38HK 18-70

38HQ 18-24

1-6 Nomin

Condensing Units

al Tons.

(50/60 Hz)

Insta

Se

llation,

ervice I

Start-

Instruct

Up

and

tions

SAFETY CONSIDERATIONS

Install and servicing air-conditioning equipment

can be hazardous due to system pressure and

electrical components. Only trained and qualified

service personnel should install or service airconditioning equipment untrained personnel may

perform basic maintenance such as cleaning and

replacing filters. All other operations should be

performed by trained service personnel. When

working on air conditioning equipment, observe

safety precautions in literature, and on tags and

labels attached to unit. Follow all safety codes.

Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have a fire

extinguisher available. Read these instructions

thoroughly. Consult local building codes and

National Electrical Code (NEC) for special

installation requirements.

CONTENTS

Page

SAFETY CONSIDERATIONS …………………...………… .

INSTALLATION …………………………………….…………

Step 1 — Complete Pre-Installation Checks ……………

• UNPACK UNIT……………………………………………….

• INSPECT SHIPMENT……………………………………….

• CONSIDER SYSTEM REQUIREMENTS………………….

Step 2 — Rig and Mount Unit ……………………………

• MOUNTING ON GROUND…………………………………

• MOUNTING ON WALL…………………………………….

• MOUNTING ON ROOF………………………………………

• RIGGING……………………………………………………..

Step 3 — Complete Refrigerant Piping Connections …

• MAKE PIPING SWEAT CONNECTIONS………………….

• PROVIDE SAFETY RELIEF……………………………….

Step 4 — Make Electrical Connections ………………..

• POWER WIRING……………………………………………

• CONTROL CIRCUIT WIRING………………………………

• CONNECTIONS TO DUCT-FREE FAN COIL UNITS……..

Step 5 — Accessory Installation………………………….

START-UP……………………................................................

SERVICE ……………………………………………………

MAINTENANCE …………………………………………..

WIRING DIAGRAMS……………………………………….

TROUBLESHOOTING ……………………………………. .

