Carrier 50JX042300, 50JX036300, 50JX024300, 50JS042300, 50JS030300 Installation Guide

...

HEA_ & COOLiING

Visit www.carfier.com

50JS, 50JX

Single-Packaged Heat Pump Units

Installation, Start-Up,

and Service Instructions

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS ..................................................... 1

INTRODUCTION .......................................................................... 2

RECEIVING AND INSTALLATION .......................................... 2

Cheek Equipment ...................................................................... 2

IDENTIFY UNIT ................................................................ 2

INSPECT SHIPMENT ........................................................ 2

Provide Unit Support ................................................................ 2

ROOF CURB ....................................................................... 2

SLAB MOUNT ................................................................... 2

GROUND MOUNT ............................................................ 2

Provide Clearances .................................................................... 2

Rig and Place Unit .................................................................... 2

INSPECTION ...................................................................... 2

INSTALLATION ................................................................ 2

Select and Install Ductwork ..................................................... 4

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (VERTICAL) DISCHARGE UNITS ......... 5

Provide for Condensate Disposal ............................................. 6

Install Electrical Connections ................................................... 7

HIGH-VOLTAGE CONNECTIONS ................................ 10

ROUTING POWER LEADS INTO UNIT ...................... l0

CONNECTING GROUND LEAD TO GROUND LUG.10

ROUTING CONTROL POWER WIRES (24-V) ............ 13

SPECIAL PROCEDURES FOR 208-V OPERATION ...15

PRE-START-UP .......................................................................... 17

START-UP ................................................................................... 17

Check for Refrigerant Leaks .................................................. 17

Start-Up Adjustments .............................................................. 17

CHECKING COOLING AND HEATING

CONTROL OPERATION ................................................. 17

CHECKING AND ADJUSTING REFRIGERANT

CHARGE ........................................................................... 18

REFRIGERANT CHARGE .............................................. 18

NO CHARGE .................................................................... 18

LOW CHARGE COOLING ............................................. 19

TO USE COOLING CHARGING CHARTS .................. 19

INDOOR AIRFLOW AND AIRFLOW ADJUST-

MENTS .............................................................................. 19

MAINTENANCE ......................................................................... 20

Air Filter. ................................................................................. 21

Indoor blower and motor ........................................................ 21

OUTDOOR COIL, INDOOR COIL, AND

CONDENSATE DRAIN PAN .............................................. .22

Outdoor fan ............................................................................. 23

Electrical controls and wiring ................................................ 23

Refrigerant circuit ................................................................... 24

Indoor airflow ......................................................................... 25

Metering device ...................................................................... 25

Liquid line strainers ................................................................ 25

High Flow Valves ................................................................... 25

Time-delay relay ..................................................................... 25

Loss of charge switch ............................................................. 25

Check defrost thermostat ........................................................ 25

Defrost Thermostat ................................................................ _25

TROUBLESHOOTING .............................................................. .25

START-UP CHECKLIST ............................................................ 25

NOTE TO INSTALLER -- READ THESE INSTRUCTIONS

CAREFULLY AND COMPLETELY before installing this unit.

Also, make sure the Owner's Manual and Service Instnu:tions are

leR with the unit after installation.

C99001

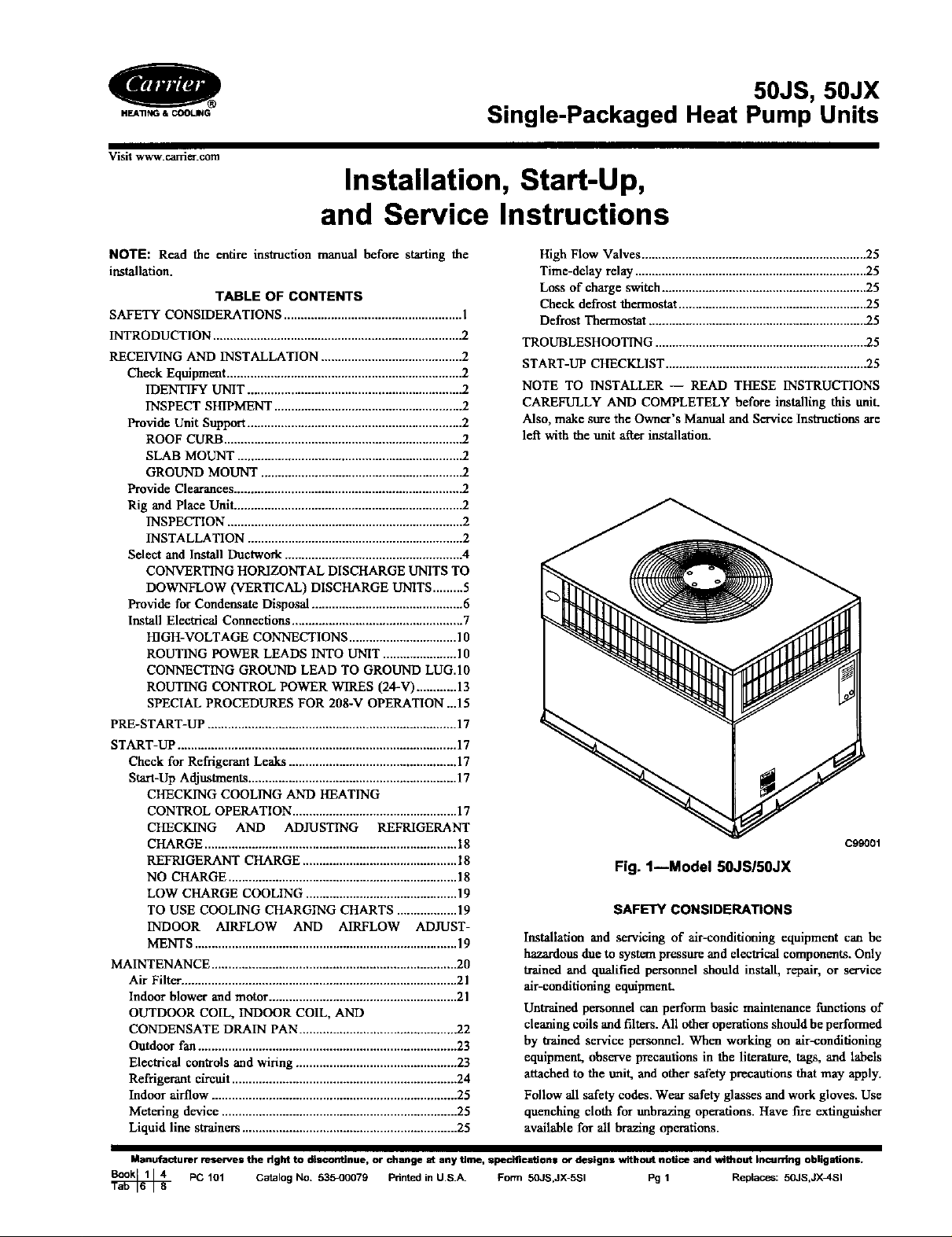

Fig. 1--Model 50JS/50JX

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipmenL

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbra_ng operations. Have fire extinguisher

available for all brazing operations.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

PC 10t CaLalog No. 5354)0079 Pdn_d in U.S.A_ Form 50JS,JX-SSI Pg 1 Replaces: 50JS,JX_SI

Improper installation, adjustment, altoration, service, mainte-

nance, or use can cause explosion, tire, electric shock, or

other occurrences, winch could cause serious injury or death

or damage your property. Consult a qualified installer or

service agency for information or assistance. The qualified

installer or agency must use only factory-authorized kits or

accessories when modifying this product.

Recognize safety information. This is the safety-alert symbolz_ x .

When you see this symbol on the product or in instructions or

manuals, be alert to the potential for personal inju_.

Understand the signal words -- DANGER, WARNING, CAU-

TION, and NOTE. Danger identifies the most serious hazards,

which will result in severe personal injury or death. Warning

indicates a condition that eolld cause serious personal injury or

death. Caution is used to identify unsafe practices, which would

result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

1. The power supply (volts, phase, and hertz) must correspond to

that specified on unit rating plato.

2. The electrical supply provided by the utility mnst be sufl']cient

to handle load imposed by this unit.

3. Tins installation must conform with local building codes and

with NEC (National Electrical Code). Refer to provincial and

hieal plumbing or wasto water codes and other applicable local

codes.

m kVl=5_1_ff[_

Before performing service or maintenance operations on

system, turn off main power to unit. Turn off accessory heater

power switch if applicable. Electrical shock could cause

severe injury or death.

