Page 1

Carrier Corporation • Syracuse, N Y 13221

Connbination Heating/Cooling Units

INDEX

Page

SAFETY CONSIDERATIONS

INSTALLATION .......................................................1-16

Step 1 — Provide Unit Support

• ROOF CURB

• SLAB MOUNT

Step 2 — Field Fabricate Ductwork

Step 3 — Rig and Place Unit.................................... I

• POSITIONING

Step 4 — Install Flue Hood

Step 5 — Trap Condensate Drain ........................... 3

Step 6 — Install Gas Piping

Step 7 — Make Electrical Connections

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

• HEAT ANTICIPATOR SETTINGS

Step 8 — Make Outdoor Air Inlet Adjust

ments and Install Outdoor Air Hood

• OPTIONAL OUTDOOR AIR DAMPER

• OPTIONAL ECONOMIZER

Step 9 — Adjust Evaporator Fan Speed

START-UP

SERVICE

..............................................................

.................................................................

SAFETY CONSIDERATIONS

....................................

..............................

........................

.....................................

.....................................

..................

.....................

...........

1

1

1

3

3

3

10

16

16,17

18-22

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainte

nance functions of cleaning coils and filters and

replacing filters. All other operations should be per

formed by trained service personnel. When workiog

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for unbrazing

operations. Have fire extinguishers available for

all brazing operations.

soçipiiçtl j^$ pî|îiï^ m above fjS

oiîit VâiYov^îaitôihe^&Èotsoected

fiotti Û,S

SfÊSS»!!

at ^ 45 m fern, A mk

ssaiïtîiihjî do$ü3Etg thè .gas. i?aìYe<$ìii,

"WARiilNiJc Before g«:Tf<*rî3aîït^ service

EEteîïtî£eitî3ïiee «peîatîoîîs oa

power switch to ’tiott- Eted:ricaî cooïd

catîse

INSTALLATION

NOTE: 004,005,006 size units in California require

the installation of an accessory NOx baffle. Refer to

Accessory NOx Baffle Installation Instructions for

details.

Step 1 — Provide Unit Support

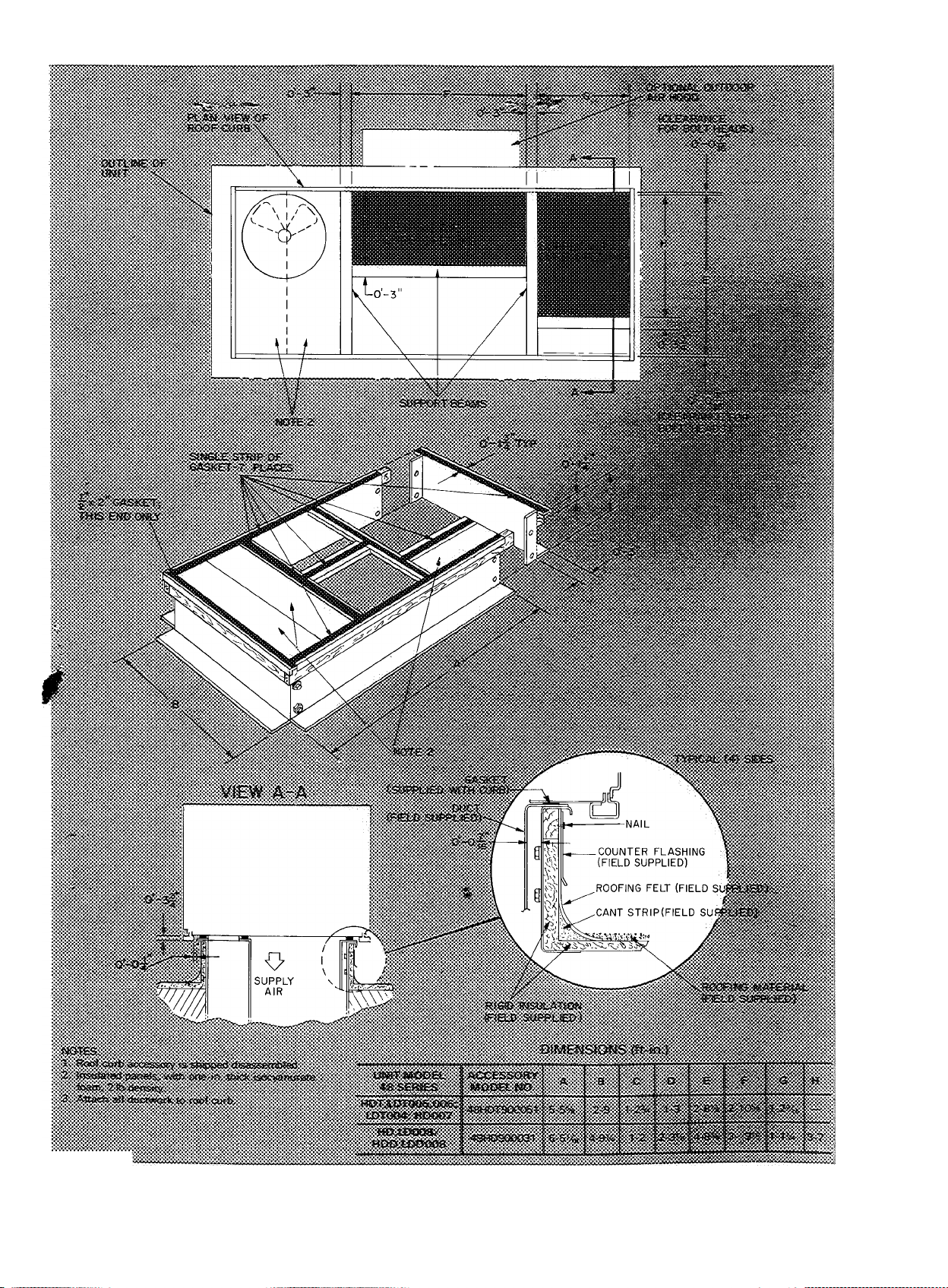

ROOF CURB (Downshot Units Only) — Assemble

and install accessory roof curb in accordance with

instructions shipped with curb. Curb details and

information required to field fabricate a roof curb

are shown in Fig. 1. Install insulation, cant strips,

roofing and flashing as shown. Ductwork must he

attached to curb.

Oie^sfcehsig of the

roof cîïïh- is CFîîîcaJ ii>r wter i'aiegjtiij'. ïastaif

^pasîietîsîg ïoàtertaî. with the ccxif corb as

io L

Curb should be level. Unit leveling tolerance is

1/16 in. per linear foot in any direction. This is

necessary for unit drain to function properly. Refer

to Accessory Roof Curb Installation Instructions

for additional information as required.

SLAB MOUNT (Horizontal Units Only) — Provide

a level concrete slab that extends a minimum of 6 in.

beyond unit cabinet. The slab should be 8 in. thick

with 4 in. above grade. Install a gravel apron in front

of condenser air inlet to prevent grass and foliage

from obstructing airflow. Trap condensate drai.n.

Allow for trap when pouring slab.

Step 2 — Field Fabricate Ductwork — On

downshot units secure all ducts to roof curb and

building structure.

Insulate and weatherproof all external duct

work, joints and roof openings with flashing and

mastic in accordance with applicable codes.

Ducts passing through an unconditioned space

must be insulated and covered with a vapor barrier.

A minimum clearance is not required around

ductwork. Cabinet return air static shall not exceed

-.35in.wg with economizer or -.45in.wg without

economizer.

