Page 1

38MGR

Multi-zone Outdoor Unit Ductless System

Sizes 18, 24, 30, 36 and 48

Product Data

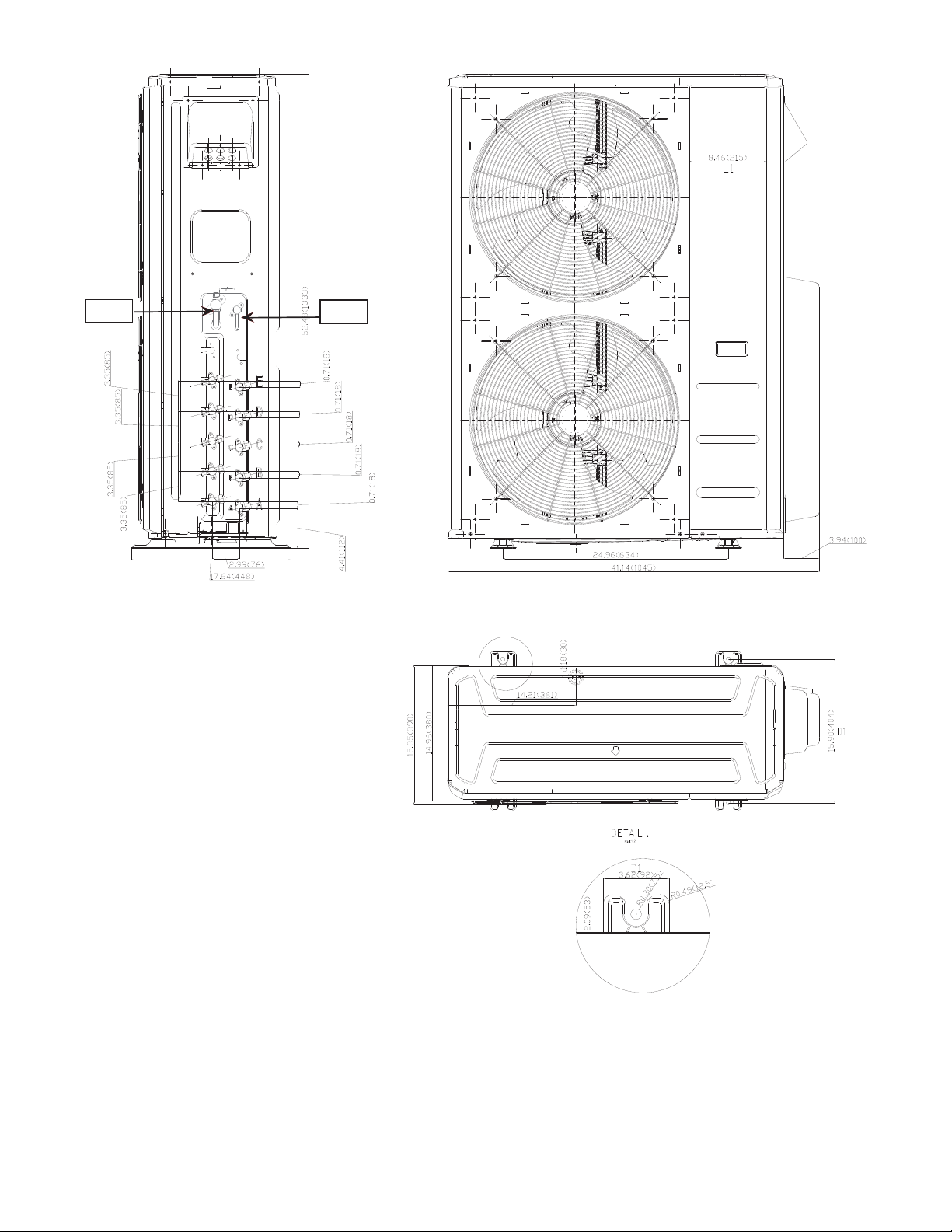

Fig. 1 − 18K

Fig. 2 − 24K and 30K

INDUSTRY LEADING

FEATURES / BENEFITS

A competitively priced and creative solution to

design problems.

The 38MGR ductless inverter driven multi−zone system provides

individual comfort control for up to 5 separate zones. Two, three,

four or five space−saving High Wall, Cassette, Ducted Style or

Floor Console fan coils can be matched with one outdoor heat

pump. The indoor fan coils are connected to the outdoor unit by

refrigerant tubing and wires.

The different styles of indoor units can be mounted in several

locations to accommodate the application. This selection of fan

coils permits inexpensive and creative solutions to design problems

such as:

S When adding air conditioning to spaces that are heated by

hydronic or electric heat and have no ductwork.

S Historical renovations or any application where preserving the

look of the original structure is essential.

S Commercial add−on jobs where the existing air conditioning

system cannot be stretched.

These compact indoor fan coil units take up very little space in the

room and do not obstruct windows. The fan coils are attractively

styled to blend with most room decors.

Advanced system components incorporate innovative technology

to provide reliable cooling and heating performance at low sound

levels.

Fig. 3 − 36K and 48K

NOTE: Images for illustration purposes only. Actual models may be slightly

different.

Page 2

Inverter Technology

The inverter driven compressor is designed to run at various input

power frequencies (Hz) which controls the compressor’s motor

speed.

Even Temperature – The control package, including the inverter,

monitors the outdoor and indoor temperatures as they relate to the

selected indoor set point and adjusts the compressor speed to match

the load and keep the system operating continuously rather than

cycling and creating temperature swings. This translates to higher

comfort levels for the occupants.

Rapid Pull Down/Warm−Up – Comfort is increased by the

inverter system’s ability to ramp up the compressor speed enabling

the system to reach the user selected room temperature set point

quicker.

Humidity Control – Running the system for longer periods and

continuously varying the compressor speed enhances the humidity

control.

Individual Room Comfort

Maximum comfort is provided because each space can be

controlled individually based on the usage pattern.

Low Sound Levels

When noise is a concern, ductless systems are the answer. The

indoor units are whisper quiet. There are no compressors indoors,

either in the conditioned space or directly over it, and there is none

of the noise usually generated by air being forced through the

ductwork.

When sound ordinances and proximity to neighbors demand quiet

operation, the 38MGR unit is the right choice. With the inverter

technology, these units run at lower speeds most of the time

resulting in reduced sound levels.

Inverter Technology – Enhanced Economical Operation

Ductless systems are inherently economical to operate. Individual

rooms are heated or cooled only when required, and since the air is

delivered directly to the space, there is no need to use additional

energy to move the air in the ductwork. This economical operation

is enhanced further when the inverter system output matches the

load resulting in a more efficient system.

Easy−To−Use Controls

The multi−zone systems have microprocessor−based controls to

provide the ultimate in comfort and efficiency. The user friendly

wired and wireless remote controls provide the interface between

the user and the unit.

Secure Operation

If security is an issue, outdoor and indoor units are connected only

by refrigerant piping and wiring to prevent intruders from crawling

through ductwork or wall openings. In addition, since the 38MGR

can be installed close to an outside wall, coils are protected from

vandals and severe weather.

Fast Installation

This compact ductless system is simple to install. A mounting

bracket is included with the indoor units and only wires and piping

need to run between the indoor and outdoor units. These units are

fast and easy to install ensuring minimal disruption to customers in

homes or the workplace. This makes the 38MGR systems the

equipment of choice for retrofit applications.

Simple Servicing and Maintenance

Removing the top panel of the outdoor unit provides immediate

access to the control compartment, providing the service technician

access to the diagnostic LEDs to facilitate the troubleshooting

process. In addition, the draw−thru design of the outdoor unit

means that dirt accumulates on the outside surface of the coil. Coils

can be cleaned quickly from the inside using a pressure hose and

detergent.

On the indoor units, service and maintenance expense is reduced

due to the permanent easy to clean filters. Also, error codes are

displayed on the front panel to alert the user to certain system

malfunctions

Built−in Reliability

Ductless system indoor and outdoor units are designed to provide

years of trouble−free operation.

Both the indoor and outdoor units are well protected. Whenever

the microprocessor detects abnormal conditions, the unit stops and

an error code appears.

Inverter systems provide additional reliability due to the soft start.

This refers to the ability of the inverter to start the compressor

motor using reduced voltage and reduced current. This feature is

beneficial from an electrical standpoint (eliminates current spikes)

as well as an overall reliability standpoint due to reduced stress on

all associated system components.

Agency Listings

All systems are listed with AHRI (Air conditioning, Heating, and

Refrigeration Institute) and are ETL certified per UL 1995

standard.

2

Page 3

MODEL NUMBER NOMENCLATURE

OUTDOOR UNIT

38 = OUTDOOR UNIT

MG = ALL

UNIT TYPE

R = OUTDOOR UNIT

SYSTEM TYPE

Q = HEAT PUMP

NOMINAL CAPACITY

18 - 1 1/2 TONS

24 - 2 TONS

30 - 21/2 TONS

36 - 3 TONS

48 - 4 TONS

38 MG 318

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

QRB

- -

VOLTAGE

3 = 208/230-1-60

NOT USED

MAXIMUM NUMBER OF FAN COIL UNITS THAT

CAN BE CONNECTED TO THE OUTDOOR UNIT

B = 1:2

C = 1:3

D = 1:4

E = 1:5

3

Page 4

STANDARD FEATURES AND ACCESSORIES

Ease of Installation

Low Voltage Controls S

Comfort Features

Microprocessor Control S

Auto Restart Function S

Auto Changeover S

Energy Saving Features

Inverter Driven Compressor S

46° F Heating Mode (Heating Setback) S

Safety And Reliability

3 Minute Time Delay For Compressor S

High Compressor Discharge Temperature S

Low Voltage Protection S

Compressor Overload Protection S

Compressor Over Current Protection S

IPM Module Protection S

Aluminum Blue Hydrophilic pre-coated fins S

Ease of Service

Diagnostic S

Error Messages Displayed On Front Panel S

Application Flexibility

Crankcase Heater S

Basepan Heater S

Legend

S Standard

A Accessory

Outdoor Units

Crankcase Heater

The crankcase heater is standard on all unit sizes. Heater clamps

must be placed around the compressor oil stump.

Base pan Heater

The base pan heater is standard on all unit sizes.

4

Page 5

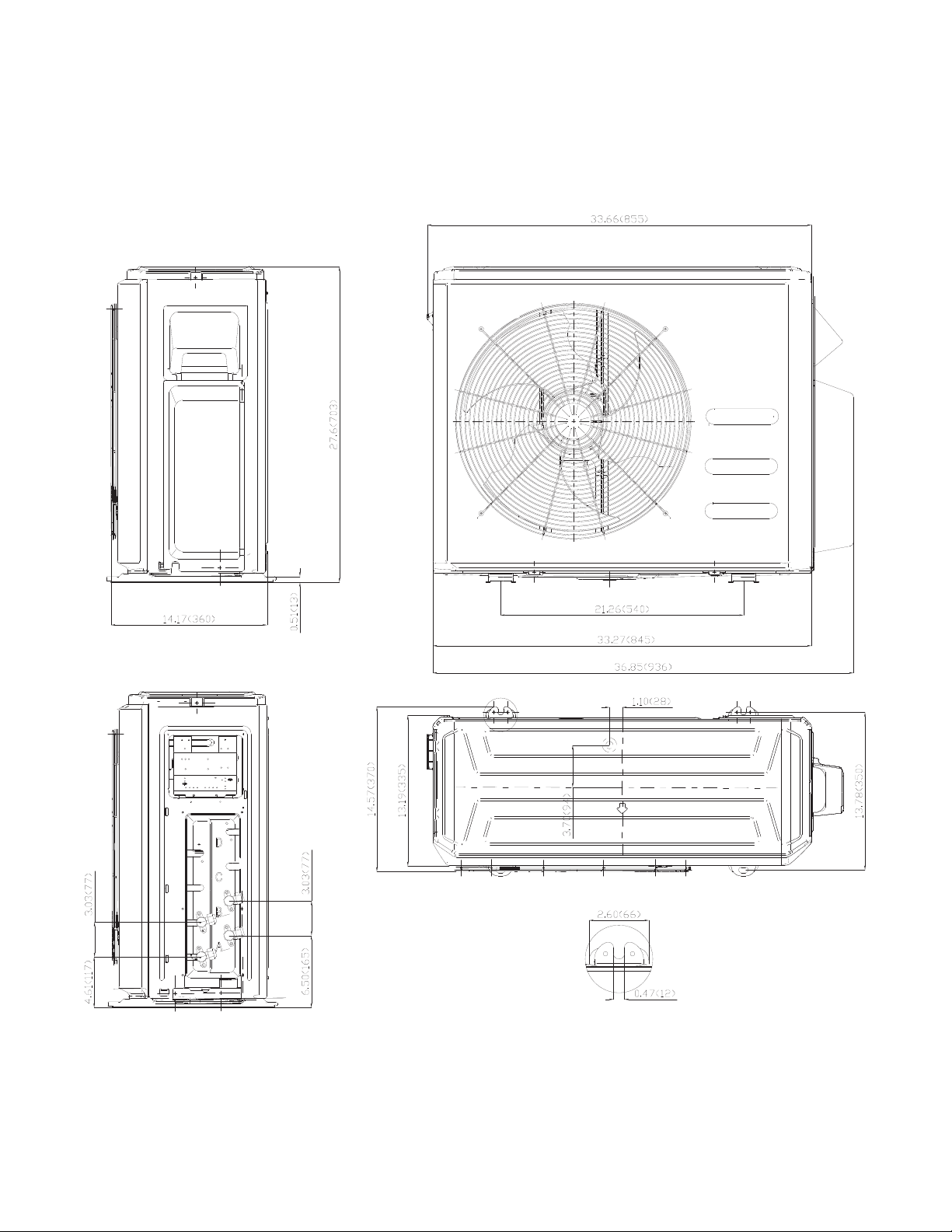

DIMENSIONS − OUTDOOR

UNIT SIZE 18 24 30 36 48

Height in (mm) 27.6 (703) 31.89 (810) 31.89 (810) 52.48 (1333) 52.48 (1333)

Width in (mm) 33.27 (845) 37.24 (946) 37.24 (946) 41.14 (1045) 41.14 (1045)

Depth in (mm) 13.19 (335) 15.20 (386) 15.20 (386) 14.96 (380) 14.96 (380)

Weight-Net lbs (kg) 105.8 (48) 149.9 (68) 156.5 (71) 223.8 (101.5) 223.8 (101.5)

Fig. 4 − Outdoor Dimensions Size 18

NOTE: Master valves are not available on the size 18 unit.

