Page 1

Number One

Airconditioning

Mater

Syracuse New York

Air-Cooled Condensing Units

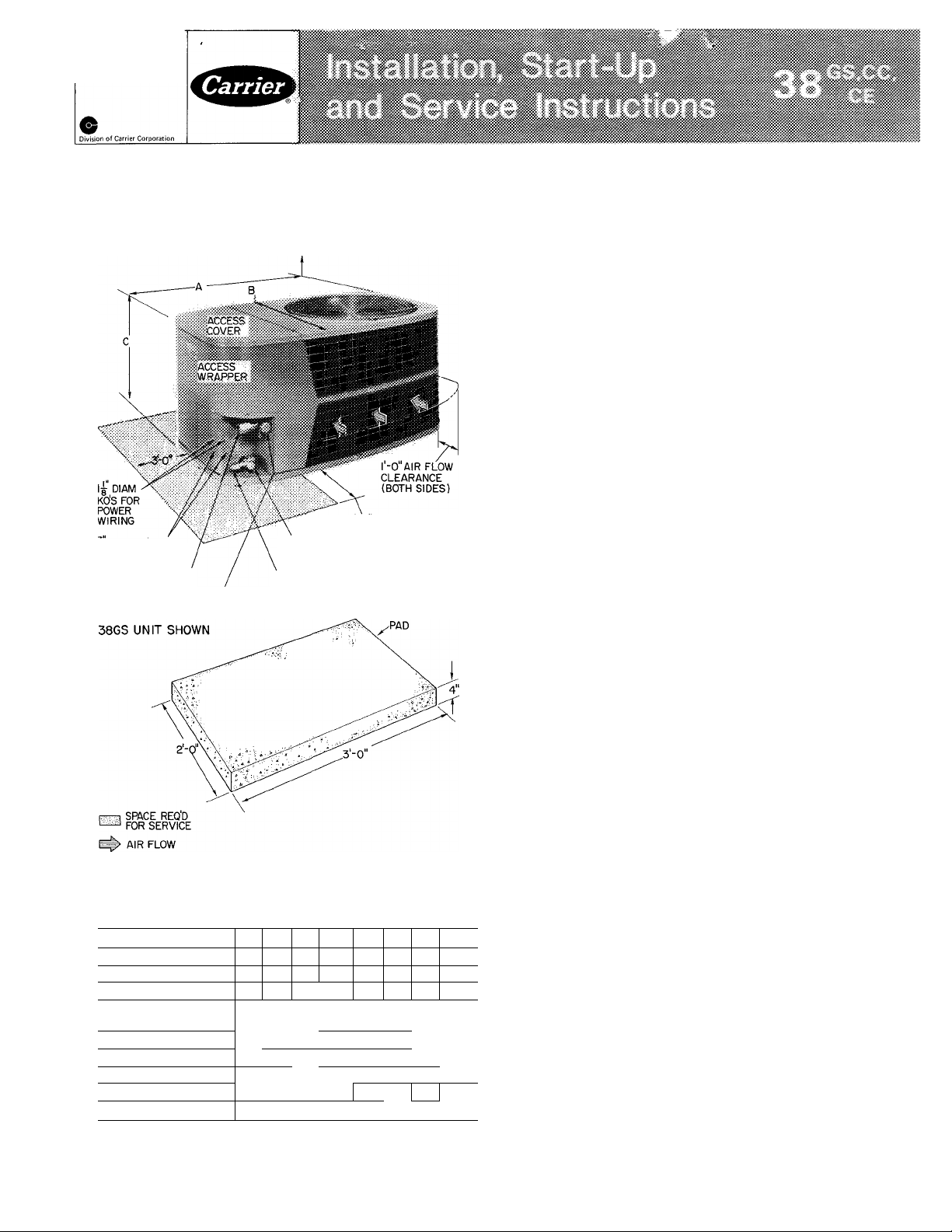

g DIAM KOS FOR

CONTROL WIRING

SUCTION LINE CONN

SUCTION LINE

VALVE

4'-0" OVERHEAD SPACE REQ'D

FOR SERVICE AND AIR FLOW

3 -0 (BOTH SIDES)

LIQUID LINE VALVE

LIQUID LINE CONN

CONCRETE

MOUNTING

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete.

Unpackaging Unit — Move condensing unit to final

location. Open carton at end marked “compressor

end.” Slide unit from carton taking special care to

not damage service valves or grilles.

PRELIMINARY SURVEY

Consult local building codes and National

Electrical Code (NEC) for special installation

requirements.

When installing unit, allow sufficient space for

air flow clearance, wiring, refrigerant piping and

servicing unit. Position unit so water from roof or

eaves does not flow directly on top of unit.

Install unit on a solid, level mounting pad. Unit

can be attached to pad with a mastic adhesive or

by drilling holes in base pan for 1/4-in. mounting

bolts. Do not block base pan water drainage holes.

38GS,CC,CE Condensing Units Connected to

Carrier Matched Evaporators with Carrier Acces

sory Tubing — Check system refrigerant charge

when tubing lengths are above or below 25 feet.

See Refrigerant Charging (page 10) for details.

