Carrier 38HDL018-060 User Manual

Light Commercial Condensing Units

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INSTALLATION ..............................1-7

Step 1 — Complete Pre-Installation

Checks ....................................1

• UNPACK UNIT

• INSPECT SHIPMENT

• CONSIDER SYSTEM REQUIREMENTS

Step 2 — Rig and Mount Unit .................3

• MOUNTING ON GROUND

• MOUNTING ON ROOF

• RIGGING

Step 3 — Complete Refrigerant Piping

Connections ...............................3

• CHECK ACCURATERt CONTROL

• MAKE PIPING SWEAT CONNECTIONS

• PROVIDE SAFETY RELIEF

Step 4 — Make Electrical Connections ........4

• POWER WIRING

• CONTROL CIRCUIT WIRING

• CONNECTIONS TO DUCT-FREE

FAN COIL UNITS

Step 5 — Accessory Installation ..............4

START-UP ...................................7

SERVICE ...................................7-9

MAINTENANCE .............................10

TROUBLESHOOTING ........................11

SAFETY CONSIDERATIONS

Install and servicing air-conditioning equipment can be hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should installor service air-conditioning equipment

Untrained personnel may perform basic maintenance such

as cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working

on air-conditioning equipment, observe safety precautions in

literature, and on tags and labels attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have a

fire extinguisher available. Read these instructions thoroughly.Consult local building codes and National Electrical

Code (NEC, U.S.A. Standard) for special installation

requirements.

38HDL018-060

COOLING

Fig. 1 — 38HDL Condensing Unit

Before installing or servicing system, always turn off

main power to system. There maybe more than one disconnect switch. Turn off accessory heater power if

applicable. Electrical shock can cause personal injury.

Step 1 — Complete Pre-Installation Checks

UNPACK UNIT — Move unit to final location. Remove carton from unit, being careful not to damage service valves or

grilles.

INSPECT SHIPMENT — File claim with shipping company if shipment is damaged or incomplete. Check unit nameplate to ensure unit matches job requirements.

CONSIDER SYSTEM REQUIREMENTS — Consult

local building codes and NEC for special installation

requirements.

