Page 1

38AO024,028,034

HEATING & COOLING

Installation, Start-Up and Service

Instructions

SAFETY CONSIDERATIONS

Installing, starting-up and servicing this equipment

can be hazardous due to system pressures, electrical com

ponents and location of equipment (roofs, elevated

structures, etc.).

Only trained, qualified installers and service mechanics

should install, start-up and service this equipment.

Untrained personnel can perform basic maintenance

functions, such as cleaning coils, filters and replacing

filters. All other operations should be performed by

trained service personnel.

When working on equipment, observe precautions in

the literature and on tags, stickers and labels attached to

the equipment.

• Follow all safety codes

• Wear safety glasses and work gloves Keep quenching

cloth and fire extinguisher nearby.

• Use care in handling, rigging and setting bulky

equipment.

Heat Pump — Outdoor Units

A WARNING

To avoid electric shock and personal injury, be sure

power to equipment is shut off before performing

maintenance or service.

INSTALLATION

IMPORTANT: Follow unit location, clearances and

piping requirements in this booklet carefully to

enhance system efficiency, and to avoid system'

failure Read entire booklet before starting

installation.

Step 1 — Complete Pre-Installation Checks

INSPECT SHIPMENT — Immediately file claim with

shipping company if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical

Code (NEC) for special installation requirements.

HINGED ACCESS DOOR-

'Measurements between mount

ing holes

Certified dimension drawings

available upon request

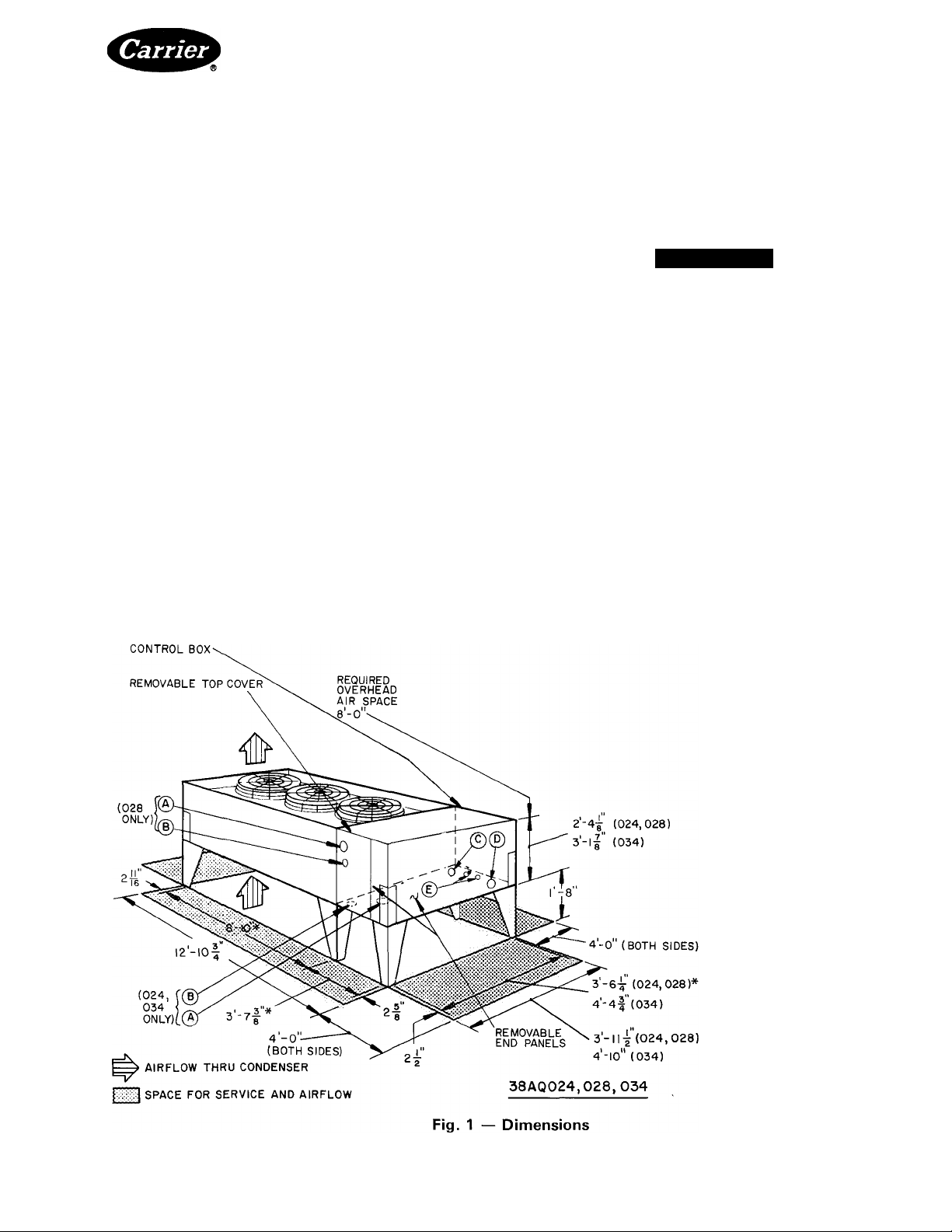

LEGEND

(38AQ024,028,034)

A — 2V2-in. Diam K O for

Suction Line

B — 1%-in. Diam K.O. for

Liquid Line (024,034)

lYz-in. Diam K.O. for

Liquid Line (028)

C — Va-in. Diam K O. for

Control Power

D — 3ya-in Diam K O for Unit

Power

E — Two %-in Diam K O. for

Defrosf Interlock Wiring

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

Tab

5a

PC111

Catalog No 533-846

PrintedinUSA Form 38AQ-9SI

For replacement items use Carrier Specified Parts

Pgi

1-89

Replaces: 38AQ-5SI

Page 2

• Allow sufficient space for airflow clearance, wiring,

refrigerant piping and servicing unit. See Fig. 1.

• Locate unit so that condenser airflow is unrestrieted

on all sides and above.

