Carrier 50YX User Manual

HEATING & COOLING

Product

Data

50YX

High Efficiency Singie-Package

Heat Pumps

1-1/2 to 5 Nominal Tons

Single-Package Heat Pump Units

with the following Premium Features

as Standard:

• scroll compressors with internal

high-pressure and overcurrent

protection

• thermostatic expansion valves

• low-pressure switch

• high efficiency operation

Accessories:

• single point box kit

• electric heaters

Featu res/Benefits

Compact, fully self-contained,

all-electric, combination

heating/cooling unit is

prewired, prepiped, and

precharged for minimum

installation expense.

Easy installation

Round side-by-side duct configuration

on 018-042 units and rectangular

configuration on 048-060 units.

Models install easily on a rooftop or

a ground-level pad.

Efficient operation

Rugged, efficient scroll compressors

are specifically designed for high effi

ciency, improved reliability, and

quiet operation. Each compressor is

mounted on rubber isolators for addi

tional sound reduction. All compres

sors have internal high-pressure,

overtemperature, and overcurrent

protection.

These high efficiency units not only

save electricity by lowering electric

bills, they are also eligible for utility

rebates offered for high efficiency

units.

Copyright 1992 Carrier Corporation

Form 50YX-2PD

Indoor-fan motors have been care

fully selected to minimize energyconsumption and to withstand the

heavy-duty, year-round operation

required by heat pumps. These motors

are designed to meet the require

ments of a wide variety of residential

and light commercial applications.

Direct-drive, PSC (permanent split

capacitor), outdoor-fan motors have

been selected to help reduce energy

consumption Units are designed

for cooling operation down to 55 F

Built-in reliability components include

a low-pressure switch that stops the

compressor if the refrigerant pressure

drops to an unsafe operating level,

a discharge thermostat on the compres

sor which protects against overheat

ing, a thermostatic expansion value

(TXV) which keeps liquid refriger

ant from flooding into the compressor

and ensures optimum performance

under all conditions, and a compressor

time-delag which prevents the com

pressor from attempting to restart for 5

minutes after shutdown, to allow for

pressure equalization

Indoor and outdoor coils are com

puter designed for optimum heat

transfer Vertical outdoor-fan discharge

carries sound and air up and away.

The high-voltage inlet panel is designed

to accommodate a field-installed elec

trical disconnect. A low-voltage ter

minal block simplifies thermostat

connections. Refrigerant service con

nections make checking operating

pressures easier

Time/temperature defrost system is

used to increase heating cycle effi

ciency. This type of defrost system has

proven to be very reliable. The time/

temperature control “looks” for coil

icing conditions only at preset time

intervals, start the defrost cycle only if

the defrost thermostat senses icing

conditions, and automatically ends the

defrost cycle when the coil has

warmed sufficiently to melt the ice.

A separate power supply is not

required for electric heaters when an

accessory single point box kit is used.

This accessory provides for a single

power supply for the packaged unit

and accessory electric heater packages,

and functions as an NEC (National

Electrical Code) approved fused

disconnect

Weatherized cabinets are con

structed of heavy-duty, phosphated,

zinc-coated steel, and are finished with

corrosion-resistant baked enamel

Interior surfaces of the blower section

are insulated to help keep the con

ditioned air from being affected by the

outdoor ambient temperature

Page

Features/Benefits

Model Number Nomenclature ... .... .................................3

ARI Capacities . . ......................................................

Physical Data . .................................

Accessories . . ....

Dimensions . . . . . ..................5

Selection Procedure ............................................. ....

Performance Data . . ...............................................................

Electrical Data

Controls . .... ....................................................................

Typical Control Wiring Schematic

Typical Installation ...

Guide Specifications ....................................... . 18,19

.............................................

....................................

................................................................

........................ ......................................

..............................

........................................

....................

. . . 4

.......................

............................

..........

14,15

......................................

......................................

