Carrier 50ZP060300, 50ZP042300, 50ZP036300 Installation Guide

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS ......................... 1

General .......................................... 2

RECEIVING AND INSTALLATION .................. 5-9

Check Equipment .................................. 5

Identify Unit .................................... 5

Inspect Shipment ................................. 5

Provide Unit Support ............................... 5

Slab Mount ..................................... 5

Provide Clearances ................................. 5

Place Unit ........................................ 5

Select and Install Ductwork ........................... 5

Install Flanges for Ductwork Connections (50ZP060 only). 5

Converting Horizontal Discharge Units to Downflow (Vertical)

Discharge ...................................... 6

Charging Unit ..................................... 6

Provide for Condensate Disposal ...................... 6

Install Electrical Connections ......................... 8

High Voltage Connections .......................... 8

Routing Power Leads into Unit ...................... 8

Connecting Ground Lead to Unit Ground .............. 8

Routing Control Power Wires ....................... 8

Special Procedures for 208-V Operation ............... 9

PRE-START-UP .................................... 9

START-UP ..................................... 10-11

MAINTENANCE ................................ 11-13

TROUBLESHOOTING .............................. 13

START-UP CHECKLIST ............................ 13

NOTE: TO INSTALLER - Before the installation , READ

THESE INSTRUCTIONS CAREFULLY AND COMPLETELY.

Also, make sure the User's Manual is left with the unit after

installation.

SAFETY CONSIDERATIONS

Improper installation adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when modifying this product Refer to the individual instructions

packaged with the kits or accessories when installing.

C00001

Fig. 1 - 50ZP (Size 036 Shown)

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes, the

current editions of the National Electrical Code (NEC) NFPA 70.

In Canada refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. This is the safety-alert symbol /_.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION. These

words are used with the safety-alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system and install lockout tag. There may be

more than one disconnect switch.

11.57

[294.0]

16.06

[408.0]

9.75

COND

COl L_\\

m

NEe, REQUIRED CLEARANCES,

BETWEEN UNITS, POWER ENTRY SIDE .................................... 42.00 [1066.8]

UNiT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

t

\

\

\

14.0 DIA.

[356.0]

DUCT OPENINGS

i

EVAP COIL_ \

REAR VIEW

50.98

[1295.0]

BOTTOM Of UNIT

\

\

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 42.00 [1066.8]

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

CONDENSER COiL ACCESS SiDE .............................................. 30_00 [762.0]

POWER ENTRY SIDE .................................................................... 30.00 [762.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ....................................................................................... 48.00 [1219.2]

SIDE OPPOSITE DUCTS .............................................................. 30.00 [762.0]

LEGEND

NEC National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdooh

fan discharge, with the exception of the condenser coil (30.00 in [914.0 mini. A

removable fence or barricade requires no clearance.

2. Dimensions are in inches. Dimensions in [] are in millimeters.

INCHES [mm]

iNCHES [ram]

\

o

31.99

[812.5]

