Page 1

Jrt<twnna y >' ^

Numb^One

AirConditbning

Maker

installation, Start-llp

Division of

Carrier Cotporalio

e

Carrier Parkway • Syracuse NY 13221

Single-Package Heat Pumps

and Service instructior^

SAFETY CONSIDERATIONS

INSTALLATION

Step 1 — Check Equipment and Jobsite

• UNPACKAGE UNITS

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER SYSTEM

REQUIREMENTS

Step 2 — Mount Heat Pump Package ..

• ON THE GROUND: MOUNT HEAT

PUMP ON AN ELEVATED FRAME

POSITIONED ON A LEVEL CON

CRETE PAD

• ON THE ROOF: MOUNT UNIT ON A

LEVEL PLATFORM OR FRAME

Step 3 — Make Ductwork Connections

• CONNECT SUPPLY AND RETURN

AIR DUCTWORK

.................................................

.........................

Page

1

, 1-4

. 1

INDEX

Step 4 — Provide for Cooling Cycle

Condensate Disposal for Cooling Cycle ... 4

• CONNECT DRAIN LINE

^Step 5 — Make Electrical Connections... 4

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER NEC

• ROUTE LINE POWER WIRES INTO

UNIT

• CONNECT GROUND LEAD TO GROUND

LUG IN SPLICE BOX FOR SAFETY

• SET INDOOR FAN MOTOR SPEED

• ROUTE CONTROL POWER WIRES

• ELECTRIC HEATER INSTALLATION

START-UP.............................................................5-7

SERVICE .............................................................7-14

V TROUBLESHOOTING

..................................

15, 16

^ SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic main

tenance functions of cleaning coils and filters and

replacing filters. All other operations should be per

formed by trained service personnel. When working

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing oper

ations. Have fire extinguisher available for all braz

ing operations.

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACKAGE UNITS — Move units to final loca

tion. Slide units from cartons taking special care nob

to damage unit.

INSPECT EQUIPMENT — File claim with ship

ping company if shipment is damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installing the 50YQ units.

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

Provide sufficient space for coil airflow clearance,

wiring, and servicing unit. (See Fig. 1.) Locate unit

where supply and return air ducts can be con

veniently brought out to unit duct connections.

Unit may be placed with duct side as close to

building as condensate drain, top removal, duct con

nections and power connections permit. Position

unit so water or ice from roof does not drop directly

on top of unit or in front of coil. Make provisions for

condensate drainage and defrost water disposal.

Roof installation method for 50YQ depends on

building construction and special requirements of

local building codes. Ensure that roof can support

unit weight. Protect unit from prevailing winds to

ensure adequate defrost.

© Carrier Corporation 1979 781 Form 50YQ-3SI

Page 2

0'-6j3^

■g CONDUIT

CONTROL-*“»

WIRING

If DKO

ELECTRIC^

HEAT X

l| DKO

LINE

WIRING'

CONN

L> INDOOR AIRFLOW

^ OUTDOOR AIRFLOW RIGHT SIDE VIEW

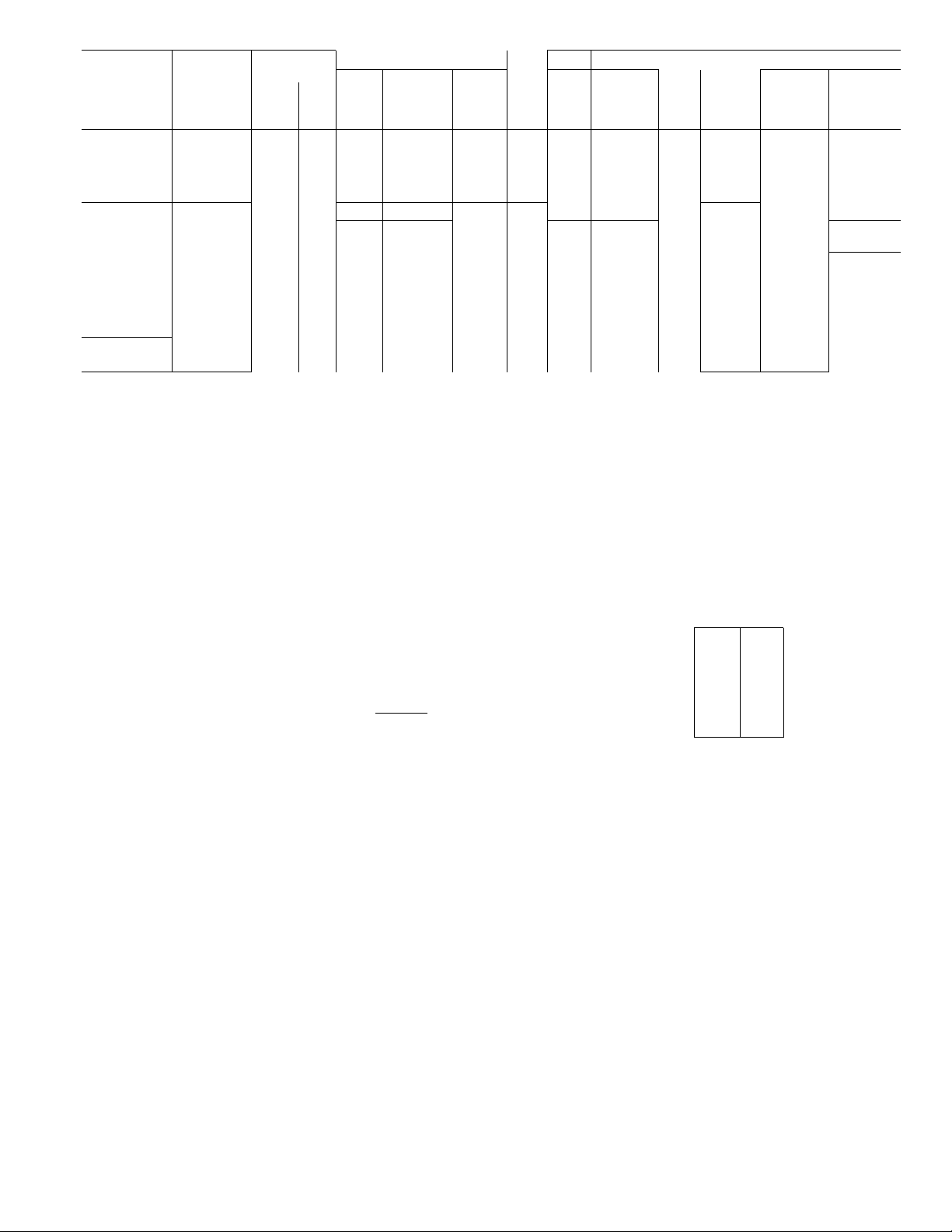

Ceitified dimension drawings available on request

Fig. 1

Dimensions and Connections

Table 1 — Installation Data (See Fig. 1)

