Page 1

Air-Cooled Condensing Units

Installation, Start-Up and

Service Instructions

CONTENTS

38AKS028-044

50/60 Hz

Page

SAFETY CONSIDERATIONS ...................1

BEFORE INSTALLATION .....................1-3

Rigging ......................................1

Placing Unit .................................3

Mounting Unit ...............................3

Compressor Mounting ........................3

INSTALLATION .............................3-12

Refrigerant Piping Connections ...............3

Liquid Line Solenoid Drop Control ............3

Filter Drier and Moisture Indicator ............3

Receiver .....................................4

Piping Procedure ............................4

Power Supply ................................6

Power Wiring ................................6

START-UP ................................13-17

Initial Check ................................13

Leak Test and Dehydration ..................13

Preliminary Charge ..........................13

Start Unit ...................................13

Charge System .............................13

Operation ...................................13

Control Module (CM) ........................13

Bypass Relay (BPR) .........................17

Time-Delay Relay (TDR) .....................17

Sequence of Operation ......................17

Complete Unit Stoppage .....................17

SERVICE ..................................17-20

Access for Servicing ........................17

Fan Adjustment .............................19

Oil Charge ..................................19

Liquid Shutoff/Charging Valve ...............19

Capacity Control ............................19

Oil Pressure Safety Switch (OPS) ............20

Compressor Protection ......................20

High-Pressure Switch .......................20

Low-Pressure Switch ........................20

Winter Start Control .........................20

Head Pressure Control ......................20

TROUBLESHOOTING ........................21

START-UP CHECKLIST .....................CL-1

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equipment can be hazardous due to system pressures, electrical

components, and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should be

performed by trained service personnel.

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Keep, quenching cloth and fire extinguisher nearby when

brazing.

• Use care in handling, rigging, and setting bulky

equipment.

• See Table 1A or 1B for physical data.

ELECTRIC SHOCK HAZARD

Open all remote disconnects before

servicing this equipment.

BEFORE INSTALLATION

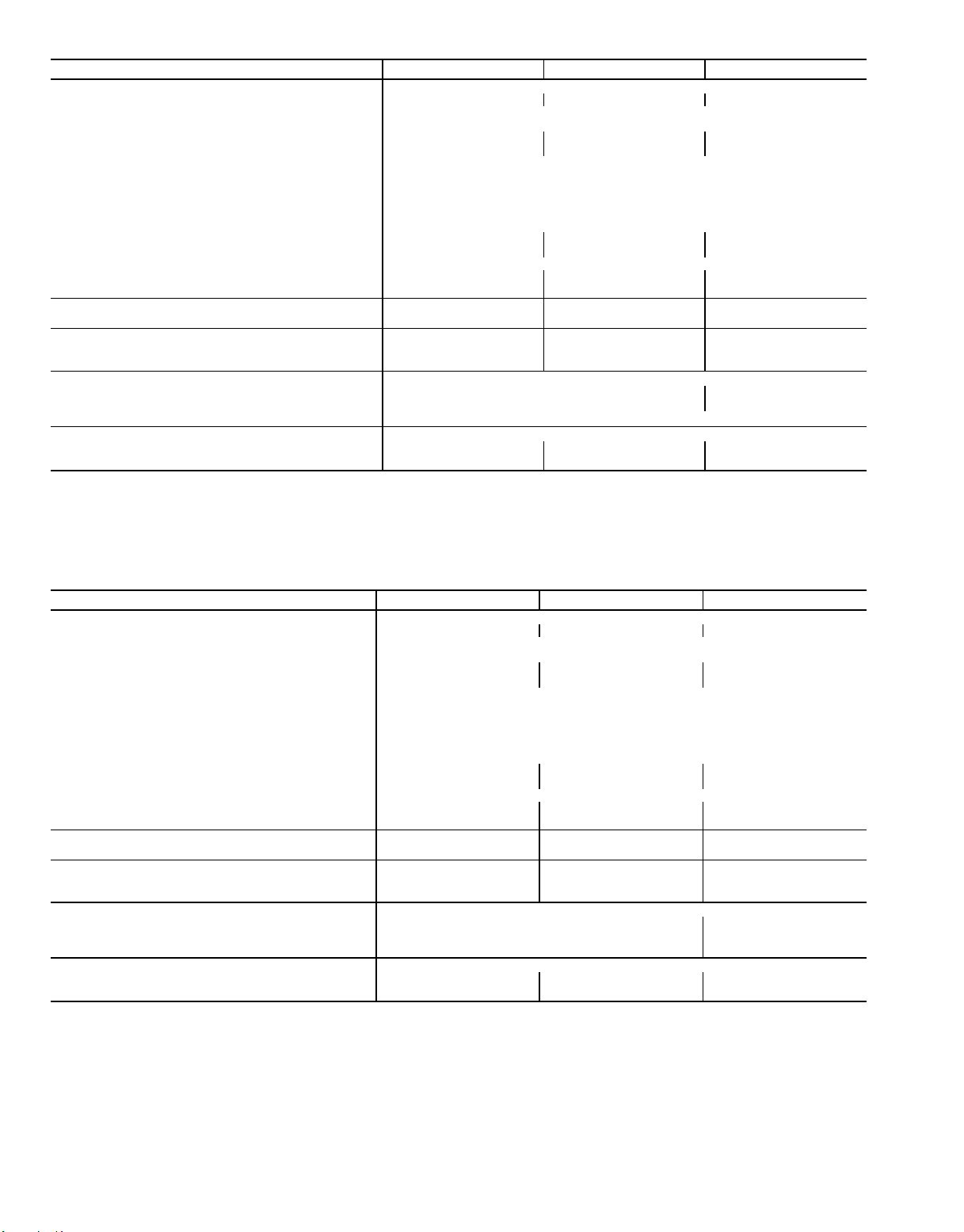

Rigging —

above the unit. Use 2-in. (50 mm) OD pipe or hooks in lifting holes. Rig with 4 cables and spreader bars. All panels

must be in place when rigging. See rigging label on unit for

details concerning shipping weights, distance between lifting holes, center of gravity, and spreader bar dimensions.

See Fig. 2.

If overhead rigging is not possible, place unit on skid or

pad for rolling or dragging. When rolling, use minimum of

3 rollers. When dragging, pull the pad. Do not apply force

to the unit. When in final position, raise from above to lift

unit off pad.

Preferred method is with spreader bars from

All panels must be in place when rigging.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 3a

PC 111 Catalog No. 533-820 Printed in U.S.A. Form 38A-5SI Pg 1 7-94 Replaces: 38AK-3SI

Page 2

Table 1A — Physical Data — English

UNIT 38AKS 028 034 044

COMPRESSOR Reciprocating Semi-Hermetic

No. ...Type 1...06E9265 1...06E9275 1...06E9299

No. Cyls (ea)...Speed, Rpm (60/50 Hz) 6...1750/1460

Capacity Steps 3

Oil Charge*, Pt 20.0 20.0 19.0

Oil Pressure Switch (psi)

Set Points — Cutout 6 6 2

Differential — Cut-in 14 Max.

Crankcase Heater (watts) 180

Protection See Note

Capacity Control (Psig) Suction Pressure Unloader(s)

No. 1 Unloader Settings

Load 76 76 76

Unload 58 58 58

No. 2 Unloader Settings

Load 78 78 78

Unload 60 60 60

REFRIGERANT CHARGE, R-22

Approximate lb 30.5 43.5 65

COIL STORAGE

(at 125 F liquid temperature

and 80% full), lb

CONDENSER FANS, Type Propeller Type, Direct Driven

No. ...Diameter, in. 2...30 3...30

Total Airflow, Cfm 15,700 23,700

Speed, Rpm 60/50 Hz 1140/950

CONDENSER COIL, Type Horizontal Plate Fin

Rows...Fins/in. 2...19 3...17 3...17

Total Face Area, sq ft 39.2 39.2 58.4

*See Service, Oil Charge, for Carrier-approved oil.

NOTE: Circuit breaker is in main power circuit.

37.7 56.6 84.4

Table 1B — Physical Data — SI

UNIT 38AKS 028 034 044

COMPRESSOR Reciprocating Semi-Hermetic

No. ...Type 1...06E9265 1...06E9275 1...06E9299

No. Cyls (ea)...Speed, R/s (60/50 Hz) 6...29.2/24.3

Capacity Steps 3

Oil Charge*, L 9.4 9.4 9.0

Oil Pressure Switch (kPa)

Set Points — Cutout 41.4 6 13.8

Differential — Cut-in 96.5 Max.

Crankcase Heater (watts) 180

Protection See Note

Capacity Control (kPa) Suction Pressure Unloader(s)

No. 1 Unloader Settings

Load 524 524 524

Unload 400 400 400

No. 2 Unloader Settings

Load 538 538 538

Unload 414 414 414

REFRIGERANT CHARGE, R-22

Approximate, kg 13.8 19.7 29.5

COIL STORAGE

(at 52 C liquid temperature

and 80% full), kg

CONDENSER FANS, Type Propeller Type, Direct Driven

No. ...Diameter, mm 2...762 3...762

Total Airflow, L/s 7,400 11,200

Speed, R/s (60/50 Hz) 19.0/15.8 19.0/15.8

CONDENSER COIL, Type Horizontal Plate Fin

Rows...Fins/mm 2...1.34 3...1.49 3...1.49

Total Face Area, sq m 3.64 3.64 5.43

*See Service, Oil Charge, for Carrier-approved oil.

