40MVC / 38MVC

40MVQ / 38MVQ

High---Wall D uct Free Split System

Sizes 009 to 024

Product Data

INDUSTRY LEADING

FEATURES / BENEFITS

AN INEXPENSIVE AND CREATIVE

SOLUTION TO DESIGN PROBLEMS.

The 38/40MVC(Q) series duct--free split systems are a matched

combination of an outdoor condensing unit and an indoor fan coil

unit connected only by refrigerant tubing and wires.

The fan coil is mounted on the wall, near the ceiling. This

selection of fan coils permits inexpensive and creative solutions to

design problems such as:

the environmentally sound refrigerant

The ideal compliment to your ducted system when it is impractical

or prohibitively expensive to use ductwork.

S Add--ons to current space (an office or family room

addition)

S Special space requirements

S When changes in the load cannot be handled by the

existing system.

S When adding air conditioning to spaces that are heated

by hydronic or electric heat and have no ductwork.

S Historical renovations or any application where

preserving the look of the original structure is essential.

These compact indoor fan coil units take up very little space in the

room and do not obstruct windows. The fan coils are attractively

styled to blend with most room decors. Advanced system

components incorporate innovative technology to provide reliable

cooling performance at low sound levels.

LOW SOUND LEVELS

When noise is a concern, the duct--free split systems are the answer.

The indoor units are whisper quiet. There are no compressors

indoors, either in the conditioned space or directly over it, and

there is none of the noise usually generated by air being forced

through ductwork.

When sound ordinances and proximity to neighbors demand quiet

operation, the 38MVC,MVQ unit is the right choice: The

advanced, horizontal airflow design distributes air more evenly

over the coil.

SECURE OPERATION

If security is an issue, outdoor and indoor units are connected only

by refrigerant piping and wiring to prevent intruders from crawling

through ductwork. In addition, since 38MVC,MVQ units can be

installed close to an outside wall, coils are protected from vandals

and severe weather.

FAST INSTALLATION

This compact duct--free split system is simple to install. A

mounting bracket is standard with the indoor units and only wire

and piping need to be run between indoor and outdoor units. These

units are fast and easy to install ensuring minimal disruption to

customers in the home or workplace. This makes the

38/40MVC, MVQ

38/40MVC,MVQ duct--free split systems the equipment of choice,

especially in retrofit situations.

SIMPLE SERVICING AND

MAINTENANCE

Removing the top panel on outdoor units provides immediate

access to the control compartment, providing a service technician

access to check unit operation. In addition, the draw--thru design of

the outdoor section means that dirt accumulates on the outside

surface of the coil. Coils can be cleaned quickly from the inside

using a pressure hose and detergent.

On all indoor units, service and maintenance expense is reduced

due to easy--to--use cleanable filters. In addition, these high wall

systems have extensive self--diagnostics to assist in

troubleshooting.

BUILT--IN RELIABILITY

Duct--free split system indoor and outdoor units are designed to

provide years of trouble--free operation.

The high wall indoor units include protection against freeze--up

and high evaporator temperatures on heat pumps.

The condensing units and heat pumps are also protected. There is

a three minute time delay before the compressor will start. The

compressor is also protected by the over--current protection. On

size 18k and 24k heat pumps, there is high temperature protection.

INDIVIDUAL ROOM COMFORT

Maximum comfort is provided because each space can be

controlled individually based on usage pattern. The air sweep

feature provided permits optimal room air mixing to eliminate hot

and cold spots for occupant comfort. In addition, year--round

comfort can be provided with heat pumps.

ECONOMICAL OPERATION

The duct--free split system design allows individual room heating

or cooling when required. There is no need to run large supply--air

fans or chilled water pumps to handle a few spaces with unique

load patterns. In addition, because air is moved only in the space

required, no energy is wasted moving air through ducts.

EASY--TO--USE CONTROLS

The high--wall units have microprocessor--based controls to

provided the ultimate in comfort and efficiency. The user friendly

wireless remote control provides the interface between user and the

unit.

ACCESSORIES

Customizing these duct--free split systems to your application is

easily accomplished. Low--ambient temperature capability

(permitting cooling operation down to --20_F (--28.89_C)outdoor

ambient) is easily added on all units.

Adding a condensate pump accessory to the high wall fan coil

provides installation flexibility.

AGENCY LISTINGS

All systems are listed with ARI (Air Conditioning & Refrigeration

Institute), and ETL.

2

MODEL NUMBER NOMENCLATURE

INDOOR UNIT

40 MVC 3---01

Fan C oil U nit

Unit Type

MVC --- C o o l i n g O n l y

MVQ --- H e a t P u m p

018

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 To n

018 --- 1 --- 1 / 2 Ton

024 --- 2 To n s

---

Volt age

--- --- 3 0 V D C

1 --- 1 1 5 --- 1 --- 6 0

3 --- 208/230--- 1 --- 60

Air---Cooled Condenser

OUTDOOR UNIT

38 MVC 3---01

Unit Type

MVC --- C o o l i n g O n l y

MVQ --- H e a t P u m p

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

018

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 To n

018 --- 1 --- 1 / 2 Ton

024 --- 2 To n s

---

Volt age

1--- 1 1 5 --- 1 --- 6 0

3--- 208/230--- 1--- 60

38/40MVC, MVQ

3

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Mounting Brackets S

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Wireless Remote Control S

Automatic Air Sweep S

Air Direction Control S

Auto Restart Function S

Cold Blow Protection On Heat Pumps S

Turb o Mo d e On Size s 9K a n d 12 K S

Auto Changeover On Heat Pumps S

Energy Saving Features

Sleep Mode S

Stop/Start Timer S

Safety And Reliability

3MinuteTimeDelayForCompressor S

Over Current Protection For Compressor S

Indoor Coil Freeze Protection S

Indoor Coil High Temperature Protection On Heat Pumps S

Condenser High Temperature Protection On heat Pumps{ S

Accumulator On Heat Pumps S

Ease Of Service And Maintenance

38/40MVC, MVQ

Cleanable Filters S

Diagnostics S

Liquid Line Pressure Taps S

Suction And Discharge Pressure Taps (Sizes 18 and 24K) S

Application Flexibility

Low Ambient Controls (--- 20° F) A

Condensate Pumps A

Crankcase Heater A

Wind Baffles F

Warranty

5 ---Year Compressor Warranty S

1 --- Parts Warranty S

Compressor Extended Warranty Years 6 Thru 10 O

All Parts And Labor Years 2 Thru 5 O

All Parts And Labor Years 2 Thru 5, Compressor Years 6

Thru 10

{ Sizes 18k & 24k

Legend

SStandard

A Accessory

OOptional

F Field Fabricated

O

INDOOR UNITS

A07892

Fig. 1 – Condensate Pump Accessory

On high wall fan coils, the condensate pump has a lift capability of

12 ft (3.6 m) on the discharge side with the pump mounted in the

fan coil or 6 ft (1.8 m) on the suction side if the pump is remote

mounted. The pump is recommended when adequate drain line

pitch cannot be provided, or when the condensate must move up to

exit.

NOTE: An external 115v power source will be required to run the

pump on unit sizes 9k and 12k.

OUTDOOR UNITS

LOW AMBIENT KIT

The kit controls condenser fan cycling using a pressure switch. It is

specifically designed to control fan--motor cycles in response to

saturated condensing pressure. This device maintains a constant

saturated condensing temperature of 100 _F ± 10 _F (37.78_C ±

--12.22 _C) at outdoor--air temperatures between 55 _F and --20 _F

(12.78_C ± --12.22_C), and can be used on all outdoor units

without changing the outdoor fan motor.

CRANKCASE HEATER

Available for units with rotary compressors. Heater clamps around

compressor oil sump. Recommended for low--ambient applications

on sizes 9, 12 , 18, 24 and long line applications.

AHRI* CAPACITY RATINGS

OUTDOOR

SECTION

3 8 M V C 0 0 9 --- --- --- 1 4 0 M V C 0 0 9 --- --- --- 1 1000 325 9,200 13 N/A N/A

3 8 M V C 0 1 2 --- --- --- 1 4 0 M V C 0 1 2 --- --- --- 1 1000 425 11,400 13 N/A N/A

3 8 M V C 0 1 2 --- --- --- 3 4 0 M V C 0 1 2 --- --- --- 3 1000 425 11,800 13 N/A N/A

3 8 M V C 0 1 8 --- --- --- 3 4 0 M V C 0 1 8 --- --- --- 3 1600 630 17,500 13 N/A N/A

3 8 M V C 0 2 4 --- --- --- 3 4 0 M V C 0 2 4 --- --- --- 3 1600 750 22,000 13 N/A N/A

3 8 M V Q009 --- --- --- 1 4 0 M V Q 0 0 9 --- --- --- 1 1000 325 9,600 13 9,400 7.7

3 8 M V Q012 --- --- --- 1 4 0 M V Q 0 1 2 --- --- --- 1 1000 425 11,500 13 11,500 7.7

3 8 M V Q012 --- --- --- 3 4 0 M V Q 0 1 2 --- --- --- 3 1000 425 12,000 13 11,500 7.7

3 8 M V Q018 --- --- --- 3 4 0 M V Q 0 1 8 --- --- --- 3 1600 560 17,500 13 17,000 7.7

3 8 M V Q024 --- --- --- 3 4 0 M V Q 0 2 4 --- --- --- 3 1600 750 22,500 13 21,500 7.7

*Air Conditioning, Heating & Refrigeration Institute

Legend

HSPF --- Heating Seasonal Performance Factor

SEER --- Seasonal E n ergy Efficiency Ratio

NOTES:

1. Ratings are net values reflecting the effects of circulating fan heat. Ratings are based on: Cooling Standard: 80_F (26.67_C) db, 67_F (19.44_C) wb air

entering indoor unit and 95_F(35_C) db air entering outdoor unit. High Temperature Heating Standard: 70_F (21.11_C) db air entering indoor unit and 47_F

(8.33_C) db, 43_F (6.11_C) wb air entering outdoor unit.

2. Ratings are based on 25 ft. (7.62 m) of interconnecting refrigerant lines.

3. All system ratings are based on fan coil units operating at high fan speed. Consult Physical Data tables for airflows at all available fan speeds.

INDOOR

SECTION

STANDARD CFM

Outdoor Indoor BTUH HSPF

COOLING BTUH SEER

HIGH HEAT

4

DIMENSIONS -- INDOOR

Model Size

9K 32.09 (815) 11.02 (280) 7.68 (195)

12K 35.67 (906) 11.26 (286) 9.25 (235)

18K 49.21 (1250) 12.80 (325) 9.06 (230)

24K 49.21 (1250) 12.80 (325) 9.06 (230)

in. (mm)

DIMENSIONS -- OUTDOOR

A07336

W

H

in. (mm)

D

in. (mm)

Operating Weight lb (kg)

17.6 (8)

25.3 (11.5)

39.6 (18)

39.6 (18)

Air Flow

H

L1

L2

L3

35

Model Size

9K 30.71 (780) 21.26 (540) 21.61 (549) 11.81 (300) 10.87 (276)

12K 29.92 (760) 23.23 (590) 20.87 (530) 12.40 (315) 11.42 (290)

18K 33.07 (840) 27.36 (695) 22.05 (560) 14.17 (360) 13.19 (335)

24K 35.00 (889) 33.50 (851) 23.11 (588) 13.98 (355) 13.11 (333)

W

in. (mm)

H

in. (mm)

L1

in. (mm)

L2

in. (mm)

SERVICE VALVE LOCATIONS

9K

12K

18K

W

L3

in. (mm)

24K

Operating Weight

lb (kg)

Cooling Only

70.4 (32) 72.6 (33)

79.2 (36) 83.6 (38)

116.6 (53) 117.7 (53.5)

149.6 (68) 151 (68.5)

Operating Weight

Heat Pumps

38/40MVC, MVQ

A07337

lb (kg)

J

Service Valve Locations

J 3.46 (88) 3.19 (81) 3.46 (88) 4.02 (102)

K 3.46 (88) 5.63 (143) 3.62 (92) 6.57 (167)

in. (mm)

9K

K

12K

in. (mm)

J

K

18K

in. (mm)

K

J

A07376a

24K

in. (mm)

J

K

5

CLEARANCES -- INDOOR

38/40MVC, MVQ

CLEARANCES -- OUTDOOR

5

"

(0.13m)

min.

6" (0.15m) min.

(1.8m)

6'

Fig. 2 – Indoor unit clearance

5

"

(0.13m)

min.