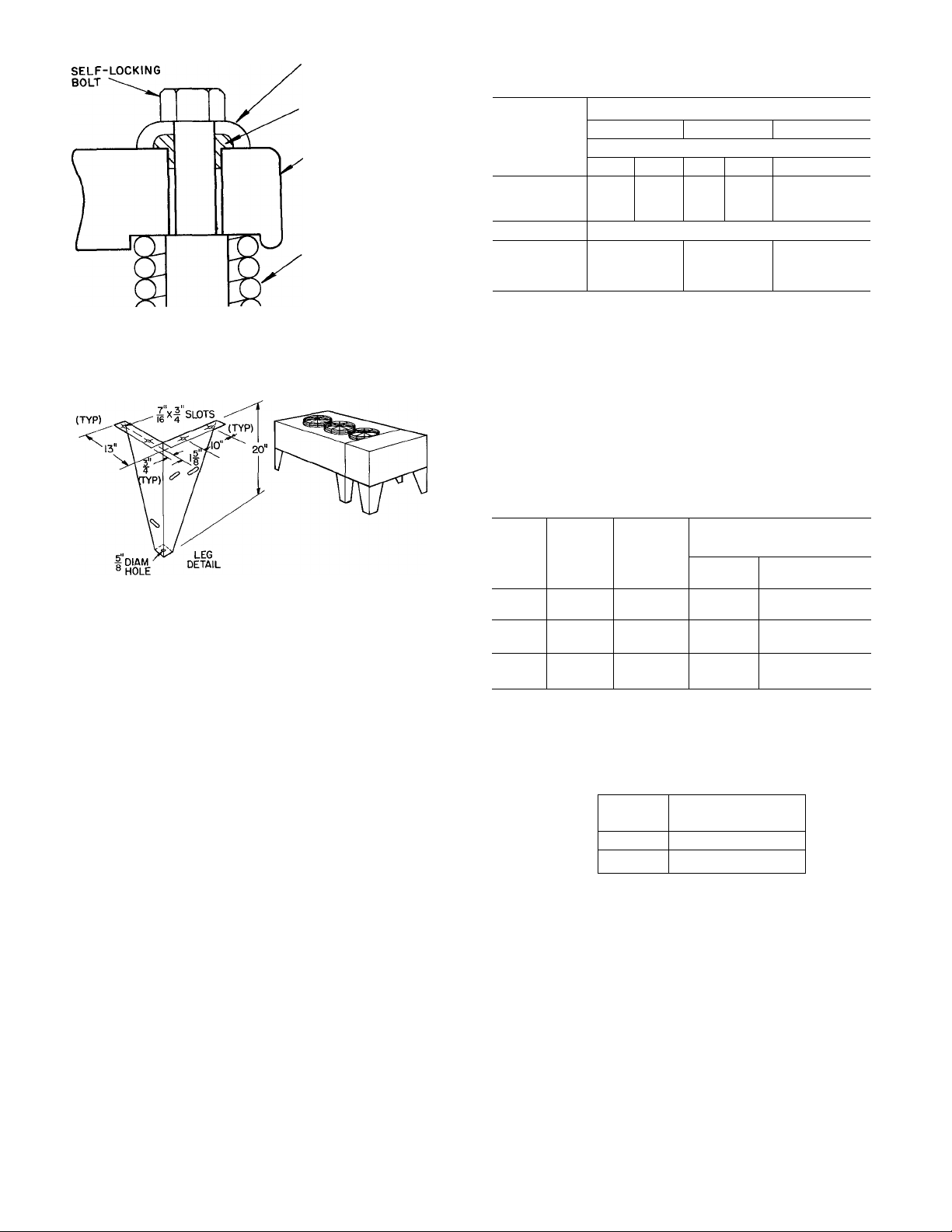

• Unit has legs for mounting on level pad. See Fig. 2

and Table 1 for weight distribution based on

recommended support points.

NOTE: If vibration isolators are required for a par

ticular installation, use the data in Table 1 and Fig. 2

to make proper selection.

Step 2 — Rig and Locate the Unit

A CAUTION

Be sure unit panels are securely in place prior to

rigging. Be careful rigging, handling and installing

unit. Improper unit location can cause system mal

function and material damage.

