Page 1

Number One

Air Conditioning

l\Mer

e

Division of Carrier Corporatio

Syracuse, New York

Packaged Direct-Expansion Air Handler

Air-Cooled Condensing Unit System

GENERAL

This publication contains application infor

mation for Carrier 38AD, AE, BA, and GR con

densing units used in split systems with 40RR

direct-expansion air handling units, including

system selection, performance data, combination

ratings, electrical and control data, and refrigerant

piping details.

■ SELECTION PROCEDURE (With Example)

I Given:

COOLING

Grand Total Load (Req’d TC) . . 600,000 Btuh

Sensible Load (Req’d SHC) . . . 430,000 Btuh

Temperature Air Entering

Condenser

...............................................

95 F

Temperature Air Entering

Evaporator — edb...............................77 F db

Temperature Air Entering

Evaporator — ewb

Evaporator Air Quantity

External Static Pressure

..........................

..................

..................

64 F wb

20,000 cfm

1.12 in. wg

Length of Interconnecting

Refrigerant Piping (Estimate)

.................

90 ft

Electrical Power Source,

Volts/Phase/Hertz

............................

460/3/60

HEATING

Heating Load............................... 900,000 Btuh

Temperature Air Entering

Coil (edb)

Steam Pressure

................................................

......................................

58 F

5 psig

II Select condensing unit/fan coil combination.

Enter the Systems Index at the desired cfm

(20,000). Select the condensing unit(s) and

fan-coil system that meets or exceeds the grand

total load (600,000 Btuh). In this example,

system no. 48 would be selected — two 38AD

024 and one 38AD016 condensing units and a

40RR054 fan-coil, yielding a nominal capacity

of 632,000 Btuh. To determine whether this

system will fully satisfy the cooling require

ments, enter the combination ratings, system

no. 48, page 9, at 20,000 cfm and 95 F condenser

entering air temperature. By interpolation, at

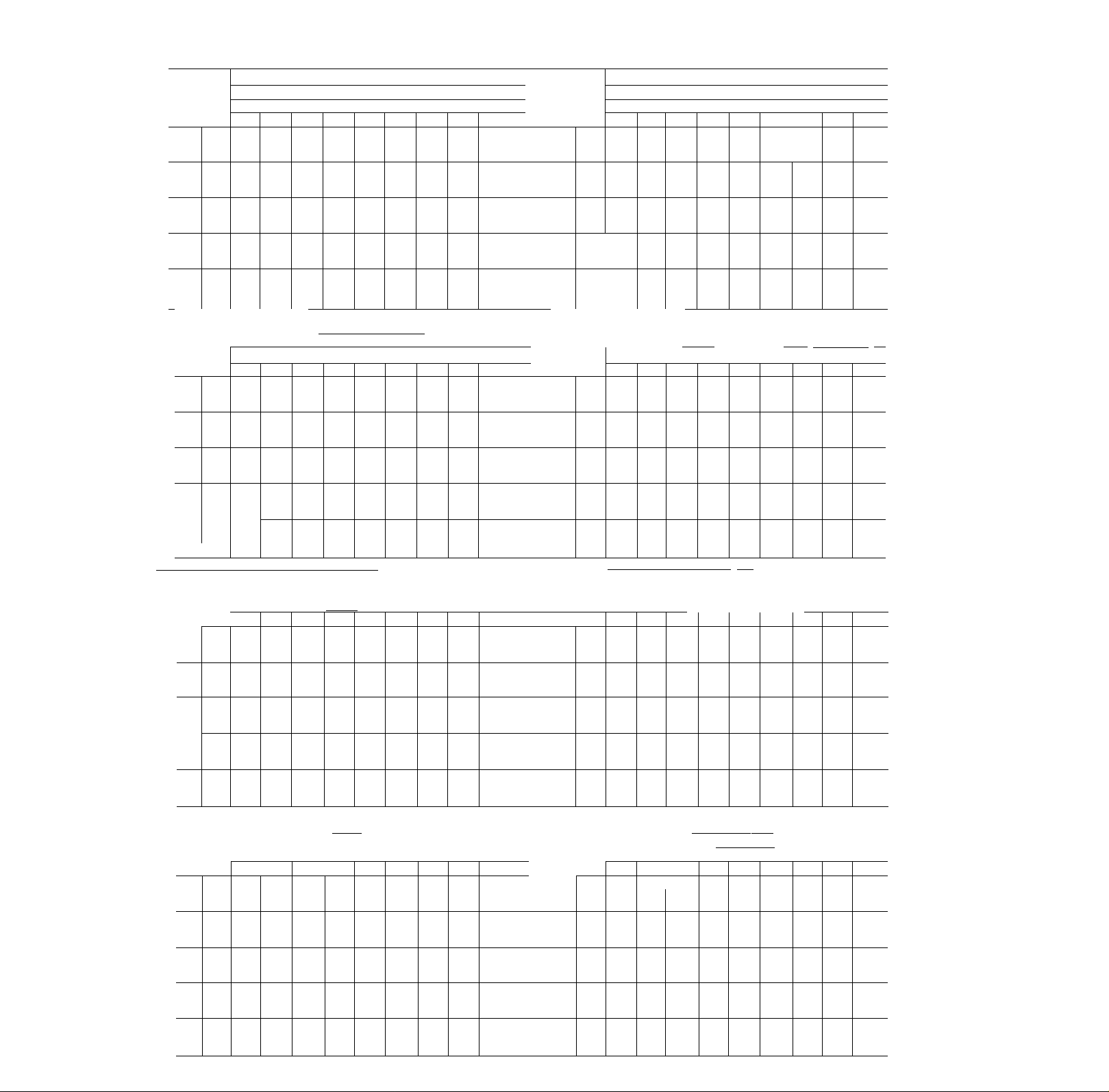

SYSTEMS INDEX

CONDENSING

_UNIT(S)

GR006

ВА008

¡38

ВД009

ВА008

38

ВА009

AD012

AD012

AD014

38

AD016

AD012

AD014

338

AD016

AD024

ADO^g-

AD012 (2)

38

AD024

AD028

AD024

AD012 (2)

AD028

38

AD016 & AD012

AD034

AD016 (2)_

ADÔ28

.............................

AD016 & AD012

AD034

38

AD016 (2)

AD024 & AD016

АЕ044

‘XÿJX'SVK

ш

в

шш

т

ШФ

Шщ

EER — Energy Efficiency Ratio

ТС — Total Capacity (1000 Btuh)

*ARI capacities, Energy Efficiency Ratios rated in accordance with

tFor units operating at 208 v, deduct 1000 Btuh from capacity

AD034

AD012 (3)

AD016 & AD024

AD016 & AD012 (2;

АЕ044

38

AD016 (2) & AD012

AD016 & AD028

AD016 & AD034

AD016 (3)

АЕ054

АЕ044

AD016 (2) & AD012

AD016 & AD034

AD016 (3)

AD024 & AD034

АЕ054

AD024 (2) & AD012

AD024 (2) & AD016

АЕ064

latest ARI Standard 210

rating

___

__

FAN

COIL

В А 009

RR 008

RR012

RR016

R R 024

RR026

R R 034

R R 044

R R 054

NOM

CFM

40

3.400

3.400

2,360*

40

3.000

3.000

j^OOO

4,5ÔÔ~

40

4.000

4.000

4/950*

6.000

40

6,000

6,000

40

8,000

40

10,000

40

12,000

40

16,000

40

20,000

ARI OR

NOM TC

'""'бЗ*''"

Î2Ô*t”^

"48I

88

100_

87

98

110

144

157

166

181

216

196

238

238

279

252

300

300

325

335

312

313

342

359

393

422

378

392

429

434

451

479

502

498

510

524

512

537

557

579

567

590

632

638

EER*

-

Tir

6 T'

9 0

7 6

7 6”'

9 5

8 2

8 6

© Carrier Corporation 1975

Form 38AD-5XA

Page 2

64 F evaporator entering air wb temperature,

the system has a total capacity (TC) of 600,800

Btuh, and a calculated sensible heat capacity

(SHC) of 498,800 Btuh. For close-coupled

systems (15 ft or less of interconnecting pipe),

an additional 2% may be added to both TC and

SHC. As this system is not close-coupled, the

ratings are used directly from the combination

ratings. At this point, the sensible heat capacity

is adjusted for the evaporator entering air db

temperature. For 20,000 cfm, the bypass factor

is 0.18. The adjusted sensible heat capacity is:

Adj SHC = SHC + [1.09 X cfm x (1—bf)

X (edb-80)]

= 498,800 + [1.09 X 20,000

X (1-.18) X (77-80)]

= 498,800- 53,600

= 445,200 Btuh

Therefore, the selected system will meet all

cooling requirements.

Find heating capacity of selected fan-coil unit.

Enter Table 3, page 10, for 40RR054 and

20,000 cfm. A one-row nonfreeze steam coil

will deliver 915,000 Btuh based on 60 F enter

ing air temp, and 2 psig steam. To find the

corrected heating capacity, enter Table 1, page

10, for steam coils at 5 psig steam and 58 F

entering air temperature. By interpolation, the

correction factor is 1.062.