5

Page 6

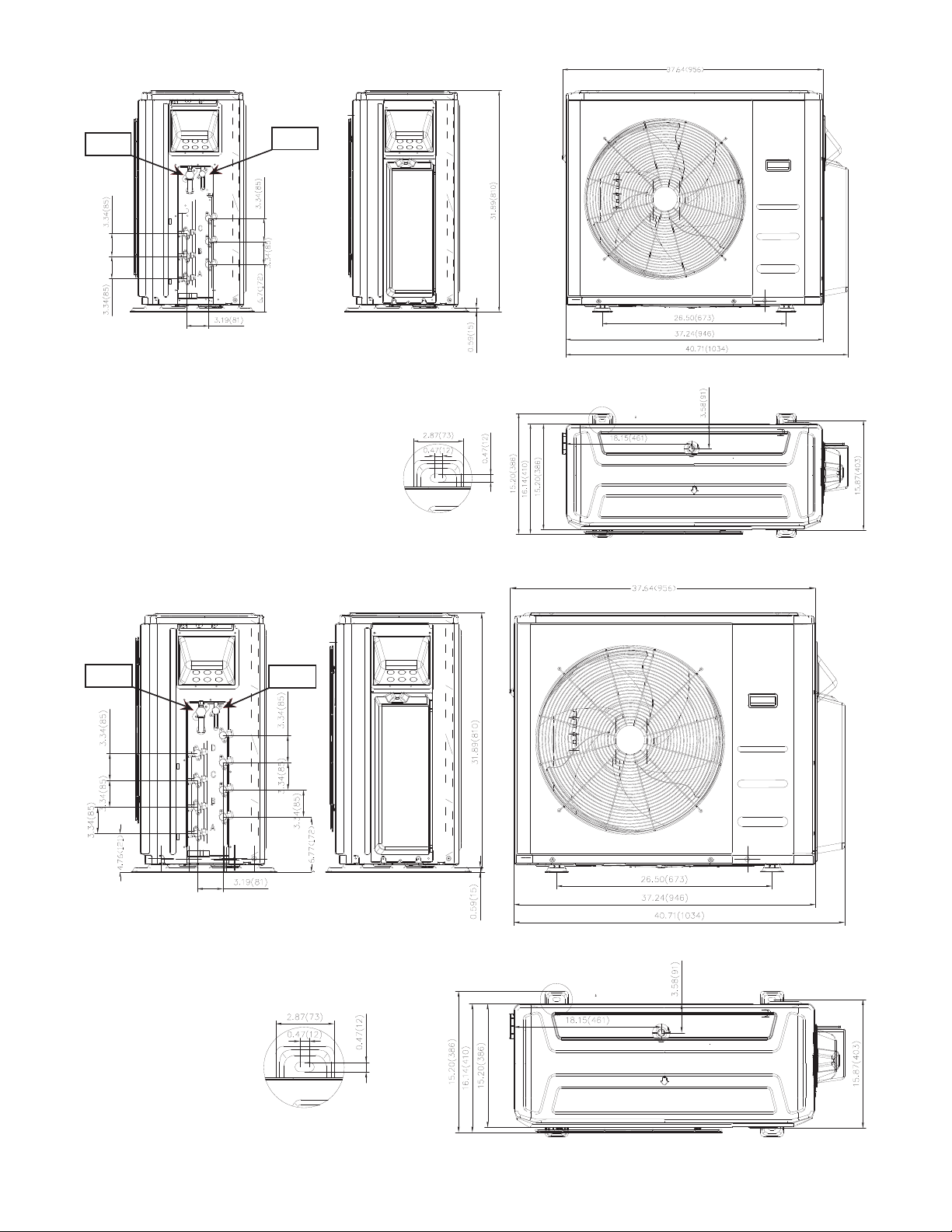

DIMENSIONS − OUTDOOR (CONTINUED)

Master Valve

Liquid Line

Master Valve

Suction Line

Fig. 5 − Outdoor Dimensions Size 24

Master Valve

Liquid Line

Master Valve

Suction Line

Fig. 6 − Outdoor Dimensions Size 30

6

Page 7

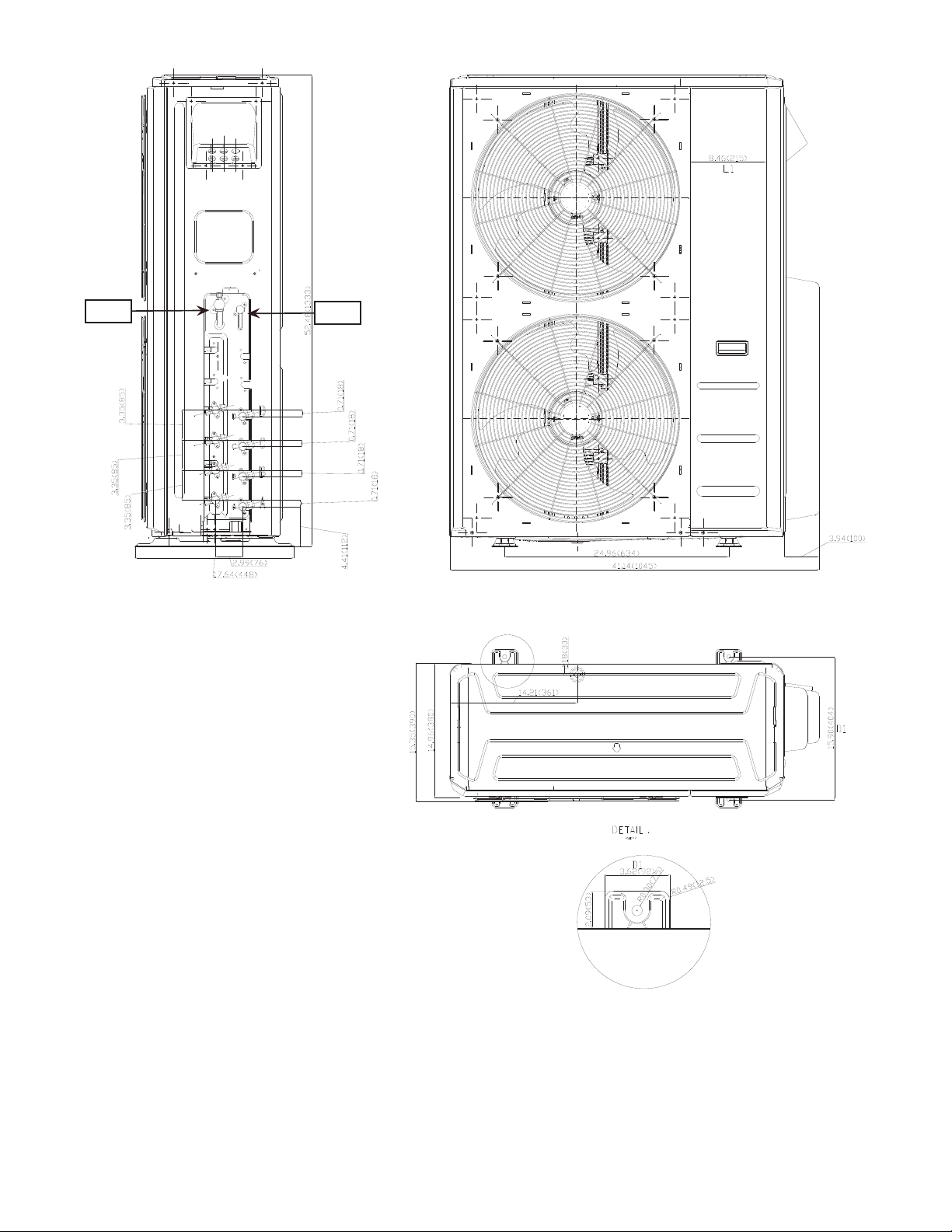

DIMENSIONS − OUTDOOR (CONTINUED)

Master Valve

Liquid Line

Master Valve

Suction Line

Fig. 7 − Outdoor Dimensions Size 36

7

Page 8

DIMENSIONS − OUTDOOR (CONTINUED)

Master Valve

Liquid Line

Master Valve

Suction Line

Fig. 8 − Outdoor Dimensions Size 48

8

Page 9

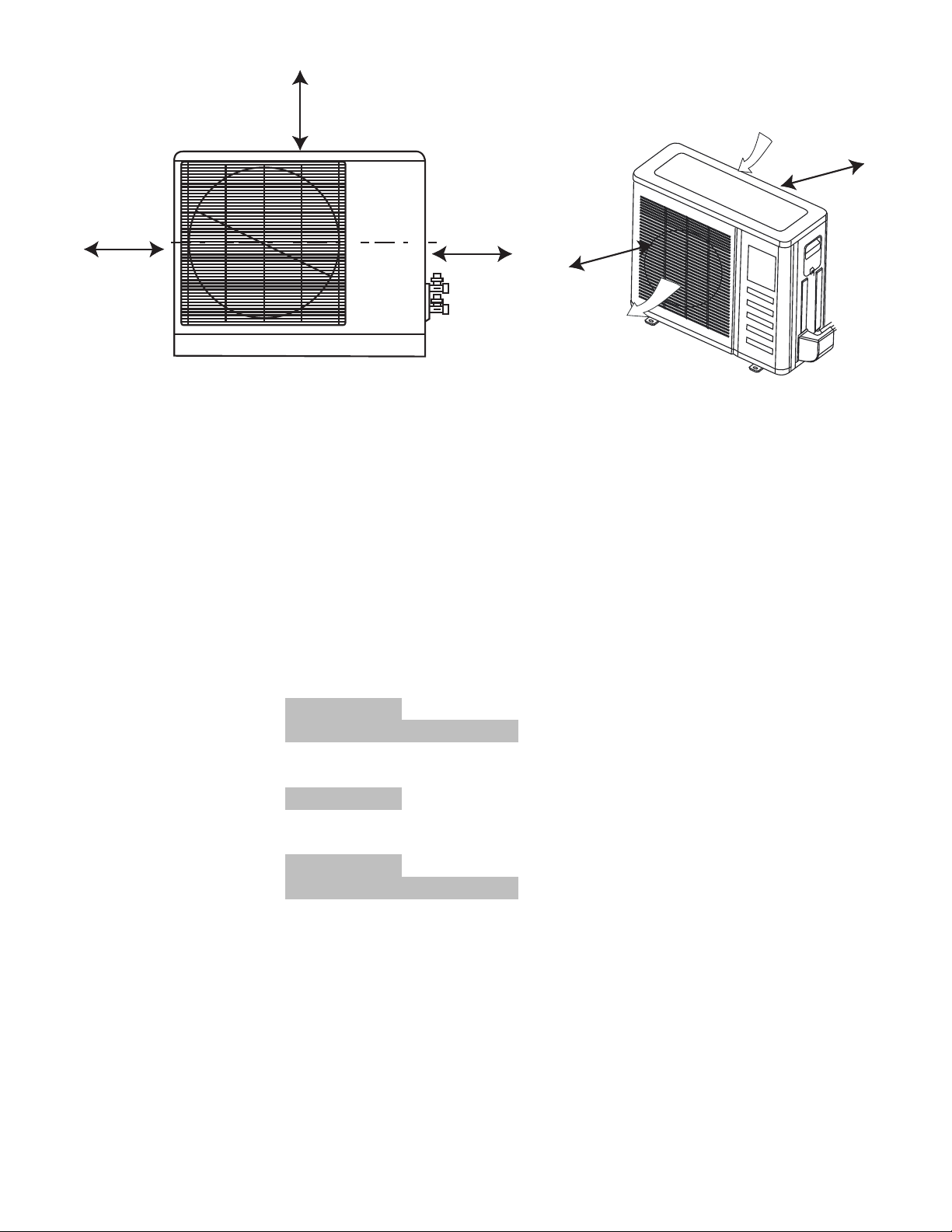

CLEARANCES − OUTDOOR

D

A

B

C

Air-outlet

Fig. 9 − Clearances Outdoor

UNIT

A 24 (609)

B 24 (609)

C 24 (609)

D 4 (101)

E 6 (152)

MINIMUM VALUE

in. (mm)

Air-inlet

E

NOTE: Outdoor Unit must be mounted at least 2in (50mm) above the maximum anticipated snow depth.

COMPATIBILITY TABLE

INDOOR UNIT

High Wall

Cassette

Ducted

Floor

Console

40MAQB09B--3

40MAQB12B--3

40MAQB18B--3

40MAQB24B--3

40MBQB09C--3

40MBQB12C--3

40MBQB18C--3

40MBQB09D--3

40MBQB12D--3

40MBQB18D--3

40MBQB24D--3

40MBQB09F--3

40MBQB12F--3

38MGRQ18B--3 38MGRQ24C--3 38MGRQ30D--3 38MGRQ36D--3 38MGRQ48E--3

• • • • •

• • • • •

• • • •

• • • • •

• • • • •

• • • •

• • • • •

• • • • •

• • • •

• • • • •

• • • • •

OUTDOOR UNIT

• • •

• • •

9

Page 10

PHYSICAL DATA − OUTDOOR

System

Per form ance

Non-Ducted

Per form ance

Combination

Ducted

and

Non-Ducted

Per form ance

Ducted

Operating

Range

Piping

Refrigerant

Electrical

Compressor

Outdoor

Size 18 24 30 36 48

Outdoor Model 38MGRQ18B--3 38MGRQ24C--3 38MGRQ30D--3 38MGRQ36D--3 38MGRQ48E--3

Max Number of Zones 2 3 4 4 5

Energy Star YES YES YES YES YES

Cooling System Tons 1.5 2.0 2.5 3.0 4.0

Cooling Rated Capacity Btu/h 18,000 24,000 30,000 36,000 48,000

Cooling Cap. Range Min - Max Btu/h 5810~ 21940 7880~ 33510 8090~ 41470 8560~ 45020 8560~ 53160

SEER 22.5 23 23.8 21.5 22.4

EER 12.5 12.5 12.5 13.5 12.5

Heating Rated Capacity (47° F) Btu/h 19,000 23,000 28,000 36,000 48,000

Heating Rated Capacity (17° F) Btu/h 12,000 13,600 17,400 23,200 29,600

Heating Maximum Capacity (5° F) Btu/h 13,900 23,000 28,000 36,000 36,000

Heating Cap. Range Min - Max Btu/h 5760~ 24480 6010~ 36180 6350~ 41950 7210~ 50350 7210~ 55820

HSPF 10.3 9.8 10.0 10.5 10.2

COP (47° F) W/W 3.6 3.9 3.8 3.8 3.6

COP (17° F) W/W 2.8 2.7 2.8 2.8 2.7

COP (5° F) W/W 2.2 2.1 2.0 1.8 2.0

Energy Star NO YES NO NO NO

Cooling System Tons 1.5 1.9 2.4 3.0 4.0

Cooling Rated Capacity Btu/h 18,000 23,000 29,000 35,500 48,000

Cooling Cap. Range Min - Max Btu/h 5795~ 20708 7765~ 31955 8060~ 39990 8510~ 42635 8510~ 52580

SEER 20.45 21 21.65 19.25 20

EER 12.15 12.5 12 12.15 11.3

Heating Rated Capacity (47° F) Btu/h 18,750 22,000 28,000 36,000 49,000

Heating Rated Capacity (17° F) Btu/h 11,700 12,900 17,300 23,800 31,300

Heating Maximum Capacity (5° F) Btu/h 14,150 22,000 28,000 35,500 36,400

Heating Cap. Range Min - Max Btu/h 5650~ 24365 5980~ 36190 6275~ 42305 7045~ 47800 7045~ 54935

HSPF 9.9 9.3 9.5 9.9 10.2

COP (47° F) W/W 3.7 3.9 3.7 3.7 3.5

COP (17° F) W/W 2.7 2.6 2.7 2.7 2.7

COP (5° F) W/W 2.1 2.0 2.0 1.8 1.9

Energy Star NO YES NO NO NO

Cooling System Tons 1.5 1.8 2.3 2.9 4.0

Cooling Rated Capacity Btu/h 18,000 22,000 28,000 35,000 48,000

Cooling Cap. Range Min - Max Btu/h 5780~ 19476 7650~ 30400 8030~ 38510 8460~ 40250 8460~ 52000