UNIT

OPER WEIGHT (lb)

dTmeNsToNS (ft-in )

A

B

C' 1-11-5/8 1-11-5/8 1-11-5/8

DUCT CONN (ft-in )

D 1- 7-3/4 1- 7-3/4

FILTER SIZEt (in.)

Disposable 20x25

Permanent 15x20

‘Dimension "C" includes 1-in built-in base support channels

fRecommended field-supplied filters are 1-in thick

50YQ024

303

50YQ030

320

15x20 (2)

20x20 20x25 20x25

Step 2 — Mount Heat Pump Package

ON THE GROUND; MOUNT HEAT PUMP ON

AN ELEVATED FRAME POSITIONED ON A

LEVEL CONCRETE PAD See Pig. 2 for pad

dimensions. Ensure pad does not obstruct coil slots

in unit basepan. (Slots drain water during heating

and defrost cycles. See Fig. 2 for drain slot loca

tions.) Construct pad a minimum of 6 in. thick to

provide clearance under basepan coil slots for

drainage and ice buildup. In areas where prolonged

subfreezing temperatures or snowfall occur,

increase clearance to 12 to 18 inches by constructing

an angle-iron frame to support unit 12 to 18 in. off

concrete base. Design cross angle of frame so as to

not obstruct basepan coil slots. See Fig. 3 for recom

mended frame construction. Alternate construction

should follow dimensions. Extend a 24-in. gravel

apron around pad for condensate and defrost water

drainage field.

ON THE ROOF: MOUNT UNIT ON A LEVEL

PLATFORM OR FRAME — Elevate unit for

proper clearance as described under ground installa

tion above. Design roof and plan water runoff so as

to prevent unit and its duct flashing from sitting in

water, in accordance with all applicable codes.

50YQ036

333

4-0-7/16

3-6-1/4

Side-by-Side Rectangular

1- 7-3/4 1 1-11-3/4

15x20

20x20

50YQ042

375

2- 3-5/8

20x20 (2)

50YQ048

417

2-7-5Z8

2-3-3/4

20x25

20x20

15x20 (2)

50YQ060

448

3-1-5/8

2-9-3/4

25x25

_2.Ûx25 ^

20x20 (2)

Step 3 — Make Ductwork Connections

CONNECT RETURN AND SUPPLY AIR

DUCTWORK — Connect ductwork to unit supply

and return air duct connections. Refer to Fig. 1 and

Table 1 for unit supply and return air connection

sizes and locations.

NtWfTSaX:OFU1«T

«ïTH «JCT coitwecTfONS.

«Nfraasc

?ïEAfîsii«e8?a«(T^

i

y-t ■

A / ■

UNIT OUTÏ-iN?-

•JEF^SSBE

WT» Access &msjs

ooKOT i««oei%E»soss«E«T>

mnotutcPimz ^

d47«IS AilES.

mres.

t to 3f«as «lowiait <w ssibir«i!iife9 «ievSKNf

fr««» as(Xi, <S«!«>s.on A «• 4S >o, <s 3S sncsse«^ 1«

3r«AS where eievsieci f:e«» is f.oi A w A2

iHmee&'cm B js 3T xiches

2 AJiow a 3'*t service, ctoarahce at frotrt fear anc feit sioe of unit

Fig. 2 — Concrete Pad Dimensions

fMm

Page 3

iz TOS'«

0C

□ «Sy iSJRSS

<D’=

O'i-

!_

Ajrets íftOfí - li TO f-s COMMt STO { ■POTAL í&6ftMTrTY 2Sf 7035Ÿ >

m.0 FRA«E TO^TtíE».

