Carrier 38HD User Manual

Ibl']-

HEATING & COOLING

Split System Condensing Units

Installation, Start-Up and Service

Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components Only trained and qualified service personnel

should install or service air conditioning equipment.

Untrained personnel can perform basic maintenance,

such as cleaning and replacing filters. All other opera

tions should be performed by trained service personnel.

When working on air conditioning equipment, observe

precautions in literature and on tags and labels attached

to unit

38HD

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instruc

tions thoroughly. Consult local building codes and

National Electrical Code (NEC) for special installation

requirements

A WARNING

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power if

applicable Electrical shock can cause personal injury.

INSTALLATION

Step 1 — Complete Pre-Installation Checks.

UNPACK UNIT (See Fig 1.) — Move unit to final

location Remove carton from unit being careful not to.

damage service valves and grilles. *

INSPECT SHIPMENT — File claim with shipping

company if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS — Consult

local building codes and National Electrical Code (NEC)

for special installation requirements.

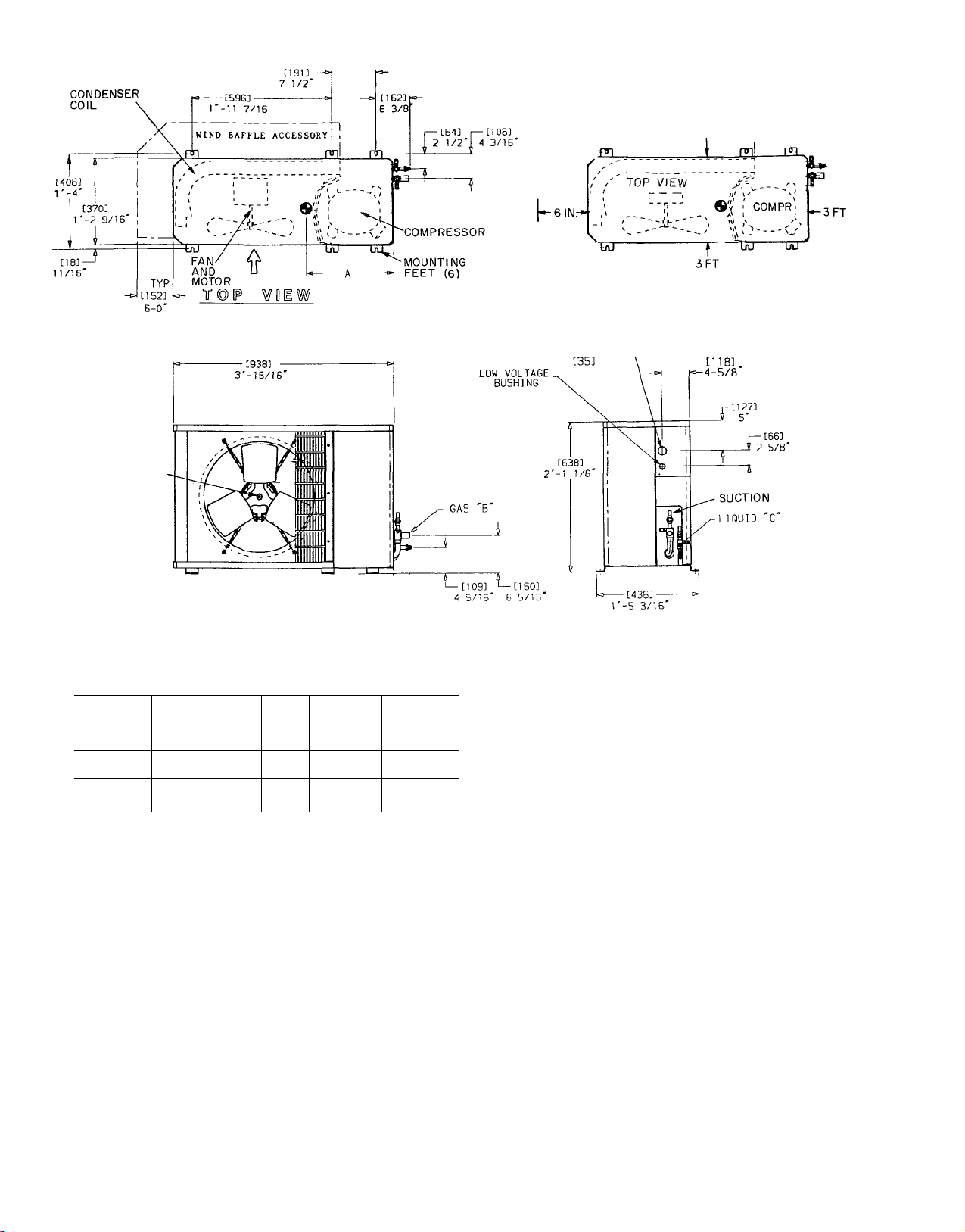

Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 2 and 3.