SEER 18.4 19 19.5 17 17.6

EER 11.8 12.5 11.5 10.8 10.1

Heating Rated Capacity (47° F) Btu/h 18,500 21,000 28,000 36,000 50,000

Heating Rated Capacity (17° F) Btu/h 11,400 12,200 17,200 24,400 33,000

Heating Maximum Capacity (5° F) Btu/h 14,400 21,000 28,000 35,000 36,800

Heating Cap. Range Min - Max Btu/h 5539~ 24249 5950~ 36200 6200~ 42660 6880~ 45250 6880~ 54050

HSPF 9.4 8.8 9.0 9.2 10.1

COP (47° F) W/W 3.8 3.8 3.6 3.6 3.4

COP (17° F) W/W 2.7 2.5 2.5 2.5 2.6

COP (5° F) W/W 2.1 2.0 2.0 1.7 1.8

Cooling Outdoor DB Min - Max °F(°C)

Heating Outdoor DB Min - Max °F(°C)

Total Piping Length ft (m) 131(40) 197(60) 263(80) 328(100) 328(100)

Piping to furthest FCU ft (m) 82 (25) 98 (30) 115(35) 115(35) 115 (35)

Drop (OD above ID) ft (m) 49(15) 49(15) 49(15) 65(20) 65(20)

Lift (OD below ID) ft (m) 49(15) 49(15) 49(15) 65(20) 65(20)

Pipe Connection Size - Liquid in (mm)

Pipe Connection Size - Suction in (mm)

Ty pe R410A R410A R410A R410A R410A

Charge lbs (kg) 4.41 (2.0) 6.17(2.8) 6.61 (3.0) 10.13 (4.6) 10.13 (4.6)

Metering Device EEV EEV EEV EEV EEV

Voltage, Phase, Cycle V/Ph/Hz 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

Power Supply Indoor unit powered from outdoor unit

MCA A. 18 25 30 35 35

MOCP - Fuse Rating A. 25 35 45 50 50

Ty pe Rotary Inverter Rotary Inverter Rotary Inverter Rotary Inverter Rotary Inverter

Model ATM150D23UFZ ATF235D22UMT ATF310D43UMT ATQ360D1UMU ATQ360D1UMU

Oil Type ESTER OIL VG74 ESTER OIL VG74 ESTER OIL VG74 ESTER OIL VG74 ESTER OIL VG74

Oil Charge Fl. Oz. 17.64 23.58 35.27 49.38 49.38

Rated Current RLA 10 15 19 21 21

Unit Width in (mm) 37.31 (948) 41.22 (1047) 41.22 (1047) 41.15 (1045) 41.15 (1045)

Unit Height in (mm) 27.64 (702) 31.88 (810) 31.88 (810) 52.48 (1333) 52.48 (1333)

Unit Depth in (mm) 14.82 (376) 17.91 (455) 17.91 (455) 17.63 (448) 17.63 (448)

Net Weight lbs (kg) 105.8 (48) 149.9 (68) 156.5 (71) 221.6 (100.5) 223.8 (101.5)

Airflow CFM 1,390 2,130 2,130 4,500 4,500

Sound Pressure dB(A) 62 63 62 64 64

-13~ 122

(-25~ 50)

-22~ 86

(-30~ 30)

1/4*2

(6.35*2)

3/8*2

(9.52*2)

HEAT PUMP

-13~ 122

(-25~ 50)

-22~ 86

(-30~ 30)

(6.35*3)

(9.52*3)

1/4*3

3/8*3

-13~ 122

(-25~ 50)

-22~ 86

(-30~ 30)

1/4*4

(6.35*4)

1/2 *1+ 3/8*3

(12.7*1+9.52*3)

-13~ 122

(-25~ 50)

-22~ 86

(-30~ 30)

1/4*4

(6.35*4)

1/2 *1+ 3/8*3

(12.7*1+9.52*3)

-13~ 122

(-25~ 50)

-22~ 86

(-30~ 30)

1/4*5

(6.35*5)

1/2 *2+ 3/8*3

(12.7*2+9.52*3)

10

Page 11

COOLING PERFORMANCE NON−DUCTED COMBINATIONS

MODEL

18

24

30

36

48

Indoor Conditions -13F

69.8F

(21C)

75.2F

(24C)

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

80.6F

(27C)

89.6F

(32C)

COOLING OUTDOOR CONDITIONS (DB)

DB WB

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

(-25C)

TC 19.12 19.86 19.66 19.26 18.87 20.69 21.78 19.94 17.92 12.00 11.58 9.89

SC 15.11 15.49 15.34 15.03 14.72 16.14 17.00 15.95 15.23 12.00 11.58 9.89

Input 1.37 1.41 1.48 1.53 1.57 1.60 1.63 1.79 1.96 1.47 1.52 1.32

TC 20.54 21.45 21.23 20.81 20.38 22.35 23.52 21.54 19.35 12.96 12.51 10.13

SC 15.35 15.61 15.29 15.40 15.28 16.98 18.35 17.01 15.87 11.53 11.88 9.93

Input 1.40 1.46 1.53 1.58 1.62 1.65 1.68 1.84 2.01 1.50 1.54 1.35

TC 21.91 22.46 22.18 22.53 22.85 24.15 25.11 23.85 21.54 14.82 14.22 10.40

SC 16.44 16.85 16.64 18.05 17.14 18.11 18.33 17.89 16.16 14.52 14.08 10.40

Input 1.41 1.45 1.51 1.58 1.62 1.65 1.68 1.88 2.05 1.52 1.57 1.36

TC 23.89 24.48 24.18 24.56 24.91 26.32 27.37 26.00 23.48 16.15 15.50 11.34

SC 17.20 17.63 17.65 18.17 18.68 19.22 22.44 21.84 20.19 15.18 14.88 11.11

Input 1.46 1.50 1.56 1.63 1.67 1.72 1.73 1.93 2.14 1.57 1.62 1.41

TC 31.96 32.76 32.58 32.60 32.15 32.75 32.44 26.94 24.46 19.98 17.56 15.45

SC 22.38 22.94 22.81 22.82 22.51 22.93 25.47 22.82 21.70 19.42 17.21 15.45

Input 2.26 2.32 2.31 2.34 2.36 2.38 2.41 2.26 2.50 2.39 2.58 2.62

TC 34.53 35.39 35.19 35.21 34.72 35.37 35.04 29.10 26.42 21.58 18.96 16.69

SC 24.17 24.77 24.63 24.65 24.31 24.76 26.28 23.86 22.72 19.42 18.02 16.52

Input 2.30 2.36 2.35 2.38 2.40 2.42 2.45 2.30 2.54 2.43 2.60 2.66

TC 36.25 37.15 37.24 37.08 37.51 37.68 37.53 35.39 32.75 24.71 23.96 20.15

SC 25.38 26.01 26.07 25.96 26.26 26.38 26.95 26.08 25.06 22.09 23.84 20.05

Input 2.20 2.25 2.28 2.34 2.35 2.41 2.47 2.75 3.04 2.48 2.62 2.74

TC 38.78 39.75 39.85 39.68 40.14 40.32 40.16 37.87 35.04 26.44 25.64 21.56

SC 27.15 27.83 27.89 27.77 28.09 30.64 32.93 32.19 31.19 24.32 24.61 21.56

Input 2.26 2.32 2.35 2.38 2.42 2.48 2.54 2.82 3.11 2.55 2.69 2.81

TC 39.15 40.12 40.28 39.54 39.18 40.81 39.79 37.98 36.16 28.21 26.56 23.46

SC 27.40 28.08 28.20 27.68 27.43 30.61 31.57 30.73 29.86 26.40 26.18 23.12

Input 3.08 3.16 3.18 3.12 3.21 3.24 3.28 3.62 3.99 3.13 3.25 2.66

TC 40.32 41.32 41.49 40.73 40.36 42.03 41.38 41.02 39.05 30.47 28.68 25.34

SC 28.23 28.93 29.04 28.51 28.25 31.53 33.93 36.10 35.15 28.03 27.25 24.83

Input 3.13 3.21 3.23 3.17 3.26 3.29 3.33 3.67 4.04 3.18 3.30 2.71

TC 41.13 42.15 42.51 42.61 42.10 42.61 42.41 40.63 38.82 32.17 30.47 27.53

SC 28.79 29.51 29.76 29.83 29.47 31.96 32.30 31.45 30.57 28.30 30.18 27.25

Input 3.13 3.21 3.25 3.29 3.31 3.38 3.42 3.67 4.05 3.21 3.31 2.76

TC 44.41 45.52 45.91 46.02 45.47 46.02 45.80 43.88 41.93 34.74 32.91 29.73

SC 31.10 31.87 32.14 32.21 31.83 34.51 37.56 38.61 37.73 31.96 31.26 29.73

Input 3.19 3.27 3.31 3.35 3.37 3.44 3.48 3.73 4.11 3.27 3.37 2.82

TC 37.82 38.76 38.32 39.02 39.41 40.44 40.91 36.89 33.97 27.85 25.60 23.33

SC 26.47 27.13 26.82 27.31 28.38 30.33 31.91 30.25 28.88 24.50 23.55 22.40

Input 2.69 2.76 2.83 2.87 2.91 2.98 3.03 3.39 3.79 3.68 3.76 3.41

TC 38.96 39.93 39.47 40.19 40.59 41.65 42.54 39.84 36.69 30.07 27.65 25.20

SC 27.27 27.95 27.63 28.13 28.42 31.24 34.88 35.06 33.02 27.67 26.26 24.69

Input 2.74 2.81 2.88 2.92 2.96 3.03 3.08 3.44 3.84 3.73 3.81 3.46

TC 42.58 43.64 43.31 44.15 44.54 45.02 45.94 43.73 41.49 34.44 31.93 27.16

SC 29.81 30.55 30.32 30.91 31.18 33.77 35.83 34.99 35.26 31.00 30.33 26.62

Input 2.79 2.86 2.89 2.91 2.95 3.06 3.10 3.48 3.91 3.80 3.85 3.47

TC 45.98 47.13 46.78 47.68 48.10 48.63 49.61 47.23 44.80 37.20 34.48 29.34

SC 32.19 32.99 32.74 33.38 33.67 36.47 40.68 41.56 40.32 34.22 32.76 29.34

Input 2.85 2.92 2.95 2.97 3.01 3.12 3.16 3.54 3.97 3.86 3.91 3.53

TC 41.22 42.25 42.51 41.87 41.24 41.97 41.47 39.32 36.26 32.97 29.86 26.54

SC 28.86 29.58 29.76 29.31 28.87 30.64 37.24 36.86 35.53 32.97 29.86 26.54

Input 2.19 2.24 2.28 2.35 2.38 2.41 2.46 2.78 3.11 3.45 3.64 3.08

TC 44.52 45.63 45.91 45.22 44.54 45.33 44.79 42.47 39.16 35.61 32.25 28.66

SC 32.50 33.31 33.51 33.01 32.51 34.90 37.17 36.10 34.07 32.05 32.25 28.66

Input 2.25 2.31 2.35 2.42 2.45 2.48 2.53 2.85 3.18 3.52 3.71 3.15

TC 53.80 55.14 54.68 55.31 56.15 56.72 60.26 56.82 53.16 40.95 38.57 35.24

SC 40.35 41.36 41.01 42.12 42.11 42.54 46.04 44.49 42.79 37.95 38.57 35.24

Input 2.99 3.06 3.15 3.25 3.29 3.46 3.94 4.36 4.80 3.79 3.98 3.43

TC 56.49 57.90 57.41 58.08 58.96 59.56 63.27 59.66 55.82 43.00 40.50 37.04

SC 41.80 42.84 42.49 42.98 43.63 46.45 52.52 51.31 50.24 40.85 40.50 37.04

Input 3.05 3.13 3.22 3.32 3.36 3.53 4.01 4.43 4.87 3.86 4.05 3.50

-4F

(-20C)0F(-17C)5F(-15C)

17F

(-8C)

47F

(8C)

77F

(25C)

86F

(30C)

95F

(35C)

104F

(40C)

113F

(45C)

122F

(50C)

LEGEND

DB - Dry Bulb

WB - Wet Bulb

TC - Total Net Cooling Capacity (1000 Btu/hour)

SC - Sensible Capacity (1000 Btu/hour)

Input - Total Power (kW)

11

Page 12

HEATING PERFORMANCE NON−DUCTED COMBINATIONS

MODEL

18

24

30

36

48

Indoor Conditions DB

HEATING OUTDOOR CONDITIONS (DB)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

Input 1.67 1.71 1.76 1.80 1.87 1.93 1.95 2.01 1.60 1.66 1.79 1.87

COP 1.36 1.64 1.93 2.04 2.19 2.92 2.92 3.00 3.80 3.83 4.21 4.28

Input 1.70 1.74 1.79 1.83 1.90 1.96 1.98 2.04 1.63 1.69 1.82 1.90

COP 1.31 1.58 1.87 1.98 2.16 2.83 2.84 2.91 3.67 3.70 4.10 4.16

Input 1.41 1.44 1.46 1.47 1.91 1.63 1.68 1.76 1.80 1.88 1.95 1.97

COP 1.15 1.33 1.54 1.62 2.15 2.70 2.78 2.85 3.08 3.05 3.59 3.96

Input 1.44 1.47 1.49 1.50 2.01 1.66 1.71 1.79 1.83 1.91 1.98 2.00

COP 1.19 1.28 1.49 1.57 1.99 2.61 2.69 2.76 2.99 2.97 3.49 3.85

Input 2.93 3.19 3.23 3.45 3.63 2.66 2.79 2.87 2.65 2.78 2.96 2.71

COP 1.41 1.65 1.84 1.93 1.98 2.83 2.74 2.89 3.37 3.40 3.65 4.43

Input 3.00 3.27 3.31 3.53 3.74 2.73 2.86 2.94 2.72 2.89 2.99 2.74

COP 1.36 1.59 1.77 1.86 1.91 2.73 2.64 2.79 3.25 3.23 3.56 4.31

Input 3.07 3.34 3.38 3.61 3.90 2.79 2.92 3.01 2.77 2.96 3.04 3.17

COP 1.32 1.54 1.72 1.81 1.81 2.65 2.56 2.71 3.16 3.09 3.49 3.76

Input 3.14 3.42 3.46 3.70 3.83 2.85 2.99 3.08 2.84 3.01 3.07 3.20

COP 1.29 1.50 1.67 1.76 1.80 2.57 2.49 2.63 3.07 3.00 3.41 3.67

Input 3.39 3.46 3.45 3.62 3.74 3.71 3.73 3.79 3.08 3.12 3.27 3.37

COP 1.61 1.91 2.08 2.17 2.29 2.51 2.52 2.59 3.34 3.48 3.45 3.64

Input 3.42 3.49 3.53 3.75 3.86 3.84 3.86 3.92 3.11 3.15 3.30 3.40

COP 1.58 1.87 2.01 2.07 2.18 2.39 2.40 2.47 3.26 3.40 3.37 3.56

Input 3.51 3.58 3.64 3.76 4.05 3.85 3.90 4.04 3.14 3.18 3.21 3.30

COP 1.39 1.69 1.78 1.87 2.04 2.11 2.11 2.31 3.17 3.33 3.40 3.58

Input 3.64 3.61 3.77 3.79 3.81 3.88 3.93 4.07 3.17 3.21 3.24 3.33

COP 1.25 1.58 1.69 1.84 2.00 2.06 2.07 2.26 3.09 3.24 3.32 3.49

Input 4.91 5.02 5.17 5.20 5.24 5.11 5.13 5.21 4.56 4.73 4.90 4.56

COP 1.42 1.67 1.74 1.89 2.05 2.25 2.28 2.31 2.77 2.84 3.40 4.04

Input 4.97 5.08 5.23 5.26 5.33 5.17 5.19 5.27 4.62 4.79 4.96 4.62

COP 1.39 1.63 1.70 1.85 2.00 2.19 2.22 2.25 2.70 2.76 3.31 3.93

Input 5.04 5.15 5.24 5.27 5.39 5.25 5.27 5.35 4.62 4.96 4.66 4.30

COP 1.34 1.58 1.62 1.77 1.96 2.09 2.10 2.18 2.69 2.74 3.18 3.71

Input 5.09 5.20 5.29 5.32 5.34 5.30 5.32 5.40 4.67 5.01 4.71 4.35

COP 1.30 1.53 1.58 1.72 1.90 2.03 2.04 2.11 2.61 2.66 3.08 3.59

Input 4.96 5.07 5.22 5.25 5.33 5.16 5.18 5.26 4.61 4.78 4.95 4.61

COP 1.42 1.67 1.74 1.89 2.05 2.24 2.27 2.31 2.76 2.83 3.39 4.31

Input 5.07 5.18 5.33 5.37 5.51 5.27 5.29 5.38 4.71 4.89 5.06 4.71

COP 1.37 1.61 1.68 1.83 1.98 2.17 2.19 2.23 2.66 2.73 3.27 4.15

Input 5.10 5.21 5.30 5.33 5.39 5.31 5.33 5.41 4.68 4.63 4.71 5.04

COP 1.34 1.58 1.63 1.77 1.96 2.09 2.10 2.18 2.69 2.98 3.47 3.82

Input 5.15 5.26 5.35 5.38 5.40 5.36 5.38 5.46 4.73 5.07 4.76 5.09

COP 1.30 1.53 1.58 1.72 1.90 2.03 2.04 2.11 2.60 2.66 3.37 3.71

-22F

-13F

(-30C)