Fig. 1 — Dimensions, Connections and Mounting Pad

38GS,CC,CE Unit

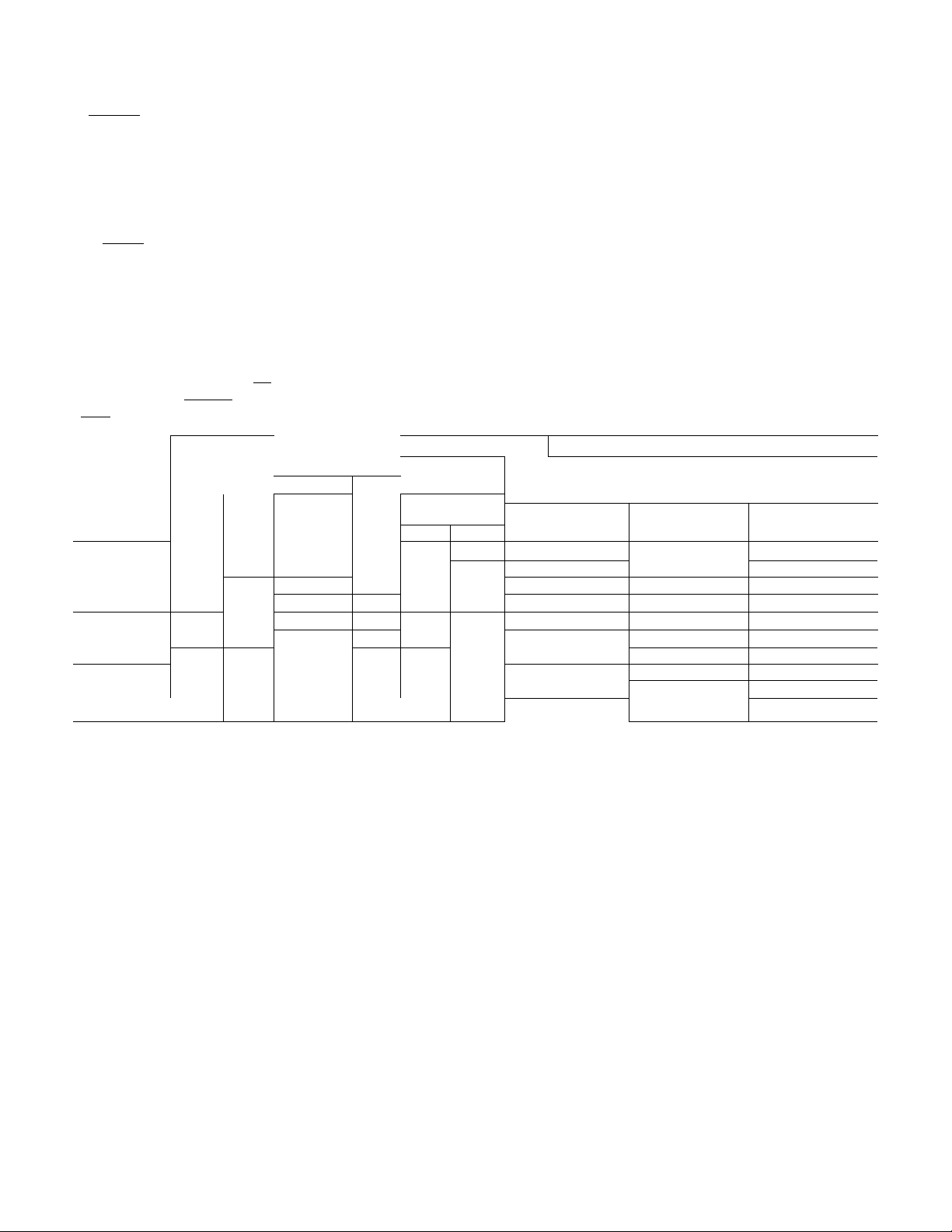

Table 1 — Installation Data

38GS

014

COND UNIT 38CC

OPER WT (lb) 130 135

UNIT DIM. (ft-in.)

Length A

Width B

Height G

REFRIG CONN.(in.)

Suction (ODF)

Liquid (ODF)

*5/8-in suction connection on 38CE002

t38CE045,005 and 38GS.CC060 are factory supplied with 3/4- to

1 1/8-in suction valve adapter (field installed) for 1 1/8-in

suction line

© Carrier Corporation 1975

38CB

- - -

- - -

'l-4

% lYsT '/b I

018

1-4

024

142|149

N4

Com

036 042

030

030 036

002* 003 004 045 005

158 191

2-10V4

1-10

1-4 1 1-4 (2-0

DOtible Fittings

%

'8

048 060t

042 048 060t

193 200

----

2-0 2-0

-----

'/4t

38GS,CC,CE Condensing Units Connected to NonCarrier Evaporators — Check refrigerant charge

when condensing unit is added to a system in

which other than a Carrier approved evaporator is

being used or where the evaporator has been

previously installed. Field-supplied refrigerant pip

ing must be in accordance with Field-Supplied

Piping Data, Table 3.

Where indicated on Table 3 for 38GS,CE units,

install a liquid line filter-drier and accessory crank

case heater on condensing unit. (Filter-drier is

factory supplied on CE045,005 units.) Accessory

start capacitor and relay also required on 38GS

units, but not normally required on 38CE units.

See Compressor Service (page 7). All above items

are standard or not required for 38CC units.

Use an evaporator coil with a bleed-type ex

pansion device. If coil does not have a bleed-type

expansion device it may be necessary to add an

accessory start capacitor and relay to condensing

unit. This would require removing compressor start

thermistor (PTC device) on units so equipped.

Form 38GS-13SI

Page 2

Table 2 — Accessories

PART

NUMBER

HH01AD040

HH93AZ040

JHH51AR00J[^

HH07AT070,

HH07AT074

H N93^076

HH0iAD042”

HH93AZ042

HH01YA092

HH_93_YZ094

32LT900301

(200-3 Ph)

32LT900601

(460-3 Ph)

38GS900102

38GS900212

38GS900112

38GS900292

38GS900172

38GS900182

38GC900031 10

38GC900071 10

38GC900041

38GC900081

38GS900221

38GC900091

38GC900061 35

38GC900101

38GC900191 50 %

38GC900ni

Low-Voltage Control — Honeywell Deluxe Thermostat

Thermostat Subbase

Comfort Control Center (Use with HH01AD040)

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase (with Automatic Changeover)

Low-Voltage Control ~ Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control — Grayson Thermostat

Thermostat Subbase

Solid State Head Pressure Control

Indoor Fan Relays (^¡x HN61KJ210)

40VA Low-Voltage Control Transformers

(24 V - Six 38GS900Q9])

Crankcase Heaters (Six 38GS900131)

Crankcase Heaters (Six 38GS900281)

Start Capacitor and Relay Package (Six 38GS900041)

Start Capacitor

Tubing Pa

Liqui d

Lgth

(ft)

18

18

25

25

35

50

(in.)

r 5/^

OD

%

%

%

% :

%

V

D6

V

V

4

Tube End

OD (in.)

DESCRIPTION

and Relay F^ackage (Six 38GS900051

ckages

Suction*

OD

(in.)

^8

^8

y« ,

%

%

%

%

%

T ubeODFnd

in.)

Evap

%

^8

% 1 % %

^8

%

%

V

/4

I V4t

%

%

Cond

^41 I

%

%t

%t %

% ^/4

%t

%

y —

/4 k4

38CC — (Fan motor suitable for 32LT)

38GS

V

014,018,024

4

3/ H

030,036,042,048

/4

V

014,018,024

/8

030,036,042,048

014,018,024

030,036,042,048

014,018,024

=/8

V

030,036,042,048

/4

014,018,024 -

%

030,036,042,048

USAGE

38GS,CC,CE

38GS,CC,CE

38GS,CC,CE

38GS (except 38G5014), 38CE

38GS0Ì4

38GS (except 38GSÒ42), 38CE

38GS042

UNIT

38CC

-

030,036,042,048

-

030,036,042,048

-

030,036,042,048

-

030,036,042,048

030,036,042,048

38CE

002

003,004,045,005

002

003,004,045,005

002

“0Ü3%O470457O0r^

002

003,004,045,005

002

003,004,045,005

*AII suction lines have a 90° bend at one end

tForb/8-in evaporator connection, cut off 3/4-in end

PIPING CONNECTIONS

Condensing units can be connected to evap

orator sections using Carrier accessory tubing

package or field-supplied tubing of refrigerant

grade. (Accessory tubing not available for

38GS060, 38CC060.) See Table 2 for accessory

tubing sizes and Table 3 for recommended fieldsupplied tubing sizes. Where evaporator is 20 ft or

more below condensing unit, reduce liquid line size

one diameter (min 1/4-in. OD).

A capacity reduction will result if accessory

tubing is used in 38CE045,005 systems. For

example, when a 25 ft accessory tubing package is

used, there will be a capacity reduction of 3 3/4%

on 38CE045 and 5% on 38CE005 systems. For

maximum capacity from these systems, use tubing

sizes shown in Table 3.

When other than 25 ft of interconnecting

tubing is used, follow special requirements de

scribed in Refrigerant Charging. Do not use less

than 10 ft of liquid line. Do not cut 5/16-in. or

1/4-in. liquid line. Bend or coil to fit.

Do not use damaged or contaminated tubing. If

accessory tubing package or evaporator section has

been open for more than 15 seconds per connec

tion, evacuate or purge evaporator coil and tubing

system (use field-supplied refrigerant, not unit

refrigerant). Always evacuate or purge if fieldsupplied tubing is used.