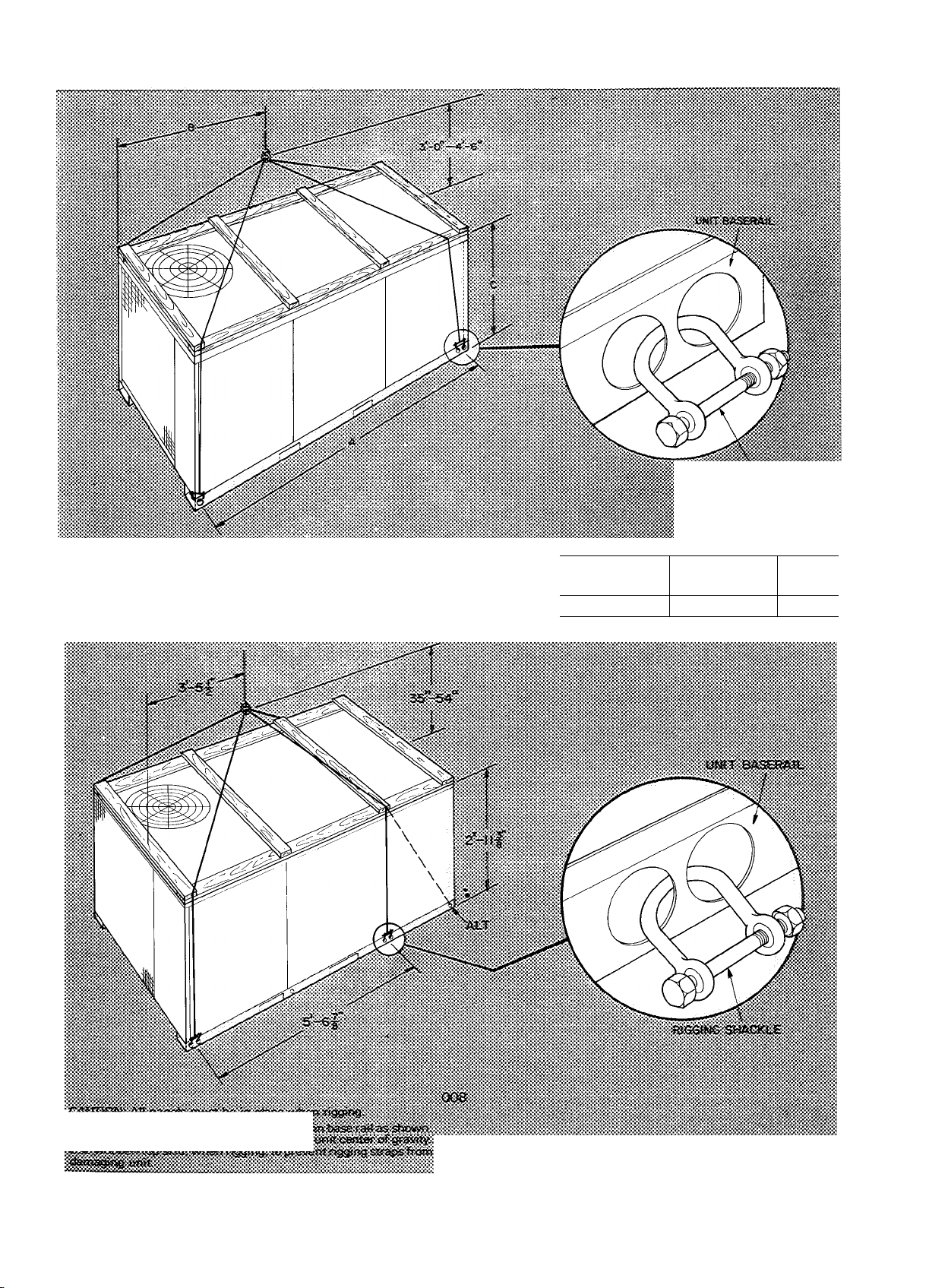

Step 3 — Rig and Place Unit — Inspect unit for

transportation damage. File any claim with trans

portation agency. Keep upright and do not drop.

Carrier Corporation 1984

Form 48H.L-7SI

Page 2

Fig. 1 — Roof Curb Details

Page 3

#

Spreader bars are not required if top crating is left

on unit. Rollers may be used to move unit across a

roof. Level by using unit frame as a reference,

leveling tolerance is ± l/16in. per linear foot in

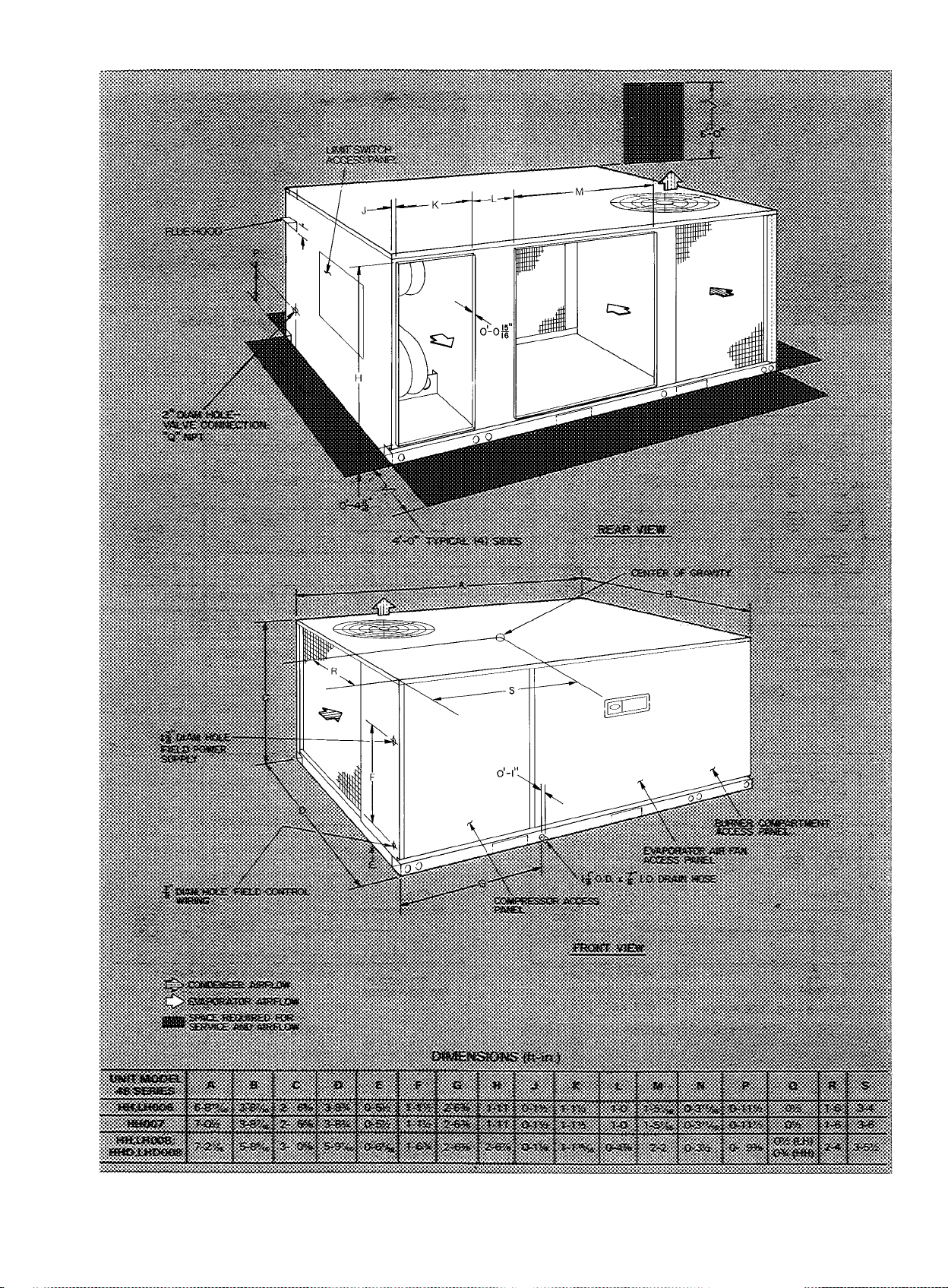

any direction. See Fig. 2 for additional information.

Weight is shown in Table 1.

Lifting holes are provided in base rails as shown in

Fig. 2. Refer to rigging instructions on unit.

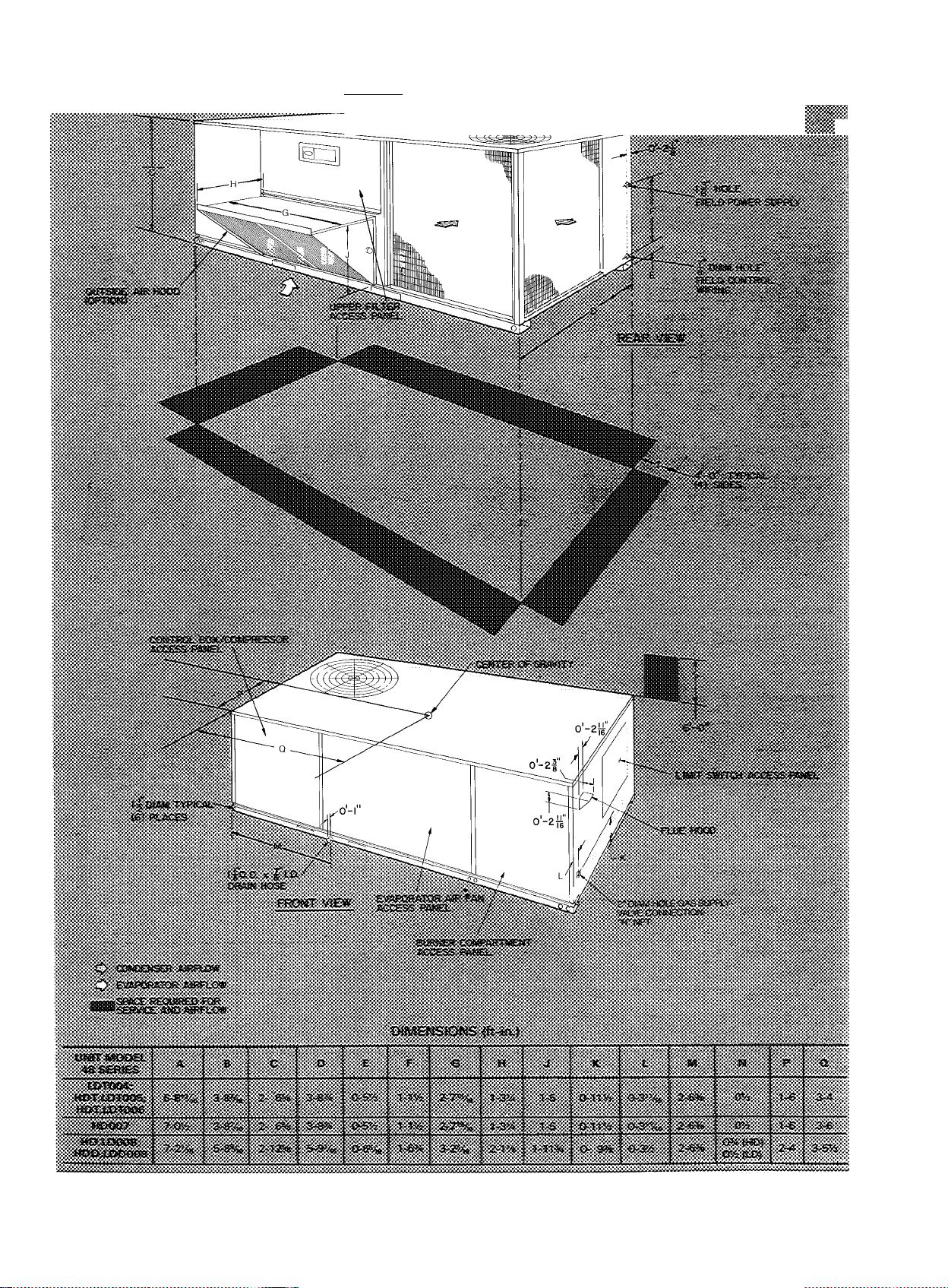

POSITIONING — Maintain clearance around and

above unit to provide minimum distance from com

bustible materials, proper airflow and service access.