(-25C)

TC 7.74 9.54 11.60 12.54 14.40 19.21 19.46 20.59 20.74 21.67 25.82 27.35

TC 7.63 9.40 11.43 12.35 14.01 18.92 19.17 20.28 20.43 21.34 25.43 26.94

TC 5.52 6.54 7.69 8.14 13.99 15.02 15.94 17.13 18.93 19.66 23.96 26.67

TC 5.84 6.44 7.57 8.02 13.65 14.79 15.70 16.87 18.65 19.37 23.60 26.27

TC 14.13 17.95 20.25 22.73 24.45 25.66 26.04 28.31 30.43 32.22 36.92 40.88

TC 13.95 17.73 20.00 22.45 24.35 25.34 25.72 27.96 30.12 31.89 36.37 40.27

TC 13.85 17.59 19.84 22.28 24.17 25.15 25.52 27.74 29.89 31.21 36.22 40.71

TC 13.78 17.50 19.75 22.16 23.55 25.02 25.39 27.60 29.74 30.78 35.68 40.10

TC 18.66 22.54 24.52 26.84 29.23 31.77 32.06 33.46 35.15 37.09 38.47 41.89

TC 18.41 22.23 24.18 26.47 28.74 31.31 31.59 32.97 34.64 36.55 37.89 41.26

TC 16.70 20.65 22.05 24.02 28.22 27.67 28.13 31.86 33.96 36.08 37.21 40.27

TC 15.51 19.42 21.79 23.73 25.99 27.27 27.72 31.38 33.45 35.54 36.65 39.67

TC 23.82 28.67 30.78 33.61 36.66 39.29 39.91 41.15 43.10 45.78 56.86 62.85

TC 23.52 28.29 30.37 33.15 36.15 38.70 39.31 40.53 42.46 45.09 56.01 61.91

TC 23.03 27.69 29.04 31.77 36.08 37.41 37.75 39.77 42.39 46.46 50.54 54.37

TC 22.63 27.20 28.52 31.20 34.64 36.66 36.99 38.97 41.54 45.53 49.53 53.28

TC 23.97 28.85 30.97 33.82 37.29 39.53 40.16 41.41 43.37 46.06 57.21 67.67

TC 23.71 28.52 30.61 33.42 36.84 39.01 39.62 40.85 42.80 45.45 56.46 66.65

TC 23.33 28.05 29.42 32.18 36.34 37.90 38.24 40.29 42.94 47.06 55.83 65.74

TC 22.88 27.50 28.83 31.54 35.02 37.06 37.40 39.40 42.00 46.03 54.71 64.43

-4F

(-20C)0F(-17C)5F(-15C)

17F

(-8C)

19.4F

(-7C)

24.8F

(-4C)

32F

(0C)

39.2F

(4C)

44.6F

(7C)

53.6F

(12C)

LEGEND

DB - Dry Bulb

WB - Wet Bulb

TC - Total Net Heating Capacity (1000 Btu/hour)

Input - Total Power (kW)

COP - W/W

12

Page 13

COOLING PERFORMANCE DUCTED COMBINATIONS

MODEL

69.8F

(21C)

75.2F

(24C)

18

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

24

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

30

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

36

80.6F

(27C)

89.6F

(32C)

69.8F

(21C)

75.2F

(24C)

48

80.6F

(27C)

89.6F

(32C)

COOLING OUTDOOR CONDITIONS (DB)

Indoor Conditions -13F

DB WB

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

59F

(15C)

62.6F

(17C)

66.2F

(19C)

73.4F

(23C)

(-25C)

TC 18.3 18.65 18.43 18.75 18.88 19.12 20.26 18.47 16.53 11.28 10.64 9.86

SC 12.81 13.06 12.90 13.13 13.22 13.38 15.17 14.04 13.10 10.91 10.24 9.73

Input 1.38 1.41 1.43 1.46 1.51 1.54 1.57 1.71 1.87 1.43 1.49 1.54

TC 19.76 20.14 19.90 20.25 20.39 20.65 21.88 19.95 17.85 12.18 11.49 10.13

SC 13.83 14.10 14.33 14.99 15.29 15.69 17.07 15.76 14.64 10.84 10.92 9.93

Input 1.43 1.46 1.48 1.51 1.56 1.59 1.62 1.76 1.92 1.50 1.54 1.35

TC 21.14 21.54 21.61 21.69 21.86 22.06 23.06 21.85 20.53 13.72 11.56 10.61

SC 14.8 15.08 15.13 15.18 15.30 15.44 16.14 15.30 14.67 12.11 11.18 10.49

Input 1.5 1.53 1.55 1.57 1.59 1.60 1.61 1.79 1.97 1.45 1.53 1.58

TC 23.04 23.48 23.55 23.64 23.83 24.05 25.14 23.82 22.38 14.95 12.60 11.56

SC 16.58 16.90 17.20 17.50 17.87 17.55 20.61 20.01 19.24 14.06 12.10 11.33

Input 1.55 1.58 1.60 1.62 1.64 1.72 1.66 1.84 2.14 1.50 1.58 1.63

TC 27.01 27.53 27.42 27.46 27.23 27.56 27.05 25.22 22.79 18.48 16.18 14.26

SC 18.91 19.27 19.19 19.22 19.06 19.29 20.83 19.93 18.92 16.82 15.86 14.16

Input 1.94 1.98 2.01 2.02 2.04 2.05 2.06 2.28 2.51 2.40 2.48 2.56

TC 29.17 29.73 29.61 29.66 29.41 29.76 29.21 27.24 24.61 19.96 17.47 15.40

SC 20.42 20.81 20.73 20.76 20.59 20.84 21.91 22.33 21.17 17.96 16.60 15.25

Input 1.98 2.02 2.05 2.06 2.08 2.09 2.10 2.32 2.55 2.44 2.60 2.60

TC 32.9 33.53 33.43 33.22 33.18 33.42 33.40 31.64 29.45 22.61 20.56 18.47

SC 23.03 23.47 23.40 23.25 23.23 23.39 23.04 22.47 21.50 18.76 20.28 18.38

Input 2.11 2.15 2.20 2.34 3.38 2.42 2.45 2.72 3.03 2.49 2.54 2.63

TC 35.21 35.88 35.77 35.55 35.50 35.76 35.74 33.85 31.51 24.19 22.00 19.76

SC 24.64 25.11 25.04 24.88 24.85 27.18 29.31 28.78 28.05 22.26 21.12 19.76

Input 2.18 2.22 2.27 2.38 3.45 2.49 2.52 2.79 3.10 2.56 2.61 2.70

TC 34.76 35.43 35.18 35.62 36.15 36.20 36.96 35.27 33.22 24.93 22.56 20.15

SC 24.33 24.80 24.63 24.93 25.31 25.34 27.94 27.17 26.27 22.53 21.98 19.49

Input 3.26 3.32 3.41 3.48 3.52 3.60 3.64 3.69 4.04 3.15 3.20 2.86

TC 35.8 36.49 36.24 36.69 37.23 37.29 38.44 38.09 35.88 26.92 24.36 21.76

SC 25.07 25.55 25.36 25.68 26.06 27.96 31.52 33.52 32.29 24.77 23.15 21.33

Input 3.31 3.37 3.46 3.53 3.57 3.65 3.69 3.74 4.09 3.20 3.25 2.91

TC 39.77 40.53 40.42 41.20 41.08 40.62 40.12 38.91 37.11 29.31 27.14 23.53

SC 27.84 28.37 28.29 28.56 28.76 28.43 30.33 27.74 27.09 24.22 26.06 23.06

Input 3.34 3.40 3.49 3.56 3.60 3.68 3.72 3.76 4.14 3.26 3.29 2.79

TC 42.95 43.77 43.65 44.49 44.37 43.87 43.33 42.02 40.08 31.65 29.31 25.41

SC 30.06 30.64 30.56 31.14 31.06 32.90 35.53 36.98 36.07 29.12 27.85 25.41

Input 3.39 3.46 3.55 3.62 3.66 3.74 3.78 3.82 4.20 3.32 3.35 2.85

TC 35.88 36.57 36.15 36.81 37.18 38.15 38.59 34.80 32.05 26.27 24.15 22.01

SC 25.12 25.60 25.31 25.77 26.03 26.71 28.94 26.73 25.64 23.09 24.07 22.01

Input 2.77 2.82 2.89 2.93 2.97 3.04 3.09 3.46 3.87 3.76 3.84 3.48

TC 38.76 39.50 39.04 39.75 40.15 41.20 41.68 37.58 34.61 28.37 26.08 23.77

SC 28.29 28.83 28.50 29.02 29.31 31.73 34.59 31.95 30.11 25.53 26.08 23.77

Input 2.84 2.89 2.96 3.00 3.04 3.11 3.16 3.53 3.94 3.83 3.91 3.55

TC 40.78 41.56 41.25 42.05 42.42 42.88 43.75 41.65 39.51 32.80 30.41 25.87

SC 28.54 29.09 28.88 29.44 29.69 30.02 31.06 29.98 28.45 25.78 30.28 25.87

Input 2.87 2.92 2.95 2.97 3.01 3.12 3.16 3.55 3.99 3.88 3.93 3.54

TC 42.82 43.64 43.31 44.15 44.54 45.02 45.94 43.73 41.49 34.44 31.93 27.19

SC 31.68 32.29 32.05 32.67 32.96 35.12 38.13 37.61 37.34 32.72 31.93 27.19

Input 2.93 2.99 3.02 3.04 3.08 3.19 3.23 3.62 4.06 3.95 4.00 3.61

TC 39.49 40.25 40.41 40.87 40.14 40.97 40.25 38.41 35.24 31.42 27.98 25.48

SC 27.65 28.18 28.29 28.61 28.10 29.91 36.89 35.46 34.61 30.86 27.98 25.48

Input 2.2 2.24 2.28 2.35 2.38 2.41 2.46 2.78 3.11 3.45 3.64 3.08

TC 42.65 43.47 43.64 44.14 43.35 44.25 43.47 41.48 38.06 33.93 30.22 27.52

SC 31.13 31.73 31.86 32.22 31.65 34.07 36.08 35.26 33.11 30.54 30.22 27.52

Input 2.27 2.31 2.35 2.42 2.45 2.48 2.53 2.85 3.18 3.52 3.71 3.15

TC 51.77 52.76 52.93 52.85 52.41 52.56 52.55 49.63 46.29 38.92 36.56 32.12

SC 36.24 36.93 37.05 37.00 36.69 36.79 37.31 36.23 34.72 36.30 35.75 32.12

Input 3.57 3.64 3.69 3.75 3.81 3.86 3.96 4.44 4.94 3.90 4.12 3.68

TC 54.36 55.40 55.58 55.49 55.03 55.19 55.18 52.11 48.60 40.87 38.39 33.76

SC 40.22 40.99 41.13 41.06 40.72 43.05 45.80 44.82 43.74 38.82 38.39 33.76

Input 3.64 3.71 3.76 3.82 3.88 3.93 4.03 4.51 5.01 3.97 4.19 3.75

-4F

(-20C)0F(-17C)5F(-15C)

17F

(-8C)

47F

(8C)

77F

(25C)

86F

(30C)

95F

(35C)

104F

(40C)

113F

(45C)

122F

(50C)

LEGEND

DB - Dry Bulb

WB - Wet Bulb

TC - Total Net Heating Capacity (1000 Btu/hour)

SC - Sensible Capacity (1000 Btu/hour)

Input - Total Power (k/W)

13

Page 14

HEATING PERFORMANCE DUCTED COMBINATIONS

MODEL

18

24

30

36

48

HEATING OUTDOOR CONDITIONS (DB)

Indoor ConditionsDB-22F

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

59F

(15C)

64.4F

(18C)

69F

(20.5C)

71.6F

(22C)

(-30C)

