Page 1

52C and 52P

52C

SERIES

SERIES

OWNER’S MANUAL

PACKAGED TERMINAL AIR CONDITIONERS

AND HEAT PUMPS

7,000-15,000 Btuh

CONTENTS

Page

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

UNIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

FRONT PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ELECTRICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ALL UNITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

VOLTAGE SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

CHASSIS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 5

WA LL THERMOSTAT INSTALLATION. . . . . . . . . . . 8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9,10

COMFORT CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING CONTROLS. . . . . . . . . . . . . . . . . . . . . . 10

OPERATING MODES. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page

CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . 11,12

INDOOR-AIR INLET FILTERS . . . . . . . . . . . . . . . . . . 11

EXTERNAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

INTERNAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PREVENTATIVE MAINTENANCE. . . . . . . . . . . . . . . . 13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1•800•894•6449 (in USA and Canada)

For Service/Technical Assistance

1•800•830•8600 (Mexico)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 9 a 1 1 a

PC 132 Catalog No. 535-20066 Printed in U.S.A. Form 52C,P-2SO Pg 1 10-04 Replaces: 52C,P-1SO

Page 2

GENERAL

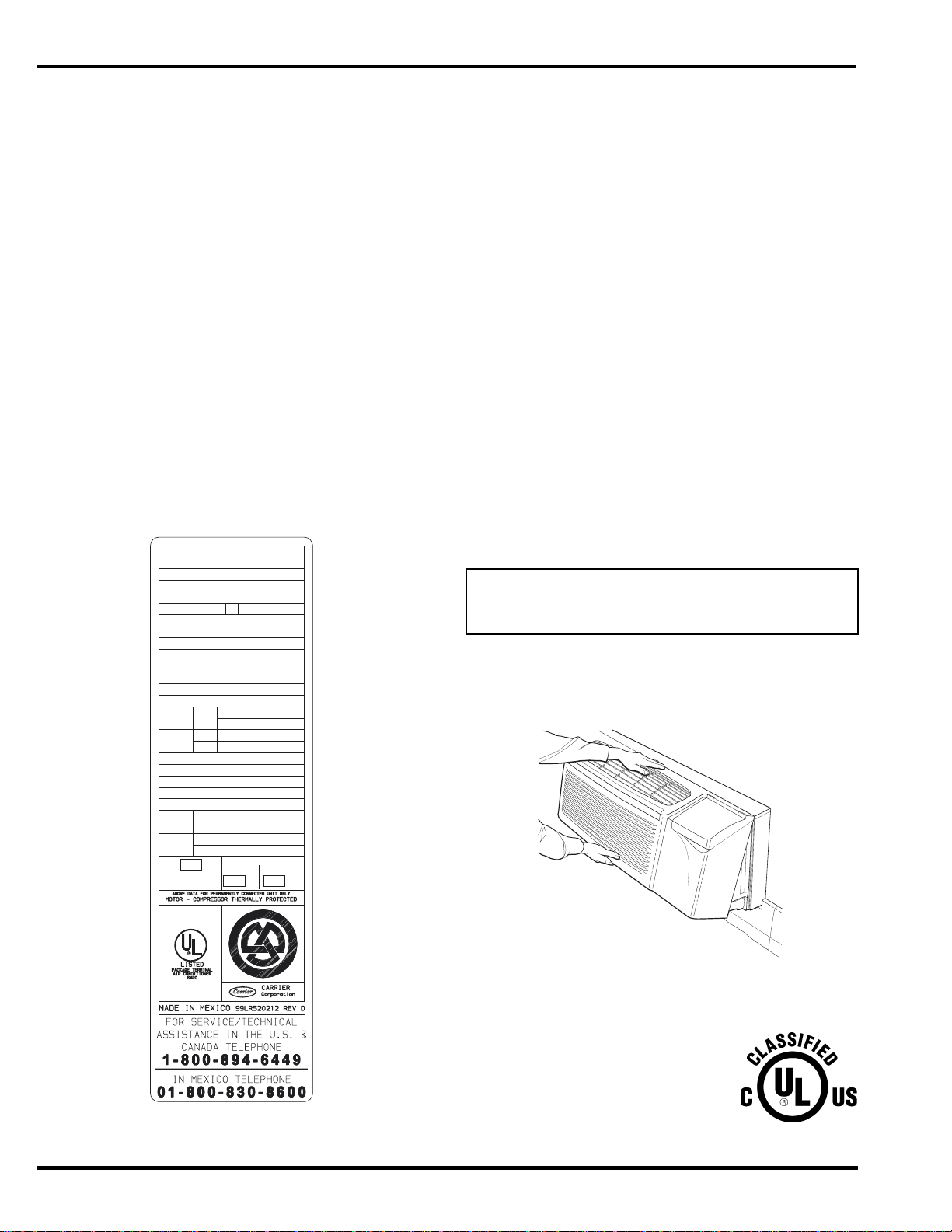

FIGURE 1 — SAMPLE DATA INFORMATION PLATE

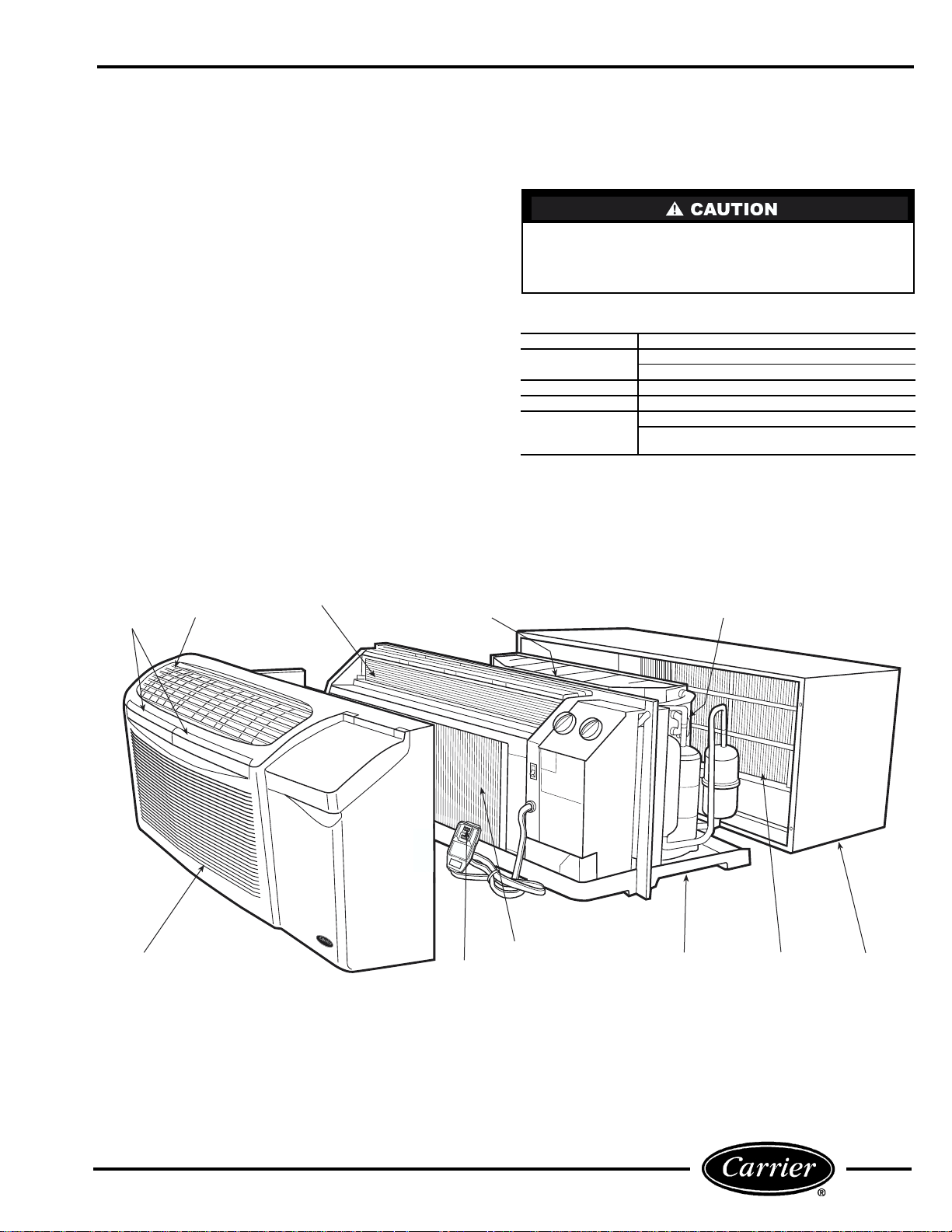

Thank you for choosing Carrier! You can feel confident

in your selection because the same pride in craftsmanship and engineering knowledge that goes into Carrier

equipment at the Astrodome in Texas, the Sistine

Chapel in Rome, the US Capitol Hall of Congress, and

thousands of other installations worldwide has gone

into the construction of this unit.

The Carrier package terminal air conditioners and

heat pumps provide a high standard of quality in performance, workmanship, durability and appearance as

they heat and cool the occupied air space year round.

This manual provides information for ease of installation, operation and maintenance of the 52C and 52P

units. The following units are covered in this manual

(see Figure 1 for additional unit information):

52CE 60 Hz cooling with electric heat units

52CQ 60 Hz cooling, electric heat, and heat pump units

52PE 60 Hz cooling with electric heat units

52PQ 60 Hz cooling, electric heat, and heat pump units

52PC 60 Hz cooling only units

All models are designed for through-the-wall installation. Separate installation instructions are included

MODEL 52PQA312301AA

SERIAL 3701X11520

DATE OF MFG. 09/12/2001

VOLT RANGE 187-253

VOLTS 230/208

PH 1

MIN CKT AMPACITY 19.3

R-22 OZ 34

DESIGN PSIG 350 HIGH SIDE, 150 LOW SIDE

BTU/HR 12,100/12,000

AMPS 4.8/5.3

WATTS 1100/1100

EER 11.0/10.9

COMP

FAN

MOTOR

BTU/HR 10,800/10,700

AMPS 15.6/14.5

WATTS 3570/2997

COP 3.2/3.2

HEATER

BTU/HR

USE

TIME DELAY FUSE

OR HACR TYPE

CIRCUIT BREAKER

HZ

COOLING

6.1

RLA

29

LRA

0.75

FLA

1/8

HP

HEATING

AMPS 14.8/13.7

WATTS 3400/2850

WATER

STEAM

CANADIAN INSTALLATION

AMP

20

MAX FUSE

60

AMP AMP

20

MAX BREAKER

20

with all accessory components. See Accessories section

on page 15 for complete listing of accessories.

UNIT INSPECTION

Examine unit for damage incurred during shipment.

File a claim immediately with the transit company if

damage is found.

The data information plate (Figure 1) lists the model

number, voltage ranges, and other important electrical

information about this product. Reading and understanding this material is important for proper use of

this unit. To access the information plate, the front

panel must be removed; see Figure 2.

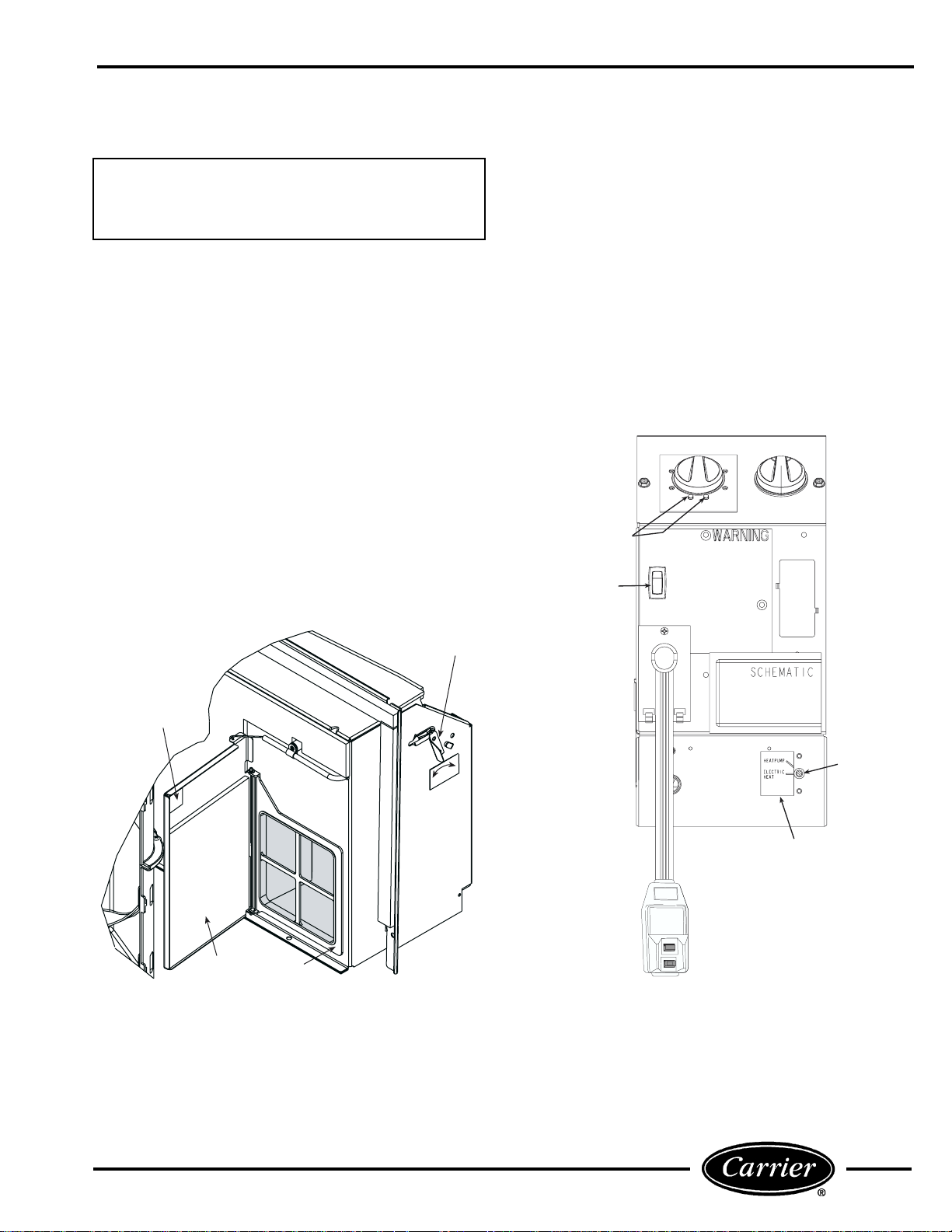

FRONT PANEL

Remove front panel from unit by grasping the panel

firmly at the center top and center bottom. Pull the

panel upward at the bottom and forward at the top to

release magnetic latches and partition hooks. See

Figure 2.