Before Connecting Unit Piping, consider the

following:

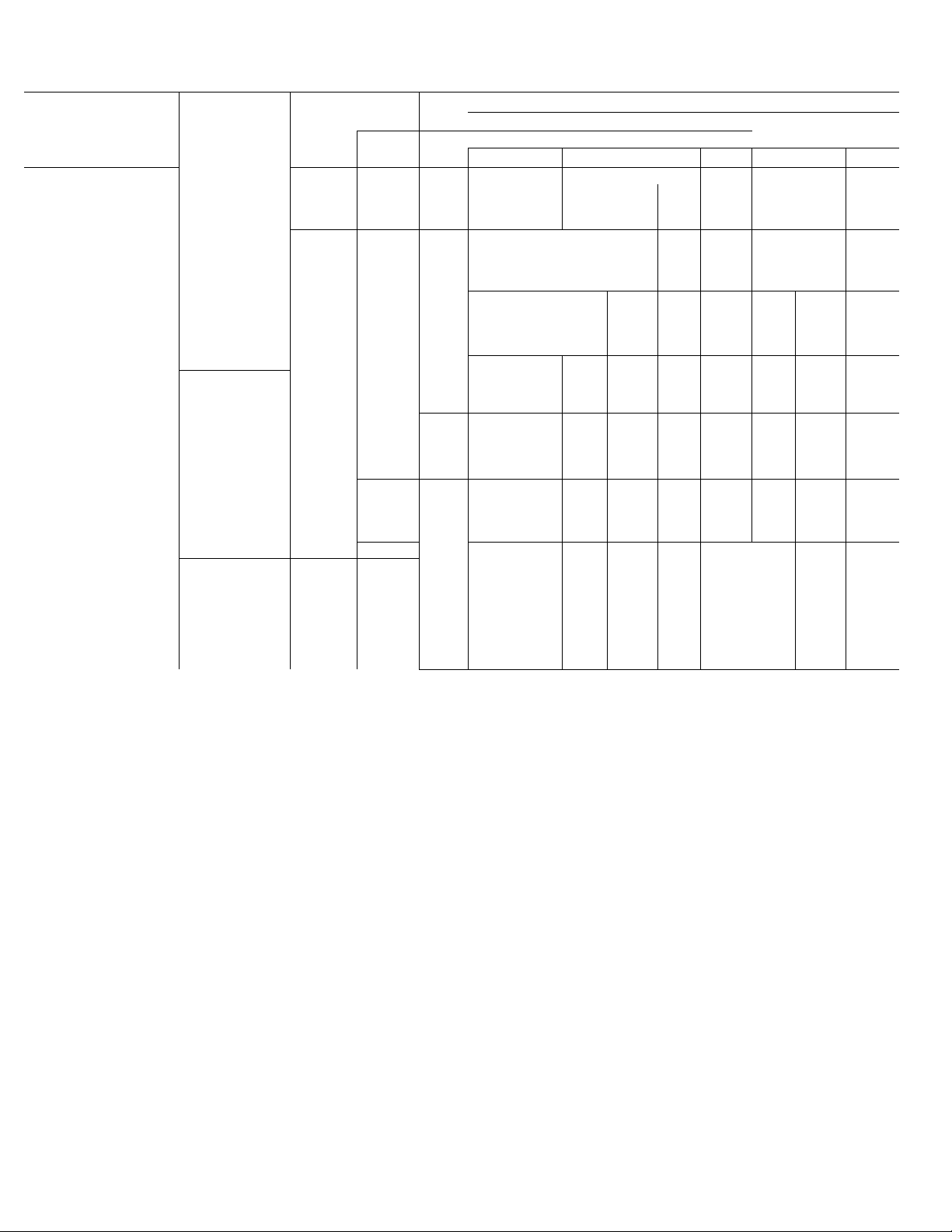

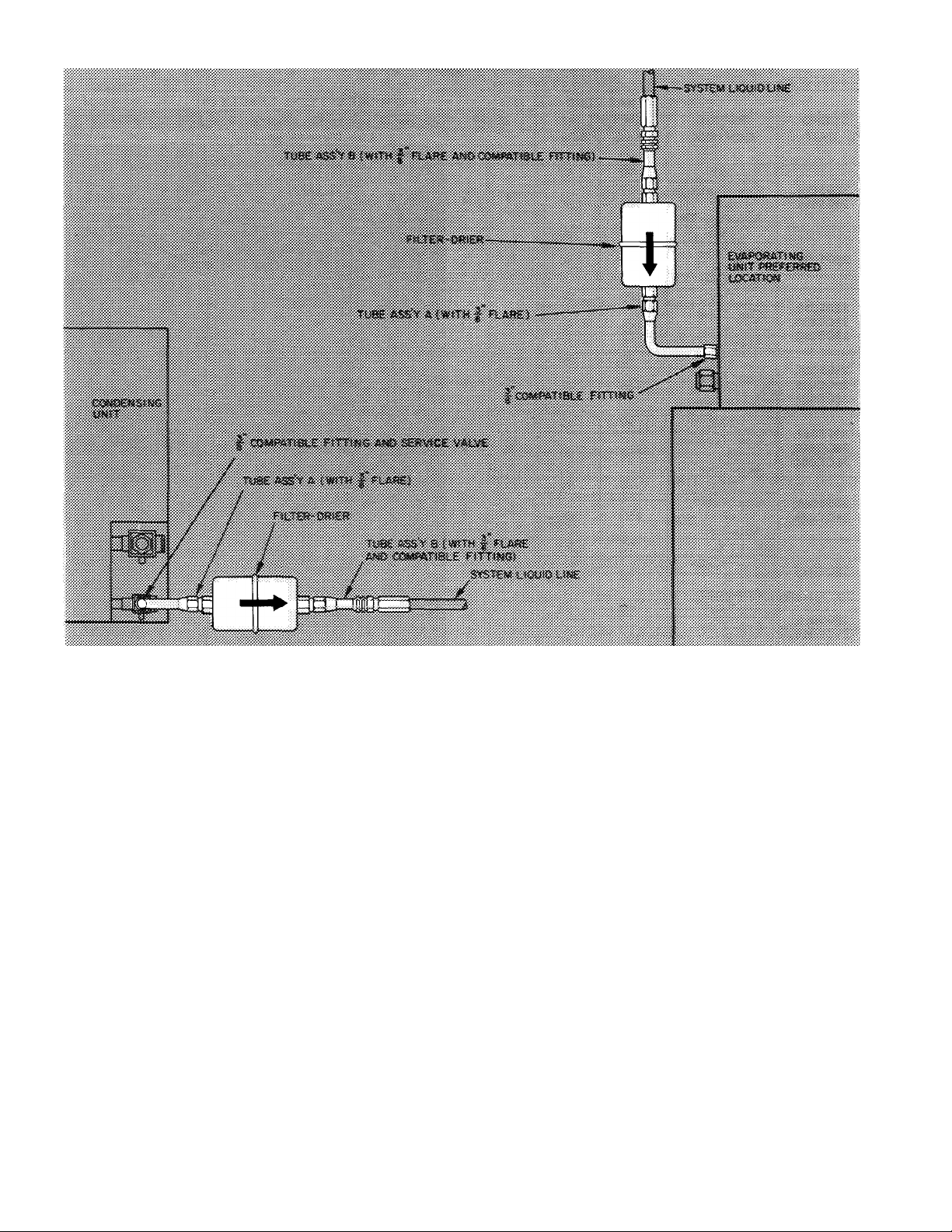

38CE045,005 AND 38CC UNITS - A filter-drier

package is shipped with these units. Included with

filter-drier are 2 short length tubing assemblies that

are equipped with flare and/or Compatible Fit

tings. Use tubing assemblies to install filter-drier

into system liquid line at evaporator or condensing

unit. See Fig. 2. Connect tubing assembly A (90°

assembly) to evaporator or condensing unit liquid

line Compatible Fitting. Complete the filter-drier

installation as shown.

