Carrier 50ZH024-060 User Manual

Single-Package Heat Pump Units

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

GENERAL ..................................1-5

RECEIVING AND INSTALLATION ............5-11

Step 1 — Check Equipment ...................5

• IDENTIFY UNIT

• INSPECT SHIPMENT

Step 2 — Provide Unit Support ...............5

• SLAB MOUNT

Step 3 — Provide Clearances .................5

Step 4 — Place Unit ..........................5

Step 5 — Select and Install Ductwork .........5

Step 6 — Provide for Condensate Disposal ....7

Step 7 — Install Electrical Connections .......7

• HIGH-VOLTAGE CONNECTIONS

• ROUTING POWER LEADS INTO UNIT

• CONNECTING GROUND LEAD TO UNIT GROUND

• ROUTING CONTROL POWER WIRES

• ACCESSORY ELECTRIC HEAT WIRING

• SPECIAL PROCEDURES FOR 208-V

OPERATION

PRE-START-UP .............................11

START-UP ................................12-15

Check for Refrigerant Leaks .................12

Start-Up Cooling Section and

Make Adjustments ........................12

Refrigerant Charge ..........................12

MAINTENANCE ............................15-17

Air Filter ....................................15

Unit Top Removal (Outdoor Coil Side) ........16

Indoor Blower and Motor ....................16

Outdoor Coil, Indoor Coil,

and Condensate Drain Pan ................16

Outdoor Fan ................................16

Electrical Controls and Wiring ...............16

Refrigerant Circuit ..........................17

Indoor Airflow ..............................17

Metering Devices ...........................17

Liquid Line Strainers ........................17

TROUBLESHOOTING ......................18,19

START-UP CHECKLIST .....................CL-1

NOTE TO INSTALLER

Before the installation, READ THESE INSTRUCTIONS

CAREFULLY AND COMPLETELY. Also, make sure the

Owner’s Manual and Service Instructions are left with the

unit after installation.

50ZH024-060

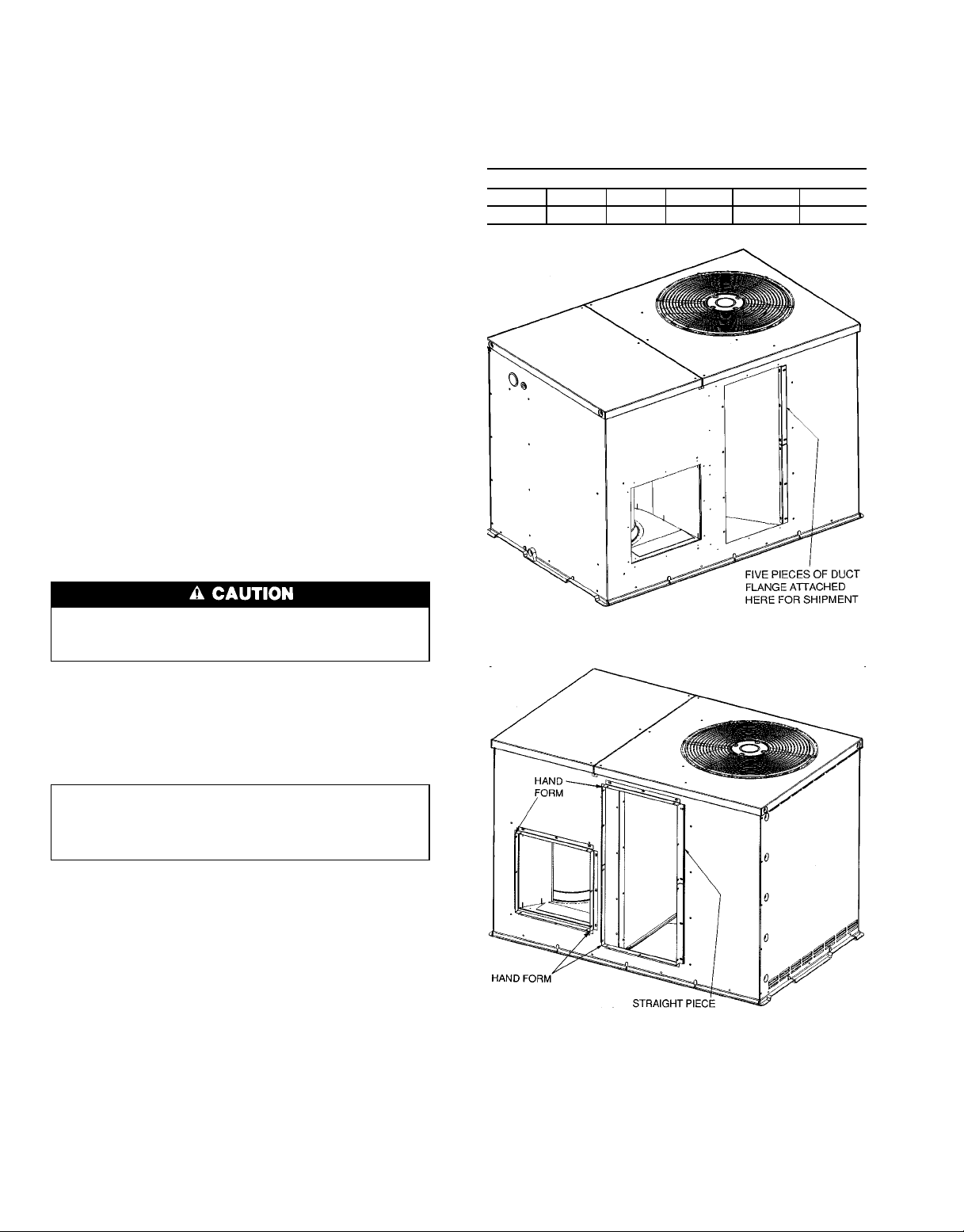

Fig. 1 — Unit 50ZH (Size 030 Shown)

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical components. Only trained and qualified workers should install,

repair, or service air-conditioning equipment.