NOTE: Front panel may be secured to chassi s wi th

2 screws located behind indoor air inlet filters. In order

to remove these screws, the filters must be removed

first. Refer to page 11 in this manual for instructions on

removing indoo r air in l et fi lt er s.

IMPORTANT: The front panel has to be off the unit

to complete future checks and installation procedures. Do not reinstall front panel at t his time.

Using Figures 1 and 3 as reference, verify that the

packaged terminal product ordered will operate properly in your facility. If you do not understand the information given or have questions about the product,

please call your local dealer or distributor.

US

C

FIGURE 2 — REMOVING FRONT PANEL

Replacement Package Terminal Air Conditioner,

CLASSIFIED BY UNDERWRITERS LABORATORIES INC., AS TO ELECTRIC

SHOCK, FIRE AND CASUALTY

HAZARDS ONLY. FOR FIELD

INSTALLATION WITH EXISTING

WALL SLEEVES, OUTDOOR LOUVERS, AND INDOOR PANELS AS

SPECIFIED ON THE PRODUCT.

2

Page 3

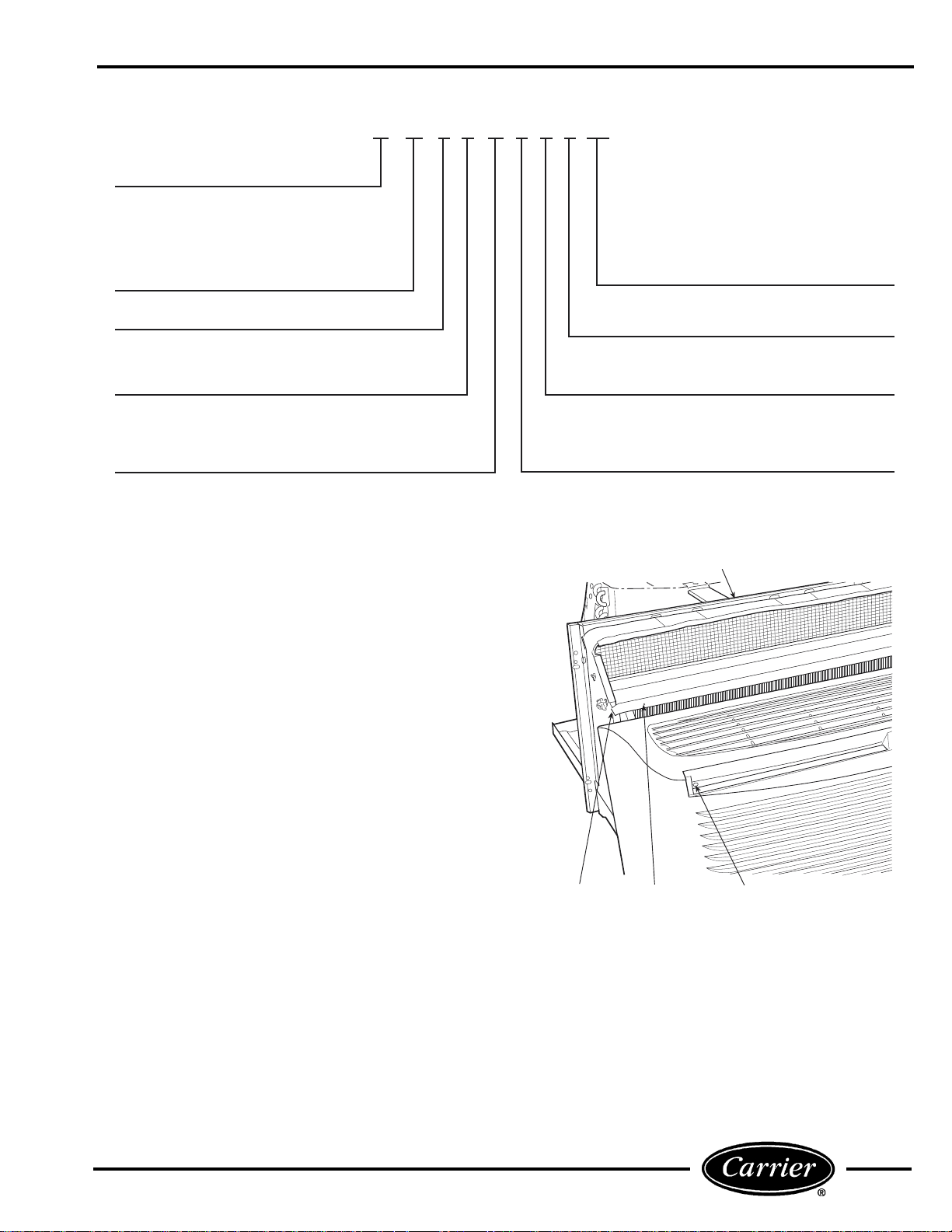

Series Designation

PTAC (Packaged Terminal Air Conditioner)

Comfort Series

CE – Cooling with Electric Heat

CQ – Heat Pump

Premier Series

PC – Cooling Only

PE – Cooling with Electric Heat

PQ – Heat Pump

Latest Revision

A – Z

Electric Heater Size

2 – 2.3 kW

3 – 3.4 kW

5 – 5.0 kW

Cooling Capacity (nominal)

07 – 7,000 Btuh

09 – 9,000 Btuh

12 – 12,000 Btuh

15 – 15,000 Btuh

FIGURE 3 — MODEL NUMBER NOMENCLATURE

52 PE A 3 12 3 0 1 AA

Chassis Options

AA – Standard

CP – Corrosion Protection

RC – Wall Thermostat Control (Not available

on cooling only units)

RP – Wall Thermostat Control with

Corrosion Protection (Not available on

cooling only units)

Packaging

1 – Domestic

Non-Performance

Changes 0-9

Electrical Data

3 – 230/208-v, 60 Hz

4 – 265-v, 60 Hz

To install the front panel, follow the procedure outlined below:

Replace the unit front panel.

1. Hold the front panel firmly at the center top and

center bottom at a 5 to 10 degree angle from

vertical.

2. Place the top of the front panel onto the unit making sure the top engagement posts have engaged

the slots on the unit. Front panel should be flat

against the top of the unit.

3. Gently lower the front panel onto the cha ssis,

ensuring that the power cord (or conduit) is routed

through the front panel notch. Magnetic la tches at

bottom of front p anel will secure th e front panel to

the unit.

To install locking feature on front panel, be sure front

panel is already installed on unit and follow the steps

below:

NOTE: Two field-supplied no. 8,

1

/2-in. sheet metal

screws are required to secure front panel to chassis.

1. Remove both indoor a ir inlet fi lters to expose fro nt

panel engagement holes. See Figure 4.

2. Secure front panel to chassis by attaching the

field-supplied screws into engagement holes. Do

not over tighten.

3. Replace both indoor air inlet filters.

NOTE: Front panel alignment may have to be

adjusted slightly to line with chassis.

TOP PARTITION

DISCHARGE

DECK

ENGAGEMENT

HOLE

FRONT PANEL

SLOT

FIGURE 4 — FRONT PANEL INSTALLATION

WITH LOCKING FEATURE

3

Page 4

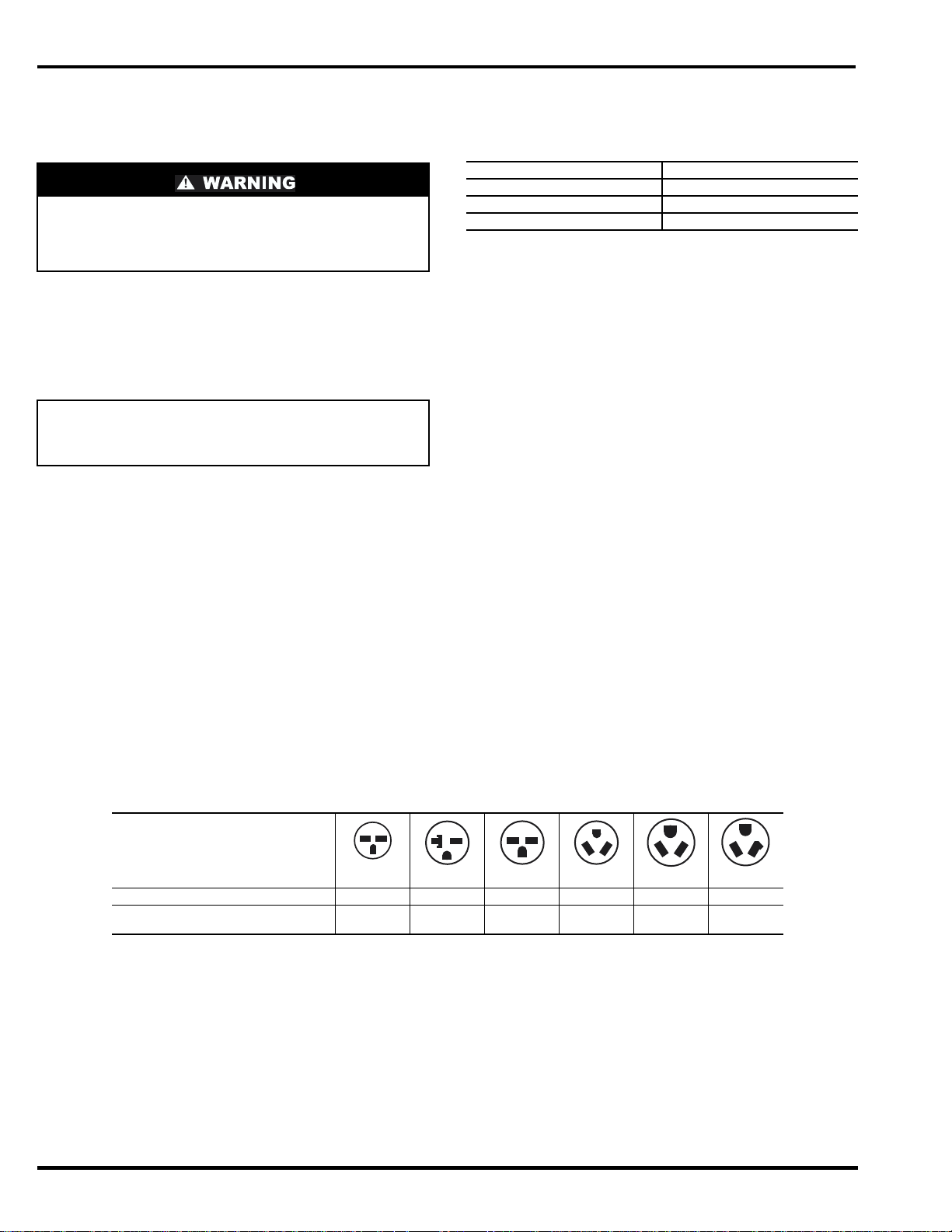

ELECTRICAL DATA

ELECTRICAL SHOCK HAZARD

DO NOT alter cord or plug, and DO NOT use an

extension cord. Personal injury or damage to the

unit may result.

Be sure that your outlet matches the appropriate

blade configuration of the supplied plug and that it is

within reach of the service cord. A hardwire kit is

available as an accessory to change cord-connected

units to hardwired units. (See Accessories table on

page 15.)

IMPORTANT: All standard cord-connected 265-v

units will require a field-installed electrical subbase accessory.

ALL UNITS

■ WIRE SIZE — Use recommended wire size given in

Table 1 and install a single branch circuit. All wiring

must comply with local and national codes. All units

are designed to operate off single branch circuits only.

NOTE: Use copper conductors only.

■ GROUNDING — For safety and protection, the

unit is grounded through the service cord plug or

through separate ground wire provided on hardwired

units. Be sure that the branch circuit or general purpose outlet is grounded.

TABLE 1 — SUGGESTED BRANCH CIRCUIT

WIRE SIZES*

NAMEPLATE AMPS AWG WIRE SIZE†

7.0 to 12 14

12.1 to 16 12

16.1 to 24 10

LEGEND

AWG — American Wire Gage

*Single circuit from main box.

†Based on copper wire at 60 C temperature rating.

VOLTAGE SUPPLY

Check voltage supply at outlet. For satisfactory

results, the voltage range must always be within the

ranges found on the data information plate

(shown in Figure 1).

■ CORD-CONNECTED UNITS — The 250-v field-

supplied outlet must match the plug for the standard

208/230-v units and be within reach of the service

cord. The standard cord-connected 265-v units require

an accessory electrical subbase for operation. See

Accessories table, page 15, for subbase selection. Refer

to Table 2 for proper receptacle and fuse type.

■ POWER CORD PROTECTION — The power cord

for the 230/208-v unit provides both personal shock

protection and power cord fire prevention. Unit power

automatically disconnects when unsafe conditions are

detected. Power to the unit can be restored by pressing

the RESET button on plug head.

Upon completion of unit installation for 230/208-v

models, an operational check should be performed

using the TEST/RESET buttons on the plug head. See

Figure 5.

NOTE: The 265-v models do not incorporate this

feature as they require use of the electrical subbase

accessory.

