Page 1

ModulineT Air Terminals

Application Data

37HS

CONTENTS

Page

INTRODUCTION ........................... 1-2

BUILDING LOAD CALCULATION .......... 2-23

Cooling ................................... 2

• LOAD CONSIDERATIONS

• DESIGN PROCEDURE

Heating ................................... 20

• OVERHEAD AIR HEATING

TERMINAL SELECTION AND LAYOUT ..... 23-41

Introduction ............................... 23

Definitions ................................ 23

Step 1 — Determine Air Volume (Cfm)

Per Terminal ............................. 24

Step 2 — Lay Out Terminals ............... 25

Step 3 — Consider Unit Combinations

and Run-Out Duct ........................ 27

Step 4 — Determine Controller Location .... 37

Final Layout ............................... 41

THE MODULINE VALVE ................... 41-44

The Moduline Control Concept ............. 41

• HIGH AND LOW PRESSURE

• BELLOWS PRESSURE

• UNIT AIRFLOW DELIVERY

CONTROL APPLICATIONS ................ 44-50

Introduction ............................... 44

System-Powered Controls ................. 44

• COMPONENTS OF THE SYSTEM-

POWERED CONTROL SYSTEM

• SYSTEM-POWERED APPLICATIONS

Constant Volume (CV) Cooling

CV Heating

Variable Air Volume (VAV) Cooling

VAV Cooling With Warm-Up

VAV Heating and Cooling With Changeover

VAV Heating

• SYSTEM-POWERED CONTROLS WITH

ELECTRIC INTERFACE

VAV Cooling With Electric Warm-Up

VAV Heating and Cooling With Electric Changeover

VAV Cooling With Electric Heat Interlock

• SYSTEM-POWERED CONTROLS WITH

PNEUMATIC INTERFACE

Pneumatic Sequenced Cooling/Heating (Hot Water)

VAV Cooling With Pneumatic Warm-Up

VAV Cooling With Fire Safety

Night Set Back Heating

VAV Cooling/Separate System Heating

CONTROL SELECTION ................... 50-54

Control Index ............................. 50

Control Packages ......................... 50

CONTROL OPERATING SEQUENCES ...... 55-71

System-Powered Controls ................. 55

• CV COOLING

• CV HEATING

• VAV COOLING

• VAV COOLING WITH WARM-UP

• VAV HEATING AND COOLING WITH

Page

SYSTEM-POWERED CHANGEOVER

• VAV HEATING

System-Powered Controls With

Electric Interface ......................... 64

• VAV COOLING WITH ELECTRIC WARM-UP

• VAV HEATING AND COOLING WITH

ELECTRIC CHANGEOVER

• VAV COOLING WITH ELECTRIC HEAT

INTERLOCK

System-Powered Controls With

Pneumatic Interface ...................... 69

• PNEUMATIC SEQUENCED HEATING/

COOLING (HOT WATER)

• VAV COOLING WITH PNEUMATIC

WARM-UP OR FIRE SAFETY SWITCH

AIRFLOW ADJUSTMENT .................. 71,72

Maximum Airflow (Cfm) Adjustment ........ 71

Minimum Airflow (Cfm) Adjustment ......... 71

Variation in Maximum Airflow .............. 72

AIR DISTRIBUTION ........................ 73

Throw for Standard Diffusers ............... 82

INTRODUCTION

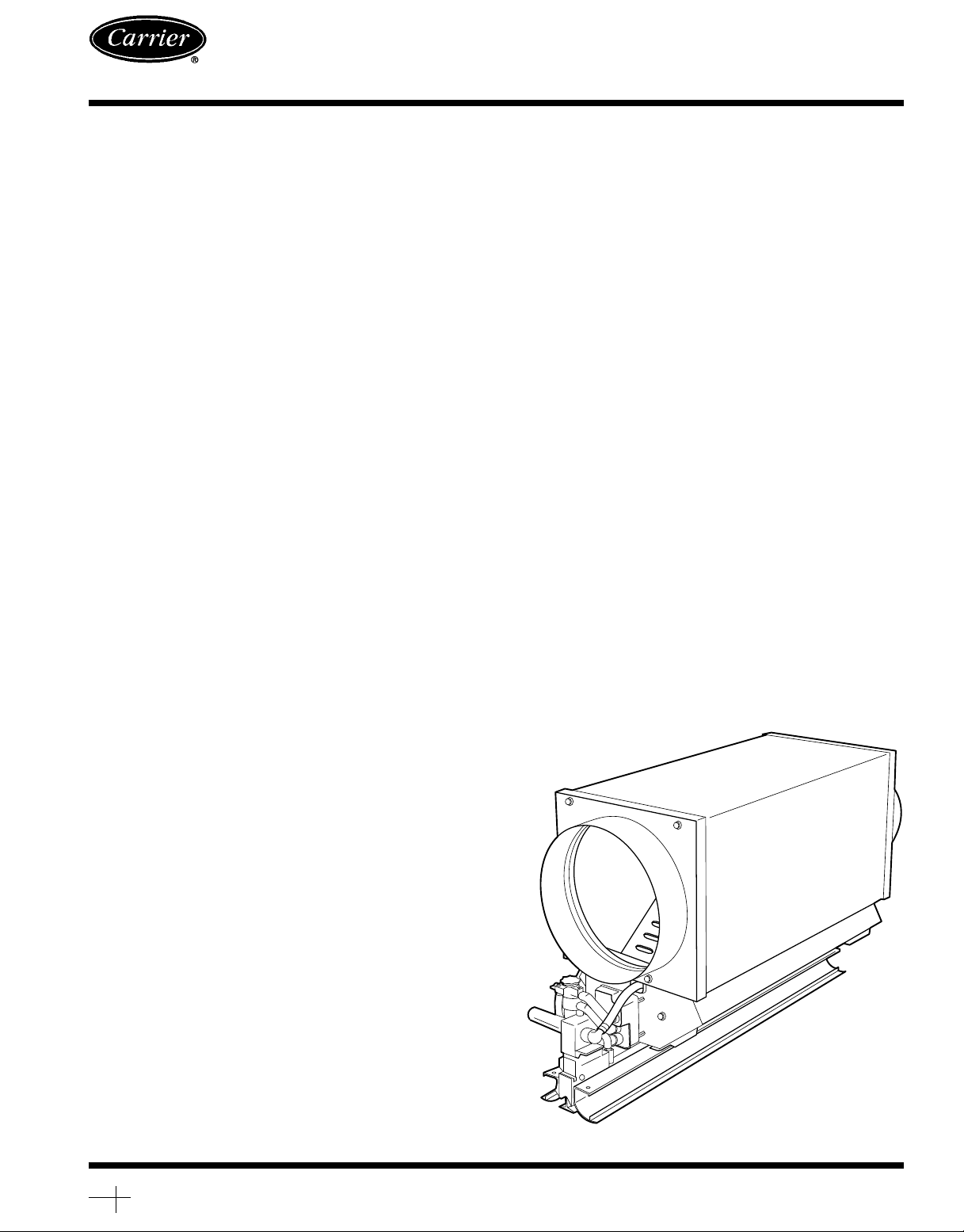

The Modulinet airterminal (Fig. 1) is a truly flexible unit

for the control and distribution of conditioned air to the occupied space. Available in 3 airflow sizes for single or multiple terminal installation, it is adaptable to a variety of

Fig. 1 — Moduline Air Terminal

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3

Tab 6a

PC 201 Catalog No. 513-741 Printed in U.S.A. Form 37HS-1XA Pg 1 6-91 Replaces: New

Page 2

ceiling designs and building control systems. Modulinet terminals installed in modular ceilings can be moved easily when

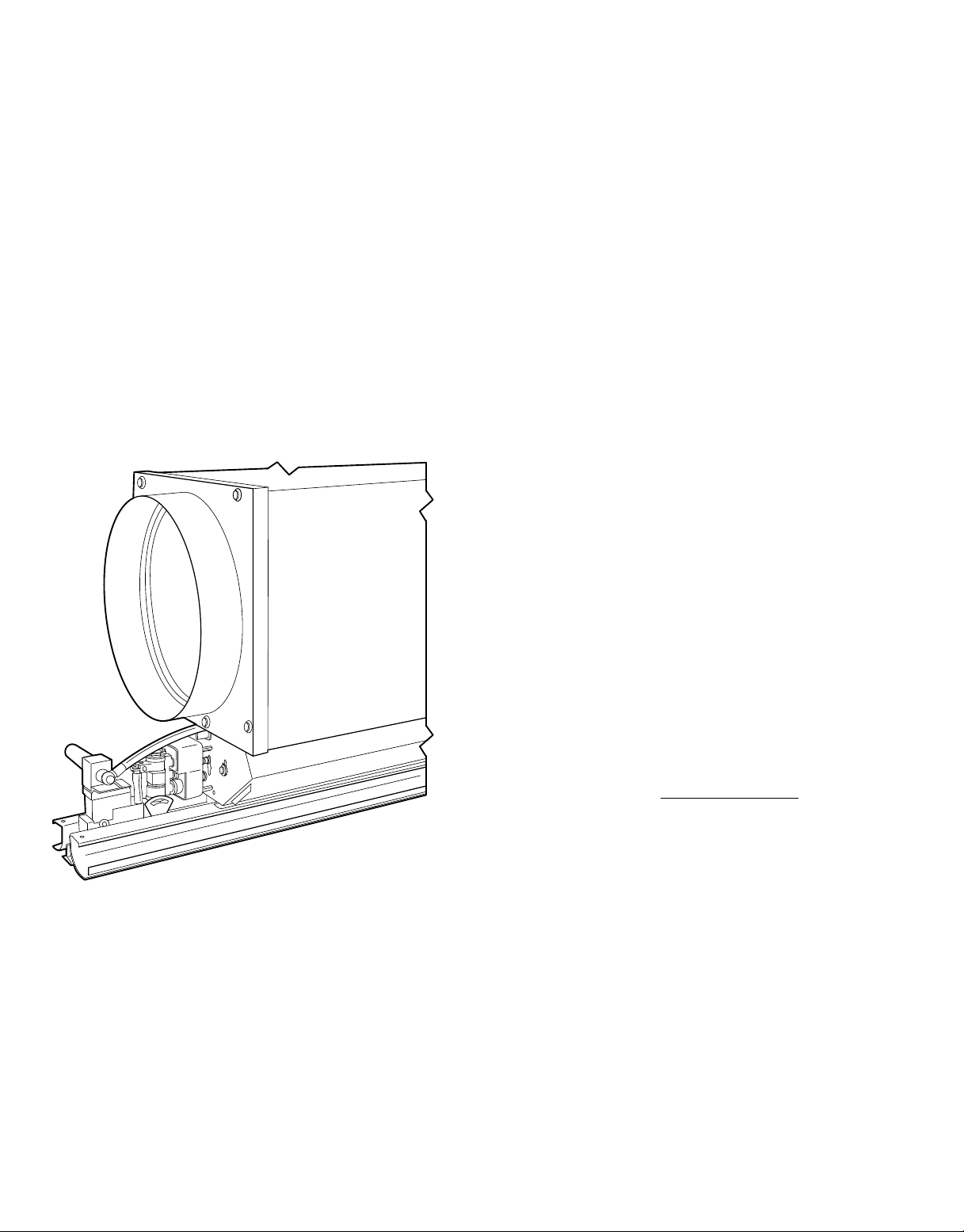

tenant requirements change, and the quiet, linear slot distribution integrates well in most commercial ceilings. Figure 2

shows a 37HS Moduline unit with variable air volume (VAV)

controls.

The basic Moduline terminal control system is system powered; the distribution duct pressure provides the energy to

operate the devices that control all the units in the system.

This system can be thought of as reactive. The control reacts

to changes in occupied space conditions and to changes in

supply duct airflow and pressure, and adjusts the unit valve

to maintain preset airflow or flow proportional to the room

load.

It is also possible to apply directive controls, both pneumatic and electric, to the Moduline terminal. In these applications, the Moduline control system is still system powered. The difference is that now the space can be controlled

by other sensors and devices, replacing the reactive control

devices.

This application data book provides design guidance for

layout of a Moduline system. All aspects of the unit application are included: Unit layout, control location, control

characteristics, control system options and air distribution

characteristics. This book covers both system-powered control and system-powered with electric or pneumatic interface controls. Application information for Carrier’s electronic

Product Integrated Controls (PIC) can be found in a separate

publication. (Moduline units with PIC controls can be controlled as part of the Carrier Comfort Network [CCN] system.) Sound power levels and sound applicationdata are found

in the 37HS Sound Application Data book. Specific mounting and installation data is found in the 37HS Installation,

Start-Up and Service instructions or, for PIC units, in the

37HC Installation, Start-Up and Service Instructions.

BUILDING LOAD CALCULATION

Cooling —

lay out the building air distribution system, it is first necessary to calculate the building cooling and heating loads

which the Moduline terminals will offset.

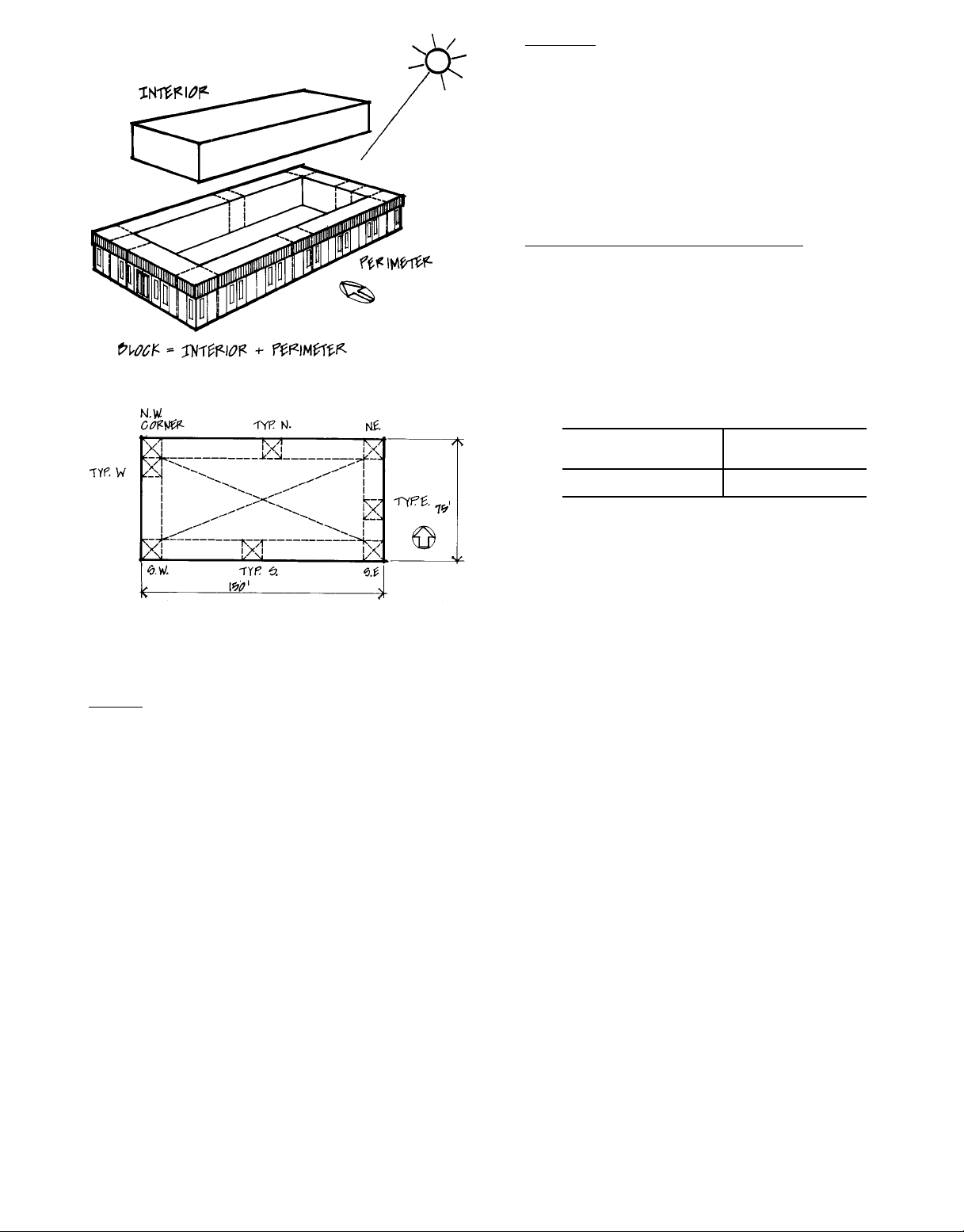

The first step is to determine the complete ‘‘block’’ load

for the building in order to size the fan, cooling equipment

and trunk duct. This estimate is for the month and hour of

greatest total building load. (See Fig. 3.)

The next step is to estimate each zone load (sensible heat

only). These are used to size the terminals and run-out ducts.

The zone peak load estimates are for different months and

hours, depending on zone window orientation. (See

Fig. 4.)

These calculations are made for a building which will utilize Moduline units in both perimeter and interior spaces.

The Moduline system supplies all building cooling. The heating system is described on page 20.

The object of making these load estimates is to arrive at

the required air volumes, so that the system can be designed

and equipment selected.

The airflow through a variable volume system is constantly changing in response to the changes in the building

cooling loads. At any one moment the airflow to each temperature control zone is determined by the room sensible heat

cooling load (RSH), the supply air temperature (T )

and the room thermostat setting (T ), as shown in the following equation:

In order to select Moduline equipment and

SA

R

Fig. 2 — 37HS Unit With VAV Controls

Zone cfm =

*1.09 is constant in this formula.

The fan airflow at the same moment is the sum of all the

zone airflow rates. (Duct leakage is assumed to be negligible

because of the high quality duct construction required by VAV

systems.)

2

1.09* (T − T )

RSH

RSA

Page 3

Fig. 3 — Estimating Block Load

Oversizing — Oversizing of variable volume systems results in unused equipment capacity and worse performance

at part load, not in increased system airflow.The actual system operation will reflect the actual system load, not the design load. If conservative data, safety factors, or provision

for future loads are included in the design estimate, the actual system airflow will not be increased. The equipment will

be capable of handling an increased load should it ever exist, but will automatically throttle back to handle only the

actual load at that moment.

It is recommended that safety factors not be included in

load calculations; they are notincluded in the following method.

Air Motion, Ventilation and Odor Dilution — Air motion,

ventilation, and odor dilution deserve special attention in the

design of a VAV system. The designer must visualize the

correct system operating condition in order to evaluate the

adequacy of these items at either full or part-load cooling

conditions, or during the heating season.

Room air motion is determined by the supply air quantity

and the diffuser induction ratio. The minimum room air velocity is higher if building humidity and temperatureare higher.

The design cfm at peak cooling load in any zone should be

not less than the minimum shown below:

Fig. 4 — Floor Plan of Typical Zones

for Single-Story Office Building

LOAD CONSIDERATIONS

Lighting — Even though lighting loads (Watts/sq ft) are con-

siderably lower in today’s buildings, the lighting is by far

the largest load component.

It is necessary, therefore, to pay close attention to getting

an accurate estimate of the lighting requirements.

In estimating the lighting load, special consideration should

be given to evaluating storage effect and the performance of

return air ceiling plenums. Both of these items reduce the

peak room load from lights and delay the time at which the

stored heat becomes a load on the central equipment.

DESIRED

ROOM TEMPERATURE

(F)

78

75

DESIGN CFM

AT PEAK COOLING

(cfm/sq ft)

0.7

0.4

These minimums are based on using the Carrier Moduline diffuser, which has very high performance; competitive

diffusers require a higher cfm/sq ft.

The outside air cfm requirement at maximum design conditions may be determined by local building code. If the outside air cfm to the central air handler is adequate to maintain

a low overall building odor level, the odor level in a particular space will depend upon the odors generated locally in

that space and the supply airflow to that space. A space with

high odor generation (a conference room with much smoking) should be provided with a separate exhaust system to

increase the air flow through the space for odor dilution. The

only way to increase the VAV airflow to that space would be

to add reheat to increase the room sensible heat, which is

unacceptable from an energy conservation standpoint.