A07891

A

D

UNIT 9k and 12k in. (mm)

A 24 (610)

B 24 (610)

C 24 (610)

D 6 (152)

E 12 (305)

B

Fig. 3 – Outdoor Unit Clearance

Air-inlet

E

C

Air-outlet

A07894

18k and 24k in. (mm)

24 (610)

36 (914)

24 (610)

6 (152)

12 (305)

6

PHYSICAL DATA

Outdoor Unit 38MVC 009 012 012 018 24

System Voltage 115 V 115 V 208/230 208/230 208/230

Nominal Capacity (Btuh) 9000 12000 12000 18000 24000

Operating Weight lb(kg) 70.4(32) 79.2(36) 79.2(36) 116.6(53) 149.6(68)

Refrigerant Type R--- 410A

Metering Device Capillary Tube at Outdoor

Charge lb (kg) 2.3 (1.0) 2.9 (1.3) 3.0 (1.4) 4.4 (2.0) 5.3 (2.4)

Compressor

Type Rotary

Model EA82X1C--- 1FZDU1 EA108X1C--- 1FZDU1 PA108X1C---3FZDU PA150X2CS--- 3KUU PA200X2CS ---3MUU

O il C h a r g e ( POE --- o z ) 11.8 11.8 11.8 25.4 25.4

Outdoor Fan

Rpm 900 900 900 840 740

Diameter (in) .. No. of Blades 15.8 … 3 15.8 … 3 15.8 … 3 18.1 … 3 18.1 … 3

Motor (watts / hp) 23 / 0.102 23 / 0.102 23 / 0.102 53 / 0.224 100 / 0.218

Outdoor Coil

Face Area ( sq. ft) 4.05 3.94 3.94 5.51 6.67

No. Rows 2 2 2 4 3

Fins per inch 17 17 17 18 18

Circuits 4 4 4 4 6

Refrigerant Lines

Connection Type Flare

Liquid (Mix Phase) (in) OD 1/4” 1/4” 1/4” 1/4” 3/8”

Vapor Line (in) OD 3/8” 1/2” 1/2” 1/2” 5/8”

Maximum Length* ft (m) 65 (20.0) 65 (20.0) 65 (20.0) 100 (30.4) 100 (30.4)

MaxLift(FanCoilAbove)ft(m) 35 (10.7) 35 (10.7) 35 (10.7) 50 (12.2) 60 (18.3)

Max Drop (Fan Coil Below)ft (m) 35 (10.7) 35 (10.7) 35 (10.7) 50 ( 12.2) 60 (18.3)

Controls

Control Voltage 13 VDC 13 VDC 13 VDC Pulse DC Pulse D C

External Finish White White White White White

38/40MVC, MVQ

Outdoor Unit

38MVQ

System Voltage 115 V 115 V 208/230 208/230 208/230

Nominal Capacity (Btuh) 9000 12000 12000 18000 24000

Operating Weight lb(kg) 72.6 (33) 83.6 (38) 83.6 (38) 117.7 (53.5) 151.0 (68.5)

Refrigerant Type R--- 410A

Metering Device Capillary Tube at Outdoor

Charge lb (kg) 2.4 (1.1) 3.0 (1.4) 3.0 (1.4) 4.5 (2.0) 5.3 (2.4)

Compressor

Type Rotary

Model EA82X1C---1FZDU1 EA108X1C---1FZDU1 PA108X1C --- 3FZDU PA150X2CS --- 3KUU PA200X2CS--- 3MUU

O il C h a r g e ( POE --- o z ) 11.8 11.8 11.8 25.4 25.4

Outdoor Fan

Rpm 900 900 900 840 740

Diameter (in) .. No. of Blades 15.8 … 3 15.8 … 3 15.8 … 3 18.1 … 3 18.1 … 3

Motor (watts / hp) 23 / 0.102 23 / 0.102 23 / 0.102 53 / 0.224 100 / 0.218

Outdoor Coil

Face Area ( sq. ft) 4.05 3.94 3.94 5.51 6.67

No. Rows 2 2 2 2 3

Fins per inch 17 18 18 18 18

Circuits 4 4 4 4 6

Refrigerant Lines

Connection Type Flare

Liquid Line (in) OD 1/4” 1/4” 1/4” 1/4” 3/8”

Vapor Line (in) OD 3/8” 1/2” 1/2” 1/2” 5/8”

Maximum Length* ft (m) 65 (20.0) 65 (20.0) 65 (20.0) 100 (30.4) 100 (30.4)

MaxLift(FanCoilAbove)ft(m) 35 (10.7) 35 (10.7) 35 (10.7) 50 (12.2) 60 ( 18.3)

Max Drop (Fan Coil Below)ft (m) 35 (10.7) 35 (10.7) 35 (10.7) 50 (12.2) 60 (18.3)

Controls

Control Voltage 13 VDC 13 VDC 13 VDC Pulse D C Pulse DC

Finish White White White White White

* Refer to Long Line Application section on page 21

009 012 012 018 024

7

PHYSICAL DATA (CONT.)

Indoor Unit 40MVC 009 012 018 024

System Voltage 115 115 or 208/230 208/230 208/230

Nominal Capacity (Btuh) 9000 12000 18000 24,000

Operating Weight lb(kg) 17.6(8) 25.3(11.5) 39.6(18) 39.6(18)

Refrigerant Type R--- 410A

Metering Device Capillary Tube at Outdoor

Charge (lb) 2.3(1.0) 2.9(1.3) 4.4(2.0) 5.3(2.4)

Indoor Fan

Rpm/Cfm (High) 1250/325 1270/425 1070/630 1070/750

Rpm/Cfm (Medium) 1000/260 1100/365 1000/570 1000/660

Rpm/Cfm (Low) 800/190 1000/340 960/500 960/ 585

Motor (Watts / hp) 20 / .034 25 / .044 31 / .075 50 / .112

Blower Diameter … Length (in) 3.84 … 25.87 4.17 … 25.2 4.21 … 37.6 4.21 … 37.6

Indoor Coil

Face Area ( sq. ft) 2.15 2.54 4.36 4.36

No. Rows 2 2 2 2

Fins per inch 19.5 19.5 19.5 19.5

Circuits 2 3 6 6

Controls Integrated Microprocessor

Remote Controller Wireless

Fan Mode High/Medium/Low/Auto

Turb o M o de Ye s Yes No No

Dehumidification Mode Ye s

Sleep Mode Ye s

Diagnostics Ye s

38/40MVC, MVQ

Timer Mode Ye s

Freeze Protection Ye s

Tes t Mo de Ye s

Auto Restart Yes

Auto Sweep Ye s

Control Voltage 13 VDC 13 VDC Pulse DC Pulse D C

Refrigerant Lines

Connection Type Flare

Liquid Line (in) OD 1/4” 1/4” 1/4” 3/8”

Vapor Line (in) OD 3/8” 1/2” 1/ 2” 5/8”

Maximum Length ft(m)* 65(19.8) 65(19.8) 100(30.5) 100(30.5)

Max Lift (Fan Coil Above) ft(m) 35(10.7) 35(10.7) 50(15.2) 60(18.3)

Max Drop (Fan Coil Below) ft(m) 35(10.7) 35(10.7) 50(15.2) 60(18.3)

Condensate Drain

Size (in) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 ( ID)

External Finish White White White White

* Refer to Long Line Application section on page 21

8

PHYSICAL DATA (CONT.)

Indoor Unit 40MVQ 009 012 018 024

System Voltage 115 115 or 208/230 208/230 208/230

Nominal Capacity (Btuh) 9000 12000 18000 24000

Operating Weight lb (kg) 17.6 (8) 25.3 (11.5) 39.6 (18) 39.6 (18)

Refrigerant Type R--- 410A

Metering Device Capillary Tube at Outdoor

Charge lb (kg) 2.35 (1.1) 3.0 (1.4) 4.5 (2.0) 5.3 (2.4)

Indoor Fan

Rpm/Cfm (High) 1250/325 1270/425 1070/630 1070/750

Rpm/Cfm (Medium) 1000/260 1100/365 1000/570 1000/660

Rpm/Cfm (Low) 800/190 1000/340 960/500 960/585

Motor (Watts / hp) 20 / .034 25 / .044 31 / .075 50 / .112

Blower Diameter … Length (in) 3.84 … 25.87 4.17 … 25.2 4.21 … 37.6 4.21 … 37.6

Indoor Coil

Face Area ( sq. ft) 2.15 2.54 4.36 4.36

No. Rows 2 2 2 2

Fins per inch 19.5 19.5 19.5 19.5

Circuits 2 3 6 6

Controls Integrated Microprocessor

Remote Controller Wireless

Fan M ode High/Medium/Low/Auto

Auto Changeover Ye s

Dehumidification Mode Ye s

Demand Defrost Ye s

Sleep Mode Ye s

Diagnostics Yes

Timer Mode Ye s

Freeze Protection Yes

Tes t Mo de Ye s

Auto Restart Yes

Auto Sweep Ye s

Control Voltage 13 VDC 13 VDC Pulse DC Pulse DC

Refrigerant Lines

Connection Type Flare

Liquid Line (in) OD 1/4” 1/4” 1/4” 3/8”

Vapor Line (in) OD 3/8” 1/2” 1/2” 5/8”

Maximum Length* ft (m) 65 (19.8) 65 (19.8) 100 ( 30.5) 100 (30.5)

MaxLift(FanCoilAbove)ft(m) 35 (10.7) 35 (10.7) 50 (15.2) 60 (18.3)

Max Drop (Fan Coil Below) ft (m) 35 (10.7) 35 (10.7) 50 (15.2) 60 (18.3)

Condensate Drain

Size (in) .65 (OD) .53 (ID) .65 (OD) .53 ( ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID)

External Finish White White White White

* Refer to Long Line Application section on page 21

38/40MVC, MVQ

9

PERFORMANCE DATA

Te m p _F(_C)

Air Entering

38/40MVC, MVQ

Condenser

55

(12.78)

65

(18.33)

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

125

(51.67)

(Edb)