PAífíT WlTH2l«C-ÍÍ}C» ?*»ÍT(StíSTf«OOP>

re“ fc&5 fíBi

3 3}í(J}fiS£0

F¡g. 3 — Heat Pump Mounting Frame

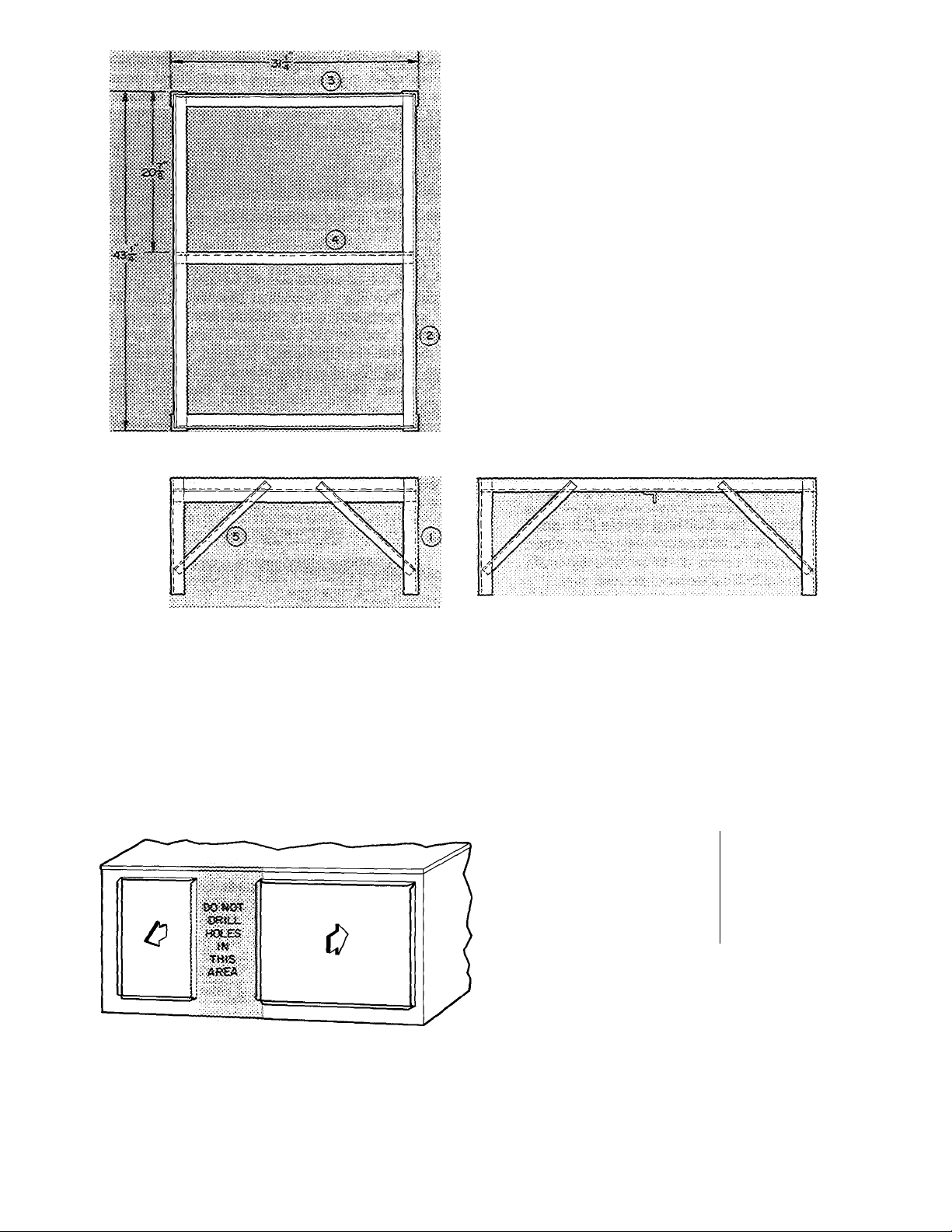

Flanges are provided on unit for rectangular duct

connections. Figure 4 shows a typical duct system

with 50YQ installed. Do not operate unit longer

than 5 minutes without ductwork. If necessary, refer

to Carrier System Design Manual, Part 2, for sys

tem air duct design. When designing and installing

ductwork, consider the following:

a. When connecting ductwork to unit, do not drill

holes in area shown below. Coil may be damaged.

b. Install field-supplied filters in return air duct

work. Recommended sizes for filters are shown

in Table I.

c. Avoid abrupt duct size increases and reductions.

■d. Use flexible connectors between ductwork and

unit to prevent transmission of vibration. When

electric heater is installed, use fireproof canvas

(or similar heat resistant material) connector be

tween ductwork and unit discharge connection.

If flexible duct is used, insert a sheetmetal sleeve

inside duct. Design this connector or sleeve so

that it extends 24 in. from electric heater element.

Size ductwork for cooling air quantity (cfm). The

e.

minimum air quantity for proper heating/ cooling

operation and electric heater operation is 400 cfm

per ARI cooling ton as listed below:

UNIT 50YQ MIN CFM

024 833

030

036

042

048

060 193 3

100 0

118 3

136 6

163 3

Heater limit switches may trip at air quantities

below those recommended.

Insulate and make weatherproof all external

ductwork. Insulate and cover with a vapor

barrier all ductwork passing thru unconditioned

spaces. Follow latest SMACNA (Sheet Metal

and Air Conditioning Contractors National

Association) and NESCA (National Environ

mental Systems Contractors Association) mini

mum installation standards for residential heat

ing and air conditioning systems.

Page 4

g. Secure all ducts to building structure. Weather

proof duct openings in wall or roof according to

good construction practices.