Untrained workers can performbasicmaintenancefunctions of cleaning coils and filters.All other operations should

be performed by trained service people. When working on

air-conditioning equipment, pay attention to precautions in

the literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes.Wearsafety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire extinguisher available for all brazing operations.

Before performing service or maintenance operations on

system, turn off main power to unit. Turn off accessory

heater power switch if applicable. Electrical shock can

cause personal injury.

GENERAL

50ZH cooling units are fully self-contained and designed

for outdoor installation. See Fig. 1. As shown in Fig. 2-4,

units are shipped in a horizontal-discharge configuration for

installation on a ground-level slab.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a 5a

PC 111 Catalog No. 535-007 Printed in U.S.A. Form 50ZH-2SI Pg 1 9-96 Replaces: 50ZH-1SI

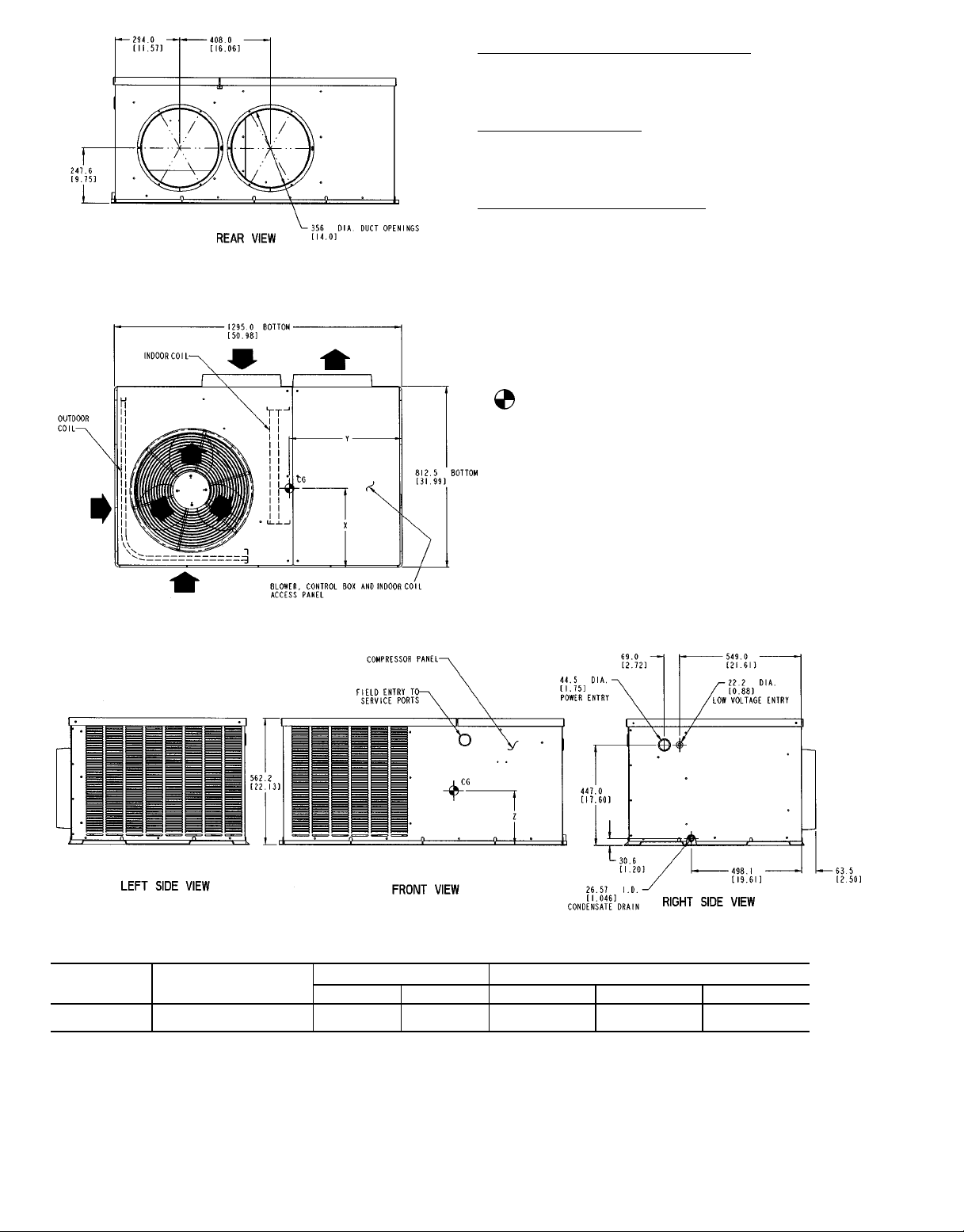

REQUIRED CLEARANCES TO COMBUSTIBLE MAT’L

Top of Unit ...................................0

Duct Side of Unit ...............................0

Side Opposite Ducts .............................0

Bottom of Unit .................................0

NEC REQUIRED CLEARANCES

Between Units, Power Entry Side .................1066.8 (42.00)

Unit and Ungrounded Surfaces, Power Entry Side ....... 914.0 (36.00)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Power Entry Side ....................1066.8 (42.00)

REQUIRED CLEARANCES FOR SERVICING

Outdoor Coil Access Side .......................762.0 (30.00)

Power Entry Side ............................762.0 (30.00)

(Except for NEC Requirements)

Unit Top ..................................914.0 (36.00)

Side Opposite Ducts ..........................762.0 (30.00)

NEC — National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-

2. Dimensions are in millimeters. Dimensions in [ ] are in inches.

3. is the center of gravity.