1,2

6

3

4

7-13

15

16

17

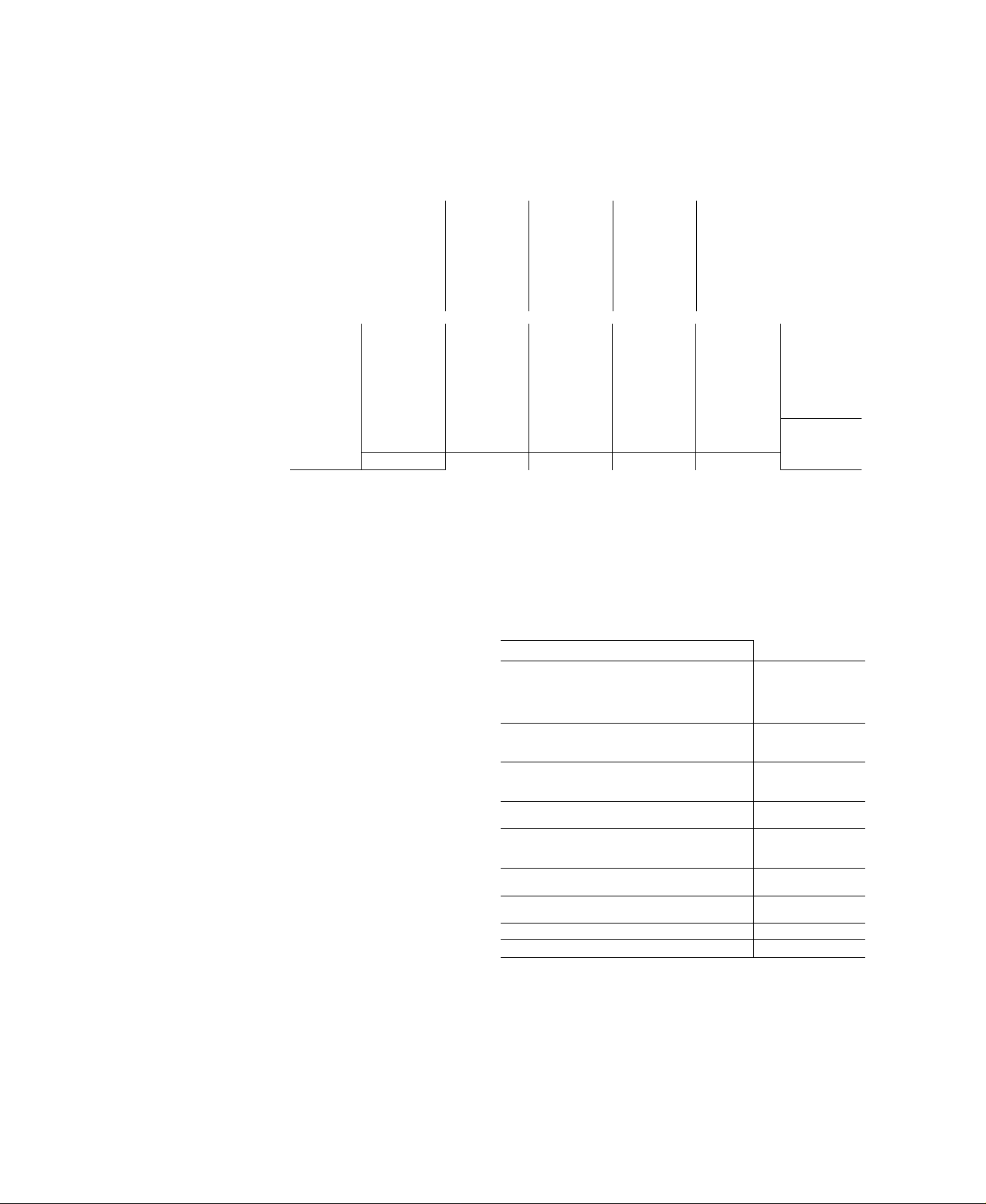

50YX 024 3

Model Number

50YX—High Efficiency

Single-Package

Heat Pumps

Nominal Capacity

018 —1 1/2 Tons

024 — 2 Tons

030 — 2 1/2 Tons

036 — 3 Tons

042 — 3 1/2 Tons

048 — 4 Tons

060 — 5 Tons

V-Ph-Hz

3-208/230-1-60

UNIT

50YX

018

024 2

030

036

042

048

060

ARI

Bels

COP

DOE

HSPF

SEER

c^pac^iii©s

COOLING AND HEATING CAPACITIES AND EFFICIENCIES

NOMINAL

TONS

1У2

STANDARD

CFM

600 18,500

900

2Уг

3

ЗУ2

1100 31,000

1300

1400 41,500

4 1600

5

2000 60,000

LEGEND

Air-Conditioning & Refrigeration Institute

Sound Levels (1 bel = 10 decibels)

Coefficient of Performance

Department of Energy

Heating Seasonal Performance Factor

Seasonal Energy Efficiency Ratio

NET COOLING*

CAPACITIES

AT 95 F (Btuh)

24,800

35,800

48,500

SEER*

12 0

NET HEATING*

CAPACITIES

AT 47 F (Btuh)

17,200

COP*

AT 47 F

30 9,300

NET HEATING*

CAPACITIES

AT 17 F (Btuh)

120 21,500 30 12,000

12 1

29,000

120 34,000

12,0 38,600

12,0

11 0

46,000

54,500

‘Rated in accordance with ARI Standard 210/240-89 and/or U.S Gov

ernment DOE test procedures

tRated in accordance with ARI Standard 270-84

3 1 16,800

3,0

32

32

19,000

21,500

27,000

30 31,000

NOTE, Ratings are net values, reflecting the effects of circulating fan

heat Ratings are based on cooling standard 80 F db, 67 F wb indoor