"Separate disconnect required for electric heater

> Fig. 4 — Typical Installation — 50YQ

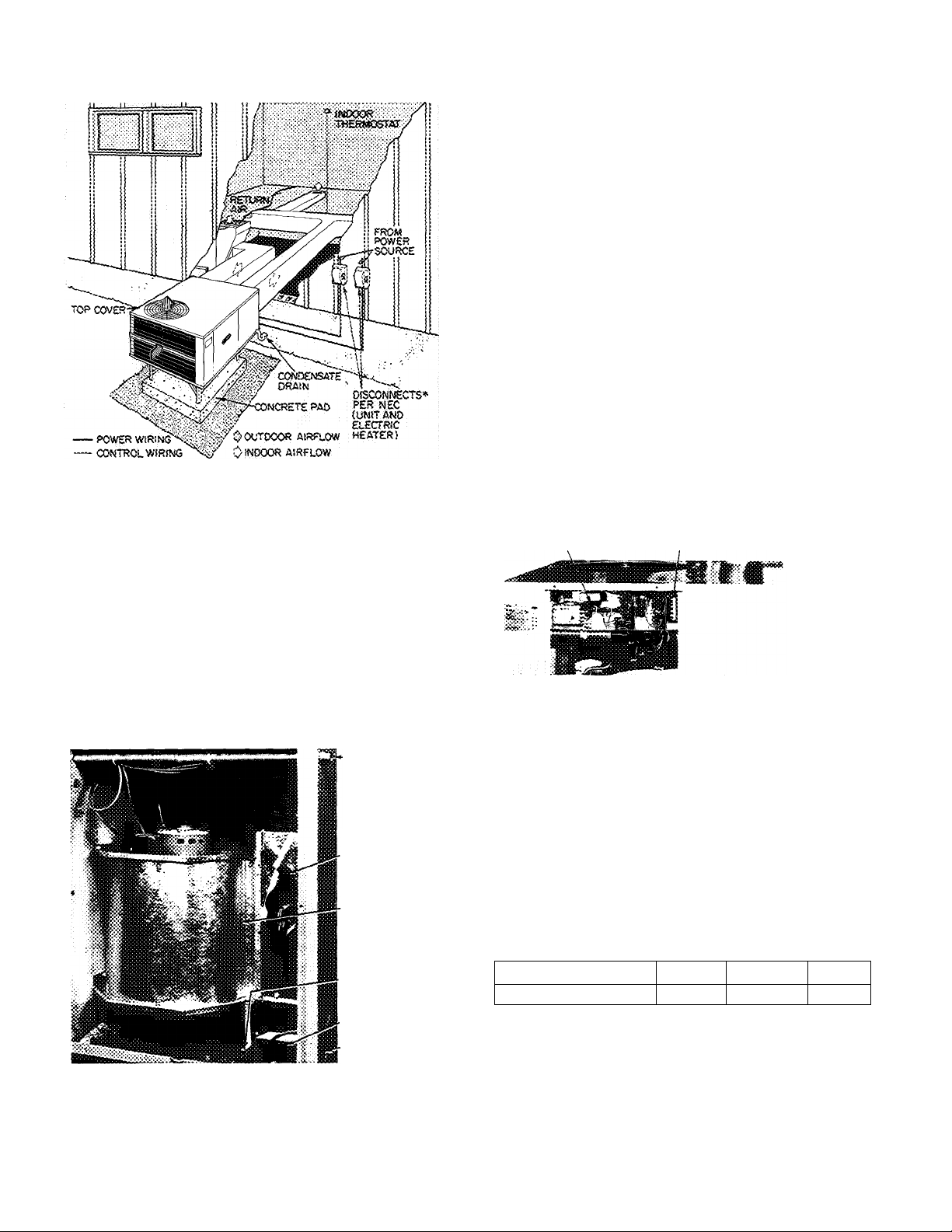

Step 4 — Provide for Cooling Cycle Conden

sate Disposal — Condensate may be drained

directly onto gravel apron or connected by drain

line(s) to a dry well. Follow local codes.

CONNECT DRAIN LINE to rubber condensate

drain fitting on side of unit (see Fig. 5). Use clamp

provided. Install factory-supplied condensate trap

(taped to indoor fan compartment for shipment) at

end of drain line. If a drain line is not used, connect

condensate trap to unit drain fitting as shown in

Fig. 5.

CONDENSATE

TRAP (SHIPPING

LOCATION, INSTALL

ON CONDENSATE

DRAIN LINE)

voltage to unit is within ± 10% of voltage indicated

on nameplate. On 3-phase units, check that phases

are balanced within 2%. Contact local power

company for correction of improper line voltage.

Oisrratton «kf tïiïÿi <M3t 3t

wth exijessm phase

¡as

coiaM

affect waCFaïïty,

See Table 2 for recommended wire and fuse

sizes.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER NEC of adequate size to handle unit starting

current. Provide a separate disconnect for unit

and for each accessory electric heater circuit as

required. (See electrie heater Installation, Start-Up

and Service Instructions.) Locate disconnect(s)

within sight of and readily accessible from the unit,

per Section 440-14 of National Electrical Code

(NEC).

ROUTE LINE POWER LEADS INTO UNIT ^

Extend leads from disconnect per NEC thru hole

provided (Fig. 1) into line wiring splice box (Fig. 6).

Use copper or copper-clad aluminum wire. (Do not

make connections with aluminum wire.)

UNIT

CONTROL BOX

CONTROL WIRING

TERMINAL BOX

Fig. 6 — Unit Control Box

CONTROL WIRING

CONDUIT,

CONNECT GROUND LEAD TO GROUND

LUG IN SPLICE BOX FOR SAFETY — Connect

power wiring. See Fig. 7. Connect line power leads

to yellow and black pigtails on single-phase units;

yellow, blue and black pigtails on 3-phase units.

SET INDOOR FAN MOTOR SPEED — Refer to

page 3 for minimum allowable air quantity for safe

electric heater operation. Three-speed indoor fan

motor is factory wired for high-speed operation.

Fan motor is equipped with spade-type speed selec

tor terminals marked 1, 2 and 3. For electric heater

operation, set motor at: “Low” — sizes 024 thru 042;

“High” — size 048; “Med” — size 060.

CONDENSATE

DRAIN LINE

¡i DKO LINE

POWER

Fig. 5 — Condensate Drain and Trap Details

Step 5 — Make Electrical Connections — In

stall field wiring in compliance with local and

national fire, safety and electrical codes. Be sure

781

MOTOR TERMINAL

FAN SPEED

1

High Medium Low

2 3

ROUTE CONTROL POWER WIRES (24-v) thru

7/8-in. conduit provided in unit. Fig. 1 and 5. Ex

tend leads to unit control wiring terminal board in

unit control box. Connect leads to terminal board

as directed in Fig. 8.

The 50YQ unit transformer supplies 24-v power

for complete system including accessory electric

heater.

Page 5

i-r'

tv

Table 2 — Unit Electrical Data (60-Hz)

OPER

VOLTAGE*

MODEL

50YQ024

50YQ030

^ 50YQ036

50YQ042

50YQ048

50YQ060

50YQ042

50YQ048

50YQ036

50YQ042

50YQ048 70

50YQ042

50YQ048 35

50YQ042

50YQ048 30 60

AWG

BCSC

FLA

IFM

LRA

OFM

RLA

HACR — Heating Air Conditioning & Refrigeration

V/PH

Max Min

207

230/1

208/230/1 253

200/3 220

200/230/3 253

230/3

460/3 506

575/3 632 518

American Wire Gage

Branch Circuit Selection Current

Full Load Amps

Indoor Fan Motor

Locked Rotor Amps

Outdoor Fan Motor

Rated Load Amps

253

253

187tt

180

180

207

414

COMPRESSOR

LRA

66

72

88

94 21.0

106

150

79 146

87 16 9 183 49

87

gT~

35

27

RLA

154

16 1

18 2

25 0 27 9 49

29 2/33 4

12 5/11 7

U6 143

14 8 16 4 4 9 2 2 10 58

g 3

7.5 8 8

49

BCSC

ELECTRIC HEATER INSTALLATION — For

complete heater installation data, refer to accessory

electric heater Installation, Start-Up and Service

Instructions.

