Carrier 52ceb515331aa Owner's Manual

52C

52C

SERIES

SERIES

OWNER’S MANUAL

PACKAGED TERMINAL AIR CONDITIONERS

AND HEAT PUMPS

7,000-15,000 Btuh

CONTENTS

GENERAL

UNIT INSPECTION

FRONT PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ELECTRICAL DATA

ALL UNITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

VOLTAGE SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INST ALLATION

CHASSIS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 5

WALL THERMOSTAT INSTALLATION . . . . . . . . . . . 7

OPERATION

COMFORT CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING MODES. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8,9

Page

CARE AND MAINTENANCE

INDOOR-AIR INLET FILTERS . . . . . . . . . . . . . . . . . .10

EXTERNAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

INTERNAL PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PREVENTATIVE MAINTENANCE

TROUBLESHOOTING

ACCESSORIES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . . . 10,11

. . . . . . . . . . . . . . . .12

1•800•894•6449

For Service/

Technical Assistance

Page

52C

SERIES

GENERAL

Thank you for choosing Carrier! You can feel confident

in your selection because the same pride in craftsmanship and engineering knowledge that goes into Carrier

equipment at the Astrodome in Texas, the Sistine

Chapel in Rome, the US Capitol Hall of Congress, and

thousands of other installations worldwide has gone

into the construction of this unit.

The Carrier package terminal air conditioners and

heat pumps provide a high standard of quality in performance, workmanship, durability and appearance as

they heat and cool the occupied air space year round.

This manual provides information for ease of installation, operation and maintenance of the 52C unit. The

following units are covered in this manual (see

Figure 1 for additional unit information):

52CE 60 Hz cooling with electric heat units

52CQ 60 Hz cooling, electric heat, and heat pump units

All models are designed for through-the-wall installation. Separate installation instructions are included

with all accessory components. See Accessories section

on page 14 for complete listing of accessories.