TABLE 2 — RECEPTACLES AND FUSE TYPES — 250,265 VOLT S

RECEPTACLE

15 Amps 20 Amps 30 Amps 15 Amps 20 Amps 30 Amps

RATED VOLTS 250 250 250 265 265 265

TIME-DELAY TYPE

FUSE (or HACR Circuit Breaker)

LEGEND

HACR — Heating, Air Conditioning, Refrigeration

*May be used for 15-amp applications if fused for 15 amp.

15 20* 30 15 20 30

4

Page 5

INSTALLATION

CHASSIS INSTALLATION

Units are shipped without a sleeve. In applications

where unit is a replacement, it is recommended that a

Carrier sleeve and grille be used.

The 52C and 52P units can retrofit General Electric,

Amana, Trane, and Friedrich sleeves/grilles (be sure

outdoor grille is installed on the sleeve). See Table 3

for details. Carrier Corporation must approve any

other retrofit application.

For competitive retrofit applications, be sure that the

foam seals (factory-installed on the tube sheets) provide a good seal between the outdoor grille and outdoor coil tube sheets. These foam seals provide a

barrier to separate outdoor coil leaving air from mixing with the outdoor incoming air (known as air recirculation).

See Figure 5.

For retrofit applications, foam seals on outdoor coil

tube sheets must make a seal between the coil and

the grille or loss of performance and premature

damage to the major components can result.

TABLE 3 — RETROFIT WALL SLEEVES

MANUFACTURER WALL SLEEVE PART NUMBER

General Electric Metal Sleeve RAB71

Amana Metal Sleeve WS900B

Trane Metal Sleeve SLV149

Friedrich T-Series Metal 11

*FR-SLEEVE-EXT accessory is required for retrofit into Friedrich

(T-Series) wall sleeves.

Plastic Sleeve RAB77

1

/2-in. deep wall sleeve*

Standard depth wall sleeve 16 x 42 x 13

PXWS

3

/4-in.

INDOOR-AIR

INLET

FILTERS

FRONT

PANEL

DISCHARGE

GRILLE

WIRE SCREEN

OUTDOOR

ORIFICE

T

E

1

S

.P

R

T

E

S

2

S

IN

.P

R

L

E

U

S

G

G

E

T

IN

R

B

T

E

U

O

C

T

P

E

T

3

P

O

O

.P

T

W

N

A

R

.

E

C

E

R

L

S

E

S

S

.

T

H

E

O

S

T

U

4

B

L

.

D

U

P

L

R

T

IG

T

E

O

S

H

N

S

T.

U

R

F

O

N

E

R

S

IT

D

U

E

O

T

S

B

N

E

.

O

U

T

T

T

U

O

S

N

E

A

I

S

G

A

T

IN

E

S

T

A

B

O

V

E

F

A

I

L

S

INDOOR

PLUG TEST/

COIL

RESET BUTTONS

FIGURE 5 — UNIT COMPONENTS

COIL TUBE

SHEETS

BASEPAN

OUTDOOR

GRILLE

WALL

SLEEVE

5

Page 6

■ COMP ETITIVE SLEEVE PREPARATION

IMPORTANT: Inspect the wall sleeve thoroughly

prior to installation. Manufacturer does not assume

responsibility for costs or damages due to defects in

the sleeve or improper installation.

Disconnect all power to unit to avoid possible electrical shock during installation.

Remove any existing foam baffles that are installed on

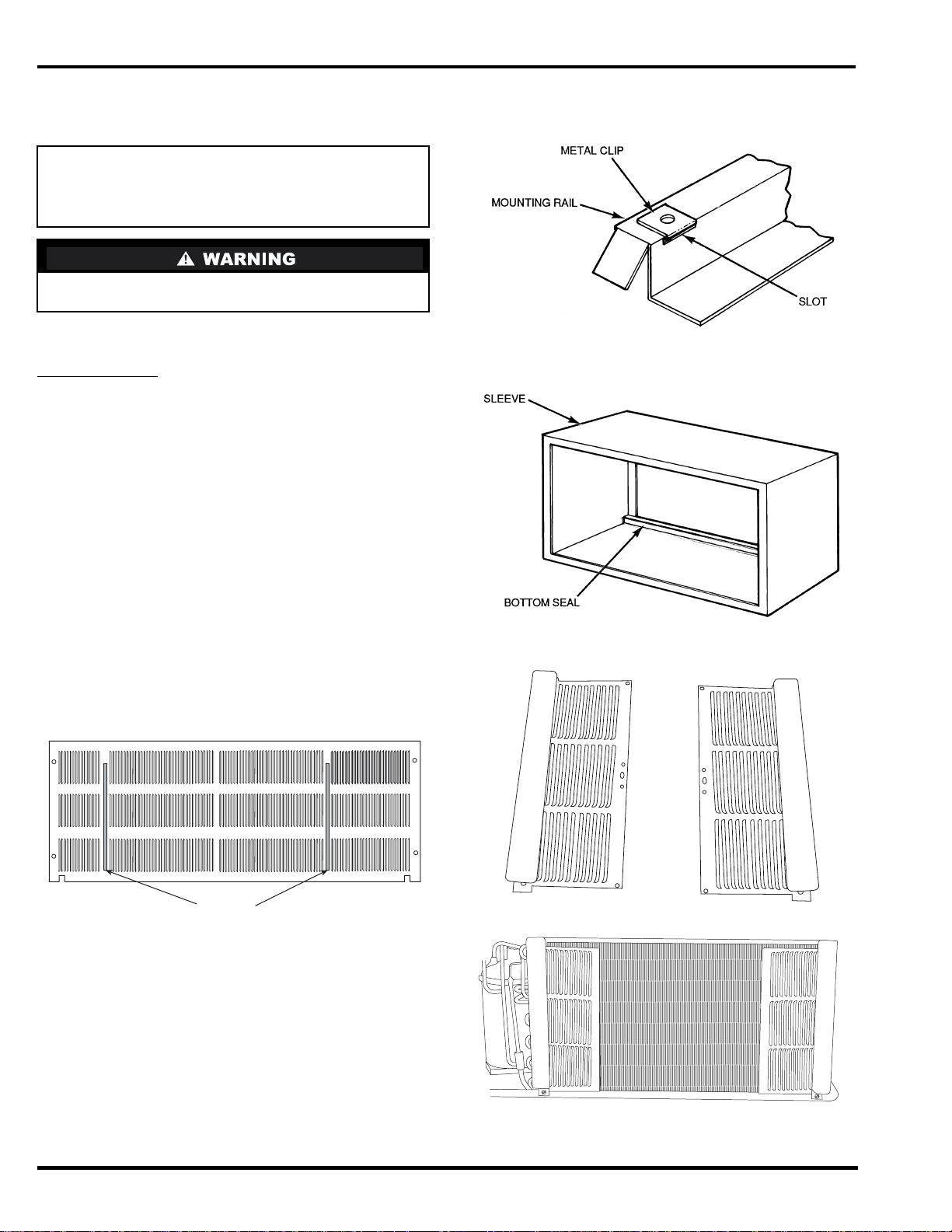

the outdoor grille if present. See Figure 6.

GE Sleeves Only

Metal Wall Sleeve — Remove metal clip on mounting

rail located on left, inside bottom of metal sleeve and

discard. See Figure 7.

Plastic Slee ve — Remove bottom seal from plastic

sleeve. See Figu re 8.

■ INSTALLATION OF A CARRIER WALL SLEEVE

USING A NON-CARRIER GRILLE

This application has become more common due to

pre-manufactured windows with built-in grilles or renovations where a Carrier sleeve is used with an existing non-Carrier grille.

Use of a Carrier wall sleeve with a non-Carrier grille

requires installation of an Accessory Baffle Kit, which

ensures a good seal between the unit and exterior

grille and prevents air recirculation. (See Figures 9

and 10.) Air recirculation is a large contributor to

performance loss and premature damage t o major

components.

FIGURE 7 — REMOVE METAL CLIP ON

GE METAL SLEEVE

FIGURE 8 — REMOVE BOTTOM SEAL FROM

GE PLASTIC SLEEVE

BAFFLES

FIGURE 6 — REMOVE EXISTING BAFFLES ON

COMPETITIVE OUTDOOR GRILLES

FIGURE 9 — ACCESSORY BAFFLE KIT

FIGURE 10 — INSTALLATION COMPLETE

6

Page 7

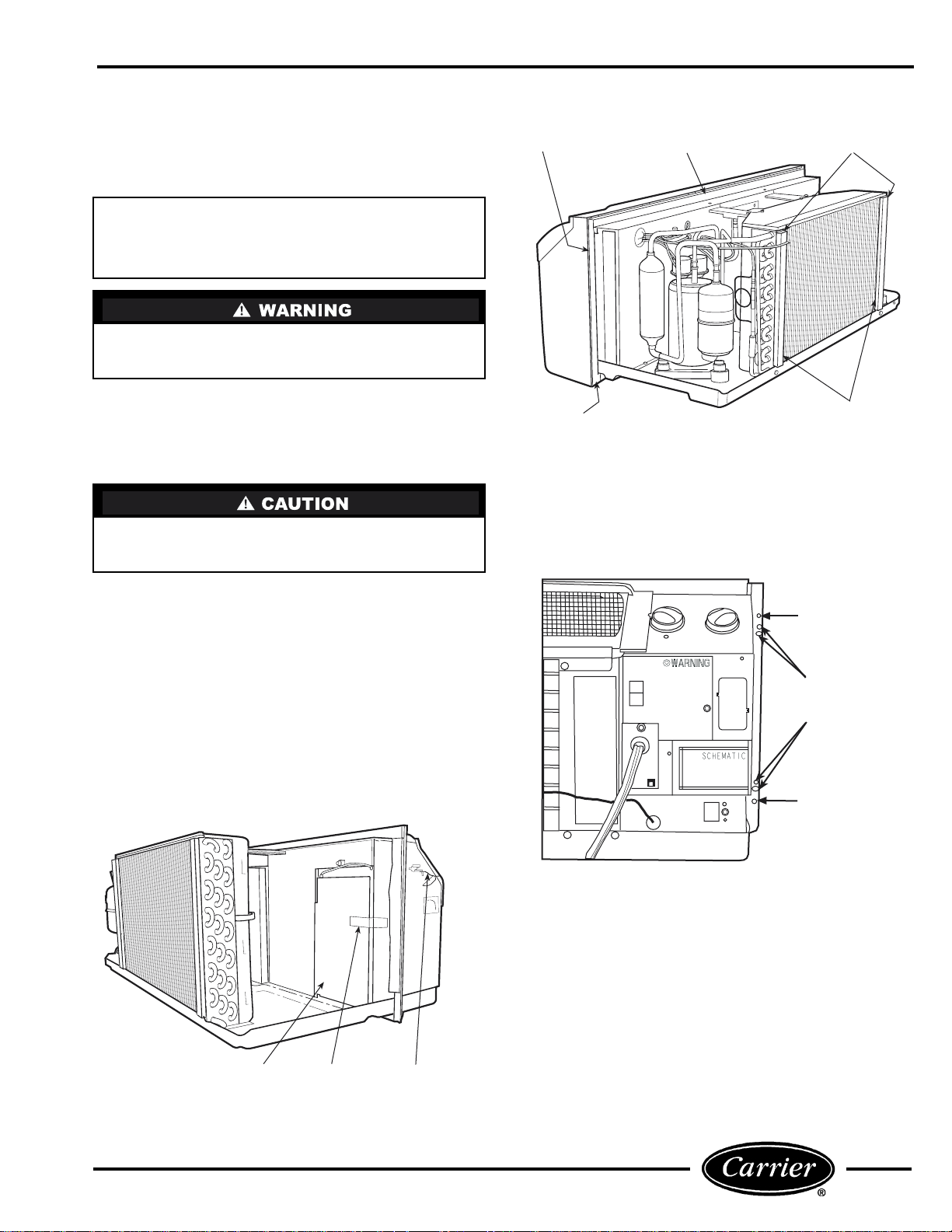

■ INSTALL CHASSIS IN SLEEVE (See Figures 11 to

13)

1. Inspect foam gaskets (top, bottom, both sides) on

chassis. Replace foam gaskets if torn or missing.

IMPORTANT: The gaskets combine with the sleeve

face to create a weather barrier. If the chassis is

installed in a non-Carrier sleeve, this weather barrier may not be effective.

Chassis weighs up to 150 lb. For personal protection,

seek help when lifting the unit. Lift unit by holding

unit basepan.

SIDE

GASKET

TOP

GASKET

FACTORY-INSTALLED

FOAM SEALS

2. If retrofitting into a GE, Amana, Trane, or

Friedrich wall sleeve/grill e, remove any existing

foam seals from competitive manufacturer’s grille

before installing unit.

3. Remove shipping tape from vent door. See Figure 1 1.

Failure to remove shipping tape will prevent fresh

air vent door from opening and may result in damage

to the vent door cable.

4. Carefully remove power cord packing material

and discard.

5. Lift chassis level with wall sleeve.

6. Slide chassis into wall sleeve until foam gaskets

rest firmly against front of wall sleeve. See

Figure 12.

7. Screw chassis to wall sleeve with four 1

3

/4-in. long

screws taped to the control box. Screw holes are

located on both sides of the mo unting angles of th e

chassis. For Carrier wall sleeves, use the top-most

and bottom-most screw holes. For competitive

wall sleeves, line up the correct attachment holes

on the chassis with the holes in the sleeves. See

Figure 13.