1

1

1

1

1

1

3

3

3

3

3

3

3

4

4

4

4

4

5

6

6

7

9

12

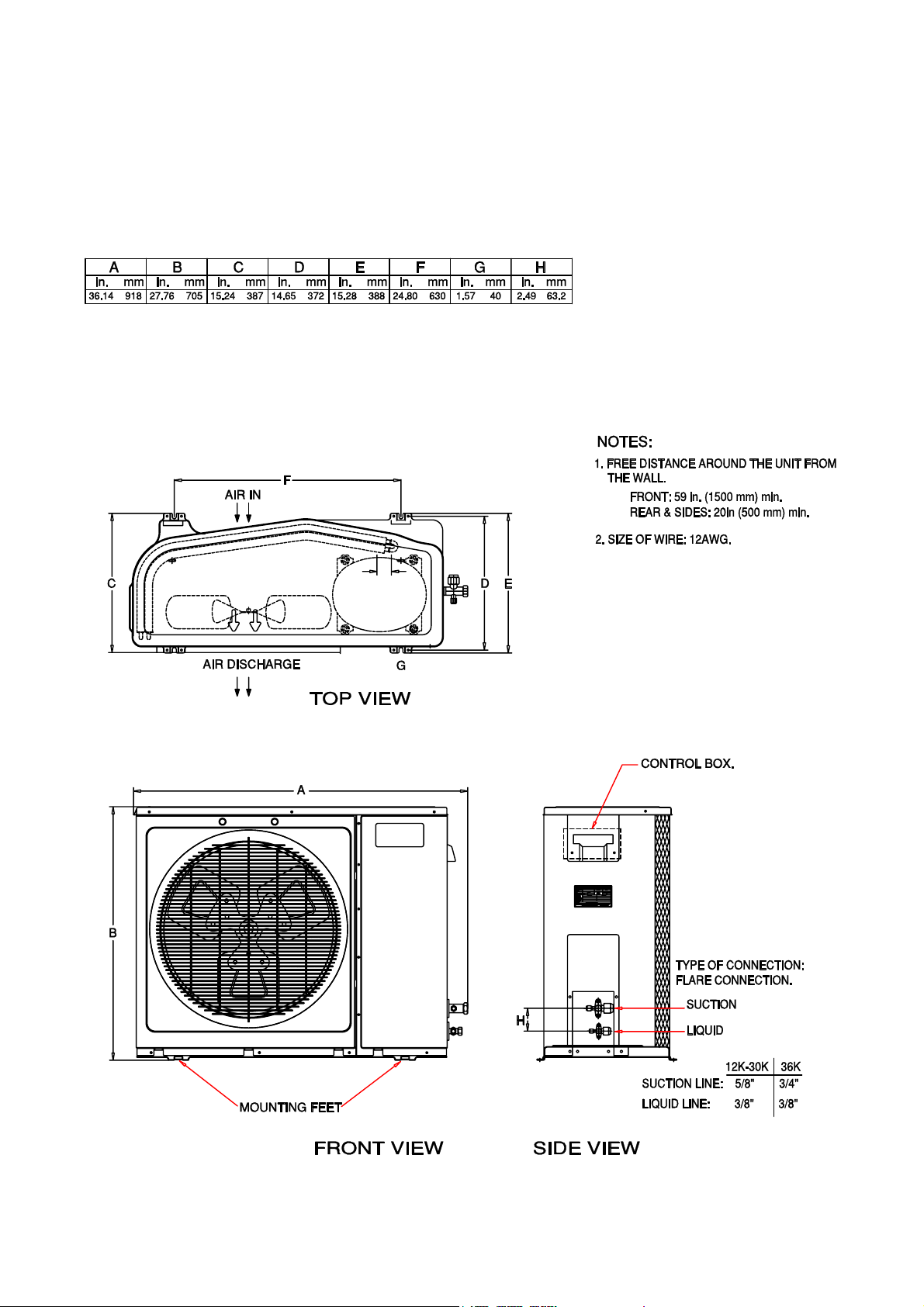

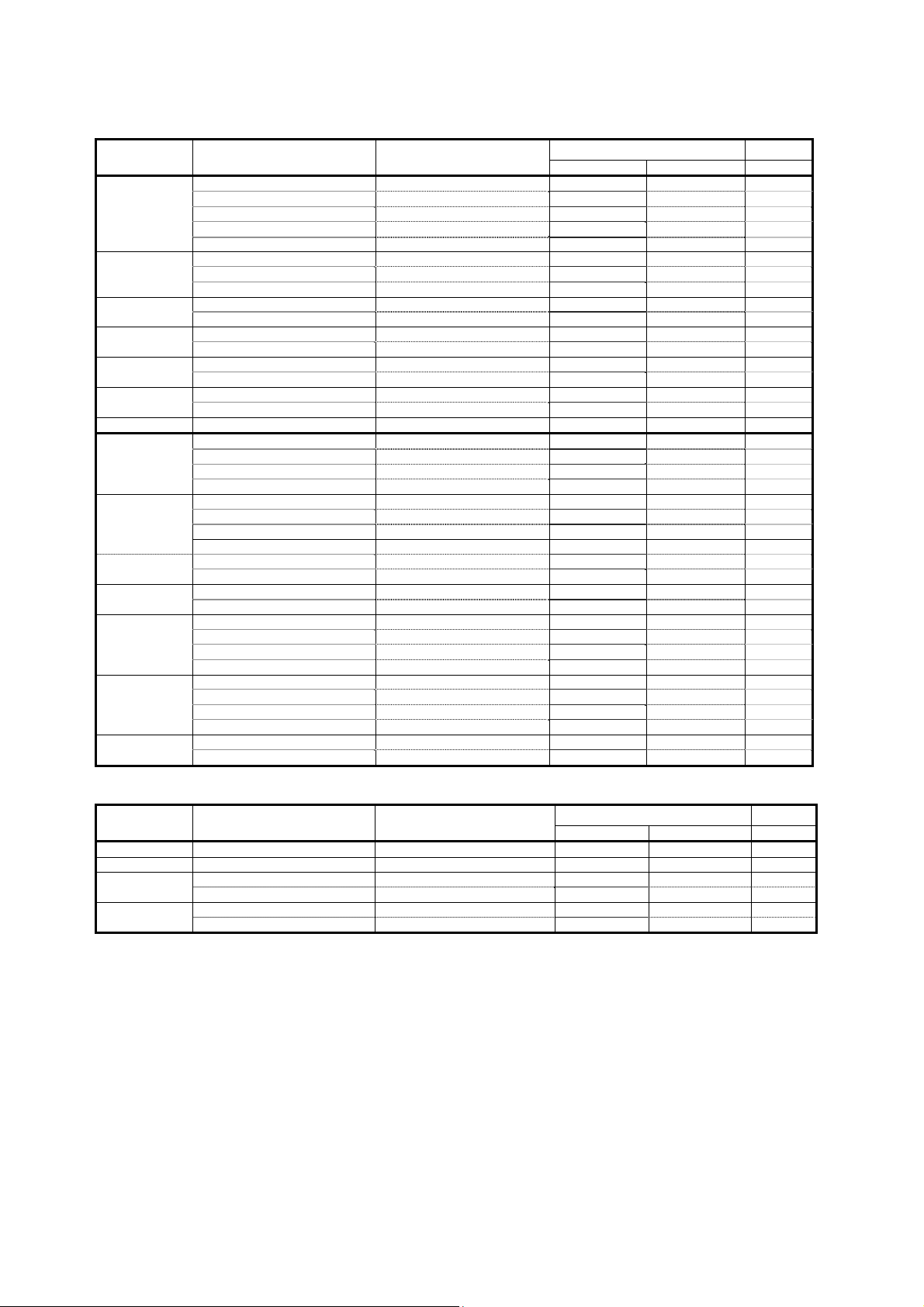

Base Unit Dimensions

38H 01

8-036

6

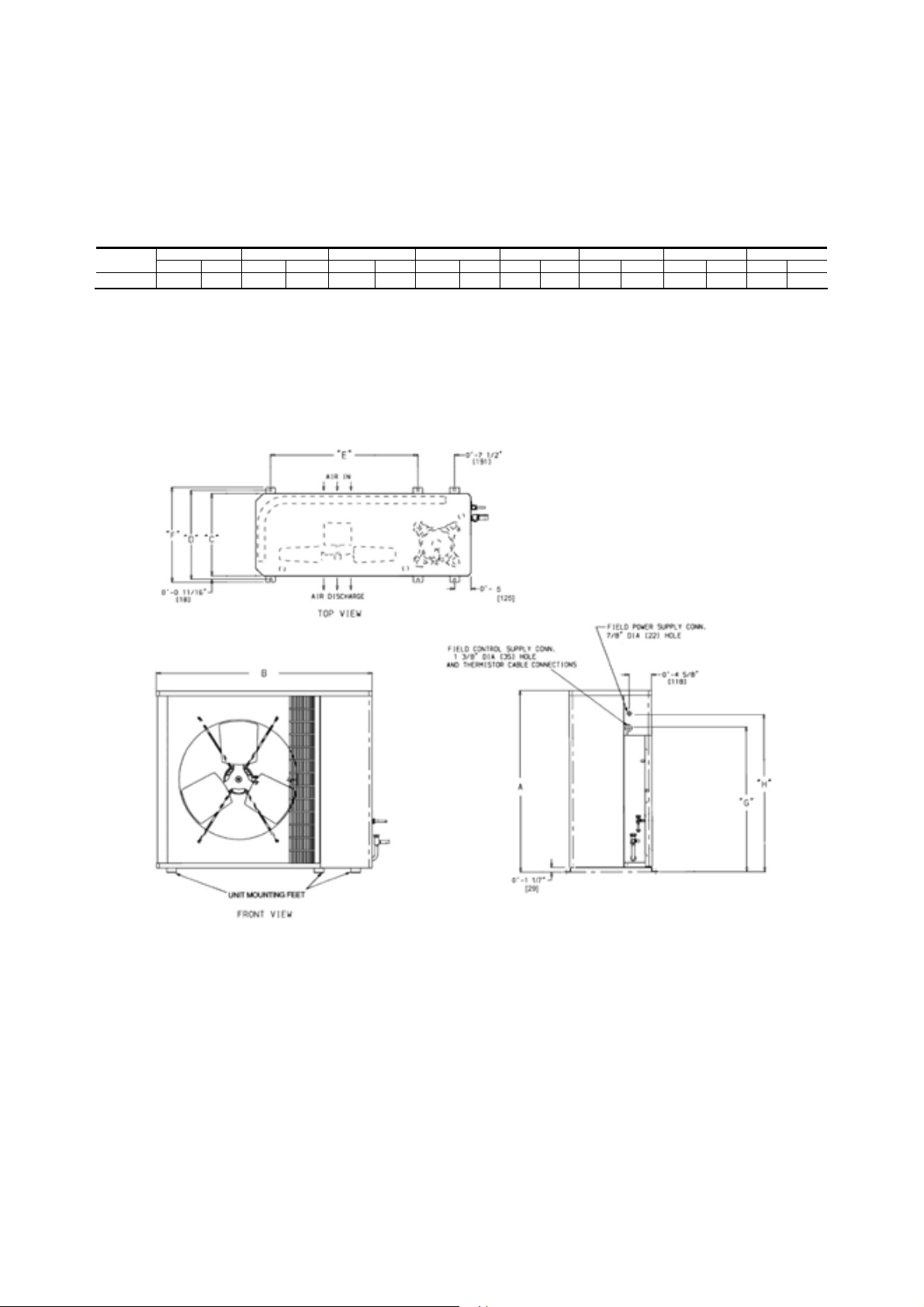

Base Unit Dimensions

38H 048-0

UNIT 38H

048-070

A B C D E F G H

Ft-in. mm Ft-in. mm Ft-in. mm Ft-in. mm Ft-in. mm Ft-in. mm Ft-in. mm Ft-in. mm

3-13⁄16 944.6 3-89⁄16 1131.9 1-51⁄16 433.4 1-67⁄16 468.3 2-61⁄2 774.7 1-75⁄8 498.5 1-75⁄8 498.5 2-55⁄8 752.5

70

NOTES:

1. Required clearances: with coil facing wall

allow 8 in. minimum clearance on coil side and

coil end, and 3 ft minimum clearance on

compressor end and fan side.