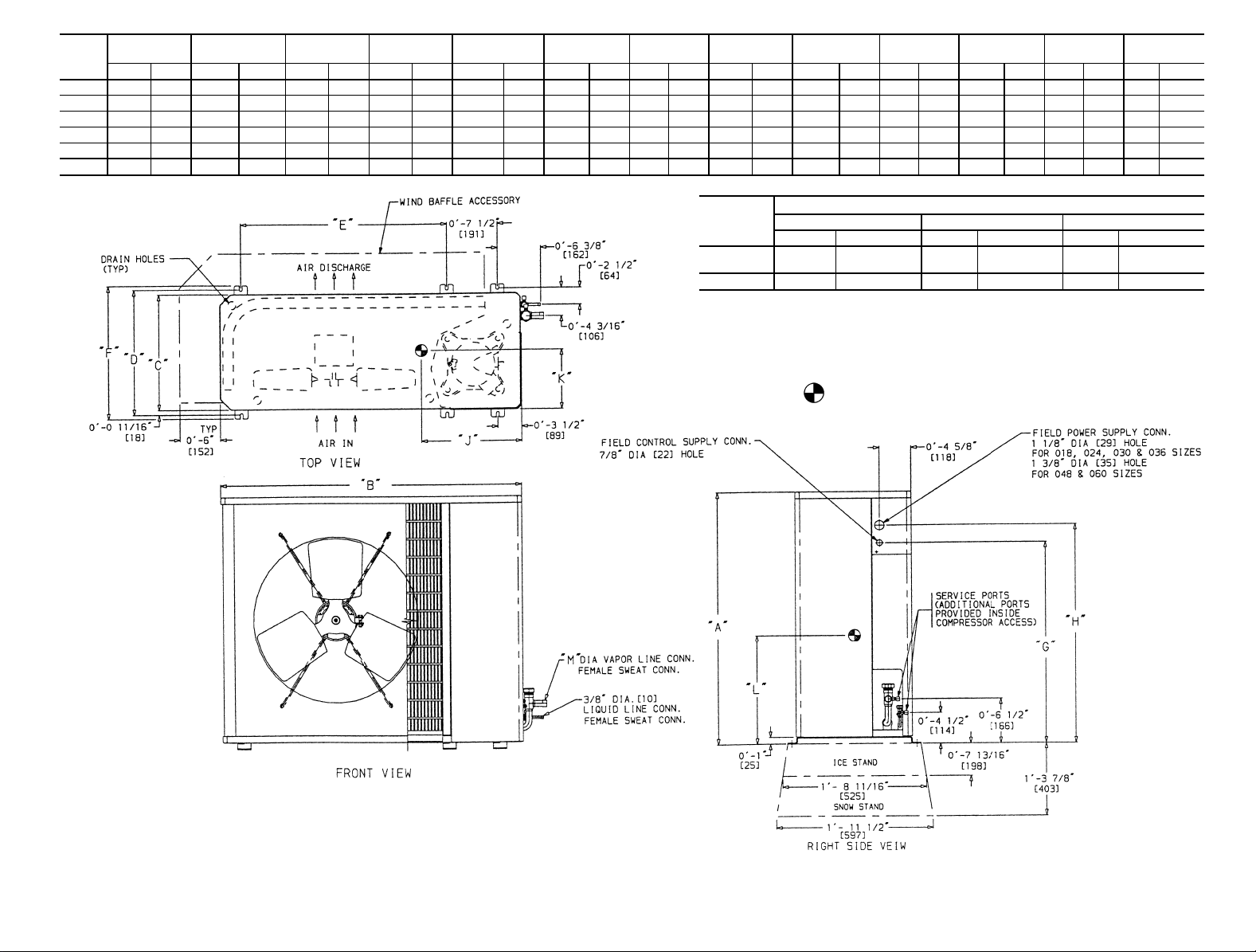

Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 1 and 2. Unit

can be mounted on a level pad directly on base legs or

mounted on raised pads at support points. See Fig. 2for center of gravity.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 3a 2a

PC 111 Catalog No. 563-899 Printed in U.S.A. Form 38HDL-1SI Pg 1 9-98 Replaces: New

UNIT

SIZE

38HDL

018 2-1

024 2-1

030 2-1

036 2-1

048 3-1

060 3-1

ABCDEFGHJKLM

OPERATING

WEIGHT

ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm ft-in. mm lb kg

1

⁄8638.2 3-015⁄16938.2 1-29⁄16369.9 1-4 406.4 1-117⁄16595.3 1-53⁄16436.6 1-51⁄2444.5 1-81⁄8511.2 1-1 330.2 0-65⁄8168.3 0-111⁄4285.8 0-05⁄815.88 130 58.9

1

⁄8638.2 3-015⁄16938.2 1-29⁄16369.9 1-4 406.4 1-117⁄16595.3 1-53⁄16436.6 1-51⁄2444.5 1-81⁄8511.2 1-1 330.2 0-63⁄4171.5 0-115⁄8295.3 0-05⁄815.88 136 61.6

1

⁄8638.2 3-015⁄16938.2 1-29⁄16369.9 1-4 406.4 1-117⁄16595.3 1-53⁄16436.6 1-51⁄2444.5 1-81⁄8511.2 1-1 330.2 0-63⁄4171.5 0-115⁄8295.3 0-03⁄419.05 161 73.0

1

⁄8638.2 3-015⁄16938.2 1-29⁄16369.9 1-4 406.4 1-117⁄16595.3 1-53⁄16436.6 1-51⁄2444.5 1-81⁄8511.2 1-1 330.2 0-63⁄4171.5 0-115⁄8295.3 0-03⁄419.05 185 83.9

3

⁄16944.6 3-89⁄161131.9 1-51⁄16433.4 1-67⁄16468.3 2- 61⁄2774.7 1-75⁄8498.5 2-55⁄8752.5 2-83⁄16817.6 1-17⁄8352.4 0-81⁄4209.5 0- 4 406.4 0-07⁄822.22 222 100.5

3

⁄16944.6 3-89⁄161131.9 1-51⁄16433.4 1-67⁄16468.3 2- 61⁄2774.7 1-75⁄8498.5 2-55⁄8752.5 2-83⁄16817.6 1-111⁄16347.7 0-81⁄8206.4 0- 37⁄8403.2 0-07⁄822.22 249 112.9