BOTTOM OF UNIT

t

LEFT SIDE VIEW

UNIT

50ZP036

BLOWER, CONTROL BOX AND EVAP COIL

ACCESS PANEL

C('WIRESSCR FANEL_\

SERdlCE PORTS

FRONT VIEW

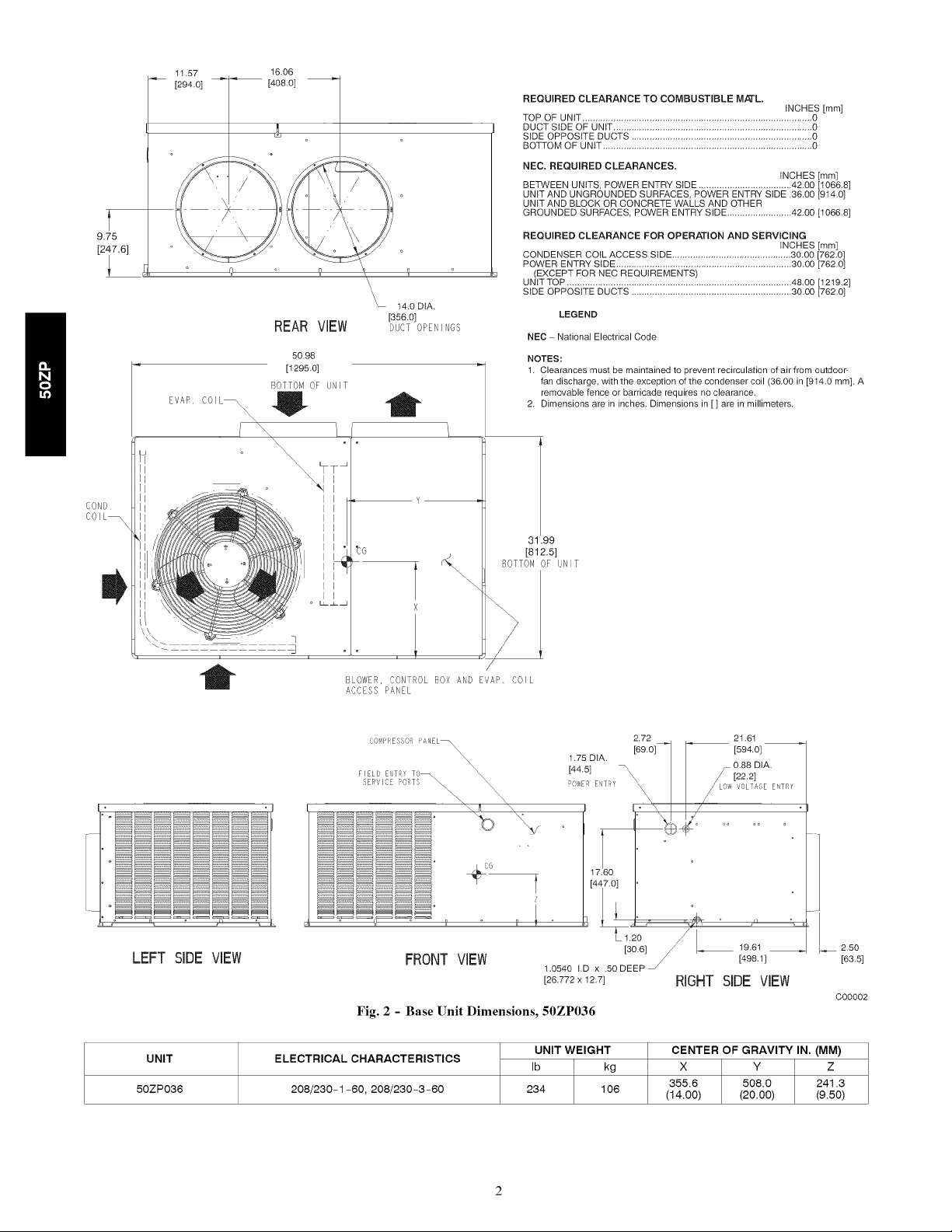

Fig. 2 - Base Unit Dimensions, 50ZP036

ELECTRICAL CHARACTERISTICS

208/230-1-60, 208/230-3-60

/

2.72 21.61

\\\\\\

\

[44.5]

1.75 DIA. [69.0]_ [594.0]

/

17.60

Z

UNIT WEIGHT

Ib kg

234 106

[447.0

1.2o/L

[30.6] 19.01

1.0540 t.D x .50 DEEP S

[26.772x12.7] RIGHT SIDE VIEW

/ [498.1]

CENTER OF GRAVITY IN. (MM)

X Y Z

355.6 508.0 241.3

(14.00) (20.00) (9.50)

2,50

[63.5]

C00002

9.75

11.57 16.06

[294.0] [408.0]

REAR VIEW

EVAPORATOR

COIL

\

\L 14.0 DIA.

[356.0]

DUCT OPENINGS

50.98

[1295.0]

BOTTOM OF UNIT

\\\

\, 77

I

I

REQUIRED CLEARANCE TO COMBUSTIBLE M/£-L.

TOP OF UNIT ......................................................................................... 0

DUCT SIDE OF UNIT ............................................................................. 0

SIDE OPPOSITE DUCTS ...................................................................... 0

BOTTOM OF UNIT ................................................................................. 0

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE .................................... 42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE ......................... 42.00 [1066.8]

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

CONDENSER COIL ACCESS SIDE .............................................. 30,00 [782.0]

POWER ENTRY SIDE .................................................................... 30,00 [782.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP ....................................................................................... 48.00 [1219.2]

SIDE OPPOSITE DUCTS .............................................................. 30,00 [762,0]

LEGEND

NEC National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recircutation of air from outdoor-

fan discharge, with the exception of the condenser coil (36.00 in [914.0 mm]. A

removable fence or barricade requires no clearance.