MODEL 52CQA312301AA

SERIAL 0201X11520

DATE OF MFG. 01/12/2001

VOLT RANGE 187-253

VOLTS 230/208

PH 1

MIN CKT AMPACITY 17.9

R-22 OZ 34

DESIGN PSIG 350 HIGH SIDE, 150 LOW SIDE

BTU/HR 12,00/11,900

AMPS 5.8/6.2

WATTS 1333/1311

EER 10.1/10.1

COMP

FAN

MOTOR

BTU/HR 10,800/10,700

AMPS 15.8/14.5

WATTS 3600/3025

COP 3.0/3.0

HEATER

BTU/HR

USE

TIME DELAY FUSE

OR HACR TYPE

CIRCUIT BREAKER

HZ

COOLING

70

RLA

33.2

LRA

1.0/0.8

FLA

1/8

HP

HEATING

AMPS 14.8/13.7

WATTS 3400/2850

WATER

STEAM

CANADIAN INSTALLATION

AMP

20

MAX FUSE

60

AMP AMP

20

MAX BREAKER

20

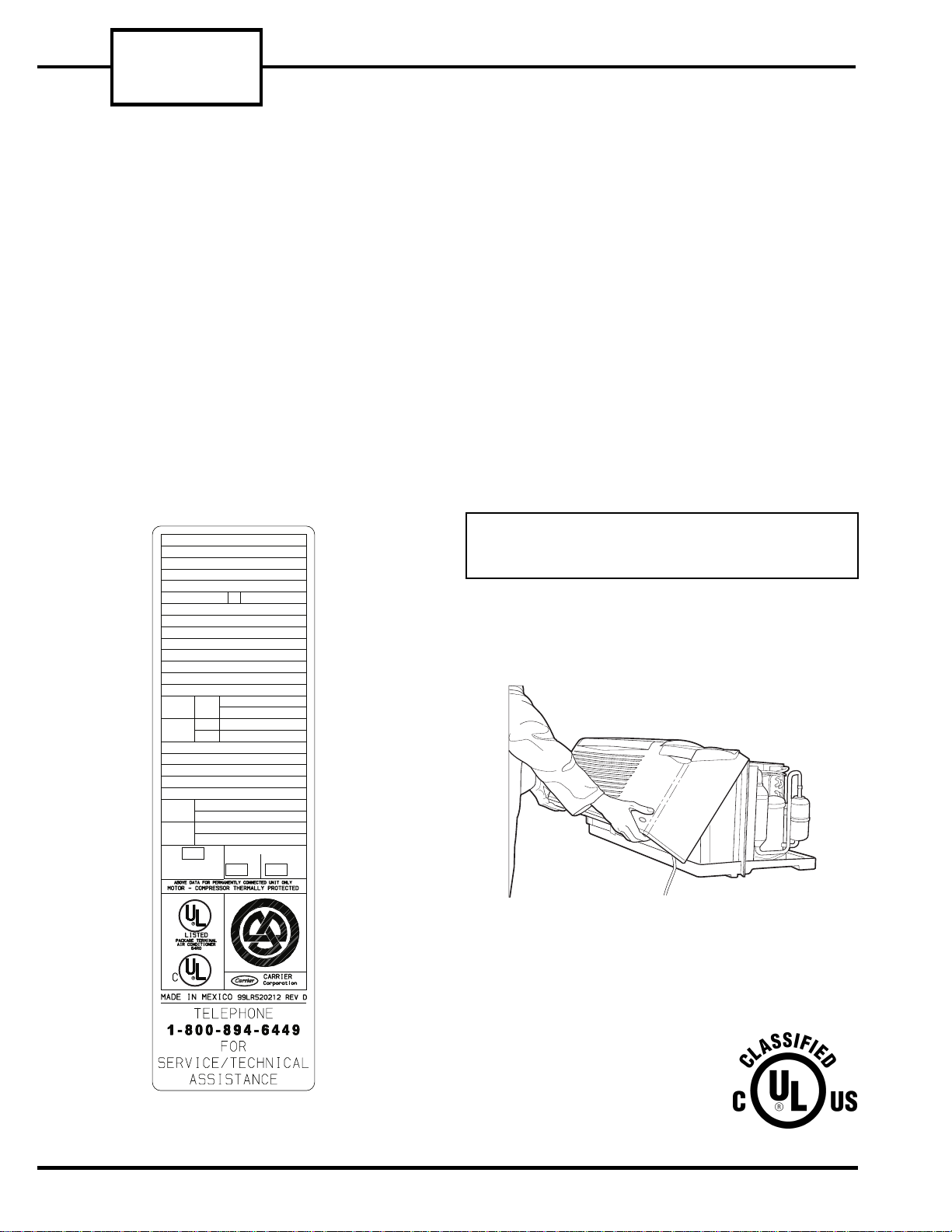

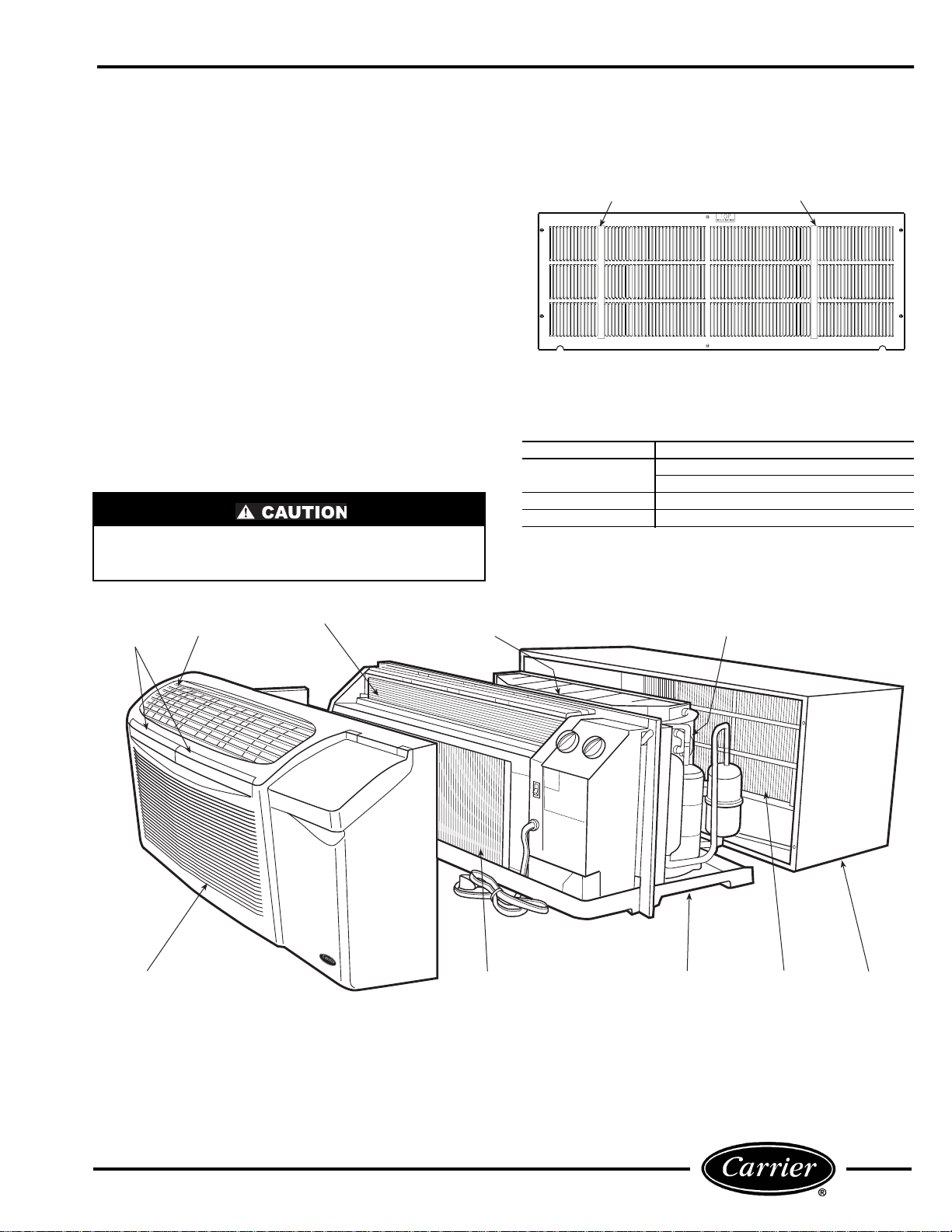

UNIT INSPECTION

Examine unit for damage incurred during shipment.

File a claim immediately with the transit company if

damage is found.

The data information plate (Figure 1) lists the model

number, voltage ranges, and other important electrical

information about this product. Reading and understanding this material is important for proper use of

this unit. To access the information plate, the front

panel must be removed; see Figure 2.

FRONT PANEL

To remove the front panel:

1. Grasp panel firmly near bottom of both sides.

2. Pull panel forward then upward to release magnetic latches and partition hooks.

NOTE: Front panel may be secured to chassi s wi th

2 screws located behind indoor air inlet filters. In order

to remove these screws, the filters must be removed

first. Refer to page 10 in this manual for instructions on

removing indoo r air in l et fi lt er s.

IMPORTANT: The front panel has to be off the unit

to complete future checks and installation procedures. Do not reinstall front panel at t his time.

Using Figures 1 and 3 as reference, verify that the

packaged terminal product ordered will operate properly in your facility. If you do not understand the information given or have questions about the product,

please call your local dealer or distributor.

FIGURE 1 — SAMPLE DATA INFORMATION PLATE

FIGURE 2 — REMOVING FRONT PANEL

Replacement Package Terminal Air Conditioner,

CLASSIFIED BY UNDERWRITERS LABORATORIES INC., AS TO ELECTRIC SHOCK, FIRE AND

CASUALTY HAZARDS ONLY. FOR FIELD INSTALLATION WITH EXISTING WALL SLEEVES, OUTDOOR LOUVERS, AND INDOOR PANELS AS

SPECIFIED ON THE PRODUCT.