The following odor dilution cfm (either VAV supply or

supplemental exhaust cfm) is usually adequate:

Private or General Office — 0.25 cfm/sq ft

Major Conference Room — 1.0 cfm/sq ft

3

Page 4

Supply Air Temperature — In systems using draw-thru air

handling units and high induction Carrier Modulinet terminal units, the acceptable range of supply air temperatures at

the terminals is from 50 to 54 F. The cooling coil ADP (Apparatus Dew Point) will be from 3 to 5° F lower than the

supply air temperature, due to allowance for coil bypass, fan

heat and duct gain.

The system installed cost for ductwork, central air handler, and VAV terminals will be greater if the air quantity is

higher because of the designer’s choice of a higher supply

air temperature. The increased fan air quantity will result in

higher fan operating cost, which may be offset by the lower

cost of operating the refrigeration system at a higher suction

temperature. The higher coil surface temperature (ADP) of

the system will result in a higher building humidity, which

will be less comfortable and require greater ventilation air.

An unduly low choice of supply air temperature may

result in unacceptably low room air motion in interior zones

with low lighting levels, and in unnecessarily low

humidity.

The same supply air temperature must be used for the zone

load and block load estimates.

Load Calculating Methods — The cooling load estimates can

be made very accurately and quickly using the Carrier E20-II

Block Load program.

Because of the computer’s speed, it is not necessary to

compromise the design procedure to obtain the most accurate result. The optimum design procedure listed here assumes the use of the E20-II program, and may require ‘‘short

cuts’’ when using manual methods.

While the E-20 program is the most convenient and rapid

method of load calculation, other methods will also provide

the required results. In particular, Carrier multi-room load

estimating form E-5056 is available for this purpose.

DESIGN PROCEDURE (with example)

Data Collection — Our example uses Cincinnati, Ohio as a

representative city. The building is a one-story office building with 11,250 sq ft. The building layout is shown in

Fig. 4 on page 3.

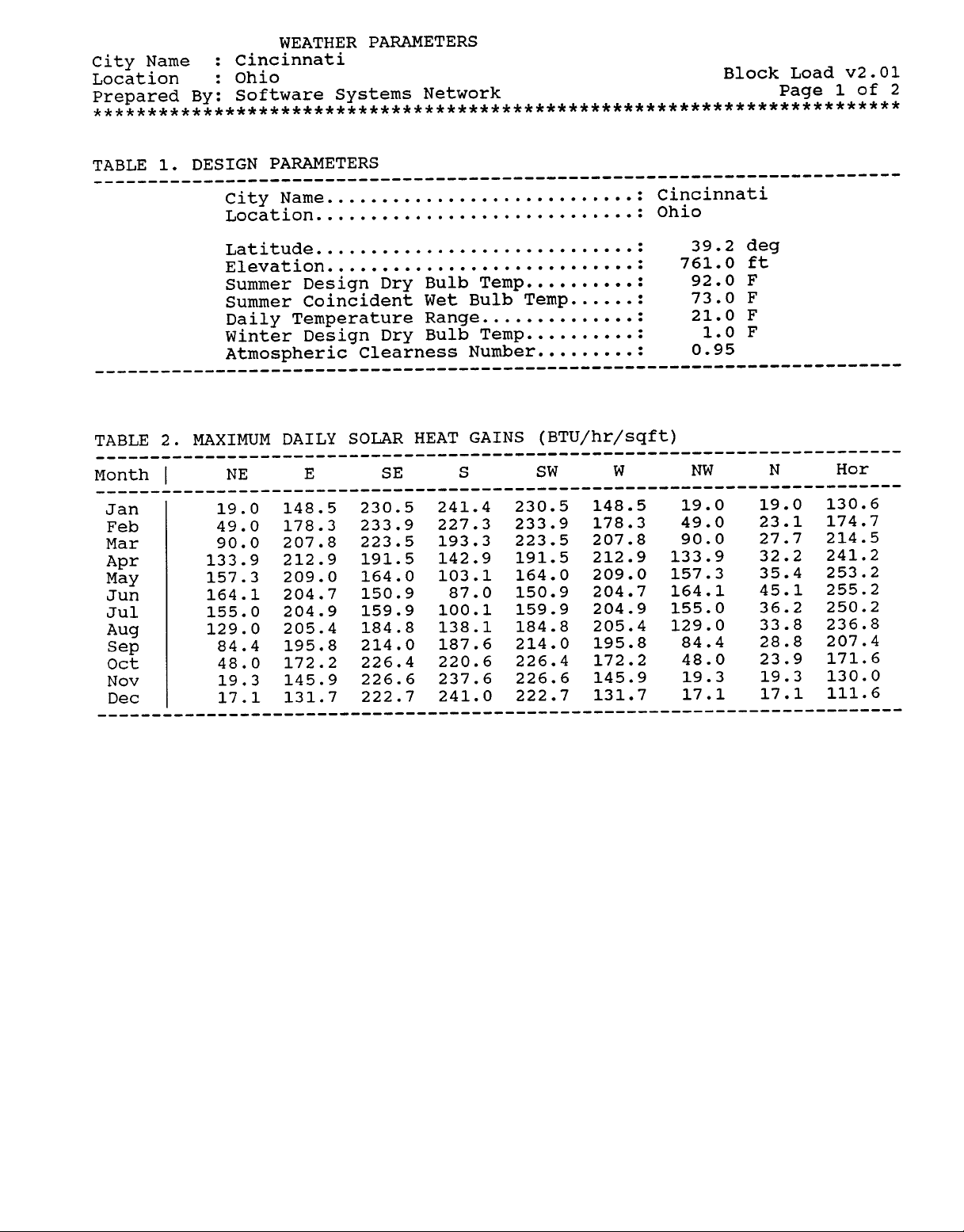

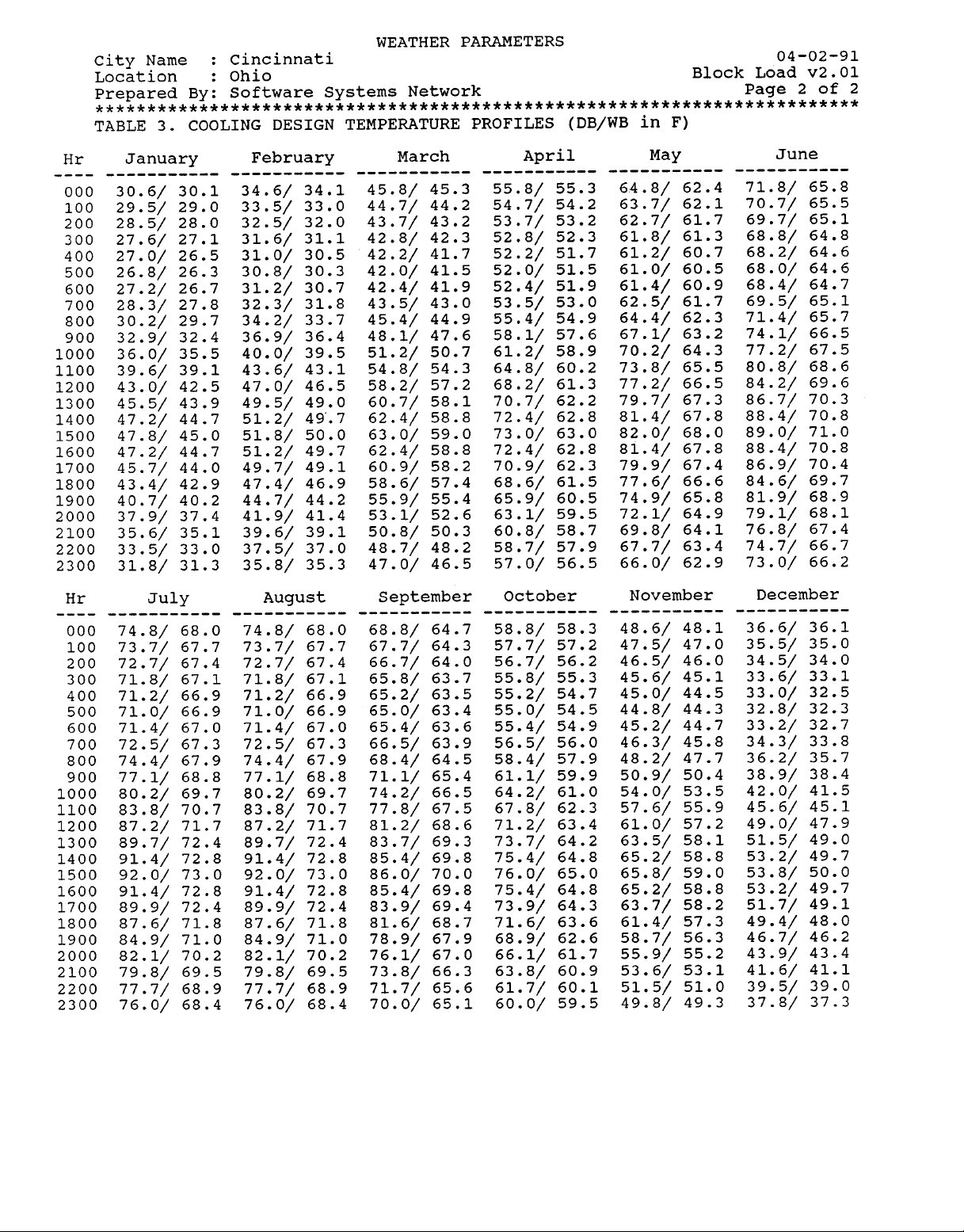

1. Using the E20-II Block Load Program, select Cincinnati

for its weather data. TheWEATHER PARAMETERSprintout shown on pages 5 and 6 shows the weather data used

for the load estimating calculations.

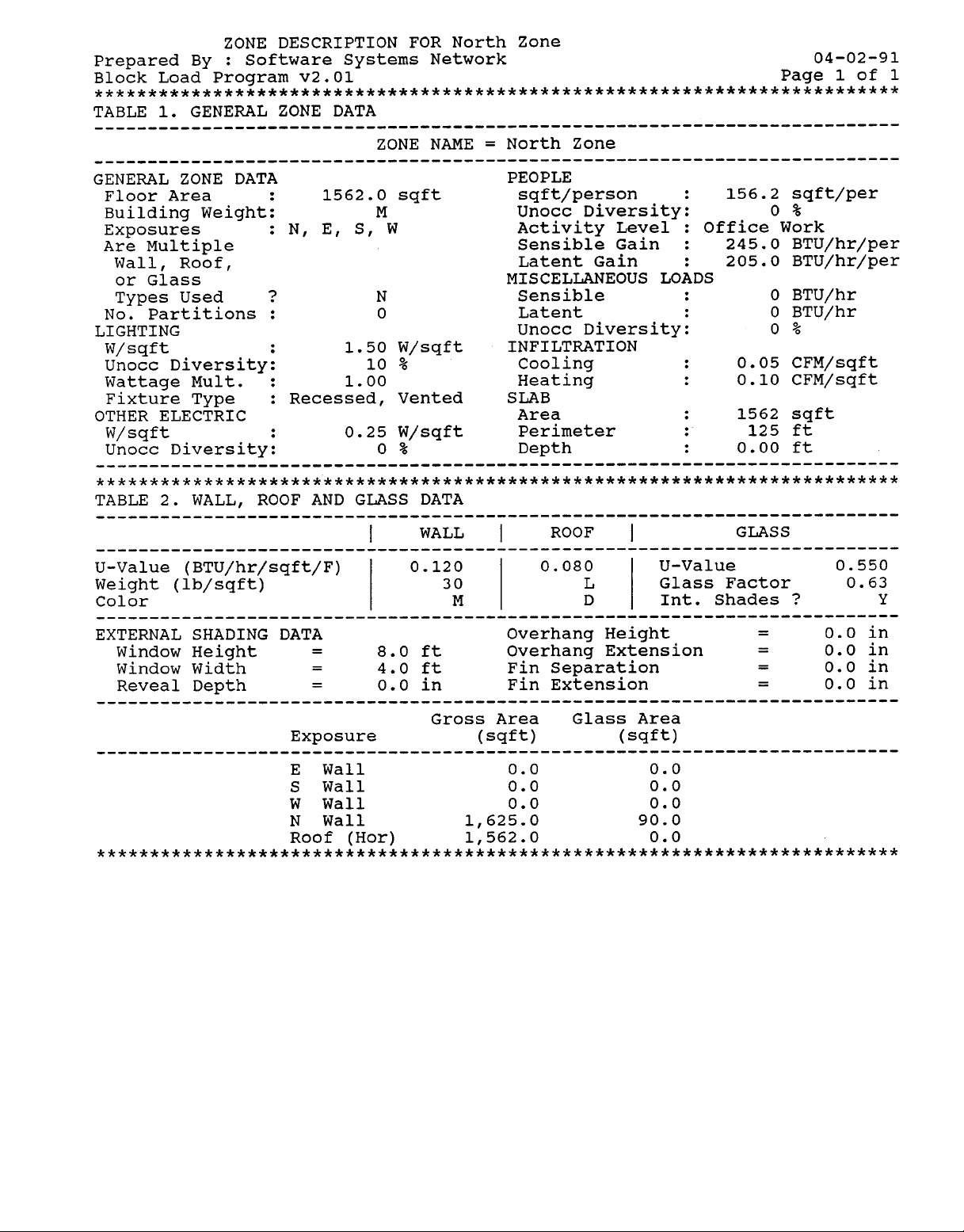

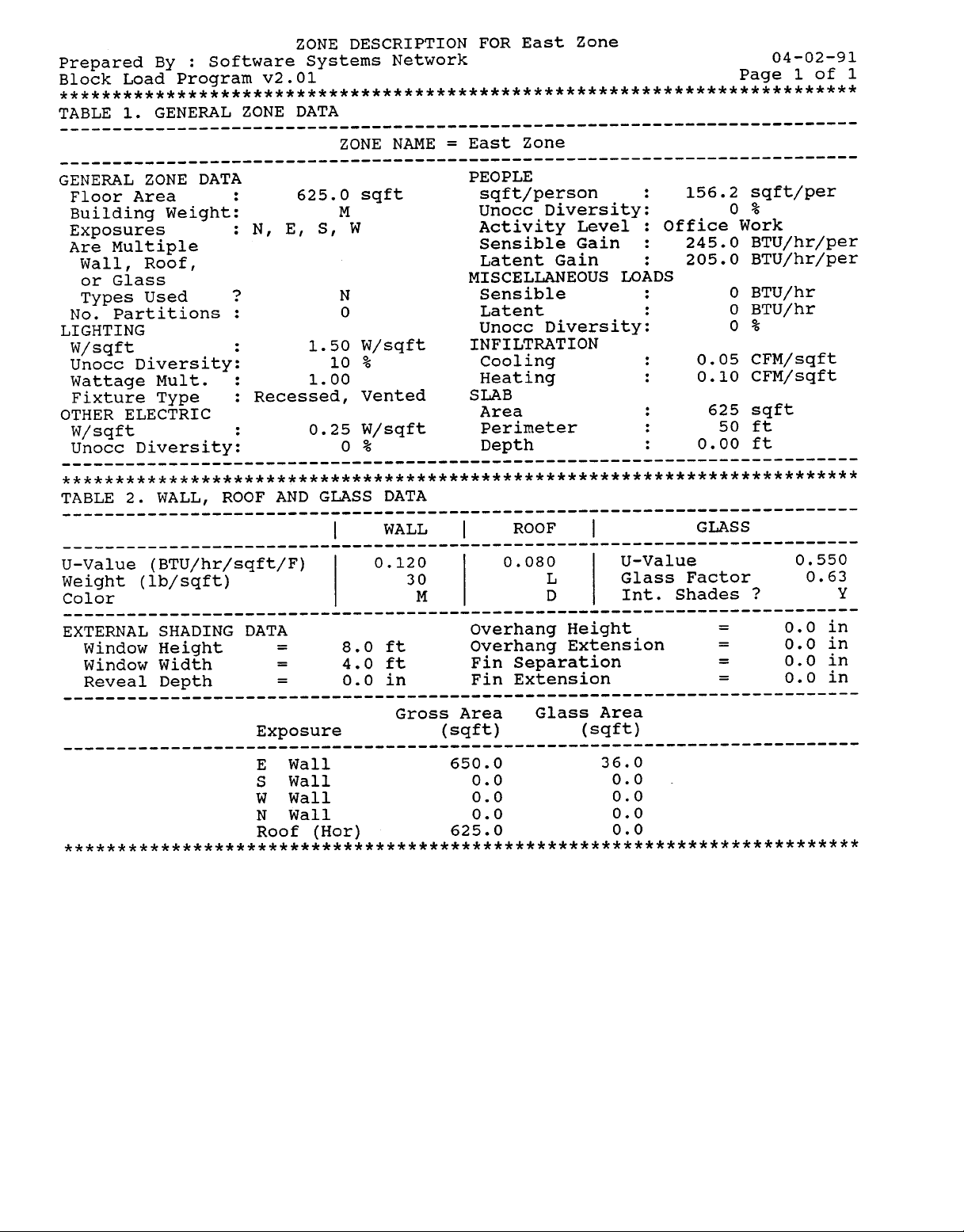

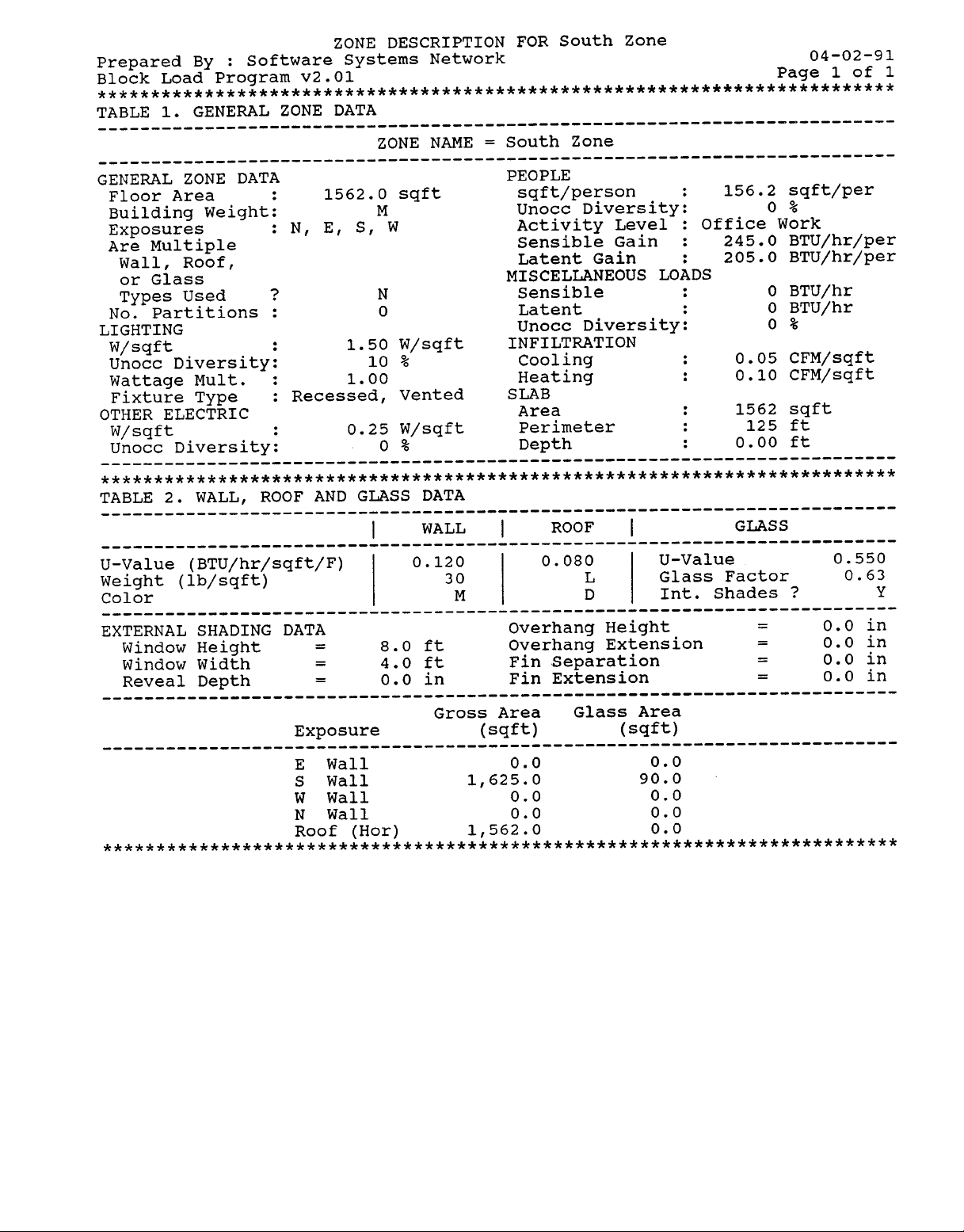

2. The next step is to gather data on the building, including

dimensions, construction materials used, internal load patterns (such as lighting levels) and the building orientation. For our example, we have divided the building into

nine zones. The actual building has ten zones on its north

exposure, but we’ve grouped them all into a single zone

because zones on the same exposure tend to have similar

load patterns. Similarly, the ten south exposure zones have

been grouped into a single zone, and the four east and

west zones have been combined into single east and west

zones respectively.