entering-air temperature and 95 F db outdoor entering-air temperature.

COP*

AT 17 F

1,8

1 8

20

1,9

20

20

1,9

HSPF

70

7,0

'7T

7 0

70

73

70

SOUND

RATINGSt

(Bels)

76 ■'

^ I

82

8 O"

(òlwillll

UNITJOYX

Ml^lGERiS^f]R-22)*

Refrigerant Control

WEIG^

COMPRESSOR

INDOOR FAN

Speeds

Rpm

Diameter (in.)

Width (in.)

Nominal Range (cfm)

Motor Hp

iNDOOiTcbiL^

Rows...Fins/in.

Face Area (sq ft)

OUTDOOR FAN ^

Cfm

Rpm

Diameter (in.)

JWotor Hp

OUTDOOR ^¡L

Rows...Fins/in.

^ace Area (^ft)

FILTER SIZE (in.jt

(Qty) Throwaway

(Qty) Permanent

.

018

330

2

840

10

6

525-750

V4

3 15

34

2200

840

22

Vs

2..17

8.3

(1) 20 X 25

(1) 15 X 20 (1) 15 X 20 (2) 20 X 20

LEGEND

TXV — Thermostatic Expansion Vaive

‘Operating charge is listed on unit nameplate.

fRecommended field-supplied filters are one-in thick.

024 030

036 042

TXV

" 336 340 ’^~407

Scroll

2

840

12

6

700-1000

Va

3 .15 3 ..15 3...15

34 3.4 4.7

2200

840

22

V4

2 17

83

(1) 20 X 25 (2) 15 X 20

Centrifugal — Direct Drive

2

840 840 840

12

6

875-1250 1050-1500

Va

Propeller — Direct Drive

2700

1100

22

V4

2. .20

8 3^__

2 2

12

6 6 6

V2 V2

2700

1100

22

1/4

2. 20

96

(1) 15 X 20

(1) 20 X 20

(2) 20 X 25 (2) 20 X 25

12 12

1100-1650

3 ..15 3. .15

6.0 65

3200

1100

22

1/4

2...17

12.0

(2) 20 X 20

(1) 20 X 25

(1) 25 X 25

(2) 20 X 20

048

423 "