2

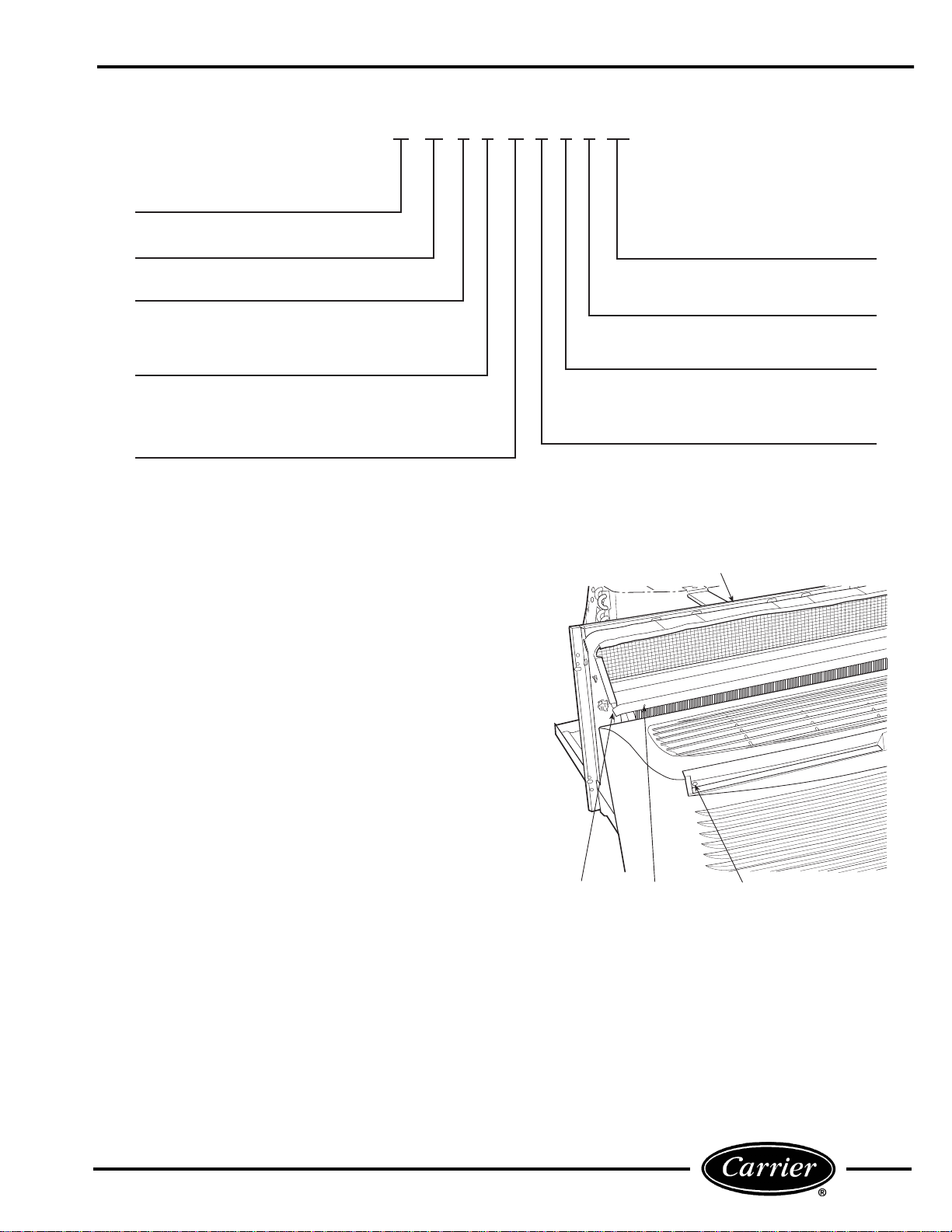

52 CE A 3 12 3 0 1 AA

TOP PARTITION

DISCHARGE

DECK

ENGAGEMENT

HOLE

FRONT PANEL

SLOT

Series Designation

PTAC (Packaged Terminal Air Conditioner)

CE – Cooling with Electric Heat

CQ – Heat Pump

Latest Revision

A – Z

Electric Heater Size

2 – 2.3 kW

3 – 3.4 kW

5 – 5.0 kW

Cooling Capacity (nominal)

07 – 7,000 Btuh

09 – 9,000 Btuh

12 – 12,000 Btuh

15 – 15,000 Btuh

FIGURE 3 — MODEL NUMBER NOMENCLATURE

To install the front panel follow the procedure outlined

below:

1. Firmly grasp bottom of front panel on both sides.

2. Hold front panel at a 45 degree angle to unit. Be

sure front panel is centered with front of unit.

3. Connect top of front panel to partition rail on top

of unit.

4. Gently lower front panel onto chassis, ensuring

service cord is positioned through front panel slot.

NOTE: Magnets on bottom of front panel will secure

front panel to unit.

To install locking feature on front panel be sure front

panel is already installed on unit and follow the steps

below:

1

NOTE: Two field-supplied no. 8,

/2 in. sheet metal

screws are required to secure front panel to chassis.

1. Remove bot h indoor ai r inlet fi lters to ex pose fron t

panel engagement holes. See Figure 4.

