Page 1

Owner’s Guide

INTERNATIONAL SERIES™

Have a question! Need help!

Call 1-800-CARRIER

DEALER’S NAME^

MODEL

51QC/QG

ADDRESS

TELEPHONE.

MODEL NO.„

________

PURCHASE DATE.

SERIAL NO..

Page 2

TABLE OF CONTENTS

Page Nc

A Few Words About Your New Unit..................................................................................................2

Some Suggestions...........................................................................................................................2

Electrical Data & Specifications....................................................................................................... 3

Glossary of Control Symbols & Operating Instructions

Economic Energy Saving Tips.........................................................................................................6

Tools Needed for Installation............................................................................................................6

Through-the-Wall Installation........................................................................................................... 7

Window Installation..........................................................................................................................9

Trouble Shooting Guide................................................................................................................. 12

Unit Warranty.................................................................................................................................. 14

...................................................................

4

Page 3

A FEW WORDS ABOUT YOUR NEW CARRIER UNIT...

Thank you for choosing Carrier! You can feel confident

in your selection because the same pride in craftsman

ship and engineering knowledge that goes into Carrier

equipment at the Astrodome in Texas, the famous Sistine Chapel in Rome, the United States Capitol’s Halls of

Congress and thousands of other installations world

wide has gone into construction of your unit.

One of the principal advantages to owning a Carrier

room air conditioner heat pump is that the unit heats

AND cools, so it can be used year-round! While cooling.

SOME SUGGESTIONS...

A) To avoid installation difficulties, read instructions

thoroughly before starting. This publication contains

information pertinent to the installation and operation of

the 51 QC/QG Room Air Conditioner Heat Pump.

B) The 51 QC/QG is normally installed through a wall.

During installation, you will be moving unit’s chassis from

the cabinet casing, installing the casing first and then

re-inserting the chassis. CAUTIQN; CQIL FINS QN

CHASSIS ARE SHARP AND CHASSIS IS HEAVY.

your new Carrier unit also filters and dehumidifies. In

cold weather, the unit gently heats and circulates air

through the room. Carrier’s room air conditioner heat

pump units quietly give you maximum comfort!

This manual will supply you with all the information

you need for installing, operating and maintaining your

new unit. Take a few moments to read and discover how

to get the most in comfort and economic operation from

your new Carrier room unit!

NOTE: This unit may also be installed in a window. An

additional accessory kit must be ordered separately for

window mounting. Contact an authorized Carrier Dealer,

or call 1-800-CARRIER for information.

C) When possible, install unit on a shaded side of the

house or building.

D) Make sure that wall mounting area (or window, if

window-installation is chosen) is structurally sound

enough to support the unit.

BEFORE YOU START

Use the following guide to insure that you have selected

the air conditioning unit that wiil properly cool the space

you desire This guide is developed for normal room

insulation, number of windows, and sun exposure, with

two people occupying the conditioned space

Adjust the room air conditioner capacity found in

the table for the following conditions

1, Reduce capacity by 10% for heavily shaded

areas.

2 Increase capacity by 10% for very sunny

areas

3 Add 600 Btu/h for each additional person

(more than two people)

4 Add 4,000 Bfu/h if area to be cooled is a

kitchen.

Area To Be Cooled

Square Feet

(Width, Ft. X Length, Ft.)