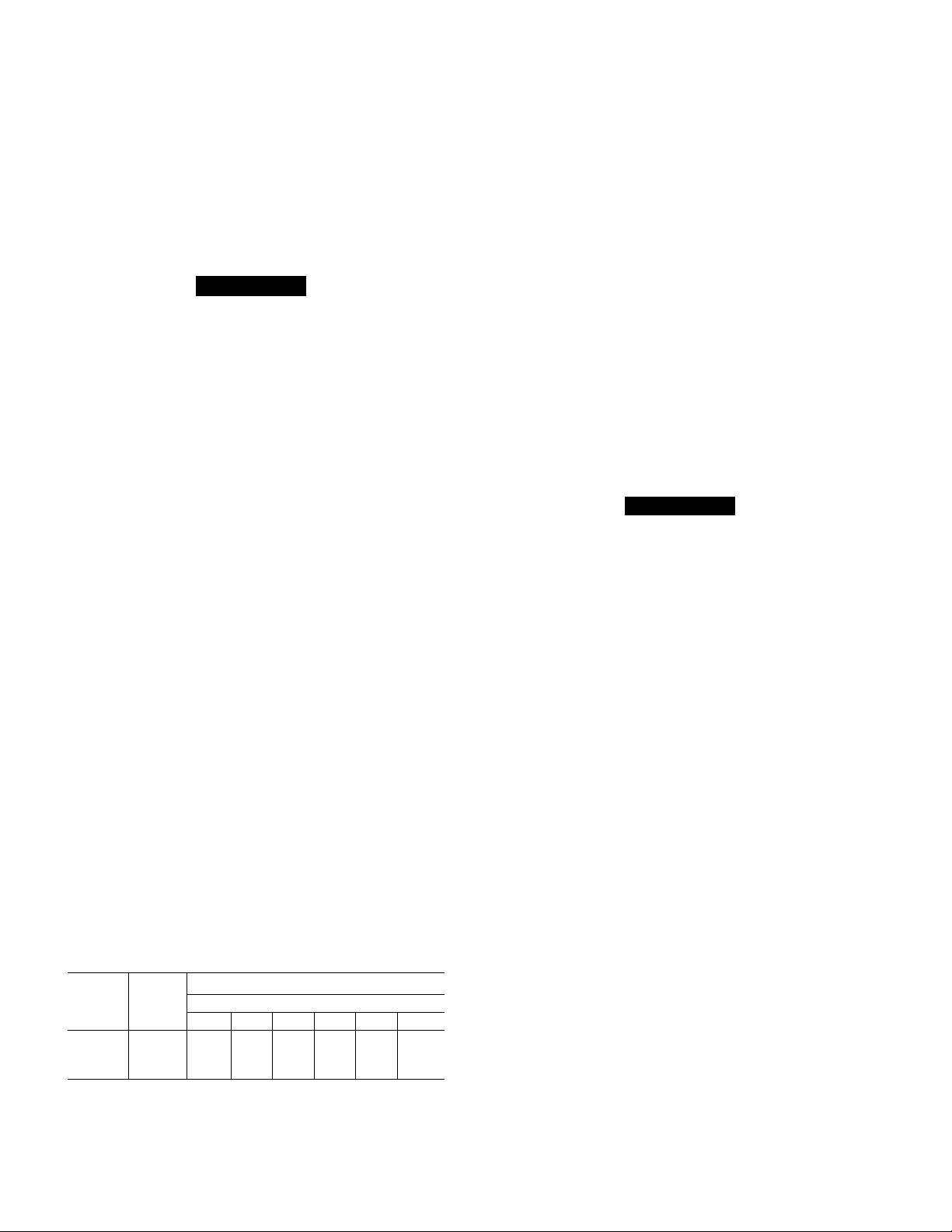

RIGGING — Lift units at points 3, 4, 7, 8 (Fig. 2). Use

eyebolts and washers supplied in parts package. Do not

sling unskidded unit. Skidded unit may be slung provided

sling does not contact sides of unit. While unit is on skid,

it can be rolled or dragged.

IMPORTANT: SPREADER BARS MUST BE USED BETWEEN POINTS

2 8 4 6

3-4 AND 7-8

+

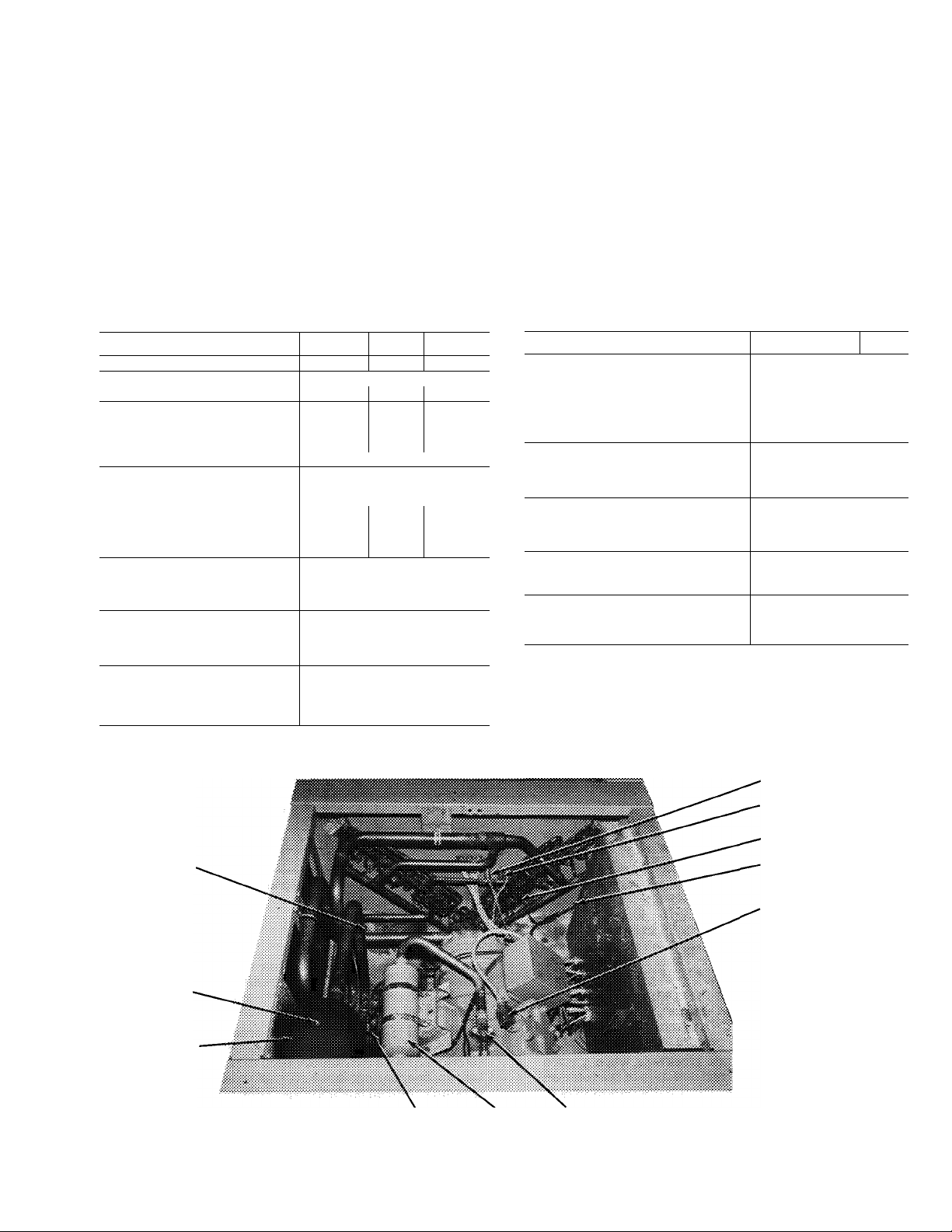

Step 3 — Mount Compressor

COMPRESSOR MOUNTING — As shipped, the com

pressor is held down by special self-locking bolts and

lockwashers. After unit is installed, remove self-locking

bolts one at a time and reassemble with flanged washers

and neoprene snubbers as shown in Fig. 4. The flanged

washers and neoprene snubbers are shipped in a cloth

bag tied to one of the compressor feet. Tighten all 4

bolts, then loosen each until the flanged washer can be

moved sideways with finger pressure.

Step 4 — Complete

Refrigerant Piping

Connections

SIZE REFRIGERANT LINES — Consider length of

piping required between outdoor and indoor units,

amount of liquid lift and compressor oil return. Refer to

Part 3 of Carrier System Design Manual for line sizing

information. Refer to indoor unit installation instruc

tions for additional information.

Maximum liquid line length is 100 feet. Carefully

determine the minimum expected unit capacity and size

interconnecting lines accordingly. For low load condi

tions, determine if there is a need for double suction

risers per Carrier System Design Manual. Consider vapor

line as hot gas line. Consider line sizes for heating as well

as cooling capacities.

