Page 1

38AUZ

Air-Cooled Condensing Units

60 Hz

®

with Puron

(R-410A) Refrigerant

Sizes 07, 08, 12, 14

Installation, Start-Up and

Service Instructions

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Step 1 — Plan for Unit Location . . . . . . . . . . . . . . . . . . 7

Step 2 — Complete Pre-Installation Checks. . . . . . . . . 7

Step 3 — Prepare Unit Mounting Support . . . . . . . . . 7

Step 4 — Rig and Mount the Unit . . . . . . . . . . . . . . . . . 7

Step 5 — Complete Refrigerant Piping Connections . 7

Step 6 — Install Accessories . . . . . . . . . . . . . . . . . . . . . 9

Step 7 – Complete Electrical Connections . . . . . . . . . . 9

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Turn On Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . 14

Preliminary Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 -18

38AUZ Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OPERATING SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ROUTINE SYSTEM MAINTENANCE. . . . . . . . . . . . . . . 18

Quarterly Inspection (and 30 days after initial start) . 18

Seasonal Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 18

SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 23

Comfort Alert Diagnostic Module. . . . . . . . . . . 19 - 21

Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compressor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Low-Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . 21

High-Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . 21

Outdoor Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NOVATION™ Coil Cleaning and Maintenance . . . . 22

Repairing NOVATION Condenser Tube Leaks. . . . . 22

Replacing NOVATION Condenser Coil . . . . . . . . . . 22

Field Refrigerant Access Ports . . . . . . . . . . . . . . . . . 22

Factory High-Flow Access Ports. . . . . . . . . . . . . . . . 22

Fastener Torque Values . . . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 23, 24

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Air Conditioner and Heat Pump with Puron® —

Quick Reference Guide . . . . . . . . . . . . . . . . . . . . . . . 25

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . CL-1, CL-2

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock

or other conditions which may cause personal injury or

property damage. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the

individual instructions package

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloths for brazing operations and have a fire

extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult

local building codes and appropriate national electrical codes

(in USA, ANSI/NFPA70, National Electrical Code (NEC); in

Canada, CSA C22.1) for special requirements.

It is important to recognize safety information. This is the

safety-alert symbol . When you see this symbol on the unit

and in instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the safetyalert symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices,

which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions

which will result in enhanced installation, reliability, or

operation.

Page 2

INSTALLATION GUIDELINE

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

or death.

Before performing service or maintenance operations on

unit, always turn off main power switch to unit and install

lockout tag. Unit may have more than one power switch.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

Puron® (R-410A) refrigerant systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron refrigerant

equipment.

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could cause personal injury

or death.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal.

Wear safety glasses and gloves when handling refrigerants.

Keep torches and other ignition sources away from

refrigerants and oils.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing 38AU units.

Replacement /Retrofit – R22 to Puron

Replacement/retrofit installations require change-out of

outdoor unit, metering device, and filter driers. Change-out of

indoor coil (evaporator) and interconnecting tubing is

recommended.

Existing evaporator coil – If the existing evaporator coil may

be re-used, check with the coil manufacturer to verify the coil

construction is suitable for operation with the higher pressures

of Puron

is compatible with R-410A, replace if necessary. The minimum

factory test pressure rating must be 250 psig (1725 kPa).

Existing coil will need to be purged with Nitrogen to remove as

much mineral oil as possible to eliminate cross contamination

of oils.

Acid test – If the existing system is being replaced because of a

compressor electrical failure, assume acid is in system. If

system is being replaced for any other reason, use an approved

acid test kit to determine acid level. If even low levels of acid

are detected, install a 100 percent activated alumina suctionline filter drier in addition to the replacement liquid-line filter

drier. Remove the suction line filter drier as soon as possible,

with a maximum of 72 hr of operation. Recommendation:

Install a ball valve in the liquid line at the filter drier location

when installing a suction filter in the suction line.

®

(R-410A). Also determine if the existing TXV valve

®

Installation –

1. Remove the existing evaporator coil or fan coil and install

the replacement coil when appropriate.

2. Drain oil from low points and traps in suction line tubing

(and hot gas bypass tubing if appropriate) and evaporator

if they were not replaced. Removing oil from evaporator

coil may require purging of the tubing with dry nitrogen.

3. Unless indoor unit is equipped with a Puron® approved

metering device, change the metering device to a thermal

expansion valve (TXV) designed for Puron® (R-410A).

4. Remove the existing outdoor unit. Install the new outdoor

unit according to these installation instructions.

5. Install a new field-supplied liquid-line filter drier at the

indoor coil just upstream of the TXV or fix orifice

metering device.

6. If a suction line filter drier is also to be installed, install

suction line drier downstream of suction line service

valve at condensing unit.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never install suction-line filter drier in the liquid-line of a

®

Puron

system.

7. If required, install a 100% activated alumina suction line

filter drier at the outdoor unit.

8. Evacuate and charge the system according to the

instructions in this installation manual.

9. Operate the system for 10 hr. Monitor the pressure drop

across the suction line filter drier. If pressure drop

exceeds 3 psig (21kPa), replace suction-line and

liquid-line filter driers. Be sure to purge system with dry

nitrogen and evacuate when replacing filter driers.

Continue to monitor the pressure drop across suction-line

filter drier. Repeat filter changes is necessary. Never leave

suction-line filter drier in system longer than 72 hr (actual

time).

