48MPD,MPE62L-10R

50MP62L-10R

Single Package Electric Cooling Units

and Gas Heating/Electric Cooling Units

With Product Integrated Controls

Installation, Start-Up and Service

Instructions

CONTENTS

Page

GENERAL ................................. 2

SAFETY CONSIDERATIONS ................. 2

INSTALLATION ............................ 3-28

Jobsite Survey ............................. 3

Unit Placement ............................ 3

Roof Mount ................................ 3

Slab Mount ................................ 3

Field-Fabricated Ductwork .................. 3

Rigging .................................... 3

Condensate Drains ......................... 3

Condensate Coil Shipping Covers .......... 3

Install Outdoor Hoods ...................... 3

Make Electrical Connections ................ 14

• POWER SUPPLY

Field Electrical Connections ................ 14

• POWER WIRING

Control Wiring ............................. 17

• SENSORS

• HUMIDITY CONTROL AND HOT WATER

AND STEAM VALVES

• SPACE TEMPERATURE SENSOR (T55)

• SPACE TEMPERATURE SENSOR (T56)

(CV Applications Only)

• SPACE TEMPERATURE AVERAGING

• HEAT INTERLOCK RELAY (VAV Units Only

— Not Necessary For DAV Applications)

• OPTION AND ACCESSORY CONTROL WIRING

Carrier Comfort Network Interface .......... 23

Air Pressure Tubing ........................ 24

Gas Piping (48 Series Units Only) ............26

Installing Flue/Inlet Hoods

(48MP Units Only) .........................26

Fan Isolator Adjustment .................... 27

Check Compressor Mounting ............... 27

Install Accessories ......................... 27

PRE-START-UP ............................28-38

System Check ............................. 28

Compressor Oil ............................ 29

Evaporator-Fan Belts, Pulleys,

and Sheaves .............................. 29

Controls Configuration and Quick Test ...... 35

• SUPPLY FAN STATUS SWITCH (FS)

• CHECK FILTER SWITCH (CFS)

• ENTHALPY CONTROL SET POINT

• KEYPAD AND DISPLAY MODULE (HSIO)

CONFIGURATION

• SET UNIT TYPE

• ENTER JOB SET POINT VALUES

• CONFIGURE UNIT CONTROLS AND

FUNCTIONS

• QUICK TEST FUNCTION

Gas Pressure Check ........................38

Page

Check Supply Fan Rotation ................. 38

START-UP ................................38-42

Initial Check ............................... 38

General .....................................39

Operating Sequences ...................... 39

• SUPPLY FAN

• ECONOMIZER

• COOLING (All Units)

• OCCUPIED COOLING

• UNOCCUPIED COOLING

• OVERRIDES

• ADAPTIVE OPTIMAL START

• ADAPTIVE OPTIMAL STOP

(CV Applications Only)

• GAS HEATING, OPERATION

(48MP Units Only)

Control Loop Checkout ..................... 41

IAQ Control Loop Adjustment ............... 42

Lead/Lag Circuits .......................... 42

Final Checks ............................... 42

CONTROL SYSTEM ........................42-45

General .................................... 42

Components ............................... 42

• PROCESSOR MODULE NO. 1

• PROCESSOR MODULE NO. 2

• HIGH-VOLTAGE RELAY MODULES (DSIO)

• KEYPAD AND DISPLAY MODULE (HSIO)

Default Set Points/Changing Set Points ..... 43

Motor Protection ........................... 43

Variable Frequency Drive (VFD) ............. 43

• DISPLAY AND KEYPAD

SERVICE ..................................45-55

Service Access ............................ 45

• UNIT CONTROL BOX

• COMPRESSORS

• LIQUID SERVICE VALVES, SOLENOID VALVES,

FILTER DRIERS, AND SIGHT GLASSES

• EVAPORATOR-FAN MOTORS, PULLEYS, AND

BELTS

• POWER EXHAUST MOTORS, PULLEYS, AND

BELTS

• GAS HEAT SECTION

• UNIT CONTROL BOX

• ECONOMIZER DAMPER MOTORS

• RETURN-AIR FILTERS

• CONDENSER FANS AND FAN MOTORS

Cleaning .................................. 46

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 1

Tab 1a 1b

PC 111 Catalog No. 534-893 Printed in U.S.A. Form 48/50MP-1SI Pg 1 12-98 Replaces: 50MP-1SI

CONTENTS (cont)

Page

Lubrication ................................ 47

• COMPRESSORS

• FAN SHAFT BEARINGS

• FAN MOTOR BEARINGS

• DOOR HINGES

Coil Cleaning .............................. 47

Refrigerant Circuit ......................... 47

Oil Charge ................................. 49

Moisture/Liquid Indicator ................... 49

Filter Driers ................................ 49

Liquid Line Service Valve ................... 50

Compressor Suction and Discharge

Service Valves ............................ 50

High-Pressure Switch ...................... 50

Low-Pressure Switch ....................... 50

Pressure Relief ............................ 50

Adjustments ............................... 50

• EVAPORATOR FAN AND POWER EXHAUST

MOTOR PLATE

• BELT INSTALLATION AND TENSIONING

• PULLEY ALIGNMENT

Gas Valve Adjustment .......................52

• NATURAL GAS

GENERAL

This installation instruction contains base unit installation, start-up, and service instructions only.For complete information on PIC (Product Integrated Controls) controls and

troubleshooting, refer to separate Controls and Troubleshooting literature also enclosed in this literature packet.

Main Burners ...............................52

Page

• MAIN BURNER REMOVAL

Protective Devices ......................... 52

• COMPRESSOR PROTECTION

• EVAPORATOR-FAN MOTOR PROTECTION

• CONDENSER-FAN MOTOR PROTECTION

• HIGH- AND LOW-PRESSURE SWITCHES

Variable Frequency Drive (VFD) ............. 53

• SUPPLY FAN VFD

• EXHAUST FAN VFD

• DISPLAYING FAULT SEQUENCE

Control Modules ........................... 53

Processor Module(s) (PSIO) ................ 54

High-Voltage Relay Modules

(DSIO1 and DSIO2) ........................ 54

Refrigerant Feed Components .............. 54

Thermostatic Expansion Valve (TXV) ........ 54

Hot Gas Bypass ........................... 55

Condenser Fans ........................... 55

Compressor Removal ...................... 55

Compressor Replacement .................. 55

TROUBLESHOOTING ......................55-58

START-UP CHECKLIST ..............CL-1 to CL-4

Before performing service or maintenance operations on

unit, turn offmain power switch to unit. Electrical shock

could cause personal injury.

IMPORTANT:

1. Tune all loops immediately after starting units. Refer to Control Loop Checkout section on page 40

for more information on tuning loops.

2. The Data Reset function should be performed any

time one or more of the unit factory configuration

values are changed.

3. The HSIO (human sensor input/output) keypad and

display module is required for initial start-up of unit.

All units are shipped in STANDBYmode. The HSIO

must be used to change the unit to RUN mode. The

HSIO is not required for normal operation, however, at any time the unit needs to be transferred

back into STANDYBYmode, such as when servicing a unit, it must be done with the HSIO.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply.

Follow all safety codes, including ANSI (American National Standards Institute) Z223.1. Wear safety glasses and

work gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing operations.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service,

or maintenance can cause injury or property damage.

Refer to this manual. For assistance or additional information, consult a qualified installer or service agency.

This unit uses a microprocessor-based electronic control system. Do not use jumpers or other tools to short

out components, or to bypass or otherwise depart from

recommended procedures. Any short-to-ground of the

control board or accompanying wiring may destroy the

electronic modules or electrical components.

Disconnect gas piping from 48 Series units when leak

testing at pressures greater than 0.5 psig. Pressures greater

than 0.5 psig will cause gas valve damage resulting in

a hazardous condition. If gas valve is subjected to pressure greater than 0.5 psig, it must be replaced. When

pressure testing field-supplied gas piping at pressures of

0.5 psig or less, the unit connected to such piping must

be isolated by manually closing the gas valve.

2

INSTALLATION

Jobsite Survey —

fore installation.

1. Consult local building codes and the NEC (National

Electrical Code) (ANSI/NFPA [National Fire Protection

Association] 70) for special installation requirements.

2. Determine unit location (from project plans) or select unit

location.

3. Check for possible overhead obstructions which may interfere with unit lifting or rigging.

Do not lift unit with forklift truck. Move unit with

overhead rigging only.

Complete the following checks be-

Unit Placement — Inspect unit for transportation dam-

age. File claim with transportation agency.

Provide clearance around and above unit for airflow, safety,

and service access. Do not restrict top (area above condenser fans) in any way. Allow at least 6 ft on all sides for

rated performance, code compliance, and service.

Check unit dimensional drawings for unit arrangement and

minimum performance and service clearances.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

On units equipped with power exhaust option, high

velocity air is exhausted out the hood. Unit should be

positioned with at least 10 ft clearance between the exhaust

hood and any obstruction.Although unit is weatherproof, guard

against water from higher level runoff and overhangs.

Level by using unit frame as a reference. Physical data is

shown in Tables 1-4.

Roof Mount — Check building codes for weight distri-

bution requirements. Unit weight is shown in Table 1. Unit

may be mounted on class A, B, or C roofing material.

