Page 1

52C,P

SERIES

SERVICE TECHNICIAN GUIDE

PACKAGED TERMINAL AIR CONDITIONERS

AND HEAT PUMPS

CONTENTS

INTRODUCTION

SUMMARY OF DANGERS, WARNINGS,

AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

UNIT DISASSEMBLY

TOOLS NEEDED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REMOVE FRONT P ANEL . . . . . . . . . . . . . . . . . . . . . . . 3

DISCONNECT POWER FOR

CORD-CONNECTED UNIT . . . . . . . . . . . . . . . . . . . . . 3

DISCONNECT POWER FOR PERMANE N TLY

CONNECTED (HARDWIRED) UNITS . . . . . . . . . . . . 3

OPEN THE CONTROL BOX. . . . . . . . . . . . . . . . . . . . . 4

REMOVE THE UNIT FROM THE W ALL SLEEVE . . 4

ACCESSING UNIT COMPONENTS

ACCESSING INDOOR-AIR SECTION

COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACCESSING OUTDOOR-AIR SECTION

COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REINSTALL FRONT PANEL. . . . . . . . . . . . . . . . . . . . . 8

GENERAL CLEANING

CLEANING AND SAFETY . . . . . . . . . . . . . . . . . . . . . . 9

TOOLS NEEDED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MONTHLY CLEANING. . . . . . . . . . . . . . . . . . . . . . . . 10

SEASONAL CLEANING . . . . . . . . . . . . . . . . . . . . . . . 11

COMPRESSOR

COMPRESSOR TROUBLESHOOTING. . . . . . . . . . . 14

BASIC HERMETIC COMPRESSOR

ELECTRICAL MEASUREMENTS . . . . . . . . . . . . . . . 14

COMPRESSOR REPLACEMENT. . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,3

. . . . . . . . . . . . . . . . . . . . . . . . . . .3,4

. . . . . . . . . . . . . .5-8

. . . . . . . . . . . . . . . . . . . . . . . . .9-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-17

Page

HEATERS

COMMON CAUSES OF HEATER FAILURE. . . . . . .18

HEATER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . .18

OPERATING CONTROLS

UNIT-MOUNTED CONTROLS. . . . . . . . . . . . . . . . . .20

WALL-MOUNTED THERMOSTAT CONTROLS. . . 21

REMOTE THERMOSTAT

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . .21

DESCRIPTION OF SELECTOR

SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . .23

NON-USER ADJUSTABLE CONTROLS . . . . . . . . . .23

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . .24

COMPONENT OPERATION AND

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . .24

ELECTRICAL COMPONENTS REMOVAL

AND REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . .27

FAN MOTOR

FAN MOTOR TROUBLESHOOTING. . . . . . . . . . . . .29

BASIC FAN MOTOR ELECTRICAL TESTS. . . . . . . . 29

FAN MOTOR REPLACEMENT. . . . . . . . . . . . . . . . . .31

FIELD TEMPERATURE CHARTS

WIRING DIAGRAMS

MOST FREQUENT PTAC SERVICE

QUESTIONS

ACCESSORIES

52C PERFORMANCE AND PHYSICAL DATA

52P PERFORMANCE AND PHYSICAL DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18,19

. . . . . . . . . . . . . . . . . . . . . 20-28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-31

. . . . . . . . . . . . . . 32-40

. . . . . . . . . . . . . . . . . . . . . . . . 41-45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

. . . . . .48

. . . . . .49

Page

PTAC Customer Support Center

1•800•894•6449

Page 2

52C,P

CANADIAN INSTALLATION

SERIAL 3701X11520

DATE OF MFG. 09/12/2001

VOLT RANGE 187-253

VOLTS 230/208

PH 1

MODEL 52PQA312301AA

HZ

60

MIN CKT AMPACITY 19.3

R-22 OZ 34

DESIGN PSIG 350 HIGH SIDE, 150 LOW SIDE

COOLING

HEATING

BTU/HR 12,100/12,000

AMPS 4.8/5.3

WATTS 1090/1122

EER 11.1/10.7

MOTOR

FAN

COMP

HP

FLA

RLA

LRA

6.1

29

0.75

1/8

BTU/HR 11,000/11,000

AMPS 15.6/14.5

WATTS 3570/2997

COP 3.2/3.2

HEATER

BTU/HR

AMPS 14.8/13.7

WATTS 3400/2850

WATER

STEAM

20

20

20

USE

TIME DELAY FUSE

OR HACR TYPE

CIRCUIT BREAKER

AMP

AMP AMP

MAX FUSE

MAX BREAKER

SERIES

INTRODUCTION

The focus of this manual is to provide basic information

on service procedures, safety, troubleshooting, cleaning, and component replacement for service technicians. It is intended for use only by HVAC service

technicians who have successfully completed

instruction and received Type I Certification

from the U.S. Environmental Protection Agency.

The instructions in this manual are general in nature

and are not to be substituted for installation and service instructions shipped with the unit. No attempt to

install, ope rate, adju st, re pair , or di smant le any equi pment should be made until the manufacturer’s i nstructions are read and thoroughly understood by the

service technician. Even equipment that seems familiar may have specific model diffe rences from year to

year. Always review manufacturer’s instructions.

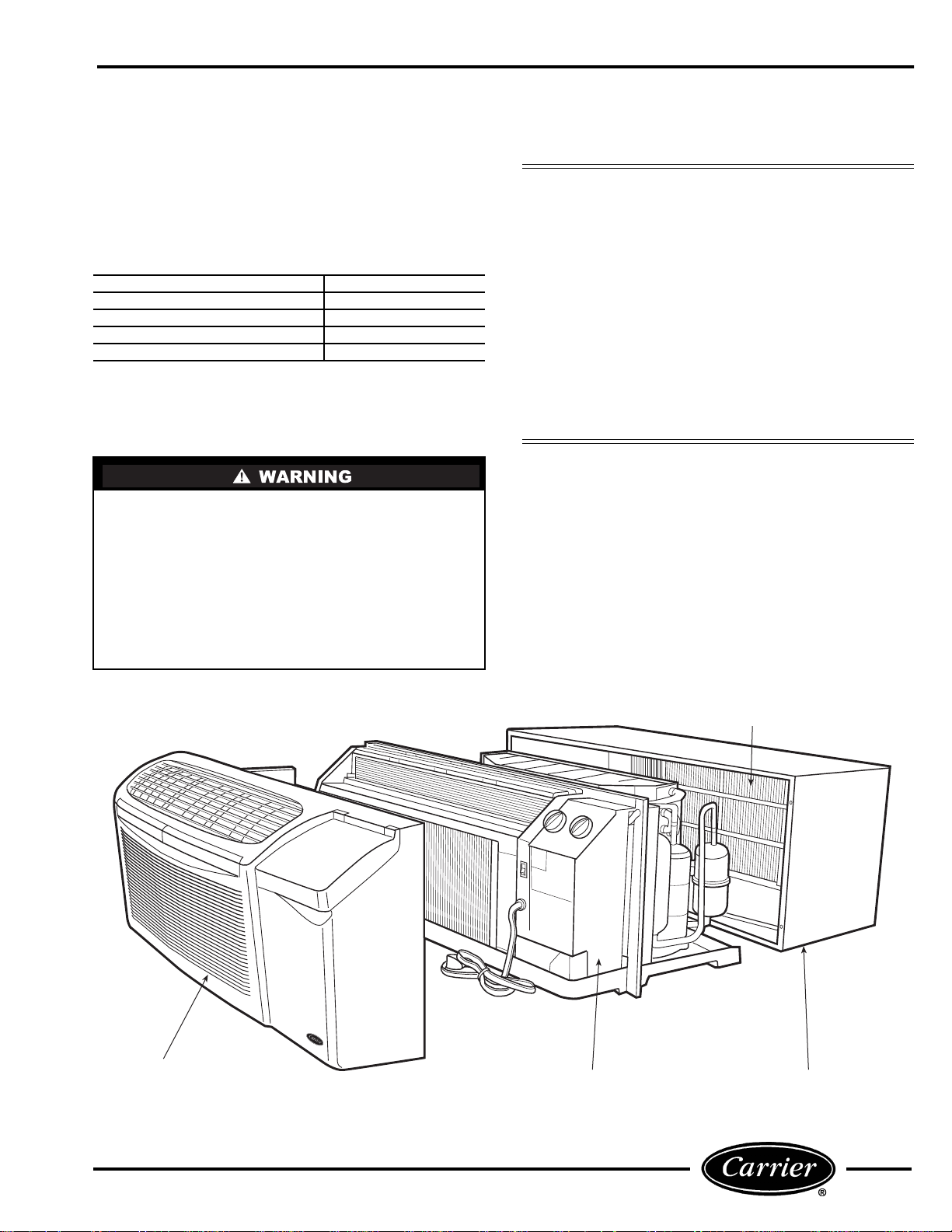

Model 52C,P packaged terminal air conditioner

(PTAC) and heat pump units are self-contained for

installation through the wall for individual room heating and cooling. The Model 52C,P polymer and metal

sleeves are permanently fastened to the wall; the unit

chassis slides out of the sleeve to allow the service

technician easy access. Many accessories are offered

to complement the unit’s performance and comfort

control.

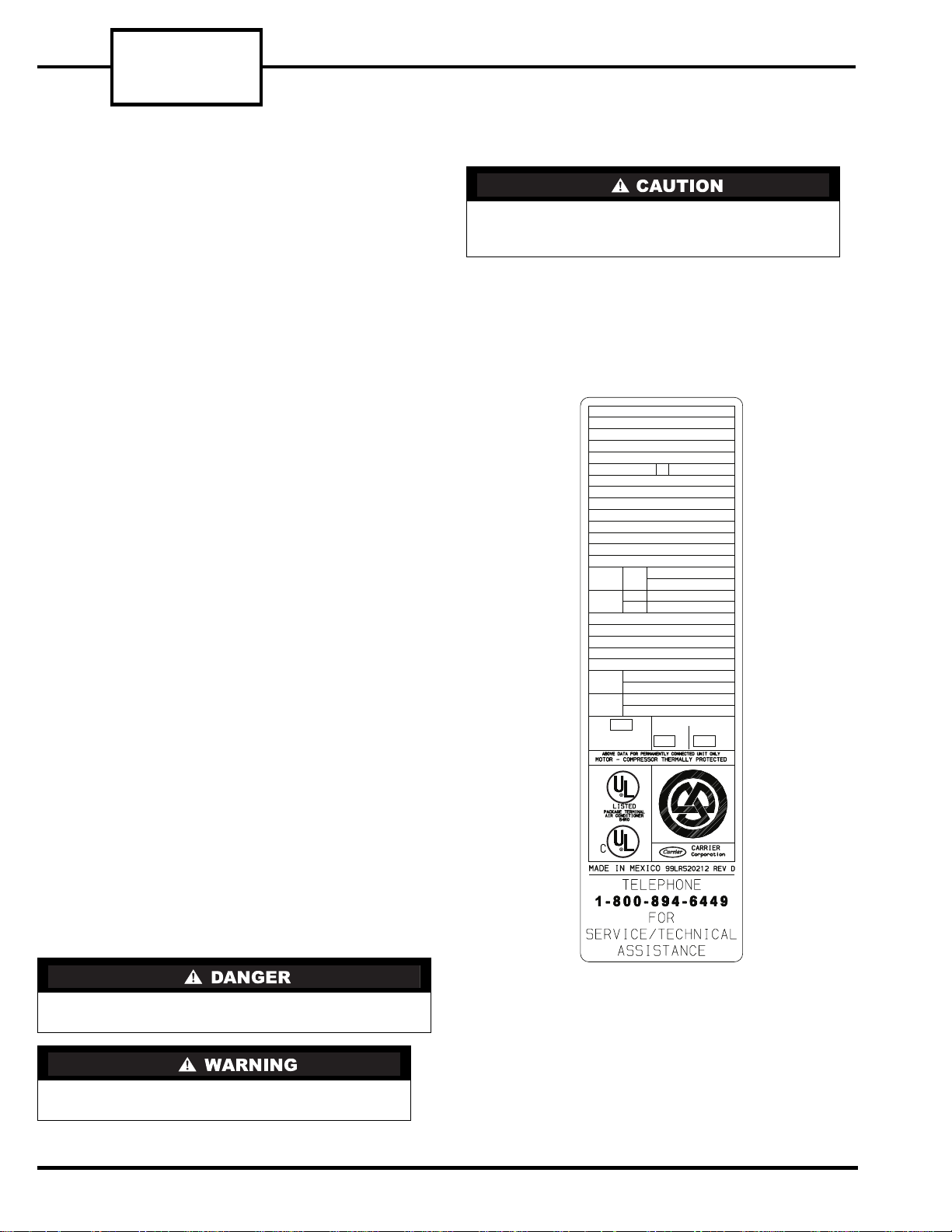

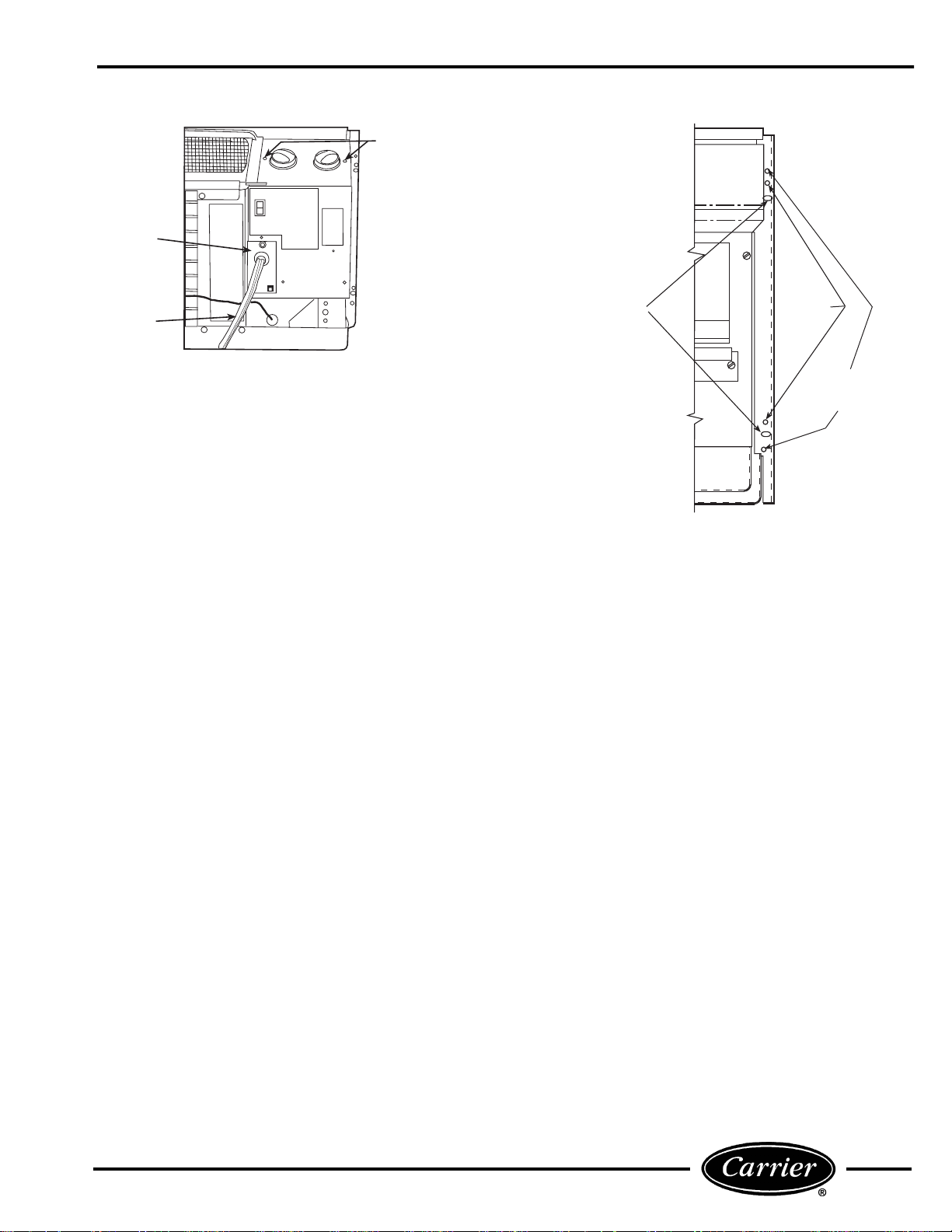

Before beginning any service procedu res, it is important to check the unit model number. See Figure 1 and

2. Units that seem similar may have subtle differences

that could affect service procedures. The following

units are covered in this manual:

52CE — 60 Hz cooling with electric heat units

52CQ — 60 Hz heat pump with electric heat units

52PE — 60 Hz cooling with electric heat units

52PQ — 60 Hz heat pump with electric heat units

52PC — 60 Hz cooling only units

Knowing which model is being serviced will help determine if the unit is performing at optimum levels. The

model number is located on the data informatio n plate

beneath the front panel of the unit. See Figure 1. The

data information plate also lis ts voltage ranges and

other important electric al information about the unit.