2

Page 3

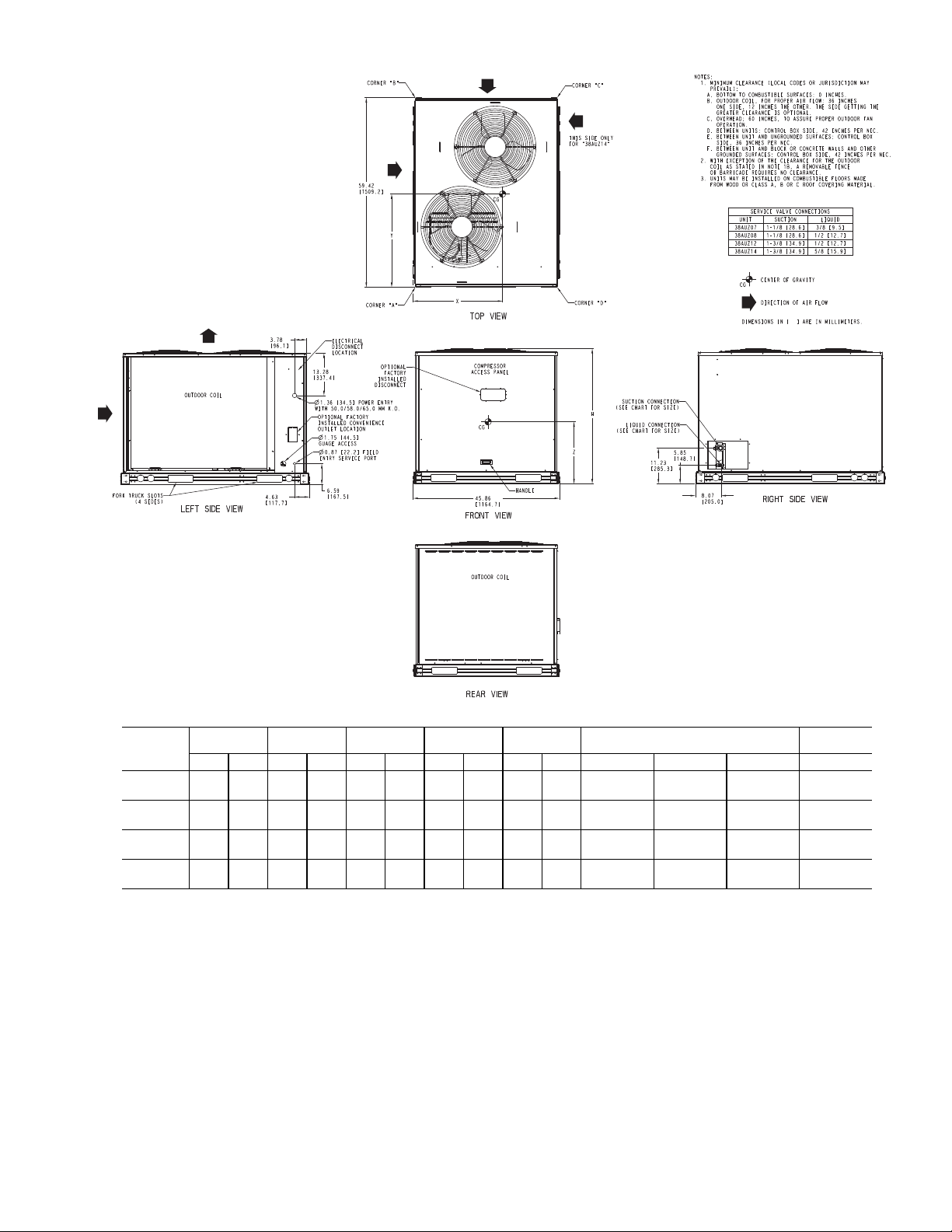

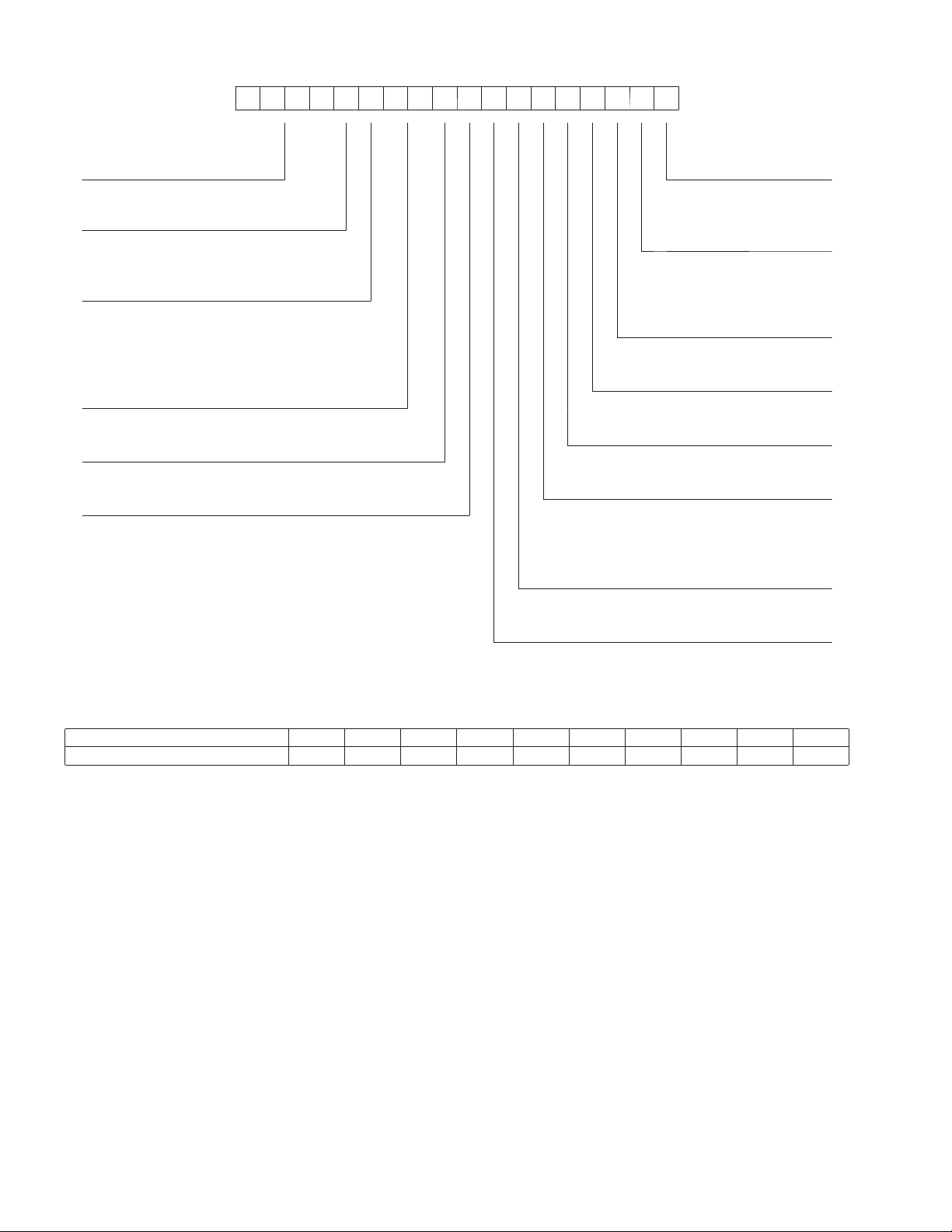

Fig. 1 — 38AUZ*07-14 Unit Dimensions

UNIT

Standard

Weight

Corner

A

Corner

B

Corner

C

Corner

D

Center of Gravity Unit Height

lbs. kg. lbs. kg. lbs. kg. lbs. kg. lbs. kg. X Y Z H

38AUZ*07

328 149 128 58 68 31 62 28 70 32

21.00

[533.4]

19.00

[482.6]

13.00

[330.2]

42.36

[1076.0]

38AUZ*08

353 160 138 63 72 33 65 29 78 35

19.00

[482.6]

23.00

[584.2]

13.00

[330.2]

42.36

[1076.0]

38AUZ*12

418 190 165 75 85 39 78 35 90 41

23.00

[584.2]

20.00

[508.0]

15.00

[381.0]

50.36

[1279.2]

38AUZ*14

431 196 162 73 82 37 92 42 95 43

19.00

[482.6]

23.00

[584.2]

15.00

[381.0]

50.36

[1279.2]

3

Page 4

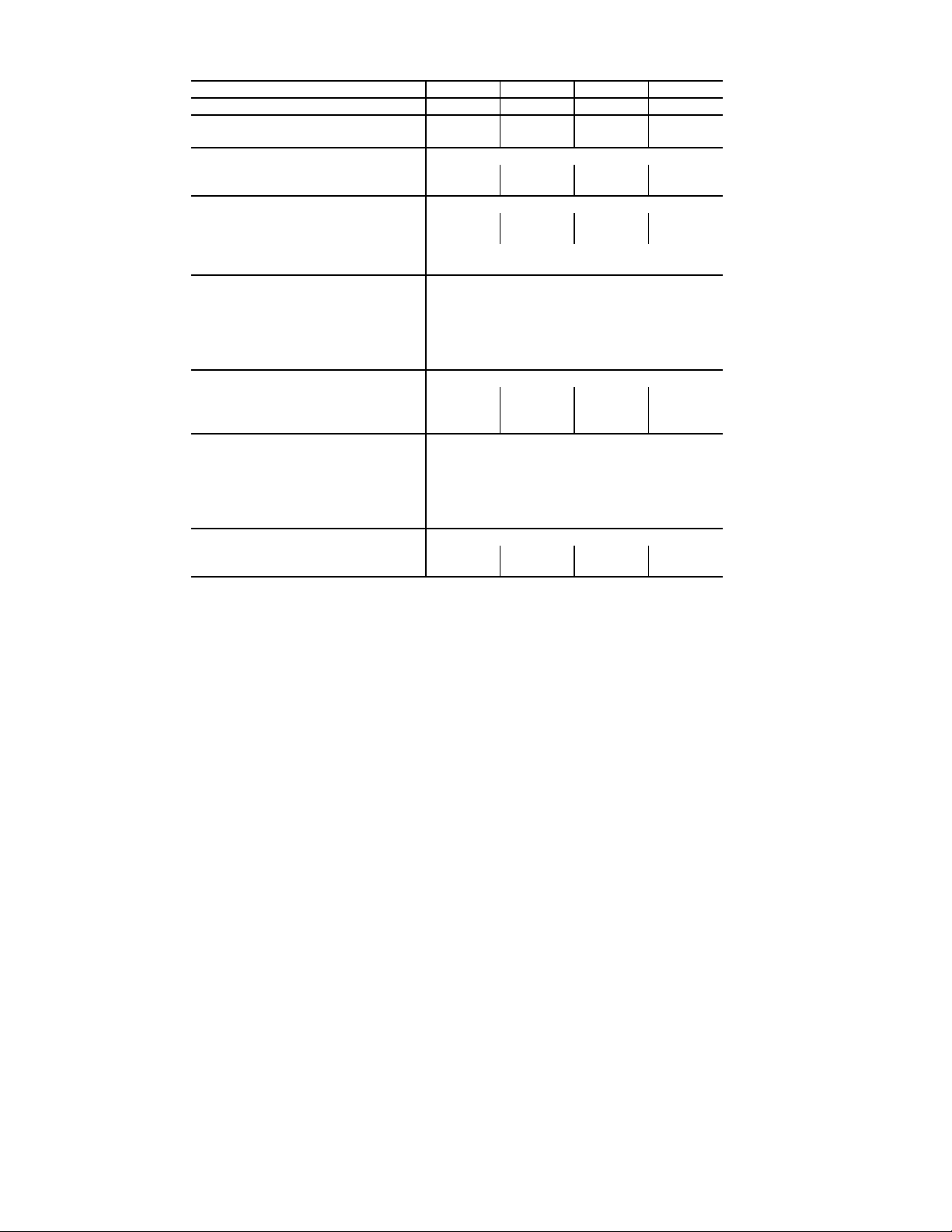

Table 1A — Physical Data — 38AUZ*07-14 Units — 60 Hz English

UNIT SIZE 38AU Z*07Z*08Z*12Z*14

NOMINAL CAPACITY (tons)

6 7.5 10 12.5

OPERATING WEIGHT (lb)

Aluminum-Fin Coils (Standard) 328 353 418 431

REFRIGERANT TYPE*

R-410A

Operating Charge, Typical (lb)† 8.4 10.2 13.8 18.0

Shipping Charge (lb) 4.4 4.9 6.3 7.3

COMPRESSOR

Scroll

Qty...Model 1...ZP61 1...ZP83 1...ZP103 1...ZP137

Oil Charge (oz) 56 60 110 110

No. Cylinders N/A

Speed (rpm) 3500

CONDENSER FANS

Qty...Rpm 2...1100

Motor Hp

1

/

4

Diameter 22

Nominal Airflow (Cfm Total) 6000

Watts (Total) 610

CONDENSER COIL (Qty)

1...NOVATION

Face Area (sq ft total) 17.5 20.5 25.0 31.8

Rows/Fins per inch (FPI) 1/17 1/17 1/17 1/17

Storage Capacity (lb)** 5.5 6.0 7.4 8.7

CONTROLS

Pressurestat Settings (psig)

High Cutout 630 ± 10

Cut-in 505 ± 20

Low Cutout 54 ± 3

Cut-in 117 ± 5

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1...1

Qty...Liquid

LEGEND

ODS — Outside Diameter Sweat (socket)

* Unit is factory-supplied with partial charge only.

† Typical operating charge with 25 ft of interconnecting piping.

** Storage capacity of condenser coil with coil 80% full of liquid R-410A at 95°F.

1...

1

/

/

8

1...1/

1...11/

8

3

1...13/

8

2

1...1/

1...13/

8

2

1...5/

8

8

4

Page 5

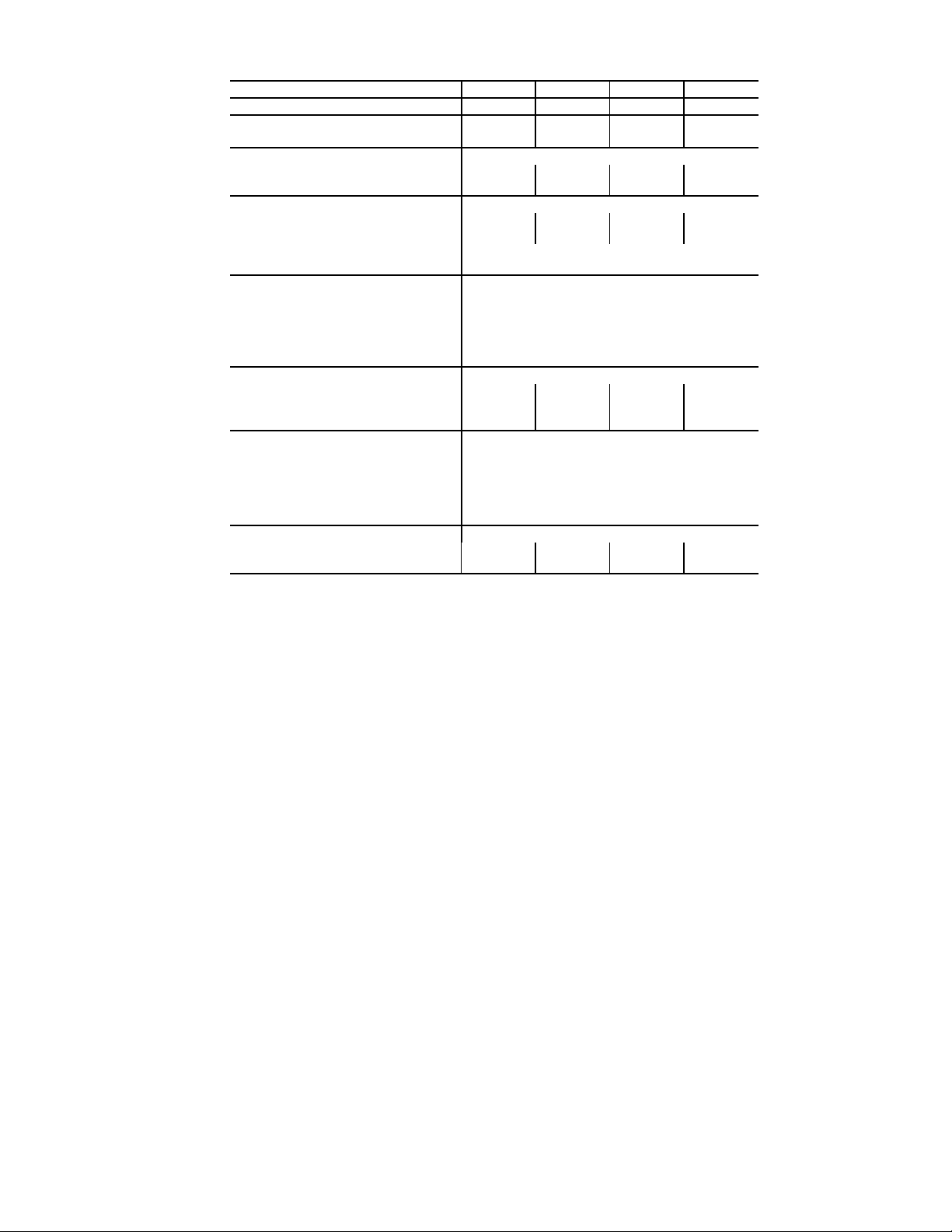

Table 1B — Physical Data — 38AUZ*07-14 Units — 60 Hz SI

UNIT SIZE 38AU Z*07 Z*08 Z*12 Z*14

NOMINAL CAPACITY (kW)