See Fig. 3 and 4.

Do not install unit in an indoor location. Do not

locate unit air inlets near exhaust vents or other

sources of contaminated air.

Although unit is weatherproof, guard against

water from higher level runoff and overhangs.

Locate mechanical draft system flue assembly at

least 48 in. from any opening through which com

bustion products could enter the building, and at

least 48 in. from an adjacent building. When unit is

located adjacent to public walkways, flue assembly

must be at least 7 ft above grade.

After unit is in position, remove polyethylene

shipping wrapper and rigging skids.

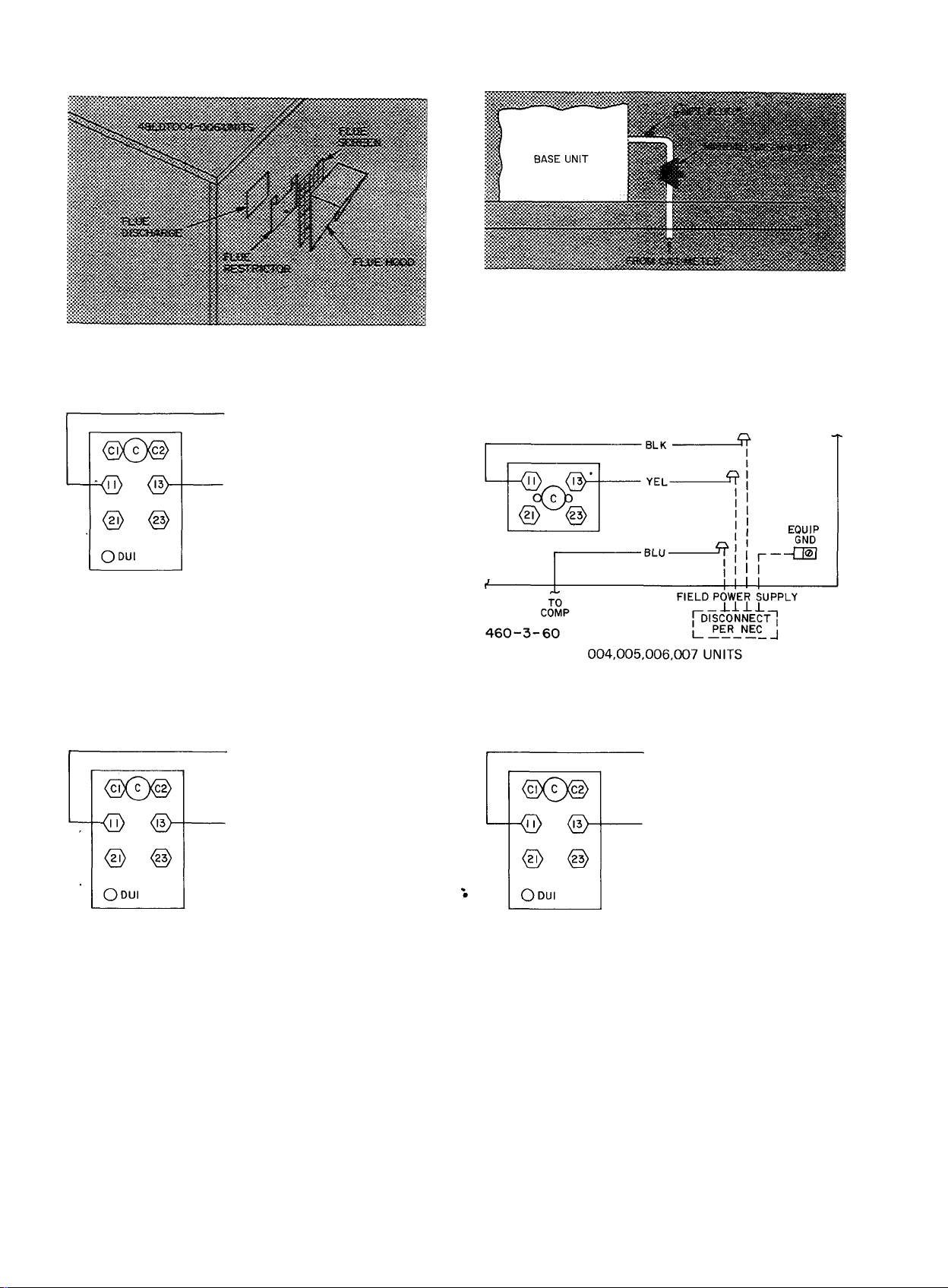

Step 4 — Install Flue Hood — Flue hood and

screen are shipped screwed to the basepan in furnace

compartment. Remove from shipping location and

using screws provided, install flue hood and screen

in location shown in Fig. 3 or 4. On 48LDT004-006

units, a flue restrictor plate MUST be assembled to

the flue discharge. The plate is shipped with the flue

hood package. Install as shown in Fig. 5.

Step 5 — Trap Condensate Drain — See Fig. 3 or

4 for drain location. A 7/8-in. preformed drain hose

is shipped clamped to the indoor basepan. At instal

lation, re-route the hose so it passes through the hole

in the indoor basepan and unit base rail.

When installed properly, the hose protrudes

through the base rail one inch. Replace clamp over

the hose where hose passes through the basepan to

ensure that hose remains level. Use a trap at least

4 in. deep and provide protection for trap against

freeze-up.

Step 6 — Install Gas Piping — Unit is equipped

for use with type of gas shown on nameplate. Refer

to local building codes, or, in the absence of local

codes, to ANSI Z223.1-1980 entitled National Fuel

Gas Code.

Natural gas pressure at unit gas connection must

not be less than 5 in. wg or greater than 13.5 in. wg

while unit is operating.

Size gas supply piping for O.Sin.wg maximum

pressure drop. Do not use supply pipe smaller than

unit gas connection. See Fig. 6 for typical pipe guide

and location of external manual main shutoff valve.

For LP gas units, pressure at unit gas connection

must not be less than 12in. wg or greater than

13.5 in. wg.

A 1/8-in. NPT plugged tapping, accessible for test

gage connection, must be installed immediately up

stream of the gas supply connection to the furnace.

Step 7 — Make Electrical Connections

FIELD POWER SUPPLY

004,005,006,007 — All units except 208/230-volt

units are factory wired for the voltage shown on the

nameplate. If the 208/230-v unit is to be connected

to a 208 power supply, the transformer must be re

wired by connecting the blue wire to C-13 and the

red wire to C-DUl.

48HDD,LDD/ HD,LD008 — 230- and 460-volt

units are factory wired for the voltage shown on

nameplate. If unit will be connected to a 208 power

supply, the transformer

ing the black wire to the 200-volt lead and insulating

the 230-volt lead.

48HHD,LHD/HH,LH008 — 230- and 460-volt

units are factory wired for the voltage shown on

nameplate. If 208/ 230-voIt unit will be connected to

a 208 power supply, the transformer must be rewired

by connecting the blue wire to C-13 and red wire

to C-DUL

All Units — Refer to unit label diagram for addi

tional information. Pigtails are provided for field

service. Use factory-supplied splices or ULapproved copper/aluminum connector.

When installing units, provide a disconnect per

NEC.

All field wiring must comply with National Elec

trical Code and local requirements.

Install conduit connectors in side panel openings

indicated in Fig. 3 or 4. Route power lines through

connector to terminal connections as shown in

Fig. 7.

Voltage to compressor terminals during opera

tion must be within voltage range indicated on unit

nameplate (also see Table 2). On 3-phase units,

voltages between phases must be balanced within

2% and the current within 10%. Use the formula

shown in Table 2, Note 2 to determine the % voltage

imbalance. Contact local power company for cor

rection of improper voltage or phase imbalance.

Operation on improper line voltage or excessive

phase imbalance constitutes abuse and may cause

damage to electrical components. Such operation,

would invalidate any applicable warranty.

FIELD CONTROL WIRING ^ Install a Carrierapproved accessory thermostat assembly according

to installation instructions included with the acces

sory. Locate thermostat assembly on a solid wall in

the conditioned space to sense average temperature.

must be rewired by connect

Page 4

=-=^--A ;y.

