Page 1

52S

SERIES

SERVICE TECHNICIAN GUIDE

PACKAGED TERMINAL AIR CONDITIONERS

AND HEAT PUMPS

CONTENTS

INTRODUCTION

SUMMARY OF DANGERS, WARNINGS, AND CAUTIONS

GENERAL DISASSEMBLY

TO DISCONNECT POWER FOR CORD-CONNECTED UNIT

TO DISCONNECT POWER FOR PERMANENTLY

CONNECTED (HARDWIRED) UNITS

TO OPEN THE CONTROL BOX

TO REMOVE THE UNIT FROM THE WALL SLEEVE

TO REMOVE THE LATERAL DUCT EXTENSION, FOR

UNITS EQUIPPED WITH THE LATERIAL DUCT

ACCESSORY PACKAGE

TO ACCESS INDOOR-AIR SECTION COMPONENTS

TO ACCESS OUTDOOR-AIR SECTION COMPONENTS

GENERAL CLEANING

CLEANING AND SAFETY

TOOLS NEEDED

MONTHLY CLEANING

SEASONAL CLEANING

COMPRESSOR

COMPRESSOR TROUBLESHOOTING

BASIC HERMETIC COMPRESSOR ELECTRICAL

MEASUREMENTS

COMPRESSOR REPLACEMENT

.................................2,3

...........................4-9

...................4

.......................4

............................5

............................10-15

..........................10

.................................11

............................11

...........................13

..................................16-21

..................17

................................17

......................19

Page

...2

..4

........4

.......6

......8

HEATERS

COMMON CAUSES OF HEATER FAILURE

HEATER REMOVAL

OPERATING CONTROLS

DESCRIPTION OF SWITCH SETTINGS

NON-USER ADJUSTABLE SWITCHES

SEQUENCE OF OPERATION

COMPONENT OPERATION AND TROUBLESHOOTING

ELECTRICAL COMPONENTS REMOVAL AND

REPLACEMENT

FAN MOTOR

FAN MOTOR TROUBLESHOOTING

BASIC FAN MOTOR ELECTRICAL TESTS

FAN MOTOR REPLACEMENT

FIELD TEMPERATURE CHARTS

WIRING SCHEMATICS

MOST FREQUENT PTAC SERVICE QUESTIONS

......................................22,23

..............22

..............................22

.........................24-31

.................25

.................25

........................26

.................................30

...................................32-34

...................32

...............32

.......................34

....................35-50

...........................51-55

..........56

PTAC Customer Support Center

1

•

800•894•6449

....27

Page

Page 2

52S

SERIES

INTRODUCTION

The focus of this manual is to provide basic information

on service procedures, safety, troubleshooting, cleaning, and component replacement for service technicians.

It is intended for use only by HVAC service technicians who have successfully completed instruction and received Type I Certification from the

U.S. Environmental Protection Agency.

The instructions in this manual are general in nature

and are not to be substituted for installation and service

instructions shipped with the unit. No attempt to install, operate, adjust, repair, or dismantle any equipment

should be made until the manufacturer’s instructions

are read and thoroughly understood by the service technician. Even equipment that seems familiar may have

specific model differences from year to year. Always

review manufacturer’s instructions.

The Model 52S packaged terminal air conditioner and

heat pump units are self-contained for installation

through the wall for individual room heating and cooling. The Model 52S polymer sleeve is permanently

fastened to the wall; the unit chassis slides out of the

sleeve to allow the service technician easy access. An

accessory louvered rear grille may be mounted on the

sleeve. Many accessories are offered to complement the

unit’s comfort control.

Before beginning any service procedures, it is important

to check the unit model number. Even units that seem

similar may have subtle differences that could affect

service procedures. The 52S units covered in this book

are the 52SC (Cooling Only model); the 52SE (Cooling

with Electric Heat model); and the 52SQ (Cooling, Electric Heat, and Heat Pump model).

Knowing which model is being serviced will help determine if the unit is performing at optimum levels. The

model number is located on the data information plate

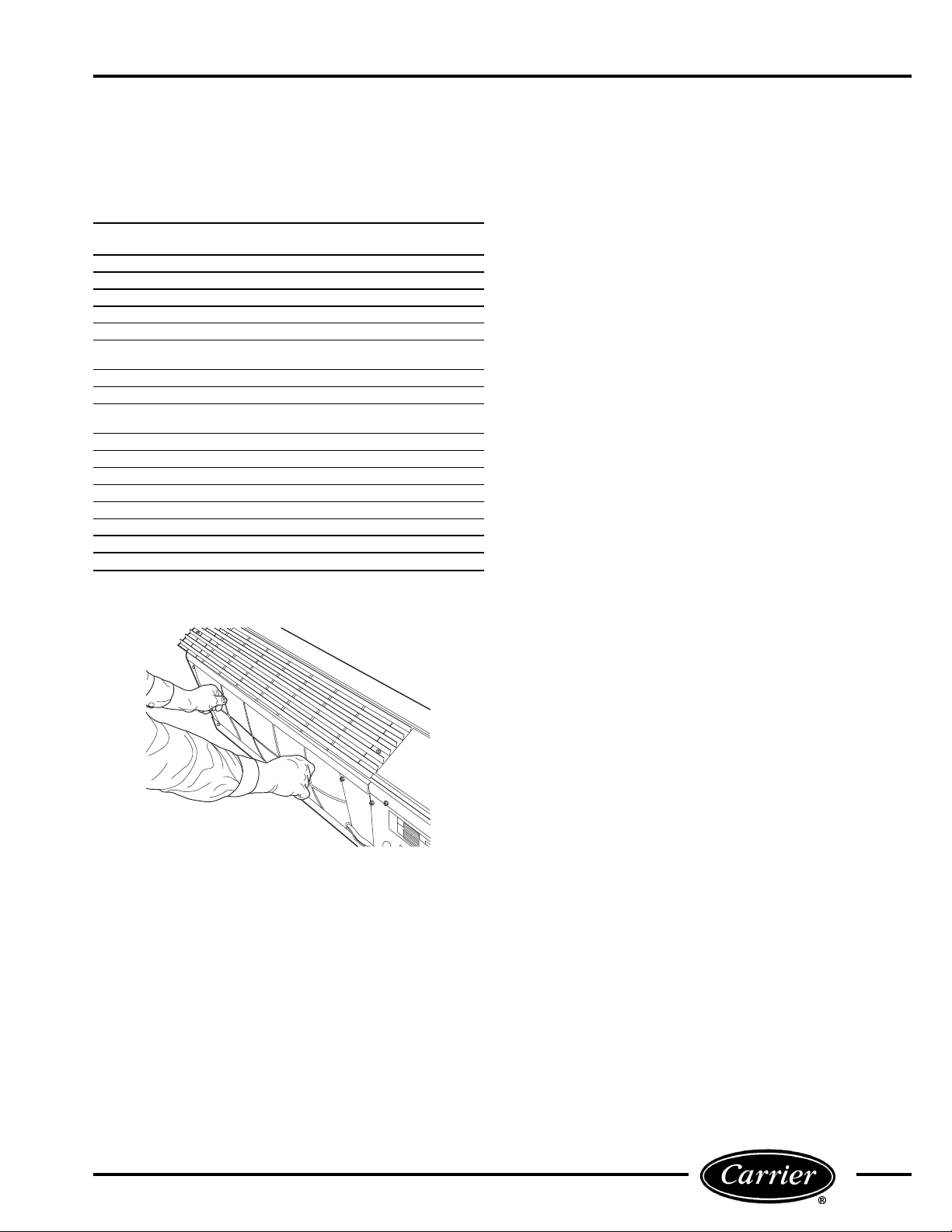

beneath the front panel of the unit. The data information plate also lists voltage ranges and other important electrical information about the unit. To access

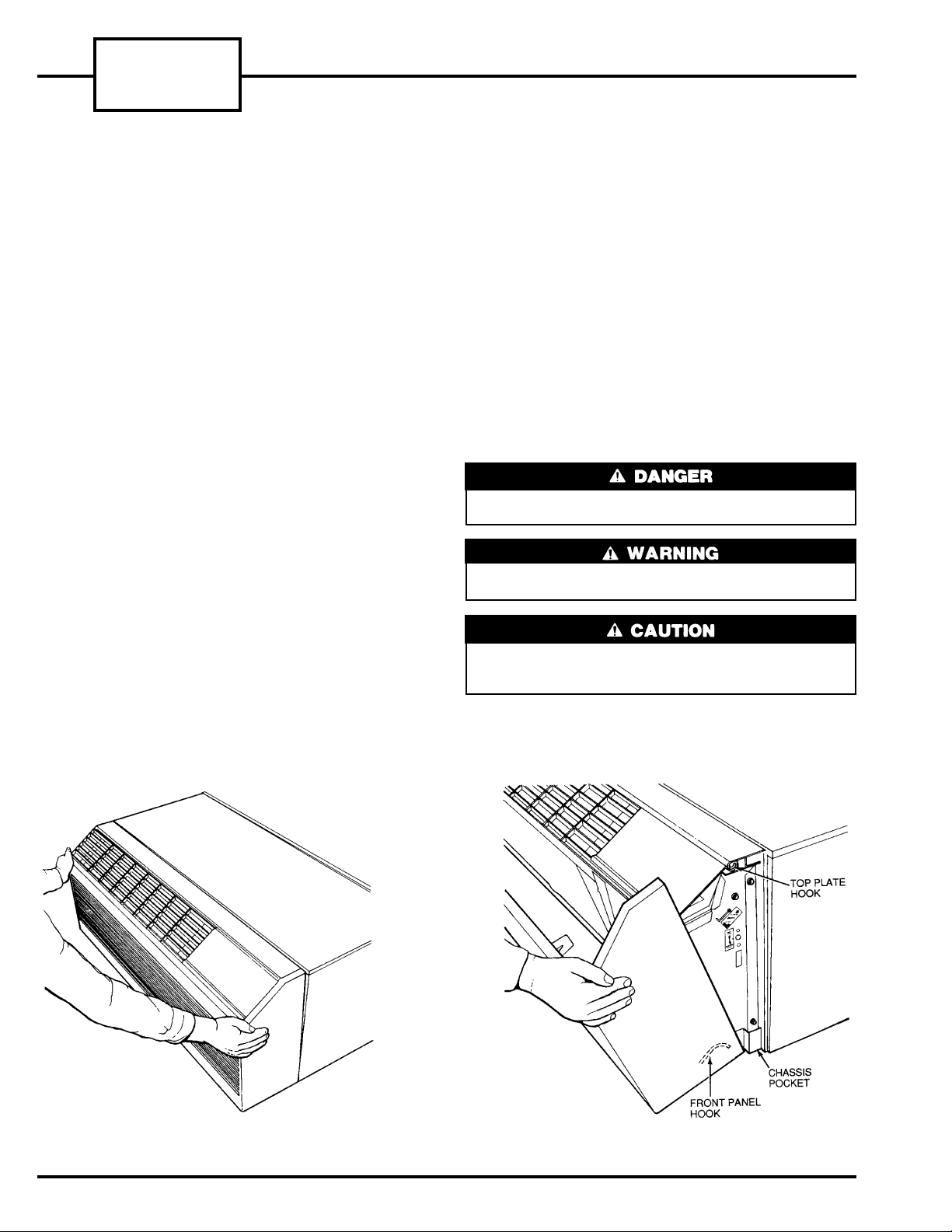

the data information plate, remove the front panel of

unit by grasping panel on each side and gently pulling

upward and out (Figure 1). See Figure 2 for model number nomenclature and Figure 3 for a sample data information plate.

SUMMARY OF DANGERS, WARNINGS,

AND CAUTIONS

The terms DANGER, WARNING, and CAUTION

have specific meanings that identify the degree of hazard. Typically in the HVAC industry, these specific

meanings are:

There is an immediate hazard which WILL result in

severe personal injury or death.

Hazards or unsafe practices which COULD result in

severe personal injury or death.

Potential hazards or unsafe practices which COULD

result in minor personal injury or equipment

damage.

FIGURE 1 — REMOVING FRONT PANEL

2

Page 3

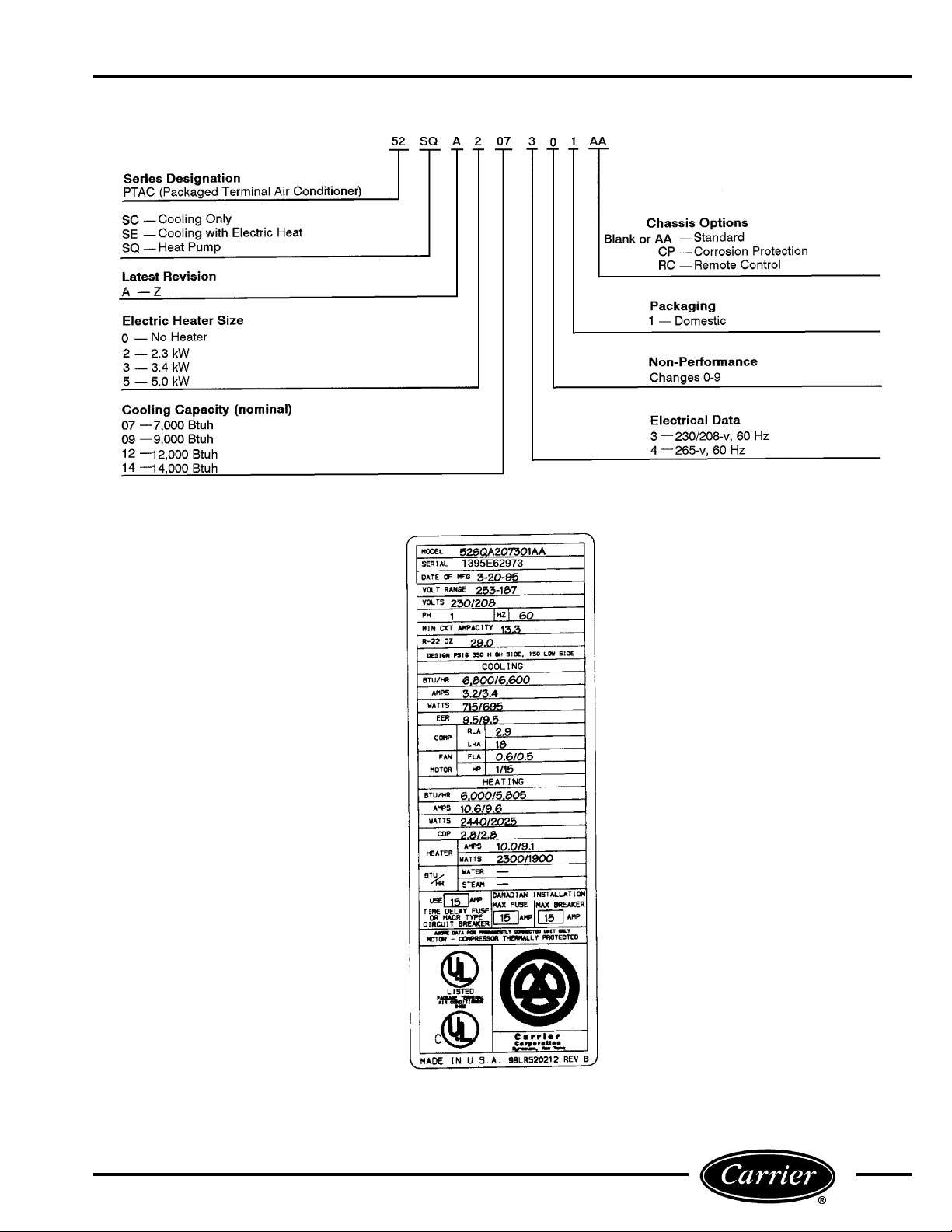

FIGURE 2 — MODEL NUMBER NOMENCLATURE

FIGURE 3 — SAMPLE DATA INFORMATION PLATE

3

Page 4

52S

SERIES

GENERAL DISASSEMBLY

This section includes common procedures for disassembly and reassembly of 52S units. These instructions

are general in nature and include procedures the technician may be called upon to perform when accessing

certain components of the 52S unit.