Corrected capacity =

915,000 X 1.062

971,700 Btuh

Leaving air db

edb -t-

58 +

corrected capacity

1.09 X cfm

97\_J00

1.09 X 20,000

= 102.6 F

The heating coil has sufficient capacity and the

leaving air db is less than the maximum

temperature of 140 F.

IV Determine fan rpm and bhp.

Refer to Table 14, page 17, for a 40RR054 at

20,000 cfm and 1.12 in. wg external static

pressure, plus 0.07 in. wg for the heating coil

(Table 4), indicates a fan rpm of 828 and

requires 12.6 bhp. As this rating point is within

the shaded area, the fan drive must be selected

and purchased locally.

V Determine size of liquid and suction lines.

Table 11, page 14, indicates the pipe sizes for

the various condensing units. These sizes are

based on an equivalent length equal to the

maximum length indicated plus 50% for fit

tings. A more accurate estimate may result in

smaller pipe sizes. Enter the table with the

condensing unit (38AD024) and the estimated

length of interconnecting pipe (90 ft). The

suction line will be 2 1/8-in. OD and the liquid

line is 7/8-in. OD. Similarly, for the 38AD016,

the suction line is 2 1/8-in. OD and the liquid

line is 7/8-in. OD. If a 38AD034 — 38AE054

condensing unit is used with more than 25 ft of

piping, a double suction riser may be required.

VI Find size nozzle, TXV and solenoid valve.

To determine the nozzle(s), TXV(s), and sole

noid valve(s), enter Table 6, page 13, with the

system number. Tables 7, 8, 9, and 10 give the

part numbers for the keys indicated in the

previous table. For this example, a C12 nozzle

would be used in each of the 3 distributors.

Also, the TXV’s and solenoid valves used would

be (using Carrier Part No.):

FAN

COIL

40RR054

COND

UNIT

38AD024

38AD024

38AD016

COIL

SECT

u

M

L

TXV

EA03PC503

SOLENOID

VALVE

EF11BS28

EE11BS28

None Requ ired

Part numbers for Alco and Sporlan valves are

obtained in a similar fashion. Also, for several

systems, a single solenoid valve will control

both the middle and lower coil sections as

exemplified by system no. 49. These systems

should be piped in accordance with Fig. 5, page

16. When the condensing unit is below the

fan-coil unit, the maximum liquid lift as pre

sented in Table 13, page 15, should be adhered

to.

Page 3

COMBINATION RATINGS

Ratings Notes

1. Direct interpolation is permissible. Do not

extrapolate.

2. SHC is based on 80 F db temperature of air

entering evaporator coil.

Below 80 F db, subtract (corr factor x cfm)

from SFIC.

Above 80 F db, add (corr. factor x drn) to SHC.

ENTERING AIR DRY

BYPASS

FACTOR

.10 97

.20

.30

...

Interpolation is permissible

Correction Factor = 1 08 x (1

79

81

86

76

78

1.95 2 92

1 73 2.59

1 51

77

Correction Factor

2.27

-BULB TEMP (F)

— r

76^

75 1 under 75

85

3 89

4.86

3 46 4 32

3 03

3 78

BF) X (db - 80)

ovec/85

use formula

shown be low

3. Gross capacities shown do not include a deduc

tion for evaporator fan motor heat.

4. Formulas:

hdb “ tedb

sensible heat capacity (Btuh)

1.08 X cfm

tiwb “ wet-bulb temperature corresponding to

enthalpy of air leaving evaporator coil

(hlwb)

hlwb - hewb

total capacity (Btuh)

4.5 X cfm

where hewb ~ enthalpy of air entering evap coil

5. Combination ratings are based on a 2 F line

loss. For a close-coupled system (less than

15 ft), add 2% to ratings. Piping sizes in Table

13 are based on 2 F line loss. All combination

ratings are based on R-22.

LEGEND

BF — Bypass Factor

TC — Total Capacity (1000 Btuh)

SHC — Sensible Fleating Capacity (1000 Btuh)

KW >- Compressor Motor Power Input

Ewb — Entering Wet-Bulb

U - Upper Coil

M — Middle Coil

L — Lower Coil

U-M-L abbreviations indicate connection of condensing unit to upper.

middle or lower coil of fan-coil unit

i 38GR006 and 40BA009

T emp(F)

Air Ent

TC

85 SHC

KW

TC

95 SHC

KW

TC

100 SHC

KW

TC

105 SHC

KW

TC

SHC

115

KW

2875/. 13

72

67

81

74

46 60

8.2

7.7

75

69

44

57

8.7

8.2 7.9

72 66

43 58

8.9

8.4

69

64 61

42 56 61 49

9.2 8.7 8.4

59

63

40

53 57

9 6

9.1

38BA008 and 40BA009

Temp(F)

Air Ent

TC

85 SHC

KW

TC

SHC

95

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

SHC

115

KW

2500/. 16

72

67

101

93 85 105

50

62 74 55

7.7

7.4 7.0

96 89

48 60

8.4

8.0

94 86

48 59 71

8.7

8.4

91

84

47

58 70

9.1 8.7

86 79

45

57 68 50

9.8 9.4

^^38BA009 and 40BA009

Air

Ci

85

95 SHC

100

105

115

Ent

TC

SHC

KW

TC

KW

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

2500/. 16

72 67

112

103

54

67 79 59

9.9

10.5

108 99 90

53

65 77 58

11.2 10.7

105

96 89 no 101

52 64 76

1 1.6

11.1 10.5 12.0

102 94 86

51

63 75

12.0

11.4 10.8 12.5

96 89 81 101

49

61

12 8 12 2 1 1 6

38GR006 and 40RR008

2525/. 19 3375/.23 42257.26

r.

85

95

100

105

115

72

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

67 62 72 67 62

79 71 65 81 74

55

43

7.7 7,2 6.9 7.9

73 67 62 75

41 54

8.2 7.7 7.4 8.1

71 64 60 73

40 53 60 47

8.4 8.0 7.6 8.6 8.2 7,9

62 58

68

39

52

8.7 8.2

58 55 65 60

63

50

38

9.1

8.6

Evgp Air - Cfm/BF

3825/. 16

Evap Air - Ewb (F)

62

72

67

69

83 77 74 84

69

53 70 74

7.4

8.3 7.9

65

77

65

51

8.9

63 74

63 50 65

8.2 9.1

71

9.4

57

64 60 60

47 60 60

8.9 9.8

62 72 67

7.7 8.4 8.0

71 69

67 69

8.4 8.3 9.0 8 5

68 67 74

67 56

8.6 8.5

66 65 71

64

8.9 8.8 9.5 9.0

9.3

9.2 8.8

65 55

65

9.3 9.9 9.5

ARI - 88,000 Btuh

Evap Air - Cfm/BF

3400/.23

Evap Air - Ewb (F)

62 72

81 100

72

7.6 8.5 8.2 7.8 8.6

79 98 89

7.9 8.9

77 95

8.2 9,3 8.9 8.4

73 90 82 75 91

9.0 9.9 9.5 9.1 10 1

Evap A

67 62 72

97 89

70

7.8 7.6

92 85 102 94

53 68 84

52 68

8.5 8,1 8.9

87 80 97 89

52 67 80 55

65 75

108 99 91

86 59 70

7.2 7.9

83 100 91

81 56 74

AR

- 100,000 Btuh

ir - Cfm/BF

57 75 87

9.4

53

3400/.23

E vap Air - E

62

72 67 62 72

94

118 108 99

9.5 10.7

113

10.2

11.6

57 72 87 61 79 95

106 98

56

72 54

13 2 12 5 11 9 13 4 12 7 12 1

wb (F)

75 90 64 82 101

10.2 9.7 11,1 10.5 9.9

104

73 88 62

11,0 10,5 11.9

1 1.4 10,8

71

11.8

92 83 103

69

121 112 102

95 1 16 107

93 113 104 95

12.3

90

109

60

86

11.0 12.7

83 58

E vap Air — Cfm/BF

E vap A ir — Ewb (F)

72

70

83

65 50 64

62 48

70

58 46 60 62

7.9

8.9

55 44 57 58

8.3 9.3 8.8 8.7

70 56

7,4

69

62 66 53

7.9 7.7 8.5 8.1

67 64 74 68 67

61 64 52

64 62

8.4

8.0

7.2

66

8.7

9,0 8.5 8,4

8.2

58

9 4 8.9

76 71 69

71 66 65

51 65 65

65

49 61

4775/. 19

62

78 77

59 76

78

57

53 62 62

7.9

72

72

8.5

69

69

8.8

67

67

9.0

62

9.6

4300/.28

67

62

91

7.6

7.3

87

8,2 7.9

85

84

8.6 8,2

82

73 82

9.0

8.5

84 77

71 77

9.7 9.3

4300/.28

67 62

98

80

98

11,3 10.6

10,9

11.7

101

92

78 92

12.1 1 1.3

95 87

76 87

67 62

76 74

74

72

7.6 7.4

69 69

7.9

67 67

8.2

8.3

61 61

61

8 9

77

72

72

70

70

67

67

62

Page 4

:^^38BA008 and 40RR008

2200/. 17

72 67 62 72

Tc

85

95

100

105

115 SHC

96 88 81 100

SHC 46 57 67

KW

7.5 7.2 6.9

TC

91 84

SHC

45 55 66 50

KW

8.2 7.7 7.4

TC

89

SHC

44 54 65

KW

8.4

TC

87

SHC

43 54 64

KW

8.9 8.4

TC

82

41 52

KW

9 6 9.1 8.7 9 8

¡38BA009 and 40RR008

2200/. 17

72 67 62 72

TC

85

95 SHC

100

105 SHC

115

105 97 89

SHC

50

KW

10.1 9.6 9.1

TC

101

48 59

KW

10.8 10.4 9.9

TC

99 91

SHC

48

KW

TC

KW

TC

SHC

KW

10.7

11.2

96 89 81 101

47 57

11.7 11.0 10.5 12.0

92

45 55

12.4 11.8 11.1

38AD012 and 40RR008

Temp(F)