'iigSBEf^^ L..'^ • I

. .^ s 1

: _ __

' ‘x-b*’

I

L

.%'^CTO^^jNf<»i'pT79W’^ifl^W99«<%CMSiW».wW.w3^‘fW«<v?0%''Xww^

■•s .• s

Fig. 2 — Rigging Details

Page 5

Table 1 — Physical Data

UNIT SIZE 48 SERIES 004

OPER WT (lb)

Unit

with Economizer

Roo f Curb 130 130

COMPRESSOR

Qty Type

Oil (oz)

REFRIG (R-22) Capillary Contre

Cha rge (lb) 61

COND COIL

Row s

Fins/in 170

Total F ace Area (sq ft) 6 3

COND FAN

Nom Cfm 2200 3100

Qty Diam (in ) 1 22

Motor Hp

Motor Rpm

EVAP COIL

Row s 2 2

Fins/in

Total F ace Area (sq ft) 5 33 5 33

EVAP FAN

Qty Size (in ) 1 10x10 1 10x10

Type

Nom Cfm

Motor Hp Std

Nom M otor Rpm

Std/Opt Low 800/ 890

Rpm Range Std

Motor Pulley

Pitch D iam

(in )

Fan Pulley

Pitch D iam

(in )

Belt. Q ty Type. Length (in

Speed Change per Full

Turn of Moveable

Pulley Flange (Rpm )

Moveable Pulley

Max Full Turns

from C losed Position

Factory Setting Std

Full Turns Open Opt

Factory Speed Setting Std

(Rpm) Opt

FUR NACE SECTION

Tem p Rise (F)

Heating Input (Btuh)

Output Cap (Btuh)

Burner Orifice D iam

(in . drill size)

Natural Gas

Pilot Orifice Diam

(in drill size)

Natural Gas

Thermostat Heat Anticipator

Setting 460 v

HIG H-PRESS SWITCH

Cutout (psig)

Reset (psig)

LOW -PRESS SW ITCH

(Suction Line)

Cutout (psig)

Reset (psig)

AIR INLET SCREEN S

Qty. Size (in )

RETURN AIR FILTERS

Qty Size (in )

High

208/230V

LDT

630

655

1 M4023E

42

2

%

850 1075

140 140

DD DD

1200 1500

Opt 3/4

'/3

— —

850/1050 1000

—

— —

LDT HDT

30-60

80,000

61,600

Std

Opt

Std

Opt

Std

Opt

Opt

005 006

HDT ] LDT HDT LDT HH

650 630

675 1 655 685 665

1 P53260 1 P6026B 1 P60-6- 1 P77

66

660

640 660 640 720 720

130

66

48 72 7 2 I 9 3 99

2

170 140

6 3

1 22 1 22

’/2 ’/2

3/4

— —

890 1000

—

35-65

120,000

92,400

LDT HDT

30-60

80,000

61,600

9 73 9 73 108 15 6

3800

1075 1075 1075 1075

140 140 140 13 9

5 33

HDT LDT

1 11x10

35-65

1 20,000

92,400

1 11x10 1 11x10 1 11x10 1 11x10 1

DD DD BD

2000 2000

1

—

1130 1050/1130

— —

—

3/4

1

—

890/1000

—

LDT HH

30-60

80,000

61,600

1 2

1 0

27 ± 4

67 ± 7

1 32x19xV2

1 16x25x1

1...20x25x1

006

LH

— —

— —

74 74

Copper Tube, Aluminum Plate Fins

Copper Tube, Aluminum Plate Fins

2 : 2

14 0 140 139

Propeller Type

3800

1 22 1 22 22

’/2 '/2

3 A

5 33 6 3 8 2

HH LH

DD

2000

’/2

3/4

1725

__

—

630- 960

796-1130

1 9-2 9

2 4-3 4

5 2

5 2

66

66

830

995

35-65

120,000

92,400

2

2

2000

3/4

1 1

_

890/1000

1050/1130

-

—

LH HD

30-60

80,000

61,600

007

HD HH

745

130

_

—

HD.HH

890

950 (HD)

125 (HD)

008

946 (LD)

125 (LD)

1 Hermetic

124

LD.LH

886

4000

BD

2200

3/4

1725

796- 130 838-1032 (@ 2 turns open)

930-1260 352-11 27 (@ 1 turn open)

2 4-3 4

2 8-3 8

5 2

5 2

1 A 43

66

66

2

2

995

35-65

120,000

92,400

113 0

120,000

HD.HH LD.LH

HH

35-65

92,400

35-65

203 ,000

160 ,370

132 29 113 33 132 29

036 64 033 66

15-45

114 ,000

91,200

008

HDD.H LD

945 941

1005(HDD)

125 (HDD)

2 P46

6 2 per system

4500

’/2

3

12x12

BD

3000

1 0

1 5

—

_

—

2 4-3 4

2 4-3 4

50

5 0

65

69

4

4Y2

907

885

HHD.HDD LDD.LHD

35-65

203 ,000

160 ,370

036 64

1 2

1 0

426 ± 7

320 ± 20

27 ± 4

67 ± 7

2 16x20x1

2 20x20x1

124

LDD.LHD

996 (LDD)

125 (LDD)

15-45

114 ,000

91,200

113 33

033 66

#

DD — Direct Drive

Page 6

-----

------

■■ . •* .*

Fig. 3 — Downshot Base Unit Dimensions

Page 7

Fig. 4 — Horizontal Base Unit Dimensions

Page 8

Fig. 5 — Flue Hood Details;

48LDT004-006 Units

BLK-

*NPT plug is field supplied

NOTE Follow all local codes

Fig. 6 — Gas Piping Guide

-YEL

-i?

FIELD POWER SUPPLY

'“dTsconnectI

230-1-60 u_PifLNJc_l

004,005,006,007 UNITS

BLK

TO

COMP

208/230-3-60 (SEE NOTE)

■ YEL •

BLU-

FIELD POWER SUPPLY

I

I

I

44

roTsCONNECT"!

PER NEC

004,005,006,007 UNITS

I

-------

I

I—dn

I

H--------

EQUIP

GND

UM

EQUIP

GND

TO INDOOR

FAN CONTACTOR

BLK •

■ YEL ■

-BLU-

FIELD POWER SUPPLY

008 UNITS

I

I

I

-+

Ti^sconne'ct”!

I

PER NEC

EQUIP

--Q®]

I

H--------

I

GND

■ Factory Wiring

. Field Wiring

NOTE If connected to 208-v power supply, rewire unit transformer

no 1 by

1 Connecting blue wire from transformer no 1 to C-13

2 Connecting red wire from transformer no 1 to C-DUl

Fig. 7 — Power Wiring Connections

8

Page 9

Table 2 — Electrical Data

UNIT

48 SERIES

LDT004

HDT/LDT005

HDT/LDT006

LH006

HH006

HD/HH

007

HD.LD/

HH.LH

008

HDD.LDD/

HHD.LHD

008

VOLTAGE

VOLTS-PH-HZ

208/230-1-60

208/230-3-60 187 254

460-3-60 414

208/230-1-60 197 254

208/230-3-60 187 254

460-3-60

575-3-60 517

230-1-60 207 254

208/230-3-60 187 254

460-3-60 414 508

575-3-60 517

230-1-60 207 254

208/230-3-60 187 254

460-3-60 414

575-3-60 508 623

208/230-3-60 187 254

460-3-60

575-3-60 518 632

208/230-3-60 187 254

460-3-60 414

575-3-60 518 632

208/230-3-60 187 254

460-3-60

RANGE

Min Max RLA LRA

254

197

508 7 6

414

508

633

633

508

414

508

508

414

508

COMPR

22 2 100 1 2 2

15 1 100 1 22

28 1 106 1

18 3 105

9 2 35 1

8 3 41

28 5

20 9

104

8 3 41

28 5

20 9

104

8 3

26 7

12 1

9 6

32 5

15 2 91 1

15 8

15 2

(ea)

7 2

(ea)

OUTDOOR

FAN MTR

Qty FLA

36 5 1 1 1

1

1 2 9 75

130 1

98 1 2 9

49 1

1

130 1

98 1

49 1

41 1

137 1

69 1

51 1 2 9 1 00

183

1 2 9

1 1 5

73 3 1

80

1

(ea)

35

1

(ea)

29

29

1.5

29

1 5

29

29

29

1 5

29

29

1 5

1 5

29

1 5

INDOOR

FAN MTR

FLA

Hp

33753 6

33'^

75

"33

.75

75 6 9 .90

75

.75 3 5 .57

75

1 006980

75

1 00

75

1 00

75

1 008069

50

75

50

75

50753 5

507569

75

1 00

75

1 00

1 0

1 5

1 0

1 5

1 0

1.5

1 0

1 5

1 0

1 5

69

3 6

6 9

3.5

6 9

6 9

69

80

3 5

40

69

80

69

80

40

80

3 6

48

1 8

2 4

7 5

5 4

6 0

2 7

3 0

1 4

2 1

48

6 5

24

33

COMBUSTION

FAN MTR

FLA

90

90

57

.90 35

90 19

90

90 40/40

57

90 30

90

90 40/40

57

90 30

90

57

90 22 4

90

57

57

90

57

MCA

30/30

50/50 60/60

POWER SUPPLY

MOCP (Amps)*

40

15

46

20

55

20

55

20

40

42

18 5

19 5

25

25

26

43

45

21

22

50

45/45

25

60

45/45

25

20

50

45/45

25

45

50

45/45

25

45

60

30

30

35

35

40

50

50

25

25

#

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA -- Min imum Circuit Amps (for wire sizing) Complies with

NOTES

1 In compliance with NEC requirements for multimotor and

2 Unbalanced 3-Phase Supply Voltage

NEC, Section 430-24

combination load equipment (ref NEC Articles 430 and 440),

the overcurrent protective device for the unit shall be fuse only

Never operate a motor where a phase unbalance in supply volt

age IS greater than 2% Use the following formula to determine

the % voltage unbalance

% Voltage Unbalance

= 100 X-

max voltage deviation from average voltage

average voltage

Supply voltage is 460-3-60

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

452 + 464 + 455

1371

3

457

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

'Fuse only

Determine maximum deviation from average voltage

(AB) 457 - 452 = 5 volts

(BC) 464 - 457 = 7 volts

(AC) 457 - 455 = 2 volts

Maximum deviation is 7 volts

Determine % voltage unbalance

% Voltage Unbalance = 100 x = 1 53%

This amount of phase unbalance is satisfactory as it is below

the maximum allowable 2%

457

iMPORTAKT' if

ffsofe

Page 10

THERMOSTAT

Factory Wiring

---------

Field Wiring

Fig. 8 — Control Wiring Connections

Route thermostat cable or equivalent single leads

of colored wire from subbase terminals through con

nector on unit to low-voltage connections as shown

in Fig. 8.