Locate unit so that condenser airflow is unrestricted

on both sides. Refer to Eig 2 and 3.

Unit may be mounted on a level pad directly on base

legs or mounted on raised pads at support points See

Fig. 2 and 3 for center of gravity

Fig. 1 — Model 38HD

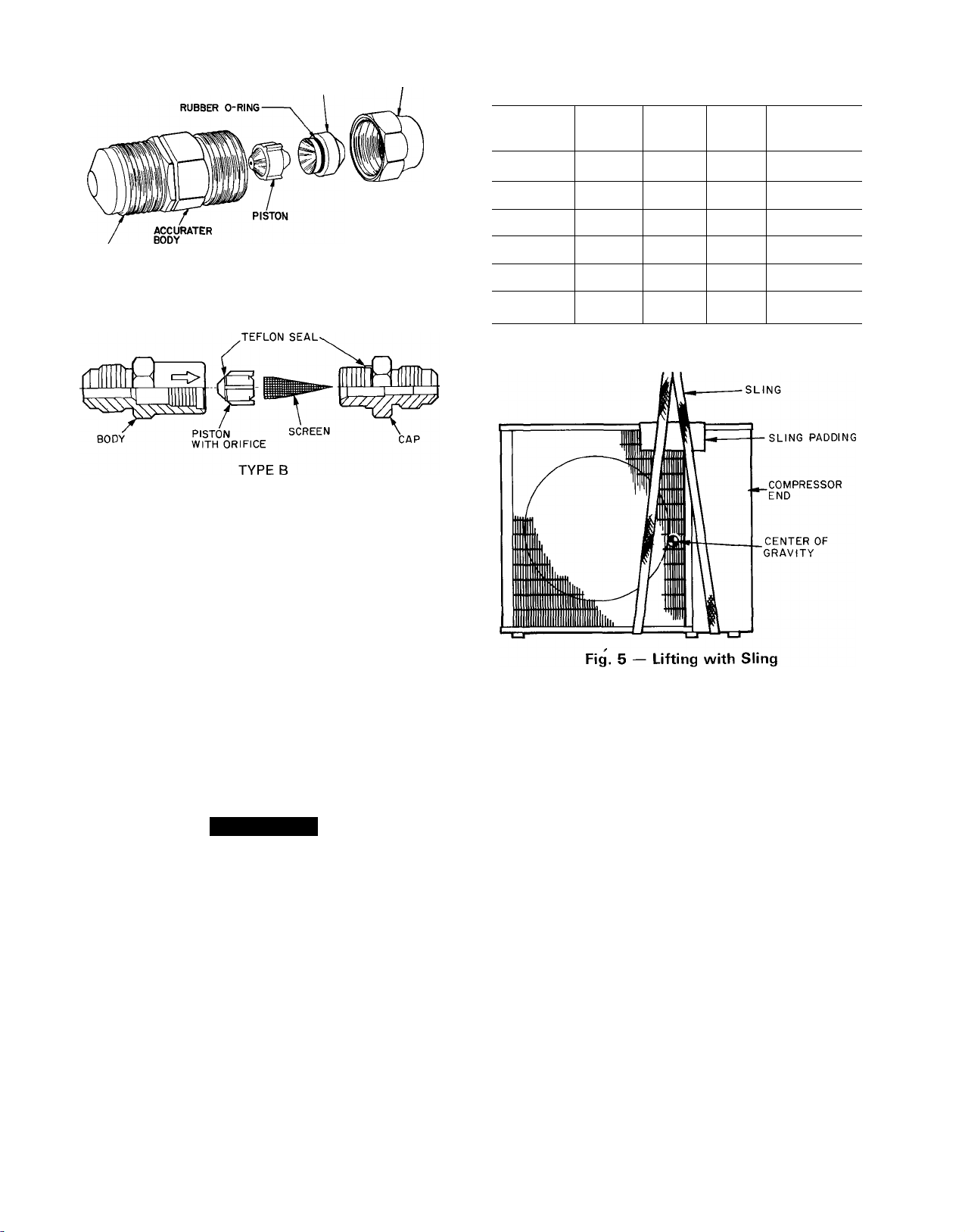

CHECK ACCURATER® — The correct AccuRater

(bypass type) refrigerant control is required for cooling

system capacity optimization. An AccuRater with fieldreplaceable piston (see Fig. 4) is supplied on evaporator.