TCG 7.70 8.60 9.37 10.14 9.08 9.34 10.07 10.66 9.75 9.74 10.44 10.93

SHG 7.44 6.61 5.80 4.95 9.08 7.59 6.45 5.29 9.75 8.30 6.95 5.50

TC 7.69 8.58 9.36 10.12 9.07 9.32 10.06 10.65 9.74 9.72 10.42 10.92

kW 0.48 0.48 0.48 0.47 0.48 0.48 0.47 0.47 0.48 0.48 0.47 0.47

CMP 0.39 0.39 0.39 0.38 0.39 0.39 0.38 0.38 0.39 0.39 0.38 0.38

LDB 45.0 48.9 52.8 56.9 48.4 53.5 57.6 61.7 52.9 56.9 60.7 64.8

LWB 40.9 45.6 50.8 56.2 43.3 49.2 54.5 60.2 45.4 51.6 56.9 62.6

TCG 7.40 8.31 9.14 9.95 8.88 9.08 9.87 10.51 9.53 9.50 10.27 10.81

SHG 7.40 6.57 5.71 4.88 8.88 7.55 6.41 5.25 9.53 8.34 6.98 5.51

TC 7.38 8.29 9.13 9.93 8.86 9.07 9.85 10.50 9.52 9.48 10.26 10.80

kW 0.54 0.55 0.55 0.54 0.55 0.55 0.54 0.54 0.55 0.55 0.54 0.54

CMP 0.45 0.45 0.46 0.45 0.46 0.46 0.45 0.45 0.45 0.45 0.45 0.45

LDB 45.1 49.1 53.2 57.2 49.1 53.6 57.7 61.9 53.5 56.7 60.6 64.8

LWB 41.6 46.2 51.2 56.5 43.6 49.6 54.8 60.3 45.7 51.9 57.1 62.7

TCG 7.50 7.94 8.88 9.73 8.56 8.72 9.57 10.33 9.28 9.12 10.00 10.61

SHG 7.50 6.52 5.62 4.80 8.56 7.49 6.33 5.21 9.28 8.24 6.93 5.50

TC 7.49 7.93 8.87 9.71 8.54 8.70 9.55 10.31 9.26 9.10 9.98 10.60

kW 0.61 0.61 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62

CMP 0.52 0.52 0.53 0.52 0.52 0.53 0.53 0.52 0.53 0.53 0.52 0.52

LDB 44.7 49.2 53.6 57.6 50.1 53.8 57.9 62.0 54.2 57.0 60.7 64.8

LWB 41.4 47.0 51.7 56.9 44.1 50.1 55.2 60.6 46.0 52.3 57.4 62.8

TCG 7.20 7.55 8.50 9.42 8.20 8.09 9.25 10.04 8.99 8.72 9.62 10.34

SHG 7.20 6.49 5.52 4.67 8.20 7.34 6.28 5.12 8.99 8.23 6.86 5.44

TC 7.18 7.53 8.48 9.41 8.19 8.07 9.23 10.03 8.97 8.71 9.61 10.33

kW 0.68 0.69 0.69 0.70 0.69 0.69 0.70 0.70 0.70 0.70 0.70 0.70

CMP 0.59 0.59 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60

LDB 46.0 49.3 54.0 58.2 51.3 54.3 58.1 62.3 54.9 57.0 60.9 65.0

LWB 42.1 47.8 52.5 57.5 44.7 51.1 55.6 60.9 46.4 52.7 57.8 63.1

TCG 6.86 7.02 8.06 9.06 7.82 7.63 8.86 9.66 8.57 8.22 9.22 9.98

SHG 6.86 6.37 5.42 4.53 7.82 7.28 6.20 5.00 8.57 8.22 6.83 5.35

TC 6.85 7.00 8.05 9.05 7.80 7.61 8.85 9.64 8.55 8.20 9.21 9.97

kW 0.76 0.76 0.77 0.78 0.77 0.77 0.78 0.78 0.78 0.78 0.78 0.78

CMP 0.66 0.67 0.68 0.69 0.67 0.67 0.68 0.69 0.68 0.68 0.69 0.69

LDB 47.5 49.8 54.4 58.8 52.6 54.4 58.3 62.7 56.0 57.0 60.9 65.2

LWB 42.8 48.9 53.3 58.1 45.3 51.7 56.2 61.4 46.9 53.3 58.2 63.4

TCG 6.40 6.54 7.59 8.70 7.39 7.09 8.26 9.20 8.10 8.10 8.73 9.56

SHG 6.40 6.19 5.28 4.40 7.39 7.09 6.11 4.86 8.10 8.10 6.74 5.26

TC 6.39 6.53 7.58 8.69 7.38 7.07 8.25 9.19 8.08 8.09 8.72 9.54

kW 0.84 0.85 0.86 0.87 0.86 0.85 0.87 0.87 0.86 0.86 0.87 0.87

CMP 0.75 0.75 0.76 0.77 0.76 0.76 0.77 0.77 0.77 0.77 0.77 0.78

LDB 49.6 50.6 55.0 59.4 54.0 55.0 58.6 63.1 57.3 57.3 61.2 65.4

LWB 43.9 49.9 54.2 58.7 46.0 52.5 57.0 61.9 47.5 53.4 58.7 63.8

TCG 5.87 5.81 7.03 8.09 6.91 6.91 7.64 8.67 7.59 7.59 8.01 8.99

SHG 5.87 5.79 5.08 4.18 6.91 6.91 5.97 4.70 7.59 7.59 6.61 5.10

TC 5.85 5.80 7.01 8.08 6.89 6.90 7.63 8.65 7.57 7.57 7.99 8.97

kW 0.93 0.93 0.95 0.96 0.95 0.95 0.96 0.97 0.96 0.96 0.96 0.97

CMP 0.83 0.83 0.85 0.86 0.85 0.85 0.86 0.87 0.86 0.86 0.86 0.87

LDB 52.0 52.4 55.9 60.3 55.6 55.6 59.0 63.6 58.7 58.7 61.5 65.8

LWB 45.0 51.3 55.2 59.7 46.7 52.8 57.8 62.5 48.1 54.0 59.4 64.3

TCG 5.33 5.33 6.22 7.44 6.37 6.37 6.80 8.09 7.03 7.03 7.00 8.35

SHG 5.33 5.33 4.75 3.96 6.37 6.37 5.71 4.54 7.03 7.03 6.31 4.96

TC 5.31 5.31 6.21 7.42 6.35 6.35 6.78 8.07 7.02 7.02 6.99 8.33

kW 1.03 1.03 1.04 1.06 1.04 1.04 1.05 1.07 1.05 1.05 1.05 1.07

CMP 0.93 0.93 0.94 0.96 0.94 0.94 0.95 0.97 0.95 0.95 0.95 0.97

LDB 54.4 54.5 57.3 61.3 57.5 57.5 59.8 64.1 60.2 60.2 62.2 66.2

LWB 46.2 52.3 56.7 60.8 47.6 53.5 58.8 63.2 48.8 54.6 60.4 64.9

57

(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)

COOLING CAPACITIES

38MVC(Q)009--1 / 40MVC(Q)009--1

A i r E n t e r i n g E v a p o r a t o r --- C f m / B F

190/0.04 259/0.04 327/0.05

Air Entering Evaporator --- Ewb _F(_C)

LEGEND

BF --- Bypass Factor

CMP --- Compressor

Edb --- Entering Dry Bulb

Ewb --- Entering Wet Bulb

k W --- Tota l Po w e r

LDB --- Leaving Dry Bulb

L WB --- L e a v i n g Wet Bu l b

SHG --- Gross Sensible Capacity (1000 Btu/hour)

TC --- Total Net Cooling Capacity (1000 Btu/hour)

---

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The SHG is based on 80_F (26.67_C) edb temperature of air

entering indoor coil.

Below 80_F (26.67_C) edb, subtract (corr factor x cfm) from

SHG.

Above 80_F (26.67_C) edb, add (corr factor x cfm) to SHG.

Correction Factor = 1.10 x (1 --- BF) x (edb --- 80).

10

PERFORMANCE DATA (CONT.)

38MVC(Q)012--1 / 40MVC(Q)012--1

Te m p _F(_C)

Air Entering

Condenser

(Edb)

55

(12.78)

65

(18.33)

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

125

(51.67)

57 (13.89)

TCG 11.97 12.10 12.93 13.50 12.26 12.28 13.10 13.60 12.71 12.61 13.33 13.76

SHG 11.97 9.93 8.34 6.68 12.26 10.27 8.58 6.77 12.71 10.96 8.95 6.97

TC 11.94 12.07 12.90 13.47 12.23 12.25 13.07 13.57 12.68 12.58 13.30 13.74

kW 0.63 0.63 0.62 0.62 0.63 0.63 0.62 0.62 0.62 0.62 0.62 0.62

CMP 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53

LDB 48.2 53.5 57.8 62.4 49.8 54.6 58.9 63.5 53.0 56.6 61.0 65.3

LWB 43.2 49.4 54.8 60.6 44.0 50.2 55.7 61.4 45.5 51.7 57.2 62.9

TCG 11.64 11.71 12.64 13.30 11.94 11.91 12.79 13.37 12.44 12.25 13.07 13.52

SHG 11.64 9.78 8.27 6.66 11.94 10.15 8.49 6.73 12.44 10.95 9.02 6.90

TC 11.61 11.68 12.61 13.27 11.91 11.88 12.76 13.34 12.41 12.22 13.04 13.49

kW 0.72 0.72 0.72 0.72 0.72 0.72 0.72 0.72 0.72 0.72 0.72 0.72

CMP 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62 0.62

LDB 49.0 53.9 58.0 62.4 50.6 54.9 59.1 63.5 53.5 56.6 60.8 65.4

LWB 43.6 49.8 55.1 60.8 44.3 50.6 55.9 61.6 45.7 52.1 57.4 63.1

TCG 11.28 11.27 12.27 13.00 11.56 11.45 12.43 13.12 12.07 11.48 12.70 13.25

SHG 11.28 9.63 8.15 6.61 11.56 9.92 8.47 6.75 12.07 10.16 8.94 6.89

TC 11.25 11.24 12.24 12.97 11.53 11.43 12.40 13.09 12.04 11.46 12.67 13.23

kW 0.81 0.81 0.82 0.82 0.81 0.81 0.82 0.82 0.82 0.82 0.82 0.82

CMP 0.71 0.71 0.71 0.72 0.71 0.71 0.71 0.72 0.71 0.71 0.71 0.72

LDB 49.9 54.3 58.3 62.5 51.5 55.5 59.1 63.5 54.3 58.3 60.9 65.4

LWB 44.0 50.3 55.5 61.1 44.8 51.2 56.3 61.9 46.1 52.7 57.7 63.3

TCG 10.79 10.76 11.78 12.63 11.12 10.68 11.96 12.76 11.63 11.29 12.24 12.93

SHG 10.79 9.24 7.98 6.49 11.12 9.50 8.25 6.64 11.63 10.62 8.81 6.89

TC 10.76 10.73 11.76 12.60 11.09 10.65 11.93 12.73 11.60 11.27 12.21 12.91

kW 0.91 0.91 0.92 0.92 0.92 0.91 0.92 0.93 0.92 0.92 0.92 0.93

CMP 0.81 0.81 0.82 0.82 0.81 0.81 0.82 0.82 0.82 0.82 0.82 0.82

LDB 51.2 55.3 58.7 62.8 52.5 56.4 59.6 63.7 55.2 57.3 61.2 65.4

LWB 44.6 51.5 56.0 61.4 45.3 52.0 56.7 62.2 46.5 52.8 58.0 63.5

TCG 10.17 9.76 11.21 12.15 10.55 10.05 11.37 12.27 11.12 11.12 11.66 12.49

SHG 10.17 9.14 7.81 6.32 10.55 9.50 8.08 6.47 11.12 11.12 8.64 6.79

TC 10.14 9.73 11.18 12.12 10.53 10.02 11.34 12.24 11.09 11.09 11.63 12.46

kW 1.02 1.01 1.03 1.04 1.02 1.02 1.03 1.04 1.03 1.03 1.03 1.04

CMP 0.91 0.91 0.92 0.93 0.92 0.91 0.92 0.93 0.92 0.92 0.93 0.93

LDB 52.7 55.4 59.1 63.2 53.8 56.4 60.0 64.1 56.2 56.2 61.5 65.6

LWB 45.4 52.0 56.6 61.8 45.9 52.5 57.3 62.6 47.0 53.0 58.5 63.8

TCG 9.51 8.95 10.54 11.55 9.87 9.86 10.70 11.68 10.54 10.55 10.96 11.88

SHG 9.51 8.73 7.59 6.12 9.87 9.86 7.88 6.28 10.54 10.55 8.44 6.60

TC 9.48 8.92 10.51 11.52 9.84 9.84 10.68 11.65 10.52 10.52 10.93 11.85

kW 1.13 1.12 1.14 1.15 1.13 1.13 1.14 1.15 1.14 1.14 1.15 1.16

CMP 1.02 1.01 1.04 1.05 1.03 1.03 1.04 1.05 1.04 1.04 1.04 1.05

LDB 54.4 56.5 59.7 63.7 55.5 55.5 60.4 64.6 57.4 57.4 61.9 66.0

LWB 46.2 52.9 57.2 62.4 46.7 52.7 57.9 63.1 47.5 53.5 59.0 64.2

TCG 8.82 8.82 9.56 10.82 9.16 9.16 9.82 10.96 9.81 9.81 10.17 11.16

SHG 8.82 8.82 7.29 5.87 9.16 9.16 7.61 6.04 9.81 9.81 8.21 6.37

TC 8.79 8.79 9.53 10.79 9.13 9.13 9.80 10.93 9.78 9.78 10.14 11.13

kW 1.25 1.25 1.26 1.28 1.25 1.25 1.26 1.28 1.26 1.26 1.27 1.28

CMP 1.14 1.14 1.15 1.17 1.14 1.14 1.15 1.17 1.15 1.15 1.16 1.17

LDB 56.2 56.2 60.4 64.4 57.2 57.1 61.0 65.1 58.9 58.9 62.4 66.4

LWB 47.0 53.0 58.2 63.0 47.4 53.4 58.7 63.6 48.2 54.1 59.6 64.7

TCG 8.11 8.14 8.49 9.97 8.42 8.41 8.65 10.10 9.01 9.01 8.81 10.30

SHG 8.11 8.14 6.97 5.59 8.42 8.41 7.18 5.77 9.01 9.01 7.63 6.11

TC 8.08 8.11 8.46 9.94 8.39 8.38 8.63 10.07 8.99 8.98 8.78 10.27

kW 1.37 1.37 1.37 1.40 1.37 1.37 1.38 1.40 1.39 1.39 1.38 1.41

CMP 1.26 1.26 1.26 1.29 1.26 1.26 1.27 1.29 1.27 1.27 1.27 1.29

LDB 58.1 58.0 61.2 65.1 58.9 58.9 62.1 65.7 60.5 60.6 63.5 66.9

LWB 47.9 53.7 59.2 63.8 48.2 54.1 59.7 64.3 49.0 54.8 60.7 65.3

339/0.04 367/0.04 427/0.05

62

(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)

COOLING CAPACITIES

A i r E n t e r i n g E v a p o r a t o r --- C f m / B F

Air Entering Evaporator --- Ewb _F(_C)

38/40MVC, MVQ

LEGEND

BF --- Bypass Factor

CMP --- Compressor

Edb --- Entering Dry Bulb

Ewb --- Entering Wet Bulb

k W --- Tota l Po w e r

LDB --- Leaving Dry Bulb

L WB --- L e a v i n g Wet Bu l b

SHG --- Gross Sensible Capacity (1000 Btu/hour)

TC --- Total Net Cooling Capacity (1000 Btu/hour)

---

11

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The SHG is based on 80_F (26.67_C) edb temperature of air

entering indoor coil.

Below 80_F (26.67_C) edb, subtract (corr factor x cfm) from

SHG.

Above 80_F (26.67_C) edb, add (corr factor x cfm) to SHG.

Correction Factor = 1.10 x (1 --- BF) x (edb --- 80).

PERFORMANCE DATA (CONT.)