NOTE: Circuit breaker is in main power circuit.

17.1 25.7 38.3

2

Page 3

Placing Unit — There must be 4 ft (1220 mm) for ser-

vice on all sides of unit, and a minimum of 8 ft (2440 mm)

clear air space above unit. For multiple units, allow 8 ft

(2440 mm) separation between units for airflow and service.

Mounting Unit — When unit is in proper location, use

of mounting holes in base rails is recommended for securing

unit to supporting structure or for mounting unit on vibration isolators, if required. Fasteners for mounting unit are

field supplied. Be sure to mount unit level to ensure proper

oil return to compressors.

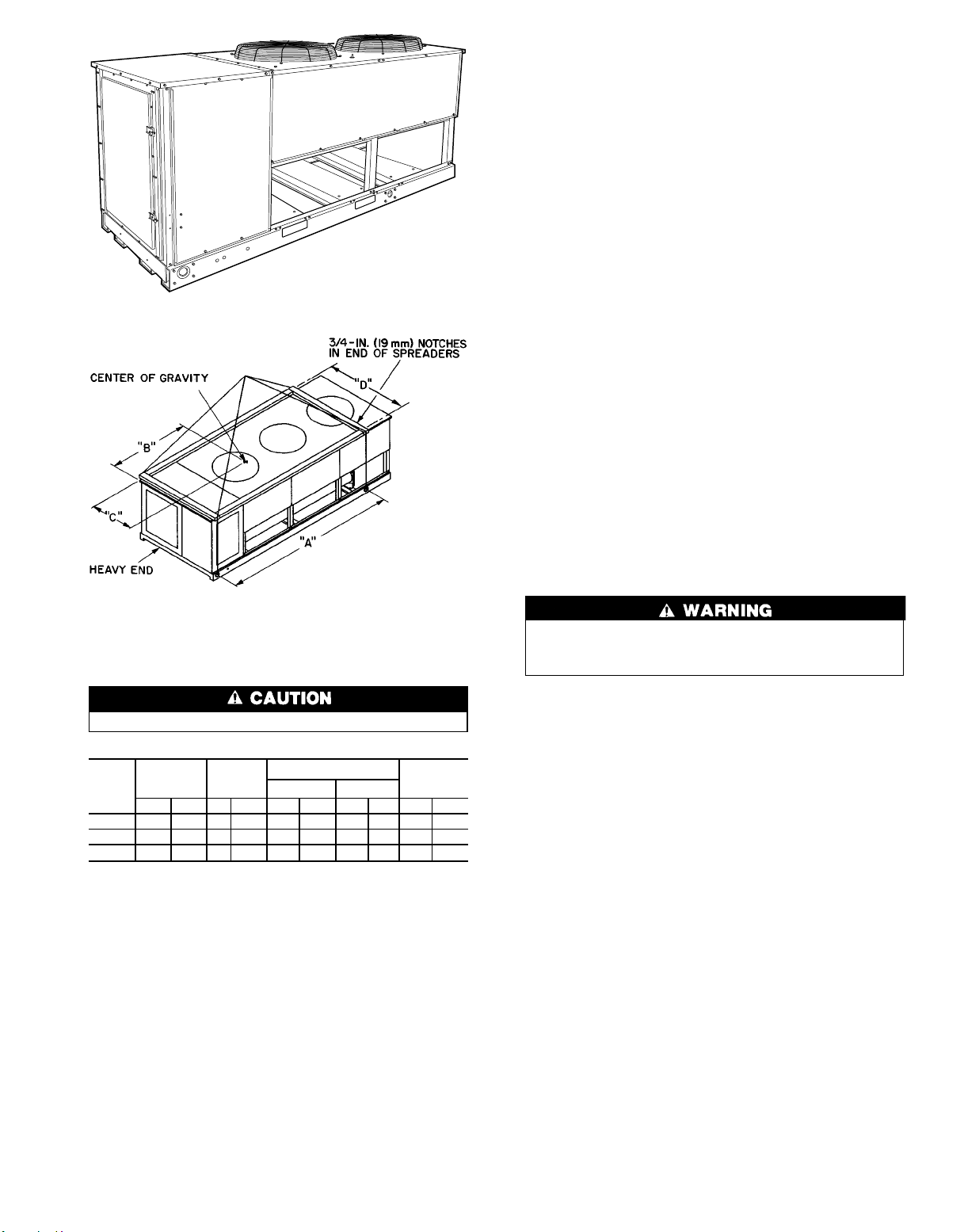

Compressor Mounting — As shipped, compressor

is held down by 4 bolts. After unit is installed loosen each

bolt using nut indicated in Fig. 3 until flatwasher (3⁄8in.

[9.5 mm]) can be moved with finger pressure.

Fig. 1 — 38AKS Units

NOTES:

1. Use 2 in. OD (50 mm) pipe or hooks in lifting holes.

2. Rig with 4 cables and spread with 2 ‘‘D’’ long and two ‘‘A’’ long

2 x 4’s in. (50 x 100 mm) or equal.

3. Run the rigging cables to a central suspension point so that the

angle from the horizontal is not less than 45 degrees.

All panels must be in place when rigging.

MAX SHIP.

UNIT

38AKS

028 1924 872 81 2057 43.0 1092 28.0 711 73.5 1867

034 2115 960 81 2057 43.0 1092 28.0 711 73.5 1867

044 2797 1207 99 2515 49.0 1245 30.5 775 73.5 1867

WT

Lb Kg in. mm in. mm in. mm in. mm

LIFTING

HOLES

CENTER OF GRAVITY

‘‘A’’

‘‘B’’ ‘‘C’’

‘‘D’’

INSTALLATION

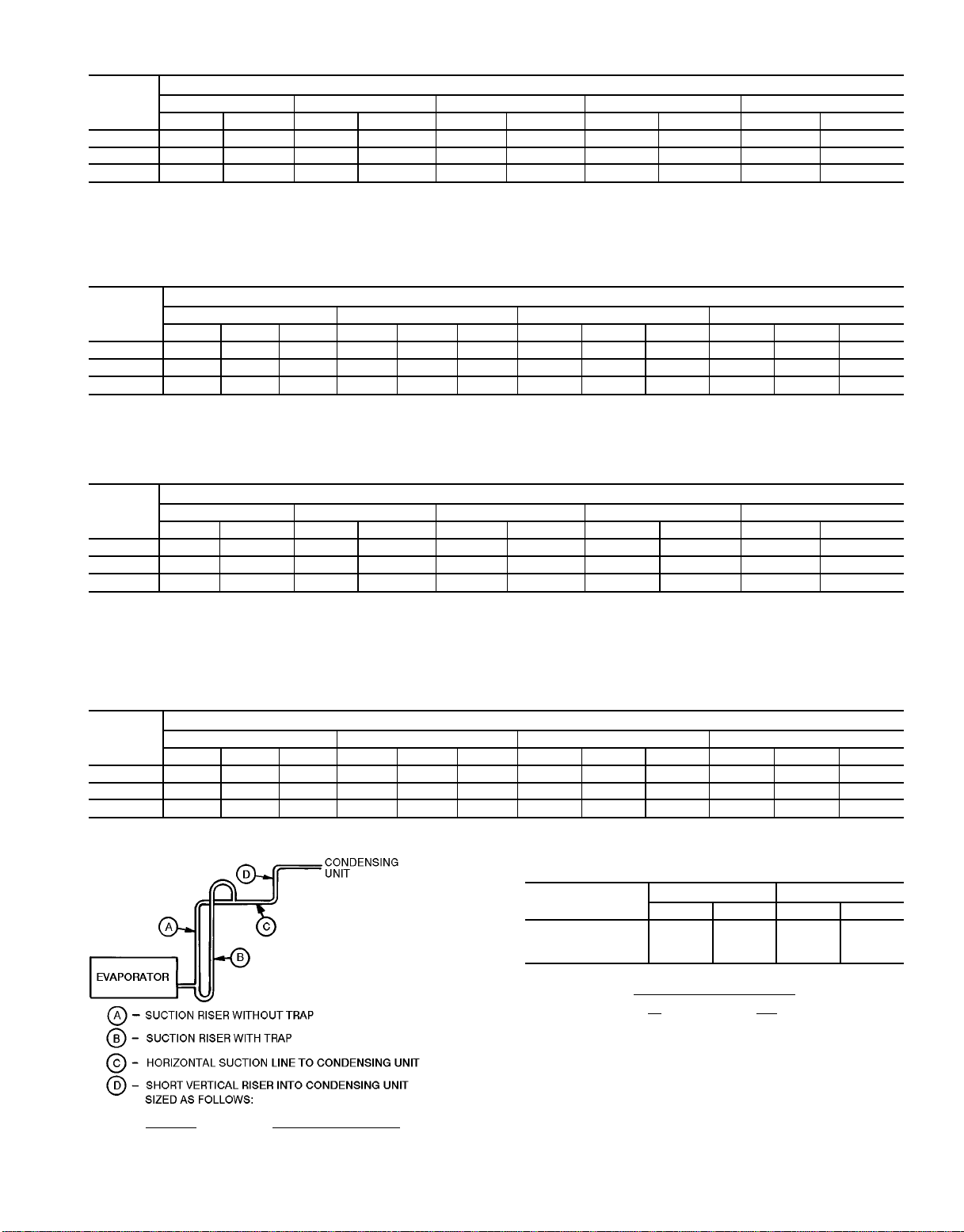

Refrigerant Piping Connections—

pend on length of piping required between condensing unit

and evaporator. See Table 2A or 2B. It is important to consider liquid lift and compressor oil return. Refer to Part 3 of

Carrier System Design Manual for line sizing information,

and Fig. 4 for recommended piping details.