A CAUTION

Piping must be properly sized and installed for the

system to operate efficiently.

COIL

SECTION

COMPR

SECTION

+

TOP VIEW

Bo LEG LOCATIONS -H LIFTING POINTS

Fig. 2 — Weight Distribution

PLACING UNIT — Place unit so that airflow is un

restricted above. Provide clearance around the unit as

shown in Fig. 1. Remove 6 hold-down bolts, releasing

skid. The legs are attached to base skid.

Block up or suspend unit. With bolts supplied, secure

legs (see Fig. 5) to unit (1, 2, 3, 4, 5 and 6 in Fig. 2 and

Table 1).

Table 1 — Weights

UNIT

38AQ

TOTAL

1

024

028 2160 203

034 2500 286 286 834

2040

204 204

The unit may be mounted on a full pad or on raised

supports at each leg. Weight distribution shown in Fig. 2

will determine type of support required. Bolt unit securely

to pad or supports when positioned and leveled.

WEIGHT (lb)

Leg Location

2

3

670

203 592

4

5 6

670 146 146

642 235 285

834

130 130

FILTER DRIERS — 38AQ units have factory-installed

filter driers. It is not necessary to add filter drier and check

valve arrangements in interconnecting piping. It is recom

mended that a field-supplied liquid moisture indicator be

installed in liquid line. Indoor units provide filter driers

with heat pump piping packages, for field installation.

Refer to indoor unit installation instructions for details.

Complete refrigerant piping from indoor coil to out

door coil before opening liquid and suction lines at the

heat pump unit. See Table 3 for proper refrigerant charge

and piping selection data.

PROVIDE SAFETY RELIEF — A fusible plug is

located on the liquid line before the liquid valve and on

top of the accumulator (Fig. 3). DO NOT CAP THIS

PLUG. If local code requires additional safety devices,

install as directed.

HEAD PRESSURE CONTROL — Fan cycling for head

pressure control is a standard offering but functions in

cooling mode only. The no. 2 fan cycles as a function of

liquid pressure sensed by fan cycling pressure switch

(FCPS). Fan no. 3 cycles as a function of outdoor air

temperature through the action of the air temperature

switch (ATS). See Table 2 for settings. These switches are

automatically bypassed in heating mode. Table 4 shows

minimum outdoor ambient temperatures at which units

will operate and provide full cooling capacity.

RECEIVER — No receiver is provided with the unit; it

is recommended that one not be used.

PIPING PROCEDURE — Do not remove caps from

vapor and liquid line stubs in compressor compartment

until piping connections are ready to be made. Pass nitro

gen or other inert gas through piping while brazing, to

prevent formation of copper oxide.

Install thermostatic expansion valves in liquid line

ahead of each indoor coil section.

Page 3

SUCTION PIPING AT INDOOR COIL AND TXV

BULB LOCATION — The purpose of these recom

mendations is to achieve good mixing of refrigerant

leaving indoor coil suction header for proper sensing by

the TXV bulb.

1. A minimum of two 90° elbows must be installed

upstream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is neces

sary, secure the bulb at approximately the 4 o’clock

position.

3. Size suction line from indoor coil through the riser

for high velocity. Enter suction pipe sizing charts in

Table 2 — Physical Data

the Carrier System Design Manual at design tons

and equivalent length (for 2 F loss). If reading falls

between 2 sizes on chart, choose the smaller pipe size.

Suction piping for the high velocity section should be

selected for about 0.5 F friction loss. If a 2 F loss is

allowed for the entire suction line, 1.5 F is left for the

balance of the suction line and it should be sized on

that basis. Check that high-velocity sizing is adequate

for oil return up the riser.

When the compressor is below indoor coil, the riser

at indoor coil does not have to extend as high as the

top level. After a 15 diameter riser has been provided,

suction line may elbow down immediately.

UNIT 38AQ 024 028 034

14

35 4

2160

R-22

61

4

19

39 0 49 6

1

426 ± 7

5 ±3

20 ±5

2500

06E2275

6 6

24 000

OPERA TING WEIGHT (lb) 2040

REFRIGERANT

Operating Charge (ib)* 55

COMPRESSOR

Model No 06E2250 06E6265

Cylinders

Oil (pts)

Crankcase Heater (watts) 180

OUTDO OR AIR FANS

Number 3

Rpm; 60-Hertz 1140 (3-Ph); 1075 (Single-Phase)

Diameter (in ) 26 30 30

Motor Hp

Cfm 15 000 24 000

Kilowatts 3 4 3 4 3 6

OUTDO OR COIL

Rows Deep . Fins/Inch 3 15

Face Area (sq ft)

Storage Capacity (lb|t 70

CONTR OLS

High Press Switch (HPS)

Cutout (psig)

Cut-in (psig) 320 ±20

Loss-of-Charge Switch (LC S) —

Liquid Line

Cutout (psig)

Cut-in (psig)

FUSIBLE PLUG

3/4 1 1

UNIT38AQ

CONTR OLS (cont)

71

19

99

Fan Cycling Press Switch (FCPS)—

No 2 Fan Cycling

Opens (psig)

Closes (psig) 257 '¿S

THERM OSTAT

Defrost Therm ostat (DFT)

Opens (F)

Closes (F)

Fan Cycling Thermostat (ATS) —

No 3 Fan Cycling

Opens (F)

Closes(F)

FUSIBLE PLUG SETTING

Liquid Line (F)

Accumulator (F)

OIL PRESS SAFETY SW ITCH (OPS)

Set Point (psig)

Differential (psig)

'Approximate charge with 25 ft of interconnecting piping Use appropriate

charging charts for actuai charging of unit

fRefrigerant storage capacity at 120 F condensing temperature with con

denser 80% fuli of iiquid

LOSS-OF-CHARGE SWITCH

FAN CYCLING PRESSU RE

SWITCH

DEFROST THERMOSTAT

AIR TEMPERATU RE

SWITCH

024 1 028 034

126 ±4

65 ±5

28 ±3

70 ±3

83 max

210 ±10

170 ±10

9

28

FUSiBLE PLUG

ACCUMULATOR

MUFFLER COMPRESSOR

SERVICE

VALVE

Fig. 3 — Component Locations

COMPRESSOR UNLOADER

SOLENOID

Page 4

SNUBBER FLANGED

WASHER

Table 3 — Refrigerant (R-22) Charge and

Piping Selection Data

. neoprene

SNUBBER

ISOLATION SPRING

Fig. 4 ~ Compressor Mounting

NOTES

1 For mounting dimensions, see Fig 1.

2 Parts package contains all fasteners required for assem

bling 20-in. legs to unit

Fig. 5 — Mounting Legs for 38AQ Units

LENGTH OF PIPING (ft)*

OUTDOOR

UNIT

38AQ

024

028

034

0-25

L

V

%

1%

%

1%

%

U/s

26-60

Line Size (in. O.D.)