It is important to carefully follow manufacturer’s instructions when disassembling or reassembling a unit for

cleaning, maintenance, or part replacement. When disassembling wiring, it is strongly recommended that

numbered stickers be attached to identify leads and terminals to aid in the reassembly process.Always review

safety procedures prior to the start of a job.

Prior to servicing electrical equipment, disconnect all

power to avoid electric shock! Never alter cord or plug

and do not use extension cords.

TO DISCONNECT POWER FOR CORDCONNECTED UNIT

1. Push OFF button.

2. Open the disconnect switch at main power supply.

Use proper Lockout and Tag procedures.

3. Unplug the unit service cord.

CONTROL

BOX

.

.

ACCESS

COVER

PLUG

ASSEMBLY

FIGURE 4 — DISCONNECTING PLUG

ASSEMBLY ON HARDWIRED UNITS

TO DISCONNECT POWER FOR

PERMANENTLY CONNECTED

(HARDWIRED) UNITS

1. Push OFF button.

2. Open the disconnect switch at main power supply.

Use proper Lockout and Tag procedures.

3. Remove screw from access cover and remove access cover.

Pull out the plug assembly and disconnect (see

4.

Figure 4).

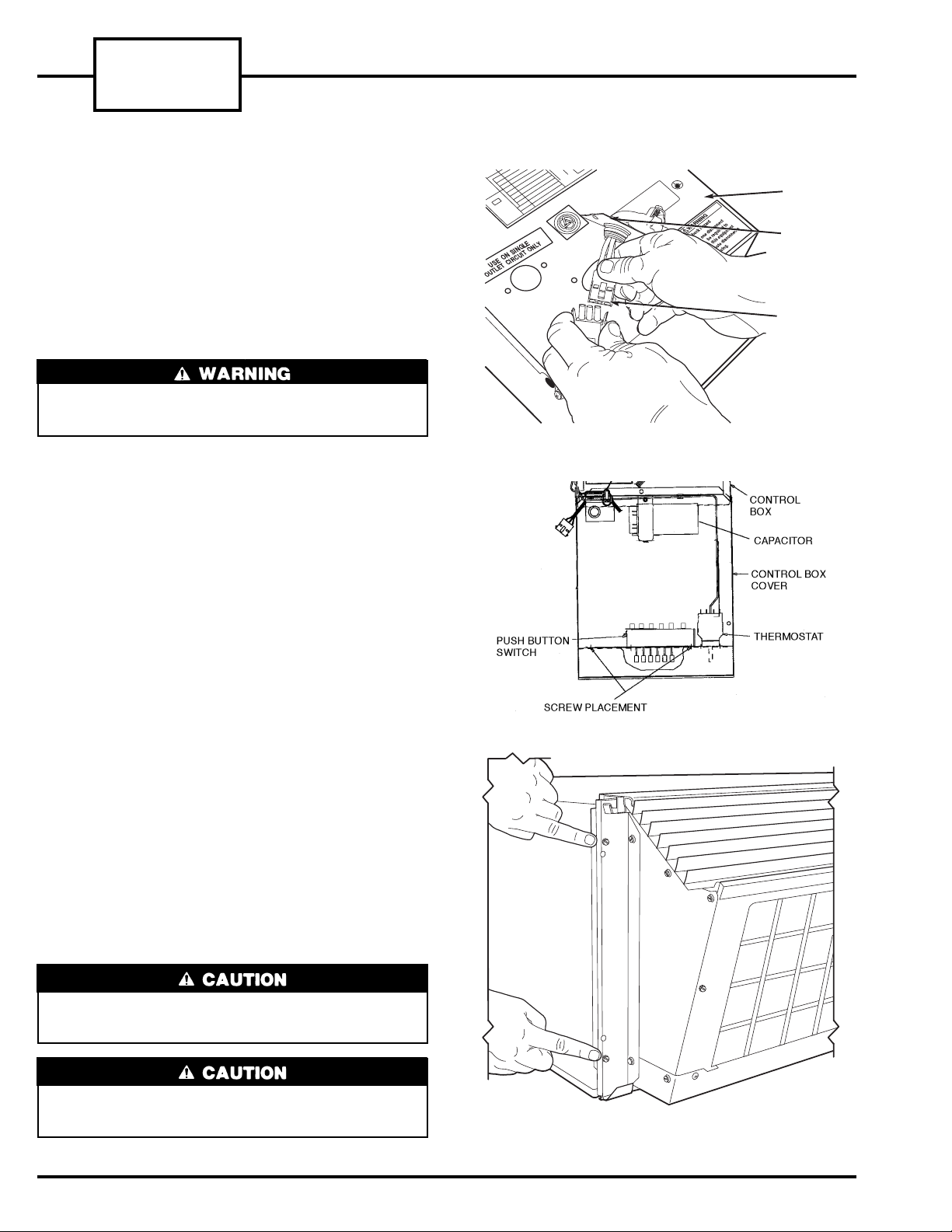

TO OPEN THE CONTROL BOX

The control box is factory wired. To open the control

box, remove the 2 screws on the front of the control box

and lower the front hinged panel. See Figure 5.

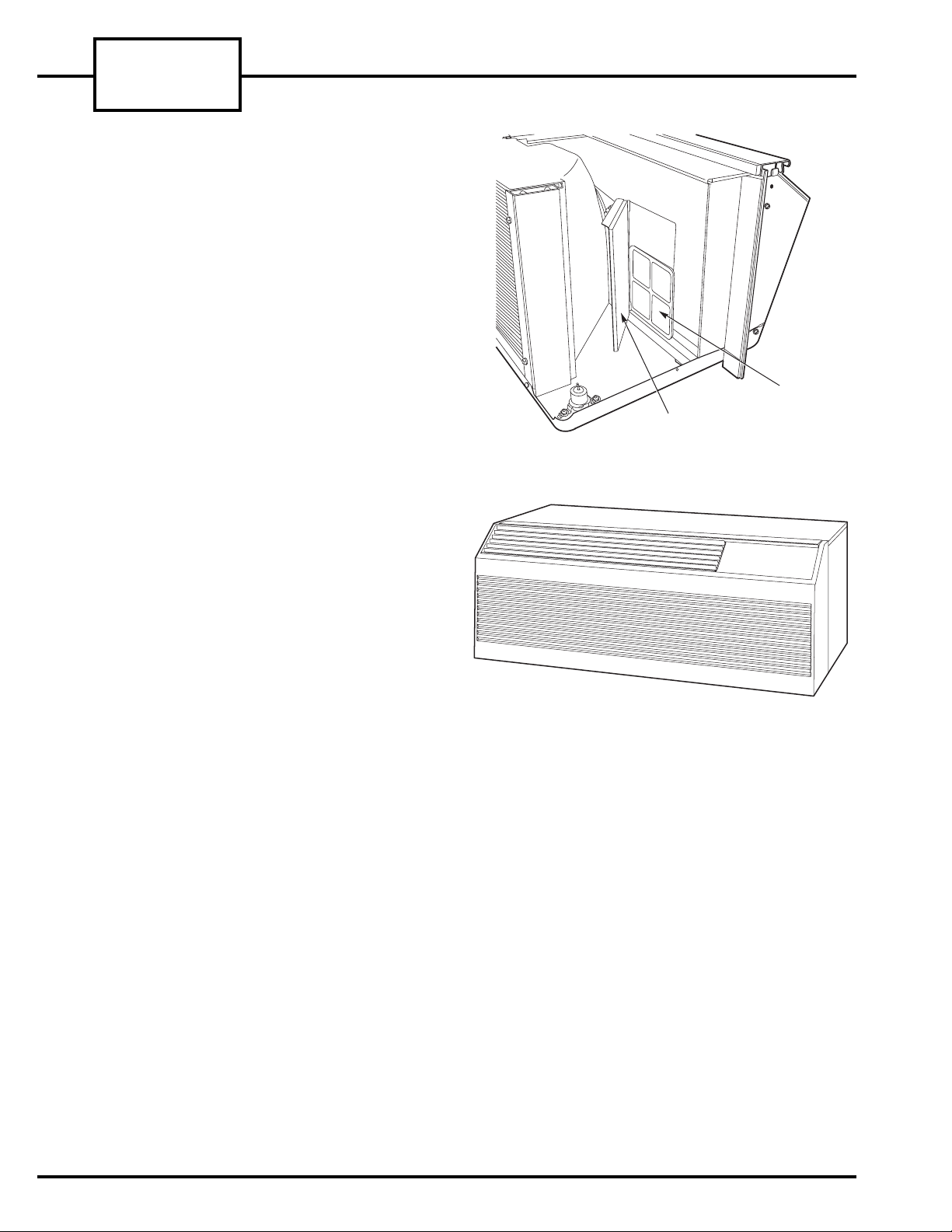

TO REMOVE THE UNIT FROM THE

WALL SLEEVE

1. Remove the four, 1

cure the unit to the wall sleeve. There are 2 screws

on each side (Figure 6).

2. Grasp the sides of the unit and slide it from the sleeve.

The chassis weighs between 110 and 150 pounds.

Take proper safety precautions to avoid personal injury when lifting and moving the chassis.

3

⁄4-in. mounting screws that se-

FIGURE 5 — OPEN CONTROL BOX

The unit basepan may have water in it. Tilt the unit

back slightly when removing it from the sleeve to

drain some of the water into the sleeve.