21.1 26.4 35.1 44

OPERATING WEIGHT (kg)

Aluminum-Fin Coils (Standard) 149 160 190 196

REFRIGERANT TYPE*

R-410A

Operating Charge, Typical (kg)† 3.8 4.6 6.3 8.2

Shipping Charge (kg) 2.0 2.2 2.9 3.3

COMPRESSOR

Scroll

Qty...Model 1...ZP61 1...ZP83 1...ZP103 1...ZP137

Oil Charge (L) 1.7 1.8 3.3 3.3

No. Cylinders N/A

Speed (r/s) 58

CONDENSER FANS

Qty...r/s 2...18

Motor Hp NEMA

1

/

4

Diameter (mm) 560

Nominal Airflow (L/s) 2832

Watts (Total) 610

CONDENSER COIL (Qty)

1...NOVATION

Face Area (sq m total) 1.6 1.9 2.3 3.0

Rows/Fins per Meter (Fins/m) 1...670 1...670 1...670 1...670

Storage Capacity (kg)** 2.5 2.7 3.4 3.9

CONTROLS

Pressurestat Settings (kPa)

High Cutout 4347 ± 70

Cut-in 3482 ±138

Low Cutout 372 ± 21

Cut-in 807 ± 34

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1...1

Qty...Liquid

1...

1

/

1...11/

8

3

/

8

1...1/

1...13/

8

2

1...1/

1...13/

8

2

1...5/

LEGEND

NEMA — National Electrical Manufacturers Association

ODS — Outside Diameter Sweat (socket)

* Unit is factory-supplied with partial charge only.

† Typical operating charge with 7.62 m of interconnecting piping.

** Storage capacity of condenser coil with coil 80% full of liquid R-410A at 35°C.

8

8

5

Page 6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

3 8 A U Z A 0 4 A 0

G

6 – 0 A 0 A 0

_____________ ____

Model Type Packaging

38AU= Carrier Condensing Unit

Puronr R ---410A Refrigerant

0=Standard

Type o f Co il

Electrical Options

Z = Single Circuit, A/C Scroll Compressor

A=None

C = Non-Fused Disconnect

1=LTL

Service Options

0=None

1 = Un-powered Convenience Outlet

Nominal Tonnage

1=

07 = 6 Tons

08 = 7.5 Tons

Not Used

12 = 10 Tons

A=PlaceHolder

14 = 12.5 Tons

Base Unit Controls

0 = Electro-Mechanical Controls

Not Used

A=Not Used

Design Rev

--- = Catalog Model Number

Voltage

1 = 575/3/60

5 = 208/ 230/3/60

6 = 460/3/60

Refrigerant Options

A = None

B = Low Ambient

Not Used

0=Not Used

Coil Options

G=Al/Al

2 = Powered Convenience Outlet

SETANGISEDNOITISOP

)radnelac lacsif( erutcafunam fo keeW1−2

)ASU ,saxeT ,PTE = G( noitacol gnirutcafunaM5

rebmun laitneuqeS6−10

12345678910

4808G12345

POSITION NUMBER

TYPICAL

Year of manufacture (”08” = 2008)3−4

Fig. 2 — Model Number Nomenclature

Fig. 3 — Serial Number Nomenclature

6

Page 7

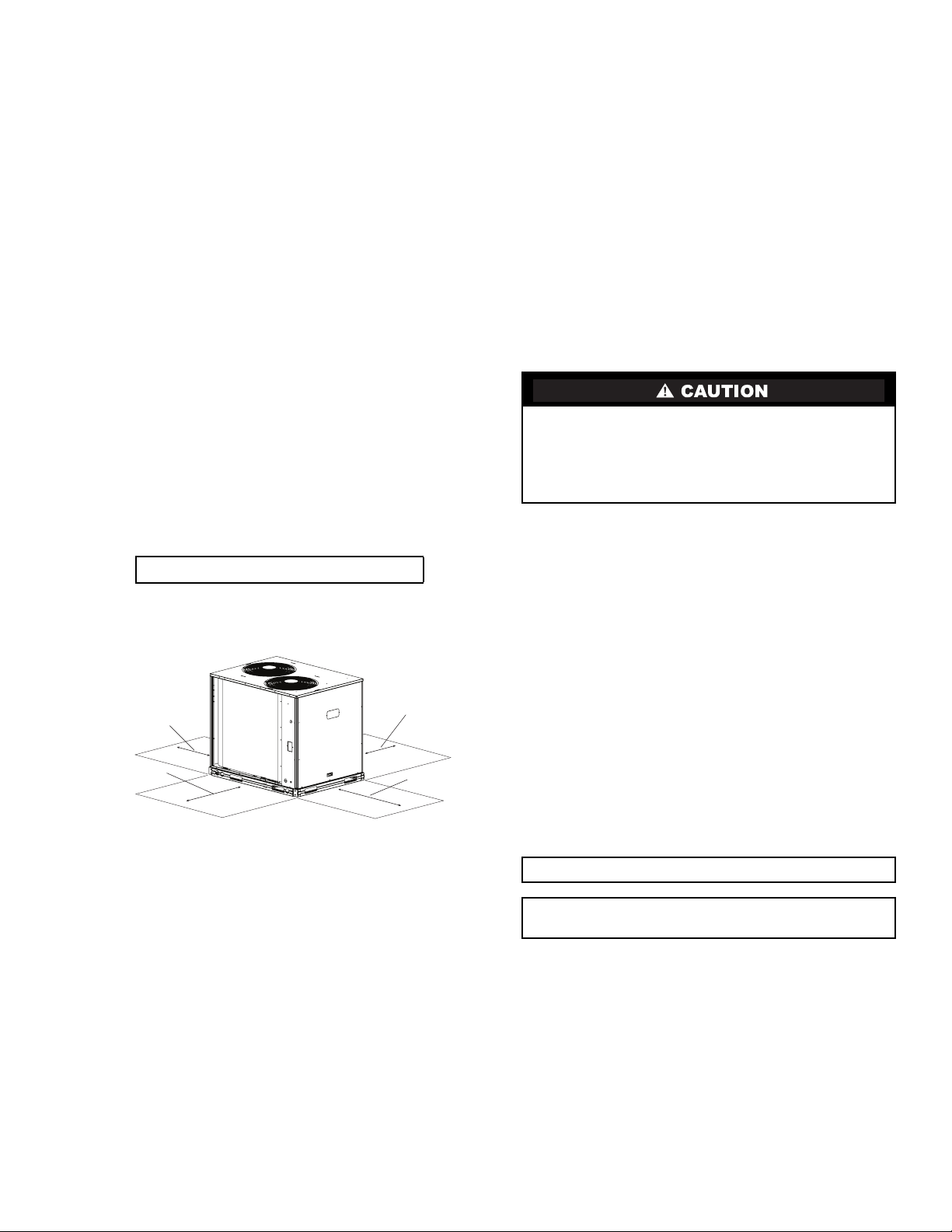

.INSTALLATION

REAR:

Min 18” (457 mm)

requried for service

Note: Observe requirements for 39” (914 mm) operating clearance

on either Left or Rear coil opening.

RIGHT:

Min 18” (457 mm)

requried for service

LEFT:

Min 18” (457 mm)

requried for service

FRONT:

42” (1067 mm)

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installation

requirements.

2. Determine unit location (from project plans) or select unit

location.

3. Check for possible overhead obstructions which may interfere with unit lifting or rigging.

Step 1 — Plan for Unit Location

Select a location for the unit and its support system (pad, rails

or other) that provides for the minimum clearances required for

safety. This includes the clearance to combustible surfaces, unit

performance and service access below, around and above unit

as specified in unit drawings. See Fig. 4.

NOTE: Consider also the effect of adjacent units on airflow

performance and control box safety clearance.

Do not install the outdoor unit in an area where fresh air supply

to the outdoor coil may be restricted or when recirculation from

the condenser fan discharge is possible. Do not locate the unit

in a well or next to high walls.

Evaluate the path and required line length for interconnecting

refrigeration piping, including suction riser requirements (outdoor unit above indoor unit), liquid line lift (outdoor unit below

indoor unit) and hot gas bypass line. Relocate sections to minimize the length of interconnecting tubing.

DO NOT BURY REFRIGERATION LINES.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto the

unit.

• Locate the unit so that the outdoor coil (condenser) airflow is unrestricted on all sides and above.

• The unit may be mounted on a level pad directly on the

base channels or mounted on raised pads at support

points. See Tables 1A and 1B for unit operating weights.

See Fig. 1 for weight distribution based on recommended

support points.

NOTE: If vibration isolators are required for a particular

installation, use the data in Fig. 1 to make the proper

selection.

Step 3 — Prepare Unit Mounting Support

Slab Mount —

Provide a level concrete slab that extends a minimum of 6 in.

(150 mm) beyond unit cabinet. Install a gravel apron in front of

condenser coil air inlet to prevent grass and foliage from

obstructing airflow.

Step 4 — Rig and Mount the Unit

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck.

.

RIGGING — These units are designed for overhead rigging.

Refer to the rigging label for preferred rigging method. Spreader bars are not required if top crating is left on the unit. All panels must be in place when rigging. As further protection for coil

faces, plywood sheets may be placed against the sides of the

unit, behind cables. Run cables to a central suspension point so

that the angle from the horizontal is not less than 45 degrees.

Raise and set the unit down carefully.

If it is necessary to roll the unit into position, mount the unit on

longitudinal rails, using a minimum of 3 rollers. Apply force to

the rails, not the unit. If the unit is to be skidded into position,

place it on a large pad and drag it by the pad. Do not apply any

force to the unit.

Raise from above to lift the unit from the rails or pad when unit

is in its final position.

After the unit is in position, remove all shipping materials and

top crating.

Step 5 — Complete Refrigerant Piping

Connections

Fig. 4 — Service Clearance Dimensional Drawing

Step 2 — Complete Pre-Installation Checks

CHECK UNIT ELECTRICAL CHARACTERISTIC —

Confirm before installation of unit that voltage, amperage and

circuit protection requirements listed on unit data plate agree

with power supply provided.