Page 3

Table 3 — Field-Supplied Piping Data

MAX COND

COND

X-

f 3 UNIT

38GS014,

38GS018

38GS024

38GS030,

38CC030,

38CE002

38GS036,

38CC036,

38CE003

38GS042,

38CC042,

38CE004

38GS048,

38CC048

38CE045

38GS06 0,

38CC060,

38CE005

Cap. Tube

TXV

NOTES

REFRIG

CONTROL

TXV

Cap. Tube

or

AccuRater'*'^

TXV

Cap. Tube

AccuRater

Cap. Tube

or

AccuRater

TXV

Cap. Tube

or

AccuRater

TXV

Cap Tube

or

AccuRater

TXV

Cap Tube

or

AccuRater

TXV

Cap. Tube

or

AccuRater

L^y

Cap. Tube

or

AccuRater

Crankcase heater and liquid line filter-drier required

on 38GS and 38CE units Accessory start capacitor

with relay also required on 38GS unit, but not

normally required on 38CE units See Compressor

Service Reduce liquid line diameter by 1/8-in OD

(min 1/4-in OD) when evaporator is 20 ft or more

below condensing unit

■ Capillary Tube

- Thermal Expansion Valve

1 The following system modifications are required adjust

refrigerant charge on systems with over 25 ft separation

UNIT HT (ft)

Above

Evap

90

150

yo

150

150

90

150

90

150

90 ■

150

90

150

90

150

Be low

Evap

90

50

90

50 %

__

50

90

50

90

50

90

50

90

50

90

50

25- 50 51» 7S 7&~ 1

Suet Liq

V

'8 V» 'x iiiiii lili

%

%

%

%

1%

IV»

Vs

V» T

V»

/4

% liM

% Iliiii

V»

REFRIGERANT LINE LENGTH (ft)

Line Diameter (in* OD)

'

IIBI

ilM

iiiiiiiiiii

wmmmmmmm

N s

T %

k

between condensing unit and evaporator (See Refrigerant

Charging ) Adjust system oil charge as described in Note 2

Oil charge adjustment add 1% of nominal oil charge in

system (Table 7) for each 10 ft of refrigerant line length

above 50 feet Eor example, a system that has a 50-oz oil

charge with 1 50 ft of interconnecting piping requires 5 oz of

additional oil as shown below:

V

iÄiii

MB

ISl

*

150 ft - 50 ft = 100 ft

100 ft -E 10 ft = 10 ft

Litj 1 LEíj

iiiiii

IH

■

ilBi %

■

11»

Äiii

10x1% = 10% ( 10)

10 X 50 oz = 5 oz

Do not permit condensing unit to short cycle, particularly on

applications with long vertical line lengths Correct short

cycling condition immediately

m

¡Mil

Í.

..............

Connection Procedure — When making tubing

connections, be sure to provide clearance at unit

for electrical connections.

Connect refrigerant liquid and suction lines to

condensing unit, Fig. 1. Unit Compatible Fittings

permit 2 methods of refrigerant line connection;

mechanical (quick connect) or sweat connection.

Make suction line connection first.

38CE045,005, 38GS060 AND 38CC060 UNITS Remove suction line adapter taped to compressor

suction line. Connect 3/4-in. end of adapter to unit

suction line Compatible Fitting. Sweat connect

refrigerant suction line to 1 1/8-in. end of adapter.

Connect liquid refrigerant line to unit.

MECHANICAL CONNECTION (Mate one set of

connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

Remove plug and be sure 0-ring is in the groove

2.

inside the Compatible Fitting.

Cut tubing to correct length.

3.

Use gage on tag attached to service valve to

4.

mark tube end for correct insertion depth.

Insert tube into Compatible Fitting until it

bottoms. (Tube should be inserted at least as

far as mark on tubing.)

Tighten nut until it bottoms on back coupling

5.

flange.

Page 4

c

Fig. 2 — Filter-Drier Assembly Installation (38CC, 38CE045 and 005)

SWEAT CONNECTION (Use refrigerant grade

tubing.)

1. Remove locking nut, rubber 0-ring and

Schrader core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to

prevent damage by heat. Solder with low

temperature (450 F) silver alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied

refrigerant.

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

nameplate. Contact local power company for

correction of improper line voltage.

of ifolt ois tmpro|>er Ime

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 4 for recommended wire and fuse sizes.

Install a Branch Circuit Fused Disconnect of

adequate size to handle unit starting current.

Locate disconnect within sight of and readily

accessible from the unit, per section 440-14 of

National Electrical Code (NEC).

Bring Line Power Leads Into Unit — Extend leads

from fused disconnect thru hole provided in service

embossment (Fig. 1) and thru 7/8-in. hole into

control box.

Connect Ground Lead to a Ground Lug in Control

Box for safety. Connect power wiring. See Fig. 3.

Splice line power leads to red and violet pigtails on

38GS,CE units or to yellow pigtails (3) on 38CC

units. Use wire nuts supplied with unit. Tape each

connection. Wire nuts are suitable for copper or

aluminum wire since they contain joint compound.