100-150

150-250

250-300

300-350

350-400

400-450

450-550

550-700

700-1,000

1,000-1,200

1,200-1,400

1,400-1,500

1,500-2,000

2,000-2,500

Approximate Nominal

Cooling Capacity

Btu/h

5.000

6.000

7.000

8.000

9,000

10,000

12,000

14.000

18.000

21,000

23.000

24.000

30.000

34.000

A

Page 4

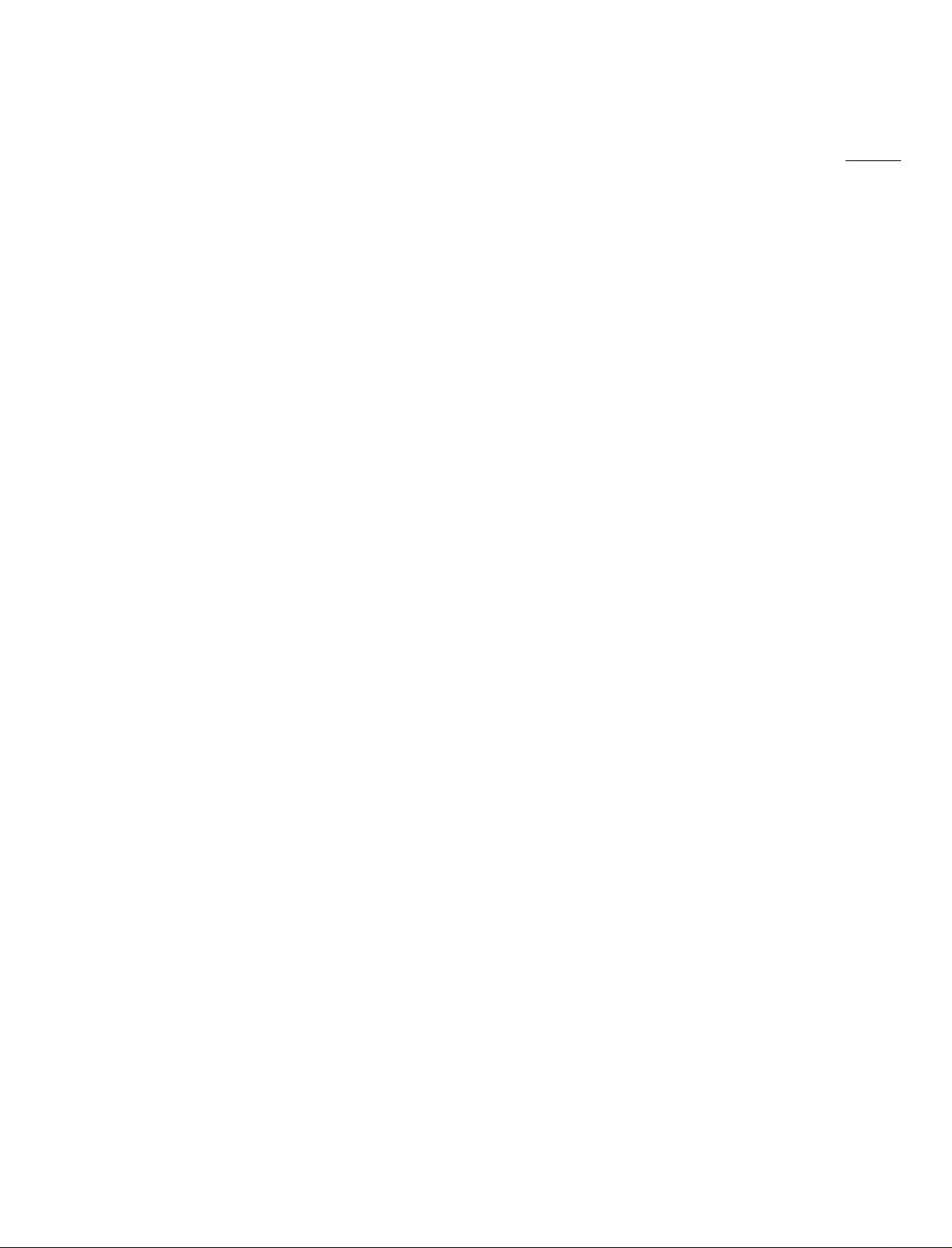

ELECTRICAL DATA...

A) All wiring must comply with local and national

electrical codes. All wiring must be installed by qualified

and skilled electricians. If you have any questions in

regard to the following instructions, contact a qualified

electrician.

B) Check available power supply and resolve any wiring

problems BEFORE installing and operating this unit.

C) For ALL units, an individual branch circuit and single

wall receptacle used only for this appliance, must be

available. See Table 1 for suggested wire sizes for

individual branch circuit.

D) For your safety and protection, this unit is grounded

through the service cord plug when plugged into a

matching wall outlet. If you have any question whether

your wall outlet is grounded or not please consult a

qualified electrician.

E) The wall outlet you select must match the plug on the

unit’s service cord and must be within reach of the

installed unit. Do NOT use adaptors or extension

cords. See Table 2 for further receptacle and fuse

information.

F) Follow fuse specifications indicated on unit’s

nameplate. (See Table 2) Nameplate is located above

unit’s control panel (See unit diagram in installation

instructions). NOTE: This unit’s model and serial

numbers can be found on the nameplate. Record your

unit’s serial number on the front of this manual for easy

future reference.

TABLE 1

SUGGESTED INDIVIDUAL BRANCH CIRCUIT

NAMEPLATE AMPS

5.0 to 12

12.1 to 16

16.1 to 24

AWG—American Wire Gauge

'Based on copper wire at 60”C temperature rating

AWG WIRE SIZE*

14

12

10

CAUTIONS...

Manufacturer strongly recommends using two people

during installation of units.

Coil fins on chassis are sharp and chassis is heavy.

Please keep this manual handy for future reference.

Please note: Condensation (water) run-off from the

unit’s back is normal during under high humidity weather

conditions. Unit should be installed where condensation

run-off will not drip onto pedestrians or neighboring

properties. To re-direct drainage flow, an optional

Accessory External Drainage Kit is available. Contact

an authorized Carrier Dealer, or call 1-800-CARRIER

for information.