UNCRATE UNIT — Remove unit packaging except for the

top skid assembly, which should be left in place until after the

unit is rigged into its final location.

INSPECT SHIPMENT — File a claim with shipping company if the shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical

Code (NEC, U.S.A.) for special installation requirements.

• Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 1 for unit

dimensions and weight distribution data.

IMPORTANT: Do not bury refrigerant piping underground.

IMPORTANT: A refrigerant receiver is not provided with

the unit. Do not install a receiver.

PROVIDE SAFETY RELIEF — The 38AUZ unit is provided

with a fusible joint in the suction line in accordance with

applicable UL standards for pressure relief. If local codes

dictate an additional safety relief device, purchase locally and

install locally. Installation will require the recovery of the

factory shipping charge before the factory tubing can be cut

and the supplemental relief device is installed.

SIZE REFRIGERANT LINES — Consider the linear length

of piping required between the outdoor unit and indoor unit

(evaporator), the amount of liquid lift (indoor section installed

above the outdoor section), and compressor oil return.

Consider and identify also the arrangement of the tubing path

(quantity and type of elbows in both lines), liquid line solenoid

size, filter drier and any other refrigeration specialties located

7

Page 8

in the liquid line. Refer to the indoor unit installation

instructions for additional details.

Determine equivalent line length adjustments for path and

components and add to linear line lengths. See Tables 2 and 3;

also refer to Part 3 of the Carrier System Design Manual and

E20-II® software for design details and line sizing.

Suction line sizing – Select a tube size that produces a suction

pressure drop in range of 1.5 to 3.0°F (0.8 to 1.7°C). (Higher

pressure drops are permissible but there will be a loss in

cooling capacity due to the higher pressure drop.) Insulate the

suction line.

Liquid line sizing – For linear line lengths up to 50-ft (15 m),

select a tube size that produces a liquid pressure drop of

approximately 2°F (1.1°C). For linear line lengths greater than

50-ft (15 m), select a line size that will permit the liquid

state-point subcooling entering the indoor coil’s TXV to be a

minimum of 2°F (1.1°C).

Hot Gas Bypass – Hot gas bypass, if used, should be

introduced before the evaporator. (A bypass route that also

bypasses the evaporator circuit may lead to oil trapping in the

evaporator circuit during low load conditions and then to oil

slugging as evaporator load increases.) Model 38AUZA units

do not include a hot gas stub connection; a tee must be fieldsupplied and installed in the compressor discharge line. Run a

½-in OD line between outdoor unit and evaporator coil inlet.

Install an Auxiliary Side Connector at the evaporator between

TXV and distributor (follow instructions for the side connector

part). Insulate the hot gas line.

Note that refrigerant suction piping should be insulated.

IMPORTANT: For 38AUZ*07-14 applications with liquid

lift greater than 20 ft (6 m), use

5

/8-in. liquid line.

Maximum lift is 60 ft (18 m).

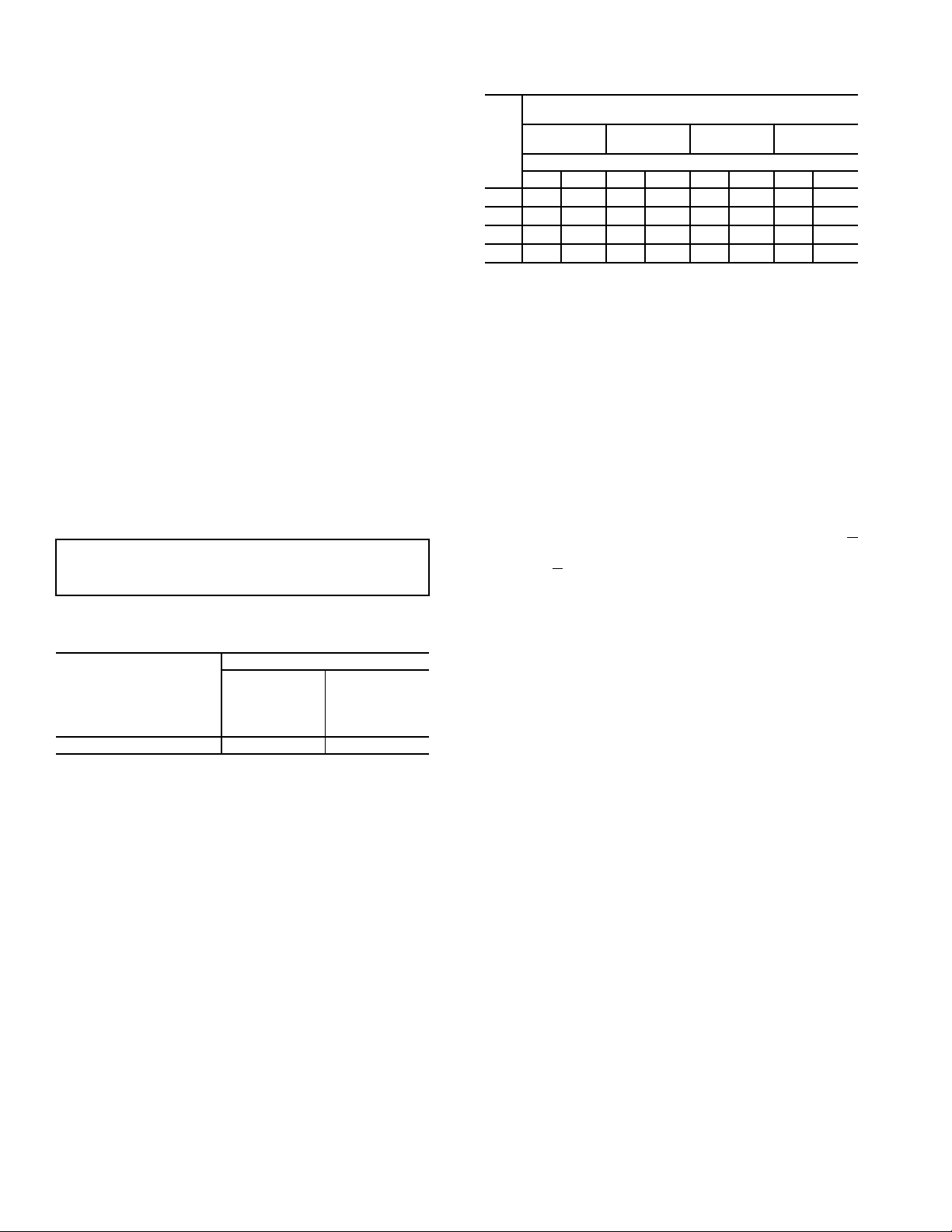

Table 2 — Liquid Line Data —

38AUZ*07-14 60 Hz Units,

Table 3 — Refrigerant Piping Sizes —

38AUZ*07-14 60 Hz Units

LINEAR LENGTH OF INTERCONNECTING PIPING —

UNIT

38AU

Z*07

Z*08

Z*12

Z*14

LEGEND

L — Liquid Line S — Suction Line

*Field-supplied suction accumulator required for pipe length 75-100 ft

(23-30 m).

NOTES:

1. Pipe sizes are based on a 2°F (1°C) saturated temperature

2. Pipe sizes are based on the maximum linear length, shown for

3. Charge unit with R-410A and verify that subcooled liquid exists

0-25

(0-7.5)

LSLSLSLS

3

/811/

3

/811/

1

/213/

1

/213/

loss for liquid and suction lines.

each column, plus a 50% allowance for fittings.

at TXV by checking for a full liquid line sight glass or by calculating subcooling at TXV.

8

8

8

8

3

/811/

1

/211/

1

/213/

1

/213/

FT (m)

25-50

(7.5-15)

Line Size (in. OD)

8

8

8

8

50-75

(15-23)

3

/811/

1

/211/

1

/213/

1

/213/

8

8

8

8

75-100

(23-30)*

3

/811/

1

/213/

1

/213/

1

/213/

8

8

8

8

INSTALL FILTER DRIER(S) AND MOISTURE

INDICATOR(S) — Every unit should have a filter drier and a

liquid-moisture indicator (sight glass). Refer to Table 4. In

some applications, depending on space and convenience requirements, it may be desirable to install 2 filter driers and sight

glasses. One filter drier and sight glass may be installed at A

locations in Fig. 5; or, 2 filter driers and sight glasses may be

installed at B

locations.

Select the filter drier for maximum unit capacity and minimum

pressure drop. Complete the refrigerant piping from the indoor

unit to the outdoor unit before opening the liquid and suction

lines at the outdoor unit.

MAXIMUM

ALLOWABLE

LIQUID LIFT

ft (m)

60 (18) 7 (48) 2 (1)

*Inlet and outlet.

NOTE: Data shown is for units operating at 45°F (7.2°C) saturated

suction temperature and 95°F (35°C) entering air temperature. For

38AUZ*07-14 applications with liquid lift greater than 20 ft (6 m),

5

use

/8-in. liquid line. Maximum lift is 60 ft (18 m).

LIQUID LINE

Maximum

Allowable

Pressure

Drop

psig (kPa)

Maximum

Allowable

Tem p.

Loss

°F (°C)

INSTALL LIQUID LINE SOLENOID VALVE —

SOLENOID DROP — It is recommended that a solenoid

valve be placed in the main liquid line (see Fig. 5) between the

condensing unit and the evaporator coil. Refer to Table 4. (A

liquid line solenoid valve is required when the liquid line

length exceeds 75 ft [23 m] or when the condensing unit is connected to a chiller barrel in a built-up chiller system.) This

valve prevents refrigerant migration (which causes oil dilution)

to the compressor during the off cycle, at low outdoor ambient

temperatures. Wire the solenoid in parallel with the compressor

contactor coil (see Fig. 5). This means of electrical control is

referred to as solenoid drop control.

INSTALL LIQUID LINE SOLENOID VALVE (Optional)

— CAPACITY CONTROL — If 2-step cooling is desired,

place a solenoid valve in the location shown in Fig. 5.