INTRODUCTION

The 50JS and 50JX heat pumps are fully self-contained and

designed for outdoor installation (See Fig. I). Standard units are

shipped in a horizontal-discharge configuration for installation on

a ground-level slab. Units can be converted to downflow (vertical)

discharge configurations for rooftop applications.

RECEIVING AND INSTALLATION

Step l_heck Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on the unit

identification plate. Check this information against shipping pa-

pers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping pallet.

If unit appears to be damaged or is torn loose from its anchorage,

have it examined by transportation inspectors before removal.

Forward claim papers directly to transportation company. Manu-

facturer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest Cartier Air Conditioning office if any item is missing. To

prevent loss or damage, leave all parts in original packages until

installation.

Step 2---Provide Unit Support

ROOP CURB

Install accessory roof curb in accordance with instructions shipped

with curb (See Fig. 5). Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORTANT: The gaskcting of the unit to the roof curb is critical

for a watertight seal. Install gasketing material supplied with the

ronf curb. Improperly applied gaskcting also can result in air leaks

and poor unit performance.

Curb should be level to within 1/4 in. (See Fig. 6). This is

necessary for unit drain to function properly. Refer to accessory

roof curb installation instructions for additional information as

required.

SLAB MOUNT

Place the unit on a solid level concrete pad that is a minimum of

4 in. thick with 2 in. above grade (See Fig. 7). The slab should

extend approximately 2 in. beyond the casing on all 4 sides of the

unit. Do not secure the unit to the slab except when required by

local codes.

GROUND MOUNT

The unit may be installed either on a slab or placed directly on the

ground if local codes permit. Place the unit on level ground

prepared with gravel for condensate discharge.