SUMMARY OF DANGERS, WARNINGS,

AND CAUTIONS

The terms DANGER, WARNING, and CAUTION have

specific meanings that identify the degree of hazard.

Typically in the HVAC industry, these specific meanings are:

There is an immediate hazard which WILL result

in severe personal injury or death.

Potential hazards or unsafe practices which

COULD result in minor personal injury or equipment damage.

FIGURE 1 — SAMPLE DATA INFORMATION

PLATE

Hazards or unsafe practices which COULD

result in severe personal injury or death.

2

Page 3

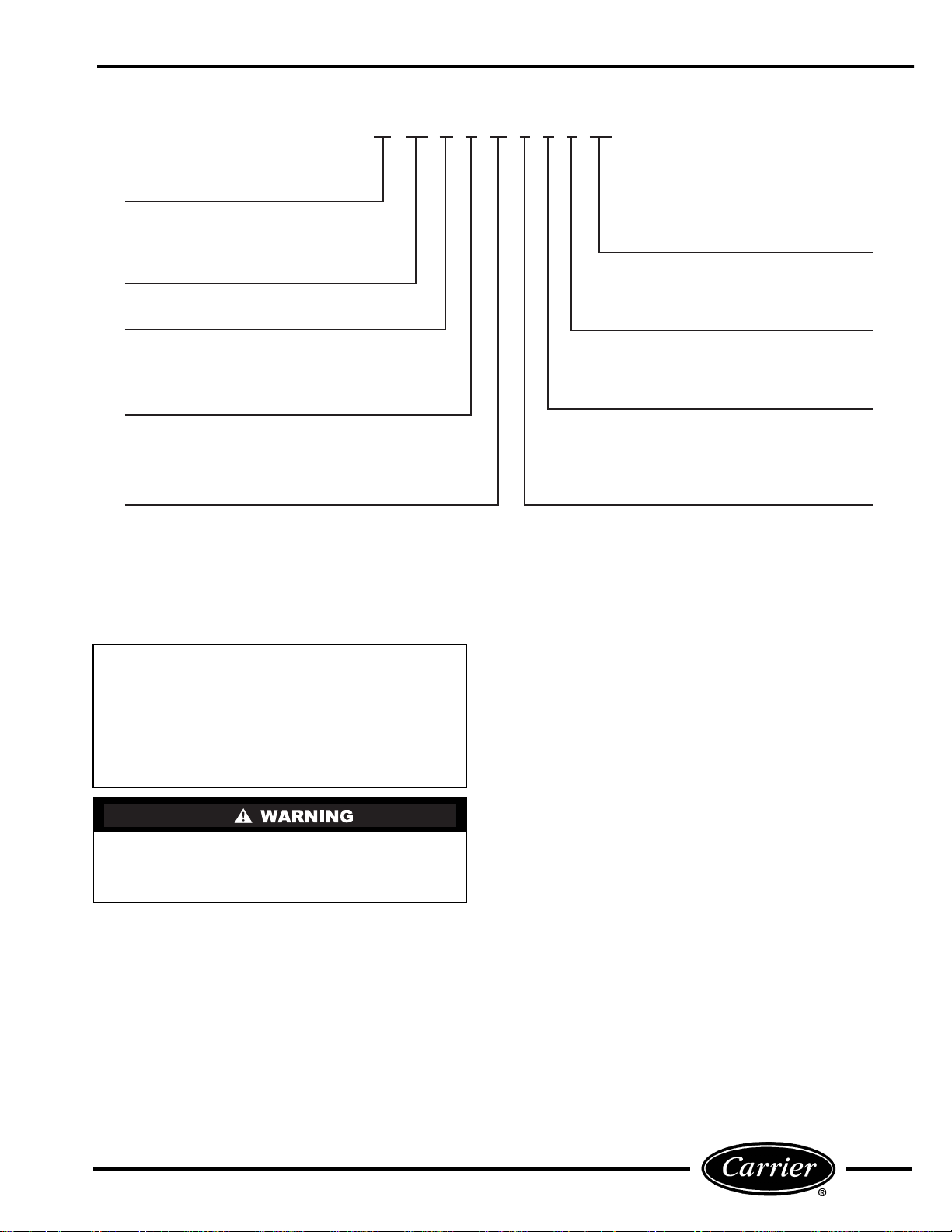

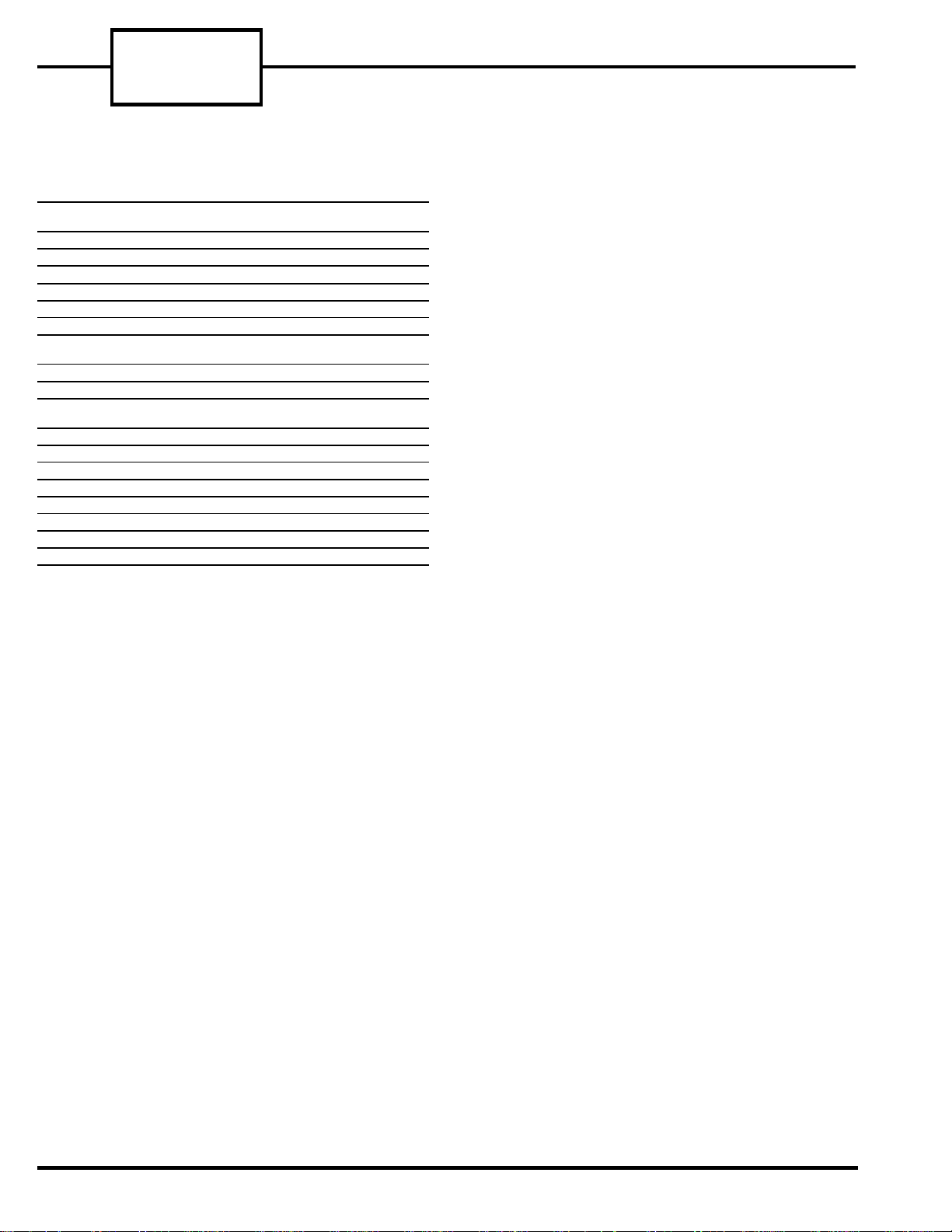

52 PQ A 3 12 3 0 1 AA

Series Designation

PTAC (Packaged Terminal Air Conditioner)

CE – Cooling with Electric Heat

CQ – Heat Pump with Electric Heat

PC – Cooling Only

PE – Cooling with Electric Heat

PQ – Heat Pump with Electric Heat

Latest Revision

A – Z

Electric Heater Size

0 – No Heating (Cooling Only Model)

2 – 2.3 kW

3 – 3.4 kW

5 – 5.0 kW

Cooling Capacity (nominal)

07 – 7,000 Btuh

09 – 9,000 Btuh

12 – 12,000 Btuh

15 – 15,000 Btuh

FIGURE 2 — MODEL NUMBER NOMENCLATURE

UNIT DISASSEMBLY

This section includes common procedures for disassembly and re-assembly of u nit.

IMPORTANT: Follow manufacturer’s instructions when disassembling and re-assembling a

unit for cleaning, maintenance, or part replacement. When disassembling wiring, it is strongly

recommended that numbered stickers be

attached to identify leads and terminals to aid in

the re-assembly process. Always review safety

procedures prior to the start of a job.

Prior to servicing electrical equipment, disconnect all power to avoid electric shock! Tag all disconnects. Never alter cord or plug and do not use

extension cords.

TOOLS NEEDED

The following field-supplied items are recommended

for general disassembly of the unit:

• Flat head screw driver

5

•

/16-in. nut driver

• Safety glasses

• Needle nose pliers

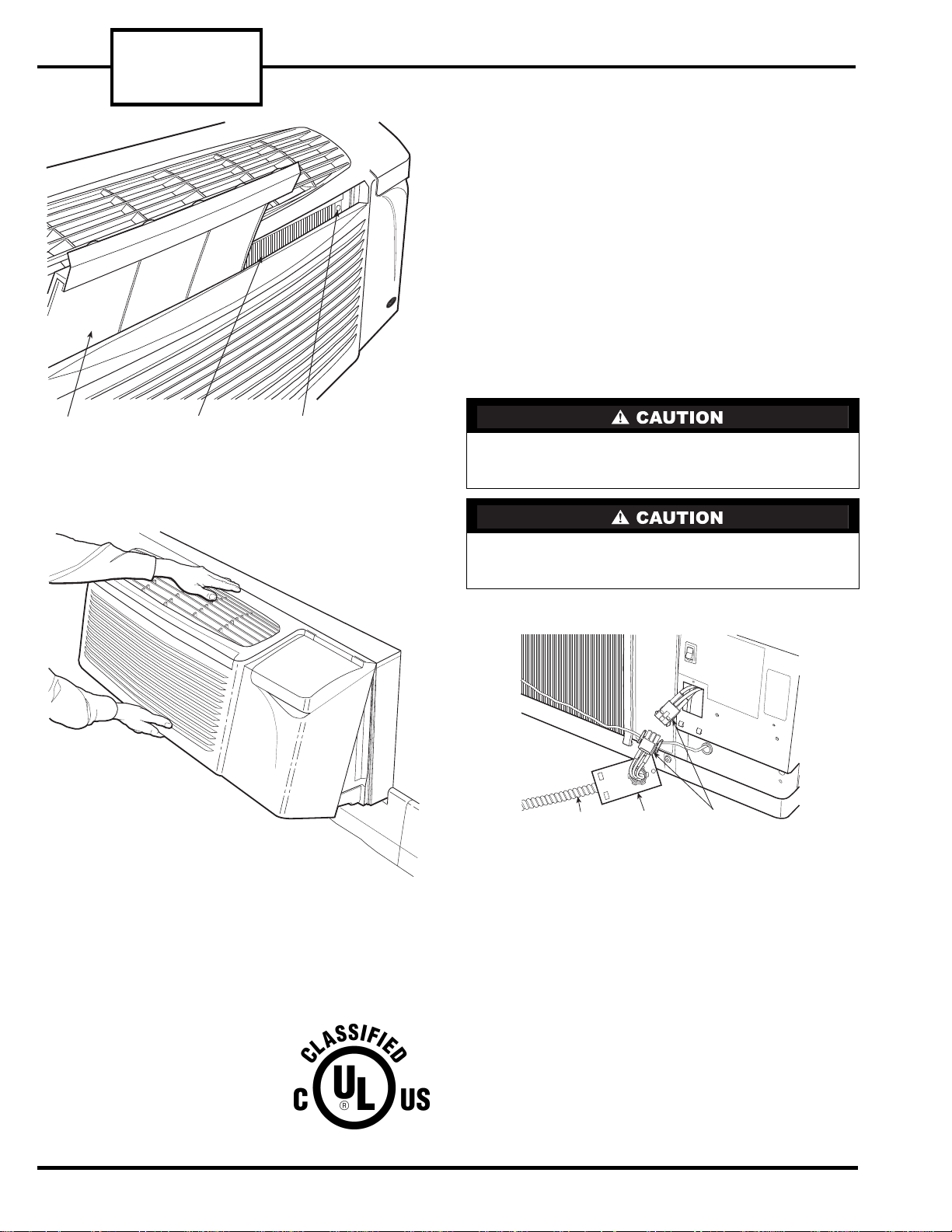

REMOVE FRONT PANEL

NOTE: Before removing front panel, remove 2 locking

screws (if installed) located behind the filter handles.