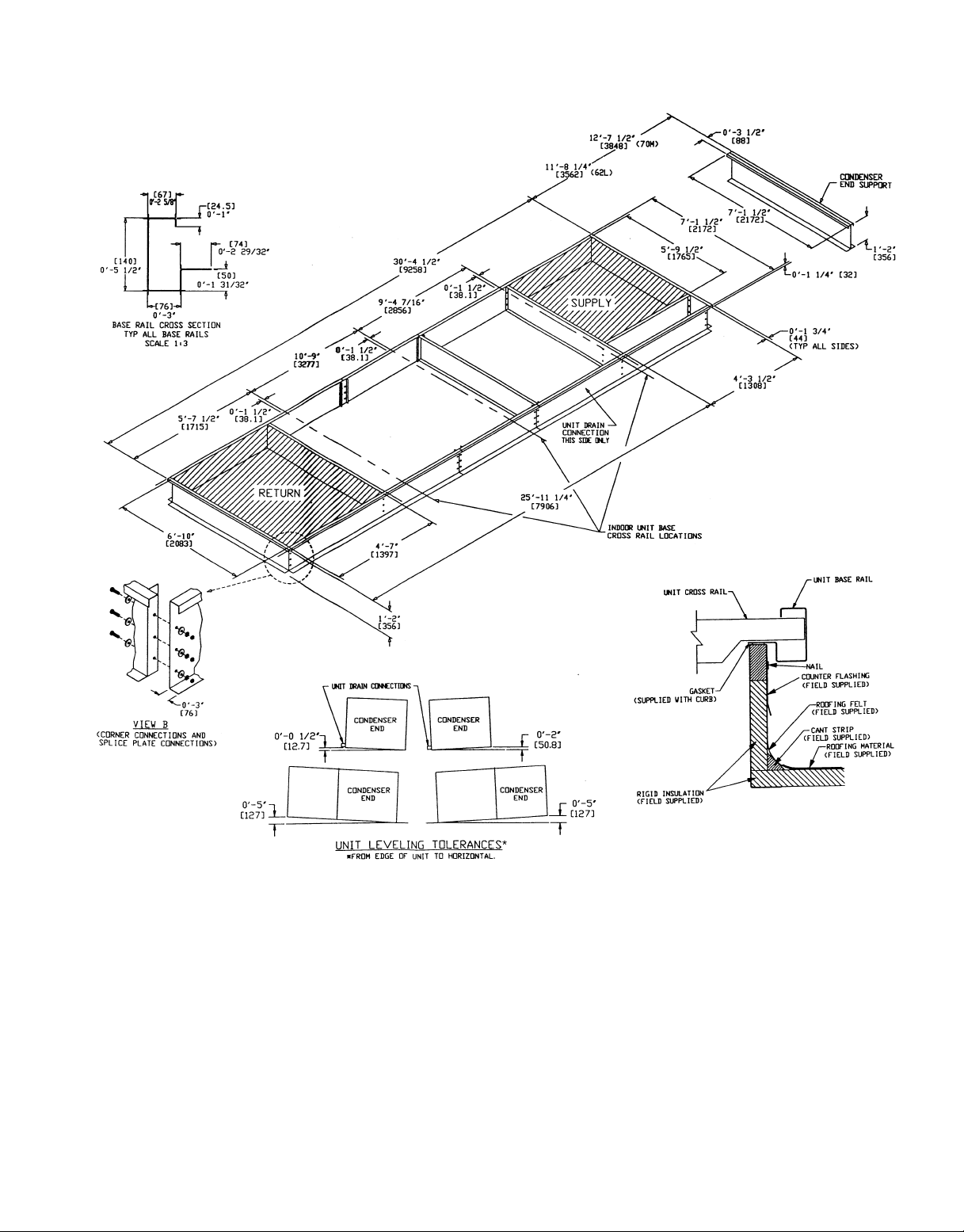

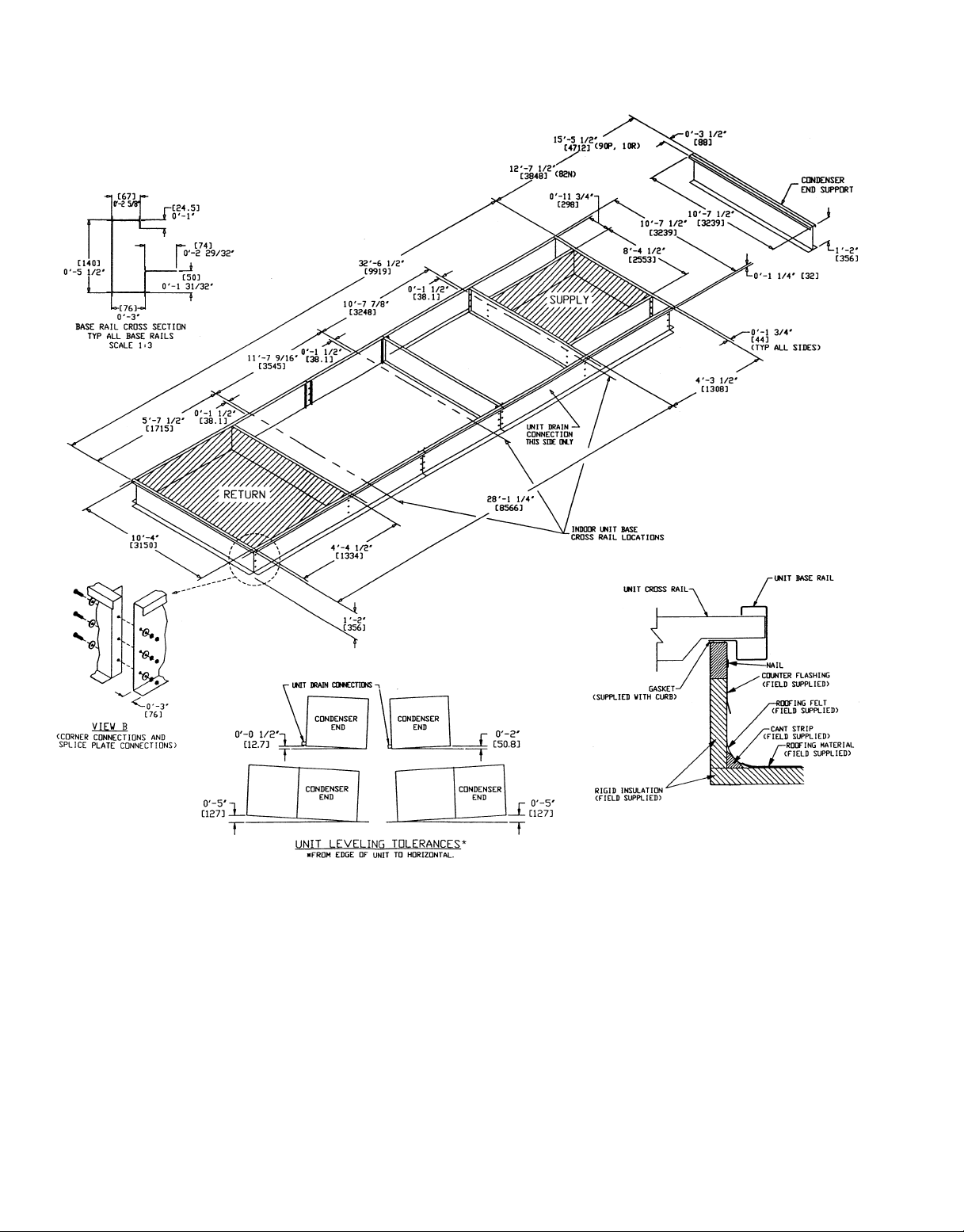

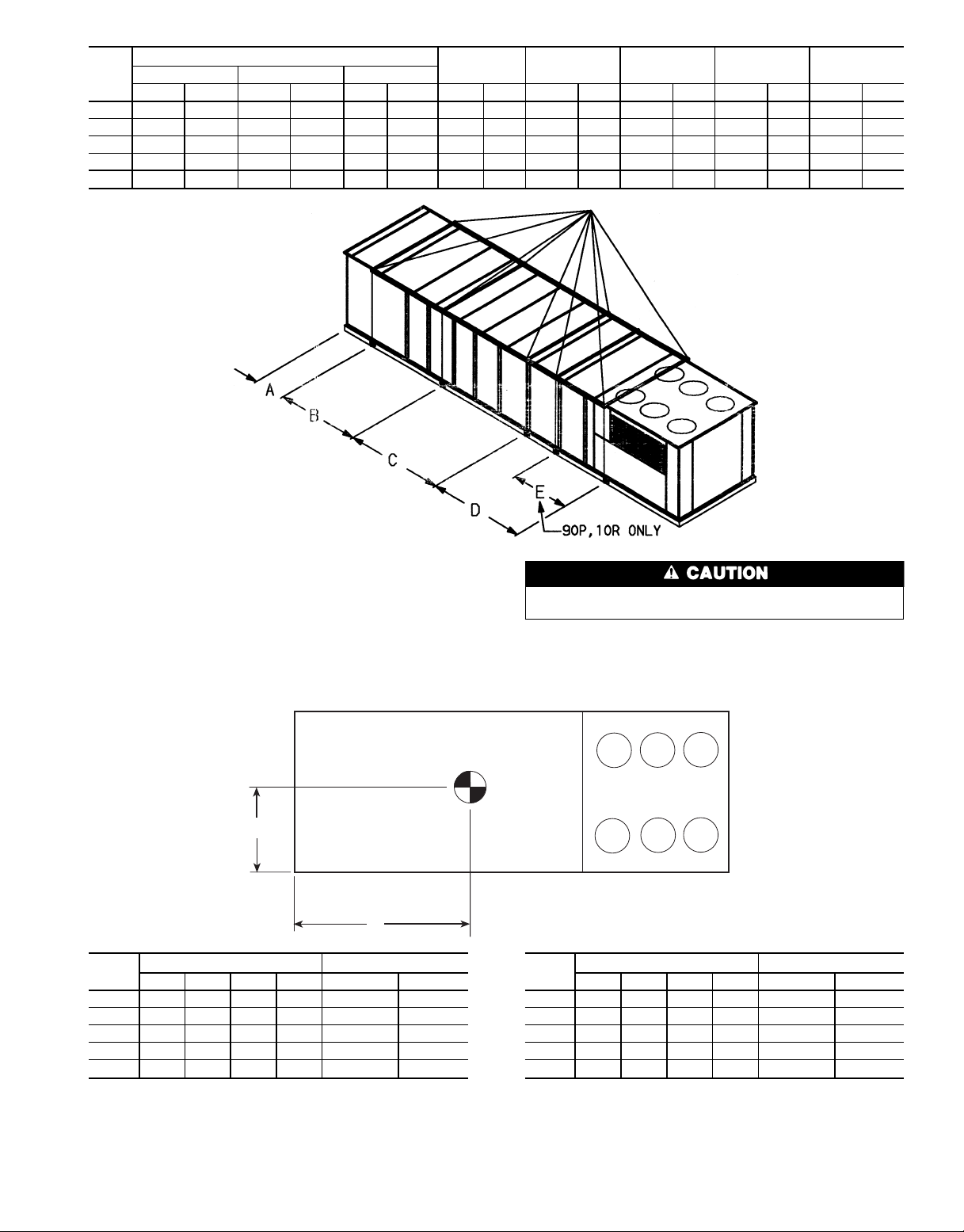

ROOF CURB — Assemble and install as described in instructions shipped with the accessory. Accessory roof curb

and information required to field fabricate a roof curb is shown

in Fig. 1 and 2. Install insulation, cant strips, roofing, and

counter flashing as required. For unit condensate drain to function properly, curb must be level or within tolerances shown

in Fig. 1 and 2.

STEEL BEAMS — If roof curb is not used, support unit

with steel beams along its entire length and then support steel

as required. As a minimum, unit must be supported across

its width at each lifting lug location.

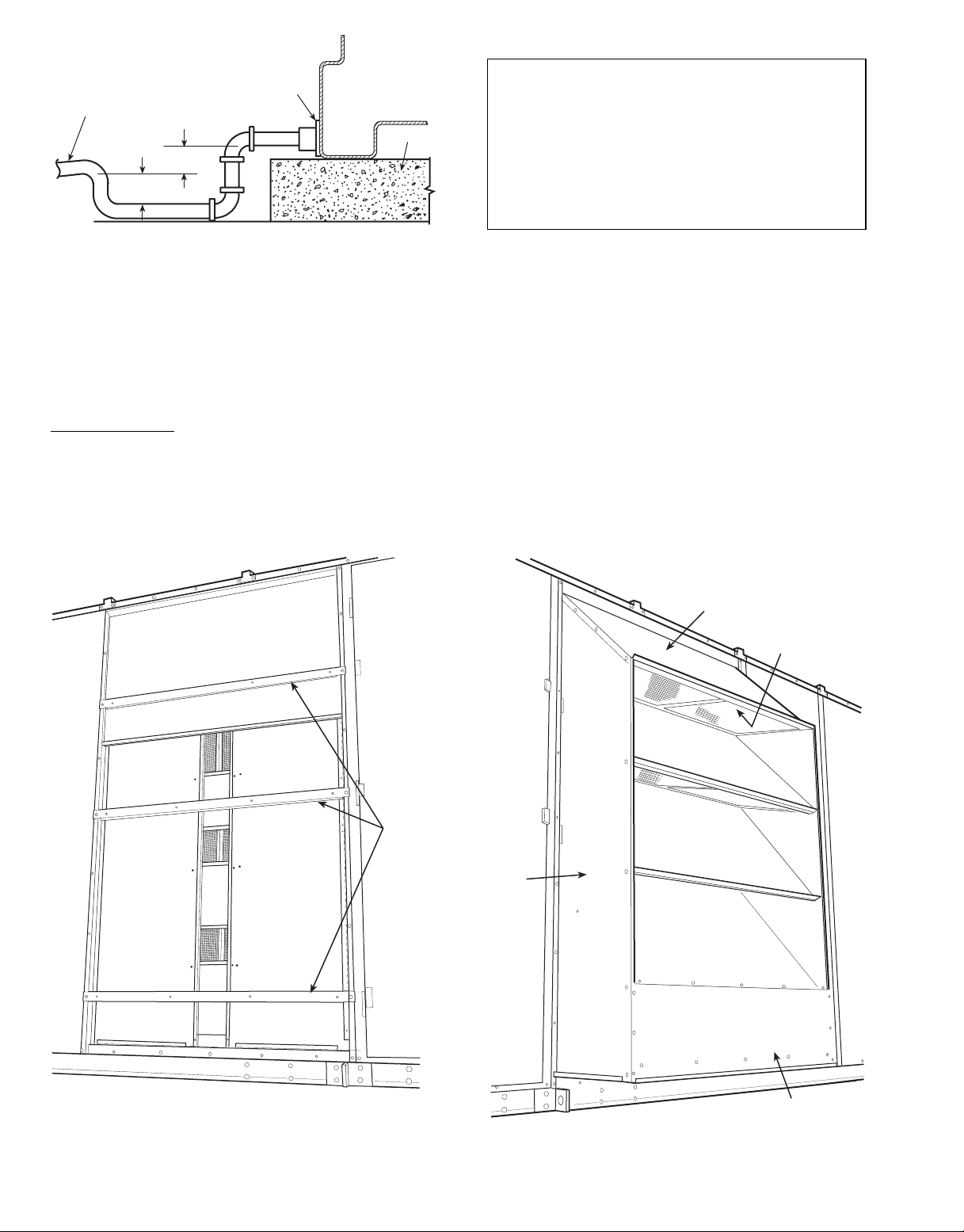

Slab Mount — Provide a level concrete slab that ex-

tends beyond unit cabinet at least 6 inches. Make a slab 8 in.

thick with 4 in. above grade. Use gravel apron in front of

condenser coil air inlet to prevent grass and foliage from obstructing airflow. Ensure that slab is of sufficient height to

allow for 7-in. condensate trap.

Field-FabricatedDuctwork — Units are designed for

vertical supply/return only.Field-fabricated ductwork should

be attached to the roof curb. Supply and return duct dimensions are shown in Fig. 1-6.

To attach ductwork to roof curb, insert duct approximately 10 to 11 in. up into roof curb. Connect ductwork to

14-gage roof curb material with sheet metal screws driven

from inside of the duct.

Secure all ducts to the building structure, using flexible

duct connectors between roof curb and ducts as required. Ducts

passing through an unconditioned space must be insulated

and covered with a vapor barrier. Outlet grilles must not lie

directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if

unit is equipped with power exhaust.

Design supply duct strong enough to handle expected static

pressures.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install 90 degree turns in the supply and return ductwork between

the unit and the conditioned space. If a 90 degree elbow

cannot be installed, then grilles of sufficientstrength and

density should be installed to prevent objects from falling into the conditioned space.

Rigging — Do not drop unit; keep upright. Use spreader

bars over unit to prevent sling or cable damage. Leave condenser coil shipping protection in place while rigging to

prevent coil damage. All lifting lugs MUST be used when

lifting unit.

Level by using unit frame as a reference. See Fig. 7 for

information. Unit and accessory weights are shown in

Tables 1-4. Weight distribution and center of gravity can be

found in Fig. 8.

Condensate Drains — The condensate drain connec-

tion is a 11⁄2-in. NPT pipe connection located on the right

hand side of the unit. See Fig. 9.

NOTE: Use a trap of at least 7-in. deep.

Condenser Coil Shipping Covers — Remove and

discard.