2. Secure front panel to chassis by attaching the

field-supplied screws into engagement holes. Do

not over tighten.

3. Replace both indoor air inlet filters.

NOTE: Front panel alignment may have to be

adjusted slightly to line with chassis.

Chassis Options

AA – Standard

CP – Corrosion Protection

RC – Wall Thermostat Control

RP – Wall Thermostat Control with

Corrosion Protection

Packaging

1 – Domestic

Non-Performance

Changes 0-9

Electrical Data

3 – 230/208-v, 60 Hz

4 – 265-v, 60 Hz

FIGURE 4 — FRONT PANEL INSTALLATION

WITH LOCKING FEATURE

3

52C

SERIES

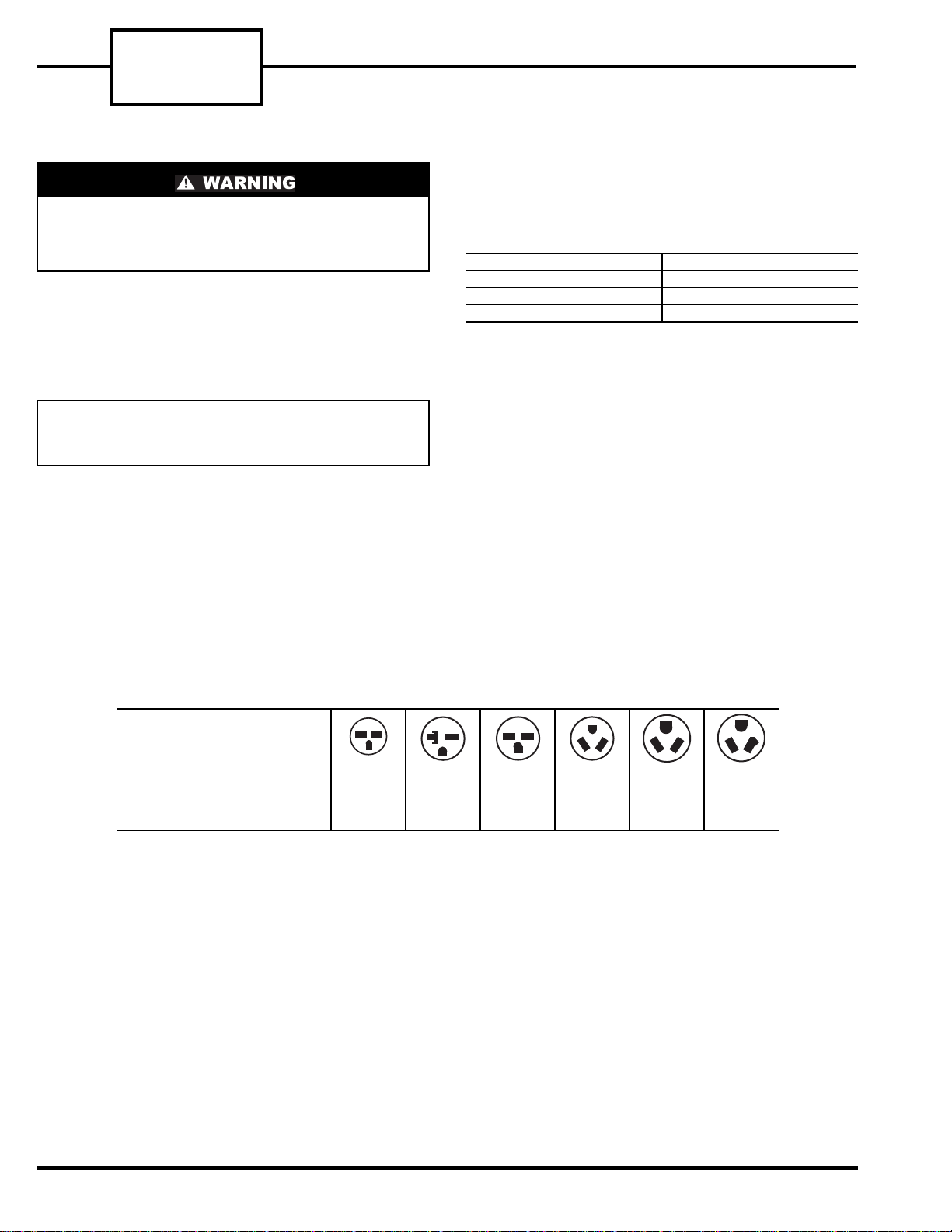

ELECTRICAL DATA

ELECTRICAL SHOCK HAZARD

DO NOT alter cord or plug, and DO NOT use an

extension cord. Personal injury or damage to the

unit may result.