Chassis Options

Blank or AA – Standard

CP – Corrosion Protection

RC – Wall Thermostat Control

RP – Wall Thermostat Control with

Corrosion Protection

Packaging

1 – Domestic

Non-Performance

Changes 0-9

Electrical Data

3 – 230/208-v, 60 Hz

4 – 265-v, 60 Hz

See Figure 3. If a lateral duct accessory is installed, the

plenum must be removed before removing the front

panel. Refer to Remove Lateral Duct Extension section

for removal instructions.

1. Grasp the front panel firmly at the center of the

top and bottom of the panel.

2. Pull the panel upward at the bottom and forward

at the top to release magnetic latches and partition

hooks. See Figure 4.

DISCONNECT POWER FOR

CORD-CONNECTED UNIT

1. Turn selector switch to OFF position.

2. Open the disconnect swi tch at main power supply.

Use proper Lockout and Tag procedures.

3. Unplug the unit service cord.

DISCONNECT POWER FOR

PERMANENTLY CONNECTED

(HARDWIRED) UNITS

1. Turn selector switch to OFF position.

2. Open the disconnect swi tch at main power supply.

Use proper Lockout and Tag procedures.

3. Remove screw from access cover and remove

access cover.

4. Pull out the plug assembly and disconnect. See

Figure 5.

3

Page 4

52C,P

SERIES

OPEN THE CONTROL BOX

The control box is factory wired. To open the box,

remove the 2 screws on the top of the control box and

lower the front hinged panel. See Figure 6.

REMOVE THE UNIT FROM THE

WALL SLEEVE

1. Remove the four moun tin g scr e ws tha t secu re th e

PTAC unit to the wall sleeve (2 screws per side).

See Figure 7.

2. Grasp the sides of the unit and slide it from the

sleeve.

NOTE: The mounting screws ma y be in a differen t

location depending on brand of wall sleeve

attached.

REMOVABLE

FILTER

LOCATION OF

REMOVED FILTER

LOCKING SCREW

(NOTE: 2nd LOCKING SCREW

IS LOCATED BEHIND

2nd FILTER)

FIGURE 3 — LOCATION OF LOCKING SCREWS

BEHIND FILTERS

FIGURE 4 — REMOVING FRONT PANEL

eplacement Package Terminal Air Conditioner,

LASSIFIED BY UNDERWRITERS LABORATOIES INC., AS TO ELECTRIC SHOCK, FIRE AND

ASUALTY HAZARDS ONLY. FOR FIELD INSTALATION WITH EXISTING WALL SLEEVES, OUT-

OOR, LOUVERS, AND INDOOR PANELS AS

PECIFIED ON THE PRODUCT.

The chassis weighs between 110 and 150 lbs. Take

proper safety precautions to avoid personal injury

when lifting and moving the chassi s.

The unit basepan may have water in it. Tilt the

unit back slightly whe n removing it fro m th e sl e eve

to drain some of the water into the sleeve.

CONDUIT

ACCESS

PANEL

MOLEX

PLUGS

FIGURE 5 — PLUG ASSEMBLY ON

HARDWIRE UNITS

4

Page 5

POWER

GE WALL

SLEEVE

HOLES

AMANA, TRANE

(SLOTTED

HOLES) WALL

SLEEVE HOLES

VARIOUS ATTACHMENT

HOLE LOCATIONS

CARRIER, BRYANT

WALL SLEEVE

HOLES

CORD

ACCESS

COVER

POWER

CORD

FIGURE 6 — CONTROL BOX COVER

CONTROL

BOX

SCREWS

FIGURE 7 — PTAC UNIT TO WALL

SLEEVE MOUNTING SCREWS

ACCESSING INDOOR-AIR SECTION

COMPONENTS

REMOVE LATERAL DUCT EXTENSION

■

ACCESSORY FOR UNITS EQUIPPED WITH THE

LATERAL DUCT

1. Remove the 2 top screws that secure the lateral

2. Locate and remove the 2 bottom bracket screws

3. Carefully lift the plenum up and away from front

REMOVE THE DISCHARGE DECK ASSEMBLY

■

1. Remove the front panel. Re fer to Remove Front

2. Remove discharge screen screw using a

3. Remove th e dischar ge deck assembly screws using

4. Gently pull the deck/grille up and away from the

5. Reassemble by reversing steps above.

ACCESSING UNIT COMPONENTS

duct plenum to the top of the lateral duct extension. See Figure 8.

(located opposite extension duct) that secure the

lateral duct plenum to the bracket flange. See

Figure 8.

panel and duct extension.

Panel section and Figure 4.

5

/16-in. nut

driver. See Figure 9.

5

a

/16-in. nut driver. See Fi gure 9.

unit.

ACCESSING THE HEATER ASSEMBLY

■

— Once the

discharge deck assembly is removed, the Heater

Assembly should now be accessible. See Figure 10.

1. Using pliers, carefully remove all wires connected

to the heater assembl y. Label ea ch wire for ea se of

re-assembly.

2. Gently pull the heater assembly up and away

from scroll. See Figure 11.

3. Reassemble by reversing steps above.

ACCESSING OUTDOOR-AIR SECTION

COMPONENTS

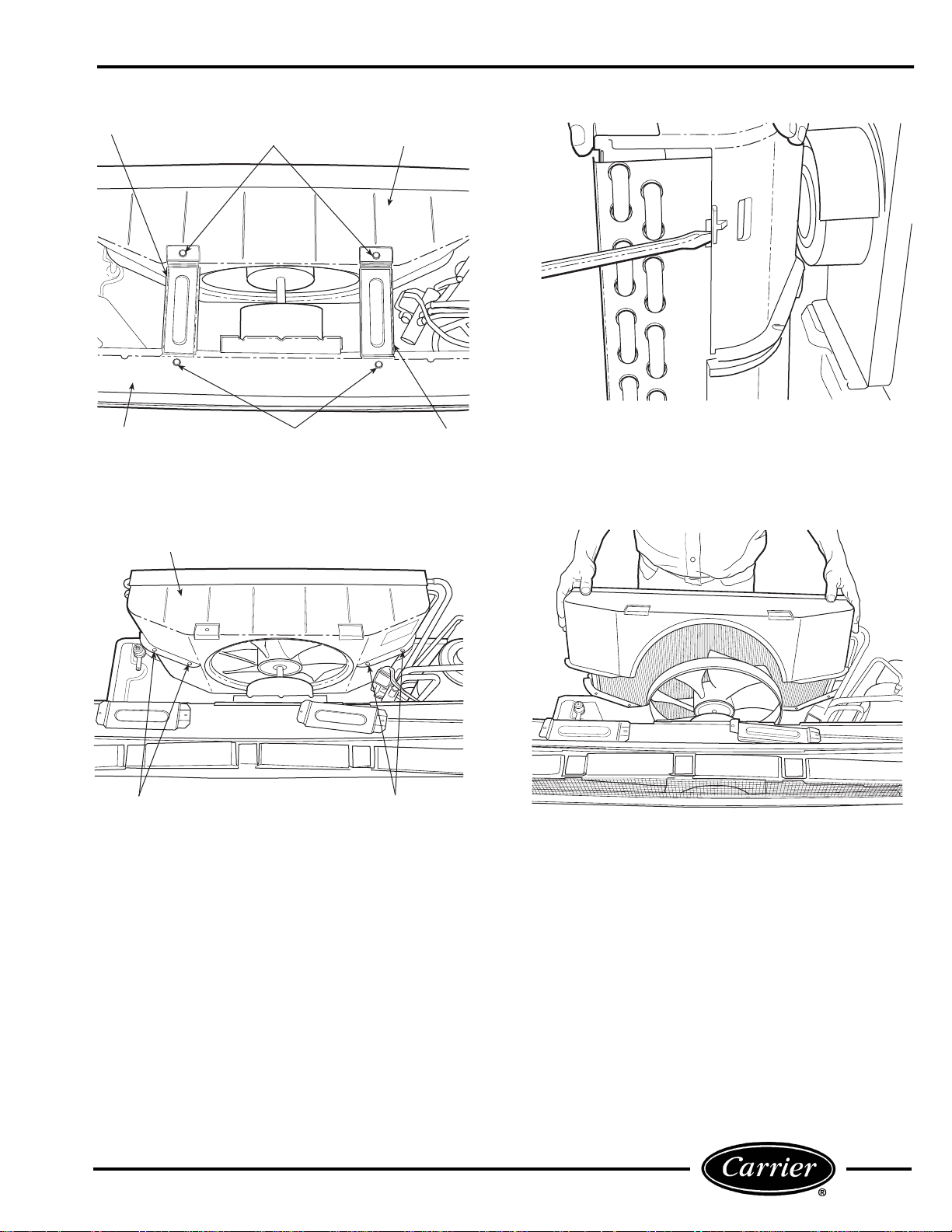

REMOVE THE GUSSETS (See Figure 12)

■

1. Remove the 2 screws on each side that secure the

gussets to the partition.

2. Remove the 2 screws that secure the gussets to

the plastic condenser orifice and remove the

gussets.

5

Page 6

52C,P

SERIES

END CAP

BRACKET

SCREWS

PLENUM LATERAL DUCT

LEFT

BRACKET

TOP

SCREWS (2)

EXTENSION

RIGHT

BRACKET

FIGURE 8 — PTAC UNIT WITH LATERAL

DUCT ACCESSORY INSTALLED

ATTACHMENT

SCREWS

WALL

BRACKET

SCREWS

DISCHARGE DECK

FIGURE 10 — ACCESSING HEAT ER

HEATER PLATE

ASSEMBLY

PLATE ASSEMBLY

DISCHARGE

SCREEN

DISCHARGE

DECK

FIGURE 9 — LOCATION OF ATTACHMENT

SCREWS ON DISCHARGE DECK OF UNIT

DETACH THE CONDENSER ORIFICE FROM THE

■

CONDENSER COIL

1. Remove top half of condenser orifice.

a. Unscrew the top half of the condens er orifi ce b y

backing off the 4 captive screws. See Figure 13.

b. Using a flat head screwdriver, gently pry the

top half of the orifice from the tube sheets. See

Figure 14.

c. Remove top of condenser orifice. See Figure 15.

2. Remove bottom half of condenser orifice.

a. Using a flat head screwdriver, gently pry the

bottom half of the orifice from the tube sheets.

See Figure 14.

b. Remove 2 outdoor coil tube sheet screws using a

Phillips head screwdriver. See Figure 16.

c. Carefully lift condenser up and away from con-

denser fan. Rest con d e nse r on bas epan . Se e

Figure 17.

FIGURE 11 — REMOVAL OF HEATER

PLATE ASSEMBLY

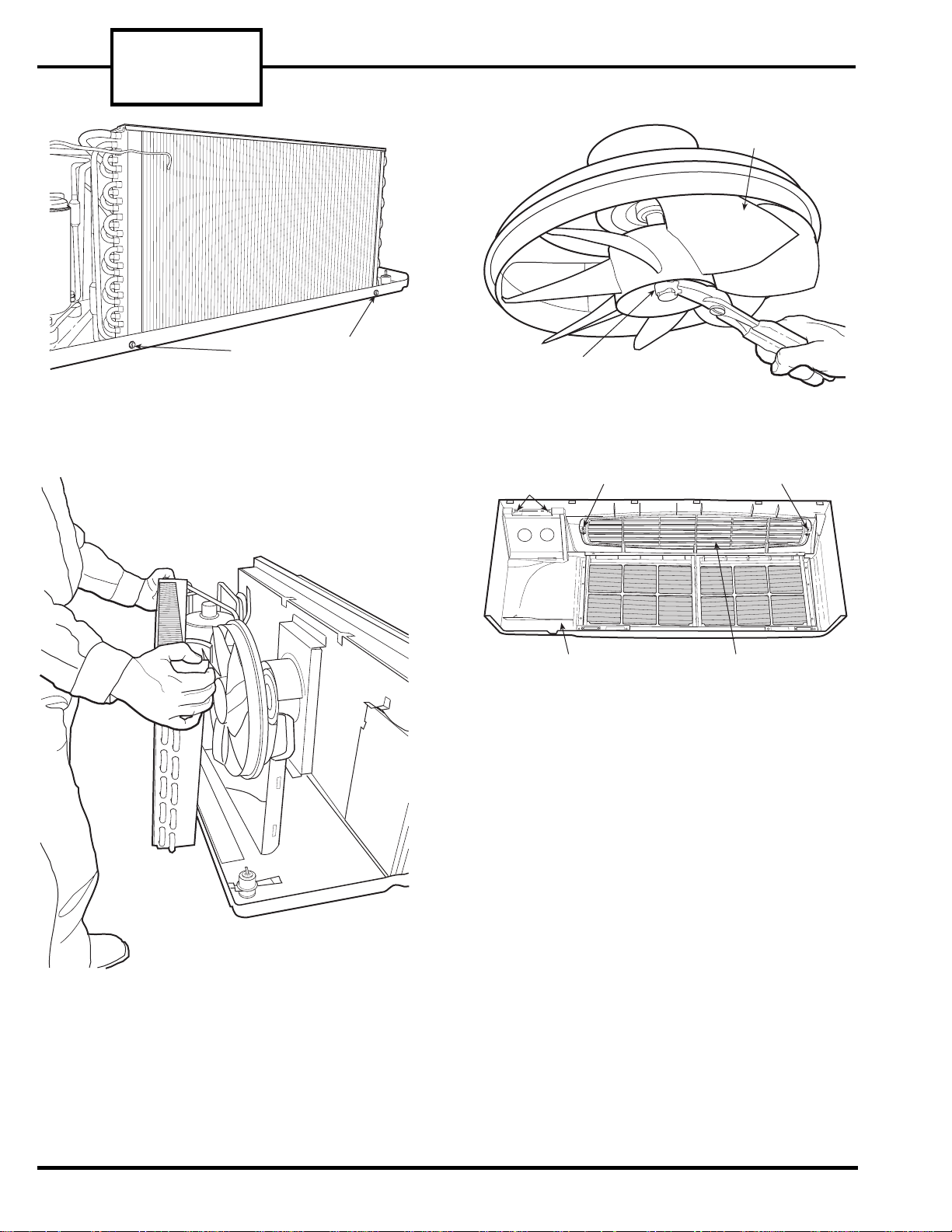

d. Using Needle Nose Pliers remove co ndenser fan

hub clamp. See Figure 18.

e. Pull condenser fan off fan motor shaft.

f. Remove bottom half of condenser orifice.

3. Reassemble by reversing steps above.

REMOVE THE AIR DISCHARGE GRILLE

■

1. Remove the front panel from the unit, reference

Remove Front Panel section.

2. Flip the front panel over to the backside. Remove

the 2 screws on each end of the air discharge grille

and remove grille. See Figure 19.

The grille can be positioned to direct the

discharge air up or out by simply rotating

the grille 180 degrees.