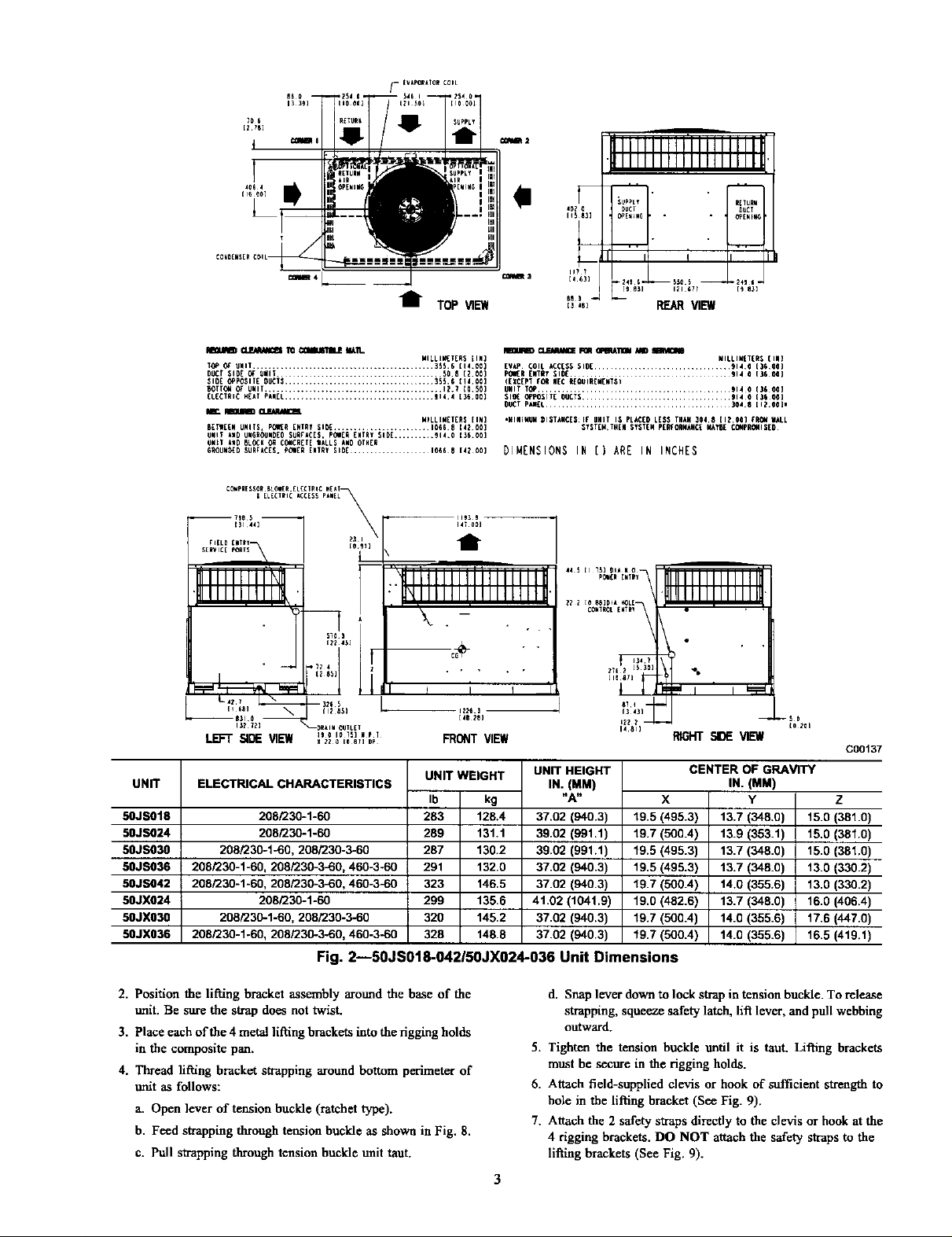

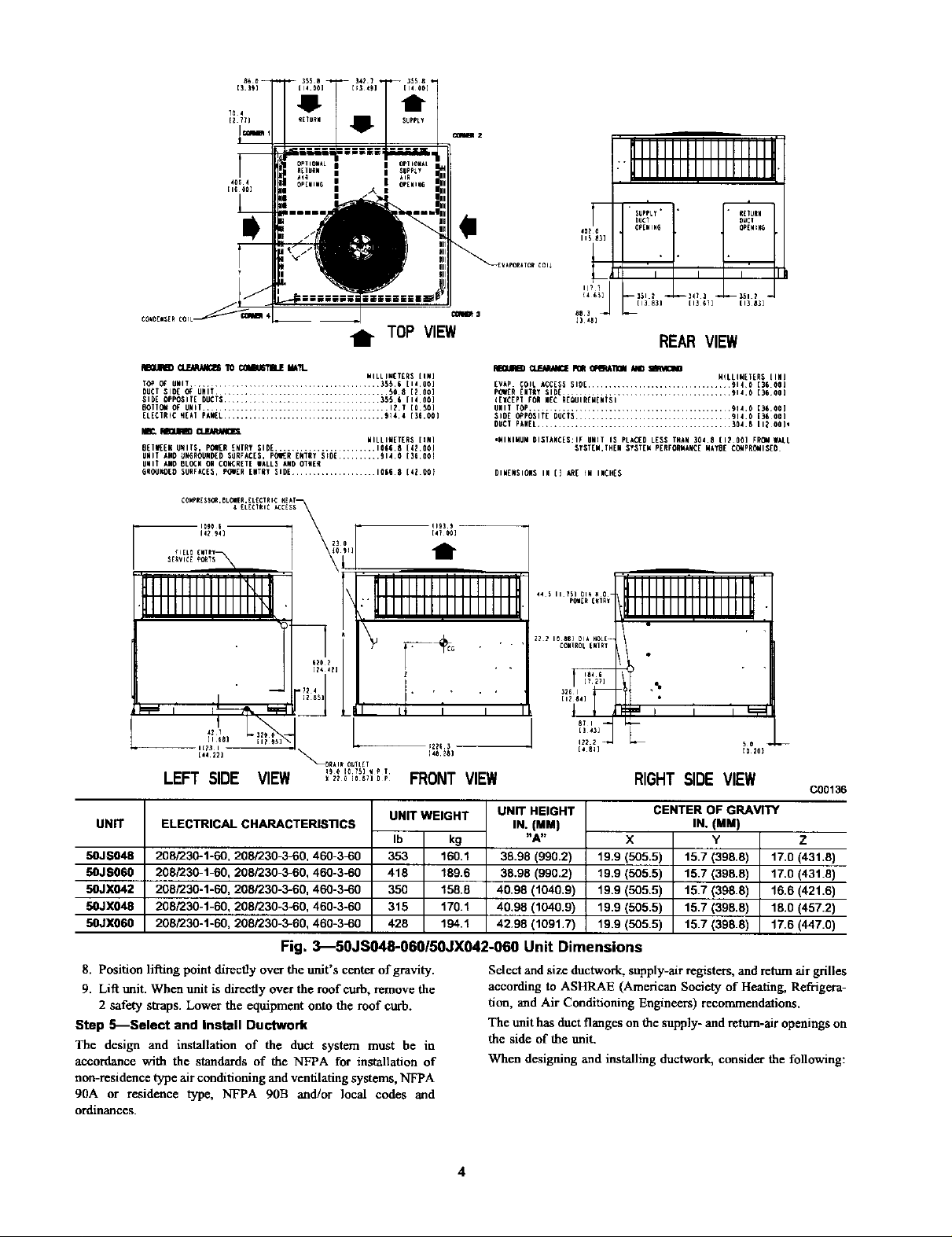

Step 3_Provide Clearances

The required minimum service clearances are shown in Figs. 2 and

3. Adequate ventilation and outdoor air must be provided. The

outdoor fan draws air through the outdoor coil and discharges it

through the top fan grille. Be sure that the fan discharge does not

recirculato to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is 36

in. above the unit top. The maximum horizontal extension of a

partial overhang must not exceed 48 in. For extended overhangs,

provide a minimum clearance of 48 in.

IMPORTANT: Do not restrict outdoor airflow. An air restriction

at either the outdoor-air inlet or the fan discharge may be

detrimental to compressor life.

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. Slab-mountod units

should be at least 4 in. above the highest expected wator and nmoff

levels. Do not use unit if it has been under water.

Step 4-_Rig and Place Unit

Rigging and handling of this equipment can be hazardous for many

reasons due to the installation location (roofs, elevated stmctures_

etc.)

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Follow all applicable safety codes. Wear safety shoes and work

gloves.

INSPECTION

Prior to initial use, and at monthly intervals, all rigging brackets

and straps should be visually inspected for any damage, evidence

of wear, structural deformation, or cracks. Particular attention

should be paid to excessive wear at hoist hooking points and load

support areas. Brackets or straps showing any kind of wear in these

areas must not be used and should be discarded.

INSTALLATION

1. Remove unit from shipping carton. Leave top shipping skid on

the unit as a spreader bar to prevent the rigging straps from

damaging the unit. If the wood skid is not available, use a

spreader bar of sufficient length to protect unit from damage.

,,,,,,,,,,

BIIIIIIIII lilllil

_" TOP VIEW

U (12.qk_iCS llD m MAll.

TOP _ UNIT ............................................. 355.5 114.0©]

DUCT Sip[ _ UNll ...................................... 50_ (20€)

SIDE _'PO$1T[ OUSTS ..................................... )5_.5 114 0_)

_TT_I OF UNIT ........................................ 1_.7 (0.50)

[L(CTRIC HEAT PAH[L ..................................... tl44 [)500)

i_ _ Ct.F.AJiJaEl_

B[TWE[N UNITS, POId_ ENTRy SI_ ............... 1066 $ 142 00]

UNiT kid UNGNOUND[OSURFACES, pOllER [HTRY _1[*[ .......... gl4.0 (35.001

IIN_I AND BLOCK OH C_ICRET[ _kLLS ANO OTHER

GNOUN_D SURIA_[S, _ONER [HTRT SIb[ ........... 1066 $ [4_ 00]

MILLI_T[R$ [IN)

MILLIMETERS tINT

402 _UCT _uCl

_PPLI

i I

sa )

t3,B_ REAR VIEW

_ CI BII_M_CE _OR oqmAllm MK) _

[VkP COIL ACCESS SIDE ................................ 9140 (3600)

PIeR ENTR? SlOE ................................ 914 _ (36 00]

([X¢[P1 F_ HE€ II{OUIItEME#TSI

UNIT l_ ............................................... 914 0 (35 0_]

$10( O_I_SIT[ OUCT$.............................. 914¸0 (_5 0_)

OUI_T PANEL.............................................. )04¸8 [12.00)1

*MINIMUM _ISTANC[S:IF UNIT IS PLAC[O L[$$ THAN 304.8 [IZ.O4) _RO_ WALL

_TSTEW,TH[H S_ST_II PERFORNkNCE NATBE C_PRI'IIIS[D

MILLIM[TERS tIN)

DIMENSIONS IN [) ARE IN INCHES

II1!111III II I IIIli

l,l llllllll+

UNIT

ELECTRICAL CHARACTERISTICS IN. (MM)

UNIT WEIGHT UNIT HEIGHT

Ib kg "A"

50JS018

50JS024

5OJS03O

50JS036

50JS042

50JX024

5OJX030

50JXO36

208/230-1-60, 208/230-3-60, 460-3-60 291 132.0 37.02 (940.3)

208/230-1-60, 208/230-3-60, 460-3_0 323 146.5 37.02 (940.3)

208/230-1-60, 208/230-3-60, 460-3-60 328 148.8 37.02 (940.3)

208/230-1-60 283 128.4 37.02 (940.3)

208/230-1-60 289 131.1 39.02 (991.1)

208/230-1-60, 208/230-3-60 287 130.2 39.02 (991.1)

208/230-1-60 299 135.6 41.02 (1041.9)

208/230-1-60, 208/230-3-60 320 145.2 37.02 (940.3)

Fig. 2--50JS018-042150JX024-036 Unit Dimensions

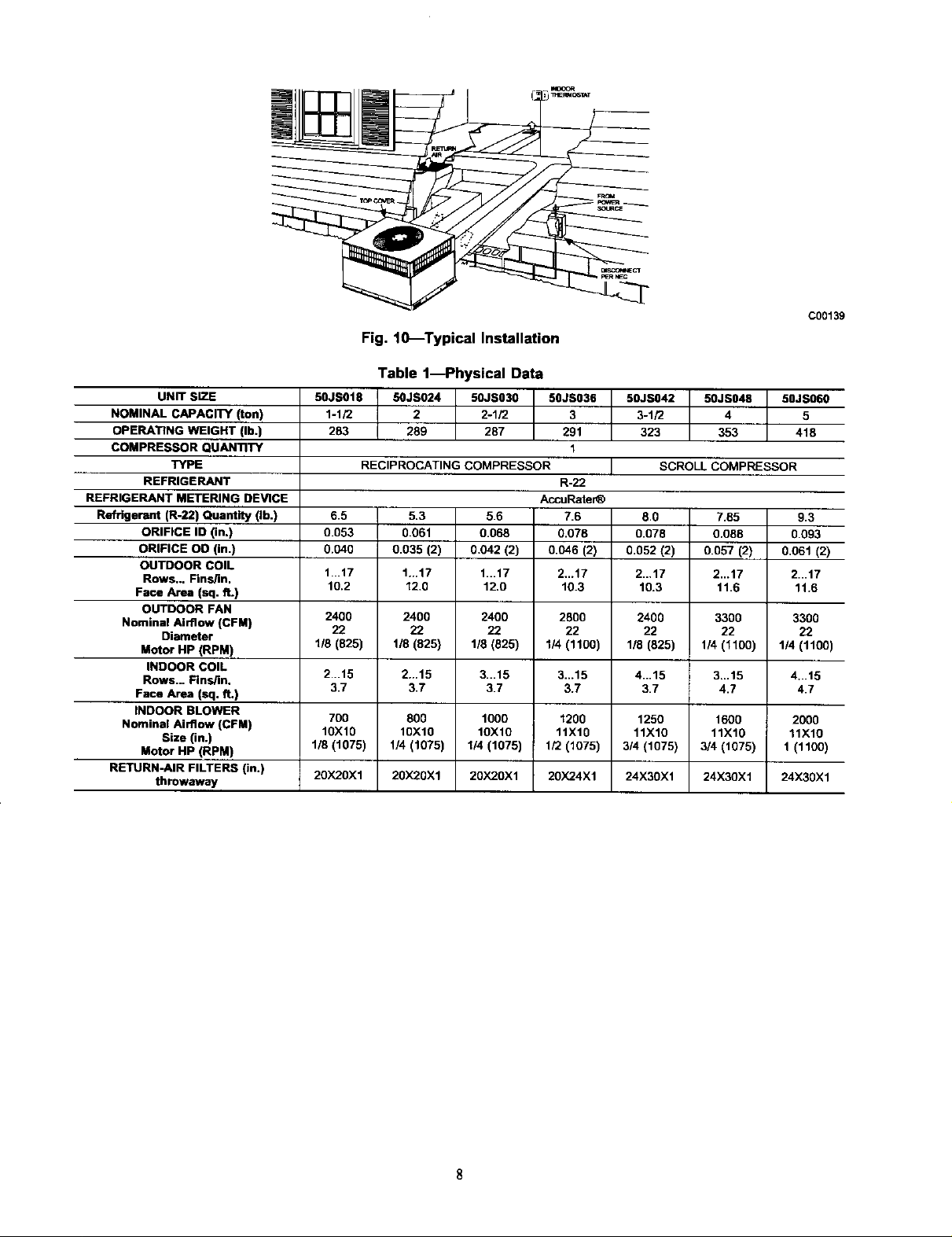

2. Position the lifting bracket assembly around the base of the

unit. Be sure the strap does not twist.