L V

1%

%

1%

%

2'/8

%

61-100t

L V

% 1 %

Vb 2 Va

% 2'/8

Approximate System Charge (lb)t

024

028 61

034

L — Liquid Line V — Vapor Line

'Approximately 4 elbows assumed in determining pipe sizes

fMaximum length of interconnecting piping is 100 feet.

^Approximate system charge is for estimating only It includes

charge requirements for one outdoor unit, matching indoor coil,

and interconnecting piping System should be charged in

accordance with installation instructions

NOTE Maximum liquid line size is %-in OD Maximum R-22

system charge is 85 lb (024), 95 lb (028), 105 lb (034)

55

71

58

65

79

75

83

93

Table 4 — Minimum Outdoor Air Operating

Temperature

MINIMUM OUTDOOR

UNIT COMPR

38AQ

024

028

034

CAP. (%)

100

50

100

67

100

67

CONO

TEMP (F)

90 28 -20

80

90

80

90 30 -20

80 33 -20

TEMPERATURE (F)*

Std Unit

Motormaster®

41

34

37

32LT

-20

-20

-20

.4^

Step 5 — Make Electrical Connections

POWER SUPPLY — Electrical characteristics of avail

able power supply must agree with nameplate rating.

Supply voltage must be within tolerances shown in

Tableó. See Fig. 6 for System Label Diagram. Phase

unbalance must not exceed 2%. Operation of unit on

improper supply voltage or with excessive phase un

balance constitutes abuse and is not covered by Carrier

Warranty.

POWER WIRING — All power wiring must comply

with applicable local requirements and National Elec

trical Codes. Install a field-supplied branch circuit dis

connect switch of a type that can be locked OFF or

OPEN. Run power wires from disconnect switch through

unit power opening (D on Fig 1 ) and connect to terminal

block just inside opening. See Table 5 for maximum

allowable wire size.

Power terminal block is in the control box. Remove

outer panel and #10 screw on the door. Swing door open,

remove screws on barrier panel and remove barrier panel.

Replace barrier panel when power wiring is completed.

Condenser fans must rotate clockwise when viewed

from above. If necessary, correct direction of fan rotation

by reversing any 2 power input wires at disconnect switch.

Affix crankcase heater decal to unit disconnect switch.

CONTROL CIRCUIT WIRING — Internal control

voltage on 38 AQ units is both 115-volts and 24-volts. All

control circuit wiring must comply with applicable local

'Applies to cooling mode of operation only

Table 5 — Maximum Allowable Field Wire Sizes

UNIT

38Aa

024,028,034

Terminal Block (with integral compression terminal)

TB

and national codes. Route remote control wiring to unit

control box through control opening (C on Fig. 1) and

connect to control terminal block inside the control box.

All external control wiring is 24-volt, NEC Class 2.

SAIL SWITCH — It is highly recommended that an

indoor airflow switch (field installed) be installed and

interlocked with the outdoor unit, to prevent the outdoor

unit from operating in the event of indoor airflow failure

(example: broken fan belt). Operation of compressor with

no indoor airflow causes compressor to operate in a

vacuum which can damage bearing surfaces. Therefore,

install a field-supplied sail switch in the supply air duct

work of the mating indoor fan coil unit, and wire to

outdoor unit. See Fig 7.

VOLTS

(60-Hz)

208/230

460, 575

WIRE SIZE

6 AWG to 350 MCM

14 AWG to 2/0

CONN.

TB

Page 5

Table 6 — Electrical Data (3 Phase, 60 Hz)

UNIT

Volts

38AQ

024

028

Model

510

Nameplate

208/230 187

600 460 414

100 575

510 208/230 187

600 460

Supplied*

Min Max

518 632 41

414

MCA

253

508

103

51

253 145 225

508 69

100 575 518 632 62

034

510 208/230 187

600 460

414

253 170

508 72

100 575 518 632 64

FLA — Full Load Amps (fan motors)

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps Compiles with NEC Section

MOCP — Maximum Overcurrent Protection (fuse only)

MTA — Must Trip Amps (circuit breaker)

NEC — National Electric Code

RLA — Rated Load Amps (compressor)

430-24

MOCP

175

80

60

110

100

250

110

100

COMPRESSOR

RLA

100 0 446

120 0

LRA MTA

76 0

345 53t

36 0 173

120

28 6

Total

50t 3

40t

(total)

70t 6 2

48 0 223

43.4

164

33t

6;t

3

506 84Í

50 0 253 35Í

45 0

176

63t 2 5 2 5

'Units are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the listed

limits

t3-Pole circuit breaker

^6-Pole circuit breaker

3 3 6

FANS

Kw

No. 1

45 4 6

3 4 1 9

1 6

34

3 0

2.5 2.5

6 2

30 3 0 3 0

FLA (ea)