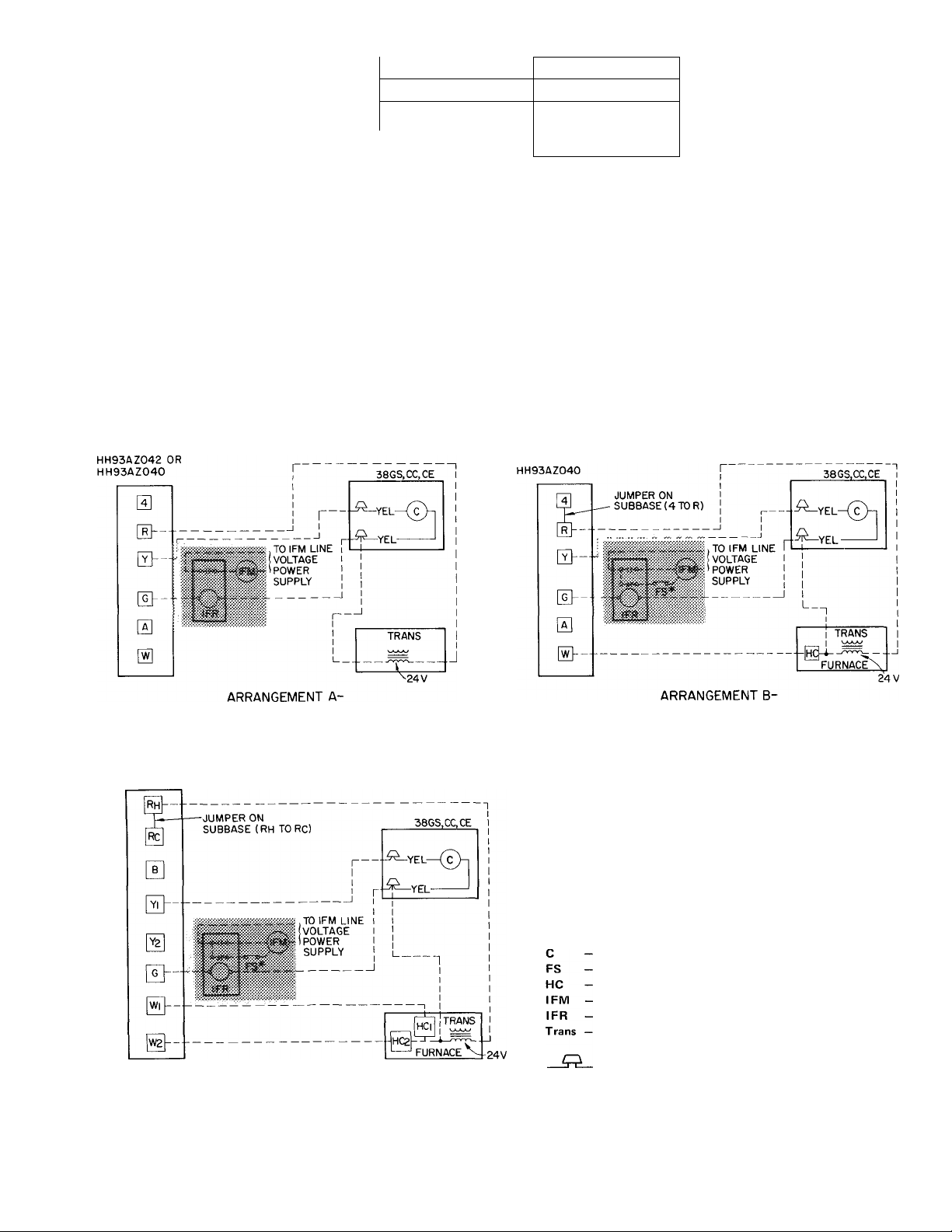

Control Power (24 v) wiring is brought thru hole in

service embossment and spliced to yellow pigtails

on all units. See Fig. 4.

Furnace or fan-coil transformer must be used as

24-v supply for system as shown in Fig. 4 (At least

a 40-va transformer is recommended.) Current

38GS048,060 and 38CC048,060 units are equip

ped with a low-voltage transformer used to power

contactor thru unit control circuit. This trans

former must not be used for powering the indoor

thermostat control circuit.

Page 5

I-PHASE

CONN. TO

FUSED

DISCONNECT

3-PHASE

CONN. TO

FUSED

DISCONNECT

SPLICE

------------

FACTORY WIRING

------------

FIELD WIRING

p

—

--I3D GROUND LUG

386S,CEC0NDUNIT

-YEL-

-YEL-

-YEL-

-------I3D GROUND LUG

38CC CONO UNIT

Fig. 3 — Line Power Connections

THERMOSTAT SUBBASE

THERMOSTAT SUBBASE

HH93AZ076

(COOLING ONLY)

THERMOSTAT SUBBASE

HH93AZ042 OR

ONE TRANSFORMER

(COOLING AND ONE-STAGE HEATING)

^CONNECT FS TO LOW-SPEED INDOOR FAN TERMINAL

WHEN 2-SPEED FAN IS USED

IFR, FS and IFM are located in furnace on heating-cooling

applications If accessory IFR is required for cooling only

applications, locate (IFR) in fan coiI

ARRANGEMENT C-

ONE TRANSFORMER

(COOLING AND 2-STAGE HEATING)

^CONNECT FS TO LOW-SPEED INDOOR FAN TERMINAL

WHEN 2-SPEED FAN IS USED

Fig. 4 -- Control Circuit Connections

Control Relay (10 va) or Contactor

Fan Switch

Heating Control

I ndoor Fan Motor

I ndoor Fan Relay

Transformer

Field Splice

---------------

Field Wiring

---------------- Factory Wiring

5

Page 6

Table 4 — Electrical Data

030

036

036

042

042

042

048

048

048

060

060

060

___

___

___

___

___

___

___

___

___

___

___

___

200/230/3 253

200/230/3 253

460/3 506

200/3

230/3 253

460/3 506

200/3

230/3 253

460/3

200/3

230/3

460/3 506

220 180 92

220

506

220

253 207

38CE

002

003

___

___

230/1 253

230/1

253

004___ 230/1 253

045

005

___

___

230/1 253

230/1 253

180

180 80/70

414

207

414 46

180 90

207 78.5

414 39 3

180

414

207 65

207 82

207

207 88 23.9

207 100 27.9

70/60

35

92

13 0/11 5

14 0/12 6

no

100

50

~88 19.8

6 5

17 0

15 8

7 8

18 6

16.1

8 3

23 0

20 5

10 3

10.3

16 8

FAN

FLA

2.4 14

2.1

2 4

2,4

.........

2 1

2.1 14

2 4

2.4 10

2 1

2.1

2 4 8

2.4

2 1 10

2.1 10 36

2 4 8

2.4

2 1

2.1

2.1 8

2.1

2 1

2 0/2 .0

2 0/2 0

1.0

2 0

2 0

1 0 14

2 0

2.0

1 0 14

2.0 8

2 0 10

1 0 14

2-.1

2 1

2.1

2.1 10 31 55

2 1

___12______

BRANCH CIRCUIT

Wire

Sizef

(AWG)

14

12

12 36 25

10

12 31 30

12 31 30

8

8

10

10 33 50

8

6

12

12

14 91

10 49

10 58

10

10

12

10

10 36

8

Max

Ft

Wiref

40

33

28

..37

..........

19

40

35

45 50

45

34

44

36

33

41

42

54

49

45 30/30

100

46

60

100 20

'■ 67 50

47

1 74

42

42

42 60

Fusei

Amps

20

20

30

20

25

35

40

50

30

45

55

65

50

65

55

75

30/25

15

35

35

15

40

35

45

20

25

35

45

FLA — Full Load Amps LRA — Locked Rotor Amps

______Electrical data shown applicable to all units for

which complete model number is not shown

•Permissible limits of the voltage range at which the units

will operate satisfactorily

START-UP INSTRUCTIONS

If unit is equipped with crankcase heater,

energize heater a minimum of 24 hours before

starting unit To energize heater only, set thermo

stat at “Off” position and close electrical dis

connect to condensing unit.

Units with Time Guard® circuit or solid state

time-delay may not start for approximately 4 to 5

minutes after thermostat closes. See compressor

controls, pages 7 and 8.

Start Procedure

1. Backseat (open) liquid and suction line service

valves.

(■Copper wire sizes Aluminum field wiring may be used when splice-

connected to copper pigtails from unit with factory-supplied wire nuts

Use latest National Electrical Code for aluminum wire sizing

^Maximum dual element fuse size

NOTE Control circuit voltage is 24 volts on all units

ov«rtii^i<?n servkc

4 Do exscod

6 fi-lb lorquc »hen

iighiiiiing.

2. Set thermostat selector switch at "Off.”

3. Set room thermostat at desired temperature.

4. Close electrical disconnects energizing entire

system.

5. Set room thermostat at “Cool” and fan switch

as desired (“Fan”) (“Auto.”).

Check system refrigerant charge. See Refrig

erant Charging.

Motors and controls will operate satisfactorily

in a range from 10% above to 10% below nominal

unit voltage (Table 4).

Page 7

Do not connect charging hoses to capillarycontrolled system during initial start procedure.