Line sizes de-

Liquid Line Solenoid Drop Control — The factory-

supplied solenoid valve must be installed at the indoor unit

(fan coil) per Fig. 5, and wired per wiring label found on

unit. The solenoid assures that system refrigerant is in the

high-pressure side (condenser and liquid line) of the system

during the off cycle. Refrigerant migration is minimized.

Factory-supplied liquid line solenoid valve connecting sizes

7

⁄8-in. (22.2 mm) ODF for inlet and7⁄8-in. (22.2 mm)

are

ODM for outlet.

Failure to properly install liquid line solenoid at the indoor unit as described, without Carrier authorization, may

VOID warranty.

Filter Drier and Moisture Indicator — Every unit

should have a filter drier and a sight glass (moisture indicator) field installed. Select the filter drier for maximum unit

capacity and minimum pressure drop. Figure 5 shows recommended locations of filter drier(s) and sight glass. Complete the refrigerant piping from the evaporator to the condenser before opening the liquid and suction lines at the

condensing unit. One filter drier may be installed at location

A in Fig. 5, or 2 filter driers may be installed at locations B.

Fig. 2 — Rigging with Spreader Bars

(Field Supplied)

3

Page 4

NOTE: All dimensions are in inches (mm).

Fig. 3 — Compressor Mounting

TXV — Thermostatic Expansion Valve

NOTES:

1. Suction line is connected to coil on same side as the entering air.

2. Lower section is first on and last off.

3. For more complete piping information, refer to Carrier System

Design Manual, Part 3.

Fig. 4 — Suction Line Piping to Unit

with 2 Section Coil Split

TXV — Thermostatic Expansion Valve

Fig. 5 — Liquid Line Solenoid Valve,

Filter Drier(s) and Sight Glass Locations

Receiver — No receiver is provided with the unit; it is

recommended that one not be used.

Piping Procedure — Do not remove run-around pipe

from suction and liquid line stubs until piping connections

are ready to be made. Pass nitrogen or other inert gasthrough

piping while brazing, to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve (TXV)

in liquid line ahead of each evaporator section. For 2-stage

cooling, the field-supplied capacity controlsolenoidusedmust

be wired to be opened by control from a 2-stage thermostat.

SUCTION PIPING AT EVAPORATOR AND TXV BULB

LOCATION (See Fig. 5) — The purpose of these recommendations is to achieve good mixing of the refrigerant leaving the evaporator suction header for proper sensing by the

TXV bulb.

1. A minimum of two 90° elbows must be installed up-

stream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is necessary,

secure the bulb at approximately the 4 o’clock position.

3. Size the suction line from the evaporator throughthe riser

for high velocity. Enter the suction pipe sizing charts in

the CarrierSystemDesignManual at design tons and equivalent length (for 2° F [1.1° C] loss). If reading falls between 2 sizes on chart, choose the smaller pipe size.

Suction piping for the high velocity section should be

selected for about 0.5° F (0.3° C) friction loss. If a 2° F

(1.1° C) loss is allowed for the entire suction line, 1.5° F

(0.8° C) is left for the balance of the suction line, and it should

be sized on that basis. Check that the high-velocity sizing

is adequate for oil return up the riser.

If an oil return connection at the bottom of this suction

header is supplied with an evaporator, this connection must

be teed-in ahead of first mixing elbow. When the compressor is below the evaporator, the riser at the evaporator does

not have to extend as high as the top level. After a

15-diameter riser has been provided, the suction line may

elbow down immediately.

SAFETY RELIEF — Afusible plug is located on unit liquid

line before the liquid valve.

4

Page 5

Table 2A — Refrigerant Piping Sizes — 60 Hz

SINGLE SUCTION RISERS

UNIT

38AKS

028

034

044

L—Liquid Line

S—Suction Line

16-25 (4.9-7.6) 26-50 (7.9-15.2) 51-75 (15.5-22.8) 76-100 (23.2-30.5) 101-200 (30.8-60.9)

LSL S L S L S L S

7

⁄

8

7

⁄

8

7

⁄

8

15⁄

21⁄

21⁄

8

8

8

7

⁄

8

7

⁄

8

7

⁄

8

*IMPORTANT — Requires a double suction riser, if evaporator is below condensing unit. See table below.

NOTE: Liquid and suction line sizes are OD (in.) Equivalent sizes in mm are listed below.

LENGTH OF INTERCONNECTING PIPING, FT (M)

21⁄8*

21⁄

21⁄

7

⁄

8

11⁄

7

⁄

8

8

8

8

21⁄8*

21⁄

8

25⁄8*1

7

⁄

8

11⁄

8

1

⁄

8

21⁄8*

21⁄

8

5

2

⁄

8

*1

DOUBLE SUCTION RISERS — 60 Hz

UNIT

38AKS

028 1

26-50 (7.9-15.2) 51-75 (15.5-22.8) 76-100 (23.2.-30.5) 101-200 (30.8-60.9)

ABCABC A B C A B C

3

⁄

8

15⁄

8

21⁄

8

034 —————— — — —1

044 ———1

NOTE: A, B, C dimensions relate to reference diagram.

LENGTH OF INTERCONNECTING PIPING, FT (M)

13⁄

8

15⁄

8

21⁄

5

⁄82

1

⁄82

8

5

⁄81

13⁄

8

5

⁄82

15⁄

8

1

⁄82

21⁄

8

5

⁄81

Table 2B — Refrigerant Piping Sizes — 50 Hz

SINGLE SUCTION RISERS

UNIT

38AKS

028

034

044

L—Liquid Line

S—Suction Line

*IMPORTANT — Requires a double suction riser, if evaporator is below condensing unit. See table below.

†For riser, use 1

16-25 (4.9-7.6) 26-50 (7.9-15.2) 51-75 (15.5-22.8) 76-100 (23.2-30.5) 101-200 (30.8-60.9)

LSL S L S L S L S

7

⁄

8

7

⁄

8

7

⁄

8

5

⁄8OD inches.

15⁄

21⁄8†

21⁄

8

8

7

⁄

8

7

⁄

8

7

⁄

8

NOTE: Liquid and suction line sizes are OD (in.) Equivalent sizes in mm are listed below.

LENGTH OF INTERCONNECTING PIPING, FT (M)

21⁄8*

21⁄8*

21⁄

7

⁄

8

7

⁄

8

8

11⁄

8

21⁄8*

21⁄8*1

25⁄8*1

7

⁄

8

1

⁄

8

1

⁄

8

21⁄8*

5

2

⁄

8

*1

5

2

⁄

8

*1

7

⁄

8

11⁄

8

1

⁄

8

13⁄

8

5

⁄82

5

⁄82

15⁄

8

1

⁄82

1

⁄82

7

⁄

8

1

⁄

8

1

⁄

8

21⁄8*

25⁄8*

5

2

⁄

8

*

21⁄

8

5

⁄

8

5

⁄

8

21⁄8*

5

2

⁄

8

*

5

2

⁄

8

*

DOUBLE SUCTION RISERS — 50 Hz

UNIT

38AKS

028 1

034 15⁄

26-50 (7.9-15.2) 51-75 (15.5-22.8) 76-100 (23.2.-30.5) 101-200 (30.8-60.9)

ABCABC A B C A B C

3

⁄

8

15⁄

8

21⁄

8

8

15⁄

8

21⁄

8

044 ———1

NOTE: A, B, C dimensions relate to reference diagram.

Unit Size Dimension — in. (mm)

028 15⁄8(41.3)

034 21⁄8(54.0)

044 21⁄8(54.0)

LENGTH OF INTERCONNECTING PIPING, FT (M)

13⁄

8

15⁄

8

5

⁄82

15⁄

8

21⁄

8

15⁄

8

21⁄

1

⁄82

8

5

⁄81

13⁄

8

15⁄

8

5

⁄82

15⁄

8

15⁄

8

1

⁄82

21⁄

8

21⁄

8

5

⁄81

13⁄

8

15⁄

8

5

⁄82

MAXIMUM LIQUID LIFT

UNIT 38AKS

028 76 23 66 20

034 67 20 60 18

044 76 23 66 20

EQUIVALENT SIZES IN MM

60 Hz 50 Hz

FtMFtM

in. mm

7

⁄

11⁄

13⁄

1

21⁄

2

8

8

8

5

⁄

8

8

5

⁄

8

22.2

28.6

34.9

41.3

54.0

66.7

15⁄

8

21⁄

8

1

⁄82

21⁄

8

25⁄

8

5

⁄

8

5

Page 6

Power Supply — Electrical characteristics of available

power supply must agree with unit nameplate rating. Supply

voltage must be within limits shown in Table 3.