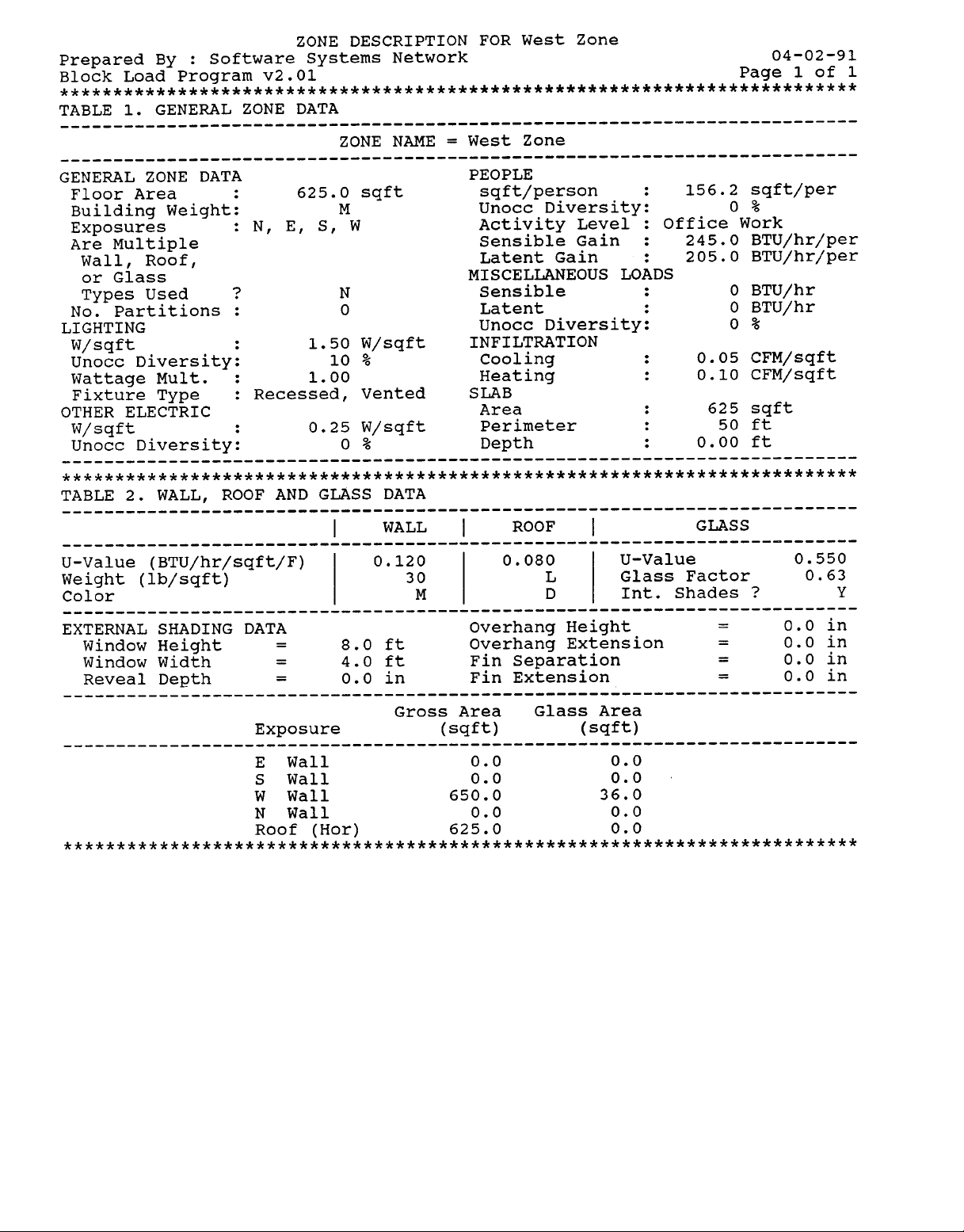

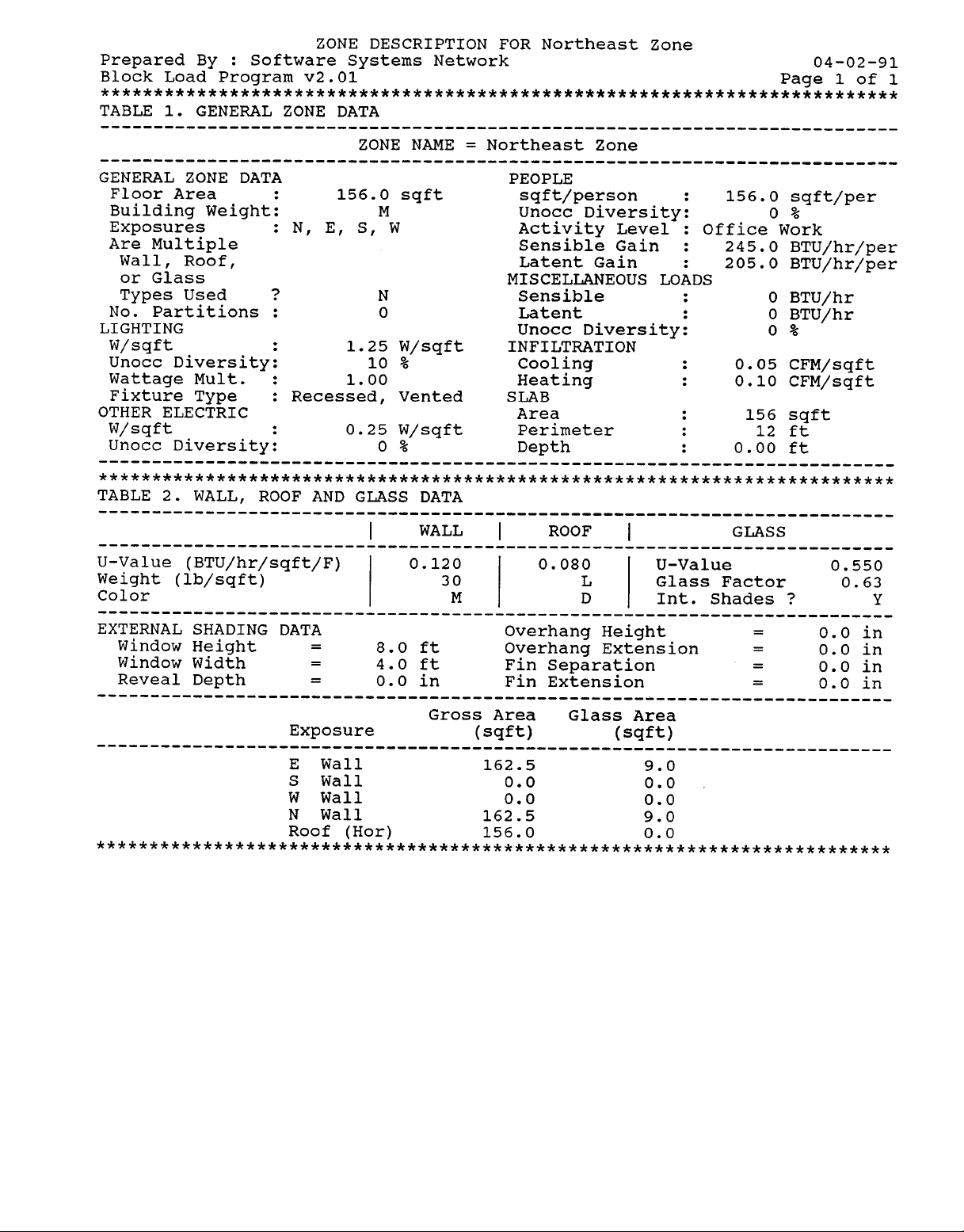

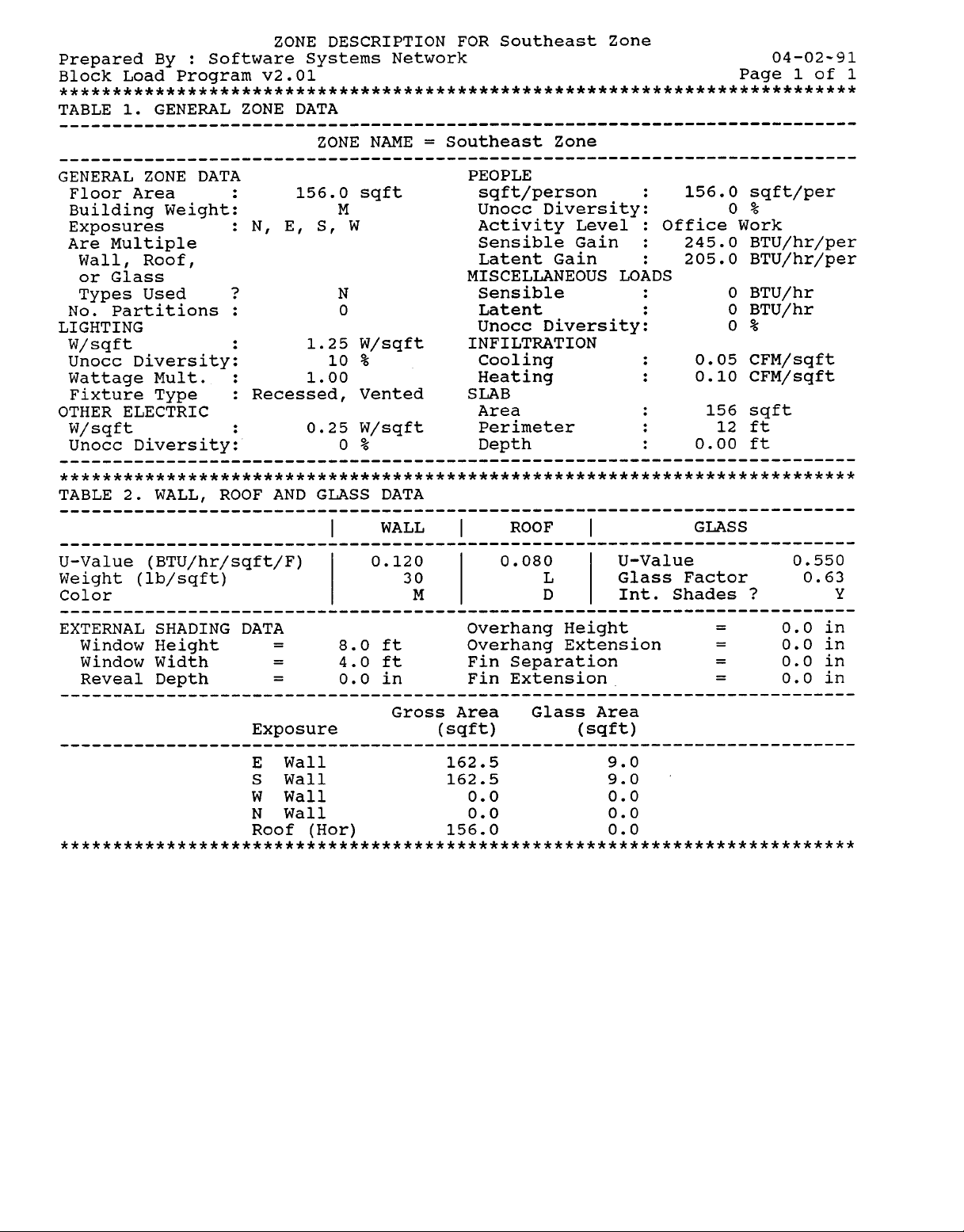

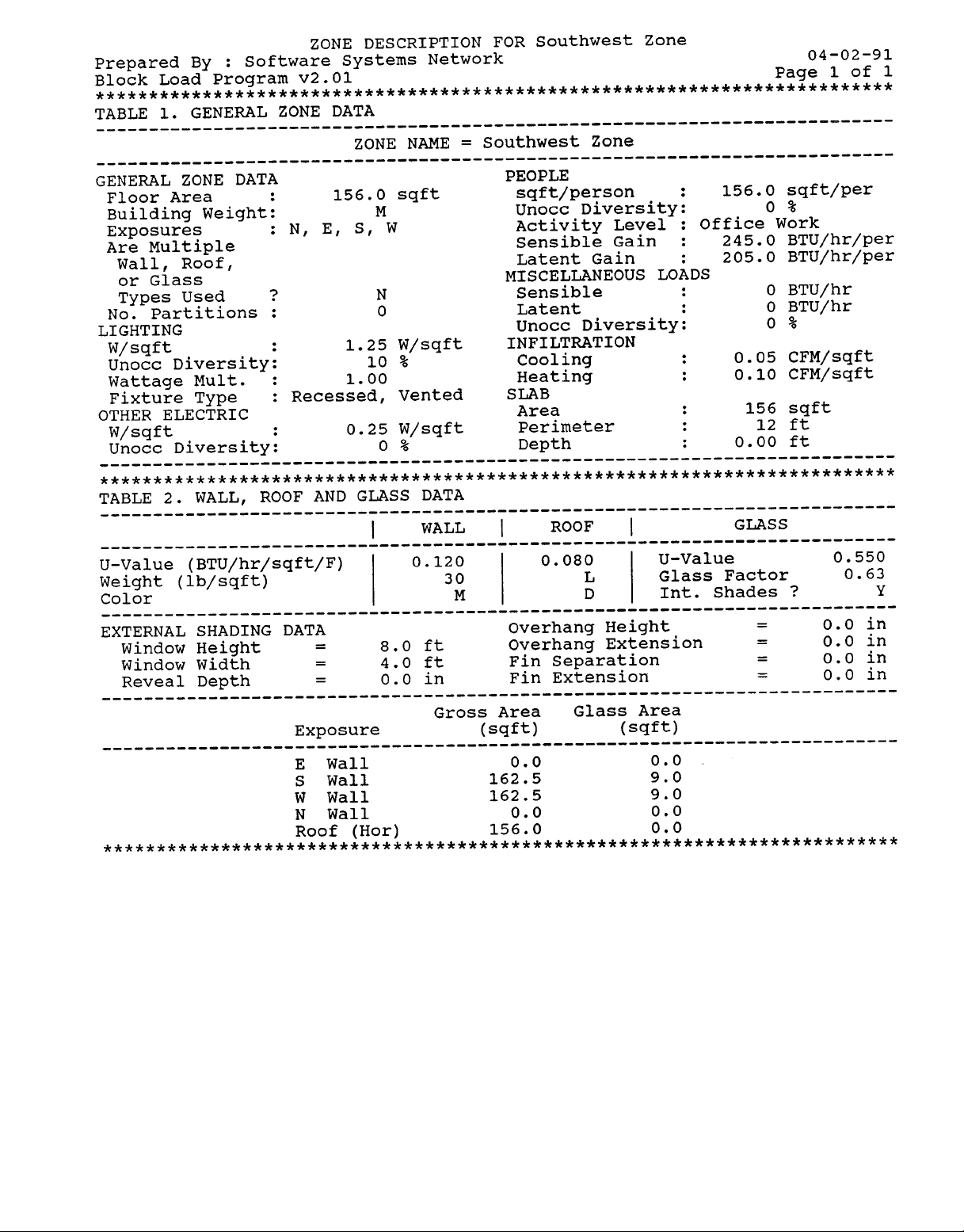

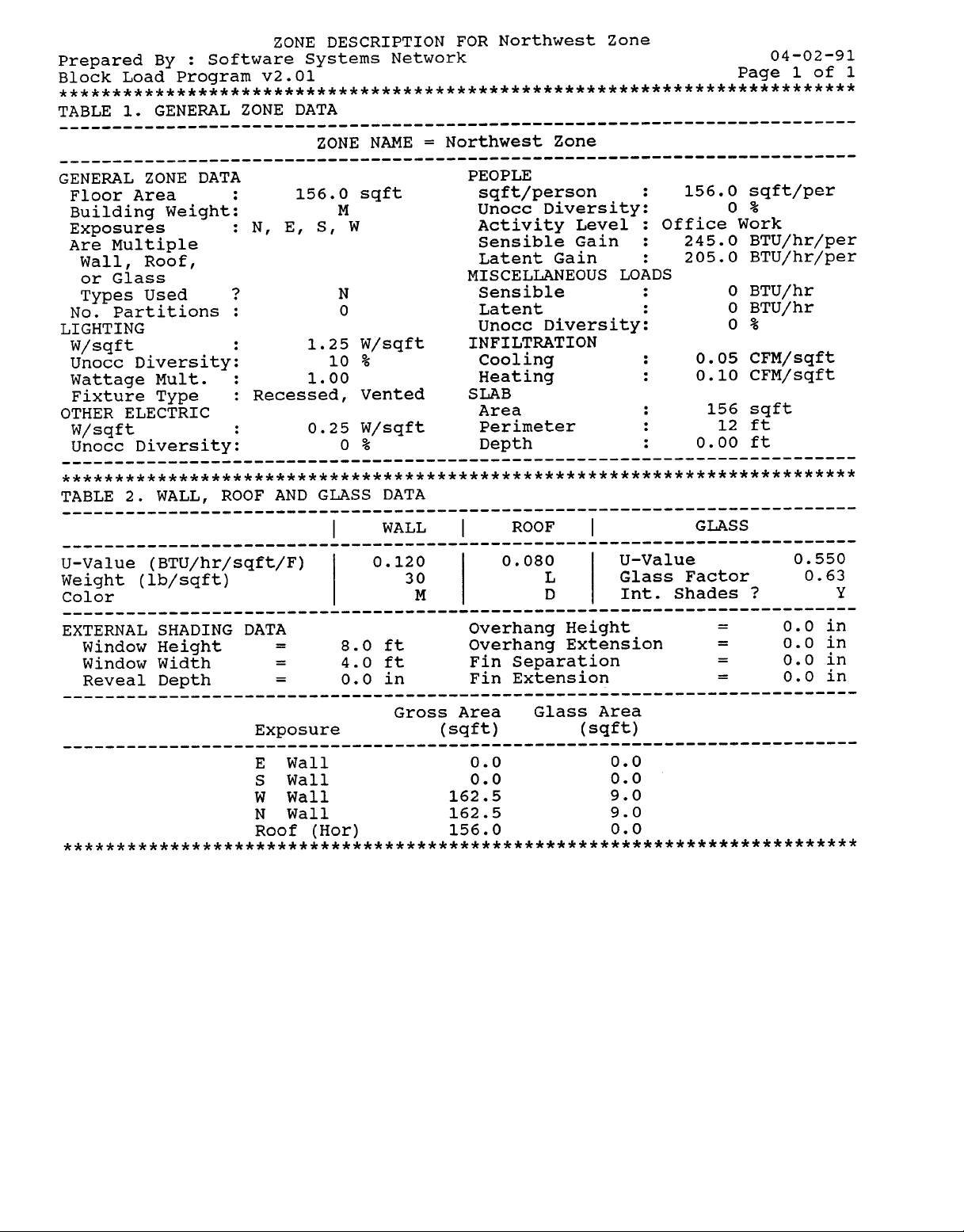

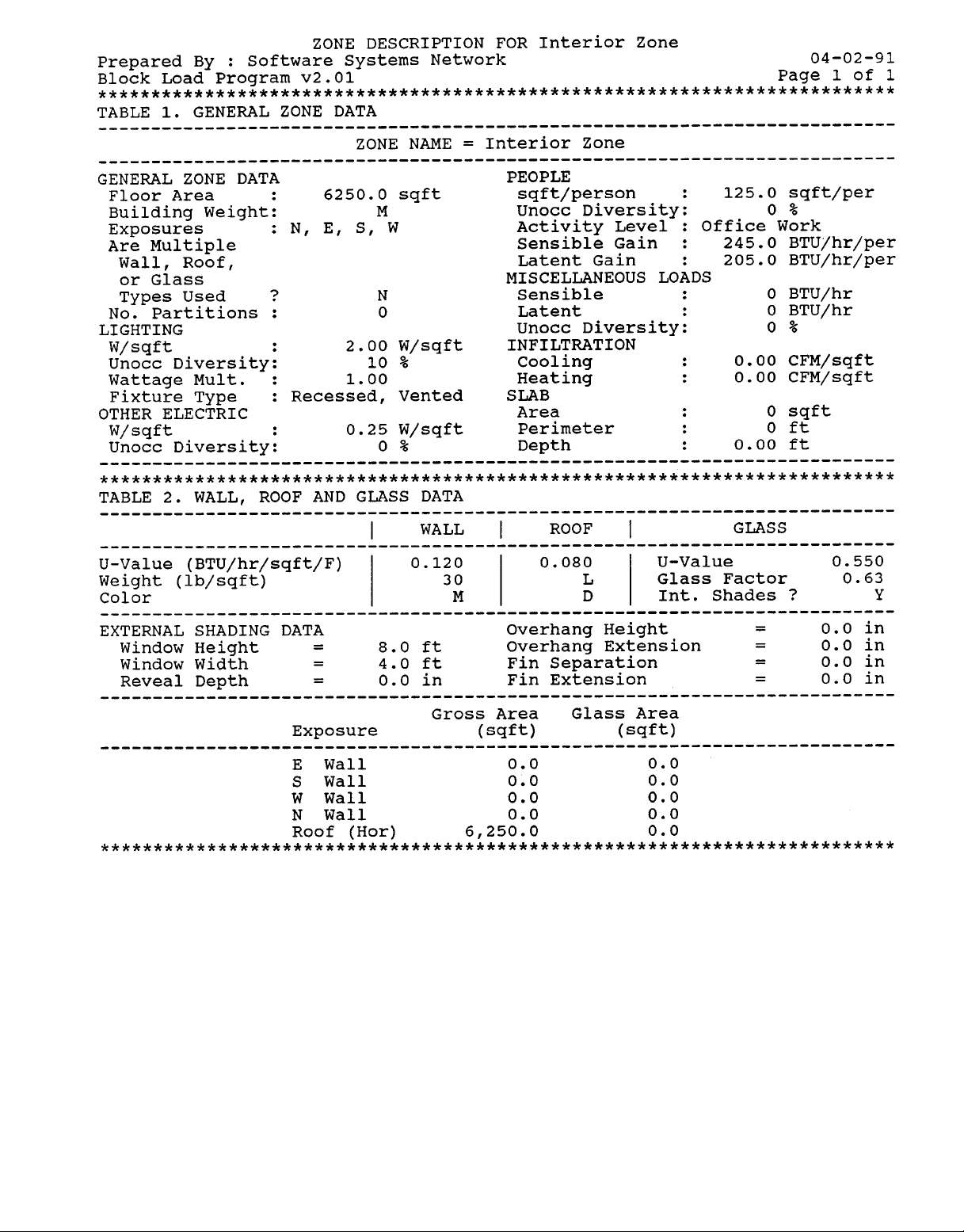

Pages 7-15 contain the ZONE DESCRIPTION printouts

for each of the nine zones.

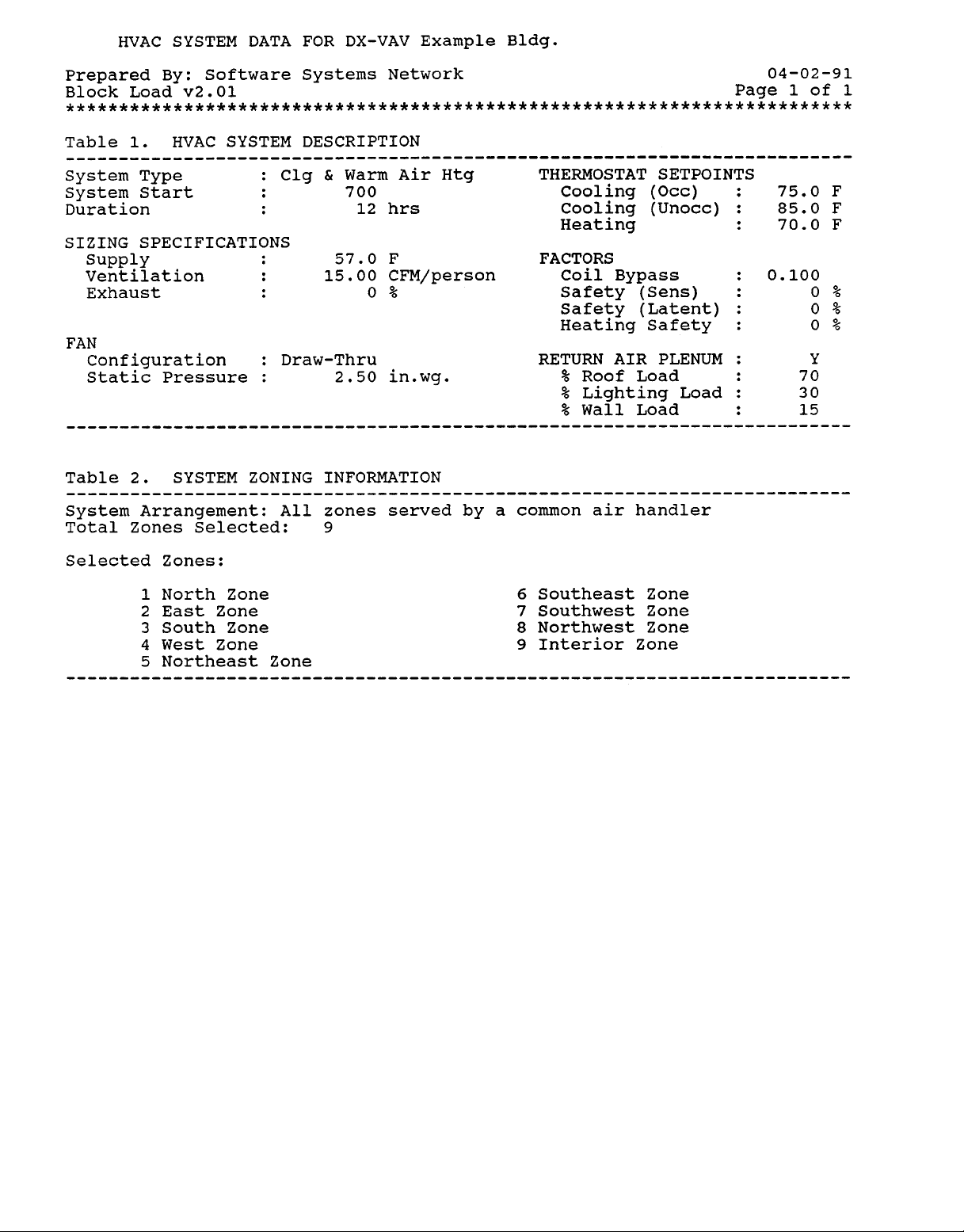

3. The final input step is to select an initial set of system

design data, including the cooling and heating set points,

the supply air temperature (or supply airflow rate, if that

is known) and the fan static pressure. This system design

data will, of course, be directly influenced by the actual

central station equipment, be it packaged or applied.

Page 16 shows the HVAC SYSTEM DATAprintout which

lists the system design data we’ve selected for this