Be sure that your outlet matches the appropriate

blade configuration of the supplied plug and that it is

within reach of the service cord. A hardwire kit is

available as an accessory to change cord-connected

units to hardwired units. (See Accessories section,

page 14.)

GROUNDING

■

— For safety and protection, the unit

is grounded through the service cord plug or through

separate ground wire provided on hardwired units. Be

sure that the branch circuit or general purpose outlet

is grounded.

TABLE 1 — SUGGESTED BRANCH CIRCUIT

WIRE SIZES*

NAMEPLATE AMPS AWG WIRE SIZE†

7.0 to 12

12.1 to 16

16.1 to 24

LEGEND

AWG —

*Single circuit from main box.

†Based on copper wire at 60 C temperature rating.

American Wire Gage

14

12

10

IMPORTANT: All standard cord-connected 265-v

units will require a field-installed elect rical subbase accessory.

ALL UNITS

WIRE SIZE —

■

Table 1 and install a single branch circuit. All wiring

must comply with local and national codes. All units

are designed to operate off single branch circuits only.

NOTE: Use copper conductors only.

Use recommended wire size given in

TABLE 2 — RECEPTACLES AND FUSE TYPES — 250,265 VOLTS

RECEPTACLE

15 Amps 20 Amps 30 Amps 15 Amps 20 Amps 30 Amps

RATED VOLTS

TIME-DELAY TYPE

FUSE (or HACR Circuit Breaker)

LEGEND

HACR —

*May be used for 15-amp applications if fused for 15 amp.

Heating, Air Conditioning, Refrigeration

250 250 250 265 265 265

15 20* 30 15 20 30

VOLTAGE SUPPLY

Check voltage supply a t outlet. For satisfactory results, the voltage range must always be within the

ranges found on the data information plate

(Figure 1).

CORD-CONNECTED UNITS

■

supplied outlet must match the plug for the standard

208/230-v units and be within reach of the service

cord. The standard cord-connected 265-v units require

an accessory electrical subbase for operation. See

Accessories section, page 14, for subbase selection.

Refer to Tab le 2 for pr o p er r ec e p ta cle and fuse ty pe .

— The 250-v field-

4

INSTALLATION

FOAM STRIP

OR BAFFLE

FOAM STRIP

OR BAFFLE

CHASSIS INSTALLATION

Units are shipped without a sleeve. In applications

where unit is a replacement, it is recommended that a

Carrier sleeve be used. The 52C unit can retrofit

General Electric, Amana and Trane sleeves/grilles (be

sure outdoor grille is installed on the slee ve). A retrofit

kit with instructions is included with every unit. See

Table 3 for details. Carrier Corporation must approve

any other retrofit application. In deep-wall applications, if an existing grille is used on an outdoor wall

opening, do not install an additional outdoor grille on

unit sleeve.

Be sure that the foam strips and/ or baffles provide a

good seal between the grille and condenser coil t ube

sheets. These foam strips or baffles provide a barrier

to separate condenser air from the major components

(compressor and fan motor). See Figures 5 to 8.

NOTE: Inspect wall sleeve for any damage or deterioration before installing chassis.

If baffles are not installed properly, loss of performance and premature damage to the major components can result.

FIGURE 5 — OUTDOOR GRILLE

TABLE 3 — RETROFIT WALL SLEEVES

MANUFACTURER* WALL SLEEVE PART NUMBER

General Electric

Amana Metal Sleeve WS900B

Trane Metal Sleeve SLV149

*Retrofit kit is

not

needed for Carrier or Bryant applications.

Metal Sleeve RAB71

Plastic Sleeve RAB77

INDOOR-AIR

INLET

FILTERS

FRONT

PANEL

DISCHARGE

GRILLE

WIRE SCREEN

OUTDOOR

ORIFICE

INDOOR

COIL

FIGURE 6 — 52C UNIT COMPONENTS

COIL TUBE

SHEETS

BASEPAN

OUTDOOR

GRILLE

WALL

SLEEVE

5

Loading...

Loading...