IMPORTANT:Operatinguniton improper supply voltage, orwithexcessivephaseimbalance,constitutes abuse

and mayaf fectCarrier warranty.SeeUnbalanced3-Phase

Supply Voltage, page 7.

Power Wiring — All power wiring must comply with

applicable localandnationalcodes.Install field-supplied branch

circuit fused disconnect(s) per NEC (National Electrical Code,

U.S.A.) of a type that can be locked OFF or OPEN. Disconnect(s) must be within sight from and readily accessible

from unit in compliance with NEC Article 440-14.

GENERAL WIRING NOTES

1. A crankcase heater is wired in the control circuit so it is

always operable as long as power supply disconnect is

on, even if any safety device is open or unit stop-start

switch is off. It is protected by a 5-amp circuit breaker in

control power.

2. The power circuit field supply disconnect should never be

open except when unit is being serviced or is to be down

for a prolongedperiod.Whenoperationisresumed, crankcase heater should be energized for 24 hours before startup. If unit is to be shut down for a prolonged period, it

is recommended that the suction and discharge valves be

closed to prevent an excessive accumulation of refrigerant in the compressor oil.

3. Power entry is one end only.

4. Maximum field wire sizes allowed by lugs on terminal

block are:

UNIT

38AKS

028 208/230-3-60

034

044

LEGEND

AWG — American Wire Gage

kcmil — Thousand Circular Mils

*All other units use 2/0 AWG (67.4 mm

V-Ph-Hz

208/230-3-60

230-3-50

208/230-3-60

230-3-50

2

).

WIRE

SIZE*

350 kcmil

5. Terminals for field power supply are suitable for copper,

copper-clad aluminum, or aluminum conductors. Insulation must be rated 167 F (75 C) minimum.

CONDENSER FANS— The fans must rotate counterclockwise when viewed from above. If necessary, correct direction of fan rotation by interchanging any 2 powerinput wires

at disconnect switch. Affix crankcase heater decal (located

in installer’s packet) to unit disconnect switch.

Table 3 — Electrical Data

60 HZ

UNIT

38AKS

500

028

034

044

028

034

044

CSA — Canadian Standards Association

FLA — Full Load Amps

ICF — Maximum InstantaneousCurrentFlow duringstarting(the point

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (complies with National

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

UL — Underwriters’ Laboratories

200

600

100

500

200

600

100

500

200

600

100

UNIT

38AKS

800

300

900

800

300

900

800

300

900

inthestarting sequence wherethesum oftheLRA forthe starting compressor,plus the total FLA for allrunningfanmotors is

maximum).

Electrical Code [NEC, U.S.A.], Section 430-24)

3 Ph, 60 Hz

208/230

208/230

3 Ph, 50 Hz

LEGEND

Volts

380

460

575

380

460

575

230

380

460

575

Volts

230

346

400

230

346

400

230

346

400

Supplied*

Min. Max.

187

342

414

518

187

342

414

518

187

342

414

518

Supplied*

Min. Max.

198

311

342

198

311

342

198

311

342

UNIT COMPRESSOR FAN MOTORS

MCA

254

418

508

632

254

418

508

632

254

418

508

632

124.6

64.7

60.7

52.5

145.5

72.5

68.7

54.9

203.0

111.1

91.0

81.5

50 HZ

UNIT COMPRESSOR FAN MOTORS

MCA

254

380

400

254

380

400

254

380

400

109.0

64.9

60.5

120.2

76.1

68.5

150.6

112.6

90.8

MOCP

(Fuse)

200

110

100

80

250

125

110

90

350

175

150

125

MOCP

(Fuse)

175

100

100

200

125

110

250

175

150

*Units are suitable for use on electrical systems where voltage sup-

ICF RLA LRA FLA (ea) Qty

452.2

250.9

226.1

167.4

512.2

283.9

256.1

179.4

702.4

389.8

351.2

282.8

ICF RLA LRA FLA (ea) Qty

348.4

263.4

226.0

372.4

298.4

256.0

557.8

408.8

351.0

pliedtounit terminals isnotbelow orabovelisted minimum andmaximum limits.

89.8

45.5

43.6

36.5

106.5

52.6

50.0

38.5

147.5

79.5

65.4

57.1

76.9

44.9

43.6

85.9

53.9

50.0

105.1

79.5

65.4

446

247

223

164

506

280

253

176

690

382

345

276

342

259

223

366

294

253

545

400

345

6.2

3.9

3.1

3.4

6.2

3.9

3.1

3.4

6.2

3.9

3.1

3.4

6.4

4.4

3.0

6.4

4.4

3.0

6.4

4.4

3.0

2

2

2

2

2

2

2

2

3

3

3

3

2

2

2

2

2

2

3

3

3

6

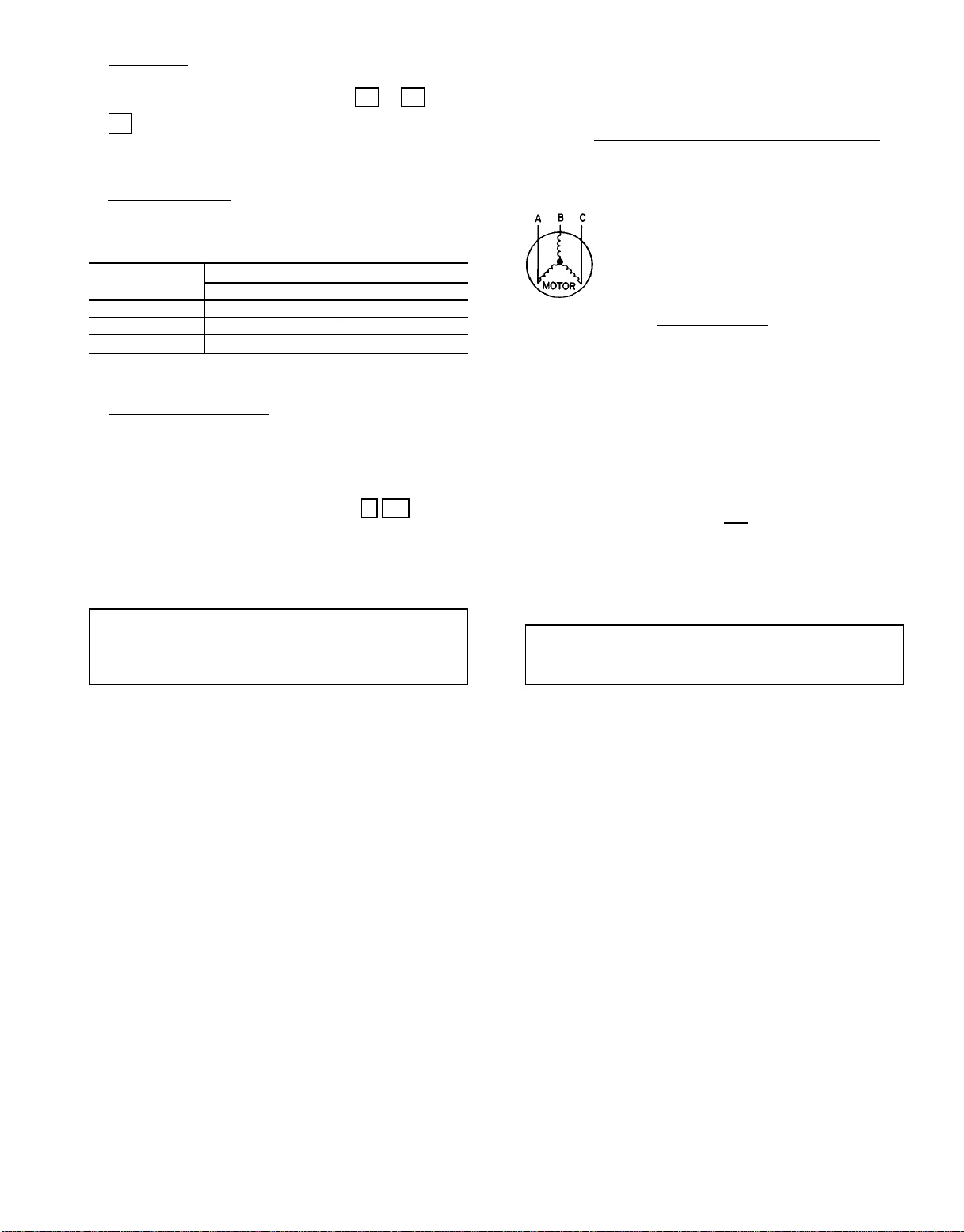

Page 7

FIELD CONNECTIONS

1. Main Power — Bring wires from the fused disconnect

switch through hole in bottom rail of unit to control box

12

(Fig. 6 and 7) and connect terminals , , and

line side of terminal block TB1 (see Fig. 8 and 9A

13

11

or 9B). To comply with NECArticle 440-14, the disconnect must be located within sight from and readily accessible from unit.

2. 24-v ControlPower—Unitshavesinglepointpower connections. Control circuit is directly connected internally

to unit. Maximum 24-v control circuit is 3 amps.

NOTE: Wire runs use the following insulated wire:

LENGTH

0-50 18 0.82

50-75 16 1.30

Over 75 14 2.08

AWG — American Wire Gage

*35 C minimum.