38/40MVC, MVQ

Te m p _F(_C)

Air Entering

Condenser

(Edb)

55

(12.78)

65

(18.33)

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

125

(51.67)

57

TCG 12.38 12.72 13.71 14.48 12.91 13.08 13.98 14.63 13.63 13.56 14.38 14.83

SHG 12.38 10.09 8.66 7.11 12.91 10.63 8.99 7.21 13.63 11.61 9.59 7.45

TC 12.35 12.69 13.69 14.45 12.88 13.05 13.95 14.61 13.60 13.53 14.35 14.81

kW 0.64 0.63 0.63 0.63 0.63 0.63 0.63 0.63 0.63 0.63 0.63 0.63

CMP 0.52 0.52 0.52 0.52 0.52 0.52 0.52 0.51 0.52 0.52 0.51 0.51

LDB 45.1 51.4 55.6 60.1 47.6 53.2 57.4 62.0 51.6 55.7 60.0 64.6

LWB 41.7 47.7 53.0 58.8 42.9 49.1 54.5 60.3 44.8 51.1 56.6 62.4

TCG 12.04 12.30 13.35 14.17 12.55 12.65 13.68 14.38 13.30 13.15 14.06 14.58

SHG 12.04 9.95 8.50 7.00 12.55 10.46 8.90 7.17 13.30 11.48 9.55 7.38

TC 12.01 12.28 13.33 14.14 12.52 12.62 13.65 14.36 13.27 13.12 14.03 14.56

kW 0.73 0.73 0.72 0.72 0.73 0.73 0.72 0.72 0.72 0.72 0.72 0.72

CMP 0.61 0.61 0.61 0.61 0.61 0.61 0.61 0.61 0.61 0.61 0.61 0.61

LDB 46.0 51.8 56.0 60.3 48.5 53.6 57.6 62.1 52.2 55.9 60.0 64.7

LWB 42.1 48.2 53.5 59.1 43.3 49.5 54.8 60.5 45.1 51.4 56.8 62.5

TCG 11.48 11.75 12.93 13.85 12.15 12.16 13.25 14.05 12.89 12.57 13.64 14.30

SHG 11.48 9.73 8.43 6.93 12.15 10.29 8.78 7.09 12.89 11.07 9.44 7.34

TC 11.46 11.72 12.90 13.83 12.12 12.13 13.22 14.03 12.86 12.55 13.62 14.27

kW 0.82 0.82 0.82 0.83 0.82 0.82 0.82 0.83 0.82 0.82 0.82 0.83

CMP 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70

LDB 47.5 52.4 56.1 60.5 49.4 54.0 57.9 62.3 53.0 56.5 60.3 64.8

LWB 42.8 48.9 53.9 59.4 43.8 50.1 55.2 60.8 45.5 51.9 57.1 62.7

TCG 10.89 10.97 12.39 13.42 11.57 11.40 12.74 13.65 12.42 12.09 13.14 13.94

SHG 10.89 9.44 8.16 6.75 11.57 9.92 8.61 6.98 12.42 11.19 9.29 7.33

TC 10.86 10.94 12.36 13.39 11.54 11.36 12.71 13.62 12.39 12.06 13.12 13.91

kW 0.92 0.92 0.93 0.93 0.93 0.92 0.93 0.93 0.93 0.93 0.93 0.94

CMP 0.79 0.79 0.80 0.81 0.80 0.80 0.80 0.81 0.80 0.80 0.80 0.81

LDB 49.1 53.1 56.9 61.0 50.8 54.6 58.3 62.5 54.0 56.5 60.5 64.8

LWB 43.6 49.8 54.5 59.8 44.5 50.9 55.7 61.2 46.0 52.3 57.5 63.0

TCG 10.25 9.77 11.79 12.87 10.89 10.51 12.08 13.12 11.87 11.26 12.51 13.44

SHG 10.25 8.87 7.95 6.55 10.89 9.81 8.37 6.79 11.87 10.76 9.11 7.21

TC 10.22 9.74 11.76 12.84 10.86 10.48 12.05 13.09 11.84 11.23 12.48 13.41

kW 1.02 1.02 1.04 1.05 1.03 1.03 1.04 1.05 1.04 1.04 1.04 1.05

CMP 0.89 0.89 0.91 0.91 0.90 0.90 0.91 0.92 0.91 0.90 0.91 0.92

LDB 50.8 54.6 57.4 61.5 52.4 55.1 58.8 63.0 55.1 57.3 60.9 65.0

LWB 44.5 51.3 55.2 60.4 45.2 51.8 56.4 61.6 46.5 53.0 58.0 63.3

TCG 9.62 9.12 10.90 12.18 10.20 9.65 11.40 12.46 11.19 11.20 11.77 12.78

SHG 9.62 8.71 7.64 6.30 10.20 9.37 8.15 6.56 11.19 11.20 8.91 6.99

TC 9.59 9.09 10.87 12.15 10.17 9.62 11.37 12.43 11.16 11.17 11.75 12.76

kW 1.14 1.13 1.15 1.16 1.15 1.14 1.16 1.17 1.16 1.16 1.16 1.17

CMP 1.00 0.99 1.02 1.03 1.01 1.00 1.02 1.03 1.02 1.02 1.02 1.03

LDB 52.5 55.0 58.2 62.2 54.1 56.1 59.3 63.5 56.4 56.4 61.3 65.4

LWB 45.3 52.0 56.2 61.1 46.0 52.7 57.0 62.2 47.1 53.1 58.6 63.8

TCG 8.94 8.92 9.89 11.41 9.47 9.47 10.34 11.67 10.38 10.39 10.93 11.98

SHG 8.94 8.92 7.31 6.02 9.47 9.47 7.81 6.29 10.38 10.39 8.66 6.73

TC 8.91 8.90 9.86 11.38 9.44 9.44 10.31 11.65 10.35 10.37 10.90 11.95

kW 1.26 1.26 1.27 1.29 1.27 1.27 1.28 1.29 1.28 1.28 1.28 1.29

CMP 1.11 1.11 1.13 1.14 1.12 1.12 1.13 1.15 1.13 1.13 1.14 1.15

LDB 54.4 54.4 59.1 62.9 55.9 55.9 60.1 64.1 58.1 58.0 61.7 65.9

LWB 46.2 52.3 57.2 61.8 46.9 52.9 58.0 62.8 47.9 53.8 59.2 64.3

TCG 8.21 8.21 8.79 10.52 8.70 8.71 9.17 10.76 9.54 9.54 9.49 11.07

SHG 8.21 8.21 6.99 5.72 8.70 8.71 7.47 5.99 9.54 9.54 8.05 6.45

TC 8.18 8.18 8.76 10.50 8.68 8.68 9.15 10.73 9.51 9.51 9.46 11.04

kW 1.38 1.38 1.39 1.41 1.39 1.39 1.40 1.42 1.40 1.40 1.40 1.42

CMP 1.23 1.23 1.24 1.26 1.24 1.24 1.25 1.27 1.25 1.25 1.25 1.27

LDB 56.3 56.4 59.9 63.7 57.7 57.7 60.9 64.9 59.8 59.8 62.9 66.5

LWB 47.1 53.1 58.4 62.7 47.7 53.7 59.1 63.6 48.6 54.5 60.3 64.9

(13.89)

339/0.04 367/0.04 427/0.05

62

(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)

COOLING CAPACITIES

38MVC(Q)012--3 / 40MVC(Q)012--3

A i r E n t e r i n g E v a p o r a t o r --- C f m / B F

A i r E n t e r i n g E v a p o r a t o r --- E w b _F(_C)

LEGEND

BF --- Bypass Factor

CMP --- Compressor

Edb --- Entering Dry Bulb

Ewb --- Entering Wet Bulb

k W --- Tota l Po w e r

LDB --- Leaving Dry Bulb

L WB --- L e a v i n g Wet Bu l b

SHG --- Gross Sensible Capacity (1000 Btu/hour)

TC --- Total Net Cooling Capacity (1000 Btu/hour)

---

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The SHG is based on 80_F (26.67_C) edb temperature of air

entering indoor coil.

Below 80_F (26.67_C) edb, subtract (corr factor x cfm) from

SHG.

Above 80_F (26.67_C) edb, add (corr factor x cfm) to SHG.

Correction Factor = 1.10 x (1 --- BF) x (edb --- 80).

12

PERFORMANCE DATA (CONT.)

38MVC(Q)018--3 / 40MVC(Q)018--3

Te m p _F(_C)

Air Entering

Condenser

(Edb)

55

(12.78)

65

(18.33)

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

125

(51.67)

