Page 1

48N

HEATING A COOLING

Packaged Heating/Cooling Units

Installation Instructions

NOTE TO INSTALLER: Leave these instructions, the User’s

Manual, and Parts Replacement Guide with the unit after

installation.

A WARNING

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poison

ing, explosion, fire, electric shock, or other occurrences

which may injure you or damage your property. Con

sult a quahfi^ed installer, service agency, or the gas suppher for information or assistance. The qualified agency

must use factory authorized kits and accessories when

modifying this unit.

NOTE: The installation of this unit must conform to the

guidelines presented in these unit Installation Instructions.

Read and become familiar with this publication before start

ing the installation.

INTRODUCTION

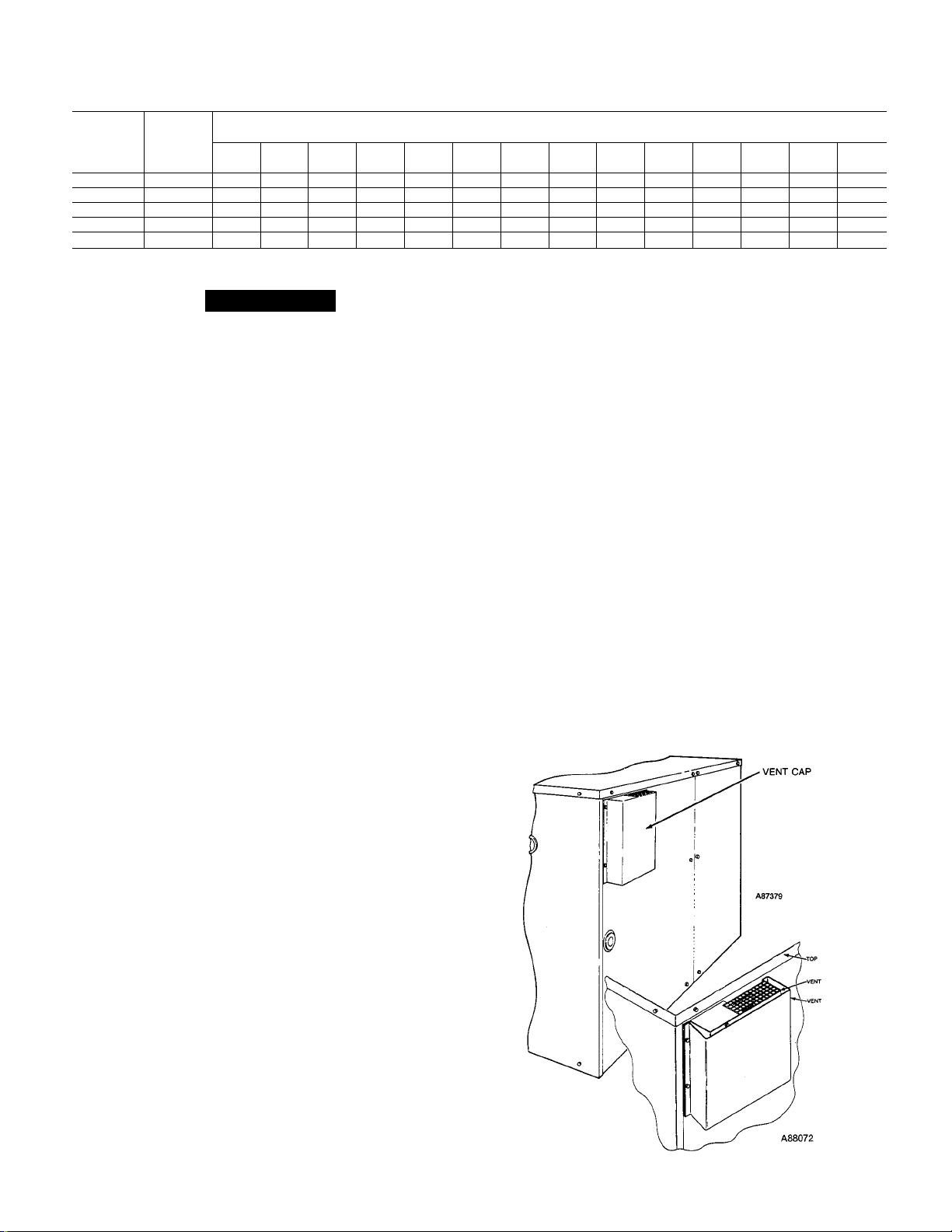

Model 48N Packaged Gas/Electric Unit is fully self-con

tained, combination gas heating/electric cooling unit

designed for outdoor installation. Model 48N may be

installed either on a rooftop or groimd-level slab. See Fig. 1.

For rooftop downflow applications, an accessory roof

mounting curb must be used.

Model 48N Unit meets the California maximum oxides of

nitrogen (Nox) emission regulations.

These units are equipped with an energy-saving, automatic,

intermittent, electric spark ignition system that does not

have a continuously burning phot. All units are manufac

tured with natural gas controls.

These units are designed for a minimum continuous return

air temperature of 60 °F. (dry bulb) or an intermittent opera

tion down to 55°F. (dry bulb) such as when used with a

night set back thermostat.

Model 48N is A.G.A. and C.G.A. design-certified. See

Tables 2 thru 7 for the heating input ratings.

These units are factory-charged with R-22 refrigerant.

Installation is simple: connect gas supply, air ducts, highand low-voltage wiring, condensate drain, and instedl a fieldsupplied air filter.

All units can be connected into existing duct systems that

are properly sized and designed to handle an airflow of 350

to 450 Cfm per each 12,000 Btuh of rated cooling capacity.

See Tables 2 thru 7 for cooling and heating airflow require

ments.

NOTE: When installing any accessory item, see the manu

facturer’s Installation Instructions packaged with the ac

cessory. The Qualified Agency must use factory authorized

kits or accessories when modifying this unit.

Fig. 1—Model 48N

IMPORTANT—READ BEFORE INSTALLING

1. This installation must conform with all applicable local

and national codes.

2. The power supply (volts, hertz, and phase) must corre

spond to that specified on unit rating plate.

3. The electrical supply provided by the utility must be

sufficient to handle load imposed by this unit.

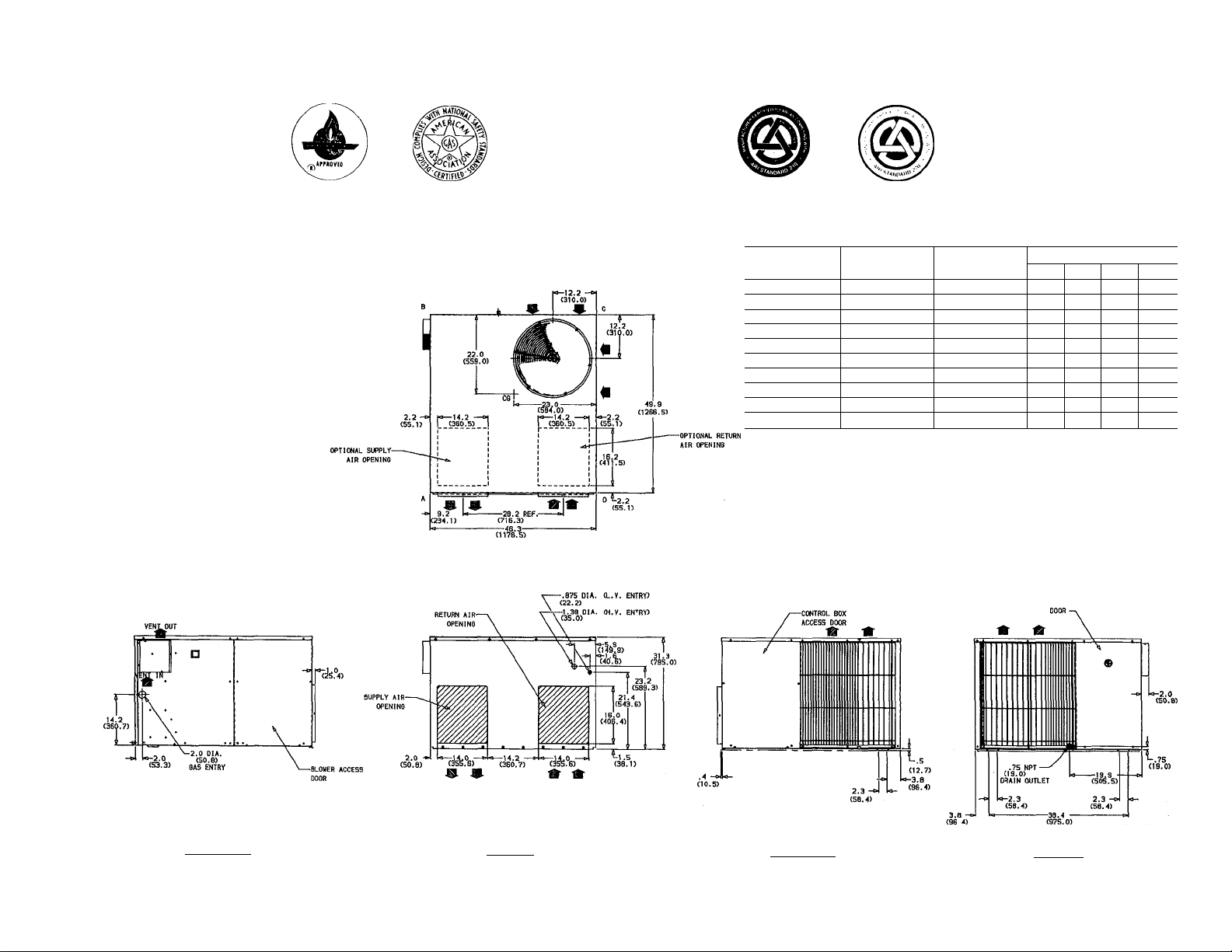

4. Refer to the 48N dimensional drawing for locations of

gas inlet, electrical inlets, condensate drain, duct con

nections, and required clearances before setting unit in

place. Figs. 2 and 3.

5. Locate the unit where the vent cap will be a minimum

of 4-ft from openable windows or doors.

6. This installation must conform with local building

codes and with the National Fuel Gas Code ANSI

Z223.1-1984 and Addenda Z223.la-1987 (In Canada,

CAN/CGA B149.1, (2)-M86) or NFPA 54-1984 TIA-5484-1. Refer to Provincial and local plumbing or

wastewater codes and other applicable local codes.

7. For outdoor installation on wood flooring or on class A,

B, C roof covering materials.

GENERAL

Model 48N Packaged Gas/Electric Unit has been designed

and tested in accordance with ANSI Z21.47-1987, ARI

Standard 210-81, and ARI Standard 270-84, CAN/CGA-2.3M86, CAN 1-2.17-M80, CAN 1-2.21-M85, CSA C22.2 No. 0-

1982, No. 3-1979 and No. 119-M1985. The appliance design

is certified by the American Gas Association (A.G.A.) and

Canadian Gas Association (C.G.A.) for use with natural or

LP (propane) gases with appropriate controls and orifices.

A87316

Tab llalla

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

I

^ PC 101 Catalog No. 564-816 Printed in U.S.A. Form 48NT-9SI Pg 1 9-88 Replaces: 48NT-8SI

Page 2

I

IV)

o

a

2--n

Z N)

(/) o

N

(D

(A

^ z

S w

2 >

C

■1^

00

Z

S

H

o

■u

IV)

S

m

D

30

>

z

o

EFFICIENCY

RATING

CERTIFIED

G

ama

Unit Weights

Unit lbs.