Use Optimization Chart, Table 1, to find AccuRater

piston size required for condenser/evaporator system

being installed. Note that one of 2 types of AccuRaters

can be found on the indoor unit. Determine from Fig. 4

and Table 1 which type is in the indoor unit. Do r/otinterchange eomponents between AccuRater types. Matching

of condensing unit with evaporator may require field

replacement of piston. Refer to Table 1. Replace piston,//

required, before connecting refrigerant lines. Piston

replacement instructions are included in evaporator

installation book. After system installation is complete,

see Refrigerant Charging to check and/or adjust refrig

erant charge

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 3a 2a

PC 111 Catalog No 533-850 PrintedinUSA Form38HD-1SI Pgl 6-89 Replaces: New

For replacement items use Carrier Specified Parts.

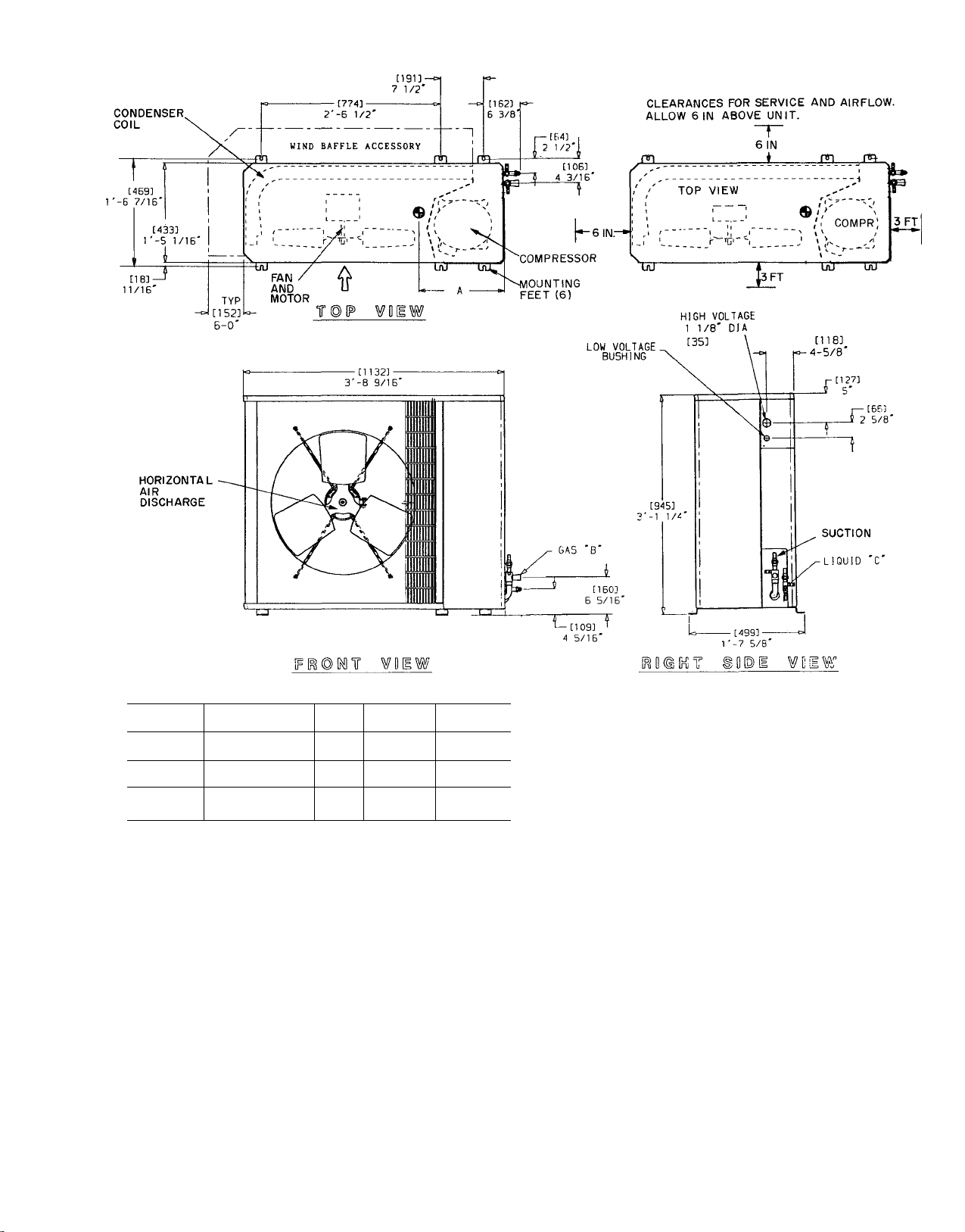

HORIZONTAL AIR

DISCHARGE

«6»

CLEARANCES FOR SERVICE AND AIRFLOW,

ALLOW 6 IN. ABOVE UNIT.

T

6 IN.

HIGH VOLTAGE

1-1/8' DIA.