FIGURE 6 — UNIT TO WALL SLEEVE

MOUNTING SCREWS

4

Page 5

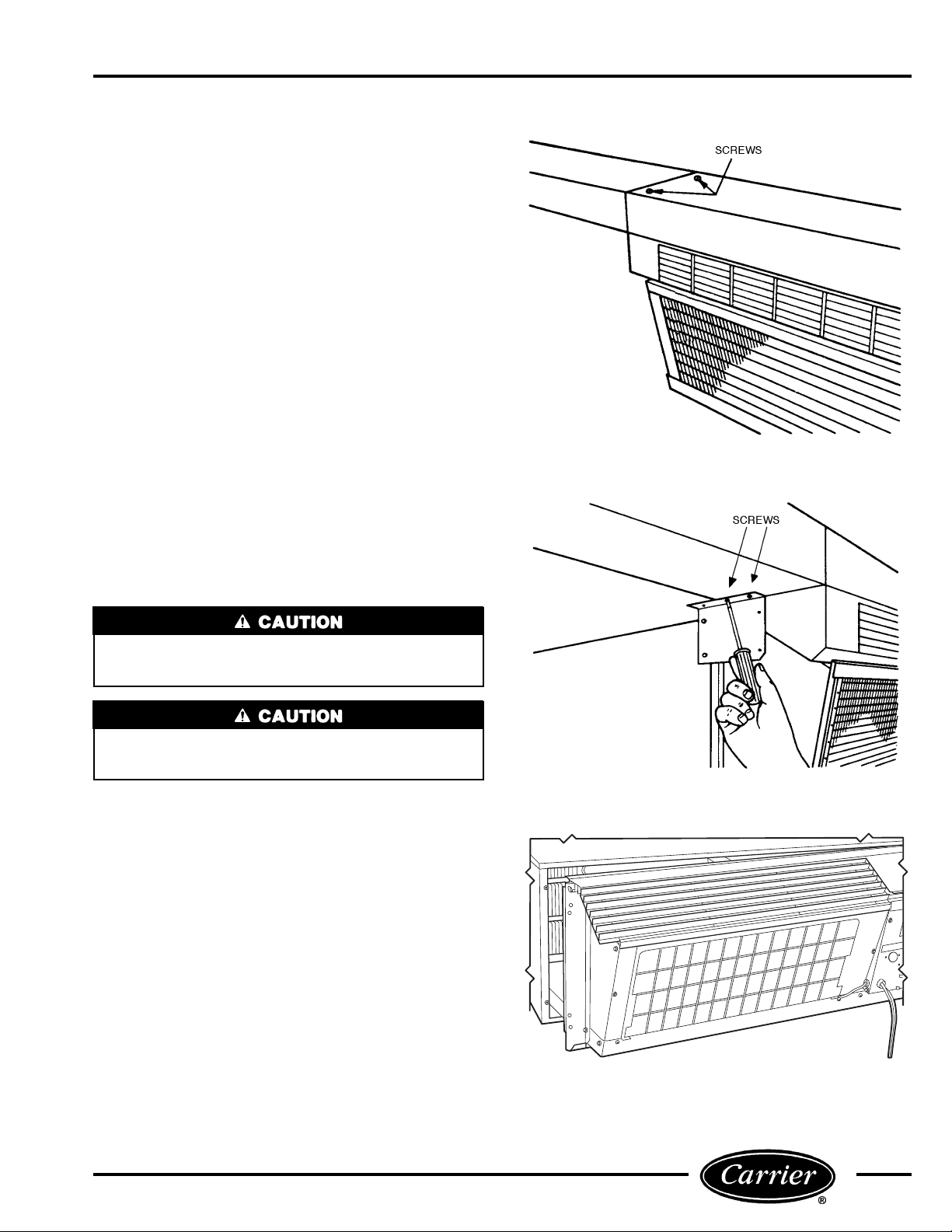

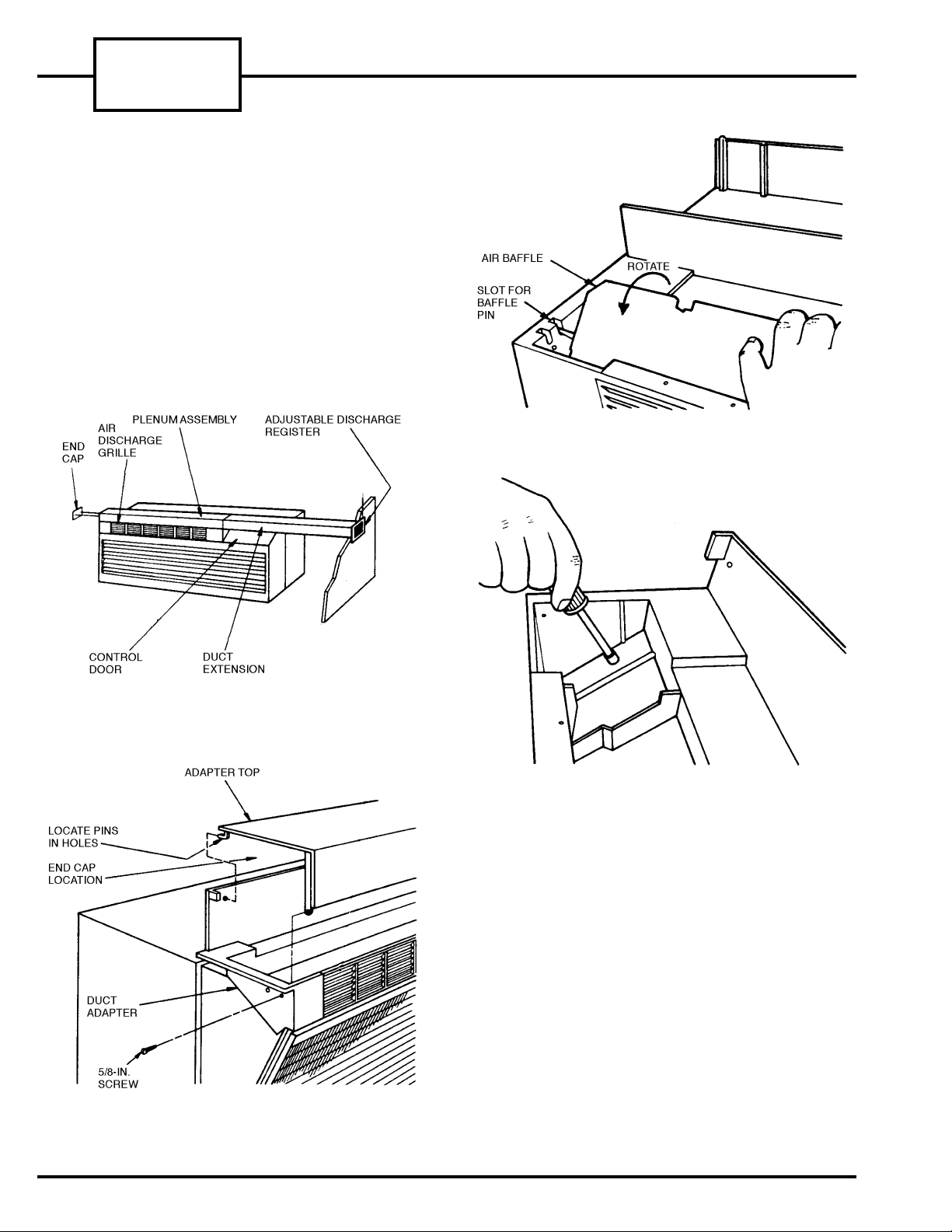

TO REMOVE THE LATERAL DUCT

EXTENSION, FOR UNITS EQUIPPED

WITH THE LATERAL DUCT ACCESSORY

PACKAGE

1. Remove the front panel as shown in Figure 1.

2. Remove the four 1

chassis to the wall sleeve (see Figure 6). There are

2 screws on each side.

3. Remove the 2 screws that secure the lateral duct ex-

tension to the top of the lateral duct adapter as shown

in Figure 7.

4. Locate and remove the 2 screws that secure the

lateral duct extension to the bracket flange as shown

in Figure 8.

5. Carefully slide the chassis away from the extension

duct and remove from the sleeve (as shown in

Figure 9).

3

⁄4-in. screws that secure the

FIGURE 7 — DUCT EXTENSION SCREWS

The unit basepan may have water in it. Tilt the unit

back slightly when removing it from the sleeve to

drain some of the water into the sleeve.

The chassis weighs between 110 and 150 pounds.

Take proper safety precautions to avoid personal injury when lifting and moving the chassis.

FIGURE 8 — BRACKET FLANGE SCREWS

FIGURE9—PARTIAL REMOVAL OF CHASSIS

FROM WALL SLEEVE

5

Page 6

52S

SERIES

TO ACCESS INDOOR-AIR SECTION

COMPONENTS

n DISASSEMBLING THE LATERAL DUCT

ADAPTER, FOR UNITS EQUIPPED WITH THE

LATERAL DUCT ACCESSORY PACKAGE

Remove the lateral duct adapter end cap, shown in

1.

Figure 10, by removing the two

2. Remove the adapter top panel by removing one screw

at each end of unit as shown in Figure 11. Rotate the

front of the panel up and back and lift free.

3. Rotate and lift the air baffle out of the unit. See

Figure 12.

4. Remove the 2 screws holding the duct adapter to the

chassis discharge air opening flanges, as shown in

Figure 13, and remove the duct adapter.

1

⁄2-in. screws

FIGURE 12 — REMOVING THE AIR BAFFLE

FIGURE 10 — WALL SLEEVE, DUCT ADAPTER,

AND EXTENSION LOCATION

(RIGHT-HAND EXTENSION)

FIGURE 11 — DISCHARGE PLENUM ASSEMBLY

FIGURE 13 — REMOVING THE DUCT ADAPTER

6

Page 7

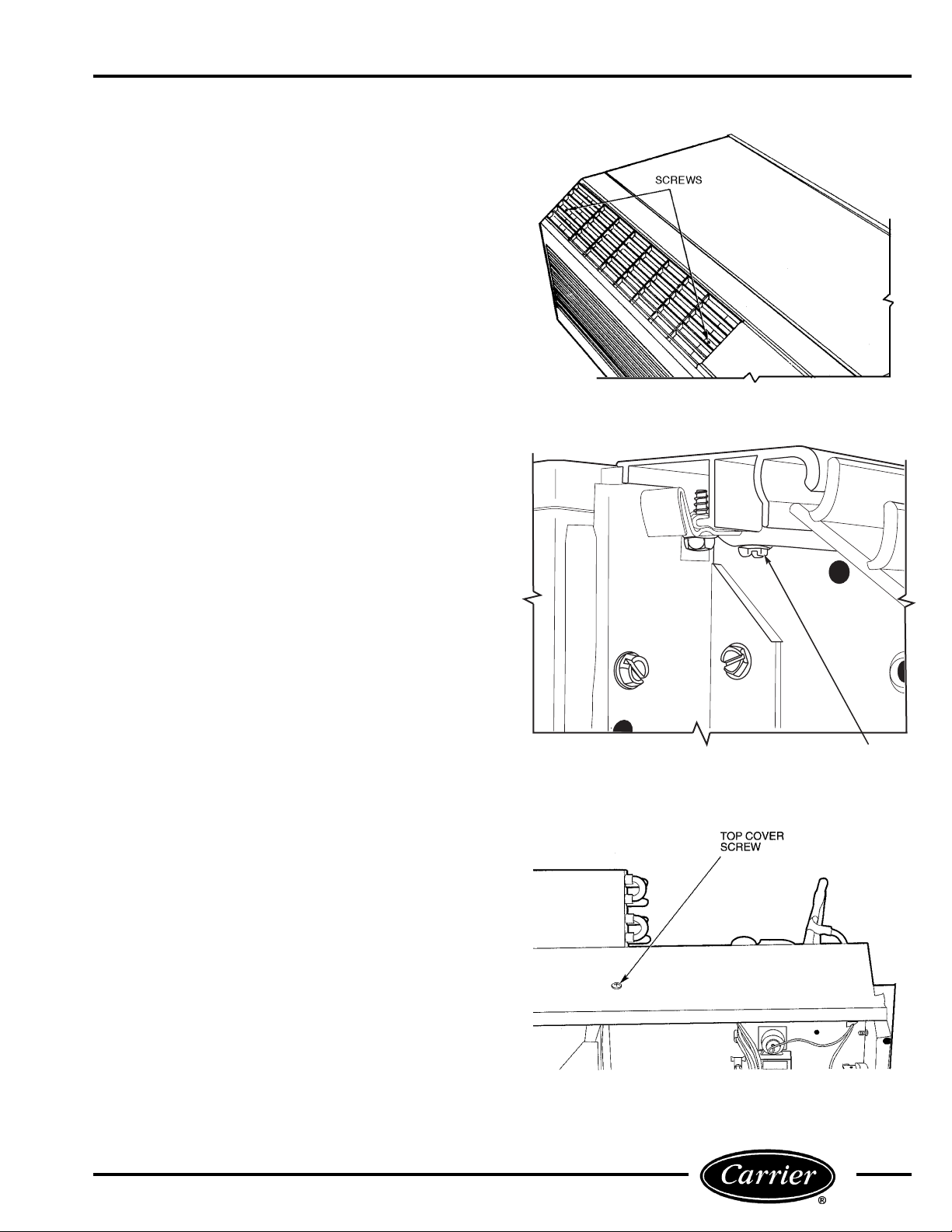

n TO REMOVE THE AIR DISCHARGE GRILLE

L

1. Remove the 2 screws on each end of the air discharge

grille as shown in Figure 14.

2. Lift and rotate back the bottom edge of the discharge

grille and remove it.

n TO REMOVE THE ALUMINUM TOP PANEL

— Remove one screw from each end of the aluminum

top panel (located on the underside of the panel) as shown

in Figure 15. On the left side of the unit, remove the

screw closest to the side of the unit.

FIGURE 14 — REMOVING AIR DISCHARGE GRILLE

n TO REMOVE THE TOP COVER — Remove the screw

located in the middle of the top cover and remove the

cover. See Figure 16.

FIGURE 15 — ALUMINUM TOP PANEL

FIGURE 16 — TOP COVER SCREW

TOP PANE

SCREW

7

Page 8

52S

SERIES

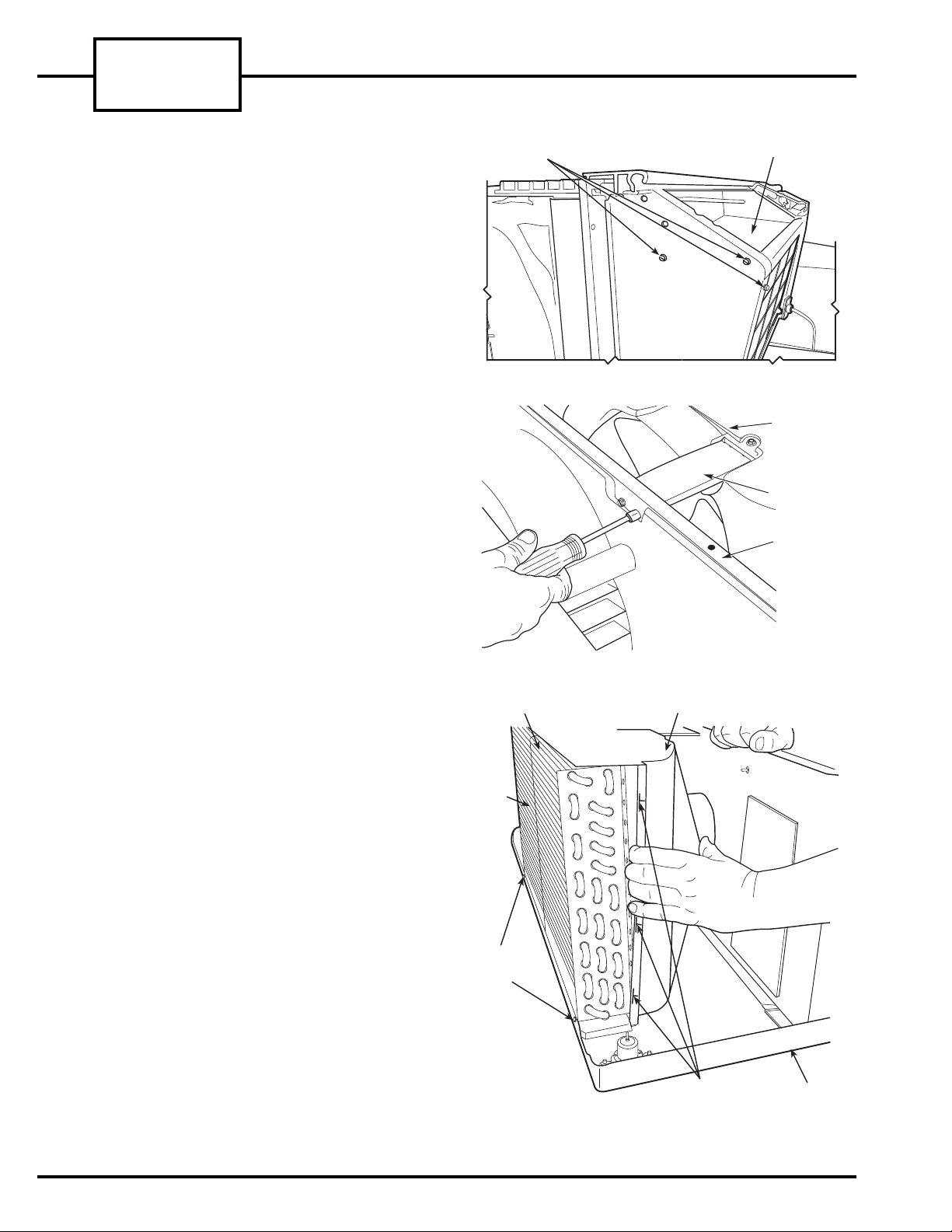

n TO REMOVE THE DISCHARGE DECK

1. Remove the 2 discharge deck screws shown in

Figure 17. Also remove the screw located at the top

left corner of the outdoor coil tube sheet.

2. Gently pull the left side panel out and lift the

end of the discharge deck that the screws were removed from, up and forward, to remove.

TO ACCESS OUTDOOR-AIR SECTION

COMPONENTS

n TO REMOVE THE GUSSET

1. Remove the 2 screws that secure the gusset to the

partition.

2. Remove the screw that secures the gusset to the

plastic condenser orifice and remove the gusset.

See Figure 18.

DISCHARGE

SCREWS

DECK

FIGURE 17 — DISCHARGE DECK REMOVAL

CONDENSER

ORIFICE

GUSSET

PARTITION

n TO DETACH THE CONDENSER ORIFICE FROM

THE CONDENSER COIL — Using a flat head screw

driver, gently pry the plastic condenser orifice tabs away

from both condenser coil tube sheets and pull the condenser orifice away as shown in Figure 19.

FIGURE 18 — GUSSET REMOVAL

COIL

ASSEMBLY

COIL

FINS

COIL

MOUNTING

SCREWS

CONDENSER

ORIFICE

CONDENSER

ORIFICE TABS

BASEPAN

FIGURE 19 — REMOVING CONDENSER ORIFICE

8

Page 9

STATOR

n TO REMOVE THE STATOR — After pulling the top

of the condenser orifice away from the condenser coil,

grasp the top of the stator and slide it up and out of the

stator track. See Figure 20.