example.

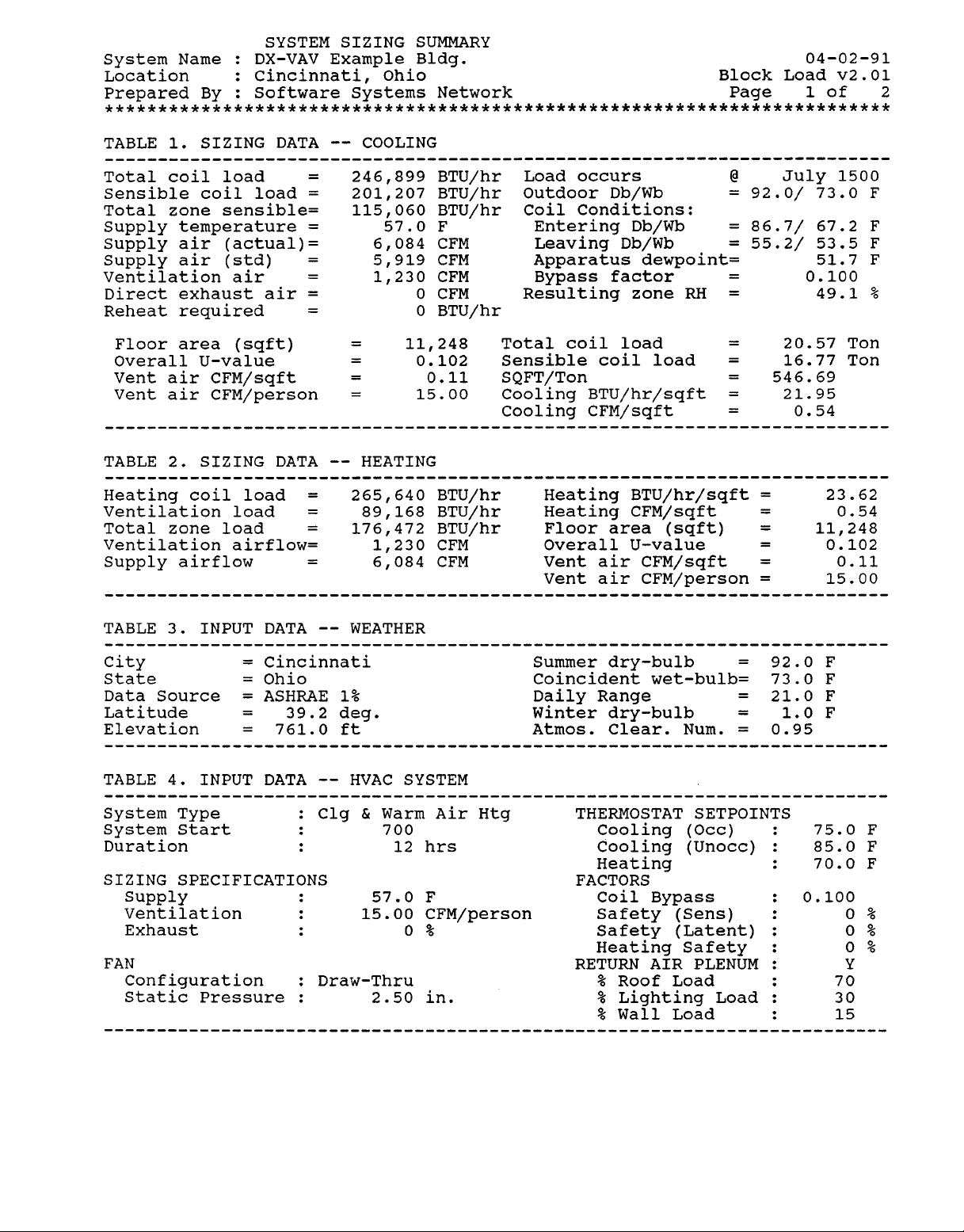

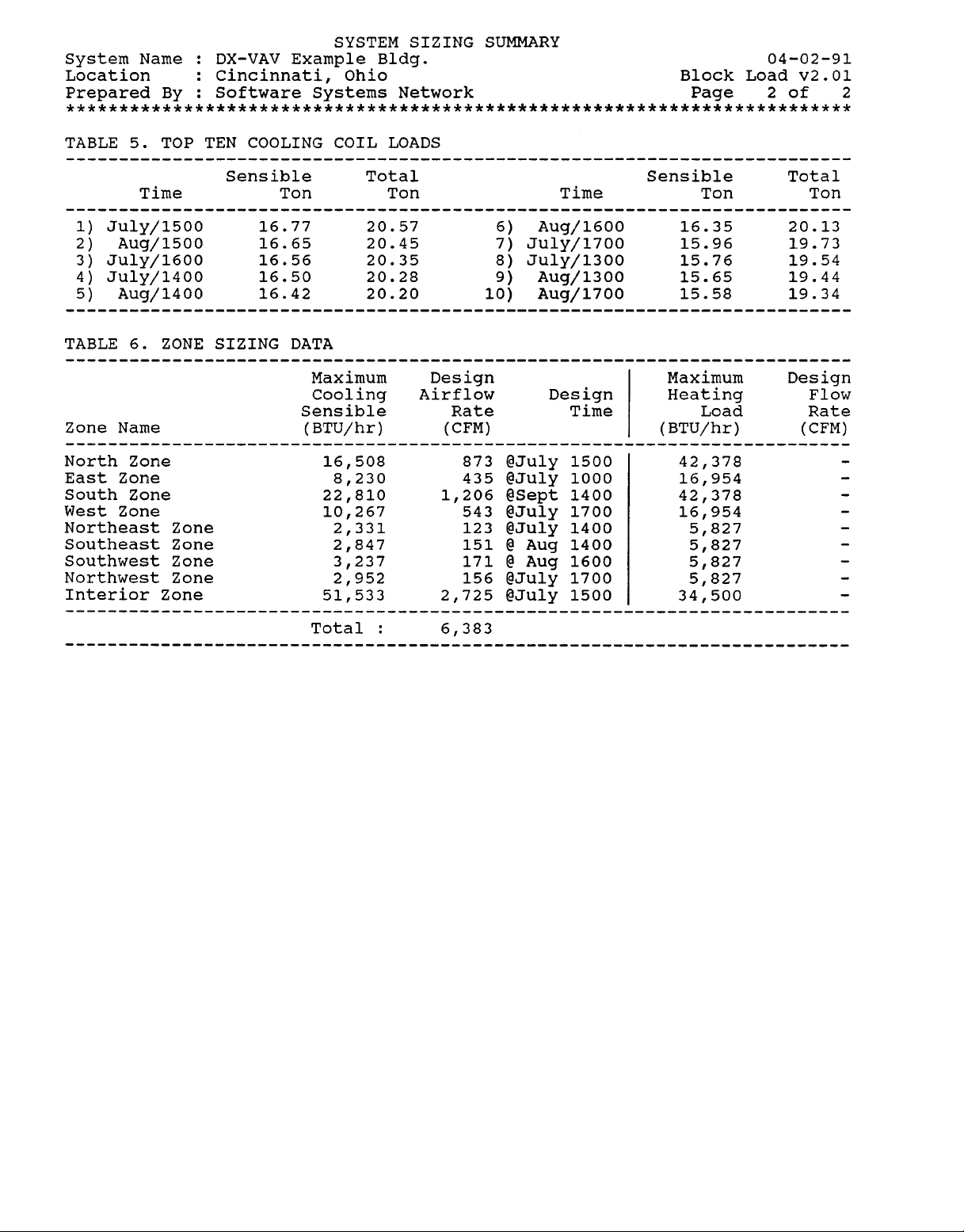

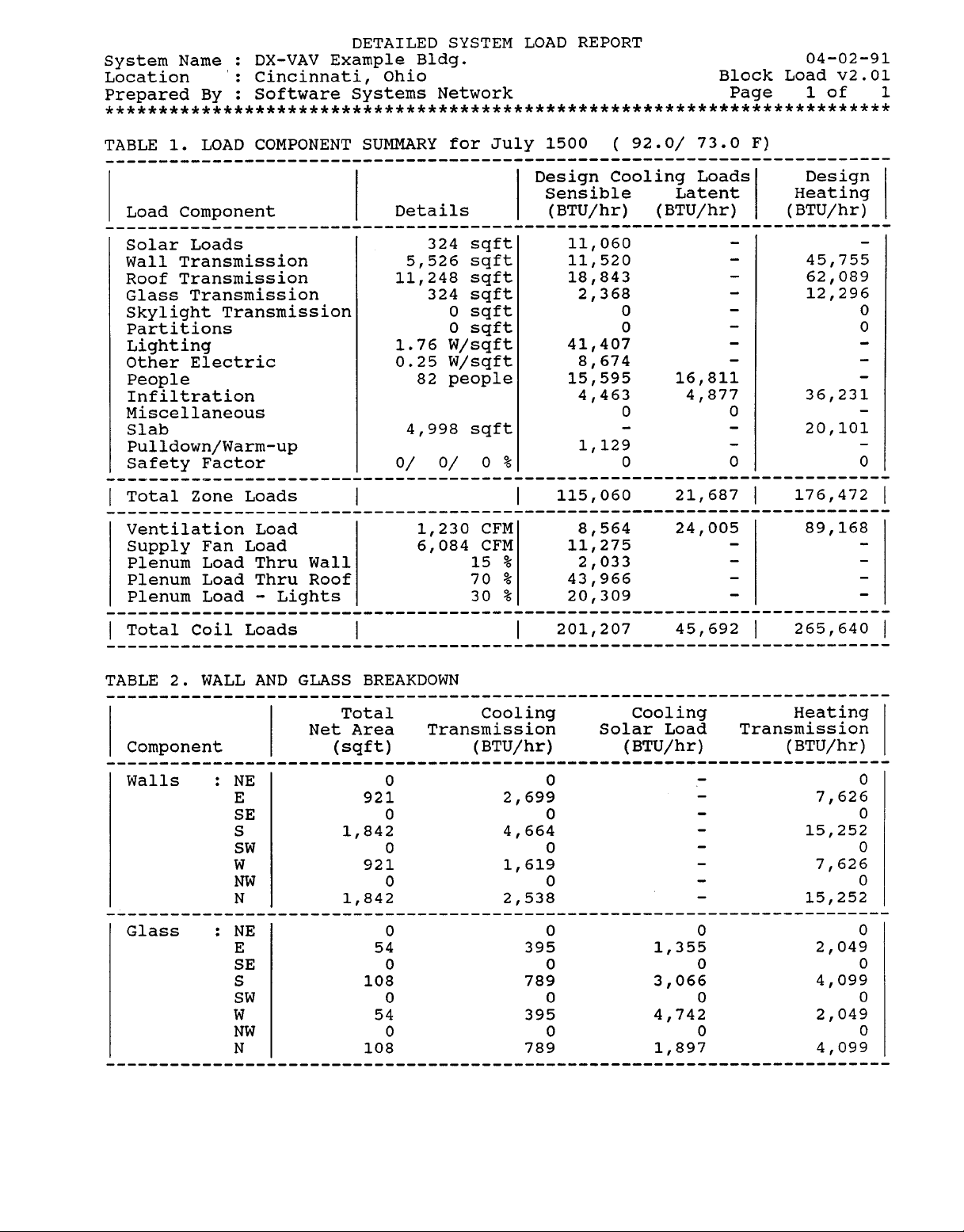

Load Calculations — With the input data from Step 1, the

Block Load Program calculates the building loads for each

month of the year to find the largest load on the building’s

air conditioning system. Typically,this will occur during the

middle or late afternoon hours in July or August. The

SYSTEM SIZING SUMMARY printout shown on pages 17

and 18 provides both the cooling and heating equipment sizing data. At the same time, it provides the maximum cooling

load, maximum heating load and design airflow rate for each

zone in the building. Notice that each zone may peak at a

month and hour different from that at which the HVAC system peaks. The detailed system load report is shown on

page 19.

