Page 1

Model Specific Instructions

NOTE: Read the entire instruction manual before starting the

installation. Refer to Split-System Heat Pump Common Installation and Start-Up Practices (included in this packet).

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions thoroughly and follow all warnings or cautions included in literature

and attached to the unit. Consult local building codes and National

Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal word DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

Before installing, modifying, or servicing system, main electrical disconnect switch must be in the OFF position. There

may be more than 1 disconnect switch. Lock out and tag

switch with a suitable warning label. Electrical shock can

cause personal injury or death.

38YCB(P), 38AYB, 38BYB

Split-System

Heat Pump

C

3

⁄8″D. (9.53) TIEDOWN

A

.

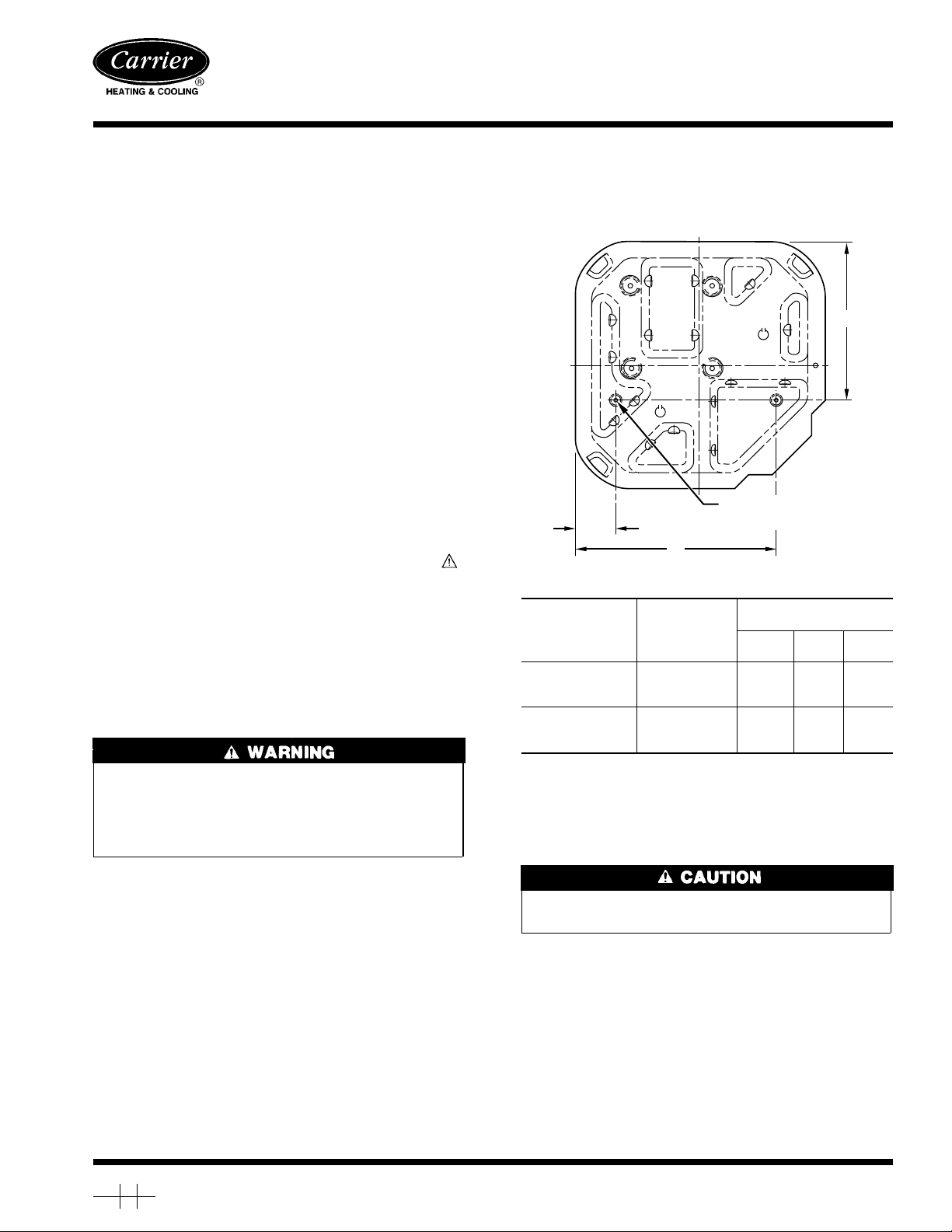

UNIT SIZE

38YCB(P)018-030

38AYB018

38BYB018

38YCB(P)036-060

38AYB024-060

38BYB024-060

B

MIN. PAD

DIM. (IN.)