48NLT018 47D

48NLT024

48NLT030

48NHT024

48NMT030

48NLT036 506

48NLT042

48NHT030

48NMT036 510

48NMT042

Above unit top

Duct side of unit____6 min. Side opposite blower access panel........30

Side opposite ducts

NOTE: Provision must be made for fresh ambient air to reach the outdoor

coil without recirculation of the air from the outdoor fan discharge.

Shipping Wt. Operating Wt.

474 454

490

480 460

486 476

516 496

500

520

48N REQUIRED CLEARANCES (Inches)

.....................

48 Blower access panel side

.........

30 Bottom of unit

lbs. A

450

470 103

486 107

480 106

490 108

500 110

..........................................

Corner Wt. lbs.

B C D

99

126 126 99

100

127 127 100

132 132 103

101

129 129 101

105 133 133 105

136 136 107

109

139 139 109

134 134 106

137 137 108

140 140 110

......................

BURNER ACCESS

30

0

RIGHT SIDE vmw

REAR VIEW

LEFT SIDE VIEM

FRONT VIFR

Page 3

00

0

Q.

— -n

2 w

1 I

(/) o

n‘ 9

<D S

» m

5 £2

o >

S r-

05

=r 3J

= I

z ^

T o

EFFICIENCY

RATING

CERTIFIED

G

ama

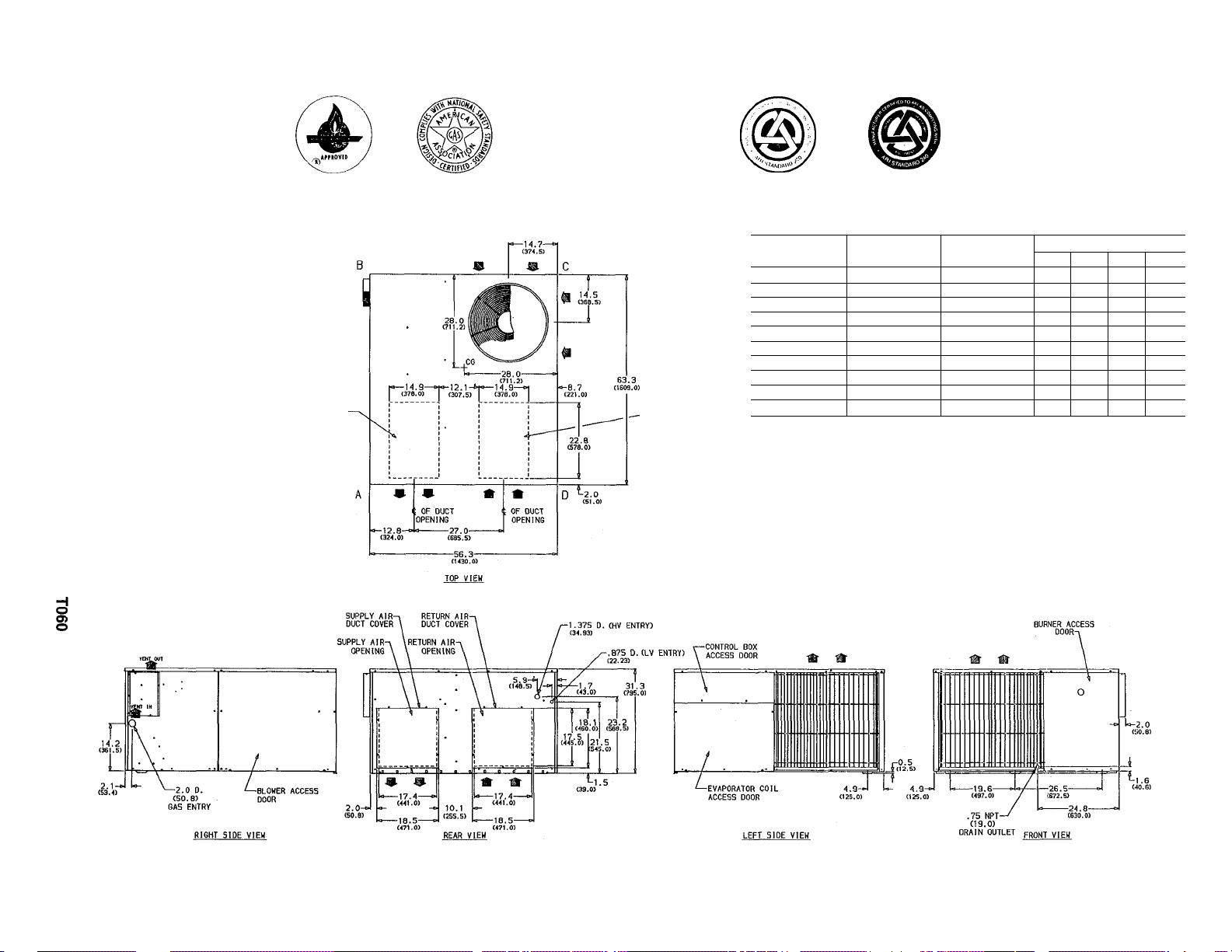

Unit Weights

Shipping Wt.

550

556

594

600

060

624

630

636 616

48N REQUIRED CLEARANCES (Inches)

...................

___

48 Blower access panel side

6 min. Side opposite blower access panel

OPTIONAL SUPPLY-

AIR OPENING

-OPTIONAL RETURN

AIR OPENING

Unit lbs. lbs. A

48NHT036

48NVT036

48NHT042 570 550 122

48NVT042 576

48NLT048

48NMT048

48NHT048

48NLT060

48NMT060

48NHT060

Above unit top

Duct side of unit

Side opposite ducts...........30 Bottom of unit

NOTE: Provision must be made for fresh ambient air to reach the outdoor

coil without recirculation of the air from the outdoor fan discharge.

o

Operating Wt.

530 117

536 119

556 124

574 128

580 130 159 160

586 131 161 162

604

610 138

..........................................

Corner Wt. lbs.

136

139 169 169 140

.......................

B C D

148

147

148 149 120

152 153 123

153

158 159 129

165 166 137

166 167 139

........

154

30

30

0

118

125

131

132

Page 4

This publication contains the following:

Step 1. Moving and Setting Unit in Place

Step

Step

Step

Step

Step

Step

Step

Step

Step 10.

Step 1—Moving and Setting Unit in Place

Condensate Disposal

Venting

Gas Piping

Duct Connections

Electrical Connections

7. Preparing Unit for Steurtup

8. Heating Section Startup and Adjustments

9. Cooling Section Startup and Adjustments

Care and Maintenance

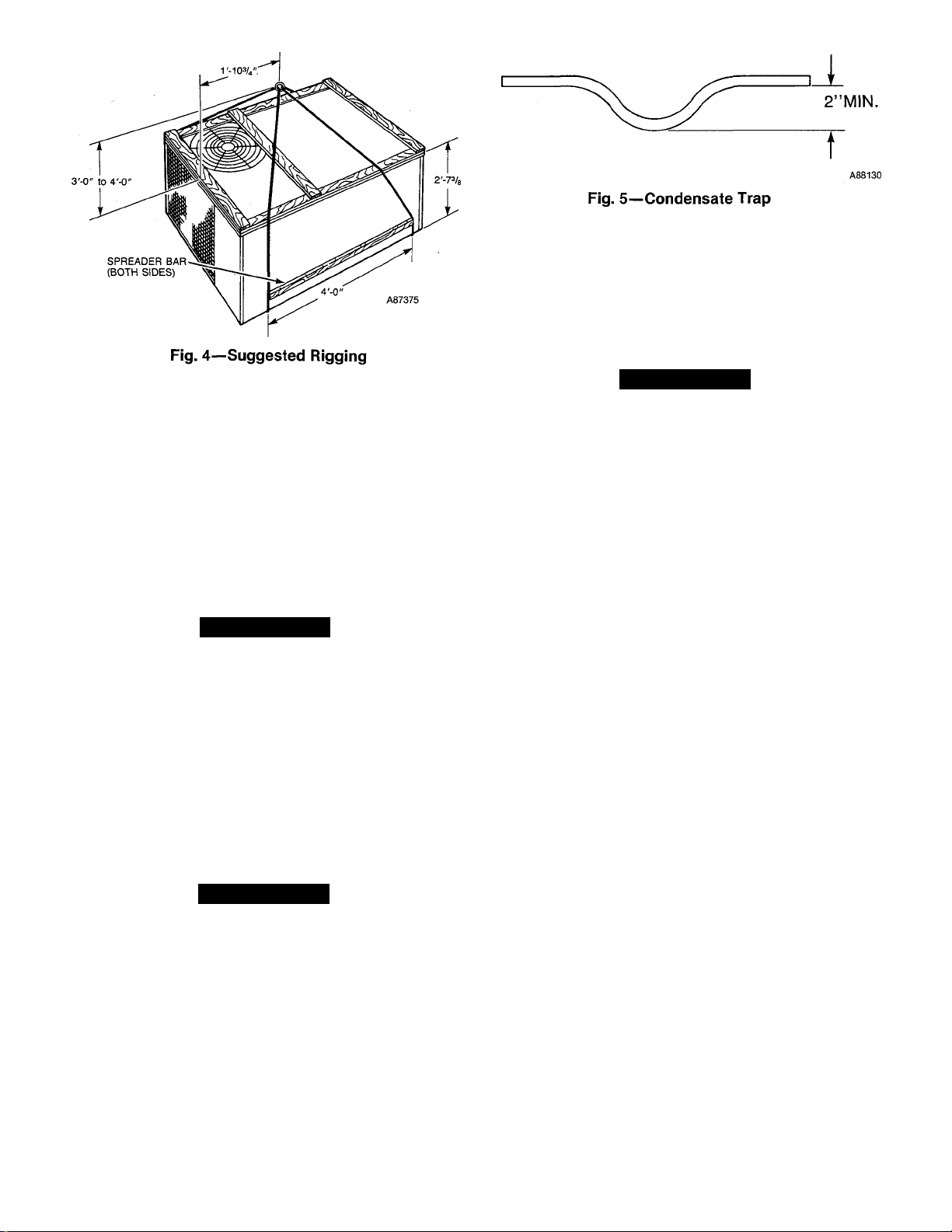

A CAUTION

Use spreader bars and crate top when rigging the unit

to be lifted. Model 48N must be rigged for lifting as

shown in Fig. 4. Use extreme caution to prevent dam

age when moving the unit. Unit must remain in an

upright position during eJl rigging and moving opera

tions. The unit must be level for proper condensate

drainage; therefore, the ground-level pad or accessory

roof-mounting curb must be level before setting the

unit in place. When a field-fabricated support is used,

ensure that the support is level and properly supports

the unit.

A. Rooftop installation

A CAUTION

When installing the unit on a rooftop, be sure that the

roof will support the additional weight. Refer to Figs. 2

& 3 for Model 48N to obtain toted weight and corner

weight information.

For downflow applications, an accessory roof-mounting

curb must be installed on, and flashed into the roof before

unit installation. The instructions for installing the acces

sory curb are packaged with the curb.

For end-discharge applications place the unit on a level base

that provides proper support. On flat roofs, be sure that the

unit is located at least 4-ins. above the highest expected

water level on the roof to prevent flooding.