No 2 No. 3

1 9 1 9

1.6 1.6

6 6 6 6

3 0 3 0

6 6 6 6

46

2.5

2 5

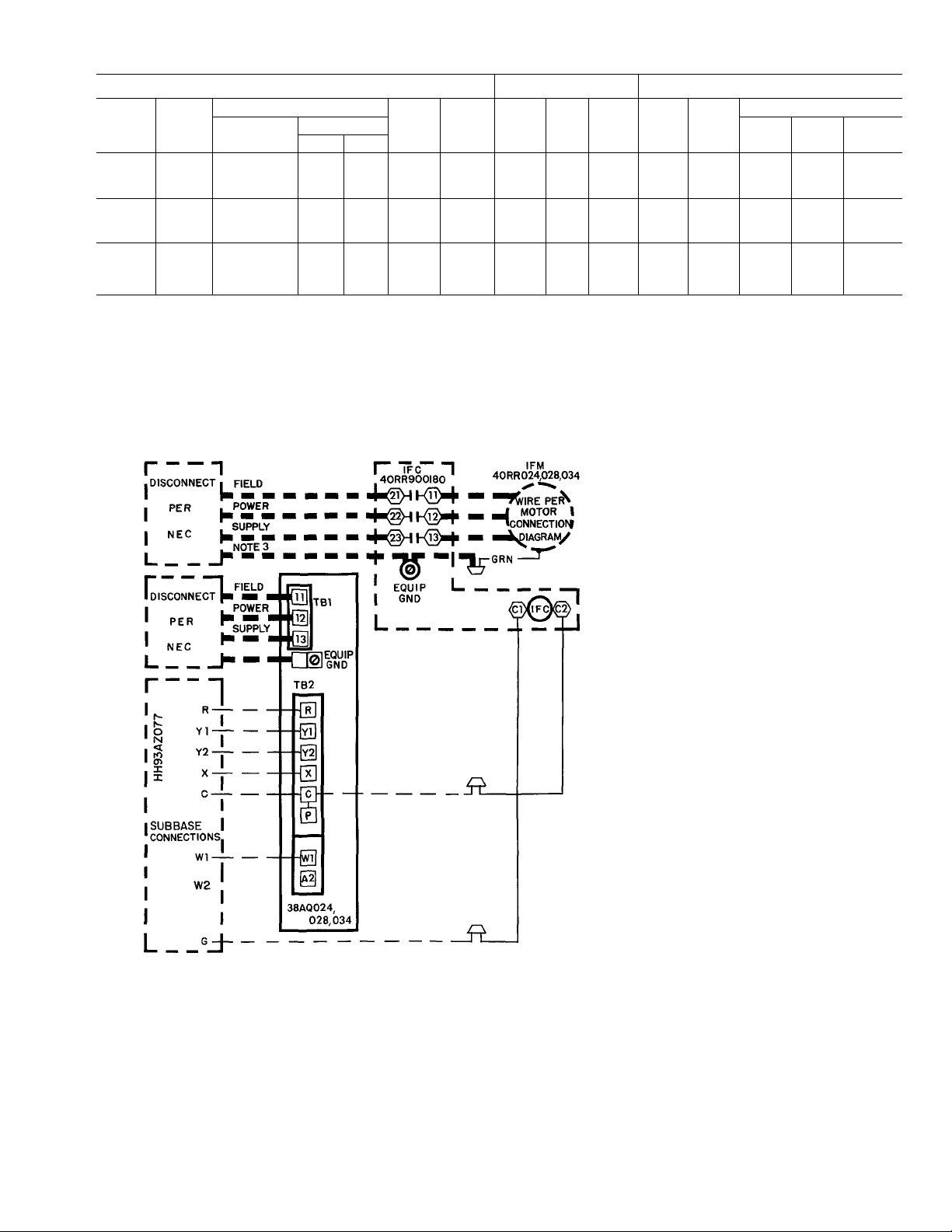

Fig. 6 — System Label Diagram; 38AQ024,028,034

NOTES ,—I

1 Locate blue wire between [jJ on TB2B and terminal 7 of CR3

and cut

2 Splice airflow switch (AFS) (field supplied) contact wires (field

provided) to 2 ends of cut blue wire as depicted

AFS — Airflow switch (sail switch)

----------

Factory Wiring

-----------

Field Wiring

Fig. 7 — Field Wiring for Airflow Switch. 38AQ024, 028 or 034/40RR

TB2B

LEGEND

Equip Gnd — Equipment Ground

IFC — Indoor Fan Contactor

IFM — Indoor Fan Motor

TB — Terminal Block (Board)

NOTES

1 This diagram applies to the follow

ing systems. 40RR024 with 38AQ

024, 40RR028 with 38AQ028 and

40RR034 with 38AQ034.

2. For wiring details of components,

see schematic in each component

3 Use copper conductors only for IFM

wiring

^SPLICE^

BLU

BLU

I I

I AFS I

CR3

Page 6

START-UP

Before Starting Unit, check the following:

1. Compressor oil level must be visible in the compressor

oil sight glass. Add oil if necessary. (See Oil Charge.)

2. Compressor hold-down bolts must be snug but not

tight.

3. All internal wiring connections must be tight; all

barriers and covers must be in place.

4. Electrical power sources must agree with unit name

plate rating.

5. All service valves must be open.

6. Crankcase heater must be firmly locked into com

pressor erankcase. Crankcase heater is inserted at the

factory with thermal conductive grease.

Evacuate and Dehydrate entire refrigerant system

as described in the Carrier Standard Service Techniques

Manual, Chapter 1, Section 1-7.

Leak Test entire refrigerant system by the pressure

method described in the Carrier Standard Service Tech

niques Manual, Chapter 1, Section 1-6. Use refrigerant

specified for unit at approximately 25 psig backed up with

an inert gas to a total pressure not to exceed 200 psig.

Energize Branch Circuit — Close field disconnect

switch to energize compressor crankcase heater. Set

room thermostat to prevent unit(s) from starting at this

time.

Heating/Cooling Thermostat (HH07AT072)

has an adjustable heat anticipator for both first- and

second-stage heating circuits.

SETTINGS — Set adjustment lever for first-stage anti

cipator at 0.79 (left-hand side). Set adjustment lever for

second-stage anticipator at 0.42 (right-hand side).

NOTES:

1 All 3 outdoor fans must be operating

2 To be used with approved 40RR combinations only

3 Applies to all approved combinations

Fig. 8 — Cooling Cycle Charging Chart, 40RR/38AQ024

Page 7

To Charge System — Refer to Carrier Standard

Serviee Teehniques Manual, Chapter 1 and the pro-

eedures described below. Use Fig. 8 for charging any

40RR/38AQ024 combination; Fig. 9 for charging any

40RR/38AQ028 combination; and Fig. 10 for charging

any 40RR/38AQ034 combination.

A CAUTION

Charge unit in cooling mode only. Charging unit

in heating mode could result in overcharging.

3. Allow system to operate for 20 minutes.Take tem

perature and pressure readings at liquid service valve

and check values with the charging chart.

4. Measure liquid line temperature close to the liquid

service valve, and the pressure at the Schrader port on

the liquid line service valve. Plot point on the charging

chart. If point is above the line, add charge. If point

is below the line, remove charge until operating point

falls on the line.