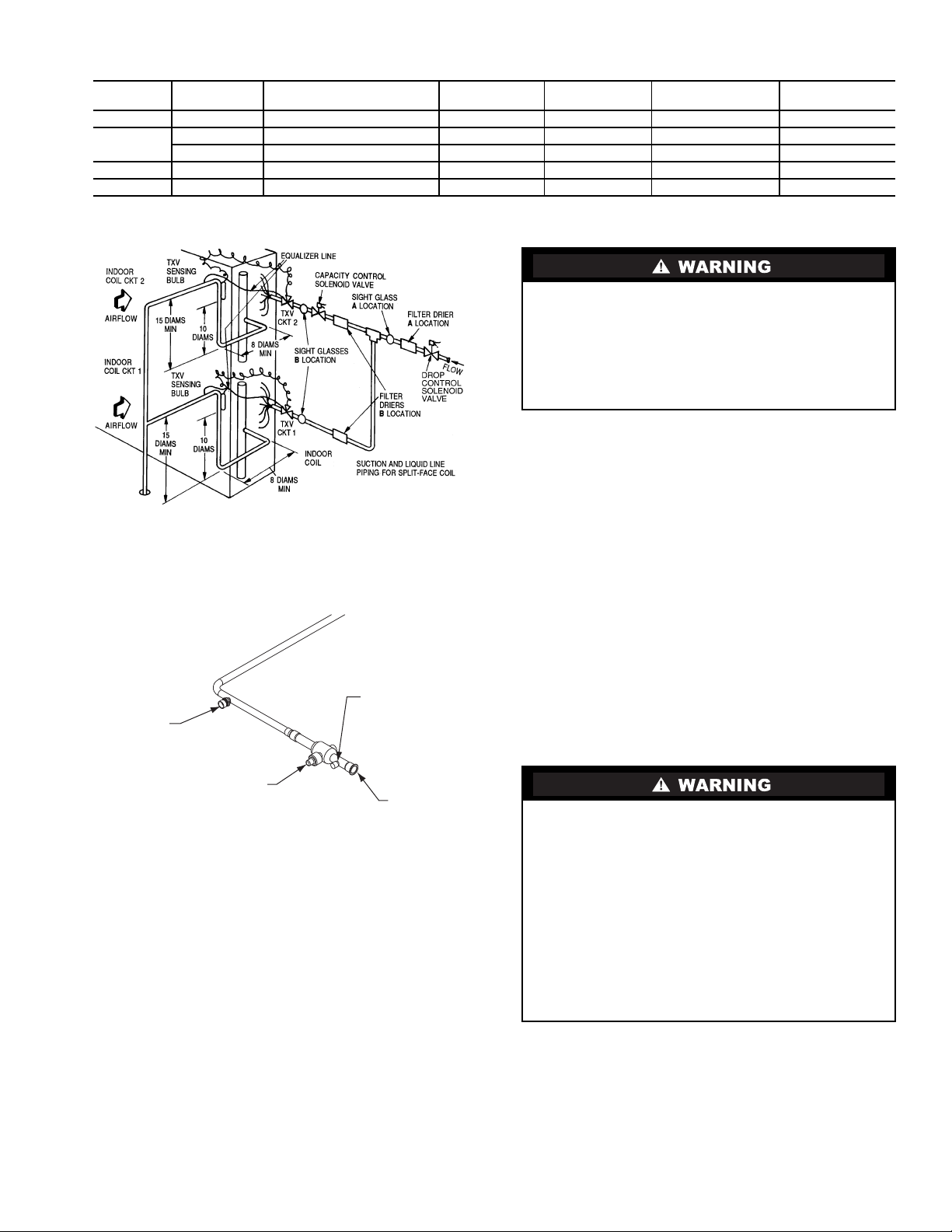

MAKE PIPING CONNECTIONS — Piping connections at

the 38AU unit are ball valves with stub tube extensions. Do not

open the unit service valves until all interconnecting tube brazing as been completed.

The stub tube connections include ¼-in SAE service fittings

with Schrader valve cores (see Fig. 6). Before making any

brazed connections to the unit service valves, remove both

Schrader valve caps and cores and save for re-installation. Connect a source for nitrogen to one of these service fittings during

tube brazing to prevent the formation of copper oxides inside

the tubes at brazed joints.

When connecting the field tubing to the 38AU service valves,

wrap the valves in wet rags to prevent overheating.

8

Page 9

Table 4 — Refrigerant Specialities Part Numbers.

LEGEND

TXV — Thermostatic Expansion Valve

Factory

High-Flow

Access Port

Service Valve

with Stem Cap

Field Service

Access Port

(Schrader core)

Sweat

Connection

UNIT

38AUZ*07

38AUZ*08

38AUZ*12

38AUZ*14

*Bushings required.

LIQUID LINE

SIZE (in.)

Fig. 5 — Location of Sight Glass(es)

3

/

8

3

/

8

1

/

2

1

/

2

5

/

8

SOLENOID VALVE (LLSV)

and Filter Driers

LIQUID LINE

200RB5T3M AMG/24V AMI-1TT3 P502-8304S* S-7063S*

200RB5T3M AMG/24V AMI-1TT3 P502-8304S* S-7063S*

200RB5T4M AMG/24V AMI-1TT4 P502-8304S S-7063S*

200RB6T4M AMG/24V AMI-1TT4 P502-8307S* S-7063

200RB6T5M AMG/24V AMI-1TT5 P502-8307S* S-7063

LLSV

COIL

SIGHT

GLASS

FILTER

DRIER

SUCTION LINE

ACCUMULATOR

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

Puron® (R-410A) refrigerant systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron refrigerant

equipment.

PRELIMINARY CHARGE — Before starting the unit, charge

R-410A liquid refrigerant into the high side of the system

through the liquid service valve. The amount of refrigerant

added must be at least 80% of the operating charge listed in the

Physical Data table (Tables 1A and 1B, pages 4 and 5) LESS

the factory charge quantity (if factory shipping charge has not

been removed). Allow high and low side pressures to equalize.

If pressures do not equalize readily, charge R-410A vapor

(using special service manifold with expansion device) into the

suction line service port for the low side of system to assure

charge in the evaporator. Refer to GTAC II, Module 5,

Charging, Recover, Recycling, and Reclamation for liquid

charging procedures.

Step 6 — Install Accessories

Accessories requiring modifications to unit wiring should be

completed now. These accessories may include Winter Start

controls, Low Ambient controls, phase monitor, Compressor

LOCout. Refer to the instructions shipped with the accessory.

Fig. 6 — Typical Piping Connection Assembly

Pressure-test all joints from outdoor unit connections over to

the evaporator coil, using nitrogen as pressure and with soapand-bubbles.

When pressure-testing is completed, remove the nitrogen

source at the outdoor unit service valves and re-install the two

Schrader valve cores. Torque the cores to 2-3 in-lbs (23-34

N-cm).

EVACUATION/DEHYDRATION — Evacuate and dehydrate

the connected refrigeration system (excluding the 38AU unit)

to 500 microns using a two-stage vacuum pump attached to the

service ports outside the 38AU service valves, following description in GTAC II, Module 4, System Dehydration.

Step 7 — Complete Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit cabinet

must have an uninterrupted, unbroken electrical ground to

minimize the possibility of personal injury if an electrical

fault should occur. This ground may consist of electrical

wire connected to unit ground lug in control compartment,

or conduit approved for electrical ground when installed in

accordance with NEC (National Electrical Code); ANSI/

NFPA 70, latest edition (in Canada, Canadian Electrical

Code CSA [Canadian Standards Association] C22.1), and

local electrical codes.

NOTE: Check all factory and field electrical connections

for tightness. Field-supplied wiring shall conform with the

limitations of 63°F (33°C) rise.

Field Power Supply —

If equipped with optional Powered Convenience Outlet: The

power source leads to the convenience outlet's transformer

primary are not factory connected. Installer must connect these

9

Page 10

leads according to required operation of the convenience outlet.

COPPER

WIRE ONLY

ELECTRIC

DISCONNECT

SWITCH

ALUMINUM

WIRE

Ground Lug

Splice Terminals

(field supplied)

DISCONNECT

BLK

YEL

BLU

LEGEND

Factory Power Connection Lead

Field Power Supply Conductor

If an always-energized convenience outlet operation is desired,

connect the source leads to the line side of the unit-mounted

disconnect. (Check with local codes to ensure this method is

acceptable in your area.) If a de-energize via unit disconnect

switch operation of the convenience outlet is desired, connect

the source leads to the load side of the unit disconnect. On a

unit without a unit-mounted disconnect, connect the source

leads to the factory connection leads (pigtails) in the unit’s

main control box (see Fig. 8).

All units except 208/230-v units are factory wired for the

voltage shown on the nameplate. If the 208/230-v unit is to be

connected to a 208-v power supply, the control transformer

must be rewired by moving the black wire with the ¼-in. female

spade connector from the 230-v connection and moving it to

the 208-v ¼-in. male terminal on the primary side of the

transformer. Refer to unit label diagram for to line-side

information. Field power wires will be connected line-side

pressure lugs on the power terminal block or at factoryinstalled option non-fused disconnect.

Field power wires are connected to the unit at the leads to the

factory connection leads (pigtails) in the unit’s main control

box (see Fig. 8) or at factory-installed option non-fused

disconnect switch. Max wire size is #4 AWG (copper only).

NOTE: TEST LEADS - Unit may be equipped with short

leads (pigtails) on the field line connection points on the

optional disconnect switch. These leads are for factory

run-test purposes only; remove and discard before connecting field power wires to unit connection points.

All units -

All field wiring must comply with NEC and all local codes.

Size wire based on MCA (Minimum Circuit Amps) on the unit

informative plate. See Fig. 8 for power wiring connections to

the unit power terminal block and equipment ground.

Provide a ground-fault and short-circuit over-current protection

device (fuse or breaker) per NEC Article 440 (or local codes).

Refer to unit informative data plate for MOCP (Maximum

Over-current Protection) device size.

Units Without Factory-Installed Disconnect —

When installing units, provide a disconnect switch per NEC

(National Electrical Code) of adequate size. Disconnect sizing

data is provided on the unit informative plate. Locate on unit

cabinet or within sight of the unit per national or local codes.

Do not cover unit informative plate if mounting the disconnect

on the unit cabinet.

Units with Factory-Installed Disconnect —

The factory-installed option disconnect switch is located in a

weatherproof enclosure located under the main control box.

The manual switch handle is accessible through an opening in

the access panel.

FIRE HAZARD

Failure to follow this warning could result in intermittent

operation or performance satisfaction.

Do not connect aluminum wire between disconnect switch

and condensing unit. Use only copper wire.

(See Fig. 7.)

Fig. 7 — Disconnect Switch and Unit

Fig. 8 — Power Wiring Connections

All field wiring must comply with the NEC and local

requirements.

Affix the crankcase heater warning sticker to the unit

disconnect switch.

Convenience Outlets —

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Units with convenience outlet circuits may use multiple

disconnects. Check convenience outlet for power status

before opening unit for service. Locate its disconnect

switch, if appropriate, and open it. Tag-out this switch, if

necessary.

Two types of convenience outlets are offered on 38AUZ

models: Non-powered and unit-powered. Both types provide a

125-volt GFCI (ground-fault circuit-interrupter) duplex

receptacle rated at 15-A behind a hinged waterproof access

cover, located on the end panel of the unit. See Fig. 9.

10

Page 11

Control Box

Access Panel

Pwd-CO

Transformer

Convenience

Outlet

GFCI

Pwd-CO

Fuse

Switch

UNIT

VOLTAGE

CONNECTASPRIMARY

CONNECTIONS

TRANSFORMER

TERMINALS

208,

230

240

L1: RED + YEL

L2: BLU + GRA

H1 + H3

H2 + H4

460 480

L1: RED

Spli ce BLU +

YEL

L2: GRA

H1

H2 + H3

H4

575 600

L1: RED

L2: GRA

H1

H2

Fig. 9 — Convenience Outlet Location

Non-powered type: This type requires the field installation of

a general-purpose 125-volt 15-A circuit powered from a source

elsewhere in the building. Observe national and local codes

when selecting wire size, fuse or breaker requirements and

disconnect switch size and location. Route 125-v power supply

conductors into the bottom of the utility box containing the

duplex receptacle.