CONDENSER

ORIFICE

CONDENSER

COIL

FIGURE 20 — REMOVING STATOR

9

Page 10

52S

SERIES

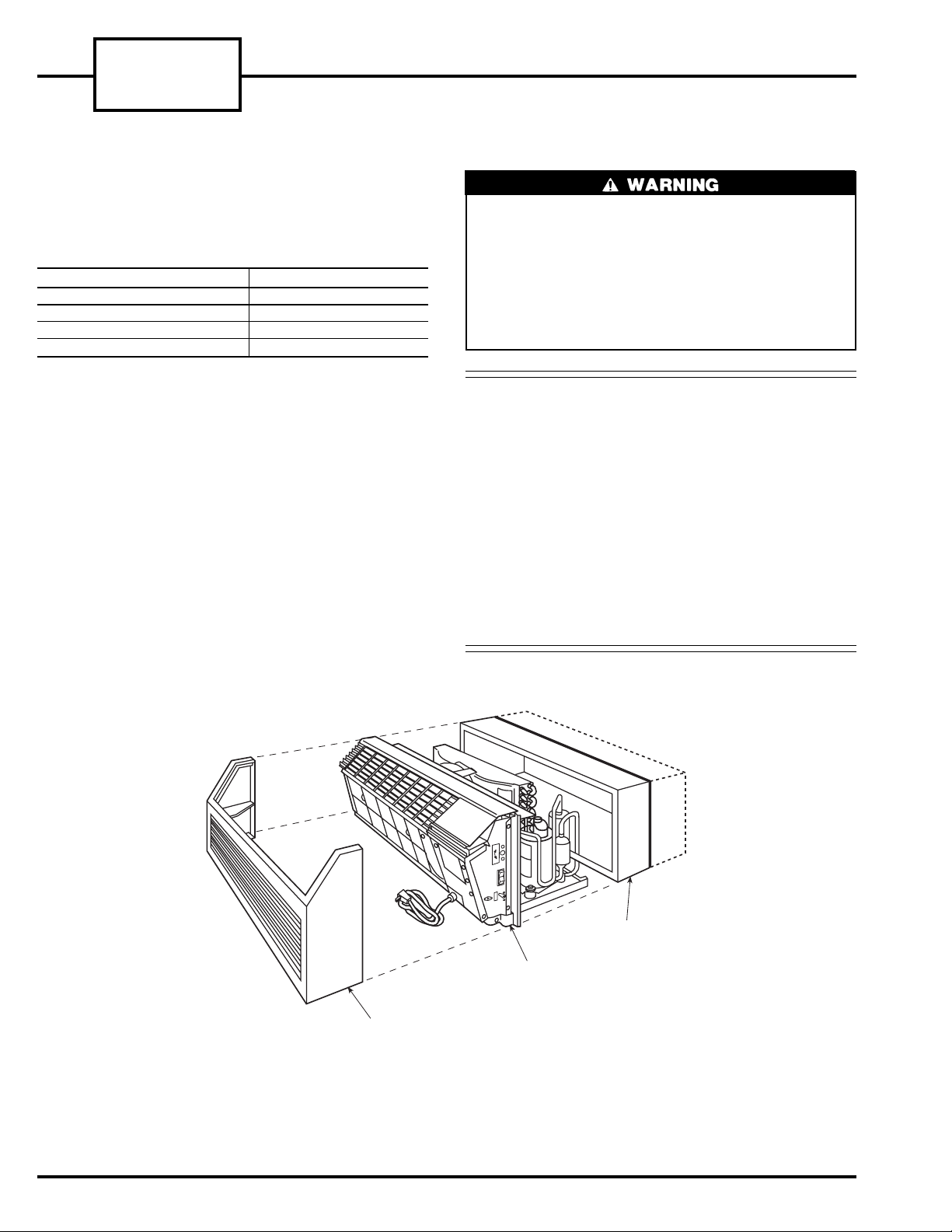

GENERAL CLEANING

Maintaining proper performance of 52S systems

(Figure 21) requires conscientious cleaning and care of

components. Specific components require periodic cleaning and/or replacement, including the following:

COMPONENT CLEANING SCHEDULE

Indoor Air Filter Monthly

Vent Air Filter Monthly

Indoor Coil Seasonally

Indoor Fan Seasonally

Outdoor Coil Seasonally

Before cleaning, servicing, performing maintenance,

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance

tasks such as cleaning and replacing filters. Refer to

General Disassembly section of this manual for

proper procedures to disconnect power to 52S units.

CLEANING AND SAFETY

Before starting to clean a unit, read the instructions

thoroughly and gather the necessary tools for the job.

Review all safety information on unit and in literature.

Consider the following safety issues before

beginning:

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety glasses

and work gloves, should be used.

• The floor around the work area should be clean and

free of debris.

• The 52S unit weighs up to 150 pounds. Use a lifting

device or ask for assistance if the unit must be moved.

• Make sure tools are the correct tools for the job,

and that they are working properly and in good

condition.

ON

OFF

WALL SLEEVE

CHASSIS

FRONT COVER

FIGURE 21 — FRONT PANEL, CHASSIS, AND SLEEVE

10

Page 11

TOOLS NEEDED

The following list includes the recommended tools, devices, and cleaning solutions for use in cleaning the 52S

unit components.

Vacuum Cleaner with Crevice Tool Attachment,

Lifting Device (or another person for assistance)

Trigger Spray Extension Tube (Part No. P9029000)

Vent Air Filter Replacement (Part No. 52SQ500204)

Condenser Coil Cleaning Solution (Part No. P9020501)

Evaporator Coil Cleaning Solution (Part No. P9021001)

3% Solution of Hydrogen Peroxide in Spray Bottle

or Soft Plastic Bristle Brush

Mild Household Detergent

Phillips Head Screwdriver

5

⁄16-in. Nut Driver

Flat Head Screw Driver

Tank Sprayer (Part No. P9021001) or

Compressed Air Tank

Clean Water Supply

Indoor Air Filter Replacement

(Part No. AIR-FILTER-25PAK)

9.5-in. by 9.5-in. Piece of Clean Cardboard

Clean Cloth

Safety Glasses

Protective Gloves

MONTHLY CLEANING

n AIR FILTERS — The indoor and vent air filters should

be cleaned once per month. Filters that are not cleaned

become clogged and will restrict airflow. This may lead

to major component damage. If a filter becomes torn, has

holes, or other damage, replace it with a new one. Replacement filters are available through Carrier Finished

Goods and Carrier Replacement Component Division.

n CLEANING THE INDOOR AIR FILTER — Remove

the indoor air filter as follows:

1. Remove the front panel to access the indoor air filter.

To remove front panel, grasp panel firmly near the

top of each side. Lift upward and pull forward. It is

not necessary to use excessive force. See Figure 1.

2. To remove the indoor air filter, gently grasp the

2 filter tabs, push down, and pull out. See Figure 22.

Once the indoor air filter has been removed, use a

vacuum cleaner, or a soft bristle brush and a small

amount of mild dish detergent to gently wash the

filter. If detergent is used, remove detergent residue with

a gentle, clean water stream. Let the filter air dry. Be

sure to reinsert the filter into the unit.

FIGURE 22 — REMOVING FILTER

n REPLACING THE INDOOR AIR FILTER — Access

and remove indoor air filter as detailed above in Cleaning the Indoor Air Filter. Use a filter replacement with

the Carrier Part No. AIR-FILTER-25PAK, available

through Carrier Finished Goods and Carrier Replacement Component Division.

11

Page 12

52S

SERIES

n CLEANING THE VENT AIR FILTER

1. Remove the unit chassis from wall sleeve as described

in the General Disassembly section of this manual.

See Figure 6.

2. Swing open vent door. The filter is located directly

behind the vent door. See Figure 23.

3. Remove the vent air filter by gently pushing on the

filter slot.

Once the vent air filter is removed, it may be cleaned

using either a vacuum cleaner, or a soft bristle brush

and a small amount of mild dish detergent. If detergent is used, remove detergent residue with a gentle,

clean water stream. Let the filter air dry. Be sure to reinsert the filter into the unit.

n REPLACING THE VENT AIR FILTER

Access and remove the vent air filter as detailed above

in Cleaning the Vent Air Filter. Use a filter replacement

with the Carrier Part No. 52SQ500204, available

through Replacement Components Division.

n CHASSIS

As-needed cleaning of the unit’s exterior surfaces

(Figure 24) optimizes the unit’s appearance and removes

particles that may enter the air system. The 52S units

are built to resist corrosion. The indoor front panel

and wall sleeve are created from non-metallic compounds

that do not rust. Additional corrosion protection may

be factory installed on the partition, control box, and outside coil for use in highly corrosive environments. Mild

detergents reduce electrostatic charges on plastic sections on the grille and are good cleaners. Use such detergent cleaners sparingly.

Use a clean cloth or brush to gently wipe exterior surfaces. Be careful not to push dirt or other fibers into the

unit’s interior.Accessible sleeve surfaces should also

be wiped clean.

VENT

FILTER

VENT

DOOR

FIGURE 23 — ACCESSING VENT AIR FILTER

FIGURE 24 — UNIT FRONT PANEL AND SLEEVE

12

Page 13

SEASONAL CLEANING

n ACCESSING THE INDOOR AND OUTDOOR

COILS — The minimum cleaning recommendation for

indoor and outdoor coils is once per season. To access

the coils for a thorough cleaning, it is necessary to

remove the Air System. To accomplish this task, perform the following steps:

1. DISCONNECT ALL POWER TO UNIT!

2. Remove the unit chassis from the sleeve as described

in the General Disassembly section of this manual.

See Figure 6.

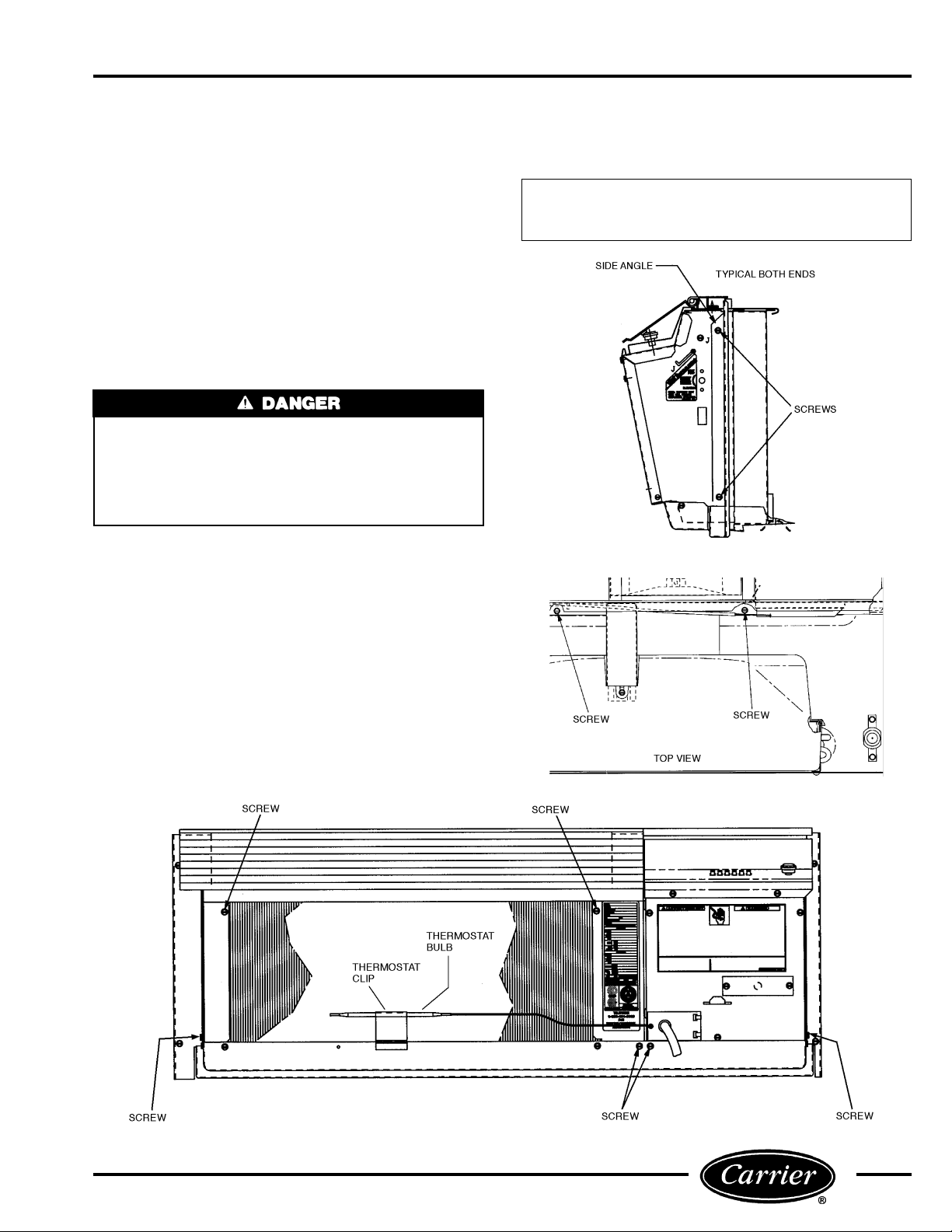

3. Remove each side angle from unit with a

driver. See Figure 25.

4. Locate and disconnect wires from the compressor.

Label each wire for easy reassembly.

For compressors that are known to be damaged: Remove refreigerant prior to disconnecting

compressor wires. Damaged hermetic compressor terminals may become loose and eject from the compressor. Wear safety glasses and keep your face away

from the area above the terminals when removing

compressor wires.

5. For Heat Pump Units — Disconnect the wire plug

on the reversing valve and carefully remove the outdoor thermostat capillary from the outdoor coil.

6. With a

8 screws mounting the fan section to the chassis. See

Figures 26 and 27.

5

⁄16-in. nut driver, locate and remove the

7. Using a flat head screw driver, gently pry the plastic

condenser orifice tabs away from both outdoor coil

tube sheets and pull the condenser orifice away as

shown in Figure 19. See GENERAL DISASSEMBLY

section.

8. Carefully remove the fan section from the chassis

by lifting fan section straight up and out. The fan

deck is awkward; 2 people may be needed for its

removal.

5

⁄16-in. nut

9. Remove the stator from the outdoor coil. See

GENERAL DISASSEMBLY section. After cleaning,

reassemble by reversing steps1-8.

IMPORTANT: During reassembly of the fan section,

carefully align the rubber seal around the tubing where

it passes through the partition.

FIGURE 25 — SIDE ANGLE SCREWS

FIGURE 26 — PARTITION FLANGE SCREWS

FIGURE 27 — FAN SECTION SCREW LOCATIONS

13

Page 14

52S

SERIES

n CLEANING THE INDOOR AND OUTDOOR COILS

Coil fins are sharp and may cut hands. Wear heavy

protective gloves when cleaning coils.

1. Use a vacuum cleaner or soft bristle brush to remove

surface fibers and dirt from each of the faces of the

coil. Both the inner and outer surfaces of the coils

must be cleaned. It is important to apply the tool in

the same direction of the fins, not against them.

Applying the tool against the fins may cause damage

(fin edges may bend over).

