect vent pipe at first joint above unit and

swing vent pipe assembly to side, supported by suit

able means (block of wood, etc.).

4. Slide vent pipe upward through rectangular opening in

top plate and remove vent pipe from furnace.

5. Remove four screws in vent pipe enclosure back, and

remove enclosure back by tilting top toweurd blower

and sliding bottom toward front of furnace.

6. Disconnect electrical leads from right side of motor

speed selector. Note location of wires for reassembly.

7. Remove screws holding blower assembly against

blower deck and shde blower assembly out of furnace.

8. Squeeze side tabs of motor speed selector and puU it

from blower housing.

9. Units with motor capacitor, loosen screw in strap hold

ing capacitor to blower housing and shde capacitor

from under strap.

10. Mark blower wheel, motor, and motor support in rela

tion to blower housing before disassembly, to insure

proper reassembly.

11. Loosen setscrew holding blower wheel onto motor

shaft.

12. Remove bolts holding motor mount to blower housing

and shde motor and mount out of housing. Some

motors have a ground wire attached to blower housing;

disconnect it also.

13. Lubricate motor (when oilers are provided).

a. Remove dust caps or plugs from oil ports located at

each end of motor.

b. Use good grade of SAE 20 nondetergent motor oil

and put one teaspoon, 5cc, 3/16 oz., or 16 to 25

drops in each oU port.

c. AUow time for total quantity of oil to be absorbed

by each bearing.

d. After oihng motor, be sure to wipe excess oil from

motor housing.

e. Replace dust caps or plugs on oil ports.

14. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff location

to insure proper reassembly.

b. Remove screws holding cutoff plate and remove cut

off plate from housing.

c. Lift blower wheel from housing through opening.

15. Clean blower wheel and motor by using vacuum with

soft brush attachment. Care must be exercised not to

disturb balance weights (chps) on blower wheel vanes.

Also do not drop or bend wheel, as balance wih be

affected.

16. Reassemble blower by reversing procedures 14a thru

14c. Be sure wheel is positioned for proper rotation.

17. Reassemble motor and blower by reversing procedures

8 thru 12. If motor has ground wire, be sure it is con

nected as before. Be sure the blower wheel setscrew is

on the flat of the motor shaft when tightening the

setscrew.

18. Reinstall blower assembly in furnace.

19. Reinstall vent enclosure back.

1

A

Fig. 15—Dual Blower With Left-Hand

Housing and Wheei Removed

20. Reinstall vent pipe through opening in top plate, secure

to drafthood and connect remainder of vent pipe

assembly.

21. Reinstall vent enclosure front, and secure with screw.

• 22. Connect electrical leads to Molex speed selector. Please

note that connections are polarized for assembly—do

not force.

23. Reinstall access door.

9

Page 10

Table 6—Trouble Analysis Chart

A WARNING

To avoid possibility of fixe, explosion, electric shock, personal injury or death, turn off gas and power supply to unit

before servicing (unless specific test requires gas and electric suppHes).

SYMPTOM CAUSE

Furnace will not operate

Pilot will not light

Burners will not ignite.

Blower operates continuously

Inadequate heating

Aldehyde odors, (CO),

sooting flame-

floating flame

No 115-volt power to furnace

Blower door not in place

Defective blower door switch Replace switch.

Vent safety shut-off switch open

No spark at electrode Readjust, if necessary, so that gap between electrode tip

Spark shorting out to main burner Readjust electrode as specified.

No gas at pilot burner

No 115-volt power to furnace Connect to power supply. Check fuse, wiring, or circuit breaker.

No 24-volt power to control circuit Replace transformer.

Miswired or loose connections

No gas at main burners

Dirty pilot—yellow flame

Thermostat fan switch in ON position

Fusible link blown

Dirty filter causing limit operating

Defective heat relay

Vent safety shut-off switch open

Furnace undersized for application

Gas input to furnace too low

Limit switch cycles main burners

Manual reset limit switch contacts open

Manual reset switch contacts open (Burner

on time must be minutes minimum.)

Thermostat anticipator set too low

Incomplete combustion—

poor flame characteristics

Copnnect to power supply. Check fuse, wiring, or circuit breaker.

Install furnace blower door.

Check for vent blockage and proper installation of vent pipe.

and pilot burner is as shown in Fig. 16.

Clean dirt or moisture accumulation from electrode ceramic with cloth.

Cracked ceramic—replace pilot electrode assembly.

Check for loose or broken wiring at and between spark generator and

electrode. Replace wire or tighten connection as necessary.

Check fuse or circuit breaker for 115-volt supply to furnace.

Check blower access panel for proper installation.

Check 24-volt input to spark generator. If you read 24 volts and above

steps have been completed, replace spark generator assembly.

Clean pilot orifice.

Check voltage to terminals 3 and 5 or TR and TH of gas valve.

Check for proper opening of pilot valve, broken wires, or loose

connections. If no deficiency is found, replace valve assembly.

Check all wiring and all wirenut connections.

Check voltage to terminals 1 and 2 or TR and TH of gas valve.

Check for proper opening of main gas valve, broken wires, or loose

connections. If no deficiency is found, replace gas valve assembly.

Clean pilot orifice.

Move thermostat fan switch to AUTO position.

Correct combustion air, vent system, and/or heat exchanger

blockage—replace fuse link with identical part.

Clean or replace dirty air filter—reinstall.

Replace printed-circuit board.

Check for vent blockage and proper installation of vent pipe.

Replace with proper size furnace.

Check gas pressure at manifold. Clock gas meter for input. If too low,

increase manifold pressure or install correct orifices.

Clean or replace dirty air filter—reinstall.

Increase blower speed.

Open registers—ductwork restricted.

Blower motor failure—replace motor.

Check and adjust thermostat anticipator to proper setting.

Replace with proper size furnace.

Check thermostat circuit amps and set anticipator accordingly.

See Fig. 6.

Adjust air shutter on burners to provide soft blue flame. Check all

screws around flue outlets and burner compartment. Tighten.

See “Section II, Location & Air for Combustion & Ventilation”

(Procedures for Natural-Draft Gas-Fired Furnaces).

Replace cracked heat exchanger.

Reduce input and check orifices—furnace overfired.

Check vent for restriction.

REMEDY

11

Page 11

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookI 1 I 4 PC 101 Catalog No. 565-873 Printed in U.S.A. Form 58DP.DR-4SI 5/89 Pg 12 Replaces; 58DP,DR-2SI

Tab I6al8a

Page 12

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab I6al8a

I

PC 101 Catalog No. 565-873 Printed in U.S.A. Form 58DP,DR-4SI 5/89 Pg 12 Replaces: 58DP,DR-2SI

Loading...

Loading...