22-1/2 X 22-1/2 3-11/16 18-1/8 14-3/8

30 X 30 6-1/2 23-1/2 20

Fig. 1—Mount Unit to Pad

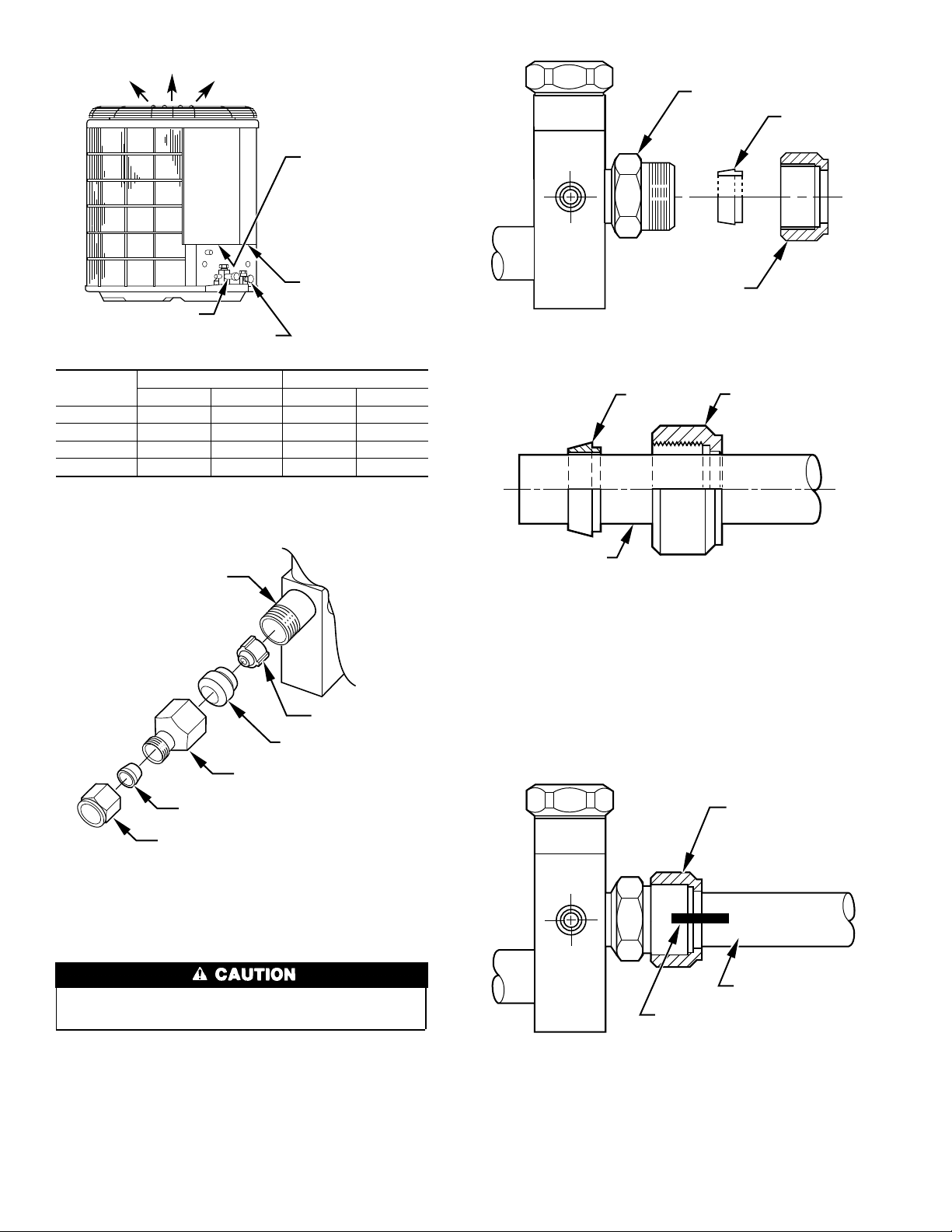

3. Remove lock nut and ferrule from plastic bag taped to service

panel. (See Fig. 4.) Remove the lock nut and ferrule from

liquid service valve adapter. (See Fig. 3.)

KNOCKOUTS (2) PLACES

TIEDOWN KNOCKOUT

LOCATIONS

A

(In.)

B

(In.)C(In.)

A94199

INSTALLATION

Step 1—Mount Unit to Pad

Refer to Fig. 1 for pad dimensions and dimensions needed to

mount unit to pad.

Step 2—Refrigerant Tubing

Refer to Fig. 2 for refrigerant tube dimensions and connections.

Step 3—Mechanical Connection (38YCP Model)

1. Remove plastic retainer holding outdoor piston and piston

retainer in the liquid service valve. Connect and tighten the

liquid service valve adapter to the valve body prior to

assembling ferrule/lock nut. (See Fig. 3.)

2. Cut tubing to the correct length, deburr and size as necessary,

making sure tube ends are square. If a large burr is evident, the

ID and OD must be deburred to allow the tube to bottom in

valve.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a 5a

PC 101 Catalog No. 563-809 Printed in U.S.A. Form 38YCB-2SI Pg 1 6-96 Replaces: 38YCB-1SI

If undersized, damaged, or elliptically shaped tubing is used

when making connection, leaks could result.