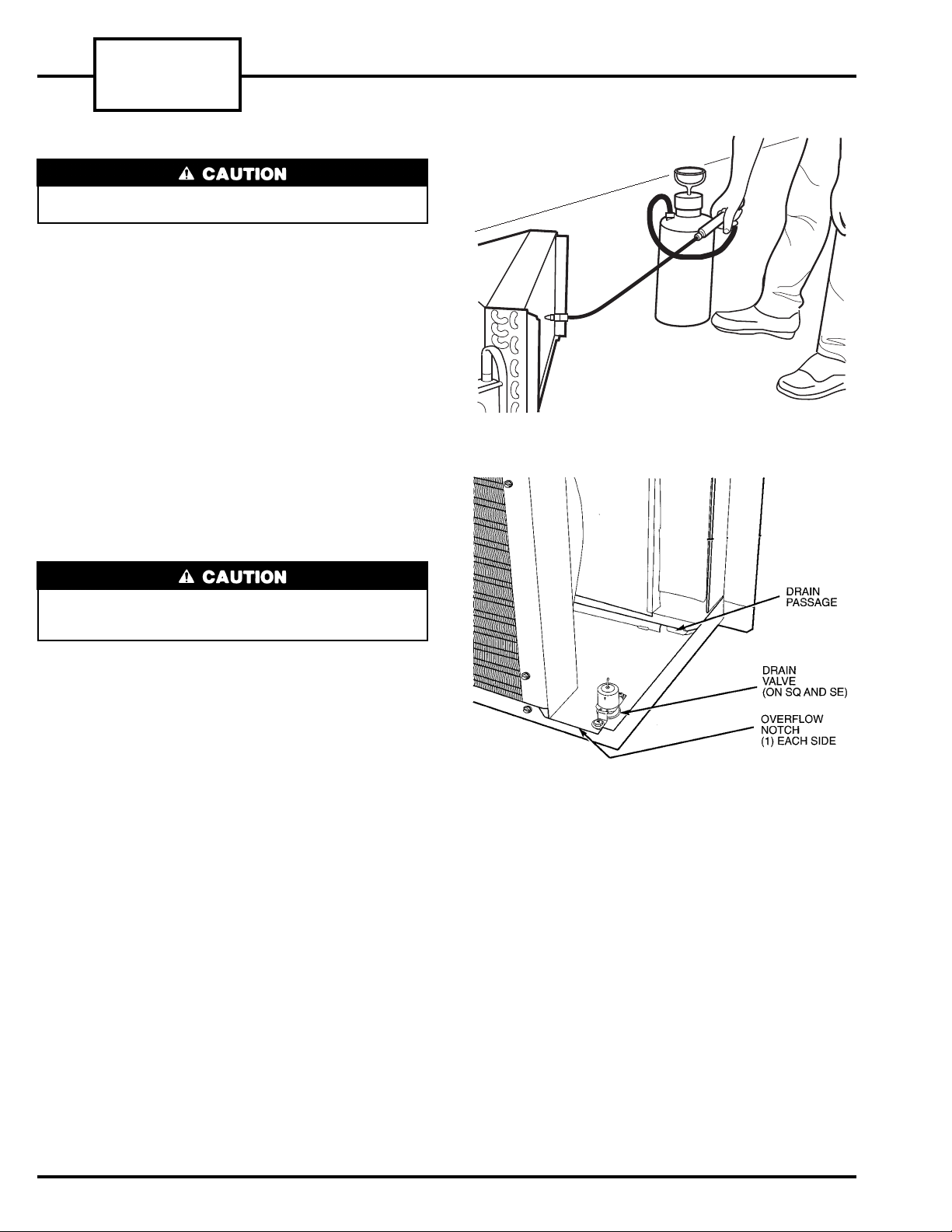

2. With a tank sprayer or a trigger spray extension tube,

spray coil cleaning solution evenly across the coils,

making sure coils are thoroughly saturated. See

Figure 28. Refer to instructions on the cleaning solution containers for best results. Do not use a high

pressure sprayer.

3. Rinse the coils thoroughly with low-velocity, clean

water.

4. Repeat steps 2 and 3.

5. Drain water and cleaning solution that may have

collected in the basepan during the cleaning process by carefully tilting the chassis. This allows

excess water to flow out of the overflow notches.

FIGURE 28 — CLEANING THE COILS

Do not set unit on end to drain water from basepan,

or at any other time. Oil will drain from the compressor sump, which could cause compressor failure.

6. Thoroughly clean the basepan and drain passages

by rinsing with clean water. Be sure all debris is removed from the drain valve. See Figure 29.

7. Allow unit components to air dry before reassem-

bling the unit. Once dry, reassemble by reversing

Steps1-9from the Accessing Indoor and Outdoor

Coils section.

n ACCESSING THE INDOOR FAN AND INDOOR

FAN SCROLL — Dried debris and build-up on the

blower wheel and blower scroll can reduce the efficiency

of the unit. To properly access the indoor fan and indoor fan scroll for cleaning, refer to the GENERAL

DISASSEMBLY section under To Access Indoor-Air

Section Components on page 6.

FIGURE 29 — BASEPAN SECTION

14

Page 15

n CLEANING THE INDOOR FAN AND FAN

SCROLL — Once the indoor fan wheel and the indoor

fan scroll have been accessed, proceed with the cleaning

instructions detailed below:

1. Insert a piece of 9.5-in. by 9.5-in. cardboard between

the blower wheel and the opening in the blower scroll

to prevent fungus and other debris from falling into

the coil.

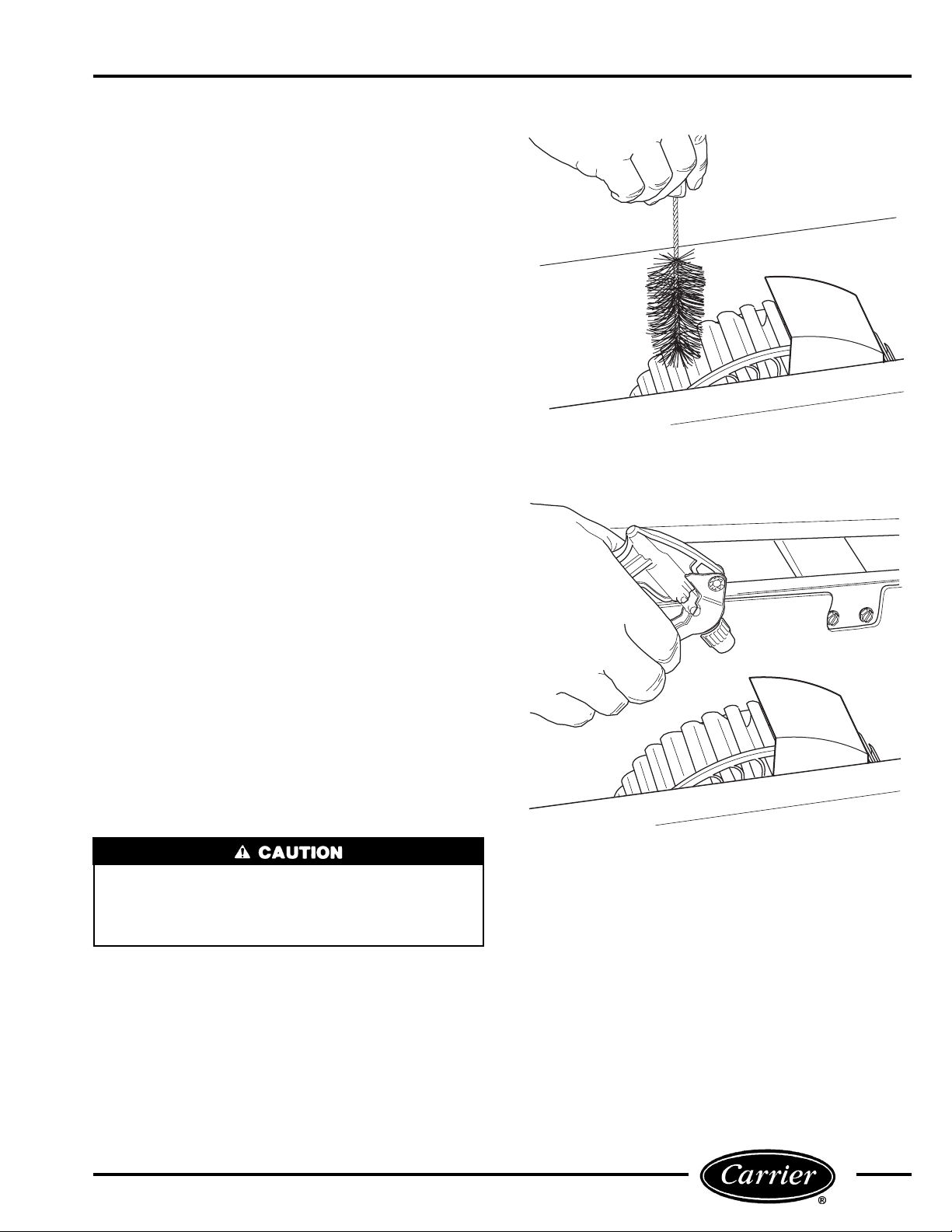

2. Bend a soft, spiral wound, long bristle brush, to con-

form to the inner curve of the blower wheel blades.

See Figure 30.

3. Insert the brush into every blower wheel blade and

gently brush out dried material.

4. Clean the walls of the blower scroll by carefully brush-

ing with the bristle brush. Vacuum loose debris that

may have fallen into the bottom of the scroll during the cleaning process.

5. Use the spray bottle to spray the blower wheel blades

and the inner surface of the blower scroll with a 3%

solution of hydrogen peroxide to kill any fungus

spores. Wipe up excess solution in the bottom of the

blower scroll with a clean cloth. See Figure 31.

6. Reassemble components by reversing the steps used

to disassemble the unit as detailed in the GENERAL

DISASSEMBLY section under To Access Indoor-

Air Section Components.

n ACCESSING THE HEATER ASSEMBLY — To access

the heater assembly for cleaning, perform the following steps:

1. DISCONNECT ALL POWER TO THE UNIT.

2. Remove the unit front panel, the discharge air grille,

and the discharge air deck as described and shown

in Figure 1 and the GENERAL DISASSEMBLY

section.

3. Once the discharge air deck is removed, the heater

assembly is accessible.

n CLEANING THE HEATER ASSEMBLY — Once the

heater assembly is accessed, use compressed air to blow

off any dust that has accumulated on the heater coils.

Do not direct the air at the bi-metal discs of the temperature limit switches. Reassemble the unit by reversing

Steps1-3.

FIGURE 30 — CLEANING INDOOR FAN

AND FAN SCROLL

Do not touch the heater coils or the temperature limit

switches. Touching or depressing the bi-metal discs

on the temperature limit switches may affect the set

point or cause the secondary temperature limit

switch to electrically open, requiring it to be replaced.

FIGURE 31 — SPRAYING BLOWER WHEEL BLADES

15

Page 16

52S

SERIES

COMPRESSOR

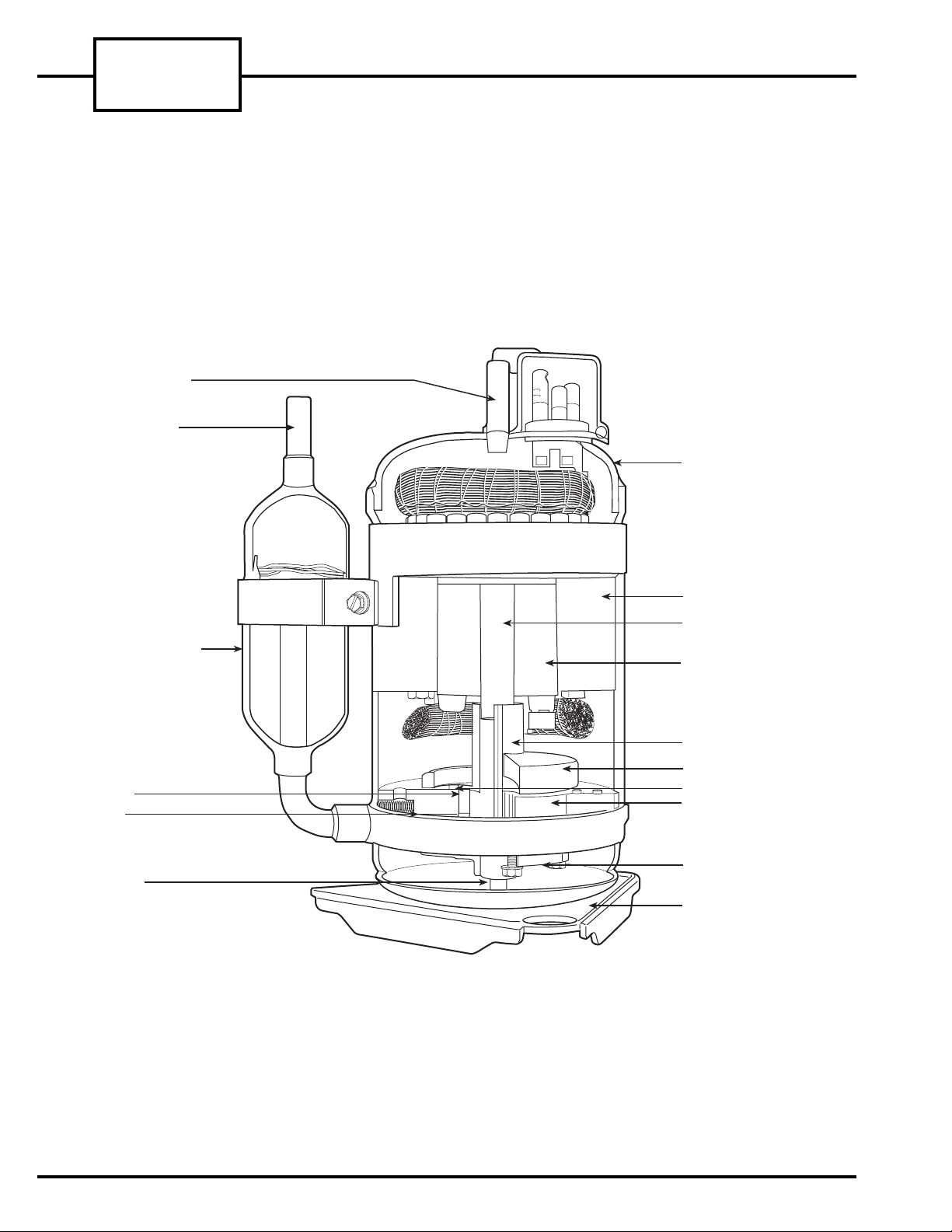

A cutaway view of the rotary compressor with key components labeled is shown in Figure 32. The motor stator is rigidly attached to the compressor shell. The rotor

is pressed onto the eccentric shaft, which is supported

by 2 bearings. Both the discharge valve and discharge

muffler are attached to the motor bearing. The pump

DISCHARGE TUBE

SUCTION INLET

SUCTION MUFFLER/

ACCUMULATOR

bearing provides a thrust surface for the shaft and the

rolling piston. Compressed gas is separated from the

suction gas by the vane. Discharge gas pressure and the

vane spring keep the vane in contact with the rolling

piston.

SHELL

STATOR

ECCENTRIC SHAFT

ROTOR

PISTON

VANE

OIL TUBE

MOTOR BEARING

DISCHARGE MUFFLER

DISCHARGE VALVE

CYLINDER

PUMP BEARING

MOUNTING PLATE

FIGURE 32 — ROTARY COMPRESSOR COMPONENTS

16

Page 17

The rotary compression process (Figure 33), starts at

top dead center as shown in (1). Suction gas flows

through the suction inlet and into the cylinder area. As

the shaft rotates through 90 degrees, the rolling piston moves to position A as shown in (2). The suction volume is now the area defined by point A and the tip of

the vane. Gas in the remaining volume has been compressed above suction pressure. After another 90 degrees

of shaft rotation, the rolling piston has moved to position B as shown in (3). Both the compressed gas and

suction gas volumes are now equal. Another 90 degrees

of shaft rotation is shown in (4). Compressed gas has

reached a pressure sufficient to open the discharge valve,

and flows from the cylinder into the compressor shell.

After another 90 degrees of shaft rotation, the entire

process begins again. Continuous suction and discharge

allows for a smooth compression process.

The rolling piston is not in actual contact with the cylinder wall, vane, or bearing faces. Hydrodynamic

sealing prevents leakage from the compressed gas volume to the suction volume via these paths. Precise control of machining tolerances, surfaces, finishes, and

assembly clearances is critical to achieve high efficiency

performance. In addition, the line contact between the

vane tip and the rolling piston requires careful selection

and control of materials to provide wear resistance and

reliable long-term operation.