Air Ent

2200/. 16 3000/.20 3800/.23

72 67

TC

85 SHC

95

100 SHC

105

115 SHC

119 107 98 124

54

KW

11.4 10.8 10.3

TC

113 103

SHC

52

KW

12.2 1 1.6

TC

1 10

52

KW

TC

SHC

KW

TC

KW

11.9

12.6

108 99

51 62 73 56

13.1 12.4

103

49 60

13 8 13 2 12 4

38AD012 and 40RR012

Temp(F)

Air Ent I

v.o na f"— -

TC il 33 122 112

SHC i 64

85

KW hi.4

TC i! 125

95

SHC j 61

3000/. 16 4000/.20

1 72

10.8

KW il2.4 11.6 10.9 il2.7 12.0

tc j 122

100

SHC 60

105

115

KW ! 12.8

TC i 118 ^

SHC 58

KW j 13.2

Tc“l n 1

SHCj 56

KW 114 0

12.0

12.4

13 1

E

vap Air - Cfm/BF

3000/.21

Evap Air — Ewb (F)

67

62

92

51

7.6

77 96

82

8.1 7.7 8.7

80

76 79

8.4

76

93

49

74 91

48

8.0 9.0

86 79

46

62

Evap A

85 104

65

79

7.4 7.0

88

81

64

77

8.0

7.6 8.4

86 79

77

63

7.9

8.2

84 77

62 76

8.5

8.2 9.2 8.8

72

60

72 51 67

9 4 8.9 10.0

ir - Cfm/BF

3000/.21

Evap A

if — Ewb (F)

67 62

61 71 55

93 85 107

58

84 77

111

10.3

69

54

11.1

104

83

68 53 67 80

11.5 1 1.0

10.2

68

52 66 79 57 74

96

66 50

12.9

94

102

69

83

9.9

9.4 10.6

98 90 no

68 81 58 75

10.7

10.2

95 88

10.5 11.8 1 1.3 10.7

86 105 96 89

93

11.2

10.8 12.3

88 81

77

64

12.1 11.5

Evap Air — Cfm/BF

Evap Air - Ewb (F)

62 72

76 60

66

64 75 58

101 92 116

63

94

11.9

94 119

10.9 12.7

74

57

13.1

11.2

90

113 104 96

11.7

13.5 12.8

108

86

70

54 69 82 60

14 2

62 72 67

67

114 105 128

75 88 65 82 101 85

11.2 10.7 ¡12.0 11.5

101

1 10

87

73

1 1.4

12.0

107 98 1 19

72 86 62

12.3 1 1.7 13.4

71 85 j 62

12.2 •il3.7

99 91 111 103

13 6 12 8

Evap Air — Cfm/BF

Evap Air — Ewb (F)

62

67

79

116 106 i 131 121 1 12

76

113 103

75

109

74 88

102 94

71

1 72 67 62

139

94

10.2

91 68 86 105 74 96

90 i 67 85 104 73

11.2

100 1123

11.6 113.6

86

12 3

129 118 143

89 108 77

jll.8 11.2 10.5

11.3

109

118

1 127

i 13.1 12.4

j 65

j 115 107

] 62 81

1143

11.6 13.3

105 128

1 14

84

102

12.0 13.8 13.0 12.3

12.8

98

98 68

13.6

12 6 14 7 13 8 13 0

COMBINATION RATINGS

ARI - 87,000 Btuh

3800/.24

72

67

62

95

56 73

7.7 7.4

98 91 84

54 71 84

95 89

53

8.8 8.4

93

53

88 81 75

ARI - 98,000 Btuh

3800/. 24

72 67

115

60 77

11.4

108

58

99 91

55

13.0 12.4

123

63

12.9 12.3 11.7

1 7

14 5

5000/. 23

72

12.0

135

12.9

132

71 93 108

118

88

88

7.2

8.1 7.7

81

70

82

8.1

86

79

69 79

8.4

75

9.6 9.1

11^ 38AD016 and 40RR012

62

106

98

93

10.0

9.6

102 93

92

10.8 10.4

99

91

74

91

89

11.7 11.0

84

71

84 115 SHC

11.7

62 72 67 62 72 67 62

118

109

11.0

114

105

81

98

111

102

79

98 100

12.6 12.0 KW

108 1 10 TC

79

96

13.1 12.5

94

77

93 115

13 9

13 1

67

62

/-¡22

132

99

121

1 1.4

10.8

125

115

115

11.4

12.2

121 112

95 112

11.8

12.6

117

108

109 101

90 101

38AD014 and 40RR012

3000/. 16 4000/.20 5000/. 23

72 67 62 72 67

tc

156 143 130 165 152

SHC

85

95

100 SHC

105 SHC

US SHC 71

-r.

T ( * 7

80 95

KW

15.7 15.0 14.2 16.3

TC

149 136 123 158 144

SHC

77 92 108

KW

16.8 15.8 15.2

TC

146 133

76 91 107 76 94

KW

17.1

TC

KW

TC

KW

16.6 15.6

141 129 117 149 136

74

16.7 15.9

17.5

134 122 Tl 1

18.5 18.0 16.7 19.2 18.2

3000/. 16

72 67 62 72 67

TC

166 153

SHC

85

95

100

105 SHC

78 93

KW

14.8 14.0

TC

161

SHC

KW

TC

SHC

KW

TC

KW

TC

KW

148

75 90 104

15.0 14.4

15.6

157 145

74

16.0 15.4 14.8 16.6 15.9

141

153

72 87 102 78 97 117 85

16.5 15.8 15.2 17.2

134

146

70 85 98 76 95

16.7 16.0 18.5 17.6

17.8

38AD012 and 40RR016

T emp(F)

Air Ent

95

105

.

»

TC

SHC

KW

TC

SHC

KW

TC

SHC

SHC

KW

TC

SHC

KW

4500/. 15 6000/. 19

150 139 128

79 101

12.5 1 1.9

142 131

76 98

12.7 12.1 13.8 13 0 12 3

13.3

127 117 142

137

75

13.7 13.1

132 122 113

73 94 113

14.2 13.5

123 113

69 91

14.9 14 2 13 4

38AD014 and 40RR016

Temp(F)

Air Ent

4500/. 15 6000/. 19

72 67 62

|tc

SSjSHC

95 SHC

I KW

lOOlSHC

i KW

105* SHC

! KW

115 SHC

179 166 152 188

91 113 135 98

KW

17.1

ftc”

171

88 1 10

18.1

|TC

166

87 108 130 93 122 148

18.7

!TC

161

85 106

19.3

rtc~

153

8 : 102

KW

20 2 19 2

16.3

158 145

17.3

154 141 174 161

17.9 17.C 19.4

149

18.3 17.2

140

E vap Air - Cfm/BF

Evap Air - Ewb (F)

79 98

111

120 154 141

89 105

86 102 71 90

Evap A

15.4

77

17.3 16.4

17.9 17.1

74

18.3 17.2 16.4

141

129

Ir — Cfm/BF

4000/.20

Low

Suet

133

131

89 103

128

122

Evap A

-

ir - Ewb (F)

176

163 150

84 104

14.6

15.3

170

157 144 175 163

82 101 120 88 111

16.0

15.5

166

153 141 171

80

162 149

16.4

154

142

Evap Air -

Evap Air — Ewb (F)

157 145

89 117

123

12.7 12.2 1 1.5

11.2

120 147 135 125

120

85 113 125

117 84 112

96

12.4

12.7 14.6

105

105

130

13.4 12.6

14.2

136 126

110

82

13.8

126 117 108 128

79 101 108

15.2 14 5 13 7

Evap Air — Cfm/BF

Evap Air — Ewb (F)