BOTTOM

GASKET

FIGURE 12 — UNIT GASKETS

AND TUBE SHEETS

TOP SCREW HOLE

(CARRIER SLEEVE)

COMPETITIVE

MANUFACTURER

SLEEVE

ATTACHMENT

HOLES

BOTTOM SCREW

HOLE

(CARRIER SLEEVE)

COIL TUBE

SHEETS

VENT

DOOR

SHIPPING

TAPE

VENT DOOR

CABLE

FIGURE 11 — LOCATION OF SHIPPING TAPE

ON VENT DOOR

FIGURE 13 — CHASSIS MOUNTING

7

Page 8

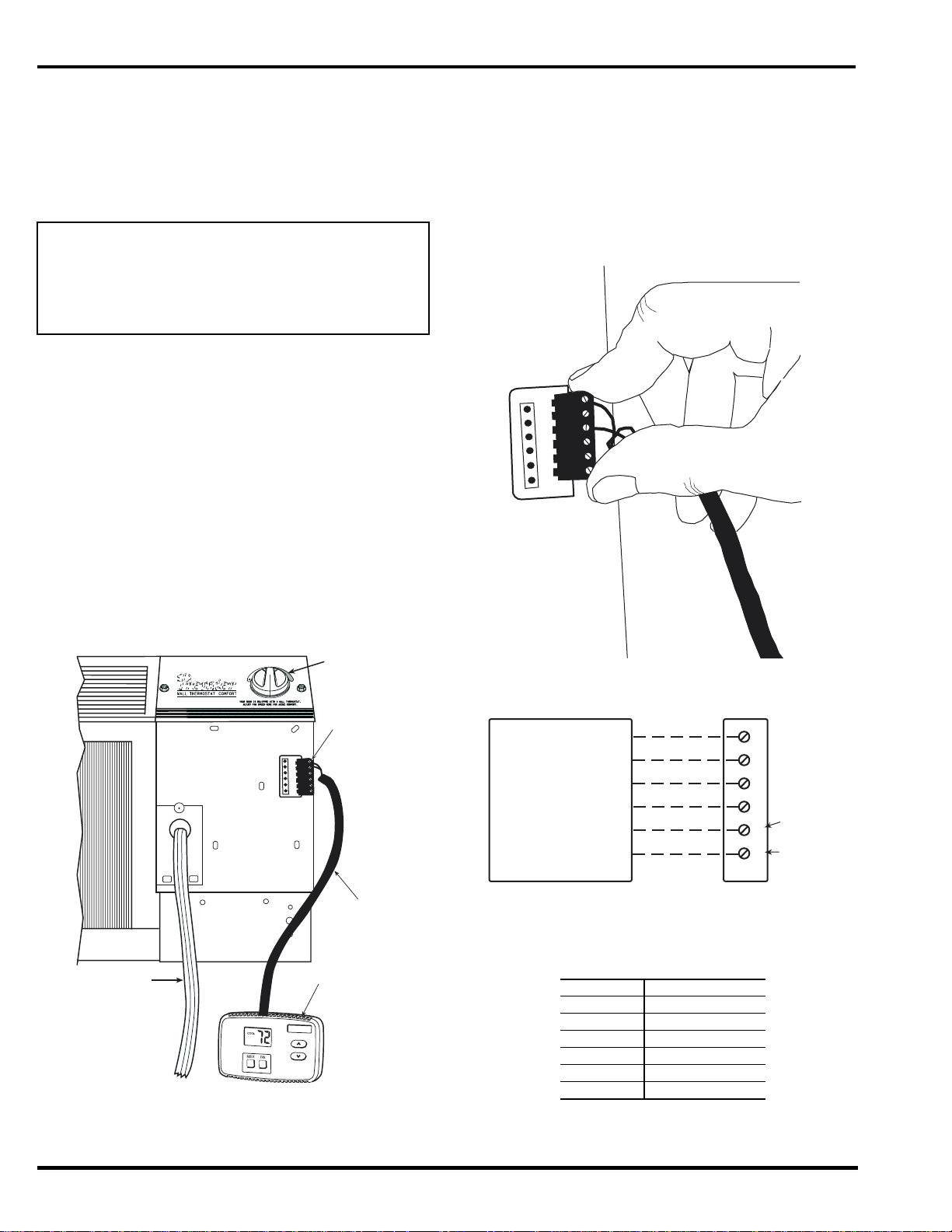

WALL THERMOSTAT INSTALLATION

The following instructions apply to RC and RP units

only.

NOTE: Carrier thermostats are recommended. See

Accessories section.

IMPORTANT: Only trained, qualified personnel

and service mechanics should install electrical

accessories on Carrier 52C and 52P series products

per Carrier’s installation instructions. Please contact your local electrical contractor, dealer, or distributor for assistance.

■ THERMOSTAT WIRE ROUTING — Thermos ta t

wire is field supplied. Recommend ed wire gage is 18 t o

20 gage solid thermo stat wire. The rmostat wire should

always be routed around or under, NEVER through,

the wall sleeve. The wire shoul d then be rout ed behind

the front panel to the easily accessible terminal connector. See Figures 14 and 15.

■ INSTALL THERMOSTAT — All remote control

units.

1. Check to be sure power to unit is disconnected.

2. Pull terminal connector to remove.

NOTE: Terminal connector can be removed and replaced to simplify thermostat wiring.

3. Connect wires from terminals on the thermostat

to terminals on chassis terminal board connector.

See Figures 15 and 16.

4. Reinstall terminal connector.

5. Restore power to unit.

NOTE: Refer to thermostat installation instructions

for details on installing thermostat.

NOTE: Fan speed is user-selectable from the control

panel on the unit.

R

Y

W

G

O

C

HI

R

Y

W

G

O

C

FAN SPEED

SELECTOR

SWITCH

TERMINAL

CONNECTOR

THERMOSTAT

WIRE (FIELD

SUPPLIED)

THERMOSTAT

POWER

CORD

LO

FAN SPEED

FIGURE 14 — CONTROL BOX TERMINAL

CONNECTOR FOR WALL THERMOSTAT MODELS

FIGURE 15 — TERMINAL CONNECTOR

REMOVAL AND REPLACEMENT

R

G

TYPICAL

WALL

THERMOSTAT

Y

W

O

C

TERMINAL

BLOCK

SEE

NOTE #1

SEE

NOTE #2

NOTES:

1. Use terminal “O” for heat pump connection only.

2. Terminal C (common) is typically only required for digital thermostats.

3. See table below for terminal descriptions.

TERMINAL DESIGNATION

R 24 VAC

G Fan

Y Compressor

W Electric Heat

O Reversing Valve

C Common

FIGURE 16 — WIRING CONNE CTIONS

8

Page 9

OPERATION

IMPORTANT: When unit is first started, high

humidity conditions can cause co ndensation to form

on discharge grille. Keep doors and windows closed.

Room humidity decreases and moisture evaporates.

COMFORT CONTROLS

■ ADJUST AIRFLOW DIRECTION — The discha rge

air grille is mounted on the front panel so that the air

discharges forward. If upward discharge is required,

remove the grille by removing screws on back of front

panel. Rotate grille 180 degrees and reinstall on the

front panel.

■ ADJUST VENT — The vent handle is on the left

side of the unit. Turn handle to open or close vent.

Vent will remain in last desired position until handle

is turned again. Magnet will ensure positive closure.

See Figure 17.

■ SETTING TEMPERATURE LIMITS — Setting tem-

perature limits on the unit provides the user a

restricted range of temperature control. See Figure 18.

NOTE: This adjustment is option al and is not applicable to remote control units.

The temperature limits are factory set to full range,

which is 60 F to 90 F. To set restricted rotation of the

temperature control knob:

1. Remove front panel.

2. Remove temperature control knob to expose temperature limiter.

3. Remove standoff pins from the 60 F and 90 F indicator holes.

4. Replace standoff pin in hole for desired minimum

temperature.

5. Replace standoff pin in hole for desired maximum

temperature.

6. Reinstall temperature control knob.

7. Reinstall front panel.

NOTE: Temperature indicators stamped on temperature limiter are approximate and represent degrees F.

75

70

65

60

90

TEMPERATURE

CONTROL

STANDOFF

PINS

FAN CYCLE

SWITCH

80

85

CON

CYC

MAGNET

VENT

DOOR

VENT

FILTER

FIGURE 17 — VENT DOOR

VENT HANDLE

E

S

O

L

C

N

PE

O

SET

SCREW

OUTDOOR

THERMOSTAT

(HEAT PUMP

UNITS ONLY)

S

L

I

A

F

E

V

O

B

A

T

S

E

T

S

I

E

S

U

T

O

N

O

D

.

E

S

U

R

O

F

N

I

A

G

A

N

O

T

T

U

B

T

E

S

E

R

S

S

E

R

P

.

4

.

T

H

G

I

L

D

L

U

O

H

S

T

I

N

U

N

O

T

T

U

B

T

S

E

T

S

S

E

R

P

.

3

.

E

L

C

A

T

P

E

C

E

R

R

E

W

O

P

O

T

N

I

G

U

L

P

.

2

.

N

O

T

T

U

B

T

E

S

E

R

S

S

E

R

P

.

1

T

E

S

T

IN

G

FIGURE 18 — OPERATING CONTROLS

9

Page 10

OPERATING CONTROLS

The following controls are located on the front of the

control box door, under front panel. To obtain access to

operating controls, remove the unit front panel as

shown on page 2. See Figure 18.

■ FAN CYCLE SWITCH — (Typically available at

wall thermostat on RC or RP units.) This allows the

fan to operate in two modes:

CON (Continuous)

run continuously, circulating air even when the temperature setting has been satisfied. This switch helps

to maintain the room temperature closer to the thermostat setting. Use this switch po sition when maximum comfort is desired. This is the factory default

setting.

CYC (Cycle)

and off with the compressor during heating or cooling.

The fan stops when the temperature setting is satisfied. This results in longer unit off-time and wider

variations in room temperature and humidity.

■ OUTDOOR THERMOSTAT (52CQ and 52PQ HEAT

PUMP UNITS ONLY) — If the setscrew is left at the

factory setting (in the heat pump position), the unit

will operate in the reverse cycle heating mode. See

Figure 18. When the temperature of the outdoor coil

reaches 20 F (approximately 35 F outdoor air temperature), the compressor will shut down as unit is no

longer capable of adequate heating in heat pump

mode. The electric heater then becomes the primary

heating source. The electric heater remains on until

the temperature of the outdoor coil reaches 40 F; then

the electric heater is shut off and the compressor is

energized. Once the compressor is energized, the heat

pump again becomes the primary heating source.

To set unit to operate in electric heat mode only, turn

the setscrew to the electric heat positi on. See Fi gure 18 .

— This setting allows the fan to

— This setting allows the fan to cycle on

IMPORTANT: If setscrew on standard heat pump

unit is set to electric heat mode operation, the compressor is disabled for both heating and cooling

operations. If setscrew on heat pump unit with wall

thermostat control is set to electric heat mode

operation, the compressor will be disabled only for

heating operation.

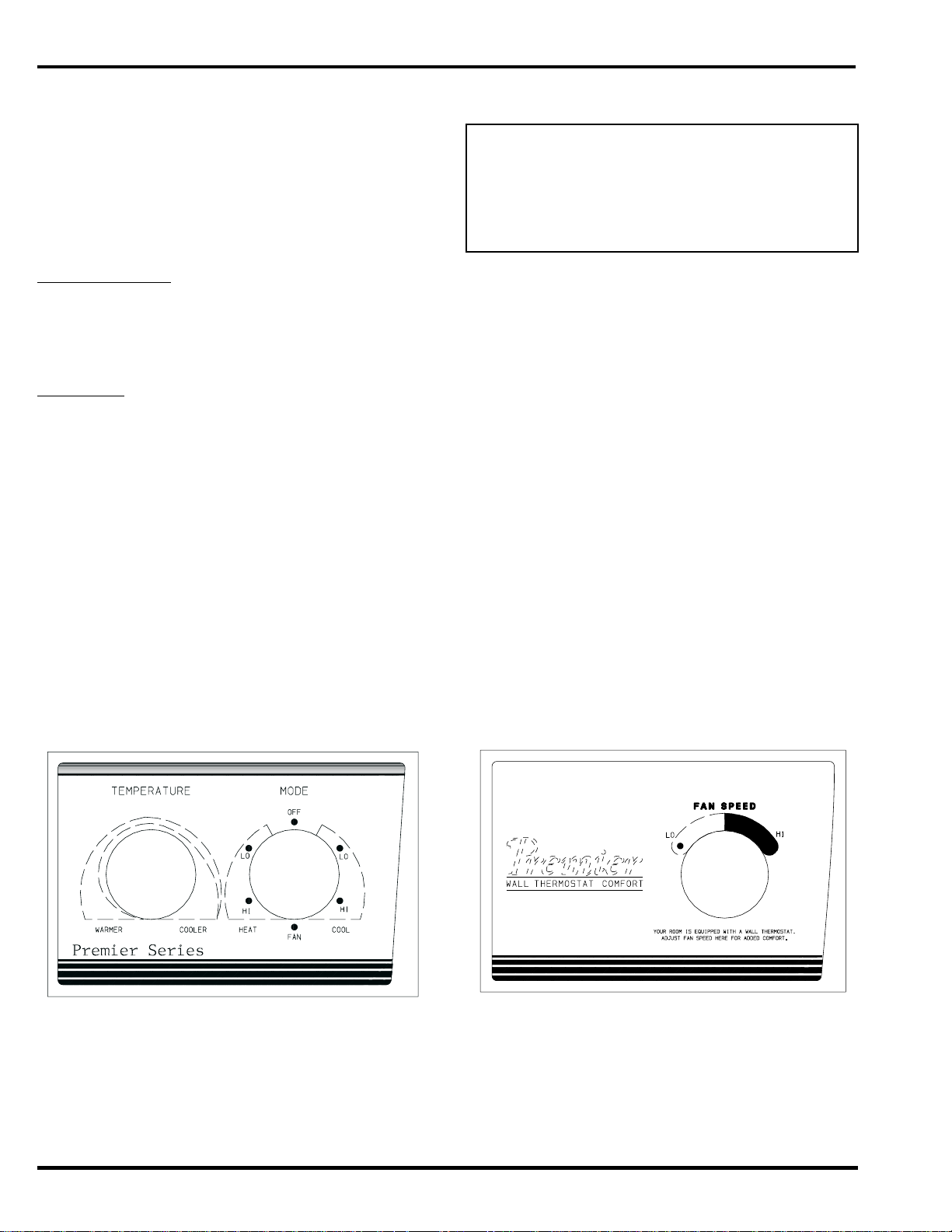

OPERATING MODES (See Figures 19

and 20.)