i

Page 5

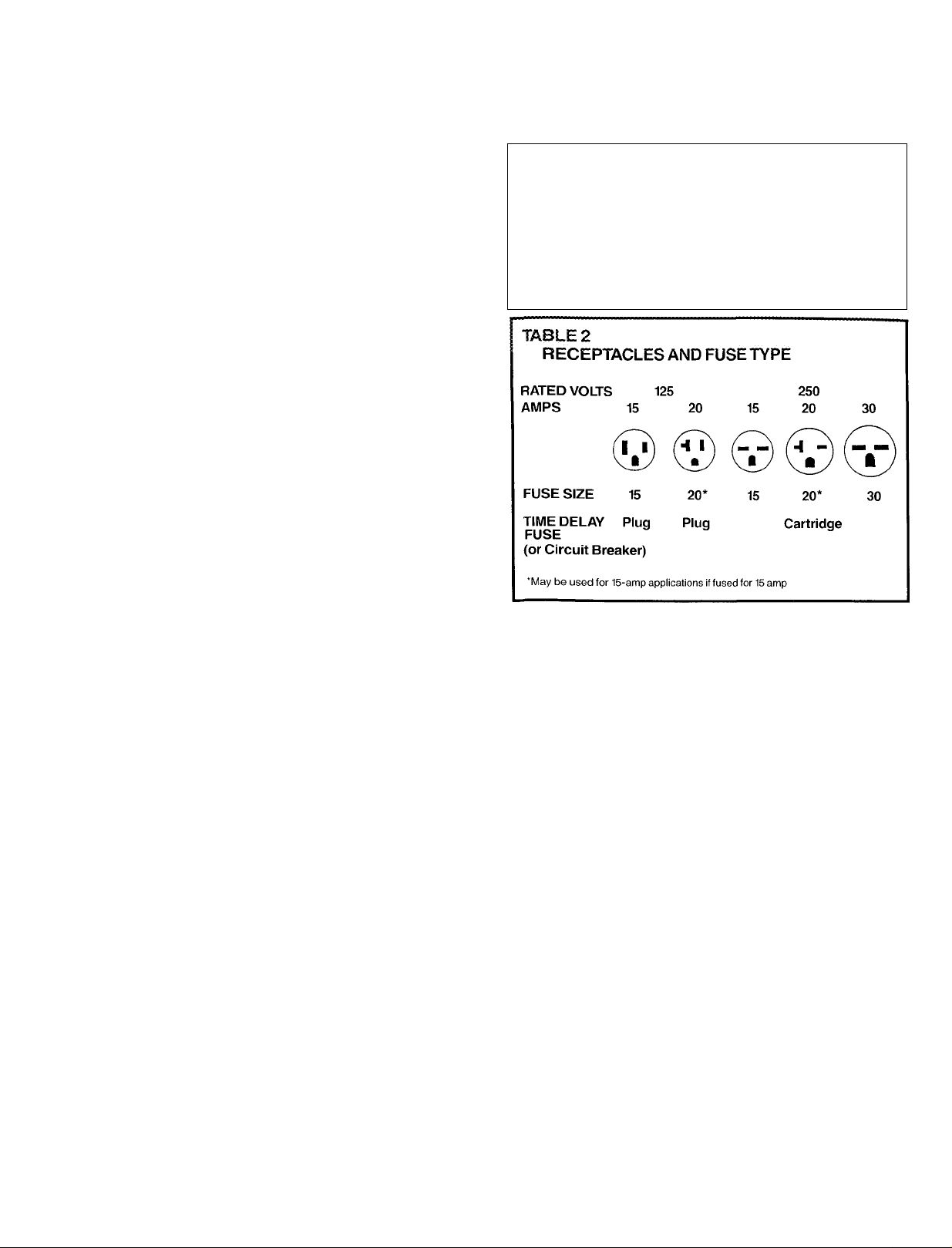

GLOSSARY OF CONTROL SYMBOLS.

OPERATING INSTRUCTIONS

INDICATOR LIGHT

Amber indicator light is on when unit is in operation.

Indicator light will NOT be on if unit has cycled off due to

a command from the timer control. In such a case, unit

will only be off for the time period set.

OFF O

O symbol on cooling/heating mode control dial is the

J^Ui

nit’s “OFF” position. When dial is turned to this

ymbol, unitwill NOT operate, in either manual or

automatic setting.

When leaving your home or office for a period of time

during which you do not wish the unit to cycle on for an

Automatic setting, be sure cooling/heating mode dial is

set to off position.

If you turn unit off, allow two minutes before turning unit

back on.

WLOW W MEDIUM W HIGH COOL

Choose the cooling setting you want simply by rotating

dial to appropriate size snowflake symbol.

Use the following as a guide for choosing cooling setting:

Low Cool: Recommended for nighttime use.

Medium Cool: Recommended during mid-morning and

early evening hours when outside temperature is lower.

High Cool: Provides maximum cooling. Recommended

for quick cooling or on extremely hot days. Once room

is cooled, manufacturer suggests switching to a lower

cool setting.

H LOW HEAT m HIGH HEAT

Choose the heat setting you want simply by turning

mode control dial to the appropriate size sun symbol.

Use the following as a guide for choosing heating

settings:

Low Heat: Recommended for mildly chilly days and for

nighttime use.

High Heat: Provides maximum heating. Recommended

for sudden temperature drops and extended heating

needs.

THERMOSTAT +oVy-0

Set dial between -FO (warmer) and -0 (cooler) symbols

to obtain desired comfort level. This dial has no effect on

fan speed.

MANUAL START

Slide switch above timer to MAN setting to operate unit

manually. Set thermostat and cooling/heating mode

dials to desired settings.

FAN ONLY

Set cooling/heating mode control dial to fan symbol.

This will produce air at the minimal fan speed WITHOUT

cooling/heating.

When switching to Fan Only, allow two minutes before

switching unit back to cooling.