57

TCG 17.50 18.57 19.75 20.70 18.16 19.02 20.07 21.03 18.68 19.33 20.33 21.34

SHG 17.50 15.22 12.67 10.45 18.16 16.04 13.10 10.71 18.68 16.68 13.46 10.89

TC 17.33 18.40 19.58 20.53 17.98 18.85 19.90 20.85 18.50 19.15 20.15 21.17

kW 0.90 0.90 0.89 0.89 0.90 0.89 0.89 0.89 0.90 0.89 0.89 0.89

CMP 0.75 0.75 0.74 0.74 0.75 0.75 0.74 0.74 0.75 0.74 0.74 0.74

LDB 48.6 52.6 57.2 61.3 51.0 54.4 59.1 63.0 53.1 55.9 60.6 64.4

LWB 43.5 49.0 54.5 60.2 44.7 50.3 55.9 61.5 45.6 51.4 56.9 62.5

TCG 17.18 18.13 19.38 20.38 17.81 18.54 19.70 20.67 18.33 18.84 19.99 20.93

SHG 17.18 15.30 12.64 10.32 17.81 16.19 13.11 10.59 18.33 16.99 13.78 10.80

TC 17.01 17.95 19.21 20.21 17.63 18.37 19.53 20.50 18.16 18.66 19.82 20.75

kW 1.03 1.03 1.02 1.02 1.03 1.03 1.02 1.02 1.03 1.02 1.02 1.02

CMP 0.88 0.88 0.87 0.87 0.88 0.88 0.87 0.87 0.88 0.87 0.87 0.87

LDB 49.1 52.5 57.3 61.6 51.6 54.1 59.1 63.2 53.5 55.5 60.1 64.5

LWB 43.8 49.3 54.7 60.4 44.9 50.6 56.1 61.7 45.9 51.7 57.1 62.7

TCG 16.66 17.56 18.85 19.97 17.39 17.91 19.22 20.23 17.89 18.25 19.48 20.46

SHG 16.66 15.36 12.54 10.15 17.39 16.30 13.20 10.45 17.89 17.20 13.59 10.68

TC 16.48 17.39 18.68 19.79 17.21 17.74 19.04 20.06 17.71 18.08 19.31 20.28

kW 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16

CMP 1.01 1.01 1.01 1.01 1.02 1.01 1.01 1.01 1.01 1.01 1.01 1.01

LDB 50.0 52.3 57.4 61.9 52.2 53.9 58.9 63.4 54.1 55.1 60.4 64.7

LWB 44.2 49.8 55.1 60.7 45.2 51.1 56.4 62.0 46.1 52.0 57.4 62.9

TCG 16.06 16.69 18.22 19.41 16.78 17.24 18.54 19.69 17.37 17.56 18.82 19.90

SHG 16.06 15.39 12.45 10.01 16.78 16.41 13.04 10.34 17.37 16.93 13.61 10.59

TC 15.89 16.52 18.05 19.24 16.60 17.06 18.37 19.51 17.19 17.39 18.64 19.72

kW 1.30 1.30 1.31 1.31 1.30 1.31 1.31 1.31 1.31 1.31 1.31 1.32

CMP 1.15 1.15 1.16 1.16 1.16 1.16 1.16 1.17 1.16 1.16 1.16 1.17

LDB 51.0 52.2 57.6 62.1 53.1 53.7 59.1 63.6 54.9 55.5 60.3 64.8

LWB 44.7 50.4 55.6 61.0 45.7 51.5 56.8 62.3 46.5 52.4 57.7 63.2

TCG 15.33 15.64 17.37 18.64 15.99 16.15 17.74 18.97 16.60 16.51 18.00 19.18

SHG 15.33 15.05 12.28 9.75 15.99 15.76 12.96 10.13 16.60 16.51 13.54 10.43

TC 15.16 15.47 17.20 18.46 15.81 15.98 17.57 18.80 16.43 16.34 17.83 19.00

kW 1.45 1.45 1.47 1.47 1.45 1.46 1.47 1.47 1.46 1.46 1.47 1.47

CMP 1.30 1.30 1.32 1.32 1.31 1.31 1.32 1.32 1.31 1.31 1.32 1.33

LDB 52.2 52.8 57.8 62.5 54.3 54.7 59.2 63.9 55.9 56.1 60.4 65.0

LWB 45.3 51.2 56.1 61.5 46.2 52.2 57.3 62.7 47.0 53.0 58.2 63.5

TCG 14.49 14.46 16.37 17.74 15.13 15.14 16.71 18.04 15.67 15.69 16.97 18.28

SHG 14.49 14.46 12.11 9.47 15.13 15.14 12.81 9.86 15.67 15.69 13.44 10.21

TC 14.32 14.29 16.19 17.57 14.96 14.96 16.54 17.87 15.49 15.52 16.80 18.10

kW 1.61 1.61 1.63 1.64 1.61 1.61 1.63 1.64 1.62 1.62 1.63 1.64

CMP 1.46 1.46 1.48 1.49 1.46 1.46 1.48 1.49 1.47 1.47 1.48 1.49

LDB 53.7 53.8 58.1 63.0 55.6 55.6 59.4 64.3 57.2 57.2 60.5 65.3

LWB 46.0 52.1 56.8 62.1 46.9 52.9 57.9 63.1 47.6 53.5 58.7 64.0

TCG 13.45 13.45 14.96 16.66 14.13 14.13 15.41 16.94 14.65 14.66 15.73 17.15

SHG 13.45 13.45 11.82 9.20 14.13 14.13 12.59 9.61 14.65 14.66 13.25 9.98

TC 13.27 13.27 14.79 16.48 13.95 13.96 15.24 16.77 14.48 14.48 15.56 16.97

kW 1.77 1.77 1.79 1.81 1.78 1.78 1.80 1.81 1.79 1.79 1.80 1.82

CMP 1.62 1.62 1.64 1.66 1.63 1.63 1.65 1.67 1.64 1.64 1.65 1.67

LDB 55.5 55.5 58.5 63.4 57.2 57.2 59.7 64.6 58.6 58.6 60.7 65.6

LWB 46.8 52.8 57.8 62.7 47.6 53.5 58.6 63.7 48.2 54.1 59.3 64.5

TCG 12.22 12.22 13.26 15.35 12.92 12.93 13.66 15.60 13.46 13.48 14.02 15.79

SHG 12.22 12.22 11.26 8.82 12.92 12.93 12.20 9.26 13.46 13.48 12.95 9.66

TC 12.05 12.05 13.09 15.17 12.74 12.76 13.48 15.43 13.29 13.30 13.84 15.62

kW 1.95 1.95 1.96 1.99 1.96 1.96 1.97 1.99 1.97 1.96 1.97 1.99

CMP 1.80 1.80 1.81 1.84 1.81 1.81 1.82 1.84 1.82 1.82 1.82 1.85

LDB 57.6 57.7 59.5 64.1 59.1 59.0 60.3 65.1 60.3 60.3 61.1 66.0

LWB 47.8 53.7 58.9 63.5 48.4 54.3 59.6 64.4 49.0 54.8 60.2 65.1

(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)57(13.89)62(16.67)67(19.44)72(22.22)

502/0.04 568/0.04 631/0.05

COOLING CAPACITIES

Air Entering Evaporator --- Cfm/BF

Air Entering Evaporator --- Ewb (_F)

38/40MVC, MVQ

LEGEND

BF --- Bypass Factor

CMP --- Compressor

Edb --- Entering Dry Bulb

Ewb --- Entering Wet Bulb

k W --- Tota l Po w e r

LDB --- Leaving Dry Bulb

L WB --- L e a v i n g Wet Bu l b

SHG --- Gross Sensible Capacity (1000 Btu/hour)

TC --- Total Net Cooling Capacity (1000 Btu/hour)

---

13

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The SHG is based on 80_F (26.67_C) edb temperature of air

entering indoor coil.

Below 80_F (26.67_C) edb, subtract (corr factor x cfm) from

SHG.

Above 80_F (26.67_C) edb, add (corr factor x cfm) to SHG.

Correction Factor = 1.10 x (1 --- BF) x (edb --- 80).

PERFORMANCE DATA (CONT.)

38/40MVC, MVQ

Te m p _F(_C)

Air Entering

Condenser

(Edb)

55

(12.78)

65

(18.33)

75

(23.89)

85

(29.44)

95

(35)

105

(40.56)

115

(46.11)

125

(51.67)

TCG 21.41 23.09 24.52 25.73 22.21 23.60 24.95 26.13 23.21 24.19 25.43 26.63

57 62 67 72 57 62 67 72 57 62 67 72

SHG 21.41 18.42 15.56 12.83 22.21 19.37 16.10 13.17 23.21 20.61 16.74 13.53

TC 21.10 22.78 24.21 25.42 21.91 23.29 24.64 25.82 22.91 23.88 25.12 26.32

kW 1.23 1.23 1.22 1.22 1.23 1.23 1.22 1.22 1.23 1.22 1.22 1.22

CMP 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 1.00 1.00 0.99 0.99

LDB 46.7 51.3 55.8 60.1 49.1 53.0 57.6 61.8 51.9 55.0 59.8 63.8

LWB 42.7 48.0 53.6 59.4 43.9 49.4 55.0 60.7 45.2 50.9 56.5 62.1

TCG 20.89 22.42 23.92 25.12 21.77 22.95 24.38 25.61 22.68 23.50 24.86 26.02

SHG 20.89 18.27 15.39 12.56 21.77 19.25 15.99 12.97 22.68 20.50 16.84 13.39

TC 20.58 22.11 23.61 24.81 21.46 22.64 24.07 25.30 22.37 23.19 24.55 25.71

kW 1.38 1.39 1.39 1.39 1.39 1.39 1.39 1.39 1.39 1.39 1.39 1.39

CMP 1.15 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16

LDB 47.4 51.5 56.0 60.5 49.7 53.2 57.8 62.1 52.5 55.1 59.6 63.9

LWB 43.1 48.4 53.9 59.7 44.2 49.8 55.3 60.9 45.5 51.2 56.7 62.4

TCG 20.21 21.66 23.21 24.61 21.15 22.15 23.67 24.95 22.04 22.71 24.13 25.32

SHG 20.21 18.13 15.13 12.37 21.15 19.10 15.83 12.75 22.04 20.44 16.61 13.19

TC 19.90 21.35 22.90 24.30 20.84 21.85 23.36 24.64 21.74 22.40 23.82 25.01

kW 1.55 1.56 1.56 1.57 1.56 1.56 1.57 1.57 1.56 1.56 1.57 1.57

CMP 1.32 1.33 1.34 1.34 1.33 1.33 1.34 1.34 1.33 1.33 1.34 1.34

LDB 48.4 51.7 56.4 60.8 50.5 53.3 58.0 62.4 53.2 55.2 59.9 64.1

LWB 43.6 49.0 54.4 60.0 44.6 50.2 55.6 61.3 45.9 51.6 57.1 62.7

TCG 19.48 20.73 22.38 23.82 20.35 21.24 22.82 24.16 21.31 21.75 23.29 24.50

SHG 19.48 17.94 14.91 12.08 20.35 18.95 15.60 12.47 21.31 20.59 16.45 12.90

TC 19.17 20.42 22.07 23.51 20.04 20.94 22.51 23.85 21.00 21.44 22.98 24.20

kW 1.72 1.74 1.75 1.76 1.73 1.74 1.75 1.76 1.74 1.74 1.75 1.76

CMP 1.49 1.51 1.52 1.53 1.50 1.51 1.52 1.53 1.51 1.52 1.53 1.53

LDB 49.5 51.9 56.7 61.2 51.6 53.5 58.2 62.7 54.1 55.0 60.0 64.5

LWB 44.1 49.6 54.9 60.4 45.1 50.8 56.1 61.6 46.3 52.1 57.4 63.0

TCG 18.65 19.49 21.39 22.87 19.47 20.11 21.81 23.21 20.47 20.70 22.25 23.56

SHG 18.65 17.94 14.65 11.76 19.47 19.09 15.32 12.14 20.47 19.99 16.23 12.61

TC 18.35 19.18 21.08 22.56 19.16 19.81 21.50 22.91 20.16 20.39 21.94 23.25

kW 1.91 1.92 1.94 1.95 1.92 1.93 1.94 1.96 1.93 1.94 1.95 1.96

CMP 1.68 1.69 1.71 1.73 1.69 1.70 1.72 1.73 1.70 1.71 1.72 1.73

LDB 50.7 51.9 57.1 61.7 52.7 53.3 58.6 63.1 55.1 55.7 60.3 64.8

LWB 44.7 50.4 55.5 60.9 45.6 51.4 56.6 62.1 46.7 52.6 57.9 63.4

TCG 17.81 18.14 20.24 21.73 18.51 18.71 20.65 22.09 19.45 19.31 21.06 22.41

SHG 17.81 17.46 14.30 11.33 18.51 18.23 15.04 11.77 19.45 19.31 15.98 12.26

TC 17.50 17.83 19.94 21.42 18.20 18.40 20.34 21.78 19.14 19.01 20.76 22.10

kW 2.11 2.11 2.14 2.16 2.12 2.12 2.15 2.16 2.13 2.13 2.15 2.17

CMP 1.88 1.88 1.91 1.93 1.89 1.89 1.92 1.94 1.91 1.90 1.92 1.94

LDB 52.0 52.5 57.5 62.3 54.0 54.4 58.9 63.6 56.3 56.4 60.5 65.2

LWB 45.3 51.3 56.1 61.5 46.2 52.2 57.2 62.6 47.3 53.3 58.4 63.8

TCG 16.73 16.67 18.93 20.40 17.42 17.43 19.28 20.74 18.31 18.33 19.67 21.05

SHG 16.73 16.67 13.90 10.86 17.42 17.43 14.66 11.30 18.31 18.33 15.64 11.81

TC 16.42 16.37 18.62 20.09 17.11 17.12 18.98 20.44 18.00 18.02 19.36 20.74

kW 2.32 2.32 2.35 2.37 2.33 2.33 2.36 2.38 2.34 2.34 2.36 2.38

CMP 2.09 2.09 2.12 2.14 2.10 2.10 2.13 2.15 2.11 2.11 2.13 2.15

LDB 53.6 53.7 58.1 63.0 55.5 55.5 59.4 64.2 57.6 57.6 60.9 65.7

LWB 46.1 52.2 56.9 62.2 46.9 52.9 57.9 63.2 47.9 53.8 59.0 64.4

TCG 15.61 15.61 17.39 18.89 16.27 16.27 17.73 19.19 17.06 17.09 18.07 19.47

SHG 15.61 15.61 13.42 10.33 16.27 16.27 14.19 10.77 17.06 17.09 15.18 11.29

TC 15.30 15.30 17.08 18.58 15.96 15.96 17.43 18.88 16.75 16.78 17.77 19.16

kW 2.53 2.53 2.56 2.59 2.54 2.54 2.57 2.59 2.56 2.56 2.57 2.60

CMP 2.30 2.30 2.33 2.36 2.32 2.32 2.34 2.37 2.33 2.33 2.35 2.37

LDB 55.3 55.3 58.8 63.8 57.0 57.0 60.0 64.9 59.1 59.0 61.4 66.3

LWB 46.9 52.9 57.8 63.0 47.6 53.6 58.7 63.9 48.5 54.4 59.7 65.0

584/0.04 657/0.04 759/0.05

COOLING CAPACITIES

38MVC(Q)024--3 / 40MVC(Q)024--3

A i r E n t e r i n g E v a p o r a t o r --- C f m / B F

A i r E n t e r i n g E v a p o r a t o r --- E w b ( _F)

LEGEND

BF --- Bypass Factor

CMP --- Compressor

Edb --- Entering Dry Bulb

Ewb --- Entering Wet Bulb

k W --- Tota l Po w e r

LDB --- Leaving Dry Bulb

L WB --- L e a v i n g Wet Bu l b

SHG --- Gross Sensible Capacity (1000 Btu/hour)

TC --- Total Net Cooling Capacity (1000 Btu/hour)

TCG --- Gross Cooling Capacity (1000 Btu/h our)

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The SHG is based on 80_F (26.67_C) edb temperature of air

entering indoor coil.

Below 80_F (26.67_C) edb, subtract (corr factor x cfm) from SHG.

Above 80_F (26.67_C) edb, add (corr factor x cfm) to SHG.

Correction Factor = 1.10 x (1 --- BF) x (edb --- 80).