72

67 62

174

127

15.5 17.6

16.7 15.9

180 166

132 95 123

16.4

18.7

17.8 16.9

18.3

137 168 156

128 91 121

19.9 18.9 17.7

_

_

-

148 134

115 134

19 7

128

124

18 2

62

138

118

14.7 16.7

131

96 114

15.6

128 160 146

1 12 81 104

15.8 18.2

125 154

93

1 11

118 145

108

17.1 19.9

62

122 91

13.9

14.8 16.2

99

119

15.2

137

15.6

130 159

1 13 82

16.5

133

133

121

121

1 16

1 16

13.0

160 191

155

153 182

152

148

17.4

143

143

18 7

72 67 62

171 158 144

85 108 131

164 150 137

83 106 127

17.6 16.7 16.0

80

18.8

77

15.0

15.8

134

126

17.3 16.4

130

142

102 124

17.7 16.7

122

134

100 121

18.5 17.6

5 000/. 23

72 67

181

15.4

87

16.8 16.1

166 155

17.4 16.6

18.8 18.1

62

154

168

114 136

14.9 14.1

150

134

15.0

15.6

159 146

110 133

15 4

142

108 131

15.9

147 136

104 127

17 0

7500/.22

72 67

160

100 133

12.8 12.3

149 137

96

13 8 13 2

144 133

95 128 123

14.2 13.5

138

93

14.7

89 118

15 4

62

147 136

136

11.7

127

127

129

12 4

123

13.0

118

128

126 118

13.6

13.9

110

118

no

14 6 13 9

7500/.22

72 67

107

17.8

105

18.9

178

104

19.4 18.8

—

_

-

_

_

-

62

165

178

145 165

17.0 16.2

170 157

157

139

18.0 17.2

164 152

152

138

17.7

158 146

135 146

18.1

19.2

137

148

137

131

19 0

20 0

Page 5

COMBINATION RATINGS

r38AD016 and 40RR016

P(F)

4500/. 15

E vap

E vap Air — 1

72 67 62 72 67

TC

199 182 168 206 191 176

SHC

85

95

100

105

115

0^38ADO24

94 117 139

KW

TC

SHC

KW 17.2 16.5 15.7

TC

SHC

KW

TC

SHC

KW

TC 166* 157 144

SHC

KW

15.4

16.1

189 174 160

114

91

184 170

90 112

17.8 17.0 16.2

180 166

88 110

18.4 17.5 16.7

84 106

19 4

18 8

and 40RR016

104 133 161

14.5

16 4 15.7

196

135 101 129

17.6

157

192 178

134 99

18.2

153 188

132 97

18.8 18.0

174* 160*

128 75 122

19 9 19.1

17.8

E vap A

A

Pr.*

4500/. 15

E vap A ir - E

72 67 62 72

TC

85 SHC

95 SHC

100

105

115

232 213 195 246 226

134 157

111

KW

19.9 18.8 17.9 20.5

TC

KW

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

204

222

107 130

20.1 19.0

21.6

199

218

105

128 150 115 144

22.2 20.8

194 177 224

213

103 126 148 113

22.8 21.5 20.3 23.5 22.3 21.1

185

203

99 122 144 109

23.0

24.4

121 151 180 131 166 201

186 235 216

117

152

22.0 20.9 19.8

182 230 21 1 193 238 219 200

19.6

22.7 21.6 20.4

168 213

25.1

21.7

38AD016 and 40RR024

T emp(F)

Air Ent

uona

TC

SHC

85

KW

TC

95 SHC

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

SHC

115

KW

6000/. 15 8000/.18 1 10,000/.2r

72 67 62 72 67 62 72 67 62

214 198 183 221 206

139 169 121 160 190

108

17,0

16.2

189

204

105 135 165 118 156 181

18.1 17.1

185 171 205 191 177

199

134

104

17.8

18.7

180

193

102 132 162 1 14 153

18,5 17.4 20.0

19.4

179* 166* 156 184* 171* 158* 188*

98 128 156 112

19.4

20.3

Evap Air — Cfm/BF

Evop Air — E\yb (F)

17.4

15.5

210 196

175

18,6 17.7 16.8 18.7

16.6

164 116 155 177 128 172 181

17.0

19.3

166 199

20 6 20 1

18 7

[38AD012 w/U, 38AD012 w/L. of 40RR024

Temp(F)

6000/. 15

E vap Air — Cfm/BF

vap Air — Ewb (F)

E

72 67 62 72 67 62

TC

85 SHC

95 SHC

100 SHC

105 SHC

115 SHC

257 237 217 269

126 156 186

KW

22.7 21.5 20.2 23.4 22.2

TC

246 226

122 1 52 181

KW

TC

KW

TC

KW

TC

KW

23.1

24,4

240

221 203

119 150 179

23.9

25.2

233 215 198 243 224

1 16 147 177 130 169 205 143

26.1 24.7

220

204 188 228 212 196 233

1 12

143 172

27.8 26. ;

139

257

208

135 174 212

21.7

25.1 23.8 22.5

250

133 172

22.4

26.0 24.6 23.2 26.5 25.2 23.8

23.1 26.9

125

24,5 28,7 26,9 25,3

A

ir — Cfm/BF

6000/. 19

7500/ 22

:wb (F)

62 72 67

211 197

1 13 147

15.1 16,8 15.9

181 168

16.7

128 156 108

17.3

174

126 154 106

200

187

109

158

16.2

164

16.7

159

17.2 19,2 18.3 17.5

149 177* 165*

146 103

18.3 20.3 19.3

143 173

17.9 17,0

196

183

141

18.5 17.6 16.9

192 178 164

139

137 154

ir - Cfm/BF

6000/. 19 7500/.22

Iwb (F)

67 62 72 67 62

254

207

18.6

19.5

198 243 224 205

147 175 127 162 196

173 125 159

206 188 232

171

142

195

178

138 166

23.8 22.5 25.6 24,3 23.0

190

15.9

16.5

181

17.4

18.4

185

172 203

172 126 171 176

18.0

18.8

149

158

18 8 21 ;

235 216

20,0 19.0

21.0

21.4

22.5

23.2 22.1

^213

157

123

24.0

22.8 21,6

220

202 185

119

153 185

226

21 1

178 195

133

16.9

17.5

215 200 186

129 173

17.9 17.0

209 195

18.4

19.6

189 176

19 1 18 2

20.5

175* 161*

167 161

122

20 1 19 0

8000/. 18 10,0007.21

72 67 62

249

178

238

231

25.4

164

277 256 ^236

228

216 152

21.0 23.7 22,6

218 264

213

209

207 249

24.G

196 138 184

199 236

244

147 193 225

25.7 24.4 23.2

257 237 220

145 191

230 214

188 214

26.0 24.5

27.4

216 201

29.2 27,5

38AD024 and 40RR024

P(F)

62

182

178

15.3

173

16.3

169

169 100 SHC

Cr

85

95

TC

SHC

KW

TC

SHC

KW 22.7

TC

KW

TC

164

154

18 7

105 SHC

KW

TC

115

SHC

KW

38AD028 and 40RRd'24

1 ciiiH VI

K

G

Slid

TC

SHC

85

KW

TC

95 SHC

20.3

KW

TC

105

115

SHC

KW

TC

SHC

KW

TC

SHC

KW

194 100

20.9

195

192

|^"38AD024 and dORRO^d”

Temp (F)

Air Ent

195

16.1

186

TC

85 SHC

KW

TC

SHC

95

KW

181

17.6

TC

100 SHC

KW

TC

105 SHC

KW

TC

115 SHC

KW

BF — Bypass Factor

TC — Total Capacity (1000 Btuh)

21.5

225

SHC — Sensible Heating Capacity (1000 Btuh)

KW — Compressor Motor Power Input

Ewb — Entering Wet-Bulb

U — Upper Coil

M — Middle Coil

220

L — Lower Coil

U-M-L abbreviations indicate connection of condensing unit to

upper, middle or lower coil of fan-coil unit

*Capacities at a minimum 38AD016 charge to prevent high

pressurestat cutout Other capacities are at optimum charge for

201

25.7

maximum capacity.

E

vap /

6000/. 15

72

67

259

238 218

128 159

21.2 20.1

247 227

124

241

121

23.4

235 216

1 19

24.2 23.0

223 205 187

115 145 175

25 9

189

19.1

208

154

185

21.5 20.4

222 203

152

182 134 174

21.0

22.2

197 246

150 180

21.7 24.9

24.5 23 2

6000/. 15

62

iir — Cfm/BF

8000/. 18

E

vap /

ur - Ewb(F)

72 67 62

271 250

142 181

21.8 20.7

258 238 218 265

137 176 215 150

23.3 22.1 21.0 23.7

252

24.5 22.8 21.7

133 172 207

233 214 196 239

129 167 196

26 5 25 2 23 8 26.9

E vap

A

229 279 257 237

220

19.7

132 213

211 147

226 207

22.4

23.6

ir — Cfm/BF

8000/. 18

10,0007.21

72 67 62

154

201

22.1

21.1

245 225

197

22.5

259

239 219

194 219

24.5

23.3 22.1

252

232 213

145

192 213

25,3 24.0

220 201

141 187 201

25.6 24 3

10,0007.21

20,1

2-n4

22.8

Evap Air — Ewb (F)

72

67

299

62 72 67 62

274

141

29.8 27,4 25.7

288 264

137

31.6

283 259

135

32.5 30,6 29.;

275

133 162 194 146

33.4

263 242 221 275

129

34 7

251 315 291 267

172 202

166 198

29.8

165 196

253 232

32.2 30,5 34.6 32.7

158 189

33 3

31.3

242

302

28.3 32.6 30.9

237 296

33.4 31.7 30.2

35 9 34 1

31 3

155 195 234

28.9

279

150 190

273 251 304

148 188 226 160

289

267 245

186

254

142 182 220 154 201 241

72

67 62

325 301

166 214

26.8 31.8

256

231 162 212

29.4

224

30.8 35 2

234

32 4 36 6 34 7

29.8 27.5

311 288 265

33.5

31.7 30.1

282 259

208 255

34.3 32.5 30,6

297 275 253

157 203 252

33.4

284 262 241

31.6

33 1

Evap Air — Cfm/BF

7500/. 15

10,000/. 18 12,500/.21

Evap Air - Ewb (F)