■ OUTSIDE AIR — To bring outside air into occupied

space, turn the vent handle to the full open position.

See Figure 17.

■ OFF — The OFF mode terminates unit operation.

■ FAN— The FAN mo de will circulate air in the space

at high speed and at high or low speed for cool ing onl y

models.

■ HIGH HEAT OR HIGH COOL — Select mode and

rotate temper atu r e kn ob to d esi re d c omfo r t le v el. T hi s

function provides maximum heating or cooling, and is

recommended to raise or lower the room temperature

quickly.

■ LOW HEAT OR LOW COOL — Select mode and

rotate temper atu r e kn ob to d esi re d c omfo r t le v el. T hi s

function provides minimum heating or cooling with

maximum dehumidification and quietest operation.

■ FAN SPEED CONTROL FOR 52P AND 52C WALL

THERMOSTAT MODELS — For maximum comfort,

fan speed is user selectable at the unit. See Figure 20.

FIGURE 19 — 52P UNIT CONTROLS SHOWN

WALL THERMOSTAT CONTROL SHOWN

FIGURE 20 — 52P UNIT WITH

(Blank Plate)

10

Page 11

CARE AND MAINTENANCE

In order to maintain proper performance of your packaged terminal air conditioner or heat pump, it is very

important that the fan and outdoor coil, the blower

wheel, blower scroll, electric heater, and all drain passages are thoroughly cleaned at least once per year.

Carrier recommends that as a minimum, the cleaning

should be conducted prior to the start of each heating

season. The air inlet filters should be cleaned every

month.

Depending on local condition s, more freq uent cleaning

of the unit may be required to ensure optimum performance and long operating life. Examples of these special conditions include areas where construction dust

or heavy airborne dirt is found, or environments that

promote the growth of fungus.

Some local conditions and environments can cause

fungi to grow inside the air conditioner, especially on

indoor blower section. Dried fungi, dirt and other

foreign material are fire hazards. Be sure to clean

unit according to the instructions that follow.

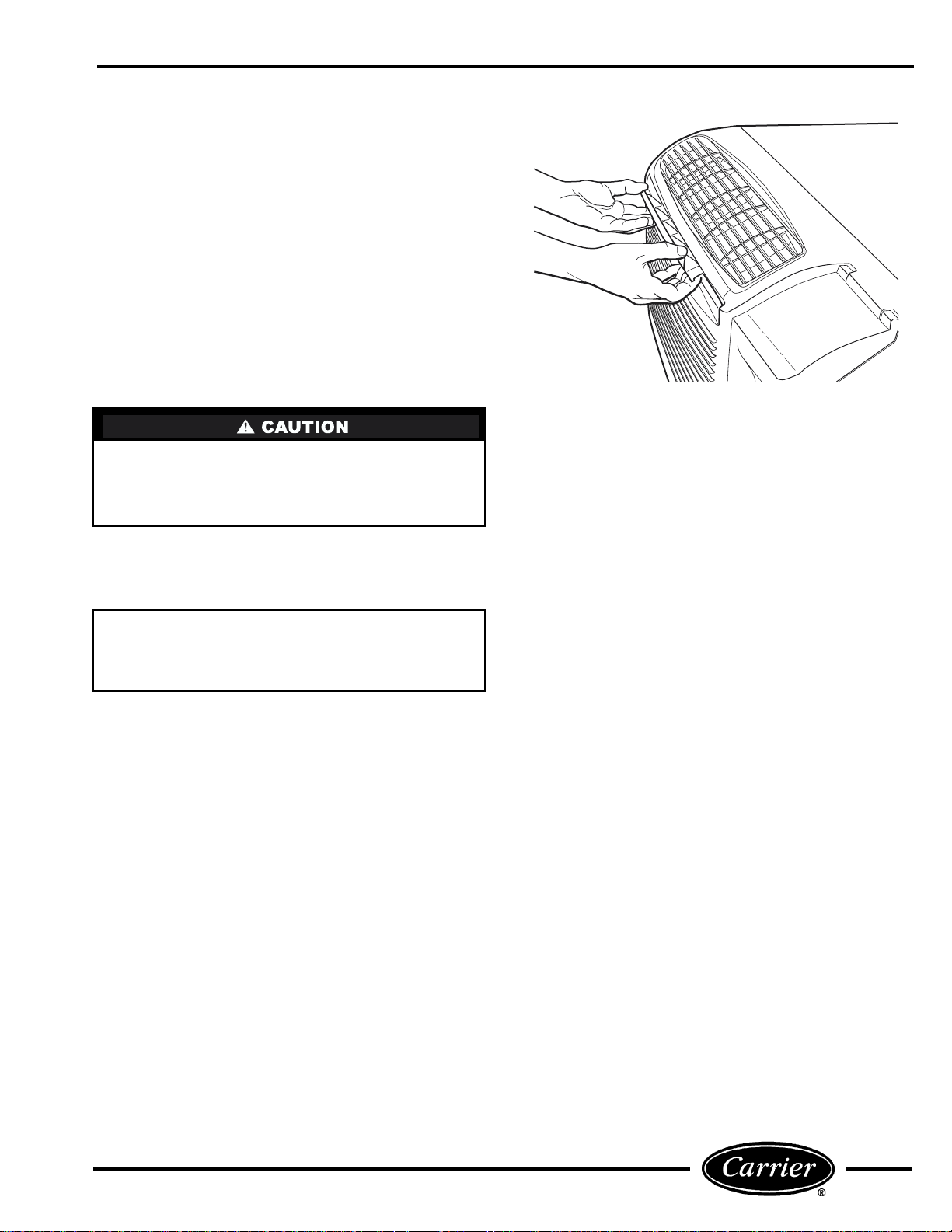

INDOOR-AIR INLET FILTERS

■ INDOOR-AIR INLET FILTERS should be cleaned

once each month.

FIGURE 21 — INDOOR-AIR INLET

FIL TER REMOVAL

IMPORTANT: Filters may become clogged if not

cleaned properly. Clogged filters will restrict airflow which may lead to severe component damage

and efficiency loss.

■ CLEANING INDOOR-AIR INLET FILTER — Two

interchangeable air filters are located on the backside

of the front panel. Each can be removed and cleaned

one at a time. To remove and clean the filter, follow the

steps below:

1. Grasp filter with both hands.

2. Gently pull the filter up and away from the unit.

See Figures 5 and 21.

3. To clean filter, use a vacuum or soft bristle brush

with a small amount of mild deterg ent.

NOTE: If detergent is used, remove any detergent

residue with a gentle stream of clean water.

4. Allow filters to air dry.

5. Re-insert dry filters back into front panel.

Additional filters are available in multi-packs. Refer to

Accessories section.

11

Page 12

EXTERNAL PARTS

■ EXTERNAL PARTS include the polymer sleeve and

grilles. The sleeve manufact urer recommends cleaning

the surface, including the grilles, with household

detergent and water.

VENT HANDLE

MAGNET

INTERNAL PARTS

■ INTERNAL PARTS should be cleaned at least once

during the year. The outdoor vent filter should be

cleaned at least once during a cooling or heating

season.

Internal parts that should be cleaned include the following (see Figures 5, 22, and 23):

• Outdoor vent filter

•Basepan

• Outdoor orifice and fan

• Indoor and outdoor refrigeration coils

• Indoor blower wheel

• Wire screen

• Scroll

• Wall sleeve internal surfaces

• Outdoor grille

P

O

VENT

DOOR

VENT

FILTER

FIGURE 22 — OUTDOOR VENT FILTER

(Left Side of Chassis)

SE

CLO

N

E

SCROLL

BLOWER

WHEEL

FIGURE 23 — BLOWER WHEEL AND SCROLL

12

Page 13

PREVENTATIVE

MAINTENANCE

Preventative maintenance is essential to proper unit

operation, efficiency and longevity. To assure equipment operates properly it must be properly maintained. Equipment operation should be checked and

verified several times during each year.

During regular unit inspection and maintenance, follow the guidelines below:

• Wash both sides of outdoor coil

• Wash basepan and outdoor vent filter

• Wash the indoor coil

• Clean the blower wheel and front panel

• Clean or install new indoor-air inlet filter(s)

• Ensure knobs are secure and operable

• Inspect cord and receptacle

• Secure electrical connections

• Ensure front panel is properly mounted and not

damaged

• Ensure wall sleeve is installed properly

• Ensure heat and cool cycles operate properly

• Check power cord protective device by pressing the

TEST button, then pressing the RESET button.

13

Page 14

TROUBLESHOOTING

POSSIBLE CAUSES SOLUTIONS

UNIT DOES NOT START

• Unit may have become unplugged • Check that plug is securely in wall receptacle.

• RESET button on cord or plug may have tripped • Check RESET button on cord or plug. See Note 1.

• Fuse may have blown • Replace the fuse. See Note 1.

• Circuit breaker may have been tripped • Reset circuit breaker. See Note 1.

• Unit mode dial may be set to the OFF position • Switch mode dial to an operating mode.

UNIT NOT COOLING/HEATING ROOM

• Unit air discharge section is blocked • Make sure that curtains, blinds or furniture are not restricting or

• Temperature setting is not high or low enough • Reset to a lower or higher temperature setting.

• Unit air filters are dirty • Remove and clean filters.

• Room is excessively hot or cold when unit is started • Allow sufficient amount of time for unit to heat or cool the room.

• Vent door left open • Close vent door.

UNIT MAKING NOISES • Clicking, gurgling and whooshing noises are normal during operation of

WATER DRIPPING OUTSIDE • If a drain kit has not been installed, condensation run-off during

WATER DRIPPING INSIDE

• Wall sleeve is not installed level • Wall sleeve must be installed level for proper drainage of condensation.

ICE OR FROST FORMS ON INDOOR COIL

• Low outdoor temperature • When outdoor temperature is approximately 55 F or below, frost

• Dirty filters • Remove and clean filters.

blocking unit airflow.

Start heating or cooling early before outdoor temperature, cooking

heat or gatherings of people make room uncomfortable.

unit.

very hot and humid weather is normal. See Note 2. If a drain kit

has been installed and is connected to a drain system, check

gaskets and fittings around drain for leaks and plugs.

Check that installation is level and make any necessary adjustments.

may form on the indoor coil when unit is in Cooling mode. Switch

unit to FAN operation until ice or frost melts.

NOTES:

1. If circuit breaker is tripped, fuse is blown or RESET button on cord or plug is tripped more than once, contact a qualified electrician.

2. If unit is installed where condensation drainage could drip in an undesirable location, an accessory drain kit should be installed and connected to

drain system.

14

Page 15

ACCESSORIES

ACCESSORY FORM NUMBER PART NUMBER DESCRIPTION

Wall Sleeves 52S-48SI WALL-SLEEVE-1PK Non-Insulated Polymer Wall Sleeve, 1 per pack

52S-50SI SLEEVE-STEEL-1PK Insulated Metal Wall Sleeve, 1 per pack

52S-49SI SLEEVE-EXT24-1PK Extended Metal Wall Sleeve for Deep Wall Applications (24 in. deep), 1 per pack

52C,P-26SI FR-SLEEVE-EXT Friedrich wall sleeve extension to retrofit Carrier PTAC unit into Friedrich 111/2″deep

Exterior Grilles* 52S-59SI GRILLE-ALU-STAMP Stamped Aluminum Exterior Grille, Clear Finish

Subbase 52C,P-1SI SUBBASE-NON-ELEC Non-electrical Subbase

Subbase

Field-Installed

Kits

Electrical

Connections

Condensate

Drain Kit

Wall

Thermostats

Wall Thermostat

Interface

Retrofit Kit

Replacement

Filters

Energy

Management

Locking Security

Control Door

Lateral Duct Kit 52C,P-25SI LATERAL-DUCT Ductwork to allow one unit to heat and cool two rooms (plenum plus extension duct and registers)

Power Ven t

Retrofit Kit

Air/Curtain

Deflector

Touch-Up Paint N/A CARRIER-TOUCH-UP Touch up paint for repainting scratches or chips.

*Custom co lors are also available.

52S-65SI

52S-60SI GRILLE-ALU-CLEAR Aluminum Architectural Exterior Grille, Clear Finish

52C,P-31SI BAFFLE-KIT-1PK Ensures good air seal and prevents air recirculation when Carrier sleeve is used with a non-Carrier grille.

52C,P-2SI SUBBASE-230V-15A Electrical subbase with factory-installed 208/230V, 15 amp receptacle

52C,P-17SI SUBBASE-265V-15A Electrical subbase with factory-installed 265V, 15 amp receptacle

52C,P-3SI SUBBASE-HARDWIRE Electrical subbase with factory-installed hardwire kit (230/208V and 265V)

52C,P-4SI SUBBASE-SWITCH Field-Installable Switch kit for an electrical subbase

52C,P-5SI SUBBASE-FUSE-15A Field-Installed Fuse Kit (15 amp) for electrical subbase

52C,P-11SI HARDWIRE-KIT-1PK Permanent power connection to the unit (includes 36″of flexible conduit and unit-mounted

52C,P-19SI CONDUIT-INTF-4PK Interface kit for field-supplied conduit to provide permanent power connection

52S-53SI DRAIN-KIT-4PK Attaches to wall sleeve for controlled internal or external disposal of condensate 4 per pack

N/A HH01AD045 Electro-mechanical Wall Thermostat (Heat/Cool and Heat Pump)

52C,P-30SI RC-FIELDKIT230HC Field-installed wall thermostat retrofit kit to convert a standard 230V Heat/Cool unit to an

52C,P-34SI 2SPEED-TSTAT-KIT Field-installed automatic heat/cool changeover thermostat with 2-speed fan control at thermostat.

N/A TSTAT-COVER-6X7 Clear plastic locking thermostat cover prevents unauthorized access to thermostat.