3. Place each of the 4 metal lilting brackets into the rigging holds

in the composite pan.

4. Thread lifting bracket strapping around bottom perimeter of

unit as follows:

a. Open lever of tension buckle (ratchet type).

b. Feed strapping through tension buckle as shown in Fig. 8.

c. Pull strapping through tension buckle unit taut.

L'? ,=

13 43)

RIGHT gDE VIEW

CENTER OF GRAVITY

X

19.5 (495.3)

19.7 (500.4)

19.8 (495.3)

19.5 (495.3)

19.7 (500.4)

19.0 (482.6)

19.7 (500.4)

19.7 (500.4)

d. Snap lever down to lock strap in tension buckle. To release

sWapping, squeeze safety latch, lift lever, and pull webbing

outward.

5. Tighten the tension buckle until it is taut. LiRing brackets

must be secure in the rigging holds.

6. Attach field-supplied clevis or hook of sufficient strength to

hole in the lifting bracket (See Fig. 9).

7. Attach the 2 safety sWaps directly to the clevis or hook at the

4 rigging brackets. DO NOT attach the safety straps to the

lifting brackets (See Fig. 9).

----se

IN. (MM)

Y

13.7 (348.0)

13.9 (353.1)

13.7 (348.0)

13.7 (348.0)

14.0 (355.6)

13.7 (348.0)

14.0 (355.6)

14.0 (355.6)

(0201

C00137

Z

15.o (381.o)

15.0 (381.o)

15.0 (381.0)

13.0 (330.2)

13.o (330.2)

16.0 (406.4)

17.6 (447.0)

16.5 (419.1)

Illlllll IIIllllll

Illlllll IIIllllll

SUppLy * * . R[IORN

_Q? 0P_MR_

DUCT _UCl

t TOP VIEW

U CLF._qidl{I TO COIU_TI.E II_TL

TI_O OF UNIT ......................................... 355.6 [1400]

DUCT SlOE O_ UNIT ................................ 50._ [?00]

SlOE OPPOSITE DUCTS ........................ 355G 114UO]

flOlT_OF UNIT ............................................ I?.T [0_0]

[L[¢IRP¢ HEAl PANEL ...................................... 91_.4 [31.00}

lmm

E[lI[[ll UNITS, POMER £gTRY Sit)[ ........................ 10_6.8 [42 001

UNIT A#O UNGROUIIpED SURFACES, POB_R ENTRY $rDE .......... 91l. G [36001

UIIIT lllO BLOCIKOB COHCRET[ IALLS AND OTHER

NILLIMEIER$ [IN]

MILLIMETERS [iNI

i' 'd l "i' '

AI

LEFT SIDE VIEW ,. ..... ,_, FRONT VIEW

UNiT

50JS048

50JSO60

60JX042

50JX048

50dXO6O

ELECTRICAL CHARACTERISllCS IN. (MM)

208/230-1-60, 208/230-3-60, 460-3_0 353 160.1 38.98 (990.2)

208/230-1-60, 208/230-3-60, 460-3-60 418 189.6 38.98 (990.2)

208/230-1-60, 208/230-3-60, 460-3_0 350 158.8 40.98 (1040.9)

208/230-1-60, 208/230-3-60, 460-3-60 315 170.1 40.98 (1040.9)

208/230-1-60, 208/230-3-60, 460-3-60 428 194.1 42.98 (1091.7)

UNiT WEIGHT UNiT HEIGHT

Ib kg "A"

Fig. 3_50JS048-060/50JX042-060 Unit Dimensions

8. Position lifting point directly over the unit's center of gravity.

9. Lift unit. When unit is directly over the roof curb, remove the

2 safety straps. Lower the equipment onto the roof curb.

Step S--Select and install Ductwork

The design and installation of the duct system must bc in

accordance with the standards of the NFPA for installation of

non-residence type air conditioning and ventilating systems, NFPA

90A or residence type, NFPA 90B and/or local codes and

ordinances.

ii ?

I I

i

i

REAR VIEW

[VkP COIL k¢C[$5 SIO[ .................................. _140 [36 00]

([_¢EPI fOR N[_ REOUIREME#TSI

UMII TOP ............................................... _14.0 [_00]

$I0[ _POSIT[ pUCTS ..................................... 914.0 [_00]

0_I FkW[L ............................................ 304.8 II_ O0}g

tMINIMUM DI$1ANC[S:IF UNIT IS PLACED LESS THAN 3048 {12 00] FR_f4WALL

DIMENSIOKS IN [I ARE IN li_.H[$

SrSTEM.TH[ISYSTENP[RFORNA#CEMNYflE_OIORO_II$[O

44 511 T_I01_XO-

P_[R [_TRY

_ONIROL {MI_

•

8T I

RIGHT SIDE VIEW

CENTER OF GRAVITY

X

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

19.9 (505.5)

Select and size ductwork, supply-air registers, and return air grilles

according to ASHRAE (American Society of Heating, Refrigera-

tion, mad Air Conditioning Engineers) recommendations.

The unit has duct flanges on the supply- and return-air openings on

the side of the unit.

When designing and installing ductwork, consider the following:

M_LLIMEIER$ [IN]

C00136

IN. (MM)

Y Z

15.7 (398.8) 17.0 (431.8)

15.7 (398.8) 17.0 (431.8)

15.7 (398.8) 16.6 (421.6)

15.7 (396.6) 18.0 (457.2)

15.7 (398.8) 17.6 (447.0)

1 2

Y

CORNER WEIGHTS (SMALL CABINET)

o_

o

q)