14

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

38/40MVC, MVQ

Air Temperature Entering Outdoor Coil --- DB/WB _F(_C)

38MVQ009--1 / 40MVQ009--1

57/53 (13.89/11.67) 47/43 (8.33/6.11) 37/33 (2.78/0.56) 27/23 ( ---2.78/---5) 17/13 ( ---8.33/--- 10.56)

Rating Rating Rating Rating Rating Rating Rating Rating Rating Rating

Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated

kW 0.83 0.77 0.71 0.66 0.61

kW 0.74 0.71 0.66 0.62 0.58

Cap 11.39 11.39 9.97 9.97 8.47 7.70 7.08 6.29 5.78 5.27

284

55 (12.78)

Cap 11.57 11.57 10.12 10.12 8.65 7.87 7.24 6.43 5.91 5.39

346

kW 0.69 0.66 0.63 0.59 0.57

Cap 10.75 10.75 9.31 9.31 7.93 7.21 6.60 5.86 5.36 4.88

Indoor

Air Temperature

Cap 10.99 10.99 9.55 9.55 8.13 7.40 6.80 6.04 5.55 5.06

Item

214

(CFM)

Airflow

L --- M --- H

Unit _F(_C)

Entering Indoor

PERFORMANCE DATA (CONT.)

kW 0.87 0.80 0.74 0.68 0.64

214

Cap 11.18 11.18 9.78 9.78 8.27 7.53 6.89 6.12 5.58 5.09

284

60 (15.56)

kW 0.78 0.74 0.69 0.64 0.61

Cap 11.36 11.36 9.93 9.93 8.46 7.70 7.05 6.26 5.71 5.21

346

kW 0.73 0.70 0.66 0.62 0.59

Cap 10.51 10.51 9.11 9.11 7.72 7.02 6.39 5.67 5.15 4.69

214

kW 0.90 0.84 0.77 0.71 0.66

Cap 10.96 10.96 9.52 9.52 8.07 7.34 6.68 5.93 5.38 4.91

284

65 (18.33)

kW 0.82 0.77 0.72 0.67 0.64

Cap 11.14 11.14 9.74 9.74 8.26 7.52 6.85 6.08 5.51 5.02

346

kW 0.77 0.73 0.69 0.65 0.62

Cap 10.28 10.28 8.88 8.88 7.50 6.83 6.18 5.48 4.93 4.50

214

15

kW 0.94 0.87 0.80 0.74 0.69

Cap 10.74 10.74 9.31 9.31 7.86 7.15 6.47 5.75 5.16 4.71

284

70 (21.11)

kW 0.86 0.81 0.75 0.70 0.66

Cap 10.93 10.93 9.56 9.56 8.06 7.33 6.63 5.89 5.30 4.83

346

kW 0.81 0.77 0.72 0.68 0.65

Cap 10.04 8.66 8.64 8.64 7.28 8.66 5.96 5.29 4.71 4.29

214

kW 0.97 0.90 0.83 0.77 0.71

Cap 10.51 8.89 9.09 9.09 7.64 8.89 6.25 5.55 4.94 4.51

284

75 (23.89)

kW 0.89 0.84 0.78 0.73 0.69

Cap 10.71 10.71 9.32 9.32 7.84 7.14 6.42 5.70 5.08 4.63

346

kW 0.84 0.80 0.75 0.71 0.67

Cap 9.80 9.80 8.40 8.40 7.06 6.42 5.74 5.09 4.47 4.08

214

kW 1.01 0.93 0.86 0.80 0.74

Cap 10.27 10.27 8.85 8.85 7.42 6.75 6.03 5.35 4.71 4.30

284

80 (26.67)

kW 0.93 0.87 0.81 0.76 0.72

Cap 10.49 10.49 9.11 9.11 7.62 6.94 6.19 5.50 4.84 0.97

346

kW 0.88 0.84 0.78 0.74 0.70

Indicates Rating Condition (* Integrated Capacity)

Indicates Integrated Rating

kW --- Total Power Input, includes compressor motor power input, outdoor fan motor power input, and indoor fan motor power input

Cap --- Heating Capacity (100 Btuh), Includes indoor fan motor heat

Note: Integrated Capacity is maximum (instantaneous ) capacity less the effect of frost on the outdoor coil and the heat to defrost it.

38/40MVC, MVQ

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

Air Temperature Entering Outdoor Coil --- DB/WB _F(_C)

38MVQ012--1 / 40MVQ012--1

57/53 (13.89/11.67) 47/43 (8.33/6.11) 37/33 (2.78/0.56) 27/23 ( ---2.78/---5) 17/13 ( ---8.33/--- 10.56)

Rating Rating Rating Rating Rating Rating Rating Rating Rating Rating

Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated

kW 1.04 0.96 0.90 0.84 0.77

kW 0.99 0.92 0.87 0.81 0.76

Cap 14.85 14.85 12.97 12.97 11.44 10.41 9.74 8.65 7.90 7.20

343

55 (12.78)

Cap 14.85 14.85 13.03 13.03 11.45 10.42 9.89 8.79 8.05 7.34

414

kW 0.92 0.86 0.82 0.78 0.73

Cap 14.63 14.63 12.81 12.81 11.21 10.20 9.32 8.28 7.60 6.93

Indoor

Air Temperature

Cap 14.78 14.78 12.92 12.92 11.39 10.36 9.62 8.55 7.80 7.11

Item

304

(CFM)

Airflow

L --- M --- H

Unit _F(_C)

Entering Indoor

PERFORMANCE DATA (CONT.)

kW 1.10 1.01 0.95 0.87 0.81

304

Cap 14.71 14.71 12.85 12.85 11.35 10.32 9.55 8.48 7.70 7.02

343

60 (15.56)

kW 1.04 0.97 0.92 0.85 0.79

Cap 14.75 14.75 12.91 12.91 11.36 10.34 9.71 8.62 7.83 7.14

414

kW 0.97 0.91 0.87 0.82 0.77

Cap 14.46 14.46 12.67 12.67 11.02 10.03 9.07 8.05 7.35 6.70

304

kW 1.15 1.07 0.99 0.91 0.84

Cap 14.56 14.56 12.73 12.73 11.17 10.16 9.22 8.18 7.47 6.81

343

65 (18.33)

kW 1.10 1.02 0.96 0.89 0.83

Cap 14.63 14.63 12.78 12.78 11.26 10.24 9.45 8.39 7.63 6.95

414

kW 1.03 0.96 0.91 0.86 0.80

16

Cap 14.29 14.29 12.52 12.52 10.82 9.84 8.82 7.83 7.10 6.47

304

kW 1.21 1.12 1.04 0.95 0.88

Cap 14.40 14.40 12.60 12.60 10.97 9.98 8.96 7.96 7.21 6.57

343

70 (21.11)

kW 1.16 1.07 1.01 0.92 0.86

Cap 14.49 14.49 12.67 12.67 11.16 10.16 9.16 8.14 7.38 6.73

414

kW 1.09 1.02 0.97 0.89 0.84

Cap 14.11 8.66 12.37 12.37 10.52 8.66 8.60 7.63 6.88 6.27

304

kW 1.27 1.18 1.07 0.99 0.92

Cap 14.24 8.89 12.46 12.46 10.75 8.89 8.72 7.74 6.98 6.37

343

75 (23.89)

kW 1.21 1.13 1.05 0.96 0.90

Cap 14.34 14.34 12.55 12.55 10.96 9.98 8.90 7.90 7.12 6.49

414

kW 1.14 1.07 1.01 0.93 0.88

Cap 13.93 13.93 12.22 12.22 10.24 9.31 8.36 7.42 6.65 6.07

304

kW 1.32 1.23 1.11 1.03 0.95

Cap 14.06 14.06 12.31 12.31 10.42 9.48 8.49 7.54 6.75 6.16

343

80 (26.67)

kW 1.27 1.19 1.09 1.01 0.94

Cap 14.18 14.18 12.41 12.41 10.74 9.77 8.66 7.69 6.89 1.38

414

kW 1.20 1.12 1.06 0.97 0.92

Indicates Rating Condition (* Integrated Capacity)

Indicates Integrated Rating

kW --- Total Power Input, includes compressor motor power input, outdoor fan motor power input, and indoor fan motor power input

Cap --- Heating Capacity (100 Btuh), Includes indoor fan motor heat

Note: Integrated Capacity is maximum (instantaneous ) capacity less the effect of frost on the outdoor coil and the heat to defrost it.

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

38/40MVC, MVQ

Air Temperature Entering Outdoor Coil --- DB/WB _F(_C)

38MVQ012--3 / 40MVQ012--3

57/53 (13.89/11.67) 47/43 (8.33/6.11) 37/33 (2.78/0.56) 27/23 ( ---2.78/---5) 17/13 ( ---8.33/--- 10.56)

Rating Rating Rating Rating Rating Rating Rating Rating Rating Rating

Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated

kW 1.08 0.99 0.91 0.84 0.77

kW 1.02 0.94 0.88 0.81 0.76

Cap 15.31 15.31 13.40 13.40 11.75 10.69 9.94 8.83 8.20 7.48

343

55 (12.78)

Cap 15.37 15.37 13.47 13.47 11.84 10.78 10.10 8.97 8.44 7.69

414

kW 0.95 0.89 0.83 0.78 0.73

Cap 15.01 15.01 13.16 13.16 11.37 10.35 9.64 8.56 7.81 7.12

Indoor

Air Temperature

Cap 15.21 15.21 13.32 13.32 11.58 10.54 9.83 8.73 8.06 7.35

Item

304

(CFM)

Airflow

L --- M --- H

Unit _F(_C)

Entering Indoor

PERFORMANCE DATA (CONT.)

kW 1.13 1.04 0.95 0.88 0.81

304

Cap 15.13 15.13 13.25 13.25 11.54 10.50 9.76 8.67 7.94 7.24

343

60 (15.56)

kW 1.08 0.99 0.92 0.85 0.79

Cap 15.23 15.23 13.33 13.33 11.71 10.65 9.92 8.81 8.12 7.40

414

kW 1.01 0.93 0.88 0.82 0.77

Cap 14.80 14.80 12.96 12.96 11.18 10.17 9.43 8.37 7.55 6.89

304

kW 1.18 1.09 1.00 0.92 0.84

Cap 14.94 14.94 13.08 13.08 11.33 10.31 9.56 8.49 7.69 7.01

343

65 (18.33)

kW 1.13 1.04 0.97 0.89 0.82

Cap 15.06 15.06 13.16 13.16 11.55 10.51 9.74 8.65 7.86 7.17

414

kW 1.06 0.98 0.93 0.86 0.80

Cap 14.58 14.58 12.77 12.77 10.97 9.99 9.10 8.08 7.28 6.64

304

17

kW 1.24 1.14 1.04 0.95 0.87

Cap 14.74 14.74 12.89 12.89 11.12 10.12 9.28 8.24 7.42 6.76

343

70 (21.11)

kW 1.19 1.09 1.01 0.93 0.86

Cap 14.90 14.90 13.01 13.01 11.33 10.31 9.53 8.46 7.61 6.94

414

kW 1.11 1.03 0.97 0.90 0.83

Cap 14.35 8.66 12.57 12.57 10.76 8.66 8.83 7.84 7.04 6.42

304

kW 1.30 1.19 1.09 0.98 0.91

Cap 14.51 8.89 12.70 12.70 10.92 8.89 8.98 7.97 7.15 6.52

343

75 (23.89)

kW 1.24 1.15 1.06 0.96 0.89

Cap 14.69 14.69 12.84 12.84 11.12 10.12 9.21 8.18 7.32 6.68

414

kW 1.17 1.09 1.02 0.93 0.87

Cap 14.12 14.12 12.32 12.32 10.52 9.57 8.56 7.60 6.80 6.20

304

kW 1.35 1.24 1.13 1.02 0.95

Cap 14.29 14.29 12.51 12.51 10.69 9.73 8.70 7.72 6.92 6.31

343

80 (26.67)

kW 1.30 1.20 1.10 1.00 0.93

Cap 14.48 14.48 12.65 12.65 10.91 9.93 8.92 7.92 7.06 1.41

414

kW 1.22 1.14 1.06 0.97 0.91

Indicates Rating Condition (* Integrated Capacity)

Indicates Integrated Rating

kW --- Total Power Input, includes compressor motor power input, outdoor fan motor power input, and indoor fan motor power input

Cap --- Heating Capacity (100 Btuh), Includes indoor fan motor heat

Note: Integrated Capacity is maximum (instantaneous ) capacity less the effect of frost on the outdoor coil and the heat to defrost it.

38/40MVC, MVQ

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

Air Temperature Entering Outdoor Coil --- DB/WB _F(_C)

38MVQ018--3 / 40MVQ018--3

57/53 (13.89/11.67) 47/43 (8.33/6.11) 37/33 (2.78/0.56) 27/23 (---2.78/---5) 17/13 ( ---8.33/--- 10.56)

Rating Rating Rating Rating Rating Rating Rating Rating Rating Rating

Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated

kW 1.48 1.38 0.00 1.17 1.20

kW 1.46 1.36 1.25 1.16 1.19

Cap 18.69 18.69 16.53 16.53 14.04 12.77 11.57 10.27 9.39 8.56

449

55 (12.78)

Cap 18.99 18.99 16.76 16.76 14.59 13.28 11.90 10.57 9.62 8.77

539

kW 1.37 1.29 1.22 1.12 1.16

Cap 18.23 18.23 16.12 16.12 13.48 12.27 11.10 9.86 8.97 8.18

Cap 18.57 18.57 16.44 16.44 0.00 0.00 11.47 10.19 9.32 8.50

Item

426

(CFM)

Indoor

Airflow

L --- M --- H

Unit _F(_C)

Entering Indoor

PERFORMANCE DATA (CONT.)