TC 7.25 9.05 11.18 12.58 14.73 16.91 17.12 17.64 18.36 19.67 23.68 25.16

Input 1.65 1.69 1.81 1.83 1.98 1.87 1.88 1.93 1.65 1.76 2.02 1.86

COP 1.29 1.57 1.81 2.01 2.18 2.65 2.67 2.68 3.26 3.28 3.44 3.96

TC 7.14 8.91 11.01 12.39 14.56 16.66 16.86 17.38 18.08 19.37 23.32 24.78

Input 1.68 1.72 1.84 1.86 2.02 1.90 1.91 1.96 1.68 1.79 2.05 1.89

COP 1.24 1.52 1.75 1.95 2.11 2.57 2.59 2.60 3.15 3.17 3.33 3.84

TC 5.31 6.16 7.02 8.13 14.40 13.39 13.48 16.58 17.86 18.05 20.60 20.09

Input 1.46 1.49 1.54 1.55 2.01 1.68 1.71 1.88 1.86 1.94 2.00 1.59

COP 1.07 1.21 1.34 1.54 2.10 2.34 2.31 2.58 2.81 2.73 3.02 3.70

TC 5.23 6.07 6.91 8.01 13.56 13.19 13.28 16.33 17.59 17.78 20.29 19.79

Input 1.49 1.52 1.57 1.58 2.05 1.71 1.74 1.91 1.89 1.97 2.03 1.62

COP 1.03 1.17 1.29 1.49 1.94 2.26 2.24 2.51 2.73 2.65 2.93 3.58

TC 13.95 17.73 20.00 22.45 23.85 25.34 25.72 27.96 30.05 31.82 36.46 40.37

Input 2.97 3.24 3.28 3.50 3.62 2.70 2.83 2.91 2.69 2.82 3.00 2.75

COP 1.38 1.60 1.79 1.88 1.93 2.75 2.66 2.81 3.27 3.31 3.56 4.30

TC 13.78 17.51 19.75 22.17 23.55 25.03 25.40 27.61 29.75 31.49 35.92 39.77

Input 3.05 3.32 3.36 3.59 3.71 2.77 2.90 2.98 2.76 2.93 3.03 2.78

COP 1.33 1.55 1.72 1.81 1.86 2.65 2.57 2.71 3.16 3.15 3.47 4.19

TC 13.68 17.37 19.60 22.00 23.37 24.83 25.20 27.40 29.52 30.82 35.77 40.21

Input 3.11 3.39 3.43 3.67 3.79 2.83 2.97 3.05 2.82 3.00 3.09 3.22

COP 1.29 1.50 1.67 1.76 1.81 2.57 2.49 2.63 3.07 3.01 3.40 3.66

TC 13.61 17.29 19.50 21.89 23.26 24.71 25.08 27.26 29.37 30.40 35.24 39.60

Input 3.19 3.47 3.51 3.75 3.88 2.89 3.03 3.12 2.88 3.06 3.12 3.25

COP 1.25 1.46 1.63 1.71 1.76 2.50 2.42 2.56 2.99 2.92 3.31 3.57

TC 18.43 22.26 24.22 26.51 27.98 31.38 31.66 33.05 34.71 36.63 37.99 41.37

Input 3.44 3.51 3.50 3.67 3.68 3.77 3.79 3.85 3.13 3.17 3.32 3.42

COP 1.57 1.86 2.03 2.11 2.23 2.44 2.45 2.52 3.25 3.39 3.35 3.54

TC 18.18 21.95 23.88 26.14 27.59 30.92 31.20 32.56 34.21 36.10 37.42 40.75

Input 3.47 3.54 3.58 3.81 3.82 3.90 3.92 3.98 3.16 3.20 3.35 3.45

COP 1.54 1.82 1.95 2.01 2.12 2.33 2.33 2.40 3.18 3.31 3.27 3.46

TC 16.49 20.39 21.78 23.72 25.98 27.33 27.78 31.46 33.54 35.63 36.75 39.77

Input 3.56 3.63 3.69 3.82 3.84 3.91 3.96 4.10 3.19 3.23 3.26 3.35

COP 1.36 1.64 1.73 1.82 1.98 2.05 2.06 2.25 3.08 3.24 3.31 3.48

TC 15.32 19.18 21.52 23.44 25.67 26.93 27.38 30.99 33.04 35.10 36.20 39.18

Input 3.69 3.66 3.83 3.85 3.87 3.94 3.99 4.13 3.22 3.26 3.29 3.38

COP 1.22 1.53 1.65 1.79 1.95 2.00 2.01 2.20 3.01 3.16 3.23 3.40

TC 23.05 27.74 29.78 32.52 35.47 38.02 38.62 39.82 41.70 44.30 55.02 60.81

Input 4.98 5.10 5.25 5.28 5.31 5.19 5.21 5.29 4.63 4.80 4.97 4.63

COP 1.36 1.60 1.66 1.81 1.96 2.15 2.17 2.21 2.64 2.70 3.24 3.85

TC 22.76 27.38 29.39 32.08 35.29 37.45 38.04 39.22 41.09 43.64 54.21 59.92

Input 5.04 5.16 5.31 5.34 5.37 5.25 5.27 5.35 4.69 4.86 5.03 4.69

COP 1.32 1.56 1.62 1.76 1.93 2.09 2.12 2.15 2.57 2.63 3.16 3.74

TC 22.29 26.80 28.10 30.75 35.14 36.21 36.53 38.49 41.03 44.96 48.91 52.62

Input 5.12 5.23 5.32 5.35 5.37 5.33 5.35 5.43 4.69 5.03 4.73 4.36

COP 1.28 1.50 1.55 1.68 1.92 1.99 2.00 2.08 2.56 2.62 3.03 3.53

TC 21.90 26.32 27.60 30.20 34.52 35.48 35.80 37.72 40.20 44.06 47.94 51.56

Input 5.17 5.28 5.37 5.40 5.42 5.38 5.40 5.48 4.74 5.09 4.78 4.42

COP 1.24 1.46 1.51 1.64 1.87 1.93 1.94 2.02 2.49 2.54 2.94 3.42

TC 23.20 27.92 29.97 32.73 36.70 38.26 38.86 40.07 41.97 44.58 55.37 65.49

Input 5.03 5.15 5.30 5.33 5.36 5.24 5.26 5.34 4.67 4.85 5.02 4.67

COP 1.35 1.59 1.66 1.80 2.01 2.14 2.17 2.20 2.63 2.69 3.23 4.11

TC 22.94 27.60 29.63 32.34 36.27 37.75 38.35 39.54 41.42 43.99 54.64 64.50

Input 5.15 5.26 5.41 5.45 5.48 5.35 5.37 5.46 4.78 4.96 5.14 4.78

COP 1.31 1.54 1.60 1.74 1.94 2.07 2.09 2.12 2.54 2.60 3.12 3.95

TC 22.58 27.15 28.47 31.15 36.13 36.68 37.01 38.99 41.56 45.55 54.03 63.62

Input 5.18 5.29 5.38 5.41 5.50 5.39 5.41 5.50 4.75 4.70 4.78 5.12

COP 1.28 1.50 1.55 1.69 1.93 1.99 2.00 2.08 2.57 2.84 3.31 3.65

TC 22.14 26.61 27.91 30.53 35.09 35.87 36.19 38.13 40.64 44.55 52.95 62.36

Input 5.23 5.34 5.43 5.46 5.52 5.44 5.46 5.55 4.80 5.15 4.83 5.17

COP 1.24 1.46 1.51 1.64 1.86 1.93 1.94 2.01 2.48 2.54 3.21 3.54

-13F

(-25C)

-4F

(-20C)0F(-17C)5F(-15C)

17F

(-8C)

19.4F

(-7C)

24.8F

(-4C)

32F

(0C)

39.2F

(4C)

44.6F

(7C)

53.6F

(12C)

LEGEND

DB - Dry Bulb

WB - Wet Bulb

TC - Total Net Heating Capacity (1000 Btu/hour)

Input - Total Power (kW)

COP - (W/W)

14

Page 15

PIPING REQUIREMENTS

SYSTEM SIZE 18K 24K 30K 36K 48K

Min. Piping Length per each indoor unit ft (m) 10 (3) 10 (3) 10 (3) 10 (3) 10 (3)

Piping

Refrigerant

Standard Piping Length per each indoor

unit

Max. outdoor-indoor height difference

(OU higher than IU)

Max. outdoor-indoor height difference

(IU higher than OU)

Max. height different between indoor units ft (m) 32 (10) 32 (10) 32 (10) 32 (10) 32 (10)

Max. Length per each indoor unit ft (m) 82 (25) 98 (30) 115 (35) 115 (35) 115 (35)

Max. Piping Length with no additional

refrigerant charge per System

(Standard Piping length x No. of Zones)

Total Maximum Piping Length per system ft (m) 131 (40) 197 (60) 263 (80) 328 (100) 328 (100)

Additional refrigerant charge

(between Standard – Max piping length)

Suction Pipe Size

Liquid Pipe Size

Refrigerant Type R410A R410A R410A R410A R410A

Charge Amount Lbs (kg) 4.41 (2.0) 6.17 (2.8) 6.61 (3.0) 10.14 (4.6) 10.14 (4.6)

ft (m) 25 (7.5) 25 (7.5) 25 (7.5) 25 (7.5) 25 (7.5)

ft (m) 49 (15) 49 (15) 49 (15) 65 (20) 65 (20)

ft (m) 49 (15) 49 (15) 49 (15) 65 (20) 65 (20)

ft (m) 49 (15) 74 (22.5) 98 (30) 123 (37.5) 123 (37.5)

Oz/ft

(g/m)

in

(mm)

in

(mm)

0.16 (15) 0.16 (15) 0.16 (15) 0.16 (15) 0.16 (15)

3/8*2

(9.5*2)

1/4 *2

(6.3*2)

3/8*3

(9.5*3)

1/4 *3

(6.3*3)

1/2*1+3/8*3

(12.7*1+9.5*3)

1/4 *4

(6.3*4)

1/2 *2+3/8*2

(12.7*2+9.5*2)

1/4 *4

(6.3*4)

1/2 *2+3/8*3

(12.7*2+9.5*3)

1/4 *5

(6.3*5)

NOTE: The refrigerant charge included is adequate for the outdoor unit’s maximum number of zones multiplied by the standard

piping length per zone.

APPLICATION DATA

Unit Selection

When selecting a variable speed system match the system capacity

range to the anticipated load range. Since a variable speed system

can accommodate a wide range of loads it is important to

understand the percentage of time that the system will be required

to run at both the maximum and the minimum load points. This

differential is most evident when a residential application is

compared with a commercial application.

Generally there will be more load diversification in the residential

application (shifting from low load to high load). The commercial

application tends to be more steady during the normal day time

hours, and will go to low load levels after normal business hours. If

it is anticipated that the system needs to run at the maximum load

point for the majority of the time, the next larger system capacity

should be selected.

The Application Data table on the following page is a guideline for

selecting the proper size for the application.

15

Page 16

APPLICATION DATA

Size No. of Zones Cooling Capacity (Btu/h) Heating Capacity (Btu/h)

18K Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

9+9

9+12 8,500 10,500 9,000 11,000

12+12 9,500 9,500 10,000 10,000

24K Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

9+9

9+12 9,500 12,000 10,000 13,000

9+18 8,400 16,600 9,000 18,000

12+12 12,000 12,000 13,000 13,000

12+18 10,000 15,000 11,200 16,800

18+18 14,000 14,000 15,000 15,000

9+9+9

9+9+12 8,667 8,667 11,667 9,500 9,500 12,000

9+9+18 8,333 8,333 13,333 9,000 9,000 14,000

9+12+12 8,500 10,000 10,000 8,500 11,000 11,000

12+12+12 9,667 9,667 9,667 10,667 10,667 10,667

30K Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

9+9

9+12 9,500 12,000 10,000 13,000

9+18 9,500 17,500 10,000 18,000

9+24 9,000 24,000 10,000 25,000

12+12 12,000 12,000 13,000 13,000

12+18 12,000 18,000 13,000 18,000

12+24 11,000 23,000 12,000 24,000

18+18 16,500 16,500 17,000 17,000

9+9+9

9+9+12 9,000 9,000 12,000 9,500 9,500 12,500

9+9+18 8,000 8,000 16,000 8,500 8,500 17,000

9+12+12 8,500 11,500 11,500 9,000 12,000 12,000

9+12+18 8,000 11,000 15,000 8,500 11,500 16,000

9+18+18 8,000 14,000 14,000 8,500 14,500 14,500

12+12+12 11,333 11,333 11,333 12,000 12,000 12,000

12+12+18 11,000 11,000 14,000 12,000 12,000 15,000

12+18+18 9,333 13,333 13,333 10,000 14,500 14,500

12+12+24 8,000 8,000 20,000 9,000 9,000 21,000

9+9+9+9

9+9+9+12 8,500 8,500 8,500 11,500 9,000 9,000 9,000 12,000

9+9+9+18 8,000 8,000 8,000 14,000 8,500 8,500 8,500 14,000

9+9+12+12 8,000 8,000 10,500 10,500 8,500 8,500 11,000 11,000

9+9+12+18 7,500 7,500 9,000 14,000 8,000 8,000 9,500 14,500

9+12+12+12 7,000 10,000 10,000 10,000 8,000 10,500 10,500 10,500

12+12+12+12 9,500 9,500 9,500 9,500 10,000 10,000 10,000 10,000

36K Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

9+18

9+24 9,500 24,000 10,000 25,000

12+12 12,500 12,500 13,000 13,000

12+18 12,000 18,000 13,000 19,000

12+24 12,000 24,000 10,000 25,000

18+18 18,500 18,500 19,000 19,000

18+24 17,500 22,500 18,000 23,000

24+24 21,000 21,000 22,000 22,000

9+9+9

9+9+12 9,500 9,500 12,000 10,000 10,000 13,000

9+9+18 9,500 9,500 18,000 10,000 10,000 19,000

9+9+24 9,000 9,000 22,500 9,500 9,500 23,500

9+12+12 9,500 12,500 12,500 10,000 10,000 13,000

9+12+18 9,000 12,000 18,000 9,500 9,500 19,000

9+12+24 9,000 12,000 21,500 9,500 12,500 22,000

9+18+18 9,000 18,000 18,000 9,500 18,500 18,500

9+18+24 8,500 15,500 21,000 9,000 16,000 21,500

9+24+24 8,000 20,000 20,000 8,500 21,000 21,000

12+12+12 12,000 12,000 12,000 13,000 13,000 13,000

12+12+18 12,000 12,000 17,000 12,500 12,500 18,000

12+12+24 11,000 11,000 22,000 11,500 11,500 23,000

12+18+18 11,000 16,500 16,500 11,500 17,000 17,000

12+18+24 10,500 15,500 21,500 11,000 16,000 22,000

12+24+24 10,000 20,000 20,000 11,000 20,500 20,500

18+18+18 16,000 16,000 16,000 16,500 16,500 16,500

18+18+24 15,000 15,000 20,000 15,500 15,500 21,000

9+9+9+9

9+9+9+12 9,000 9,000 9,000 12,000 9,500 9,500 9,500 12,500

9+9+9+18 9,000 9,000 9,000 17,000 9,500 9,500 9,500 17,500

9+9+9+24 8,500 8,500 8,500 20,500 9,000 9,000 9,000 21,000

9+9+12+12 9,000 9,000 12,000 12,000 9,500 9,500 13,000 13,000

9+9+12+18 9,000 9,000 11,000 17,000 9,500 9,500 11,500 17,500

9+9+12+24 8,500 8,500 10,500 20,500 9,000 9,000 11,100 21,000

9+9+18+18 8,500 8,500 15,500 15,500 9,000 9,000 16,000 16,000

9+9+18+24 8,000 8,000 14,500 20,000 8,500 8,500 15,000 20,000

9+12+12+12 9,000 12,000 12,000 12,000 9,500 12,500 12,500 12,500

9+12+12+18 9,000 11,000 11,000 16,000 9,500 11,500 11,500 16,500

9+12+12+24 8,500 10,000 10,000 20,000 9,000 10,500 10,500 20,500

9+12+18+18 8,500 10,000 15,000 15,000 9,000 10,500 15,500 15,500

9+18+18+18 8,000 14,000 14,000 14,000 8,500 14,500 14,500 14,500

12+12+12+12 12,000 12,000 12,000 12,000 12,500 12,500 12,500 12,500

12+12+12+18 11,000 11,000 11,000 16,000 11,500 11,500 11,500 16,500

12+12+12+24 10,000 10,000 10,000 20,000 10,500 10,500 10,500 20,500

12+12+18+18 10,000 10,000 15,000 15,000 10,500 10,500 15,500 15,500

2-Zone

2-Zone

3-Zone

2-Zone

3-Zone

4-Zone

2-Zone

3-Zone

4-Zone

9,000 9,000 9,500 9,500

9,500 9,500 10,000 10,000

9,000 9,000 9,000 9,500 9,500 9,500

10,000 10,000 10,500 10,500

9,333 9,333 9,333 9,667 9,667 9,667

9,000 9,000 9,000 9,000 9,500 9,500 9,500 9,500

9,500 18,000 10,000 18,000

9,500 9,500 9,500 11,000 11,000 11,000

9,250 9,250 9,250 9,250 9,500 9,500 9,500 9,500

16

Page 17

APPLICATION DATA (CONTINUED)