B. Ground-Level Installation

Place the unit on a sohd, level, concrete pad that is a mini

mum of 2-ins. thick and that extends approximately 2-in.

beyond the casing on all four sides of the unit. Do not secure

the unit to the pad except when required by local codes.

C. Clearances

The required minimiim operating and service clearances are

shown in Figs. 2 and 3. Adequate combustion, ventilation

and condenser air must be provided.

A CAUTION

Do not restrict condenser airflow. An air restriction at

either the outdoor-air inlet (the entire surface of the out

door cofl.) or the fan discharge can be detrimental to

compressor hfe.

The condenser fan discharges through the top of the unit.

Ensure that the fan discheirge does not recirculate to the

condenser coil. Do not locate the unit in either a corner or

under a complete overhead obstruction. The minimum clear

ance under a partial overhang (such as a normal house roof

overhang) is 48-ins. above unit top. The maximum horizon

tal extension of a partial overhang must not exceed 48-in..

Do not locate the unit where water, ice, or snow from an

overhang or roof wiU damage or flood the unit by falling on

the top. Do not locate the unit where grass, shrubs, or other

plants will interfere with the airflow either into or out of the

unit. Do not install the unit on carpeting, tile, or other com

bustible material other than wood flooring. Furnace may be

installed on wood flooriag or on Class A, B, or C roof cover

ing materials.

Step 2—Condensate Disposal

NOTE: Ensure that condensate-water disposal methods

comply with local codes, restrictions, and practices.

Model 48N disposes of condensate water through a 3/4-in.,

Male Female NPT drain fitting. See Figs. 2 and 3 for

location.

Install a 2-in. trap at the drain fitting to ensure proper

drainage. See Fig. 5. Make sure that the outlet of the trap is

at least 1-in. lower than the unit drain pan connection to

prevent the pan from overflowing. Prime the trap with

water.

If the installation requires draining the condensate water

away from the unit, connect a drain tube using a minimum

of 7/8-in. OD copper tubing, 3/4-in. galvanized pipe, or

3/4-in. plastic pipe. Do not undersize the tube. Pitch the

drain tube downward at a slope of at least 1-in. in every 10ft of horizontal run. Be sure to check the drain tube for

leaks.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel

apron in ground-level installations. When using a gravel

apron, make sure it slopes away from the unit.

Step 3—Venting

The vent-cap assembly is shipped in the burner compart

ment. Remove the access door to locate the assembly.

Page 5

Table 1—Maximum Gas Flow Capacity of Pipe in Cubic Feet of Gas Per Hour for Gas

Pressures of 0.5 PSIG or Less and a Pressure Drop of 0.5 inch Water Coiumn

(Based on a 0.60 Specific Gravity Gas)

Nominal

Iron Pipe,

Size,

Inches

1/2 .622

3/4

1

1-1/4

1-1/2

Ref: Table 0^4, NFPA 54—1984

*This length includes an ordinary number of fittings.

Internal

Diameter,

Inches

.824

1.049

1.380

1.610

10 20 30 40 50 60 70 80 90

175 120 97 82 73 66

360 250

680 455 375 320 285 260 240 220 205 195 175 160 145

1,400 950 770 600 580 530 490 460 430 400 360 325 300 280

2,100 1,460 1,180 990 900 810

170 151 138

200

A CAUTION

The venting system is designed to ensure proper vent

ing. The vent cap assembly must be installed as indi

cated in this section of the unit Installation

Instructions.

NOTE: Screw holes in the flue assembly and the unit flue

panel are not symmetrically located; thereby, ensuring

proper orientation when installing these components.

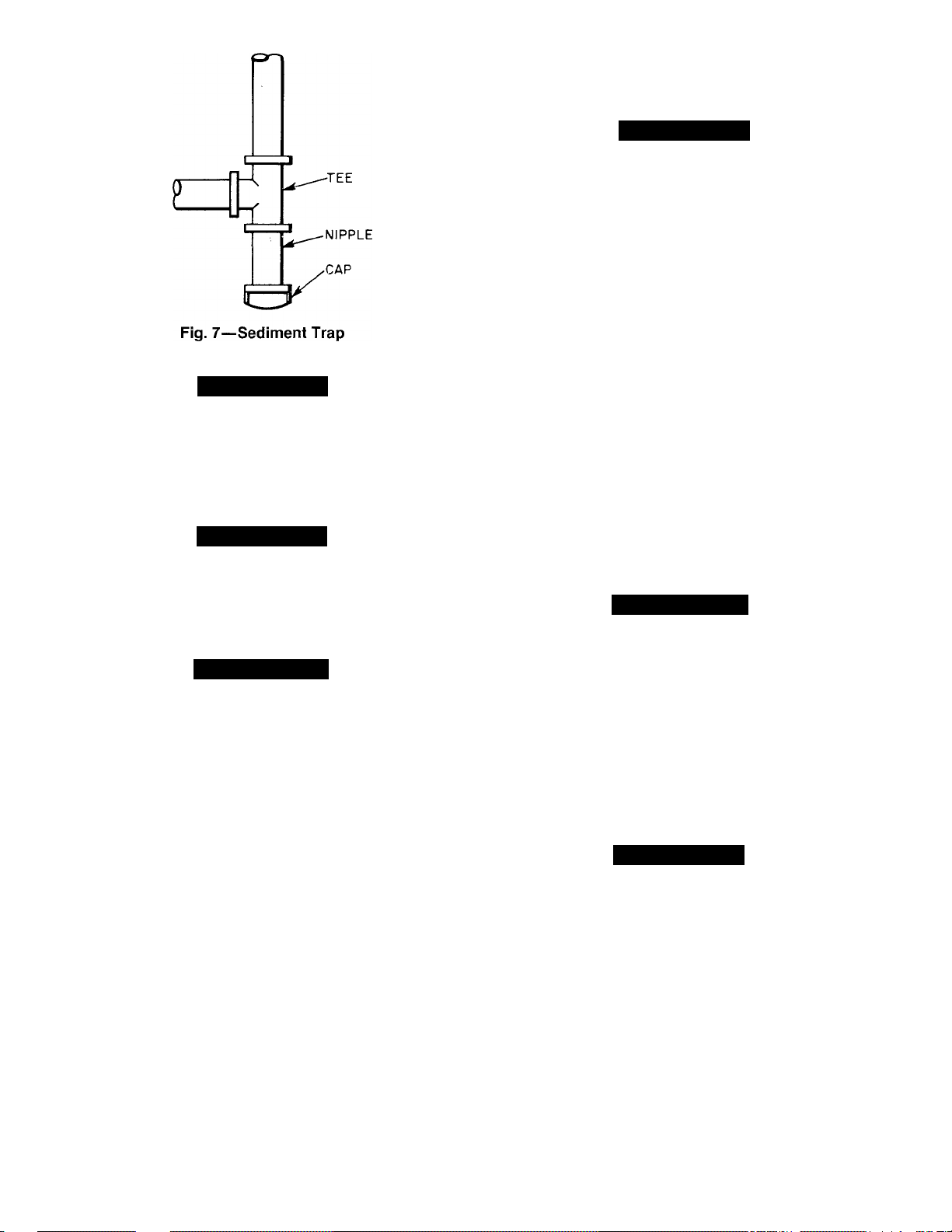

Refer to Fig. 6 and install the vent cap as follows:

1. Place vent cap assembly over flue panel, orient screw

holes in vent cap with holes in flue panel, and secure

vent cap in place by inserting the single screw on the

right side of vent cap.

2. Place the vent cap guard over the vent cap, orient holes

in vent cap guard with holes in vent cap and flue panel.

Secure the entire assembly with the remaining two

screws on the left side of vent cap and vent cap guard

assembly.

Step 4—Gas Piping

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the

1/2-in. FPT gas inlet on the manual shutoff or gas valve.

Install a separate gas supply line that runs directly from

the meter to the heating section. Refer to Table 1 and the

National Fuel Gas Code for gas pipe sizing. Do not use cast-

iron pipe. Check the local utihty for recommendations con

cerning existing lines. Choose a supply pipe that is large

enough to keep the pressure loss as low as practical. Never

use pipe smaller than the 1/2-in. FPT gas inlet on the unit

gas valve.

When instaUing the gas supply hne, observe local codes per

taining to gas pipe installations. Refer to the National Fuel

Gas Code ANSI Z223.1-1984 (In Canada, CAN/CGA

B 149.1, (2)-M86) or NFPA 54-1984 in the absence of local

buUding codes. Adhere to the following pertinent recom

mendations:

1. Avoid low spots in long runs of pipe. Grade aU pipe

1/4-in. in every 15-ft to prevent traps. Grade all hori

zontal runs downward to risers. Use risers to connect

to heating section and to meter.

2. Protect all segments of piping system against physical

and thermal damage. Support all piping with appropri

ate straps, hangers, etc. Use a minimum of one hanger

every 6-ft. For pipe sizes larger than 1/2-in., follow rec

ommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only

to male threads of joint when making pipe connections.

Use only pipe dope that is resistant to action of lique

fied petroleum gases as specified by local and/or

national codes. Never use teflon tape.

Length of Pipe, Feet*

200

— —

135

61

125

750

100 125

57

118

690 650 620 550 500 460 430

53 50 44

110 103 93

150 175

40

84 77 72

4. Install sediment trap in riser leading to heating sec

tion. This drip leg functions as a trap for dirt and con

densate. Install trap where condensate can not freeze.

Install this sediment trap by connecting a piping tee to

riser leading to heating section, so that straightthrough section of tee is vertical. See Fig. 7. Then, con

nect capped nipple into lower end of tee. Extend

capped nipple below level of gas controls.

Install an accessible, external, manual main shut-off

5.

valve in gas supply pipe within 6-ft of heating section.

Install ground-joint union close to heating section

6.

between unit manual shutoff and external manual main

shut-off valve.

7. Pressure-test all gas piping in accordance with local

and national plumbing and gas codes before connecting

piping to unit.

NOTE: When pressure testing the gas supply system after

the gas supply piping has been coimected to the unit gas

valve, the supply piping must be disconnected from the gas

vedve during any pressure testing of the piping systems at

test pressure in excess of 0.5 psig. When pressure testing

the gas supply piping system at test pressures equal to or

less than 0.5 psig, the unit heating section must be isolated

from the gas piping system by closing the external main

manual shut-off valve and slightly opening the ground-joint

union.

Fig. 6—Vent Cap Assembly

Page 6

A73130

A CAUTION

Unstable operation may occur when the gas valve and

manifold assembly are forced out of position while con

necting improperly routed rigid gas piping to the gas

valve. Use a backup wrench when making connection to

avoid strain on, or distortion of, the gas control piping.

A CAUTION

If a flexible conductor is required or allowed by the

authority having jurisdiction, black iron pipe shall be

installed at the gas valve and extend a minimum of

2-ins. outside the unit casing.

A WARNING

Never use a match or other open flame when checking

for gas leaks. Never purge gas line into combustion

chamber. Failure to adhere to this warning could result

in an explosion.

8. Check for gas leaks at all field-installed and factoryinstalled gas lines after all piping connections have

been completed. Use soap-and-water solution (or

method specified by local codes and/or regulations).

2. Select and size ductwork, supply-air registers, and

return-air grilles according to ASHRAE recom

mendations.