2. Dimensions are in inches. Dimensions in [] are in millimeters.

INCHES [mm]

INCHES [mm]

INCHES [mm]

t

_9

[812.5]

BOTTOMOF UNIT

LEFT SIDEVIEW

UNIT

50ZP048

I

o _

BLOWER, CONTROL BOX AND

EVAPORATOR COIL ACCESS PANEL

CC.'qPRESSORPA EL _\\

SERVICE PO_TS

FIELD E_T_f TC¸

FRONT VIEW

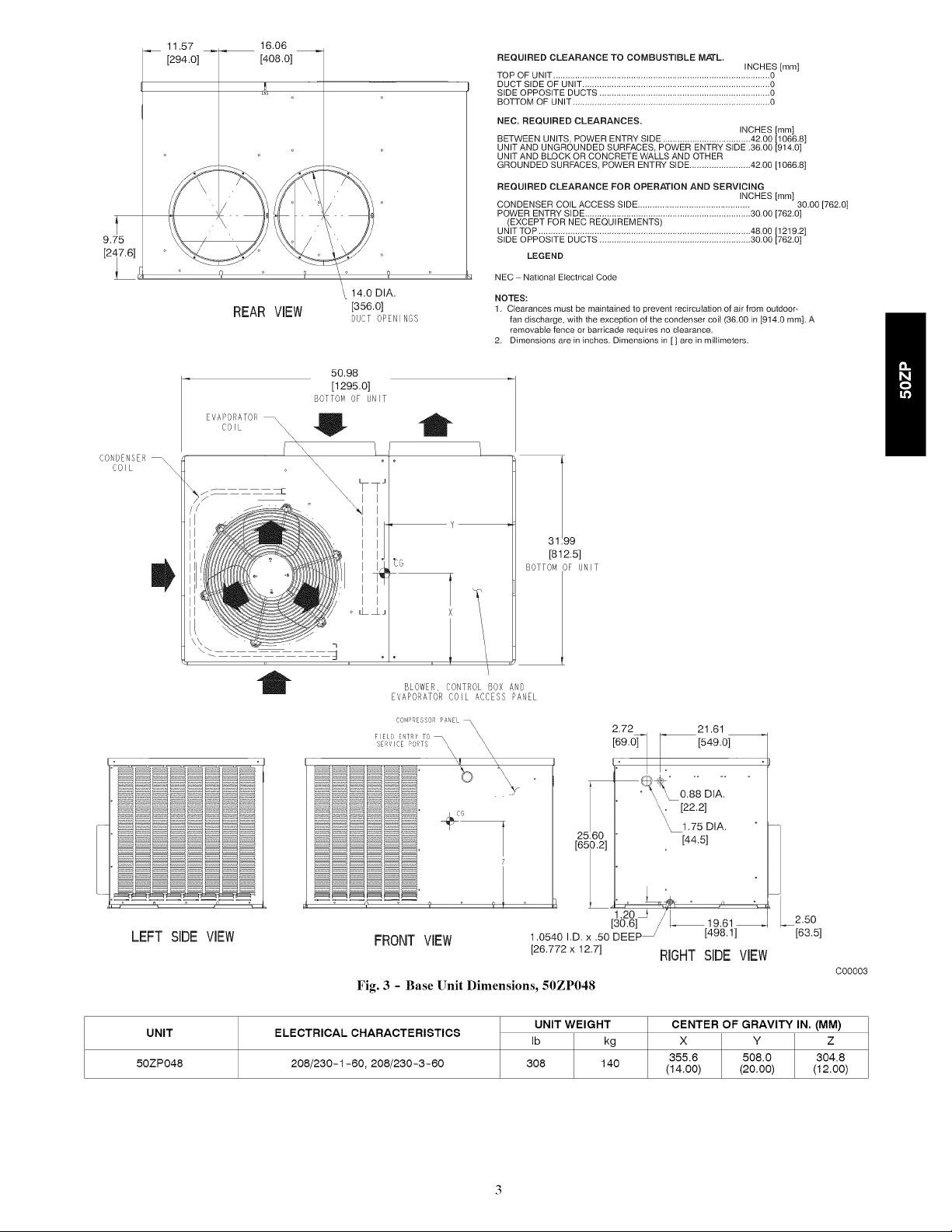

Fig. 3 - Base Unit Dimensions, 50ZP048

ELECTRICAL CHARACTERISTICS

208/230-1-60, 208/230-3-60

X

/ "

2.72

21.61

[549.0]

° \ , 088DIA.