INSULATED WIRE SIZE*

AWG mm

2

3. Control Circuit Interlock — An airflow switch may be

installed in the indoor air handler to prevent unit from

running when indoor air is not flowing. This switch (no.

HR81JE001) is available from Service Parts Center, or

equivalent can be field supplied. This should be electrically interlocked in the control circuit, between thermo-

2

stat TC1 (stage 1, cooling) and terminal on TB3.

Y1

See Fig. 8 for typical field wiring. This is in the 24-v circuit. Wires must be run in conduit with ground wire.

4. Transformer Connections — See unit wiring label diagram, notes 1 and 2, located behind compressor compartment end access door.

IMPORTANT: Ensure power to the crankcase heater

is always on (except when servicing the unit). If circuit breakerinsideunitshutsdown the compressor,crankcase heater remains on.

UNBALANCED 3-PHASE SUPPLY VOLTAGE — Never

operate a motor where a phase imbalance in supply voltage

is greater than 2%. Use the following formula to determine

the percent voltage imbalance:

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

average voltage

Example: Supply voltage is 240-3-60.

AB = 243 v

BC = 236 v

AC = 238 v

Average Voltage =

243 + 236 + 238

3

= 239 volts

Determine maximum deviation from average voltage:

(AB) 243 − 239=4v

(BC) 239 − 236=3v

(AC) 239 − 238=1v

Maximum deviation is 4 v. Determine percent voltage

imbalance:

% Voltage Imbalance = 100 x

4

239

= 1.7%

This amount of phase imbalance is satisfactory as it is be-

low the maximum allowable 2%.

IMPORTANT: Contact your local electric utility company immediately if the supply voltage phase imbalance is more than 2%.

7

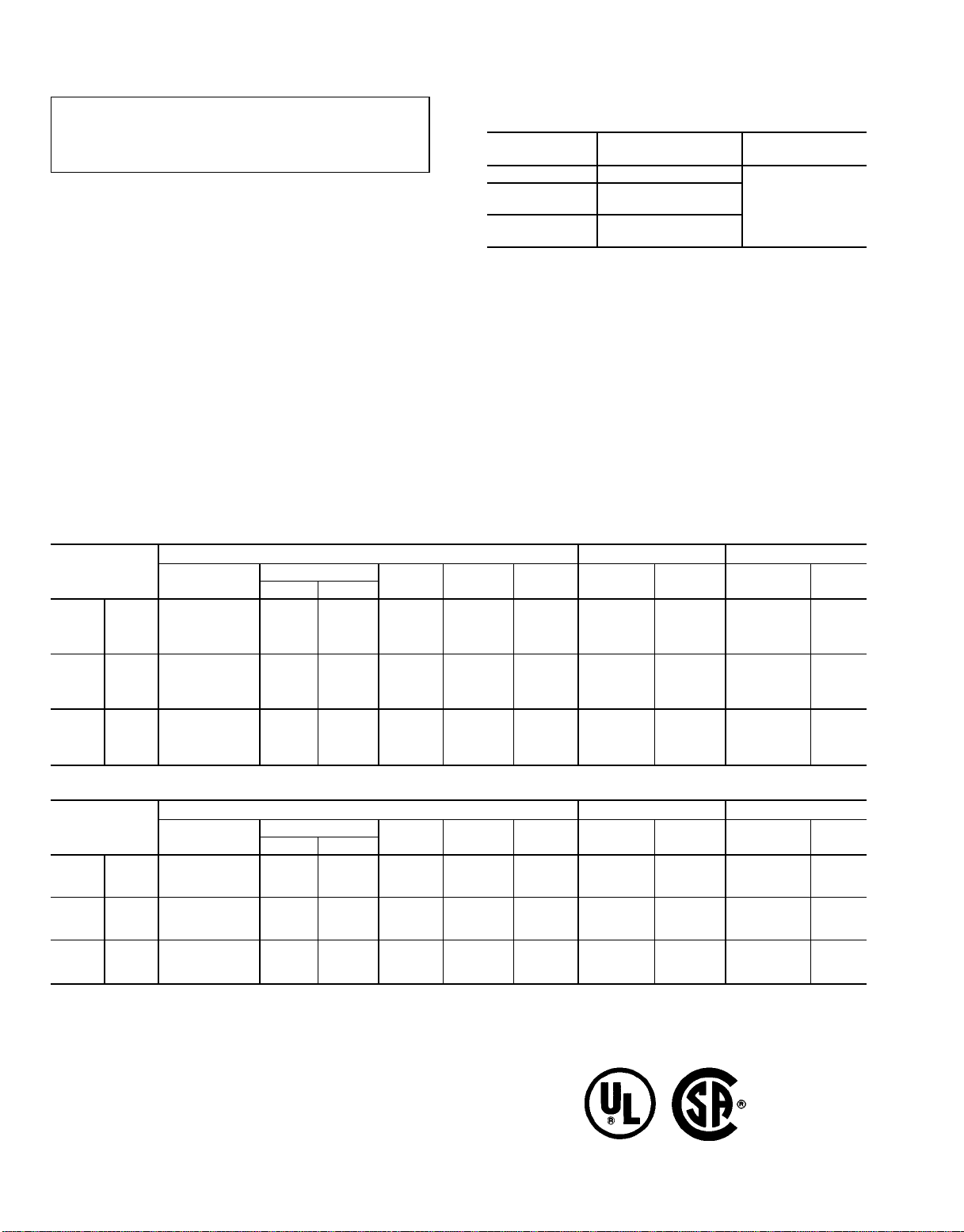

Page 8

LEGEND

NEC — National Electrical Code

VAV — Variable Air Volume

NOTES:

1. There must beminimum(2440mm) 8 ft. clear air spaceabove

unit.

2. The approximate operating weight of the unit is:

50 AND 60 HZ

UNIT

38AKS028 1650 748

38AKS028C 1804 818

38AKS034 1803 818

38AKS034C 2009 911

3. A ‘‘C’’in the model number indicates unit has factory-installed

copper coil.

WT

(Lb)WT(Kg)

Fig. 6 — Dimensional Drawing, 38AKS028,034

8

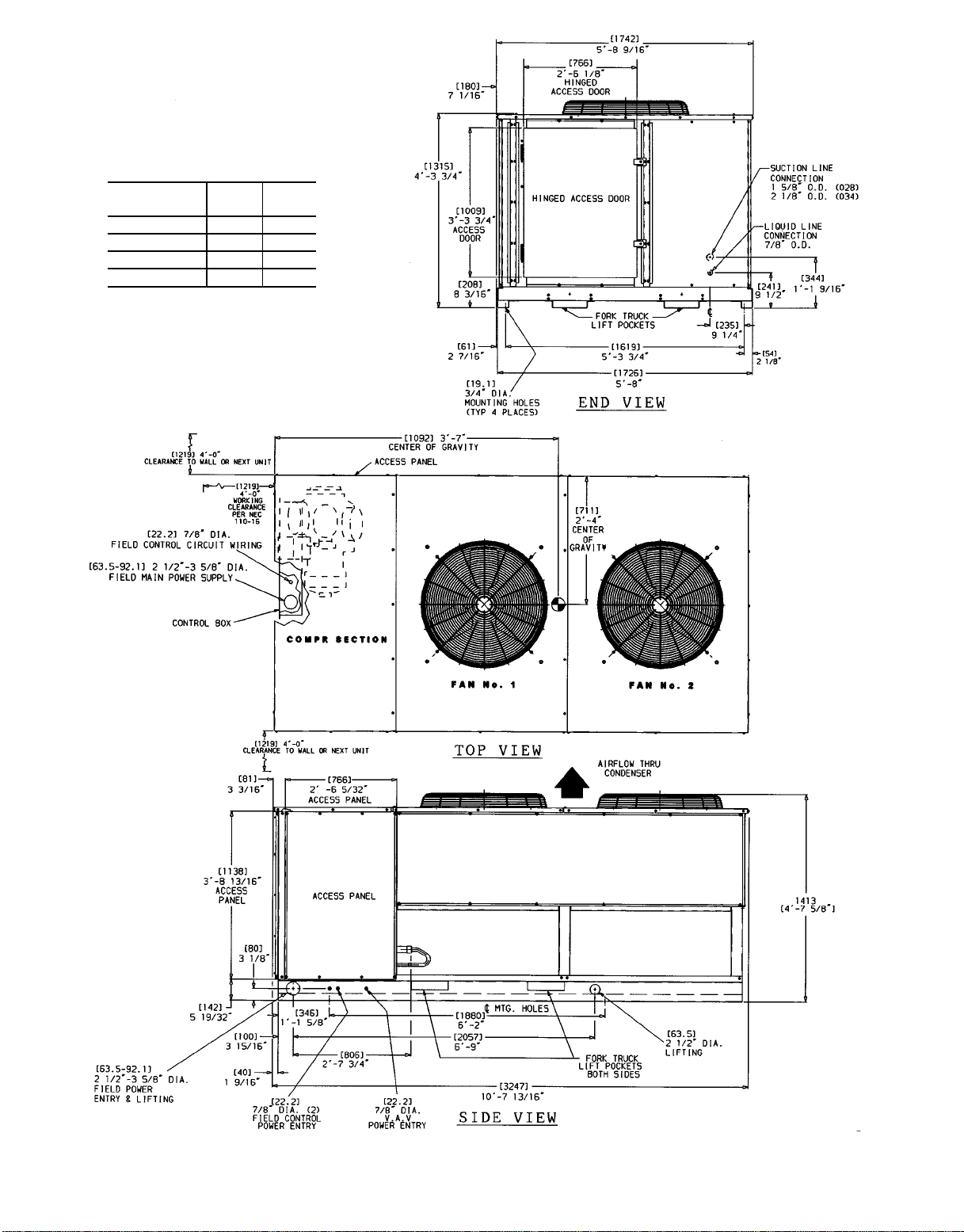

Page 9

LEGEND

NEC — National Electrical Code

NOTES:

1. There must beminimum(2440mm) 8 ft. clear air spaceabove

unit.