COMPRESSOR TROUBLESHOOTING

Refer to Figure 34 for a basic compressor troubleshooting chart.

BASIC HERMETIC COMPRESSOR

ELECTRICAL MEASUREMENTS

There are 2 basic electrical tests for hermetic compressors that will determine the electrical state of the motor. The first test requires checking the electrical

resistance of each of the electrical motor windings. The

second test requires checking the electrical resistance

of each of the electrical motor windings to ground. These

tests may be accomplished by performing the following

steps:

1. DISCONNECT ALL POWER TO THE UNIT.

2. Remove the unit chassis from the sleeve as detailed

in the GENERAL DISASSEMBLY section.

3. Open the control box as detailed in the GENERAL

DISASSEMBLY section, then locate, label, and remove the 3 compressor wires from the following locations: the RUN wire (BLACK) from the capacitor,

the START wire (BLUE) from the capacitor. The third

wire, COMMON wire (YELLOW) may be connected

to one of the following locations: for SC units the

wire is on the indoor thermostat, for SE Remote

Control Units the wire is on the indoor frost thermostat, for all other SE Units the wire is located

on the push button switch, for ALL SQ Units the

wire is on the outdoor frost thermostat.

FIGURE 33 — ROTARY COMPRESSOR

COMPRESSION PROCESS

For compressors that are known to be damaged: Remove refrigerant prior to disconnecting com-

pressor wires. Damaged hermetic compressor

terminals may become loose and eject from the compressor. Wear safety glasses and keep your face

away from the area above the terminals when removing compressor wires.

4. To measure the resistance between the windings of

the compressor motor, use a volt-ohmmeter set to

the lowest ohm reading level then read and record

the resistance between the RUN and START, START

and COMMON, and RUN and COMMON wires.

See Figure 35. The typical resistance readings will

be about 4, 3, and 1 ohms respectively. The smaller

values should add to equal the larger value. If this is

not true then the compressor is likely shorted winding to winding.

NOTE: The rotary compressor has the compressor overload located under the terminal cover. If the overload

is open it can show ohm readings that are infinite. The

unit should be off for at least an hour to give this overload time to reset if it is open.

17

Page 18

52S

SERIES

SYMPTOM

POSSIBLE CAUSE

g

f

COILS/FILTERS DIRTY OR PLUGGED X

AIR OR NONCONDENSABLE GASES

SYSTEM REFRIGERANT OVERCHARGED X X

DISCHARGE LINE RESTRICTED XX

CAPILLARY TUBE OR STRAINER

RESTRICTED OR PLUGGED

FAN BLADE OR MOTOR DEFECTIVE X X

FAN BLADE OR BLOWER WHEEL STUCK X X

SYSTEM REFRIGERANT UNDERCHARGED X X

EVAPORATOR AIRFLOW RECIRCULATION X

UNIT OVERSIZED FOR APPLICATION X

COMPRESSOR REQUIRES START ASSIST XX

OVERLOAD PROTECTOR OPEN X

OVERLOAD PROTECTOR INCORRECT

CAPACITOR INCORRECT OR DEFECTIVE XXX X

THERMOSTAT CONTACTS ARE OPEN X

THERMOSTAT IS SET TOO HIGH OR LOW X

SELECTOR SWITCH IS OPEN

WIRING IS INCORRECT OR DEFECTIVE XXXX

SYSTEM PRESSURES NOT EQUALIZED XX X

COMPRESSOR MOTOR OR

COMPRESSOR GROUNDED X

IN SYSTEM

NO POWER TO UNIT X

LOW VOLTAGE TO UNIT XXX X

OR DEFECTIVE

OR DEFECTIVE

MECHANISM DEFECTIVE

COMPRESSOR

STARTS AND

RUNS BUT

CYCLES ON THE

OVERLOAD

XX

XX X

XXX

XXXXX

COMPRESSOR

STARTS AFTER

CYCLING THE

OVERLOAD

SEVERAL TIMES

COMPRESSOR

WILL NOT

START. IT HUMS

AND CYCLES ON

THE OVERLOAD

COMPRESSOR

WILL NOT START

AND MAKES NO

NOISE

X

COMPRESSOR

CYCLES OFF

(NOT ON

OVERLOAD)

FIGURE 34 — BASIC COMPRESSOR TROUBLESHOOTING GUIDE

18

Page 19

5. Next, test the resistance individually of each wire to

the shell of the compressor. The paint on the compressor can prevent good contact between the probe

and the metal. The paint should be removed from

a small section of the shell of the compressor to ensure

good contact by the meter probe. The volt-ohmmeter

should be set to at least the 100X ohm level. The

measured resistance between each wire and ground

should be infinite or O.L. on the readout. If there

is measurable resistance one of the windings is likely

shorted to ground. See Figure 36.

6. A compressor that has a winding to winding short or

a winding to compressor shell short is electrically

failed and needs to be replaced. See the Compres-

sor Replacement section for details.

COMPRESSOR REPLACEMENT

Before working on the compressor, read the instructions

thoroughly and gather the necessary tools for the job.

Review all safety information on unit and in literature.

Always turn off all power to unit to avoid the possibility of electrical shock.

Consider the following safety issues before

beginning:

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as work gloves

and safety glasses, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job

and that they are working properly and in good

condition.

• Never replace a blown fuse without correcting the

cause of the original failure. If thermally operated circuit breakers or overloads are tripping, make sure

the trip is not due to excessively high temperatures

or loose connections.

• When brazing suction and discharge lines, cool the

lines with a damp, clean cloth to prevent injury.

• Oil may be present in the compressor accumulator

and interconnecting tubing. Use caution when removing tubing.

FIGURE 35 — SHORTED/OPEN WINDINGS TEST

FIGURE 36 — GROUNDED WINDINGS TEST

For compressors that are known to be damaged: Remove refrigerant prior to disconnecting com-

pressor wires. Damaged hermetic compressor

terminals may become loose and eject from the compressor. Wear safety glasses and keep your face

away from the area above the terminals when removing compressor wires.

n TOOLS NEEDED — The following list includes the

recommended tools and devices for removing and replacing the compressor.

1

⁄2-in. and3⁄8-in. Tube Benders

1

⁄2-in. Nut Driver

5

⁄16-in. Nut Driver

Flat Head Screwdriver

Piercing Valve

2 Parker Access Valves (Part No. AVUSE-5)

Pinch Off Tool

Filter Drier for 52SQ Units (Part No. Sporlan C-164S)

Filter Drier for 52SC or SE Units (Part No. KH43LG060)

Carrier TOTALTESTT Kit (Part No. TT1-001)

TotalclaimT System

Charging Cylinder or an Electronic Scale

Refrigerant-22

Tubing Cutter

Torch

Nitrogen Cylinder with Regulator

19

Page 20

52S

SERIES

n REMOVING THE COMPRESSOR — Follow the steps

below to remove the compressor:

1. Disconnect all power to unit.

2. Remove unit from wall sleeve as detailed in the

GENERAL DISASSEMBLY section. The unit

weighs up to 150 pounds. Seek assistance or use a

lifting device when removing unit from wall sleeve.

3. If the unit is a heat pump: Disconnect the wire

plug on the reversing valve solenoid and carefully

remove the outdoor thermostat capillary from the

outdoor coil.

4. Attach the piercing valve to the suction side pro-

cess tube below the crimps. Attach Carrier

TOTALTESTt kit (Part No. TT1-001), to the piercing valve to verify acidity of the system. After

verifying the system acidity, attach the Totalclaimt

System to the access port to remove and clean the

refrigerant.

5. When all the refrigerant has been recovered, re-

move the terminal cover from the compressor with

a nut driver. Disconnect the 3 wires from the

compressor and label the location of each. Once the

wires are labeled, replace the terminal cover to

protect the compressor terminals.

6. Remove the air system assembly by following the

procedure detailed in the SEASONAL CLEANING

section under Accessing the Indoor and Out-

door Coils.

7. Remove the piercing valve and cut the crimped por-

tion of both process tubes off with a small tubing

cutter. Braze a Parker access valve on each process

tube. Using a torch, disconnect the suction and

discharge tubes from the compressor connections.

8. Remove the compressor mounting bolts, and remove

the compressor.

FIGURE 37 — STRAINER AND LIQUID TUBE

52mm

CUT HERE

The compressor may still be hot from the brazing

process.

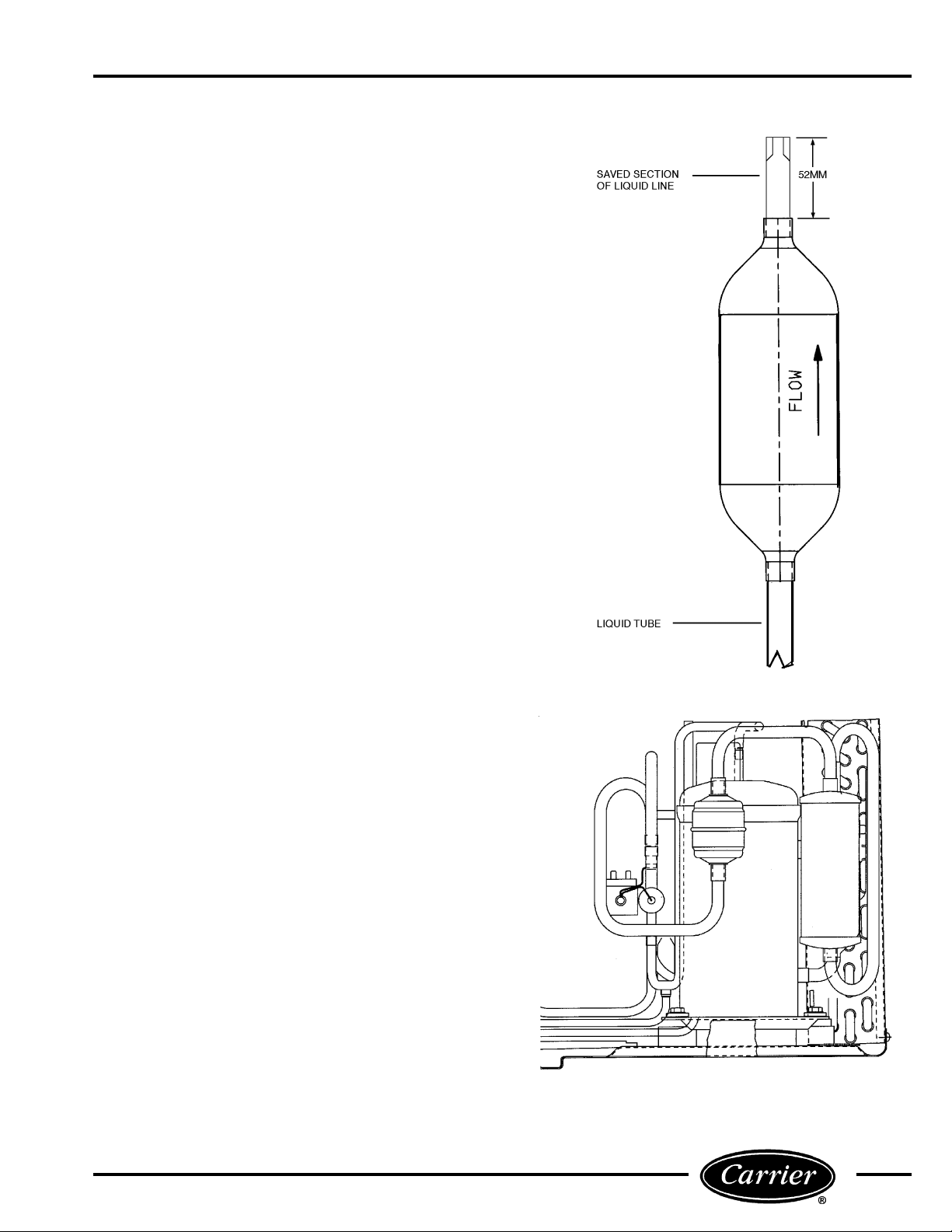

9. For Cooling Only units and Heat/Cool Units:

Remove the strainer and capillary tubes from the

system. A Cooling Only or Heat/Cool unit will have

one strainer located in the liquid line between the

outdoor coil and the capillary tube. The strainer may

be an external bulb type or a tube inserted type.

The tube inserted type must be cut out with a tubing cutter. Remove and save the section of liquid

line tube that was connected to the capillary tube.

Remove and discard the strainer. See Figures 37

and 38.

STRAINER

OUTDOOR COIL

CONNECTOR

TUBE

FIGURE 38 — TUBE INSERTED STRAINER

20

Page 21

10. For Heat Pump Units remove the capillary tube

only.

11. For Heat/Cool Units the filter drier is installed in

the liquid line, in place of the strainer. Trim the

saved liquid line tube from Step 9, to be 1.5 in. long

(saving the crimped portion), and braze it into the

filter drier, Part No. KH43LG060. See Figure 39.

For Heat Pump Units: A suction line filter drier

(Part No. Sporlan C-164S) is used and is installed

between the reversing valve and the compressor accumulator. There are several suction

tube configurations and the suction line filter drier

will be field piped and brazed into the suction

tube for your unit. See Figure 40 for a general installation view.

12. Remove the grommets from the existing compressor

and install them onto the new compressor.

13. Install the new compressor and the new capillary

assembly (the correct capillary may be obtained

from Carrier RCD), into the unit.

14. Leak check the unit with 150 psi of nitrogen

pressure.

15. For 52S units, the system should be evacuated from

the high side to the low side to a minimum of

200 microns of mercury. This evacuation removes

residual moisture from the system prior to charging.

16. For Heat Pump Units: Recharge unit to the name-

plate refrigerant charge using a charging cylinder.

For Cooling Only and Heat/Cool Units: Add

one ounce of refrigerant to the nameplate charge to

compensate for the size of the liquid line drier.

17. Pinch off each access valve on the process tubes, in

2 places, using a pinch off tool such as Imperial tool

#105-FF or Robinair Tool #12294. Release any refrigerant pressure trapped in the access valve by

depressing the valve core, then confirm that no

R-22 is leaking past the pinch off tool location. Cut

the access valve stem of the process tube above

the top crimp and braze the top of each process tube

to ensure the system is sealed, (leave the pinch off

tool in place until after the brazing process is

complete).

18. Reassemble the unit by reversing steps1-9.

19. Connect the compressor wires and energize the unit

to verify operation.

n REFRIGERANT CHARGING — Every mechanical

refrigeration system that is opened for servicing must

be accurately charged before it is returned to service.

Run the compressor ONLY after charging the system

with refrigerant. The compressor should never be

operated on air!

It is important to remember that recovered and/or recycled refrigerant may only be recharged into the system

from which it was initially recovered, or another one

owned by the same customer. Charge level is important.

Charge units only as recommended by manufacturer.

FIGURE 39 — INSTALLED FILTER DRIER

21

FIGURE 40 — SUCTION LINE FILTER DRIER

Page 22

52S

SERIES

HEATERS

The heater in 52S units is located directly behind the

evaporator coil. The heater assembly includes the heater

(2.3 kW, 3.4 kW or 5 kW), a primary limit switch, and

a secondary limit switch (Figure 41). The primary and

secondary limit switches are safety switches that

regulate heater operation. The primary limit switch disables current to the heater when the temperature exceeds the setting on the switch.