A CAUTION

When the duct-system fastening holes are being drilled

into side of Model 48N instead of the unit duct flanges,

use extreme ceire to avoid puncturing the coil or cofl.

tubes.

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition

may be screwed or bolted to duct flanges. Use suitable

gaskets to ensure weather and airtight seal.

4. Install external, field-supplied air filter(s) in return-air

ductwork where it is easily accessible for service. Rec

ommended filter sizes are shown in Tables 2 thru 7.

5. Size aU ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid

abrupt duct size increases or decreases.

6. Adequately insulate and weatherproof all ductwork

located outdoors. Insulate ducts passing thru uncondi

tioned space, and use vapor barrier in accordance with

latest issue of SMACNÀ and ACCA minimum installa

tion standards for heating and air conditioning sys

tems. Secure aU ducts to building structure.

7. Flash, weatherproof, and vibration-isolate all openings

in building structure in accordance with local codes and

good building practices.

Step 6—Electrical Connections

A WARNING

The unit cabinet must have an uninterrupted, unbro

ken, electrical ground to minimize the possibility of per

sonal injury if an electrical fault should occur. This

ground may consist of electrical wire connected to the

unit ground lug in the control compartment, or conduit

approved for electrical ground when installed in accor

dance with the National Electrical Code ANSI/NFPA

70-1987 (in Canada, Canadian Electrical Code CSA

C22.1) and local electrical codes. Do not use gas piping

as an electrical ground. A failure to adhere to this warn

ing could result in the installer being hable for the per

sonal injury of others.

Step 5—Duct Connections

Model 48N has duct flanges on the supply- and return-air

openings on the side and bottom of the unit. See Figs. 2 and

3 for connection sizes emd locations.

NOTE: The design and installation of the duct system must

be in accordance with the standards of the National Fire

Protection Association for installation of nonresidence-type

air conditioning and ventilating systems, NFPA No. 90A or

residence-type, NFPA No. 90B; and/or local codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Remove appropriate panels from unit to obtain either

side or bottom discharge. If models 48NLT018 thru

48NMT042 are installed in horizontal discharge apphcations, remove side duct covers, save screws, and

install the covers on bottom duct openings. For models

48NHT036 thru 48NHT060 remove either side or bot

tom duct covers as needed and discard.

A CAUTION

A failure to follow these precautions could result in

damage to the unit being installed:

1. Make all electrical connections in accordance with

National Electrical Code ANSI/NFPA 70-1987 and

local electrical codes governing such wiring. In Canada,

all electrical connections must be in accordance with

CSA standard C22.1 Cemadian Electrical Code Part 1

and applicable local codes. Refer to Unit Wiring

Diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Ensure that high-voltage power to unit is within oper

ating voltage range indicated on unit rating plate. On

3-phase units, ensure that phases are balanced within

2%. Consult local power company for correction of

improper voltage and/or phase balance.

Page 7

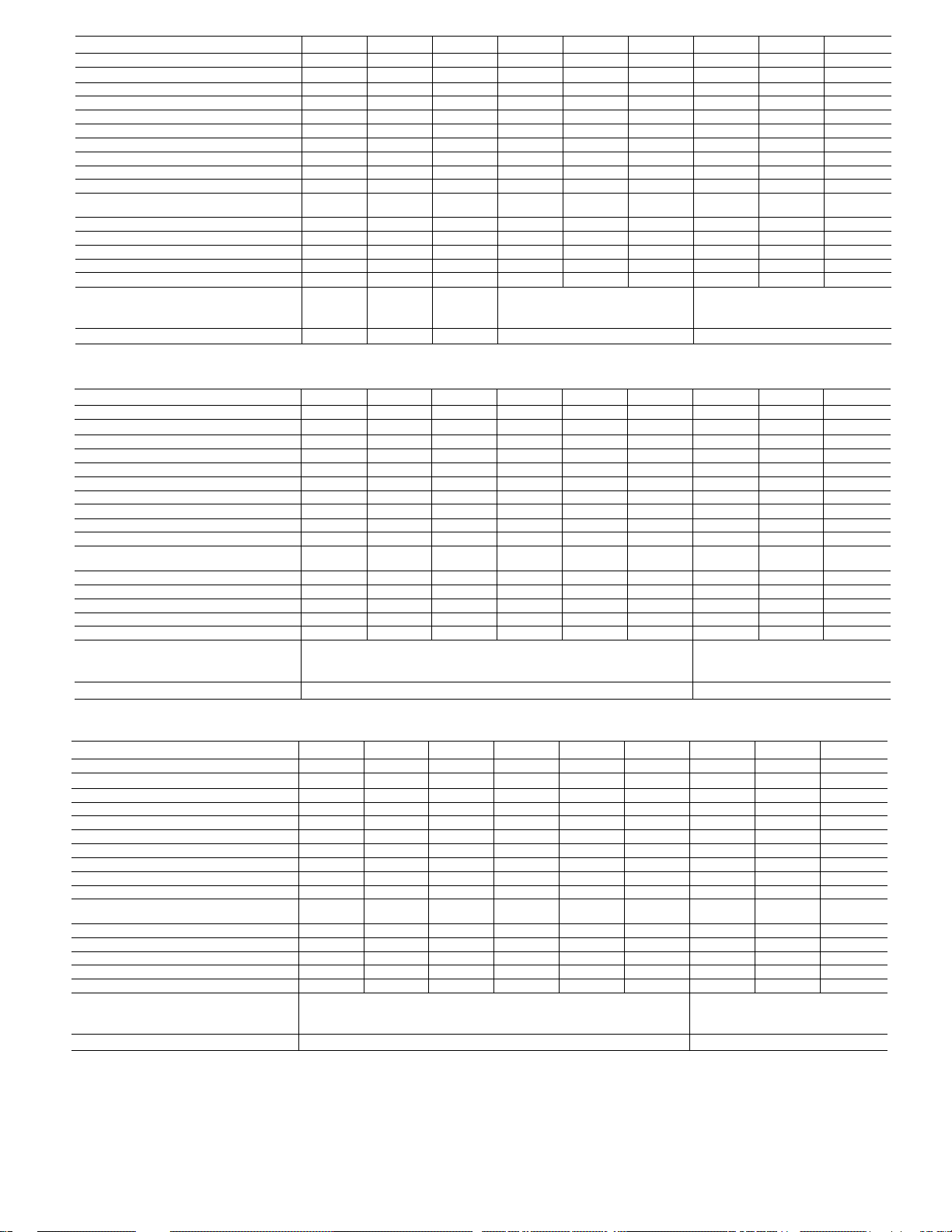

Table 2—Specifications—Models 48N (Sizes NLT018300 thru NLT036600)

MODEL 48N

SIZE

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps)

Minimum Ampacity for Wire Sizing*

Minimum Wire Size (75 C Copper)

Maximum Wire Length (Ft.)

Cooling Capacity (Btuh)t

Rated Cooling Airflow (cfm)t

External Static Pressure (In.

water)t

ARI Sound Rating^

Rated Heating Input (cfm)

Output Capacity (Btuh)**

AFUE(%)**

Rated Heating Airflow (cfm)

Recommended Minimum Field-

Supplied Filter Size (Sq ln.)tt

Disposable-Type

Cleanable- or High-Capacity Type

LT018300 LT024300

208/230—1 208/230—1

187—253

(Applicable notes are listed below Table 4.)

48N 48N

HT024300 LT030300 MT030300

48N 48N

HT030300

208/230—1 208/230—1 208/230—1 208/230—1

11.5

187—253

14.2

187—253 187—253 187—253 187—253

14.2

16.8 16.8 17.3

20 25 25 30 30

13.6 17.1 17.1 20.4 20.4

14

60 70

17,800 23,800 23,800 29,000 29,000

600

0.10

7.8

40,000 40,000 60,000 40,000

31,000 31,000 46,000

12 12

70

10 10 10 10

100 100 100 75

29,000

800 800 1100 1100 1100 1300 1300

0.10 0.10 0.15 0.15 0.15 0.15 0.15

8.0 8.0 8.0 8.0 8.0 8.0 8.0

60,000 80,000 60,000 60,000 60,000

31,000 46,000 61,000 46,000 48,000

77.5 77.5 77.5 77.5 77.5 77.5

658 658 740 658

288

192 256

384 384 528

256 352

740 987

48N

30

20.7

48N 48N

LT036300 LT036500

208/230—1

187—253

208/230—3

187—253 414—506

21.2 14.6

40 25

26.9

18.6

12

65

35,200 35,200

77.5

—

987 987 987

624

416

48N

LT036600

460—3

7.7

15

9.0

14

110

35,200

1300

0.15

8.0

48,000

—

Table 3—Specifications—Models 48N (Sizes MT036300 thru VT036600)

MODEL

SIZE

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps)

Minimum Ampacity for Wire Sizing*

Minimum Wire Size (75 C Copper)

Maximum Wire Length (Ft.)

Cooling Capacity (Btuh)f

Rated Cooling Airflow (cfm)f

External Static Pressure (In.

water)t

ARI Sound Ratingf:

Rated Heating Input (cfm)

Output Capacity (Btuh)**

AFUE(%)**

Rated Heating Airflow (cfm)

Recommended Minimum FieldSupplied Filter Size (Sq ln.)tt

Disposable-Type

Cleanable- or High-Capacity Type

48N 48N

MT036300

MT036500 MT036600 HT036300

48N 48N 48N

208/230—1 208/230—3 460—3

187—253

21.2 14.6

40

26.9

10

75

35,200

1300

0.15 0.15

8.0

80,000

61,000

77.5

187—253 414—506

7.7

25 15

18.6 9,0

12 14 41

65 110

35,200 35,200 35,800

1300 1300

0.15 0.15 0.15 0.15

8.0 8.0 8.0

80,000 80,00 100,0000

64,000 64,000 78,000

__

—

987 987 987 1481

624

416

HT036500 HT036600

208/230—1 208/230—3

48N

460—3 208/230—1

187—253 187—253 414—506

22.4 16.8 8.5 '

40 25 15

26.2 19.3 9.8

12 12

60 70 70

35,800 35,800

1300 1300 1300

8.0 8.0

100,000 100,000

80,000 80,000

77.5

—

— 77.5

1481 1481

48N 48N

VT036300

VT036500 VT036600

208/230—3

187—253

187—253 414—506

22.4 16.8

40

26.2

25

19.3 9.8

10 10

100

35,800

1300

0.15

8.0

100

35,800 35,800

1300 1300

0.15

8.0 8.0

120,000 120,000

93,000 96,000

—

1367

1367 1367

624

416

(Applicable notes are listed below Table 4.)

Table 4—Specifications-

MODEL

SIZE

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps)

Minimum Ampacity for Wire Sizing*

Minimum Wire Size (75 C Copper)

Maximum Wire Length (Ft.)