GROUND LUG

(IN SPLICE BOX)

--GROUND LEAD-

l-PHASE

CONN

TO

DISCONNECT

PER NEC

3-PHASE

CONN

TO

DISCONNECT

PER NEC

_____

Field Wiring Splice Connections

NOTE Use copper or copper-clad aluminum wire

________________

Ll

________________

L2

------

GROUND LEAD-

LI----------------------------------------------

L2-

______________________________

L3

BLK

-YEL

50YQ HEAT PUMP

GROUND LUG

(IN SPLICE BOX)

■ -^-BLK--

BLU

-YPl

------------------------

-YEL

50YQ HEAT PUMP

-----------

----------

-----------

------------

(

i

i

i

Fig. 7 — Line Power Connections

START-UP

The 50YQ unit compressors are equipped with

crankcase heaters. It is recommended that heater be

energized a minimum of 24 hours before starting unit.

To energize heater only, set thermostat at OFF posi

tion; turn on unit main power at disconnect switch.

IFM

OFM

Min

FLA FLA

—

2 4 1 3 10 48

—

24 1 3 10

—

21 2

35 3

16 6 49 20 10

— 3 6

6 8

64 49 2 2

^Permissible limits of the voltage range at which units will operate

satisfactorily

tCopper wire sizes based on 60 C Use copper or copper-clad aluminum wire

only Use latest NEC for copper-clad aluminum conductor sizing

^Required when using nonmetallic conduit

“Maximum dual element fuse

ttMinimum voltage is 197 when outdoor ambient temperature exceeds

105 F

2 1 10 38 10 45

3 6

1 9 8

49

2 2

6 4 20

2 2

2 1 10 74

49”

i¥~ 67

1 9 ‘

49

4 9 2 2 14 90

49 1 9

Wire

Size

(AWG)t

6

4

10

14

14 164 14

14 141 14 15

BRANCH CIRCUIT

Min Gnd

Max

Ft

Wire

(AWG)t

}— -1

46

52 10 50

71 10

43

55 10 40

48

104 14 15

Max Fuse

Wire

or HACR

Type Ckt»*

Size

Bkr Amps

10

6

10 45 30 0

10 30 21.3/25 3

id 24 7

10 40 27 6

12 20

Min

Circuit

Amps

35 23 0

35

60

60

15 11 2

23 8

28 5

33 3

42 0

52 5

27 6

12 4

14 6

10 9

Heat Anticipator Settings for Room Thermo

stat — Set anticipator settings for room thermostat

according to Table 3. These settings may be changed

slightly to provide a greater degree of comfort for a

particular installation.

Table 3 — Thermostat Anticipator Setting

ACCESS.

ELECTRIC

HTR (Kw)

240 V 280 V

5 0 3 75

5 6

7 5

7 5

100

15 0 11 3

20 0 150

25 0 188

27 0

22 25

SECOND STAGE

ANTICIPATOR

SETTING

-gg— —

26

26

52

52

52

78

UNIT

50YQ024,

030,036,

042,048,

060

FIRST STAGE

ANTICIPATOR

SETTING

Fixed

Accessory Outdoor Thermostat provides adjust

able outdoor control of accessory electric heaters

of 15 Kw and over. This thermostat makes contact

when a drop in outdoor temperature occurs. It ener

gizes a stage of electric heat when the outdoor tem

perature setting is reached, provided the room

thermostat is on the second stage of heating. One

outdoor thermostat is recommended for each stage

of electric heat after the first stage. Set the outdoor

thermostat(s) progressively lower for each stage.

Refer to heat load of building and unit capacity to

determine the correct outdoor thermostat settings.

The accessory emergency heat relay is required

when 2 outdoor thermostats are used. It is auto

matically energized by the manually operated emer

gency heat switch in the indoor thermostat subhase.

The indoor thermostat locks out compressor and the

relay bypasses the outdoor thermostats for electric

heater operation during heat pump shutdown.

When one outdoor thermostat is used, an emergency

heat relay is not required. The emergency heat

switch in the indoor thermostat subbase bypasses

outdoor thermostat, locks out compressor and acti

vates electric heater.

184

Page 6

MOUNT OUTDOOR THERMOSTAT(S) —

Locate maximum of 2 outdoor thermostats in the

compressor section on the partition to the left of the

reversing valve. Fasten with sheet metal screws using

engagement holes provided. Uncoil a short length of

capillary and insert bulb into rubber grommet in the

partition. Moisten bulb to assist insertion. Insert all

but 1 in. of bulb. Secure remaining capillary.

MOUNT EMERGENCY HEAT REEAY in the

compressor section on the partition to the left of the

reversing valve using engagement hole provided.

Fasten with sheet metal screws.

To Start Unit — Check that main power is on and

that compressor crankcase heater has been ener

gized for at least 24 hours.

1. Check that heater main power is on as applicable.

2. Set selector switch at OFF.

3. Set fan switch as desired (FAN) (AUTO.).

4. Set thermostat dial at the desired temperature.

5. Set selector switch at HEAT or COOL. Check

system refrigerant charge. See Refrigerant

Charging.

Unit Single-Phase Compressors that are

Equipped with a Compressor Start Thermistor

(PTC device) (024,030,036) — When supply

voltage is within 10% limit and compressor does not

start, check the start thermistor with an ohmmeter.

CHECKING START THERMISTOR

1. Shut off all power to unit and wait 10 minutes

for thermistor to cool to ambient temperature.

2. Remove thermistor from circuit.

3. Measure resistance of thermistor with ohmmeter. Normal resistance readings are 25 ohms

± 20% at 75 F ambient temperature.

4. If ohmmeter resistance reading is not within the

± 20%, the thermistor is defective and must be

replaced.