NOTE: For wire runs up to 50ft, use no. 18 AWG

insulated wire (35 C mininum). For 50 to 75 ft, use

no. 16 AWG insulated wire (35 C minimum).

Pass the control wires through the hole provided

in the corner post; then feed wires through the race

way built into the corner post to the 24-v barrier

located on the left side of the control box.

HEAT ANTICIPATOR SETTINGS — Set heat

anticipator settings at 1.20 for 460-voIt units and

1.00 for 208/ 230-volt units. Settings may be changed

slightly to provide a greater degree of comfort for a

particular installation.

Step 8 — Make Outdoor Air Inlet Adjustments and Install Outdoor Air Hood

OPTIONAL OUTDOOR AIR DAMPER

48HDT,LDT004,005,006 and HD007 — Optional

outdoor air damper is shipped with hood broken

down inside of unit. See Fig. 9.

Assembly

1. Remove filter access panel.

2. Remove sheet metal parts from filter area.

3. Using screws provided, a.s.semble sides to the

inside of the hood. See Fig. 9.

4. Discard baffle.

5. Install damper blade by inserting threaded pins

through hole in side plates.

6. Use wing nuts provided to hold blade in place.

7. Install outdoor air hood assembly, using screws

provided.

8. Install outdoor air inlet screen and screen

retainer.

9. Replace access panel.

Fig. 9 — Outdoor Air Damper and Hood

Installation and Details

(004,005,006.007 Units)

Fig. 10 — Access Panel Location

(008 Units)

lO. Loosen wing nut on side plate to adjust blade.

Adjust damper blade to desired setting for out

side air intake.

48HD,LD/ HDD,LDD008 — Optional outdoor air

damper is shipped with hood broken down in unit

filter section. See Fig. lO.

Assembly

1. Remove protective cover from unit. See Fig. lO.

2. Remove upper filter aecess panel (save screws).

See Fig. lO.

3. Remove hood parts from unit evaporator fan

and filter area. Assemble hood top and side

plates as shown in Fig. 11. Do n ot atta ch hood

to u ni t a t th is tim e .

4. Adjust outdoor air damper blade to desired

setting for outside air intake by releasing linkage

rod setscrew and adjusting linkage rod. See

Fig. 12. Secure damper blade in desired position

with setscrew.

5. Remove screws holding manual outdoor air

damper to unit. See Fig. 13.

lO

Page 11

Install outdoor air hood assembly, using screws

from step 5. These screws secure the manual

outdoor air damper assembly and the outdoor

air hood to unit. See Fig. 13.

7.

Slide outdoor air inlet screens into screen tracks

on hood side plates. While holding screens in

place, fasten screen retainer to hood using screw

provided. Make sure bottom edge of screens rest

inside base rail as shown in Fig. 14.

Replace upper access panel with screws saved

from step 2.

Fig. 11

Outdoor Air Hood Details

(008 Units)

MANUAL OUTDOOR

AIR DAMPER ASSEMBLY

!»>•■ LINKAGE ROD BLADE

LINKAGE

ROD SETSCREW

Fig. 12 — Damper Blade Adjustment

(008 Units)

Fig. 14 — Outdoor Air Hood Installed

(008 Units)

<2> ®

0

0

0

(rXjF^

0

0

0

0

0

m

6RN/YEL

1

1

TBI

C — Contactor Compressor

CLO — Compressor Lockout

IDR — Induced Draft Relay

IFC — Indoor Fan Contactor

_ _

(D ®

<2> ®

® ©•

TRAN^

^ '0*

<n> <®

o@o

® <§>

XCLO

(D

(D

LEGEND

<n> <Ì3>

□

FUSE-

IFR — Indoor Fan Relay

TB — Terminal Block

TDR — Time-Delay Relay

TRAN — Transformer

Fig. 15 — Control Box Details

(008 Units)

EQUIPMENT

GROUND

Viol

a

Fig. 13 — Manual Outdoor Air Damper

(008 Units)

OPTIONAL ECONOMIZER

48HDT,LDT004.005.006/ HD007

1. Remove upper filter access panel (save screws).

See Fig. \b.

2. Remove economizer hood parts from unit filter

area, and assemble leaving out the damper

blade. See Fig. 17. Remove tape from baro

metric relief damper.

3. Remove indoor blade linkage retaining strap

(Fig. 18). Place washer on linkage rod supplied

with accessory. Place linkage rod into hole “B”

of outdoor damper blade. Secure rod with blue

retaining clip provided.

11

Page 12

4. Remove mixed air thermostat (MAT.) capillary

retaining strap and stretch capillary through

notch in filter support. See Fig. 19. Route

through hook on upper left side of indoor coil

and secure end of capillary to retainer on lower

right side of indoor coil.

5. Fasten baffle to left side of damper plate with

round head screws provided. See Fig. 19.

6. Set vent position of damper by turning base unit

power on and allowing only the indoor fan to

run. Adjustment is made on left side of damper

motor by loosening vent position setscrew and

moving vent position lever back towards indoor

coil to CLOSE DAMPER or forward to OPEN

DAMPER. Once adjustment is made, retighten

setscrew and turn indoor fan off.

HOOD

UPPER FILTER

ACCESS PANEL

ACTUATOR

MOTOR

LINKAGE ROD

RETAINING STRAP

INDOOR DAMPER BLADE

Fig. 18 — Removing Indoor Blade Linkage

Retaining Strap (004,005,006,007 Units)

OUTDOOR AIR

INLET SCREEN

AIR SCREEN

RETAINER

Fig. 16 — Removing Economizer Upper Filter

Access Panel (004,005,006,007 Units)

DAMPER FILTER

MOTOR SUPPORT

• BAROMETRIC

RELIEF DAMPER

NOTCH

BASE UNIT

RECEPTACLE

Fig. 19 — Economizer

(004,005,006,007 Units)

7. Remove 4 screws holding economizer to unit.

Use screws to fasten hood to front of econo

mizer section.

MIXED AIR

THERMOSTAT

CAPILLARY

Fig. 17 — Economizer Hood Installation

and Details (004,005,006,007 Units)

8. Remove tape from outdoor air thermostat

(OAT.) and cooling lockout switch (CLS), and

fasten to inside of the hood with screws and

speed clips provided. See Fig. 20. Place knob,

12

Page 13

supplied with accessory, on OAT. and set for 3 F

below indoor room thermostat setting.

If accessory enthalpy control is used in lieu of

OAT., refer to instructions shipped with

accessory.

9. Place outdoor air inlet screen in hood and

secure with retaining bracket across hood front.

See Fig. 16.

10. Replace upper filter access panel with screws

saved from step 1.

POWER FAILURE — Dampers have a spring

return. In event of power failure, dampers close

until power is restored. Do not manually operate

damper motor.

48HD,LD/ HDD,LDD008 — Optional economizer

is shipped with hood broken down in unit filter

section. See Fig. 21.

Fig. 22 — Outdoor Air Hood Details

(008 Units)

#

SPEED CLIPS

OUTDOOR AIR THERMOSTAT

OR ENTHALPY CONTROL

OUTDOOR AIR HOOD SIDE PLATE

Fig. 20 — Enthalpy Control Position

(004,005,006,007 Units)

COOLING

LOCKOUT

SWITCH

(CLS)

BAROMETRIC RELIEF

DAMPER LOCATION

CLS — Cooling Lockout Switch

EC — Enthalpy Control

OAT — Outdoor Air Thermostat

BASE UNIT

RECEPTACLE

OUTDOOR AIR

INLET SCREENS (2)

Fig. 23 — Economizer Installed in Unit

(008 Units)

Assembly

1. Remove protective cover from unit. See Fig. 21.

#

Fig. 21 — Access Panel Location

(008 Units)

2. Remove upper filter access panel (save screws).

See Fig. 21.

3. Remove hood parts from unit evaporator fan

and filter area. Assemble hood top and side

plates as shown in Fig. 22. Remove tape from

barometric relief damper (see Fig. 23). Do not

atta ch hood to unit at this tim e. Put aside

baffle, screen retainer and retainer screw for

later assembly.

13

Page 14

DRIVE

SHAFT

OUTDOOR BLADES (2)

MOTOR

ACCESS

HOLE

^FOR VENT

¡^POSITION

i SETSCREW

BAFFLE

ECONOMIZER ASSEMBLY

OUTDOOR DRIVE LINKAGE

Fig. 24 — Economizer Details (008 Units)

PINK WIRE

VIOLET WIRE

TERMINAL D

Fig. 25 — Economizer Motor Connections

(008 Units)

4. Determine if vent air is required in building to

be conditioned. If so, check for percentage of

vent air needed and record quantity for vent

adjustment in step 11.

5. Remove jumper plug from base unit receptacle

and discard. Insert economizer plug into recep-

. tacle. See Fig. 23.

Steps 6 through 8 involve releasing and adjust

ing indoor damper blades from factory set

position.

6. Release indoor blades drive linkage by loosen

ing linkage connector setscrew at indoor crankarm on drive shaft. See Fig. 24.