5. Record final refrigerant charge on unit nameplate.

1. Use Refrigerant R-22 only.

2. Regulate refrigerant drum valve to maintain suction

pressure at 80 psig while charging. Charge with vapor

only at suction side of unit.

NOTE: Do not depend on sight glass when charg

ing unit. Use charging chart.

To Start Unit — After compressor crankcase

heater has been on for at least 24 hours, set room

thermostat so unit will start on desired mode.

HEATING — Place thermostat selector at HEAT and

set temperature selector above room ambient.

COOLING — Place thermostat selector at COOL and

set temperature selector below room ambient.

NOTES:

1. All 3 outdoor fans must be operating

2 To be used with approved 40RR combinations only.

3. Applies to all approved combinations

Fig. 9 — Cooling Cycle Charging Chart, 40RR/38AQ028

7

Page 8

f

NOTES

1 All 3 outdoor fans must be operating

2 To be used with approved 40RR combinations only

3. Applies to all approved combinations.

Fig. 10 — Cooling Cycle Charging Chart, 40RR/38AQ034

Oil Charge (Table 1) — Allow unit to run for about

20 minutes. Stop unit and check compressor oil level. Add

oil only if necessary to bring oil into view in sight glass.

Use only Carrier-approved compressor oil. Approved

oils are:

Suniso 3GS

Capella B1

DuPont Synthetic

Refrigeration Oil (150 SSU only)

Zerol 150 (synthetic)

Do not reuse drained oil or use any oil that has been

exposed to atmosphere. Procedures for adding or remov

ing oil are given in Carrier Standard Service Techniques

Manual,Chapter 1, Refrigerants.

If oil is added, run unit for additional 10 minutes. Stop

unit and check oil level. If level is still low, add oil only

after determining that piping system is designed for

proper oil return and that the system is not leaking oil.

Check Operation of all safety controls. Replace

all service panels. Be sure that control panel cover is

closed tightly.

Page 9

SERVICE

Capacity Control is by one electrically actuated

unloader which controls 2 cylinders. Unloader does not

require field adjustment.

Compressor Motor Protection

CIRCUIT BREAKER — A manual reset calibrated-trip

magnetic circuit breaker protects the compressor against

overcurrent. Do not bypass connections to increase size

of breaker for any reason If trouble occurs, determine

cause and correct before resetting the breaker. Circuit

breaker Must Trip Amps (MTA) are listed in Tableó,

Electrical Data.

DISCHARGE GAS THERMOSTAT — A sensor in the

discharge gas of the compressor reacts to excessively high

discharge gas temperature and shuts off compressor.The

high temperature of discharge gas is a direct indication

of an overtemperature condition in compressor motor.

CRANKCASE HEATER — The compressor has an

electric heater located in the bottom cover, held in place

by a clip. Heater musi be tight to prevent backing out

(heater will burn out if exposed to air). The heater is

wired into compressor control circuit through a relay to

energize only when compressor shuts off. This keeps the

oil at a temperature that will prevent excessive absorption

of refrigerant during shutdown periods. Crankcase heater

is located in a lockout circuit. If crankcase heater is defec

tive, the compressor locks off Heat pump remains off

until corrective action is taken. This lockout circuit

cannot be reset by adjusting the thermostat.

Crankcase heater should be energized at all times when

unit is not running except during prolonged shutdown

or during servicing. In these cases, heater should be

energized for 24 hours before unit is restarted.

Fan Motor Protection — Fan motors are inherently

protected, grouped on a single circuit breaker.

Fan Adjustment — When replacing a fan, adjust fan

until top surface of hub plate is below top of orifice ring

as indicated in Fig 11. Then, tighten both setscrews,

located over the keyway of fan hub of motor shaft. Seal

recessed area of fan hub bore with Permagum to prevent

rusting.

Head Pressure Control reduces condensing capacity

under low-ambient conditions. For intermediate season

operation, fan cycling is employed. Fan no. 2 is cycled by

pressure control, with the pressure sensor located in the

liquid line. Fan no. 3 is cycled by an air temperature

thermostat (see Table 2).

Liquid Line Solenoid Valve closes when compressor

is off, and opens when compressor is on. The valve mini

mizes refrigerant migration during heat pump OFF cycle,

protecting against flooded starts.

Accumulator Oil Return is external. The accu

mulator drains through an extenal port at bottom of

accumulator. The port feeds an orifice which regulates the

rate of oil and refrigerant returned to the compressor. The

orifice is removable and cleanable when the system does

not contain refrigerant. The oil return mechanism also

contains a solenoid valve that opens when compressor is

ON, and closes when compressor is OFF. The oil return

solenoid does not allow liquid refrigerant to drain from

the accumulator during the heat pump OFF cycle, pro

tecting the compressor against flooded starts.

Lubrication

FAN MOTORS — Fan motors have permanently lubri

cated bearings. No provisions for lubrication are made.

COMPRESSOR — The compressor has its own oil

supply. Loss of oil due to a leak in the system should be

the only reason for adding oil after system has been in

operation.

Coil Cleaning — Clean coils with a vacuum cleaner,

fresh water, compressed air or a bristle brush (not wire).

Set up coil cleaning as part of a planned maintenance

schedule when units are installed in corrosive environ

ments. Wash all accumulations of dirt from coil in these

applications. Keep condenser coil drain holes free of dirt

and debris to ensure adequate coil drainage.

UNIT

38AO

024

028

034

DIMENSION A (in.)

Center Fan

%

1%

Fig. 11 — Fan Adjustment

End Fan

%

2%

Page 10

OPERATING SEQUENCE

(Refer to wiring diagrams in 38AQ wiring booklet)

Standby (OFF) Mode — During the standby or OFF

mode, crankcase heater is energized. Reversing valve

may Or may not be energized depending on mode of

operation (heating or cooling) when thermostat is

satisfied.

COOLING — When thermostat calls for first-stage

cooling (TCI closed), indoor fan motor starts imme

diately. Compressor and outdoor fans start between 3

seconds and 5 minutes depending on length of time unit

is off after thermostat is satisfied, due to 5-minute Time

Guard® II circuit. Outdoor fan motors nos. 2 and 3 may

or may not operate depending on position of fan cycling

pressure switch (FCPS) and air temperature switch

(ATS). The reversing valve solenoid (RVS) becomes de

energized causing reversing valve to shift to cooling

position. Crankcase heater is off. Liquid line and accu

mulator oil return solenoid valves open, allowing refrig

erant and oil flow.