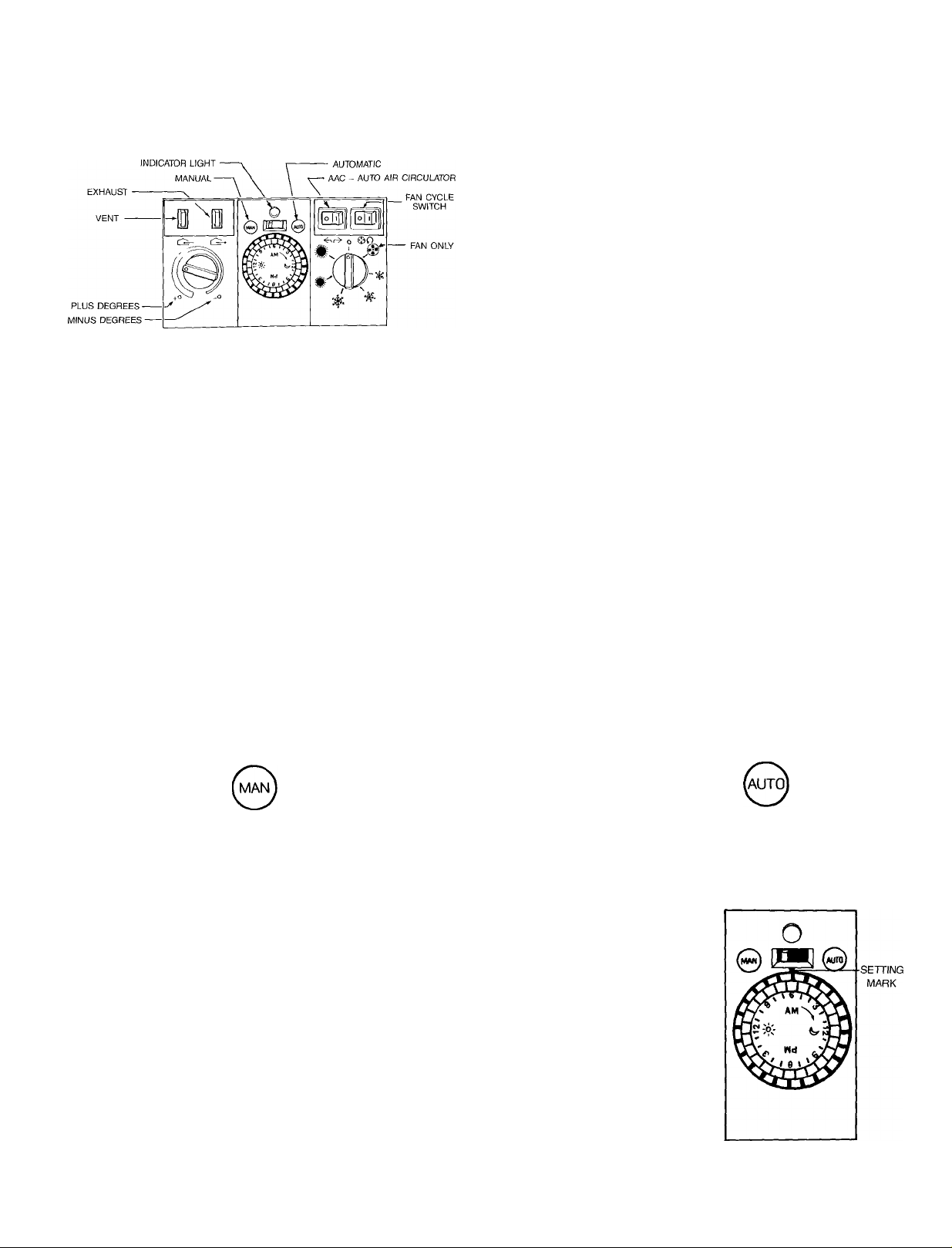

AUTOMATIC OPERATION

Your Carrier unit has a timer that allows pre-setting of

“on” and “off” times. Set unit to turn on and cool or heat

your home or office before you arrive. Set unit to auto

matically turn off after you leave.

NOTE: Timer must be reset after power failures or

interruptions.

SET TiMER TO TIME OF DAY

Rotate timer dial clockwise

until current time of day lines up

with the setting mark on flat

surface behind dial.

—Noon

-'i-

—Midnight

Page 6

Timer pins are positioned inwards (towards center of

dial) from factory to allow continuous operation.

SETTING THE TIMER FOR

AUTOMATIC ON/OFF OPERATION

To set the timer, simply slide a pin outward from the dial’s

center for each hour (approximately) that you wish the

unit to be off.

EXAMPLE; You work days 8-4 and want the unit off

while you are at work, and cooling your room when you

arrive home at 5:00 p.m.

1) Slide the pins beginning at 8:00 a.m. through 3:00

p.m. on the dial, away from the center.

2) Switch the timer to AUTO setting.

Now the unit will automatically turn off at 8:00 a.m. and

start at 4:00 p.m. (an hour before you return home so

that the room where your unit is installed is cool and

refreshing).

You can program the timer similarly for heating

operation.

NOTE; If timer’s switch is on MAN, timer setting will be

overridden and the unit will run continuously.

You may adjust the cooling or heating speed

while unit is on AUTO, without changing

your timer’s setting.

The timer can be programmed to turn off and on,

one or more times during 24-hour period.