Remove pink wire from economizer damper

motor terminal D and temporarily tape bare

wire end.

Remove violet wire from economizer damper

motor and connect to terminal D on economizer

damper motor. See Fig. 25.

7. Jumper red (base unit 24-v power) and black

wires in 24-volt control box compartment. See

Fig. 10 and 12.

DAMPER PLATE

BASE RAIL

Fig. 26 — Baffle Installation Details

(008 Units)

...............

iiSiSKiSSi

Fig. 27 ~ Vent Position Setting Details

(008 Units)

Turn on base unit power to energize evaporator

fan. The economizer’s outdoor blades should

open completely.

8. Adjust the indoor blades drive linkage so that

indoor blades are fully closed. Tighten the

linkage connector setscrew. Turn off base unit

power. Reconnect pink and violet wires to

economizer motor, as shown in Fig. 25.

9. If vent air is required, leave red and black wires

jumpered. If vent air is not needed, remove

jumper between red and black wires.

10. Fasten baffle to left side of damper plate with

round head screws provided. See Fig. 26.

11. If vent air is not required, go on to step 12. If

vent air is required, proceed as follows:

a.b.Turn on base unit power. This energizes the

evaporator fan motor.

Slide economizer out of unit so that access

hole to vent position setscrew is visible. See

Fig. 27.

#

14

Page 15

- " ■■ 'OUTDOOR AIR VhERMOSTAT

' (TERMINALS ARE UP)

il:TERMINALS :;i-:;Sv TTyT,;'

&s;i® COOLING lockout

.................................i SWITCH

iismM

c. Adjust vent opening by loosening vent posi

tion setscrew on left side of economizer

damper motor and setting vent position

lever to adjust damper (see Fig. 27). Move

vent position lever back toward evaporator

coil to close damper or forward to open

damper. When adjustment is completed,

retighten setscrew.

d. Turn off base unit powerand removejumper

from red and black wires.

e. Slide economizer assembly back into unit.

12. Remove tape from outdoor air thermostat

(OAT.) and cooling lockout switch (CLS), and

fasten to inside of hood with screws and speed

clips provided. Make sure terminals on OAT.

are up. See Fig. 28.

............

•v\ ENTHALPY

. ! CONTROL\

ACCESSORY

I

CONTROL

>:¥

COOLING

LOCKOUT

v‘ X'^ SWITCH

HOOD

HOOD

Fig. 29 — Economizer and Outdoor Air Hood

Assembled to Unit (008 Units)

13. Fasten hood top and side plate assembly

(Fig. 29) and economizer to unit with screws

supplied. Before attaching, make sure bottom

of hood assembly is resting on top of unit base

rail.

14. Place knob supplied with accessory economizer

on OAT. See Fig. 28. Set for 3 degrees below

indoor room thermostat setting.

If accessory enthalpy control (EC) (Fig. 28) is

used in lieu of OAT., refer to instructions

shipped with accessory enthalpy control .for

installation and adjustment.

15. Connect OAT./EC and CLS per unit label.

See Fig. 30.

Connect 2 economizer wires to each switch

with quick-connects. Unit connecting wires are

shipped taped on outdoor blade. See Fig. 23.

16. Slide outdoor air inlet screens in hood screen

tracks. Secure screens with screen retainer

across hood front. Secure screen retainer with

screw provided. See Fig. 29.

Fig. 28 — Outdoor Air Thermostat/Enthalpy

Control and Cooling Lockout Switch

Installation (008 Units)

17. Replace upper filter access panel with screws

saved from step 2.

18. Turn base unit power on.

15

Page 16

PINK

CLS

SEE NOTE

EC

¡—0O^t5(3>-

PINK

RED

CLS — Cooling Lockout Switch

EC — Enthalpy Control

OAT. — Outdoor Air Thermostat

NOTE: When enthalpy control (EC) is installed, outdoor air thermo

stat (OAT ) is removed from economizer

Fig. 30 — Wiring Connections for Outdoor Air

Thermostat/or Enthalpy Control and

Cooling Lockout Switch (008 Units)

Step' 9 — Adjust Evaporator Fan Speed — On

! ^ OAT „

BLUE ■

48HDT,LDT004,005,006 and 48LH006 units, the

evaporator fan motor factory speed setting is shown

on label diagram affixed to base unit. If other than

faetory setting is desired, refer to label diagram for

motor reconnection.

On 48H H006 and all 007 and 008 units, fan motor

pulleys are factory set for speed shown in Table 1.

To change fan speeds:

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting

plate nuts.

3. Loosen movable pulley flange setscrew (see

Fig. 31).

4. Screw movable flange toward fixed flange to in

crease speed and away from fixed flange to

decrease speed. Increasing fan speed increases

load on motor. Do not exceed maximum speed

specified in Table 1.

5. Set movable flange at nearest key way of pulley

hub and tighten setscrew. (See Table 1 for speed

change for each full turn of pulley flange.)

To align fan and motor pulleys, loosen fan pulley

setscrews and slide fan pulley along fan shaft. Make

angular alignment by loosening motor from mount

ing plate.

To Adjust Belt Tension — Loosen fan motor pivot

bolts. Move motor mounting plate up or down for

proper belt tension (1/2-in. deflection with one

finger) and tighten pivot bolts. Adjust lock bolt and

nut on mounting plate to secure in fixed position.

Fig. 31 — Indoor Air Fan Pulley Adjustment

START-UP

Unit Preparation — Make sure that unit has been

installed in accordance with installation instructions

and applicable codes.

Return Air Filters — Make sure correct filters are

installed in filter tracks. See Table 1. Do not operate

unit without return air filters.

Outdoor Air Inlet Screens — Outdoor air inlet

screen(s) must be in place before operating unit.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove

compressor holddown bolts.

Internal Wiring — Check all electrical connections

in unit control boxes. Tighten as required.

Refrigerant Service Valves — Each unit system

has 2 Schrader type service ports, one on the suction

line and one on the compressor discharge line. Be

sure that caps on the ports are tight.

Cooling — To start unit, turn on main power

supply. Set system selector switch at COOL and

fan switch at AUTO. Adjust thermostat to a setting

below room temperature. Compressor starts on

closure of contactor.

Check cooling effects at a setting above room

temperature. Check unit charge. Refer to Refrig

erant Charge in Service section.

Reset thermostat at a position above room tem

perature. Compressor will shut off.

TO SHUT OFF UNIT — Set system selector switch

at OFF position or reset thermostat at a position

above room temperature. Units are equipped with

Signal-LOC™ protection device. Unit shuts down on

#

L

16

Page 17

any safety trip, and indicator light on thermostat

comes on. Check reason for safety trip.

Compressor restart is accomplished by manual

reset at the thermostat by turning the selector switch

to OFF and then to ON.

Heating

1. Purge gas supply line of air by opening union

ahead of gas valve. When gas odor is detected,

tighten union and wait 5 minutes before

proceeding.

2. Turn on manual gas valve and unit electrical

supply.

3. Set system switeh selector at FI EAT and fan

switch at AUTO, or ON. Set heating temperature

lever at above room temperature.

4. The induced draft combustion air fan will start.

Pilot lights within 30 seconds. Refer to Service,

Pilot Light if pilots do not light.

5. Main gas valve will open and main burners ignite

within 2 minutes from the pilot light ignition.

Natural gas burners are factory adjusted and

should burn with a soft blue flame. Flame should

not lift off burner face. Refer to Service, Main

Burners, if required.

6. Adjust airflow to obtain a temperature rise with

in the range specified on the unit nameplate.

TO SHUT OFF UNIT — Set system selector switch

at OFF or set heating selector lever below room

temperature.

Safety Relief — A soft solder joint at the service

Schrader port provides pressure relief under

abnormal temperature and pressure conditions.

Ventilation (Continuous Fan) — Set fan and sys

tem selector switches at ON and OFF, respectively.

Indoor air fan operates continuously to provide

constant air circulation.

Economizer Operating Sequence

COOLING MODE — When there is no power

applied to the indoor fan motor, the outdoor

damper is closed.

If outdoor ambient temperature is above the

outdoor air thermostat (OAT.) setting, the OAT.

contact is open. No power is supplied to DR2. Upon

a first-stage call for cooling, the indoor and outdoor

fans and compressor energize. The economizer

goes to vent position.

If outdoor ambient temperature is below the

outdoor air thermostat (OAT.) setting, the OAT.

contact is closed and power is supplied to DR2

(normally open contacts close and normally closed

contacts open). Upon a first-stage call for cooling

through Y1, power goes through contacts 4 and 6 of

DR2 causing DRl to energize (normally open con

tacts close and normally closed contacts open). The

economizer switches from vent or closed position

to modulation mode.

Modulation is accomplished by using the mixed

air thermostat (MAT.) in conjunction with the stall

circuitry inside the actuator. If the mixed air

temperature is above the MAT. setting, C-Tl and

C-T2 are made causing the damper motor to open

(which causes the air temperature to fall). As the

mixed air temperature falls to the MAT. setting

(54 L), C-T2 opens causing the motor to stall. When

mixed air temperature goes 4L below the MAT.

setting, C-Tl opens causing the spring to close the

damper. This in turn raises the mixed air tempera

ture and causes C-Tl to again stall the motor into

a less than full open position. If over-shoot should

occur, this process would oscillate a few times until

the mixed air temperature stabilizes.

Upon a second-stage call for cooling through Y2,

power goes through contacts 1,3 and 5 of DR2 and

CLO and the compressor is energized. Mechanical

cooling is integrated with economizer cooling.