Cooling Capacity (Btuh)t

Rated Cooling Airflow (cfm)f

External Static Pressure (In.

water)t

ARI Sound Rating^:

Rated Heating Input (cfm)

Output Capacity (Btuh)**

AFUE(%)**

Rated Heating Airflow (cfm)

Recommended Minimum FieldSupplied Filter Size (Sq ln.)ft

Disposable-Type

Cleanable- or High-Capacity Type

48N

LT042300

208/230—1

187—253

24.6 16.0

50

31.1

8

95

41,500

1500 1500

0.15 0.15

7.8 8.0

60,000 60,000

46,000 48,000 48,000

77.5

987

- Models 48N (Sizes LT042300 thru HT042600)

48N 48N 48N

LT042500 LT042600 MT042300

208/230—1 460—3

208/230—1 208/230—3

187—253 414—506 187—253

8.8 24.6

30

15 50 30

20.4 10.3 31.1

10

100 100

14 8 10

95 100 100

41,500 41,500 41,500

1500 1500

0.15 0.15 0.15 0.15

8.0 8.0

60,00 80,000 80,000

61,000 64,000 64,000

—

987

—

77.5

987 987 987 987

720

480

48N 48N

MT042500

MT042600 HT042300

460—3 208/230—1

187—253 414—506

16.0 8.8

2.4 10.3

41,500 41,500

1500 1500 1500

8.0 8.0

80,000 100,000

-

48N

187—253

26.7

15 45

31.7

14 10

75

41,500 41,500

0.15

8.2 8.2

_

78,000

77.5

1481 1481

48N 48N

HT042500

208/230—3

187—253

18.2 9.6

30

21.1

12

65 110

1500

0.15

100,000

80,000 80,000

— —

720

480

*lf other than 75 C copper wire is used, determine size from unit ampacity and the National Electrical Code. Voltage drop of wire must be less than 2%

of unit rated voltage.

tRated in accordance with U.S. Government D.O.E. test procedures and/or ARI Standard 210.

tRated in accordance with ARI Standard 270.

**The capacity ratings of single-phase units are in accordance with U.S. Government D.O.E. test procedures and/or A.G.A. certification requirements. For

3-phase units, the efficiency rating is a product thermal efficiency rating determined under continuous operating conditions, independent of any

installed system.

ttRequired filter areas shown are based on the larger of the ARI-rated cooling airflow or the heating airflow at a velocity of 300 ft/min for disposable type

or 450 ft/min for high-capacity type. Air filter pressure drop must not exceed 0.08 in.-water.

48N

460—3

8.5

15

10

100

0.15

120,000

96,000

—

HT042600

460—3

414—506

15

11.1

14

41,500

1500

0.15

8.2

100,000

1481

Page 8

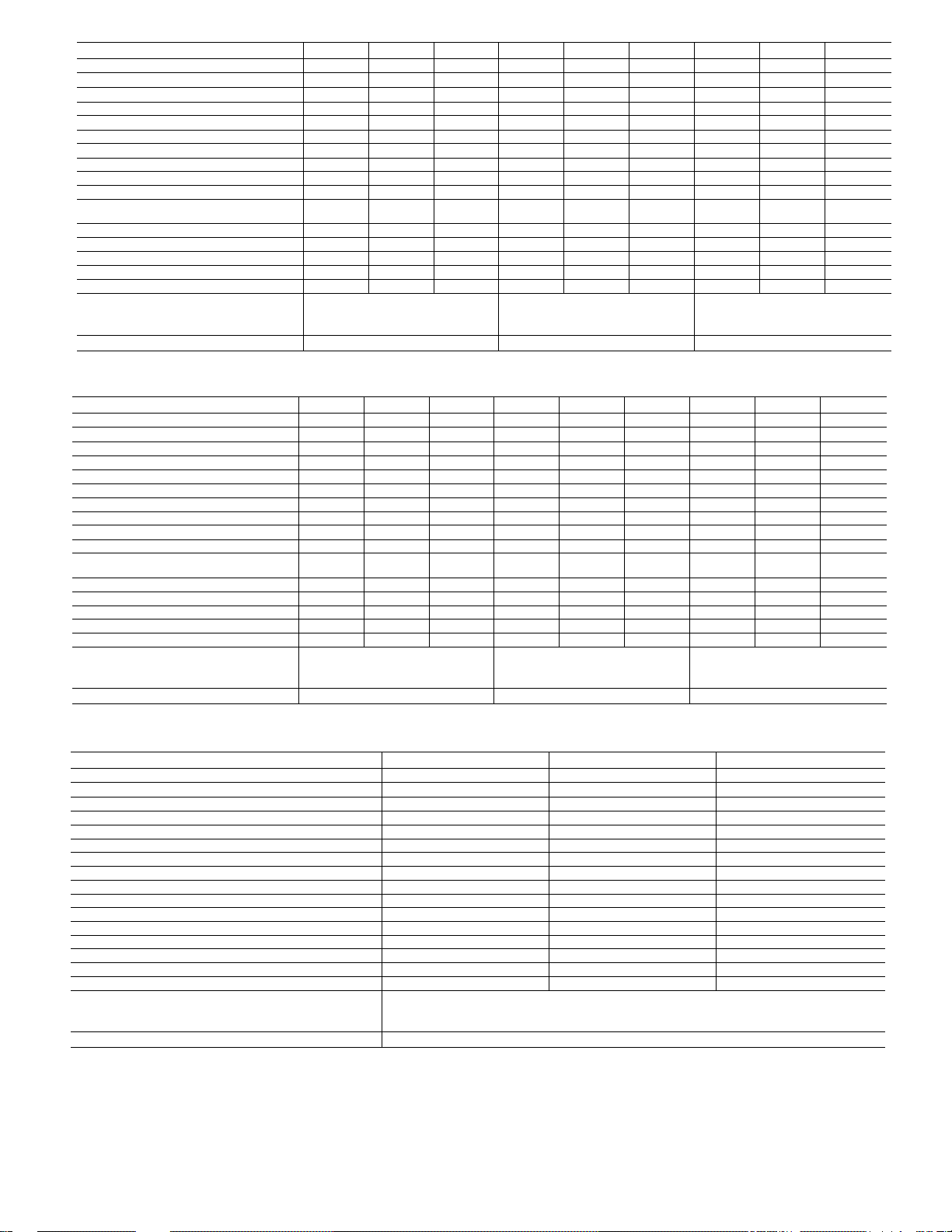

Table 5—Specifications—Models 48N (Sizes VT042300 thru MT048600)

MODEL 48N 48N 48N 48N

SIZE VT042300

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps)

Minimum Ampacity for Wire Sizing*

Minimum Wire Size (75 C Copper) 10 12

Maximum Wire Length (Ft.)

Cooling Capacity (Btuh)f

Rated Cooling Airflow (cfm)f

External Static Pressure (In.

water)t

ARI Sound Rating^:

Rated Heating Input (cfm)

Output Capacity (Btuh)** 93,000 96,000 96,000

AFUE(%)** 77.5

Rated Heating Airflow (cfm)

Recommended Minimum Field-

Supplied Filter Size (Sq ln.)tt

Disposable-Type

Cleanable- or High-Capacity Type 480 544

208/230—1 208/230—3 460—3 208/230—1

187—253 187—253 414—506

26.7

45 30 15

31.7

75

41,500

1500

0.15 0.15 0.15

8.2

120,000

1367 1367 1367

VT042500 VT042600 LT048300

187—253 187—253

18.2 9.6 27.2

50 40 20

21.1

65

11.1 32.7

14

8

110 95

41,500 41,500 47,500

1500 1500 1700

0.20

8.2

8.2

8.2

120,000 120,000 80,000

62,000 64,000 48,000

—

—

77.5

1481

720 816

(Applicable notes are listed below Table 7.)

48N

LT048500

208/230—3

22.1

26.0 13.1

10

100

47,500

1700 1500

0.20

8.2

80,000

— —

1481

48N

LT048600

460—3

414—506

11.0

14

100

47,500

0.15

8.2

60,000

1481

48N

MT048300

208/230—1

187—253 187—253 414—506

27.5 22.1 11.0

50

32.7 26.1 13.1

8 10 14

95

47,500

1700

0.20 0.20 0.20

8.2 8.2 8.2

100,000 100,000 100,000

78,000

77.5

1481 1481 ,1481

48N 48N

MT048500

MT048600

208/230—3

40 20

100 100

47,500

47,500

1700 1700

80,000 80,000

— —

816

544

460-3

Table 6—Specifications—Models 48N (Sizes HT048300 thru MT060600)

MODEL

SIZE

Unit Volts—Phase (60 Hz)

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps)

Minimum Ampacity for Wire Sizing*

Minimum Wire Size (75 C Copper)

Maximum Wire Length (Ft.) 75 65

Cooling Capacity (Btuh)t

Rated Cooling Airflow (cfm)t

External Static Pressure (In.

water)t

ARI Sound Ratingf:

Rated Heating input (cfm)

Output Capacity (Btuh)**

AFUE (%)** 77.5

Rated Heating Airflow (cfm)

Recommended Minimum FieldSupplied Filter Size (Sq ln.)tt

Disposable-Type

Cleanable- or High-Capacity Type

48N

HT048300

48N 48N

HT048500 HT048600

208/230—1 208/230—3 460—3 208/230—1 208/230—3 460—3

187—253 187—253 414—506 187—253 187—253 414—506

27.5 22.1 11.0 40.8 31.6 14.6

50

32.7

26.0 13.1 48.5 37.0

10 12 14 8 10 14

47,500 47,500 47,500 59,500 59,500 59,500

1700

1700

0.20 0.20

8.2 8.2 8.2 8.4 8.4 8.4

120,000

120,000

93,000 96,000 96,000

1367 1367 1367 1481 1481 1481

816 960

544

40

20 60 50 25

110 95 100 100

1700 2000 2000 2000

0.20 0.20

120,000 80,000

_

—

48N

LT060300 LT060500 LT060600

48N 48N

17.2 48.5

0.20 0.20

80,000 100,000

—

62,000

77.5

0.20

80,000

64,000 64,000

—

640

48N

MT060300 MT060500 MT060600

208/230—1

187—253

40.8

60 50 25

8 10

95 100 100

59,500 59,500 59,500

2000 2000 2000

8.4

78,000

77.5

1646 1646 1646

(Applicable notes are listed below Table 7.)

Table 7—Specifications-

MODEL

SIZE HT060300

Unit Volts—Phase (60 Hz) 208/230—1 208/230—3

Operating Voltage Range

Unit Full Load Amps

Maximum Fuse Size (Amps) 60 50

Minimum Ampacity for wire Sizing* 48.5 37.0

Minimum Wire Size (75 C Copper)

Maximum Wire Length (Ft.) 75 65

Cooling Capacity (Btuh)t

Rated Cooling Airflow (cfm)t

External Static Pressure (in. water)t

ARI Sound Ratingt

Rated Heating Input (Btuh)**

Output Capacity (Btuh)** 93,000 96,000 96,000

AFUE(%)** 77.5

Rated Heating Airflow (cfm)

Recommended Minimum Field-

Supplied Filter Sizeft

Disposable-Type

Cleanable- or High-Capacity Type 640

- Models 48N (Sizes HT060300 thru HT060600)

48N 48N

187—253

40.8 31.6

10 12

59,500 59,500

2000 2000

0.20 0.20

8.4 8.4

120,000

1975 1975

HT060500 HT060600

187—253 414—506

120,000

— —

960

*lf other than 75 C copper wire is used, determine size from unit ampacity and the National Electrical Code. Voltage drop of wire must be less than 2%

of unit rated voltage.

fRated in accordance with U.S. Government D.O.E. test procedures and/or ARI Standard 210.

tRated in accordance with ARI Standard 270.