Size No. of Zones Cooling Capacity (Btu/h) Heating Capacity (Btu/h)

48K Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

9+18

9+24 9,500 24,000 10,000 25,000

12+12 12,500 12,500 13,000 13,000

12+18 12,000 18,000 13,000 19,000

12+24 12,000 24,000 10,000 25,000

18+18 18,500 18,500 19,000 19,000

18+24 17,500 22,500 18,000 23,000

24+24 21,000 21,000 22,000 22,000

9+9+9

9+9+12 9,500 9,500 12,000 10,000 10,000 13,000

9+9+18 9,500 9,500 18,000 10,000 10,000 19,000

9+9+24 9,000 9,000 22,500 9,500 9,500 23,500

9+12+12 9,500 12,500 12,500 10,000 10,000 13,000

9+12+18 9,000 12,000 18,000 9,500 9,500 19,000

9+12+24 9,000 12,000 21,500 9,500 12,500 22,000

9+18+18 9,000 18,000 18,000 9,500 18,500 18,500

9+18+24 8,500 15,500 21,000 9,000 16,000 21,500

9+24+24 8,000 20,000 20,000 8,500 21,000 21,000

12+12+12 12,000 12,000 12,000 13,000 13,000 13,000

12+12+18 12,000 12,000 17,000 12,500 12,500 18,000

12+12+24 11,000 11,000 22,000 11,500 11,500 23,000

12+18+18 11,000 16,500 16,500 11,500 17,000 17,000

12+18+24 10,500 15,500 21,500 11,000 16,000 22,000

12+24+24 10,000 20,000 20,000 11,000 20,500 20,500

18+18+18 16,000 16,000 16,000 16,500 16,500 16,500

18+18+24 15,000 15,000 20,000 15,500 15,500 21,000

9+9+9+9

9+9+9+12 9,000 9,000 9,000 12,000 9,500 9,500 9,500 12,500

9+9+9+18 9,000 9,000 9,000 17,000 9,500 9,500 9,500 17,500

9+9+9+24 8,500 8,500 8,500 20,500 9,000 9,000 9,000 21,000

9+9+12+12 9,000 9,000 12,000 12,000 9,500 9,500 13,000 13,000

9+9+12+18 9,000 9,000 11,000 17,000 9,500 9,500 11,500 17,500

9+9+12+24 8,500 8,500 10,500 20,500 9,000 9,000 11,100 21,000

9+9+18+18 8,500 8,500 15,500 15,500 9,000 9,000 16,000 16,000

9+9+18+24 8,000 8,000 14,500 20,000 8,500 8,500 15,000 20,000

9+12+12+12 9,000 12,000 12,000 12,000 9,500 12,500 12,500 12,500

9+12+12+18 9,000 11,000 11,000 16,000 9,500 11,500 11,500 16,500

9+12+12+24 8,500 10,000 10,000 20,000 9,000 10,500 10,500 20,500

9+12+18+18 8,500 10,000 15,000 15,000 9,000 10,500 15,500 15,500

9+18+18+18 8,000 14,000 14,000 14,000 8,500 14,500 14,500 14,500

12+12+12+12 12,000 12,000 12,000 12,000 12,500 12,500 12,500 12,500

12+12+12+18 11,000 11,000 11,000 16,000 11,500 11,500 11,500 16,500

12+12+12+24 10,000 10,000 10,000 20,000 10,500 10,500 10,500 20,500

12+12+18+18 10,000 10,000 15,000 15,000 10,500 10,500 15,500 15,500

9+9+9+9+9

9+9+9+9+12 9,000 9,000 9,000 9,000 12,000 9,500 9,500 9,500 9,500 13,000

9+9+9+9+18 8,500 8,500 8,500 8,500 16,000 9,000 9,000 9,000 9,000 16,500

9+9+9+9+24 7,750 7,750 7,750 7,750 19,500 8,000 8,000 8,000 8,000 20,000

9+9+9+12+12 9,000 9,000 9,000 11,500 11,500 9,500 9,500 9,500 12,000 12,000

9+9+9+12+18 8,000 8,000 8,000 11,000 16,000 8,500 8,500 8,500 11,500 16,500

9+9+9+18+18 8,000 8,000 8,000 11,000 16,000 8,500 8,500 8,500 16,500 16,500

9+9+12+12+12 8,500 8,500 11,000 11,000 11,000 9,000 9,000 12,000 12,000 12,000

9+9+12+12+18 8,500 8,500 10,000 10,000 15,000 8,500 8,500 10,500 10,500 15,500

9+12+12+12+12 8,000 11,000 11,000 11,000 11,000 8,500 11,500 11,500 11,500 11,500

9+12+12+12+18 7,500 10,000 10,000 10,000 14,500 8,000 10,500 10,500 10,500 15,000

12+12+12+12+12 10,500 10,500 10,500 10,500 10,500 11,000 11,000 11,000 11,000 11,000

2-Zone

3-Zone

4-Zone

5-Zone

9,500 18,000 10,000 18,000

9,500 9,500 9,500 11,000 11,000 11,000

9,250 9,250 9,250 9,250 9,500 9,500 9,500 9,500

9,000 9,000 9,000 9,000 9,000 9,500 9,500 9,500 9,500 9,500

17

Page 18

Unit Mounting (Outdoor)

Refer to the unit’s installation instructions for further details.

Support – A location which can bear the weight of outdoor unit.

Refer to the Physical Data section for weights, and base

dimensional drawings.

Unit Leveling – For reliable operation, units should be level in all

planes.

Clearances – Minimum clearances, as shown in Fig. 9, must be

provided for airflow. The outdoor units are designed for free−blow

applications. Air inlets and outlets should not be restricted.

Unit location – A location which is convenient to installation and

not exposed to strong wind.

NOTE: Do not install the indoor or outdoor units in a location

with special environmental conditions. For those applications,

contact your sales representative.

System Operating Conditions

OPERATING RANGE (Min / Max °F (°C))

Cooling Heating

Outdoor DB -13 / 122 (-25 / 50) -22 / 86 (-30 / 30)

Metering Devices

The outdoor unit has multiple electronic expansion valves to

manage the refrigerant flow to the different indoor fan coils

connected to that unit.

Refrigerant Lines

General Guidelines:

1. The outdoor units are shipped with a full charge of R−410A

refrigerant. All charges, line sizing, and capacities are based

on runs of 25 ft. (7.6 m). For runs over 25 ft. (7.6m),

consult long−line section on this page for proper charge

adjustments.

2. Refrigerant lines should not be buried in the ground. If it is

necessary to bury the lines, do not bury more than 36 inches

(914 mm). Provide a minimum of 6 inch (152 mm) vertical

rise to the service valves to prevent refrigerant migration.

3. Both lines must be insulated. Use a minimum of ½−inch

(12.7 mm) thick insulation. Closed−cell insulation is

recommended in all long−line applications.

4. Special consideration should be given to isolating the

interconnecting tubing from the building structure. Isolate

the tubing so vibration or noise does not transmit into the

structure.

Long Line Applications:

S No change in line sizing is required.

Unit

Zones

Size

18 2 70.55 (2.0) 49 (15) 0.16 (15) 131 (40)

24 3 98.76 (2.8) 74 (22.5) 0.16 (15) 197 (60)

30 4 105.82 (3.0) 98 (30) 0.16 (15) 263 (80)

36 4 162.26 (4.6) 123 (37.5) 0.16 (15) 328 (100)

48 5 162.26 (4.6) 123 (37.5) 0.16 (15) 328 (100)

Charge

oz. (kg.)

Additional Charge

Required

After ft. (m)

Additional

Charge

oz./ft. (g/m)

Total

Maximum

Piping

Length ft.

(m.)

Drain Connections

Install drains that meet the local sanitation codes.

Wiring

The main power is supplied to the outdoor unit. Four field supplied

connecting cables from the outdoor unit to each of the indoor units

are: L1, L2, Ground, and S for communication between the

outdoor unit and each indoor unit.

Control System

The 38MGR unit is equipped with a microprocessor control to

operate the system and give optimum levels of comfort and

operating efficiency. There are microprocessor boards and

thermistors located in both the indoor and outdoor units. The

thermistors monitor the system operation and control the operating

mode.

Sequence of Operation

NOTE: Simultaneous heating and cooling is not allowed.

The Heating Mode is the priority in the system and controls the

mode of operation for the rest of the indoor units connected to the

same outdoor unit. If any unit in the system is set into Heating

Mode the system switches to Heat. If any unit is setup in

COOLING, while any unit in the system is setup as Heating, the

ones on COOLING would enter in conflict mode and an error

message would appear on the units set as COOLING.

All units must be set in cooling or fan mode for the system to cool.

When a unit is set to COOL, HEAT or the DRY mode, the

electronic expansion valve is first initialized (closed) and then is

opened to a preset position.

Superheat heating for each fan coil (the ones that are energized) is

monitored and the position of the electronic expansion valve is

adjusted to ensure that each fan coil gets the appropriate amount of

refrigerant to maintain the required superheat. In the COOLING

mode, after the set point is satisfied, the electronic expansion valve

remains open for a specified time to ensure the system pressures

equalize. In the HEATING mode, after the set point is satisfied,

the electronic expansion valve remains open to ensure proper oil

flow back and keep low pressure.

When the system is set for COOL, HEAT or DRY mode, the

compressor speed is varied by comparing the indoor air

temperature with the set point and continuously adjusting the

compressor speed (to keep the compressor running as long as

possible) in an effort to maintain the greatest comfort possible.

The indoor fan can run in either the MANUAL or AUTO mode.

When the fan is runs in the AUTO mode, the speed is determined

by comparing the room temperature to the set point.

For High Walls and Floor Consoles Fan Coils, when the set point

is satisfied, the fan speed is reduced. For Cassettes and Ducted Fan

Coils when the set point is satisfied, the fan continues to run. The

Fan Coils are not de−energized.

When the unit goes through the defrost cycle, the indoor fans are

de−energized and the refrigerant is circulated through all the fan

coils (even if they were off or on standby before the defrost cycle)

to maximize the heat transfer surface area available for defrost

operation.

NOTE: Additional Refrigerant Calculation Sum Total Liquid

Pipe ft. (m) Additional Charge Required After ft. (m.) x

Additional Charge oz./ft. (g/m) 0.16 (15).

NOTE: If the calculation results in a negative number, no

additional refrigerant is required.

18

Page 19

AIR FLOW DATA

OUTDOOR MULTI-ZONE

SYSTEM SIZE 18 24 30 36 48

Outdoor (CFM) 1390 2130 2130 2130 3500

SOUND PRESSURE

OUTDOOR MULTI-ZONE

SYSTEM SIZE 18 24 30 36 48

Outdoor Sound Pressure Level DB(A) 62.4 63.4 62.3 63 64

SOUND POWER IN OCTAVE BANDS

Frequency (Hz) 63 125 250 500 1000 2000 4000 8000

2 ZONE 18K

3 ZONE 24K

4 ZONE 30K

4 ZONE 36K

5 ZONE 48K

Cooling dB(A)

Heating dB(A)

Cooling dB(A) 62.0 63.2 58.5 56.0 54.7 49.3 46.3

Heating dB(A) 64.4 65.9 65.4 58.5 57.7 52.7 50.3 52.2

Cooling dB(A) 58.4 60.1 58.3 52.6 51.0 47.6 44.2 38.7

Heating dB(A) 62.1 62.7 61.8 56.4 55.5 51.5 49.8 46.0

Cooling dB(A) 67.9 64.6 58.7 58.3 55.4 50.3 44.7 38.5

Heating dB(A) 65.1 61.8 62.4 59.0 56.7 52.2 45.5 41.6

Cooling dB(A) 68.4 65.8 58.6 58.3 55.5 51.8 45.3 44.2

Heating dB(A) 68.5 62.3 62.4 61.3 59.1 54.0 48.7 44.0

53.9 52.0 55.4 48.9 44.5 40.4 36.3 30.8

57.0 55.8 59.3 52.8 49.5 45.2 41.6 38.6

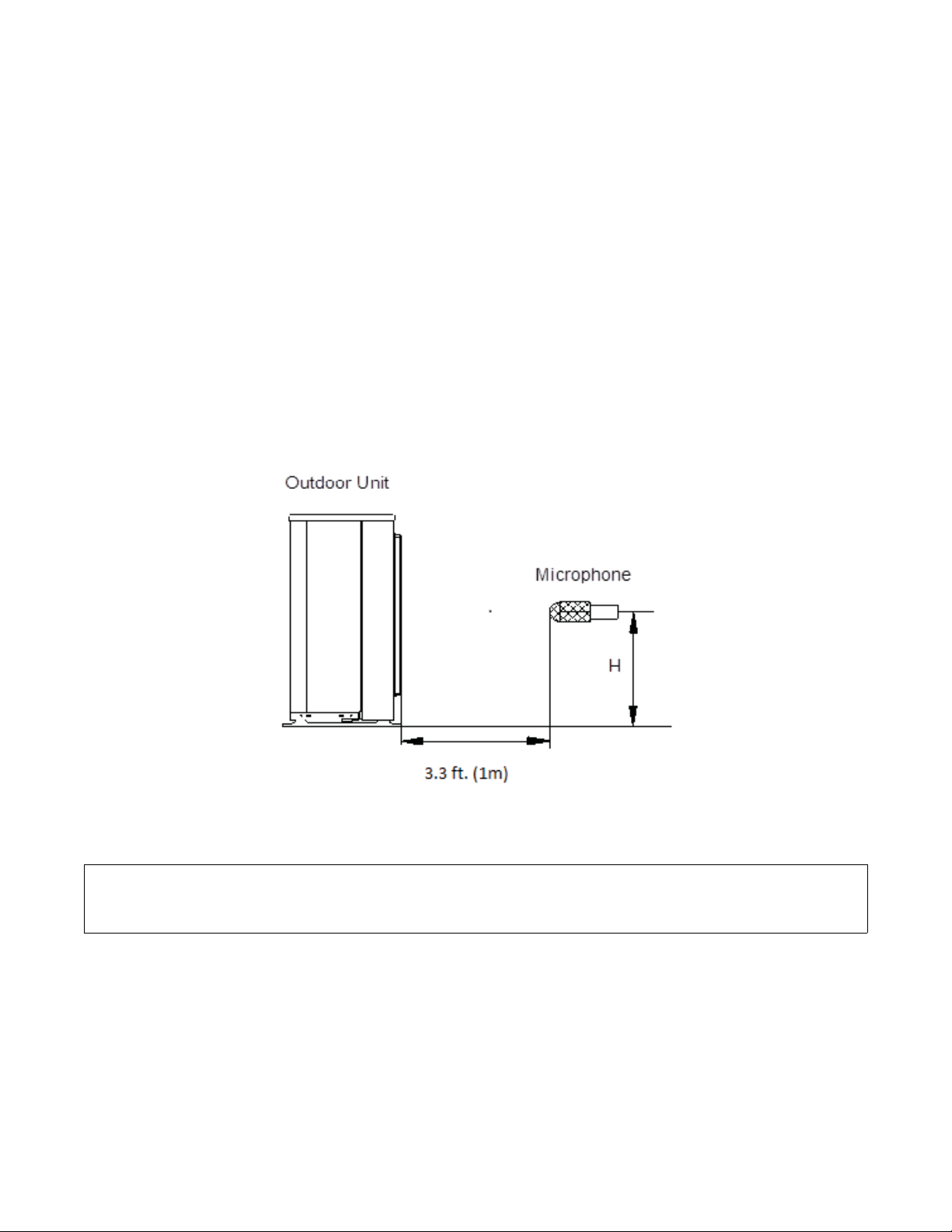

OUTDOOR UNIT SOUND PRESSURE TEST CONDITIONS

41.8

Fig. 10 − Outdoor Unit Sound Pressure Test Conditions

NOTE: H=0.5 x Height of the outdoor unit.