4

Page 5

5678910111213141516171819

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

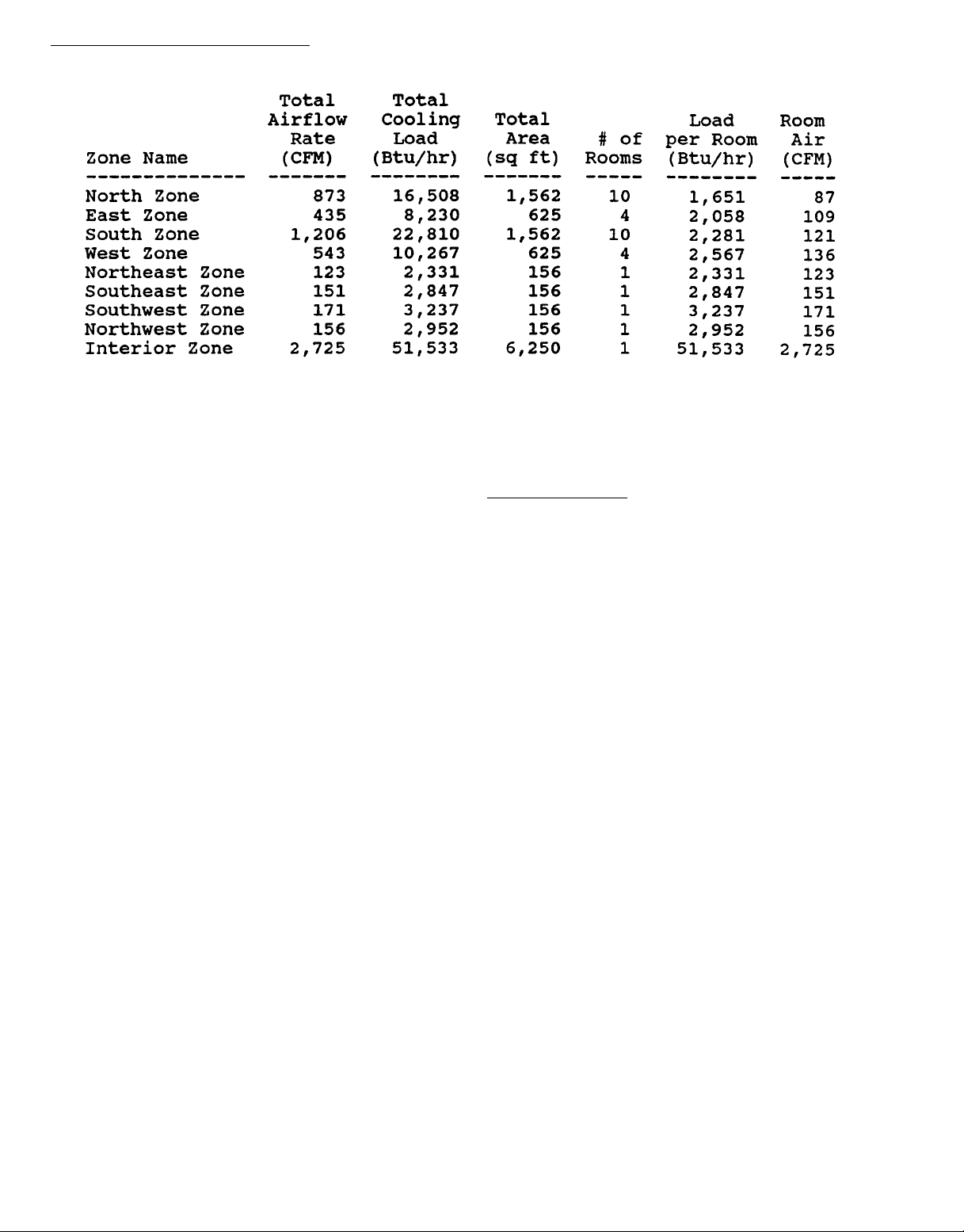

Modulinet Selection (Analysis of Data) — The printout shown below presents an analysis of the preceding data.

Heating — Heat must be provided in a building to offset

losses through the perimeter walls, windows, and roof. In

the interior spaces the heat gain from lights and people will

in many cases be enough to cause a cooling load even in

winter.

The two most commonly used heating systems are these:

• Baseboard

• Overhead air

Baseboard has been used historically in the North because

it is effective in overcoming the downdraft from windows,

particularly with the large single pane windows used in the

past.

Now, with improvements in the building thermal enve-

lope due to better materials and construction methods, overhead air heating is a viable and attractive alternative.

Overhead air heating, when properly applied, can handle

all requirements except the severe cases in which the wall U

values and temperature differences are large.

Overhead air heating is the method which will be con-

sidered for these procedures.

OVERHEAD AIR HEATING — Two basic forms of over-

head heating are used with Moduline cooling systems:

• Separate duct heating

• Changeover Moduline heating/cooling

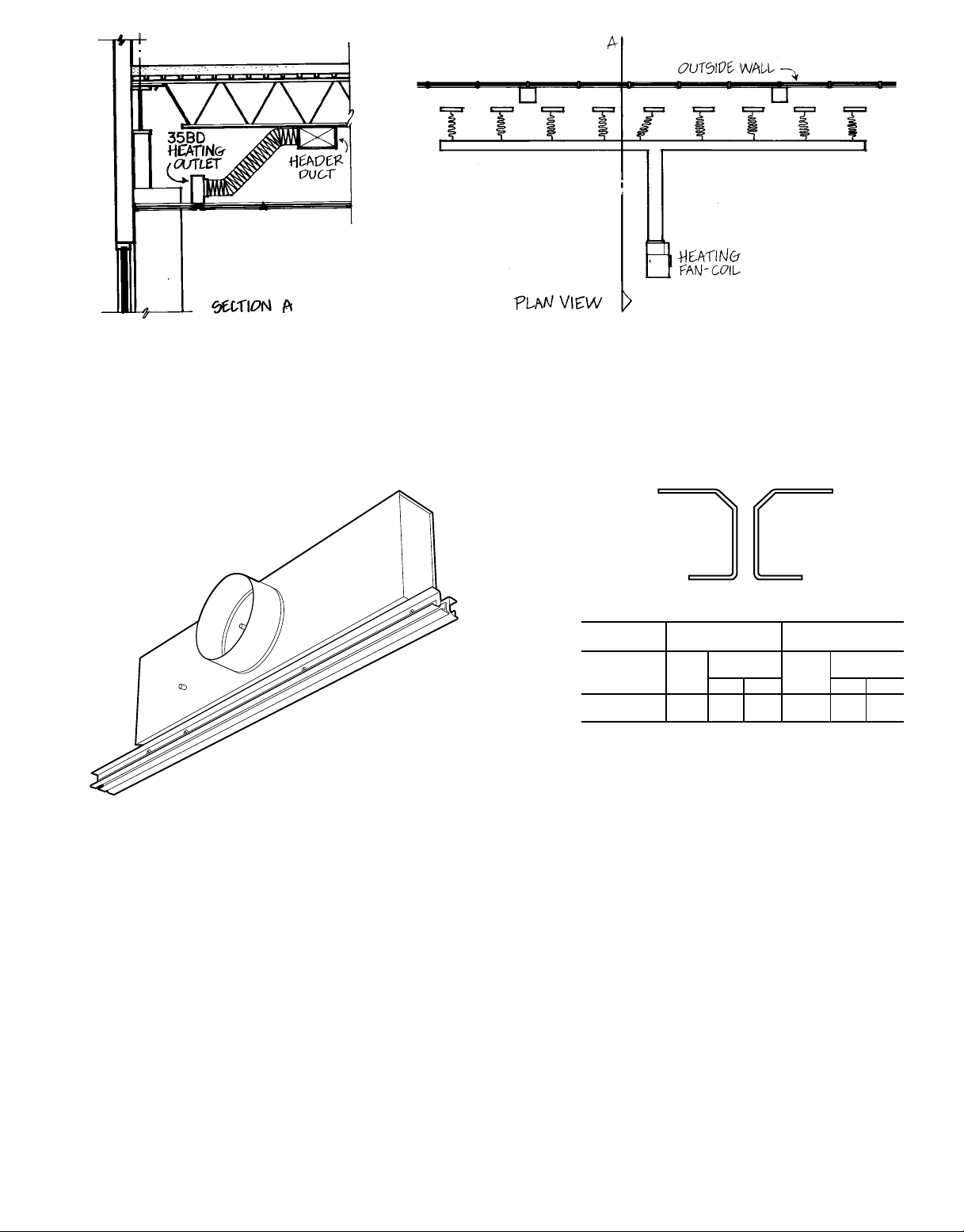

Separate Duct Heating — A simple type of overhead air heating system for use with a Moduline cooling system consists

of a series of ceiling outlets, placed around the perimeter of

the building close to the outside wall, which blow warm air

outward and/or downward to floor level. The outlets are connected by a simple duct system to an electric (or hot water)

heating-only fan coil unit located above the ceiling. (See

Fig. 5.) Aminimum of one fan coil unit per exposure is used

for each story of the building. The fan coil unit draws air

from the ceiling plenum and distributes it to the building perimeter by means of a separate duct system. This type of

heating system operates at constant volume.

The separate duct heating approach allows heat to blanket

the outside wall, eliminating the transmission of heat through

the outside wall and permits the Moduline cooling units to

be located in the best arrangement for cooling distribution.

Control interlock between separate system heating and Moduline cooling is outlined in the Control Applications section,

on page 44.

The 35BD heating slot boot diffuser (Fig. 6) is specifically designed for this heating approach and will provide excellent distribution of the hot air necessary to offset the load.

20

Page 21

Fig. 5 — Separate Duct Heating System

Performance Heating — Downblow Slot

NOMINAL

LENGTH (ft)

TYPE

DIFFUSER

Heating Slot

Boot Diffuser

NOTES:

1. Minimum and maximum show distance diffuser should be located from perimeter wall in inches.

2. For optimumperformance ofthediffuser,the airtemperature should

be held between 90 and 115 F.

24

Placement

Cfm

20-70 12 24 25-120 12 24

(in.)

Min Max Min Max

Cfm

Placement

(in.)

Fig. 6 — 35BD Heating Slot Boot Diffuser

21

Page 22

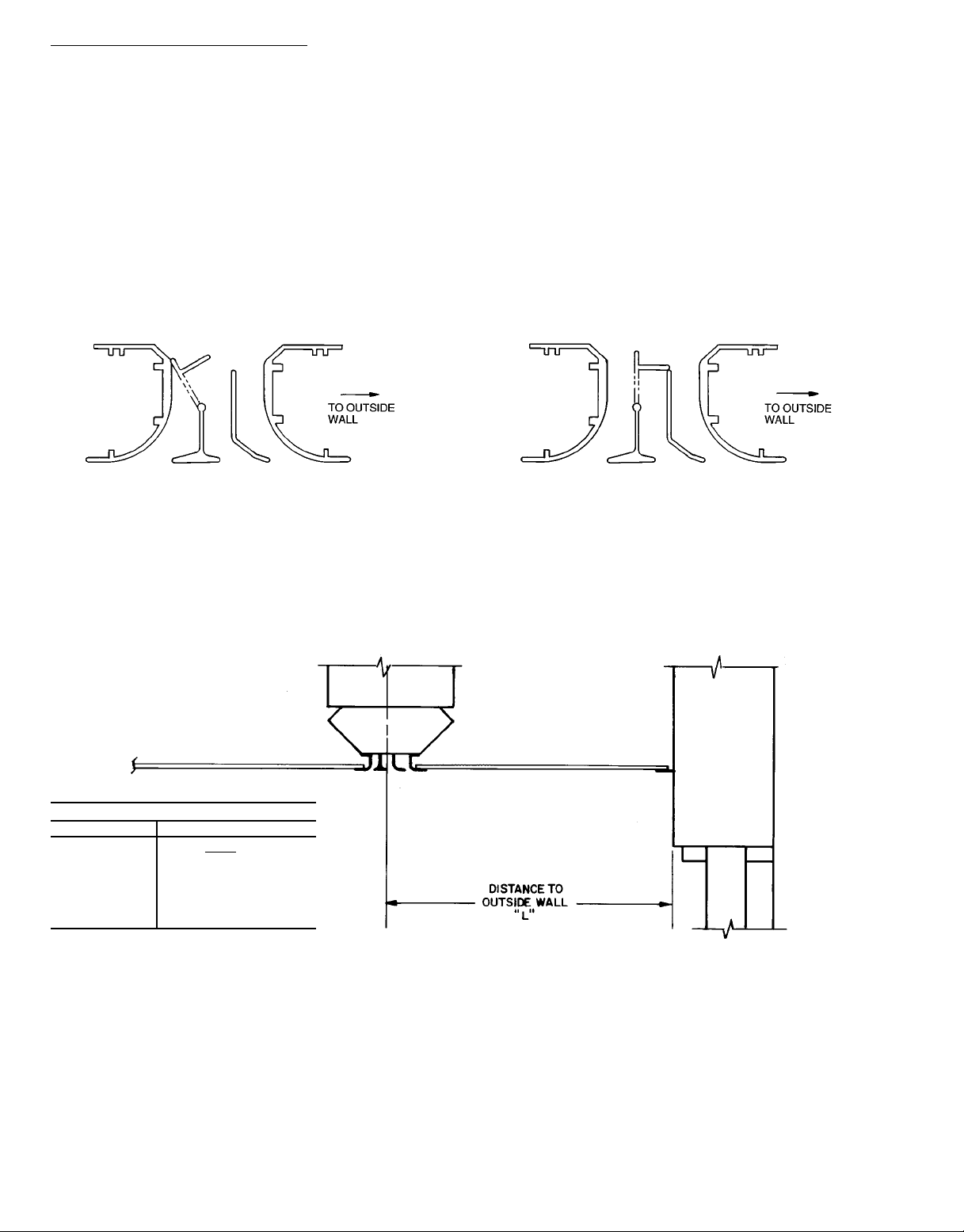

Changeover Modulinet Heating/Cooling — Both hot air and

cold air distribution are possible with a Moduline system.

The Moduline unit uses a director diffuser which, sensing

the duct temperature of the supply air, directs the air towards

or away from the perimeter wall. (Fig. 7.)

The Moduline location for heating and cooling requires

the unit to be a specific distance from the outside wall in

order to produce satisfactory distribution of the hot air. The

recommended location is shown in Fig. 8.

HEATING

With hot air in the duct, all discharge air is directed towards the

perimeter wall to offset the transmission.

Fig. 7 — Director Diffuser

COOLING

With cold air in the duct, the discharge is two-way blow — both into

the room and towards the wall.

DISTANCE TO OUTSIDE WALL ‘‘L’’

Minimum Maximum

2.5 Ft

M−H

L=

2

Where:

M = Max Throw

for Heating

One-Way Blow

H = Ceiling Height

Fig. 8 — Recommended Location for Changeover ModulineT Heating/Cooling

22

Page 23

Additional Guidelines for Heating — In addition to downblow slot boot diffusersand Moduline director diffusers, round

nozzles spaced along the perimeter wall will also provide

satisfactory overhead heating distribution. Some guidance for

outlet use are shown in Tables 1 and 2.

Moduline heating and cooling is less flexible than sepa-

rate duct system heating with Moduline cooling because:

• Moduline heating/cooling is a changeover system requiring complete replacement of the cooling duct supply air

with heated air, making zone control difficult.

• Moduline location is a compromise between obtaining outside wall coverage with hot air and good cooling

distribution.

Thus, separate duct heating can provide heat for a given

exposure without materially affecting the building cooling

system. The heating outlets and Moduline terminals can be

located in the most efficientair distribution places of the conditioned space.

Table 1 — Optimum Outlet Discharge

DIFFUSER SLOTS VELOCITY (Fpm) TEMPERATURE (F)

Downblow slots 500 to 1250 90 to 115

Round nozzles 900 to 1800 90 to 125

One-way blow slots 600 to 2200 80 to 105

Director Diffusers 800 to 2200 90 to 105

Table 2 — Location Guidelines

DIFFUSER STYLE

Round Nozzles and

Downblow Slots

One-Way Blow Slots 0.5 L†

Director Diffusers 2.5 L†

*Feet away from outside wall.

†See Fig. 8.

MINIMUM

DISTANCE (ft)*

1.0 2.0

MAXIMUM

DISTANCE (ft)*

TERMINAL SELECTION

AND LAYOUT

Introduction —

layout is one of the most important steps in the design process. This is where you use your knowledge to lay out the

job at a low cost and still give your client a satisfactory job.

There are 4 items which must be considered when select-

ing an air terminal:

• air volume (Cfm) per terminal — a function of 1) the desired sound level in the space, and 2) cost

• layout — a function of 1) the proper room air motion and

2) physical spacing

• unit combinations and run-out duct

• controller location

Selecting the terminals and making a

Definitions — Following are definitions of terms used

when discussing the layout of a Moduline system.

Moduline units are arranged as single units or as units in

an air series.

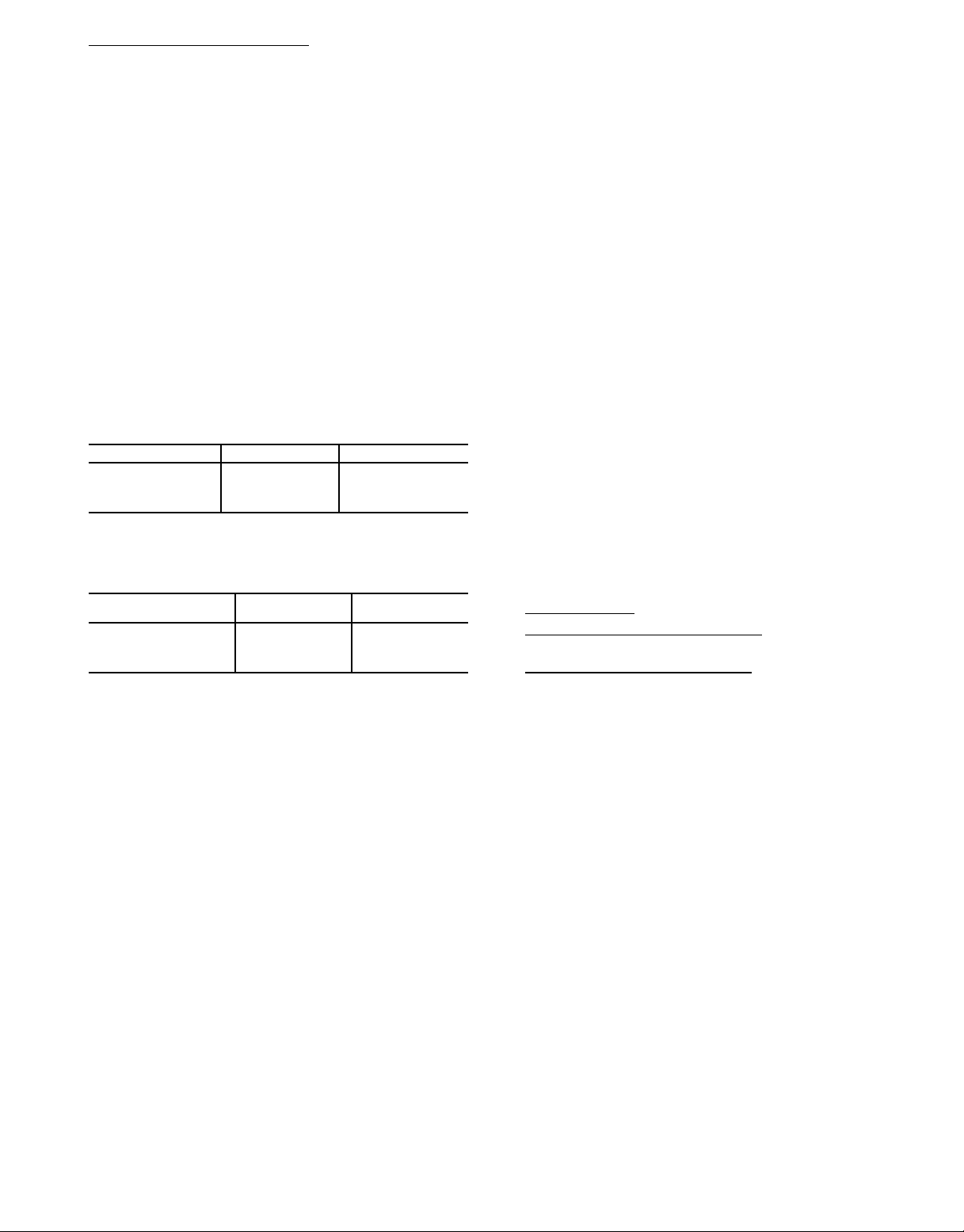

SINGLE UNIT — A single unit is connected to the supply

duct and supplies conditioned air to a space or part of a space.