**The capacity ratings of single-phase units are in accordance with U.S. Government D.O.E. test procedures and/or A.G.A. certification requirements. For

3-phase units, the efficiency rating is a product thermal efficiency rating determined under continuous operating conditions, independent of any

installed system.

ttRequIred filter areas shown are based on the larger of the ARI-rated cooling airflow or the heating airflow at a velocity of 300 ft/min for disposable type

or 450 ft/mln for hIgh-capacIty type. Air filter pressure drop must not exceed 0.08 in.-water.

48N 48N

208/230—3 460-3

187—253

31.6

414—506

14.6

37.0 17.2

14

0.20 0.20

8.4

8.4

100,000 100,000

80,000

— —

80,000

960

640

48N

460—3

14.6

25

17.2

14

110

59,500

2000

0.20

8.4

120,000

1975

8

Page 9

4. Insulate low-voltage wires for highest voltage con

tained within conduit when low-voltage control wires

are run in same conduit as high-voltage wires.

5. Do not deunage internal components when drilling thru

any panel to mount electrical hardware, conduit, etc.

A. High-Voltage Connections

The unit must have a separate electrical service with a field-

supphed, waterproof, fused disconnect switch mounted at,

or within sight from the unit. Refer to the unit rating plate

for maximum fuse size and minimum circuit amps (ampac

ity) for wire sizing. Tables 2 thru 7 show recommended wire

sizes based on rating plate data.

The field-supphed disconnect switch box may be mounted

on the unit over the high-voltage inlet hole in the control

corner panel. See Figs. 2 and 3.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Connect ground lead to chassis ground connection

when using separate ground wire.

2. Run high-voltage leads into unit control box and con

nect to contactor. See unit wiring label, and Fig. 8.

B. Special Procedures for 208-V Operation

A WARNING

Make sure that the power supply to the unit is switched

OFF before making any wiring changes. Electrical

shock can cause personal injury or death.

For operation on 208 volts, disconnect the orange

transformer-primary lead from the contactor. See the unit

wiring label. Remove the tape and cover from the terminal

on the end of the red transformer-primary lead. Save the

cover. Connect the red lead to the contactor terminal from

which the orange lead was disconnected.

Using the cover removed from the red lead, insulate the

loose terminal on the orange lead. Wrap the cover with elec

trical tape so that the metal terminal can not be seen.

Indoor blower motor speed taps should be changed for 208V

operation on 208/230v rated units. Interchange motor leads

at printed circuit board (PCI) in unit control box. High

speed for coohng and medium speed for heating operation.

See Step 9-C and unit wiring label. Do not change blower

speed setting for 460V rated units.

C. Control Voltage Connections

Locate the room thermostat on an inside wall in the space

to be conditioned where it will not be subjected to either a

coohng or heating source or direct exposure to sunhght.

Mount the thermostat 4 to 5-ft above the floor.

Use No. 18 AWG color-coded, insulated (35 C minimum)

wires to make the control voltage connections between the

thermostat and the unit. If the thermostat is located more

than 100-ft from the unit (as measured along the control

voltage wires), use No. 16 AWG color-coded, insulated (35 C

minimum) wires.

A grommeted, control voltage inlet hole is located in the

panel adjacent to the control access panel. See Figs. 2 and 3.

Run the low-voltage leads from the thermostat, thru the

inlet hole, and to the control voltage terminals through a

hole in the bottom of the unit control box. Pass control volt

age leads through wire ties located under unit control box.

Connect the thermostat leads to the terminals as shown in

Fig. 8.

D. Heat Anticipator Setting

The room thermostat heat anticipator must be properly

adjusted to ensure proper heating performance. Set the heat

anticipator, using an ammeter to determine the exact

required setting.

NOTE: For thermostat selection purposes, use 1.0 amp for

the approximate required setting.

THERMOSTAT (TYPICAL)

-TERMINAL BOARD

rCONTACTOR TERMINALS

(SEE UNIT WIRING LABEL)

©5^

CONTROL BOX

• FIELD CONTROL-VOLTAGE WIRING

' FIELD HIGH-VOLTAGE WIRING

Fig. 8—High and Control Voltage Connections

Failure to make a proper heat anticipator adjustment will

result in improper operation, discomfort to the occupants of

the conditioned space, and inefficient energy utilization;

however, the required setting may be changed shghtly to

provide a greater degree of comfort for a particular

installation.

E. Circuit Breaker

Unit has manual reset circuit breaker which is located in the

low voltage wiring box adjacent to low voltage terminal

board. If unit fails to operate, first check breaker for tripped

position. If breaker is tripped, re-set and try to start unit. If

breaker continues to trip there is a problem in the low volt

age electrical circuit. (Electrical short, ground, or trans

former overload) Correct the condition and check for normal

unit operation.

Step 7—Preparing Unit for Startup

DANGER: Failure to observe the following warnings

could result in serious personal injury;

1. Follow recognized safety practices and wear protec

tive goggles when checking or servicing refrigerant

system.

2. Do not operate compressor or provide any electric

power to unit unless compressor termineJ cover is in

place and secured.

3. Do not remove compressor terminal cover until all

electrical sources have been disconnected.

4. Reheve all pressure from system before touching or

disturbing anything inside terminal box if refriger

ant leak is suspected around compressor terminals.

5. Never attempt to repair soldered connection while

refrigeremt system is under pressure.

6. Do not use torch to remove any component. System

contains oil emd refrigerant under pressure. To

remove a component, wear protective goggles and

proceed as follows:

a. Shut off gas supply and then electrical power to

unit.

b. Relieve all pressure from system.

c. Cut component connecting tubing with tubing

cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

r

GND

FIELD SUPPLIED

FUSED DISCONNECT

- 3-PHASE

UNITS ONLY

A WARNING

A87380

9

Page 10

A. Prestartup Procedures

Proceed as follows to inspect eind prepare the unit for initial

startup:

1. Remove all access panels.

2. Read and follow instructions on aU WARNING, CAU

TION, and INFORMATION labels attached to, or

shipped with unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. Detecting oil generally indicates a

refrigerant leak. Leak-test all refrigerant tubing

connections using electronic leak detector, hahde

torch, or hquid-soap solution. If refrigerant leak is

detected, see “Refrigerant Leaks” in the next part

of this section.

c. Inspect aU field- and factory-wiring connections. Be

sure that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and

handling, carefully stredghten fins with a fin comb.

4. Verify the following conditions:

A WARNING

Do not purge gas supply into the combustion cham

ber. Do not use a match or other open flame to check

for gas leaks. Failure to adhere to this warning could

result in an explosion.

a. Make sure that gas supply has been purged, and

that aU gas piping has been checked for leaks.

b. Make sure that outdoor fan blade is correctly posi

tioned in fan orifice. Blades should clear fan motor

by no more than 1/4-in..

c. Make sure that air filter(s) is in place.

d. Make sure that condensate drain pan is filled with

water to ensure proper drainage.

e. Make sure that all tools and miscellaneous loose

parts have been removed.

Unit is now ready for initial startup.

B. Refrigerant Leaks

Proceed as foUows to repair a refrigerant leak and to charge

the unit:

1. Locate leak and ensure that refrigerant system pres

sure has been relieved.

2. Repair leak following accepted practices.

NOTE: Install a filter-drier whenever the system has been

opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system

and leak-test unit.

4. Evacuate refrigerant system if additional leaks are not

found.

5. Charge unit with R-22 refrigerant, using a volumetric-

charging cylinder or accurate scale. Refer to unit rating

plate for required charge. Be sure to add extra refriger

ant to compensate for internal volume of filter-drier.

NOTE: See Step 9, part B for checking and adjusting refrig

erant charge.

Step 8—Heating Section Startup and Adjustments

A CAUTION

Complete the required procedures given in Step 7, '

paring Unit for Startup,” before starting the unit.

‘Pre-

Do not jumper any safety devices when operating the unit.

Ensure that burner orifices are properly aligned. Unstable

operation may occur when the burner orifices in the mani

fold are misaligned.

NOTE: When installing a unit in extremely cold chmate

areas, a run-in period for the inducer motor is recom

mended. After the unit has been installed disconnect the red

wire from terminal 2 at the ignition control (IGN) and

jumper terminals R-W at the control voltage termineJ

board. See Figs. 12, 13, & 14. The inducer motor should run

but burner ignition will not occur. Allow inducer motor to

run for 4 to 5 hours. Reconnect red wire to terminal 2 at

ignition control (IGN) and remove R-W jumper at the con

trol voltage terminal board. Proceed as follows to complete

heating section start up.

Follow the fighting instructions on the heating section oper

ation label (located inside the burner access door) to start

the heating section.

However, when fighting the unit for the first time, perform

the following additional steps:

1. If the gas supply pipe was not purged before connect

ing the unit, it will be full of air. It is recommended

that the ground joint union be loosened, and the supply

fine be allowed to purge until the odor of gas is

detected. Never purge gas fines into a combustion

chamber. Immediately upon detection of gas odor,

retighten the union. Allow 5 minutes to elapse, then

fight unit in accordance with Step 8, part A below.

A. Checking Heating Controi Operation

Start and check the unit for proper heating control opera

tion as follows: (See furnace fighting instructions located

inside burner access panel.)

Place the room thermostat SYSTEM switch in the HEAT

position and the FAN switch in the AUTO position. Set the

heating temperature control of the thermostat above room

temperature. Observe that after built-in time delays, the

pilot automatically fights, the burners fight, and the blower

motor starts. Observe that the burners and pilot go out, and

that after a built-in delay the blower motor stops when the

heating control setting of the thermostat is satisfied.

NOTE: 060 size 460V models are equipped with a 3-phase

blower motor. Check blower wheel for correct rotation as

indicated by arrow on blower housing. If blower wheel

rotates in opposite direction, reverse any two blower motor

leads or any two fine voltage leads. Recheck blower wheel

rotation if necessary to reverse leads.

B. Gas Input

Check gas input and manifold pressure after unit start-up.

(See Table 8) If adjustment is required proceed as follows.

A CAUTION

These units are designed to consume the rated gas

inputs using the fixed orifices at specified manifold

pressures as shown in Table 8. DO NOT REDRILL

THE ORIFICES UNDER ANY CIRCUMSTANCES.

The rated gas inputs shown in Table 8 are for eiltitudes from

sea level up to 2000-ft above sea level. These inputs are

based on natural gas with a heating value of 1050 Btu/ft^ at

0.65 specific gravity, or LP (propane) gas with a heating

value of 2500 Btu/ft^ at 1.5 specific gravity. For elevations

above 2000-ft, reduce input 4% for each 1000-ft above sea

level. When the gas supply being used has a different heat

ing value or specific gravity, refer to national and local

10

Page 11

codes, or contact your Distributor or Branch to determine

the required orifice size.

C. Adjusting Gas Input

The gas input to the unit is determined by measuring the

gas flow at the meter or by measuring the manifold pres

sure. Measuring the gas flow at the meter is recommended

for natural gas units. The manifold pressure must be mea

sured to determine the input of propane gas units.

1. Measuring Gas Flow at Meter Method—Natural Gas

Units

Minor adjustment can be made by changing the manifold

pressure. The manifold pressure must be maintained

between 3.2 and 3.8-in. water. If larger adjustments are

required, change main burner orifices following the recom

mendations of national and local codes.

NOTE: All other apphances that use the same meter must

be turned off when gas flow is measured at the meter.