6

Page 7

GUSSET

GUSSET

SCREWS

CONDENSER

ORIFICE (PLASTIC)

PARTITION GUSSET

GUSSET

SCREWS

FIGURE 12 — GUSS ET RE M O VAL

CONDENSER

ORIFICE

CAPTIVE

SCREWS (2)

CAPTIVE

SCREWS (2)

FIGURE 13 — LOCATION OF CAPTIVE SCREWS

ON CONDENSER ORIFICE

FIGURE 14 — PRYING CONDENSER ORIFICE

AWAY FROM TUBE SHEET

FIGURE 15 — REMOVING TOP OF

CONDENSER ORIFICE

7

Page 8

52C,P

SERIES

OUTDOOR COIL TUBE

SHEET SCREWS

FIGURE 16 — LOCATION OF OUTDOOR

COIL TUBE SHEET SCREWS

CONDENSER

FAN

HUB CLAMP

FIGURE 18 — REMOVING COND EN SER

FAN HUB CLAMP

FIGURE 17 — REMOVING OUTDOOR COIL

FROM CONDENSER FAN

CONTROL DOOR

HINGE PINS

FRONT PANEL

(BACK VIEW)

SCREW SCREW

DISCHARGE

GRILLE

FIGURE 19 — LOCATION OF SCREWS ON

DISCHARGE GRILLE

REINSTALL FRONT PANEL

1. Grasp the front panel firmly at the center of the

top and bottom of the panel, tilti ng it fo rwar d 5 to

10 degrees from the vertical. See Figure 4.

2. Place the top of the front panel onto the unit,

making sure the top engagement posts have

engaged the slots on the unit. The top edge of the

front panel should be flat against the top of the

unit.

3. Gently lower the front panel onto the chassis,

ensuring the conduit/cord is routed through the

panel notch. Magnetic latches at the bottom of the

front panel will secure the front panel to the unit.

8

Page 9

GENERAL CLEANING

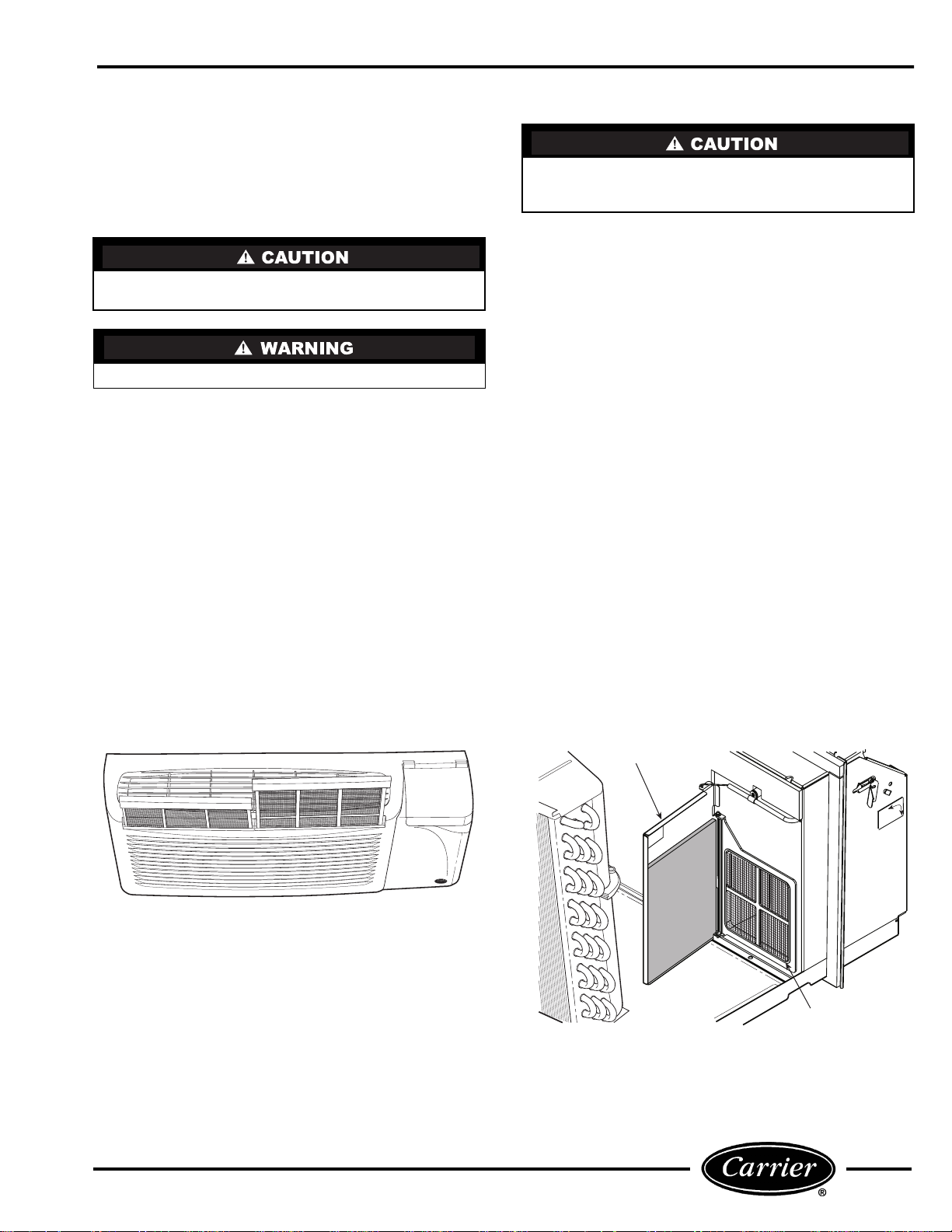

Maintaining proper performance of 52C,P systems

requires conscientious cleaning and care of components. See Figure 20. Specific components require

periodic cleaning and/or replacement, including the

following:

COMPONENT CLEANING SCHEDULE

Indoor Air Filter

Vent Air Filter

Indoor Coil

Indoor Fan

Outdoor Coil

Monthly

Monthly

Seasonally

Seasonally

Seasonally

CLEANING AND SAFETY

Before starting to clean a unit, read the instructions

thoroughly and gather the necessary tools for the job.

Review all safety information on unit and in literature.

Before cleaning, servicing, performing maintenance,

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance tasks such as cleaning and replacing filters.

Refer to General Disassembly section of this ma nual

for proper procedures to disconnect power to 52C,P

units.

Consider the following safety issues before

beginning:

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety

glasses and work gloves, should be used.

• The floor around the work area shoul d be clea n and

free of debris.

• The 52C,P unit weighs up to 150 pounds. Use a lifting device or ask for assistance if the unit must be

moved.

• Make sure tools are the correct tools for the job,

and that they are working properly and in good

condition.

FRONT

PANEL

(STANDARD)

CHASSIS

(STANDARD)

FIGURE 20 — STANDARD 52C UNIT

EXTERIOR

GRILLE

(ACCESSORY)

WALL SLEEVE

(ACCESSORY)

9

Page 10

52C,P

SERIES

TOOLS NEEDED

The following list includes the recommended tools,

devices, and cleaning solutions for use in cleaning the

52C,P unit and components.

Vacuum Cleaner with Crevice Tool Attachment,

Lifting Device (or another person for assistance)

Trigger Spray Extension Tube (Part No. P9029000)

Vent Air Filter Replacement (Part No. 52CQ500144)

Condenser Coil Cleaning Solution (Part No. P9020501)

Evaporator Coil Cleaning Solution (Part No. P90221001)

3% Solution of Hydrogen Peroxide in Spray Bottle

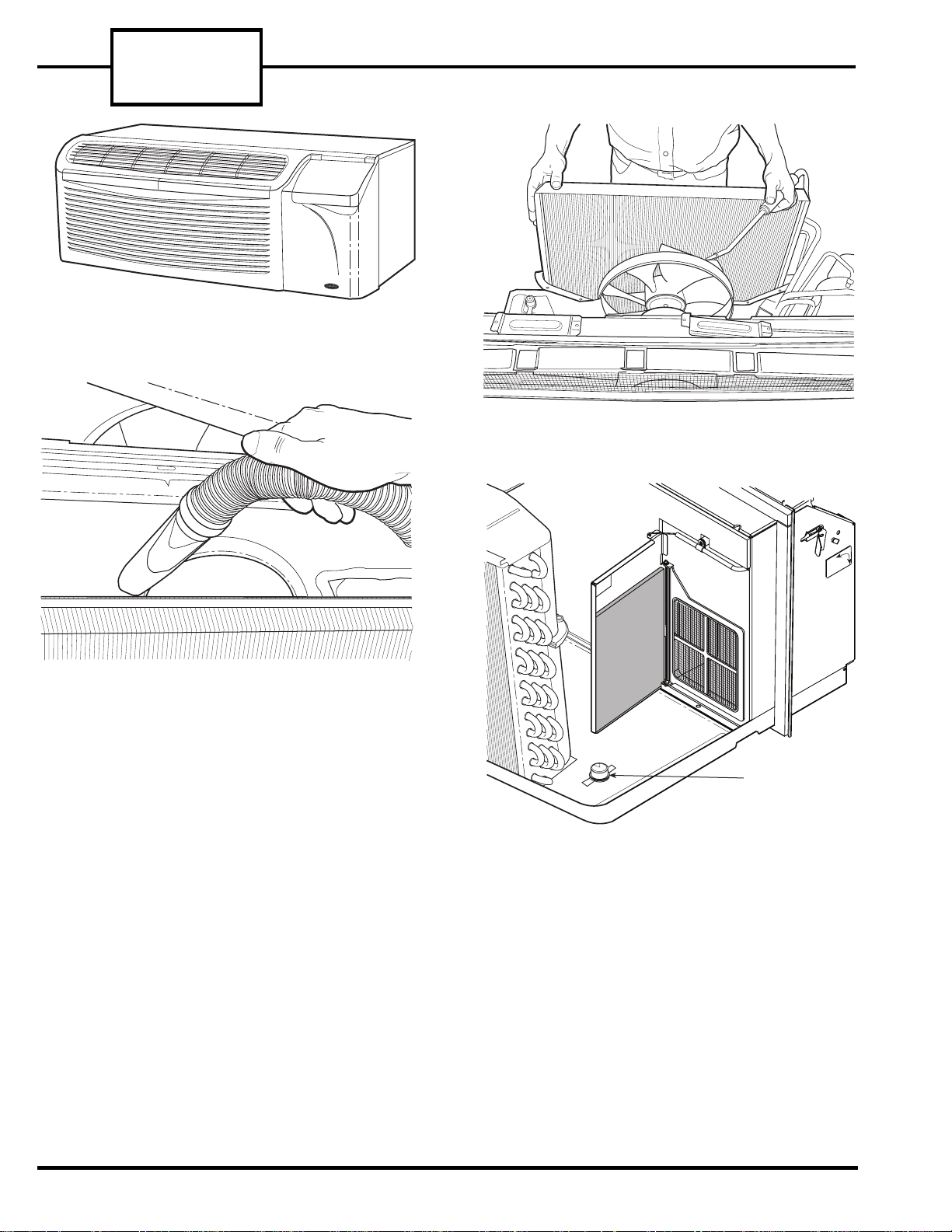

MONTHLY CLEANING

AIR FILTERS

■

should be cleaned once per month. Filt ers tha t are not

cleaned become clogged and will restrict airflow. This

may lead to major component damage. If a filter

becomes torn, has holes, or other damage, replace it

with a new one. Replacement filters are available

through Carrier Finished Goods and Carrier Replacement Component Division.

CLEANING THE INDOOR AIR FILTER

■

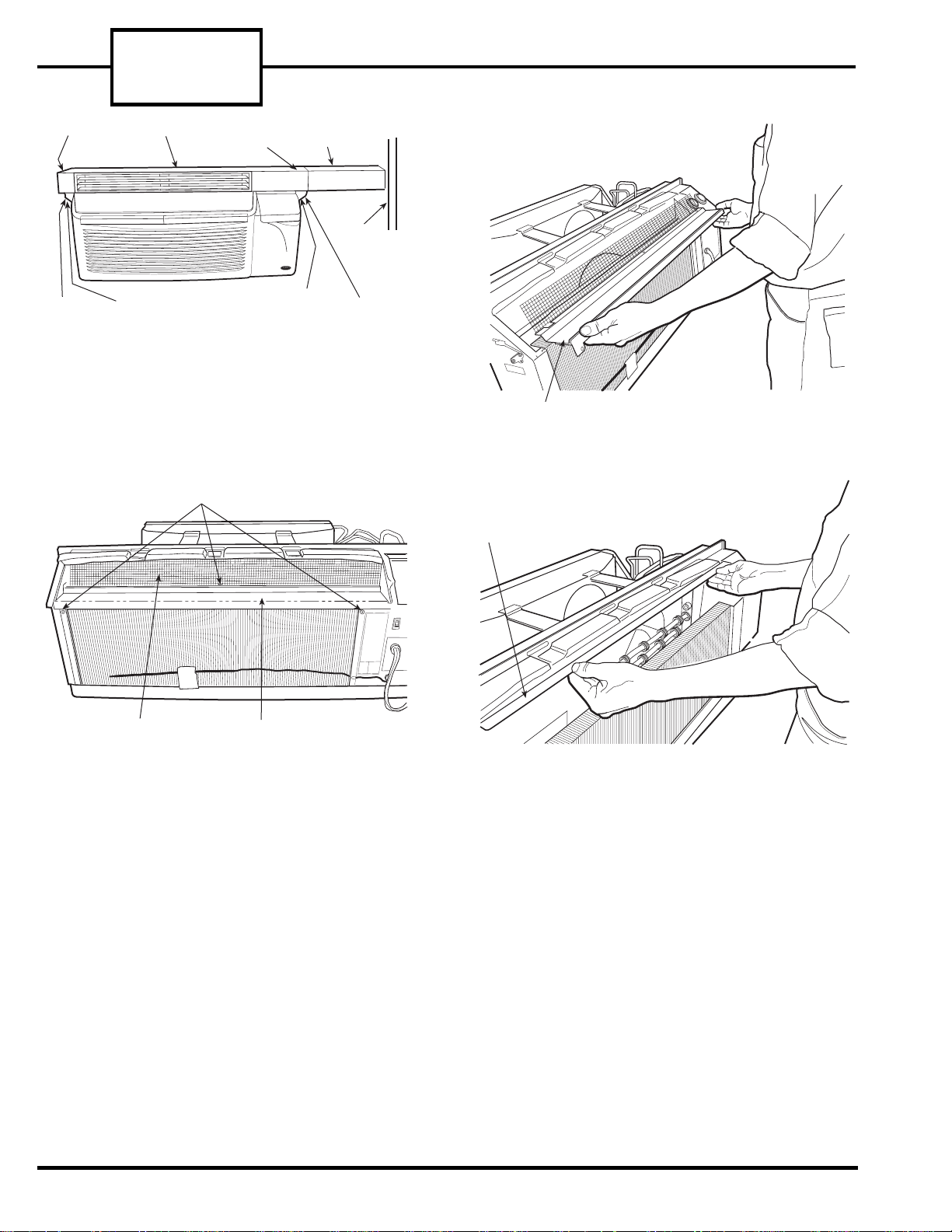

filters are located in the unit’s front panel. To remove

each filter simply grasp each filter handle with both

hands and gently pull the filter up and away from the

unit. See Figure 21.

or Soft Plastic Bristle Brush

Mild Household Detergent

Phillips Head Screwdriver

5

/16-in. Nut Driver

Flat Head Screw Driver

Needle Nose Pliers, 90° Bend

Tank Sprayer (Part No. P9021001) or

Compressed Air Tank

Clean Water Supply

Indoor Air Filter Replacement

(Part No. AIR-FILTER-10PK)

10-in. by 29-in. Piece of Clean Cardboard

Clean Cloth

Safety Glasses

Protective Gloves

— The indoor and vent air filters

— Two air

REPLACING THE INDOOR AIR FILT ER

■

—

Remove the indoor air filter as detailed in Cleaning

the Indoor Air Filter. If damaged, use a filter replacement with the Carrier Part No. AIR-FILTER-10PK,

available through Carrier Finished Goods and Carrier

Replacement Component Division.