N/A TSTAT-COVER-7X10 Clear plastic locking thermostat cover prevents unauthorized access to thermostat. Cover for

N/A AIR-FILTER-10PK Replacement air filters in package of 10

52C,P-24SI EM-KIT Allows unit to be turned on and off from a remote location (includes freeze guard protection)

52C,P-23SI SECURITY-DOOR Key-locking security door to prevent access to heating and cooling controls

52C,P-32SI PWR-VENT-DOOR230 Power vent with automatic door that opens and closes when the fan turns on and off (230V).

52C,P-9SI DEFLECTOR-1PK Lateral air deflector, with individually adjustable louvers, to enhance air circulation, 1 per pack

52C,P-21SI CURTDFL-52CP-1PK Curtain deflector for 52C and 52P models — prevents curtains from blowing into

WALL-SLEEVE-9PK Non-Insulated Polymer Wall Sleeve, 9 per pack

SLEEVE-INSUL-1PK Insulated Polymer Wall Sleeve, 1 per pack

SLEEVE-EXT26-1PK Extended Metal Wall Sleeve for Deep Wall Applications (26 in. deep), 1 per pack

SLEEVE-EXT28-1PK Extended Metal Wall Sleeve for Deep Wall Applications (28 in. deep), 1 per pack

SLEEVE-MOLDING Molding kit to trim the wall sleeve to the wall

(T Series) wall sleeve. 1 per pack

GRILLE-PLA-BROWN Polymer Architectural Rear Grille, Brown

GRILLE-PLA-BEIGE Polymer Architectural Rear Grille, Beige

GRILLE-ALU-WHITE Aluminum Architectural Exterior Grille, White

GRILLE-ALU-BRONZ Aluminum Architectural Exterior Grille, Light Bronze

GRILLE-ALU-MBRNZ Aluminum Architectural Exterior Grille, Medium Bronze

GRILLE-ALU-BROWN Aluminum Architectural Exterior Grille, Brown (Dark Bronze)

GRILLE-ALU-BEIGE Aluminum Architectural Exterior Grille, Beige

GRILLE-ALU-ALPIN Aluminum Architectural Exterior Grille, Alpine (matches Carrier Wall Sleeve)

GRILLE-ALU-PEACH Aluminum Architectural Exterior Grille, Peach

GRILLE-ALU-MELON Aluminum Architectural Exterior Grille, Melon

GRILLE-ALU-LGREY Aluminum Architectural Exterior Grille, Light Grey

GRILLE-ALU-SGREY Aluminum Architectural Exterior Grille, Slate Gray

GRILLE-ALU-RDBRK Aluminum Architectural Exterior Grille, Red Brick

GRILLE-ALU-BLUE Aluminum Architectural Exterior Grille, Blue

GRILLE-ALU-GREEN Aluminum Architectural Exterior Grille, Green

SUBBASE-230V-20A Electrical subbase with factory-installed 208/230V, 20 amp receptacle

SUBBASE-230V-30A Electrical subbase with factory-installed 208/230V, 30 amp receptacle

SUBBASE-265V-20A Electrical subbase with factory-installed 265V, 20 amp receptacle

SUBBASE-265V-30A Electrical subbase with factory-installed 265V, 30 amp receptacle

SUBBASE-FUSE-20A Field-Installed Fuse Kit (20 amp) for electrical subbase

SUBBASE-FUSE-30A Field-Installed Fuse Kit (30 amp) for electrical subbase

connector, 230/208V and 265V) 1 per pack

(230/208V and 265V) to the unit. Kit includes Molex connector for easy connect/disconnect.

4 per pack

TSTATCCBPC01-B Value Series Electronic Thermostat w/Digital display (Heat/Cool Models)

TSTATCCBPH01-B Value Series Electronic Thermostat w/Digital display (Heat Pump Models)

TSTATCCPAC01-B 7-Day Programmable Electronic Thermostat (Heat/Cool Models)

TSTATCCPHP01-B 7-Day Programmable Electronic Thermostat (Heat Pump Models)

RC-FIELDKIT230HP Field-installed wall thermostat retrofit kit to convert a standard 230V Heat Pump unit to an

RC-FIELDKIT265HC Field-installed wall thermostat retrofit kit to convert a standard 265V Heat/Cool unit to an

RC-FIELDKIT265HP Field-installed wall thermostat retrofit kit to convert a standard 265V Heat Pump unit to a

PWR-VENT-DOOR265 Power vent with automatic door that opens and closes when the fan turns on and off (265V).

RC unit. Wall thermostat sold separately (can be used to convert a cool only unit to RC).

RC unit. Wall thermostat sold separately.

RC unit. Wall thermostat sold separately (can be used to convert a cool only unit to RC).

RC unit. Wall thermostat sold separately.

Cover for use with non-programmable and electro-mechanical thermostats.

Outside dimensions: 6

use with programmable thermostats. Outside dimensions: 71/4″ x 93/4″ x 33/8″. 1 per pack

discharge air stream. 1 per pack.

NOTE: Curtain deflector for previous models are also available. Contact Carrier Representative.

1

/2″ x 71/2″ x 215/16″. 1 per pack

15

Page 16

Page 17

normal maintenance as outlined in the owner’s manual.

installation.

tion. This is the responsibility of the installer.

or any other damages due to the inadequacy or interruption of electrical

services.

unauthorized alteration, improper ser vicing or operation.

environment, or other conditions beyond the control of CARRIER.

EXCEPTION TO CORROSIVE ENVIRONMENT IN ABOVE PARAGRAPH —

Packaged terminal units (52 Series) built with corrosion protection are exempt

from the exclusion — “Corrosive Environment.” The unit model number is

identified on the nameplate with a CP suffix.

plied or designated by CARRIER and which are specifically covered under

this warranty.

and Canada.

responsibility of the selling dealer or the authorized Room Air Conditioner

service station.

MERCIAL DAMAGE OF ANY NATURE WHATSOEVER. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

1. CLEANING REQUIRED PRIOR TO WARRANTY REPAIR.

2. Standard maintenance, cleaning or damage resulting from failure to perform

3. Instruction on methods of control and use of air conditioning unit after initial

4. Damage or repairs needed as a consequence of faulty installation or applica-

5. Failure to star t due to voltage conditions, blown fuses, open circuit breakers

6. Damage or repairs needed as a consequence of any misapplication, abuse,

CARRIER WILL NOT BE RESPONSIBLE FOR:

7. Damage as a result of floods, winds, fires, lightning, accidents, corrosive

8. Reimbursement for replacement parts or repair services which are not sup-

9. CARRIER products installed outside the continental U.S.A., Alaska, Hawaii

10. Shipping damage or damage as a result of transporting the unit. This is the

11. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR COM-

12. Warranty coverage of accessory items (wall thermostats, wall sleeves, etc.).

NOTE: Service and Maintenance items excluded in this warranty may be covered by

a separate service agreement through the seller at time of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Carrier

Packaged Terminal

Air Conditioner Warranty

FULL ONE-YEAR WARRANTY — During the first year after purchase, CARRIER

will, through its authorized independent servicing dealers or service stations*, and

free of charge to the user or subsequent users, repair or replace any par ts which

are defective in material or workmanship. The replacement part can be a new or

remanufactured part as provided at CARRIER’S sole option.

FULL EXTENDED FOUR-YEAR WARRANTY ON SEALED REFRIGERATION

SYSTEM ONLY — During the second through fifth years after date of original pur-

chase, CARRIER will, through its authorized servicing dealers and service stations*

and free of charge to the end user or subsequent users, repair or replace the

compressor, condenser, evaporator or connecting tubing if defective in material or

workmanship. This includes system refrigeration charge. The replacement part can

be new or a remanufactured part as provided at CARRIER’S sole option.

LIMITED EXTENDED FOUR-YEAR WARRANTY ON NON-SEALED REFRIGER-

ATION SYSTEM ONLY — During the second through fifth years after date of origi-

nal purchase, Carrier will, through its authorized servicing dealers and service

stations and free of charge to the end user or subsequent users, repair or replace

any non-sealed system part (motor, solenoid, thermistor, thermostat, relays, switch,

capacitor, overload, drain valve, bulb heater, fan, stator) if defective in material or

workmanship. The replacement part can be new or a remanufactured par t at

CARRIER’S sole option. THIS LIMITED WARRANTY DOES NOT INCLUDE

LABOR, user is responsible for labor, including cost of diagnosis of problem,

removal and transportation of the air conditioner to and from the service center, and

reinstallation charges necessary to accomplish repair.

LIMITATION OF WARRANTIES — ALL IMPLIED WARRANTIES (INCLUDING

IMPLIED WARRANTIES OF MERCHANTABILITY) ARE HEREBY LIMITED IN

DURATION TO THE PERIOD FOR WHICH EACH LIMITED WARRANTY IS GIVEN

AND APPLIES. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG

AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY

TO YOU. THE EXPRESSED WARRANTIES MADE IN THIS WARRANTY ARE

EXCLUSIVE AND MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY

DISTRIBUTOR, DEALER, OR OTHER PERSON WHATSOEVER.

ALL WORK UNDER THE TERMS OF THIS WARRANTY SHALL BE PERFORMED

DURING NORMAL WORKING HOURS. ALL REPLACEMENT PARTS, WHETHER

*Authorized independent dealers or service stations are registered with Carrier Air Conditioning through its distributor organization.

NEW OR REMANUFACTURED, ASSUME AS THEIR WARRANTY PERIOD ONLY

THE REMAINING TIME PERIOD OF THIS WARRANTY.

Catalog No. 530-122 (Rev. 3/02)

17

Page 18

Carrier Air Conditioning

Consumer Relations Department

Carrier Parkway, P.O. Box 4808

Syracuse, New York 13221

Telephone: 1-800-894-6449

3. CONTACT THE CARRIER DISTRIBUTOR SERVING YOUR AREA.

Your dealer can provide the distributor’s name or you can consult your

yellow pages.

4. CONTACT CARRIER IF A SATISFACTORY SOLUTION IS NOT

REACHED IN STEPS 2 AND 3.

IF YOUR AIR CONDITIONER DOES NOT WORK, FOLLOW THESE STEPS IN ORDER:

1. CHECK THE THINGS YOU CAN DO YOURSELF. These include

being sure the air conditioner is plugged in firmly in an appropriate

receptacle, checking the fuse or circuit breaker and ensuring its re-

placement or resetting, if necessary, and rereading the instruction

book to ensure that all controls are set properly. By doing this you

can save money. Many unnecessary service calls in the serviceman

doing what the owner can do for him or herself.

2. CONTACT YOUR DEALER OR THE RECOMMENDED CARRIER

AUTHORIZED SERVICE CENTER. They have been set up

to handle the great majority of all possible service problems. The

quickest, surest and best way to get your air conditioner back in

service is to use this step before proceeding further.

Carrier Corporation

Copyright 2004 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 9a 11a

PC 132 Catalog No. 535-20066 Printed in U.S.A. Form 52C,P-2SO Pg 18 10-04 Replaces: 52C,P-1SO

Page 19

52C,P-1S0

OBLIGACIONES

PC 132 Catalogo No. 535-20066 Printed in U.S.A. Forma 52C,P-2S0 10-04 Sustituye:

EL FABRICANTE SE RESERVA EL DERECHO DE MODIFICAR O DESCONTINUAR LAS ESPECIFICACIONES DE DISEÑO SIN INCURRIR EN

2. CONTACTE AL DISTRIBUIDOR CARRIER O AL CENTRO

cortacircuito disparado. Si es necesario repase el manual de

instrucciones para verificar que los controles están bien ajustados.

Haciendo esto Usted mismo, ahorra dinero. Tal vez el técnico de

servicio venga y haga las cosas que pudo haber hecho Usted

mismo.

AUTORIZADO DE SERVICIO CARRIER RECOMENDADO. Ellos

están preparados para resolver la mayoría de los posibles problemas

de servicio. El mejor medio, más rápido y seguro para poner de

nuevo a funcionar su acondicionador es el seguir esta

recomendación antes de seguir adelante.

4. CONTACTE DIRECTAMENTE A CARRIER SI NO ENCONTRÓ UNA

Carrier Air Conditioning

Consumer Relations Departament

Carrier Parkway, P.O. Box 4808

Syracuse, New York 13221

Telefono: 1-800-894-6449

Carrier México, S.A. De C.V.

Galeana 469 Ote.

Santa Catarina, N.L.,

C.P. 66350 México

Teléfono: 01.800.830.8600 (México)

SOLUCIÓN SATISFACTORIA EN LOS PASOS 2 Y 3.

Telefónico.

1. VERIFIQUE LAS COSAS QUE PUEDE HACER USTED MISMO.

Esto incluye verificar si la unidad es bien conectada y en el contacto

correcto, verificar que los fusibles no están quemados o el

Corporación Carrier

SI SU ACONDICIONADOR DE AIRE NO FUNCIONA, SIGA LOS PASOS A CONTINUACIÓN:

3. CONTACTE AL DISTRIBUIDOR CARRIER QUE MÁS CERCA DE

USTED. Su distribuidor independiente puede darle su nombre o bien,

Usted puede consultarlo en la Sección Amarilla del Directorio

Page 20

R

* La red de distribuidores independientes autorizados está registrada en CARRIER a través de su organización de distribución.

Catalog No. 530-122 (Rev. 3/02)

Esta garantía le otorga derechos legales específicos, y Usted puede tener algunos otros derechos los cuales pueden variar entre los estados de la unión americana.

MISMO PERÍODO DE GARANTÍA RESTANTE.

TODOS LOS TRABAJOS BAJO LOS TÉRMINOS DE ESTA GARANTÍA DEBERÁN SER

REALIZADOS DURANTE HORAS DE TRABAJO NORMALES. TODAS LAS PARTES

DE REEMPLAZO, YA SEAN NUEVAS O RE-MANUFACTURADAS, ADOPTAN EL

(INCLUYENDO GARANTÍAS DE COMERCIALIZACIÓN), ESTÁN POR LA PRESENTE

LIMITADAS EN SU DURACIÓN AL PERÍODO PARA EL CUAL CADA GARANTÍA

LIMITADA SE HA OTORGADO. LAS GARANTÍAS EXPRESADAS EN ESTA GARANTÍA

SON EXCLUSIVAS Y NO DEBERÁN SER ALTERADAS, ALARGADAS O CAMBIADAS

POR NINGÚN DISTRIBUIDOR, CONCESIONARIO O CUALQUIER OTRA PERSONA.

centro de servicio y cargos de re-instalación necesarios para efectuar la reparación.