THERMOSTAT

a SUBBASE

(SEE BELOW)

CHANGEOVER

Automatic

Manual

Manual

Automatic

___

SUBBASE

J-IH93AZ073

HH93AZ075

Subbase included

Subbase included

50YQ UNIT

CONTROL WIRING

TERMINAL BOX

THERMOSTAT

HH07AT071

HH07PZ085

HH07PZ08^6

COOLING AND ONE-STAGE HEATING

(without Electric Heater)

THERMOSTAT

a SUBBASE

(SEE BELOW)

R -

G —

—

Y -

0 --

E —

L

HR — Heater Relay

INSTALL r'

JUMPER

50Y0 UNIT

CONTROL WIRING

TERMINAL BOX

-- R

- G

- Y

0

-W3 —

-VI0-(HRI

-0RN-(HR3

-BRN

COOLING AND TWO-STAGE HEATING

(Unit equipped with 88EJ Electric Heater,

Emergency Heat, no Outdoor Thermostats)

Fig. 8 — Control Connections

THERMOSTAT

a SUBBASE

(SEE BELOW)

R -

G -

Y -

0 -

W2-

E -

INSTALLJUMPER

CONTROL WIRING

TERMINAL BOX

ro^—

! =^00

50YQ UNIT

- R

• G

--------

Y

- 0

-E-

- -W3-

C -

-VI0-(HR1

--------

^BLK-(hR2)

-0RN-(hR3

-BRN

ODT — Outdoor Thermostat

HR — Heater Relay

COOLING AND TWO-STAGE HEATING

(Unit equipped with 88EJ Electric Heater,

Emergency Heat, one Outdoor Thermostat)

THERMOSTAT

a SUBBASE

(SEE BELOW)

R - -- R

G - - G

Y -

0 -

W2--

(EH^ j0DT2[^"U0DTl

E --

1 L -|

c —

L

— Emergency Heat Relay

EHR

— Heater Relay

HR

— Outdoor Thermostat

ODT

50YQ UNIT

CONTROL WIRING

TERMINAL BOX

— Y

-- 0

-^W2^:

■ - E —^

-W3—^

— C — -

-VI0-(HRI

I"LI

Lehr"

J

-■bRN-(HR3'

COOLING AND TWO-STAGE HEATING

(Unit equipped with 88EJ Electric Heater, Emergency

Heat Relay, two Outdoor Thermostats)

781

Page 7

If start thermistor is good and compressor does

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described below. Run compressor for

10 minutes, then shut off and allow system pressure

to equalize. Reconnect start thermistor and try

restarting compressor without boost capacitor. If

after 2 attempts the compressor does not start, re

move thermistor and add an accessory start capaci

tor relay package.

Single-Phase Units 50YQ024,030,036 and

042 — When supply voltage is within 10% limit

and compressor does not start, give compressor a

temporary capacitance boost.

^TEMPORARY CAPACITANCE BOOST — If

necessary, see Carrier Standard Service Techniques

Manual, Chapter 2, Electrical, for details.

WARKSNG; Cajjaciiaace boost Ls to be perfotaacfd írasaeá porsoKoeL improper proce-

tlare cottjá «sose injxtry.

SERVICE

High-Pressure Relief Valve (Safety Control) is

located in compressor. Relief valve opens at a

pressure differential of approximately 550 psi

between suction (low side) and discharge (high side)

to allow pressure equalization.

Internal Current and Temperature Sensitive

Overload (Safety Control) resets automatically

when internal compressor motor temperature drops

to a safe level (overloads may require up to 1 hour to

reset). When an internal overload is suspected of

being open, check by using an ohmmeter or con

tinuity tester. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 2, Electrical,

for complete instructions.

Defrost Control, consisting of a defrost timer,

defrost thermostat and defrost relay, interrupts

normal system heating operation to remove frost

and ice formation on outdoor coil. Frost impairs

unit performance. Defrost control simultaneously

stops outdoor fan, energizes reversing valve sole

noid to switch system into cooling cycle (outdoor

unit as condenser, indoor unit as evaporator), and

activates accessory electric heater. Unit can defrost

every 90 minutes, but will do so only if outdoor tem

peratures are in the frosting temperature zone.

For heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature must be cold enough to

cause defrost thermostat contacts to close. Con

tacts close at 27 ± 3F.

Every 90 minutes of elapsed running time, the de

frost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit de

frosts. The defrost timer limits defrosting period to

10 minutes. Normally the frost is removed and the

defrost thermostat contacts will open to terminate

defrosting before 10 minutes have elapsed. Defrost

thermostat contacts open at 80 ( ± 6)F. When de

frosting is terminated, the outdoor fan motor is

energized and reversing valve solenoid is de

energized, returning unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 9 are

refrigerant flow diagrams for heating and cooling

cycles.

> Refrigerant Charging

CAUTION: To mcvem personal injttxy, wear

safety glasses and gloves when handHng

refrigerasL

Do not overcharge systemv An overcharge

can cause compressor flooding.

7Q I

Page 8

Table 4 — Service Data

UNIT 50YQ

R-22 CHARGE* (lb)

Refrig Control

INDOOR FAN

Rpm

Diameter (in.) 9 9

Width (in.)

Range (cfm)

Motor Hp

OUTDOOR FAN

Cfm 2500

Rpm

Diameter (in.) 20 20

Motor Hp 1/5

"Factory refrigerant charge

024

54 5 7 5 15

7 7

833-1040 1000-1250

1/5 1/5

1050

030 036

2500 2500

1050 1050

1/5 1/4

Unit refrigerant system is factory charged. When

recharging is necessary, weigh in total charge indi

cated in Table 4. (Charge must be weighed in during

heating season.) Remove any refrigerant remaining

in system before recharging. If system has lost com

plete charge, evacuate system to 500 microns

(29.7 in. vacuum) before recharging. Service port

connections are provided on unit suction and dis

charge lines for evacuation and charging. (See

Fig. 10 for service port location.) Dial-a-charge

charging cylinder is an accurate device used to re

charge systems by weight. These eylinders are avail

able at refrigeration supply firms.

042

AccuRater^M

Centrifugal — Direct Drive — 3-Speed

1100/1050/900

9

9

1183-1480

1/3

Propeller — Direct Drive

20

6 7

10

9

1367-1708

1/2

2700

1050

20

1/4

048

7 3

10

9

1633-2040

1/2

3200 3600

1050

20

1/4

1800-2250

To check system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 17 thru 22). These charts indicate whether a

correct relationship exists between system operating

pressures and air temperatures entering unit. If

pressure and temperature lines do not intersect on

chart, the system refrigerant charge may not be cor

rect or other sysem abnormalities may exist. Do not

use Operation Check Charts to adjust refrigerant

charge. Weigh charge into system.