NOTE: Both filters are completely interchangeable.

CLEANING THE OUTDOOR AIR VENT FILTER

■

1. Remove the unit chassis from wall sleeve as

described in the General Disassembly section of

this manual. Refer to Remove the Unit from

the Wall Sleeve section.

2. Swing open vent door. The filter is located directly

behind the vent door. See Figure 22.

3. Once the filter is accessed, it may be cleaned using

either a vacuum cleaner, or a soft bristle brush

and a small amount of mild dish detergent. If

detergent is used, remove detergent residue with

a gentle, clean water stream. Allow the filter to

air dry.

REPLACING THE OUTDOOR AIR VENT FIL TER —

■

If vent filter requires replacement:

1. Open vent door to access vent filter.

2. Remove vent door from hinges.

3. Using a small flat head screwdriver, pry the filter

from the partition.

4. Replace vent filter using Carrier Part No.

52CQ500144.

5. Reverse Steps 1-3 to reattach vent door.

■

CHASSIS

Occasional cleaning of the e xterior surfaces of the

PTAC unit optimizes the unit’s appearance and

removes particles that may enter the air system. See

Figure 23. Mild detergents clean and reduce electrostatic charges on the plastic components of the PTAC

unit.

Use a clean cloth or brush to gently wipe exterior s urfaces. Be careful not to push dirt or other fibers into

the unit’s interior components. Accessible wall sleeve

surfaces should also be wiped clean.

10

Page 11

SEASONAL CLEANING

VENT DOOR

OUTDOOR

AIR FILTER

The indoor and outdoor coils should be cleaned at least

once during every season. Refer to ACCESSING

UNIT COMPONENTS section to prepare unit.

CLEANING THE INDOOR AND OUTDOOR

■

COILS

Coil fins are sharp and may cut hands. Wear heavy

protective gloves when cleaning coils.

Use only cleaning solutions that meet local codes.

1. Use a vacuum cleaner or soft bristle brush to

remove surface fibers and dirt from the interior

surface of evaporator coil and both surfaces of condenser coil. See Figure 24. It is important to apply

the tool in the same direction of the fins, not

against them. Applying the tool against the fins

may cause damage (fin edges may bend over).

2. With a tank sprayer or a trigger spray extension

tube, spray coil cleaning solution evenly across

the coils, making sure coils are thoroughly saturated. See Figure 25. Refer to instructions on the

cleaning solution containers for best results. Do

not use a high-pressure sprayer.

3. Rinse the coils thoroughly with low-velocity, clean

warm water (less than 200 F).

4. Repeat steps 2 and 3 for each coil surface.

5. Drain water and cleaning solution that may have

collected in the basepan during the cleaning process by carefully tilting the chassis. This allows

excess water to flow out of the overflow notches.

Do not set unit on end to drain water from basepan,

or at any other time. Oil will drain from the compressor sump, which could cause compressor failure.

6. Thoroughly clean t he base pan an d drain pa ssages

by rinsing with clean water. Be sure all debris is

removed from the drain valve. Se e Fig ure 26.

7. Thoroughly clean outdoor fan assembly and all

other mechanical components located in outdoor

coil area. Be sure to remove all dirt and debris.

8. Clean wall sleeve.

CLEANING THE INDOOR FAN AND FAN

■

SCROLL —

Dried debris and build-up on the blower

wheel and fan scroll can reduce the efficiency of the

unit.

1. ACCESS AND CLEAN INDOOR FAN AND

FAN SCROLL

a. Reach behind the indoor coil and vacuum any

loose debris from the condensat e drai n pan, fan

and other areas accessible to the fan scroll,

being careful to avoid damage to the coil fins.

b. Use mild detergent and a damp cl oth to remov e

stubborn debris from surfaces around scroll and

fan blades.

2. CLEAN HEATER ASSEMBLY — Use compressed air to blow off any dirt or dust that has

accumulated on the heater coils.

NOTE: Do not direct air at the bi-metal discs on

the temperature limiter switches.

FIGURE 21 — LOCATION OF

TWO-PIECE INDOOR FILTER

FIGURE 22 — LOCATION OF OUTDOOR AIR

VENT FILTER

11

Page 12

52C,P

SERIES

FIGURE 23 — PTAC EXTERIOR SURFACES

FIGURE 25 — CLEANING COILS

FIGURE 24 — VACUUMING EVAPORATOR

COIL

DRAIN VALVE

FIGURE 26 — BASEPAN SECTION

12

Page 13

COMPRESSOR

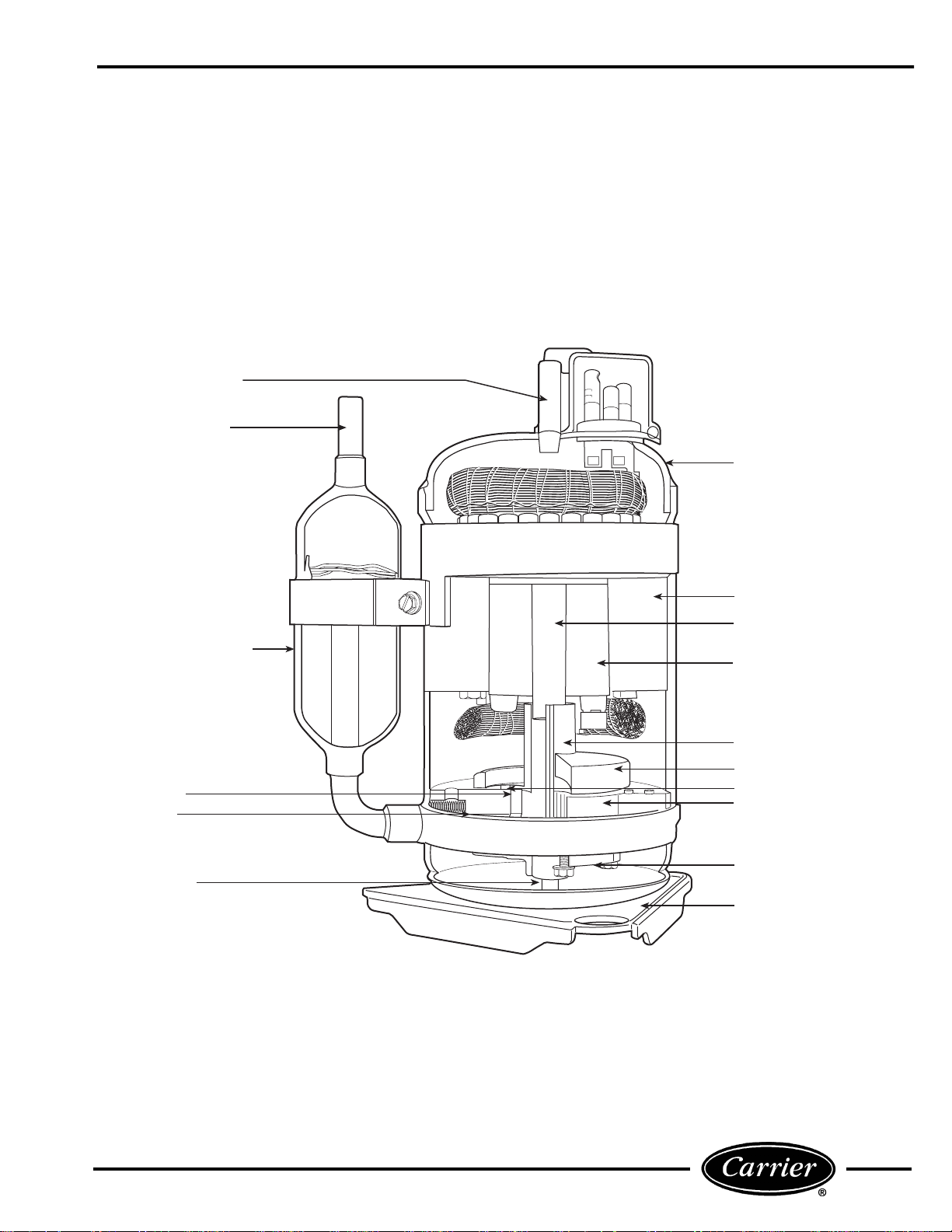

A cutaway view of the rotary compressor with key

components labeled is shown in Figure 27. The motor

stator is rigidly attached to the compressor shell. The

rotor is pressed onto the eccentric shaft, which is supported by 2 bearings. Both the discharge valve and discharge muffler are attached to the motor bearing. The

DISCHARGE TUBE

SUCTION INLET

pump bearing provides a thrust surface for the shaft

and the rolling piston. Compressed gas is separated

from the suction gas by the vane. Discharge gas pressure and the vane spring keep the vane in contact with

the rolling piston.

SHELL

STAT OR

SUCTION MUFFLER/

ACCUMULATOR

PISTON

VANE

OIL TUBE

ECCENTRIC SHAFT

ROTOR

MOTOR BEARING

DISCHARGE MUFFLER

DISCHARGE VALVE

CYLINDER

PUMP BEARING

MOUNTING PLATE

FIGURE 27 — ROTARY COMPRESSOR COMPONENTS

13

Page 14

52C,P

SERIES

The rotary compression process (Figure 28), starts at

top dead center as shown in (1). Suction gas flows

through the suction inlet and into the cylinder area.

As the shaft rotates through 90 degrees, the rolling

piston moves to positio n A as shown in (2). The su ction

volume is now the area defined by point A and the tip

of the vane. Gas in the remaining volume has been

compressed above suction pressure. After another

90 degrees of shaft rotation, the rolling piston has

moved to position B as shown in (3 ). Both the compressed gas and suction gas volumes are now equal.

Another 90 degrees of shaft rotation is shown in (4 ).

Compressed gas has reached a pressure sufficient to

open the discharge valve, and flows from the cylinder

into the compressor shell. After another 90 degrees of

shaft rotation, the entire process begins again. Continuous suction and discharge allows for a smooth compression process.

The rolling piston is not in actual contact with the cylinder wall, vane, or bearing faces. Hydrodynamic sealing prevents leakage from the compressed gas volume

to the suction volume via these paths. Precise control

of machining tolerances, surfaces, finishes, and assembly clearances is critical to achieve high efficiency performance. In addition, the line contact between the

vane tip and the rolling piston requires careful selection and control of materials to provide wear resistance and reliable long-term operation.

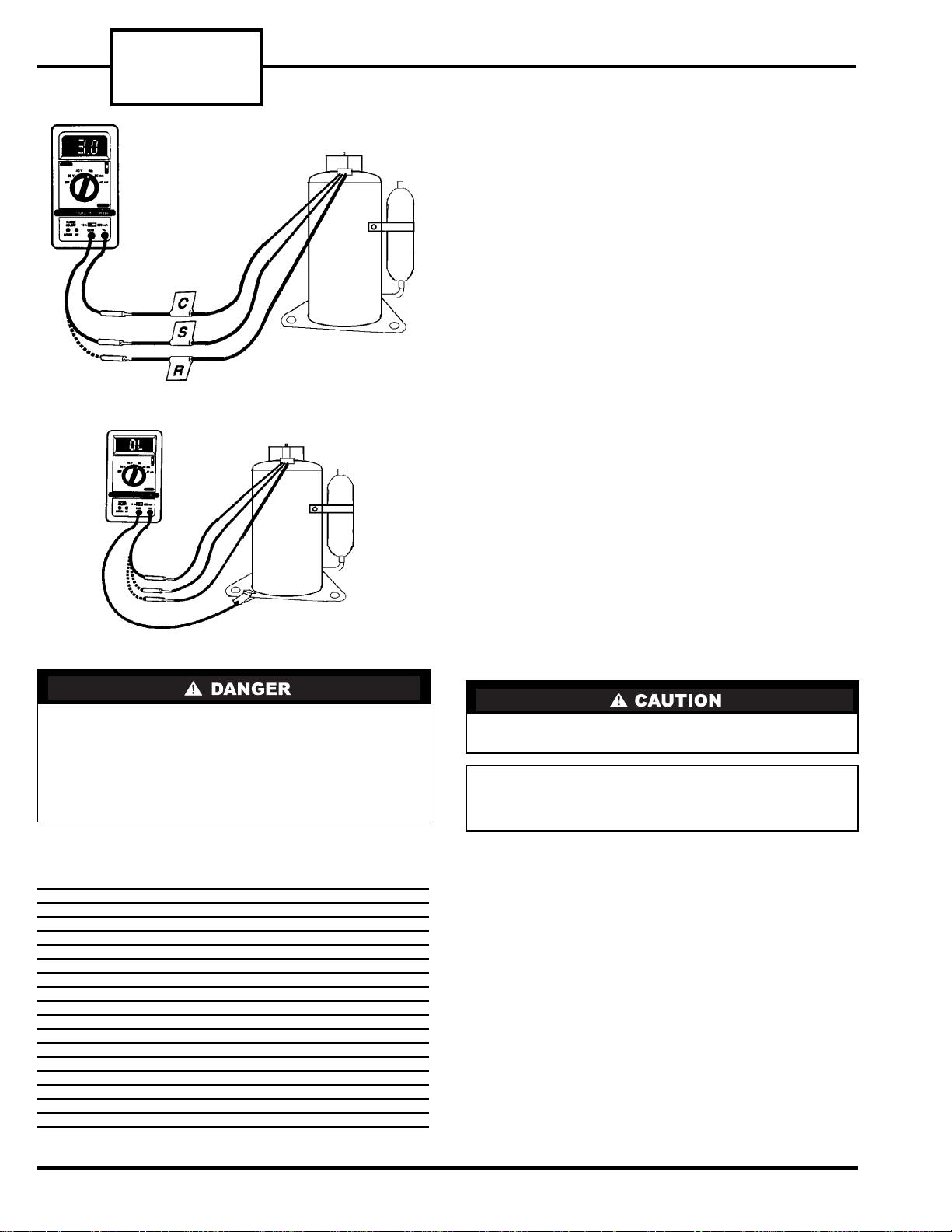

BASIC HERMETIC COMPRESSOR

ELECTRICAL MEASUREMENTS

There are 2 basic electrical te st s for herme tic compres sors that will determine the electrical state of the

motor. The first test requires checking the electrical

resistance of each of the electric al motor windin gs. The

second test requires checking the electrical resistance

of each of the electrical motor windings to ground.