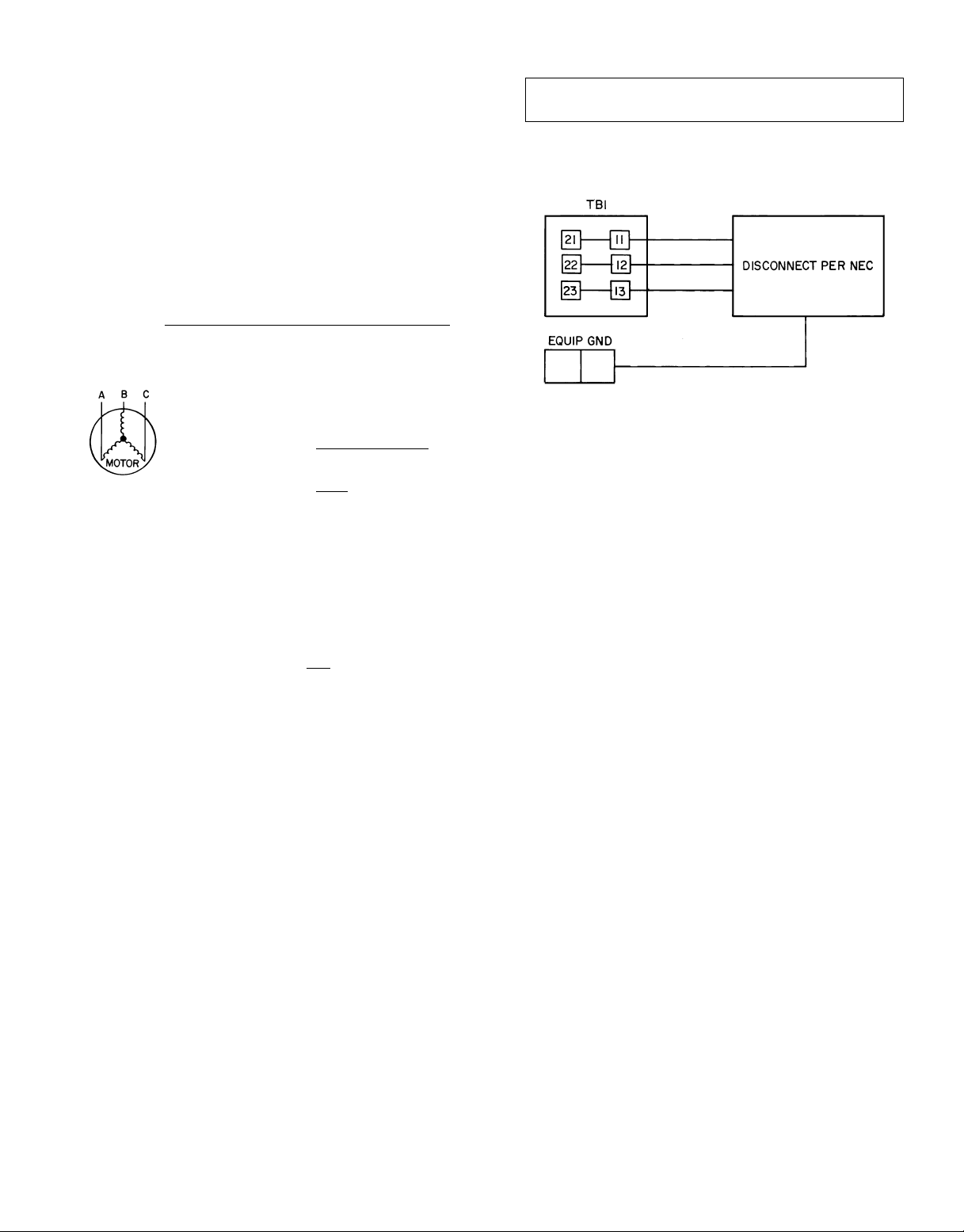

Install Outdoor Hoods

1. Outdoor-air hoods are shipped bolted to the unit in a ship-

ping position. To open hoods, remove the 3 holddown

bars holding the air hood in shipping position. See

Fig. 10.

2. Lift up the highest hood top and swing out hood sides to

form the outside frame of the air hood. Fasten hood top

to hood sides at middle and top holes only,using two screws

on each side. See Fig. 11.

3. Remove the bottom hood block-off plate and set aside.

4. Swing up second hood (from the top of unit) into place

and fasten to hood sides with screws provided using upper hole only.

5. Swing up third hood (from the top of unit) into place and

fasten to hood sides with screws provided using upper

hole only.

6. Swing up fourth hood (bottom hood) into place. Before

fastening hood to hood sides, swing down bottom filter

rack. Fasten hood to hood sides with screws provided using upper hole only.

7. Attach block off plate removed from Step 3.

8. Clip wire tie holding filter track. Swing filter track into

position and fasten to hood sides using screws provided.

Repeat until all 4 filter racks have been installed.

9. Apply a bead of RTVor similar sealant to corner of each

hood at pivot point to prevent water leaks.

Copy continues on page 14.

3

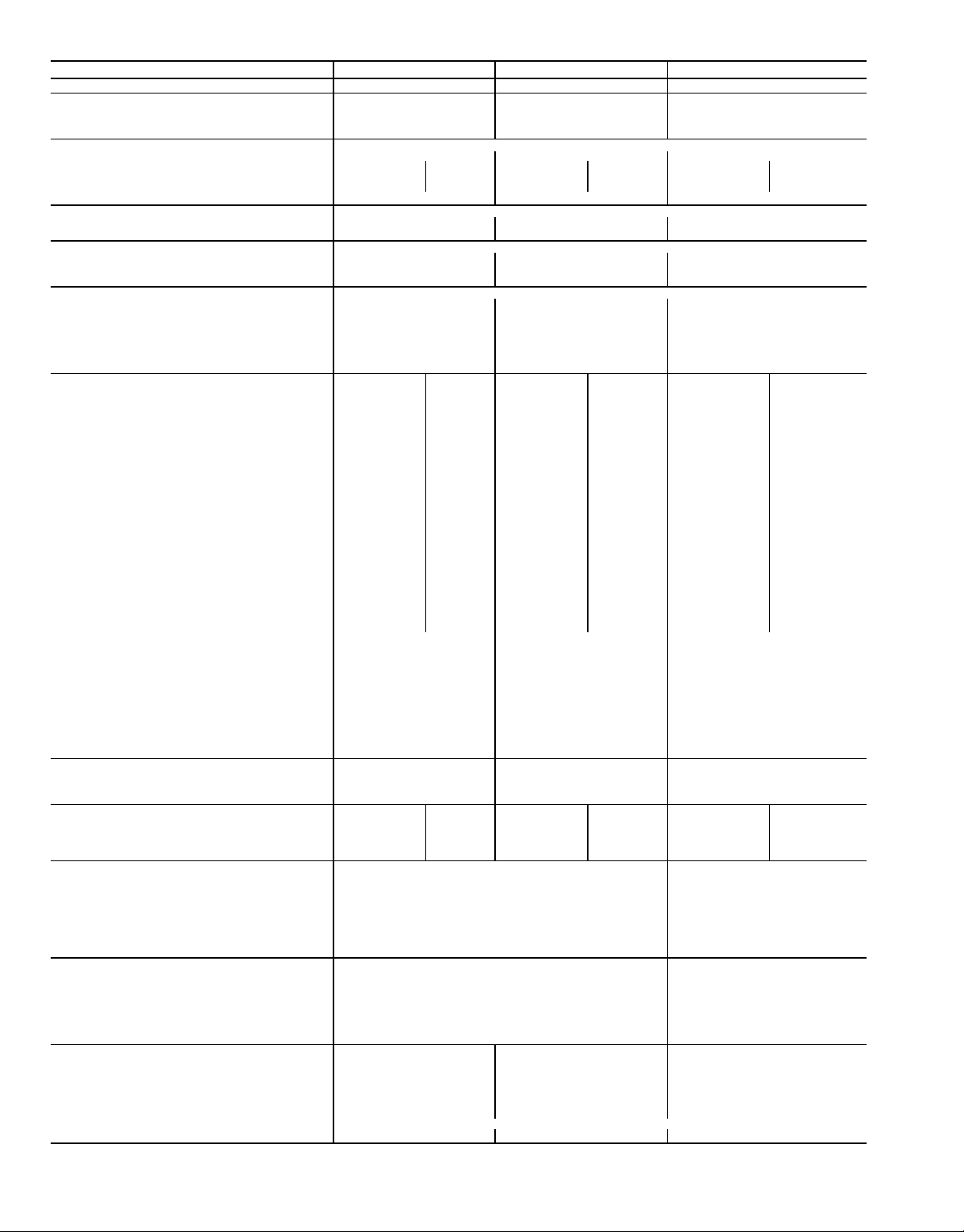

Table 1 — Physical Data

NOMINAL CAPACITY (tons) 80 90 105

OPERATING WEIGHT (lb)

Base Unit (48MP/50MP) 16,810/16,550 18,060/17,800 22,660/22,400

Copper Condenser Coils 675 725 725

Exhaust Fan 1,675 1,775 2,375

COMPRESSORS Semi-Hermetic

Number of Refrigerant Circuits 22 2

Circuit (No. of Cylinders) A (6) B (6) A1 (6), A2 (4) B (6) A1 (6), A2 (4) B1 (6), B2 (6)

Model 06E −299 −299 −275, −250 −299 −265, −250 −265, −265

Oil Charge (pints) 19 19 19, 14 19 19, 14 19,19

Capacity Steps (%) 17,33,50,67,83,100 11,22,33,41,56,67,78,89,100 18,26,35,44,53,56,65,74,82,91,100

REFRIGERANT R-22

Operating Charge (lb), Sys 1/Sys 2 (Standard Coil) 78/78 85/82 85/82

Operating Charge (lb), Sys 1/Sys 2 (Alternate Coil) 83/83 94/85 92/88

CONDENSER COILS Grooved Tube (

Quantity 44 4

Rows...Fins/in. 3...17 3...17 3...17

Total Face Area (sq ft) 116.7 128.3 128.3

EVAPORATOR COILS Smooth Tube (

Quantity 22 2

Rows...Fins/in.

Standard 3...14 3...14 3...14

Alternate 4...14 4...14 4...14

Total Face Area (sq ft) 62.6 70.0 82.0

Refrigerant Feed

Device...No. per Circuit TXV...2 TXV...2 TXV...2

EVAPORATOR FANS

Forward Curved Fan

Motor Hp 30 40 40 50 40 50

Motor Frame Size 286T 324T 324T 326T 324T 326T

Efficiency at Full Load (%)

Standard Efficiency 92.4 93.0 93.0 93.0 93.0 93.0

High Efficiency 93.6 94.5 94.5 94.5 94.5 94.5

Fan Pulley Pitch Diameter (in.) 18.4 16.0 15.4 15.4 20.0 18.4

Motor Pulley Pitch Diameter (in.) 6.2 6.4 5.6 6.4 5.8 6.0

Fan Rpm 608 705 658 747 526 590

Belts Quantity...Model No. 3...BX128 4...BX124 5...BX124 5...BX124 5...BX115 6...BX112

Center Distance Range (in.) 42.1-46.1 43.1-48.2 43.1-48.2 43.1-48.2 35.4-40.2 35.4-40.2

Maximum Rpm 835 835 835 835 715 715

Air Foil Fan

Motor Hp 30 40 40 50 40 50

Motor Frame Size 286T 324T 324T 326T 324T 326T

Efficiency at Full Load (%)

Standard Efficiency 92.4 93.0 92.4 93.0 92.4 93.0

High Efficiency 93.6 94.5 93.6 94.5 93.6 94.5

Fan Pulley Pitch Diameter (in.) 11.0 12.4 12.4 9.1 12.5 12.5

Motor Pulley Pitch Diameter (in.) 7.4 9.4 9.4 7.5 6.9 7.5

Fan Rpm 1192 1337 1337 1442 966 1050

Belts Quantity...Model No. 3...B111 3...B120 3...B120 3...5VX1120 3...5VX1060 3...5VX1060

Center Distance Range (in.) 39.7-43.7 40.4-45.2 40.4-45.2 40.4-45.2 35.4-39.4 35.4-39.4

Maximum Rpm 1595 1595 1595 1595 1298 1298

Air Foil Fan (cont)

Motor Hp 50 60 60

Motor Frame Size 326T 364T 364T

Efficiency at Full Load (%)

Standard Efficiency 93.0 94.5 94.5

High Efficiency 94.5 95.4 95.4

Fan Pulley Pitch Diameter (in.) 9.1 8.1 11.0

Motor Pulley Pitch Diameter (in.) 7.5 7.1 7.1

Fan Rpm 1442 1534 1119

Belts Quantity...Model No. 3...5VX1120 4...5VX1080 4...5VX1030

Center Distance Range (in.) 40.4-45.2 39.4-44.9 34.4-39.1

Maximum Rpm 1595 1595 1298

CONDENSER FANS

Quantity...Diameter (in.) 6...30 6...30 6...30

Nominal Cfm 52,000 52,000 52,000

Motor Hp...Rpm 1...1140 1...1140 1...1140

SUPPLY FAN Forward Curve Airfoil Forward Curve Airfoil Forward Curve Airfoil

Nominal Cfm 32,000 32,000 36,000 36,000 42,000 42,000

Size (in.) 30.0 33.0 30.0 33.0 36.0 40.25

Maximum Allowable Rpm 835 1595 835 1595 715 1298

Shaft Diameter at Pulley (in.) 2.69 2.44 2.69 2.44 2.69 2.44

FURNACE SECTION (48MP Units Only)

Rollout Switch Cutout Temp (F) 190 190

Number of Burners 77

Burner Orifice Diameter (in. ...drill size) 0.136...29 0.136...29

Gas Input (Btuh) 342,000 342,000

Manifold Pressure (in. wg) — Natural Gas 3.3 3.3

Gas Valve Input Pressure Range

in. wg 5.5-13.5 5.5-13.5

psig 0.235-0.487 0.235-0.487

LOW HEAT (48MPD)/HIGH HEAT (48MPE)

Number of Sections 2/3 2/3

Gas Input (Btuh) Stage 1 515,000/770,000 515,000/770,000

Efficiency (Steady State %) 81/81 81/81

Temperature Rise Range (F) 10-40/20-50 5-35/10-40

Minimum Heating Airflow (cfm) 12,850/15,400 14,700/19,250

Field Gas Connection Size (in.) 22

FILTERS

Medium Efficiency (30%)

Pleated (Standard)

Quantity...Size (in.)