3

1100

1400-1800

Va

3200

1100

22

1/4

2.17

12.7

060

432

2

1100

12

6

1750-2400

%

4...15

6.4

3400

1100

22

1/2

2.. 17

12.7

(1) 20 X 25

(1)25x25

(2) 20 X 20

Electric heaters that mount inside the heat pump indoor-

fan compartment are available in a variety of kW and volt

age options. Each heater assembly includes automatic-reset

switch, and heat limiters for primary and secondary, over

current, and thermal protection

Single point box allows for a single power supply for the

base unit and accessory electric heater, and functions as an

NEC-approved fused disconnect

Service Sentry™ kit provides immediate warning when

the compressor fails to operate after a call for heating or

cooling The control energizes a warning light located on the

indoor thermostat

Outdoor thermostat kit allows for staging of electric heat

ers based on outdoor-air temperature

Thermostat and Subbase provides heating and cooling

unit control Automatic and manual changeover types are

available

ACCESSORY

Electric Heater 5.0 kW

Single Point Box

For 5.0-kW Heaters (Unit Sizes

018,024)

For 7.5- and 10.0-kW Heaters

(Unit Sizes 018,024); For 5.0-kW

Heaters (Unit Sizes 030-060)

For 7.5- and 10.0-kW Heaters

(Unit Sizes 030-048)

For 15.0-kW Heaters (Unit Sizes

030-060); For 20.0-kW Heaters

(Unit Sizes 036-060)

Thermostat and Subbase

Autochangeover

Thermostat and Subbase,

Manual Changeover

Service Sentry™ Kit

Outdoor Thermostat

7.5 kW

10.0 kW

15.0 kW

20.0 kW

PART NO.