2. The approximate operating weight of the unit is:

50 HZ AND 60 HZ

UNIT

38AKS044 2437 1106

38AKS044C 2745 1246

3. A ‘‘C’’in the model number indicates unit has factory-installed

copper coil.

WT

(Lb)WT(Kg)

Fig. 7 — Dimensional Drawing, 38AKS044

9

Page 10

modifications or additions must be in compliance

NOTES:

1.Factorywiring in accordancewith the NEC.Any field

with all applicable codes.

ing of 180 va pilot duty plus capacity required for

2. All field interlock contacts must have minimum rat-

field-installed equipment. All field interlock con-

tacts inthe24-vcontrol circuit must have minimum

rating of 70 va pilot duty plus capacity required for

field-installed equipment.

3.Forinternal unit wiring,referencewiring bookorunit

wiring label diagram. TB2 is 115-1-60, TB3 is

24-1-60.

38AKS unit control box: LLS1, LLS2, field control

4. The following components are not located in the

thermostat, AFS, alarm shut-off switch, and alarm

or light.

Fig.8—Typical Wiring Schematic

LEGEND

AFS — Airflow Switch

CB — Circuit Breaker

EQUIP — Equipment

FU — Fuse

GND — Ground

LLS1 — Liquid Line Solenoid for

Solenoid Drop Control

Capacity Control

LLS2 — Liquid Line Solenoid for

NEC — National Electrical Code, U.S.A.

TB — Terminal Block

Field Power Wiring

TC — Thermostat Cooling

Field Control Wiring

Factory Installed Wiring

10

Page 11

FM — Fan Motor

FU — Fuse

LEGEND

BPR — Bypass Relay

C—Contactor, Compressor

GND — Ground

LLSV — Liquid Line Solenoid Valve

NEC — National Electrical Code (U.S.A.)

DB — Circuit Breaker

CR — Control Relay

CM — Control Module

TB — Terminal Block

TRAN — Transformer

EQUIP — Equipment

FC — Fan Contactor

Fig. 9A — Component Arrangement — 60 Hz

11

Page 12

12

LEGEND

BPR — Bypass Relay

C—Contactor, Compressor

CB — Circuit Breaker

CR — Control Relay

CM — Control Module

EQUIP — Equipment

FC — Fan Contactor

FM — Fan Motor

FU — Fuse

GND — Ground

LLSV — Liquid Line Solenoid Valve

NEC — National Electrical Code (U.S.A.)

TB — Terminal Block

TDR — Time Delay Relay

Fig. 9B — Component Arrangement — 50 Hz

TRAN — Transformer

Page 13

Initial Check

START-UP

The start-up of the compressor can occur between 3 seconds

and approximately 5 minutes from the time the control circuit is energized due to the anti-short cycle feature of the

control module (CM).

Do not attempt to start the condensing unit, even momentarily, until the following steps have been completed. Compressor damage may result.

1. Check all auxiliary components, suchasair-handlingequipment, and other equipment. Consult the manufacturer’s

instructions regarding any other equipment connected

to the condensing unit. If used, airflow switch must be

properly installed. See Fig. 8.

2. Backseat (open) compressor suction and discharge valves.

Close valves one turntoallowpressuretoreachtest gages.

3. Open liquid line service valve.

4. Set thermostat.

5. Check tightness of all electrical connections.

6. Compressor oil level should be visible in sight glass.

See Service, Oil Charge section on page 19.

7. Be sure unit isproperlyleaktested, dehydrated, and charged.

See below.

8. Electrical power source must agree with nameplate

rating.

9. Crankcase heater must be firmly locked into compressor crankcase. Be sure crankcase is warm(heater should

be on for 24 hours before starting compressor).

10. Be sure compressor floats freely on the mounting springs.

See Compressor Mounting section on page 2 and Fig. 3

for loosening compressor bolts.

Leak Test and Dehydration — Leak test the entire

refrigerant system by the pressure method described in the

Carrier Training Booklet; GTAC II, Module 4 - System

Dehydration.

PreliminaryCharge— Refer to Carrier TrainingBook-

let; GTAC II, Module 5 for charging methods and procedures. Charge system with approximately 25 lbs (11.3 kg) of

R-22 by the liquid charging method (charging through liquid service valve), on the high side, and charging by weight.

Charge per Fig. 10-12.

StartUnit — Close field disconnect. Set thermostat above

ambient temperature so that there is no demand for cooling.

Now,onlythe crankcase heater is energized.After the heater

has been on for 24 hours, the unit can be started. If no time

has elapsed since the preliminary charge step has been completed, it is unnecessary to wait the 24-hour period.

Close the compressor circuit breaker, then reset the indoor thermostat below ambient temperature, so that a call

for cooling is ensured.

NOTE: Do not use the compressor circuit breaker to start

and stop compressor, except in an emergency.

Charge System — Actual start-up should be done only

under supervision of a qualified refrigeration mechanic. Refer to charging charts.

See Fig. 10-12 for the particular unit being charged. Measure pressure at the liquid line service valve, being sure a

Schrader depressor is used if required. Also, measure liquid

line temperature as close to the liquid service valve as possible. Add or reduce charge until the pressure and temperature conditions of the charging charge curve are met. If liquid pressureandtemperaturepointfallabove curve, add charge.

If liquid pressure and temperature point fall below curve,

reduce the charge until the conditions match the curve.

Never charge liquid into the low-pressure side of system. Do not overcharge. During charging or removal of

refrigerant, be sure indoor fan system is operating.

Operation— Refer to control circuit diagram on the unit,

or in the unit wiring book.

Control Module (CM) — The unit control module is

located in the control section of the control box. See

Fig. 9A or 9B. It performs several functions. The CM has a

built-in compressor anti-short-cycle timer which will not allow the compressor to restart until 5 minutes (190 seconds/

–75 seconds) have elapsed since the previous shutdown.

The compressor oil pressure is monitored through the CM.

The unit is allowed to remain operational as long as the oil

pressure safety switch (OPS) has not been open for more

than 2 minutes after the compressor hasstarted. If after startup, the OPS is open for more than 2 minutes, the CM shuts

down the compressor and places the unit in a lockout condition. The CM activates the fault indication circuit, and the

field-supplied unit service lamp isilluminated(ifsoequipped).

The unit cannot be restarted until power is interrupted at the

unit, resetting the CM. The 5-minute recycle time relay is

initiated.

The CM also monitors the high-pressure switch (HPS) and

compressor thermal protection. If at any time the HPS opens,

the CM shuts down the compressor and places the unit in a

lockout condition. The CM activates the fault indication circuit, and the field-supplied unit service lamp is illuminated

(if so equipped). The unit cannot be restarted until the HPS

is reset and until power is interrupted at the unit, resetting

the CM. The 5-minute recycle time relay is initiated.

If the unit shuts down on an automatic reset switch, such

as the low-pressure switch (LPS), the compressor will be allowed to restart when the switch recloses and the CM antishort-cycle time has elapsed.

13

Page 14

14

Fig. 10 — 38AKS028 Charging Chart, 50/60 Hz

Page 15

15

Fig. 11 — 38AKS034 Charging Chart, 50/60 Hz

Page 16

16

Fig. 12 — 38AKS044 Charging Chart, 50/60 Hz

Page 17

FOR SERVICING ONLY — To speed up the 5-minute antishort cycle, a temporary jumper may be placed between terminals T1 and T6 of the control module.

This jumper must be removed after servicing is complete. Failure to remove this jumper is considered abusive treatment and will void the Carrier warranty.

Bypass Relay (BPR) — All units are equipped with a

BPR located in the control section of the control box. See

Fig. 9Aor 9B. The function of the BPR istoprovidea2-minute

bypass of the LPS at start-up, and to energize the unloader(s) at start-up to provide unloaded compressor starting. Two

minutes after the compressor starts, the BPR completes its

function and is no longer active in the control circuit until

the next restart of the unit.

Time-DelayRelay(TDR)(50 Hz Only) — This solid-

state delay-on-make relay is factoryset for a 1-second delay.

The number 1 dip switch is set to the ON position, and all

the other dip switches are set to the OFF position. Once the

control relay (CR) is energized, the compressor contactor C1

is powered, and the first set of compressor windings is energized.After the 1-second timedelay, contactor C1Ais powered and the second set of compressor windings is energized

(part-wind start).

Sequence of Operation — When space thermostat

calls for cooling, the no. 1 condenser fan and compressor

start after CM initial time delay of 3 (12/–1) seconds. If an

optional airflow switch is used, compressor and no. 1 condenser fan will not start until sufficient indoor airflow has

closed the switch.After 3 seconds the compressor starts and

the liquid line solenoid valve for solenoid drop control opens.