Economizer continues in modulation mode.

When outdoor ambient temperature goes below

50 E, the cooling lockout switch (CLS) opens and

mechanical cooling is locked out.

An economizer control thermostat (ECT) on the

evaporator coil guards against abnormally low

suction temperatures while operating mechanical

cooling in conjunction with economizer. Low

suction temperatures can lead to frost on the evap

orator coil. If frost buildup is detected, thermostat

de-energizes economizer, thus closing the outdoor

air damper. This raises air temperature entering the

evaporator coil and melts frost. Once frost is melted,

the economizer is re-energized.

When cooling load is satisfied, the damper motor

is de-energized causing the spring to close the

damper.

During unoccupied periods, if a field-supplied

night switch is used and is opened, the outdoor

air damper closes.

HEATING MODE — With no power applied to the

indoor fan motor, the outdoor air damper is closed.

Upon a call for heat through Wl, the indoor fan

contactor is energized and provides power to the

indoor fan motor and economizer.

If the night set-back switch is closed, the outdoor

dampers will open to the manually preset vent

position by power passing through contacts 1 and 2

of DR 1 and goingto switches SW1 and SW2through

terminal XV of actuator. The switches are set with

3 degree angular difference between each other,

acting as a dead spot or stall region. Thus, if the

damper is below vent position, SW2 is closed power

ing the damper open until SWl closes and SW2

opens which stalls the motor. If the damper is too far

open, both SWl and SW2 are open causing the

spring to close the damper until SWl closes, again

stalling the motor.

When heating load is satisfied, the damper motor

is de-energized causing the spring to close the

damper.

During unoccupied periods, if a night set-back

switch is used and opened, the damper closes.

17

Page 18

SERVICE

Cleaning — Inspect unit interior at the beginning

of each heating and cooling season or as operating

conditions require.

EVAPORATOR COIL

1. Turn unit power off. Remove indoor fan motor

access panel.

2. Diseonnect indoor motor wiring from main

control box.

3. Remove screws from base of fan motor housing.

4. Slide fan motor housing out of base unit.

5. Clean coil using a commercial coil cleaner

(i.e., Oakite 164) or dishwasher detergent in a

pressurized spray canister. Wash both sides of

coil and flush with clean water. For best results,

backflush toward return air section to remove

foreign material. Flush condensate pan after

completion.

6. Reinstall fan motor housing, reconnect wiring

and replace indoor fan motor access panel.

Fig. 34 — Separating Coil Sections

CONDENSER COIL — Inspect coil monthly.

Clean condenser coil annually, or as required by

location or outdoor air conditions.

Fins are not continuous through coil sections.

Dirt and debris may pass through first section,

become trapped between the 2 rows of fins, and

restrict condenser airflow. Shine flashlight through

coil to determine if dirt or debris has collected

between coil sections.

Fig. 32 — Cleaning Condenser Coil

Clean coil as follows:

1. Turn off unit power.

2. Remove top panel screws on condenser end of

unit. Remove screws from coil side of coil center

post. Do not remove center post.

3. Remove condenser coil corner post. See Fig. 32.

To hold top panel open, place coil corner post

between top panel and center baffle. See Fig. 33.

4. Remove device holding coil sections together at

return end of condenser coil. Carefully separate

the outer coil section 3 to 4 in. from the inner coil

section. See Fig. 34.

5. Use a water hose or other suitable equipment to

flush down between the 2 coil sections to remove

dirt and debris. Clean the outer surfaces with

a stiff brush in the normal manner.

»

6. Reposition the outer coil section, remove the coil

corner post from between the top panel and

center baffle. Secure the sections together. Install

the coil corner post, coil center post and replace

all screws.

CONDENSATE DRAIN — Check and clean each

year at start of cooling season. In winter, keep drain

and trap dry or protect against freeze-up.

Fig. 33 — Propping Up Top Panel

FILTERS — Clean or replace at start of each heat

ing and cooling season, or more often if operating

conditions require it.

OUTDOOR AIR INLET SCREENS (Downshot

Units) — Clean screens with steam or hot water

and a mild detergent. Do not use throwaway filters

in place of screens.

18

Page 19

TO USE COOLING CHARGING CHART ^

Take the outdoor ambient temperature and read the

suction pressure gage. Refer to chart to determine

what suction temperature should be. If suction tem

perature is high, add refrigerant. If suction tempera

ture is low, carefully blow some of the charge. Re

check the suction pressure as charge is adjusted.

Example; (Fig. 40)

Outdoor Temperature

...........................................

85 F

Suction Pressure............................................. 70 psig

Suction Temperature should be............................52 F

(Suction Temperature may vary ± 5 F.)

Fig. 35 — Condenser Air Fan Adjustment

Lubrication

COMPRESSORS — Each compressor is charged

with correct amount of oil at the factory.

FAN MOTOR BEARINGS — No lubrication of

condenser or evaporator fan motors is required for

first 5 years of operation. Annually thereafter, clean

and repack bearings with a suitable bearing grease.

Condenser Air Fan Adjustment (Fig. 35) — Shut

off unit power supply. Remove condenser fan

assembly (grille, motor, motor cover and fan) and

loosen fan hub setscrews. Adjust fan height as

shown in Fig. 35. Tighten setscrews and replace

condenser fan assembly.

Manual Outdoor Air Damper (Downshot Units

Only) — If outdoor air damper blade adjustment is

required, see Optional Manual Outdoor Air

Damper Section.

Economizer Adjustment (Downshot Units) —

Refer to Economizer section under Installation.

Refrigerant Charge — Amount of refrigerant

charge is listed on unit nameplate (also refer to

Table 1). Refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants.

Unit panels must be in place when unit is oper

ating during charging procedure.

NO CHARGE — Use standard evacuating tech

niques. After evacuating system, weigh in the speci

fied amount of refrigerant. (Refer to Table 1.)

LOW CHARGE COOLING — Using Cooling

Charging Chart, Fig. 36 through 41, vary refrigerant

until the conditions of the chart are met. Note the

charging chart is different from type normally used.

Chart is based on charging the units to the correct

superheat for the various operating conditions.

Accurate pressure gage and temperature sensing

device are required. Connect the pressure gage to the

service port on the suction line. Mount the tempera

ture sensing device on the suction line and insulate it

so that outdoor ambient temperature does not affect

the reading. Indoor air cfm must be within the

normal operating range of the unit (maximum 3750;

minimum 2250).

(A

<

O

g 620-

o 90

Ql

O

=i

^ 551

iii

tr

§483

iij

L.

: 345

276

207 30

80

60

50

20 30

40 50 60 70

SUCTION LINE TEMPERATURE (F)

-I 4 10 16 21

SUCTION LINE TEMPERATURE (C)

Fig. 36 — Cooling Charging Chart;

48LDT004

<

w620

<

0.

o

80

551

] 483

? 70

^414

:345-

276-

207 30

60

50

40

20 30

40 50 60 70

SUCTION LINE TEMPERATURE (F)

-I 4 10') 16 21

SUCTION LINE TEMPERATURE (C)

Fig. 37 — Cooling Charging Chart;

48HDT,LDT005

OUTDOOR TEMP

(F) (C)

115 46

105 41

95 35

85 29

75 24

1 1 1 1

65 18

(F) (C)

115 46

105 41

1 1 1 1 1

Mi tr

95 35

Mill

85 29

75 24

1 1 1 1 1

65 18

19

Page 20

- -

"414--' 60

207- 30

nilTnnnR

115 46

1 1 1 1

lOf 41

80

50

20

SUCTION LINE TEMPERATURE (F)

-7

SUCTION LINE TEMPERATURE (C)

30 40 50 60 70

-1 4 lb 16 21

IMI

9£ 35

4__L_U_

1 1 1 1

05 29

il 24

65 IB

III!

55 13

Fig. 38 — Cooling Charging Chart;

48HDT.LDT006; HH.LH006

TEMP

689

(/)

< 621

o

CO

s

0552

liJ

^483

cc

0-414

z345

O

’276-

207- 30

100

90

: 80

70

60

50

40

SUCTION LINE TEMPERATURE (0 )

- -

-

-

-

-

-

-

--

-

-

SUCTION LINE TEMPERATURE ( F)

-

20 30 40 50 60

-7 -Ì 4 lb 16

OUTDOOR TEMP

70 80

21

Fig. 40 — Cooling Charging Chart;

48HD.LD,HH.LH008

(F) (C)

115 46

105 41

95 35

85 29

75 24

65 18

55 13

45 7

- -

#

27

689

^552

r)

UÌ

llJ

(E

“-483

414

345

276

100

OUTDOOR TEMP

m 90

80

70

3 60

50

40

20 30 40 50 60 70

-7

SUCTION LINE TEMPERATURE (F)

-Ì 4 IÒ 16 2Ì

SUCTION LINE TEMPERATURE (C)

Fig. 39 — Cooling Charging Chart;

48HD,HH007

(F) (C)

105 41

95 35

85 29

75 24

OUTDOOR TEMP

(F) (C)

115 46

«620

90

<

551

a: 80

483

70-

276

207

60

50

40

30

20

30 4 0 50 60 70 80

-7

SUCTION LINE TEMPERATURE (F)

-Ì 4 IÓ 16 21 27

SUCTION LINE TEMPERATURE (C)

uj 414

2

Z

O

p345

o

3

«

80

27

105 41

95 35

85 29

75 24

65 18

Fig. 41 — Cooling Charging Chart;

48HDD.LDD.HHD,LHD008

L

20

Page 21

If Chargemaster® charging device is used, tem

perature and pressure readings must be accom

plished using the charging chart.