"o

o

X

Unit 18 24 30 36 42

Comer Weight 1 2683 2689 26867 269; 3823

Comer Weight 2 53 56 54 55 55

Total Weight 103 104 105 106 107

Comer Weight 3 61 62 62 63 78

Comer Weight 4

Cnmer WRiaht 1 R:_ 63 64 -- --

Comer Weight 2 62 74 76 -- --

Comer Weight 3 56 56 58 -- --

Comer Weight 4 118 127 130 -- --

CORNER V_EIGHTS tSmall C_hinet'=

Unit 24 .30 RR -- --

Total WP-iaht 2_1_1 :_gN 32g -- --

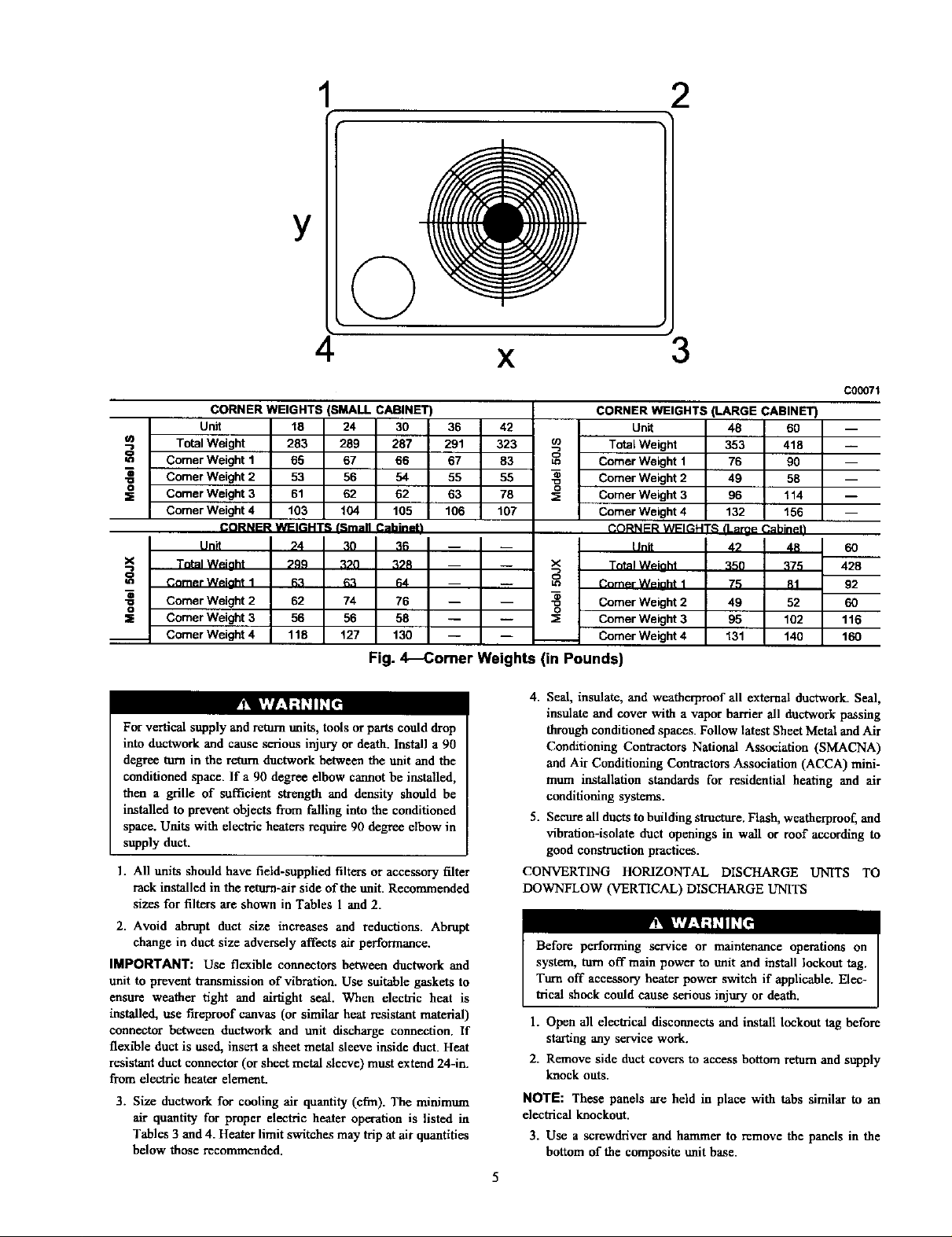

Fig. 4---Comer Weights (in Pounds)

For vertical supply and rentrn units, tools or parts could drop

into ductwork and cause serious injury or death. Install a 90

degree turn in the return ductwork between the unit and the

conditioned space. If a 90 degree elbow cannot be installed,

then a grille of sufficient strength and density should be

installed to prevent objects from falling into the conditioned

space. Units with electric heaters require 90 degree elbow in

supply duct.

l. All units should have fiald-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recommended

sizes for filters are shown in Tables 1 and 2.

2. Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between duetwork and unit discharge cormeetion. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The minimm'n

air quantity for proper electric heater operation is listed in

Tables 3 and 4. Heater limit switches may trip at air quantities

below those recommended.

X

CORNER WEIGHTS (LARGE CABINET)

Comer Weight 1

i Unit 48 60 --

Comer Weight 2 49 58 --

(n Total Weight 132 156 --

Comer Weight 3 96 114 --

Comer Weight 4

CORNER WFIGHTR (Lnme CabJnet_

X TntnlW_inht 350 R75 428

[ _ _'mm"r WRinht 1 75 81 92

Comer Weight 3 95 102 116

_ Comer Weight 2 49 52 60

Comer Weight 4 131 140 160

4. Seal, insulate, and weatherproof all external ductwork. Seal,

insulate and cover with a vapor barrier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and Air

Conditioning Contractors National Association (SMACNA)

and Air Conditioning Contractors Association (ACCA) mini-

mum installation standards for residential heating and air

conditioning systems.

5. Secure all ducts to building structure. Flash, weatherproof, and

va'bration-isolate duct openings in wall or roof according to

good construction practices.

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (VERTICAL) DISCHARGE UNITS

Before performing service or maintenance operations on

systera, turn off main power to unit and install lockout tag.

Turn off accessory heater power switch if applicable. Elec-

tahcalshock could cause serious injury or death.

1. Open all electrical disconnects and install lockout tag before

starting any service work.

2. Remove side duct covers to access bottom return and supply

knock outs.

NOTE: These panels are held in place with tabs similar to an

electrical knockout.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the composite unit base.

3

IJnit 42 4_ 60

C0007t

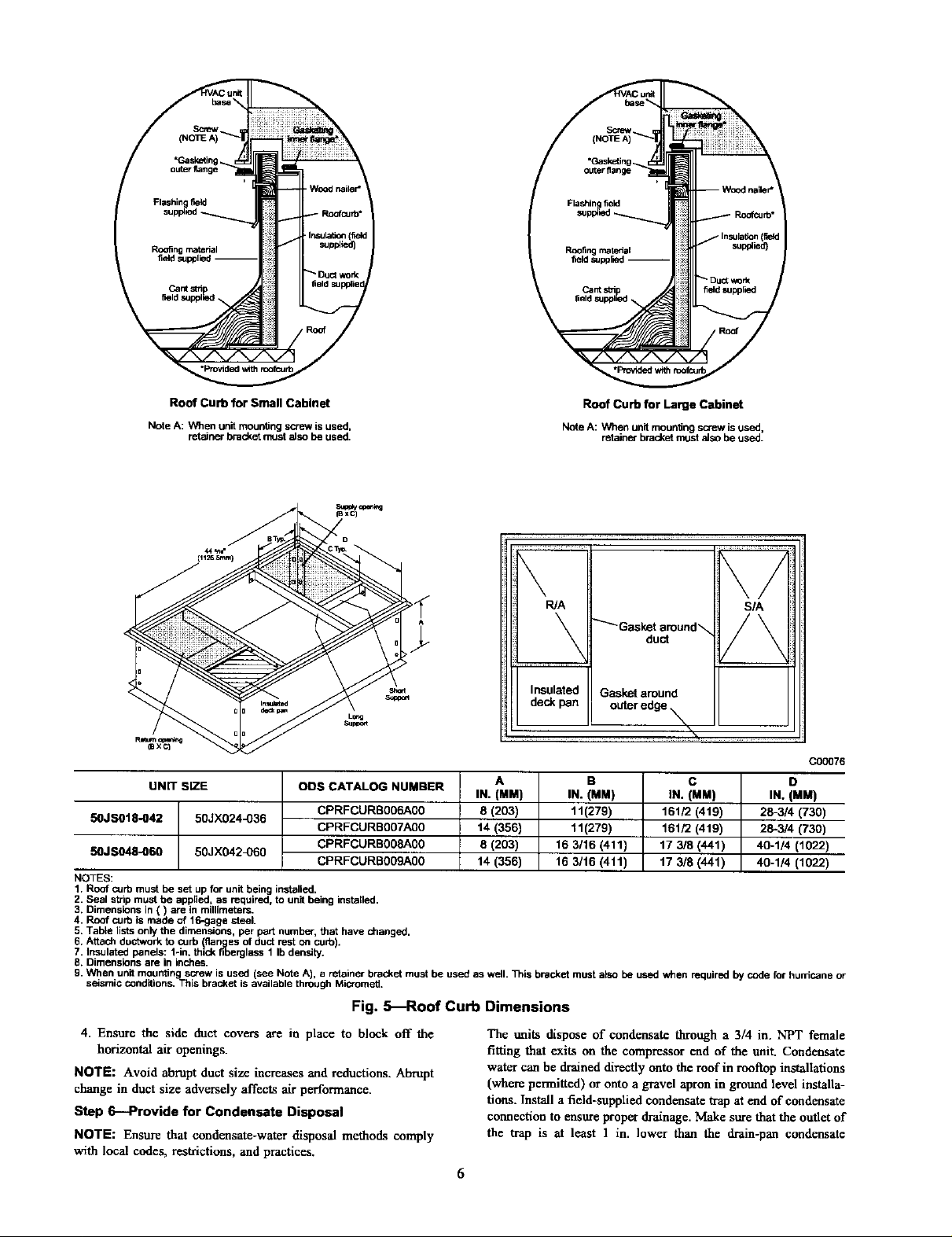

Roof Curb for Small Cabinet

Note A: When unit mounting screw is used,

retather brad(at must also be used.