For example, a 3.4 kW heater may have a primary limit

switch setting of 150 F.If the temperature at the switch

exceeds 150 F, the primary limit switch will electrically

open and shut off power to the heater. Once the temperature drops below 110 F, the primary limit switch will

automatically reset.

The secondary limit switch works in the same manner

as the primary limit switch, except it is a one time switch

and has a slightly higher temperature setting. Once

this switch is thermally opened, it must be replaced. Together the primary and secondary switches help maintain safe temperature limits for unit operation.

COMMON CAUSES OF

HEATER FAILURE

Heater failure may result from broken heater coils, primary limit switch failure, or an open secondary limit

switch. These conditions are generally caused by low or

no airflow.

HEATER REMOVAL

Before working on the heater, read the instructions

thoroughly and gather the necessary tools for the job.

Review all safety information on the unit and in the product literature.

Before performing any cleaning, servicing, or maintenance to the unit, Disconnect All Power to avoid

the possibility of electric shock and personal injury.

The manufacturer reserves the right to discontinue, or

change at any time, specifications or designs without

notice and without incurring obligations.

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical equipment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety glasses

and work gloves, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job,

and that they are working properly and in good

condition.

FIGURE 41 — LIMIT SWITCH LOCATION

n TOOLS NEEDED — The following list includes rec-

ommended tools and devices for working on the heater

section of 52S units.

Phillips Head Screw Driver

Needle Nose Pliers

Volt-ohmmeter

Nut Drivers,

Perform the following steps to remove the Heater

Assembly.

5

⁄16-in. and1⁄4-in.

1. DISCONNECT ALL POWER TO UNIT.

2. Remove the front panel of the unit by grasping panel

on each side, lifting upward and out. See Figure 1.

22

Page 23

3. Remove the unit from the sleeve as detailed in the

GENERAL DISASSEMBLY section.

4. Remove the discharge air grille and the discharge air

deck as detailed in the GENERAL DISASSEMBLY

section. Save screws.

5. Once the air discharge deck is removed, the heater

assembly is exposed. After noting positions of wires

and labelling them, use a pair of needle nose

pliers to carefully remove the wires connected to the

heater assembly.

6. Remove the two

1

⁄4-in. screws mounting the heater

assembly to the inside of the partition. Save the

screws. See Figure 42.

7. Remove the heater assembly (Figure 43).

Examine the heater as follows to determine if it is

operational:

Perform a visual inspection. The heater coil should be

free of breaks. If there are any breaks in the coil, replacement of the heater assembly is necessary.

Coil resistance must also be checked to verify the heater

is operating correctly. The resistance of the heater coils

must meet approximate levels for the heater to perform at its optimum efficiency. See Figure 44 for approximate resistance for heaters at 75 F. Before checking

the heater coil resistance, be sure all power to unit

is off.

To check resistance, set the volt-ohmmeter selector

switch to the lowest ohms value. Next connect the voltohmmeter leads to each side of the heater coil at the

studs that hold the limit switches in place. Incorrect

readings can be obtained if the wires are not removed

from the limit switches on the heater assembly. If the

resistive reading is infinite or zero, the heater is failed

and replacement is necessary. Reinstall the heater

assembly by reversing steps1-7.

SCREWS (2)

FIGURE 42 — REMOVING HEATER SCREWS

FIGURE 43 — HEATER REMOVED

HEATER SIZE WATTS VOLTS

2.3 kW

3.4 kW

5.0 kW

2300 230 20 - 23

2300 265 28 - 31

3400 230 13 - 16

3400 265 19 - 21

5000 230 9 - 11

5000 265 13 - 15

ACCEPTABLE RESISTANCE

(Ohms)

23

FIGURE 44 — ACCEPTABLE HEATER

RESISTANCE VALUES

Page 24

52S

SERIES

OPERATING CONTROLS

The controls and components used in the 52S cooling

only or heat/cool units are as follows: the selector

switch, the indoor thermostat, the dual capacitor, the

temperature limiter, the vent lever, and the fan cycle

switch (Figure 45).

The selector switch is used to determine the mode of operation: heat, cool, fan, or off. The indoor thermostat

controls the room ambient temperature and cycles the

heater or the compressor based on the selector switch

setting. The dual capacitor aids in the start-up of the

compressor and the fan motor. The temperature limiter

is mounted on the thermostat under the escutcheon.

It is a mechanical device that restricts the amount of rotation of the thermostat. The temperature limiter device may be adjusted by moving the plastic temperature

selector tabs to another temperature location on the

device. The vent lever is located in the upper right corner of the control box. It is a slide mechanism that

opens and closes the vent door. The control may be accessed by removing the front panel of the unit. The fan

cycle switch is used to provide 2 options of fan control.

The first option, CON, causes the fan to run continuously.

The second option, CYC, causes the fan to cycle on

when venting, heating, or cooling is requested and off

when the thermostat is satisfied.

The 52S heat pump unit contains all the components

of the heat/cool and cooling only unit, and the following additional ones: the outdoor frost thermostat and the

reversing valve. The outdoor frost thermostat prevents

operation of the unit in the heat pump mode when the

outdoor coil temperature drops below 15 F, or at about

30 to 35 F outdoor ambient temperature (about 40 to

45 F outdoor ambient temperature for 1999 models). The

unit automatically engages the electric heat strip under these conditions.

The outdoor frost thermostat has a manual override to

place the unit in electric heat mode operation only.

The override switch is located behind the front panel on

the right side of the unit control box. Placing the override switch into electric heat mode operation will dis-

able the compressor for ALL heating or cooling operations.

The reversing valve allows for operation in reverse cycle

heat pump mode. The valve is located in the piping system and is controlled by the reversing valve solenoid

coil. The coil is energized only during the heating mode.

For 52S remote control (RC) units, all controls are

located on the wall mounted thermostat except the vent

lever and outdoor thermostat. Remote control is a

factory-installed option only. There are 2 styles of thermostats qualified for use with 52S series Remote Control units. See Figures 46 and 47. For all other 52S units,

room controls are located on the unit or unit control

panel. Remote control units do not have a fan cycle

switch.

See Figure 48 for sample control panels and Figure 49

for controls locations.

FIGURE 45 — TYPICAL 52S UNIT

OPERATING CONTROLS

FIGURE 46 — MANUAL THERMOSTAT

RCD P/N TSTATCCPAC01-A or TSTATCCPHP01-A

FIGURE 47 — PROGRAMMABLE THERMOSTAT

24

Page 25

DESCRIPTION OF SWITCH SETTINGS

NON-USER ADJUSTABLE SWITCHES

n OFF BUTTON — The OFF button terminates unit

operation.

n FAN ONLY BUTTON — Push button for air circula-

tion without heating or cooling.

n HIGH HEAT OR HIGH COOL — Push button and

rotate temperature knob to desired comfort level. This

function provides maximum heating or cooling, and is

recommended to raise or lower the room temperature

quickly.

n LOW HEAT OR LOW COOL — Push button and ro-

tate the temperature knob to desired comfort level.

This function provides minimum heating or cooling with

maximum dehumidification. This setting also allows

for very quiet fan operation.

n FINDING TEMPERATURE SETTING FOR COM-

FORT LEVEL — Set temperature knob between number 5 and number 6. Push High or Low Heat or Cool

button and allow unit to run for 15 to 30 minutes. If room

is not comfortable, turn knob one number setting at a

time. When room is comfortable, keep control knob at

that position.

A. 52S COOLING ONLY UNIT

n OUTSIDE OR VENT AIR — Push the FAN ONLY

button and slide vent lever to OPEN position.

n FAN CYCLE — The fan cycle switch allows the fan to

operate in 2 modes:

CON — Fan runs continuously, circulating air even when

the temperature setting has been satisfied. This helps

to maintain the room temperature closer to the thermostat setting.

CYC —Fan cycles on and off with the compressor during heating or cooling. Fan stops when the temperature

setting is satisfied. This results in longer unit off-time

and slightly larger variations in room temperature and

humidity.

Units built after the start of 1996 incorporate singlepole, double-throw fan cycle switches that have only 3

terminals. Units built prior to 1996 incorporate a doublepole, double-throw fan cycle switch with 6 terminals

and a thermostat bulb heater. The additional terminals

control the thermostat bulb heater.

n OUTDOOR THERMOSTAT (52SQ Units Only) —

The outdoor thermostat has 2 operating modes. The heat

pump mode (selector screw set fully clockwise), allows

the unit to operate normally in the reverse cycle mode.

The electric heat mode (selector screw set fully counterclockwise), disables all compressor operating modes,

both heating and cooling.

VENT

LEVER

B. 52S COOLING/HEATING UNIT

C. 52S COOLING/HEATING UNIT

WITH REMOTE CONTROL (BLANK PLATE)

FIGURE 48 — SAMPLE CONTROL PANELS

CLOSED

VENT

OPEN

HEAT

PUMP

ELECTRIC

HEAT

CON

CYC

OUTDOOR

THERMOSTAT

(ON HEAT

PUMP ONLY)

FAN CYCLE

SWITCH

(NOT ON RC

UNITS)

FIGURE 49 — CONTROLS LOCATION

25

Page 26

52S

SERIES

SEQUENCE OF OPERATION

n HEAT/COOL UNITS

(Figure 50)

Fan Mode — With the selector switch set to FAN and

the fan switch set to fan cycle, contacts L1 to LO and

FCS1 to LS are made.

Cooling (Low) — With the selector switch set to low

speed cooling and the fan switch set to fan cycle, contacts

FCS2 to LO, COMP to FCS1, and COMP to IT3 are

made.

NOTE: The contact in low cooling sequence of operation

for FCS2 is MED on units built prior to 1996.

Cooling (High) — With the selector switch set to high

speed cool and the fan switch set to fan cycle, contacts

FCS2 to HI, COMP to FCS1, and COMP to IT3 are made.

Heating (Low) — With the selector switch set to low

speed heat and the fan switch set to fan cycle, contacts

FCS2 to LO, IT1 to LS, L2 to HTR, and FCS1 to LS

are made.

NOTE: The contact in low heating sequence of operation

for FCS2 is MED on units built prior to 1996.

Heating (High)

speed heat and the fan switch set to fan cycle, contacts FCS2 to HI, IT1 to LS, L2 to HTR, and FCS1 to

LS are made.

SWITCH

POSITION

OFF FCS TO LS

FAN L1 TO LO*, FCS1 TO LS

LO HEAT FCS2 TO LO, IT1 TO LS, L2 TO HTR, FCS1 TO LS

HI HEAT FCS2 TO HI, IT1 TO LS, L2 TO HTR, FCS1 TO LS

LO COOL FCS2 TO LO, COMP TO FCS1, COMP TO IT3

HI COOL FCS2 TO HI, COMP TO FCS1, COMP TO IT3

*L1 to MED, some models.

FIGURE 50 — SELECTOR SWITCH CONTACTS,

— With the selector switch set to high

CONTACTS MADE

ALL 52SE AA AND CP MODELS

SWITCH

POSITION

OFF NONE

FAN L1 TO LO*

LO COOL L1 TO IT3, FCS TO LO

HI COOL L1 TO IT3, FCS TO HI

*L1 to MED, some models.

CONTACTS MADE

FIGURE 51 — SELECTOR SWITCH CONTACTS,

ALL 52SC AA AND CP MODELS

n HEAT PUMP UNITS (Figure 52)

Fan Mode — With the selector switch set to fan cycle,

contacts L1 to LO are made.

Cooling (Low) — With the selector switch set to low

cool and the fan switch set to fan cycle, contacts L1 to

IT3 and FCS to LO are made.

NOTE: The contact in low cooling sequence of operation

for FCS2 is MED on units built prior to 1996.

Cooling (High) — With the selector switch set to high

cool and the fan switch set to fan cycle, contacts L1 to

IT3 and FCS to HI are made.

Heating (Low) — With the selector switch set to low

heat and the fan switch set to fan cycle, contacts L1 to

IT1, FCS to LO and L2 to HTR are made.

Heating (High) — With the selector switch set to high

heat and the fan switch set to fan cycle, contacts L1 to

IT1, FCS to HI, and L2 to HTR are made.

Defrost Cycle — When heat pump unit is operating in

reverse cycle, the outdoor coil may begin to frost. As frost

accumulates on the outdoor coil the unit may switch

into defrost mode. The defrost mode is activated when

the outdoor frost thermostat sensor detects a temperature below 15 F on the coil. At this point, the thermostat deenergizes the compressor and activates the

electric heat. The unit will remain in electric heat mode

until the outdoor thermostat senses 35 F. The defrost

mode is a passive operation and may take some time before the coil defrosts.

COOLING ONLY UNITS (Figure 51)

n

Fan Mode — With the selector switch set to FAN and

the fan switch set to fan cycle, contact L1 to LO is made.

Cooling (Low) — With the selector switch set to low

speed cooling and the fan switch set to fan cycle, contacts

FCS to LO and L1 to IT3 are made.

NOTE: The contact in low cooling sequence of operation

for FCS2 is MED on units built prior to 1996.

Cooling (High) — With the selector switch set to high

speed cool and the fan switch set to fan cycle, contacts

FCS to HI, L1 to IT3 are made.

SWITCH

POSITION

OFF NONE

FAN L1 TO LO*

LO HEAT L1 TO IT1, FCS TO LO, L2 TO HTR

HI HEAT L1 TO IT1, FCS TO HI, L2 TO HTR

LO COOL L1 TO IT3, FCS TO LO

HI COOL L1 TO IT3, FCS TO HI

*L1 to MED, some models.

CONTACTS MADE

FIGURE 52 — SELECTOR SWITCH CONTACTS,

ALL 52SQ AA AND CP MODELS

26

Page 27

COMPONENT OPERATION AND

TROUBLESHOOTING

n TOOLS NEEDED

Volt-Ohmmeter

Flat and Phillips Screw Drivers

5

⁄16-in. Nut Driver

Side Cutting Pliers

Before cleaning, servicing, performing maintenance

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance

tasks such as cleaning and replacing filters. Refer to

GENERAL DISASSEMBLY section of this manual

for proper procedures to disconnect power to 52S

units.

The Manufacturer reserves the right to discontinue, or

change at any time, specifications or designs without

notice and without incurring obligations.

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical equipment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed under

the supervision of an experienced service technician.

• Personal protective equipment, such as safety glasses

and work gloves, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for job, and that

they are working properly and in good condition.

• The 52S unit may weigh up to 150 pounds. Use a lifting device or ask for assistance if the unit must be

moved.

n INDOOR THERMOSTAT (Heat/Cool and Cool Only

Units) (Figure 53) — The thermostat maintains the

selected temperature by cycling the compressor on and

off during cooling operation and the electric heater

during heating operation. The thermostat DOES NOT

switch from heating to cooling, or cooling to

heating. If the switch is in the CYCLE position, then

the fan will be cycled off when the thermostat satisfies.

A bulb heater was incorporated on models built prior

to 1996 to help provide closer temperature control. This

heater does not affect the mechanical operation of the

switch.

To verify the operation of the thermostat switch, a continuity test may be performed as follows:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove wire leads from thermostat. Note their loca-

tions to ease re-assembly.