[22.2]

25160

Z

[650.2]

X_1.75 DIA.

[44.51

_ LJ

1.0540 I.D. x .50 DEEP_

[30.6]

[26.772 x 12.7]

UNIT WEIGHT

Ib kg

308 140

RIGHTSIDEVIEW

19.61 2.50

[498.1] [63.5]

C00003

CENTER OF GRAVITY IN. (MM)

X Y Z

355.6 508.0 304.8

(14.00) (20.00) (12.00)

DIMENSIONS IN []ARE IN mm

4.63

[117.6]

18.88 _ 0

[352"5] ii ]

5.44

[138.3]

13.89

[352.8]

13.89

[352.7]

211

[53.7]

° i

i

REAR ViEW

50.98

1

3.50

[88.9]

REQUIRED CLEARANCE TO COMBUSTIBLE M/_L.

TOP OF UNIT .................................................................................. 0

DUCT SIDE OF UNIT ............................................................................. 0

SIDE OPPOSITE DUCTS ...................................................................... 0

BOTTOM OF UNIT ................................................................................. 0

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE .................................... 42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY StDE ......................... 42.00 [1066.8]

27!80

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

[706.0]

CONDENSER COIL ACCESS SiDE .............................................. 30.00 [762.0]

POWER ENTRY StDE .................................................................... 30.00 [762.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNtTTOP ....................................................................................... 48.00 [1219.2]

SIDE OPPOSITE DUCTS .............................................................. 30.00 [762.0]

LEGEND

NEC National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-

fan discharge with the exception of the condenser coil (36.00 in [914.0 mm]. A

removable fence or barricade requires no clearance.

2. Dimensions are in inches. Dimensions in [] are in millimeters.

iNCHES [ram]

INCHES [mm]

iNCHES [mm]

t

Col,

C01L_

31 99

[812.5]

OTTO, OF JI,IT

i

CO[,TROL BOX ,:ND E,AP COIL

:,CC ESS PA_\EL

2.72 21.61

CoMPr_ESSQR PANEL \

F I ELO_,,_T 'f TO

t

2960

[751.8]