These tests may be accomplished by performing the

following steps:

1. DISCONNECT ALL POWER TO THE UNIT.

2. Remove the unit chassis from the sleeve as

detailed in the UNIT DISASSEMBLY section.

3. Open the control box as detailed in the UNIT

DISASSEMBLY section, then locate, label, and

remove the 3 compressor wires from the following

locations: the RUN wire (BLACK) from the capacitor, the START wire (BLUE) from the capacitor.

The third wi re, C OM M O N wire (YELLOW ) ma y

be connected to one of the following locations: for

PC units the wire is on the indoor thermostat,

for CE, PE Remote Control Units the wi r e is

on the RC Control Board, for all other CE, PE

Units the wire is located on the rotary selector

switch. For ALL CQ, PQ Units the wire is on the

outdoor frost thermostat.

COMPRESSOR TROUBLESHOOTING

Refer to Figure 29 for a basic compressor troubleshooting chart.

FIGURE 28 — ROTARY COMPRESSOR

COMPRESSION PROCESS

For compressors that are known to be damaged: Remove refrigerant prior to disconnecting

compressor wires. Damaged hermetic compressor

terminals may become loose a nd eject f rom the compressor. Wear safety glasses and keep your face

away from the area above the terminals when

removing compressor wires.

4. Perform a shorted/open windings test to measure

the resistance between the windings of the compressor motor. Use a volt-ohmmeter set to the

lowest ohm reading level then read and record the

resistance between the RUN and START, START

and COMMON, and RUN and COMMON wires.

See Figure 30. The typical resistance readings will

be about 4, 3, and 1 ohms respectively. The

smaller values should add to equal the larger

value. If this is not true then the compressor is

likely shorted winding to winding.

NOTE: The rotary compressor has the compressor

overload located under the terminal cover. If the overload is open it can show ohm readings that are infinite.

The unit should be off for at least an hour to give this

overload time to reset if it is open.

14

Page 15

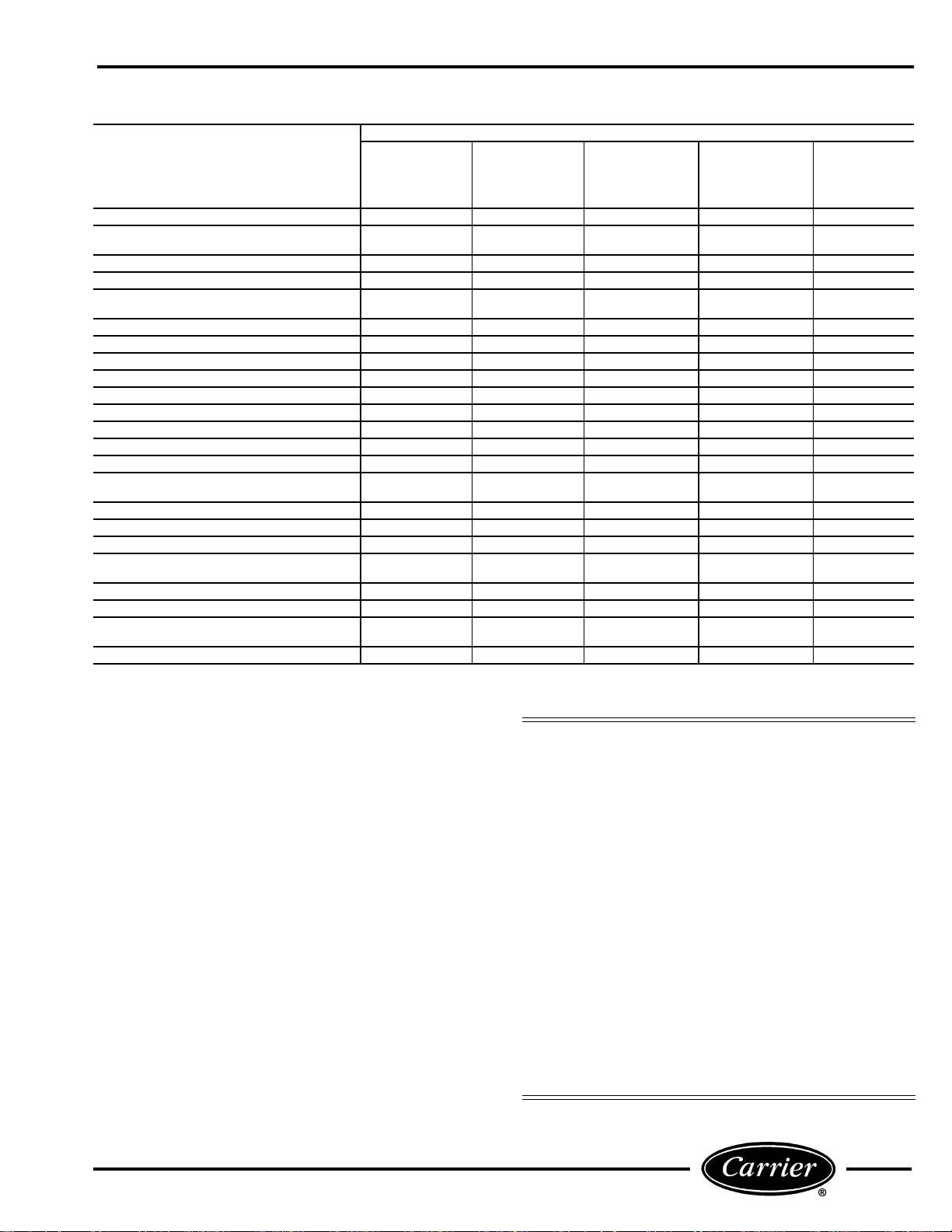

POSSIBLE CAUSE

COILS/FILTERS DIRTY OR PLUGGED

AIR OR NONCONDENSABLE GASES

IN SYSTEM

SYSTEM REFRIGERANT OVERCHARGED

DISCHARGE LINE RESTRICTED

CAPILLARY TUBE OR STRAINER

RESTRICTED OR PLUGGED

FAN BLADE OR MOTOR DEFECTIVE

FAN BLADE OR BLOWER WHEEL STUCK

SYSTEM REFRIGERANT UNDERCHARGED

EVAPORATOR AIRFLOW RECIRCULATION

UNIT OVERSIZED FOR APPLICATION

COMPRESSOR REQUIRES START ASSIST

NO POWER TO UNIT

LOW VOLTAGE TO UNIT

OVERLOAD PROTECTOR OPEN

OVERLOAD PROTECTOR INCORRECT

OR DEFECTIVE

CAPACITOR INCORRECT OR DEFECTIVE

THERMOSTAT CONTACTS ARE OPEN

THERMOSTAT IS SET TOO HIGH OR LOW

SELECTOR SWITCH IS OPEN

OR DEFECTIVE

WIRING IS INCORRECT OR DEFECTIVE

SYSTEM PRESSURES NOT EQUALIZED

COMPRESSOR MOTOR OR

MECHANISM DEFECTIVE

COMPRESSOR GROUNDED

SYMPTOM

Compressor

Starts and

Runs But

Cycles On the

Overload

X

XX

X X

XX

XX X

X X

X X

X X

XX X X

XXX

XX X X

XXXX

XX X XX

Compressor

Starts After

Cycling the

Overload

Several Times

XX

XX X

Compressor

Will Not

Start. It Hums

and Cycles On

the Overload

X

Compressor

Will Not Start

and Makes No

Noise

X

X

X

X

X

Compressor

Cycles Off

(Not On

Overload)

X

X

FIGURE 29 — BASIC COMPRESSOR TROUBLESHOOTING GUIDE

5. Next, perform a grounded windings test to test

the resistance individually of each wire to the

shell of the compressor. The paint on t he compres sor can prevent good contact between the probe

and the metal. The paint should be removed from

a small section of th e shell of the compressor to

ensure good contact by the meter probe. The voltohmmeter should be set to at least the 100X ohm

level. The measured resistance between each wire

and ground should be infinite or O.L. on the

readout. If there is measurable resistance one of

the windings is likely shorted to ground. See

Figure 31.

6. A compressor that has a winding to winding short

or a winding to compressor shell short is electrically failed and needs to be replaced. See the

Compressor Replacement section for details.

COMPRESSOR REPLACEMENT

Before working on the compressor, read the instructions thoroughly and gather t he necessar y tools fo r the

job. Review all safety information on unit and in literature. Always turn off all power to unit to avoid the

possibility of electrical shock.

Consider the following safety issues before

beginning:

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as work gloves

and safety glasses, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are th e cor r ect to ol s for the jo b a nd

that they are working properly and in good condition.

• Never replace a blown fuse without correcting the

cause of the original fail u re. If thermally operated

circuit breakers or overloads are tripping, make

sure the trip is not due to excessi vely high temperatures or loose connections.

• When brazing suction and discharge lines, cool the

lines with a damp, clean cloth to prevent injury.

• Oil may be present in the compressor accumulator

and interconnecting tubing. Use caution when

removing tubing.

15

Page 16

52C,P

SERIES

FIGURE 30 — SHORTED/OPEN WINDINGS TEST

FIGURE 31 — GROUNDED WINDINGS TEST

REMOVING THE COMPRESSOR

■

— Follow the

steps below to remove the compressor:

1. Disconnect all power to unit.

2. Remove unit from wall sleeve as detailed in the

UNIT DISASSEMBLY section. The unit weighs

up to 150 pounds. Seek assistance or use a lifting

device when removing unit from wall sleeve.

3. If the unit is a heat pump: Disconnect the wire

plug on the reversing valve solenoid and carefully

remove the outdoor thermostat capillary from the

outdoor coil. See Figure 32.

4. Attach the piercing va lve to the suction side process tube below the crimps. Attach Carrier

TOTALTEST® kit (Part No. TT1-001), to the

piercing valve to verify acidity of the s ystem. After

verifying the system acidity, remove the refrigerant using a certified refrigerant recovery system.

5. When all the refrigerant has been recovered,

remove the terminal cover from the compressor

with a nut driver. Disconnect th e 3 wire s from the

compressor and label the location of each. Once

the wires are labeled, replace the terminal cover

to protect the compressor terminals.

6. Remove the air system components by following

the procedure detailed in the ACCESSING UNIT

COMPONENTS section.

7. Remove the piercing valve and cut the crimped

portion of both process tubes off with a small tubing cutter. Braze an access valve on each process

tube. Using a torch, disconnect the suction and

discharge tubes from the compressor connections.

8. Remove the compressor mounting bolts, and

remove the compressor.

For compressors that are known to be damaged: Remove refrigerant prior to disconnecting

compressor wires. Damaged hermetic compressor

terminals may become l oos e and eje ct f r om the compressor. Wear safety glasses and keep your face

away from the area above the terminals when

removing compressor wires.

TOOLS NEEDED

■

— The following list inclu des the

recommended tools and devices for removing and

replacing the compressor.

1

/2-in. and 3/8-in. Tube Benders

1

/2-in. Nut Driver

5

/16-in. Nut Driver

Flat Head Screwdriver

Piercing Valve

2 Parker Access Valves (Part No. AVUSE-5)

Pinch Off Tool

Filter Drier — All Units (Part No. P504-80845)

Carrier TOTALTEST Kit (Part No. TT1-001)

Totalclaim System

Charging Cylinder or an Electronic Scale

Refrigerant-22

Tubing Cutter

To rch

Nitrogen Cylinder with Regulator

Strainers

Capillary Tubes

The compressor may still be hot from the brazing

process.

IMPORTANT: Any time the compressor is

replaced, the strainer and capillary tubes must

be removed and replaced also.

9. For all units: Remove and replace the strainer

and capillary tubes from the system. See Figure 32

for strainer and capillary tube location.

10. For Heat/Cool Units: Use an in-line filter drier

(P/N P504-80845). The filter drier can be installed

in any location in suction line. See Figure 33A for

general installation location.

For Heat Pump Units: Use an in-line filter drier

(P/N P504-80845) and install between the

reversing valve and the compressor accumulator. There are several suction tube configura-

tions and the in-line filter drier will be field piped

and brazed in to the su ction tube for your uni t. See

Figure 33B for a general installation location.

11. Remove the grommets from the existing compressor and install them onto the new compressor.

16

Page 17

12. Install the new compressor and the new capillary

IN-LINE

FILTER DRIER

COMPRESSOR

IN-LINE

FILTER DRIER

COMPRESSOR

assembly (the correct capillary and strainer may

be obtained from Carrier RCD), into the unit.

13. Leak check the unit with 150 psi of nitrogen

pressure.

14. For 52C,P units, the system should be evacuated

from the high side to the low side to a minimum

of 200 microns of mercury. This evacuation

removes residual moisture from the system prior

to charging.

15. For Heat Pump Units: Recharge unit to the

nameplate refrigerant charge using a charging

cylinder.

16. Pinch off each access valve on the process tubes,

in 2 places, using a pinch off tool such as Imperial

tool #105-FF or Robinair Tool #12294. Release any

refrigerant pressure trapped in the access valve

by depressing the valve co re, then confi rm that no

R-22 is leaking pa st the pinch off tool location. Cut

the access valve stem of the process tube above

the top crimp and braze the top of each process

tube to ensure the system is sealed, (leav e the

pinch off tool in place until after the brazing process is complete).

17. Reassemble the unit by reversing steps 1-9.

18. Connect the compressor wires and energize the

unit to verify operation.

REFRIGERANT CHARGING —

■

Every mechanical

refrigeration system that is opened for servicing must

be accurately charged before it is returned to service.

Run the compressor ONLY after charging the system

with refrigerant.

FIGURE 32 — STRAINER AND

CAPILLARY TUBE LOCATION

IMPORTANT: The compressor should never be

operated without refrigerant!

It is important to remember that recovered and/or

recycled refrigerant may only be recharged into the

system from which it was initially recovered, or

another one owned by the same customer. Charge

level is important. Charge units only as recommended

by manufacturer.

FIGURE 33A — IN-LINE FILTER DRIER —

GENERAL INSTALLATION LOCATION

FOR HEAT/COOL UNIT

FIGURE 33B — IN-LINE FILTER DRIER —

GENERAL INSTALLATION LOCATION

FOR HEAT PUMP UNIT

17

Page 18

52C,P

SERIES

HEATERS

The heater in 52C,P units is located directly behind

the evaporator coil. The heater assembly includes the

heater (2.3 kW, 3.4 kW or 5 kW), a primary limit

switch, and a secondary limit switch. See Figure 34.

The primary and secondary limit switches are safety

switches that regulate heater operation. The primary

limit switch disables current to the heater when the

temperature exceeds t he setting on the switch.

For example, a 3.4 kW heater may have a primary

limit switch setting of 150 F. If the temperature at the

switch exceeds 150 F, the primary limit switch will

electrically open and shut off power to the heater.

Once the temperature drops below 110 F, the primary

limit switch will automatically reset.