88EMOO5OMAO0

88EM0075MA00

88EM0100MAOO

88EM0150MA00

88EM0200MAOO

50YX-900—001

50YX-900—002

50YX-900—003

50YX-900—004

99TZ-900—521

99TZ-900—571

50LQ-900—011

50LQ-900—001

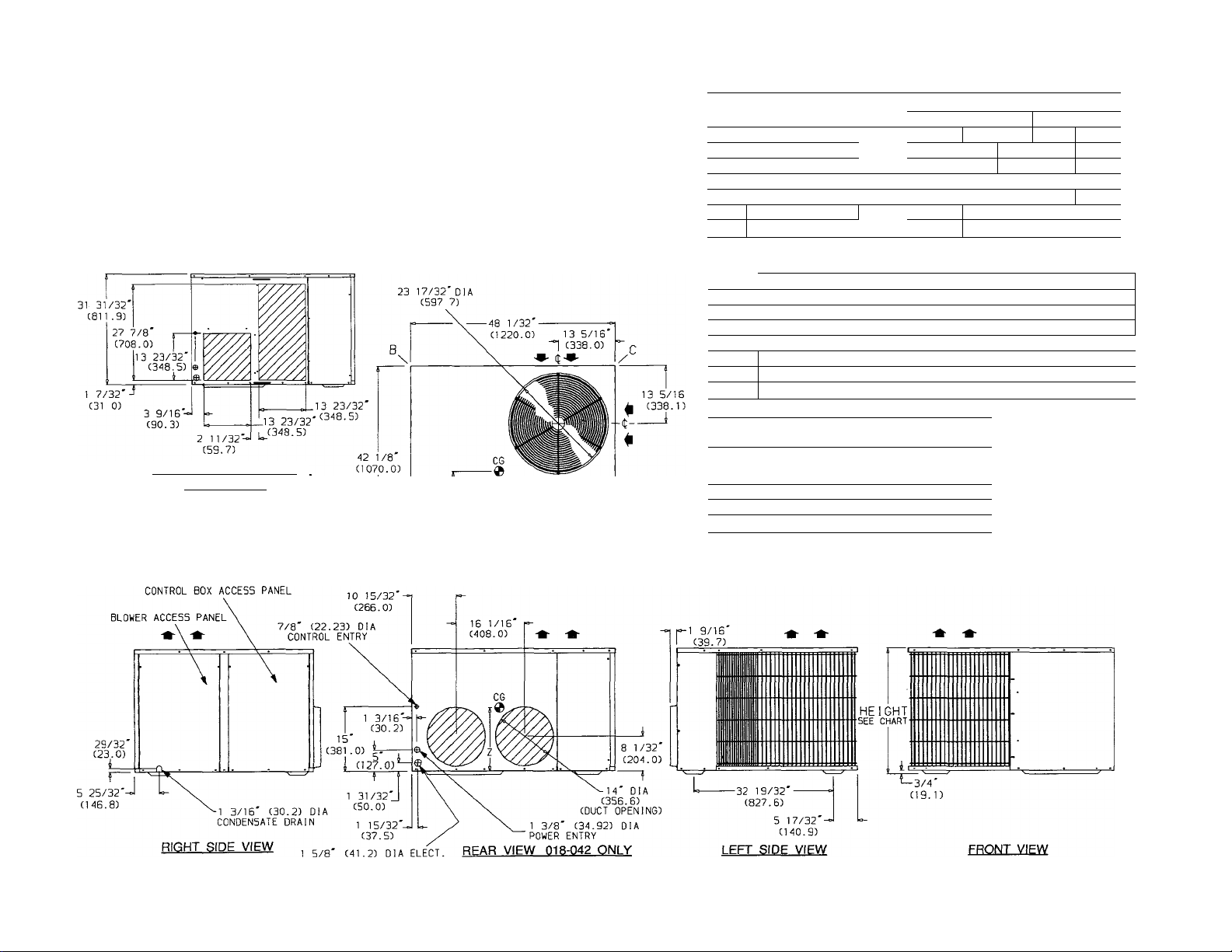

REQUIRED CLEARANCES TO COMBUSTIBLE MATE

RIAL, INCHES (mm)

Maximum Extension of Overhang 48(1219.2)

Unit Top 36(914.4)

Duct Side of Unit 6 min. (152.4 min.)

Side Opposite Ducts 30 (762.0)

Bottom of Unit . 0

NOTES:

1. Clearances must be maintained to prevent recirculation of air from outdoor-fan discharge.

2. CG IS center of gravity.

REQUIRED CLEARANCES FOR SERVICING, INCHES

(mm)

Indoor-Fan Access Panel Side 30 (762.0)

Control Box Access Side 30 (762.0)

3. Dimensions in ( ) are in millimeters.

REAR VIEW FOR 50YX048

AND 060 ONLY

UNIT

50YX

ELECTRICAL

CHARACTERISTICS

HEIGHT

UNIT WT CORNER WT Lb/Kg

Lb/Kg

018 208/230-1-60 330/150

024 208/230-1-60

030 208/230-1-60

(561.2)

036 208/230-1-60

042

048 208/230-1-60

060 208/230-1-60

UNIT

50YX

018

024 19%" (504.8)

030 20y,6'' (509.6)

036 20y,6'' (519.1)

042 20y2" (520.7)

048 20%" (523.9)

060

50YX

018-060 : 88EM0075MA00 7.5

030-060

036-060

208/230-1-60 i (622.3) j 407/185 j 86/39 ¡ 98/45

32«/,6"

(833.4)

CENTER OF GRAVITY in./mm

X

19%" (501.7) 21 Ve" (555.6) 101/4" (260.4)

213/4" (552.5) IOV4" (260.4)

211/2" (546.1) 105/16" (261.9)