LEFT SIDE ViEW

UNIT

50ZP060

FRONT VIEW

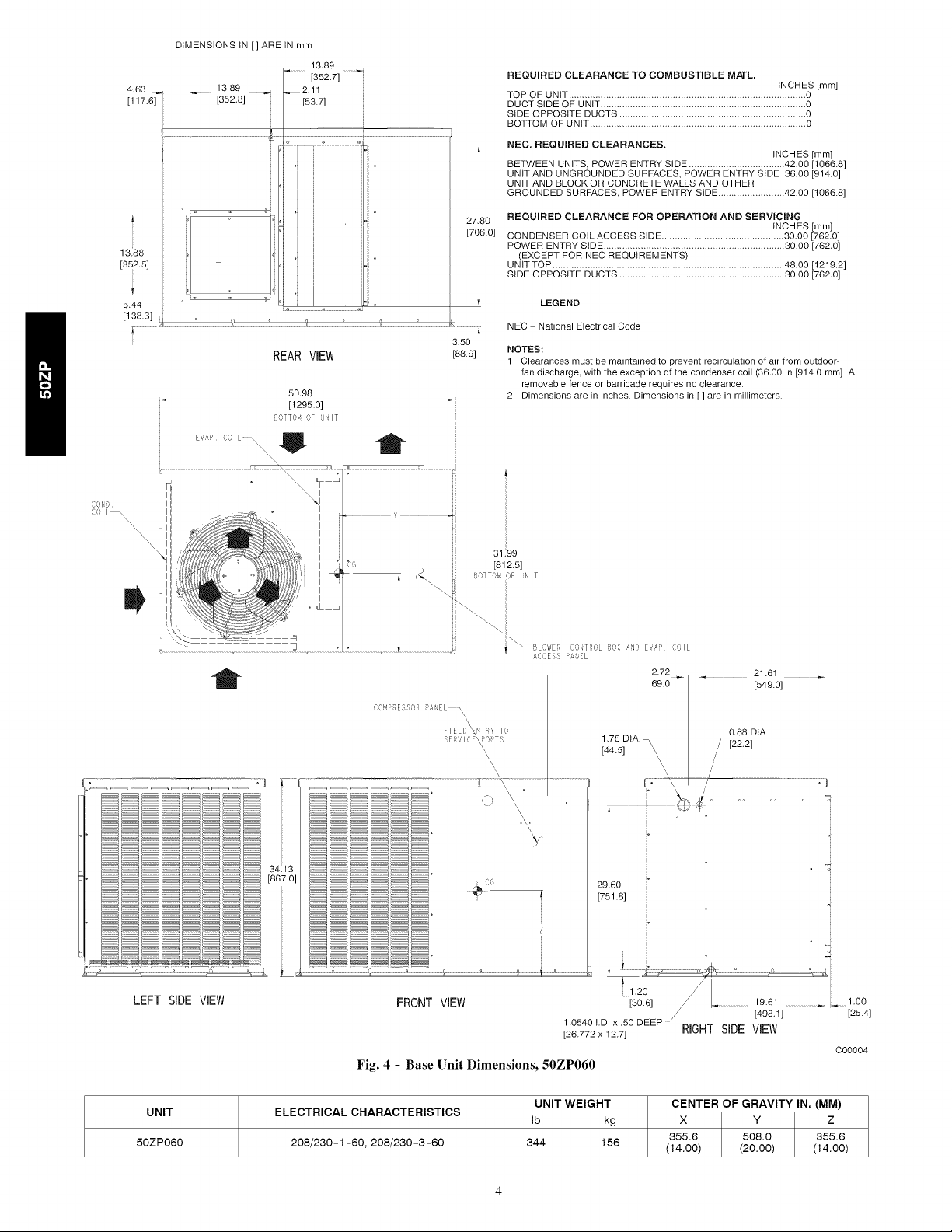

Fig. 4 - Base Unit Dimensions, 50ZP060

ELECTRICAL CHARACTERISTICS

208/230-1-60, 208/230-3-60

1.0540 I.D. x .50 DEEP ......

[26.772 x 12.7]

UNIT WEIGHT

Ib kg

344 156

i'

.2O

[3o.6]

...........................19.61...........................

/ [498.1 ] [25.4]

RIGHT SIDE VIEW

000004

CENTER OF GRAVITY IN. (MM)

X Y Z

355.6 508.0 355.6

(14.00) (20.00) (14.00)

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate clothing.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing

residential construction practices. We require these instructions as a

minimum for a safe installation.

GENERAL -- 50ZP cooling units are fully self-contained and

designed for outdoor installation. See Fig. 1. As shown in Fig. 2-4,

units are shipped in a horizontal-discharge configuration for

installation on a ground-level slab. All units can be

field-converted to downflow discharge configurations for rooftop

applications with a field-supplied plenum

RECEIVING AND INSTALLATION

Step 1 -- Check Equipment

IDENTIFY UNIT -- The unit model number and serial number

are stamped on the unit identification plate. Check this information

against shipping papers.

INSPECT SHIPMENT -- Inspect for shipping damage while unit

is still on shipping pallet. If unit appears to be damaged or is torn

loose from its securing points, have it examined by transportation

inspectors before removal. Forward claim papers directly to

transportation company. Manufacturer is not responsible for any

damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest Carrier Air Conditioning office if any item is missing.

To prevent loss or damage, leave all parts in original packages until

installation.

Step 2 -- Provide Unit Support

SLAB MOUNT -- Place the unit on a rigid, level surface, suitable

to support the unit weight. The flat surface should extend

approximately 2-in. (51 mm) beyond the unit casing on the 2

sides. The duct connection side and condensate drain connection

sides should be flush with the edge of the flat surface. A concrete

pad or a suitable fiberglass mounting pad is recommended.

A 6-in. (152 mm) wide gravel apron should be used around the

flat surface to prevent airflow blockage by grass or shrubs. Do not

secure the unit to the flat surface except where required by local

codes.

The unit should be level to within 1/4 in. (6 mm). This is necessary

for the unit drain to function properly,

Step 3 -- Provide Clearances

The required minimum service clearances and clearances to

combustibles are shown in Fig. 2-4. Adequate ventilation and

condenser air must be provided.