72

67 62 I 72

275

253

142 180

22.0 20.9

261

137

23.4 22.2

254

134

24.1 22.9 21.7

247

132

24.9

233 212 193 241 221 201 247 226 206

127 164

26 5 25 1

231

218 159

19.8 22,5 21.4

239 218 271 249

175 212 154

21.0

233 212

209

173

226

206

170

206 149 197

23.6

22.3

193

23 7 27 1 25 7

67 62 72 67 62

287 264

24.0

264 242 221

152 200 221 168 225 227

24.7 23.5 22.2 25.1

256

25.5

144 191

242 294 271 248

208 242 175 233 248

202 228

22.8 21.6 24.3 23.1

235

24.2

22.9 21.7 20.7

20.3

228 278 255 234

170

227 234

270

214

262 240 220

214

165

22.9 25.9 24.5

160

201

27 5 26 0

24 2

21.9

227

247

22.6

23.8

222

23.3

217 206

24 6

LEGEND

237

225

276

261

257

220

Page 6

COMBINATION RATINGS

[38AD012 w/U, 38AD012 w/L of 40RR028 38AD016 w/U, 38AD016 w/L of .

E

P(F)

A

TC

85

SHC

KW

TC

95

SHC

KW

TC

100 SHC

KW

TC

105

SHC

KW

TC

115 SHC

KW

7500/. 15

72 67 62 72

278 257 236

180

147

22.7

23.9

262 242 222 273

137 174 206 154

25.6 24.1 22.9 26.3

254 235 216 265

134 171

26.4 24.8

245 227

168 195 148

131

27.3 25.5

238 211 198

125

162 184 142

27.1 25.3 29.5

28.8

vgp Air - Cfm/BF

10,000/. 18 12,5007.21

E

vgp Air —

291

216 160

21.3 24.5

201

151

23.4

27.1

209 254

24.0 28.0

236

=wb (F)

67 62 72

269

246

208

23.4

252 232

202 224 168 225

24.9

244

199

25.6 24.2 71.1 26.1 24.6

235 217

195

26.4

219

188

27.8

298 276 255

236 175

25.1 23.7

22.1

280 259

23.6 26.8

270 250

225

219 165 222

260

213 162

24.8 28.6

241 224

203

201

156 203

26.1 30.0

¡38AD028 and 40RR028

Temp (F}:r

Air ent

Cond

TC

85

SHC

KW

TC

95

SHC

KW

TC

100

SHC

KW

TC

105 SHC

KW

Ffc

115

SHC

KW

7500/. 15

72 67 62 72

327 301

160

198 234 176

30.9

29.0

31 1 287 264 325

191

153

31.3

33.1

304 279 257 317

151

188 223

34.0 32.3 30.5

296 272 250 308

147 185 220 164

35.3 33.3

281 258

177

142

35.8 34.8 32.9 37.4

Evgp Air — Cfm/BF

10,000/. 18 12.500/.21

E

vgp A

ir -

Ewb (F)

67 62 72 67

276 342

31.9

27.3

230 171 220

34.1

29.6

167

34.9

31.4

36.0

237

293

213 158 206 250

291

316

225 274

30.2 28.5 32.4

300 276 334 308

267 186 245 285

30.7 35.0 32.9

32.3

292 270 325 300

216

263 184

31.5

33.1

285 261

259 181 239

212

34.1 32.3 36.6

247 299 275

268

35.5 33.7

352 325 300

193

35.7

316

174 233 253

38.0

^^38AP016 w/U. 38AD012 w/L of 40RR028

•.ässsSi_^

________

Temp (F)r

Air Ent

100 SHC

105

115 SHC

j Evap Air — Cfm/BF

--------------

————k._

7500/. 15

Evgp Air — Ewb (F)

72 67 62 72

TC

SHC

85

KW

TC

95 SHC

KW

TC

KW

TC

SHC

KW

TC

KW

329

303 278

151

198

27.7 26.2 24.7

312 288 265 326 300 277 335

152 191

29.4 27.9 26.5

280

304

150

188 225

30.4 28.8 27.2 31.2 29.6 28.1

295 272

184

147

31.4 29.7 28.0 32.1

285* 255 235 286* 266 245 292* 268* 251

141 178 214

31.6

33.1

345

234 176

28.4

227 169

30.4

317

258

167

250 308 284

164

222

157

29.8 33.8 32.4

---------

---

10,000/. 18 12,500/.21

------------

67 62 72 67 62

318

145

26.9 25.7

218 265 185 242 286

28.7

292 270 327

215 259 183

212 253

30.6

204 240 174 228 251

354

293

192

273

28.9 27.5 26.1

27.4

30.8 29.3 27.9

31.7

317 291 269

262

180 236

28.8 32.6 31.2 29.4

30.9

34.3

I38AD034 and 40RR028

Temp(F)

Air Ent

TC

85

SHC

KW

TC

95 SHC

KW

TC

100 SHC

KW

TC

105

SHC

KW

TC

115 SHC

KW

7500/. 15

72 67 62

354 324 296

172 21 1 248

29.9 28.5

337 308 281 355 325 297 366

165 203 241 183

32.0 30.4

329 300

162 200

33.C 31.4 29.6

320

292

159 196 234

34.1

32.3 30.6

276

303

189

152

36.4

34.2 32.5

Evgp Air — Cfm/BF^

10,000/. 18

12,500/.21

Evgp Air — Ewb (F)

72

67 62

374

343

190

27.0 30.9

28.7

274 346 316 289 356 327 299

238

266

250

227

239 287

29.4 28.0

232

33.0

31.3

180

220

34.1 32.3 30.6 34.7

336

307 280 346

176

225

35.2 33.4 31.6

318

290

170

218

37.5

35.5

72 67 62

i314 386 355 326

206 265

31.4 30.0

280 199 257

29.7 33.6 31.9 30.4

276

196

192

272

35.8

263 327

263 186 243 272

33.5 38.1 36.2 34.0

...

67 ^ 62

232 251

22.5

239

239

25.4

24.1

231

231

241

223

219

223

26.9

25.2

207

207

28.3 26.5

62

252 300

30.9

29.0

285

31.2

276

241

276

33.7

31.9

292

269

269

34.9

33.0

253

36.3 34.5

327

302

249

295

310

286

301

278

239

278

30.2 28.6

269

32.7 31.4

323

28.6

336

308

308

254

299

32.9

31.3

317 290

250 290

34.0

32.2

299

272

'' '

1 tsmp ^r;

7500/. 15

72 67 62

TC

361

85

SHC

KW

TC

95 SHC

KW

TC

SHC

100

KW

TC

105 SHC

KW

TC

115 SHC

KW

332 .305

174

211

30.6 29.Ü

346 317

167 205 242 181 230

30.8

32.5

338 311

164 202

33.5 31.9 30.2 34.8 32.9

330 304 279

160

198

34.6

33.1 31.3

305* 285

154 192 228

36 5

35.3 33 4 37 6 36 4

38AD028 and 40RR034

Temp(F)

Air ent

Cond

TC

85 SHC

KW

TC

SHC

95

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

SHC

115

KW

9000/. 15

72 67 62 72

346 317

172 219

30.4

31.9

325 300

164

210 256 186 245

34.4 32.5 30.7 35.6 33.7

317

293 269

161

207

33.6

35.5

315 286

204

158

36.1

34.3

294 270

152 197 242

37 4

35.6 33.6 38.0

138AD016 w/U, 38AD012 w/L of 40RR034

Temp (F) —

Air Ent

9000/. 15

72 67 62 72

85

95

100 SHC

105

•

115

TC

SHC

KW

TC

SHC

KW

TC

KW

TC

SHC

KW

TC

SHC

KW

320

346

219

172

28.8

27.3 25.9 29.5 27.9

327 301 277

166

212

29.1

30.6

317 292 269 330

163 208

31.5 30.0

307

283

160 204 246 180

32.5 30.9 29.0

284* 264 243 294*

197 234

153

34.1

32.7

I38AD034 and 40RR034

Temp(F)

Air Ent

TC

SHC

85

KW

TC

95. SHC

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

115 SHC

KW

9000/. 15

72

67 62 72 67

376 344 '314

187

233 278

31.0

29.5

357

326 297

180 226 270 201

33.1

31.4

348 317 289

177 222 267

32.4 30.6 35.1

34.2

338 308 281

218

173

35.3 33.4 31.6 36.2 34.3 32.4 36.7 34.9 33.1

319 291 264

167

211 256 187 244 277

37.5 35.5 33.5 38.5 36.5

Evgp Air - Cfm/BF

10,0007.18

Evgp Air -

72 67

380 351

24/

18/ 236

27.4 31.5

293 363 335 309

33.7

29.2

286

355 328

239

178 227

346 320

235 175

35.9 34.1

319* 300

262

170

Ewb (F)