2. Dimensions in [ ] are in millimeters.

7

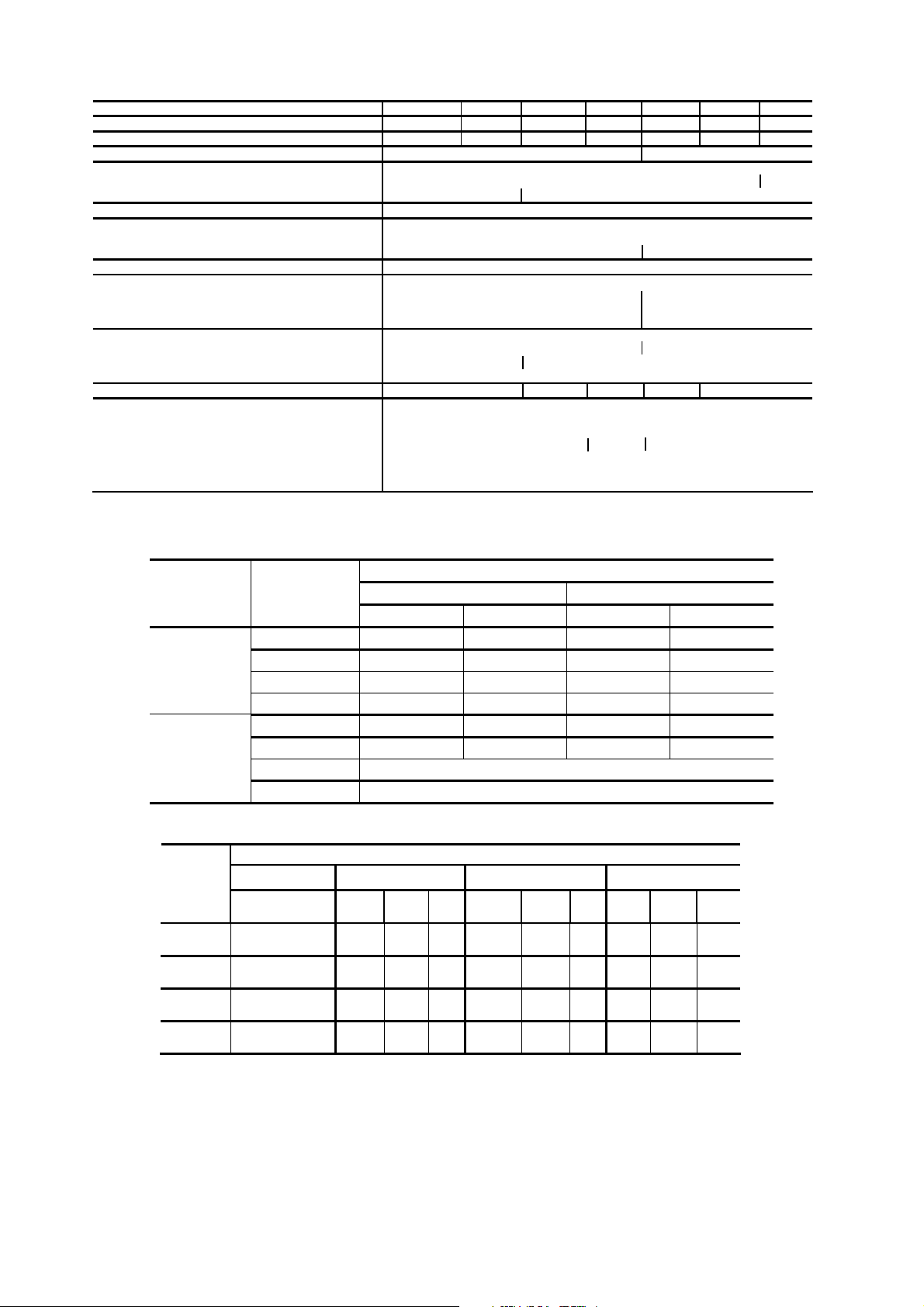

Physical Data

UNIT 38H 18 24 30 36 48 60

NOMINAL CAPACITY (Tons)

OPERATING WEIGHT (lb)

SHIPPING DIMENSIONS (in) (W X H X D)

COMPRESSOR

Heat Pump Rotary --

REFRIGERANT TYPE

METERING DEVICE

Ducted Application Nozzle, in the indoor unit

Un-ducted Application Capillary Tube Nozzle, in the indoor unit

FINISH

OUTDOOR FAN

RPM/CFM 1100/2000 860/3,000

Diameter, No. Blades 18 in, 3 24 in, 3

Motor Horsepower, 1/12 1/3

COIL DATA

Face Area (sq ft) 6.3 12.05

Tubes Smooth Helical grooved

Fins Aluminium, Double Wavy

FPI 15 17 17

REFRIGERANT LINES

Connection Type Flare

Liquid Line 3/8 inch

Vapour Line 5/8 in. 3/4 in. 7/8 inch*

Max Length 50 ft

Max Lift 30 ft

Max Drop 30 ft

* Sweat adapter kit is provided for 7/8” tube size

1.5 2 2.5 3 4.0 5.0

123

139 154 161 211 227

37 x 29.7 x 16.1 50.4 X 40.2 X 30

ReciprocatingCool Only

R22

Gray

Propeller Type

15

12 14

253

Scroll

70

6.0

FREQUENCY INDOOR UNIT

FB4A

60HZ

FREE STAND

42TX

CASSETTE

42TX

50HZ

FB4A

CASSETTE

FREE STAND

COMPRESSOR CHARGE & NOZZLE SIZE

INDOOR

UNIT

MODEL

42TX

FB4A

40GKX

42S/HD-B

VOLTAGE

SIZE 048 060 070 048 060 070 048 060 070

Nozzle Size(in)

Charge (lb)

Nozzle Size(in)

Charge (lb)

Nozzle Size(in)

Charge (lb)

Nozzle Size(in)

Charge (lb)

0.076

10.2 ————

0.084

9.57

0.07

8.73 ————

0.084

10.67

Matching Matrix

38HD

SINGLE PHASE THREE PHASE

SIZE 48 SIZE 60 SIZE 48 SIZE 60

38HD48-3-CF 38HD60-3-CF 38HD48-5-CF 38HD60-5-CF

38HD48-3-CT 38HD60-3-CT 38HD48-5-CT 38HD60-5-CT

38HD48-3-CT — 38HD48-5-CT —

38HD48-3-CT — 38HD48-5-CT —

— — 38HD48-9-CT —

— — 38HD48-9-CF 38HD60-9-CF

TBD

TBD

38HD

208/230-1-60 208/230-3-60 400-3-50

0.088

10.03 ——

0.098

11.86 ——

0.076

10.3

0.084

9.48

0.07

10.75 ——

0.084

10.9

—

—

0.088

9.6 ——

0.098

12.03 ——

——0.076

10.2 ——

0.076

0.088

9.92

9.72 ——

——TBD —

TBD —

—

—

—

—

—

—

—

—

2

LEGEND

- Unit shipped with a holding factory charge of 2.2 lb.