AIR DIRECTION

Your 51 QC/QG unit has an Auto Air Circulator control I

feature, allowing vertical air deflectors to move automa

tically from left to right for better air distribution around

the room. For straightforward air discharge, vertical air

deflectors may be adjusted manually (with air sweep

switch in off position). The horizontal air deflectors are

also adjusted manually.

OFF- O

FAN CYCLE

I — Setting lets fan cycle on and off with compressor or

electric heater. Fan stops when thermostat setting

is satisfied. This mode is recommended for max

imum comfort during heating operations, to elimi

nate circulation of unheated room air by the unit.

When used in cooling, this mode results In longer

off time and wider variations in temperature and

humidity.

O — Setting allows continuous fan function, circulating

air even when compressor or heater has cycled off

and thermostat setting has been reached. This

mode is recommended for maximum comfort

during cooling operations.

O

ON- I

t

Vent

Exhaust

AIR EXCHANGE

Your Carrier unit is equipped with vent and exhaust air

exchange systems. Use the following guide when

choosing the appropriate system:

Vent: Draws outside air into the room.

Exhaust: Expels stale, smokey or odor laden air from

the room to the outside.

For either system operation, push appropriate button

and turn cooling/heating mode dial to Fan Only setting.

When air exchange is completed, return to normal cool

ing or heating by pushing vent or exhaust button again

and rotating mode dial from Fan Only to desired setting.

NOTE: Vent and exhaust usage is not recommended

during cooling or heating as these operations either vent

outside air into the room, or exhaust cooled or heated

air out.

REMEMBER: Button pushed in opens vent or exhaust

system. Button pushed out, closes vent or exhaust

system.

5

Page 7

IMPOFTTANT FACTS ABOUT

.^EAT PUMP OPERATIONS

C)perating Sounds: A momentary ‘whooshing’ sound is

normai when unit is switched over to the heating mode.

Auto Coil Defrost: Low outside temperature and high

humidity can combine to cause ice buiid-up on the

butside coii when your unit is set on heat mode, in such

an instance, the unit automaticaiiy switches to a defrost

cycie, shutting its compressor off. A buiit-in eiectric

heater wiii continue to heat your room during the defrost

cycie. After defrosting is compieted, the unit automat

icaiiy switches back to heat pump operation.

Drain Valve: Your unit has a thermostatically operated

drain valve located in its basepan. Valve remains closed

in warm weather, channeling condensate to outdoor

coil to increase cooling efficiency. In cooler weather

(50°F or lower), valve automatically opens, draining

condensate and preventing possible ice build-up in

basepan.

Electric Heater: Should outdoor temperatures drop to

35°F or lower, the unit’s compressor automatically shuts

off and electric heater will take over the heating process.

In such a case, the unit’s thermostat maintains the

comfort setting and room temperature you desire by

turning heater and fan on and off as needed.

Compressor Override/Low-Temp Control: Control is

located at the top right corner of air discharge.

Normal Heat Pump:

Control knob must line up with “Normal” position on

label: This allows the electric heater to take over the

heating process from the compressor during heat

pump operation at an outdoor temperature of 35°F.

Electric Heat:

To have the electric heater take over the heating

process at an outdoor temperature above the factory

preset 35°F, the control knob can be set closer toward

the “Electric Heat” position on label until desired

setting is reached (see note).

NOTE: Override Feature: If compressor fails during

cold weather, turn control knob counterclockwise to

“Electric Heat” position to activate electric heater

while awaiting service.

ECONOMIC ENERGY SAVING TIPS

Select thermostat setting that suits your comfort needs

and leave thermostat at that chosen setting.

Keep unit’s filter clean. Normally filter should be cleaned

every 30 days. Filter is very efficient in removing airborne

particles. More frequent cleaning may be necessary

depending on outside and inside air quality. To remove

filter: grasp filter tab at bottom of front grille and pull

down and out. Filter may be vacuumed or washed by

hand in warm water. Dry thoroughly and replace filter by

sliding it upward behind front grille.

TOOLS YOU WILL NEED FOR INSTALLATION

Through-the-Wall Installation:

Construction and masonry tools needed for throughthe-wall installation.

I>crewdrivers—Both Phillips and regular head types

Power drill (1 /8" dia. drill bit)

Pencil

Measuring Tape

Scissors or a razor-edged knife

Use drapes, curtains, shades et. al. to keep direct sun

light from heating room.

Do not obstruct front of unit.

Use built-in timer to turn unit on just before you return,

rather than running unit while you are out.

When outdoor temperatures are cool enough, use fan

control in conjunction with vent control to bring cool

outside air into room. This utilizes much less electricity.

REMEMBER: Maximum cooling and heating efficiency

is achieved when vent and exhaust systems are off.

Check to make sure vent and exhaust controls are not

on while unit is cooling room.

Even without above tips, your Carrier unit is designed to

be highly efficient in energy savings!

Page 8

THROUGH-THE-WAUL

INSTALLATION STEPS

The 51 QC/QG is normally installed through a wall.

During installation, you will be moving unit’s chassis from

the cabinet casing, installing the casing first and then

re-inserting the chassis.

CAUTION; COIL FINS ON CHASSIS ARE SHARP AND

CHASSIS IS HEAVY.