Unit-powered type: A unit-mounted transformer is factoryinstalled to stepdown the main power supply voltage to the unit

to 115-v at the duplex receptacle. This option also includes a

manual switch with fuse, located in a utility box and mounted

on a bracket behind the convenience outlet; access is through

the unit's control box access panel. See Fig. 9.

The primary leads to the convenience outlet transformer are not

factory-connected. Selection of primary power source is a

customer-option. If local codes permit, the transformer primary

leads can be connected at the line-side terminals on the unitmounted non-fused disconnect or HACR breaker switch; this

will provide service power to the unit when the unit disconnect

switch or HACR switch is open. Other connection methods

will result in the convenience outlet circuit being de-energized

when the unit disconnect or HACR switch is open. See Fig. 10.

Duty Cycle: the unit-powered convenience outlet has a duty

cycle limitation. The transformer is intended to provide power

on an intermittent basis for service tools, lamps, etc; it is not

intended to provide 15-amps loading for continuous duty loads

(such as electric heaters for overnight use). Observe a 50%

limit on circuit loading above 8-amps (i.e., limit loads

exceeding 8-amps to 30 minutes of operation every hour).

Test the GFCI receptacle by pressing the TEST button on the

face of the receptacle to trip and open the receptacle. Check for

proper grounding wires and power line phasing if the GFCI

receptacle does not trip as required. Press the RESET button to

clear the tripped condition.

Fig. 10 - Powered Convenience Outlet Wiring

Fuse on power type: The factory fuse is a Bussman “Fusetron”

T-15, non-renewable screw-in (Edison base) type plug fuse.

Using unit-mounted convenience outlets: Units with unitmounded convenience outlet circuits will often require that two

disconnects be opened to de-energize all power to the unit.

Treat all units as electrically energized until the convenience

outlet power is also checked and de-energization is confirmed.

Observe National Electrical Code Article 210, Branch Circuits,

for use of convenience outlets.

Installing Weatherproof Cover –

A weatherproof while-in-use cover for the factory-installed

convenience outlets is now required by UL standards. This

cover cannot be factory-mounted due its depth; it must be

installed at unit installation. For shipment, the convenience

outlet is covered with a blank cover plate.

The weatherproof cover kit is shipped in the unit's control box.

The kit includes the hinged cover, a backing plate and gasket.

DISCONNECT ALL POWER TO UNIT AND

CONVENIENCE OUTLET.

Remove the blank cover plate at the convenience outlet;

discard the blank cover.

Loosen the two screws at the GFCI duplex outlet, until

approximately 1/2-in (13 mm) under screw heads are exposed.

Press the gasket over the screw heads. Slip the backing plate

over the screw heads at the keyhole slots and align with the

gasket; tighten the two screws until snug (do not over-tighten).

Mount the weatherproof cover to the backing plate as shown in

Fig. 11. Remove two slot fillers in the bottom of the cover to

permit service tool cords to exit the cover. Check for full

closing and latching.

11

Page 12

RECEPTACLE

NOT INCLUDED

COVER – WHILE-IN-USE

WEATHERPROOF

BASE PLATE FOR

GFCI RECEPTACLE

R

G

Y1

O/B/Y2

(Notes 1, 2)

W2

X

C

G

Central

Terminal

Board

X

C

G

W2

Fig. 11 — Weatherproof Cover Installation

All Units —

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate. See Table 5.

On 3-phase units, voltages between phases must be balanced

within 2% and the current within 10%. Use the formula shown

in the legend for Table 5, Note 5 (see page 13) to determine the

percent of voltage imbalance. Operation on improper line

voltage or excessive phase imbalance constitutes abuse and

may cause damage to electrical components. Such operation

would invalidate any applicable Carrier warranty.

Field Control Wiring — Unit control voltage is 24 v. See

Fig. 8 and the unit’s label diagram for field-supplied wiring

details. Route control wires through the opening in unit’s end

panel to the connections terminal board in the unit’s control

box.

The 38AUZ unit requires an external temperature control

device. This device can be a thermostat (field-supplied) or a

PremierLink controller (available as factory-installed option or

as field-installed accessory, for use on a Carrier Comfort

Network or as a stand alone control).

Thermostat —

Install a Carrier-approved accessory thermostat according to

installation instructions included with the accessory. For

complete economizer function, select a two—stage cooling

thermostat. Locate the thermostat accessory on a solid wall in

the conditioned space to sense average temperature in

accordance with the thermostat installation instructions.

If the thermostat contains a logic circuit requiring 24-v power,

use a thermostat cable or equivalent single leads of different

colors with minimum of four leads. If the thermostat does not

require a 24-v source (no “C” connection required), use a

thermostat cable or equivalent with minimum of three leads.

Check the thermostat installation instructions for additional

features which might require additional conductors in the

cable.

For wire runs up to 50 ft. (15 m), use no. 18 AWG (American

Wire Gage) insulated wire (35°C minimum). For 50 to 75 ft.

(15 to 23 m), use no. 16 AWG insulated wire (35°C minimum).

For over 75 ft. (23 m), use no. 14 AWG insulated wire (35°C

minimum). All wire sizes larger than no. 18 AWG cannot be

directly connected to the thermostat and will require a junction

box and splice at the thermostat.

PremierLink (accessory installation) – Refer to Form 33CS58SI for details on connecting the PremierLink controller and

its various sensors.

W1

Y2

C

(Note 3)

Note 1: Typical multi-function marking. Follow manufacturer’s configuration

instructions to select Y2.

Note 2: Y2 to economizer required on single-stage cooling units when

integrated economizer function is desired

Note 3: Connect only if thermostat requires 24-vac power source.

Field Wiring

Y1

R

T– STAT

W1

Y2

Y1

R

Fig. 12 — Typical Remote Thermostat Connections

CONTROL CIRCUIT WIRING — Control voltage is 24 v.

See Fig. 8 and the unit’s label diagram for field-supplied

wiring details. Route control wires through the opening in

unit’s end panel to the connection in the unit’s control box.

CONTROL TRANSFORMER WIRING (38AUZ07-14

Units) — On multivoltage units, check the transformer

primary wiring connections. See Fig. 13 or refer to the unit’s

label diagram.

If the unit will be operating at 208-3-60 power, remove the

black wire (BLK) from the transformer primary connection

labelled “230” and move it to the connection labelled “208”.

See Fig. 13.

Fig. 13 — Control Transformer Wiring

12

Page 13

Table 5 — Electrical Data — 38AUZ*07-14 60 Hz Units

Example: Supply voltage is 230-3-60

AB = 224 v

BC = 231 v

AC = 226 v

Average Voltage =

(224 + 231 + 226)

=

681

3

3

=227

Determine maximum deviation from average voltage.

(AB) 227 – 224 = 3 v

(BC) 231 – 227 = 4 v

(AC) 227 – 226 = 1 v

Maximum deviation is 4 v.

Determine percent of voltage imbalance.

%VoltageImbalance =100 x

4

227

=1.76%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

% Voltage Imbalance = 100 x

max voltage deviation from average voltage

average voltage

UNIT

SIZE

38AU

Z*07

Z*08

Z*12

Z*14

FLA —

LRA —

MCA —

MOCP —

NEC —

RLA —

*Units are suitable for use on electrical systems where voltage supplied to

the unit terminals is not below or above the listed limits.

NOTES:

1. The MCA and MOCP values are calculated in accordance with the NEC,

2. Motor RLA and LRA values are established in accordance with Underwriters’

3. The 575-v units are UL, Canada-listed only.

4. Convenience outlet is available as a factory-installed option and is 115-v,

Full Load Amps

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent

Protection

National Electrical Code

Rated Load Amps

Article 440.

Laboratories (UL), Standard 1995.

1 ph, 60 Hz.

FACTORY-

INSTALLED

OPTION

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

NONE OR DISCONNECT

CONVENIENCE OUTLET

LEGEND

NOMINAL

VOLTAGE

V-Ph-Hz MIN MAX RLA LRA FLA (ea) LRA (ea) MCA MOCP

208/230-3-60 187 253 19 123 1.5 3.7 25.2 45

460-3-60 414 506 9.7 62 0.8 1.9 12.9 20

575-3-60 518 633 7.4 50 0.6 1.6 9.9 15

208/230-3-60 187 253 25 164 1.5 3.7 32.7 50

460-3-60 414 506 12.2 100 0.8 1.9 16.0 25

575-3-60 518 633 9.0 78 0.6 1.6 11.8 20

208/230-3-60 187 253 30.1 225 1.5 3.7 39.1 60

460-3-60 414 506 16.7 114 0.8 1.9 21.7 30

575-3-60 518 633 12.2 80 0.6 1.6 15.8 25

208/230-3-60 187 253 48.1 245 1.5 3.7 61.6 80

460-3-60 414 506 18.6 125 0.8 1.9 24.0 30

575-3-60 518 633 14.7 100 0.6 1.6 19.0 30

VOLTAGE

RANGE*

COMPRESSOR

5. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%. Use the following formula to determine the percentage

of voltage imbalance.

FAN MOTORS

(Qty 2)

POWER

SUPPLY

13

Page 14

PRE-START-UP

START-UP

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

review Start-Up Checklist at the back of this book. The

Checklist assures proper start-up of a unit and provides a

record of unit condition, application requirements, system

information, and operation at initial start-up.

UNIT DAMAGE HAZARD

Do not attempt to start the condensing unit, even

momentarily, until the following steps have been

completed. Compressor damage may result.

System Check

1. Check all air handler(s) and other equipment auxiliary

components. Consult the manufacturer’s instructions

regarding any other equipment connected to the condensing unit. If the unit has field-installed accessories,

be sure all are properly installed and correctly wired. If

used, the airflow switch must be properly installed.

2. Be sure the unit is properly leak checked and dehydrated.

3. Check tightness of all electrical connections.

4. Open the liquid line and suction line service valves.

5. Be sure the unit is properly charged. See “Preliminary

Charge”, on page 9.

6. The electrical power source must agree with the unit’s

nameplate rating.

7. The crankcase heater must be firmly attached to the compressor crankcase. Be sure the crankcase is warm (heater

must be on for 24 hours before starting compressor).

Turn On Crankcase Heater — Turn on the crankcase

heater for 24 hours before starting the unit to be sure all the

refrigerant is out of the oil. To energize the crankcase heater,

proceed as follows:

1. Set the space thermostat set point above the space temperature so there is no demand for cooling.

2. Close the field disconnect.

Preliminary Charge — Before starting the unit, charge

liquid refrigerant into the high side of the system through the

liquid service valve. The amount of refrigerant added must be

at least 80% of the operating charge listed in the Physical Data

table (Tables 1A and 1B, pages 4 and 5). Allow high and low

side pressures to equalize before starting compressor. If

pressures do not equalize readily, charge vapor on low side of

system to assure charge in the evaporator. Refer to GTAC II,

Module 5, Charging, Recover, Recycling, and Reclamation for

liquid charging procedures.

UNIT DAMAGE HAZARD

Prior to starting compressor, a preliminary charge of

refrigerant must be added to avoid possible compressor

damage.