62 ] 72

323 391 362 334

204

288

28.4

29.7

31.8

224

216

32.1 30.5

372 346 319

277 197 257

34.2 32.6 31.0

30.3

302 364 336

271 195 254 289

35.2 33.6

31.2

294 356 328

265 192

36.3 34.7 33.0

32.2

275 328* 302* 284

251 186 243 268

34.6

38 2

Evgp Air - Cfm/BF

12.000/. 18 15.000/.21

vap / Or -

E

359

292

263 193 252

28.5 32.8 31.3 29.7

276 337 312

328 304

253 183 241

31.6 36.4 34.4

320

262

249 180

36.9 35.1

32.2

247

303

172 231

Ewb (F)

67

62 72 67 62

332

296

238

279

36.3

367 341

306

306 211 279 314

33.1 31.9 30.2

289 344 319 295

289 204 271

31.7 35.9 34.1

281 335 311 288

201

281

32.5 37.0 35.2

273 326 303 279

197

273

33.5 37.5

257 308 287

257 192 257

34.8 38.8

Cfm/BF

12,000/. 18

Evgp Air - Ewb (F)

67

62 72 67 62

293 360

263 193 251

254

27.6 31.4 29.8

250

28.3 32.3 30.7

261

30.7

333 308

341

313 288 350 324 299

186 244

303 280 339 314 290

185 241

319 294

238

33.3 31.6

274

229

172

34.9

33.5

372 344

298 202 270 319

26.7 30.1 28.7 27.9

196 264 295

288

28.4

32.6 .30.5

280

193

29.1

33.1 31.3

272 328

191

272

29.8 33.7 32.2 30.5

252 302* 279* 260

184 250 260

252

31.5 35.5

Evgp Air - Cfm/BF

12,000/. 18

Evgp Air - Ewb (FJ

62 72 67 62

395 362

267

208

28.0

31.8 30.3

373 342

29.7

263

259

33.9

32.3

363 333

198 255

33.3

353 323 295 362 332 ^303

194 251

304

333

406

331

324 227 297 342

28.8 32.3 30.8

384

313

220

313

34.5 32.8 31.2

30.6

304

373

304 217 286 313

35.6 33.8 32.1

31.5

295 213 282 303

277 341 312

206

34.2 39.1 37.1

12,5007.21

67 62

262

^31 1

250

36 5

267 288

263 279

35.8

37.0

15,000/.21

261 290

303

258

34.0

15,000/.21

142

373

352 323

289 323

342 313

274

307

29.0

295

32.0

303

282

34.3

314

295

32.2

33.1

34.0

263

263

35.1

319

29.0

29.7

280

280

32.1

29.4

285

285

35.1

Page 7

COMBINATION RATINGS

f38AD0i6V/U, 38AD016 w/L of 40RR034

n (F\

Tem

A

TC

SHC 187 234

85

KW

TC

SHC

95

KW

Tc

100 SHC

KW

TC

SHC

105

KW

TC

SHC

115

KW

9000/. 15

72

391 361 331

32.1

372 344

180 227 270

34.2 32.6

363 335 306

177

35 3 33.6 31.9

354 326

174 219 264

36.5

327* 305

168

38.4 37.1 35.1

62

67

278

30.6

29.2 33.1

312 ■

31.1

267

223

299

34.7 32.8 37.0

280

219 256

Evap A

Evap A ir — 1:wb (F)

Ir — Cfm/BF

12

,000/ 18 15

72

67

407 378 348

208 266 321 227

31.5

359 330 399

388

201 259 316

35.3 33.5 32.5

379 350

198 256

36 1 34.5

369 340 313

194

253

35.6 34.3

340*

318 292

180 244 292 207

37.9 36.1

39.2

I38AD024 w/U, 38AD016 w/L of 40RR034

%

Air

85

95

100

105

115

P f >

9000/.15 12

72 67 62

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW

TC

SHC

KW 140.8

TC

SHC

KW 143.6

391

426

206 252

35.8

34.3 32.4 37.1

406 373 342

198 245

138.4 36.4 34.5

397 364 333

194 241 286

39.5 37.5 35.6 40.9

354

087

237

190

38.7

367 334 306

229

183

41.2 39.0

vap A

E

ir — Cim/B

000/ 18 15

Evap A Ir — Ewb (F)

72

359

298 227

290

324

282

36.6

273

67 62 72

447

413 379 462

286

35.3

426 393 360 440

219 278 336

39.6 37.7 35.7 40.4

416

383

215 274

38.8 36.7

405 373 341 418

270 327

21 1

42.2 39.9 37.8

383 351 321 395

205 262 316 223

44.8 42.5 40.2 45.5

P8AE044 and 40RR034

A

f end

PI“/

9000/.

72

TC 449 410

SHC 230

85

KW

TC 430

SHC

95

KW

TC

100 SHC 201 247

KW 43.6 40.5

TC 410

SHC

105

KW 45.3

TC

SHC

115

KW

257

39.7 37.9 36.1

392 358 452

205 251

39.7

42.4

420

383

373

198 244 289

42.7

390 355 323 410

237 280

192

48.1 45.4 42.9 49.6 46.8 42.9 50.6 47.9

67

E

>5

62

375

307

298 230

З8.3

349

293 227

39.4

340 430

40.4

ir — Cfm/BF

vap A

12 ,000/

Ёvap A ir - E

72 67 62 72 67

472 435 398 487 450

237

294 352 255 327

40.8 39.2 37.3 41 .6

415

287 344

43.5 41.6 39.6 44.3

440

405

283

45.2 42.8

395

279

223

46.5 43.6 41.8

376 342 422 387

271

215

I38AD034 and 40RR044

Tern

^ona

85

95

100

105

115

P(F)

tnt

TC

SHC

KW

TC

SHC

KW

TC

SHC

TC

SHC

TC

SHC

12 000/.

67 62“^

72

420 386

283 343 249 326 368

221

30.8

32.3

399 365

214 275

34.5 32.9 31.3 35.3 33.6

388 356

210 271

KW

35.7 34.9 32,4

346 315

377

267 315 234 310

206

KW

36.9 35.2

356 325

199 259 297 226 303

KW

39.3

37.4

Evap A ir — Cfm/BF

15 ^

Evap A

000/. 18

16

ir — Ewb (F)

72 67

352

29.3

334

334

324

324

33.4 37.6 35.9

297 367 337 308

35,5

401

436

31.5 30.0 33.3

32.9

413 378

317 348

240

402 367

314 338 262

237

36.4

34.7 33.1

391

359

40.0 38.1 36.2

,000/. 21

62

72

67 62

419

388 359 TC

295 359 85 SHC

33.6

30.6

322

311

33.4 36.7

305 215

32.0

30.5

340

368 ■'

220

289 340

35.7

34.0

389

218

379

37.7

349*

39.6 37.9 36.7

32.5

359

331

286 331

35.1

33.4

349 322

282

322

36.2 34.3

300

320*

297 300

F

000/. 21

62

67

344

33.6 37.7

351 429

331

18 15

^426 392

246

217 386

35.9

34.2

405

239

235

41.6

231 301

42.9

373

310 371 95 SHC

36.5

38.3

394

363

305 362 100 SHC

39.5 37.5

384

353

353

40.7 38.6

362 331

293 331

43.3 41.0

21

,000/

wb (F)

62

413

396

38.1

380 467 430

370

340

40.6

360

335 241

320

62 72

368

348 422 389

32.0 35.7 34.1 32.5

338

327 398 366 336

327 259

34.1 38.C

308 251

39.8

249

455 420 384

245

45.8 43.6

444

47.3

233

20

394

319

383

42.4 40.2

315 373

41.5

407

373

312 367

45.1 42.7

354

303 352

45.1

000/. 21

67

446

368 366 377

266

410

36.8 35.2 33.5

374 344 315

40.5 38.6

377

411

31.9 30.4

357

357

359

377 346

346

355

336

351

34.6

36.3

315

343

36.7

62

w/U, 38AD012 w/M, 38AD012 w/L of 40RR044

E

vap A

P f );

Cc

KW

TC

95 SHC

KW

TC

100

SHC

KW

TC

105 SHC

KW

TC

SHC

115

KW

12

,000/.

15 1

72

67

434

402 369 ;

223

281 350 !

36.3

34.5 32.7 i

408

377 346

212

272 330 :

39 3 37 1

395 364

208 267 321 i

40 4

38.2 35 8| 41 2

382 351

204 262

41.5

39.3 36.9 :

354 328

194

252

43.4 41.4

62/

35.0; 40.1 38.0

336 ;

325 ;

312 ;

302 !

301

38 8

Evap A ir — Ewb (F)

ir — Cfm/BF

16 ,000/ 18 /

72 67 62 ;

452

247 320 374 ; 273

37.2 35.5

423 392

237 312 351 j 364 351 370

409

233 307 341 i 258

394 364 337 : 401

228 302 331 253

42.3 40.1 38.0 43..0

366 338 312 373

218

44.6

385 ; 461

418

33.9 I 37.4

360^

35.8 c

349 ;

378

39 0 36 9 41.7

291 310

42.2 39.8

20

,000/

72 67 62

427

360 396

36.0 34.4

432 399

40.5

38.7 36.6

417

386 357

347 357

39.7

372

342 344

40.8 38.5

346 318

243

331 318

45.3

42.9 40.4

p8AD016 w/U, 38AD024 w/M and L of 40RR044

P (F)

A

TC

85

SHC

KW

TC

KW

TC

KW

TC

105 SHC

KW

TC

115 SHC

KW

j

i 12 000/.