Fig. 9.

AIR SERIES — Units in air series are connected unit-tounit or with interconnecting ductwork and the supply air for

all units enters the first unit in the series. Fig. 10.

MASTER UNIT — A Moduline unit with controller, alone

or in air series, is a master unit. Fig. 11.

SLAVE UNIT — A unit in air series, controlled by another

unit (master unit) is a slave unit. Fig. 11.

CONTROLS — System-powered controls are installed at the

jobsite and consist of the components shown below:

Constant Volume — Filter and volume controller.

Variable Volume, Diffuser Thermostat — Filter, volume con-

troller, thermostat with aspirator.

Variable Volume, Wall Thermostat — Filter, volume con-

troller, wall thermostat.

23

Page 24

Fig. 9 — Single ModulineT Unit Connected to

Supply Duct

Fig. 10 — Moduline Units in Air Series

Fig. 11 — Master Unit and Slave Units

CONTROL END — The control end of a Modulinet unit is

the end containing a control block at the end plate of the

valve section of the unit. (Fig. 12.) The end of the unit opposite the control end contains a blank block. The control

end of the Moduline unit is at the longer of the diffuser projections from the plenum. In Fig. 13, the longer projection,

B, is the control end.

The filter, volume controller, and diffuser-mounted ther-

mostat are applied to the control end of a master unit.

Fig. 12 — Control Block

Fig. 13 — Control End of Unit

Step 1 — Determine Air Volume (Cfm) Per Terminal —

know the required air volumes (cfm).

Use the cfm per zone you obtained from the cooling load

calculation and, using Table 3, Recommended Maximum Cfm

Per Terminal, decide on the number of terminals you will

need in each zone.

Cost dictates that the fewest number of Moduline units be

used consistent with good design. The maximum cfm per

unit that can be used (to keep the total number of units down)

is mainly a function of maximum acceptable sound level.

Perimeter zones with glass in the east, west, and south

building zones have peaks of rather short duration (i.e. loads

vary widely during the course of the day and year). Therefore, a higher sound level can be tolerated for these short

peaks.

Before you can start making a layout, you must

24

Page 25

As a result, slightly higher maximum cfm per unit is allowed as compared to interior zones or the north perimeter,

which have relatively constant loads.

The maximum cfm per unit also is affected by the desired

sound level in the room and the type of use of the space.

For example, an executive office uses low sound levels

but the furnishings generally absorb more sound so the allowable cfm/unit is only slightly lower than other types of

rooms.

Table 3 — Recommended Maximum Cfm

Per Terminal

TYPE OF

SPACE USE

General

Office

Private

Office

Executive

Office

With

Carpet

With

Tile

37HS1 37HS2 37HS4

East

West

and

South

110 95 220 190 400 350

100 90 200 180 330 300

90 80 180 160 300 270

85 75 170 150 280 250

Interior

and

North

MODULINE UNITS

East

Interior

West

South

and

and

North

East

West

and

South

Interior

and

North

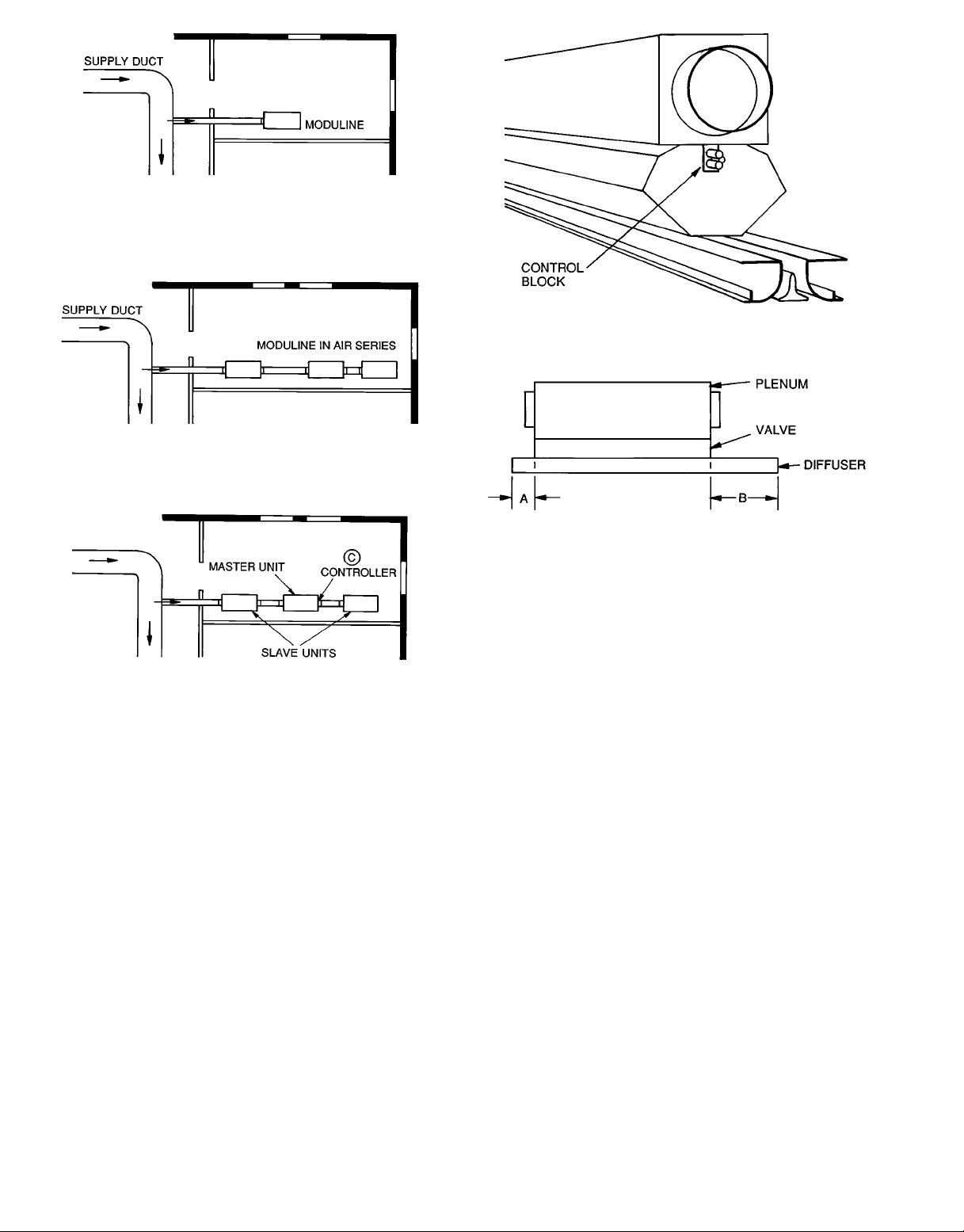

Step 2 — Lay Out Terminals

LOCATE UNITS IN T-BAR GRID — In making a layout,

begin with a plan view of the ceiling. Normally, the ceiling

grid and the lighting is done first and the diffuser plan must

fit the layout.

The center of the room is the ideal location, but where

that space has been reserved for lighting, the Moduline diffuser has enough flexibility to provide good distribution when

not centered in the room.

For a two-way blow diffuser, anywhere from the

to the1⁄4point (wall to wall) is usually suitable. Outside of

the1⁄4points, a one-way blow diffuser may be needed. Use

two-way blow diffuserwherever possible and one-way blow

only when really necessary. (See Fig. 14.)

1

⁄4point

Most jobs use a 2- x 4-ft grid T-Bar ceiling with 2- x 4-ft

or2-x2fttiles.

The first consideration in making a layout is to place the

terminals as economically as possible in the grid, which means

locating the terminals perpendicular to the main tees.

Main tees (the ones with hangers) are 4 ft on center (normally) and the cross tees are spaced 2 ft apart between the

mains to make up a 2- x 4-ft T-bar grid. Additional trim tees

may be used to divide the ceiling into a 2- x 2-ft grid.

The Moduline units use mounting brackets and hang from

(run perpendicular to) the main tees. While the units can be

installed anywhere between mains, the most common location is on the center line of the cross tee (replaces the cross

tee). The next most common location is half way between

cross tees. See Fig. 15.

While less desirable, the units can be run parallel to the

main tees. Unless absolutely necessary the units should not

replace the main tee because this means the main tee must

be cut. A location halfway between the mains is common

and in this case additional hangers are required to the upper

plenum of the unit or to the cross tee near the unit.

Special units are available for many other types of

ceilings.

Fig. 14 — Diffuser Locations for

Preferred 2-Way or One-Way Blow

Fig. 15 — Terminal Location

25

Page 26

EVALUATE THE THROW OF MODULINEt UNITS IN

POSSIBLE LOCATIONS — Check minimum throw for

2-way blow diffuser near walls and all one-way blow

diffusers.

Exceeding maximum throw is almost never a problem. A

2-way blow unit covers 50 ft at nominal cfm.

In perimeter rooms, if 2-way blow units are off center,

favor the exterior wall if possible.

Generally,one-wayblow diffusers should blow away from

the nearest wall.

Air throw data in Tables 4 and 5 for the Modulinet air

terminals provides the suggested minimum and maximum

coverages the units can handle in a typical installation while

maintaining the desired room conditions.

The optimum air throw values given in the table are distances from the unit centerline to the outside wall or nearest

obstruction (wall, light fixture, or opposing air stream).

When given a choice, always put diffusersin line with each

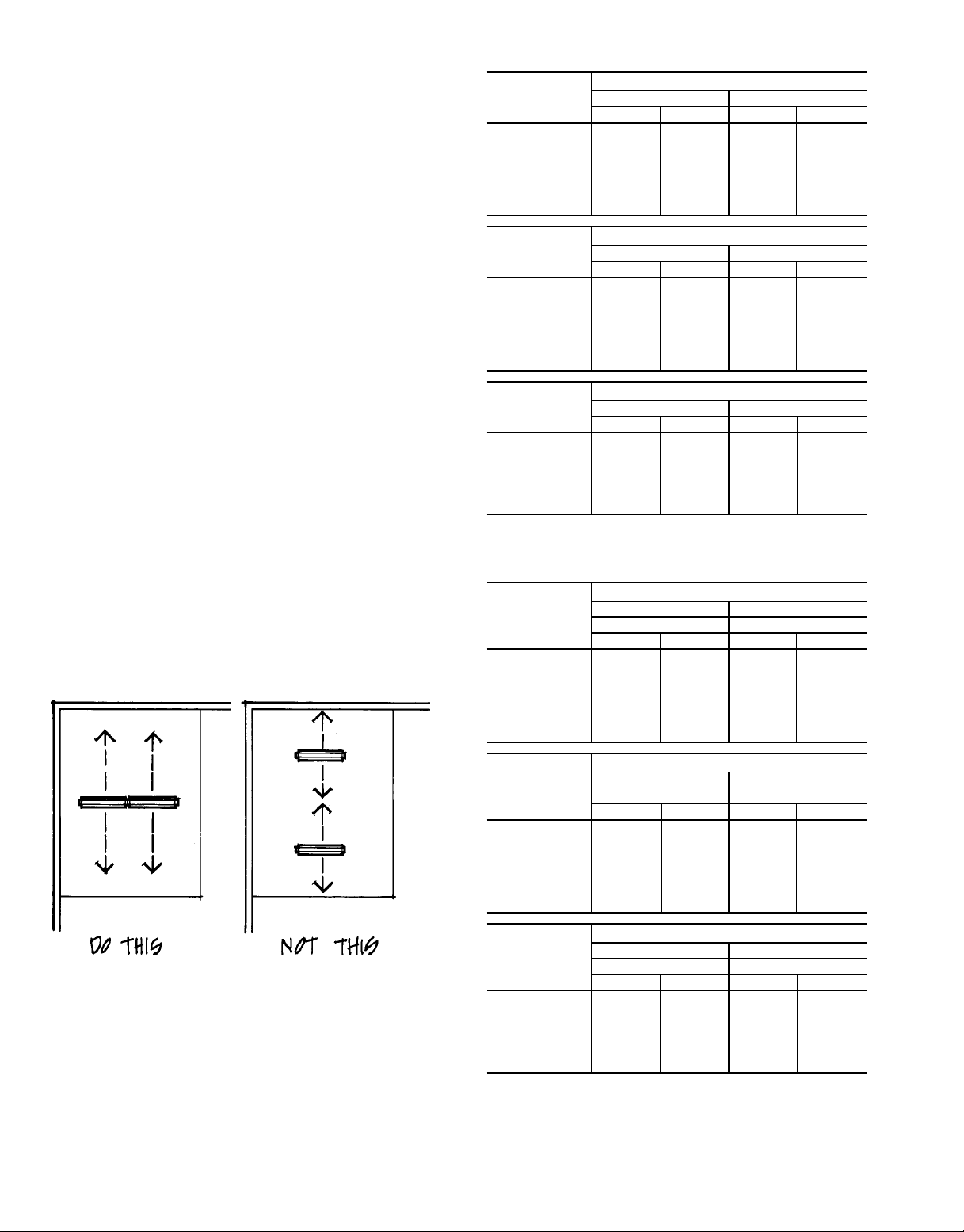

other, not blowing at each other. If diffusers must be placed

so they are blowing at each other, the minimum throw must

be checked. Do not put units closer together than minimum

allows. Down-drafts caused by going below minimum will

bother room occupants. (Fig. 16)

Modulinet units can be placed fairly close to a wall or

partition. This is because the down-draft follows the wall

(stays close to the wall) and doesn’t bother the room occupant. If furniture is placed against the wall near a Moduline

unit, it causes the air to be deflected causing drafts. The problem can often be solved by moving the furniture 6 in. or so

away from the wall.

Table 4 — Air Throw Data —

1-Way and 2-Way Blow, 2-Slot Diffusers

37HS1 UNIT

AIRFLOW

(Cfm)

40 2.0 7.0 2.0 5.0

50 4.0 9.0 3.0 6.0

60 7.5 12.0 3.5 7.5

70 8.0 15.0 4.0 9.0

80 9.0 18.0 4.5 10.5

90 10.0 20.0 5.0 11.5

100 11.0 22.0 6.0 13.0

110 12.0 24.0 7.0 15.0

37HS2 UNIT

AIRFLOW

(Cfm)

80 2.0 7.0 2.0 5.0

100 4.0 9.0 3.0 6.0

120 7.5 12.0 3.5 7.5

140 8.0 15.0 4.0 9.0

160 9.0 18.0 4.5 10.5

180 10.0 20.0 5.0 11.5

200 11.0 22.0 6.0 13.0

220 12.0 24.0 7.0 15.0

37HS4 UNIT

AIRFLOW

(Cfm)

160 8.5 16.0 5.0 7.0

200 10.0 20.0 6.0 10.0

250 11.0 21.0 7.0 13.0

300 12.0 22.0 8.0 17.0

350 14.0 23.0 9.0 19.0

400 15.0 25.0 10.0 21.0

440 17.0 29.0 13.0 24.0

OPTIMUM AIR THROW (ft)

1-Way Blow 2-Way Blow

Min Max Min Max

OPTIMUM AIR THROW (ft)

1-Way Blow 2-Way Blow

Min Max Min Max

OPTIMUM AIR THROW (ft)

1-Way Blow 2-Way Blow

Min Max Min Max

Table 5 — Air Throw Data —

2-Way and 1-Way Director, 3-Slot Diffusers

37HS1 UNIT

AIRFLOW

(Cfm)

40 2.0 7.0 2.0 5.0

50 4.0 9.0 3.0 6.0

60 7.5 12.0 3.5 7.5

70 8.0 15.0 4.0 9.0

80 9.0 18.0 4.5 10.5

90 10.0 20.0 5.0 11.5

100 11.0 22.0 6.0 13.0

110 12.0 24.0 7.0 15.0

OPTIMUM AIR THROW (ft)

Heating Cooling

1-Way Blow 2-Way Blow

Min Max Min Max

Fig. 16 — Locate Units to Prevent Down-Drafts

37HS2 UNIT

AIRFLOW

(Cfm)

80 2.0 7.0 2.0 5.0

100 4.0 9.0 3.0 6.0

120 7.5 12.0 3.5 7.5

140 8.0 15.0 4.0 9.0

160 9.0 18.0 4.5 10.5

180 10.0 20.0 5.0 11.5

200 11.0 22.0 6.0 13.0

220 12.0 24.0 7.0 15.0

37HS4 UNIT

AIRFLOW

(Cfm)

160 8.5 16.0 5.0 7.0

200 10.0 20.0 6.0 10.0

250 11.0 21.0 7.0 13.0

300 12.0 22.0 8.0 17.0

350 14.0 23.0 9.0 19.0

400 15.0 25.0 10.0 21.0

440 17.0 29.0 13.0 24.0

NOTES:

1. Minimum air throw refers to the distance from the diffuser where the air velocity is 150fpm. In maximum air throw,this velocity has dropped to 50 rpm.

2. Data is based on an area with a 9-ft ceiling. For higher ceilings, values may

be reduced by one foot for each foot of height increase. For specific installations, minimum values can be reduced if properly qualified. Values are

dependent on cfm only and are not affected by duct pressure.

OPTIMUM AIR THROW (ft)

Heating Cooling

1-Way Blow 2-Way Blow

Min Max Min Max

OPTIMUM AIR THROW (ft)

Heating Cooling

1-Way Blow 2-Way Blow

Min Max Min Max

26

Page 27

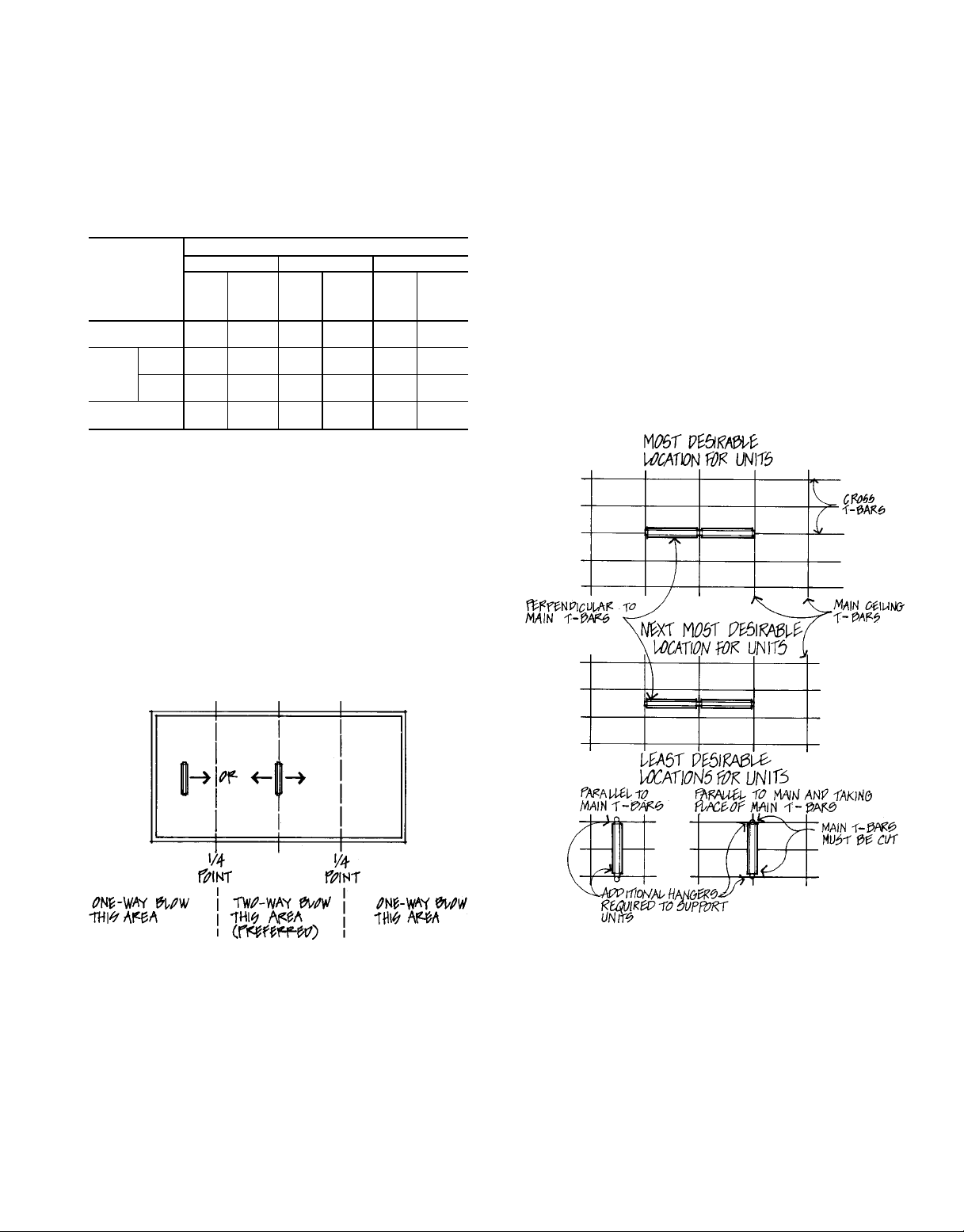

STAGGER SPACING — A frequently used layout method

is to stagger the units. This arrangement gives good coverage, solves the problem of drafts when units blow at each

other, and is low cost. It also gives good flexibility for future

partition changes. (Fig. 17.)