LEGEND

fan discharge, with the exception of the outdoor coil (914 mm [36 in.]). A

removable fence or barricade requires no clearance.

Millimeters (in.)

Millimeters (in.)

Millimeters (in.)

UNIT

50ZH024 208/230-1-60 232 106 356 (14.0) 483 (19.0) 305 (12.0)

50ZH030 208/230-1-60 254 116 356 (14.0) 483 (19.0) 305 (12.0)

ELECTRICAL

CHARACTERISTICS

V-Ph-Hz

UNIT WEIGHT CENTER OF GRAVITY mm (in.)

Lb Kg X Y Z

Fig. 2 — Base Unit Dimensions, 50ZH024 and 030

2

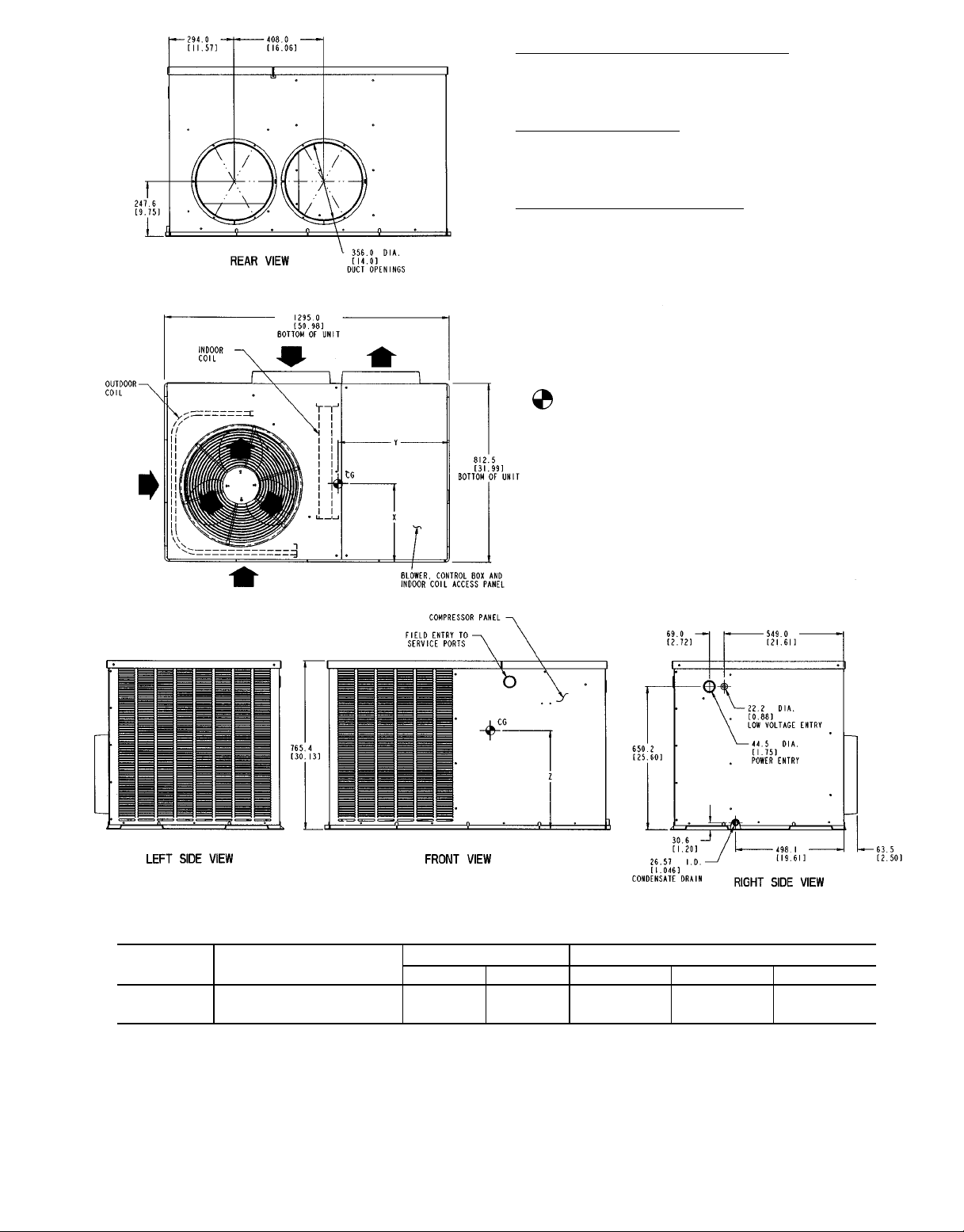

REQUIRED CLEARANCES TO COMBUSTIBLE MAT’L

Top of Unit ...................................0

Duct Side of Unit ...............................0

Side Opposite Ducts .............................0

Bottom of Unit .................................0

NEC REQUIRED CLEARANCES

Between Units, Power Entry Side .................1066.8 (42.00)

Unit and Ungrounded Surfaces, Power Entry Side ....... 914.0 (36.00)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Power Entry Side ....................1066.8 (42.00)

REQUIRED CLEARANCES FOR SERVICING

Outdoor Coil Access Side .......................762.0 (30.00)

Power Entry Side ............................762.0 (30.00)

(Except for NEC Requirements)

Unit Top ..................................914.0 (36.00)

Side Opposite Ducts ..........................762.0 (30.00)

NEC — National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-

2. Dimensions are in millimeters. Dimensions in [ ] are in inches.

3. is the center of gravity.