Main and Pilot Burners — At the beginning of

each heating season, inspect for deterioration or

blockage due to corrosion or other causes. Observe

the pilot and main burner flames and adjust, if

necessary, referring to automatic Pilot Adjustment

or Main Burners sections of instructions.

Flue Gas Passageways — Inspect flue collector

box and upper areas of heat exchanger cells by

removing burner compartment access panel; then

remove flue cover and inspect heat exchangers.

Using a wire brush, clean all surfaces as required.

Combustion Air Blower — Clean periodically to

assure proper airflow and heating efficiency. Inspect

blower wheel every fall and periodically during

heating season. For the first heating season, inspect

blower wheel bimonthly to determine proper clean

ing frequency.

To inspect blower wheel, remove draft hood and

screen. Shine a flashlight into opening to inspect

wheel. If eleaning is required, remove motor and

wheel as follows:

1. Remove burner access panel.

2. Remove the 6 screws that attach induced draft

motor mounting plate to blower housing

(Fig. 42). The mounting plate will drop down.

3. Remove the 4 wires attached to the motor and

remove assembly from unit.

4. To remove blower, remove setscrews.

5. To remove motor, remove blower, then remove

the nuts that hold motor to mounting plate.

NOTE; Do not lose spacers for induced draft

motor.

6. To reinstall, reverse the procedure outlined

above.

Limit Switch — Aceess panel is located on the heat

section side panel (Fig. 3 and 4).

004,005,006,007 UNITS AND 48HDD,LDD/HD,

LD008 UNITS — Limit switch is located in the

upper section of the heat exchangers. Bi-metal

sensor is facing the airstream. Remove bracket

holding limit switch and remove screw holding

switch.

48HHD,LHD/HH,LH008 UNITS ^ Limit switch

is located on partition between blower section and

heat section. Remove plate and screw holding

switch.

Pilot Light — If pilot does not light as described in

Start-Up, Heating: Be sure pilot orifice is not

obstructed, gas pressure is not less than 3in. wg;

and air has been bled from gas supply. Check for

spark ignitor malfunctions as follows:

1. Shut off unit power supply.

2. Check that spark gap is 1/8 to 3/16 inch.

3. Check that spark generator is securely grounded

to furnace vestibule plate.

4. Check that high-voltage lead is securely con

nected between generator and electrode body.

5. Restore power. Check that 24 volts is supplied to

primary side of generator.

6. Check unit label diagram for correct terminal

usage if any wires are removed.

Automatic Pilot Adjustment

1. Turn off unit power supply, set system selector

switch at HEAT, and adjust thermostat to call

for heat.

2. Remove burner compartment access panel.

3. Remove screw cap cover on the top of the main

gas valve to expose pilot adjusting screw.

4. With a small screwdriver, turn adjustment screw

until flame is approximately 1 to 1-1/2 in. high.

5. Replace screw cap cover on pilot gas valve.

6. Observe burner operation and adjust main gas

valve for correct burner operation as required.

See Fig. 43 for proper flame appearance.

7. Replace all panels.

Automatic Gas Valve Sequence of Operation

— Thermostat calls for heat, energizing the spark

ignitor and simultaneously opening the pickup and

hold solenoids of the pilot gas valve (inside main gas

valve). The pilot gas ignites within 2 seconds, stop

ping the ignitor. Within 11 seconds, the pilot contact

(normally closed) opens, drops out the pickup sole

noid. Within 35 seconds, the pilot contact (normally

MAIN

BURNER

SECTION

Fig. 42 — Burner Section Details

MAIN

GAS

VALVE

Fig. 43 — Proper Flame Appearance

21

Page 22

open) closes, energizing the heat motor in the main

gas valve. The main gas valve will open within

45 seconds.

Main Burners are factory set and should require

no adjustment. However, if burner adjustment is

necessary:

1. Perform Automatic Pilot Adjustment.

2. Turn gas valve to ON. Allow unit to operate at

least 15 minutes with furnace access panel in

place.

3. Remove access panel.

4. Loosen primary air shutter and adjust to a mini

mum opening of 5/8 inch.

5. Retighten primary air shutter and reinstall access

panel.

TO CHECK ignition of main burners and fan

switch operation, move thermostat dial above and

below room temperature several times pausing at

least one minute between cycles.

REMOVAL

1. Shut off manual main gas valve.

2. Shut off power to unit.

3. Remove evaporator air fan access panel, burner

compartment access panel and center post.

4. Disconnect gas piping at unit gas valve.

5. Remove (and mark) red wire from terminal no. 4

or W1 and brown wire from terminal no. 3 or C2

and violet wire from terminal W2 (connections

are dependent on whether a 2-stage or singlestage valve is on the unit).

6. Remove the 2 screws at rear of housing just

inside burner section.

7. Lift and slide assembly out.

REPLACEMENT

1. Slide assembly into burner section and push

snugly against vestibule plate.

2. Screw assembly down.

3. Connect red wire to terminal no. 4 or W1 and

brown wire to terminal no. 3 or C2 and violet

wire to terminal W2 (connections are dependent

on whether a 2-stage or single-stage valve is on

the unit).

4. Connect gas piping at unit gas valve.

5. Replace center post and access panels.

6. Turn on manual main gas valve.

7. Restore power to unit.

CLEANING

1. Remove burner assembly from unit as described

above.

2. Inspect burners and if dirty, remove by removing

retaining plate.

3. Using a soft brush clean burners as required.

4. Replace burners.

5. Replace burner assembly as described above.

Replacement Parts — A complete list of replace

ment parts may be obtained from any Carrier dis

tributor upon request.

22

Page 23

m

TYPICAL WIRING DIAGRAM LEGEND

AHA

—

Assy

C

CAP.

CC

CH —

CLO —

CLS

COMP

CS —

DM —

DR —

EC —

ECT

Equip

Fu

Gnd

HPS

1

IDM

IDR

IFC

IFM

IFR

IPP Ignitor Power Pack

L

LPS

LS

MAT.

MGV

Mtr

NS

OAT.

OFM

PGV Pilot Gas Valve

Adjustable Heat Anticipator

—

Assembly

—

Contactor Compressor QT -

—

Capacitor RLC —

—

Cooling Compensator RS —

Crankcase Heater Std —

Compressor Lockout Sw —

__

Cooling Lockout Switch TB —

—

Compressor Motor TC —

Centrifugal Switch

Damper Motor

Damper Relay

Enthalpy Control

—

Economizer Thermostat

Equipment

—

Fuse

—

Ground

High-Pressure Switch

—

—

Ignitor Electrode

—

Induced Draft Motor

_

__

Induced Draft Relay

—

Indoor Fan Contactor

Indoor Fan Motor

—

—

Indoor Fan Relay

—

Light

Low-Pressure Switch

Limit Switch

—

Mixed Air Thermostat

__

Main Gas Valve

Motor

Night Setback Switch

—

Outdoor Air Thermostat

—

Outdoor Fan Motor

(48HD,LD008)

PI PS —

TDR —

TH TRAN -

o

o

□

•o

—•—

_

_________

—

——

Plug Assembly

Pilot Sensor

Ouadruple Terminal

Rotor Locking Circuit

Rollout Switch

Standard

Switch

Terminal Block

Thermostat, Cooling

Time-Delay Relay

Thermostat, Heating

Transformer

Marked Wire

Denotes Connection Point Between

Subbase and Thermostat

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Field Splice

Splice (Marked)

Factory Splice

Factory Wiring

Internal Connection

Accessory or Optional Wiring

Field Control Wiring

Field Power Wiring

To indicate common potential only,

not to represent wiring

TYPICAL WIRING DIAGRAM NOTES

(48HD,LD008)

1. Compressor and fan motors are thermally pro

tected — 3-phase motors are protected against

primary single-phasing conditions.

2. If any original wires must be replaced, use 90 C

wire or equivalent.

3. Numbers indicate the line location of used con

tacts. A bracket over (2) numbers signifies a

single pole double throw contact. An underlined

number signifies a normally closed contact. Plain

(no line) number .^signifies a normally open

contact.

4. Must use thermostat HH07AT172 or 174 with

subbase HH93AZ177.

5. Set heat anticipators at one amp (208/230-3-60).

Set heat anticipators at 1.2 amp (460-3-60).

6. Factory connected to 230-v or 460-v lead per unit

rated voltage. If 208-v power supply is used,

connect to 200-v lead and insulate 230-v lead.

23

Page 24

ECONOMIZER ASSY.

<g>

DM ^

<T>

<£)

DM ^

<D

<E>

<±>®

0^j)D

TWO POSITION DAMPER MOTOR ASSY.

<0®

<2 >

<±> <£>

<E>

i®®'

L®fj

CLS

CiXD

OAT

to 1=0

EOT. LPS

HPS .ECT

CAP

o o

QT

BRN—

ORN/YEL

<i><D<]X^<l><»>

Q^El

PL I

o o

o

COMP

Typical Component Arrangement (48HO,LD008 Shown)

24

1PM

Page 25

1 H

1 гг

из

О 1

Page 26

-< ^

a.vt

C

5

o

£

w

00

o

0

Q

_l

Q

1

00

o

'■P

W

'q.

t-

(C

E

03

u

O)

c

(0

o

>•

5

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book 1

Tab la 6a

4

Form 48H,L-7S1 Supersedes 48HD-5SI: 48H,L-4SI

Printed in U S A

9-84 PC 111 Catalog No 534-805

Loading...

Loading...