High Efficiency (90%) Cartridge Filters

with Prefilters (Optional)

Quantity...Size (in.)

Outdoor Air Inlet Screens Cleanable Aluminum

Quantity...Size (in.) 16...20 x 25 x 1 16...20 x 25 x 1 24...20 x 25 x 1

TXV — Thermostatic Expansion Valve

BASE UNIT 48/50MP 62L 70M 82N

3

⁄8-in. OD)

5

⁄8-in. OD)

Stage 2 685,000/1,025,000 685,000/1,025,000

LEGEND

15...24 x 24 x 2,

5...24 x 12 x 2

15...24 x 24 x 4,

5...24 x 12 x 4

15...24 x 24 x 2,

5...24 x 12 x 2

15...24 x 24 x 4,

5...24 x 12 x 4

20...24 x 24 x 2,

20...24 x 24 x 4,

5...24 x 12 x 2

5...24 x 12 x 4

4

Table1 — Physical Data (cont)

NOMINAL CAPACITY (tons) 115 120

OPERATING WEIGHT (lb)

Base Unit (48MP/50MP) 24,660/24,750 25,110/25,100

Copper Condenser Coils 950 950

Exhaust Fan 2400 2400

COMPRESSORS Semi-Hermetic

Number of Refrigerant Circuits 22

Circuit (No. of Cylinders) A1 (6), A2 (6) B1 (6), B2 (6) A1 (6), A2 (6) B1 (6), B2 (6)

Model 06E −265, −275 −265, −275 −265, −299 −265, −275

Oil Charge (pints) 19, 19 19, 19 19, 19 19, 19

Capacity Steps (%) 15,23,30,38,45,58,65,73,85,92,100 14,21,28,35,42,61,68,75,86,93,100

REFRIGERANT R-22

Operating Charge (lb), Sys 1/Sys 2 (Standard Coil) 85/85 86/87

Operating Charge (lb), Sys 1/Sys 2 (Alternate Coil) 93/93 93/96

CONDENSER COILS Grooved Tube (

Quantity 44

Rows...Fins/in. 3...17 3...17

Total Face Area (sq ft) 168.0 168.0

EVAPORATOR COILS Smooth Tube (

Quantity 22

Rows...Fins/in.

Standard 3...14 3...14

Alternate 4...14 4...14

Total Face Area (sq ft) 90.3 101.4

Refrigerant Feed

Device...No. per Circuit TXV...2 TXV...2

EVAPORATOR FANS

Forward Curved Fan

Motor Hp 50 60 60

Motor Frame Size 326T 364T 364T

Efficiency at Full Load (%)

Standard Efficiency 93.0 94.5 94.5

High Efficiency 94.5 95.4 95.4

Fan Pulley Pitch Diameter (in.) 18.8 18.8 21.3

Motor Pulley Pitch Diameter (in.) 5.9 6.7 6.7

Fan Rpm 555 630 556

Belts Quantity...Model No. 4...5VX1120 4...5VX1120 4...5VX1150

Center Distance Range (in.) 35.4/40.2 35.4/40.2 34.2/40.2

Maximum Rpm 715 715 715

Air Foil Fan

Motor Hp 50 60 50 60

Motor Frame Size 326T 364T 326T 364T

Efficiency at Full Load (%)

Standard Efficiency 93.0 94.5 93.0 94.5

High Efficiency 94.5 95.4 94.5 95.4

Fan Pulley Pitch Diameter (in.) 12.5 13.7 13.7 13.7

Motor Pulley Pitch Diameter (in.) 7.5 8.7 8.1 8.7

Fan Rpm 1050 1111 1035 1111

Belts Quantity...Model No. 3...5VX1030 3...5VX1060 3...5VX1060 3...5VX1060

Center Distance Range (in.) 35.4/39.4 34.4/39.1 35.4/39.4 34.4/39.1

Maximum Rpm 1298 1298 1298 1298

Air Foil Fan (cont)

Motor Hp 75 75

Motor Frame Size 365T 365T

Efficiency at Full Load (%)

Standard Efficiency 95.4 95.4

High Efficiency ——

Fan Pulley Pitch Diameter (in.) 16.1 16.1

Motor Pulley Pitch Diameter (in.) 11.1 11.1

Fan Rpm 1207 1207

Belts Quantity...Model No. 3...5VX1120 3...5VX1120

Center Distance Range (in.) 34.4/39.1 34.4/39.1

Maximum Rpm 1298 1298

CONDENSER FANS

Quantity...Diameter (in.) 8...30 8...30

Nominal Cfm 69,500 69,500

Motor Hp...Rpm 1...1140 1...1140

SUPPLY FAN Forward Curve Airfoil Forward Curve Airfoil

Nominal Cfm 46,000 46,000 52,000 52,000

Size (in.) 36.0 40.25 36.0 40.25

Maximum Allowable Rpm 715 1298 715 1298

Shaft Diameter at Pulley (in.) 2.69 2.44 2.69 2.44

FURNACE SECTION (48MP Units Only)

Rollout Switch Cutout Temp (F) 190

Number of Burners 7

Burner Orifice Diameter (in. ...drill size) 0.136...29

Gas Input (Btuh) 342,000

Manifold Pressure (in. wg) — Natural Gas 3.3

Gas Valve Input Pressure Range

in. wg 5.5-13.5

psig 0.235-0.487

LOW HEAT (48MPD)/HIGH HEAT (48MPE)

Number of Sections 2/3

Gas Input (Btuh) Stage 1 515,000/770,000

Efficiency (Steady State %) 81/81

Temperature Rise Range (F) 5-35/10-40

Minimum Heating Airflow (cfm) 14,700/19,250

Field Gas Connection Size (in.) 2

FILTERS

Medium Efficiency (30%)

Pleated (Standard) Quantity...Size (in.)

High Efficiency (90%)

Cartridge Filters with Prefilters (Optional)

Quantity...Size (in.)

Outdoor Air Inlet Screens Cleanable Aluminum

Quantity...Size (in.) 24...20 x 25 x 1 24...20 x 25 x 1

TXV — Thermostatic Expansion Valve

BASE UNIT 48/50MP 90P 10R

3

⁄8-in. OD)

5

⁄8-in. OD)

Stage 2 685,000/1,025,000

20...24 x 24 x 2,

5...24 x 12 x 2

20...24 x 24 x 4,

5...24 x 12 x 4

LEGEND

20...24 x 24 x 2,

5...24 x 12 x 2

20...24 x 24 x 4,

5...24 x 12 x 4

5

Table 2 — Optional Power Exhaust Specifications

UNIT 48/50MP 62L 70M 82N

Type 100% Mod 100% Non Mod 100% Mod 100% Non Mod 100% Mod 100% Non Mod

Motor Hp 30 30 40 40 40 40

Motor Frame Size 286T 286T 324T 324T 324T 324T

Efficiency at Full Load (%)

Standard Efficiency 92.4 92.4 93.0 93.0 93.0 93.0

High Efficiency 93.6 93.6 94.5 94.5 94.5 94.5

Fan Pulley Pitch Diameter (in.) 18.4 18.4 18.4 18.4 25.0 20.0

Motor Pulley Pitch Diameter (in.) 5.6 6.0 6.2 6.6 6.8 5.8

Fan Rpm 552 590 608 646 491 526

Belts Quantity...Model No. 4...BX80 4...BX81 5...BX80 5...BX80 5...B90 5...BX90

Center Distance Range (in.) 19.9-23.3 19.9-23.3 18.6-22.8 18.6-22.8 21.8-25.9 21.8-25.9

Maximum Allowable Rpm 650 650 835 835 560 560

Type 50% Non Mod 50% Non Mod 50% Non Mod

Motor Hp 7.5 7.5 7.5

Motor Frame Size 213T 213T 213T

Efficiency at Full Load (%)

Standard Efficiency 88.5 88.5 88.5

High Efficiency 91.7 91.7 91.7

Fan Pulley Pitch Diameter (in.) 15.4 16.0 18.4

Motor Pulley Pitch Diameter (in.) 3.6 3.6 3.6

Fan Rpm 412 397 346

Belts Quantity...Model No. 2...BX75 2...BX77 2...BX90

Center Distance Range (in.) 21.3-24.1 21.7-24.2 24.9-27.4

Maximum Allowable Rpm 690 650 600

Table 2 — Optional Power Exhaust Specifications (cont)

UNIT 48/50MP 90P 10R

Type 100% Mod 100% Non Mod 100% Mod 100% Non Mod

Motor Hp 50 50 60 60

Motor Frame Size 326T 326T 364T 364T

Efficiency at Full Load (%)

Standard Efficiency 93.0 93.0 94.5 94.5

High Efficiency 94.5 94.5 95.4 95.4

Fan Pulley Pitch Diameter (in.) 28.1 28.1 28.1 28.1

Motor Pulley Pitch Diameter (in.) 8.1 8.1 9.1 9.1

Fan Rpm 508 508 558 558

Belts Quantity...Model No. 3...5VX1060 3...5VX1060 3...5VX1060 3...5VX1060

Center Distance Range (in.) 21.8/25.9 21.8/25.9 20.9/25.6 20.9/25.6

Maximum Allowable Rpm 560 560 560 560

Type 50% Non Mod 50% Non Mod

Motor Hp 10 15

Motor Frame Size 215T 254T

Efficiency at Full Load (%)

Standard Efficiency 89.5 89.5

High Efficiency 91.7 91.7

Fan Pulley Pitch Diameter (in.) 20.0 20.0

Motor Pulley Pitch Diameter (in.) 4.5 4.0

Fan Rpm 362 371

Belts Quantity...Model No. 2...BX90 3...BX90

Center Distance Range (in.) 24.9/27.4 23.9/26.8

Maximum Allowable Rpm 600 600

Table 3 — Compressor Oil Charge

OIL CHARGE (pints)

UNIT 48/50MP

62L 19 — 19 19 — 19

70M 19 14 33 19 — 19

82N 19 14 33 19 19 38

90P 19 19 38 19 19 38

10R 19 19 38 19 19 38

Compressor

Circuit A

A1 A2 B1 B2

Total Circuit A

Compressor

Circuit B

Table4—Variable Frequency Drive (VFD) Physical Data

FAN MOTOR

HP

30 24.02 12.99 11.22 68

40 24.02 12.99 11.22 68

50 30.91 12.99 11.22 106

60 30.91 12.99 11.22 106

75 33.46 12.99 11.22 106

Height Width Length

DIMENSIONS (in.)

6

Total Circuit B

WEIGHT (lb)

NOTES:

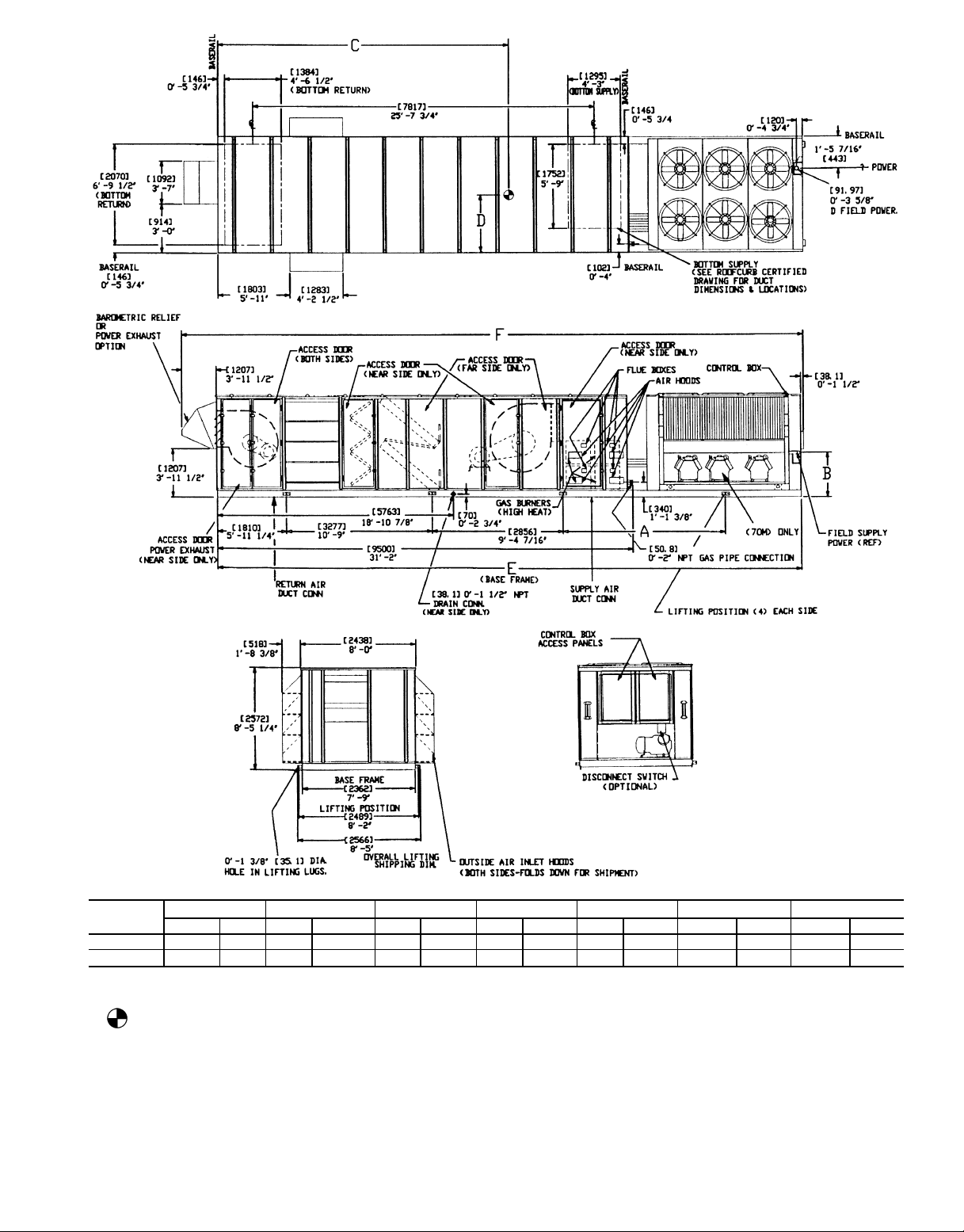

1. Roof curb is shipped disassembled.

2. Roof curb: 14 gage [VA03-56] steel.

3. Dimensions in [ ] are in millimeters.

4. Toprevent standing water in the drain pan of the

indoor section, roof curb and unit must be level

within tolerances shown.