NOTE: This unit may also be installed in a window. An

additional accessory kit must be ordered separately for

window mounting. Contact an authorized Carrier Dealer,

or call 1-800-CARRIER for information.

Two people recommended for installation.

Use Steps 1 through 8 from Window installation

Instructions to prepare unit chassis and casing for Wall

installation.

Standard Construction and masonry tools are needed

for through-the-wall installation. This will include at least

the following:

Screwdrivers—Both Phillips and regular head types

Power drill (Vs" dia. drill bit)

Pencil

Measuring Tape

Scissors or a razot^edged knife

Note: If wall thickness obstructs unit’s side vents, make wall

opening wider as shown in Figure A. Allow for condensate

drainage from thermostatic drain valve located in basepan. If

outside wali projects beyond back of unit, use baffies on casing’s rear corners. See Figure A for minimum dimension ^

requirements and placement of baffles.

For Wood Framing: Provide a wooden framing

support for fastening casing into wall opening.

Cut opening into wall for insertion of unit’s

casing. Finished wall opening must be at least V4

inch larger than unit’s casing on all sides. (See

casing dimensions below.)

51 QC

Notes

Through-the- Wall installation of the air conditioner unit is

possible in wood framing or masonry wall, using units casing

as a sleeve. Installation should be level as unit has a built-in

pitch for draining condensation.

Good framing construction practices must be used to insure a

properly installed unit.

- W (24 7/16") xH (15 9/16")

QG - W (26") xH (17.9/16")

*7 To prevent a possible air leakage path, seal the hole in the

bottom of the casing near the front of ibe unit.

Page 9

For Masonry Framing: Use lintel to support upper

wall and mounting angles if desired. If mounting

angles are used, you may choose to use a plaster

Fasten casing into wall opening using masonry

or wood screws, anchors, mounting angles or

expansion shields as needed (depending on type of

construction frame used).

lyil Recheck pitch of unit for level installation. *3

Using 2 people, lift chassis and re-insert into

casing installed in wall opening. See steps through

28 through 32 under Window installation. Follow

same procedures for Through- the-Wall Installation.

CAUTION: Coil fins on chassis are sharp and

chassis is heavy.

Finish exterior and interior of wall opening

surrounding installed unit. Grouting, caulking or

flashing may be used for sealing and weather

proofing exterior. *4

be drilled through each side of casing to fasten it in

wall opening. NOTE: If existing holes in casing will

suffice for attachment to framing, additional drilled

oles may not be required. Be sure to seal any

unused holes in this area. Make sure unit is

level.*2

„.7.:... If needed, drill 2 or 3 screw holes (spaced as

needed, depending on construction frame used) for

each side of casing.

ifei. Paint or apply silicone on edges of drilled holes

to protect against corrosion.

*2 Front of unit casing must project at least ’/2 inch into room

to assure proper fit of grille casing on units front.

Plug in unit and slide excess cord into cord

storage opening.

*3 When cabinet casing is installed, using proper installation

steps, unit is properly pitched towards the outdoors to allow

for condensation runoff. An optional Accessory External Drain

Kit is available to expel unit condensation away from build

ing’s exterior. If unit is installed where condensate drainage

will drip onto pedestrians or neighboring properties, contact

an authorized Carrier Dealer, or call 1-800-CARRIER tc order

the External Drain Kit

*4 Be sure to weatherproof exterior area around the wall

installed unit, and finish surrounding interior walls.

Page 10

WINDOW INSTALLATION STEPS

TOOLS YOU WILL NEED FOR INSTALLATION

Screwdrivers—Both Phillips and regular head types

Power drill (1.8" dia. drill bit)

Pencil

Measuring Tape

Scissors or a razor-edged knife

Remove air conditioner from box by breaking

away sides of box (Cutting box couid result in

damage to unit).*1

\ Remove front grille with filter

Remove securing screw and lift grille frame off

chassis and away from cabinet.

Loosen chassis security screw, located above

control panel, and slide to unlocked position.*2

Place unit on stable surface for remainder of

steps.

Remove two shipping screws at bottom of

cabinet’s rear panel.

Notes

PRIOR to installation, plug in unit and verify operation. Refer

to Owner’s Manual section for operating instructions. Some

clicking and gurgling sounds are normal during unit opera

tion. If you received a damaged or non-functioning unit,

contact your dealer.

If storm window is present, see Step # 10 before starting.

8y inserting wood strip, you will create a level surface for unit

insolation.

Two people recommended for installation.

I While one person holds back of cabinet,

second person slides chassis out from casing.

NOTE: coil fins on chassis are sharp and chassis is

heavy.

Place cabinet casing and chassis aside while

preparing window for installation.

Remove bottom track from unit mounting

accessory kit.

*2 Unit has slide-out chassis design with easy access for ser

vice or maintenance needs. A specO locking screw secures

the slide-out chassis to prevent unit from being forced out

through the casing to the house, thus allowing an intruder to

gain entry from the outside.

Page 11

'0f%

is "

m Measure center of window on sash and sill.

Make a small pencil mark to indicate spot. Raise

1

Slide wing panels from unit mounting kit into

kit’s upper guide, with drain holes on bottom of wing

panels facing outward.

i Slip lower portion of connected wing panels

into bottom track now on sill.