38AUZ Units — The compressor crankcase heater must be

on for 24 hours before start-up. After the heater has been on for

24 hours, the unit can be started. If no time elapsed since the

preliminary charge step was completed, it is unnecessary to

wait the 24-hour period.

PRELIMINARY CHECKS

1. Check that electric power supply agrees with unit

nameplate data.

2. Verify that the compressor crankcase heater is securely in

place.

3. Check that the compressor crankcase heater has been on

at least 24 hours.

4. Recheck for leaks using the procedure outlined in the

Pre-Start-Up section, Leak Test and Dehydration. If any

leaks are detected, repair as required. Evacuate and

dehydrate as described in the Leak Test and Dehydration

section.

5. Ensure that the preliminary charge has been added as

described in the Pre-Start-Up section, Preliminary

Charge.

6. All internal wiring connections must be tight, and all

barriers and covers must be in place.

NOTE: The 38AUZ units are factory charged with the

required amount of oil. If recharging in required, use Emkarate RL 32-3MAF for the 38AUZ units.

COMPRESSOR ROTATION — On 3-phase units with scroll

compressors, it is important to be certain that the compressor is

rotating in the proper direction. To determine whether or not

compressor is rotating in the proper direction:

1. Connect service gages to the suction and liquid pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the liquid pressure

should rise, as is normal on any start-up.

If the suction pressure does not drop and the liquid pressure

does not rise to normal levels:

1. Turn off power to the unit, tag disconnect.

2. Reverse any two of the unit power leads.

3. Reapply power to the compressor, verify correct

pressures.

The suction and liquid pressure levels should now move to

their normal start-up levels.

COMPRESSOR OVERLOAD — This overload interrupts

power to the compressor when either the current or internal

motor winding temperature becomes excessive, and automatically resets when the internal temperature drops to a safe level.

This overload may require up to 60 minutes (or longer) to reset.

If the internal overload is suspected of being open, disconnect

the electrical power to the unit and check the circuit through the

overload with an ohmmeter or continuity tester.

14

Page 15

ADVANCED SCROLL TEMPERATURE PROTECTION

0

10

20

30

40

50

60

70

80

90

100

110

120

0 102030405060708090

Compressor Unloaded Run Time (Minutes)

Recommended Cooling Ti me

(Mi

nut

es)

*Times are approximate.

NOTE: Various factors, including high humidity, high ambient tem-

perature, and the presence of a sound blanket will increase cooldown times.

(ASTP) — Advanced Scroll Temperature Protection (ASTP)

is a form of internal discharge temperature protection, used in

38AUZ*12 and 38AUZ*14 units, that unloads the scroll compressor when the internal temperature reaches approximately

300°F. At this temperature, an internal bi-metal disk valve

opens and causes the scroll elements to separate, which stops

compression. Suction and discharge pressures balance while

the motor continues to run. The longer the compressor runs unloaded, the longer it must cool before the bi-metal disk resets.

See Fig. 14.

Fig. 14 — Recommended Minimum Cool-Down Time

After Compressor is Stopped

To manually reset ASTP, the compressor should be stopped

and allowed to cool. If the compressor is not stopped, the motor

will run until the motor protector trips, which occurs up to

90 minutes later. Advanced Scroll Temperature Protection will

reset automatically before the motor protector resets, which

may take up to 2 hours. A label located above the terminal box

identifies Copeland Scroll compressor models (ZP103 and

ZP137) that contain this technology. See Fig. 15.

START UNIT — The field disconnect is closed, the indoor

fan circuit breaker is closed, and the space thermostat is set

above ambient so that there is no demand for cooling. Only the

crankcase heater will be energized.

Reset the space thermostat below ambient so that a call for

cooling is ensured.

Never charge liquid into the low-pressure side of system.

Do not overcharge. During charging or removal of refrigerant, be sure indoor-fan system is operating. Ensure both

outdoor fan motors are running; bypass any Motormaster

function.

ADJUST REFRIGERANT CHARGE — The unit must be

charged in Cooling mode only. Refer to Cooling Charging

Charts, Fig. 16 through Fig. 19. For applications with line

lengths greater than 100 ft, contact Carrier representative. Vary

refrigerant until the conditions of the chart are met. Note that

the charging charts are different from the type normally used.

The charts are based on charging the units to the correct subcooling for the various operating conditions. Accurate pressure

gage and temperature sensing device are required. Connect the

pressure gage to the service port on the liquid line service

valve. Mount the temperature sensing device on the liquid line

close to the liquid line service valve, and insulate it so that outdoor ambient temperature does not affect the reading. Indoor

airflow must be within the unit’s normal operating range. Operate the unit for a minimum of 15 minutes. Ensure that pressure

and temperature readings have stabilized. Plot the liquid pressure and temperature on chart and add or reduce the charge to

meet the curve. Adjust the charge to conform with the charging

chart, using the liquid pressure and temperature to read the

chart.

FINAL CHECKS — Ensure that all safety controls are

operating, control panel covers are on, and the service panels

are in place.

Fig. 15 — Advanced Scroll Temperature

Protection Label

15

Page 16

Fig. 16 — 38AUZ*07 Charging Chart

Fig. 17 — 38AUZ*08 Charging Chart

Fig. 18 — 38AUZ*12 Charging Chart

16

Page 17

Fig. 19 — 38AUZ*14 Charging Chart

Fig. 20 — 38AU Wiring Diagram

17

Page 18

OPERATING SEQUENCE

ROUTINE SYSTEM MAINTENANCE

Base Unit Controls

Indoor (Supply) Fan

The indoor fan contactor (IFC) is remotely located at the fan

coil or fan section. If the thermostat fan operation is selected as

Continuous, the IFC is energized and the indoor (supply) fan

motor runs continuously. If the thermostat fan operation is

selected as Automatic, the IFC will be energized on a call for

Cooling; indoor (supply) fan motor runs. When thermostat call

for Cooling is satisfied, the IFC is de-energized and indoor

(supply) fan motor stops.

Cooling, Unit Without Economizer

On a thermostat call for Cooling, IFC will be energized and

indoor (supply) fan motor runs. Thermostat contact TC1

closes; terminal Y1 at 38AU unit receives 24-v. 24-v received

at CADM terminal Y. If anti-recycle time delay period has not

expired, CADM relay will remain open, preventing

compressor start. When safety pressure switches are closed, the

liquid line solenoid valve opens. When CADM time delay

expires, the compressor contactor is energized; both outdoor

fan motors start and compressor starts.

When space cooling load is satisfied, thermostat contacts TC1

open, removing 24-v at 38AU terminal Y. Compressor and

outdoor fan motors stop. Liquid line solenoid valve is

de-energized and valve closes. CADM begins its three-minute

anti-recycle time delay.

If either the Low Pressure Switch or High Pressure Switch

opens while thermostat contact TC1 remains closed, the

compressor contactor is de-energized (both fan motors and

compressor stop) and liquid line solenoid is de-energized

(valve closes). CADM initiates a TRIP event (cooling demand

sensed at CADM terminal Y but no current is measured at T1,

T2, T3 motor sensors); CADM relay opens and RED LED is

illuminated. TRIP condition maintains lockout of compressor

operation until CADM is manually reset. Reset CADM by

cycling unit main power.

Complete system shutdown may be caused by loss of main

power, open compressor internal overload, open low-pressure

or high-pressure switch, or a fault detected by the CADM

logic. Compressor operation without cooling may indicate the

compressor’s ASTP feature is active (unit sizes 12 and 14

only); disconnect unit power and allow compressor to cool. See

Service section for further details.

Cooling, Unit With Economizer

Refer to fan coil unit installation instructions and economizer

accessory installation instructions for operating sequences

when system is equipped with accessory economizer.

Heating

Refer to fan coil unit installation instructions and accessory

heating device installation instructions for operating sequences

in heating mode.

These items should be part of a routine maintenance program,

to be checked every month or two, until a specific schedule for

each can be identified for this installation:

Quarterly Inspection (and 30 days after initial

start)

Indoor section

• Condenser coil cleanliness checked.

• Return air filter replacement

• Outdoor hood inlet filters cleaned

• Belt tension checked

• Belt condition checked

• Pulley alignment checked

• Fan shaft bearing locking collar tightness checked

• Condensate drain checked

Seasonal Maintenance

These items should be checked at the beginning of each season

(or more often if local conditions and usage patterns dictate):

Air Conditioning

• Condenser fan motor mounting bolts tightness

• Compressor mounting bolts

• Condenser fan blade positioning

• Control box cleanliness and wiring condition

• Wire terminal tightness

• Refrigerant charge level

• Evaporator coil cleaning

• Evaporator blower motor amperage

Heating

• Power wire connections

• Fuses ready

• Manual-reset limit switch is closed

Economizer or Outside Air Damper

• Inlet filters condition

• Check damper travel (economizer)

• Check gear and dampers for debris and dirt

18

Page 19

SERVICE

Comfort Alert Diagnostic Module

The Comfort Alert Diagnostic Module (CADM) monitors and

analyzes data from the Copeland Scroll® three-phase compressor and the thermostat demand. The CADM also provides a

3-minute anti-recycle time delay to compressor cycling.

The CADM detects causes for electrical and system related

failures without any sensors. Flashing LEDs communicate the

Alert codes to guide service technicians in accurately and

quickly troubleshooting the system and determining root cause

for the failure.

Inputs to the CADM include 24-vac power, thermostat Y1,

compressor contactor coil (common side) and compressor

power leads (from the compressor contactor).

Input Terminal Voltage

Control

Power

Control

Common

Cooling Y 24-V

Contactor

Coil

Line A T1 Line

Line B T2 Line

Line C T3 Line

Control of the compressor contactor coil is through a

normally-closed (power on the module) contact between

terminals P and C.

Communications of status and alert conditions is through three

LEDs located on the top edge of the module housing (see Fig.

21): POWER (green), ALERT (yellow), and TRIP (red).

The POWER LED indicates the presence of control power to

the CADM.

R 24-V

C 24-V

P 24-V

POWER

(GRN)

ALERT

(YEL)

TRIP

(RED)

Fig. 21 — CADM Housing/LED Locations

The ALERT LED indicates an abnormal condition exists in the

system through a flash code. The ALERT LED will blink a

number of times consecutively, pause and the repeat the

process. The number of blinks, defined in Table 6, correlates to

a particular abnormal condition; troubleshooting tips are

provided for each Alert code. Reset of the ALERT may be

automatic or manual. If the fault condition causing the Alert is

self-corrected, the Alert code will be removed and the CADM

will automatically reset and allow the system to restart

normally. Manual reset requires that main power to the 38AU

unit be recycled after the cause for the Alert condition has been

detected and corrected.

The TRIP LED indicates either a time-delay period is currently

active (RED LED is blinking) or the module has locked out the

compressor (RED LED is on steady). A lockout condition will

occur when the CADM detects a thermostat demand at input Y

but there is no power at the compressor line terminals T1 or T2

or T3. This lockout can occur due to a safety switch (LPS or

HPS) opening and de-energizing the compressor contactor, the

compressor-motor internal overload opens, or other internal

power interruption has occurred. Reset of the TRIP LED

requires that unit main power be recycled after the loss of

power to the compressor condition has been detected and

corrected.