NOTE: Charge based on 25 ft of interconnecting tubing. For longer tube line, add (0.22 lb) for every 10 ft increase in

length.

Electrical Data

COOL ONLY MODELS

Nominal Cap.

MBtuh

18

24

30

36

48

60

70 38HKS70DS90 400/3/50 9.6 82.0 2.3

18

24

30

36

48

60

70

OUTDOOR MODEL Power Supply

38HKC018US70 220-240/1/50 9.7 51.0 1.0

38HKR018US70 220-240/1/50 9.7 51.0 1.0

38HKC018DS70 220-240/1/50 9.7 51.0 1.0

38HKC018US70 220-240/1/50 9.7 51.0 1.0

38HKR018US70 220-240/1/50 9.7 51.0 1.0

38HKC024US70 220-240/1/50 14.0 58.0 1.0

38HKR024US70 220-240/1/50 14.0 58.0 1.0

38HKC024DS70 220-240/1/50 14.0 58.0 1.0

38HKC030US70 220-240/1/50 13.4 85.0 1.0

38HKC030DS70 220-240/1/50 13.4 85.0 1.0

38HKC36US70 220-240/1/50 13.4 85.0 1.0

38HKC36DS70 220-240/1/50 17.0 90.0 1.0

38HKC48US90 400/3/50 6.7 53.0 2.3

38HKC48DS90 400/3/50 6.7 53.0 2.3

38HKC60DS90 400/3/50 9.1 82.0 2.3

38HKC60US90 400/3/50 9.1 82.0 2.3

38HKC018US30 220/1/60 9.6 55.0 0.9

38HKR018US30 220/1/60 9.1 40.0 0.9

38HKC018UP30 220/1/60 9.6 55.0 0.9

38HKC018DS30 220/1/60 9.6 55.0 0.9

38HKC024US30 220/1/60 12.5 60.0 0.9

38HKR024US30 220/1/60 10.1 53.0 0.9

38HKC024UP30 220/1/60 12.5 60.0 0.9

38HKC024DS30 220/1/60 12.5 60.0 0.9

38HKC030US30 220/1/60 13.5 82.0 0.9

38HKC030DS30 220/1/60 13.5 82.0 0.9

38HKC036US30 220/1/60 14.4 88.0 0.9

38HKC036DS30 220/1/60 14.4 88.0 0.9

38HKC048US30 220/1/60 18.5 118.0 2.1

38HKC048US50 220/3/60 11.4 78.0 2.1

38HKC048DS30 220/1/60 18.5 118.0 2.1

38HKC048DS50 220/3/60 11.4 78.0 2.1

38HKC060US30 220/1/60 26.6 178.0 2.1

38HKC060US50 220/3/60 15.0 114.0 2.1

38HKC060DS30 220/1/60 26.6 178.0 2.1

38HKC060DS50 220/3/60 15.0 114.0 2.1

38HKS070DS50 220/3/60 16.0 150.0 2.1

38HKS070DS20 380/3/60 8.3 75.0 2.1

Heat Pump

Nominal Cap.

MBtuh

18 38HQR018US70 220-240/1/50 9.7 51.0 1.0

24 38HQR024US70 220-240/1/50 14.0 58.0 1.0

18

24

OUTDOOR MODEL Power Supply

38HQR018US30 220/1/60 9.1 40.0 0.9

38HQR018UP30 220/1/60 9.1 40.0 0.9

38HQR024US30 220/1/60 10.1 53.0 0.9

38HQR024UP30 220/1/60 10.1 53.0 0.9

Compressor Fan

FLA LRA FLA

Compressor Fan

FLA LRA FLA

3

INSTALLATION

Step 1 — Complete Pre-Installation Checks

UNPACK UNIT—Move unit to final location. Remove

carton from unit, being careful not to damage service

valves or grilles.

INSPECT SHIPMENT — File claim with shipping

company if shipment is damaged or incomplete. Check

unit nameplate to ensure unit matches job requirements.

CONSIDER SYSTEM REQUIREMENTS — Consult

local building codes and NEC for special installation

requirements. Allow sufficient space for airflow

clearance, wiring, refrigerant piping, and servicing unit.

See Fig. 1 and 2. Unit can be mounted on a level pad

directly on base legs or mounted on raised pads at

support points.

WARNING

Before installing or servicing system, always turn off

main power to system.