The condenser fan pulls air through the condenser coil and

discharges it through the fan on the top cover. Be sure that the fan

discharge does not recirculate to the condenser coil. Do not locate

the unit in either a corner or under an overhead obstruction. The

minimum clearance under a partial overhang (such as a normal

house overhang) is 48 in. (1219 mm) above the unit top. The

maximum horizontal extension of a partial overhang must not

exceed 48 in. (1219 mm).

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. The unit may be installed on

wood flooring or on Class A, B, or C roof covering materials.

Step 4 -- Place Unit

Unit can be moved with the handholds provided in the unit

basepan. Refer to Table 1 for operating weights. Use extreme

caution to prevent damage when moving the unit. Unit must

remain in an upright position during all moving operations. The

unit must be level for proper condensate drainage; the

ground-level pad must be level before setting the unit in place.

When a field-fabricated support is used, be sure that the support is

level and that it properly supports the unit.

Step 5 -- Select and Install Ductwork

The design and installation of the duct system must be in

accordance with:

• the standards of the NFPA (National Fire Protection Association)

for installation of nonresidence-type air conditioning and

ventilating systems;

• NFPA90A or residence-type, NFPA90B; and/or local codes and

residence-type, NFPA 90B;

• and/or local codes and ordinances.

Select and size ductwork, supply-air registers and return-air grilles

according to ASHRAE (American Society of Heating,

Refrigeration, and Air Conditioning Engineers) recommendations.

Use the duct flanges provided on the supply- and return-air

openings on the side of the unit. See Fig. 2-4 for connection sizes

and locations. The 14-in. (356 mm) round duct collars (size

036-048 units) are shipped inside the unit attached to the indoor

blower. They are field-installed and must be removed from the

indoor cavity prior to start-up, even if they are not used for

installation.