Defrost Timer does not operate during cooling mode.

When thermostat calls for second-stage cooling (TC2

closed), unloader is de-energized causing compressor to

run fully loaded.

If a malfunction occurs, causing high-pressure switch

(HPS) discharge gas thermostat (DGT) or loss-of-charge

switch (LCS) to open, compressor and outdoor fans

stop and are locked out by a Signal-Loc circuit, and a

warning light comes on at the thermostat. RVS remains

de-energized so reversing valve does not shift. These

safeties reset by adjusting thermostat up to open TCI and

TC2, or by momentarily switching subbase to OFF posi

tion. When thermostat is satisfied (TCI open), com

pressor, indoor fan motors shut off. Liquid line and

accumulator oil return solenoid valves close. Reversing

valve does not shift, but remains in cooling position until

there is a call for heating. If compressor oil pressure is

lost, or if oil pressure fails to build on start-up, an oil

pressure safety switch shuts down unit. Switch must be

manually reset at the unit. DO NOT RESET MORE

THAN ONCE! If oil pressure switch trips, determine

cause and correct. DO NOT JUMPER OIL PRESSURE

SAFETY SWITCH!

Crankcase Heater is in a lockout circuit. If crankcase

heater is defective, compressor is locked off. The heat

pump remains off until corrective action is taken. This

lockout circuit cannot be reset by adjusting the thermostat.

Unit is equipped with a no-dump reversing valve

circuit. When unit is in cooling mode, reversing valve

remains in cooling mode position until thermostat calls

for heating. When unit is in heating mode, reversing valve

remains in heating mode position until thermostat calls

for cooling.

HEATING — When thermostat calls for heating (THl

closed), indoor fan motor starts. Compressor and out

door fans start between 3 seconds and 5 minutes depend

ing on length of time unit is off after thermostat is satis

fied, due to 5-minute Time Guard II circuit. Liquid line

and accumulator oil return solenoid valves open when

compressor operates, and close when compressor is OFF.

Compressor always runs fully loaded in the heating mode.

All 3 outdoor fans also run during heating mode. Revers

ing Valve Solenoid (RVS) shifts for heating operation

at start-up.

Defrost Timer runs continuously during heating mode.

Crankcase heater is off whenever compressor is on. If a

malfunction occurs, causing high-pressure switch (HPS),

discharge gas thermostat (DGT) or loss-of-charge switch

(LCS) to open, compressor and outdoor fan motors stop

and are locked out by a Signal-LOC eircuit, and a

warning light appears on the thermostat. RVS remains

energized so reversing valve does not shift. Reset lockout

system by adjusting thermostat down to open THl and

TH2, or by momentarily switching subbase to the OFF

position. If compressor oil pressure is lost or if oil pres

sure fails to build on start-up, an oil pressure safety

switch shuts down unit. Switch must be manually reset at

the unit. DO NOT RESET MORE THAN ONCE! If oil

pressure switch trips, determine cause and correct. DO

NOT JUMPER OIL PRESSURE SAFETY SWITCH!

Crankcase Heater is in a lockout circuit. If crankcase

heater is defective, compressor is locked off. The heat

pump remains off until corrective action is taken. This

lockout circuit cannot be reset by adjusting the thermo

stat. When thermostat is satisfied (THl opens), com

pressor, indoor fan motor and outdoor fan motors shut

off. Reversing valve remains in heating mode until

thermostat calls for cooling.

If outdoor ambient temperature is above approxi

mately 45 F, defrost thermostat (DFT) senses outdoor

coll temperature is above 28 F, and prevents start of any

defrost cycle. When outdoor ambient temperature is

below approximately 45 F, DFT senses outdoor coil

temperature is below 28 F and allows defrost cireuitry to

be energized every 60 minutes. When this occurs, revers

ing valve switches back to cooling position and outdoor

fans shut off. Defrost is terminated when liquid refrig

erant becomes warm enough to open defrost thermostat.

Defrost timer limits length of each defrost cycle to a

maximum of 10 minutes.

Two defrost interlock relays are provided for use on

systems having more than one 38AQ unit. When any

38AQ unit is in defrost mode, up to 2 additional 38AQ

units can be prevented from defrosting by temporarily

stopping their defrost timer motors until defrost on

another unit is completed.

Compressor and outdoor fan motor overcurrent pro

tection is achieved with circuit breakers (heating and

cooling modes). These require manual reset at the out

door unit control box.

Refer to Fig. 12 for typical 38 AQ heat pump refrigerant

circuit operation.

10

Page 11

Hot gas from compressor flows through the 4-way valve and is

directed to the outdoor coil header At the header it is con

densed and subcooled through converging circuits Refrig

erant leaves the outdoor coil by way of the check valve to the

liquid line

The refrigerant then fiows through the filter drier and feeds the

indoor coil by way of capillary tubes on each circuit

3 Each circuit evaporates the refrigerant and the circuits are

combined in the indoor coil header

4 The refrigerant then flows through the 4-way valve, accu

mulator and back to the compressor.

Hot gas from compressor flows through the 4-way valve and is

directed to the indoor coii header At the header it is con

densed and directed through subcooling circuits and out the

indoor coil check valve to the liquid iine. (The TXV’s stop

the refrigerant fiow during the heating cycle )

The refrigerant then feeds the outdoor coil by way of a strainer

and then through capiliary tubes on each circuit

NOTES:

1 Check valves are designated “A” through “D ”

2. Illustrations are typicai and do not portray exact coil circuiting

3 Check valve positions: A open, A closed.

Fig. 12 — Typical Heat Pump Operation

Each circuit evaporates the refrigerant and the circuits are

combined in the outdoor header with some of the circuits

flowing through the check valve

The refrigerant then flows through the 4-way valve, accu

mulator and back to the compressor

4 Only one outdoor coil is shown above The 38AQ024,028 and

034 have 2 coils plus 2 of each check valve shown above

11

Page 12

TROUBLESHOOTING CHART, COOLING CYCLE

Page 13

TROUBLESHOOTING CHART. HEATING CYCLE

Page 14

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book

Tab

1

5a

PC 111

Catalog No 533-846 PrintedinUSA Form38AQ-9SI

For replacement items use Carrier Specified Parts.

Pg 14

1-89

Replaces: 38AQ-5SI

Loading...

Loading...