The secondary limit switch works in the same manner

as the primary limit switch, except it is a one time

switch and has a slightly higher temperature setting.

Once this switch is thermally opened, it must be

replaced. Together the primary and secondary

switches help maintain safe temperature limits for

unit operation.

COMMON CAUSES OF

HEATER FAILURE

Heater failure may result from broken heater coils,

primary limit switch failure, or an open secondary

limit switch. These conditions are generally caused by

low or no airflow.

HEATER REMOVAL

Before working on the heater, read the instructions

thoroughly and gather the necessary tools for the job.

Review all safety information on the unit and in the

product literature.

Before performing any cleaning, servicing, or maintenance to the unit, Disconnect All Power to avoid

the possibility of electric shock and personal injury.

The manufacturer reserves the right to discontinue, or

change at any time, specifications or desig ns without

notice and without incurring obligations.

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical equipment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety

glasses and work gloves, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job,

and that they are working properly and in good

condition.

FIGURE 34 — LIMIT SWITCH LOCATION

18

Page 19

TOOLS NEEDED

■

— The following list inclu des recommended tools and devi ces for worki ng on t he heater

section of 52C,P units.

Phillips Head Screw Driver

Needle Nose Pliers

Volt-ohmmeter

Nut Driver

5

/16-in.

Perform the follo w in g ste ps to rem ove the Heater

Assembly.

1. DISCONNECT ALL POWER TO UNIT.

2. Remove heater by follo wing instructions in

ACCESSING UNIT COMPONENTS section.

After the heater is removed, examine the heater

as follows to determine if it is operational:

Perform a visual inspection. The heater coil should be

free of breaks. If there are any breaks in the coil,

replacement of the heater assembly is necessary. See

Figure 35.

Coil resistance must also be checked to verify the

heater is operating correctly. The resistance of the

heater coils must meet approximate levels for the

heater to perform at its optimum effici ency. See

Figure 36 for approximate resistance for heaters at

75 F. Before checking the heater coil resistance, be

sure all power to unit is off.

To check resistance, set the volt-ohmmeter selector

switch to the lowest ohms value. Next connect the voltohmmeter leads to each side of the heater coil at the

studs that hold the limit switches in place. Incorrect

readings can be obtained if the wires are not removed

from the limit switches on the heater assembly. If the

resistive reading is infinite or zero, the heater is failed

and replacement is necessary. Reinstall the heater

assembly.

FIGURE 35 — HEATER COIL (Removed)

HEATER SIZE WATTS VOLTS

2.3 kW

3.4 kW

5.0 kW

2300 230 20-23

2300 265 28-31

3400 230 13-16

3400 265 19-21

5000 230 9-11

5000 265 13-15

FIGURE 36 — ACCEPTABLE HEATER

RESISTANCE VALUES

ACCEPTABLE RESISTANCE

(Ohms)

19

Page 20

52C,P

SERIES

OPERATING CONTROLS

UNIT-MOUNTED CONTROLS

The controls and components used in the 52C,P cooling only or heat/cool units are as follows: the selec-

tor switch, the indoor thermostat, the dual capacitor,

the temperature limiter, the vent lever, and the fan

cycle switch. See Figure 37.

The selector switch is used to determine the mode of

operation: heat, cool, fan, or off. The indoor thermostat

controls the room ambient temperature and cycles the

heater or the compressor based on the selector switch

setting. The dual capacitor aids in the start-up of the

compressor and the fan motor. The temperature limiter

is integrated into the control box top cover located

under front panel. I t is a mecha n ica l dev i ce th at

restricts the amount of rotation of the thermostat. The

temperature limiter device may be adjusted by moving

the plastic temperature selector tabs to another temperature location on the control box. The vent lever is

located on the front left side of the chassis. It is a slide

mechanism that opens and closes the vent door. The

vent control may be accessed by removing the front

panel of the unit. The f an cycle switch is used to provide

2 options of fan control. The first option, CON, causes

the fan to run continuously. The second option, CYC,

causes the fan to cycle on with the compressor or electric heater and off when the thermostat is satisfied.

INDOOR

THERMOSTAT

80

85

75

70

65

60

90

SELECT0R

SWITCH

The 52C,P heat pump unit contains all the components of the heat/cool and cooling only unit, and the

following additional ones: the outdoor frost thermostat

and the reversing valve. The outdoor frost thermostat

prevents operation of the unit in the heat pump mode

when the outdoor coil temperature drops below 20 F,

or at about 35 F o utdoor ambient temperature. The

unit automatically engages the electric heat strip and

disables the compressor und er these conditions.

The outdoor frost t hermost at has a manual override to

place the unit in electric heat mode operati on only . The

override switch is located behind the front panel on

the front side of the unit control box door.

IMPORTANT: Placing the override switch to electric heat mode operation will disable the compres-

sor for ALL heating or cooling operations (for all

units except RC units). Placing the override switch

to electric heat mode operation on RC units will

only disable the compressor in heating mode.

The reversing valve allows for operation in reverse cycle

heat pump mode. The valve is located in the piping system and is controlled by the reversing valv e solenoid

coil. The coil is energized only during the heating mode.

TEMPERATURE

LIMITER

CON

FAN CYCLE

SWITCH

CYC

OUTDOOR FROST

THERMOSTAT

(HEAT PUMP

UNITS ONLY)

FIGURE 37 — 52C,P OPERATING CONTROLS

20

Page 21

WALL-MOUNTED THERMOSTAT

TYPICAL

WALL

THERMOSTAT

R

G

Y

W

O

C

TERMINAL

BLOCK

R

G

Y

W

O

C

CONTROLS

For 52C,P wall thermostat control (RC, RP)

units, all controls are located on the wa ll-mounted

thermostat except the v ent lever and outdoor thermostat. Remote control is a factory or field-installed

option. There are 3 styles of thermostats qualified for

use with 52C,P series Remote Control units. See Figures 38-40. On remote control units, the fan cy cle function is located on the wall thermostat. The rocker

switch on the control box door is used to set fan speed

to high or low. Factory defau lt is low spee d .

See Figures 41-43 for thermostat wiring.

A field conversion kit is available to convert an AA

model (standard unit-mounted controls) to an RC

model (wall-mounted controls).

IMPORTANT: No conversion kit is available to

convert from an RC model back to an AA model.

FIGURE 38 — NON-PROGRAMMABLE

THERMOSTAT

FIGURE 39 — MANUAL THERMOSTAT

TERMINAL DESIGNATION

R

24 VAC

G

Fan

Y

Compressor

W

Electric Heat

O

Reversing Valve

C

Common

NOTES:

Use terminal “O” for heat pump con-

1.

nection only

2. See table at left for terminal descriptions.

3. Common wire “C” is typically used only

for digital thermostats.

4. Power stealing is NOT allowed. There

must always be a hard common connection between unit and digital thermostat.

.

FIGURE 41 — WIRING CONNECTIONS

REMOTE THERMOSTAT

TROUBLESHOOTING

Thermostat display is blank:

Check to make sure there is 24 VAC to the thermostat

(measure across terminals R and C at the thermostat).

If there is 24 VAC at the thermostat, check connections at the thermostat terminal block. If connections

are good and there is 2 4 VAC wit h no dis play, the ther mostat should be replaced.

Thermostat display is working but unit is not

heating or cooling:

At the RC terminal block on the unit, measure the control inputs coming from the thermostat. (Place one of

the meter leads on C and use the other to check the

voltage at each of the terminals.)

TERMINAL

MODE

Fan Only

Cooling

Heating

Heat Pump Unit

Heat/Cool Unit

*24 VAC supplied if thermostat is in 2nd stage heating demand (large

difference between room temperature and setpoint).

NOTE: For heat pump units, the Outdoor Frost Thermostat (OFT) will

determine, based on outdoor temperature, whether to bring on the compressor or electric heat in the Heating mode.

FIGURE 42 — THERMOSTAT TROUBLESHOOTING

METER READINGS (VAC)

RGY W

24 24 0 0 0

24 24 24 0 24

24 24 24 0/24* 0

24 24 0 24 0

O (For

HP Only)

FIGURE 40 — PROGRAMMABLE THERMOSTAT

If the inputs are not correct, then the thermostat is not

making a call for the mode requested. This could be

because the thermostat is in a unit protection mode,

not set up properly, miswired, has a broken wire, or it

may have failed.

21

Page 22

52C,P

SERIES

MASTER

PTAC

UNIT 1

UNIT 2

R

Y

W

G

O

C

R

Y

W

G

O

C

R

Y

W

G

O

C

R

Y

W

G

O

C

T’STAT

UNIT 3

R

Y

W

G

O

C

NOTES:

1. Do not daisy chain R (24 VAC).

2. Maximum of 4 PTAC units can be connected

to one single wall thermostat.

All units must be connected to same ground source.

To accomplish this, be sure to connect all units back

to the same breaker box.

FIGURE 43 — TYPICAL WIRING FOR MULTIPLE 52C PTAC UNITS CONNECTED

TO ONE WALL THERMOSTAT

22

Page 23

DESCRIPTION OF SELECTOR SWITCH

SETTINGS (Figure 44)

OFF MODE

■

operation.

FAN ONLY MODE

■

circulation without heating or cooling. Fan runs at

high speed.

HIGH HEAT OR HIGH COOL MODE

■

selector and temperature control knobs to desired comfort level. This function provides maximum heating or

cooling, and is recommended to raise or lower the room

temperature quickly.

LOW HEAT OR LOW COOL MODE

■

selector and temperature control knobs to desired comfort level. This function provides minimum heating

or cooling with maximum dehumidification duri ng

cooling. This setting also allows for very quiet fan

operation.

FINDING TEMPERATURE SETTING FOR COM-

■

FORT LEVEL

Select High Heat, Low Heat or Cool position and allow

unit to run for 15 to 30 minutes. If roo m is not co mfort able, turn knob setting slowly to change setting. When

room is comfortable, keep control knob at that

position.

— The OFF position terminates unit

— Use fan only position for air

— Position

— Position

— Set temperature knob in the middle.

NON-USER ADJUSTABLE CONTROLS

OUTSIDE OR VENT AIR

■

the fully open position for outside air or fully closed

position for vented air.

FAN CYCLE

■

— The fan cycle switch allows the fan

to operate in 2 modes:

CON — Fan runs continuously, circulating air even

when the temperature setting has been satisfied. This

helps to maintain the room temperature closer to the

thermostat setting.

CYC —Fan cycles on and off with the compressor

during heating or cooling. Fan stops when the temperature setting is satisfied. This results in longer unit

off-time and slightly larger variations in room temperature and humidity.

OUTDOOR THERMOSTAT (52CQ, PQ Units Only)

■

— The outdoor thermostat has 2 opera ting modes. The

heat pump mode (selector screw set fully clockwise),

allows the unit to operate normally in the reverse cycle

mode. The electr i c hea t mo d e (s el ec t or scr e w se t fully

counterclockwise), disables all compressor operating

modes, both heating and cooling for units with

mounted controls. For wall thermostat controlled models the compressor is only di sab le d i n hea t ing an d st il l

allowed to run in cooling.

— Slide the vent lever to

TYPICAL 52C UNIT CONTROLS

FIGURE 44 — TYPICAL CONTROL PANEL (52C Unit Shown)

WALL THERMOSTAT CONTROLS (Blank Plate )

TYPICAL 52C UNIT WITH

23

Page 24

52C,P

SERIES

SEQUENCE OF OPERATION

HEAT/COOL UNITS (Figure 45)

■

Fan Mode

tacts L1 to HI and FCS1 to LS are made.

Cooling (Low)

speed cooling contacts FCS2 to LO, COMP to FCS1,

and COMP to IT3 are made.

Cooling (High)

speed cool contacts FCS2 to HI, COMP to FCS1, and

COMP to IT3 are made.

Heating (Low)

speed heat conta cts FCS2 to LO, IT 1 to LS, L2 to HTR ,

and FCS1 to LS are made.

Heating (High) —

speed heat cont acts FCS2 to HI, IT1 to LS, L 2 to HT R,

and FCS1 to LS are made.

SWITCH

POSITION

OFF

FAN

LO HEAT

HI HEAT

LO COOL

HI COOL

FIGURE 45 — SELECTOR SWITCH CONTACTS,

COOLING ONLY UNITS (Figure 46)

■

Fan Mode (Low)

contact L1 to LO is made.

Fan Mode (High)

FAN contact L1 to HI is made.

Cooling (Low)

speed cooling contacts FCS to LO and L1 to IT3 are

made.

Cooling (High)

speed cool contacts FCS to HI, L1 to IT3 are made.

OFF

FAN L O

FAN HI

LO COOL

HI COOL

FIGURE 46 — SELECTOR SWITCH CONTACTS,

HEAT PUMP UNITS (Figure 47)

■

Fan Mode

L1 to HI is made.

Cooling (Low)

cool contacts L1 to IT3 and FCS to LO are made.

— With the selector switch set to FAN con-

— With the selector switch set to low

— With the selector switch set to high

— With the selector switch set to lo w

With the selector switch set to high

CONTACTS MADE

NONE

L1 TO HI, FCS1 TO LS

FCS2 TO LO, IT1 TO LS, L2 TO HTR, FCS1 TO LS

FCS2 TO HI, IT1 TO LS, L2 TO HTR, FCS1 TO LS

FCS2 TO LO, COMP TO FCS1, COMP TO IT3

FCS2 TO HI, COMP TO FCS1, COMP TO IT3

ALL 52CE, PE ELECTRIC HEAT/COOL UNITS

—

With the selector switch set to FAN

—

With the selector switch set to

—

With the selector switch set to low

—

With the selector switch set to high

SWITCH

POSITION

CONTACTS MADE

NONE

L1 TO LO

L1 TO HI

L1 TO IT3, FCS TO LO

L1 TO IT3, FCS TO HI

ALL 52CE, PE COOLING ONLY UNITS

—

With the selector switch set to fan contact

—

With the selector switch set to low

Cooling (High)

—

With the selector switch set to high

cool, contacts L1 to IT3 and FCS to HI are made.

Heating (Low)

—

With the selector switch set to low

heat contac ts L1 t o I T 1, FC S to LO an d L 2 to HT R a re

made.

Heating (High)

—

With the selector switch set to high

heat contacts L1 to IT1, FCS to HI, and L2 to HTR are

made.

Defrost Cycle

—

When heat pump unit is operating in

reverse cycle, the outdoor coil may begin to frost. As

frost accumulates on the outdoor coil the unit may

switch into defrost mode. The defrost mode is activated when the outdoor frost thermostat sensor

detects a temperature below 20 F on the coil. At this

point, the thermostat deenergizes the compres sor and

activates the electric heat. The unit will remain in

electric heat mode until the outdoor thermostat senses

35 F coil temperature. The defrost mode is a passive

operation and may take some time before the coil

defrosts.