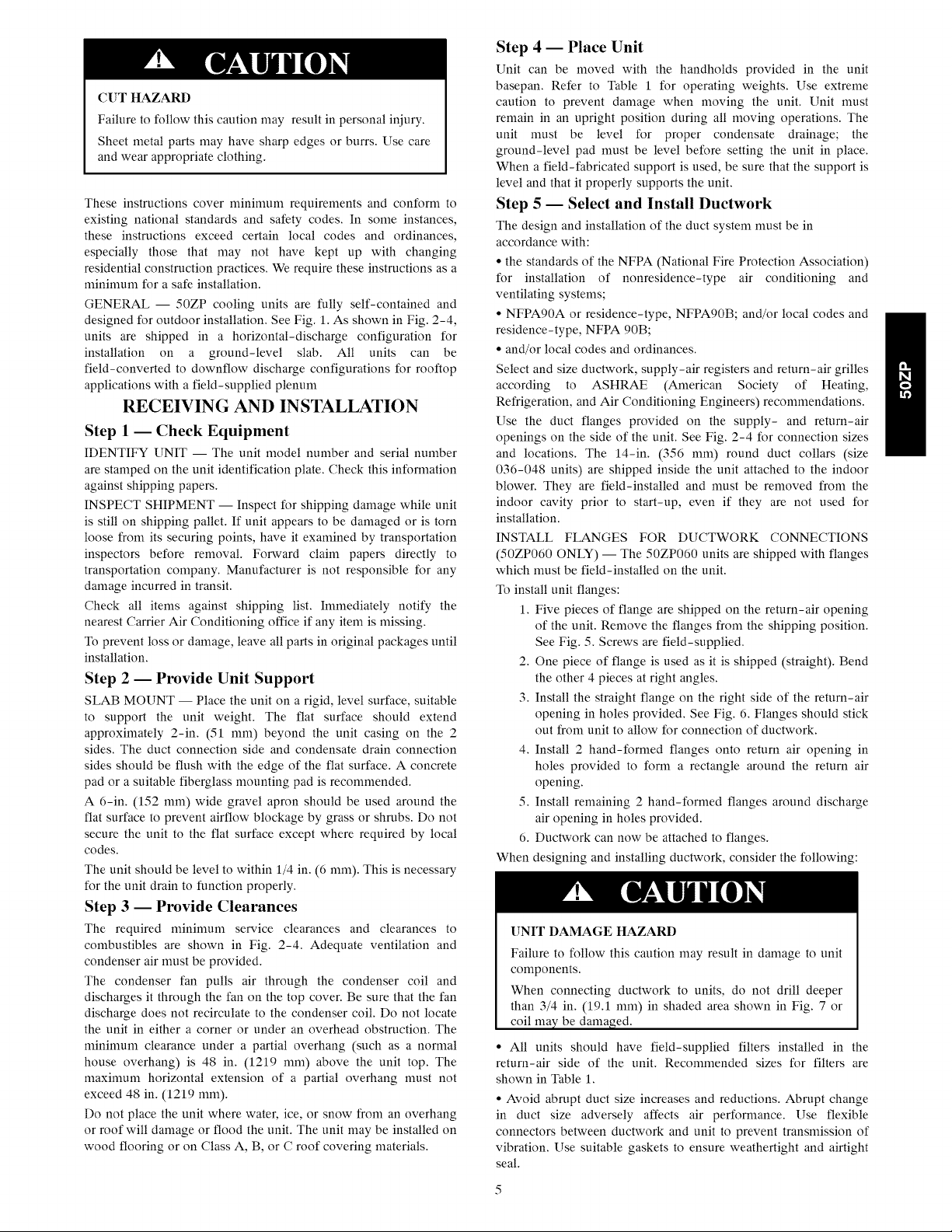

INSTALL FLANGES FOR DUCTWORK CONNECTIONS

(50ZP060 ONLY) -- The 50ZP060 units are shipped with flanges

which must be field-installed on the unit.

To install unit flanges:

1. Five pieces of flange are shipped on the return-air opening

of the unit. Remove the flanges from the shipping position.

See Fig. 5. Screws are field-supplied.

2. One piece of flange is used as it is shipped (straight). Bend

the other 4 pieces at right angles.

3. Install the straight flange on the right side of the return-air

opening in holes provided. See Fig. 6. Flanges should stick

out from unit to allow for connection of ductwork.

4. Install 2 hand-formed flanges onto return air opening in

holes provided to form a rectangle around the return air

opening.

5. Install remaining 2 hand-formed flanges around discharge

air opening in holes provided.

6. Ductwork can now be attached to flanges.

When designing and installing ductwork, consider the following:

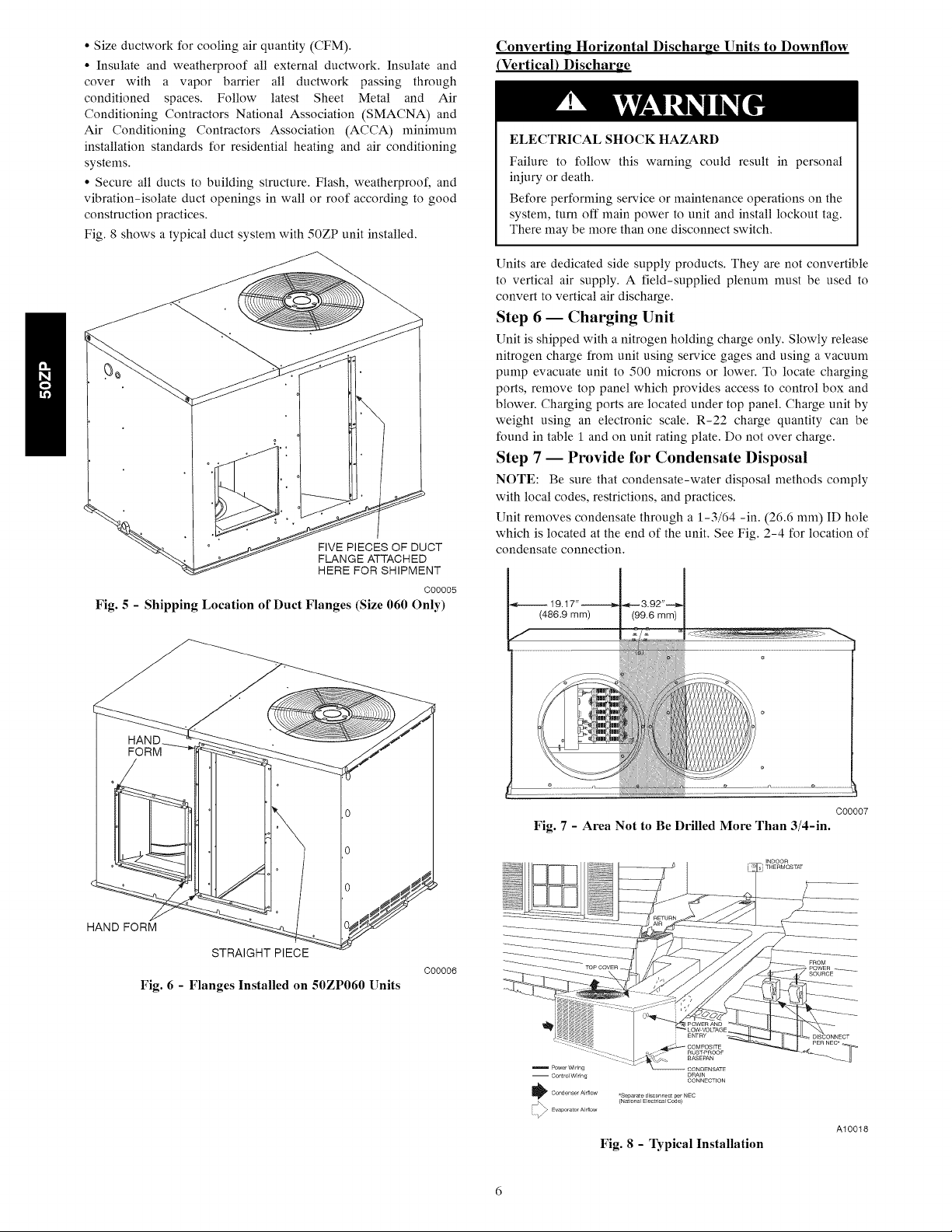

[]NIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit

components.

When connecting ductwork to units, do not drill deeper

than 3/4 in. (19.1 mm) in shaded area shown in Fig. 7 or

coil ma}zbe damaged.

• All units should have field-supplied filters installed in the

return-air side of the unit. Recommended sizes for filters are

shown in Table 1.

• Avoid abrupt duct size increases and reductions. Abrupt change

in duct size adversely affects air performance. Use flexible

connectors between ductwork and unit to prevent transmission of

vibration. Use suitable gaskets to ensure weathertight and airtight

seal.

• Size ductwork for cooling air quantity (CFM).

• Insulate and weatherproof all external ductwork. Insulate and

cover with a vapor barrier all ductwork passing through

conditioned spaces. Follow latest Sheet Metal and Air

Conditioning Contractors National Association (SMACNA) and

Air Conditioning Contractors Association (ACCA) minimum

installation standards for residential heating and air conditioning

systems.

• Secure all ducts to building structure. Flash, weatherproof, and

vibration-isolate duct openings in wall or roof according to good

construction practices.

Fig. 8 shows a typical duct system with 50ZP unit installed.

FIVE PIECES OF DUCT

FLANGE ATTACHED

HERE FOR SHIPMENT

C00005

Fig. 5 - Shipping Location of Duct Flanges (Size 060 Only)

Converting Horizontal Discharge Units to Downflow

(Vertical) Discharge

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before performing service or maintenance operations on the

system, turn off main power to unit and install lockout tag.

There may be more than one disconnect switch.

Units are dedicated side supply )roducts. They are not convertible

to vertical air supply. A field-supplied plenum must be used to

convert to vertical air discharge.

Step 6 -- Charging Unit

Unit is shipped with a nitrogen holding charge only. Slowly release

nitrogen charge from unit using service gages and using a vacuum

pump evacuate unit to 500 microns or lower. To locate charging

ports, remove top panel which provides access to control box and

blower. Charging ports are located under top panel. Charge unit by

weight using an electronic scale. R-22 charge quantity can be

found in table 1 and on unit rating plate. Do not over charge.

Step 7 -- Provide for Condensate Disposal

NOTE: Be sure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

Unit removes condensate through a 1-3/64 -in. (26.6 mm) ID hole

which is located at the end of the unit. See Fig. 2-4 for location of

condensate connection.

HAND FORM

Fig. 6 - Flanges Installed on 50ZP060 Units

STRAIGHT PIECE

C00006

Fig. 7 - Area Not to Be Drilled More Than 3/4-in.

Power Wiring

-- Control Wiring

Condenser Airflow

*Separate disconnect per NEC

(National El_trioal Code)

Fig. 8 - Typical Installation

FROM

POWER ......

SOURCE

DISCONNECT

PER NEC*.

C00007

A10018

Loading...

Loading...