Roof Curb for Large Cabinet

Note A: When unit mounting screw is used,

rstaine¢bracket must also be used.

\

R/A

""_ Gasket around\

\

Insulated Gasket around

deck pan outer edge _

(BXC)

UNIT SIZE

50JS018-042 50JX024_36

50JS048-060 50JX042_60

NOTES:

1. Roof curb must be sat up for unit being installed.

2. Seal strip must be applied, as required, to unit being insatlled.

3. Dimensions in ( ) are in millimeters.

4. Roof curb is made of 16-gage steel.

5. Table lists only the dimensions, per part number, that have changed.

6. Attach dustwork to curb (flanges of dust rest on curb).

7. Insulated panels: 1-in. thick fiberglass 1 Ib density.

8. Dimensions are in inches.

9. When unit mounting screw is used (see Note A), a retainer brachat must be used as well. This bracket must also be used when required by code for hun_cane or

seismic conditions. This bracket is available through Mic_omatL

ODS CATALOG NUMBER

CPRFCURB006A00

CPRFCURB007A00

CPRFCURB008AO0

CPRFCURBOO9AO0

A

IN. (MM)

8 (203)

14 (356)

8 (203)

14 (356)

B

IN. (MM)

11(279)

11(279)

16 3/16 (411)

16 3/16 (411)

duct

IN. (MM)

161/2 (419)

161/2 (419)

17 3/8 (441)

17 3/8 (441)

\/

S/A

/\

C00076

C

D

IN. (MM)

28-3/4 (730)

28-3/4 (730)

40-1/4 (1022)

40-1/4 (1022)

Fig. 5--Roof Curb Dimensions

4. Ensure the side duct covers are in place to block off the

horizontal air openings.

NOTE: Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

Step 6--Provide for Condensate Disposal

NOTE: Ensure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

The units dispose of condensate through a 3/4 in. NPT female

fitting that exits on the compressor end of the unit. Condensate

water can be drained directly onto the roof in rooftop installations

(where permitted) or onto a gravel apron in ground level installa-

tions. Install a field-supplied condensate trap at end of condensate

connection to ensure proper drainage. Make sure that the outlet of

the trap is at least 1 in. lower than the drain-pan condensate

6

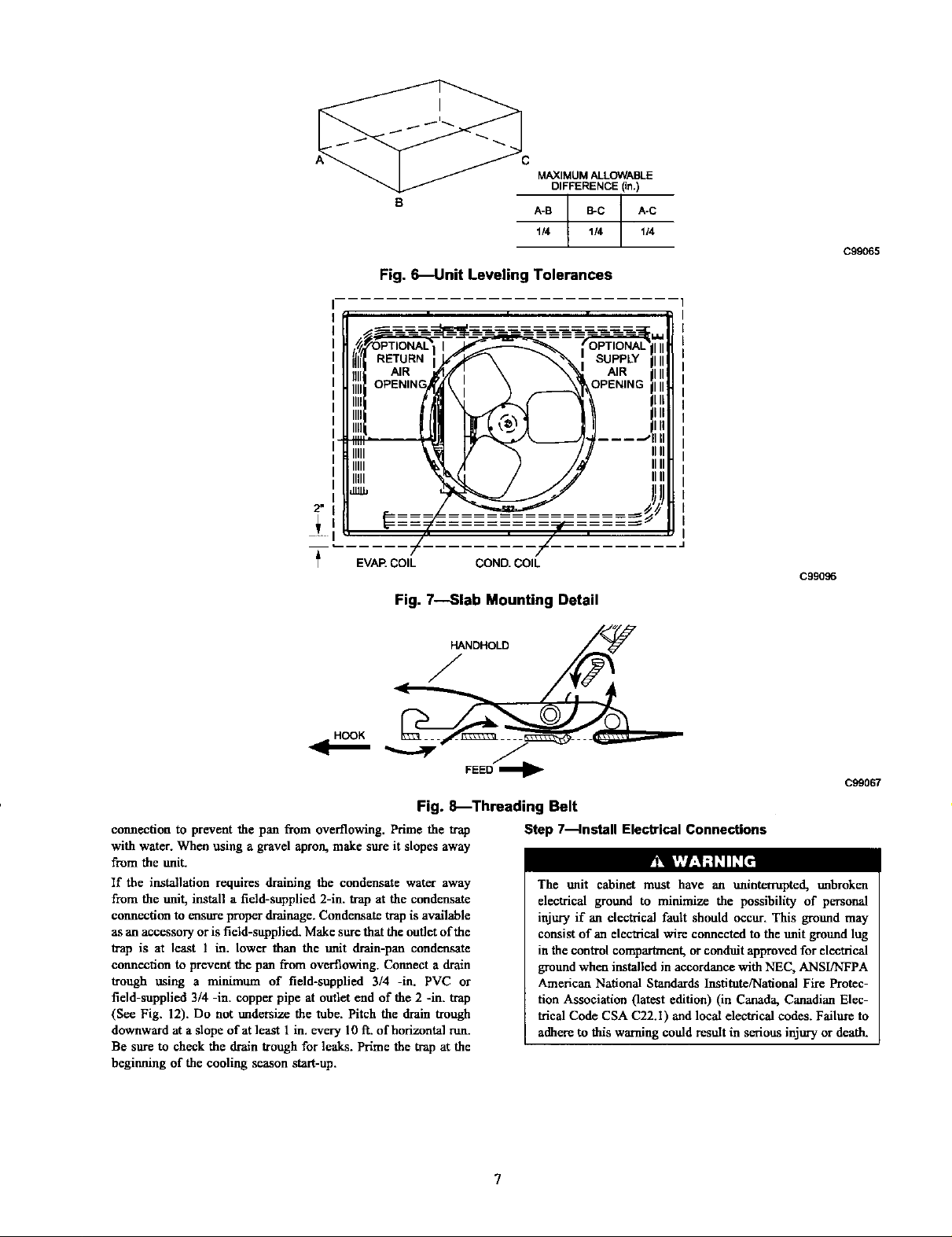

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

t/4 1/4 t/4

Fig. 6--Unit Leveling Tolerances

| i |

[I RETURN Iz_-_-''_x _ _ = SUPPLY I II

II I

IllAi R _//_, \ _1 AiR III

iiiilOPENINGfl It i, _ ._-_-._1_ OPENING i111

lllli .# I _ _ (" _i _ II II

IIIll |l I l_r//'_,'_ | II IIII

III1 I L_IIt t}, j i !1 II il

lllll \ 71 V _ II IIII

I

IIIII _ _k ,4" ) /z_ II II

lllll _._._I / /j IIII

I

,ll,l,, JJJJ

2.[

#

EVAR COIL COND. COIL

Fig. 7--Slab Mounting Detail

C99065

C99096

HANDHOLD

/

Fig. 8_Thraading Belt

connection to prevent the pan from overflowing. Prime the trap

with water. When using a gravel apron, make sure it slopes away

from the unit.

If the installation requires draining the condensate water away

from the unit, install a field-supplied 2-in. trap at the condensate

connection to ensure proper drainage. Condensate trap is available

as an accessory or is field-supplied. Make sure that the outlet of the

trap is at least 1 in. lower than the unit drain-pan condensate

connection to prevent the pan from overflowing. Connect a drain

trough using a minimum of field-supplied 3/4 -in. PVC or

field-supplied 3/4 -in. copper pipe at outlet end of the 2 -in. trap

(See Fig. 12). Do not undersize the tube. Pitch the drain trough

downward at a slope of at least 1 in. every 10 ft. of horizontal run.

Be sure to check the drain trough for leaks, prime the trap at the

beginning of the cooling season start-up.

C99067

Step 7_lnstall Electrical Connections

Ill l"l:.1.111 h'[d

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an dectrical fault should occur. This ground may

consist of an electrical wire connected to the unit ground lug

in the control compartment, or conduit approved for electrical

ground when installed in accordance with NEC, ANSI/NFPA

American National Standards Institute/National Fire Protec-

tion Association (latest edition) (in Canada, Canadian Elec-

trical Code CSA C22.1) and local electrical codes. Failure to

adhere to this warning could result in serious injury or death.