Step 2 — Rig and Mount Unit

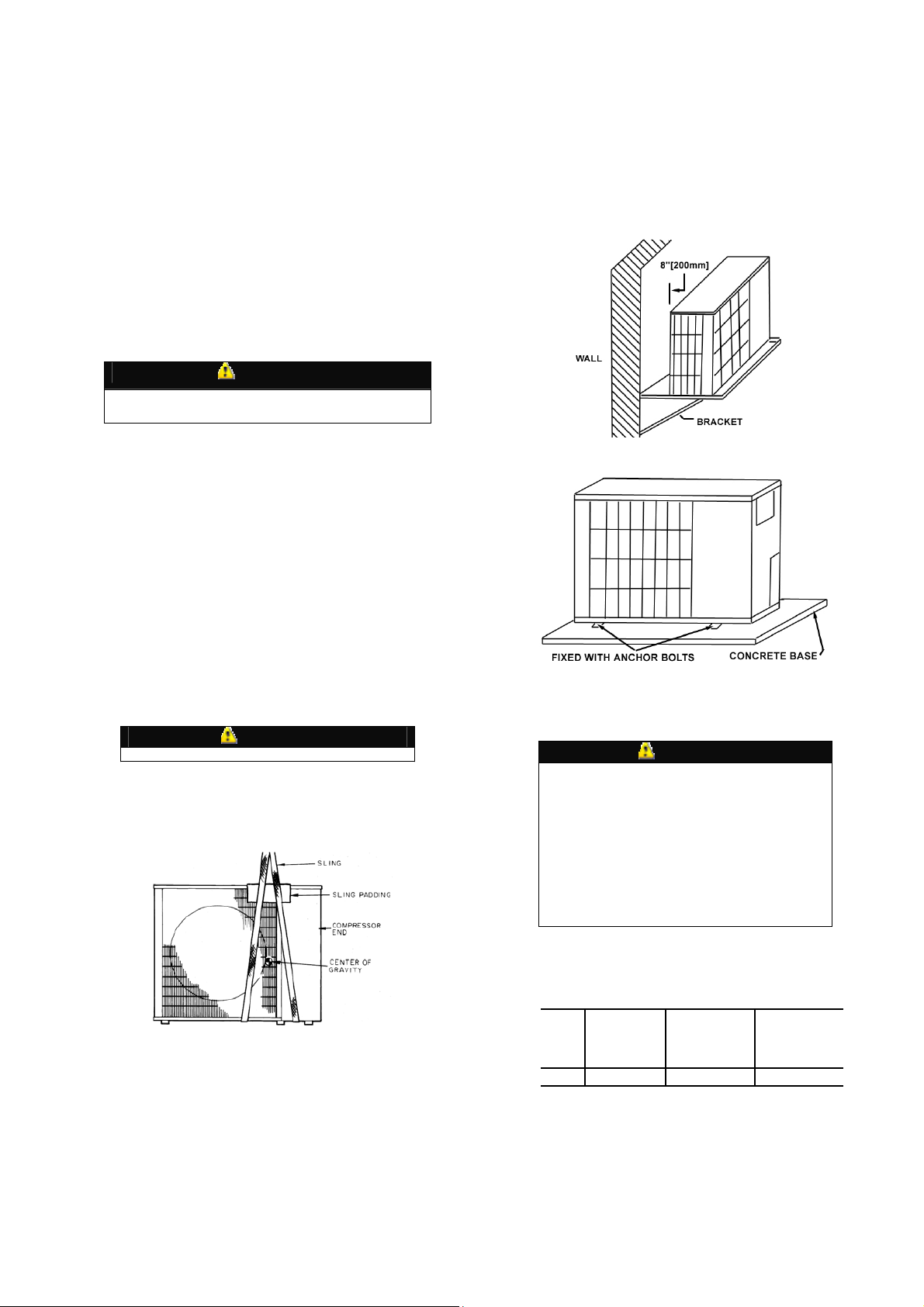

MOUNTING ON GROUND—Mount unit on a

solid, level concrete pad. Position unit so water

from roof does not fall directly into unit.

Accessory stacking kits can be used when units

are to be stacked. If conditions or local codes

require unit to be fastened to a pad, 6 fieldsupplied tiedown bolts should be used and

fastened through slots provided in unit mounting

feet. See Fig. 5 .

around the unit for air flow clearance, wiring,

refrigerant piping and servicing. The unit should

not be installed near to any source of heat, steam

or any flammable gas.

Step 3—Complete Refrigerant Piping

Connections

Outdoor units may be connected to indoor

—

units using field-supplied tubing of refrigerant

Fig.-4 Wall Mounting

MOUNTING ON WALL—See Fig. 4 for wall

mounting.

MOUNTING ON ROOF—Mount unit on level

platform or frame at least 6 in. above roof

surface. Isolate unit and tubing from structure.

RIGGING

CAUTION

All panels must be in place when rigging.

Keep unit upright. Lift unit using sling. Use

cardboard or padding under sling, and spreader

bars to prevent sling damage to unit. See Fig. 3.

Install unit so coil does not face into prevailing

winds.

Fig.-3 lifting unit with sling

MOUNTING POSITION— The unit should be

installed outdoors in a place where air will not

be stagnant. In case of installing more than one

unit, units should be arranged in a way that no

exhausted air will be sucked in as an intake for

another unit. Enough space should be kept

Fig.-5 Ground Mounting

grade and condition. Do not use less than 10 ft

of interconnecting tubing.

CAUTION

DO NOT BURY MORE THAN 36 IN. OF

REFRIGERANT PIPE IN THE GROUND. If

any section of pipe is buried, there must be a 6

in. vertical rise to the valve connections on the

outdoor unit. If more than the recommended

length is buried, refrigerant may migrate to the

cooler, buried section during extended periods

of system shutdown. This causes refrigerant

slugging and could damage compressor at startup.

When more than 50 ft of interconnecting tubing

and more than 30 ft of vertical lift is used, refer

to appendix in page 15.

Table 1-MAXIMUM LINE LENGTHS

UNIT

38HK

*Maximum distance permitted is 30 ft from lowest

system component to highest system component.