LEGEND

fan discharge, with the exception of the outdoor coil (914 mm [36 in.]). A

removable fence or barricade requires no clearance.

Millimeters (in.)

Millimeters (in.)

Millimeters (in.)

UNIT

50ZH036 208/230-1-60, 208/230-3-60 277 126 356 (14.0) 483 (19.0) 381 (15.0)

50ZH042 208/230-1-60, 208/230-3-60 295 134 356 (14.0) 483 (19.0) 381 (15.0)

50ZH048 208/230-1-60, 208/230-3-60 328 149 356 (14.0) 483 (19.0) 381 (15.0)

ELECTRICAL

CHARACTERISTICS

V-Ph-Hz

UNIT WEIGHT CENTER OF GRAVITY mm (in.)

Lb Kg X Y Z

Fig. 3 — Base Unit Dimensions, 50ZH036-048

3

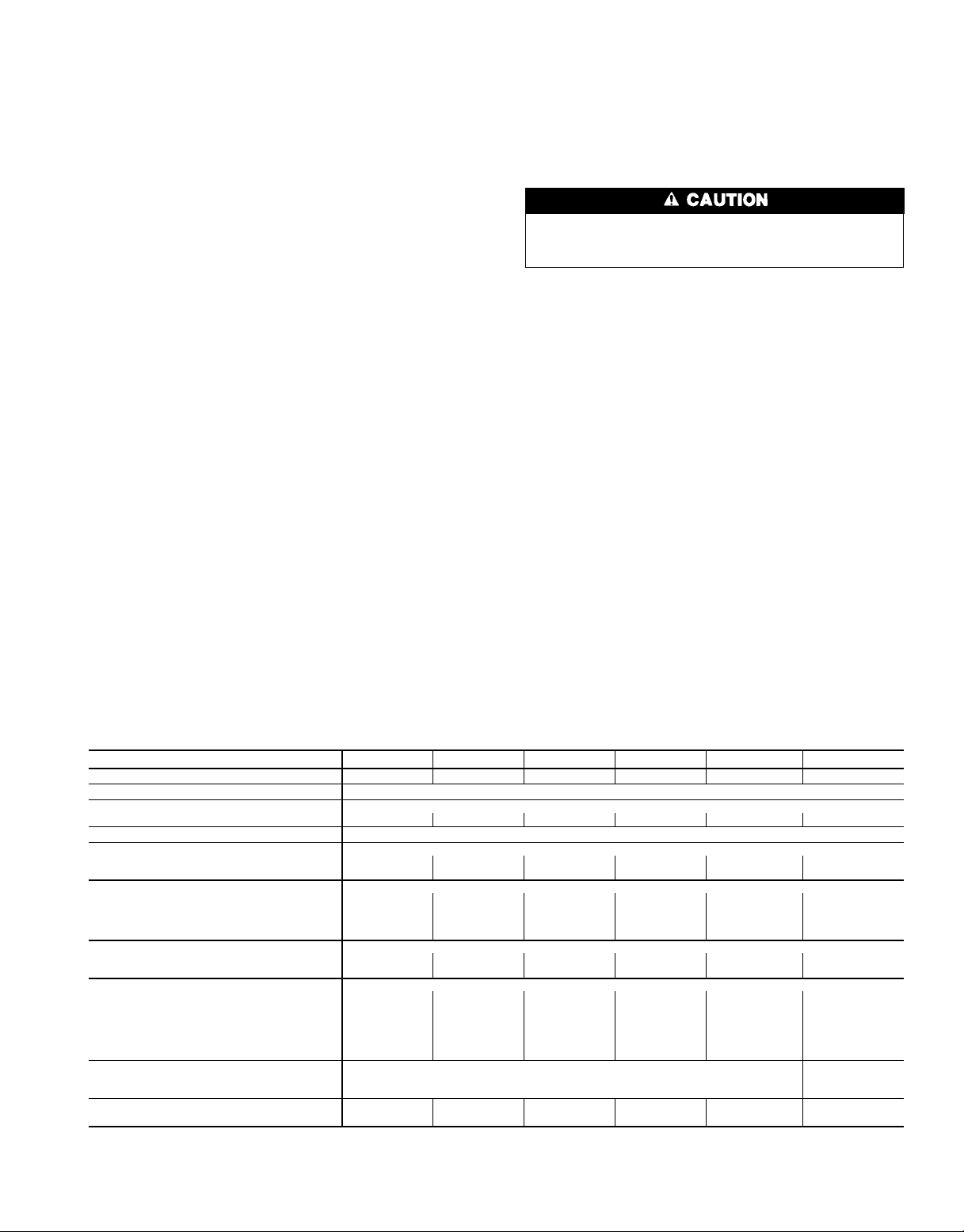

REQUIRED CLEARANCES TO COMBUSTIBLE MAT’L

Top of Unit ...................................0

Bottom of Unit .................................0

Side of Unit with Duct Openings ......................0

Side of Unit Opposite Duct Openings ...................0

NEC REQUIRED CLEARANCES

Between Units, Power Entry Side .................1066.8 (42.00)

Unit and Ungrounded Surfaces, Power Entry Side ....... 914.0 (36.00)

Unit and Block or Concrete Walls and Other Grounded

Surfaces, Power Entry Side ....................1066.8 (42.00)

REQUIRED CLEARANCES FOR SERVICING

Top of unit ................................914.0 (36.00)

Side of Unit Opposite Duct Openings ................762.0 (30.00)

Side of Unit with Power Entry ....................762.0 (30.00)

(Except for NEC Requirements)

NEC — National Electrical Code

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-

2. Dimensions are in millimeters. Dimensions in [ ] are in inches.

3. is the center of gravity.