67 62

1 72

|469

432

1235 288 345

137.9 36.1

Й47 411 378

221 279 337

140.6 38.4 36.6

401

¡436

217 275 333

И1.8 40.4 37.7

1425 390

271 329

G13

|43.1 42.5 38.8

369

W2*

205

263

И6.2

43 8

E

vap A Ir — Cfm/BF

15

397

34.3

368

358

337

317

41.4

16 000/. 18 20

E

vap A ir - Ewb (F)

67

72

488 452

255 328 393 286

38.8 37.1

465 429 395

247

41.5 39.5 37.6

453 418

243

42.9 40.8 38.8 43.6 41.4

441

239

44.3 42.2

417* 384 352 428*

232

47 2 44 9

62 72

414 501

35.3

320 377

385 466

369

316

407 374

312 361

40.0 44.9

304

345 262

42 5 47.8 45 5

000/. 21

67 62

464 427

378

39.5

37.7

476 440

278

370 406

42.3

40.2

429 395

274

365 395

452 417 384

270

360 384

42.7 40.7

394TI

352

P8AD016 w/U, 38AD012 w/M, 38AD012 w/L of 40RR044

P (•")

A

r*«_1

TC

85 SHC

KW

TC

95 SHC

KW

TC

100 SHC

KW

TC

105 SHC

KW

TC

115 SHC

KW

Evap A

12 000/. 15

E

72 67 62

438 403

474

236 288 345

39.7 37.8

450 415

220

42.8 40.4

434

216

44.0 41.7 39.4 45.1

425 391 361

212

45.3

399* 368 339

203

48.1 45.7 43.C

35.8 40.7 38.9

382

279 336

38.3 43.7 41.6

403 372 454 421

330

275

270

323

43.0

40.5

261 307

ir — Cfm/BF

)

20

,000/. 21

16 , 000/ 18

vap A ir - Ewb (F

72 67 62 72

494 458 "423

254 326

434 400

467

245 318 373

241 314

42.9

440

408

310 359 369

237

46.5 44.2 41.9 47.2 44.8

413 382

228 299 343

49.3 46.8

506 469

390

288 379 435

41.0

37.2

479

279

39.4

44.5 42,4 40.8

389

465 430

366 274

45.8

40.6

377 450

353 422 391 362

259

50 1

44.2

67

39.5 37,8

443

369 411

364 399

43.6 41.9

417

359 386

347 362

47 5

LEGEND

BF — Bypass Factor

TC — Total Capacity (1000 Btuh)

SHC — Sensible Heating Capacity (1000 Btuh)

KW — Compressor IVlotor Power Input

Ewb — Entering Wet-Bulb

U — Upper Coil

M — Middle Coil

L — Lower Coil

U-M-L abbreviations indicate connection of

upper, middle or lower coil of fan-coil unit

*Capacities at a minimum 38AD016 charge to prevent high

pressurestat cutout Other capacities are at optimum charge for

maximum capacity.

condensing unit to

21

396

370

37.4

344

427

36.0

406

38.4

39.5

361

361

43 2

62

435

41 1

399

386

43.0

44,9

Page 8

COMBINATION RATINGS

g^38AE044 and 40RR044

E

P(F)

P»»

A:.

TC

85 SHC

KW

TC

95 SHC

KW

TC

100 SHC

KW

TC 450

SHC

105

KW

TC

SHC

115

KW

15 ,000/

72 67 62 72

491

451

302

243

40,1

41 .9

471 432

237

294

44.7 42.6

460

'423 385 481 440

290

234

43.8

46,2

412

230

285 344 256 329

47.9 45.3 42.9 49.0

390

428

224 277

48.0 44.9

51.0

vap Air — Cfm/BF

.15

414

361 271

36.3

395

352 263 337

40.4

347 259

41.6 47.4

375 468

356

336

16,000/

E

vap >¡Vir -

514 471

42.5 41 .0

491

45.8 43.6

_

_

-

.18

iwb (

67

62

434

346

417

39.3 43.4

451

414

407

41.5 46.5 44.5

404

333 402

45.5 42.8

428 394

393

46.5 44.1

407

373

320

369

49.4

46.8

= )

¡38AD016 w/U, 38AD016 w/M, 38AD012 w/L of 40RR044

E

Temp(F)

Air Ent

Cond

TC

85 SHC

KW

TC

95 SHC

KW

TC

100 SHC

KW

TC

105 SHC

KW

TC

115 SHC

KW

12,000/.15

72 67

519 479

250

311 370

43.1

41.2 39.3 44.2

496 459

240 302 361 267 344 419

44.1

46,3

486 448

237

298 357

48.0 45.5 43,0

472 437

233 293 352 259

49.7 46.9

439*

412 379 455*

224 284

52.2 50.4 47.4 54.0

vap /tir - Cfm/BF

16,000/.18

vap Air — 1

E

72

62

440 540 502

271

515 479

423

41.8 47.5 45.4 43.4

413 502 467 433

263

49,2

402 489 455

50.9 48,7

44.3

342 250 325

Ewb (F)

67 62

464

429

353

40.7

42.0

444 528 491

340 407

47.0

44.6 50.1 47.5

422 501 466

336 396

45.8 51.6 49,1 46.7

428 396

388 274 367

52,0

48.8 54.5 52.1

38AD028 w/M and L of 40RR044

Temp (F'

Air Ent

T2,00o7.T5"

72 67 62 72

TC

85 SHC

95 SHC

100

105

115

542 499 457 567 525

264 319 377 285

KW

46.7 44.4 42.1 48.1 45.8

TC

519

249

KW

50.2 47.4 45.1 51,4

TC

508 466

SHC 245 305 364

KW

51.8 49.0 46.5 53.2 50.1

TC

496 454 416 517 477

SHC

241 300 359 267

KW

53.4

_

TC

SHC

KW

-

477

309

50.7 47.9 55.1

430 394

291 349 407

54.1 51.0

Evap Air — Cfm/BF

16,000/. 18"

Evap Air — Ewb (F)

62 ! 72

67

482 ¡584 541

362 438 ¡317 413

43.5'48.9 46.2

438 543 502 461 1559

368 276 362 427 ¡308 403 476

427

48.9

530 490

272 352 422 ¡302

_ _

- -

46.5 ¡52.6

449 [546

48.0154.3

438 ¡ 531

343 417 ¡300 394 452

51.3 49.6 ¡56.0

414 j -

52 71 -

w/U, 38AD034 w/M and L of 40RR044

T emp(F)

Air Ent

\^ond

TC

85 SHC

KW

TC

95 SHC

KW

TC

SHC

100

KW

TC

105 SHC

KW

TC

115

SHC

KW

12,000/.15

r 6'7

72

539 476 455 565 522 480 583

262 315 373 282 356

45.5 43.4 41.2 46.7 44.6

515

473

246 305

48.8 46.2 43.9 50.3 47.6

504 462 424 527

301

242

50.3 47.7

492 450

237 296

51.9

49.3 47,7

467*

428 390

228 287

55.7

52.6

Evap Air — Cfm/BF

16,000/. 18

_Evap Air — Ewb (F)

62 72 67 62 72 67 62

431 313

434 540

363 273

359 269

45.8 51.9 49.2

413

514 473 434

264

354

53.6 50.9

488* 449

344

256

49.9

57.1

42.6 47.6

498 457 555

347

420 304

45.4

446

486

343 415

47.3

410

338

48.3 54.4 51.8

410 501* 462* 422 TC

329

401 286 377 422

54.3 51.3

38AD016 w/U, 38AD016 w/M, 38AD016 w/L of 40RR044

.21

20,000/

72 67 62

488

525

298 386

503 466

292 376 426

_

_

_

_

_

_

_

„

448

448

39.9

41.8

426

42.2

416

455

371 416

46.0

43.5

444

405

366

403

47.5 44.8

420

382

357 379

47,6

50.5

........