LIMITACIONES DE LA GARANTÍA - TODAS LAS GARANTÍAS CONTENIDAS

17

quinto año después de la compra original, CARRIER, a través de sus Distribuidores

Autorizados y libre de cargos para el usuario final o usuarios subsecuentes, reparará o

reemplazará el compresor, condensador, evaporador o tubería de interconexión en caso

de que resultase defectuoso su material o su fabricación. Esto incluye carga del sistema

de refrigeración. El reemplazo podrá ser nuevo o re-manufacturado a criterio de

CARRIER.

después de la compra original, CARRIER, a través de sus Distribuidores Autorizados y

libre de cargos para el usuario final o usuarios subsecuentes, reparará o reemplazará

cualquier parte del circuito no sellado (Motor, Solenoide, Termistor, Termostato,

Relevadores, Interruptor, Capacitor, Válvula de Desagüe, Calentador de Bulbo, Abanico,

Estator) en caso de que resultase defectuoso su material o fabricación. El reemplazo

podrá ser nuevo o re-manufacturado a criterio de CARRIER. ESTA GARANTÍA

LIMITADA NO INCLUYE MANO DE OBRA, el usuario es responsable de la misma

incluyendo costo de diagnóstico del problema, retiro y transportación del aparato al

EXTENSIÓN DE GARANTÍA LIMITADA A CUATRO AÑOS EN CIRCUITOS DE

REFRIGERACIÓN NO SELLADOS -

Durante el lapso del cuarto y quinto año

EXTENSIÓN DE GARANTÍA A CUATRO AÑOS EN CIRCUITO DE

REFRIGERACIÓN SELLADO ÚNICAMENTE -

Durante el lapso entre el segundo y

a través de sus Distribuidores Autorizados y libre de cargos para el usuario final o

usuarios subsecuentes, reparará o reemplazará cualquier parte de la cual resultase

defectuoso su material o fabricación. El reemplazo podrá ser nuevo o re-manufacturado

a criterio de CARRIER.

GARANTÍA POR UN AÑO - Durante el primer año posterior a su compra, CARRIER,

Acondicionadores de Aire Tipo Consola

Carrier

Garantía para

NOTA: Las partidas de mantenimiento y servicio excluidos en esta garantía pueden ser

cubiertos mediante un acuerdo de servicio a través del vendedor al momento de la compra.

12. La cobertura de la garantía en accesorios (Termostatos de Pared,

Gabinetes, etc.)

11. CUALQUIER DAÑO COMERCIAL O DE PROPIEDAD ESPECIAL,

INDIRECTO O CONSECUENTE, DE CUALQUIER NATURALEZA. Algunos

estados de la unión americana no permiten la exclusión o limitación en

daños incidentales o consecuentes, de manera que la limitación de

exclusión anterior puede no aplicarse en su caso.

9. Productos Carrier instalados fuera de los Estados Unidos de Norteamérica,

10. Daños durante el embarque o daños como resultado de la transportación

sean suministrados o designados por CARRIER y que están cubiertos

específicamente por esta garantía.

Alaska, Hawai y Canadá.

de la unidad. Esto es responsabilidad del distribuidor que efectúa la venta.

EXCEPCIÓN POR AMBIENTE CORROSIVO EN PÁRRAFO ANTERIOR –

8. El reembolso por reemplazo de las partes o servicios de reparación que no

ambiente corrosivo u otras condiciones fuera del control de CARRIER.

Las unidades acondicionadas con protección anti-corrosiva están exentas

de la exclusión – “Ambiente Corrosivo”. El número del modelo de la unidad

está identificado en la placa de la unidad con un sufijo CP.

6. Daños o reparaciones necesarias como consecuencia de una mala

7. Daño como resultado de inundaciones, vientos, fuego, rayos, accidentes,

interrupción o servicios eléctricos inadecuados.

aplicación, abuso, alteración no autorizada, servicio u operación

inapropiada.

4. Daños o reparaciones necesarias como consecuencia de una mala

5. Una falla en el arranque debido a condiciones de voltaje, fusibles fundidos,

de aire después de su instalación inicial.

instalación o aplicación. Esto es responsabilidad del instalador.

interruptores de circuito abierto o cualquier otro daño debido a la

CARRIER NO SE HARÁ RESPONSABLE POR:

1. LIMPIEZA REQUERIDA ANTERIOR A LA REPARACIÓN EN GARANTÍA.

2. Mantenimiento de rutina, limpieza o daños debido a la falta de

3. Instrucciones o métodos de control y uso de la unidad de acondicionadora

mantenimiento normal como se especifica en el manual del usuario.

Page 21

Page 22

/16”. 1 Por paquete.

15

” de fondo. 1 por paquete

1/2

15

*También disponibles colores sobre pedido.

Pintura para retoques debidos a raspones a pintura.

Nota: El deflector de cortina para modelos anteriores está disponible. Contacte a su representante Carrier.

Deflector de cortinas para modelos 52C y 52P - evita que las cortinas obstruyan el flujo del aire, 1 por paquete.

Deflector de aire lateral, con persianas ajustables individualmente para mejorar la circulación de aire, 1 por paquete

Arrancador de ventilación con puerta automática que se abre y cierra cuando el abanico se enciende y apaga (265V).

Arrancador de ventilación con puerta automática que se abre y cierra cuando el abanico se enciende y apaga (230V).

Ductos para permitir que una unidad caliente o enfríe dos habitaciones (extensión de pleno y registros)

Puerta de seguridad con llave para evitar el acceso a los controles de calefacción y enfriamiento

Permite que la unidad sea encendida o apagada desde lugar remoto (incluye protección contra riesgos)

Filtros de repuesto, paquetes de 10

/8”, 1 por paquete.

3

/2”

x 71/2” x 2

1

1

3

/4” x 9

/4” x 3

programables. Dimensiones exteriores: 7

Cubierta plástico transparente con llave para termostato, evita acceso no autorizado al termostato. Se puede utilizar con termostatos

no programables y electro-mecánicos. Dimensiones exteriores : 6

Cubierta plástico transparente con llave para termostato, evita acceso no autorizado al termostato. Se puede utilizar con termostatos

Termostato automatico frio/calor de 2 velocidades para instalación en campo.

se vende por separado .

Termostato Pared instalable en campo para convertir unidad estándar Ciclo Reversible 265V a unidad RC. El termostato de pared

vende por separado (Se puede usar para convertir unidad Solo Frío a RC).

Termostato Pared instalable en campo para convertir unidad estándar Calor/Frío de 265V a unidad RC. El termostato de pared se

se vende por separado.

Termostato Pared instalable en campo para convertir unidad estándar Ciclo Reversible 230V a unidad RC. El termostato de pared

vende por separado (Se puede usar para convertir unidad Solo Frío a RC).

Termostato Pared instalable en campo para convertir unidad estándar Calor/Frío de 230V a unidad RC. El termostato de pared se

Termostato Electrónico programable 7 días (Modelos Bomba de Calor)

Termostato Electrónico programable 7 días (Modelos Calor/Frío)

Termostato Electrónico Value Series con pantalla digital (Modelos Calor/Frío)

Termostato Electrónico Value Series con pantalla digital (Modelos Calor/Frío)

Termostato de Pared Electromecánico (Calor/Frío y Bomba de Calor)

Unido a la manga para disposición controlada interna y externa del condensado. 4 por paquete

incluye conector Molex para fácil conexión. 4 por paquete.

Paquete de interfase para tubo conduit (NO incluido) para proveer conexión permanente (230/208V y 265V) a la unidad. Paquete

1 por paquete

Conexión permanente de corriente a la unidad (incluye 36" de tubo conductor y conector montado en la unidad, 230/208V y 265V)

Kit de fusible para instalación en campo (30 amp) para subbase eléctrica

Kit de fusible para instalación en campo (20 amp) para subbase eléctrica

Kit de fusible para instalación en campo (15 amp) para subbase eléctrica

Kit de interruptor instalable en campo para una subbase eléctrica

Kit de subbase alambre duro, para hacer una subbase no eléctrica, alambrada en campo (230V/208V y 265V)

Subbase eléctrica con receptáculo instalado en fábrica 265V, 30 amp.

Subbase eléctrica con receptáculo instalado en fábrica 265V, 20 amp.

Subbase eléctrica con receptáculo instalado en fábrica 265V, 15 amp.

Subbase eléctrica con receptáculo instalado en fábrica 208/230V, 30 amp

Subbase eléctrica con receptáculo instalado en fábrica 208/230V, 20 amp

Subbase eléctrica con receptáculo instalado en fábrica 208/230V, 15 amp

Subbase No eléctrica

Asegura un correcto sello y previene la recirculación de aire cuando se usa un chasis Carrier con una rejilla de otra marca.

Rejilla Exterior arquitectónica, Aluminio, Verde

Rejilla Exterior arquitectónica, Aluminio, Azul

Rejilla Exterior arquitectónica, Aluminio, Rojo Ladrillo

Rejilla Exterior Arquitectónica, Aluminio, Gris Pizarra

Rejilla Exterior Arquitectónica, Aluminio, Gris Claro

Rejilla Exterior Arquitectónica, Aluminio, Melón

Rejilla Exterior Arquitectónica, Aluminio, Durazno

Rejilla Exterior Arquitectónica, Aluminio, Alpino (igual a gabinete Carrier)

Rejilla Exterior Arquitectónica, Aluminio, Beige

Rejilla Exterior Arquitectónica, Aluminio, Café (Bronce Obscuro)

Rejilla Exterior Arquitectónica, Aluminio, Bronce Mediana

Rejilla Exterior Arquitectónica, Aluminio, Bronce Claro

Rejilla Exterior Arquitectónica, Aluminio, Blanca

Rejilla Exterior Arquitectónica, Aluminio, Acabado Claro

Rejilla Arquitectónica Posterior, Plástico, Beige

Rejilla Arquitectónica Posterior, Plástico, Café

Rejilla Exterior Aluminio Estampada Acabado claro

Extensión Gabinete Friedrich para instalar unidades Carrier en Gabinete Friedrich (Serie T) de 11

Marco decorativo

Gabinete de pared metálico de extensión para pared profunda (28" espesor), 1 por paquete

Gabinete de pared metálico de extensión para pared profunda (26" espesor), 1 por paquete

Gabinete de pared metálico de extensión para pared profunda (24" espesor), 1 por paquete

Gabinete de pared metálico, aislada, 1 por paquete

Gabinete de pared plástica aislada, 1 por paquete

Gabinete de pared plástica, no aislada, 9 por paquete

Gabinete de pared plástico, no aislado, 1 por paquete

DESCRIPCION

CARRIER-TOUCH-UP

CURTDFL-52CP-1PK

DEFLECTOR-1PK

PWR-VENT-DOOR265

PWR-VENT-DOOR230

LATERAL-DUCT

SECURITY-DOOR

EM-KIT

AIR-FILTER-10PK

TSTAT-COVER-7X10

TSTAT-COVER-6X7

2SPEED-TSTAT-KIT

RC-FIELDKIT265HP

RC-FIELDKIT265HC

RC-FIELDKIT230HP

RC-FIELDKIT230HC

TSTATCCPHP01-B

TSTATCCPAC01-B

TSTATCCBPH01-B

TSTATCCBPC01-B

HH01ADO45

DRAIN-KIT-4PK

CONDUIT-INTF-4PK

HARDWIRE-KIT-1PK

SUBBASE-FUSE-30A

SUBBASE-FUSE-20A

SUBBASE-FUSE-15A

SUBBASE SWITCH

SUBBASE-HARDWIRE

SUBBASE-265V-30A

SUBBASE-265V 20A

SUBBASE-265V-15A

SUBBASE-230V-30A

SUBBASE-230V-20A

SUBBASE-230V-15A

SUBBASE-NON-ELEC

BAFFLE-KIT-1PK

GRILLE-ALU-GREEN

GRILLE-ALU-BLUE

GRILLE-ALU-RDBRK

GRILLE-ALU-SGREY

GRILLE-ALU-LGREY

GRILLE-ALU-MELON

GRILLE-ALU-PEACH

GRILLE-ALU-ALPIN

GRILLE-ALU-BEIGE

GRILLE-ALU-BROWN

GRILLE-ALU-MBRNZ

GRILLE-ALU-BRONZ

GRILLE-ALU-WHITE

GRILLE-ALU-CLEAR

GRILLE-PLA-BEIGE

GRILLE-PLA-BROWN

GRILLE-ALU-STAMP

FR-SLEEVE-EXT

SLEEVE-MOLDING

SLEEVE-EXT28-1PK

SLEEVE-EXT26-1PK

SLEEVE-EXT24-1PK

SLEEVE-STEEL-1PK

SLEEVE-INSUL-1PK

WALL-SLEEVE-9PK

WALL-SLEEVE-1PK

PARTE

N/A

52C,P-21SI

52C,P-9SI

52C,P-32SI

52C,P-25SI

52C,P-23SI

52C,P-24SI

N/A

N/A

N/A

52C,P-34SI

52C,P-30SI

N/A

52S-53SI

52C,P-19SI

52C,P-11SI

52C,P-5SI

52C,P-4SI

52C,P-3SI

52C,P-17SI

52C,P-2SI

52C,P-1SI

52C,P-31SI

52S-60SI

52S-65SI

52S-59SI

52C,P-26SI

52S-49SI

52S-50SI

52S-48SI

FORMA No.

Pintura de Retoque

Deflector de Aire

de Aire

Arrancador de Ventila

Kit de Ducto Lateral

Llave de Seguridad

Puerta de Control con

Manejo de Energía

Filtros de Repuesto

Reemplazo.