Proceed as follows:

Turn off gas supply to unit.

a.

Remove pipe plug on outlet of gas valve, then con

b.

nect manometer at this point. Turn on gas to unit.

Record number of seconds for gas meter test dial to

c.

make one revolution.

Divide number of seconds in step c into 3600 (num

ber of seconds in 1 hour).

Multiply result of step d by the number of cubic ft

e.

shown for one revolution of test dial to obtain cubic

ft of gas flow per hour.

f. Multiply result of step e by Btu heating value of gas

to obtain total measured input in Btuh. Compare

this value with heating input shown in Table 8.

(Consult the local gas suppher if the heating value

of gas is not known.)

Example: Assume that the size of test dial is 1 cubic ft, one

revolution takes 30 seconds, eind the heating value of the

gas is 1050 Btu/ft®, then proceed as follows:

a. 30 seconds to complete one revolution.

b. 3600 -30 = 120.

c. 120 X 1 = 120 ft® of gas flow/hr.

d. 120 X 1050 = 126,000-Btuh input.

If the desired gas input is 125,000 Btuh, only a minor

change in the manifold pressure is required.

Observe manifold pressure and proceed as follows to adjust

gas input:

Remove cover screw over regulator adjustment

a.

screw on gas valve.

Turn regulator adjustment screw clockwise to

b.

increase gas input, or turn regulator adjustment

screw counterclockwise to decrease input. Manifold

pressure must be between 3.2 and 3.8-in.-water.

A WARNING

Unsafe operation of the unit may result if manifold

pressure is outside this range. Personal injury or unit

damage may result.

c. Replace cover screw cap on gas valve.

d. Turn off gas supply to unit. Remove manometer

from pressure tap. Replace pipe plug on gas valve.

Turn on gas to unit. Check for leaks.

2. Measuring Manifold Pressure—Propane Gas Units

The main burner orifices on a propane gas unit are sized for

the unit rated input when the manifold pressure is 10.5-in.

water.

Proceed as follows to adjust gas input on a propane gas

unit:

a. Turn off gas to unit.

b. Remove pipe plug on outlet of gas valve then con

nect memometer at this point.

c. Turn on gas to unit.

d. Remove cover screw over REG ADJ screw on gas

valve.

e. Adjust regulator adjustment screw for a manifold

pressure reading of 10.5-in.-water. Turn adjusting

screw clockwise to increase manifold pressure, or

turn adjusting screw counterclockwise to decrease

manifold pressure.

f. Replace cover screw.

g. Turn off gas to unit. Remove manometer from pres

sure tap. Replace pipe plug on gas valve, then tmrn

on gas to unit. Check for leaks.

D. Check Burner Flame

Observe the unit heatmg operation, and watch the burner

flames through the observation port to see if they are light

blue and soft in appearance, and the flames are approxi

mately the same for each burner. See Fig. 10.

E. Blower Heat-Relay Operation

Blower relay PCI (See the unit wiring diagram.) is located in

the control box and adjusts to permit either longer or

shorter “off” cycles. The “on” cycle is factory set for 1 min

ute on timing. The adjusting dial on the relay (See Fig. 9) is

factory-set at the minimum position to provide optimum

performance for most installations. On unusual installa

tions, the length of time the blower remains on may require

increasing. To increase blower operation time, rotate the

adjusting dial counter-clockwise. To decrease blower opera

tion time, rotate dial clockwise. (Minimum time 1 minute.)

Maximum time 3 minutes.)

F. Airflow and Temperature Rise

The heating section of each size of unit is designed and

approved for heating operation within the temperature rise

range stamped on the unit rating plate.

Table 8—Rated Gas Inputs at Indicated Manifold Pressures

Gas Supply Pressure

Number

Model

No.

48NLT018, 024, 030

48NHT024, MT030, LT036, LT042

48NHT030, MT036, MT042, LT048, LT060 4 5.0

48NHT036, HT042, MT048, MT060 5 5.0 13.6 11.0 13.6 3.5

48NVT036, VT042, HT048, HT060 6 5.0 13.6 11.0 13.6 3.5 10.5 5536544 120,000 55365-55 120,000

♦Based on altitudes from sea level up to 2000 feet above sea level. For altitudes above 2000 feet, reduce input rating 4% for each 1000 feet above sea

level. In Canada, from 2000 ft. above sea level to 4,500 ft. above sea level, derate the unit 10%.

fWhen a 48N is converted to propane, the burners must be modified. See kit instructions.

of

Orifices

Min Max Min Max Natural Propane

2 5.0 13.6

3 5.0 13.6 11.0

(in. wc)

Natural Propane

11.0 13.0 3.5 10.5

13.6

11.0 13.0 3.5 10.5 55365-44 80,000 55365-55 80,000

13.0

Manifold

Pressure

(In. wc)

3.5

10.5

12.5

Natural Gas

Orifice

P/N

55365-44

55365-44

55365-44 100,000

Heating

Input

(Btuh)*

40,000 55365-55 40,000

60,000 55365-55 60,000

Propane Gast

Input

P/N

55365-55

Heating

(Btuh)*

100,000

11

Page 12

Table 9 shows the approved temperature rise range for each

unit, and the air delivery Cfm at various temperature rises.

The heating operation airflow must produce a temperature

rise that fedls within the approved range.

Refer to Step 9, part C, of these instructions to adjust heat

ing airflow, when required.

G. Safety Check of Limit Control

The control shuts off the combustion gas supply and ener

gizes the circulating-air blower motor if the furnace

overheats.

The recommended method of checking this hmit control is

to gradually block off the return air after the furnace has

been operating for a period of at least 5 minutes. As soon as

the hmit control functions, the retum-air opening should be

unblocked to permit normal eiir circulation. By using this

method to check the hmit control, it can be estabhshed that

the hmit is functioning properly and the furnace will “fail

safe” if there is a restricted circulating air supply or motor

failure. If the hmit control does not function during this

test, the cause must be determined emd corrected.

H. Heating Sequence of Operation See Figs. 12,13 or 14

Room thermostat cahs for heat closing circuit between “ R”

and “W” 24 volt control circuit terminals. (Power to the

“R” terminal is supphed through “CB” Circuit Breaker and

“LS, ALS Emd FL” safety switches) “PC2” inducer control

board is energized which starts the inducer motor “IM”.

The inducer motor comes up to speed, the vacuum in the col

lector box increases, opening the normahy closed and clos

ing the normahy open contacts of the contacts of the pres

sure switch “PS” energizing the circuit to the “IGN” igni

tion control and the phot valve “PV”. If the flame sensor

proves the presence of the pilot flame the internal switching

of the ingition control de-energizes the spark generator and

energizes the main gas valve, “MV” and the “IFR2” elec

tronic timer. Gas flows to the main burners and is ignited

by the phot flame. The “PCI” electronic timer will close the

“IFR2” relay between 60 to 90 seconds after the burners

are ignited and the blower motor “IFM” will start. When

the thermostat is satisfied the “R” and “W” circuit is

opened and power is removed from the “PC2” inducer con

trol and the “IGN” ignition module which causes the main

gas vedve to close instantly and the inducer motor is de

energized. The electronic timer “PCI” will keep the “IFM”

blower motor running Em additional 1 to 3 minutes. Then

the blower stops and the unit is on standby until another

call for heat.

NOTE: If the main limit switch opens due to the unit over

heating, the blower motor is turned on thru the electronic

board.

If the pilot fails to hght within a 50 second trail for ignition

period from the initial caff for heat the ignition control

“IGN” will lockout the system and prevent further hghting

attempts. To reset, open the “R” - “W” thermostat circuit

for 30 seconds and re-close.

I. Limit Switches

Furnace limit switch “LS” (See Figs. 12, 13 or 14.) closes

the gas valve if the leaving-eur temperature exceeds the

maximum allowable temperature.

Normally closed hmit switch “LS” completes the control

circuit through the thermostat “R” circuit, See Figs. 12, 13

or 14. Should the leaving-air temperature rise above the

maximum allowable temperature the hmit switch opens emd

the “R” control circuit “bresiks.” Any interruption in the

“R” control circuit instantly closes the gas valve and stops

gas flow to the burners and phot. The blower motor contin

ues to run until the time-delay sequence of blower relay

“PCI” is completed.

When the air temperature at the hmit switch drops to the

low-temperature setting of the hmit switch, the switch

closes and completes the “R” control circuit. The electricspark ignition system cycles and the unit retm-ns to normal

heating operation.

J. Auxiliary Limit Switch

Auxihary hmit switch “ALS” is a temperature-actuated

manual reset switch and is connected in series with the hmit

switch “LS.” The function of the switch is to prevent abnor

mal blower compartment temperatures. The switch is

mounted on the blower housing. When the temperature at

the auxihary switch reaches the maximum allowable tem

perature the “R” control circuit “breaks”, closing the gas

valve and stopping gas flow to the burners and pilot. To

reset switch push in on red push button. If it cycles again,

shut down the unit and cah for service.

K. Fusible Link

Fusible Link “FL” is a temperature-actuated device con

nected in series with the hmit switch “LS.” It is located iu

the wire bundle adjacent to the burner manifold.

The function of the device is to prevent abnormaUy high

burner compartment temperatures. The hnk will melt if an

overheating condition caused by inadequate combustion air

supply or improper venting occurs. Do not jumper this fuse.

Correct the condition and replace the fuse with an identical

part.

Step 9—Cooling Section Startup and Adjustments

CAUTION

Complete the required procedures given in Step 7, “Pre

paring Unit for Startup,” before starting the unit.

Do not jumper emy safety devices when operating the

unit.

Do not operate the compressor when the outdoor tem

perature is below 55 F (unless accessory low-temp kit is

installed).

Do not rapid-cycle the compressor. AUow 5 minutes

between “on” cycles to prevent compressor damage.

A. Checking Cooling Control Operation

StEurt and check the unit for proper cooling control operation

as follows:

1. Place room thermostat SYSTEM switch in OFF posi

tion. Observe that blower motor starts when FAN

switch is placed in ON position and shuts down when

FAN switch is placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN

switch in AUTO position. Set cooling control below

room temperature. Observe that compressor, con

denser fan, and evaporator blower motors start.

Observe that cooHng cycle shuts down when control

setting is satisfied. Blower motor has off delay of

approximately one minute on shut down.

3. When using an autochangeover room thermostat, place

both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in heating mode when tem

perature control is set to “caU for heating” (above

room temperature) and operates in coohng mode when

temperature control is set to “call for cooling” (below

room temperature).

NOTE: 060 size 460V models are equipped with a 3-phase

12

Page 13

blower motor. Check blower wheel for correct rotation as

indicated by arrow on blower housing. If blower wheel

rotates in opposite direction, reverse any two blower motor

leads or any two line voltage leads. Recheck blower wheel

rotation if necessary to reverse leads.

B. Checking and Adjusting Refrigerant Charge

The refrigerant system is fuUy charged with R-22 refriger

ant, tested, and factory-sealed.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-22

charge. For all appHcations, the correct R-22 charge for the

best performance is the charge that results in a suction gas

superheat of 5 F at the compressor inlet when the unit is

operating at the ARI rating conditions of 95 F DB outdoor

and 80 F DB/67 F WB indoor.

A superheat charging label is attached to the outside of the

compressor access door. The label includes a “Field Super

heat Charging Table” and a “Required Suction-Tube (F)”

temperature chart.