3. Place one of the leads of the continuity tester on the

terminal marked 2, and the other lead on either the

terminal marked 1 or the terminal marked 3.

4. Adjust the thermostat up or down to verify the con-

tacts of the switch open and close. When verifying

continuity of a closed switch, the ohm reading should

be 0 ohms. An open switch will show OL on the

meter.

5. When testing is complete, reconnect the leads.

FCS

IT3

6

4

COMP

SW

TBH

BLK

OR WHT

IT

2

See Legend on page 28.

BLK

OR WHT

1

3

BRN

5

GRY

GRY

FIGURE 53 — INDOOR THERMOSTAT (IT)

CONTACTS, ALL 52SE AA AND CP MODELS

n INDOOR THERMOSTAT (Heat Pump Units)

(Figure 54) — The heat pump indoor thermostat uses a

two-stage switch for the heating mode. The first stage

engages the compressor and reversing valve, and the

unit operates in normal heat pump mode. The indoor

thermostat maintains the selected temperature by

cycling the compressor on and off in cooling mode. In

the heating mode, the indoor thermostat will cycle the

compressor or the heater, depending on the difference

between the actual room temperature and the thermostat

temperature setting.

When the room temperature is more than 4 F cooler

than the indoor thermostat setting, the second heating

stage of the indoor thermostat engages the electric

heat strip. This design feature allows the user to rapidly warm the room with the electric heat strip by turning the thermostat to its highest setting. When room

temperatures approach the desired temperature, the user

may adjust the thermostat to a personal comfort setting, which allows for normal heat pump operation.

NOTE: For outdoor temperatures below approximately

35 F (45 F for 1999 models), the outdoor frost thermostat prevents heat pump mode operation and immediately engages the electric heat strip upon a call for

heating. The electric heat strip is NEVER energized at

the same time as the compressor.

27

Page 28

52S

SERIES

n INDOOR THERMOSTAT (Heat Pump Units) (cont)

(Figure 54) — To verify operation of the heat pump indoor thermostat switch, a continuity test may be performed as follows:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove wire leads from thermostat. Note their loca-

tions to ease re-assembly.

3. To test stage A, place one lead of the continuity

tester on the terminal marked 2, and the other lead

on either the terminal marked 1 or the terminal

marked 3.

4. Adjust the thermostat up or down to verify the con-

tacts of the switch open and close. When verifying

continuity of the closed switch, the reading on the

meter should be 0 ohms. An open switch will show OL

on the meter.

5. To test stage B contacts, place one lead of the conti-

nuity tester on contact 5 and the other lead on either

contact 4 or contact 6.

6. Adjust the thermostat up or down to verify the con-

tacts of the switch open and close as in Step 4.

7. When testing is complete, reconnect the leads.

1

BLK

2

ORN

5

3

4

6

IT

BLU

GRY

BRN

n OUTDOOR FROST THERMOSTAT (Heat Pump Units)

(Figure 55) — The Outdoor Frost Thermostat (OFT) is

a thermostat that uses a single-pole switch with a

manual override selector. The thermostat switches between electric heat and compressor operation when the

temperature of the outdoor coil falls below 15 F or

rises above 35 F. Switching the override selector to electric heat disables the reverse cycle operation of the

thermostat is manually switched to electric heat operation, the compressor is disabled for heating and cooling operations.

To verify the OFT is operational, a continuity test may

be performed as follows:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove the leads from the OFT. Note their locations

to ease re-assembly.

3. Connect the continuity tester to the switch terminals

marked 1 and 2.

4. Rotate the override switch to the electric heat setting

and verify that there is continuity between terminals 1 and 2.

5. To check the other contacts, move the lead on termi-

nal 1 to terminal 3. Rotate the override switch to the

heat pump setting. There should now be continuity

between terminals 2 and 3.

6. Once the test is complete, reconnect the leads.

FIGURE 54 — INDOOR THERMOSTAT (IT)

CONTACTS, ALL 52SQ AA AND CP MODELS

LEGEND (Figures 53 - 55)

COMP — Compressor

FCS — Fan Control Switch

IT — Indoor Thermostat

OFT — Outdoor Frost Thermostat

OL — Overload

PLS — Primary Limit Switch

SLS — Secondary Limit Switch

TBH — Thermostat Bulb Heater

FIGURE 55 — OUTDOOR FROST THERMOST AT (OFT)

CONTACTS, ALL 52SQ AA AND CP MODELS

28

Page 29

n CAPACITOR — The 52S units use a dual capacitor.

One part of the capacitor is used with the fan

motor. The other part of the capacitor is used by the

compressor.

Run circuits on single-phase compressor motors use

capacitors which dramatically affect the motor operation. Run capacitors are connected to the motor circuit at

all times.

To evaluate the capacitor, perform a visual check first. A

shorted capacitor may give a visual indication of its

failure. For example, the pop-out hole at the top of a start

capacitor may bulge or blow out. A run capacitor may

bulge or leak. In these instances, the capacitor must be

replaced with one recommended by the manufacturer.

If there are no visual signs of capacitor failure, testing

of the capacitor resistance may be done with a voltohmmeter as detailed below:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section but do not unplug the

service cord; it will supply ground connection for the

unit chassis. Check to ensure power is off and

LOCKED OUT.

2. Connect one lead of a 20,000 ohm, 2-watt resistor to

the center group of terminals on the dual capacitor.

Attach the other lead from the resistor to an unpainted metal section of the unit chassis. This

allows that section of the dual capacitor to discharge.

Repeat this process between the other group of

terminals.

Capacitors are capable of holding charge similar to a

battery and may cause an electrical shock.

3. Locate and disconnect the wires from the start and/or

run capacitor to isolate them from the remainder of

the circuit. Refer to the unit wiring diagram if you

need assistance locating wires.

4. Set up the volt-ohmmeter to measure resistance by

connecting the meter across the capacitor terminals.

See Figure 56.

5. The reading on the meter should first indicate zero,

or a low resistance, then slowly rise toward infinity

or some high value or measurable resistance. This

indicates the capacitor is most likely good. If the reading goes to zero or a low resistance and stays there,

the capacitor is likely shorted and needs replacement. If the reading immediately indicates infinity,

the capacitor is likely open and must be replaced.

6. Replace the capacitor if failed and rewire according

to the WIRING SCHEMATICS located in the control

box of the unit.

FIGURE 56 — CAPACITOR TEST

n FAN CYCLE SWITCH — The fan cycle switch has

2 operating modes, continuous (CON) and cycle (CYC).

To verify the fan cycle switch is operational, a continuity test may be performed as follows:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Label and remove the leads connected to fan cycle

switch. See Figure 57.

3. Connect the volt-ohmmeter for 1X ohms and check

for continuity from terminal 2 to 1 then change the

switch position and check for continuity from terminal 2 to 3. For a 6-terminal switch this test should

be done on terminals 5 to 4 and 5 to 6 as well.

4. Once test is complete, reconnect the leads.

FIGURE 57 — FAN CYCLE SWITCH (3 Terminal)

29

Page 30

52S

SERIES

ELECTRICAL COMPONENTS REMOVAL

AND REPLACEMENT

n INDOOR THERMOSTAT — To remove the indoor

thermostat, perform the following steps:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove the thermostat knob.

3. Remove control box escutcheon (Figure 58) to expose

2 Phillips head mounting screws. Remove the temperature limiter by gently lifting it off the thermostat

knob shaft (Figure 59).

4. Open the control box as described in the GENERAL

DISASSEMBLY section of this manual.

5. Remove the thermostat bulb from the clip by gently

pressing it down and out of the clip. See Figure 27.

6. Remove the 2 screws mounting the thermostat to the

control box.

7. Remove the leads from the indoor thermostat and

remove it. Route the capillary out of the control box.

Note the wire locations to ease re-assembly.

8. Reverse Steps1-7toreinstall.

CONTROL BOX ESCUTCHEON

n OUTDOOR FROST THERMOSTAT (Heat Pump Units)

— To remove the outdoor frost thermostat (OFT), per-

form the following steps:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove the 2 screws mounting the thermostat to the

right side of the control box. See Figure 60.

3. Remove the thermostat capillary from the outdoor

coil and clip any wire ties holding the capillary in

place.

4. Disconnect the wires and carefully remove the ther-

mostat and capillary from the unit.

5. Reverse Steps1-4toreinstall.

THERMOSTAT

ESCUTCHEON SCREWS

FIGURE 58 — ESCUTCHEON REMOVAL

FIGURE 59 — TEMPERATURE LIMITER

KNOB

FIGURE 60 — OUTDOOR FROST

THERMOSTAT SCREWS

30

Page 31

n CAPACITOR — To remove the capacitor, perform

the following steps:

Turn off unit power as described in GENERAL

1.

DISASSEMBLY section.

2. Open the control box (Figure 61) as detailed in the

GENERAL DISASSEMBLY section of this manual.

3. Properly discharge the capacitor as described in the

Capacitor section under Component Operation

and Troubleshooting.

4. Remove the leads to the capacitor. Note the wire loca-

tions to ease re-assembly.

5. Close the control box door and remove the screw hold-

ing the capacitor.

6. Open the control box door and remove capacitor.

7. Reverse Steps1-6toreinstall.

n FAN CYCLE SWITCH — The fan cycle switch is lo-

cated on the right side of the control box. To remove the

fan cycle switch, perform the following steps:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Open the control box as described in GENERAL

DISASSEMBLY section of this manual.

3. Remove the 3 wires from the fan cycle switch. See

Figure 61 for location.

4. Push the snaps of the switch housing toward the

switch with a pair of pliers or small screwdriver.

Gently push the switch out of the housing.

5. Reverse Steps1-4toreinstall.

n SELECTOR SWITCH — To remove the selector switch

from the unit, perform the following steps:

1. Turn off unit power as described in GENERAL

DISASSEMBLY section.

2. Remove thermostat knob and unit escutcheon. See

Figure 58.

3. Open control box as described in the GENERAL

DISASSEMBLY section of this manual.

4. Remove all the wires to the selector switch. Label

wires to simplify re-assembly.

5. Remove the 2 screws mounting the switch and re-

move switch. See Figure 61.

6. Reverse Steps1-5toreinstall.

FIGURE 61 — COMPONENT LOCATIONS

IN OPEN CONTROL BOX

31

Page 32

52S

SERIES

FAN MOTOR

The fan motor is a permanent split capacitor (PSC) type

motor. This motor is common in air-conditioning system applications. A PSC motor does not require the use

of a relay and always has a run capacitor connected

between the run and start windings of the motor. See

Figure 62.

The 52S series fan motor has a motor shaft extended

through both ends. It powers both the indoor and the outdoor fans. It has permanently sealed bearings that require no lubrication. There are many different fan motor

models, but they typically are 2 speed or 3 speed and

in 2 voltage categories, 208/230 and 265 volts.

FIGURE 62 — TWO-SPEED, PERMANENT

SPLIT CAPACITOR MOTOR (PSC)

FAN MOTOR TROUBLESHOOTING

Refer to Figure 63 for a basic fan motor troubleshooting

chart.

n TOOLS NEEDED — The following list includes rec-

ommended tools and devices for working on the fan

motor of 52S units.

Gloves

Safety Glasses

Regular and Phillips Head Screw Drivers

Small Adjustable Wrench

Allen Wrench Set (extra length)

3

⁄8-in. Socket Set

Channel Lock Pliers

Volt-ohmmeter

5

⁄16-in. and1⁄4-in. Nut Drivers

Before cleaning, servicing, performing maintenance

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance

tasks such as cleaning and replacing filters. Refer to

GENERAL DISASSEMBLY section of this manual

for proper procedures to disconnect power to 52S

units.

The Manufacturer reserves the right to discontinue, or

change at any time, specifications or designs without

notice and without incurring obligations.

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical equipment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed under

the supervision of an experienced service technician.

• Personal protective equipment, such as safety glasses

and work gloves, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job, and

that they are working properly and in good condition.

• The 52S unit may weigh up to 150 pounds. Use a lifting device or ask for assistance if the unit must be

moved.

BASIC F ANMOTOR ELECTRICAL TESTS

There are 2 basic electrical tests for PSC fan motors

that will determine the electrical state of the motor. The

first test requires checking the electrical resistance between the motor windings. The second test requires

checking the electrical resistance between the motor

windings and ground. These tests may be accomplished

by performing the following steps:

1. DISCONNECT ALL POWER TO UNIT.

2. Remove the unit from the sleeve and open the con-

trol box as detailed in the GENERAL DISASSEMBLY section.

3. Label and disconnect the fan motor wires from the

push button switch and capacitor as shown in

Figure 5. Two-speed motors have 2 wires on the capacitor and 2 wires on the push button switch.

Three-speed motors have 2 wires on the capacitor

and 3 wires on the push button switch. Refer to the

unit wiring diagram inside the control box.

4. Measure and record the resistance between the black

wire and each of the other wires. Make sure the motor is cool before attempting to measure resistance.

The internal thermostat of the motor may be electrically open and will not close until the motor cools.

See Figure 64 for typical motor winding resistance

measurements. The resistance values in the table

are approximate. Values that are within 10% of those

listed are acceptable. If the motor in your model is

not listed, find a motor of similar horsepower and

voltage on the chart and compare it to the resistance

measurements of your motor.

5. Measure the resistance of each of the motor wires to

the motor casing. The resistance should be infinite.

Make sure the motor is cool before attempting to measure resistance. The internal thermostat of the motor may be electrically open and will not close until

the motor cools. A motor that has measurable resistance to ground is shorted to ground and must be

replaced.

32

Page 33

SYMPTOM g

POSSIBLE CAUSE

f

MOTOR HUMS

BUT DOES

NOT START

MAKES NO NOISE

AND DOES NOT

START

STARTS BUT

STOPS AFTER

SHORT TIME

STARTS

BUT RUNS

SLOW

RUNS ON

ONE SPEED,

NOT ON

OTHERS

DEFECTIVE BEARING XXX

CAPACITOR DEFECTIVE XX

SWITCH DEFECTIVE XX

LOW LINE VOLTAGE XXX

SHORTED MOTOR WINDING XX X

NO POWER TO UNIT X

INTERNAL THERMOSTAT OPEN X

MISWIRED XXX X

FAN STUCK X

BROKEN MOTOR WIRE XXX X

MOTOR WINDING GROUNDED XX

OPEN MOTOR WINDING XXX X

FIGURE 63 — FAN MOTOR TROUBLESHOOTING CHART

TYPICAL 208/230 VOLT MOTORS

CARRIER PART NUMBER HC37CE246 HC37CE242 HC35CE234 HC37CE211

MANUFACTURER’S

PART NUMBER

MOTOR VOLTAGE 208/230 208/230 208/230 208/230

MOTOR HORSEPOWER

MOTOR SPEEDS 2322

RESISTANCE (OHMS)

BLACK TO WHITE WIRE

RESISTANCE (OHMS)

BLACK TO BROWN WIRE

RESISTANCE (OHMS)

BLACK TO BLUE WIRE

RESISTANCE (OHMS)

BLACK TO RED WIRE

NOTE: Resistance values are approximate.

5KCP39BGT165S 5KCP39BGR198S 5KCP39CGT162S 5KCP39DGT164S

1

⁄

15

1

⁄

10

1

⁄

8

1

⁄

6

147 90 74 58

169 71 53 24

N.A. 38 N.A. N.A.

42 31 28 41