UNIT SIZE

38HDL

018,024,030

and 036

Support Feet Snow Stand Ice Stand

ft-in. mm ft-in. mm ft-in. mm

1-11 x 3-6 584.2 x 1066.8 2-2 x 3-6 660.4 x 1066.8 2-2 x 3-6 660.4 x 1066.8

MINIMUM MOUNTING PAD DIMENSIONS

048 and 060 2- 0 x 4-2 609.6 x 1270.0 2-4 x 4-4 711.2 x 1270.0 2-2 x 4-2 660.4 x 1270.0

NOTES:

1. Required clearances: With coil facing wall, allow 69 (156.4 mm)minimumclearance on coil side and

coil end, and 3 ft (914.4 mm) minimum clearance on compressor end and fan side. With fan facing

wall, allow 89 (203.2 mm) minimum clearanceonfan side and coilend, and 3 ft (914.4mm) minimum

clearance on compressorend and coil side.Withmulti-unit application, arrange unitsso discharge of

one does not enter inlet of another.

2. Dimensions in parenthesis are in millimeters.

3. Center of gravity .

2

Fig. 2 — 38HDL018-060 — Dimensional Drawing

Step 2 — Rig and Mount Unit

MOUNTING ON GROUND — Mount unit on a solid, level

concrete pad. Position unit so water or ice from roof does

not fall directly into unit. Field-fabricated stacking kits can

be used when units are to be stacked. If conditions or local

codes require unit to be fastened to a pad, 6 field-supplied

tiedown bolts should be used and fastened through slots provided in unit mounting feet.

MOUNTING ON ROOF — Mount unit on level platform or

frame at least 6 in. (154 mm) above roof surface.Isolate unit

and tubing from structure.