S

20,000/.21 12,0007.15 16,000/.18 20,0007.21

72 67 62

555 515 478

301 395

45.0 43.0

291

48.3 45,9

515 479 444

287

283 376 428 105 SHC

465* 433*

478

41.2 1 KW

456

386 456

44.0

381 442 lOOlSHC 270

45.3

432 iTC

405

405

49.4

Temp (F)r

Air Ent I

^ona

85 SHCj 259

95 SHC 250

12,000/. 15 16,000/. 18 20,000/.21

67

ITC 549

¡KW ]45.8

TC 1527

¡KW |49.2 46.5 44.2 50.7

506

320 356 281

43.3

487 448 549 510

312

TC 515 476

100 SHC 247

|KW |51.0

308 342 274 351 427

48.5

iTC 1503 465

105 SHC 243 303

¡KW 152.9

jTC '1477* 439

115 SHC 234

|kW ¡55.8 54.1 50.8

50.5

294

38AE054 and 40RR044

Temp(F)

Air Ent

Cond

851 SHC 280 334

¡TC

9SiSHC

t

KW

" Ire“ 529

1

KW

1

KW

if'e

115 SHC 259

! KW 59.1

67

72

561 516 475 586 545

46.4 44.4

48,4

541 494

274 322 378 291

49.1

51.6

486 445

317 372

50.7

53,3

518 475

312 369

266

55.3 52.5

494 453

303 361

56.0

Evap Air - Cfm/BF

Evap Air — Ewb (F)

62 72 67 62 1 72

465

41.6

346 278

438 537

45.8 52.6 50.1 47.5

42¿ 524 486 449 539 501

337

47.4

403 485*

327 261 336

E

532 491

573

364

47.2 44.0

355

48.2

498

270 347

54.5 52.0 48,9

458 423 498* 462* 435

57.5 55.7

Ur — Cfm/BF

vap /

592

440

309

42.9

48.4

471

566 525

300

431

46.0 51.7

460

553 513 475

297 390 451

53.5

422 293 386 441

55.3 52.7

411 284 377 419

52.5 58.2

55.7

E vap / Ur - Ewb (F)

62 72

386

456 565 524

47.0 53.2 50.7 48.2

48.6

436 542 500 458 556 515

49.9

414

53.0 60 8 57 6 54 7 61 8 58 6 56 0

67 62 72 67 62

500

298

373 453

50.0 47.6 45.5 50.5

366

553

512 468 568

287

361 435

54 8

52.4

355

283

56.8 54.2 51 .2

517 476

272 344 417

602 562

325 408

479 581 541

317 400 482

441

54,0 51.6 49.2

312 396

49.9 56.9 53,4

429

307 393

57.7 55.2 52.5

530 490 452

436

300

48.4 46.4

528 488

385

38AE044 and 40RR054

20,000/. 21

62

67

499

499

45.5

516

476

50.0 47.6

464

504

399 464 100 SHC

51.6 48.1

452

491

50.6

53.2

_

425

__

425 115

53 7

“

Temp (F)r

Air Ent r

105 SHC

•

\wona

TC

85 SHC

KW

TC

95 SHC

KW

TC

KW

TC

KW

TC

SHC

KW

15,000/.14 20,000/. 18 25,000/.20

72 67

527

483 443

271 347 420

43 9 41 8 39 8 - 42.8

—

460

—

341

-

44.3 42.2

_

448 410

_

337

45.8

435

—

334 298

47.2

_

408 374

_

328 374

50 0

-

Evap Air — Cfm/BF

Evap Air — Ewb (F)

_

_

_

_

-

_

_

-

_

—

-

_

_

-

67

505 463

394 461

481

384

45.6 43.3

470 429

381 428

47.2

45 6

376

48.5

429 393

368 393

50 9

62 72

421

412

408

43.3

398

44.7

47 2

62

40.6

441

439

44.7

417

417

46.0 -

48 7

72

_

-

_

_

-

_

_

-

_

—

__

- -

516 474

446

43 3 41 4

492

438 449

46.0

479

434 437

47.6 45.1

466 424

430 424

49.2

138AD016 w/U, 38AD016 w/M, 38AD012 w/L of 40RR054

20,000/.21

539 496

427 492

45.5 43.4

473

513

397 473 95 SHC

51.1 48.6

542

300 392 461

52.7 50.2

529 488 448

295

58,1 55.2

46.4 KW

501 461

47.8

387 448 105

49.3

52.4

Temp(F)

Air Ent

cona

TC

SHC

85

KW

TC

TC

SHC

100

KW

TC

SHC

KW

SHC

115

KW

15,000/.14

72 67 62 72 67 62 72 67 62

560 518 477 582 539 498

282 357 432 314 408 498

43.0

45.0

532 492 453 551 512 472 562 522

278 347 421

46.1 43.8

48.6

518 478

270

342 413

50,1

47.6

503 463

263 336 406 295 388

49.0 46.2 52.6

51.5

436

3t

3t 325

51.9

3t

Evap Air — Cfm/BF

20,000/. 18

Evap Air — Ewb (F)

41,0

440 550

45.0

427 520

400

389

49.2

44.1 42.9 46.7 44.6

46.3

304

399 472 336

49,7

47.3

497

300

393 458 331

51,2 48,8 46.3

482

50,2 47.5

2t 4t

2t 4t

2t 4t

25,000/.20

594

552

345 459 512

449

45.2 50.6

458

444 530

439 326 437

415

415

50.3 It

48.0

546 508

443

49.3

51.8

493

50.7

53.0

It

It

67

'62"

546

508

403 474

46.0 43.1

487

395 461

49.2 47.0

51.0

48.6

463

50.2

53.4

520

501

500

472

51.0

476

462

446

67 62

470

450

43.7

437

46.4

_

397

_

397

49 1

512

43.6

484

484

45.7

469

469

47.1

454

449

48.5

425

3t

425

3t

51.1

3t

Page 9

COMBINATION RATINGS

38AD016 w/U, 38AD034 w/M and L of 40RR054

n (F\

Ten-

Air

r

TC

SHC

85

KW

TC

SHC

95

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

115 SHC

KW

38AD016 w/U, 38AD016 w/M, 38AD016 w/L of 40RR054 38AD024 w/U, 38AD024 w/M, 38AD016 w/L of 40RR054

« /F\

T 1

P V”;

TC

SHC

85

KW

TC

SHC

95

KW

TC

100 SHC

KW

TC

SHC

105

KW 55.9

TC

SHC

115

KW

38 AD 024

n

Tcm

A

TT'

SHC

85

KW

TC

SHC

95

KW

TC

SHC

100

KW

TC

SHC

105

KW

TC

SHC

115

KW

38AE054 and 40RR054

Temp(F)

Cond

TC

SHC

85

KW

tt

95 SHC

KW

TC

100 SHC 228 287

KW

TC

SHC

105

KW

TC

115 SHC

KW

15,000/.14

72 67 62 72 67

590 541 497297

372

47.7

45.5

560 515

287 361 435

48.6

51.2

505

546

356 430

282

52.9

50.2 47.6

532 488 446

350

277

54.6 51.8 49.0

461* 419

503*

339 416

266

55 1

58.1

15,000/

67

72

604 559 516 629 583

295 371 445

48.6 46.5

577 534 493 599 557

361

287

49.6

52.1

564 519 481 585 544

282 356 430

54.0

51.2 48.7 55.2 52.8 50.9 56.1 53.4 51.9

550 504 468 571 530

351 424

277

53.2

509* 478 419

339 414 297 391

266

58.9 56 8 54.1 59 8 57 8

38AD034 w

w/U,

is^ooci/.14

72 67 62 72 67 62 72 67 62

580

633

391 466 349 446 541 379 497

315

52.0 49.5 47.1 53.4 50.9 48.5 54.3 51.8

552 505

603

379

303

55.6 52.8

588 538 492 614 564

298 373

57.5 54.5

524

572

367

292

59.4

56.3 53.3

495 451

543

355

281

60.0 56.9 65 0 6 6 58.4

63 3

15,000/.14

67

72

617 566 518

300

240

48 7 46.6

51 1

541

592

292 350

231

54.7 52.0

579 529

53.6 50 7

56 5

566 517

223 233 341 254 410

58.4 55 3 52.4

489

536

215 275 333

62 2 58 9

Evap Air - Cfnti/E F

20,000/ .18

:vap / Ur -

615 566

457

330 426

43.4 49.C 46.7 45.0 49.6

472

583

321 415

46.2

52.4

459

568

316

54.1

553

310 405

425

55.8

522*

299 393 430 330

59 4

52 ;

E vap /

.14

20

L.vap /

62 72 67 62 72

322 422 518 358

44.4

50.0 47.6

317

435

53.4 51.0 49.9

47.2

313

308 402 489

57.1 54.7

50.2

527*

/M and L of 40RR054

E

Ivap Air — Cfm/B F

Eivap / Ur - Ewb (1

532 663

630

337

453

50.1 57.1 54.4

:wb (1

521

521

537 493 597

493

50.0

48.1

523 480 582 537 498 TC

410

480 346 460 498

51.6

49.2

509

466 566

466 341 453

50.4 56.5

53.2

480*

438* 533* 491*

56.6

53.6

Ur — Cfm/B F

,000/

.18

Ur - Ewb (F)

540 643

46.4

516

412 504 348 463 528

503

407 495 344

489 582 542

51.8

488* 457 538* 498*

457 329 441

55 3 60.3 58 2 56 2

20,000/ .18 25

610

560 682

579 530 648

517 368 484 547

433

51.6

516

448 332 428 506 362 478

51.7 58.0

478 598

442 326 422 494

430

E

62

358 338

496 6 1 6 567 519 630

49.3 55.9 53.4

484

345 325 415

472 588 541

447

55 8

56.2

53.2

549

502

60.9 57.9 54.9

518

566

315

Evop Air — Cfm/BF

20,000/. 18

'.vap A Ur —

72 67

643 592

52.2

328

409

430

49.9

420

473

471

Ewb (F)

543

525

47.7

511 361

50.7 56.6 54.2

603 554 507

58.0

59.6 56.8 53.7 -

_

-