Air Temperature

kW 1.55 1.44 1.31 1.22 1.24

426

Cap 18.34 18.34 16.23 16.23 13.61 12.39 11.19 9.94 9.04 8.25

449

60 (15.56)

kW 1.52 1.42 1.30 1.21 1.23

Cap 18.66 18.66 16.49 16.49 14.03 12.77 11.49 10.20 9.26 8.45

539

kW 1.44 1.35 1.26 1.17 1.20

Cap 17.87 17.87 15.60 15.60 13.05 11.87 10.71 9.51 8.61 7.85

426

kW 1.62 1.49 1.36 1.26 1.29

Cap 18.00 18.00 15.88 15.88 13.18 11.99 10.81 9.60 8.68 7.92

449

65 (18.33)

kW 1.59 1.48 1.35 1.25 1.28

Cap 18.32 18.32 16.19 16.19 13.59 12.37 11.10 9.86 8.90 8.11

539

kW 1.50 1.41 1.30 1.22 1.25

18

Cap 17.53 17.53 15.09 15.09 12.60 11.46 10.32 9.16 8.26 7.53

426

kW 1.68 1.54 1.41 1.31 1.33

Cap 17.65 17.65 15.26 15.26 12.73 11.59 10.41 9.25 8.32 7.58

449

70 (21.11)

kW 1.66 1.52 1.40 1.30 1.32

Cap 17.98 17.98 15.88 15.88 13.16 11.98 10.71 9.51 8.52 7.77

539

kW 1.57 1.47 1.35 1.27 1.30

Cap 17.17 8.66 14.66 14.66 12.15 8.66 9.92 8.81 7.86 7.17

426

kW 1.75 1.59 1.46 1.36 1.50

Cap 17.29 8.89 14.79 14.79 12.27 8.89 10.01 8.89 7.93 7.24

449

75 (23.89)

kW 1.72 1.57 1.45 1.35 1.37

Cap 17.64 17.64 15.30 15.30 12.69 11.54 10.30 9.14 8.16 7.44

539

kW 1.64 1.52 1.40 1.31 1.35

Cap 16.75 16.75 14.19 14.19 11.72 10.67 9.51 8.45 7.46 6.80

426

kW 1.81 1.65 1.51 1.41 1.43

Cap 16.92 16.92 14.35 14.35 11.84 10.77 9.60 8.53 7.53 6.86

449

80 (26.67)

kW 1.79 1.63 1.50 1.40 1.42

Cap 17.28 17.28 14.82 14.82 12.22 11.12 9.88 8.78 7.73 1.54

539

kW 1.71 1.57 1.46 1.36 1.40

Indicates Rating Condition (* Integrated Capacity)

Indicates Integrated Rating

kW --- Total Power Input, includes compressor motor power input, outdoor fan motor power input, and indoor fan motor power input

Cap --- Heating Capacity (100 Btuh), Includes indoor fan motor heat

Note: Integrated Capacity is maximum (instantaneous ) capacity less the effect of frost on the outdoor coil and the heat to defrost it.

INSTANTANEOUS AND INTEGRATED HEATING RATINGS

38/40MVC, MVQ

Air Temperature Entering Outdoor Coil --- DB/WB _F(_C)

38MVQ024--3 / 40MVQ024--3

57/53 (13.89/11.67) 47/43 (8.33/6.11) 37/33 (2.78/0.56) 27/23 (---2.78/---5) 17/13 ( ---8.33/--- 10.56)

Rating Rating Rating Rating Rating Rating Rating Rating Rating Rating

Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated Instant. Integrated

kW 1.76 1.63 1.52 1.41 1.32

kW 1.70 1.58 1.49 1.38 1.30

Cap 25.99 25.99 22.72 22.72 19.81 18.03 16.40 14.57 13.43 12.25

689

55 (12.78)

kW 1.63 1.53 1.45 1.36 1.29

Cap 26.14 26.14 22.85 22.85 20.12 18.31 16.65 14.78 13.59 12.39

774

Cap 25.42 25.42 22.28 22.28 18.96 17.26 15.78 14.02 12.90 11.76

Cap 25.79 25.79 22.58 22.58 19.52 17.77 16.24 14.42 13.28 12.11

Item

625

(CFM)

Indoor

Airflow

L --- M --- H

Unit _F(_C)

Entering Indoor

PERFORMANCE DATA (CONT.)

Air Temperature

kW 1.84 1.71 1.58 1.47 1.37

625

kW 1.78 1.66 1.55 1.45 1.36

Cap 25.61 25.61 22.42 22.42 19.26 17.53 15.98 14.19 13.00 11.85

689

60 (15.56)

kW 1.72 1.61 1.51 1.42 1.34

Cap 25.80 25.80 22.55 22.55 19.56 17.80 16.20 14.38 13.16 12.00

774

kW 1.92 1.78 1.64 1.53 1.43

Cap 25.02 25.02 21.92 21.92 18.39 16.74 15.36 13.64 12.39 11.29

625

kW 1.87 1.73 1.61 1.50 1.42

Cap 25.23 25.23 22.08 22.08 18.73 17.05 15.49 13.75 12.54 11.44

689

65 (18.33)

kW 1.80 1.68 1.58 1.48 1.39

Cap 25.44 25.44 22.26 22.26 19.03 17.32 15.71 13.95 12.70 11.58

774

kW 2.01 1.86 1.71 1.59 1.49

Cap 24.62 24.62 21.46 21.46 18.00 16.38 14.87 13.21 11.92 10.87

625

19

kW 1.95 1.81 1.68 1.57 1.47

Cap 24.82 24.82 21.68 21.68 18.24 16.60 15.01 13.33 12.07 11.00

689

70 (21.11)

kW 1.89 1.76 1.64 1.54 1.45

Cap 25.04 25.04 21.90 21.90 18.50 16.83 15.23 13.52 12.26 11.18

774

kW 2.09 1.92 1.78 1.65 1.55

Cap 24.18 8.66 20.85 20.85 17.46 8.66 14.38 12.77 11.43 10.43

625

kW 2.04 1.88 1.74 1.63 1.53

Cap 24.41 8.89 21.23 21.23 17.65 8.89 14.52 12.89 11.59 10.56

689

75 (23.89)

kW 1.98 1.84 1.71 1.60 1.51

Cap 24.64 24.64 21.49 21.49 17.96 16.34 14.74 13.09 11.75 10.71

774

Cap 23.70 23.70 20.22 20.22 16.93 15.41 13.82 12.28 10.94 9.97

625

kW 2.16 1.99 1.84 1.71 1.60

kW 2.11 1.95 1.81 1.69 1.59

Cap 23.94 23.94 20.59 20.59 17.17 15.62 14.01 12.44 11.08 10.11

689

80 (26.67)

Cap 24.22 24.22 20.98 20.98 17.44 15.87 14.22 12.63 11.25 2.25

774

kW 2.06 1.91 1.78 1.67 1.57

Indicates Rating Condition (Integrated Capacity)

Indicates Integrated Rating

kW --- Total Power Input, includes compressor motor power input, outdoor fan motor power input, and indoor fan motor power input

Cap --- Heating Capacity (100 Btuh), Includes indoor fan motor heat

Note: Integrated Capacity is maximum (instantaneous ) capacity less the effect of frost on the outdoor coil and the heat to defrost it.

APPLICATION DATA

UNIT SELECTION

Select equipment to either match or be slightly less than anticipated

peak load. This provides better humidity control, fewer unit cycles,

and less part--load operation.

For units used in spaces with high sensible loads, base equipment

selection on unit sensible load, not on total anticipated load. Adjust

for anticipated room wet bulb temperature to avoid undersizing

equipment.

UNIT MOUNTING (INDOOR)

Unit leveling -- For reliable operation, units should be level in all

planes.

Clearance -- Provide adequate clearance for airflow as shown in

Fig. 2.

Unit location -- Select a location which will provide the best air

circulation for the room.

These units should be positioned as high as possible on the wall for

best air circulation. The unit return and discharge should not be

obstructed by furniture, curtains, or anything which may cause unit

short cycling or air recirculation. Place the unit in the middle of the

selected wall (if possible). Use an outside wall, if available, to

make piping easier, and place the unit so it faces the normal

38/40MVC, MVQ

location of room occupants.

UNIT MOUNTING (OUTDOOR)

Unit leveling -- For reliable operation, units should be level in all

planes.

Clearance -- Minimum clearance, as shown in Fig. 3, must be

provided for airflow. The condensing units are designed for

free--blow application. Air inlets and outlets should not be

restricted.

Unit location -- A location which is convenient to installation and

not exposed to strong wind. If unit is exposed to strong winds it is

recommended that a wind baffle be used. Contact your Carrier

representative for drawings.

A location which can bear the weight of outdoor unit and where

the outdoor unit can be mounted in a level position.

Do not install the indoor or outdoor units in a location with special

environmental conditions. For those applications, contact your

Carrier representative.

MOUNTING TEMPLATE

The fan coil units are furnished with mounting to mark the location

of the wiring, and refrigeration line hole locations.

SUPPORT

Adequate support must be provided to support the weight of all fan

coils. Refer to the Physical Data section for fan coil weights, and

the base unit dimensional drawings for the location of mounting

brackets.

SYSTEM OPERATING CONDITIONS

Cooling operating range:

Maximum Minimum

DB

_F(_C)WB_F(_C)DB_F(_C)WB_F(_C)

Outdoor Unit

Indoor Unit

125

(51.67)

85

(29.44)

---

72

(22.22)64(17.78)52(11.11)

55

(12.78)

---

Heating operating range:

Maximum Minimum

DB

_F(_C)WB_F(_C)DB_F(_C)WB_F(_C)

Outdoor Unit

Indoor Unit

75

(23.89)

80

(26.67)

67

(19.44)

---

5

( --- 1 5 )

55

(12.78)

50% RH

---

LOW AMBIENT OPERATION

Units can operate in cooling down to 55_F (12.78_C) under all

conditions without a low--ambient kit.

Units equipped with accessory low--ambient kits should also be

equipped with field fabricated (drawings available) wind baffle and

crankcase heater to prevent refrigerant migration during

compressor off cycle.

METERING DEVICES

These units have capillary tube metering devices in the outdoor

unit.

DRAIN CONNECTIONS

Install drains to meet local sanitation codes. If adequate gravity

drainage cannot be provided, unit should be equipped with

accessory condensate pump. High wall fan coil unit condensate

pumps have a maximum lift of 10’ (3.05 m) for 9k and 12k units

and 25’ (7.62 m) for 18k and 24k units.

See physical dimension tables for drain sizes.

NOTE: High wall fan coil units have internal condensate traps.

A trap is not required.

Drain connections may be routed through alternate locations on

mostfancoilsasshowninFig.4.

Pipe cover

Right piping

Pipe holder

1

2

Fig. 4 – Piping Locations

Right back piping

Size 012

Only

Pipe cover

4

Left piping

3

Left back piping

A07344

20

REFRIGERANT LINES

General refrigerant line sizing:

1. The 38MVC/MVQ units are shipped with a full charge of

R410A refrigerant. All charges, line sizing, and capacities

are based on runs of 25 ft (7.6 m). For runs over 25 ft (7.6

m), consult long--line section on this page for proper charge

adjustments.

2. Refrigerant lines should not be buried in the ground. If it is

necessary to bury the lines, not more than 36--in (914 mm)

should be buried. Provide a minimum 6--in (152 mm)

vertical rise to the service valves to prevent refrigerant

migration.

3. Both lines must be insulated. Use a minimum of 1/2--in.

(12.7 mm) thick insulation. Closed--cell insulation is

recommended in all long--line applications.

4. Special consideration should be given to isolating

interconnecting tubing from the building structure. Isolate

the tubing so that vibration or noise is not transmitted into

the structure.

Long Line Applications, 38MVC Units:

1. A crankcase heater should be added for line lengths longer

than 25 ft (7.62 m) to prevent the migration of refrigerant to

the compressor during the “OFF” cycle.

2. A field fabricated wind baffle is recommended.

3. No change in line sizing is required.

4. Add refrigerant per table below.

ADDITIONAL CHARGE TABLE

Tot a l

Line Length,

Unit

Size

9K

cool

only

9K

hp

12K

cool

only

12K

hp

18K

cool

only

18K

hp

24K

cool

only

24K

hp

ft

Min. Max.

65

10

100

(3.05 --- 7.62)

5. Reduction in capacity due to long lines can be calculated

from the chart below.

CAPACITY LOSS

Capacity,%Loss

Cooling: 25 45 65 100

9&12KBTU/Hmodels 0% 2% 5%

18 & 24 KBTU/H models 0% 2% 4% 7%

Heating:

9&12KBTU/Hmodels 0% 7% 11%

18 & 24 KBTU/H models 0% 7% 11% 15%

Additional Charge, oz.

10 --- 25

none

ft (m)

> 2 5 --- 65

(7.62 --- 19.81)

0.1 oz per

foot

Line Length, ft

> 6 5 --- 10 0

(19.81 --- 30.48)

0.3 oz. per

foot

WIRING

The main power is supplied to the outdoor unit. the field supplied

connecting cable from the outdoor unit to indoor unit consists of

four wires and provides the power for the indoor unit as well as the

communication signal between the outdoor unit and indoor unit.

For 9K and 12K units, all four wires are low voltage DC.

For 18K and 24K, two wires are high voltage AC power, one is

low voltage DC, and one is a ground wire.

CONTROL SYSTEM

The 40MVC/MVQ unit is equipped with a microprocessor controls

to operate the system and give optimum levels of comfort and

operating efficiency.

The main microprocessor is located in the control box of the fan

coil unit (there is one in the outdoor unit too) with thermistors

located in the fan coil inlet and on the indoor coil. These

thermistors monitor the system operation and control the operating

mode. To change the settings or the modes of operation, use the

factory supplied wireless remote control.

The 40MVC/MVQ unit has 5 operating modes:

S Fan Only

S Auto (heat pump models only)

S Heating (heat pump models only)

S Cooling

S Dehumidification (Dry)

FAN ON LY -- In Fan Only mode, the system filters and circulates

the room air without changing the room air temperature.