An accurate superheat thermocouple-, or thermistor-type

thermometer, a shng psychrometer, and a gauge manifold

are required when using the superheat charging method for

evaluating the unit charge. Do not use mercury or small

dial-type thermometers because they are not adequate for

this type of measurement.

A CAUTION

When evaluating the refrigerant charge, an indicated

adjustment to the specified factory charge must always

be very minimal. If a substantial adjustment is indi

cated, an abnormal condition exists somewhere in the

cooling system; such as insufficient airflow across

either coil or both coils.

Proceed as follows:

1. Remove caps from low- and high-pressure service

fittings.

2. Using hoses with valve core depressors, attach low-and

high-pressure gauge hoses to low- and high-pressure

service fittings, respectively.

3. Start unit in cooling mode and let unit run until system

pressures stabilize.

4. Measure and record the following:

a. Outdoor eunbient-air temperature (F DB).

b. Evaporator inlet-air temperature (F WB).

c. Suction-tube temperature (F) at low-side service fit

ting.

d. Suction (low-side) pressure (PSIG).

5. Using “Field Superheat Charging Table,” compare

PILOT FLAME BURNER FLAME

outdoor-air temperature (F DB) with evaporator inletair temperature (F WB) to determine desired system

operating superheat temperature. See Table 10.

6. Next, using “Required Suction-Tube (F)” table, com

pare desired superheat temperature with suction (lowside) operating pressure (PSIG) to determine proper

suction-tube temperature. See Table 11.

7. Compare actual suction-tube temperature with proper

suction-tube temperature. Using a tolerance of ,± 3 F,

add refrigerant if actual temperature is more than 3 F

higher than proper suction-tube temperature, or

remove refrigerant if actual temperature is more than

3 F lower than required suction-tube temperature.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, see Step 7, part B, of these instructions.

C. Indoor Airflow and Airflow Adjustments

A CAUTION

For coohng operation, the recommended airflow is 350

to 450 Cfm per each 12,000 Btuh of rated cooling capac

ity. For heating operation, the airflow must produce a

temperature rise that falls within the range steunped on

the unit rating plate.

Model 018-048 size units have direct-drive blower motors.

Blower motors are factory-connected to dehver the proper

heating and coohng airflows at normal external static pres

sures (medium speed coohng, low speed heating for 230v

units and high speed coohng, heating for 460v units).

060 size units have belt drive blower motors which have the

motor puUey factory set at four turns open.

For 208v operation on 208/230v rated direct drive units,

interchange motor leads to high speed for coohng and

medium speed for heating operation.

Table 9 shows the temperature rise at various airflow rates.

Tables 12 and 13 show both heating and coohng airflows at

various external static pressures. Refer to these tables to

determine the airflow for the system being instaUed. See

Tables 2 thru 7 for the rated heating and coohng airflows.

NOTE: Be sure that ah supply- emd return-air grflles are

open, free from obstructions, and adjusted properly.

A WARNING

Disconnect electrical power to the unit before changing

blower speed. (Be sure to turn off gas supply before dis

connecting electrical power.) Electrical shock can cause

personal injury or death.

13

Page 14

A CAUTION

Do not change the blower-motor lead connections on

460-V units from the factory setting. Damage to unit

may result.

The heating emd/or cooling airflow of 208/230-V direct-drive

blower motors can be changed by changing the lead connec

tions of the blower motor. The motor leads are color-coded

as follows:

black = high speed

blue = medium speed

red = low speed

NOTE: For all 208/230 V direct-drive units, the motor lead

connected to the heat relay (L) on PCI blower control deter

mines the heating speed and resulting air-flow; and the

motor lead connected to the cooMng relay (H) on PCI blower

control determines the coohng speed and resulting airflow.

See the unit wiring label.

To change the heating and/or coohng speed of a direct-drive

motor, connect the appropriate color-coded lead to the

appropriate relay. Connect unused motor lead to terminal

Ml on the PCI blower control.

When installing a 208- or 230-V direct-drive unit that is

factory-connected for heating and coohng speeds that are

not the same, and the same speed for both heating and cool

ing is required for a particular application, connect the

appropriate color-coded lead to terminal H of coohng relay

and connect a field-supplied jumper between terminal L on

heat relay and terminal H of coohng relay. Connect unused

leads to terminals Ml and M2 on PCI blower control.

D. Unit Controls

All compressors have the following internal-protection

controls:

1. High-pressure Relief Valve—T\ds valve opens when the

pressure differential between the low and high side

becomes excessive.

2. Compressor Overload—This overload interrupts power

to the compressor when either the current or internal

temperature become excessive, and automatically

resets when the internal temperature drops to a safe

level. This overload may require up to 60 minutes (or

longer) to reset; therefore, if the internal overload is

suspected of being open, disconnect the electrical

power to the unit and check the circuit thru the over

load with an ohmmeter or continuity tester.

E. Cooling Sequence of Operation

NOTE: Although the actual unit wiring may vary slightly

from that shown in Figs. 12, 13 or 14, the sequence of opera

tion win not be affected.

With the room thermostat SYSTEM switch in the COOL

position and the FAN switch in the AUTO position, the

cooling sequence of operation is as follows:

When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the

thermostat completes the circuit between thermostat termi

nal “R” to terminals “Y” and “G.” These completed cir

cuits through the thermostat connect contactor coil “C”

(through unit wire “Y”) and relay coil “IFRl” (through unit

wire “G”) across the 24-volt secondary of tremsformer

“TRAN.”

The normally open contacts of energized contactor “C”

close and complete the circuit through compressor motor

“COMP” and condenser fan motor “OFM.” Both motors

start instantly.

The set of normally open contacts of energized relay

“IFRl” closes and completes the circuit through evapora

tor blower motor “IFM.” The blower motor starts

instantly.

NOTE: The cooling cycle remains “on” until the room

termperature drops to point that is slightly below the cool

ing control setting of the room thermostat. At this point,

the thermostat “breaks” the circuit between thermostat ter

minal “R” to terminals “Y” and “G.” These open circuits

deenergize contactor coU “C” and relay coil “IFRl”. The

condenser and compressor motors stop. After a one minute

delay the blower motor stops. The unit is in a “standby”

condition, waiting for the next “call for cooling” from the

room thermostat.

Step 10—Care and Maintenance

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic mainte

nance must be performed on this equipment. This combina

tion heating/cooling unit should be inspected at least once

each year by a qualified service person.

NOTE TO EQUIPMENT OWNER: Consult your local Dealer

about the avedlability of a maintenance contract.

A WARNING

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools, and equipment. If you do not possess these, do

not attempt to perform any maintenance on this equip

ment other than those procedures recommended in the

Users Manual. A FAILURE TO HEED THIS WARN

ING COULD RESULT IN SERIOUS PERSONAL

INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

The rninimum maintenance requirements for this equipment

are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect cooling coil, drain pan, and condensate drain

each cooling season for cleanliness. Clean when

necessary.

3. Inspect blower motor and wheel for cleanliness and

check lubrication each heating and cooling season.

Clean and lubricate when necessary.

4. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service when necessary.

5. Check emd inspect heating section before each heating

season. Clean and adjust when necessary.

6. Check and clean vent screen if needed.

A WARNING

A failure to foUow these warnings could result in seri

ous personal injury:

1. Turn off gas supply, then turn off electrical power

to the unit before performing any maintenance or

service on the unit.

2. Use extreme caution when removing panels and

parts. As with any mechanical equipment, personal

injury can result from sharp edges, etc.

3. Never place anything combustible either on, or in

contact with, the unit.

4. Should overheating occur, or the gas supply fail to

shut off, shut off the external main manual gas

valve to the unit, then shut off the electrical supply.

14

Page 15

Table 9—Air Delivery (Cfm) at Indicated

Temperature Rise and Rated Heating Input

Nominal Size

48NLT018

48NLT024

48NLT030

48NHT024

48NMT030

48NLT036

48NLT042 60,000

48NHT030

48NMT036

48NMT042

48NLT048

48NLT060 80,000 2370

48NHT036

48NHT042

48NMT048

48NMT060 100,000

48NVT036

48NHT042

48NHT048

48NHT060

NOTE: Dashed areas of the table do not fall in the approved temperature rise range of the unit.

Heating

Input (Btuh) 25

40,000

60,000

80,000

100,000

120,000

_

— — — —

—

—

120,000

30 35 40

—

987 846 740

_ _ _

_

1481 1269

1975

—

2469 2116

— —

2962 2539 2222

1111

1693 1481

2116 1851

1851

—

45 50

658 592

987 888

987

888 808

1316 1185

1316 1185 1077

1646

1481

1646 1481 1346 1234

—

1975

1777 1616

1777

Table 10—Superheat Charging Table

(Superheat Entering Suction Service Valve)

Outdoor

Temp (F)

55 9

60 7

65

70

75

80

85 —

90

95 —

100

105

110 — — —

115

50

52 54 56

12 14 17

10 12 15

—

6 10 13

— —

—

—

—

—

— ~ 6 9 12

— —

— —

_

— —

— — —

—

— —

7 10

_

—

— —

—

— —

—

— —

—

— — — — — — —

NOTE: Do not attempt to charge system under these conditions or refrigerant slugging may occur.

Indoor Coil Entering Air Temp (F WB)

58 60 62 64

20 23

18 21

16 19

13 16

26 29

24 27 30

21 24 27

19 21 24

15 18 21 24 28

5 8

—

—

—

— —

12 15 18

_

8

5 9 13

—

11

__

— — —

— — —

— —

6

55

538

808

1077

1346

60 65 70

493

740

740

— — —

683 634 592

_ _ _

987 911

_ _

1234 1139

846

_ _

— — —

— —

1481

1616 1481

66

32 35

1367

— — — —

68

70

37

33 35

1269 1185 1111

72

40 42

38

30 33 36 38 41

27

30

33 36

31

15 19 22

21

25

28 31

26 30 33

16 210 24

10 14 18 22 25

12 15

8

20 23 27

5 9 13 17 22

11

6

15 20

8

14 18 23

75 80

790

74

40

34

27

31

29

26

25

—

—

_

—

76

45

43

39

37

35

Table 11—Required Suction-Tube Temperature (F)

(Entering Suction Service Valve)

Superheat

Temp (F) 61.5 64.2 67.1 70.0

0

35 37 39 41

2 37 39 41

4 39 41 43 45 47

6

8 43 45

10 45

41

43 45 47

47

47

49 51 53

12 47 49 51

14 49 51 53

16 51 53 55 57 59

18 53 55 57 59 61

20

22

24 59

55 57

57

59 61 63

61 63 65 67

59

26 61 63 65 67 69

28 63

65

67

30 65 67 69 71 73

32 67

34

69 71 73 75 77

36 71

69

73

71

75 77 79

38 73 75 77 79

40 75 77 79

Suction Pressure At Service Port (Psig)

43 45 47

49 ~ 51

53 55

55 57

61

69 71

73 75

81

15

73.0 76.0 79.2

43 45

47 49 51

82.4

49 51

49

49

51 53 55

53

55 57

51 53 55

55

57 59

59

57 59 61 63

59 61 63 65

61 63 65

63 65 67 69

63

65

67

69

65 67 69 71 73

69

71

73 75

71 73 75 77

73 75 77 79

75

77

79

77 79 81

79

81