NOTES:

1. Toprevent the hazard of stagnant water build-up in the drain pan on the indoor section, unit cannot

exceed leveling tolerances shown.

2. If a Carrier roof curb is not used, curb cross rails must be postioned to clear unit base rail locations

shown.

Fig. 1 — Roof Curb Dimensions, 48/50MP62L and 70M

7

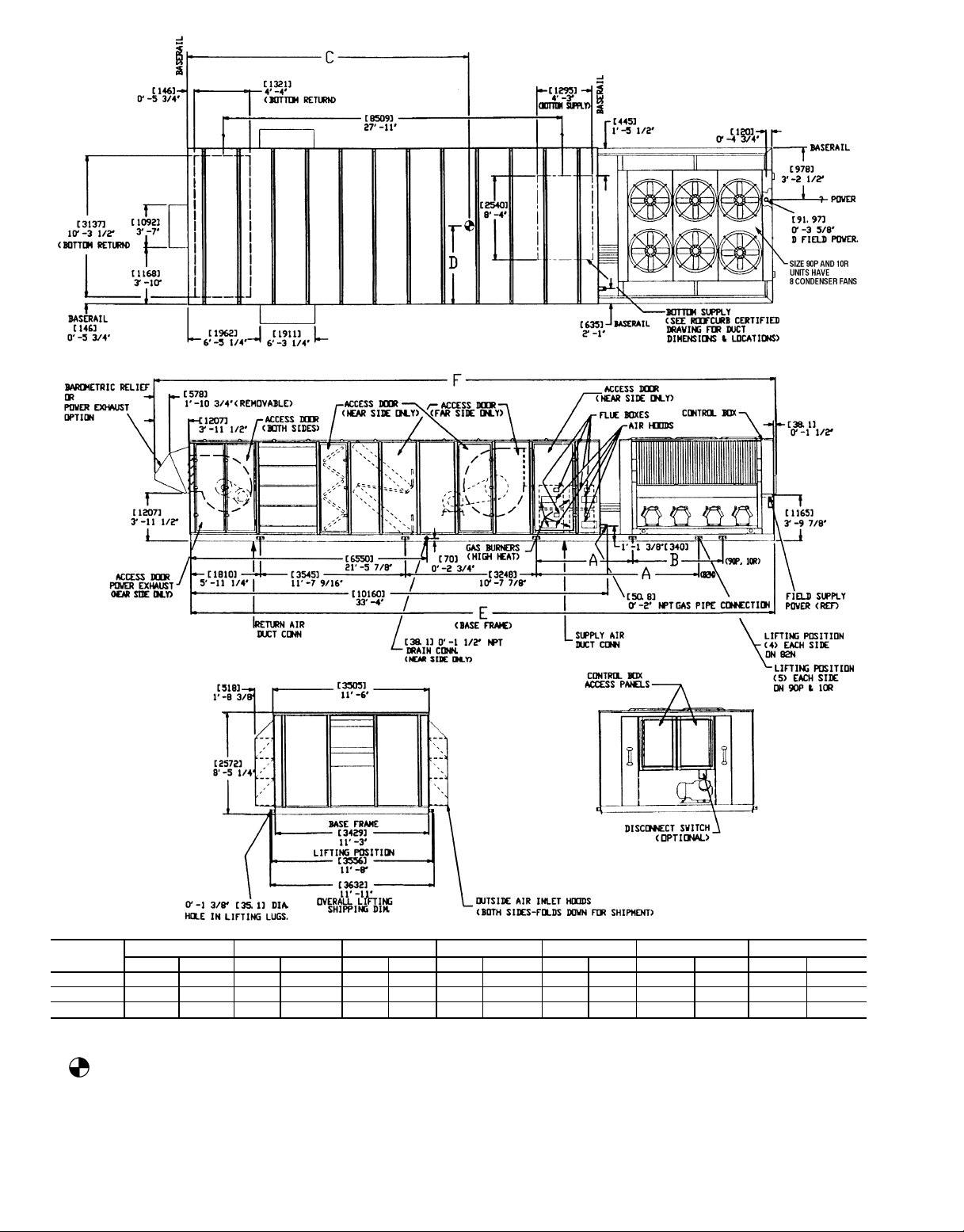

NOTES:

1. Roof curb is shipped disassembled.

2. Roof curb: 14 gage [VA03-56] steel.

3. Dimensions in [ ] are in millimeters.

4. Toprevent standing water in the drain pan of the

indoor section, roof curb and unit must be level

within tolerances shown.

NOTES:

1. Toprevent the hazard of stagnant water build-up in the drain pan on the indoor section, unit cannot

exceed leveling tolerances shown.

2. If a Carrier roof curb is not used, curb cross rails must be postioned to clear unit base rail locations

shown.

Fig. 2 — Roof Curb Dimensions, 48/50MP82N-10R

8

UNIT SIZE

48MPD,E

62L 16,810 7624 3505 11- 6 957 3-1

WEIGHT A B C D E F

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

11

⁄165909 19-45⁄81203 3-113⁄813 011 42-81⁄414 256 46-91⁄

70M 18,060 8190 3647 11-119⁄161165 3-97⁄86166 20-23⁄41264 4- 13⁄413 297 43-71⁄214 542 47-81⁄

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Centerof gravity includes exhaust fan and high heat options. Unitweight does not include exhaust fan or high

heat options.

3. High heat add: 260 lb [118 kg]

Exhaust fan add: 1675 lb [761 kg] on 62L

4. Unit clearances:

Top — Do not restrict condenser fans, control box end — 68-09.

Sides — 68-09 (except on return fan equipped units — 108-09).

Economizer end — 68-09 (except power exhaust units — 108-09).

For smaller service and operational clearances, contact Carrier Application Engineering Department.

5. Downshot ducts designed to be attached to accessory roof curb. If unit is mounted on dunnage, it is recommended

the ducts be supported by cross braces as done on the accessory roof curb.

1775 lb [807 kg] on 70M

Fig. 3 — Base Unit Dimensions, 48MP62L, 70M

9

4

2

UNIT SIZE

48MPD,E

WEIGHT A B C D E F

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

82N 22,660 10 295 3646 11-11

90P 24,660 11 203 1938 6- 45⁄

10R 25,110 11 408 1938 6- 45⁄

9

⁄

16

— — 6734 22- 11⁄81753 5-9 13 957 45-91⁄215 202 49-101⁄

16

2572 8-51⁄47283 23-103⁄41765 5-91⁄214 821 48-71⁄216 066 52- 81⁄

16

2572 8-51⁄47268 23-101⁄81759 5-91⁄414 821 48-71⁄216 066 52- 81⁄

2

2

2

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of gravity includes exhaust fan and high heat options. Unit weight

does not include exhaust fan or high heat options.

3. High heat add: 260 lb [118 kg]

Exhaust fan add: 2275 lb [1034 kg] on 82N

2400 lb [1090 kg] on 90P and 10R

Fig. 4 — Base Unit Dimensions, 48MP82N-10R

4. Unit clearances:

Top — Do not restrict condenser fans, control box end — 68-09.

Sides — 68-09 (except on return fan equipped units — 108-09).

Economizer end — 68-09 (except power exhaust units — 108-09).

For smaller service and operational clearances, contact Carrier Application Engineering Department.

5. Downshot ducts designedto be attachedto accessory roof curb. If unit ismounted

on dunnage, it is recommended the ducts be supported by cross braces as done

on the accessory roof curb.

10

UNIT

SIZE

50MP

62L 16,550 7511 3505 118-69 957 38-1

70M 17,800 8078 3647 118-11

WEIGHT

(See Note 3)

AB

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

9

⁄169 1165 38-97⁄86166 208-23⁄46649 218-93⁄49 1264 48-13⁄49 13 297 438-71⁄29 14 542 478-81⁄

C1

(See Note 2)C2(See Note 2)

11

⁄169 5880 198-31⁄29 6325 208-99 1203 38-113⁄89 13 011 428-81⁄49 14 256 468-91⁄

DE F

4

9

2

9

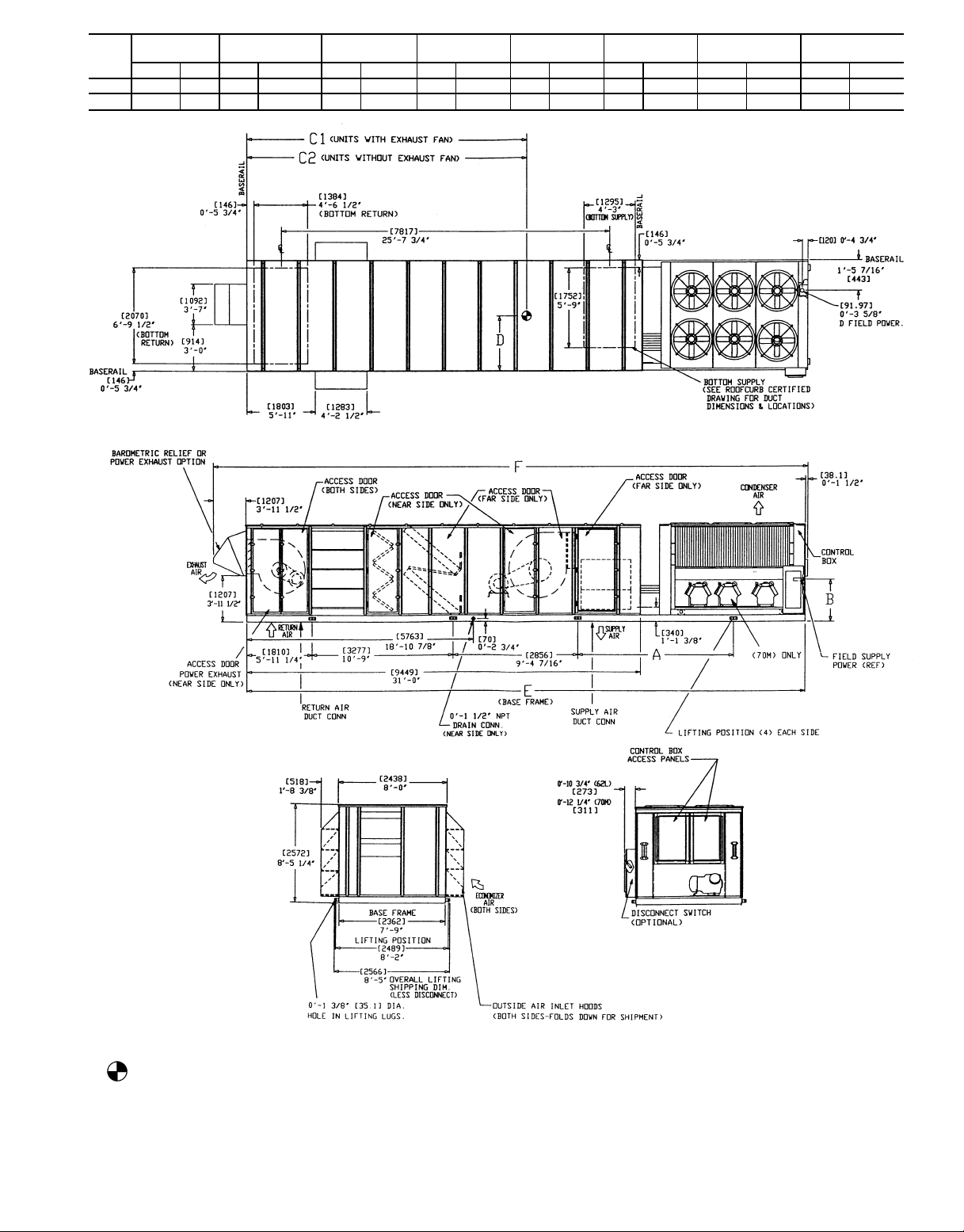

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of gravity. Use appropriate column for units with or without

exhaust fan option.

3. Unit weight does not include exhaust fan option.

Exhaust fan add: 1675 lb [761 kg] on 62L

4. Unit clearances:

Top — Do not restrict condenser fans.

1775 lb [807 kg] on 70M

Fig. 5 — Base Unit Dimensions, 50MP62L and 70M

Sides — 68-09

Economizer End — 68-09 (Except power exhaust units 108-09).

Control Box End — 68-09

For smaller service and operational clearances, contact Carrier Application

Engineering department.

5. Downshot ducts designed to be attached to accessory roof curb. If unit is

mounted on dunnage, it is recommended the ducts be supported by cross

braces as done on the accessory roof curb.