H

F1^ © T ¥ f:

UNIT

38HD018 (67 1 kg) 148 lbs

38HD024

38HD030

WEIGHT

(72 6 kg) 160 lbs

(77 6 kg) 171 lbs

A

(329)

r-1"

(329)

r-1"

(329)

r-1"

B

(15 88) %"

(15 88) %"

(15.88) %"

C

(9 53) %"

(9 53) %"

(9.53) %"

Fig. 2 — 38HD Dimensional Drawing, 018-030

[^¡©[Hlir ®DlS)i WOiW

NOTES

1 Dimensions in [ ] are in millimeters

2 Air Direction

3. Center of Gravity ^

4 Footprint 018-030, 3 7 sq ft ( 34 m*)

f''

UNIT

38HD036 (108 9 kg) 240 ibs

38HD048

38HD060

WEIGHT

(110 7 kg) 244 ibs

(110 7 kg) 244 ibs

A B C

(352)

1 '-1 %"

(347)

I'-iya"

(368)

1'-2'/2"

(19 05) 3/4"

(19 05) %"

(22 22) %"

(9 53) %"

(9.53) %"

(9 53) %"

1 Dimensions in [ ] are in miilimeters

2 Air Direction

3 Center of Gravity

4 Footprint 036-060, 5 3 sq ft ( 49 m^)

Fig. 3 — 38HD Dimensional Drawing, 036-060

NOTES

RETAINER

FLARE NUT

Table 1 — AccuRater Optimization Chart

FLARE

CONNECTION

(Arrow on AccuRater body points in metering direction.)

(Arrow on AccuRater body points in free flow direction.)

TYPE A

Fig. 4 — AccuRater® (Bypass Type) Components

OUTDOOR

UNIT

38HD018

38HD024

38HD030

38HD036

38HD048

38HD060

INDOOR

UNIT

28RD024

40HD024

28RD030

40HD024

28RD043

40HD036

28RD043

40HD036

28RD049

40HD048

28RD061

40HD060

INDOOR

PISTON

_

61 A

70 A

73 A

86 A

88

PISTON

TYPE

A

B

B

B

B

B

A

B

REQUIRED

SYSTEM

CHARGE (lb)

—

55

5 7

11.5

97

11 2

Step 2 — Rig and Mount Unit

MOUNTING ON GROUND — Mount on a solid, level,

concrete pad Position unit so water or ice from roof

cannot drop directly onto unit. Stacking Kit 38H D900031

and -041 are available where such application is required.

See instructions provided with accessory kit. If conditions

or local codes require unit be fastened to pad, tiedown

bolts should be used and fastened through slots provided

in unit mounting feet.

MOUNTING ON ROOF

Mount on a level platform

or frame.

RIGGING

A CAUTION

Be sure unit panels are securely in place prior to

rigging.

Keep unit upright. Lift unit using sling. Use cardboard

or padding under sling, and spreader bars to prevent sling

damage to unit. See Fig. 5. See Fig. 2 and 3 for center of

gravity reference. Install unit so that coil does not face

into prevailing winds. If this cannot be done, and constant

winds above 25 mph are expected, use Accessory Wind

Baffle, Part Number 38QR900041 or -051. See instruc

tions provided with accessory kit

Step 3 — Complete Refrigerant Piping Con

nections — Condensing units may be connected to

evaporator sections using field-supplied tubing of refrig

erant grade, correct size and condition. See Table 2.

Do not use less than 10 ft of interconnecting tubing and

do not bury more than 3 ft of line set undergrouiid. If any

section is buried, there must be a 6-in. vertical rise to the

valve connections on the outdoor unit

If more than the recommended length is buried, refrig

erant may migrate to cooler buried section during

extended periods of unit shutdown. This causes refrig

erant slugging and possibly compressor damage at

start-up.

When more than 50 ft of interconnecting tubing and

more than 30 ft vertical lift is used, consider the amount of

liquid lift, and compressor oil return See Part 3 of Carrier

System Design Manual for design details, or contact your

local Distributor

If either refrigerant tubing or indoor coil is exposed to

atmospheric conditions for longer than 5 minutes, it must

be evacuated to 1000 microns to eliminate contamination

and moisture in the system.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes

so they do not damage insulation on vapor tube and do

not transmit vibration to structure Also, when passing

refrigerant tubes through wall, seal opening, so vibration

is not transmitted to structure. Leave some slack in refrig

erant tubes between structure and unit to absorb vibra

tion Refer to evaporator installation instructions for

additional information.

USE FILTER DRIER AND MOISTURE INDI

CATOR — The filter drier is factory supplied. Moisture

indicator (sight glass) is a field-supplied option and

Loading...

Loading...