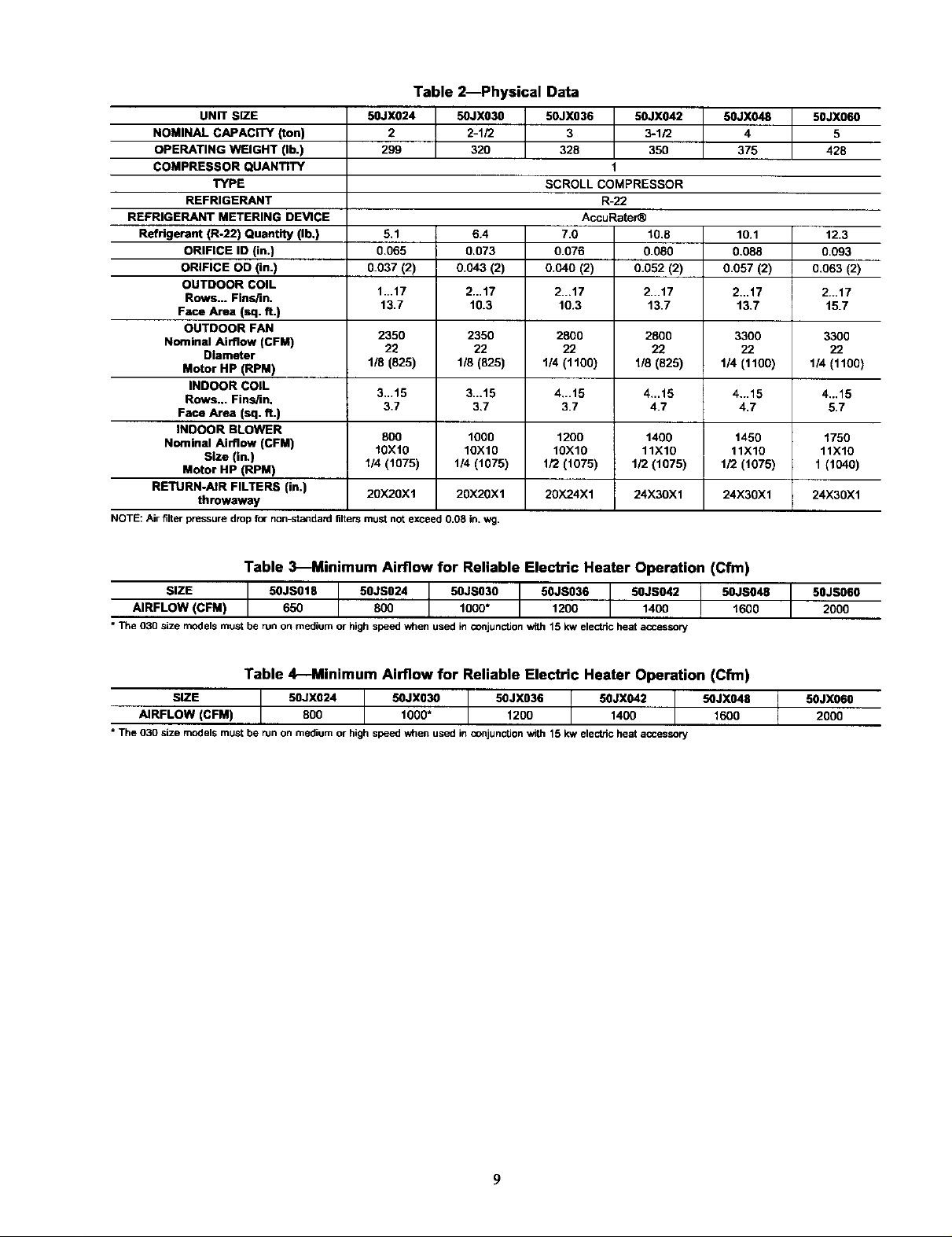

UNIT SIZE

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSOR QUAN'IITY

TYPE

REFRIGERANT

REFRIGERANT METERING DEVICE

Refrigerant (R-22) Quantity (lb.)

ORIFICE ID (in.)

ORIFICE OD (in.)

OUTDOOR COIL

Rows... Fins/in.

Face Area (sq. ft.)

OUTDOOR FAN

Nominal Airflow (CFM)

Diameter

Motor HP (RPM)

INDOOR COIL

Rows... Fins/in.

Face Area (sq. ft.)

INDOOR BLOWER

Nominal Airflow (CFM)

Size (in.)

Motor HP (RPM)

RETURN-AIR FILTERS (in.)

throwaway

Fig. 10_Typical Installation

Table l_hysical Data

50JS018 50JS024 5OJS030 50JS036

1-1_ 2 2-1_ 3

283 289 287 291

1

RECIPROCATING COMPRESSOR

R-22

AccuReter_

6.5

0.053

0.040

1...17

10.2

2400

22

1/8 (825)

2...15

3.7

700

10X10

1/8 (1075)

20X20X1

5.3 5.6 7.6

0.061 0.068 0.078

0.035 (2) 0.042 (2) 0.046 (2)

1...17 1...17 2,..17

12.0 12.0 10.3

2400 2400 2800

22 22 22

1_ (825) 1_ (825) 1_ (1100)

2...15 3...15 3.,.15

3.7 3.7 3.7

800 1000 1200

10X10 10X10 11X10

1_ (1075) 1_ (1075) 1_ (1075)

20X20X1 20X20X1 20X24X1

50JS042 50JS048 50JS06O

3-1_ 4 5

323 353 418

I

SCROLL COMPRESSOR

8.0 7.85 9.3

0.078 0.088 0.093

0.052 (2) 0.057 (2) 0.061 (2)

2...17 2...17 2...17

10.3 11.6 1t.6

2400 3300 3300

22 22 22

118(825) 1/4 (1100) 1/4 (1100)

4...15 3,,,15 4...15

3.7 4.7 4.7

1250 1600 2000

11X10 11X10 11X10

3/4 (1075) 3/4 (1075) 1 (1100)

24X30X1 24X30XI 24X30X1

C00139

Table 2_Physical Data

UNIT SIZE

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSOR QUANTITY

TYPE

REFRIGERANT

REFRIGERANT METERING DEVICE

Refrigerant (R-22) Quantity (lb.)

ORIFICE ID (in.)

ORIFICE OD (in.)

OUTDOOR COIL

Rows... Fins/in.

Face Area (sq. ft.)

OUTDOOR FAN

Nominal Airflow (CFM)

Diameter

Motor HP (RPM)

INDOOR COIL

Rows... Fins/in.

Face Area (sq. R.)

INDOOR BLOWER

Nominal Airflow (CFM)

Size (in.)

Motor HP (RPM)

RETURN-AIR FILTERS (in.)

throwaway

NOTE:Airfilterpressuredropfor non-standardfiltersmustnotexceed0.08in.wg.

50JX024 50JXO30 50JX036 50JX042 50JX048

2 2-1/2 4

299 320 375

5.1 6.4 10.1 12.3

0,065 0.073 0.088 0.093

0.037 (2) 0.043 (2) 0.057 (2) 0,063 (2)

1...17 2.,,17 2,,,17 2...17

13.7 10.3 13.7 15.7

2350 2350 3300 3300

22 22 22 22

1/8 (825) 1/8 (825) 1/4 (1100) 1/4 (1100)

3,..15 3...15 4...15 4..,15

3.7 3.7 4.7 5.7

800 1000 1450 1750

10X10 10X10 11X10 11X10

1/4 (1075) 1/4 (1075) 1/2 (1075) 1 (1040)

20X20XI 20X20X1 24X30X1 24X30X1

3 3=1/2

328 350

1

SCROLL COMPRESSOR

R-22

AccuRater_

7.0 10.8

0.076 0.080

0.040 (2) 0.052 (2)

2...17 2...17

10.3 13.7

2800 2800

22 22

1/4 (1100) 1/8 (825)

4...15 4-.15

3.7 4.7

1200 1400

10X10 11X10

1/2 (1075) 1/2 (1075)

20X24X1 24X30X1

50JX060

5

428

Table 3_Minimum Airflow for Reliable Electric Heater Operation (Cfm)

SIZE 50JS018 50JS024 50JSO30 50JS036 50JS042 50JS048 5OJS060

AIRFLOW (CFM) 650 800 1000" 1200 1400 1600 2000

• The030 sizemodelsmustbe runonmediumor highspeedwhen usedin conjunctionwith15kwelectricheataccessory

Table 4---Minimum Airflow for Reliable Electric Heater Operation (Chn)

SIZE 50JX024 50JXO30 50JX036 50JX042 50JX048

AIRFLOW (CFM) 800 1000" 1200 1400 1600

* The030 sizemodelsmustbe runonmediumor highspeedwhenusedin conjunstJonwith15kwelectricheataccessory

5OJXO60

2000

9

1"(25mm) MIN.