6. All lifting lugs must be used when rigging unit.

11

UNIT

SIZE

50MP

WEIGHT

(See Note 3)

AB

lb kg mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in.

82N 22,400 10 295 3646 118-11

90P 24,750 11 375 1938 68-4

10R 25,100 11 536 1938 68-4

C1

(See Note 2)

9

⁄169 — — 6702 218-117⁄89 7180 238-611⁄169 1753 58-99 13 957 458-91⁄29 15 202 498-101⁄

5

⁄169 2572 88-51⁄47383 238-103⁄47787 258-69⁄169 1765 58-91⁄29 14 821 488-71⁄29 16 066 528-81⁄

5

⁄169 2572 88-51⁄47383 238-101⁄87793 258-613⁄169 1759 58-91⁄49 14 821 488-71⁄29 16 066 528-81⁄

C2

(See Note 2)

DE F

2

9

2

9

2

9

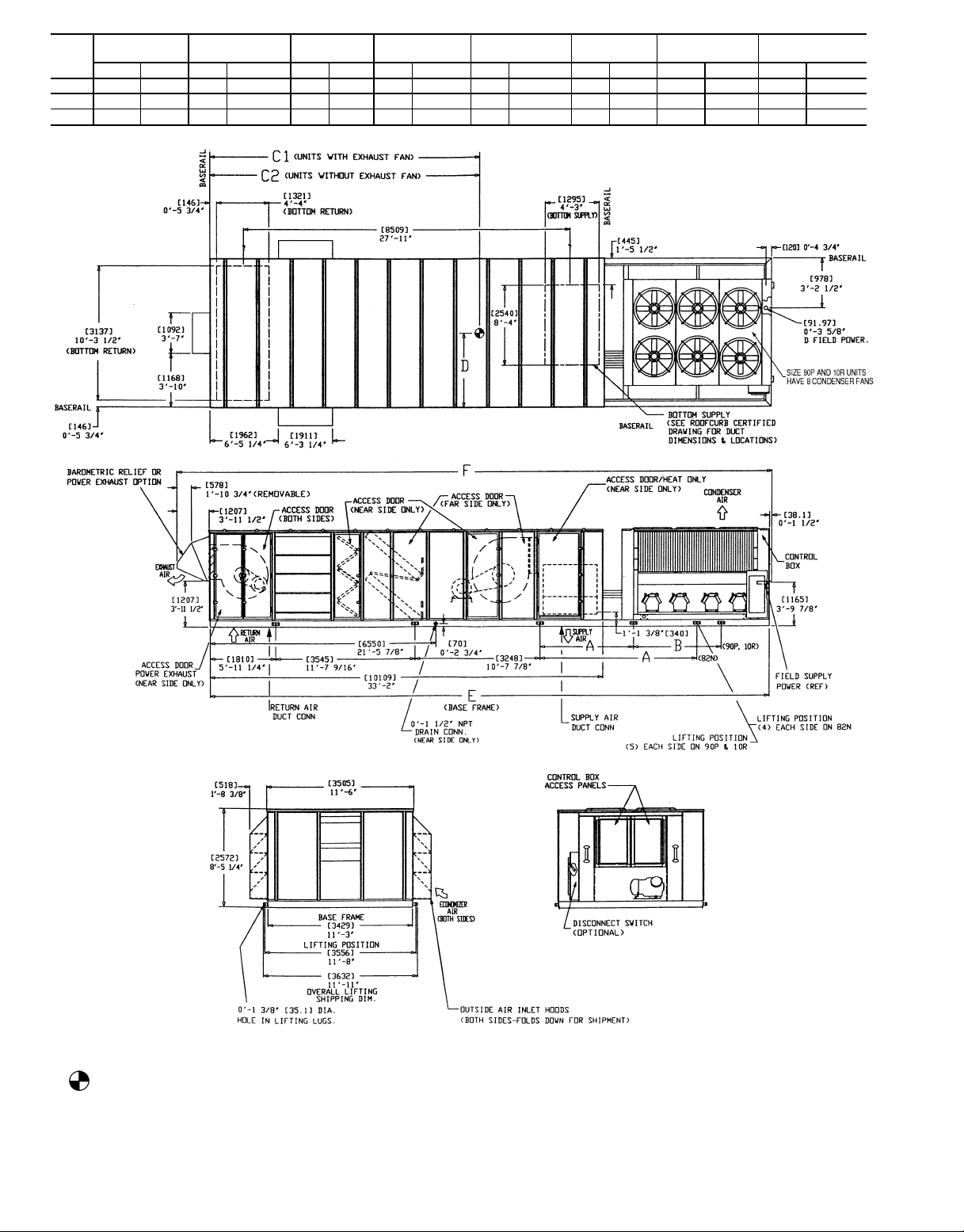

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of gravity.Use appropriate column for units with or without exhaust fan option.

3. Unit weight does not include exhaust fan option.

Exhaust fan add: 2275 lb [1034 kg] on 82N

4. Unit clearances:

Top — Do not restrict condenser fans.

2300 lb [1090 kg] on 90R and 10R

Fig. 6 — Base Unit Dimensions, 50MP82N-10R

Sides — 68-09

Economizer End — 68-09 (Except power exhaust units 108-09).

Control Box End — 68-09

For smaller service and operational clearances, contact Carrier Application

Engineering department.

5. Downshot ducts designed to be attached to accessory roof curb. If unit is

mounted on dunnage, it is recommended the ducts be supported by cross

braces as done on the accessory roof curb.

6. All lifting lugs must be used when rigging unit.

12

NOTICE TO RIGGERS

UNIT

SIZE

WEIGHT

Unit 48MP Unit 50MP Exhaust Fan

lb kg lb kg lb kg in. mm in. mm in. mm in. mm in. mm

ABCDE

62L 16,810 7 624 16,550 7 507 1675 760 71.25 1810 129.00 3277 112.44 2856 138.00 3505 N/A N/A

70M 18,060 8 190 17,800 8 074 1775 805 71.25 1810 129.00 3277 112.44 2856 143.56 3646 N/A N/A

82N 22,660 10 295 22,400 10 161 2275 1032 71.25 1810 139.56 3545 127.87 3248 143.56 3646 N/A N/A

90P 24,660 11 203 24,750 11 227 2400 1089 71.25 1810 139.56 3545 127.87 3248 177.56 4510 101.25 2572

10R 25,110 11 408 25,100 11 385 2400 1089 71.25 1810 139.56 3545 127.87 3248 177.56 4510 101.25 2572

NOTE: All lifting lugs must be used when rigging with eight or ten

cables and spread with four or five 95 in. (2413 mm) and two

‘‘B+C+D’’long suitable spreader bars. Unit weight does not include

exhaust fan option.

Fig. 7 — Rigging Label

2

B

1

A

UNIT

48MP

62L 5095 5000 4339 4051 19- 4

70M 5337 5338 5290 3969 20- 23⁄

82N 6614 6326 6444 5651 22- 11⁄

90P 7156 6789 7330 6226 23-10

10R 7174 6897 7345 6254 23-101⁄

CORNER WEIGHT (lb) DIMENSIONS (ft-in.)

1234 A B

5

⁄

8

3-113⁄

8

4

4- 13⁄

4

8

5- 9

3

⁄

4

5- 91⁄

2

8

5- 91⁄

4

1. All panels must be in place when rigging.

2. Unit is not designed for handling by fork truck.

3

4

UNIT

50MP

CORNER WEIGHT (lb) DIMENSIONS (ft-in.)

1234 A B

62L 4237 3967 5038 4933 19- 3

70M 5258 3955 5185 5167 20- 23⁄

82N 6351 5571 6574 6279 21-117⁄

90P 7211 6132 7045 6761 23-10

10R 7288 6196 7195 6820 23-101⁄

1

⁄

2

3-113⁄

8

4

4- 13⁄

4

8

5- 9

3

⁄

4

5- 91⁄

2

8

5- 91⁄

4

Fig. 8 — Unit Center of Gravity and Corner Weights

13

Field Electrical Connections

PITCH DRAIN LINE

TO OFFSET LINE

FRICTION

7" MIN.

SEALANT

2" MIN.

UNIT

BASE

RAIL

SLAB

SLAB MOUNT DRAIN

Fig. 9 — Condensate Drain Piping Details

Make Electrical Connections

POWER SUPPLY — Electrical characteristics of available

power supply must agree with unit nameplate rating. Supply

voltage must be within the limits shown in Table 5.

Field Wire Routing — Field wiring is brought into the unit

through the bottom of the control box.

5

⁄8-in. hole for field power wiring and a7⁄8-in. hole for

A3

24-v control wiring are provided in the bottom of the control

box. Field-supplied couplings must be used when routing wiring into the control box.

IMPORTANT: The 48/50MP units generate, use, and

can radiate radio frequency energy. If units are not installed and used in accordance with these instructions,

they may cause radio interference. They have been tested

and found to comply with limits of a Class A computing device as defined by FCC (Federal Communications Commission) regulations, Subpart J of Part 15,

which are designed to provide reasonable protection

against such interference when operated in a commercial environment.

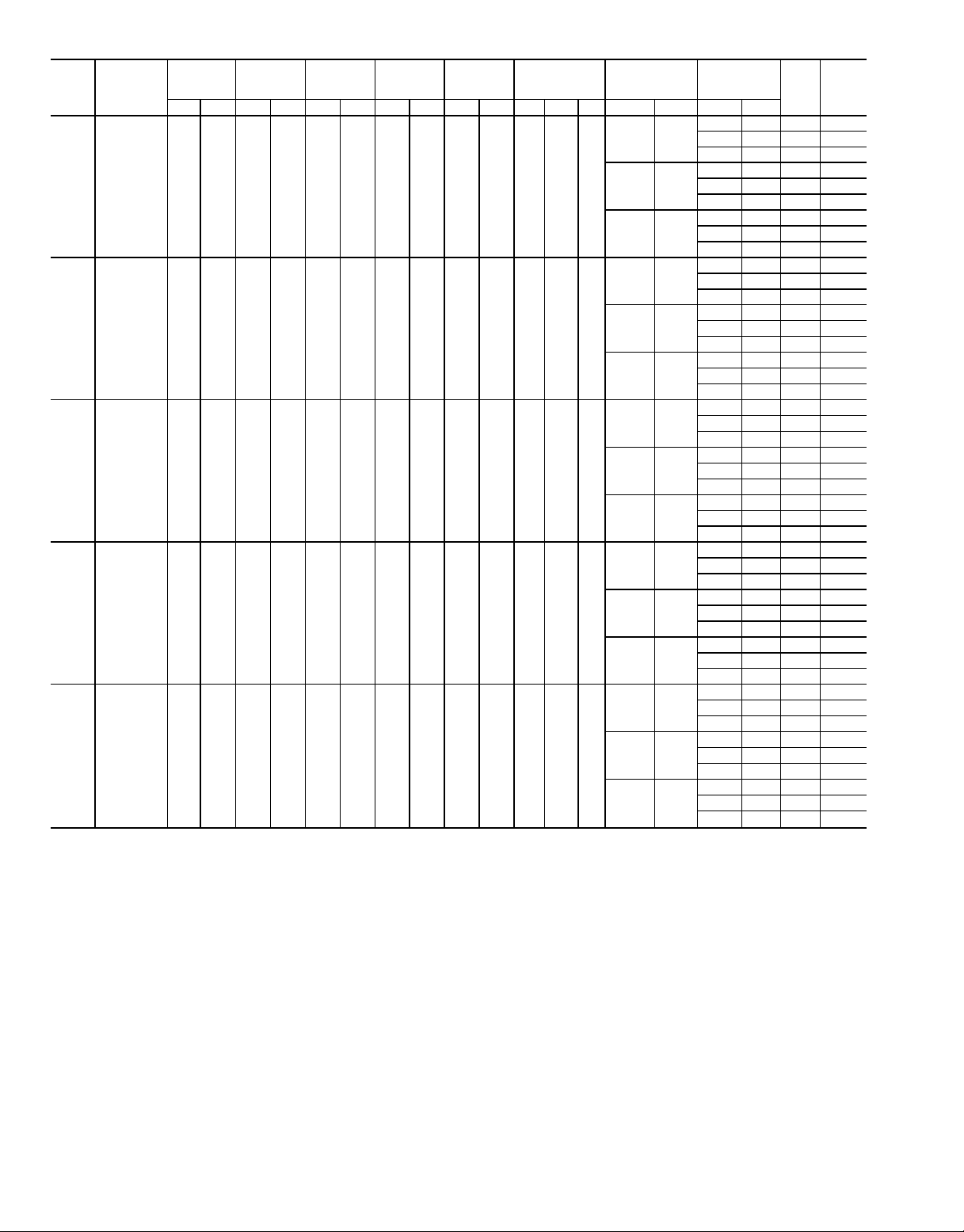

POWER WIRING — Units are factory wired for 460-v as

shown on the unit nameplate. The main terminal block is

suitable for use with aluminum or copper wires. Maximum

wire size is 500 MCM.

Branch circuit for power supply to unit must be protected

against ground fault or short circuit. Provide an overcurrent

protection device in the branch circuit. The MOCP (Maximum Overcurrent Protection) value for this device is shown

on unit informative data plate.

When installing units, provide and install a unit safety disconnect per NEC of adequate size. Refer to Electrical Data

tables for disconnect sizing. Disconnect may incorporate branch

circuit fusing (if local or national codes permit) but combination disconnect fuse is not required. Disconnect must be

able to be locked OFF.