Fig. 17 — Staggered Units

MAXIMUM UNIT SPACING— Interior zones use less air,

as low as 0.4 to 0.6 cfm per sq ft. Using the large capacity

37HS4 unit at 250 to 350 cfm each may cause units to be too

widely separated. This results in poor coverage and poor air

distribution.

A good solution is to use a larger number of lower ca-

pacity 37HS2 units at 150 to 190 cfm each.

The maximum distance between units parallel to each other

(blowing at each other) can and should be fairly great, 25 to

45 ft. (See Tables 4 and 5.) But the maximum distance between the ends of the units in the same row must be more

limited for good coverage.

The unit will effectively cover a strip whose width is 3 to

4 times the unit’s length. A 4-ft unit would therefore cover

an area whose width is 12 to 16 ft (maximum). See

Fig. 18.

The high induction ratio of the Modulinet diffuser keeps

total room air motion up to acceptable levels when the cfm

per sq ft is low.

Step 3 — Consider Unit CombinationsAndRunOut Duct

plete, the trunk or main duct can be laid on the floor plan.

We are now ready for positioning the units in the space according to the load calculations and the design of the run-out

ducts.

The zone load calculation provides the cfm requirements

for each space. Using those requirements and the ceiling layout, the unit location and run-out can be determined. Figure

19 shows a single Moduline unit located on the grid line in

the approximate center of the space. Figure 20 shows multiple units in an air series located in similar fashion.

RECOMMENDED UNIT COMBINATIONS — Tables 6-8

list the recommended combinations of Moduline terminals.

Each model (size) of Moduline terminal is shown in combinations of 2, 3, 4 and 5 plenum sizes. To illustrate the use

of the tables, consider the 37HS2 for a space requiring 550

cfm. Three units in air series will provide the capacity. (Note

that 550 cfm is below the max cfm limit of 660 shown in

Table 7.) Six combinations of 37HS2 units are available; all

will produce a good installation. However, some factors influence the choice:

If it is desirable to have common plenum sizes throughout

the space, the choice will be three 9 x 9-in. plenums.

The lowest inlet velocities will result in the least variance

of discharge cfm among the 3 units on one control.

If this is a consideration, the choice would be three 11 x 11in. plenums.

The lowest cost choice would be 9- x 9-in., 9- x 9-in., and

7- x 7-inches.

If the requirement of the space is for maximum cfm from

the unit combination, one of the larger plenum combinations

would be favored.

Conversely,a conservative design with small cfm per unit

can use the smaller plenum sizes.

The selection of plenum sizes will not affect the sound

level of the space; there is no measurable difference in the

recommended plenum combinations.

NOTE: The listing of recommended air series combinations

does not indicate that one controller will always handle the

combination; in some cases, a second controller may be required. Refer to Determine Controller Location section,

page 37.

— When the preliminary office layout is com-

Fig. 18 — Unit Spacing

Table 9 provides an overall limitation on cfm in the inlet

collar of units in air series.

27

Page 28

Fig. 19 — Run-Out Duct for Single ModulineT Unit

Fig. 20 — Run-Out Duct for Moduline Units in Air Series

28

Page 29

Table 6 — 37HS1 Units in Air Series

29

Page 30

Table 6 — 37HS1 Units in Air Series (cont)

30

Page 31

Table 7 — 37HS2 Units in Air Series

31

Page 32

Table 7 — 37HS2 Units in Air Series (cont)

Table 8 — 37HS4 Units in Air Series

32

Page 33

Table 8 — 37HS4 Units in Air Series (cont)

33

Page 34

Table 9 — Maximum Cfm Through the Inlet Collar

of a Single Unit or of Units in Air Series

INLET

COLLAR

DIAM

(in.)

MAXIMUM TOTAL

AIRFLOW

(Cfm)

MODEL

37HS1

37HS2

37HS4

PLENUM

SIZE

(in.)

5x7 4 110

7x7 6 400

9x9 8 800

11x11 10 1100

7x7 6 400

9x9 8 800

11x11 10 1100

9x9 8 800

11x11 10 1100

13 x 13 12 1600

In general, units in an air series should not be of mixed

sizes (cfm capacities). If units of different capacities are used,

a controller must be applied for each size unit. For example,

an application for 800 cfm using different capacity units, as

shown in Fig. 21, is acceptable only with multiple controls.

This arrangement, although not preferred, can be used if care

is taken to use the necessary controllers. In this case, 3 controllers are required. However, the best installation for an

800 cfm (nominal cfm total) would be one in which all the

units are the same size. (Fig. 22.) In this case, a single controller can be used in the space.

Fig. 21 — Air Series of Units with Different Capacities

34

Page 35

Fig. 22 — Air Series of Units of the Same Size and Capacity

FLEX DUCT INAIR SERIES — Flexible duct is often used

in air series to connect Modulinet units. In calculating pressure requirements for units in air series, use the following

guidelines:

1. For close-coupled units (either continuous dif fuseror units

in adjoining ceiling modules) where the flexible duct used

is 6 to 8 in. in length, add 0.1 in. wg to unit requirement

for minimum static pressure at control unit (Table 10).

For example, consider three 37HS2 units in air series, in

adjoining modules, with 200 cfm per unit (Fig. 23). The

minimum static pressure for multiple units is equal to 0.75

in. wg (from Table 10). Adding 0.1 in. wg for flexible

duct, the total pressure downstream of run-out duct equals

0.85 in. wg.

2. For units in air series with extended flexible duct lengths,

add DP from Table 11.

For example, consider four 37HS2 units in air series,

200 cfm per unit (Fig. 24). The units are in alternate

series modules; 8-in. duct; 9- x 9-in. plenum. The

minimum static pressure for multiple units is equal to 0.75

in. wg. Three lengths of flex duct at 4.5 ft equal 13.5 ft.

From Table 11, read with 8-in. duct diam, DP is equal to

0.16 in. wg for each 10 ft. of flex duct. Therefore, for

13.5 ft, DP is equal to 0.16 + 0.06 in. wg. The total DP

downstream of run-out duct is equal to 0.75 + 0.22

= 0.97 in. wg.

3. Flexible duct, unsupported, tends to sag; this deflection

increases the pressure drop. Whenever possible, support

the duct with wire between connections. Sagging will increase the DP as much as 0.06 in. wg in a 10-ft length;

therefore rigid duct is recommended for lengths greater

than 5.5 ft.

4. The use of flexible duct in air series run-out when 90 degree turns are required will also add DP. Table 12 provides the additional pressure drop.

For example, refer to Fig. 25. The ‘‘straight’’ line DPis

equal to 0.97 in. wg. If a bend is added to the run-out, the

total pressure drop becomes:

0.97 + 0.16 = 1.13 in. wg.

35

Page 36

Table 10 — Minimum Static Pressure at Control

(Master) Unit — Units with System-Powered

Controls and Standard Diffusers

37HS1 37HS2 37HS4

AIRFLOW

(Cfm)

40

50

60

70

80

100

110 0.90 0.90 0.75 N/A

120

140

160

200

220 N/A N/A 0.90 0.75

240

280

320

360

400

440 N/A N/A N/A 0.90

N/A — Not Applicable

NOTE: Maximum inlet pressure — 3.0 in. wg.

5x7 9x9 9x9 11x11

0.75 0.75 N/A N/A

0.75 0.75 0.75 N/A90

N/A N/A 0.75 N/A

N/A N/A 0.75 0.75180

N/A N/A N/A 0.75

PLENUM SIZE (in.)

7x7 7x7 9x9

11x11 11x11 13x13

Minimum Static Pressure (in. wg)

Table 11 — Additional DP for

Extended Lengths of Flexible Duct

FLEX

DUCT

DIAM

(in.)

6 400 0.2

8 800 0.16

10 1100 0.1

12 1600 0.07

TOTAL

CFM

IN AIR

SERIES

ADDITIONAL

DP PER

10 FT FLEX DUCT

(in. wg)

Table 12 — Additional DP for

Flexible Duct with 90-Degree Bend

FLEX

DUCT

DIAM

(in.)

6 400 18 0.26

8 800 24 0.16

10 1100 30 0.08

12 1600 36 0.04

TOTAL

CFM

IN AIR

SERIES

RADIUS

OF

BEND

(in.)

ADDITIONAL DP

FOR 90° BEND

IN FLEXIBLE DUCT

(in. wg)

C—Controller

Fig. 23 — Three 37HS2 ModulineT Units in Adjoining Modules

Fig. 24 — Four 37HS2 Moduline Units in Alternate Series Modules

36

Page 37

Fig. 25 — Flexible Duct Used with 90-Degree Bend

Step 4 — Determine Controller Location — The

final step in the terminal selection and layout process is to

decide where the controllers will be placed.

The temperature control zones in the building will be determined by the final partition layout. Before the final partition layout has been determined, you must install enough

controllers to meet job requirement; the controllers can then

be relocated when the tenant layout is finished.

One of the main features of Moduline controls is that controller locations can be changed quickly and easily at any

time.

Another main feature of Moduline controls is that more

than one unit can be controlled from a single thermostat. In

large interior zones the ‘‘master’’unit (the one with the thermostat) can be hooked up with control tubing to control several ‘‘slaves’’. Table 13 shows the maximum number of units

that can be controlled by one controller.

Table 13 — Maximum Number of Units in an

MODEL

37HS1

37HS2

37HS4

*See Tables 6-8 for recommended combinations of units in air series.

†The 37HS1 unit with5x7size plenum is available with blank end only; mul-

tiple units of this size would not be used on one control.

NOTE: The conditions stated in Table 9 must be included in evaluations for

selecting the number of units in an air series.

Air Series on One Controller

PLENUM

SIZE (in.)

FIRST UNIT

IN AIR

SERIES*

5x7† X ————

7x7 X X X X —

9x9 X XXXX

11x11 X XXXX

7x7 X ————

9x9 X X X X —

11x11 X X X X —

9x9 X ————

11x11 X X X X —

13x13 X X X X —

NUMBER OF UNITS ON ONE CONTROLLER

Single

Unit

Units in Air Series

2345

GUIDELINES FOR CONTROLLER LOCATION

1. A master unit is mounted in the ceiling so that the air

intake is on the end of the unit opposite the end with the

control block and controller. (Fig. 26.)

2. A slave unit can receive air from either end of the unit.

Either end can be the inlet, assuming the inlet collar is

the same size as the connecting unit. At the same time, it

is good practice to place the ‘‘control’’end of a slave unit

downstream as shown in Fig. 26. Should the slave unit be

later converted to a master unit, the unit would be in its

correct configuration for control installation.

3. The volume controller for a single unit should be located

on the end of the unit opposite the inlet end. (Fig. 27.)

Fig. 26 — Air Intake on Master Unit

37

Page 38

4. The controller for units in an air series should be located

as shown in Fig. 28.

5. Volume controllers for units in an air series must be connected from master to slave units in the same air series;

they must not be connected to units in a different air

series from that of the master unit. See examples shown

in Fig. 29 and 30.

6. To connect slave units with control tubing, use the end

bellows fittings only; do not attempt to use the 0.25 molded

connection on the filter. See Fig. 31 for examples of control tubing connections.

C—Controller

Fig. 27 — Location of Volume Controller

on Single Unit

C—Controller

Fig. 28 — Location of Volume Controller on Units in an Air Series

38

Page 39

EXAMPLES OF GUIDELINE USE — Figure 29 shows an incorrect application. Figure 30 shows the corrected layout.

An incorrect application:

1. Room A & B units are on the same controller but on different duct

air series.

2. Room B calls for half the cfm as in units in room A — not feasible

because there is only one controller.

3. Units in room C are on different duct runs with one control — not

correct.

4. Units in room D are fine for one control, but controller should be

on second unit in air series.

Fig. 29 — Incorrect Layout of ModulineT Units with Controls

39

Page 40

The corrected layout:

1. Room A has its own controller.

2. Room B has its own controller.

3. Room C has a correct air series for one control.

4. Room D has the controller in the proper location.

Fig. 30 — Corrected Layout

Fig. 31 — Control Tubing Connection

40

Page 41

Final Layout — After these 4 steps are complete, you

are ready to make a final layout.

The final layout should show not only the number and lo-

cation of the Moduline units, but also:

• the round duct size connected to the unit

• the controller location

THE MODULINET VALVE

• the control tube layout for connecting the master unit (with

thermostat) to all its slaves

• the cfm for the master unit (all slaves will be the same cfm

and need not be indicated)

• the model number of the unit to be used

TheModuline ControlConcept —

line system-powered control concept is based on using the

building’s primary air supply as a source of energy.The distribution duct pressure provides energy to operate the controls that modulate the flow of air through the unit. The heart

of this system is a bellows-operated unit air valve, which is

positioned by varying the pressure of the air in the bellows

relative to the supply air pressure in the duct. As the pressure in the bellows approaches the pressure in the supply

duct, the unit air valve opening is reduced, finally closing

completely when the pressures are equal.

The 37HS Modu-

Figure 32 shows the Moduline terminal in cross section

with the valve in three positions — shutoff, partially open

and fully open. The valve opening varies with the pressure

of the bellows and the pressure of the plenum.

Figure 33 shows the internal components of the Moduline

unit.

Figure 34 shows the comparison of operating characteristics between Carrier’s new Moduline unit (the 37HS) and

the previous design.

41

Page 42

UNIT SHUTOFF — BELLOWS FULLY INFLATED

UNIT MODULATING — BELLOWS PARTIALLY INFLATED

Fig. 32 — Bellows and Unit Air Valve Arrangement

UNIT FULL CAPACITY — BELLOWS DEFLATED

42

Page 43

HIGHAND LOW PRESSURE —As primary air flows from

the unit plenum to the unit air valve and from there to the

conditioned space, it passes through a slotted plate called

the distribution baffle. The resistance of the baffle tends to

‘‘even out’’ the airflow through the unit. The baffle also creates a pressure differential which forms the basis of the sensing side of the unit control.

Static pressure from above the baffle is called the high

pressure; static pressure below the baffle is the low pressure.

Figure 35 shows the pick-up tubes for the high and low pressures, the differential pressure across the distribution baffle.

Fig. 33 — Cross Section of 37HS Moduline

Air Terminal

Fig. 34 — Bellows Comparison

43

Page 44

delivers maximum flow, as determined by the existing plenum pressure. Units normally operate between these extremes. In constant volume applications, the bellows pressure is automatically adjusted in proportion to the plenum

pressure, providing a constant pre-set flow within the operating limits of the unit. In variable air volume operation, the bellows pressure is further modulated to reduce

flow below the preset level as load requirements are satisfied. After passing through the valve, the primary air flows

down through the diffuser and out to the conditioned space.

CONTROL APPLICATIONS

Introduction —

a variety of cooling and heating control options which adapt

to many building applications. In this section, the various

control applications are described and the functions they include are identified. Each application has a function number

which corresponds to the function number shown in

Tables 14 and 15 in the Control Selection section, page 50.

Table 14 describes the functions; Table 15 shows the control

packages required for each function. The part numbers shown

are found on the Moduline air terminal price pages.

Detailed operating sequences for each control application

are found beginning on page 55.

The Modulinet terminal is offered with

Fig. 35 — High and Low Pressure Pick-Up Tubes

BELLOWS PRESSURE — As the airflow through the unit

changes, the high and low pressures vary proportionately.

Comparing these 2 pressures, the unit volume controller provides a bellows pressure which in turn inflates the unit air

valve. Bellows pressure varies from near zero at full flow to

plenum or duct pressure at shutoff.

UNIT AIRFLOW DELIVERY — The relationship between

the bellows pressure and the plenum pressure determines the

unit air valve position, which controls unit airflow delivery.

When the pressures become nearly equal, the valve closes

and the unit shuts off. Conversely, as the bellows pressure

approaches zero, the valve opens completely and the unit

System-Powered Controls

COMPONENTS OF THE SYSTEM-POWERED CONTROLSYSTEM — The 37HS system-powered control consists of a set of custom design and manufacturer’s components which provide airflow and temperature regulation of a

Moduline air terminal. These devices are interchangeable,

field-installed components which plug into the Moduline unit

without the use of tools.

Figure 36 shows the basic components: Control block (part

of the unit); filter/manifold; volume controller; and thermostat. Figure 37 demonstrates the control air paths in a sectional view of the control system. Note that the high pressure and low pressure pick-ups ofthe unit are connected through

the control block to the filter and from there to the volume

controller and thermostat.

Figure 38 shows the control filter/manifold; Fig. 39, the

airflow volume controller; Fig. 40, the diffuser thermostat

with aspirator; and Fig. 41, the wall thermostat and alternate

to diffuser mounting.

44

Page 45

Fig. 36 — 37HS Control Components

Fig. 37 — Basic 37HS Control Operation

45

Page 46

Fig. 38 — 37HS Control Filter/Manifold

O

S

Both CV and VAV control packages include a plastic baffle

which is installed over the vertical leg of the center diffuser

and blocks the unused portion of the diffuser slots. See

Fig. 42. On VAV units, this prevents stray air currents from

influencing thermostat operation.

Other control components used in extended systempowered electric and pneumatic control schemes are described in the control applications which follow.

50 70 90

Fig. 41 — Wall-Mounted Thermostat

%

CFM

120

100

80

40

Fig. 39 — 37HS Airflow Volume Controller

Fig. 40 — Unit-Mounted (Diffuser) Thermostat

Fig. 42 — Diffuser Baffle Assembly

46

Page 47

SYSTEM-POWERED APPLICATIONS

Constant Volume (CV) Cooling — (Function No. 1.) This is

the most basic operating configuration. The control arrangement consists of the volume controller and the filter. The unit

maintains a steady flow of primary air at the quantity set on

the volume controller over a range of supply pressures. Figure 43 shows constant volume controls mounted on the Modulinet unit.

CV Heating (Function No. 1.) Constant volume heating controls are the same as for CV cooling.

Variable Air Volume (VAV) Cooling — (Function No. 2 and

3.) The addition of a cooling thermostat to the constant volume controls allows the unit to vary the flow of primary air.

The unit will provide just enough airflow to satisfy the thermostat setting at existing load conditions, up to the maximum flow set on the volume controller. The cooling thermostat is direct acting (DA); thus the branch pressure output

from the thermostat increases as the space temperature increases. Both diffuser-mounted and wall-mounted variations

are available. Figure 44 shows the system-powered VAV controls (with diffuser thermostat) mounted on the unit.