UT%T!

C99013

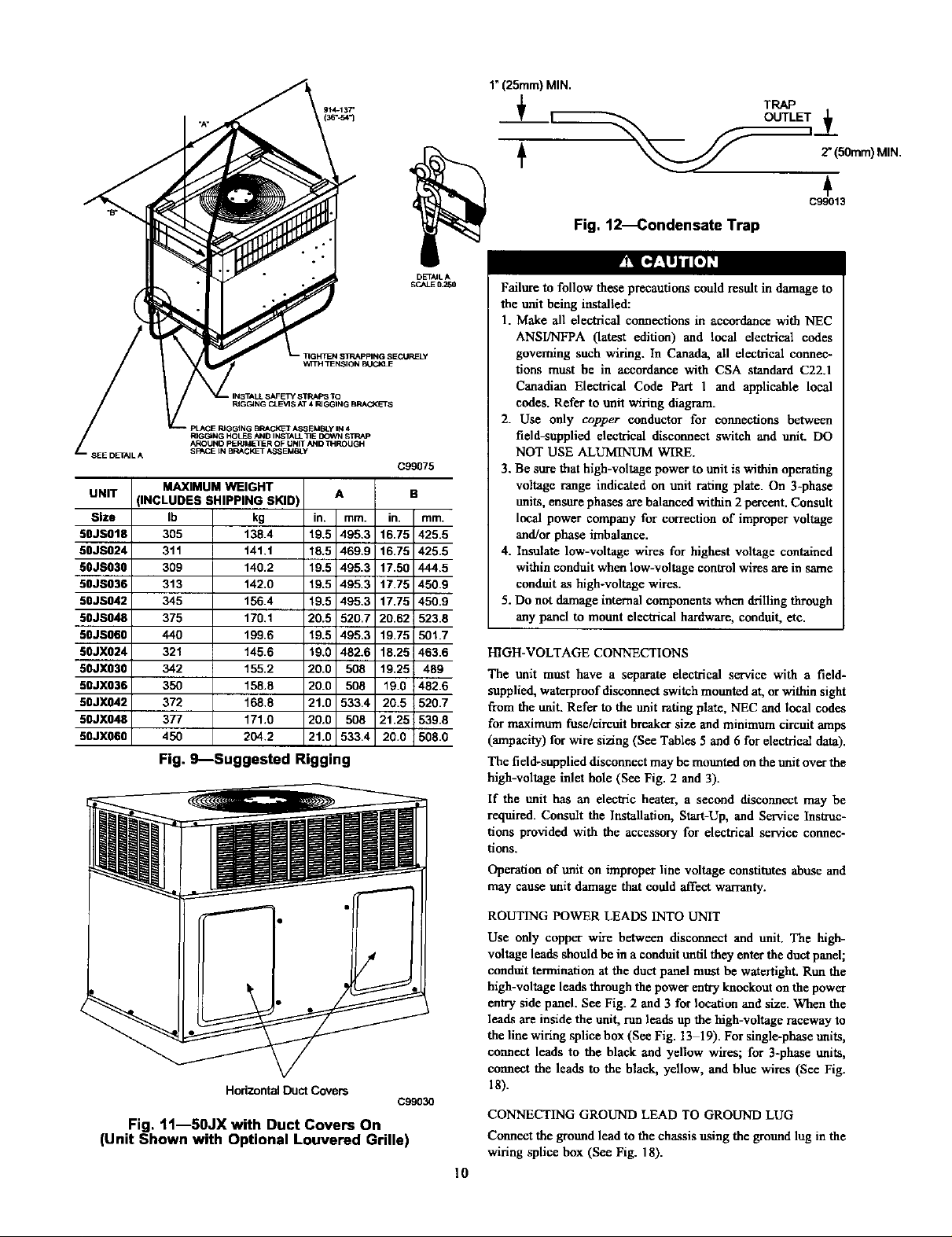

Fig, 12_Condensate Trap

. INSTALL SAFETY STRAPS TO

RIGG4NG C_EVIS AT 4 RIGGING B_S

RIGGING HOLES AND INSTALL _i]E DOWN STRAP

L SEE DET_J L A

UNIT

Size

50JS018

50JS024

5OJS03O

50JS036

50JS042

50JS048

50JS060

50JX024

5OJX030

50JX036

50JX042

50JXO48

50JXO60

INCLUDES SHIPPING SKID

AROUND FE RIMElflE:R OF UNIT AND THROUGH

SR_E IN B_Ck_r ,_EMSLY

MAXIMUM WEIGHT

A

Ib kg in. mm.

305 138.4 19.5 495,3

311 141.1 18.5 469,9

309 140.2 19.5 495.3

313 142,0 19.5 495.3

345 156.4 19.5 495,3

375 170.1 20.5 520,7

440 199.5 19.5 495.3

321 145.8 19.0 482.6

342 155.2 20.0 508

350 158,8 20.0 508

372 168,8 21.0 533,4

377 171,0 20.0 508

450 204.2 21.0 533,4

Fig. S--Suggested Rigging

Hodzontal DuctCovers

Fig, 1t--50JX with Duct Covers On

(Unit Shown with Optional Louvered Grille)

DETAIL A

SCALE 0250

C99075

B

in. mm.

16.75 425.5

16.75 425.5

17.50 444.5

17.75 450.9

17.75 450.9

20.62 523.8

19.75 501.7

18.25 463.6

19.25 489

19.0 482.6

29.5 520.7

21.25 539.8

20.0 508.0

C9903O

M [q=l|l i[.]_l

Failure to follow these precautions could result in damage to

the unit being installed:

1. Make all electrical connections in accordance with NEC

ANSI/NFPA (latest edition) and local electrical codes

governing such wiring. In Canada, all elecbJeal connec-

tions must be in accordance with CSA standard C22.1

Canadian Electrical Code Part 1 and applicable local

codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within operating

voltage range indicated on unit rating plate. On 3-phase

units, ensure phases are balanced within 2 percent. Consult

local power company for correction of improper voltage

and/or phase imbalance.

4. Insulate low-vultage wires for highest voltage contained

within conduit when low-voltage control wires are in same

conduit as high-voltage wires.

5. Do not damage internal components when drilling through

any panel to mount electricai hardware, conduit, etc.

HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof disconnect switch mounted at, or within sight

from the unit. Refer to the unit rating plate, NEC and local codes

for maximum fuse/circuit breaker size and minimum circuit amps

(ampacity) for wire sizing (See Tables 5 and 6 for electrical data).

The field-supplied disconnect may be mounted on the unit over the

high-voltage inlet hole (See Fig. 2 and 3).

If the unit has an deetric heater, a second disconnect may be

required. Consult the Installation, Start-Up, and Service Instruc-

tions provided with the accessory for electrical service connec-

tions.

Operation of unit on improper line voltage constitutes abuse and

may cause unit damage that could affect warranty.

ROUTING POWER LEADS INTO UN/T

Use only copper wire between disconnect and unit. The high-

voltage leads should be in a conduit until they enter the duct panel;

conduit termination at the duet panel must be watertight. Run the

high-voltage leads through the power entry knockout on the power

entry side panel. See Fig. 2 and 3 for location and size. When the

leads are inside the unit, run leads up the high-voltage raceway to

the line wiring splice box (See Fig. 13 19). For single-phase units,

connect leads to the black and yellow wires; for 3-phase units,

connect the leads to the black, yellow, and blue wires (See Fig.

18).

CONNECTING GROUND LEAD TO GROUND LUG

Connect the ground lead to the chassis using the ground lug in the

wiring splice box (See Fig. 18).

10

Loading...

Loading...