21s/,6" (547.7) 111/2" (292.1)

213/4" (552.5)

213/4" (552.5) 155/8" (356.9)

20ys" (511)

UNIT ; HEATER kW @

211/4" (540) 151/8" (384)

PART NO. 1 240 V

1 88EM0050MA00 | 5.0

! 88EM0100MAO0 i: 10.0

Í 88EM0150MA00 I 15.0

¡ 88EM0200MA00 I 20.0

060

i 88EM0250MA00

336/152 69/31

340/154 70/32 83/38 79/36

350/159 71/32 85/39 i 84/38

24V2"

423/192 92/42 99/45 108/49

432/196

Y

B

A

68/31

82/37

c

73/33

83/38 76/34 108/49

100/45

95/43 ! 96/44 110/50 131/60

Z

133/4" (349.3)

25.0

D

107/49

109/49

110/50

123/56

124/56

li

il

m

cn

\

HEAT POWER ENTRY

^ecpiiire

I Determine cooling and heating requirements at

design conditions.

Given:

Required Cooling Capacity (TC) .... 28,000 Btuh

Sensible Heat Capacity (SHC)

Required Heating Capacity

Outdoor Entering-Air Temperature

Outdoor-Air Winter Design Temperature

.........

20,500 Btuh

..................

..............

30,000 Btuh

95 F

......

20 F

Indoor-Air Winter Design Temperature..........70 F

Indoor Entering-Air Temperature

...........

80 F edb,

67 F ewb

Indoor-Air Quantity

External Static Pressure

..............................

............

... 0.40 in. wg

1125 cfm

Field-Supplied Filter Pressure Drop . . .0.15 in. wg

Electrical Characteristics (V-Ph-Hz)

.......

230-1-60

II Select unit based on required cooling capacity.

Enter Cooling Capacities table at condenser entering

temperature of 95 F, indoor air entering at 1125 cfm

and 67 F ewb (entering wet bulb). The 50YX030 unit

will provide a total cooling capacity of 31,000 Btuh and

a sensible heat capacity of 24,400 Btuh.

For indoor-air temperature other than 80 F edb (en

tering dry bulb), calculate sensible heat capacity cor

rection, as required, using the formula found in Note 3

following the cooling capacities tables.

NOTE: Unit ratings are net capacities.

Ill Select electric heat.

Enter the Heating Capacities table at 1125 cfm. At

70 F return indoor air and 20 F air entering outdoor

coil, the integrated heating capacity is 16,200 Btuh. (Se

lect integrated heating capacity value since deductions

for outdoor-coil frost and defrosting have already been

made. No correction is required.)

The required heating capacity is 30,000 Btuh. There

fore, 13,800 Btuh (30,000 — 16,200) additional elec

tric heat is required.

Determine additional electric heat capacity in kW

13,800 Btuh

3414 Btuh/kW

= 4.0 kW of heat required

Enter the Electric Heater Packages table for 50YX030

unit. The 5-kW heater at 240 v most closely satisfies

the heating required. To calculate kW at 230 v.

5 kW X .92 = 4 6 kW

5 kW X .92 X 3414 = 15,704 Btuh

To calculate kW at 208 v, see note below Electric Heater

Packages table on page 13.

Total unit heating capacity is 31,904 Btuh (16,200 -f

15,704).

IV Determine fan speed and power requirements at

design conditions.

Before entering Air Delivery tables, calculate the total

static pressure required. From the given and the Elec

tric Heat Accessory Pressure Drop table, find-

External static pressure

Filter

Electric heat

Total static pressure

0.40 in. wg

0.15 in. wg

0.04 in. wg

0.59 in. wg

Enter the Air Delivery table, page 12, at 1125 cfm and

230-v high speed for wet coil. By interpolation, the stan

dard motor will deliver 0.65 in. wg static pressure. This

will adequately handle job requirements.

Loading...

Loading...