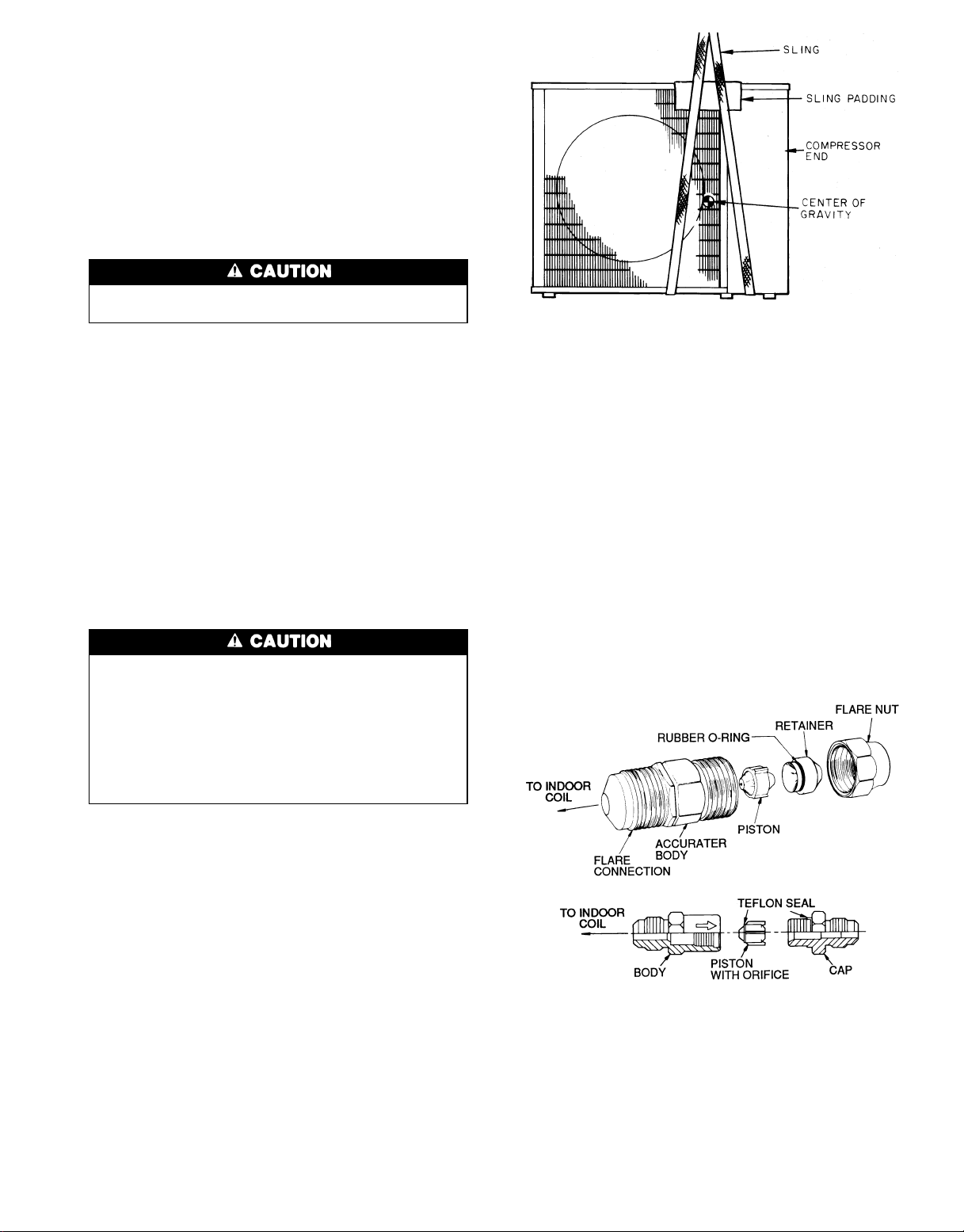

RIGGING

Be sure unit panels are securely in place prior to

rigging.

Keep unit upright. Lift unit using sling. Use cardboard or

padding under sling, and spreader bars to prevent sling damage to unit. See Fig. 3. See Fig. 2 for center of gravity reference. Install unit so coil does not face into prevailing winds.

If this is not possible and constant winds above 25 mph are

expected, use field-fabricated wind baffle.

NOTE: Field-fabricated wind baffles should be used on all

units with accessory low-ambient control.

Field-fabricated snow stand may be used to raise unit when

operation will be required during the winter. Units may also

be wall mounted using the accessory wall mounting kit.

Step 3 — CompleteRefrigerant Piping Connections —

using field-supplied tubing of refrigerant grade and condition. See Tables 1A and 1B for correct line sizes. Do not use

less than 10 ft (3 m) of interconnecting tubing.

DO NOT BURY MORE THAN 36 IN. (922 mm) OF

REFRIGERANT PIPE IN THE GROUND. If any section of pipe is buried, there must be a 6 in. (154 m) vertical rise to the valve connections on the outdoor unit.

If more than the recommended length is buried, refrigerant may migrate to the cooler, buried section during

extended periods of system shutdown. This causes

refrigerant slugging and could damage compressor at

start-up.

Outdoor units may be connected to indoor units

Fig. 3 — Lifting Unit with Sling

with field-replaceable piston should be supplied with the indoor unit. Refer toAccuRater metering device table in separate indoor unit installationinstructionstodeterminethecorrect

AccuRater piston size required for the condenser/evaporator

system being installed.

Note that one of 2 types of the AccuRater devices can be

found on the indoor unit. See Fig. 4. Do notinterchangecomponents between AccuRater device types. Matching of outdoor unit with indoor unit may require field replacement of

piston. Replace piston, if required, before connecting refrigerant lines. Piston replacement instructions are included

in the indoor unit installation instructions. After system installation is complete, see Refrigerant charging section on

page 8 to check and/or adjust refrigerant charge.

The 38HDL018-060 units may also be installedwith units

using a thermostatic expansion valve (TXV). If a TXV is

used, be sure to remove the piston from the indoor coil. See

installation instructions shipped with the TXV for proper positioning and adjustment.

When more than 50 ft (15.2 m) of interconnecting tubing

and more than 30 ft (9.1 m) of vertical lift is used, refer to

Part 3 of the Carrier System Design Manual for design details, or contact your local distributor.

If either refrigerant tubing or indoor coil is exposed to atmospheric conditions for longer than 5 minutes, it must be

evacuated to 1000 microns to eliminate contamination and

moisture in the system.

Run refrigerant tubes as directly as possible, avoiding unnecessary turns and bends. Suspendrefrigerant tubes so they

do not damage insulation on vapor tube and do not transmit

vibration to the structure.Also,whenpassingrefrigeranttubes

through the wall, seal opening so that vibration is not transmitted to structure. Leave some slack inrefrigerant tubes between structure and outdoor unit to absorb vibration. Refer

to separate indoor unit installation instructions for additional information.