(Loss of charge from this procedure may result in

capacity reduction.) If necessary to add manifold

f • gages for servicing, refer to Carrier Standard

Service Techniques Manual, Chapter 1, pages 1—5,

Fig. 8, for bypass method of returning charge to

system. (A charging hose valve must be used to

accomplish bypass of refrigerant on all units.)

Table 5 — Service Data

CONO

UNIT

38GS014

38GS018

38GS024

38GS030

38GS036

38GS042 4-12

38GS048 5- 3

38GS060

38CC030 3- 2

38CC036

38CC042 3-12

38CC048

38CC060 5- 3

38CE002

38CE003

38CE004 5- 2

38CE045

38CE005

"■Factory refrigerant charge adequate for complete system when

connected to Carrier approved evaporators mat are the same

size as condensing unit, with 25 ft of tubing

R-22

CHG*

(lb—oz)

3- 0 2600

3- 0

3- 0

3- 2

3-M

5- 3

3-14

5- 3

4- 7

4-11

5- 6

5-11

CONDENSER

Rpm

1060 17/2

1070/870

975/800

Diam

COMPRESSOR SERVICE

Unit Single-Phase Compressors of the Split Capaci

tor (PSC) Type require an equalized system pres

sure to start. When supply voltage is within 10%

limit and compressor does not start, give com

pressor a temporary capacitance boost. See Carrier

Standard Service Techniques Manual, Chapter 2,

for details. Use a 130-mfd start capacitor. Connect

wires with insulated probes to each capacitor

terminal. Touch probes to each side of run

capacitor or to compressor motor terminals R and

S. Start compressor; pull probes away after 3

seconds. Discharge start capacitor. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Try restarting without boost

capacitor. If after 2 attempts (without boost

capacitor) the compressor does not start, add an

accessory start capacitor relay package.

Unit Single-Phase Compressors That are Equipped

With a Compressor Start Thermistor (PTC device);

if compressor will not start, check the thermistor

with an ohmmeter as described below. (If evap

orator coil does not have a bleed-type expansion

device, it may be necessary to remove PTC device

and replace with accessory start capacitor and

relay.)

(in.)

17/2

17/2

FAN

2600/2100

2600/2100

2800/2300

2700/2200

2700/2200

Cfm

2600

2600

2600

2600

2800

2800

2800

2600

2600

2800

2800

2800

CHECKING START THERMISTOR

1. Shut off all power to unit and wait 5 minutes

for thermistor to cool to outdoor temperature.

2. Measure resistance of thermistor with ohmmeter.

Normal resistance readings are 50 to 90 ohms at

75 F outdoor temperature.

3. If ohmmeter resistance reading is 0 or much

higher than 90 ohms the thermistor is defective

and must be replaced.

If start thermistor is good and compressor will

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described above. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Reconnect start thermistor

and try restarting compressor without boost capac

itor. If after 2 attempts the compressor does not

start, remove thermistor and add an accessory start

capacitor relay package.

38CC Units — Compressor start capacitor and relay

or thermistor (PTC) are not required on 3-phase

38CC units.

Safety Devices — Refer to Table 6 for particular

safety controls that each unit is equipped with.

Table 6 — Compressor Safety Controls

SAFETY CONTROLS

INTERNAL CURRENT-

TEMP SENSITIVE

OVERLOAD

INTERNAL THERMO

(Pilot Duty)

LOW-PRESS. SWITCH

HIGH-PRESS. SWITCH

CRANKCASE HEATER Accessory

OUTDOOR FAN

THERMOSTAT

TIME GUARD®

CPCS

SOLID STATE TIMER

CPCS

Compressor Protection Control System

38GS

014,018

024,030

036,042,048

060

-

-

-

060

-

ENSING 1

030,036,

042,048

030, Ò3C

042,048,

030,036,

042,048.

030,036,

042,048.

030,036,

048,060 -

38CC ^

060

060

060

060

-

042

-

NITS

38CE

002,003,

004,045,

005

Accessory

-

Accessory

002,003,

004,045,005

-

045,005

COND

UNIT PROTECTION

Internal Current And Temperature Sensitive Over

loads reset automatically when internal motor

temperature drops to a safe level (overloads may

require up to 30 minutes to reset). When an

internal overload is suspected of being open, check

by using an ohmmeter or continuity tester. If

necessary, refer to Carrier Standard Service

Techniques Manual, Chapter 2, for complete

instructions.

Page 8

Low-Pressure Switch is located on unit suction line

and resets automatically. Low-pressure switch set

tings are: cutout, 31+4 psig; cut-in, 60 (+ 15, - 0)

psig.

High-Pressure Switch is located on unit liquid line

and resets automatically. High pressurestat settings

are; cutout, 425 ± 5 psig; cut-in, 320 ± 20 psig.

Crankcase Heater warms compressor crankcase.

Prevents refrigerant dilution of oil in crankcase.

Outdoor Fan Thermostat maintains proper con

densing temperature at high outdoor temperatures

by switching fan to high speed. Located in control

box (on 38CE).

Filter-Drier is installed in liquid line.

Time Guard® Circuit provides for a 5-minute delay

before restarting compressor after shutdown for

any reason. On normal start-up the Time Guard

timer causes a delay of 15 seconds after thermostat

closes before compressor will start. On compressor

shutdown, the timer recycles for 4 minutes, 45

seconds. During this time the compressor cannot

start.

Solid State Time Delay provides for a 4-minute

delay before restarting compressor after shutdown

for any reason. On normal start-up, timer is

energized after thermostat closes and causes a

4-minute delay before compressor will start.

Compressor Protectibn Control System (CPCS —

Solid State) provides; compressor motor locked

rotor protection; compressor start winding pro

tection; compressor motor running overload pro

tection; compressor overtemperature protection;

contactor antichatter protection.

The CPCS also provides for a 4- to 6-minute

delay before restarting compressor after shutdown

for any reason. I f compressor loading was light at

the moment compressor was shut off, the delay

will be approximately 4 minutes. If loading was

heavy, the delay will be approximately 6 minutes.

To troubleshoot the CPCS, use unit label diagram

or wiring booklet and the following Control Circuit

Troubleshooting Chart.

CONTROL CIRCUIT TROUBLESHOOTING

CHART NOTES:

2. To disconnect plug from receptacle on CPCS

board — press in tabs located on the receptacle

and pull plug gently while holding tabs. Do not

pull on wiring.

When performing troubleshooting checks, CPCS

3.

receptacle must be plugged into CPCS board.

Receptacle female connections, which do not

4.

grip the male pin tightly, may be repaired with

a small pen knife.

When taking meter readings at CPCS receptacle,

5.

bottom meter probe into terminal hole to

ensure good electrical contact.

Replace CPCS board if electrical short circuit

6.

causes compressor failure. An electrical short in

compressor can short the triac (electronic

switch located on CPCS board). Triac may fail

in a closed (conducting) position and will not

open the control circuit.

Compressor Removal (See Table 7 for compressor

information and Fig. 5 for component location.)

1. Shut off power to unit. Vent refrigerant to

atmosphere or use refrigerant removal methods

shown in Carrier Standard Service Techniques

Manual, Chapter 1.

Remove top access cover and rear access wrap

2.

per (Fig. 5).

Remove power leads from compressor terminal

3.

box. Unsweat suction and hot gas lines.

Remove compressor hold-down bolts. Lift

4.

compressor out thru top or back of unit.

CONTROL

COMPRESSOR

TERMINAL

BOX

CAUTiON: Iks nmt

i>ece|siacle fiHscomsctsd fr«i ebm*

will up CICS

1. Ensure thermostat calls for cooling before

troubleshooting unit.