LEGEND

fan discharge. A removable fence or barricade requires no clearance.

Millimeters (in.)

Millimeters (in.)

Millimeters (in.)

UNIT

50ZH060

ELECTRICAL

CHARACTERISTICS

208/230-1-60, 208/230-3-60,

V-Ph-Hz

460-3-60

Fig. 4 — Base Unit Dimensions, 50ZH060

UNIT WEIGHT CENTER OF GRAVITY mm (in.)

Lb Kg X Y Z

368 167 356 (14.00) 508 (20.00) 406 (16.00)

4

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFYUNIT — The unit model number and serial number are stamped on the unit identification plate. Check this

information against shipping papers.

INSPECT SHIPMENT — Inspect for shipping damage while

unit is still on shipping pallet. If unit appears to be damaged

or is torn loose from its securing points, have it examined by

transportation inspectors before removal. Forward claim papers directly to transportation company. Manufacturer is not

responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original packages until installation.

Step 2 — Provide Unit Support

SLAB MOUNT — Place the unit on a rigid, level surface,

suitable to support the unit weight. The flat surface should

extend approximately 2-in. beyond the unit casing on the 2

outdoor coil sides. The duct connection side and condensate

drain connection sides should be flush with the edge of the

flat surface. A concrete pad or a suitable fiberglass mounting

pad is recommended.

A 6-in. wide gravel apron should be used around the flat

surface to prevent airflow blockage by grass or shrubs. Do

not secure the unit to the flat surface except where required

by local codes.

1

The unit should be level to within

⁄4inch. This is nec-

essary for the unit drain to function properly.

Step 3 — Provide Clearances — The required mini-

mum service clearances and clearances to combustibles are

shown in Fig. 2-4. Adequate ventilation and outdoor air must

be provided.

The outdoor fan pulls air through the outdoor coil and discharges it through the fan on the top cover. Be sure that the

fan discharge does not recirculate to the outdoor coil. Do not

locate the unit in either a corner or under an overhead obstruction. The minimum clearance under a partial overhang

(such as a normal house overhang) is 48 in. above the unit

top. The maximum horizontal extension of a partial overhang must not exceed 48 inches.

Do not restrict outdoor airflow. An air restriction at either the outdoor-air inlet or the fan discharge can be harmful to compressor life.

Do not place the unit where water, ice, or snow from

an overhang or roof will damage or flood the unit. The unit

may be installed on wood flooring or on Class A, B, or C

roof covering materials.

Step 4 — Place Unit — Unit can be moved with the

handholds provided in the unit basepan. Refer to Table 1 for

operating weights. Use extreme caution to prevent damage

when moving the unit. Unit must remain in an upright position during all moving operations. The unit must be level

for proper condensate drainage; the ground-level pad must

be level before setting the unit in place. When a fieldfabricated support is used, be sure that the support is level

and that it properly supports the unit.

Step 5 — Select and Install Ductwork — The de-

sign and installation of the duct system must be in accordance with:

• the standards of the NFPA (National Fire Protection

Association) for installation of nonresidence-type air conditioning and ventilating systems;

• NFPA90Aor residence-type, NFPA90B; and/or local codes

and residence-type, NFPA 90B;

• and/or local codes and ordinances.

Table 1 — Physical Data

UNIT 50ZH 024 030 036 042 048 060

OPERATING WEIGHT (lb) 232 254 277 295 328 368

COMPRESSOR TYPE Scroll

REFRIGERANT R-22

Charge (lb) 4.0 5.8 5.9 9.2 10.9 11.0

REFRIGERANT METERING DEVICE Acutrol™ System

OUTDOOR COIL Copper Tubes, Aluminum Plate Fins

Rows...Fins/in. 1...17 2...17 1...17 2...17 2...17 2...17

Total Face Area (sq ft) 7.9 6.7 11.1 11.1 11.1 12.7

OUTDOOR-FAN MOTOR Propeller

Nominal Cfm 1800 2000 2600 2600 2600 3200

Nominal Rpm 825 1100 1100 1100 1100 1100

Motor Hp

Diameter (in.) 20 20 20 20 20 20

INDOOR COIL Copper Tubes, Aluminum Plate Fins

Rows...Fins/in. 2...15 3...15 3...15 3...15 4...15 4...15

Total Face Area (sq ft) 3.1 3.1 4.0 4.0 4.4 4.9

INDOOR-FAN MOTOR Direct Drive

Blower Motor Size (in.) 10x8 10x8 10x9 10x9 10x9 10×10

Nominal Cfm 800 1000 1200 1400 1600 2000

Rpm Range 550-1000 550-1000 800-1050 800-1050 1000-1100 950-1100

Number of Speeds 3333 2 3

Factory Speed Setting Low Med Low Med Low Low

Motor Hp

CONNECTING DUCT SIZES Round Square

Supply Air (in.) 14 13.9 × 13.9

Return Air (in.) 14 13.9 × 27.8

FIELD-SUPPLIED RETURN AIR FILTER*

Throwaway (in.) 24x24 24x24 24x24 24x24 24x30 24×30

*Required filter sizes shown are based on the ARI (Air Conditioning and Refrigeration Institute) rated airflow at a

velocity of 300 ft/min for throwaway type or 450 ft/min for high capacity type. Recommended filters are 1-in. thick.