INDOOR CONDITION OUTDOOR CONDITION

DB WB DB WB

Cooling 80.6F (27C) 66.2F (19C) 95F (35C) 75.2F (24C)

Heating 68F (20C) 59F (15C) 44.6F (7C) 42.8F (6C)

19

Page 20

FAN AND MOTOR SPECIFICATIONS

Outdoor

Outdoor

Fan

Motor

18K

(208/230 V)

Material AS AS AS AS AS

Type ZL490*151*12-3KN ZL560*139*12-3KN ZL560*139*12-3KN ZL554*148*12-3KFN ZL554*148*12-3KFN

Diameter inch 490 560 560 554 554

Height inch 151 139 139 148 148

Model ZKFN-50-8-2 ZKFN-120-8-2 ZKFN-120-8-2 ZKFN-85-8-22 ZKFN-85-8-22

Volts V 208/230 208/230 208/230 208/230 208/230

Phase 1 1 1 1 1

Hertz Hz 60 60 60 60 60

FLA 0.74 0.9 1.3 1.0x2 1.0x2

Rated HP HP 0.07 0.16 0.16 0.11 0.11

Output W 50 120 120 85 85

Type DC DC DC DC DC

Insulation

class

Safe class IPX4

Input W 115 156 156 108 108

Range

of current

Rated

current

Capacitor µF No Capacitor

Speed

Rated

RPM

Max. input W 130 173 173 126 126

Amps 0.41±10% 1.34±10% 1.34±10% 0.92±10% 0.92±10%

Amps 0.41 1.34 1.34 0.92 0.92

rev/

min

rev/

min

850~150 1000~150 1000~150 870~300 870~300

800 900 900 800 800

24K

(208/230 V)

30K

(208/230 V)

A

36K

(208/230 V)

ELECTRICAL DATA

UNIT SIZE

18

SYSTEM VOLTAGE OPERATING VOLTAGE COMPRESSOR OUTDOOR FAN

VOLT / PHASE / HZ MAX / MIN* RLA FLA HP W

10 0.74 0.07 50 18 25

24 15 0.9 0.16 120 25 35

30 19 1.3 0.16 120 30 45

208-230/1/60 253 / 187

36 21 1.0x2 0.11 85 35 50

48 21 1.0x2 0.11 85 35 50

MCA

48K

(208/230 V)

MOCP

*Permissible limits of the voltage range at which the unit will operate satisfactorily.

LEGEND

FLA - Full Load Amps

MCA - Minimum Circuit Amps

MOCP - Maximum Over Current Protection

RLA - Rated Load Amps

20

Page 21

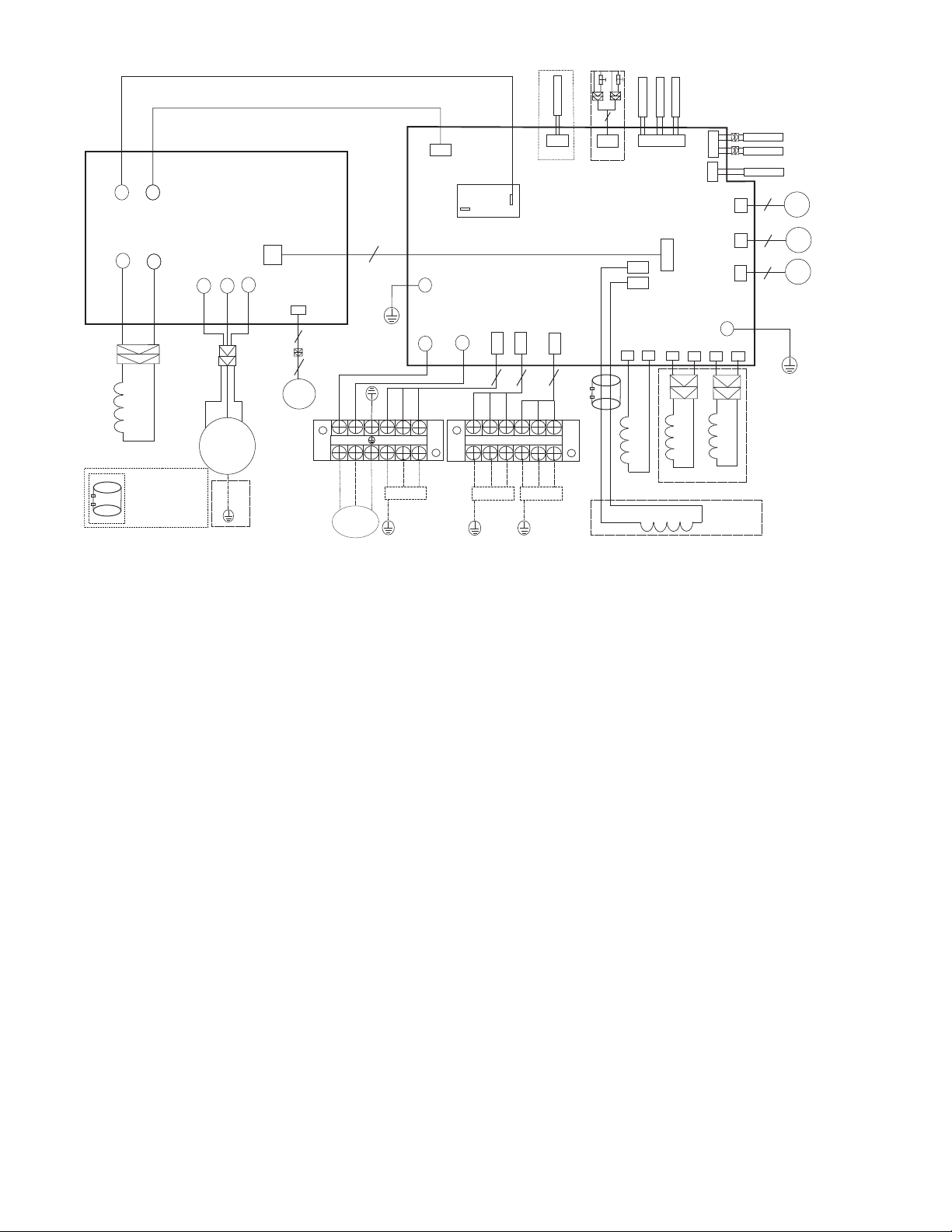

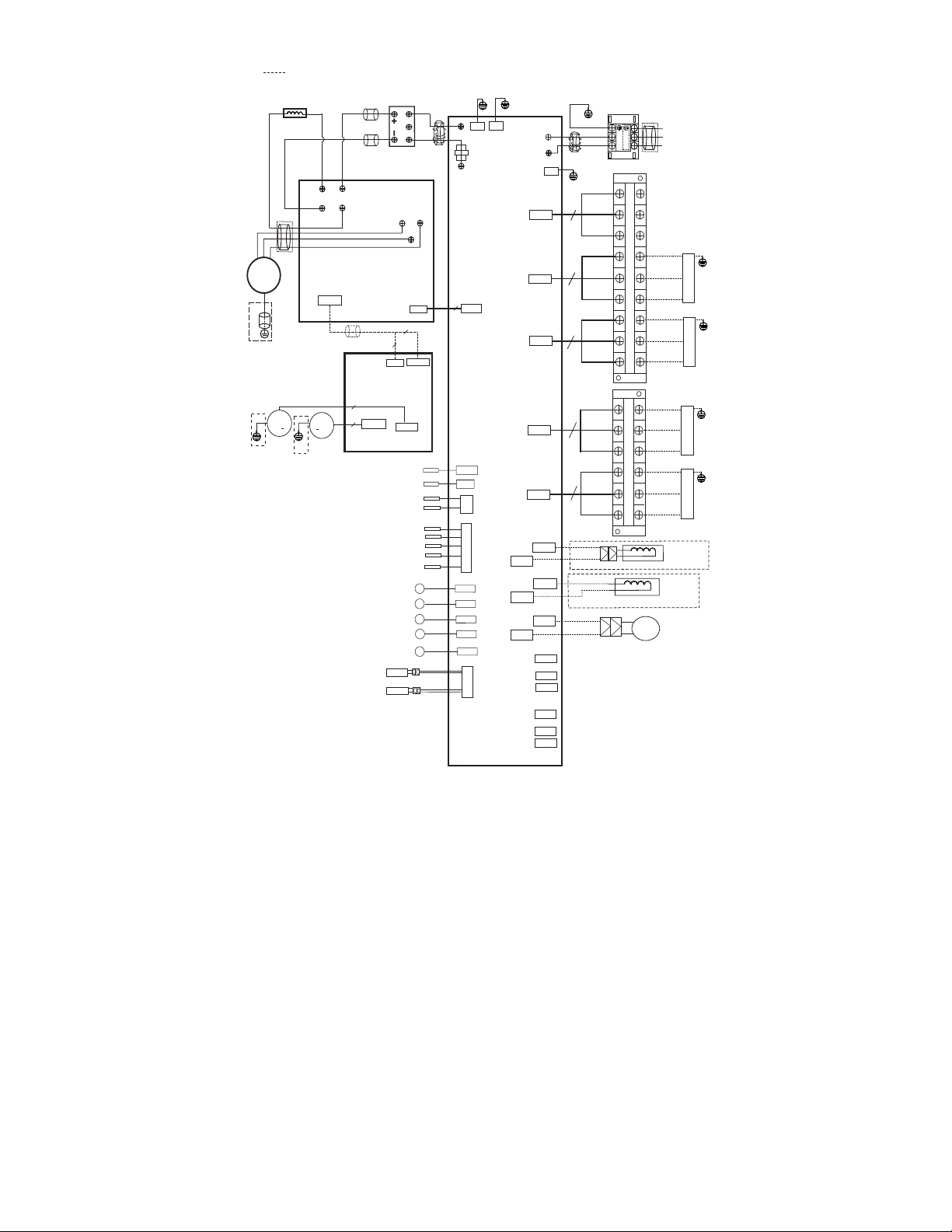

WIRING DIAGRAM

CN4

CN2

BLUE

REACTOR

CN5

~

~

CN3

BLUE

NOTE:Use the magnetic ring

(not supplied, optional part)

to hitch the connective cable

of indoor and outdoor units

after installation. one magnetic

ring is used for one cable.

IPM BOARD

V

U

RED

BLUE

V(S)

U(R)

COMPRESSOR

Y/G

W

W(C)

BLACK

CN1

RED(BROWN)

BLUE

CN14

3

3

DC FAN

CN29

L-OUT

21

&20

5<

BROWN

L2(A)

72$

BLUE

S(A)

L1-IN

CN3

BLACK

L1(B)

P-1

BROWN

L2(B)

TO B

Y/G

L2-IN

CN4

BLUE

S(B)

BLACK

S-B

S-A

CN25

CN23

3

3

L1

RED

BLACK

L2

POWER

6833/<

Y/G

Y/G

L1(A)

Y/G

Fig. 10 − Wiring Diagram 18K − 2 Zone

A

RED

YELLOW

4

LOW PRESSURE PROTECT

HIGH PRESSURE PROTECT

CN12

CompTop

CN14

LOW/HIGH

MAIN BOARD

P1

P2

WHITE

WHITE

4-WAY

CN1

CN2

4-WAY

REACT0R2 R05094A

CN15

T2B

B

INDOOR PIPE

OUT TEMP

CN21

HEAT1

CN6

CN5

HEATER1

OPTIONAL

CN17

CN7

VALVE-B

VALVE-A

P-2

HEAT2

CN9

HEATER2

OPTIONAL

CN8

CN19

CN18

287'225$0%,(17

T4

7(03(5$785(6(1625

&21'(16(5

T3

7(03(5$785(6(1625

',6&+$5*(6(1625

6

6

Y/G

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

OUTDOOR UNIT MAIN BOARD

CODE PART NAME

CN3~CN4 Input: 230VAC High voltage

CN23,CN25 Output: Pin1 (Connection of the high voltage)---“S"Pin2~Pin3 (230VAC High voltage)---“L1 & L2"

P1~P2 Output: Connection of the REACTOR

CN1~CN2 Output: 230VAC High voltage ----4 Way Valve

CN5~CN6 Output: 230VAC High voltage----Compressor Crankcase Heater

CN8~CN9 Output: 230VAC High voltage----Chassis Crankcase Heater

P-1~P-2 Connection to the earth

CN18, CN19 Output: Pin1-Pin4: Pulse waveform (0-12VDC), Pin5, Pin6 (12VDC)--EEV

CN7 Input:Pin1 (0-5VDC), Pin2 (5VDC)--Discharge Sensor

CN17 Input: Pin3, Pin4 (5VDC), Pin2 (0VDC), Pin1, Pin5 (0-5VDC)-Cond. and Ambient Temperature

CN15 Input: Pin1, Pin3, Pin5 (5VDC) Pin2, Pin4, Pin6 (0-5VDC)--IDU Pipe Temp

CN14 Input: Pin2, Pin4 (0VDC), Pin1, Pin3 (0-5VDC)---H/L Pressure Switches

CN12 Input: Pin1 (0-5VDC), Pin2 (5VDC)--Compressor Temp

CN29~L-OUT Output: 230VAC High voltage--to IPM Board

CN 21 Connect to IPM BOARD

OUTDOOR UNIT IPM BOARD

CODE PART NAME

CN4~CN5 Input: 230VAC High voltage---from the Main Board

CN2~CN3 Output: Connection of the REACTOR

U~V~W Connection to compressor voltage among phases 0~200VAC

CN14 Connection to DC FAN

CN1 Connection to MAIN BOARD

21

Page 22

WIRING DIAGRAMS (CONT)

RED(BROWN)

BLUE

CN4

CN2

BLUE

REACTOR

CN5

~

~

CN3

BLUE

NOTE:Use the magnetic ring

(not supplied, optional part)

to hitch the connective cable

of indoor and outdoor units

after installation. one magnetic

ring is used for one cable.