Simultaneous Blinking of YELLOW and RED LEDs indicates

control power input to the CADM is low. Check control circuit

transformer and wiring.

Troubleshooting the CADM Wiring – Flashing LEDs also

indicate wiring problems to the CADM. See Table 7 for

discussion of additional LED flash codes and troubleshooting

instructions.

19

Page 20

Table 6 — LED Status Codes

Status LED Status LED Description Status LED Troubleshooting Information

Green “POWER” Module has power Supply voltage is present at module terminals

Red “TRIP”

LED On Solid

Red “TRIP” LED

Flashing

Module locks out compressor when compressor damaging ALERT code appears.

Lockout ALERT codes are noted in the Status LED Description.

During a compressor lock out, 24VAC power must be removed from module to manually reset.

Yellow “ALERT”

LED On Solid

Yellow “ALERT”

Flash Code 2

Yellow “ALERT”

Flash Code 3

Yellow “ALERT”

Flash Code 4

Yellow “ALERT”

Flash Code 5

Yellow “ALERT”

Flash Code 6

Yellow “ALERT”

Flash Code 7

Yellow “ALERT”

Flash Code 8

Yellow “ALERT”

Flash Code 9

Thermostat demand signal Y

is present, but the

compressor is not running.

The anti-short cycle timer (3 minutes), in module is preventing compressor

restart.

A short circuit or over current

condition exists on PROT

terminal.

System Pressure Trip

Discharge pressure out of

limits or compressor

overload (if no high pressure

switch in system)

LOCKOUT

Short Cycling

Compressor is running only

briefly LOCKOUT

Locked Rotor

LOCKOUT

Open Circuit 1. Condensing unit power disconnect is open

Missing Phase

LOCKOUT

Reverse Phase

LOCKOUT

Welded Contactor

Compressor always runs

Low Voltage

Control circuit < 18VAC

1. Compressor protector is open

2. Condensing unit power disconnect is open

3. Compressor circuit breaker or fuse(s) is open

4. Broken supply wires or connector is not

making contact

5. Compressor power wires not routed through

Comfort Alert

6. Compressor contactor has failed open

1. Compressor contactor coil shorted

2. Electrical load too high for PROT circuit

(maximum 1 Amp)

3. 24 V AC wired directly to PROT terminal

1. High head pressure

2. Condenser coil poor air circulation (dirty,

blocked, damaged)

3. Condenser fan is not running

4. If low pressure switch is open:

Refer to Code 3 for troubleshooting

1. If low pressure switch is open:

a. Low refrigerant charge

b. Evaporator blower is not running

c. Evaporator coil is frozen

d. Faulty metering device

e. Condenser coil is dirty

f. Liquid line restriction (filter drier blocked if

present)

2. If high pressure switch is open, go to Flash

Code 2 information

3. Intermittent thermostat demand signal

4. System or control board defective

1. Low line voltage to compressor

2. Excessive liquid refrigerant in compressor

3. Compressor bearings are seized

2. Compressor circuit breaker or fuses are open

3. Compressor contactor has failed open

4. High pressure switch is open and requires

manual reset

5. Broken supply wires or connector is not

making contact

6. Unusually long compressor protector reset

time due to extreme ambient temperature

7. Compressor windings are damaged

1. Compressor fuse is open on one phase

2. Broken wire or connector on one phase

3. Compressor motor winding is damaged

4. Utility supply has dropped one phase

1. Compressor running backward due to supply

phase reversal

1. Compressor contactor has failed closed

2. Thermostat demand signal not connected to

module

1. Control circuit transformer is overloaded

2. Low line voltage to compressor

20

Page 21

Table 7 — CADM Troubleshooting

Miswired Module Indication Recommended Troubleshooting Action

Green LED is not on,

module does not power up

Green LED Intermittent,

module powers up only

when compressor runs

TRIP LED is on but system

and compressor check OK

TRIP LED and ALERT LED

flashing together

ALERT Flash Code 3

(Compressor Short Cycling)

displayed incorrectly

ALERT Flash Code 5 or 6

(Open Circuit, Missing Phase)

displayed incorrectly

Alert Flash Code *

(Welded Contactor)

displayed incorrectly

Determine if both R and C module terminals are

connected. Verify voltage in present at module’s R and C

terminals.

NOTE: The CADM requires a constant nominal 24VAC

power supply. The wiring to the module’s R and C

terminals must be directly from the control transformer.

The module cannot receive its power from another device

that will interrupt the 24VAC power supply. See Fig. 20,

the 38AU Wiring Diagram.

Determine if R and Y terminals are wired in reverse. Verify

module’s R and C terminals have a constant source. See

“NOTE” above for details on R and C wiring.

Verify Y terminal is wired properly per the 38AU wiring

diagram (see Fig. 19). Verify voltage at contactor coil falls

below 0.5VAC when off. Verify 24VAQC is present across

Y and C when thermostat demand signal is present. If not,

R and C are reverse wired.

Verify R and C terminals are supplied with 19-28VAC.

Verify Y terminal is connected to 24VAC at contactor coil.

Verify voltage at contactor coil falls below 0.5VAC when

off.

Check that compressor T1 and T3 wires are through

module’s current sensing holes. Verify Y terminal is

connected to 24VAC at contactor coil. Verify voltage at

contactor coil falls below 0.5VAC when off.

Determine if module’s Y terminal is connected. Verify Y

terminal is connected to 24VAC at contactor coil. Verify

24VAC is present across Y and C when thermostat

demand signal is present. If not, R and C are reverse

wired. Verify voltage at contactor coil falls below 0.5VAC

when off.

Crankcase Heater — The heater prevents refrigerant

migration and compressor oil dilution during shutdown whenever compressor is not operating. The heater is wired to cycle

with the compressor; the heater is off when compressor is running, and on when compressor is off.

The crankcase heater will operate as long as the power circuit

is energized.

Compressor Protection

COMPRESSOR OVERTEMPERATURE PROTECTION

(IP) — A thermostat installed on the compressor motor winding reacts to excessively high winding temperatures and shuts

off the compressor.

CRANKCASE HEATER — The heater minimizes absorption of liquid refrigerant by oil in the crankcase during brief or

extended shutdown periods. The main disconnect must be on

to energize the crankcase heater.

IMPORTANT: Never open any switch or disconnect that

energizes the crankcase heater unless unit is being serviced

or is to be shut down for a prolonged period. After a prolonged shutdown on a service job, energize the crankcase

heater for 24 hours before starting the compressor.

ADVANCED SCROLL TEMPERATURE PROTECTION

(ASTP) — See “Advanced Scroll Temperature Protection

(ASTP)” on page 15.

Low-Pressure Switch — The 38AUZ low-pressure

switch is stem-mounted on the suction line. Switches are all

fixed, non-adjustable type.

High-Pressure Switch — The 38AUZ high-pres-

sure switch is stem-mounted on the discharge line. The switch

is a fixed, non-adjustable type.

Outdoor Fans — Each fan is supported by a formed-wire

mount bolted to the fan deck and covered with a wire guard.

Fan motors have permanently lubricated bearings.

Lubrication

FAN MOTORS have sealed bearings. No provisions are made

for lubrication.

COMPRESSOR has its own oil supply. Loss of oil due to a

leak in the system should be the only reason for adding oil after

the system has been in operation.

21

Page 22

NOVATION™ Coil Cleaning and Maintenance —

To clean the NOVATION condenser coil, chemicals are NOT

to be used; only water is approved as the cleaning solution.

Only clean potable water is authorized for cleaning

NOVATION condensers.

Clean the coil as follows:

1. Turn off unit power.

2. Remove screws holding rear corner posts and top cover

in place. Pivot top cover up 12 to 18 in. (305 to 457 mm)

and support with a rigid support. See Fig. 21.

Fig. 21 — Pivot and Support Top Cover

3. Carefully remove any foreign objects or debris attached

to the coil face or trapped within the mounting frame and

brackets.

4. Using a high pressure water sprayer, purge any soap or

industrial cleaners from hose and/or dilution tank prior to

wetting the coil.Clean condenser face by spraying the coil

core steadily and uniformly from top to bottom, directing

the spray straight into or toward the coil face. Do not

exceed 900 psig or a 45 degree angle; nozzle must be at

least 12 in. (30 cm) from the coil face. Reduce pressure

and use caution to prevent damage to air centers (fins).

Do not fracture the braze between air centers and

refrigerant tubes. Allow water to drain from the coil core

and check for refrigerant leaks prior to start−up.

5. Replace top cover and rear corner posts.

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury

or equipment damage.

Chemical cleaning should NOT be used on the aluminum

microchannel condenser. Damage to the coil may occur.

Only approved cleaning is recommended.

Repairing NOVATION Condenser Tube Leaks

RCD offers service repair kit Part Number 50TJ660007 for

repairing tube leaks in the NOVATION coil crosstubes. This kit

includes approved braze materials (aluminum fluxcore braze

rods), a heat shield, a stainless steel brush, replacement fin

segments, adhesive for replacing fin segments, and instructions

specific to the NOVATION aluminum coil. See EPIC for

instruction sheet 99TA526379.

The repair procedure requires the use of MAPP gas and torch

(must be supplied by servicer) instead of conventional

oxyacetylene fuel and torch. While the flame temperature for

MAPP is lower than that of oxyacetylene (and thus provides

more flexibility when working on aluminum), the flame

temperature is still higher than the melting temperature of

aluminum, so user caution is required. Follow instructions

carefully. Use the heat shield.

Replacing NOVATION Condenser Coil

The service replacement coil is preformed and is equipped with

transition joints with copper stub tubes. When brazing the

connection joints to the unit tubing, use a wet cloth around the

aluminum tube at the transition joint. Avoid applying torch

flame directly onto the aluminum tubing.

Field Refrigerant Access Ports

Field service access to refrigerant pressures is through the

access ports located at the service valves (see Fig. 6). These

ports are ¼-in SAE Flare couplings with Schrader check valves

and service caps. Use these ports to admit nitrogen to the field

tubing during brazing, to evacuate the tubing and evaporator

coil, to admit initial refrigerant charge into the low-side of the

system and when checking and adjusting the system refrigerant

charge. When service activities are completed, ensure the

service caps are in place and secure; check for leaks. If the

Schrader check valve must be removed and re-installed, tighten

to 2-3 in-lbs (23-34 N-cm).

Factory High-Flow Access Ports

There are two additional access ports in the system - on the

suction tube between the compressor and the suction service

valve and on the liquid tube near the liquid service valve (see

Fig. 6). These are brass fittings with black plastic caps. The

hose connection fittings are standard ¼-in SAE Male Flare

couplings.

The brass fittings are two-piece High Flow valves, with a

receptacle base brazed to the tubing and an integral springclosed check valve core screwed into the base. (See Fig. 22.)

This check valve is permanently assembled into this core body

and cannot be serviced separately; replace the entire core body

if necessary. Service tools are available from RCD that allow

the replacement of the check valve core without having to