4. Slide the lock nut and ferrule onto each tube. (See Fig. 5.)

5. Apply a few drops of refrigerant oil to the ferrule and valve

threads and adapter threads to reduce assembly torque and

assist sealing.

6. Insert tube end into the service valve or adapter until it

bottoms.

7. Push the ferrule into place and hand tighten the nut until an

increase in torque is felt.

8. Mark the nut and tube and tighten 1-1/2 turns from the mark.

(See Fig. 6.) Keep the tube bottomed in the valve and adapter

while tightening nut.

Page 2

AIR DISCHARGE

FIELD POWER

SUPPLY CONN

7

⁄8″ DIA HOLE WITH

1 1⁄8″ DIA KNOCKOUT

AND

1 3⁄8″ DIA

KNOCKOUT

VALVE FITTING

FERRULE

FIELD CONTROL

SUPPLY CONN

7

SUCTION LINE CONN

LIQUID LINE CONN

UNIT SIZE

018, 024 3/8 3/8 5/8 5/8

030, 036 3/8 3/8 3/4 3/4

042, 048 3/8 3/8 7/8 7/8

060 3/8 3/8 7/8 1-1/8

Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50

ft, consult your local distributor.

LIQUID TUBE VAPOR TUBE

Conn Dia Tube Dia Conn Dia Tube Dia

⁄8″ DIA HOLE

A93578

Fig. 2—Refrigerant Tube Dimensions/Connections

PISTON BODY

PISTON

PISTON RETAINER

LIQUID SERVICE

VALVE ADAPTER

FERRULE

LOCK NUT

A92120

Fig. 4—Suction Service Valve with Mechanical

Adapter (38YCP Model)

FERRULE LOCK NUT

TUBING

A92121

Fig. 5—Lock Nut/Ferrule Positioning

4. Close suction service valve and recover refrigerant in tubing.

5. Back-off locknut and ferrule onto tube.

6. Remove damaged part of tubing using tubing cutter. Repeat

installation procedure previously outlined using new ferrule.

7. Evacuate tubing set and indoor coil. Check for leaks.

8. Open service valves or recharge unit. Check refrigerant

charge.

LOCK NUT

LOCK NUT

A94030

Fig. 3—Liquid Service Valve Mechanical Fitting

Assembly (38YCP Model)

NOTE: A backup wrench on the hex part of the suction valve

fitting is required while tightening.

The tube end must stay bottomed in the service valve during

final assembly to ensure proper seating, sealing, and rigidity.

MECHANICAL FITTING REPAIR

To replace damaged ferrule or tubing, proceed as follows.

1. Attach gages to service valves.

2. Close liquid service valve and operate unit in cooling mode to

pump refrigerant charge into condenser coil.

3. When suction pressure reaches 5 psig, shut unit off. Do not

operate unit in a vacuum.

TUBING

MARK ON LOCK NUT

AND TUBE

A92122

Fig. 6—Proper Marking of Valve Assembly

2

Page 3

NOTE: A thermostatic expansion valve (TXV) is required on all

38BYB units. Step 4 refers to the installation of the TXV.

Step 4—Remove Indoor AccuRater® Piston and Install

TXV

For proper unit operation and reliability, units must be

installed with a field-supplied hard shut-off TXV. Do not

install with evaporator coils having capillary tube metering

devices or piston.

After removing existing AccuRater from indoor coil, install

field-supplied bi-flow hard shut-off TXV kit. (See Fig. 7 and 8.)

COIL

THERMOSTATIC

EXPANSION

VALVE

SENSING

BULB

EQUALIZER

TUBE

A88382

Fig. 7—Typical TXV Installation

10 O'CLOCK

2 O'CLOCK

SENSING BULB

STRAP

SUCTION TUBE

4 O'CLOCK

7⁄

8

IN. OD

A81032

7

⁄

IN. OD & SMALLER

8

8 O'CLOCK

LARGER THAN

Fig. 8—Positioning of Sensing Bulb

For TXV kit part number and charging instruction, refer to TXV

label in your unit. If the indoor unit (fan coil) comes factory

equipped with a bi-flow hard shut-off TXV, no TXV change is

required.

Install TXV kit to indoor coil as follows:

1. Install suction tube adapter.

2. Install liquid flare-to-sweat adapter.

3. Connect external equalizer tube to fitting on suction tube

adapter.

4. Position sensing bulb on horizontal portion of suction tube

adapter. Secure using supplied hardware.

5. Insulate bulb after installation. (See Fig. 8.)

6. Leak check all connections.

3

Page 4

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

Copyright 1996 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231 38ycb2si

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a 5a

PC 101 Catalog No. 563-809 Printed in U.S.A. Form 38YCB-2SI Pg 4 6-96 Replaces: 38YCB-1SI

Loading...

Loading...