^ Stretch wing panels out on both sides to meet

window frame.

Lower window sash onto upper guide piece.

___

I With sash firmly down upon upper guide,

make a pencil mark on lowered window sash

through center hole on upper guide piece.

a 2" wide wood strip to window’s sill. Thickness of

wood strip should equal height of storm window’s

ledge. By inserting wood strip, you will create a

level surface for unit installation.

Make pencil marks through all holes in bottom

track while track is positioned on window sill.

Remove track and drill three holes in window

sill at marked spots.

SC

Screw track onto sill using 3 short screws.

*3 If your window width exceeds our maximum recommen

dation, then your unit will require additional support.

I

Drill hole at mark and insert provided short

screw. DO NOT completely tighten screw.

Move accordion folds aside to reveal holes on

sides of wing panels. Use previous marking tech

nique (Step #11) and drill holes in pencil marked

spots. Secure wing panels in sash tracks by insert

ing long screws in drilled holes and tightening.

Remove paper backing from narrow seal strip

in unit mounting accessory kit and fasten strip to top

of casing, aligning with pre-drilled holes. Fasten top

channel to top of casing using four screws, inserted

upwards from inside casing.

msM Remove screw inserted through center hole of

upper guide in Step #19. This aliows for freedom of

movement in future steps. DO NOT RAISE SASH.’'4

*4 When cabinet is installed in window, using proper installa

tion steps, unit is properly pitched towards he outdoors to

allow for condensation runoff. An optional Accessory External

Drain Kit is available to route excess unit condensation away

from building’s exterior. Contact an authorized Carrier Dealer,

or call 1-800-CARRIER for informa^on.

<•

Page 12

\.9 'rf

ikssi Insert casing (without chassis) into framework

now secured in window. Push casing outward, until

bottom slides up and over bend in lower track and

casing’s top channel rests against upper guide of

wing panel assembly.

Expand accordion folds to meet sides of

installed casing. Screw accordion side panels to

casing sides through pre-made screw openings in

panels. Be sure to use all (three) screw openings S

to prevent air seepage. ^

•isaki. Make pencil mark through center hole in

bottom of casing. Drill hole into window sill

at spot. Screw casing to window sill.

1 Align center hole in top channel of casing with

center hole in upper guide and previously drilled

hole in sash. Replace and fasten screw removed in

Step #22, TIGHTEN SECURELY.

laik Cut foam window seal from unit mounting

accessory kit to fit window width. Insert foam down

between top raised lower sash and glass panes

of upper sash making sure of a firm fit to provide

an air seal. This also prevents insects from gaining

entrance.

fcki With one person on each side, lift chassis

and slide into casing in window. Slide in chassis

all the way.

iksS With chassis back in casing, slide security

screw to locked position and tighten. Refer to

Step #6. *5

■kk: Replace grille frame on front of unit and fasten

securing screw removed in Step #5.

Replace grille insert removed in step #4.

Plug in unit, slide excess cord into cord storage

opening.

11

*5 Unit is designed with power cord extending from right side.

Should socket be located on leftside, unit can be modified for

leftside power cord exit. Remove front grille by grasping top

and bottom of insert and pulling forward. Remove grille frame

by unscrewing screw in frame. Redirect power cord to exit at

bottom left corner. Use pliers to snap out indicated plas^c

area on lower left side of front grille frame. Replace grille

frame and insert.

Page 13

TROUBLE SHOOTING GUIDE

If you have problems with your Carrier unit, check this convenient

trouble-shooting guide before contacting your Carrier service representative.

POSSIBLE CAUSES

UNIT DOES NOT START

• Unit may have come unplugged.

• Fuse may have blown.

• Circuit breaker may have been tripped.

• Unit may have been left in AUTO setting.

UNIT NOT COOLING/HEATING ROOM

• Unit’s air output is blocked.

• Temperature setting not high or low enough.

• Unit’s air filter is dirty.

• Room excessively hot or cold when unit

is started.

• Exhaust or vent left open.

UNIT MAKING NOISES

• Clicking, gurgling and whooshing noises are

#

normal during operation of unit.

SOLUTIONS

• Check that unit is securely plugged into wall socket.

• Replace the fuse!

• Reset circuit breaker!

• Switch into MANUAL mode.

• Remove any curtains, blinds or furniture that may be

blocking unit’s output.

• Reset unit to a lower or higher temperature setting.

• Remove and clean unit’s filter.

• Allow sufficient amount of time for unit to heat or cool

room.

• Close exhaust or vent.

WATER DRIPPING OUTSIDE

• Condensation run-off during very hot and

humid weather is normal.*’'

• Units with heat feature a thermostatically

operated drain valve in the basepan. The

valve automatically opens to drain conden

sate. In the case of unusual water drippage,

check to make sure drain valve is not blocked.

WATER DRIPPING INSIDE

• Unit not installed level.

' Unit must be installed level for proper run-off

of condensation. Check that installation is

level and make any necessary adjustments.

ICE OR FROST BUILD-UP ON COIL

• Low outside temperature.