The crankcaseheaterisdeenergized. If the head pressurereaches

260 psig (1792 kPa) the second condenser fan starts. Fan

no. 3 (38AKS044 only) starts if outdoor ambient air rises

above 80 F (26.7 C).

If cooling demand is low, suction pressure at the compressor drops. As the pressure drops, the compressor unloads 2 banks of cylinders as required. If cooling demand is

high and 2-stage operation is used, the second stage of the

thermostat activates the capacity control liquid line solenoid

which activates the second stage evaporator coil. The compressor cylinders load or unload in response to compressor

suction pressure to meet evaporator load.

T wominutes after compressor starts, the BPR timer is deenergized and the LPS bypass is deactivated. If the LPS trips

during the first 2 minutes of operation, the compressor will

remain operational. If the LPS trips after 2 minutes,the compressor operation is interrupted, and the compressor cannot

restart until the 5-minute CM anti-short cycle timer expires.

As the space cooling load is satisfied, the second stage of

the thermostat opens, and closes the field-supplied capacity

control liquid line solenoid valve to deactivate the second

stage coil. The compressor adjusts the number of active cylinders to meet the new load. When the space temperature is

satisfied, the first stage of the thermostat opens and the control relay and the BPR open. This closes the solenoid drop

control valve. The compressor stops and the crankcase heater

is energized,preventingrefrigerantfrommigratingtothecompressor during the off cycle (solenoid drop refrigerant control). The CM anti-short cycling timer is energized and runs

for approximately 5 minutes. During this time, the compressor is not able to restart.

Complete Unit Stoppage

CAUSES — Interruption of supplied power,compressor overtemperature protection, or open HPS causes compressor

stoppage.

RESTART — The unit recycles and restarts automatically

under the CM when power is restored. Stoppage by HPS, or

compressor circuit breaker requires manual resetting of the

control circuit. Torestartthe CM timer when HPS is tripped,

it is necessary to interrupt power to the unit, restarting the

CM logic. It is necessary to manually reset the compressor

circuit breaker at the unit.

If LPS is not closed within 2 minutes after compressor

starts, the compressor locks out and the outdoor fans continue to run. It stays locked out for 5 minutes until the CM

anti-short cycle timer expires. After 5 minutes, the LPS is

bypassed by the BPR (winter start control). It remains jumpered for 2 minutes. Because the LPS is jumpered, the compressor restarts and runs for the 2-minute time period. At

the end of this 2 minutes, if the LPS has still not closed, the

compressor is again locked out. The outdoor fans continue

to run as long as there is a call for cooling. Automatic reset

of the LPS causes the CM to recycle so that the compressor

can start.

If sufficientcompressoroilpressurehasnot been built within

2 minutes after the compressor starts, the unit is completely

deenergized until the oil pressure switch is manually reset at

the unit.

If unit or circuit stoppage occurs more than once due to

any safety device, the trouble should be corrected before any attempt to restart.

SERVICE

Turn off all power to unit before proceeding.

Access for Servicing (See Fig. 13)

COMPRESSOR SECTION — The compressor compartment has 2 side access panels and one front door for servicing, providing access to compressor, all components of

the refrigerant system, electrical controls, and control box.

After opening front door there is an inner cover that must be

removed for access to control box (except 208/230-v and

460-v units).

OIL PRESSURE SAFETY SWITCH — Switch is manually

reset, and accessed by removing the side access panel on the

left side of the unit (as viewed from the compressor end).

See Fig. 13. The OPS is found in the compressor junction

box. Open the compressor circuit breaker prior to removing

the compressor junction box cover in order to access the OPS.

The liquid line service valve can be found behind the side

access door on the right side of the unit (as viewed from the

compressor end).

CONDENSER SECTION — Condenser fan motors and fans

can be serviced by removal of outlet grilles or side panels.

If a fan motor is serviced, be sure the wire fan guard is in

place over each fan before starting unit. See Fig. 14 for proper

fan adjustment. Tightenfanhub securely on motor shaft with

setscrew which bears against the key. Be sure to replacePermagum and rubber cap over end of motor shaft to protect

against moisture causing fan to rust on shaft.

17

Page 18

TRAN1

CM

CR1

FC

FC3

FC2

COMPRESSOR END AND RIGHT-SIDE VIEW

TRAN2

C1

TB2

CB2

CB1

TB3

COMPRESSOR END, CONTROL PANEL REMOVED

LIQUID LINE

SERVICE

VALVE

OIL PRESSURE SAFETY SWITCH

COMPRESSOR END, LEFT-SIDE ACCESS DOOR

(JUNCTION BOX COVER REMOVED)

Fig. 13 — 38AKS Unit with Access Panels Removed

COMPRESSOR END, RIGHT-SIDE ACCESS DOOR

18

Page 19

Fan Adjustment — Adjust fan as shown in Fig. 14.

NOTE: Dimension in ( ) is in millimeters.

Capacity Control — Capacity control is by 2 suction

pressure actuated unloaders. Each controls 2 cylinders. Unloaders are factory set (see Table 1Aor 1B) but may be field

adjusted. Number 1 unloader is on cylinder bank on same

side of compressor as terminal box.

CONTROL SET POINT — The control set point (cylinder

load point) is adjustable from 0 to 85 psig (0 to 586 kPag).

T oadjust, turn control set point adjustment nut (Fig. 15) clockwise to its bottom stop. In this position, set point is

85 psig (586 kPag). Then, turn adjustment counterclockwise

to desired control set point. Every full turn counterclockwise decreases set point by 7.5 psig (52 kPag).

Fig. 14 — Location of Prop on Motor Shaft from

Outside of Orifice Ring

Oil Charge — Compressors are factory charged with oil

as follows:

COMPRESSOR

06E9265 20.0 (9.4)

06E9275 20.0 (9.4)

06E9299 19.0 (9.0)

AMOUNT

pints (liters)

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil:

Petroleum Specialities Inc. ..................Cryol 150

Texaco, Inc. .........................Capella WF-32

Witco Chemical Corp. ...................Suniso 3 GS

IMPORTANT: Do not use drained oil or use oil that

has been exposed to atmosphere. Refer to Carrier Training Booklet, GTAC II, Module 5, for procedures to

add oil. To remove oil, isolate the compressor, reclaim

internal compressorcharge,anduse the compressor drain

plug.

Liquid Shutoff/Charging Valve — Valve is located

inside the compressor compartment and is provided with

1

⁄4-in. flare connection for field charging.

Fig. 15 — Capacity Control Valve

PRESSURE DIFFERENTIAL — The pressure differential

(difference between cylinder load and unload points) is adjustable from 6 to 22 psig (41 to 152 kPag). To adjust, turn

pressure differential adjustment screw (Fig. 15) counterclockwise to its backstop position. In this position, differential is 6 psig (41 kPag). Then, turn adjustment clockwise

to desired pressure differential. Every full turn clockwise increases differential by 1.5 psig (10 kPag).

19

Page 20

Oil Pressure Safety Switch (OPS) — The OPS in

the control circuit stops the compressor and unit, if proper

oil pressure differentialis not established at start-up or maintained during operation. If OPS stops the unit, determine the

cause and correct before restarting unit. Failure to do so will

constitute abuse. Equipment failure due to abuse may void

the warranty.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual reset, ambient compensated, magnetic breaker protects against motor

overload and locked rotor conditions.

CONTROLMODULETIMER—This controlprotectscompressor against short cycling. See Sequence of Operation on

page 17.

CRANKCASE HEATER — This minimizes absorption of

liquid refrigerant by oil in crankcase during brief or extended shutdown periods.

IMPORTANT: Never open any switch or disconnect

that deenergizes the crankcase heater unless unit is being serviced or is to be shut down for a prolonged period. After a prolonged shutdown on a service job, energize the crankcase heater for 24 hours before starting

the compressor.

High-Pressure Switch — This switch has fixed, non-

adjustable settings. Switch is mounted on the compressor (See

Table 4).

Low-Pressure Switch — This switch has fixed, non-

adjustable settings. Switch is mounted on the compressor.

(See Table 4.)

Head Pressure Control — Control maintains ad-

equate dischargepressureunderlowambienttemperatureconditions. See Table 5.

FAN CYCLING — These 38AKS units have standard provision for fully automatic intermediate-season head pressure

control through condenser fan cycling. Fan no. 2 is cycled

by a fan cycling pressure switch (FCPS) which responds to

variation in discharge pressure. The pressure sensor is located in the liquid line of the refrigerant circuit. Fan no. 3

cycling is controlled by outdoor-air temperature through an

air temperature switch (ATS) (38AKS044 units only).

Table 5 — Minimum Outdoor-Air

Operating Temperature

UNIT

38AKS

028

034

044

COMPR

CAP. (%)

100 90 (32) 31 (–1) –20 (–29)

67 80 (27) 35 (2) –20(–29)

33 70 (21) 43 (6) –20(–29)

100 90 (32) 30 (–1) –20 (–29)

67 80 (27) 34 (1) –20(–29)

33 70 (21) 42 (6) –20(–29)

100 90 (32) 25 (–4) –20 (–29)

67 80 (27) 30 (–1) –20 (–29)

33 70 (21) 35 (2) –20(–29)

COND

TEMP,

F (C)

TheATS is located in the lower divider panel between the

compressor compartment and condenser section. Through a

hole in the panel, the sensing element is exposed to air entering the no. 1 fan compartment. Fan no. 1 is noncycling.