LIQUID LINE

Fig. 5 — Condensing Unit with Access

Panels Removed

(38CE Unit Shown)

Page 9

■ .

CONTROL CIRCUIT TROUBLESHOOTING CHART (GS,CC048 and 060)

Before attempting any corrective action, wait 8 minutes after power is supplied to permit CPCS time delay period to end. If control circuit

broken and unit has no time delay (or if time delay is over 8 minutes), replace CPCS board

tVoltage reading less than 20 volts may result from feedback circuit

I—mnrnnrtWfsrr—I

r* Olif *—

26VA

O CPCS Receptacle ^Component Connections

TYPICAL CONTROL CIRCUIT

INDOOR UNIT TRANSFORMER

THERMOSTAT

" ^Q—-—(CR

--0-^-0-

TRIAC

(COOLING), ,

Page 10

Table 7 — Compressor Data

COND

UNIT

38GS014__.

38GS014-..

38GS018200

38GS0182iO

38GS018300

38GS0183IO

38GS024200

38GS0242i0

38GS024300

38GS024370

38GS030200

38GS0302I0

38GS030300 230/1

38GS0303i0

38GS036200

38GS0362fO

38GS036300

38GS0363i0

38GS042___

38GS048___

38GS060

38CC030.__ 200/230/3

38CC036___

38CC036___

38CC042___

38CC042

38CC042__.

38CC048___

38CC048

38CC048-__ 460/3

38CC060

38CC060___ 230/3

38CC060

38CE002

38CE003

38CE004

38CE045

38CE005

---------

* Refer to Service Parts Catalog for replacement compressor

model numbers Single-phase units may include compressor

start assist device

___

___

___

___

___

___

___

___

___

___

Tabular data shown applicable to all models except

those shown italicized 000

V/PH

208/1

230/1

208/1

208/1

230/1

230/1

208/1

208/1

230/1

230/1

208/1

208/1

230/1

208/1

208/1

230/1

230/1

230/1

230/1

230/1

200/230/3

460/3

200/3

230/3

460/3

200/3

230/3

200/3

400/3

230/1

230/1

230/1

230/1

230/1

PRODUCTION

COMPR*

38GS400804

38GS400804

38GC401994

MD2023CB

38GC400224 21

MD2023CB 44

38GL400314

MB2723CB 44

38GL400324

MD2723CB

38GC401984 42

MB3423CB

38GC401404

MC3423CB 44

38GC402004

MB4023CB

38GC401564

MC4023CB 44

38GS400424

PC5329AD

PC6728AB

MF3423BC

MF4023CB

MH4023CB 44

38GR403364 46

38GR403364 46

38GR403374 46

PF5326AD 76

PG5326AD 76

PH5326AD 76

PF6725AA

PG6725AA 76

PH6725AA

MD2023CB 44

MD3023CB 44

MC3423CB

PC4629AD 76

PC5329AD 76

OIL

RECHG

(Oz)

21

21

21

44

42

42

44

44

42

46

44

46

46

76

76

44

44

• 76

76

44

PUMPDOWN PROCEDURE

The 38GS,CC,CE units may be pumped down in

order to make repairs on low side of system

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Jumper low-pressure switch (if unit is so

equipped).

4. Start unit and run until suction pressure reaches

5 psig (see Caution).

5. Shut unit off and frontseat suction valve.

6. Vent remaining pressure to atmosphere.

I

REFRIGERANT CHARGING

The 38GS,CC,CE condensing units contain

correct operating charge for complete system when

connected to Carrier approved evaporators that are

the same size as condensing unit, with 25 ft or less

of tubing of recommended size. Charge adjustment

may be required on other systems.

Listed (Table 8) and described below are

recommended methods of checking, adjusting or

recharging Carrier approved systems. When recharg

ing these systems, evacuate system to 5000 mi

crons (29.7-in. vacuum), and weigh in charge

shown in Table 5. When system is not evacuated,

subtract the following amount from total charge.

38GS014,018,024; 38CE002 - .11 lb (1.6 oz)

38GS030,036; 38CE003,004; 38CC030,036 - .21

lb (3.2 oz)

38GS042,048,060; 3 8CC042,048,060;

38CE045,005 - .31 lb (4.8 oz)

(Dial-a-charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply

firms.) After weighing in charge, check or adjust

charge using the Chargemaster® charging device,

charging chart or sight glass method as recom

mended in Table 8. Refer to Carrier Standard

Service Techniques Manual, Chapter 1, for system

evacuation — dehydration instructions.

When 38GS,CC,CE condensing units are con

nected to other than a Carrier evaporator, evacuate

system and weigh in charge shown in Table 5 or

use sight glass method of recharging (38CC thermal

expansion valve systems only).

10

Page 11

Table 8 — Refrigerant Charging Methods

(Carrier Approved Systems)

METHODS OF CHECKING

CONO

UNIT

AccuRater^ ^

38GS

38CC

38CE

TXV — Thermal Expansion Valve

0^ ADJUSTING CHARGE

System Refrigerant Control

Capillary

Tube

Chargemaster ®

or

Charging Chart

Chargemaster

or

Charging Chart

Chargemaster

or

Charging Chart

TXV

Charging Chart

Charging Chart

Sight Glass

Charging Chart

Charging Chart Method — For thermal expansion

valve systems, use Charging Chart, Fig. 6 or 7. See

Carrier Standard Service Techniques Manual,

Chapter 1, for procedure. For capillary tube or

AccuRater"''i'^ systems, use Charging Chart, Fig. 8

or 9 and the following procedure:

1. Operate unit a minimum of 10 minutes before

checking charge.

2. Measure suction pressure by attaching a gage to

suction valve service port.

3. Measure suction line temperature by attaching a

service thermometer to unit suction line near

compressor. (Insulate thermometer for accurate

readings.)

4. Measure outdoor (condenser inlet) air dry-bulb

temperature with second thermometer.

5. Refer to Charging Chart (Fig. 8 or 9). Find

condenser air temperature and project hori

zontally to curve showing suction pressure.

6. From intersect point, project vertically down

ward to chart suction hne temperature.

7. If unit has a higher suction line temperature

than chart, add refrigerant until chart tempera

ture is reached.

8. If unit has a lower suction line temperature

than chart, bleed refrigerant until chart tem

perature is reached.

9. If condenser inlet air temperature or unit

suction pressure changes, change to new suction

line temperature on chart.

Chargemaster® Operation — Operate unit 10 min

utes before using Chargemaster (Carrier Part No.

38GC680004).

RECHARGING METHODS

System Refrigerant Control

AccuRater

Weight Method

Chargemaster or

Charging Chart

Wei ght Method

or

Chargemaster or

Charging Chart

Weight Method

Chargemaster or

Charging Chart

Capillary

Tube

plus

plus

plus

TXV

Wei ght Method

plus

Charging Chart

Weight Method

plus

Charging Chart or

Sight Glass

Wei ght Method

plus

Charging Chart

1. Tape Chargemaster feeler bulb to suction line

close to condensing unit. Insulate bulb. Ensure

suction line is clean for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with drum in position for vapor charging.

3. Connect Chargemaster outlet port to unit suc

tion valve service port.

4. Crack valves on refrigerant drum and Chargemaster to purge lines from drum to suction

valve. After purging lines, close valve on Charge-

master only.