HOLD

DOWN

BARS

HOOD

SIDE

HOOD

TOP

FILTER

RACK

Fig. 10 — Outdoor Air Hoods Shipping Position

14

BLOCK-OFF

PLATE

Fig. 11 — Outdoor Air Hoods Installed

Disconnect must be located within sight of the unit and readily accessible from the unit in compliance with NEC

Article 440-14.

All field wiring must comply with NEC and all local codes.

Size wire based on MCA (Minimum Circuit Amps) value

shown on the unit informative plate. See Fig. 12 for power

wiring connections to the unit power terminal block and equipment ground.

Operating voltage to the compressor must be within the voltage range indicated on the unit nameplate. Voltages between

phases must be balanced within 2%, and the current must be

balanced within 10%. See Table 5 for unit electrical data.

Use the following formula to determine the percent voltage

imbalance.

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452 + 464 + 455

3

1371

=

3

457

=

Determine maximum deviation from average voltage:

(AB) 457 − 452 = 5 v

(BC) 464 − 457 = 7 v

(AC) 457 − 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance:

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is be-

low the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance

is more than 2%, contact local utility immediately.

Unit failure as a result of operation on improper line voltage or excessive phase imbalance constitutes abuse and may

cause damage to electrical components.

LEGEND

EQUIP — Equipment

GND — Ground

NEC — National Electrical Code

TB — Terminal Block

Fig. 12 — Field Power Wiring Connections

15

Table 5 — Electrical Data

UNIT

48MP/

VOLTAGE

3 Ph, 60 Hz

50MP

62L 460 414 508 65.4 345 — — 65.4 345 — — 6 3.3 1

70M 460 414 508 46.8 253 34.6 173 65.4 345 — — 6 3.3 1

82N 460 414 508 43.6 223 34.6 173 43.6 223 43.6 223 6 3.3 1

90P 460 414 508 43.6 223 46.8 253 43.6 223 46.8 253 8 3.3 1

10R 460 414 508 43.6 223 65.4 345 43.6 223 46.8 253 8 3.3 1

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA RLA LRA RLA LRA Qty FLA Hp FLA Hp FLA Hp

COMP

NO. A1

COMP

NO. A2

COMP

NO. B1

COMP

NO. B2

CONDENSER

FAN

MOTORS

LEGEND

COMP — Compressor

FLA — Full Load Amps

Hp — Nominal Horsepower

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (for wire sizing)

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

EVAPORATOR

FAN MOTOR

40 30

52 40

65 50

52 40

65 50

77 60

52 40

65 50

77 60

65 50

77 60

96 75

65 50

77 60

96 75

POWER

EXHAUST

FAN MOTOR

— — 207.0 250

11 7.5 218.0 250

40 30 247.0 300

— — 219.0 250

11 7.5 230.0 250

40 30 259.0 300

— — 232.0 250

11 7.5 243.0 300

40 30 272.0 300

— — 235.0 300

11 7.5 246.0 300

52 40 287.0 350

— — 248.0 300

11 7.5 259.0 300

52 40 300.0 350

— — 262.9 300

11 7.5 273.9 350

52 40 314.9 350

— — 250.2 300

11 7.5 261.2 300

52 40 302.2 350

— — 266.5 300

11 7.5 277.5 300

52 40 318.5 350

— — 281.5 350

11 7.5 292.5 350

52 40 333.5 400

— — 288.5 350

14 10 302.5 350

65 50 353.5 350

— — 303.5 350

14 10 317.5 350

65 50 368.5 400

— — 327.5 400

14 10 341.5 400

65 50 392.2 450

— — 307.2 350

14 15 321.1 350

77 60 387.1 450

— — 322.1 350

14 15 336.1 400

77 60 399.1 450

— — 345.8 400

14 15 359.8 450

77 60 422.8 500

MCA MOCP

16

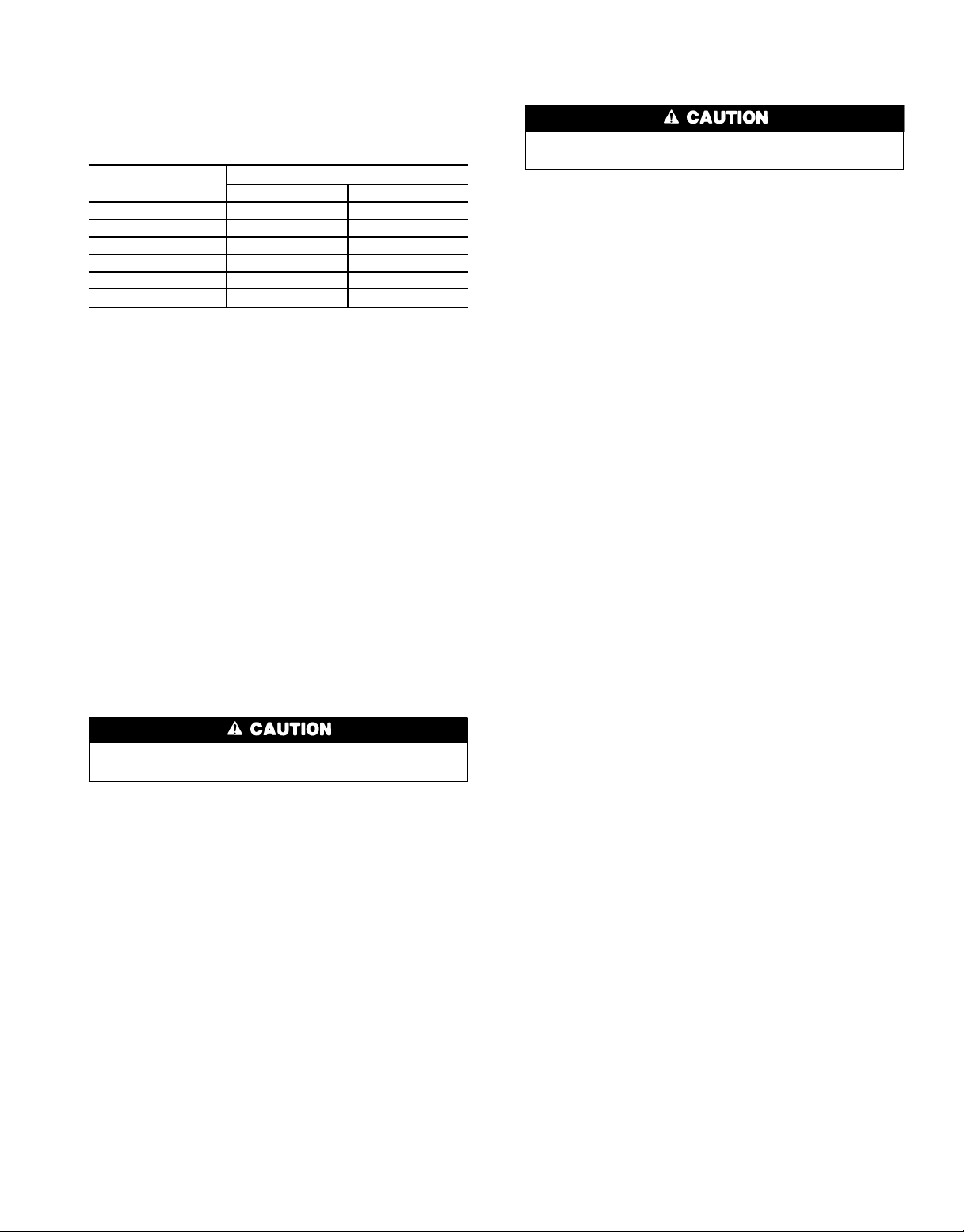

Control Wiring — See Fig. 13 for sensor wiring con-

nections to main and auxiliary control boxes. The recommended types of control wiring for 48/50MP unit devices

are shown in Table 6.

pins E2 and E3, and an RJ11 female connector. The RJ11

connector is used to tap into the CCN at the sensor. See RJ11

Plug Wiring section on page 24 to connect the RJ11 connector to the CCN.

Table 6 — Recommended Sensor and

Device Non-Shielded Cable

MANUFACTURER

Alpha 1895 —

American A21451 A48301

Belden 8205 884421

Columbia D6451 —

Manhattan M13402 M64430

Quabik 6130 —

Regular Wiring Plenum Wiring

PART NO.

SENSORS — Sensors should be wired using single twisted

pairs of 20AWG(American Wire Gage) conductor cable rated

for the application, except for the T56 accessory sensor which

requires 3-conductor cable.

NOTE: Humidity and CO2sensors must be powered from

isolated 24-v power supplies.

HUMIDITY CONTROLAND HOT WATER AND STEAM

VALVES — These devices require 20 AWGtwisted pair conductor cables rated for the application for the 4 to 20 mA

signal.

SPACETEMPERATURESENSOR (T55) — The space temperature sensor (P/N CEC0121448-01) is shipped standard

with every unit, and is located in the main control box. Space

temperature sensor wires are to be connected to terminals in

the unit main control box. The space temperature sensor

includes a terminal block (TB1), a jumper between pins E2

and E3, and an RJ11 female connector. The RJ11 connector

is used to tap into the Carrier Comfort Network (CCN) at

the sensor. See RJ11 Plug Wiring section on page 24 to connect the RJ11 connector to the CCN. A 3-lead cable must

run from the RJ11 connector to the unit for communication

through the sensor.

Jumper MUST be in place between pins E2 and E3 or

inaccurate readings could result.

To connect the space temperature sensor (Fig. 13):

1. Connect 1 wire of the twisted pair to terminal T1 (T55)

and connect the other wire to terminal T2 on terminal

block 1 (TB1) located on the cover of the space temperature sensor using a 20 AWG twisted pair conductor cable

rated for the application.

2. Connect the other ends of the wires to terminals 1 and 2

on TB3 located in the unit main control box.

NOTE: This sensor should be installed for all applications. For VAV (variable air volume) applications, it is

used to control heating and cooling during unoccupied

periods. For DAV (digital air volume) applications, it is

used to maintain control of the space during linkage failures with the TSM (terminal system manager).

NOTE: Either the T55 or T56 sensor must be connected for CV (constant volume) applications to function

properly.

SPACE TEMPERATURE SENSOR (T56) (CV Applications Only) — The space temperature sensor

(P/N CEC0121503-01) wires are to be connected to terminals in the unit main control box. The space temperature

sensor includes a terminal block (TB1), a jumper between

Jumper MUST be in place between pins E2 and E3 or

inaccurate readings could result.

To connect the space temperature sensor (Fig. 13):

1. Connect one wire of the 3-conductor cable to terminal

TH, one wire to terminal COM, and the other wire to terminal SW on terminal block 1 (TB1) located on the cover

of the space temperature sensor using a 20 AWG twisted

3-conductor cable rated for the application.

2. Connect the other ends of the wires to terminals 1, 2, and

3 on TB3 located in the unit main control box. The wire

from terminal SW MUST be connected to terminal 3.

NOTE: Either the T55 or the T56 sensor must be connected for CV applications to function properly.

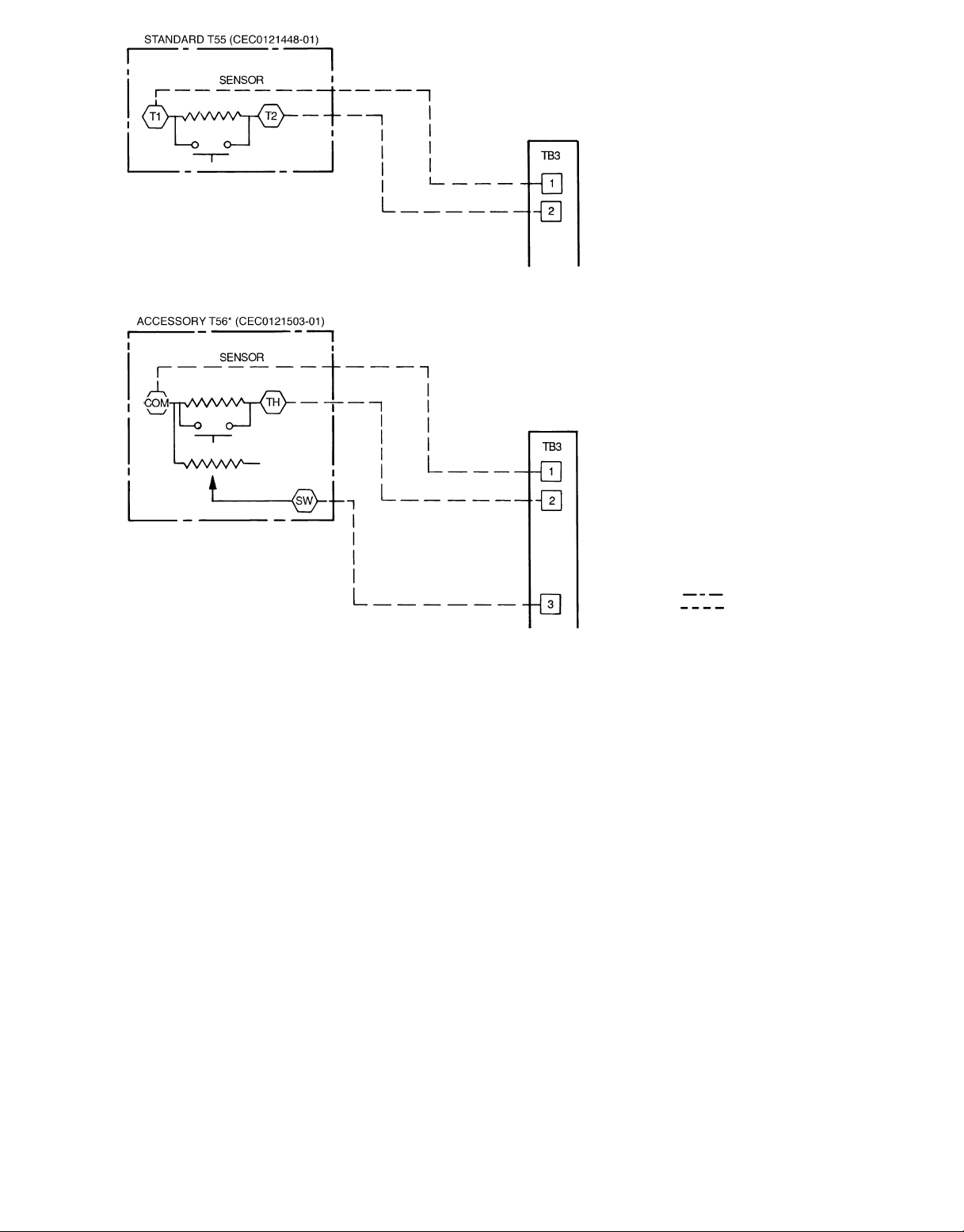

SPACETEMPERATUREAVERAGING —Applications that

require averaging using multiple space temperature sensors

can be satisfied using either 4 or 9 sensors as shown in

Fig. 14.