MAXIMUM

EQUIVALENT

FT

50 30* 30*

If either refrigerant tubing or indoor coil is

exposed to atmospheric conditions for longer

than 5 minutes, it must be evacuated to 1000

MAXIMUM LIFT

— FAN COIL

BELOW

CONDENSING

UNIT

MAXIMUM LIFT

— FAN COIL

ABOVE

CONDENSING

UNIT

4

microns to eliminate contamination and

moisture in the system.

Run refrigerant tubes as directly as possible,

avoiding unnecessary turns and bends. Suspend

refrigerant tubes so they do not damage

insulation on vapor tube and do not transmit

vibration to the structure. Also, when passing

refrigerant tubes through the wall, seal opening

so that vibration is not transmitted to structure.

Leave some slack in refrigerant tubes between

structure and outdoor unit to absorb vibration.

Refer to separate indoor unit installation

instructions for additional information.

MAKE PIPING SWEAT CONNECTIONS—

Remove plastic caps from liquid and suction

service valves. Use refrigerant grade tubing.

Service valves are closed from the factory and

ready for brazing. After wrapping the service

valve with a wet cloth, the tubing set can be

brazed to the service valve using either silver

bearing or non-silver bearing brazing material.

Consult local code requirements. Refrigerant

tubing and indoor coil are ready for leak testing.

NOTE: Unit is shipped with R-22 Holding

factory charge indicated on nameplate. Pass

nitrogen or other inert gas through piping while

brazing to prevent formation of copper oxide.

CAUTION

To avoid damage while brazing, service valves

should be wrapped in a heat-sinking material

such as a wet cloth.

CAUTION

When brazing tubing sets to the service valves, a

brazing shield must be used to prevent damage

to the painted unit surface.

PROVIDE SAFETY RELIEF—A fusible plug

is located in unit suction line; do not cap this

plug. If local code requires additional safety

devices, install as directed.

Step 4 — Make Electrical

Connections

WARNING

Unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the

possibility of personal injury if an electrical fault

should occur. This ground may consist of

electrical wire connected to the unit ground lug

in control compartment, or conduit approved for

electrical ground when installed in accordance

with NEC, ANSI/NFPA (American National

Standards Institute/National Fire Protection

Association) 70, and local electrical codes.

Failure to follow this warning could result in the

installer being liable for personal injury to others.

CAUTION

Unit failure as a result of operation on improper

line voltage or excessive phase imbalance

constitutes abuse and may cause damage to

electrical components. Such operation will

invalidate any applicable Carrier warranty.

POWER WIRING—Unit is factory-wired for

voltage shown on nameplate. Provide adequate,

fused disconnect switch within sight of unit,

readily accessible but out of reach of children.

Provision for locking the switch open (off) is

advisable to prevent power from being turned on

while unit is being serviced. Disconnect switch,

fuses, and field wiring must be in compliance

with NEC and applicable local codes. Use

minimum 60 C wire for field power connection.

Route power wires through opening in the unit

side panel and connect in unit control box. Unit

must be grounded.

CONTROL CIRCUIT WIRING — See

Electrical Data Table and unit label diagram for

field-supplied wiring details. Route control wire

through opening in the unit side panel to

connection in unit control box.

NOTE: Use no. 10 AWG (American Wire Gage)

insulated wire

NOTE: Operation of unit on improper line

voltage constitutes abuse and could affect

Carrier warranty. See Table7.

Do not install unit in system where voltage may

fluctuate above or below permissible limits.

See Table 7 for recommended fuse sizes. When

making electrical connections, provide clearance

at unit for refrigerant piping connections.

WARNING

Before performing service or maintenance, be

sure the indoor unit main power switch is off

and indoor blower has completely stopped.

Failure to do so may result in electrical shock or

injury from rotating fan blades.

CONNECTIONS TO DUCT-FREE FAN COIL

UNITS —

The 38HD units are designed for easy match-up

to FB4A Fan Coil, 42TX Fan Coil,40GKX

Cealling Cassette and 42S/HD Free Standing fan

coils. See wiring diagrams page 9 – 11.

5

START-UP

Preliminary Checks

1. Check that all internal wiring connections are

tight and that barriers, covers, and panels are in

place.

2. Make certain field electrical power source

agrees with unit nameplate rating.

3. Open all service valves.

Leak Test— Field piping and fan coil must

be leak tested by pressure method described in

Carrier Standard Service Techniques Manual,

Chapter 1, Section 1-6. Use R-22 at

approximately 25 psig backed up with an inert

gas to a total pressure not to exceed 245 psig.

Evacuate and Dehydrate— Field piping

and fan coil must be evacuated and dehydrated

by either of the methods described in Carrier

Standard Service Techniques Manual, Chapter

1, Section 1-7.

Charge System — Release factory charge

into system by opening (backseating) liquid and

suction line service valves. Add charge amount

as required for the total system.

Refer to separate indoor unit installation

instructions for the required total system charge

when connected to the indoor unit.

PERCENTAGE DECREES IN CAPACITY DUE TO

MAXIMUM LINE LENGTHS

UNIT

38HK 50 30* 30*

*Maximum distance permitted is 30 ft from lowest

system component to highest system component. For

longer line application please refer to appendix A.