' Unit’s filter is dirty.

f>f circuit breaker is tripped repeatedly, or fuse is blown more than once, contact a qualified electrician

** When cabinet casing is installed, using proper installation steps, unit is properly pitched towards the outdoors to allow for condensation

runoff. An optional Accessory External Drain Kit is available to expel unit condensation away from building’s exterior. If unit is installed where

condensate drainage will drip onto pedestrians or neighboring properties, contact an authorized Carrier Dealer, or call 1-800-CARRIER to

order the External Drain Kit.

• When outdoor temperatures are 55°F or below, frosting

may occur when unit is in cooling mode. Switch unit to

FAN operation until ice or frosting melts.

• Remove and clean filter.

Page 14

FULL ONE-YEAR WARRANTY — During the first year after original date of

purchase, Carrier will, through its authorized independent servicing dealers

or service stations* and free of charge to the end user or subsequent user,

repair or replace any part which is defective in material or workmanship

LIMITED TWO- TO FIVE-YEAR WARRANTY - During the 2nd through 5th

years after date of original purchase. Carrier will, through its authorized

servicing dealers and service stations', repair or replace any part which is

defective in material or workmanship This warranty includes a fixed labor

allowance for repair or replacement of the defective part, BUT DOES NOT

INCLUDE an allowance for labor or other costs incurred in diagnosing the

defect, pick-up or delivery of the product, or transportation or handling

related to the defective part or replacement part ALL IMPLIED WARRAN

TIES HEREUNDER (INCLUDING THE IMPLIED WARRANTIES OF MER

CHANTABILITY AND FITNESS FOR PURPOSE) ARE LIMITED IN DURA

TION TO THE PERIOD FOR WHICH THE EXPRESS WARRANTY IS

GIVEN Some states do not allow limitations on how long an implied war

ranty lasts, so the above limitation may not apply to you

LIMITATION OF EXPRESS WARRANTIES - THE EXPRESS WARRAN

TIES MADE IN THIS WARRANTY CERTIFICATE ARE EXCLUSIVE AND

MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBU

TOR, DEALER OR OTHER PERSON WHATSOEVER

All work under the terms of this warranty are to be performed during nor

mal working hours Any replacement part assumes the unused portion of

this warranty The replacement part assumes the unused portion of this

warranty The replacement part can be a new or remanufactured part as

provided at Carrier’s sole option

NOTE: Service and maintenance items excluded under this warranty certificate may be covered by a service agreement through the seller at time of purchase

’Authorized independent dealers or service stations are registered with Carrier Corporation through its distributor organization

Form No 530-018 (Rev 7/89)

This warranty gives you specific rights, and you may also have other rights which vary from state to state

CARRIER WILL NOT BE RESPONSIBLE FOR:

1 Normal maintenance or service, including cleaning of condenser or eva

porator coil, cleaning or replacement of air filter, replacement of blown

fuses, or repair of loose connections or defects in house wiring

2 Use or installation of products other than as outlined in the owner’s

manual, including failure to connect to a grounded power supply of suffi

cient voltage

3 Damage to finish after purchase

4 Damage or repairs needed as a consequence of faulty installation or

misapplication, abuse, unauthorized alteration, improper servicing or

operation

5 Damage as a result of floods, winds, fires, lightning, accidents, corrosive

atmosphere or other conditions beyond the control of Carrier

6 Any parts not supplied or designated by Carrier

7 Product installed outside the continental USA, Alaska, Hawaii and

Canada.

8 Shipping damage or damage as a result of transporting the unit

9 ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR

COMMERCIAL DAMAGE OF ANY NATURE WHATSOEVER Some

states do not allow the exclusion of incidental or consequential damages,

so the above limitation may not apply to you

IF YOUR AIR CONDITIONER DOES NOT WORK,

FOLLOW THESE STEPS IN ORDER-

if

CHECK THE THINGS YOU CAN DO YOURSELF These include

being sure the air conditioner is plugged in firmly in an appro

priate receptacle, checking the fuse or circuit breaker and

insuring its replacement or resetting, if necessary, and reread

ing the instruction book to insure that all controls are set prop

erly By doing this you can save money Many unnecessary

service calls result in the serviceman doing what the owner can

do for him or herself

2 CONTACT YOUR DEALER OR THE CARRIER AUTHORIZED

SERVICE CENTER You may find his name on the product, on

your invoice or in your Homeowners Packet

Unit Model No _

Date of Installation^

Name of Owner

___

3 CONTACT THE NEAREST CARRIER DISTRIBUTOR SERVING

YOUR AREA (See Telephone Yellow Pages )

4 CONTACT CARRIER IF A SATISFACTORY SOLUTION IS NOT

REACHED IN STEPS 2 AND 3

Carrier Air Conditioning

Consumer Relations Department

PO Box 4808

Syracuse, New York 13221

Telephone. 1-800-CARRlER (227-7437)

From Canada 1-315-432-7885

Unit Serial No.

Installed By

___

Address of Installation.

Page 15

WE AREN’T COMFORTABLE

UNTIL YOU ARE

Carrier

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

I 8a I 10a

Catalog No 535-127 Printed in U S A

Form No 51QC,QG-1SI

Replaces: OM51-118 &

51C,G,Q-1SIM

Loading...

Loading...