SWITCH

POSITION

OFF

FAN

LO HEAT

HI HEAT

LO COOL

HI COOL

NONE

L1 TO HI

L1 TO IT1, FCS TO LO, L2 TO HTR

L1 TO IT1, FCS TO HI, L2 TO HTR

L1 TO IT3, FCS TO LO

L1 TO IT3, FCS TO HI

CONTACTS MADE

FIGURE 47 — SELECTOR SWITCH CONTACT,

ALL 52CQ, PQ HEAT PUMP UNITS

COMPONENT OPERATION AND

TROUBLESHOOTING

TOOLS NEEDED

■

Volt-Ohmmeter

Flat and Phillips Screw Drivers

5

/16-in. Nut Driver

Side Cutting Pliers

Before cleaning, servicing, performing maintenance

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance tasks such as cleaning and replacing filters.

Refer to UNIT DISASSEMBLY section of this manual for proper procedures to disconnect power to

52C,P units.

24

Page 25

The Manufacturer reserves the right to discontinue, or

change at any time, specifications or designs without

notice and without incurring obligations.

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical eq ui pment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety

glasses and work gloves, should be worn.

• The floor around the work area should be clea n and

free of debris.

• Make sure tools are the correct tools for job, and

that they are working properly and in good

condition.

• The 52C,P unit may weigh up to 150 pounds. Use a

lifting device or ask for assistance if the unit must

be moved.

INDOOR THERMOSTAT (Heat/Cool and Cool Only

■

Units) (Figure 48) —

The thermostat maintains the

selected temperature by cycli ng the compressor on and

off during cooling operation and the electric heater

during heating operation. The thermostat DOES

NOT switch from heating to cooling, or cooling

to heating. If the switch is in the CYCLE position,

then the fan will be cycled off when the thermostat

satisfies.

To verify the operation of the thermostat switch, a continuity test may be performed as follows:

1. Turn off unit power as described in UNIT

DISASSEMBLY section.

2. Remove wire leads from thermostat. Note their

locations to ease re-assembly.

FIGURE 48 — INDOOR THERMOSTAT (IT)

CONTACTS, ALL 52CE, PE MODELS

LEGEND (Figures 48-50)

COMP —

HTR —

IT —

OFT —

OL —

PLS —

SLS —

Compressor

Heater

Indoor Thermostat

Outdoor Frost Thermostat

Overload

Primary Limit Switch

Secondary Limit Switch

3. Place one of the leads of the continuity tester on

the terminal marked 2, and the other lead on

either the terminal marked 1 or the terminal

marked 3.

4. Adjust the thermostat up or down to verify the

contacts of the switch open and close. When verifying continuity of a closed switch, the ohm reading should be 0 ohms. An open switch will show

OL on the meter.

5. When testing is complete, reconnect the leads.

INDOOR THERMOSTAT (Heat Pump Units)

■

(Figure 49) —

The heat pump indoor thermostat uses a

two-stage switch for the heating mode. The first stage

engages the compressor and reversing valve, and the

unit operates in normal heat p u mp mode. The indoor

thermostat maintains the selected temperature by

cycling the compressor on and off in cooling mode. In

the heating mode, the indoor thermostat will cycle the

compressor or the heater, de pending on the difference

between the actual room temperature and the thermostat temperature setting.

When the room temperature is more than 4 F cooler

than the indoor thermostat setting, the second hea ting

stage of the indoor thermostat engages the electric

heat strip. This design feature allows the user to rapidly warm the room with the electric heat strip by

turning the thermostat to its highest setting. When

room temperatures appro ach the desired temperatu re,

the user may adjust the thermostat to a personal

comfort setting, which allows for normal heat pump

operation.

NOTE: For outdoor coil temperatures below approximately 20 F, the outdoor frost thermostat prevents

heat pump mode operation and immediately engages

the electric heat strip upon a call for heating. The electric heat strip is NEVER energized at the same time

as the compressor.

To verify operation of the heat pump indoor thermostat switch, a continuity test may be performed as

follows:

1. Turn off unit power as described in UNIT

DISASSEMBLY section.

2. Remove wire leads from thermostat. Note their

locations to ease re-assembly.

3. To test stage A, place one lead of the continuity

tester on the terminal marked 2, and the other

lead on either the terminal marked 1 or the terminal marked 3.

4. Adjust the thermostat up or down to verify the

contacts of the switch open and close. When verifying continuity of the closed switch, the reading

on the meter should be 0 ohms. An open switch

will show OL on the meter.

5. To test st age B contacts, place one lead of the continuity t ester on contact 5 and the other lead on

either contact 4 or contact 6.

6. Adjust the thermostat up or down to verify the

contacts of the switch open and close as in Step 4.

7. When testing is complete, reconnect the leads.

25

Page 26

52C,P

SERIES

1

BLK

2

ORN

5

3

4

6

IT

BLU

GRY

BRN

FIGURE 49 — INDOOR THERMOSTAT (IT)

CONTACTS, ALL 52CQ, PQ MODELS

OUTDOOR FROST THERMOSTAT (Heat Pump

■

Units) (Figure 50A and 50B) —

The Outdoor Frost

Thermostat (OFT) is a thermostat that uses a singlepole switch with a manual override selector. The thermostat switches betwe en elect ric heat and co mpres sor

operation when the temperature of the outdoor coil

falls below 20 F or rises above 35 F. Switching the

override selector to electric heat disables the reverse

cycle operation of the thermostat and is manually

switched to electric heat operation.

IMPORTANT: Pla c ing th e over ri de sw it c h to elec tric heat mode operation will disable the compres-

sor for ALL heating or cooling operations (for all

units except RC units). Placing the override swi tch

to electric heat mode operation on RC units will

only disable the compressor in heating mode.

FIGURE 50A — OUTDOOR FROST THERMOSTAT

(OFT) CONTACTS, ALL 52CQ, PQ UNITS WITH

MOUNTED CONTROLS

To verify the OFT is operational, a continuity test may

be performed as follows:

1. Turn off unit power as described in UNIT

DISASSEMBLY section.

2. Remove the leads from the OFT. Note their locations to ease re-assembly.

3. Connect the continuity tester to the switch terminals marked 1 and 2.

4. Rotate the override switch to the electric heat setting and verify that there is continuity between

terminals 1 and 2.

5. To check the other contacts, move the lead on terminal 1 to terminal 3. Rotate the override switch

to the heat pump setting. There should now be

continuity between terminals 2 and 3.

6. Once the test is complete, reconnect the leads.

CAPACITOR —

■

The 52C,P units use a dual

capacitor. One part of the capacitor is used with the

fan motor. The other part of the capacitor is used by

the compressor.

Run circuits on single-phase compressor motors use

capacitors which dramatically affect the motor operation. Run capacitors are connected to the motor circuit

at all times.

To evaluate the capacitor, perform a visual check first.

A shorted capacitor may give a visual indication of its

failure. For example, the pop-out hole at the top of a

start capacitor may bulge or blow out. A run capacitor

may bulge or leak. In these instances, the capacitor

must be replaced with one recommended by the manufacturer. If there are no visual signs of capacitor failure, testing of the capacitor resistance may be done

with a volt-ohmmeter as detailed below:

1. Turn off unit power as described in UNIT

DISASSEMBLY section but do not unplug the

service cord; it will supply ground connection for

the unit chassis. Check to ensure power is off

and LOCKED OUT.

2. Connect one lead of a 20,000 ohm, 2-watt resistor

to the center group of te rminal s on the dua l ca pacitor. Attach the other lead from the resistor to an

unpainted metal section of the unit chassis. This

allows that section of the dual capacitor to discharge. Repeat this process between the other

group of terminals.

FIGURE 50B — OUTDOOR FROST THERMOSTAT

(OFT) CONTACTS, ALL 52CQ, PQ UNITS WITH

WALL THERMOSTAT CONTROL

Capacitors are capable of holding charge similar to a

battery and may cause an electrical shock.

3. Locate and disconnect the wires from the start

and/or run capacitor to isolate them from the

remainder of the circuit. Refer to the unit wiring

diagram if you need assistance locating wires.

4. Perform capacitor test. Set up the volt-ohmmeter

to measure resistance by connecting terminals C

to FAN and C to HERM on the meter. See

Figure 51.

26

Page 27

TEMPERATURE

CONTROL

STANDOFF

PINS

FAN CYCLE

SWITCH

OUTDOOR FROST

THERMOSTAT

(HEAT PUMP

UNITS ONLY)

80

85

90

60

65

70

75

CON

CYC

SELECT0R

SWITCH

OFT

MOUNTING

SCREWS

FIGURE 51 — CAPACITOR TEST

5. The reading on the meter should first indicate

zero, or a low resistance, then slowly rise toward

infinity or some high value or measurable resistance. This indicates the capacitor is most likely

good. If the reading goes to zero or a low resistance and stays there, the capacitor is likely

shorted and needs replacement. If the reading

immediately indicates infinity, the capacitor is

likely open and must be replaced.

6. Replace the capacitor if failed and rewire according to the WIRING SCHEMATICS located in the

control box of the unit.

FAN CYCLE SWITCH —

■

The fan cycle switch has

2 operating modes, continuous ( CON) and cycle (CYC).

To verify the fan cycle switch is operational, a continuity test may be performed as follows:

1. Turn off unit power as described in UNIT

DISASSEMBLY section.

2. Label and remove the leads connected to fan cycle

switch. See Figure 52.

3. Connect th e volt-o hmmeter for 1X ohms a nd check

for continuity from terminal 2 to 1 then change

the switch position and check for continuity from

terminal 2 to 3.

4. Once test is complete, reconnect the leads.

ELECTRICAL COMPONENTS

REMOVAL AND REPLACEMENT

INDOOR THERMOSTAT

■

thermostat, perform the following steps:

1. Turn off unit power as described in UNIT

DISASSEMBLY section.

2. Remove front panel.

3. Remove thermostat knob to expose 2 Phillips head

mounting screws.

4. Open the control box as described in the UNIT

DISASSEMBLY section of this manual.

5. Carefully remove the thermostat bulb from the

clip by gently pressing it down and out of the clip.

6. Remove the leads from the indoor thermostat.

Note the wire locations to ease re-assembly.

— To remove the indoor

7. Remove the 2 screws mounting the thermostat to

the control box. Route thermostat bulb and capillary out of control box.

8. Remove thermostat.

9. Reverse Steps 1-8 to reinstall.

OUTDOOR FROST THERMOSTAT (Heat Pump

■

Units)

— To remove the outdoor frost thermostat

(OFT), perfor m th e fo ll ow in g ste ps :

1. Turn off unit power as described in UNIT

DISASSEMBLY secti on.

2. Remove front panel.

3. Remove the 2 screws mounting the thermostat to

the bottom of the control box. See Figure 53.

FIGURE 52 — FAN CYCLE SWITCH (3 Terminal)

FIGURE 53 — 52C,P OPERATING CONTROLS

27

Page 28

52C,P

SERIES

4. Remove the thermostat capillary from the outdoo r

coil and clip any wire ties holding the capillary in

place.

5. Disconnect the wires and carefully remove the

thermostat and capillary from the unit, noting

location of wires for easy re-assembly.

6. Reverse Steps 1-5 to reinstall.

CAPACITOR

■

the following steps:

1. Turn off unit power as descri b e d i n UNIT

DISASSEMBLY section.

2. Open the control box as detailed in the UNIT

DISASSEMBLY section of this manual.

3. Properly discharge the capacitor as described in

the Capacitor section under Component Opera-

tion and Troubleshooting.

4. Remove the leads to the capacitor. Note the wire

locations to ease re-assembly.

5. Remove the screw holding the capacitor.

6. Remove capacitor.

7. Reverse Steps 1-6 to reinstall.

FAN CYCLE SWITCH —

■

located on the front of the control box. To remove the

fan cycle switch, perform the following steps:

1. Turn off unit power as descri b e d i n UNIT

DISASSEMBLY section.

2. Open the control box as described in UNIT

DISASSEMBLY section of this manual.

3. Remove the 3 wires from the fan cycl e s witch. S ee

Figure 54 for location, noting location of wires for

re-assembly.

4. Push the snaps of the switch housing toward the

switch with a pair of pliers or small screwdriver.

Gently push the switch out of the housing.

5. Reverse Steps 1-4 to reinstall.

To remove the capacitor, perform

—

The fan cycle switch is

SELECTOR SWITCH —

■

To remove the selector

switch from the unit, perform the following steps:

1. Turn off unit power as described in UNIT

DISASSEMBLY secti on.

2. Remove selector switch knob. See Figure 53.

3. Open control box as described in the UNIT

DISASSEMBLY section of this manual.

4. Remove all the wires to the selector switch. Label

wires to simplify re-assembly. See Figure 54.

5. Remove the 2 screws mounting the switch and

remove switch.

6. Reverse Steps 1-5 to reinstall.

CAPACITOR

OUTDOOR FROST

THERMOSTAT

POWER CORD

RIBBED WIRE (L2)

TO CAPACITOR (C)

POWER CORD

PLAIN WIRE (L1)

GROUND SCREW

FAN CYCLE

SWITCH

INDOOR

THERMOSTAT

TO ROTARY SWITCH

SELECTOR

SWITCH

FIGURE 54 — COMPONENT LOCATIONS

IN OPEN CONTROL BOX

28

Page 29

FAN MOTOR

The fan motor is a permanent split capacitor (PSC)

type motor. This motor is common in air-conditioning

system appl icat io ns. A PSC moto r do es not req uire the

use of a relay and always has a run capacitor connected between the run and start windings of the

motor. See Figure 55.

The 52C,P series fan moto r has a motor shaf t extended

through both ends. It powers both the indoor and the

outdoor fans. It has permanently sealed bearings that

require no lubrication. There are many different fan

motor models, but they typically are 2-speed and in

2 voltage categories, 208/230 and 265 volts.

FAN MOTOR TROUBLESHOOTING

Refer to Figure 56 for a basic fan motor troubleshooting chart.

TOOLS NEEDED

■

ommended tools and devices for working on the fan

motor of 52C,P units

Regular and Phillips Head Screw Drivers

Before cleaning, servicing, performing maintenance

or removing the chassis from the wall sleeve, disconnect all power to the unit to avoid the possibility of

electrical shock and personal injury. Only trained

and qualified service personnel should perform

installation and service procedures on these units.

Untrained personnel may perform basic maintenance tasks such as cleaning and replacing filters.

Refer to UNIT DISASSEMBLY section of this manual for proper procedures to disconnect power to

52C,P units.

The Manufacturer reserves the right to discontinue, or

change at any time, specifications or designs without

notice and without incurring obligations.

FIGURE 55 — TWO-SPEED, PERMANENT

SPLIT CAPACITOR MOTOR (PSC)

— The following list includes rec-

.

Gloves

Safety Glasses

Small Adjustable Wrench

Channel Lock Pliers

Volt-ohmmeter

5

/16-in. Nut Driver

Consider the following safety issues:

• Prior to performing any service or maintenance on

electrical equipment you must Disconnect All

Power.

• New and unfamiliar tasks should be performed

under the supervision of an experienced service

technician.

• Personal protective equipment, such as safety

glasses and work gloves, should be worn.

• The floor around the work area should be clean and

free of debris.

• Make sure tools are the correct tools for the job,

and that they are working properly and in good

condition.