COOLING CYCLE CHARGING CHART

METHOD

060

8 6

10

10

3/4

1050

20

1/4

OUTDOOR FAN

DISCHARGE GRILL

TOP COVER

UNIT CONTROL

BOX

REVERSING

VALVE \

SUCTION LINE'

SCHRADER

FITTING

COMPRESSOR

HOLD DOWN

BOLTS

CONTROL WIRING

TERMINAL BLOCK

ELECTRIC

COMPRESSOR aIsEMBLY

INDOOR INDOOR BLOWER

COIL MOTOR I

CONTROL WIRING

CONDUIT

CONDENSATE \

DRAIN LINE LINEWIRING

SPLICE BOX

Fig. 10 — Component Location (Typical)

To check and/or adjust charge during cooling

season, use correct Cooling Cycle Charging Chart

(Fig. 11 thru 16) and follow Charging Chart Method

below. The charging chart may also be used as an

alternate method of recharging system.

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port. (See Fig. 10 for correct

service port location.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature. Use service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan coil.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than ehart

pressure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

781

Page 9

SUCTION PRESSURE <§) SCHRADER VALVE (PSIG)

Fig. 11 — Cooling Charging Chart —

50YQ024

Fig. 13 — Cooling Charging Chart —

50YQ036

Fig. 12 — Cooling Charging Chart —

50YQ030

Fig. 14 — Cooling Charging Chart

50YQ042

Page 10

Fig. 15 — Cooling Charging Chart —

50YQ048

Fig. 17 — Heating Operation Check Chart —

50YQ024

40

50 60 70 80 90

SUCTION PRESSURE @ SCHRADER VALVE (PSIG)

Fig. 16 — Cooling Charging Chart

50YQ060

Fig. 18 — Heating Operation Check Chart —

50YQ030

i

10

Page 11

10 20 30 40 50 60 70

SUCTION PRESSURE @ SCHRADER VALVE (PSIG)

Fig. 19 — Heating Operation Check Chart

50YQ036

Fig. 21 — Heating Operation Check Chart

50YQ048

Fig. 20 — Heating Operation Check Chart

50YQ042

10 20 30 40 50 60 70 80

SUCTION PRESSURE @ SCHRADER VALVE (PSI8)

Fig. 22 — Heating Operation Check Chart —

50YQ060

Page 12

AccuRater™ (Dual-Piston Type) Servicing —

See Fig. 23 for dual-piston AccuRater components.

The pistons have a refrigerant metering orifice thru

them. The retainers form a stop for the pistons in the

refrigerant bypass mode, and a sealing surface for

liquid line flare connection. To check, clean or

replace piston;

1. Shut off power to unit.

2. Remove refrigerant from unit.

3. Remove liquid line flare connections from

AccuRater.

4. Note position of arrow on AccuRater body with

respect to unit.

5. Pull retainer out of body. Be careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use vise grips to remove

retainer. Replace scratched or damaged retainer.

6. Slide piston out by inserting a small soft wire thru

metering hole (18-gage thermostat wire). See that

metering hole, sealing surface around piston

cones and fluted portion of piston are not

damaged.

7. Chart on unit access panel illustrates proper

arrangement and sizes of pistons.

8. Clean piston refrigerant metering orifice.

9. Replace container O-ring before reassembling

AccuRater. Carrier O-ring part no. is

99CC501052.

LIQUID LINE STRAINERS (protect Accu

Rater), are made of wire mesh and located in the

liquid line on each side of the AccuRater. The

strainers are pressed into the line. Remove strainer

by threading a #10 sheet metal screw into strainer

and pulling the screw with pliers.

Compressor Removal — See Table 5 for com

pressor information and Fig. 10 for component

location. Follow safety codes, and wear safety

glasses and work gloves. Have quenching cloth

available (step 8).

CAUTION: ttibijag leased ki 50 ¥Q

ccals. po xiot «yediest place excessive

Stiais iabxag or dasjage may result.

Table 5 — Compressor Data

MODEL

50YQ024 M24

50YQ030

50Y0036

50YQ042

50Ya048

50YQ060

Refer to compressor nameplate for complete model number

PRODUCTION

COMPRESSOR*

M27

M34

P46

P53

P64 76

OIL RECHARGE (oz)

44

44

44

76

76

1. Shut off power to unit. Remove unit access

panel. Fig. 10.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1,

Refrigerants.

3. Remove core from suction and discharge line

Schrader valves.

4. Disconnect compressor wiring at compressor

terminal box.

5. Using a tubing cutter, cut suction and discharge

lines at convenient place near compressor for

easy reassembly to new compressor with copper

clip couplings.

CAUTION: Excessive tiiovemesit of copper

Jities at compressor may cso&e a break where

Imes connect to other system componcius.

6. Remove crankcase heater from compressor

base.

7. Remove compressor hold-down bolts and lift

compressor out.

8. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

CAUTION: MoSkr may copiainquantity of

Braze piping stubs (removed in step 8) on new

9.

compressor.

Install new compressor in unit. Braze suction

10.

and discharge lines to compressor piping stubs

(at points where cut, step 5) using field-supplied

copper couplings. Ensure compressor hold

down bolts are in place. Connect wiring.

COOU^NS

PiSTON

fLARS

NUT

S,TBA!Ï£B -,

RETAiiÆR

\ ^

COOLfNS

TO:

COTOOOR

cote

NOTE P«ton sizes are tabuteîed on unit access par.ef. Saainefs are îocateci >n iKjciti tine on eecti side ot AccuRater

Relative poS't'on of coccpor^er.ts is critical for ccrect operet.or.

RUeSERO-RlNG

Fig. 23 — AccuRater^^ (Dual-Piston) Components

Plow

COOUfiS PiSTON

STAii«PEDAf?i?OWOK

CCOPUING SOOr

(TCWAROiNDOOR COfU

12

HEATiwe

PLOW

PJSTO«

RUЭДeЯO'Rl^4й

STRAiNER

RETAINER

TO

■«DOOR

PCARE

NUT

Page 13

11. Clean system. Add new suction line filter-drier

as described below.