VAVCooling With Warm-Up — (Function 4.) During an extended off period (overnight or during a holiday), the space

temperature will often be lowered. It is necessary to provide

heated air, temporarily, to reestablish comfortable temperatures when occupancy resumes. Since the cooling thermostats are satisfied at the reduced temperature, the units will

be shut off and the system will not be able to deliver warm

air. It is necessary, therefore, to provide a means of temporarily overriding the cooling thermostat. System-powered

warm-up is achieved by adding a warm-up switch to the VAV

cooling control arrangement (Fig. 45). The warm-up switch,

located inside the unit plenum, closes when it senses that

warm air is being supplied to the unit. This causes the bellows to bleed, opening the unit. This condition is maintained

until cool air is returned to the system and thewarm-up switch,

sensing cool supply air, returns control to the thermostat.

Where all Moduline units on a main duct-run are provided with thermostats for variable air volume control, it is

often difficult to get warm air to the end units on a run; with

the units in shutoff there is no significant flow which will

trigger the warm-up switch. Solutions to this situation are

found on page 58 in the Control Operating Sequences, VAV

Cooling with Warm-Up section.

Fig. 43 — Constant Volume Control

Arrangement

Fig. 44 — Variable Air Volume Control

Arrangement

Fig. 45 — VAV Control Arrangement for

System-Powered Warm-Up

47

Page 48

VAV Heating and Cooling With Changeover — (Function

5.) A VAV control arrangement for cooling/heating includes

a wall-mounted cooling/heating thermostat and provision to

change the thermostat from cooling to heating configuration

and back again. Figure 46 shows the control arrangement

with Modulinet control for heating and cooling. The wall

thermostat is shown in Fig. 47. The system-powered heating

and cooling changeover uses an assembly consisting of 2

temperature-operated pneumatic switches located inside the

unit plenum and installed in-line between a cooling/heating

thermostat and the volume controller. These switches sequence the thermostat between the cooling and heating modes,

depending upon the temperature of the primary air supply.

VAV Heating — (Function 9.) Variable air volume heating

controls are the same as for VAV cooling except that only a

wall-mounted heating thermostat is offered (Fig. 48). The

heating thermostat is reverse acting (RA); thus the output

pressure decreases as the space temperature increases.

SYSTEM-POWERED CONTROLS WITH ELECTRIC

INTERFACE

VAV Cooling With Electric Warm-Up — (Function 6.) Electric warm-up uses an electric changeover valve to perform

the same function as system-powered warm-up; that is, to

provide heated air to reestablish comfortable temperatures

when occupancy resumes after an extended unoccupied period. Since the cooling thermostats are satisfied at the reduced temperature, the units will be shut off and the system

will not be able to deliver warm air. It is necessary, therefore, to provide a means of temporarily overriding the cooling thermostat.

The changeover control is an electrically operated, remotely controlled 3-way solenoid valve. The normally closed

port of the valve is capped. The valve usually is wired to

activate automatically with the supplemental heating switch;

however, it can also be manually activated. This option may

be used with either a unit-mounted or wall-mounted thermostat. See Fig. 49.

VAVHeatingand Cooling With Electric Changeover — (Function 7.) A VAV control arrangement for cooling/heating includes a wall-mounted cooling/heating thermostat (Fig. 47)

and provision to change the thermostat from a cooling to

heating configuration and back again.System-powered cooling/

heating with electric changeover uses a 3-way electric solenoid valve to switch control between the cooling and heating functions of a cooling/heating wall-mounted thermostat.

It is installed in-line between the volume controller of a CV

cooling control package and the thermostat. The valve may

be activated separately or interlocked with an electric heating system. See Fig. 50.

90

70

50

Fig. 46 — System-Powered Changeover

Switch Arrangement with Heating/Cooling

Wall Thermostat

50 70 90

Fig. 47 — Cooling/Heating Wall Thermostat

50 70 90

Fig. 48 — Wall-Mounted Heating Thermostat

90

70

50

Fig. 49 — VAV Control Arrangement

for Electric Warm-Up

90

70

50

Fig. 50 — VAV Control Arrangement

for Electric Changeover

48

Page 49

VAV Cooling With Electric Heat Interlock — (Function 8.)

In cases where VAV cooling terminals are used in conjunction with a separate heating system, such as perimeter heating, it is necessary to prevent the heating equipment from

turning on before the cooling system turns off. The addition

of a differential pressure switch to the unit controls makes

this possible. When the switch detects that control pressures

are approaching a shutoff condition (cooling load satisfied),

it closes a set of contacts. This allows the heating system to

operate as the heating thermostat dictates. See Fig. 51.

VAVCoolingWithFire Safety — (Functions 11 and 12.) Code

requirements may specify that air distribution terminals be

open or closed during a fire. For example, in tower construction there may be a requirement that if a fire begins on one

floor the terminals on the ‘‘fire floor’’ must be shut off to

prevent the addition of oxygen to the fire; terminals on the

floors above and below the fire floor must be wide open to

ventilate the space. These actions must occur regardless of

the space temperature and the position of the individual ductpowered thermostats (unit mounted or wall mounted). This

application is effectively the same as the pneumatic warm-up

previously described. In this case, the pneumatic switch is

remotely operated by the fire master control to open the adjacent floor units. Air supply to units on the ‘‘fire floor’’ is

interrupted by the use of duct fire-dampers.

Fig. 51 — VAV Control Arrangement with

Electric Heat Interlock

SYSTEM-POWERED CONTROLS WITH PNEUMA TICINTERFACE — The Moduline unit is designed as a standalone, reactive air terminal in which the only source of energy for control purposes is the distribution air itself. There

are applications where separate system energy affords additional control functions not possible with system power.

This section covers the use of 20 psi pneumatic energy and

standard and custom pneumatic devices for the application

of Moduline terminals in a conditioning system.

Pneumatic Sequenced Cooling/Heating (HotW ater)— (Function 10.) A37HS VAV cooling system can be sequenced with

a hot water heating system through the use of a pilot valve

and a single proportional pneumatic thermostat (one-pipe or

2-pipe). See Fig. 52. By properly matching the operating pressure ranges of the pilot valve and the field-supplied hot water heat valve, the system can be configured to automatically

change over from cooling to heating and back again based

on the thermostat branch line pressure. The cooling and heating functions can be separated by a deadband or they can be

overlapped, depending upon pressure ranges selected. The

system may be designed to use either of the following

combinations:

• pilot valve (NO), hot water valve (NO) and thermostat (DA,

one- or 2-pipe)

• pilot valve (NC), hot water valve (NC), and thermostat (RA,

one- or 2-pipe)

VAV Cooling With Pneumatic Warm-Up — (Functions 11

and 12.) Pneumatic warm-up is accomplished by using a remotely operated pneumatic switch in place of the systempowered warm-up switch. The pneumatic switch is installed

in-line between the volume controller and the thermostat (unit

mounted or wall mounted) and must be closed during

warm-up. It may be either normally open or normally closed,

but must match the pneumatic line pressure available. See

Fig. 53.

50

70

90

Fig. 52 — Pilot Valve for Pneumatic Sequenced

Cooling/Heating (Hot Water)

Fig. 53 — VAV Control Arrangement with

Pneumatic Warm-Up Switch

49

Page 50

NOTE: The following applications require the control packages shown for Function 10, plus field-supplied thermostats

as described below.

Night Set Back Heating — In the interest of energy conservation, it may be desirable to raise a system’s cooling set

point during unoccupied time periods, whether they occur at

night or on weekends, holidays or other occasions. This application requires a field-supplied dual set point DA pneumatic thermostat operating on a switched-main pressure supply.

The air supply must have 2 pressure levels available. A normally open pilot valve, controlled by the dual thermostat, is

also required. The thermostat set point is determined by the

supply pressure selected.

VAVCooling/Separate System Heating —AModulinet cool-

ing system may be interlocked with a separate hot water heating system and controlled by a common thermostat. This application requires a field-supplied switched-main pressure

supply,a field-supplied dual set point DA/RA pneumatic thermostat, a pneumatic switching relay,a pilot valve, and a pneumatic hot water valve. The summer mode (cooling) or the

winter mode (heating) is selected by switching the pneumatic supply system pressure between high or low pressure

ranges. The pneumatic thermostat operates in either the cooling mode (DA) or the heating mode (RA) depending on the

supply pressure provided. The pneumatic switching relay responds to the pressure level by selecting either the pilot valve

and the Moduline cooling system or the hot water valve and

the hot water heating system, to match the thermostat mode.

CONTROL SELECTION

Control Index —

tions available with 37HS Moduline air terminals. These functions are described in detail in the preceding Control Applications section.

Table 14 summarizes the control func-

Control Packages — In order to obtain a desired set

of control functions with Moduline air terminals, the correct

combination of control packages is required. Table 15 shows

the control packages that must be installed on a master unit

in order to achieve each function. The control package numbers correspond to the numbers on the 37HS Price Pages.

Table 14 — Control Index

FUNCTION

NO.

1 Cooling or Heating Only, Constant Volume

2 Cooling Only, Variable Volume, Diffuser Thermostat

3 Cooling Only, Variable Volume, Wall Thermostat

VAV Cooling with System-Powered Warm-Up,

4

Wall Thermostat

VAV Cooling/Heating, System-Powered Changeover,

5

Wall Thermostat

VAV Cooling with Electric Warm-Up, Wall Thermostat

6

or Diffuser Thermostat

VAV Cooling/Heating, Electric Changeover,

7

Wall Thermostat or Diffuser Thermostat

8 VAV Cooling with Electric Heat Interlock

9 Heating Only, Variable Volume, Wall Thermostat

VAV Cooling with Pneumatic Sequenced Heating (Hot Water)

10

and Pneumatic Thermostat*

VAV Cooling with Pneumatic Warm-Up or Fire Safety Switch,

11

Wall Thermostat

VAV Cooling with Pneumatic Warm-Up or Fire Safety Switch,

12

Diffuser Thermostat

*For night set back heating, a field-supplied dual set point DA thermostat must

be used with the control packages and components shown in Table 15. For

VAV cooling/separate system heating, a field-supplied dual set point DA/RA

thermostat must be used with the control packages and components shown

in Table 15.

FUNCTION DESCRIPTION

50

Page 51

Table 15 — 37HS Control Combinations

NO. FUNCTION MODEL

SYSTEM POWERED

CONSTANT VOLUME

COOLING

1

SYSTEM POWERED

VARIABLE VOLUME

COOLING

DIFFUSER

THERMOSTAT

37HS1 37HS900003

37HS2 37HS900003

37HS4 37HS900003

37HS1 37HS900001

37HS2 37HS900002

37HS4 37HS900004

CONTROL

REQUIRED

CONNECTION ARRANGEMENTPACKAGES

2

SYSTEM POWERED

VARIABLE VOLUME

WALL THERMOSTAT

3

COOLING

37HS1

37HS2

37HS4

37HS900003

37CM901012

37HS900003

37CM901012

37HS900003

37CM901012

51

Page 52

Table 15 — 37HS Control Combinations (cont)

NO. FUNCTION MODEL

SYSTEM POWERED

VARIABLE VOLUME

COOLING

SYSTEM POWERED

WARM-UP

WALL THERMOSTAT*

4

SYSTEM POWERED

VARIABLE VOLUME

HEATING & COOLING

SYSTEM POWERED

CHANGEOVER

WALL THERMOSTAT

37HS1

37HS2

37HS4

37HS1

37HS2

37HS4

CONTROL

REQUIRED

37HS900003

37CM900152

37CM901012

37HS900003

37CM900152

37CM901012

37HS900003

37CM900152

37CM901012

37HS900003

37CM900192

37CM900992

37HS900003

37CM900192

37CM900992

37HS900003

37CM900192

37CM900992

CONNECTION ARRANGEMENTPACKAGES

5

SYSTEM POWERED

VARIABLE VOLUME

COOLING

ELECTRIC WARM-UP

WALL THERMOSTAT*

6

37HS1

37HS2

37HS4

37HS900003

37CM900792†

37CM901012

37HS900003

37CM900792†

37CM901012

37HS900003

37CM900792†

37CM901012

*To use a diffuser thermostat in place of the wall thermostat, replace constant volume package 37HS900003 and wall thermostat 37CM901012

with variable volume package 37HS900001 (37HS1), 37HS900002 (37HS2) or 37HS900004 (37HS4).

†Package 37CM900792 is 24 v; other voltages available.

52

Page 53

Table 15 — 37HS Control Combinations (cont)

NO. FUNCTION MODEL

SYSTEM POWERED

VARIABLE VOLUME

HEATING & COOLING

ELECTRIC CHANGEOVER

WALL THERMOSTAT

7

SYSTEM POWERED

VARIABLE VOLUME

COOLING

DIFFUSER THERMOSTAT**

INTERLOCK TO FAN COIL

OR BASEBOARD HEATING

ELECTRIC

37HS1

37HS2

37HS4

37HS1

37HS2

37HS4

CONTROL

REQUIRED

37HS900003

37CM900792†

37CM900992

37HS900003

37CM900792†

37CM900992

37HS900003

37CM900792†

37CM900992

37HS900001

37CM900922

37HS900002

37CM900922

37HS900004

37CM900922

CONNECTION ARRANGEMENTPACKAGES

8

SYSTEM POWERED

VARIABLE VOLUME

HEATING

WALL THERMOSTAT

9

37HS1

37HS2

37HS4

37HS900003

37CM901002

37HS900003

37CM901002

37HS900003

37CM901002

†Package 37CM900792 is 24 v; other voltages available.

**To use a wall thermostat in place of the diffuser thermostat, replace variable volume packages 37HS900001 (37HS1), 37HS900002 (37HS2) or

37HS900004 (37HS4) with constant volume package 37HS900003 and add wall thermostat 37CM901012.

53

Page 54

Table 15 — 37HS Control Combinations (cont)

NO. FUNCTION MODEL

SYSTEM POWERED

VARIABLE VOLUME

COOLING

PNEUMATIC

PILOT VALVE FOR

HEATING/COOLING

SEQUENCE

PNEUMATIC

10

THERMOSTAT††

SYSTEM POWERED

VARIABLE VOLUME

COOLING

WALL THERMOSTAT

PNEUMATIC

WARM-UP/FIRE

SWITCH

WALL

37HS1

37HS2

37HS4

37HS1

37HS2

37HS4

CONTROL

REQUIRED

37HS900003

37CM900972 (NO)

with

37HS900007 (DA)

37CM900982 (NC)

with

37HS900008 (RA)

37HS900003

37CM900972 (NO)

with

37HS900007 (DA)

37CM900982 (NC)

with

37HS900008 (RA)

37HS900003

37CM900972 (NO)

with

37HS900007 (DA)

37CM900982 (NC)

with

37HS900008 (RA)

37HS900003

37CM901012

37HS900017

37HS900003

37CM901012

37HS900017

37HS900003

37CM901012

37HS900017

CONNECTION ARRANGEMENTPACKAGES

11

SYSTEM POWERED

VARIABLE VOLUME

DIFFUSER

THERMOSTAT

PNEUMATIC

WARM-UP/FIRE

12

COOLING

SWITCH

37HS1

37HS2

37HS4

37HS900001

37HS900017

37HS900002

37HS900017

37HS900004

37HS900017

LEGEND

DA — Direct Acting NO — Normally Open

NC — Normally Closed RA — Reverse Acting

††For night set back heating, a field-supplied dual set point DA ther-

mostat must be substituted for thermostat packages shown. For

VAV ModulineT cooling/separate system heating, a field-supplied

dual set point DA/RA thermostat must be substituted for thermostat packages shown.

54

Page 55

CONTROL OPERATING SEQUENCES

System-Powered Controls

CV COOLING — See Fig. 54. Air from above the distribution baffle (high pressure) enters the filter through the upper port of the control block, while the lower port receives

air from below the baffle (low pressure). These air streams

pass through separate filter chambers where particulate contaminants are removed.

The low pressure air stream enters the low pressure chamber of the volume controller from the top port of the filter,

while the bottom port of the filter feeds the high pressure

stream into the controller’s high pressure chamber.

Air from the high pressure chamber feeds into the bellows

pressure chamber of the controller through the fixed orifice.

Pressure in the bellows chamber of the volume controller is

determined by the relationship between the entering flow resistance of the fixed orifice and the leaving flow resistance

of the control valve variable orifice.

As the control valve opens, its resistance decreases and

relatively more air is allowed to bleed, lowering the pressure

in the bellows chamber. As the control valve closes, the effect is reversed, increasing the bellows pressure. This is the

principle of control by matched orifices.

The control valve is positioned by 2 diaphragms, one in

the low pressure chamber and one in the high pressure chamber, and an adjustable spring. Pressure above the low pressure diaphragm tends to open the control valve while the

high pressure diaphragm tends to hold it closed. The spring

tension balances these forces as the pressures vary and determines the valve position. Rotating the adjusting dial on

the volume controller changes the spring tension and provides a means of establishing a flow set point.

The bellows pressure determined by the action of the control valve is communicated to the bellows. As the plenum

pressure changes, the control bellows valve is constantly reset to maintain a corresponding bellows pressure. The bellows pressure chamber of the volume controller feeds air back

through the middle port and chamber of the filter (also called

a bellows pressure chamber), to the bellows connection on

the unit end panel, and into the bellows. The bellows pressure re-sets the bellows on the unit air valve to provide a

constant airflow through the unit at the value selected on the

volume controller dial.

CV HEATING — Control arrangements and operation are

the same for CV heating as for CV cooling. The controls and

their operation are not affected by the temperature of the supply air.

Fig. 54 — Constant Volume Controls — Controller Bleeding, Unit Supplying Air

55

Page 56

VAV COOLING — In VAVoperation, the filter and volume

controller perform the same functions as in CV operation.

The unit-mounted thermostat modifies control operation as

described below.

Refer to Fig. 55. The air enters the low pressure chamber

of the volume controller through a fixed orifice. The low pressure chamber is connected through a stub fitting and tube to

the unit-mounted thermostat. The thermostat senses room temperature, closes its port as the temperature rises, and opens

it as the temperature falls. This makes it possible to control

the pressure in the low pressure chamber in response to the

space temperature. With normal space temperatures, and the

thermostat satisfied, the low pressure chamber valve is open

to the atmosphere through the thermostat. The rate at which

the valve bleeds air from the low pressure chamber is high

in relation to the rate at which air enters through the orifice,

and the pressure decreases in relation to the high pressure.

The high pressure force is stronger than the low pressure

force and the bleed valve of the bellows pressure chamber of

the controller is held closed. Since no air escapes, the bellows pressure becomes equal to the high pressure in the plenum and the unit damper is closed, shutting off the unit.

As the room load increases, the space temperature increases. The thermostat senses this change and starts to close,

raising the pressure in the low pressure chamber of the controller. As the low pressure rises, it gradually overcomes

the high pressure and opens the bellows pressure-chamber

bleed valve, lowering the bellows pressure proportionally.

This allows the unit damper to open and gradually increase

the flow of conditioned primary air into the space. See

Fig. 56.

This process continues until the flow of primary air is sufficient to offset the load, or until the flow level set point of

the volume controller is reached (Fig. 57). At this point, the

thermostat bleed is closed and the unit is actually operating

in CV configuration. As the load is reduced, the process is

reversed and the unit flow decreases proportionally until the

unit is shut off when the thermostat is satisfied (bleed fully

open) (Fig. 58). In this manner, the unit normally delivers

only the actual amount of primary air needed to offset the

existing load.

When the wall-mounted DA thermostat is used in place of

the unit-mounted thermostat, variable air volume control operation is the same as described above for the unit-mounted

thermostat. The only differenceis that the wall-mounted thermostat does not include the aspiration feature.

Fig. 55 — Variable Volume Controls Schematic

56

Page 57

Fig. 56 — Variable Volume Controls — Minimum Flow: Thermostat Partially Open,

Controller Partially Open, Unit Delivering Minimum Flow

Fig. 57 — Variable Volume Controls — Full Cooling, Thermostat Closed, Controller Bleeding,

Unit Supplying Air

57

Page 58

Fig. 58 — Variable Volume Controls — Thermostat Open,

Controller Shut Off, Unit Shut Off

VAV COOLING WITH WARM-UP— Including the warmfup switch in the volume controller/thermostat circuit allows the unit to deliver air when there is warm air in the duct