IPM BOARD

CN1

V

U

W

BLACK

RED

BLUE

V(S)

U(R)

W(C)

COMPRESSOR

Y/G

CN14

3

3

DC FAN

RED

L1 L2

6833/<

BLACK

POWER

C

A

B

INDOOR PIPE

CN2

4-WAY

CN15

T2B

CN21

CN6

HEAT1

OUT TEMP

CN5

HEATER1

OPTIONAL

CN17

CN7

VALVE-C

VALVE-B

VALVE-A

P-2

HEAT2

CN9

HEATER2

OPTIONAL

CN8

CN22

CN19

CN18

287'225$0%,(17

T4

7(03(5$785(6(1625

&21'(16(5

T3

7(03(5$785(6(1625

',6&+$5*(6(1625

6

6

6

Y/G

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

ELECTRONIC

EXPANSIVE

VALVE

RED

YELLOW

4

LOW PRESSURE PROTECT

HIGH PRESSURE PROTECT

L-OUT

5<

CN12

CompTop

CN29

21

&20

BROWN

L2(A)

72$

Y/G

BLUE

S(A)

L1-IN

CN3

P-1

BLACK

L2-IN

CN4

BROWN

L1(B)

S-A

BLUE

L2(B)

72%

Y/G

S-B

CN25

CN23

33

BLACK

BROWN

S(B)

L2(C)

L1(C)

72&

Y/G

BLUE

S-C

3

BLACK

S(C)

Y/G

Y/G

L1(A)

CN14

LOW/HIGH

MAIN BOARD

P1

P2

WHITE

WHITE

CN20

4-WAY

CN1

REACT0R2 R05094A

Fig. 11 − Wiring Diagrams 24K − 3 Zone Max

OUTDOOR UNIT MAIN BOARD

CODE PART NAME

CN3~CN4 Input: 230VAC High voltage

CN20,CN23,CN25 Output: Pin1 (Connection of the high voltage)---“S" Signal Pin2~Pin3 (230VAC High voltage)---IDU Power

P1~P2 Output: Connection of the REACTOR

CN1~CN2 Output: 230VAC High voltage---4 way Valve

CN5~CN6 Output: 230VAC High voltage---Compressor Crankcase Heater

CN8~CN9 Output: 230VAC High voltage---Chassis Crankcase Heater

P-1~P-2 Connection to the earth

CN18,CN19,CN22 Output: Pin1-Pin4: Pulse waveform (0-12VDC), Pin5, Pin6 (12VDC)---EEV

CN7 Input: Pin1 (0-5VDC), Pin2 (5VDC) --- Discharge Temp

CN17 Input: Pin3, Pin4 (5VDC), Pin2 (0VDC), Pin1, Pin5 (0-5VDC)-Conditioner and Ambient Temperature

CN15 Input: Pin1, Pin3, Pin5 (5VDC) Pin2, Pin4, Pin6 (0-5VDC) --- IDU Pipe Temp

CN14 Input: Pin2, Pin4 (0VDC), Pin1, Pin3 (0-5VDC) --- H/L Pressure Switch

CN12 Input: Pin1 (0-5VDC), Pin2 (5VDC) --- Compressor Temp

CN29~L-OUT Output: 230VAC High voltage to IPM Board

Cn21 Connect to the IPM BOARD

OUTDOOR UNIT IPM BOARD

CODE PART NAME

CN4~CN5 Input: 230VAC High voltage

CN2~CN3 Output: Connection of the REACTOR

U~V~W Connect to compressor voltage among phases 0~200VAC

CN14 Connect to the DC FAN

CN1 Connect to the MAIN BOARD

22

Page 23

WIRING DIAGRAMS (CONT)

Applicable to the units

adopting DC motor only

3

3

CN19

CN55

CN53

CN52

CN54

DRIVER BOARD

BLUE

BLUE

Y/G

COMP

BLACK

W

RED

V

BLUE

U

U

V

W

CN51

FM1

7

Y/G

OPTIONAL

BLACK

RED

4-WAY1

BLUE

HEAT_Y

HEAT_D

SV

BLUE

7

BLUE

RED

RED

CN43

CN3

CN4

CN10

CN5

CN6

CN1

CN2

BLUE

BLACK

BLACK

L-PRO

CN41

CN42

CN22

CN40

CN44

CN7

CN30

3

H-PRO

T4

CN8

CN9

MAIN BOARD

CN29

3

3

T3

CN28

CN33

TP

A

CN20

CN21

B

C

CN17

D

CN18

E

CN19

T2B-A B C D E

CN13

P-1

CN27

3

5(6)

5(6)

5(6)

5(6)

5(6)

M

M

EEV

M

M

M

TEMP A B C D E

Y/G

INDOOR PIPE OUT

YELLOW

L

YELLOW

RED

L1 L2

POWER

6833/<

BLACK

YELLOW

L1(A)

BLUE

BROWN

L2(A)

TO A

S(A)

BLACK

L1(B)

Y/G

Fig. 12 − Wiring Diagrams 30K − 4 Zone Max

OUTDOOR UNIT MAIN BOARD

CODE PART NAME

CN1~CN2 Input: 230VAC High voltage

CN5~CN6 Output: 230VAC High voltage

P-1 Connection to the earth

CN10~CN44 Output: 230VAC High voltage Chassis Crankcase Heater

CN4~CN40 Output: 230VAC High voltage Compressor Crankcase Heater

CN3~CN22 Output:230VAC High voltage

CN17~CN21 Output: Pin1-Pin4: Pulse waveform (0-12VDC), Pin5, Pin6 (12VDC)

CN7 Output: Pin1 (12VDC), Pin2 (5VDC), Pin3 (EARTH)

CN27~CN30 Output: Pin 2~Pin 3 (230VAC High voltage) - IDU Power & "S"

CN13 Pin1, Pin3, Pin5, Pin7, Pin9 (5VDC ); Pin2, Pin4, Pin6, Pin8, Pin10 (0-5VDC)

CN33 Input: Pin1 (0-5VDC), Pin2 (5VDC) - Discharge Temp

CN8 Input: Pin3, Pin4 (5VDC), Pin2 (0VDC), Pin1, Pin5 (0-5VDC) T3 & T4

CN9 Input: Pin2, Pin4 (0VDC), Pin1, Pin3 (0-5VDC) H/L Pressure Switches

BLUE

BROWN

L2(B)

TO B

S(B)

BLACK

L1(C)

Y/G

BROWN

L2(C)

TO C

BLUE

S(C)

BLACK

L1(D)

Y/G

BLUE

BROWN

L2(D)

TO D

BLACK

S(D)

Y/G

OUTDOOR UNIT PFC & IPM BOARD

CODE PART NAME

CN53~CN54 Input: 230VAC High voltage

CN55 Output: Pin1 (12VDC),Pin2 (5VDC),Pin3 (EARTH)

CN19 Pin1~Pin3: Connect to FAN voltage among phases 0~200VAC

U~V~W Connect to compressor voltage among phases 0~200VAC

CN51~CN52 CN51~EARTH ,CN52~EARTH Output: 224-380VDC High voltage

CODE PART NAME CODE PART NAME

COMP COMPRESSOR L PFC INDUCTOR

CAP1 FAN MOTOR CAPACITOR L-PRO LOW PRESSURE SWITCH

HEAT CRANKCASE HEATING TP EXHAUST TEMPERATURE SENSOR

FM1 OUTDOOR DC FAN SV 4-WAY VALVE

FAN1 OUTDOOR AC FAN T3 CONDENSER TEMPERATURE SENSOR

EEV ELECTRONIC EXPANSION VALVE T4 OUTDOOR AMBIENT TEMPERATURE SENSOR

H-PRO HIGH PRESSURE SWITCH TH HEATSINK TEMPERATURE SENSOR

23

Page 24

WIRING DIAGRAMS (CONT)

b

Notes:

This symbol indicates the element

is optional,the actual shape shall

e prevail.

L

BLACK

YELLOW

CN2

CN6

CH1

Ferrite bead

V

U

W

COMP

Y/G

Ferrite bead

CH2

Y/G

DCFAN2

DCFAN1

Y/G

CH2

D

Ferrite bead

CH2

Ferrite bead

BLUE

RED

BLACK

DC MOTOR

DRIVER BOARD

3

3

FAN 1

PIPE TEMP.SENSOR

AMBIENT SENSOR

INDOOR

PIPE OUT

TEMP

4

5

U

3

CN1

FAN 2

VA LVE E

L-PRO

H-PRO

12

3

2

PAIQI

RED

YELLOW

CN1

CN3

IPM & PFC BOARD

FAN1

Ferrite bead

CH2

ELECTRONIC EXPANSIVE VALVE A

ELECTRONIC EXPANSIVE VALVE B

ELECTRONIC EXPANSIVE VALVE C

ELECTRONIC EXPANSIVE VALVE D

ELECTRONIC EXPANSIVE

BLACK

~

~

RED

~

W

V

CN9

CON1

TH

A

B

C

D

E

RED

RED

RED

RED

RED

RED

YELLOW

P6

CN4

CT1

CN2

MAIN BOARD

10

CN6

CN12

CN8

T3

CN9

T4

T2B

A

B

C

D

CN11

E

CN15

A

CN23

B

CN26

C

CN30

D

CN33

E

CN10

XT1

XT2

L2

L1

XT3

SV

N

L

S(E)

L2(E)

L1(E)

S(D)

L2(D)

L1(D)

S(C)

L2(C)

L1(C)

S(B)

L2(B)

L1(B)

S(A)

L2(A)

L1(A)

Ferrite bead

OPTIONAL

4-WAY

MAIN

POWER SUPPLY

OPTIONAL

HEAT_D

HEAT_Y

TO D

TO C

TO B

TO A

CN1

E

CN13

D

C

CN21

B

A

CN20

CN25

CN18

CN28

CN31

CN36

CN32

CN27

CN34

Y/G

BLACK

WIHTE

/RED

P9

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

RED

ORANGE

ORANGE

BLUE

BLUE

P5

CN3

CN16

CN29

CN37

CN19

CN24

CN17

Fig. 13 − Wiring Diagrams 36K − 4 Zone Max

OUTDOOR UNIT MAIN BOARD

CODE PART NA M E

CN1~ CN3 Input: 230VAC High voltage

CN13, CN16, CN21, CN29, CN37 Output: Pin1(Connection of the high voltage) “S" Pin2~ Pin3 (230VAC High voltage)“L1&L2"

P5, P6, P9 Connection to the earth

CN22 Output:-24VDC-24VDC

CN17~ CN18 Output: 230VAC High voltage to 4 way valve

CN19~ CN20 Output: 230VAC High voltage Compressor Crankcase Heater

CN24~ CN25 Output: 230VAC High voltage Chassis Crankcase Heater

CN11 Input: Pin1, Pin3, Pin5, Pin7, Pin9 (5VDC) Pin2, Pin4, Pin6, Pin8, Pin10 (0-5VDC) indoor pipe out sensor

CN12 Input: Pin1 (0-5VDC), Pin2 (5VDC) Heatsink Temperature Sensor

CN8 Input: Pin1 (0-5VDC), Pin2 (5VDC) Compressor top sensor(PAIQI)

CN9 Input: Pin3, Pin4 (5VDC), Pin2 (0VDC), Pin1, Pin5 (0-5VDC) Pipe sensor and ambient sensor

CN15, CN23, CN26 CN30, CN33 Output: Pin1-Pin4: Pulse waveform (0-12VDC), Pin5, Pin6 (12VDC) to EEV

CN6

Communication: Pin1-Pin6: Pulse waveform (0-5VDC), Pin7, Pin9 (0VDC) Pin8 (0-5VDC), Pin10

(5VDC)--to IPM & PFC board

CN2~ CN4 Output: 230VAC High voltage to IPM & PFC Board

CN10 Input: Pin2, Pin4 (0VDC), Pin1, Pin3 (0-5VDC)--H/L Pressure switch

24

Page 25

OUTDOOR UNIT PFC and IPM BOARD

CODE PART NAME

CN1~CN6 Output: 224-380VDC High voltage

CN2~CN6 Output: 224-380VDC High voltage

CN3~CN6 Output: 224-380VDC High voltage

U~V~W Connect to compressor voltage among phases 0~200VAC

CN9

FAN1

CODE PART NAME

CON1 Output: Pin1~Pin2:High voltage (224-380VDC)

CN1 Input:Pin4: Pulse waveform (0-15VDC), Pin3 (0-6.5VDC) Pin2 (0VDC), Pin1 (15VDC)

FAN1 Pin1-Pin3: Connect to FAN voltage among phases 0~200VAC

FAN2 Pin1-Pin3: Connect to FAN voltage among phases 0~200VAC

CODE PART NAME

COMP COMPRESSOR

CAP1,CAP2 FAN MOTOR CAPACITOR

CT1 AC CURRENT DETECTOR

D DIODE MODULE

EEV ELECTRONIC EXPANSION VALVE

FM1, FM2 OUTDOOR DC FAN

FAN1, FAN2 OUTDOOR AC FAN

HEAT CRANKCASE HEATING

H-PRO HIGH PRESSURE SWITCH

L PFC INDUCTOR

L-PRO LOW PRESSURE SWITCH

KM AC CONTACTOR

SV 4-WAY VALVE

TP EXHAUST TEMPERATURE SENSOR

T3 CONDENSER TEMPERATURE SENSOR

T4 OUTDOOR AMBIENT TEMPERATURE SENSOR

TH HEATSINK TEMPERATURE SENSOR

PAIQI COMPRESSOR TOP SENSOR(GAS PIPE)

CH1, CH2, CH3 FERRITE BEAD

Communication: Pin1-Pin6: Pulse waveform (0-5VDC), Pin7, Pin9 (0VDC), Pin8 (0-5VDC), Pin10 (5VDC) to the main

board

Output: Pin1~Pin2: High voltage (224-380VDC), Pin4 (0-15VDC) Pin5 (0-5.6VDC), Pin6: Pulse waveform (0-15VDC)

to drive board

OUTDOOR UNIT DC MOTOR DRIVER BOARD

25

Page 26

WIRING DIAGRAMS (CONT)

b

Notes:

This symbol indicates the element

is optional,the actual shape shall

e prevail.

L

BLACK

YELLOW

CN2

CH1

Ferrite bead

V

U

W

COMP

Y/G

Ferrite bead

CH2

Y/G

DCFAN2

Y/G

CH2

Ferrite bead

RED

CH2

Ferrite bead

YELLOW

CN1

CN3

CN6

BLUE

RED

BLACK

IPM & PFC BOARD

FAN1

Ferrite bead

CH2

CN1

DC MOTOR

DRIVER BOARD

3

3

FAN 1

DCFAN1

PIPE TEMP.SENSOR

AMBIENT SENSOR

INDOOR

PIPE OUT

TEMP

ELECTRONIC EXPANSIVE VALVE A

ELECTRONIC EXPANSIVE VALVE B

ELECTRONIC EXPANSIVE VALVE C

ELECTRONIC EXPANSIVE VALVE D

ELECTRONIC EXPANSIVE

VA LV E E

L-PRO

H-PRO

D

4

12

3

5

U

V

2

3

CON1

FAN2

PAIQI

BLACK

~

~

RED

~

W

CN9

TH

A

B

C

D

E

RED

RED

RED

RED

RED

RED

YELLOW

P5

P6

CN4

CT1

CN2

MAIN BOARD

10

CN6

CN12

CN8

T3

CN9

T4

T2B

A

B

C

D

CN11

E

CN15

A

CN23

B

CN26

C

CN30

D

CN33

E

CN10

CN19

CN24

CN17

CN3

CN1

E

CN13

D

CN16

C

CN21

B

CN29

A

CN37

CN20

CN25

CN18

CN28

CN31

CN36

CN32

CN27

CN34

P9

Y/G

BLACK

WIHTE

/RED

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

3

BLUE

BROWN

BLACK

RED

ORANGE

ORANGE

BLUE

BLUE

XT2

XT1

Ferrite bead

N

L2

L

L1

XT3

S(E)

L2(E)

L1(E)

S(D)

L2(D)

L1(D)

S(C)

L2(C)

L1(C)

S(B)

L2(B)

L1(B)

S(A)

L2(A)

L1(A)

4-WAY

SV

MAIN

POWER SUPPLY

OPTIONAL

HEAT_D

HEAT_Y

OPTIONAL

TO E

TO D

TO C

TO B

TO A

Fig. 15 − Wiring Diagrams 48K − 5 Zone Max

OUTDOOR UNIT MAIN BOARD

CODE PART NAME