NOTE: If a compressor failure was caused by

motor winding burnout, the by-products of the

burnout must be separated from the circulating

refrigerant. This must be done before the by

products enter the reversing valve or accumu

lator and render parts inoperative. Burnout by

products can cause future system operating

problems if left in the system.

Clean the system by installing a suction line

drier in the refrigerant line where the suction gas

enters the reversing valve. During the cooling

cycle, this is the line from the indoor coil run

ning across the top of compressor compart

ment; during heating cycle, install drier in line

between outdoor coil and reversing valve. If

possible, run unit in cooling mode when clean

ing system as installation of temporary suction

drier is simplified.

For drier installation during heating cycle, cut

vertical line below reversing valve to install

fittings and tubing as suction drier must be

placed outside of cabinet. Fabricate and install a

temporary access panel to provide protection

against entry and possible electric shock hazard.

-> To provide protection for the reversing valve,

do not place filter-drier between reversing valve

and accumulator. Since the suction drier works

on one mode only, temporarily wire the unit in

the selected mode (heating or cooling, based on

suction drier location). To insure cooling opera

tion only, install a jumper between terminals

“R” and “O” on the low voltage terminal board.

For heating operation only, remove and insulate

one of the reversing valve solenoid leads. Run

unit for 48 hours and check oil for acidity. If

satisfactory, remove suction line drier. Refer to

and follow procedure under AccuRater™ Ser

vicing for cleaning of AccuRater. Rewire unit

to normal condition.

12. Triple-evacuate and recharge unit. See Refrig

erant Charging.

Filter-Drier — Install an accessory 50YQ900001

reversible, liquid line filter-drier assembly. Remove

dual piston AccuRater — save pistons. Cut 11 in.

from liquid line. Install flare nut on new end of line

and flare line. Install new strainers from accessory

package. Following the instructions in accessory

package, install filter-drier package components.

NOTE; Follow instructions carefully as AccuRater

piston locations are reversed from those shown

when a filter-drier is not used. On model 50YQ060,

install filter-drier and AccuRater in a vertical

position.

Lubrication

COMPRESSOR contains factory oil charge. Re

place oil when lost. See Table 5 for oil recharge. If

necessary, refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants, page 1-21,

for oil recharging procedure. Use Carrier PP33-1,

Texaco Capella B or Suniso 3G oil.

■ FAN MOTOR BEARINGS are prelubricated for 3

years heavy duty or 5 years normal duty. If oiling

holes are provided at each end of fan motor, remove

fan motor and lubricate motor with 32 drops (16

drops per hole) of SAE 10 nondetergent oil at

intervals described below;

a. Annually, when environment is very dirty,

ambient temperature is higher than 105 F and

average unit operating time exceeds 15 hours

a day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F and

unit operating time averages 8 to 15 hours a day.

c. Every 5 years when environment is clean,

ambient temperature is less than 105 F and

unit operating time averages less than 8 hours

a day.

Indoor Coil

CAiniOJ?' Before petjibri33S(ng;

marntmance».

isr tamed

TOP COVER

INDOOR COIL

Fig. 24 — Fan, Top Cover, Coil Details

Lift or remove unit top cover for access to indoor

coil. See Fig. 24. Inspect coil periodically. Clean as

described under Outdoor Coil below.

Condensate Drain — Clean condensate drain trap

with bottle brush; then flush condensate pan be

neath indoor coil with clean water. Ensure water

flows freely thru condensate drain.

^Indoor Fan Assembly (Fig. 25) — Fan wheel

should be centered in fan housing. To adjust fan,

remove as follows;

1. Disconnect motor wires.

2. Remove sheet metal screws holding assembly in

place.

3. Slide entire fan assembly out of unit.

4. Loosen setscrew securing wheel to motor shaft.

5. Adjust wheel and tighten setscrew.

Page 14

6. Reassemble in reverse order.

To clean fan wheel and housing, use a brush,

warm water and detergent. Do not splash water on

motor.

to-outside the unit or top to bottom between rows of

tubing. For 2-row coils, separate rows by removing

screws at hairpin end. Do not strain connections.

Spread coils slightly to wash between rows. Replace

screws after cleaning. Flush dirt from basepan by

spraying water thru top of unit. Avoid splashing

mud on coil or water on the fan motor and electrical

control box.

Outdoor Air Fan — Fan position is shown in Fig.

26. Adjust fan by loosening setscrews and moving

blades up or down. To remove outdoor air fan and

motor: remove screws holding discharge grille in

place. Disconnect fan motor leads from controllers

and capacitor. Lift complete fan, motor, and orifice

assembly (Fig. 24) out of unit. After replacing fan

motor assembly, reconnect fan motor leads.

Fig. 25 — Indoor Fan Assembly Removal

Outdoor Coil — Lift or remove top cover for access

to outdoor coil. See Fig. 24. Inspect coil periodically.

Clean coil with water at the beginning of every cool

ing season or more often if required. Use ordinary

garden hose at a pressure high enough to clean effi

ciently. For best results, spray coil fins from inside-

Fig. 26 — Outdoor Air Fan Adjustment

Return Air Filter (Field Supplied) — Replace

throwaway filter 4 times a year. Clean permanent-

type filter a minimum of 4 times yearly. Flush per

manent filter with hot water, steam or soak in mild

solution of soap or detergent and water. Allow

filters to dry and replace. Refer to filter manufac

turer’s instructions, as required, for other types of

filters.

184

14

Page 15

V

TROUBLESHOOTING CHART — COOLING CYCLE

Page 16

UJ

_l

O

>

o

o

z

1-

<

liJ

X

QC

<

X

o

O

z

I-

o

o

X

(/)

LU

_l

CQ

D

O

X

I-

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a

5a

Form 50YQ-3SI Supersedes 50YQ-1 SI

Printed in U S A 184

5-79 PC 101 Catalog No 535-064

Loading...

Loading...