Table 6 shows the operating settings of the FCPS and the

ATS.

MIN OUTDOOR TEMP, F (C)

Standard

Unit

Low Ambient

Control

(MotormasterT)

Table 4 — Pressure Switch Settings, psig (kPa)

HIGH PRESSURE LOW PRESSURE

Cutout Cut-in Cutout Cut-in

426±7

(2937 ± 48)

320±20

(2206 ± 138)

27±3

(186 ± 21)

44±5

(303 ± 34)

Winter Start Control — Bypass relay timer bypasses

low-pressure switch for 2 minutes on unit start-up.

Table 6 — Fan Cycling Controls

CONTROL BY SWITCH OPENS SWITCH CLOSES

Temp, F (C) 70 ± 3 (21 ± 1.7) 80 ± 3 (27 ± 1.7)

Pressure,

psig (kPa)

NOTE: See Fig. 6 and 7 for fan arrangement.

160 ± 10 (1103 ± 69) 260 ± 15 (1793 ± 103)

20

Page 21

TROUBLESHOOTING

SYMPTOM AND PROBABLE CAUSE PROBABLE REMEDY

COMPRESSOR DOES NOT RUN

1. Control circuit breaker tripped 1. Reset control circuit breaker

2. Power line open 2. Reset circuit breaker

3. Oil pressure switch tripped 3. Reset oil pressure switch at unit

4. Safety device tripped 4. Reset control circuit with thermostat

5. Contactor stuck open 5. Replace contactor

6. Loose terminal connection 6. Check connections

7. Improperly wired controls 7. Check and rewire

8. Seized compressor 8. Check motor winding for open or short.

9. Low line voltage 9. Check line voltage — determine location of

10. Compressor motor defective 10. Check motor winding for open or short.

COMPRESSOR STOPS ON LOW-PRESSURE

CONTROL

1.Compressorsuctionshutoffvalvepartiallyclosed 1. Open valve

2. Low refrigerant charge 2. Add refrigerant

3. Liquid line solenoid valve(s) fails to open 3. Check liquid line solenoid valve for proper

4. Liquid line shutoff valve closed 4. Open valve

COMPRESSOR STOPS ON HIGH-PRESSURE

CONTROL

1. Compressor discharge valve partially closed 1. Open valve or replace if defective

2. Air in system 2. Purge and evacuate system

3. Condenser fan(s) not operating 3. Check motor wiring and repair or replace if

4. System is overcharged. 4. Reclaim charge as needed

UNIT OPERATES TOO LONG OR

CONTINUOUSLY

1. Low refrigerant charge 1. Add refrigerant

2. Control contacts fused 2. Replace control

3. Air in system 3. Purge and evacuate system

4. Partially plugged expansion valve or filter drier 4. Clean or replace

SYSTEM IS NOISY

1. Piping vibration 1. Support piping as required

2. Compressor noisy 2. Check valve plates for valve noise. Replace

COMPRESSOR LOSES OIL

1. Leak in system 1. Repair leak

2. Crankcase heaters not energized during 2. Check wiring and relays. Check heater and

shutdown replace if defective

3. Improper interconnecting piping design 3. Check piping for oil return. Replace if

FROSTED SUCTION LINE

1. Expansion valve admitting excess refrigerant 1. Adjust expansion valve

HOT LIQUID LINE

1. Shortage of refrigerant due to leak. 1. Repair leak and recharge

2. Expansion valve opens too wide 2. Adjust expansion valve

FROSTED LIQUID LINE

1. Restricted filter drier 1. Remove restriction or replace

COMPRESSOR WILL NOT UNLOAD

1. Defective unloader 1. Replace

2. Defective capacity control solenoid valve 2. Replace valve

3. Miswired liquid line solenoid 3. Rewire correctly

4. Weak, broken, or wrong valve body spring 4. Replace spring

COMPRESSOR WILL NOT LOAD

1. Miswired capacity control liquid solenoid 1. Rewire correctly

2. Defective capacity control solenoid valve 2. Replace valve

3. Plugged strainer (high side) 3. Clean or replace strainer

4. Stuck or damaged unloader piston or piston 4. Clean or replace the necessary parts

ring(s)

Replace compressor, if necessary

voltage drop and remedy deficiency

Replace compressor, if necessary

operation. Replace if necessary

defective

compressor if bearings are worn

necessary

21

Page 22

PACKAGED SERVICE TRAINING

Our packaged service training programs provide an excellent way to increase your knowledge of the

equipment discussed in this manual. Product programs cover:

• Unit Familiarization

• Installation Overview

A large selection of product, theory, and skills programs is available. All programs include a video

cassette and/or slides and a companion booklet. Use these for self teaching or to conduct full training

sessions.

For a free Service Training Material Catalog (STM), call 1-800-962-9212. Ordering instructions are

included.

• Maintenance

• Operating Sequence

Copyright 1994 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 3a

PC 111 Catalog No. 533-820 Printed in U.S.A. Form 38A-5SI Pg 22 7-94 Replaces: 38AK-3SI

Page 23

START-UP CHECKLIST

(Remove and store in job file)

A. Preliminary Information

OUTDOOR:MODELNO. SERIALNO.

INDOOR: AIR HANDLER MANUFACTURER

MODEL NO. SERIAL NO.

ADDITIONAL ACCESSORIES

B. Pre-Start-Up

OUTDOOR UNIT

IS THERE ANY SHIPPING DAMAGE? (Y/N)

IF SO, WHERE:

WILL THIS DAMAGE PREVENT UNIT START-UP? (Y/N)

CHECK POWER SUPPLY. DOES IT AGREE WITH UNIT? (Y/N)

HAS THE GROUND WIRE BEEN CONNECTED? (Y/N)

HAS THE CIRCUIT PROTECTION BEEN SIZED AND INSTALLED PROPERLY? (Y/N)

ARE THE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? (Y/N)

HAVE COMPRESSOR HOLDDOWN BOLTS BEEN LOOSENED? (Y/N)

CUT ALONG DOTTED LINE

CONTROLS

ARE THERMOSTAT AND INDOOR FAN CONTROL WIRING

CONNECTIONS MADE AND CHECKED? (Y/N)

ARE ALL WIRING TERMINALS (including main power supply) TIGHT? (Y/N)

HAS CRANKCASE HEATER BEEN ENERGIZED FOR 24 HOURS? (Y/N)

INDOOR UNIT

HAS WATER BEEN PLACED IN DRAIN PAN TO CONFIRM PROPER DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

PIPING

ARE LIQUID LINE SOLENOID VALVE(S) LOCATED AT THE EVAPORATOR COIL AS REQUIRED? (Y/N)

HAVE LEAK CHECKS BEEN MADE AT COMPRESSOR, CONDENSER, EVAPORATOR,

TXVs (Thermostatic Expansion Valves), SOLENOID VALVES, FILTER DRIERS, AND FUSIBLE PLUGS

WITH A LEAK DETECTOR? (Y/N)

LOCATE, REPAIR, AND REPORT ANY LEAKS.

HAVEALL COMPRESSOR SERVICE VALVES BEEN FULLY OPENED (BACKSEATED)? (Y/N)

ARE THE COMPRESSOR OIL SIGHT GLASSES SHOWING ABOUT1⁄2FULL? (Y/N)

CHECK VOLTAGE IMBALANCE

LINE-TO-LINE VOLTS: AB V AC V BC V

(AB + AC + BC)/3 = AVERAGE VOLTAGE = V

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE = V

VOLTAGE IMBALANCE = 100 X (MAX DEVIATION)/(AVERAGE VOLTAGE) = %

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START SYSTEM!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

CL-1

----------------------------------------------------------------------------------------

Page 24

C. Start-Up

CHECK EVAPORATOR FAN SPEED AND RECORD.

CHECK CONDENSER FAN SPEED AND RECORD.

AFTER AT LEAST 10 MINUTES RUNNING TIME, RECORD THE FOLLOWING MEASUREMENTS:

OIL PRESSURE

SUCTION PRESSURE

SUCTION LINE TEMP

DISCHARGE PRESSURE

DISCHARGE LINE TEMP

ENTERING CONDENSER AIR TEMP

LEAVING CONDENSER AIR TEMP

EVAP ENTERING AIR DB TEMP

EVAP ENTERING AIR WB TEMP

EVAP LEAVING AIR DB TEMP

EVAP LEAVING AIR WB TEMP

COMPRESSOR AMPS (L1)

COMPRESSOR AMPS (L2)

COMPRESSOR AMPS (L3)

CHECK THE COMPRESSOR OIL LEVEL SIGHT GLASSES; ARE THE SIGHT GLASSES SHOWING

OIL LEVEL AT1⁄8TO1⁄3FULL? (Y/N)

NOTES:

Copyright 1994 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 3a

PC 111 Catalog No. 533-820 Printed in U.S.A. Form 38A-5SI Pg CL-2 7-94 Replaces: 38AK-3SI

Loading...

Loading...