Interfase. Paquete de

Termostato Pared

Termostatos de Pared

Condensado

Kit de Desagüe de

Conexiones Eléctricas

Campo

Instalados en

Kits Subbase

Subbase

Rejillas Exteriores *

Gabinete de Pared

ACCESORIO

ACCESORIOS

Page 23

R

14

SOLUCIONES

Retire y limpie los filtros.

hielo o escarcha se derritan.

enfriamiento. Cambie el selector a operación de FAN (abanico) hasta que el

posible que se forme escarcha en el serpentín interior si esta en el modo de

Cuando la temperatura exterior es de aproximadamente 55F o menos, es

necesarios.

del condensado. Revise que éste quede bien nivelado y haga los ajustes

El gabinete de pared deberá quedar bien nivelado para un buen desagüe

tapones.

los empaques y herrajes alrededor de éste para ver que no haya fugas ni

instalado un kit de desagüe y se ha conectado al sistema de desagüe, revise

de condensado en clima muy cálido y húmedo. Vea la Nota 2. Si se ha

Si no se ha instalado un kit de desagüe será normal que haya escurrimiento

zumbido al operar.

Es normal que la unidad produzca ruidos como golpeteo, gorgoteo o

Cierre la puerta del respiradero.

cocinar o reunión de personas hagan incómoda la habitación.

Inicie calefacción o enfriamiento antes de que la temperatura exterior, calor al

Conceda suficiente tiempo para que la unidad caliente o enfríe la habitación.

Retire y limpie los filtros.

Reajuste la temperatura a más baja o más alta.

bloqueando flujo de aire.

Asegúrese que no haya cortinas, persianas o muebles obstruyendo o

Ajuste el selector en un modo de operación.

Restablezca interruptor de circuito (Nota 1).

Reemplazar fusible (Nota 1).

Revise el botón "RESET" en el cordón o clavija. Vea la Nota 1.

Revise que la clavija esté bien insertada en receptáculo de pared.

CAUSAS POSIBLES

un kit de desagüe accesorio y conectarse al sistema de desagüe.

2. Si la unidad ha sido instalada donde el desagüe del condensado pudiese gotear sobre un espacio no deseado, se deberá instalar

calificado.

1. Se el interruptor de circuito se activó o el filtro se fundió o el botón "RESET" se ha soltado más de una vez, contacte a un electricista

NOTAS:

Filtros sucios

Baja temperatura exterior

Hielo o escarcha se forma en serpentín interior

El gabinete de pared no quedó nivelado el serpentín interior

Agua escurriendo en el interior

Agua goteando en el exterior

Unidad haciendo ruido

Puerta del respiradero ha quedado abierta.

Habitación excesivamente caliente o fría al arrancar la unidad

Filtros de la unidad sucios

Ajuste de temperatura es demasiado baja/alta

Sección de descarga de aire se encuentra bloqueada

La unidad no enfría/calienta la habitación

Selector de modo posiblemente se encuentra en posición de apagado (OFF)

Posiblemente se activó el interruptor de circuito

Posible fusible fundido

El botón "RESET" en el cordón de servicio o en la clavija puede estar suelto.

Clavija pudo haberse zafado

La unidad no arranca

TABLA DE SOLUCIÓN DE PROBLEMAS

Page 24

R

13

de "RESET"

presionando el botón "TEST", y después presionando el botón

Revise el mecanismo de protección del cordón de servicio

adecuadamente

Asegúrese de que los ciclos de enfriamiento y calor funcionen

Asegúrese de que el gabinete esté bien montado

buen estado

Asegúrese de que el panel frontal esté bien colocado y en

en modo continuo de operación

Asegúrese de que el interruptor del abanico esté posicionado

Inspeccione el cordón de servicio y el receptáculo de pared

funcionales

Asegúrese de que los botones y perillas estén seguros y

Limpie o instale filtros nuevos

Limpie el Blower wheel y el panel frontal

Lave el serpentín interior

Lave el Basepan y el Filtro de Ventilación exterior

Lave el serpentín exterior de adentro hacia afuera

los siguientes puntos:

Durante la inspección regular y mantenimiento de la unidad siga

vericada durante varias ocasiones durante el año.

durabilidad. La operación del equipo deberá ser revisada y

funcionamiento de su unidad, así como para su eficiencia y

El mantenimiento preventivo es esencial para el adecuado

PREVENTIVO

MANTENIMIENTO

Page 25

WHEEL

BLOWER

12

FIGURA 23 - BLOWER WHEEL Y SCROLL

SCROLL

(Lado izquierdo del gabinete)

FIGURA 22 - FILTRO EXTERIOR VENT.

VENT

FILTRO

OPEN

C

L

O

S

E

VENT

PUERTA

Parrila exterior

Superficies internas del gabinete

Scroll

Pantalla de alambre

Blower Wheel

Serpentines Exteriores e Interiores

Orificio Exterior y Abanico

Basepan

Filtro Ventila Exterior

siguientes (vea las Figuras 5, 22, y 23):

Las partes internas que deberán ser limpiadas incluyen a las

una vez durante la temporada de frío y calor.

al año. El filtro de la ventila exterior deberá ser limpiado por lo menos

LAS PARTES INTERNAS deberán ser limpiadas al menos una vez

PARTES INTERNAS

MAGNETO

incluyendo las rejillas, con detergente de uso doméstico y agua.

rejillas. El fabricante del gabinete recomienda limpiar la superficie,

VENT

PALANCA

LAS PARTES EXTERNAS - Incluyen el gabinete de polímero y las

PARTES EXTERNAS

Page 26

R

11

Refierase a la sección de Accesorios.

Filtros adicionales se encuentran disponibles en multipacks.

5. Re-instale el filtro en la parrilla frontal.

4. Permita al filtro secarse.

mismo con un gentil chorro de agua limpia.

NOTA: Si se usa un detergente, remueva cualquier residuo del

suave con una pequeña cantidad de detergente suave.

3. Limpiar el filtro mediante aspirado o lavado con un cepillo

unidad. Vea las Figuras 5 y 21.

2. Gentilmente empuje el filtro hacia arriba y hacia afuera de la

1. Tome el filtro con ambas manos.

indicaciones siguientes:

uno a la vez. Para remover y limpiar el filtro, siga las

rejilla frontal. Cada uno de ellos puede ser removido y limpiado

intercambiables están localizados en el lado posterior de la

LIMPIANDO EL FILTRO DE AIRE - Dos filtros

componentes y perdida de eficiencia.

el flujo de aire lo cual conduciría a daño severo en los

limpiados apropiadamente. Un filtro obstruido puede restringir

IMPORTANTE: Los filtros pueden obstruirse si no son

FILTRO DE AIRE debe ser limpiado una vez al mes.

FILTRO DE AIRE (INTERIOR)

instrucciones siguientes.

Asegurese de limpiar la unidad de acuerdo con las

materiales extraños representan peligro potencial de incendio.

interior. Hongos/bacterias deshidratados, polvos y otros

FIGURA 21 - REMOCION DE FILTRO UNIDAD

PRECAUCIÓN

!

aire acondicionado, especialmente en el área del ventilador

crecimiento de hongos /bacterias en el interior de la unidad de

Algunas condiciones ambientales locales pueden provocar el

hongos.

polvo en el aire o ambientes que promueven el crecimiento de

son áreas donde hay polvo de construcción, o partículas de

operación de vida. Ejemplos de estas condiciones especiales

asegurar un optimo desempeño de la unidad y una mas larga

realizar la limpieza de la unidad con mayor frecuencia, para

Dependiendo de las condiciones locales, puede ser requerido el

limpiados cada mes.

calentamiento. Los filtros de aire del interior deberán ser

unidad previo a su arranque durante la temporada que requiere

recomienda que como mínimo se realice una limpieza a la

de objetos extraños cuando menos una vez al año. Carrier

eléctrico y los canales de drenaje sean limpiados y despejados

como el serpentín del exterior, la turbina de aire, el calentador

óptimas de operación, es muy importante que tanto el ventilador

Con la finalidad de mantener su unidad PTAC en condiciones

CUIDADO Y MANTENIMIENTO

Page 27

10

CON TERMOSTATO DE PARED (PLACA EN BLANCO)

FIGURA 20 - CONTROLES UNIDAD 52P

FIGURA 19 - CONTROLES UNIDADES 52P

Premier Series

COOL

LO

OFF

HEAT

HI HI

LO

MODE

COOLER

desde la unidad por el usuario. Vea la Figura 20.

PARED- Para un máximo confort, la velocidad es seleccionada

UNIDADES 52P Y 52C, MODELOS CON TERMOSTATO DE

CONTROL DE VELOCIDAD DEL ABANICO PARA

operación.

enfriamiento con máxima deshumidificación y la más callada

nivel de confort deseado. Esta función provee mínimo calor o

Seleccione el modo y gire la perilla de control de temperatura al

BAJO CALOR O BAJO FRÍO (LO HEAT OR LO COOL) -

temperatura de la habitación rápidamente.

enfriamiento, y es recomendado para aumentar o disminuir la

confort deseado. Esta función provee un máximo de calor o

Seleccione el modo y gire la perilla de temperatura al nivel de

ALTO CALOR O ALTO FRÍO (HI HEAT OR HI COOL)-

modelos de solo enfriamiento.

en el ambiente a alta velocidad y a alta o baja velocidad para

SOLO VENTILADOR (FAN) - Este modo hará circular el aire

APAGADO (OFF) - El botón apaga la unidad.

17.

control de la ventila hacia la posición de abierto. Vea la Figura

aire exterior hacia dentro de la habitación deslice la perilla de

VENTILACIÓN EXTERIOR (OUTSIDE AIR) - Para brindar

MODOS DE OPERACION (Ver figuras 19 y 20)

desabilitado solo para la operación de calor.

modo de operación de calefacción eléctrica el compresor será

unidad heat pump con termostato de pared es colocado en el

ambas (Frío/calor) operaciones. Si el tornillo selector de la

calefacción eléctrica, el compresor será desabilitada para

heat pump es colocado en el modo de operación de

IMPORTANTE: Si el tornillo selector en la unidad standard

WARMER

TEMPERATURE

manecillas del reloj. Vea la figura 18.

solamente gire el tornillo-selector en sentido contrario a las

Para operar la unidad en el modo de calentamiento eléctrico

fuente primaria de calor.

energizado, de nuevo el sitema "heat pump" se convertirá en la

el comprensor energizado. Una vez que el compresor es

alcance los 40 F; entonces el calefactor eléctrico será apagado y

continuara hasta que la temperatura del serpentín externo

convertirán en la fuente primaria de calor. El calentador eléctrico

calentar en modo "heat pump". Las resistencias eléctricas se

se apagara como la unidad no será adecuadamente capáz de

(aproximadamente 35 F de temperatura exterior), el compresor

temperatura en el serpentín externo alcanza 20 F

durante el modo de calentamiento. Vea la figura 18. Cuando la

posición de bomba de calor) la unidad operará en ciclo inverso

se encuentra a la izquierda len la posición de fábrica (en la

UNIDADES 52SQ: CICLO REVERSIBLE)- Si el tornillo-selector

TERMOSTATO DE EXTERIOR (SOLAMENTE PARA

temperatura y humedad de la habitación.

largos de compresor apagado y menores variaciones en la

temperatura deseada es alcanzada. Esto resulta en lapsos

calentamiento o enfriamiento. El ventilador se detiene si la

apagarse conjuntamente con el compresor durante el

CYC (Ciclo)- Esta selección permite al ventilador encenderse o

planta.

de máximo confort. Este es una seleccion predeterminada de

uso de este interruptor cuando se quiere el alcanzar condiciones

temperatura que se define en el termostato. Se recomienda el

a mantener la temperatura de la habitación más cerca de la

específica (de control) ha sido alcanzada. Este interruptor ayuda

continuamente, circulando aire aún cuando la temperatura

CON (Continuo)- Esta selección permite al ventilador operar

operar el ventilador en 2 modalidades (modos).

disponible en las unidades RC o RP) este selector permite

SELECCIÓN DE OPERACIÓN DEL VENTILADOR- (No

la Figura 18.

el panel frontal de la unidad como se mostró en la página 2. Vea

consola. Para tener acceso a los controles de operación, retirar

Los siguientes controles están localizados en el frente de la

CONTROL DE OPERACIÓN:

Page 28

R

TORNILLO

CON HEAT PUMP)

(SOLO MODELOS

EXTERIOR

TERMOSTATO

1.PR

2.PLUG

RECEPTACLE.

3.PRES

SHOULD LIGH

4. PRESS RESE

FOR USE.

D

O

N

TESTING

ESS RESET BUTTO

INTO

S TEST BU

O

T

U

S

E

IS

9

FIGURA 17 - PUERTA DE VENTILACIÓN

FIGURA 18 - CONTROLES DE OPERACIÓN

N.

POW

ER

TTO

N UNIT

T.

T BU

TTO

N AGA

IN

T

E

S

T

A

B

O

V

E

F

A

I

L

S

O

P

E

N

C

LO

SE

VENT

FILTRO

VENT

PUERTA

MAGNETO

VENT

PALANCA

control remoto.

ABANICO

CYC

CON

INTERRUPTOR

NOTA: Este ajuste es opcional y no es aplicable en unidades de

control de temperatura al usuario. Vea la Figura 18.

límite de temperatura en la unidad, permite restringir el rango de

AJUSTE DE LIMITE DE TEMPERATURA - El ajuste de

DE TEMPERATURA

DEL CONTROL

90

60

65

70

75

85

80

“PINS”

asegurará el cerrado de la puerta. Vea la Figura 17.

permanecerá en la posición seleccionada. El magneto

ventilación manualmente para abrir o cerrar la puerta. La ventila

izquierdo de la unidad. Deslice la perilla de la puerta de

la puerta de ventilación se encuentra localizada al costado

AJUSTE DE LA PUERTA DE VENTILACIÓN - La perilla de

chasis.