1

⁄

8

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

2

1

⁄

4

1

⁄

2

1

⁄

4

3

⁄

4

1

⁄

2

1

5

Select and size ductwork, supply-air registers and

return-air grilles according to ASHRAE (American Society

of Heating, Refrigeration, and Air Conditioning Engineers)

recommendations.

Use the duct flanges provided on the supply- and returnair openings on the side of the unit. See Fig. 2-4 for connection sizes and locations. The 14-in. round duct collars are

shipped inside the 024-048 size units, attached to the indoor

blower. They are field-installed and must be removed from

the indoor cavity prior to start-up, even if they are not used

for installation.

INSTALLFLANGES FOR DUCTWORK CONNECTIONS

(50ZH060 Only) — The 50ZH060 units are shipped with

flanges which must be field-installed on the unit.

To install unit flanges:

1. Five pieces of flange are shipped on the return-air open-

ing of the unit. Remove the flanges from the shipping position. See Fig. 5. Screws are field-supplied.

2. One piece of flange is used as it is shipped (straight). Bend

the other 4 pieces at right angles.

3. Install the straight flange on the right side of the return

air opening in holes provided. See Fig. 6. Flanges should

stick out from unit to allow for connection of ductwork.

4. Install 2 hand-formed flanges onto return air opening in

holes provided to form a rectangle around the return air

opening.

5. Install remaining 2 hand-formed flanges around dis-

charge air opening in holes provided.

6. Ductwork can now be attached to flanges.

INSTALLING DUCTWORK — When designing and in-

stalling ductwork, consider the following:

• Secure all ducts to building structure. Flash, weatherproof, and vibration-isolate duct openings in wall or roof

according to good construction practices.

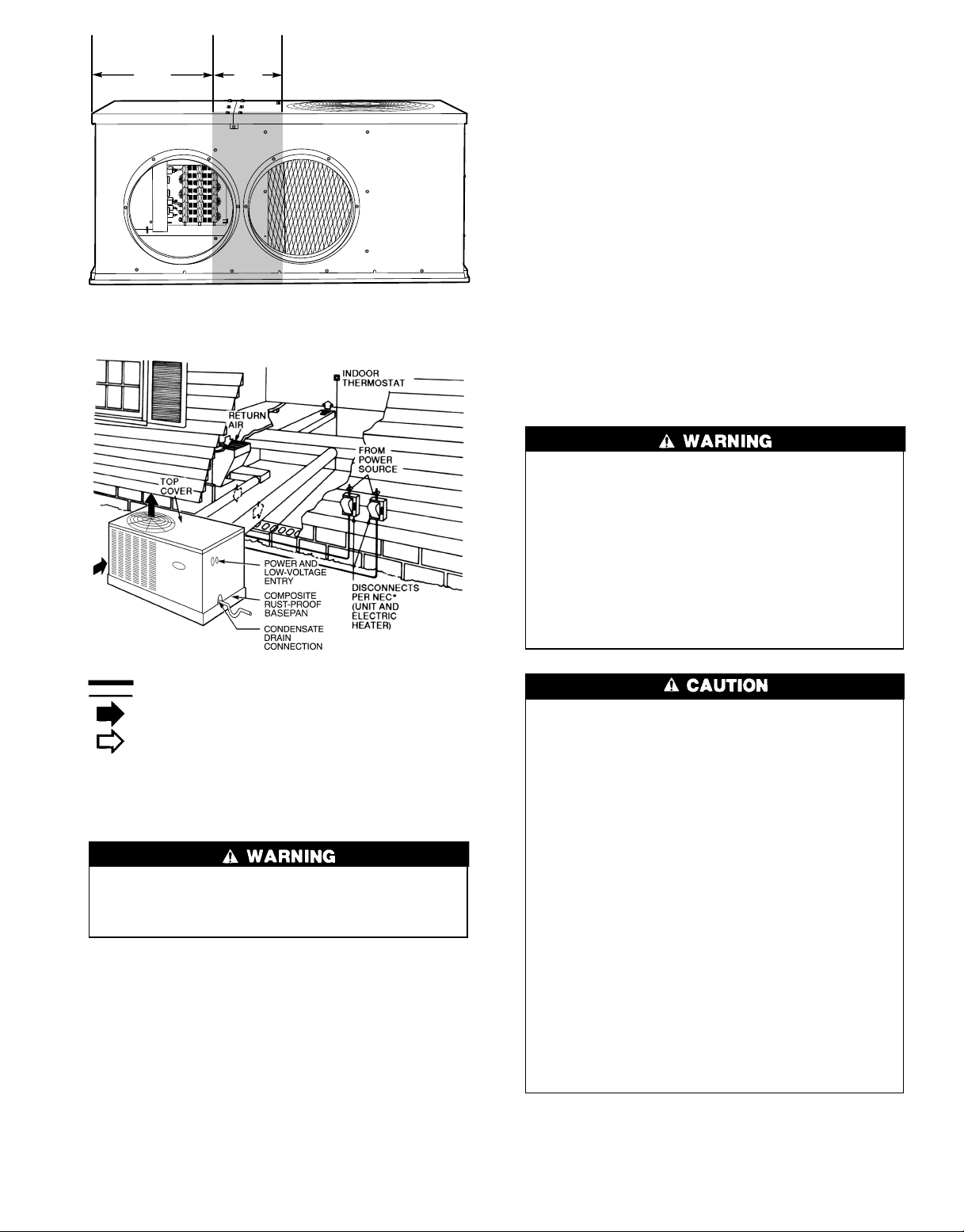

Figure 8 shows a typical duct system with 50ZH unit

installed.