CHECK ACCURATERt CONTROL — The correct

AccuRater (bypass type) refrigerant control is required for

cooling system capacity optimization.AnAccuRater device

TYPE A (BYPASS TYPE)

TYPE B

NOTE: Arrow on AccuRater body points in free-flow direction, away

from the indoor coil.

Fig. 4 — AccuRater Metering Device Components

MAKE PIPING SWEAT CONNECTIONS —Remove plastic caps from liquid and suction service valves. Use refrigerant grade tubing. Service valves are closed from the factory and ready for brazing.After wrapping the service valve

3

with a wet cloth, the tubing set can be brazed to the service

valve using either silver bearing or non-silver bearing brazing material. Consult local code requirements. Refrigerant

tubing and indoor coil are ready for leak testing.

NOTE: Unit is shipped with R-22 full factory charge indicated on nameplate.

Pass nitrogen or other inert gas throughpiping while braz-

ing to prevent formation of copper oxide.

To avoid damage while brazing, service valves should

be wrapped in a heat-sinking material such as a wet cloth.

When brazing tubing sets to the service valves, a brazing shield must be used to prevent damagetothe painted

unit surface.

PROVIDE SAFETY RELIEF — A fusible plug is located in

unit suction line; do not cap this plug. If local code requires

additional safety devices, install as directed.

Step 4 — Make Electrical Connections

Unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of electrical wire connected totheunitground

lug in control compartment, or conduit approved for

electrical ground when installed in accordance with

NEC, ANSI/NFPA (American National Standards

Institute/National Fire Protection Association) 70 (U.S.A.

Standards), and local electrical codes. Failure to follow

this warning could result in the installer being liable for

personal injury to others.

Unit failure as a result of operation on improper line

voltage or excessive phase imbalance constitutes

abuse and may cause damage to electrical components.

Such operation will invalidate any applicable Carrier

warranty.

POWER WIRING — Unit is factory-wired for voltage shown

on nameplate. Provideadequate,fuseddisconnectswitchwithin

sight of unit, readily accessible but out of reach of children.

Provision for locking the switch open (off) is advisable to

prevent power from being turned on while unit is being serviced. Disconnect switch, fuses, and field wiring must be

in compliance with NEC (U.S.A. Standard) and applicable

local codes. Use minimum 60 C wire for field power

connection.

Route power wires through opening in the unit side panel

and connect in unit control box as shown on unit label diagram and Fig. 5 and 6. Unit must be grounded.

CONTROL CIRCUIT WIRING — Control voltage is 24 v.

See Fig. 5 and unit label diagram for field-supplied wiring

details. Route control wire through opening in the unit side

panel to connection in unit control box.

NOTE: For wire runs up to 50 ft (15 m), use no. 18 AWG

(American Wire Gage) insulated wire (35 C minimum). For

50 to 75 ft (15 to 23 m), use no. 16AWG insulated wire. For

more than 75 ft (23 m), use no. 14 AWG insulated wire. See

Table 2 for conversion to European wire sizes.

NOTE: Operation of unit on improper line voltage constitutes abuse and could affect Carrier warranty. See Table 3.

Do not install unit in system where voltage may fluctuate

above or below permissible limits.

See Table 3 for recommended fuse sizes. When making

electrical connections, provide clearance at unit for refrigerant piping connections.

Use indoor unit transformer as 24-v (40-va minimum)

supply for system as shown in Fig. 5 or use accessory

transformer.

Before performing service or maintenance, be sure the

indoor unit main power switch is off and indoor blower

has completely stopped. Failure to do so may result in

electrical shock or injury from rotating fan blades.

CONNECTIONS TO DUCT-FREE FAN COIL UNITS —

The 38HDL units are designed for easy match-up to 40QAB,

40QKB, and 40QNB018,024 duct-free fan coils. These units

provide 24-v power for the outdoor unit from the fan coil.

Connect the Y and C terminals of the indoor unit to the blue

and brown wires of the outdoor unit with 20 gage (minimum) thermostat wire.

Step 5 — Accessory Installation — Install all unit

accessories per accessory installation instructions prior to

start-up.

Do not use accessory Time Guardt II device when combining a 38HDL unit with 40QNB indoor units.

When ambient temperature will fall below 55 F (13 C),

accessory low ambient controller (part no. 53DS900060) is

required. When accessory low ambient kit is used, unit should

also be equipped with accessory winter start kit and fieldfabricated wind baffles.

4

Loading...

Loading...