5. Measure outdoor air dry-bulb temperature.

6. Crack unit suction valve and read evaporator

temperature at red needle position on Chargemaster temperature gage and suction line tem

perature at black needle position.

CAIHIOI^; Do myi tmé

7. Enter Chargemaster Charging Chart, Table 9 or

10, at outdoor air temperature (step 5) and

evaporator temperature (step 6). Find the

suction line temperature required for correct

system charge. If actual suction line tempera

ture (step 6) is higher than table value, the

system is undercharged. If suction line tempera

ture is lower than table value, the system is

overcharged.

Example (Table 10): At outdoor air tempera

ture of 85 F and evaporator temperature of

44 F, the system will be correctly charged at

71 F ± 2 F suction line temperature.

11

Page 12

8. Add charge by slowly opening Chargemaster®

valve. If necessary, reduce charge by bleeding at

liquid line service valve. Check outdoor air and

evaporator temperature during procedure. If

they change, refer back to Chargemaster

Charging Chart for new value.

Correct use of Chargemaster ensures an opti

mum refrigerant charge will be in system when

conditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge

for condition of system. It will not make correc

tions for dirty filters, slow fans, excessively long or

short suction lines or other abnormal conditions.

This charging device ensures that a correct relation

ship exists between outdoor temperature, evap

orator temperature, and suction line temperature

on a specific system.

Sight Glass Method — A satisfactory operating

charge can be obtained on thermal expansion valve

systems by charging to a clear sight glass. For

optimum charge, elevate high-side pressure to

380 ± 10 psig by blocking condenser fan discharge

or condenser entering air. Charge to a clear sight

glass while holding high-side pressure constant. For

peak efficiency, adjust charge to yield a liquid

refrigerant temperature at the evaporator that is

approximately the same as outdoor dry-bulb

temperature.

A

I

12

Page 13

Table 9 — 38GS,CC Chargemaster® Charging Chart

(Capillary Tube or AccuRaterTM Systems)

30 40 50 60 70

SUCTION LINE TEMPERATURE (»F)

80

Fig. 8 — 38GS,CC Charging Chart

(Capillary Tube or AccuRaterTM Systems)

UU1UUUK

TEMP (F)

60

62

64

66

32 40

30- 38

28

27

68

70

72

74

76

78

80

82

90

84

86

88

90

92

94

96

98 36

100

102

104

106

108

no

112

114

*Saturated evaporator temperature which is the equivalent tem

perature of pressure taken at the condensing unit suction service

valve

EVAPORATOR TEMP (F)*

28

25 _

“1"

34 37

3ii

Suction L.ine Temperatures

51 ^

49

37 47

35 45 57

34

32

31

30

29 36 46

27 35 44

26

43

41

39 50

37

33

32 40

31

29 37

60

67

54

64

52

61 72

58

48

56

54 63 75

52 61

42

50 59

48

38

46 55

44 53 61 70

35

42 51

34

41 49 57

33

39

38

69

66

57 66

47 55

45 53

44 51

42

41 48 55

39 46

40

43 45 48

72

68

80

76

63

73 85

81

59

68 78 90

65 75 86

63 72 83

70 80

61

67 77

59

49 57

53 61

45 51 59 68

43 49 57 65

41

47 55 63

46 53

75

65

73

63

70

61

59

50

Fig. 9 — 38CE Charging Chart

(Capillary Tube or AccuRaterTM Systems)

13

Table 10 — 38CE Chargemaster® Charging Chart

(Capillary Tube or AccuRaterTM Systems)

EVAPORATOR TEMP (F)

TEMP (F)

60

65

70

75

80

85

32

60

49

41 48 58

35

31

iii

90 40

95

100

105 44

no

115

Example

36j3Sj40|42

Suction Line

58 65

41 48 58

36 42

......

.1.

— •1

68

50

70

68

59

>, V'

47 53

42

'em

75

69

48 53

43

4^48|50

44

peratore (F]

82

'

6; 69

59

4/ 52

48 53

__

78

67 79

68 88

58

60

49 54 65

50

52

75

62

54

104

80

69

Page 14

COMPATIBLE FITTING REPAIR

Leaking Mechanical Connection — Frontseat con

densing unit service valves and relieve refrigerant

pressure in tubing. Back locknut off Compatible

Fitting onto tube. Cut fitting between threads and

seal ring head as shown in Fig. 10. Remove tubing

section remaining in threaded portion of fitting.

Discard locknut.

Clean, flux, and insert new tube end into

remaining portion of Compatible Fitting. Wrap

valve base in wet rag. Heat and apply low tempera

ture (450 F) solder.

Leaking Sweat Connection — Frontseat service

valves and relieve refrigerant pressure in tubing.

Clean and flux area around leak and apply low

temperature (450 F) solder.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge (see charging

instructions).

Off íA&m

Fan Motor Removal

1. Shut off power to unit.

2. Remove unit top access cover and fan grille.

3. Disconnect fan motor wires from fan capacitor

and control relay or contactor. Pull wires out of

control box.

4. Remove fan from motor shaft by pulling

upward on fan hub.

5. Loosen bolt holding fan motor to motor

mounting bracket. Remove motor thru top of

unit. To replace motor, place motor on self

positioning motor mounting flanges and re

tighten bolt.

Fig. 11 — Condenser Fan Position

Fig. 10 — Repair of Mechanical Connection

CONDENSER

Coil Cleaning — Ensure power to unit is shut off

Clean the condensing unit coil at the beginning of

every cooling season or more often if required. Use

ordinary garden hose at a pressure high enough to

clean efficiently. For best results, unscrew and

remove unit top cover (grille). Insert hose nozzle

between fan blades and spray coil fins from

inside-to-outside the unit. If unit has a double-row

coil, loosen screws to separate coils, and flush dirt

toward outside of both coils. Flush dirt from base

pan by spraying water thru top of unit. Avoid

splashing mud on coil or water on the fan motor.

Metal Fan — Required fan position is shown in Fig.

11. Adjust fan by loosening setscrew and moving

fan blades up or down.

Plastic Fan is correctly positioned in unit by

placing fan on motor shaft — align flat mark on top

of fan hub with flat on shaft. Press down evenly on

top of fan hub until shaft bottoms in fan hub.

LUBRICATION

Fan Motor Bearings — Oiling holes are provided at

each end of current condenser fan motor. Remove

fan motor and lubricate motor with 32 drops (16

drops per hole) of SAE-10 nondetergent oil at

intervals described below:

a. Annually, when environment is very dirty,

ambient temperature is higher than 105 F and

average unit operating time exceeds 15 hours a

day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F

and unit operating time averages 8 to 15 hours

a day.

c. Every 5 years when environment is clean,

ambient temperature is less than 105 F and unit

operating time averages less than 8 hours a day.

Compressor contains factory oil charge. When oil is

lost, see Table 7 for oil charge and Carrier Standard

Service Techniques Manual, Chapter 1, page 1—21,

for instructions. Use Carrier PP33-1, Texaco

Capella B or Suniso 3G oil.

14

Page 15

TROUBLESHOOTING CHART*

*To troubleshoot control circuit on 38GS048,060 and 38CC048.060 units, see Control Circuit Troubleshooting Chart, page 9.

15

Page 16

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Tab 4

Form 38GS-13SI Supersedes 38GS-10SI

Printed in U.S.A. 2-75 Codes D and MS Catalog No. 533-810

Loading...

Loading...