Table 2 — Minimum Airflow for Safe Electric

Heater Operation (Cfm)

SIZE

024 030 036 042 048 060

600 750 900 1050 1200 1500

When connecting ductwork to units, do not drill deeper

than3⁄4inch in shaded area shown in Fig. 7 or coil may

be damaged.

• All units should have field-supplied filters installed in the

return-air side of the unit. Recommended sizes for filters

are shown in Table 1.

• Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between

ductwork and unit to prevent transmission of vibration. Use suitable gaskets to ensure weathertight and

airtight seal.

• Size ductwork for cooling air quantity (cfm). The minimum air quantity for proper electric heater operation is

listed in Table2. Heater limit switches may trip at air quantities below those recommended.

• Insulate and weatherproof all external ductwork. Insulate

and cover with a vapor barrier all ductwork passing through

conditioned spaces. Follow latest Sheet Metal and Air

Conditioning Contractors National Association (SMACNA)

andAir Conditioning ContractorsAssociation (ACCA) minimum installation standards for residential heating and air

conditioning systems.

Fig. 5 — Shipping Location of Duct Flanges

(Size 060 Only)

Fig. 6 — Flanges Installed on 50ZH060 Units

6

19.17″ 3.92″

Fig. 7 — Area Not to Be Drilled More Than3⁄4-in.

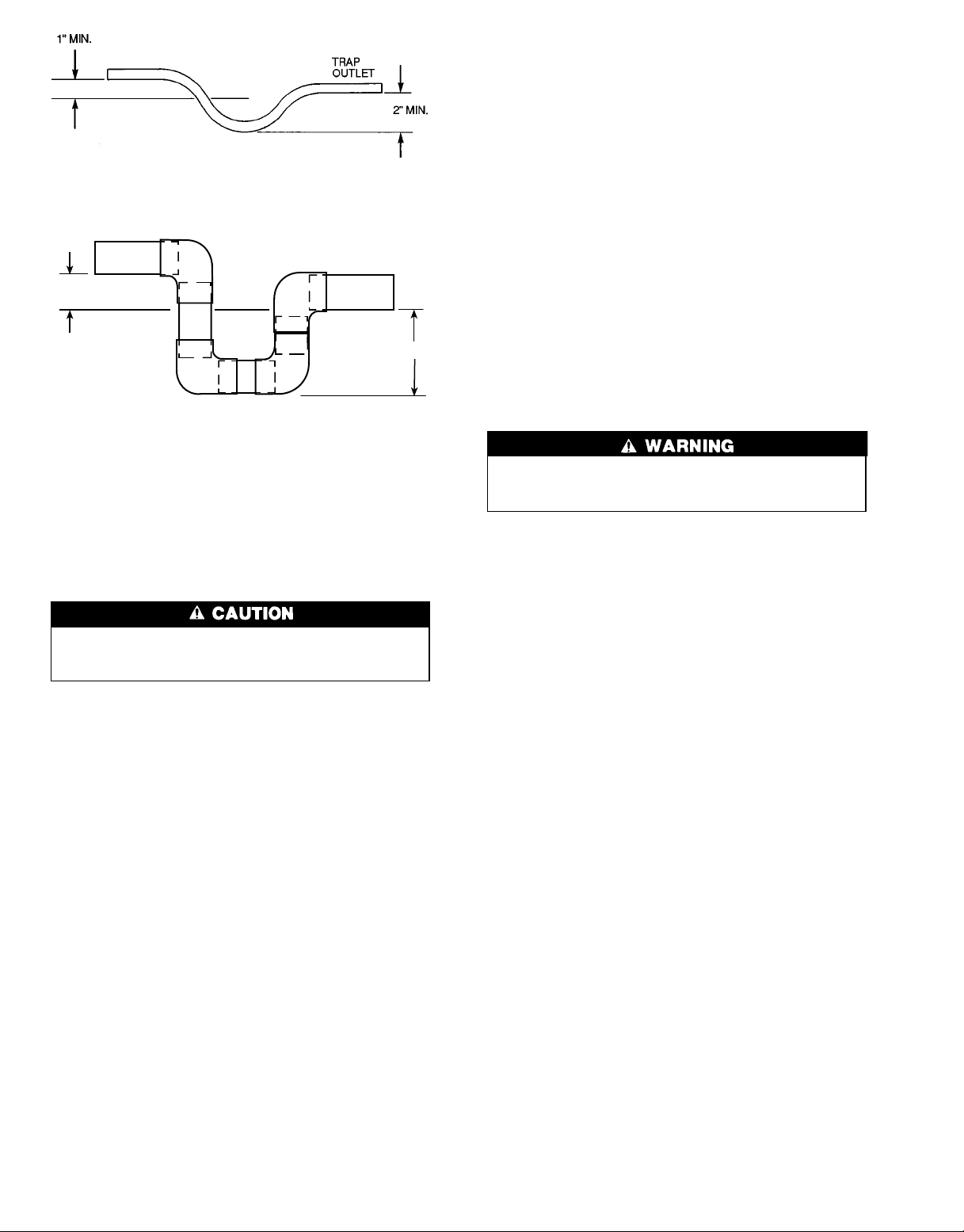

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel apron

in ground-level installations. Install a field-supplied condensate trap at end of condensate connection to ensure proper

drainage. Make sure that the outlet of the trap is at least

1 in. lower than the drain pan condensate connection to

prevent the pan from overflowing. See Fig. 9Aand 9B. Prime

the trap with water. When using a gravel apron, make sure

it slopes away from the unit.