AUTO -- In Auto mode, the system will automatically select one of

the following operating modes: cooling, heating or fan only based

on the difference between the room temperature and the set point

temperature.

HEATING -- In the Heating mode, the system heats and filters

room air.

COOLING -- In Cooling mode, the system cools, dries and filters

room air.

DEHUMIDIFICATION (DRY) -- in Dehumidification (Dry)

mode, the system dries, filters and slightly cools room temperature.

This mode does not take place of a dehumidifier.

In addition to the above modes that are selected by using the

remote control, The unit can run in two other modes selected by

the manual button:

S EMERGENCY RUN

S TEST MODE

EMERGENCY mode is used when the remote control is

misplaced or the batteries in the remote control died. Pushing the

manual button once will put the unit in Auto mode with a

predetermined set point (76 _F/ 24.4 _C) .

TEST mode is used when a technician needs to diagnose the unit

for a malfunction. Pushing the manual button twice will put the

unit in test mode. The unit will run continuously for 30 min

regardless of the set point.

For more details on the sequence of operation please refer to the

service manual for those units.

WIRELESS REMOTE CONTROL

1. A wireless remote control is supplied for system operation

of all high--wall units.

2. Each battery--operated wireless (infrared) remote control

may be used to control more than one unit.

3. The wireless remote control has a range of 25 ft. (7.6 m).

38/40MVC, MVQ

21

AIR THROW DATA

UNIT

CAPACITY

009 115v 14 (4.3 m) 18 (5.5) 28 (8.5)

012 115v 16 (4.9) 20 (6.1) 30 (9.1)

012 208/230v 16 (4.9) 20 (6.1) 30 (9.1)

018 208/230v 22 (6.7) 37 (8.2) 35 (10.7)

024 208/230v 23 (7.0) 31 (9.4) 40 (12.2)

SOUND RATINGS

Outdoor Units

Model Number Sound Power dBa Sound Pressure dBa

3 8 M V C 0 0 9 --- --- --- 1 65 54

3 8 M V C 0 1 2 --- --- --- 1 65 54

3 8 M V C 0 1 2 --- --- --- 3 65 54

3 8 M V C 0 1 8 --- --- --- 3 68 57

3 8 M V C 0 2 4 --- --- --- 3 67 56

38/40MVC, MVQ

3 8 M V Q009 --- --- --- 1 64/66 (Clg/Htg) 53/55 (Clg/Htg)

3 8 M V Q012 --- --- --- 1 63/64 (Clg/Htg) 52/53 (Clg/Htg)

3 8 M V Q012 --- --- --- 3 63/64 (Clg/Htg) 52/53 (Clg/Htg)

3 8 M V Q018 --- --- --- 3 68/72 (Clg/Htg) 57/61 (Clg/Htg)

3 8 M V Q024 --- --- --- 3 65/67 (Clg/Htg) 54/56 (Clg/Htg)

APPROXIMATE AIR THROW ft. (m)

Low Medium High

Indoor Units

High Me dium Low

Model Number

4 0 M V C 0 0 9 --- --- --- 1 53 42 47 36 39 28

4 0 M V C 0 1 2 --- --- --- 1 58 47 53 42 51 40

4 0 M V C 0 1 2 --- --- --- 3 58 47 53 42 51 40

4 0 M V C 0 1 8 --- --- --- 3 59 48 56 45 54 43

4 0 M V C 0 2 4 --- --- --- 3 64 53 61 50 59 48

4 0 M V Q009 --- --- --- 1 52/54 (Clg/Htg) 41/43 (Clg/Htg) 47/ 47 (Clg/Htg) 36/36 (Clg/Htg) 42/44 (Clg/Htg) 31/33 (Clg/Htg)

4 0 M V Q012 --- --- --- 1 59/58 (Clg/Htg) 48/47 (Clg/Htg) 54/ 51 (Clg/Htg) 43/40 (Clg/Htg) 51/47 (Clg/Htg) 40/36 (Clg/Htg)

4 0 M V Q012 --- --- --- 3 59/58 (Clg/Htg) 48/47 (Clg/Htg) 54/ 51 (Clg/Htg) 43/40 (Clg/Htg) 51/47 (Clg/Htg) 40/36 (Clg/Htg)

4 0 M V Q018 --- --- --- 3 58/57 (Clg/Htg) 47/46 (Clg/Htg) 56/ 56 (Clg/Htg) 45/45 (Clg/Htg) 54/54 (Clg/Htg) 43/43 (Clg/Htg)

4 0 M V Q024 --- --- --- 3 65/66 (Clg/Htg) 54/55 (Clg/Htg) 62/ 64 (Clg/Htg) 51/53 (Clg/Htg) 59/60 (Clg/Htg) 48/49 (Clg/Htg)

NOTES:

1. Sound power ratings are per ARI 270 and ARI 350

2. Sound pressure ratings are estimated sound pressure, 3 feet (.91 m) from the unit, based on sound power data.

Sound Power

dBa

Sound Pressure

dBa

Sound Power

dBa

Sound Pressure

dBa

Sound Power

dBa

Sound Pressure

dBa

ELECTRICAL DATA

OPERATING

UNIT

SIZE

*Permissible limits of the voltage range at which the unit will operate satisfactorily

LEGEND

FLA --- F u l l L o a d A m ps

LRA --- L o c k e d R o t o r A m p s

MCA --- Minimum Circuit Amps

RLA --- RatedLoadAmps

VOLTAGE*

MAX/MIN VO LT S --- P H --- H Z RLA LRA FLA HP W VOLTS FLA HP W

009

012 9.9 47 1.18 0.044 25 15 25

012

018 7.3 32.6 0.78 0.224 53

024 9.7 34.8 0.62 0.218 100 0.39 0.112 50 14 25

127/104 1 1 5 --- 1 --- 6 0

253/187 208/230---1--- 60

COMPRESSOR OUTDOOR FAN INDOOR FAN

7.5 40

5.2 21 0.38 0.116 36 35 DC 1.18 0.044 25 9 15

0.60 0.102 23 35 DC

208/230--- 1--- 6.

1.1 0.034 20 12 20

0.26 0.075 31 11 20

MCA

FUSE/CB

MAX

AMP

22

38/40MVC, MVQ

Fig. 5 – Wiring Diagram 38MVC009------1 W/ 40MVC009------1

WIRING DIAGRAMS

23

38/40MVC, MVQ

INDOOR UNIT (40MVC012 --- - -- ---101 --- --- )

Fig. 6 – Wiring Diagram 38MVC012------1 W/ 40MVC012------1

WIRING DIAGRAMS (CONT.)

24

38/40MVC, MVQ

Fig. 7 – Wiring Diagram 38MVC012------3 W/ 40MVC012------3

WIRING DIAGRAMS (CONT.)

25

38/40MVC, MVQ

Fig. 8 – Wiring Diagram 38MVC018------3 W/ 40MVC018------3

WIRING DIAGRAMS (CONT.)

26

38/40MVC, MVQ

Fig. 9 – Wiring Diagram 38MVC024------3 W/ 40MVC024------3

WIRING DIAGRAMS (CONT.)

27

38/40MVC, MVQ

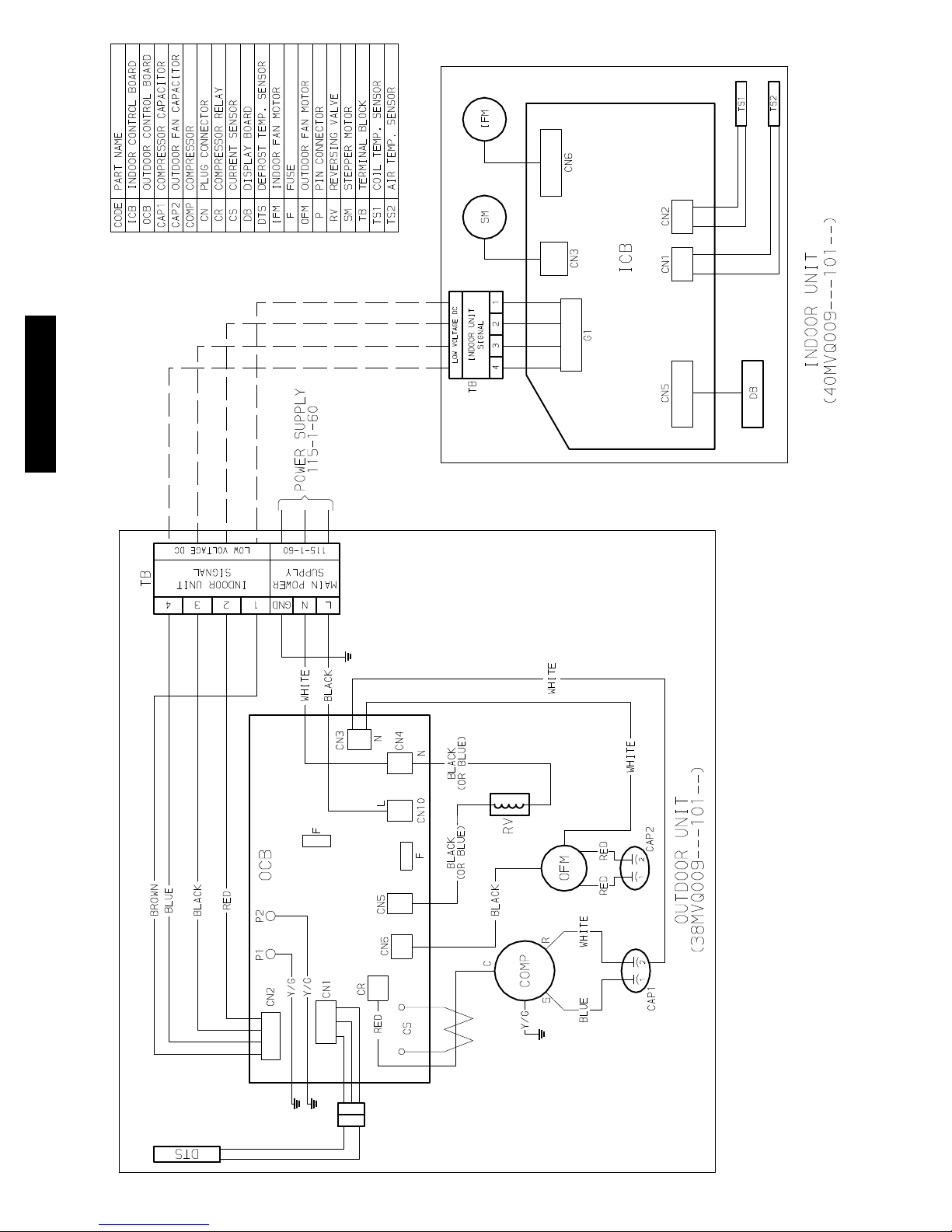

Fig. 10 – Wiring Diagram 38MVQ009------1 W/ 40MVQ009------1

WIRING DIAGRAMS (CONT.)

28

38/40MVC, MVQ

Fig. 11 – Wiring Diagram 38MVQ012------1 W/ 40MVQ012------1

WIRING DIAGRAMS (CONT.)

29

38/40MVC, MVQ

Fig. 12 – Wiring Diagram 38MVQ012------3 W/ 40MVQ012------3

WIRING DIAGRAMS (CONT.)

30

38/40MVC, MVQ

Fig. 13 – Wiring Diagram 38MVQ018------3 W/ 40MVQ018------3

WIRING DIAGRAMS (CONT.)

31

38/40MVC, MVQ

Fig. 14 – Wiring Diagram 38MVQ024------3 W/ 40MVQ024------3

WIRING DIAGRAMS (CONT.)

32

GUIDE SPECIFICATIONS

INDOOR WALL--MOUNTED DUCT--FREE UNITS

Size Range: 3/4 to 2 Ton Nominal Cooling Capacity / 3/4 to 2 Ton Nominal Heating Capacity

Carrier Model Number: 40MVC/40MVQ

PART 1 -- GENERAL

1.01 System Description

Indoor, wall--mounted, direct--expansion fan coils are matched with

cooling only or heat pump outdoor unit .

1.02 Agency Listings

Unit shall be rated per ARI Standards 210/240 and listed in the

ARI directory as a matched system.

1.03 Delivery, Storage, And Handling

Units shall be stored and handled per unit manufacturer’s

recommendations.

1.04 Warranty (For Inclusion By Specifying

Engineer)

PART 2 -- PRODUCTS

2.01 Equipment

A. General:

Indoor, direct--expansion, wall--mounted fan coil. Unit shall be

complete with cooling/heating coil, fan, fan motor, piping

connectors, electrical controls, microprocessor control system, and

integral temperature sensing. Unit shall be furnished with integral

wall mounting bracket and mounting hardware.

B. Unit Cabinet:

Cabinet discharge and inlet grilles shall be attractively styled,

high--impact polystyrene. Cabinet shall be fully insulated for

improved thermal and acoustic performance.

C. Fans:

1. Fan shall be tangential direct--drive blower type with air