MAXIMUM

EQUIVALENT

FT

MAXIMUM LIFT

— FAN COIL

BELOW

CONDENSING

UNIT

MAXIMUM LIFT

— FAN COIL

ABOVE

CONDENSING

To Start Unit

NOTE: When using in conjunction with FB4A

Fan Coil, 42TX Fan Coil,40GKX Ceiling

Cassette and 42S/HD Free Standing fan coils.,

refer to start-up instructions included with fan

coil for correct start-up procedures. Be sure that

field disconnect is closed. Set room thermostat

below ambient temperature. Operate unit for 15

minutes, then check system refrigerant charge.

Unit compressor starts after a 5-minute delay if

equipped with accessory Time Guardt II device.

Table 6 - SYSTEM OPERATING CONDITIONS

TEMPERATURE CONDITIONS LIMITS

Maximum Cooling Ambient (F)

Minimum Cooling Ambient (F) (without

accessory low-ambient kit)

Minimum Cooling ambient (F) (with

accessory low-ambient kit)

Saturated Suction Temperature Range

Minimum (F) / Maximum (F)

Saturated Condensing Temperature

Range Minimum (F) / Maximum (F)

Maximum Compressor Discharge

Temperature (F)

Minimum Discharge Superheat (F)

NOTE: For system controls see Electrical Data.

20 / 55

60 / 150

6

UNIT

125

55

35

275

60

SERVICE

WARNING

Before performing recommended maintenance, be

sure unit main power switch is off. Failure to do so

may result in electrical shock or injury from

rotating fan blade.

Outdoor Fan— A reinforced wire mount

holds the outdoor fan assembly in place.

Compressor Pressure Relief Valve —

Valve is located in compressor. Relief valve

opens at a pressure differential of approximately

450 ± 50 psig between suction (low side) and

discharge (high side) to allow pressure

equalization.

Internal Current and Temperature

Sensitive Overload—

automatically when internal compressor motor

temperature drops to a safe level (overloads may

require up to 45 minutes to reset). When an

internal overload is suspected of being open,

check by using an ohmmeter or continuity tester.

If necessary, refer to Carrier Standard Systems

Techniques Manual, Chapter 2, for complete

information.

Control resets

Pumpdown Procedure— The system

may be pumped down in order to make repairs

on low side without losing complete refrigerant

charge. To pumpdown:

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

CAUTION

The 38HDL unit coils hold only the factorydesignated amount of refrigerant. Additional

refrigerant may cause units to relieve pressure

through compressor internal pressure relief

valve (indicated by sudden rise of suction

pressure) before suction pressure reaches 5 psig.

If this occurs, shut off unit immediately, then

frontseat the suction valve and remove and

recover excess refrigerant following accepted

practice.

3. Start unit and run until suction pressure

reaches 5 psig.

4. Shut unit off and frontseat suction valve.

5. Depressurize low side of unit and recover

refrigerant following accepted practice.

Loss of Charge Pressure Switch —

This switch, mounted on the suction line, has

fixed non-adjustable settings. To check pressure

switch, attach pressure gage to suction service

valve gage port. Slowly close liquid shutoff

valve and allow compressor to pump down. Do

not allow compressor to pump down below 2

psig. Compressor should shut down when

suction pressure drops to cutout pressure in

Table 2, and should restart when pressure builds

up to cut-in pressure shown in Table 2.

High Pressure Switch —This switch,

mounted on the discharge line, has fixed nonadjustable settings & auto reset. To check

pressure switch, attach pressure gauge to

compressor discharge service port, block

condenser coil, monitor pressure till compressor

trips, remove blockage and observe at which

pressure compressor restarts.

CAUTION

If the compressor does not trip at the cut-out

pressure (450 psig), remove the blockage

immediately and contact your local Carrier

service center.

Service Valves —The service valves in the

outdoor unit come from the factory frontseated.

This means the refrigerant charge is isolated

from the line-set connection ports. To prevent

damage to the valve, use a wet cloth or other

acceptable heat sink material on the valve before

brazing. The service valves must be backseated

(turned counterclockwise until seated) before the

service port caps can be removed and the hoses

of the gage manifold connected. In this position,

refrigerant has access from the through outdoor

and indoor unit. The service valve cannot be

field repaired; only a complete valve or valve

stem seal and service port caps are available for

replacement.

MAINTENANCE

WARNING

Before performing recommended maintenance,

be sureunit main power is off. Failure to do so

may result inelectrical shock or injury from

rotating fan blades.

Lubrication

COMPRESSOR—Compressor contains factory

oil charges; replace oil when lost. See Table 1

for oil recharge and refer to Carrier Standard

Service Techniques Manual, Chapter 1, pages 1

to 21 for oil recharging procedure.

Cleaning Coils — Coil should be washed

out with water or blown out with compressed

air. Note that the blowthru design causes dirt

and debris to build up on the inside of the coils.

Clean coil annually or as required by location

and outdoor air conditions. Inspect coil monthly

and clean as required. Fins are NOT continuous

through coil sections. Dirt and debris may pass

through the first section, become trapped

between the rows of fins, and restrict condenser

airflow. Use a flashlight to determine if dirt or

debris has collected between coil sections. Clean

coil as follows:

1. Turn off unit power.

2. Use a garden hose or other suitable equipment

to flush coil from the outside to remove dirt. Be

sure to flush all dirt and debris from drain holes

in the base of unit. Fan motors are waterproof.

WARNING

Do not use harsh chemicals to clean the coils,

use only water, compressed air or Carrier

approved coil cleaners.

7

Loading...

Loading...