NOTE: Only Carrier sensors may be used for standard T55

space averaging. Sensors must be used in multiples of 1, 4,

and 9 only, with total sensors wiring not to exceed 1000 ft.

However, space temperature reset can be accomplished with

only one sensor.

NOTE: Do not use T56 sensors for space temperature

averaging because the 5 degree offset function will not work

in a multiple sensor application.

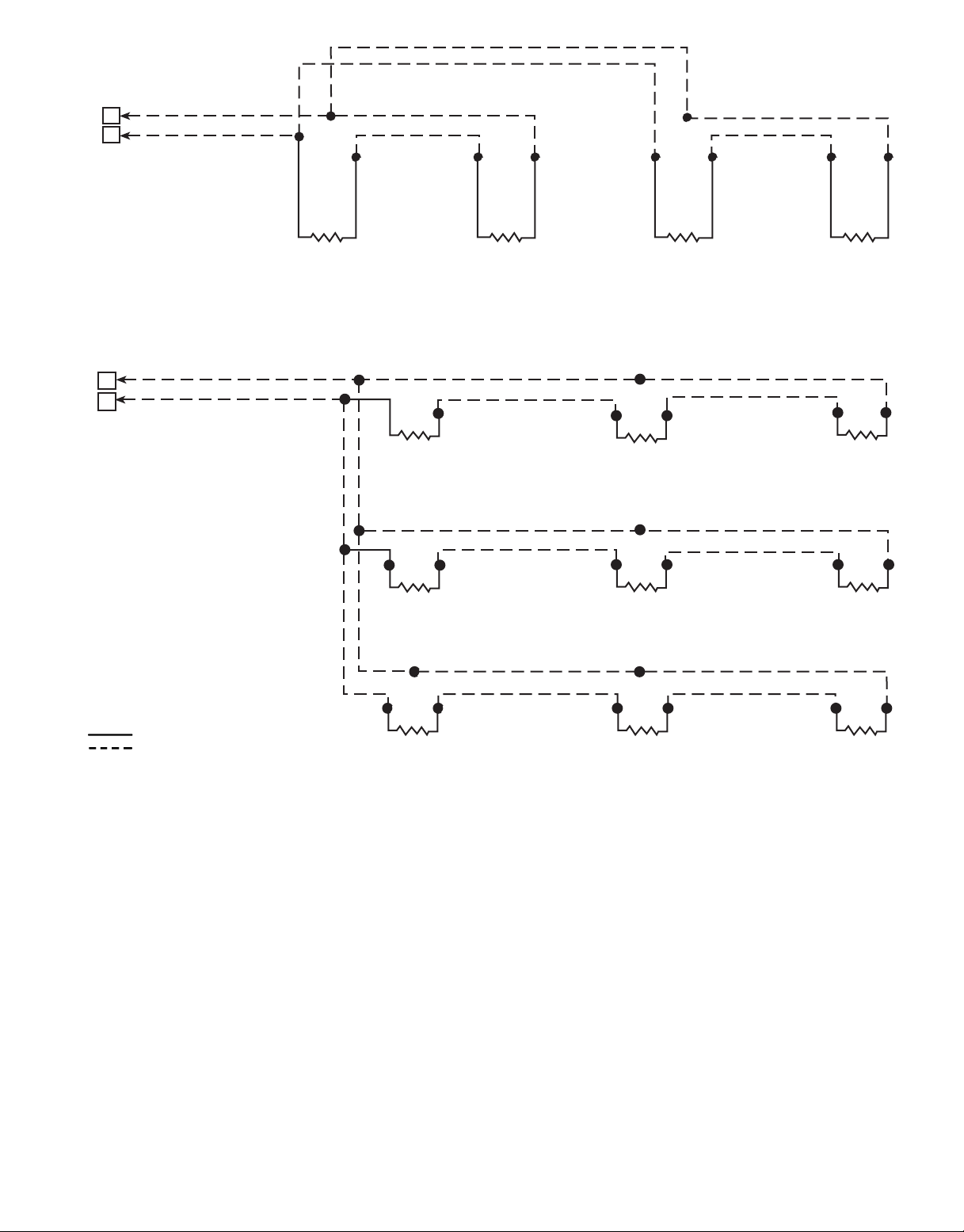

HEATINTERLOCK RELAY(VAVUnits Only — Not Necessary For Digital Air VolumeApplications) — Variable air

volume (VAV) units using optimal start (morning warm-up)

and/or occupied heating require that room terminals be controlled to the fully open position when the unit goes into

heating mode. The HIR (Heat Interlock Relay) function is

provided for this control on DSIO no. 2, channel 60. When

the unit goes into heating mode, the HIR is energized to provide switch closure or opening (depending on how the fieldsupplied power source is set up) to open the room terminals.

The field connections for the HIR are: Normally Closed, terminals 8 and 10 on TB3; and Normally Open, terminals 8

and 9 on TB3. See Fig. 15.

OPTION AND ACCESSORYCONTROL WIRING — The

48/50MP units may be used in applications with additional

control features, options, or accessories. Refer to the Controls and Troubleshooting manual for more information concerning installation and configuration of options and accessories. Figures 15 to 29 contain wiring information on the

following features:

• heat interlock relay (Fig. 15)

• differential enthalpy sensor (Fig. 16)

• remote start (Fig. 17)

• accessory humidity control (Fig. 18)

• fire/smoke control (Fig. 19)

• indoor air quality (Fig. 20)

• outdoor airflow control (Fig. 21)

• timed discrete output (Fig. 22)

• humidifier (Fig. 23)

• hydronic heating (Fig. 24)

• freezestat (Fig. 25)

• remote supply air temperature/space temperature offset

(Fig. 26)

• transducer/thermistor (Fig. 27)

• CCN Building Supervisor (Fig. 28)

• variable frequency drive (VFD) (Fig. 29)

17

Fig. 13 — Space Temperature Sensor Wiring

LEGEND

COM — Common

SW — Switch

T—Terminal

TB — Terminal Block

TH — Thermostat Heating

*Constantvolumeapplicationsonly.

Accessory

Field Wiring

18

RED

BLK

RED

BLK

TB3

1

2

TO PROCESSOR

MODULE NO. 1

RED

BLK

TB3

1

2

TO PROCESSOR

MODULE NO. 1

RED

BLK

RED

BLK

SENSOR 1 SENSOR 2 SENSOR 3 SENSOR 4

RED

BLK

SPACE TEMPERATURE AVERAGING — 4 SENSOR APPLICATION

RED

BLK

RED

BLK

BLK

SENSOR 1

RED

RED

BLK

SENSOR 2

RED

BLK

SENSOR 3

LEGEND

TB — Terminal Block

Factory Wiring

Field Wiring

SENSOR 4

BLK

RED

RED

BLK

SENSOR 8SENSOR 7 SENSOR 9

SPACE TEMPERATURE AVERAGING — 9 SENSOR APPLICATION

Fig. 14 — Space Temperature Sensor Averaging

SENSOR 6SENSOR 5

RED

BLK

19

DSIO2

J5

12

11

10

CHANNEL

60

LEGEND

TB — Terminal Block

Field Wiring

Component Terminal

□

Terminal Block Terminal

Fig. 15 — Heat Interlock Relay

RED

BLU

ORN

TB3

10

8

9

FIELD

CONTROL

WIRING

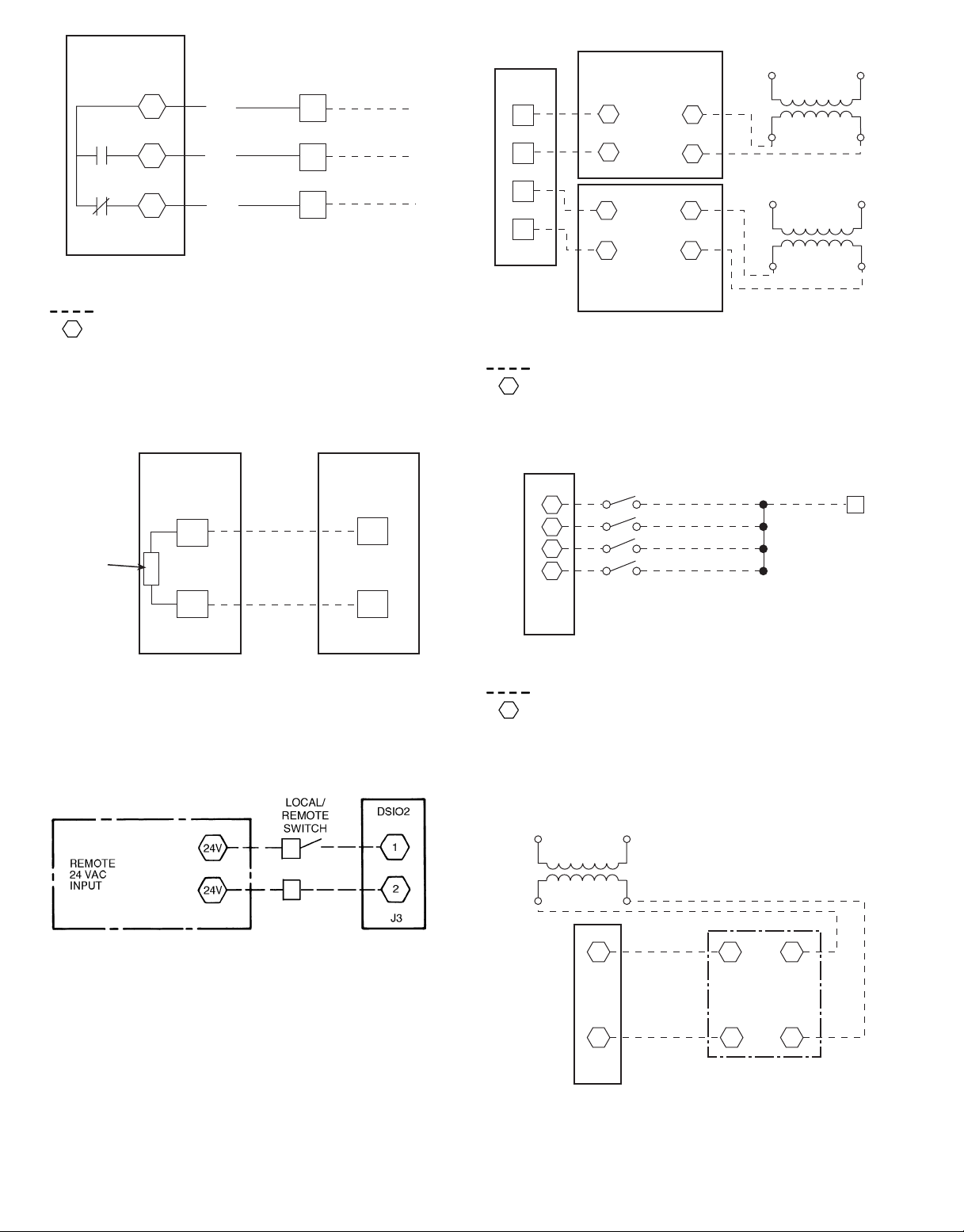

ACCESSORY

OUTSIDE AIR

TB3

7

12

13

15

RELATIVE HUMIDITY

2

J2

1

2

J2

1

SPACE/RETURN

RELATIVE HUMIDITY

1

J1

2

1

J1

2

LEGEND

TB — Terminal Block

Field Wiring

Component Terminal

□

Terminal Block Terminal

Fig. 18 — Accessory Humidity Control

FIELD-SUPPLIED

24-V ISOLATED

POWER SUPPLY

24V

FIELD-SUPPLIED

24-V ISOLATED

POWER SUPPLY

24V

ENTHALPY

CONTROL

SR

REMOVE

620 Ω

RESISTOR

+

Fig. 16 — Differential Enthalpy Sensor

ENTHALPY

SENSOR

S

+

DIFFERENTIAL

ENTHALPY SENSOR

(RETURN AIR)

J7

PRESSURIZATION

19

22

25

28

PSIO

NO. 2

LEGEND

TB — Terminal Block

Field Wiring

Component Terminal

□

Terminal Block Terminal

Fig. 19 — Fire/Smoke Control

FIELD-SUPPLIED

24-V ISOLATED

POWER SUPPLY

24V

TB2

6

PURGE

EVACUATION

SHUTDOWN

LEGEND

DSIO — Relay Module

Fig. 17 — Remote Start

20

J7

16

17

PSIO

NO. 2

+

9

INDOOR AIR

QUALITY ACY

10

-

Fig. 20 — Indoor Air Quality

1

5

Loading...

Loading...