If the installation requires draining the condensate water

away from the unit, install a 2-in. trap using

3

⁄4-in. tubing or

piping. See Fig. 9A and 9B. Make sure that the outlet of the

trap is at least 1 in. lower than the unit drain pan condensate

connection to prevent the pan from overflowing. Prime the

trap with water. Connect a drain tube using a minimum of

3

⁄4-in. PVC,3⁄4-in. CPVC, or3⁄4-in. copper pipe (all field supplied). Do not undersize the tube. Pitch the drain tube downward at a slope of at least 1 in. for every 10 ft of horizontal

run. Be sure to check the drain tube for leaks. Prime trap at

the beginning of the cooling season start-up. Allowable glues

for condensate trap connection are: Standard ABS, CPVC,

or PVC cement.

Step 7 — Install Electrical Connections

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of an electrical wire connected to the unit

ground in the control compartment, or conduit approved for electrical ground when installed in accordance with NEC (National Electrical Code), ANSI

(American National Standards Institute)/NFPA (latest edition) (in Canada, Canadian Electrical Code CSA

[Canadian Standard Association] C22.1) and local electrical codes. Failure to adhere to this warning could result in personal injury or death.

Power Wiring

Control Wiring

Outdoor Airflow

Indoor Airflow

*Separate disconnect per NEC

(NationalElectrical Code) required

for electric heater when singlepoint connection is not used.

Fig.8—Typical Installation

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (VERTICAL) DISCHARGE

Before performing service or maintenance operations on

the system, turn off the main power to the unit. Turn off

accessory heater power switch if applicable. Electrical

shock can cause personal injury.

Units are dedicated side-supply products. They are not convertible to vertical air supply. A field-supplied plenum must

be used to convert to vertical air discharge.

Step 6 — Provide for Condensate Disposal

NOTE: Be sure that condensate-water disposal methods comply with local codes, restrictions, and practices.

Unit removes condensate through a 1

(using3⁄4-in. OD piping or tubing) which is located at the

end of the unit. See Fig. 2-4 for location of condensate

connection.

3

⁄64-in. ID hole

Failure to follow these precautions could result in damage to the unit being installed:

1. Make all electrical connections in accordance with

NEC ANSI/NFPA (latest edition) and local electrical codes governing such wiring. In Canada, all

electrical connections must be in accordance with CSA

Standard C22.1 Canadian Electrical Code Part 1

and applicable local codes. Refer to unit wiring

diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit.

DO NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within operating voltage range indicated on unit rating plate.

On 3-phase units, ensure that phases are balanced within

2%. Consult local power company for correction of

improper voltage and/or phase imbalance.

4. Insulate low-voltage wires for highest voltage contained within conduit when low-voltage control wires

are run in same conduit as high-voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electrical hardware, conduit, etc.

7

Fig. 9A — Condensate Trap (Using Tubing)

TRAP

OUTLET

1" MIN.

2" MIN.

Fig. 9B — Condensate Trap (Using PVC Piping)

CONNECTING GROUND LEAD TO UNIT GROUND

— Refer to Fig. 11 and 12. Connect the ground lead to the

chassis using the unit ground lug in the control box.

ROUTING CONTROL POWER WIRES — Form a driploop with the thermostat leads before routing them into the

unit. Route the thermostat leads through grommeted hole provided in unit (see Fig. 10) into unit control box. Connect

thermostat leads to unit control power leads as shown in

Fig. 13.

Route thermostat wires through grommet providing a drip

loop at the panel. Connect low-voltage leads to the thermostat as shown in Fig. 13.

The unit transformer supplies 24-v power for complete

system including accessory electrical heater. Transformer is

factory wired for 230-v operation. If supply voltage is

208 v, rewire transformer primary as described in the

Special Procedures for 208-v Operation section below.

ACCESSORY ELECTRIC HEAT WIRING — Refer to accessory electric heat installation instructions for information

on installing accessory electric heat.Accessory electric heat

wiring is shown in Fig. 14.

SPECIAL PROCEDURES FOR 208-V OPERATION

HIGH-VOLTAGE CONNECTIONS — The unit must have

a separate electrical service with a field-supplied, waterproof disconnect switch mounted at, or within sight from the

unit. Refer to the unit rating plate for maximum fuse/circuit

breaker size and minimum circuit amps (ampacity) for wire

sizing. See Table 3 for electrical data.

The field-supplied disconnect may be mounted on the unit

over the high-voltage inlet hole. See Fig. 2-4.

Operation of unit on improper line voltage constitutes

abuse and may cause unit damage that could affect

warranty.

ROUTING POWER LEADS INTO UNIT — Use only copper wire between disconnect and unit. The high-voltage leads

should be in a conduit until they enter the unit; conduit termination at the unit must be watertight. Run the highvoltage leads through the hole on the control box side of the

unit (see Fig. 10 for location). When the leads are inside the

unit, run leads to the control box (Fig. 11). For single-phase

units, connect leads to the black and yellow wires; for 3-phase

units, connect the leads to the black, yellow, and blue wires

(see Fig. 12).

Make sure that the power supply to the unit is switched

OFF before making any wiring changes. Electrical shock

can cause personal injury or death.

1. Disconnect the orange transformer-primary lead from the

contactor. See unit wiring label.

2. Remove the wirenut from the terminal on the end of the

red transformer-primary lead.

3. Save the wirenut.

4. Connect the red lead to the contactor terminal from which

the orange lead was disconnected.

5. Using the wirenut removed from the red lead, insulate

the loose terminal on the orange lead.

6. Wrap the wirenut with electrical tape so that the metal

terminal cannot be seen.

Indoor blower-motor speeds may need to be changed for

208-v operation. Refer to Indoor Airflow and Airflow

Adjustments section on page 14.

8

Loading...

Loading...